Sulfide-coated positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material and sulfide technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering electrode preparation, unstable surface structure, and increased battery polarization, so as to improve electrochemical performance and enhance battery life. Chemical properties, the effect of uniform and dense coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

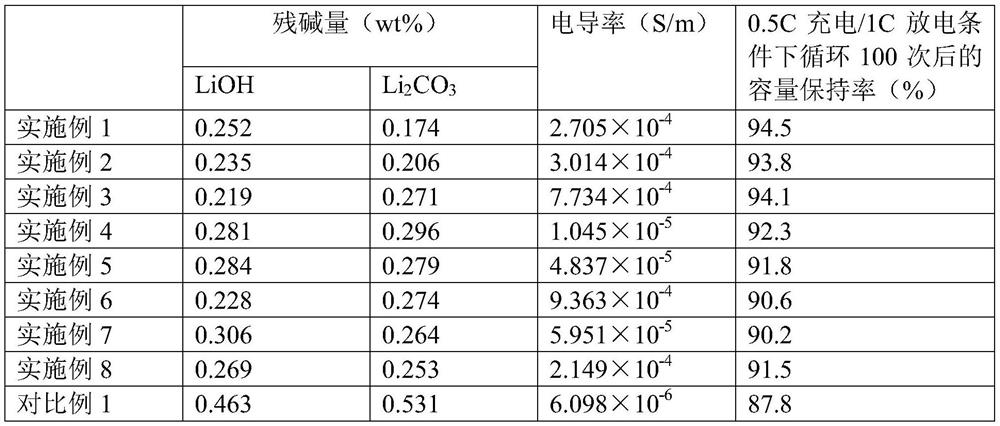

Examples

Embodiment 1

[0068] This embodiment provides a positive electrode material coated with a sulfide which includes a lithium-containing positive electrode material LINI. 0.88 CO 0.1 Mn 0.02 O 2 And a sulfide solid electrolyte cladding layer covering a lithium-containing positive material surface 2 S-P 2 S 5 -ZRO 2 , That is, by Li 2 S, p 2 S 5 Zro 2 Preparation as a raw material, Li 2 S, p 2 S 5 Zro 2 The molar ratio is 75: 20: 5. P 2 S 5 The average particle size is 60 nm, Zro 2 The average particle diameter was 40 nm. Positive material LINI 0.88 CO 0.1 Mn 0.02 O 2 The average particle diameter was 4.0 μm, and the thickness of the sulfide solid electrolyte coating layer was 5 nm.

[0069] This embodiment also provides a method of preparation of the sulfide coated positive electrode material, and the specific method is:

[0070](1) Disperse the positive electrode material in anhydrous ethanol, and continuously introduced into a hydrogen sulfide gas at a rate of 2 l / min, and mix well for 1 h;

...

Embodiment 2

[0076] This embodiment provides a positive electrode material coated with a sulfide which includes a lithium-containing positive electrode material LINI. 0.88 CO 0.1 Mn 0.02 O 2 And a sulfide solid electrolyte cladding layer covering a lithium-containing positive material surface 2 S-P 2 S 5 -ZRO 2 , That is, by Li 2 S, p 2 S 5 Zro 2 Preparation as a raw material, Li 2 S, p 2 S 5 Zro 2 The mole percentage is 80: 15: 5. P 2 S 5 The average particle size is 60 nm, Zro 2 The average particle diameter was 60 nm. Positive material LINI 0.88 CO 0.1 Mn 0.02 O 2 The average particle diameter is 4.0 μm, and the thickness of the sulfide solid electrolyte coating is 15 nm.

[0077] This embodiment also provides a method of preparation of the sulfide coated positive electrode material, and the specific method is:

[0078] (1) Disperse the positive electrode material in anhydrous ethanol, and continuously introduced into a hydrogen sulfide gas at a rate of 2 l / min, and mix well for 1 h;

[0...

Embodiment 3

[0084] This embodiment provides a positive electrode material coated with a sulfide, and the sulfide coated positive material comprises a lithium positive electrode material Li 0.9 Ni 0.8 CO 0.15 Al 0.05 O 2 And a sulfide solid electrolyte cladding layer covering a lithium-containing positive material surface 2 S-P 2 S 5 -Fes 2 , That is, by Li 2 S, p 2 S 5 FES 2 Preparation as a raw material, Li 2 S, p 2 S 5 FES 2 The mole percentage is 70: 25: 5. P 2 S 5 The average particle size is 100 nm, FES 2 The average particle diameter was 30 nm. Positive material LI 0.9 Ni 0.8 CO 0.15 Al 0.05 O 2 The average particle diameter is 10.0 μm, the thickness of the sulfide solid electrolyte coating is 50 nm.

[0085] This embodiment also provides a method of preparation of the sulfide coated positive electrode material, and the specific method is:

[0086] (1) Dispersion of the positive electrode material in the inert reactor in diethyl ether, continuously at a rate of 1 l / min, and mix thirat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com