Ternary positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material, high nickel ternary material technology, applied in the field of lithium ion battery, ternary positive electrode material and its preparation, can solve the problems of high cost, complex liquid phase method and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] According to the total mass of boron atom and phosphorus atom and Li 1.01 Ni 0.8 co 0.1 mn 0.1 o 2 According to the mass ratio of 0.001:1, the mixture of orthoboric acid and ammonium dihydrogen phosphate (the molar ratio of B:P is 1.5:1) is put into the high-speed coating machine (referred to as the coating machine), and its volume occupies 10% of the volume of the high-speed mixer. 1 / 3 (that is, the filling amount is 1 / 3), and mixed at a speed of 100rpm for 0.5h, filled in a sagger, and then placed in a kiln to raise the temperature to 300°C at 5°C / min, and keep it warm for 10h. Introduce oxygen. After the sintering is completed, sieve through a 325-mesh sieving machine to obtain a high-nickel ternary material coated with boron-containing compounds and phosphorus-containing compounds.

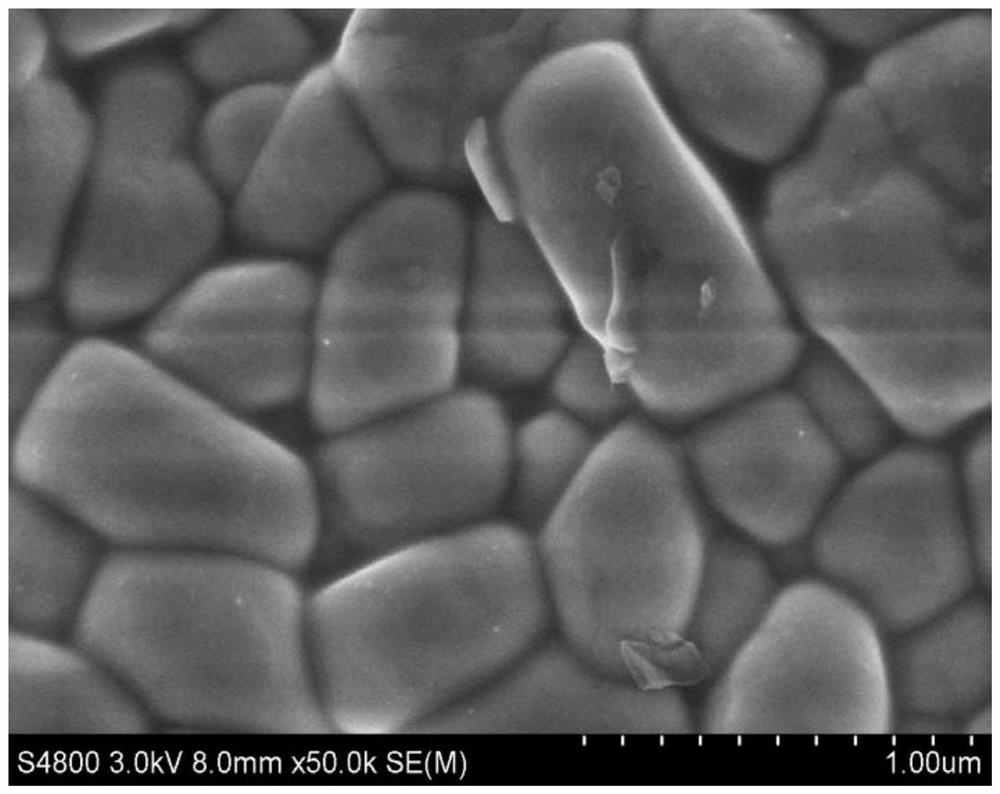

[0058] figure 1 The scanning electron microscope (SEM) picture of the boron-containing compound and phosphorus-containing compound composite coating ternary cathode material prepa...

Embodiment 2

[0062] According to the total mass of boron atom and phosphorus atom and Li 1.03 Ni 0.8 co 0.1 mn 0.1 o 2 According to the mass ratio of 0.005:1, the mixture of metaboric acid and ammonium dihydrogen phosphate (the molar ratio of B:P is 2.5:1) is put into the high-speed coating machine (referred to as the coating machine), and its volume occupies 10% of the volume of the high-speed mixer. 1 / 3 (that is, the filling amount is 1 / 3), and mixed at a speed of 50rpm for 2 hours, filled in a sagger, and then placed in a kiln to raise the temperature to 300°C at 3°C / min, keep it warm for 10h, and put it in the kiln Introduce oxygen. After the sintering is completed, sieve through a 325-mesh sieving machine to obtain a high-nickel ternary material compositely coated with a boron-containing compound and a phosphorus-containing compound.

[0063] The test results of the ternary cathode material prepared in this example are shown in Table 1.

[0064] The ternary positive electrode ma...

Embodiment 3

[0066] According to the total mass of boron atom and phosphorus atom and Li 1.05 Ni 0.9 co 0.05 mn 0.05 o 2 According to the mass ratio of 0.003:1, the mixture of tetraboric acid and ammonium monohydrogen phosphate (the molar ratio of B:P is 2.5:1) is put into the high-speed coating machine (referred to as the coating machine), and its volume occupies 10% of the volume of the high-speed mixer. 2 / 3 (that is, the filling amount is 2 / 3), and mixed at a speed of 80rpm for 2 hours, filled in a sagger, and then placed in a kiln to raise the temperature to 400°C at 5°C / min, keep it warm for 8h, and put it in the kiln Introduce oxygen. After the sintering is completed, sieve through a 325-mesh sieving machine to obtain a high-nickel ternary material compositely coated with a boron-containing compound and a phosphorus-containing compound.

[0067] The test results of the ternary cathode material prepared in this example are shown in Table 1.

[0068] The ternary positive electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com