Patents

Literature

132 results about "Metaboric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metaboric acid is the name for a family of inorganic compounds formed by the dehydration of boric acid. Metaboric acids are colourless solids with the empirical formula HBO₂. There are two forms of metaboric acid, all are white solids. One form of metaboric acid is molecular, and the other forms are polymers.

Surface covering building materials resistant to microbial growth staining

InactiveUS20030037698A1Promote resultsWithstand high heat and mixing and abrasionBiocideHeavy metal active ingredientsMicroorganismMicrobiology

The present disclosure relates to surface covering building materials for roofs, sidewalls and other exterior surfaces exposed to the weather such as, but not limited to, asphaltic and non-asphaltic roofing materials, wherein said surface covering building materials exhibit long-term resistance to microbial growth-induced staining. The surface covering building materials include a component having antimicrobial potential which consists essentially of (a) a copper component or a tin component and (b) a barium metaborate monohydrate component.

Owner:ELK PREMIUM BUILDING PROD

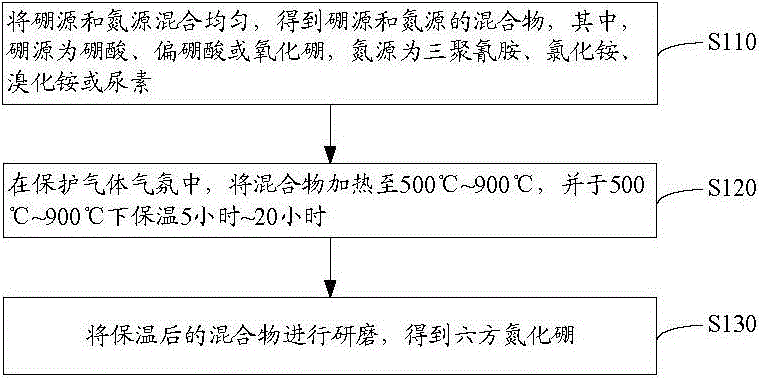

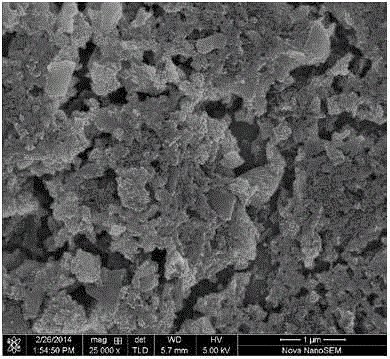

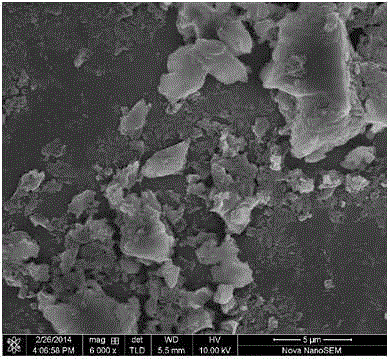

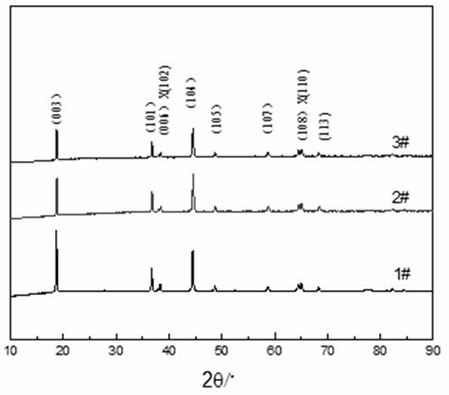

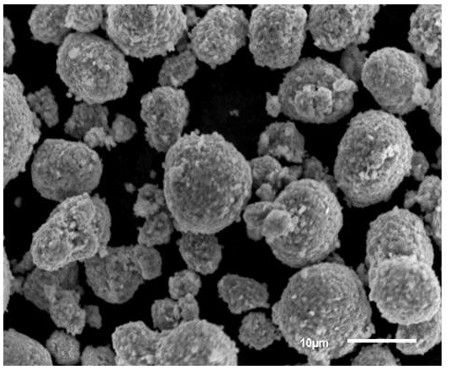

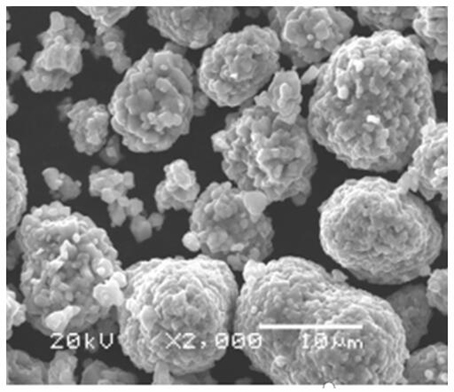

Preparation method of hexagonal boron nitride

ActiveCN103910344APromote decompositionAvoid picklingNitrogen compoundsHexagonal boron nitrideShielding gas

The invention relates to a preparation method of hexagonal boron nitride. The method comprises the following steps: uniformly mixing a boron source and a nitrogen source to obtain a mixture of the boron source and the nitrogen source, wherein the boron source is boric acid, metaboric acid or boric oxide and the nitrogen source is tripolycyanamide, ammonium chloride, ammonium bromide or urea; under a protective gas atmosphere, heating the mixture to 500-900 DEG C, and insulating for 5-20 hours at 500-900 DEG C; and grinding the insulated mixture to obtain the hexagonal boron nitride. The boron source and the nitrogen source used by the preparation method of hexagonal boron nitride are materials easy to decompose and less in residue, so that metal impure particles by using metal boride are avoided and the subsequent tedious pickling and washing steps are avoided. The method is simple in process, and hexagonal boron nitride after reaction can be used after being grinded. Reaction is not carried out at high temperatures, so that the energy consumption is low and the production is low.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

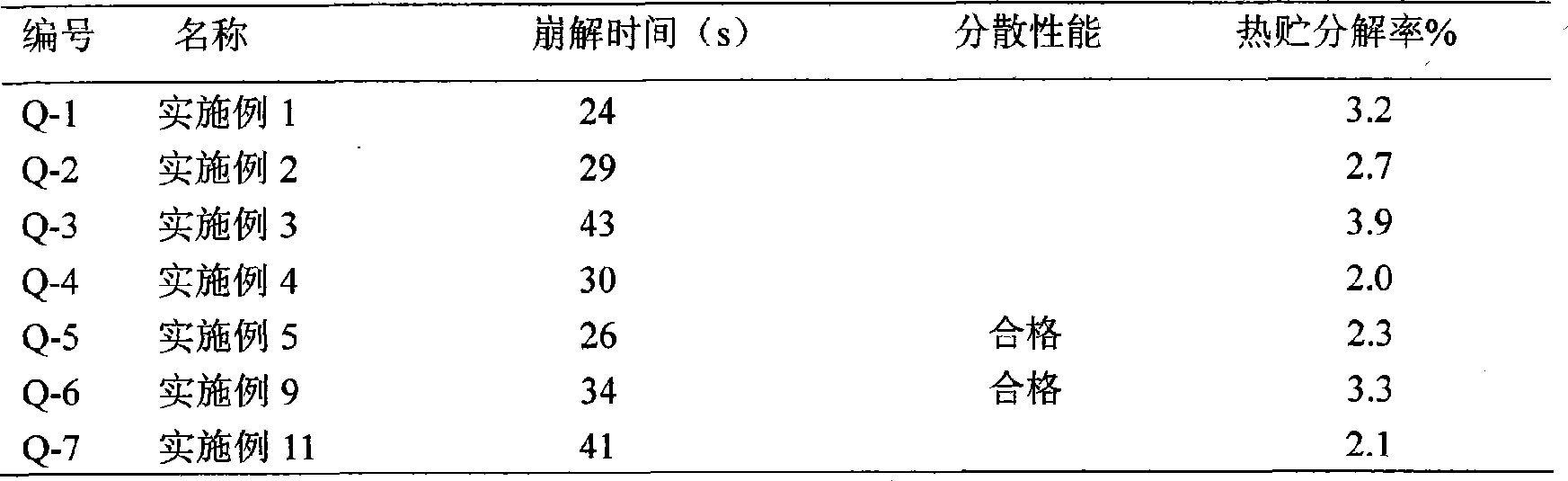

Boric fertilizer water dispersing granule and preparing method thereof

InactiveCN101531550AFast disintegrationDissolve (disperse) completelyFertiliser formsFertilizer mixturesMagnesium phosphatePotassium

The invention belongs to a new boric fertilizer, referring to a boric fertilizer water dispersing granule and preparing method thereof. The invention comprises one or more than one boric fertilizers and at least one surfactant; the materials are processed as the regular or irregular granules water dispersing granule; the weight part of the boric fertilizer is 5-95 parts; the rest is the assistant. The preferable solution of the invention is following: the boric fertilizer comprises one of the boric acid, boron oxide, boric acid ammonium, sodium tetraborate, calcium borate side, partial sodium borate, sodium borate tetrahydrate, magnesium diboride, sodium perborate, zinc borate, boric acid manganese, high-sodium borate, partial acid potassium, boron and magnesium fertilizer, boron and magnesium phosphate and boron mud or the mixture of the two or more than two of the above. The preparing method of the invention is scaling the prescription, mixing, crushing, and granule and drying to obtain the product. The boric fertilizer water dispersing granule of the invention has a fast disintegration, dissolving (dispersing) completely, not plugging the nozzle and the dropping pipe lines, no heating while using, easy to absorb moisture, packaging, storage and transportation, measurement, the use of low cost, widely used in food crops, cash crops, horticulture, lawns and urban greening; the market prospect is very broad.

Owner:SHENZHEN LANGTAI BIOTECH

Calcium hypochlorite composition

Calcium hypochlorite compositions that are classified as a Packing Group III Division 5.1 oxidizer material or as a non-Division 5.1 oxidizer material are described. In one embodiment, the compositions comprise an admixture of particulate calcium hypochlorite and particulate metaboric acid. The calcium hypochlorite is present in the composition in an amount and is of a concentration such that the composition would be classified as a Packing Group II Division 5.1 oxidizer in the absence of said particulate metaboric acid. Other embodiments described are solid shaped articles, e.g., tablets, comprising the described calcium hypochlorite-metaboric acid composition.

Owner:AXIALL OHIO

Boron-oxide and related compounds for hydrogen storage

InactiveUS6991773B2High adsorption heatGas treatmentReversible hydrogen uptakeHydrated sodium borateBoron oxide

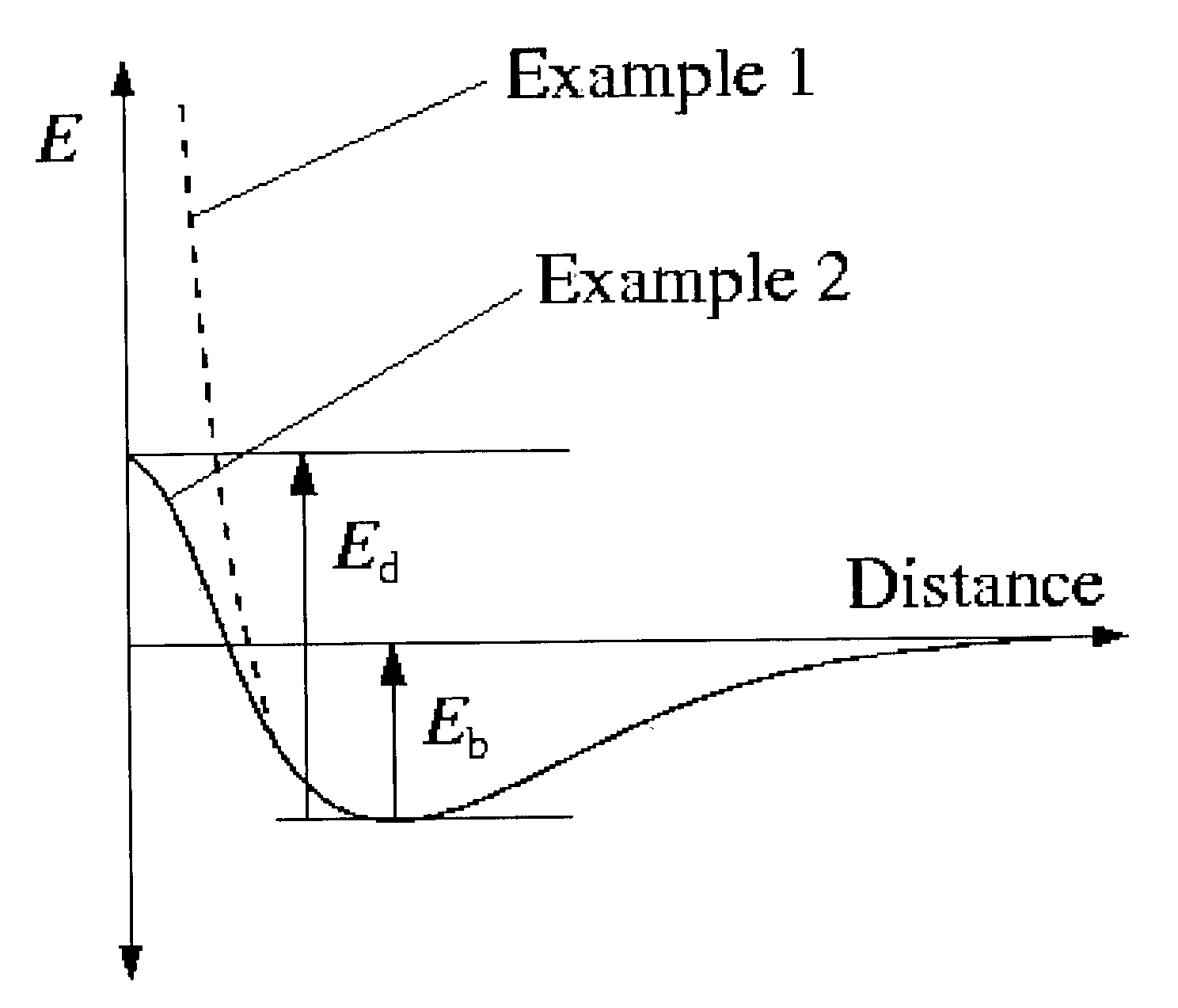

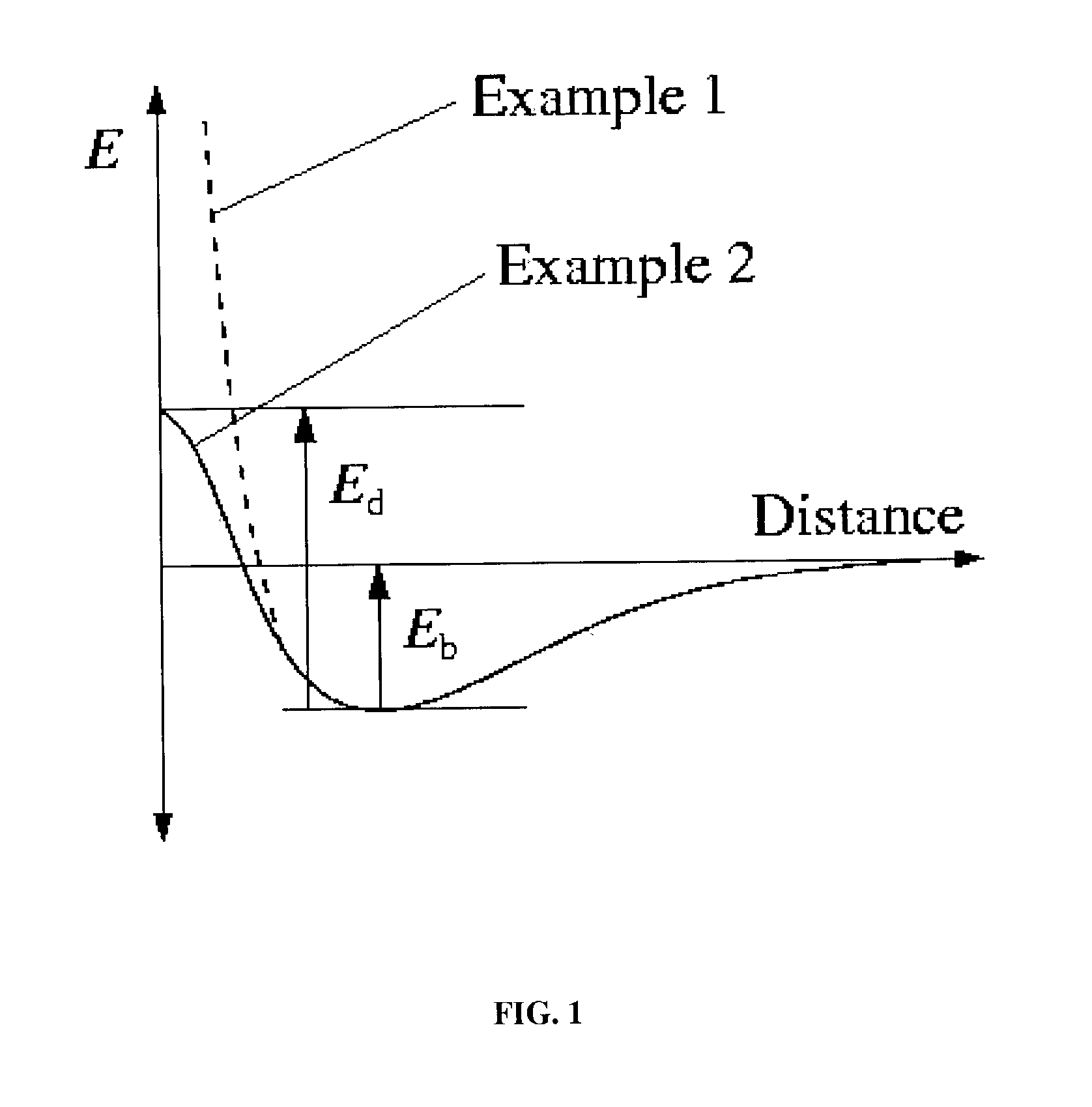

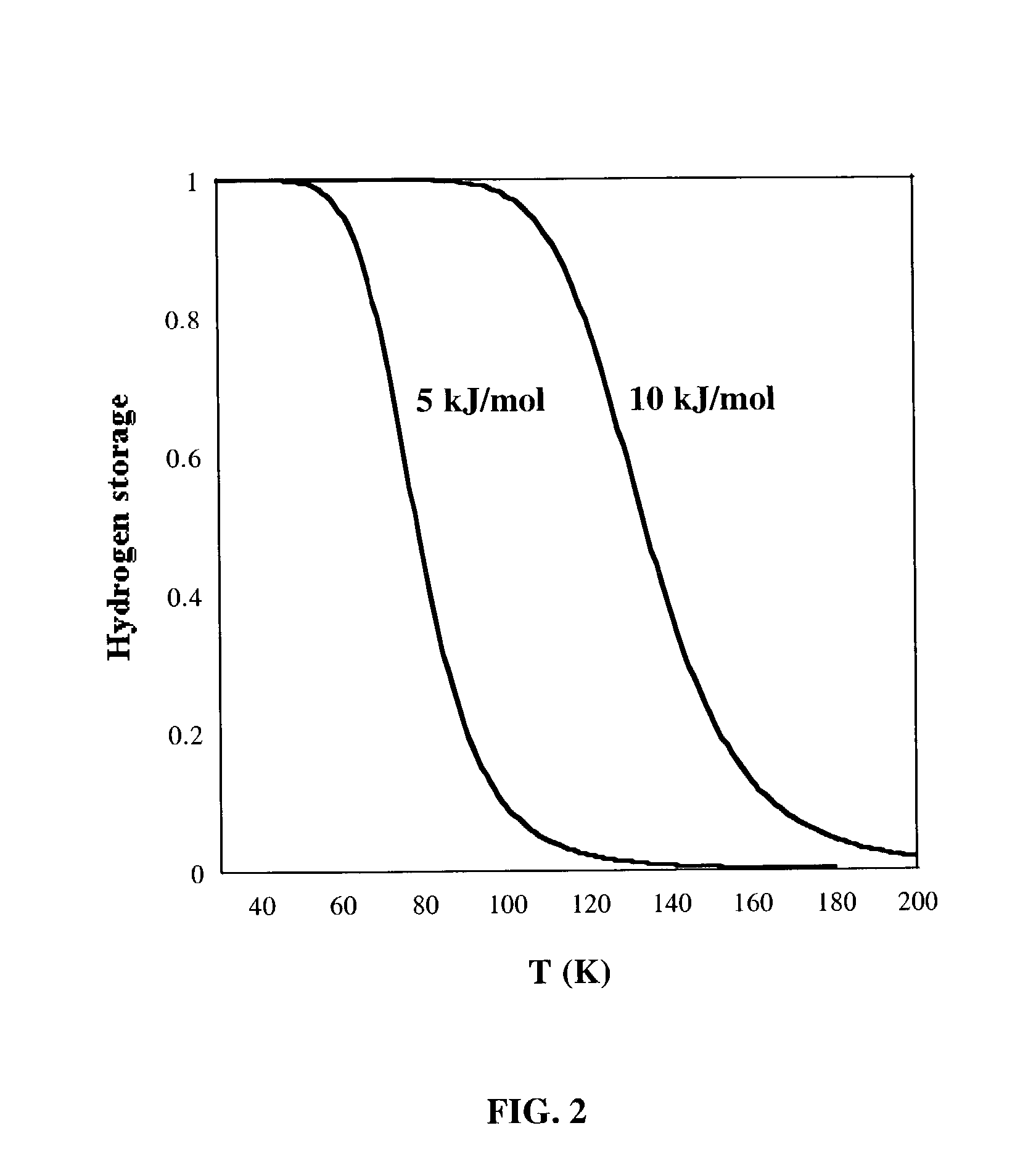

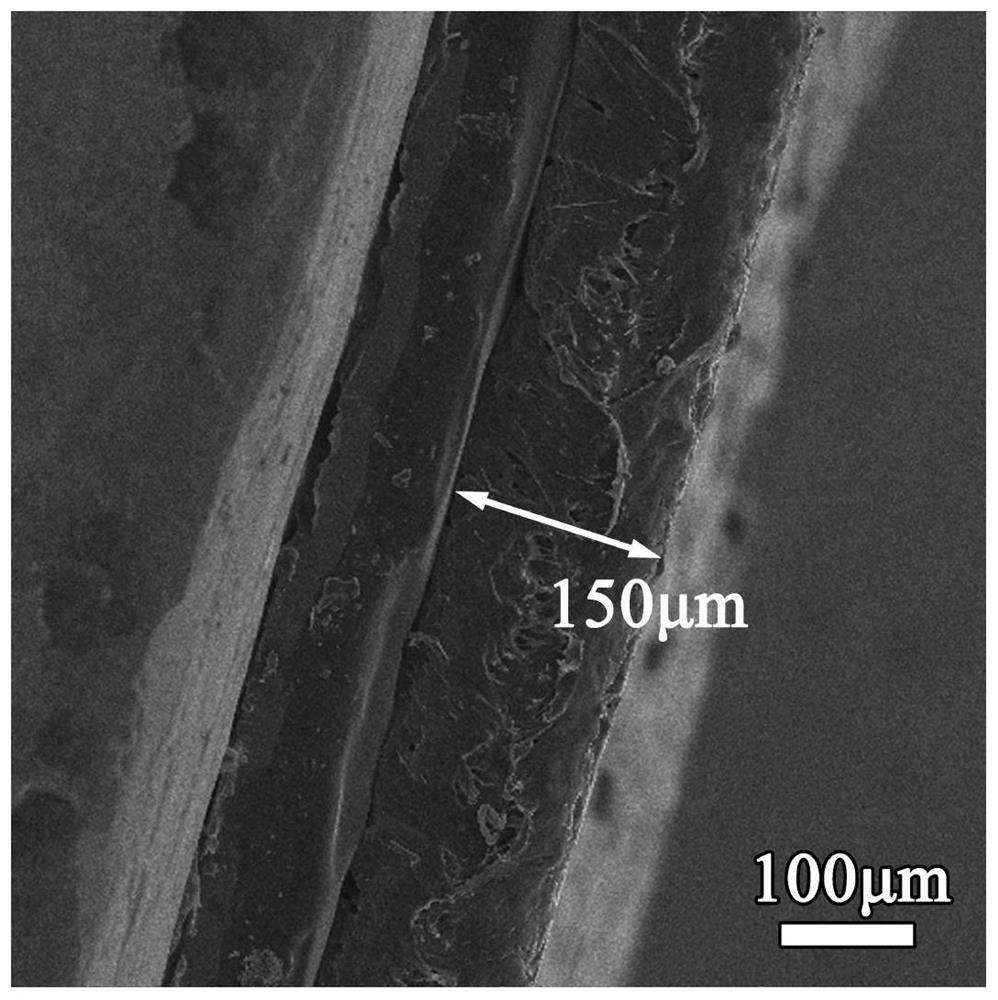

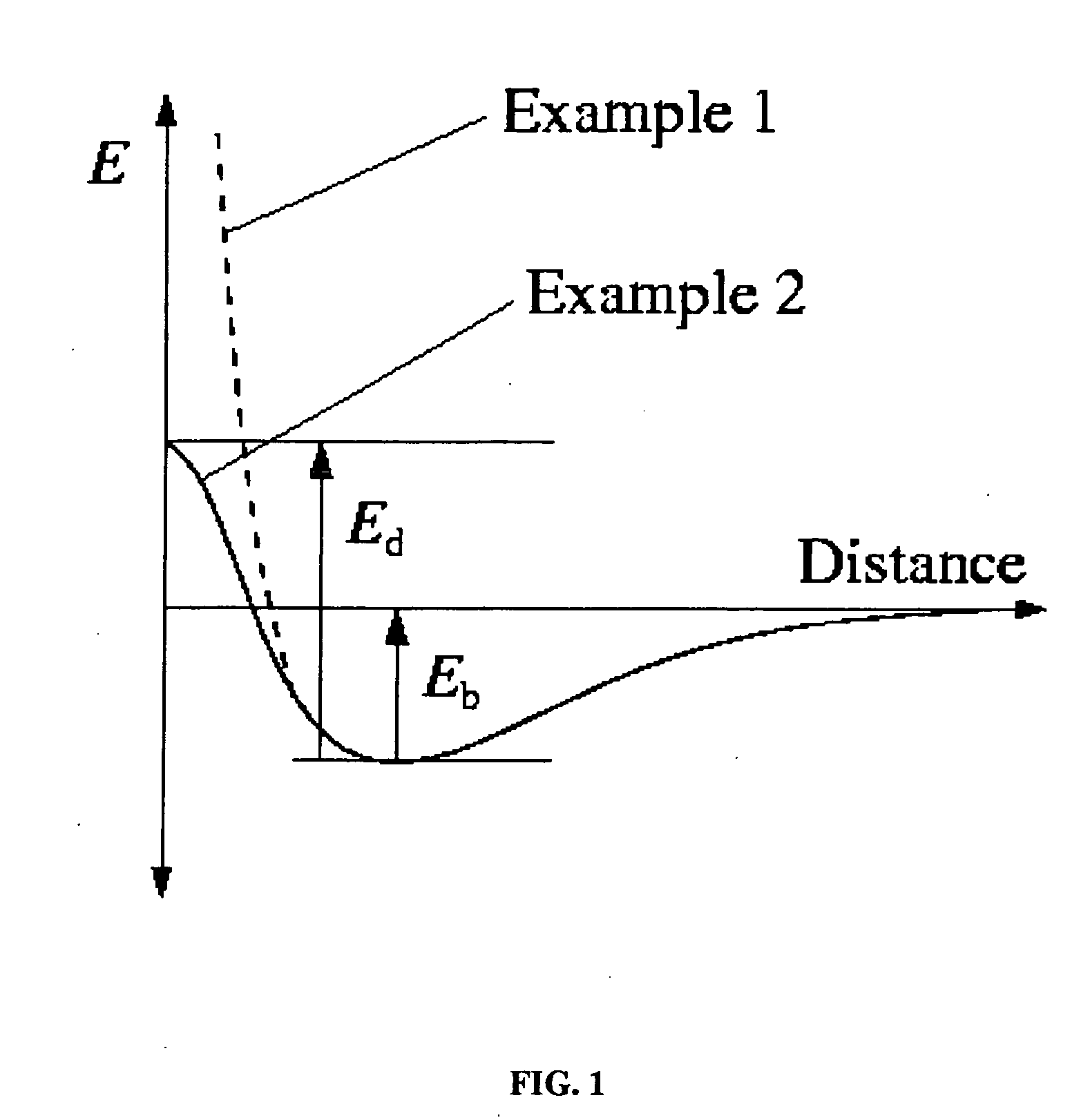

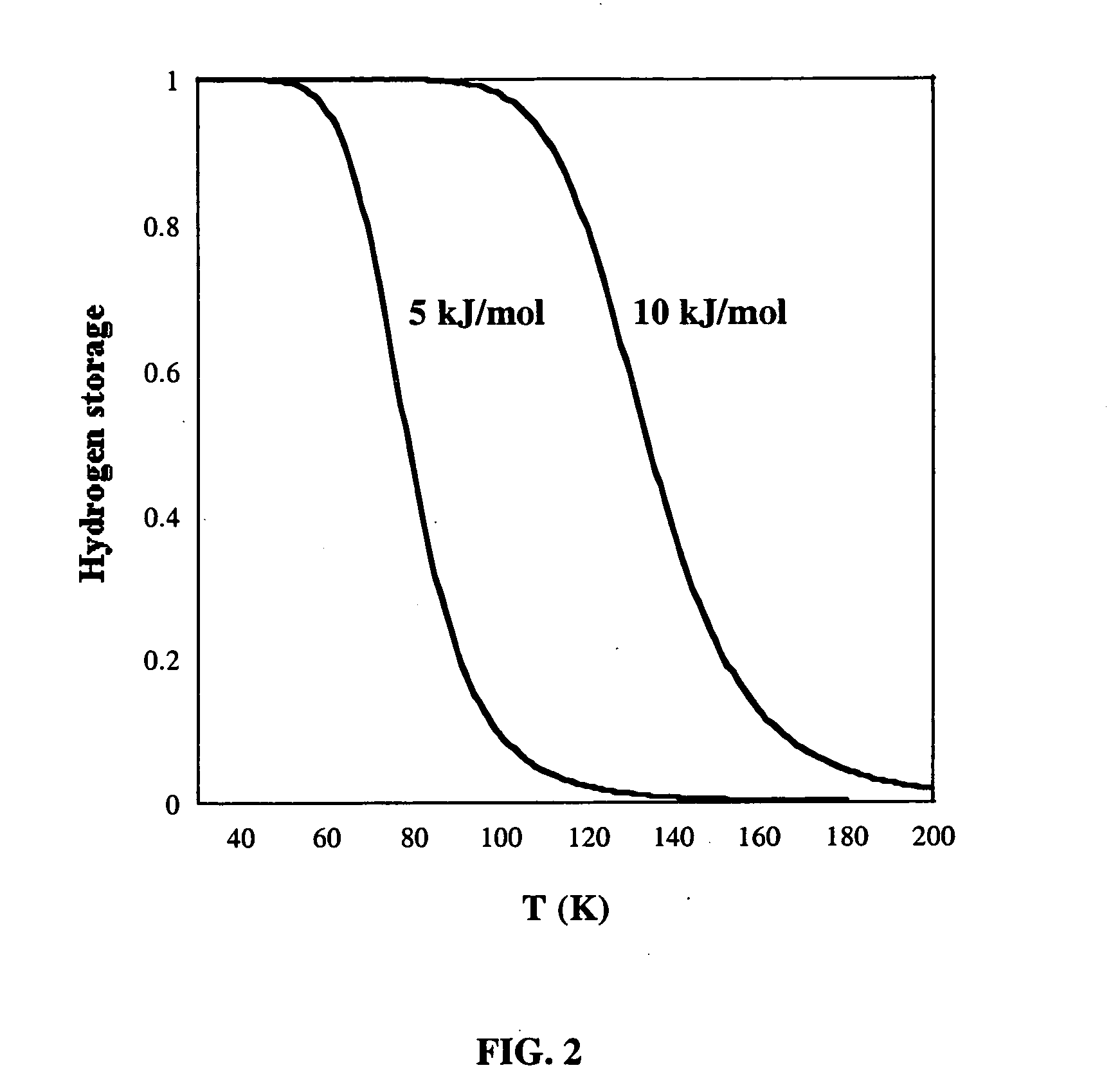

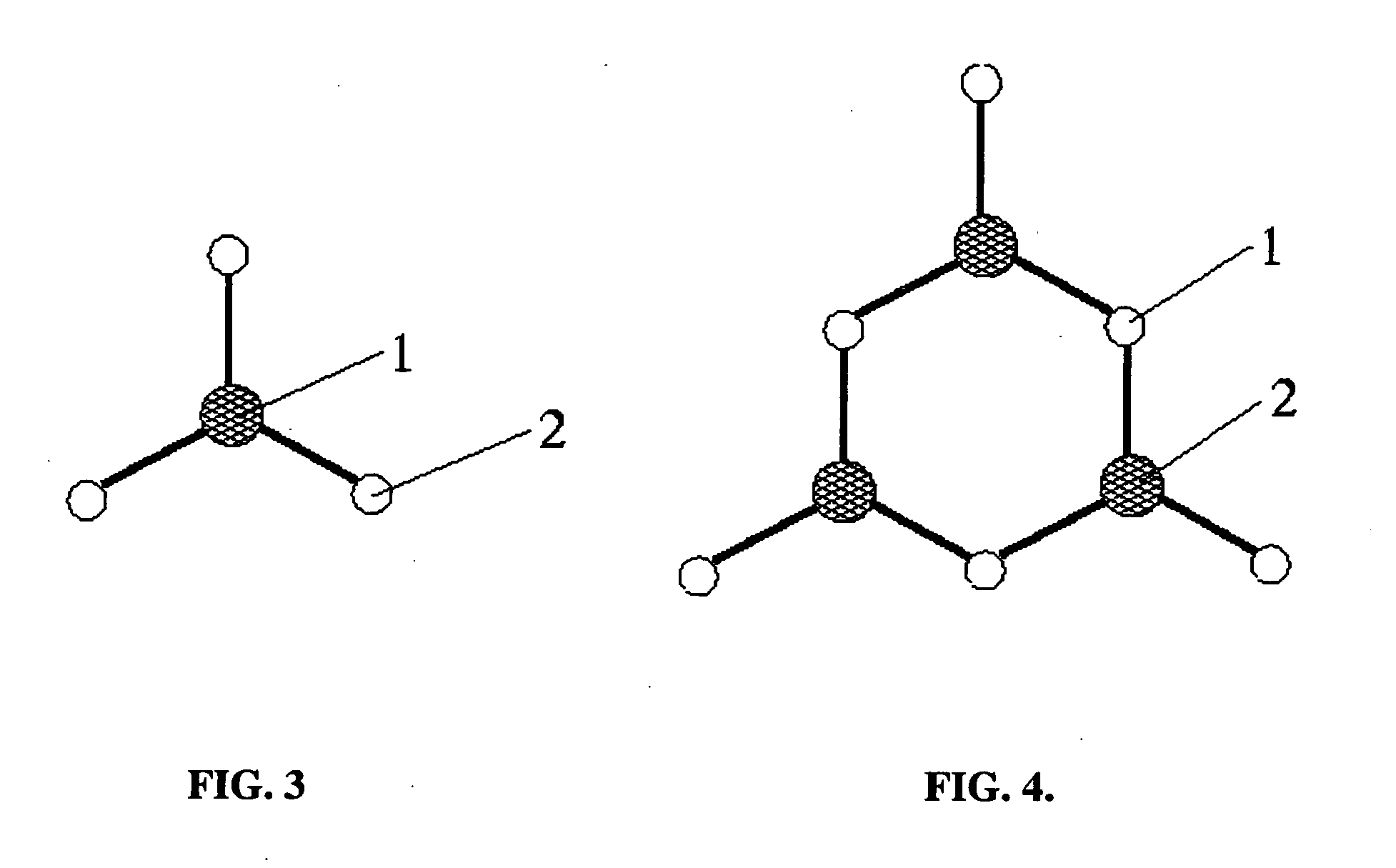

A hydrogen storage medium is provided, where the medium is comprised of boron oxide and closely related compounds such as orthoboric acid, metaboric acid, hydrated boric acid, and disodium borohydrate. The medium is substantially an amorphous glassy network, albeit with local regions of order, pores, and networks that provide surface area. Hydrogen is adsorbed by the medium with a heat of adsorption of about 9 kJ / mol to about 13 kJ / mol, a value which is higher than that of the heat of adsorption of hydrogen on carbon. The value for the heat of adsorption of hydrogen on the inventive storage medium is provided by computation, and corroborated by experimental observation. The higher heat of adsorption of the medium provides for operation at temperatures higher temperatures higher than those provided by carbon. Further provided are methods by which the storage medium can be prepared in such a form so as to permit high capacity hydrogen storage, as well as an apparatus, with the inventive medium disposed therein, for storing hydrogen.

Owner:NANOMIX

High temperature resistant composite silicone rubber insulator formulation

The invention relates to high temperature resistant composite silicone rubber insulator formulation. The formulation comprises the following components in percentage by weight: 30-50 percent of methyl vinyl silicone rubber, 10-20 percent of fumed silica, 30-50 percent of aluminium hydroxide, 0.3-1.5 percent of hydroxyl silicone oil, micro-dosage of stearic acid , micro-dosage of platinum complex, 1-2 percent of hydrogen silicon oil, 0.02 percent of retarder, 1-3 percent of cerium siloxane, and micro-dosage of metaboric acid, wherein the content sump of the components is 100 percent. By adopting the formulation provided by the invention, only one-step vulcanization process is required, the heat resistance performance of the silicone rubber can be improved better, the components of the silicone rubber can be mixed uniformly, the processing performance of the rubber material can be improved, and the mechanical strength of the vulcanizing silicone rubber can be improved.

Owner:GUIZHOU XINKAIRONG RUBBER PLASTIC ELECTRONICS TECH

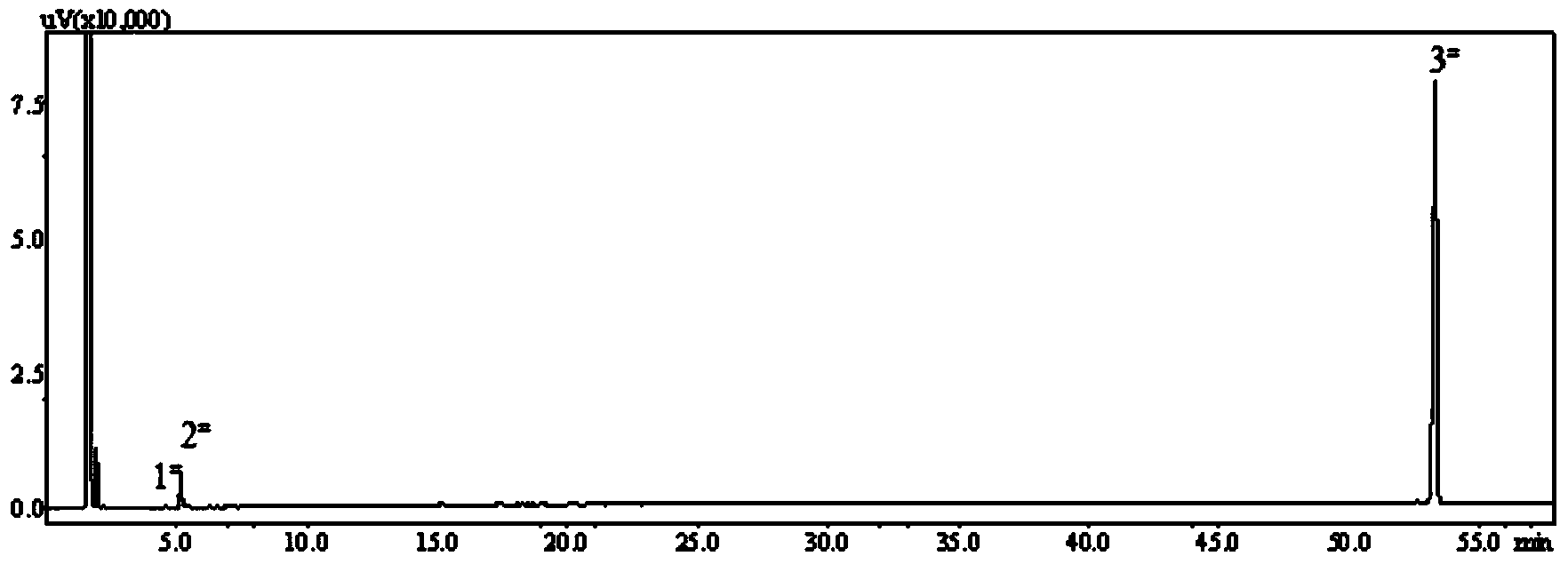

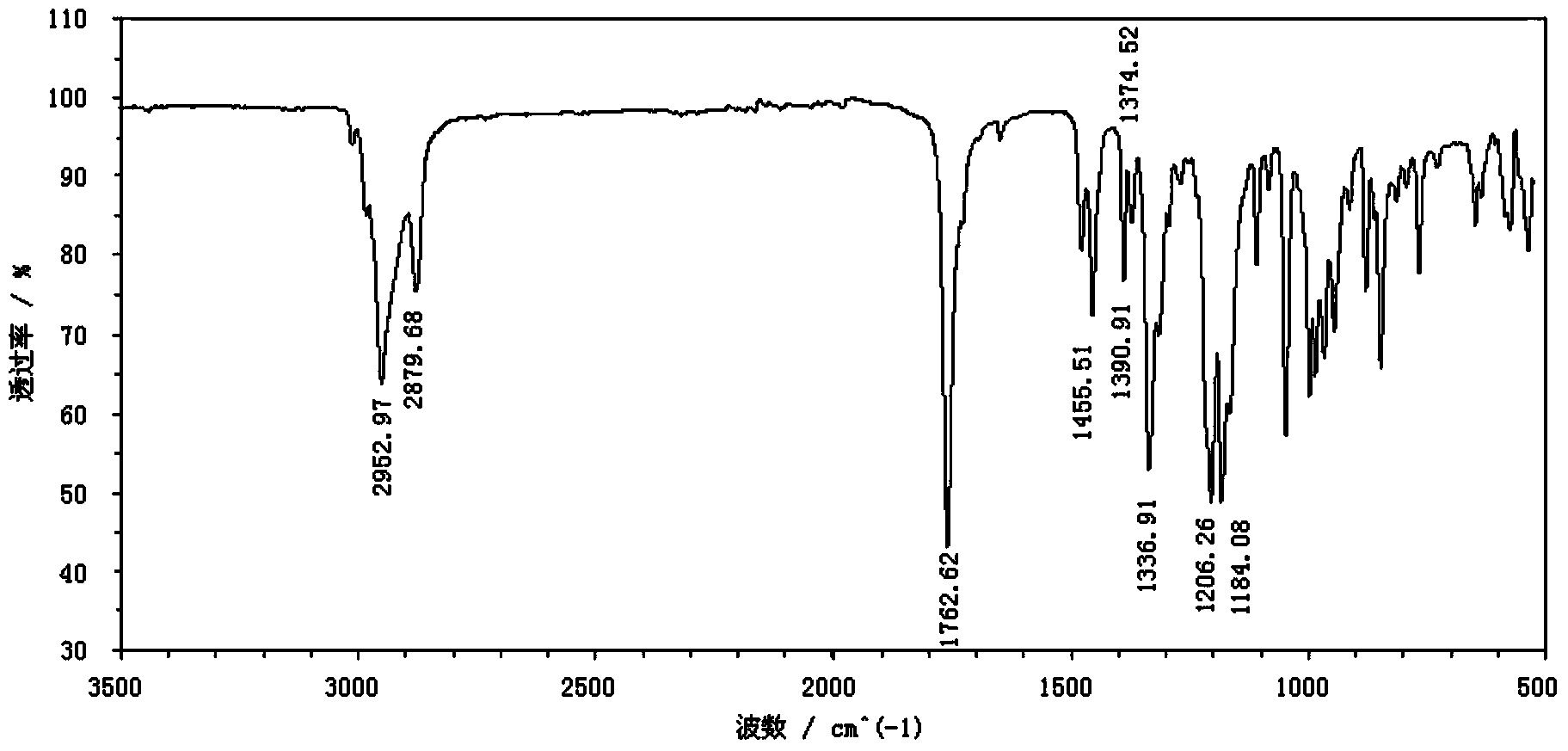

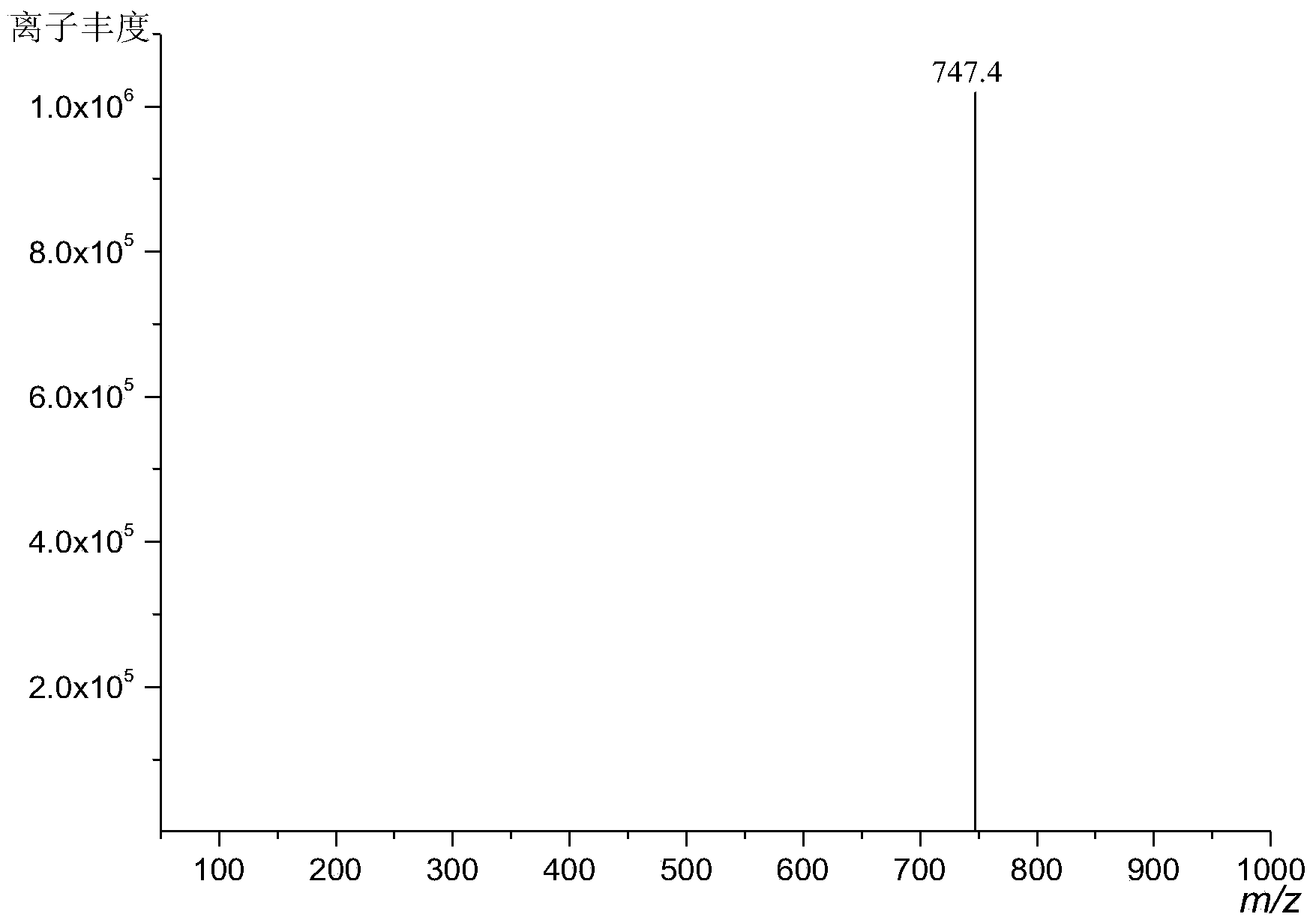

Method for synthesizing diisoborneol oxalate

ActiveCN103980117AMild reaction conditionsEasy to getOrganic compound preparationCarboxylic acid esters preparationWater vaporSolvent

The invention discloses a method for synthesizing diisoborneol oxalate. The diisoborneol oxalate is prepared from such raw materials as industrial camphene, camphene, tricyclene and isoborneol. The method comprises the following steps: dissolving raw materials in a certain amount of an organic solvent, reacting with anhydrous oxalic acid at certain temperature for a certain duration in the presence of such catalysts as boron anhydrous, pyroboric acid or metaboric acid or titanium sulfate, or metatitanic acid, filtering and removing the catalysts and unreacted anhydrous oxalic acid, washing for several times, rotatably evaporating upper liquid to remove most solvents, removing camphene and tricyclene as raw materials which are not reacted completely as well as a few of isoborneol as a byproduct to obtain a crude product, and recrystallizing to obtain diisoborneol oxalate. The method disclosed by the invention can adopt such organic solvents as aromatic hydrocarbon and branched paraffin as reaction mediums in reaction. The method, which adopts conventional heating, is moderate in conditions, simple and convenient to operate, low in side reaction and high in product yield, and raw materials are easily separated from products.

Owner:株洲松本药业有限公司

Extreme-pressure anti-wear lubricating agent

InactiveCN104450143ALow high temperature coefficient of frictionImprove the lubrication effectLubricant compositionCelluloseSodium tetrafluoroborate

The invention provides an extreme-pressure anti-wear lubricating agent, and relates to the technical field of high-temperature lubricating agents. The extreme-pressure anti-wear lubricating agent comprises components in weight ratio as follows: 0.1%-3% of a component A, 8%-35% of a component B, 2%-6% of a component C, 0.5%-5% of a component D, 0.5%-4% of a component E, 0.5%-4% of a component F, 0.8%-4% of a component G, 0.2%-1% of a component H and the balance of water, wherein the component A is one of or a mixture of sodium carboxymethylcellulose and xanthan gum; the component B is one of or a mixture of talc powder and bentonite; the component C adopts sodium silicate; the component D adopts one of or a mixture of two or three of sodium fluoborate, borax decahydrate and calcium metaborate; the component E adopts one of zinc stearate and lithium stearate; the component F adopts one of nano fullerene and alkaline sulfonate; the component G adopts sodium polyacrylate; and the component H adopts a water-based defoaming agent. The high-temperature friction coefficient value is very low, the lubricating property is excellent, and the lubricating requirement of current equipment under the high-temperature and high-load conditions can be well met.

Owner:NANHUA UNIV +1

Preparation method of trimethyl borate

InactiveCN102002064AEasy to implementProcess condition controlGroup 3/13 element organic compoundsReaction speedRaffinate

The invention discloses a preparation method of trimethyl borate. The method comprises the following steps of: (1) heating and dehydrating a boric acid solid to prepare metaboric acid and pyroboric acid solids; (2) adding the metaboric acid and pyroboric acid solids which are obtained in the step (1) to methanol to make the mixture react under a stirring state; (3) heating and distilling the reaction solution obtained in the step (2) to obtain an azeotrope solution of the methanol and the trimethyl borate, distilling and cooling raffinate to obtain boric acid; and (4) separating the azeotrope solution of the methanol and the trimethyl borate, which is obtained in the step (3), to obtain a trimethyl borate product. In the invention, by firstly heating and dewatering the boric acid to prepare the metaboric acid and the pyroboric acid and then making the metaboric acid and the pyroboric acid react with the methanol to prepare trimethyl borate, the reaction speed is accelerated, the conversion per pass is improved, the reaction conditions are mild and no risks exist.

Owner:SHANDONG GUOBANG PHARMA

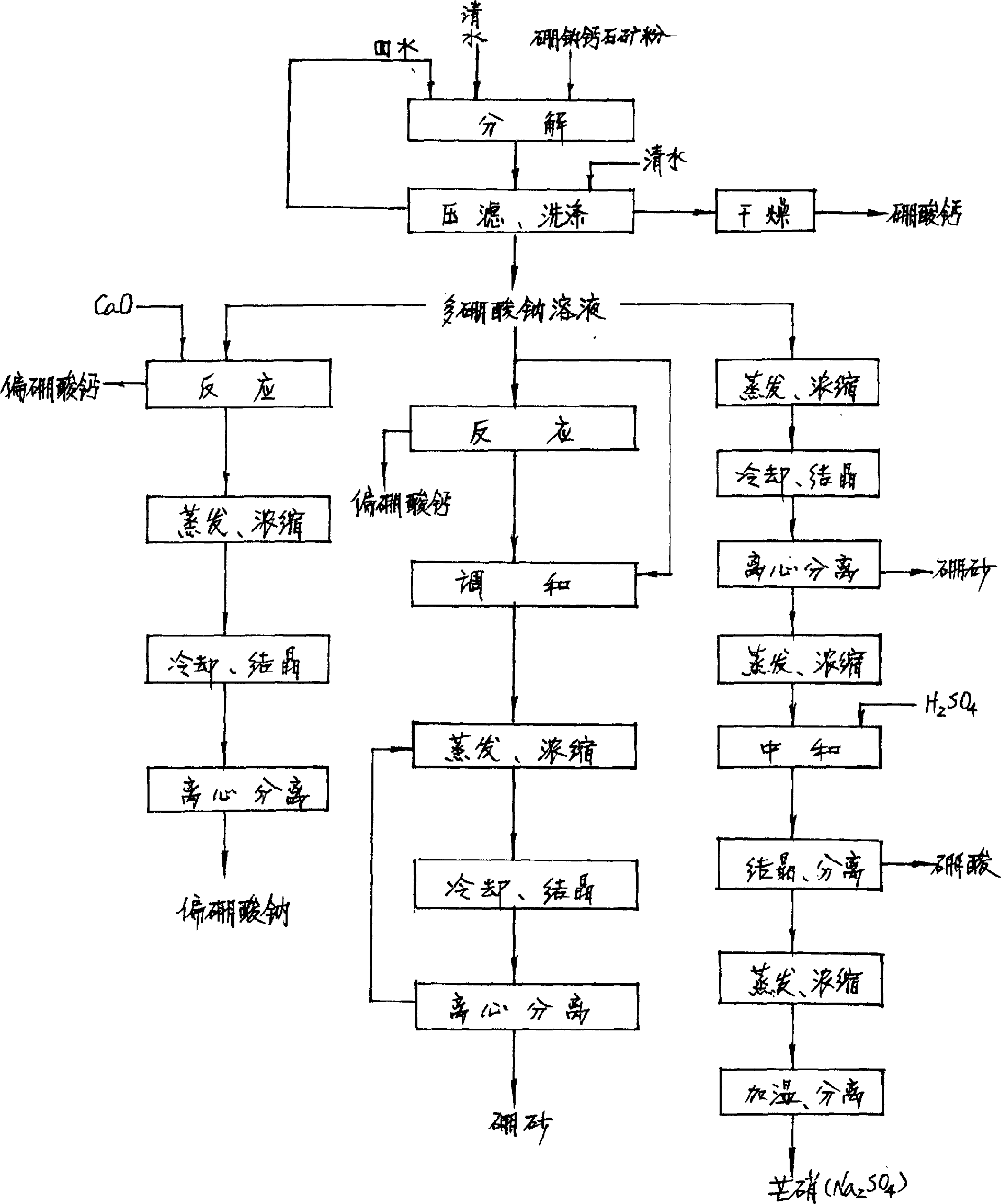

Manufacture of boron-containing compound using cotton balls hydrothermal method and its comprehensive utilization

The invention provides a boron-containing compound prepared by ulexite hydrothermal method and the synthetic utilization thereof. And the raw material is 80-200 mesh ulexite or probertite powder containing B2O3 >=37.5 wt%, which is prepared into calcium borate product and sodium polyborate solution containing B2O3 >=40wt% and Na2O >=0.5wt%, meeting alkali free glass and boron-containing raw material requirements; synthetically utilizing the sodium polyborate solution, evaporating and concentrating, cooling and crystallizing without adding in sodium- containing alkali or salt, so as to be able to prepare borax product; adding less sulphuric acid into borax mother liquor after crystallization and separation processing to be able to prepare boric acid; adding CaO or Ca(OH)2 into the borax mother liquor or sodium-containing polyborate with borax to be able to prepare purer calcium metaborate and simultaneously sodium metaborate by-product.

Owner:DALIAN UNIV OF TECH

Bathing agent possessing health and medical function and its preparation method

InactiveCN1839785ARegulates metabolismPrevent agingCosmetic preparationsToilet preparationsAdditive ingredientLotion

The invention relates to a bathing lotion with the action of medical treatment, which comprises the following ingredients (by weight portion), sodium hydrogen carbonate 2.0-40.0%, sodium carbonate 1.5-6.0%, metasillicio acid 20.0-26.0%, sodium fluoride 0.5-5.0%, metaboric acid 2.5-6.0%, sodium bromide 5.0-8.0%, strontium chloride 2.0-6.0%, sodium chloride 10.0-15.0%, complexing agent 18.0-25.0%, and perfume compound 0.5-1.0%. The lotion has the effect of moistening and whitening skin.

Owner:高明全

Doped low-temperature phase barium metaborate single crystal, the manufacturing method thereof and wave changing elements therefrom

ActiveUS20110170174A1Polycrystalline material growthOptical filtersMohs scale of mineral hardnessNonlinear optics

The present invention relates generally to the field of synthetic crystal, and more particularly, this invention relates to doped low-temperature phase barium metaborate single crystal, growth method and frequency-converter. Molten salt method was adopted. The single crystal completely overcome the shortcomings of BBO with strong deliquescence, almost no deliquescence; its frequency doubling effect and optical damage threshold has improved greatly compared with the BBO; its hardness increased significantly, the single crystal with Shore hardness of 101.3 and Mohs hardness of 6, however, BBO with Shore hardness of 71.2 and Mohs hardness of 4. From the UV-Vis region transmittance curves tests, the cut-off wavelength of the single crystal is 190 nm, wavelength of absorption onset is 205 nm. BBSAG is widely applied in the fields of laser and nonlinear optics, and in terms of frequency-converter of ultraviolet and deep-ultraviolet due to its excellent properties better than BBO.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Composite powder with efficient adsorption effect

InactiveCN104353420AImprove adsorption capacityNo harm to healthGas treatmentOther chemical processesPhysical well beingAdsorption effect

The invention discloses a composite powder with an efficient adsorption effect. The composite powder comprises the following raw materials in parts by weight: 50-60 parts of attapulgite, 10-20 parts of diatomite, 25-30 parts of rice hull powder, 4-10 parts of ethyl orthosilicate, 2-3 parts of absolute ethanol, 4-5 parts of 25% ammonia water, 0.4-1 part of sodium potassium silicate, 0.1-0.2 part of ammonium ferrous sulfate, 0.5-1 part of metaboric acid, 80-100 parts of de-ionized water and 1-2 parts of ammonium zirconium carbonate. The powder is strong in adsorption power, can be used for effectively adsorbing formaldehyde in air, is natural, nontoxic, odor-free and good in environmental protection property, and is a natural environment-friendly product; no harmful chemical substances are volatilized, and the body health of users cannot be harmed.

Owner:ANHUI BOSHUO TECH

Catalyst for preparing cyclic carbonate compound by taking CO2 as raw material

ActiveCN111560002AEfficient responseEfficient CatalysisOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention provides a catalyst for preparing a cyclic carbonate compound by taking carbon dioxide (CO2) and an epoxypropane derivative as raw materials. The catalyst is ionic liquid containing metaborate anions (BO2<->). The cyclic carbonate compound can be prepared under the conditions of no additional organic solvent and lower CO2 pressure. According to the method, the catalyst is easy to synthesize, the process is green and simple, no pollution is caused, and the application value is high. Research on a reaction mechanism finds that basic anions BO2<-> in the ionic liquid are the key toa catalytic reaction, CO2 can be effectively adsorbed, ring opening of the epoxypropane derivative is promoted, and then the cyclic carbonate compound is generated through the reaction.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing special magnesium borate for oriented silicon steel

The invention relates to the field of oriented silicon steel plate manufacture, in particular to a method for preparing special magnesium borate for oriented silicon steel. The method solves the problems of poor adhesion, dispersibility and electromagnetic performance and the like of the conventional boron aid. The method comprises the following steps of: (1) pouring aqueous solution of magnesium bicarbonate and boric acid in a ratio into a reaction kettle; (2) performing sedimentation treatment on the mixed solution; (3) then conveying the sediment into a pyrolysis tank, adding finished magnesium borate crystal seeds and silane coupling agent into the pyrolysis tank, and producing a mixture of nano magnesium carbonate and metaboric acid by using a liquid phase precipitation method; (4) filter-pressing the pyrolysis product to obtain filter cakes; (5) treating the filter cakes in a high-temperature crystal oven to form nano magnesium borate powder with complete crystal; and (6) grading the material discharged out of the high-temperature crystal oven with jet milling to obtain a screened substance of less than or equal to 320 meshes. All indexes of the special magnesium borate are superior to that of the primary product, and in particular, the adhesion, dispersibility and electromagnetic performance are remarkably improved, and the quality of the oriented silicon steel plate is improved; and the method has the advantages of simple production process, lower cost and no three-waste pollution.

Owner:山西银圣科技有限公司

Low-cost automobile repairing paint

InactiveCN104927608AImprove adhesionGood acid and alkali resistanceAnti-corrosive paintsPolyether coatingsPolymer sciencePolyethylene glycol

Low-cost automobile repairing paint is prepared by the following raw materials in part by weight: 13-18 parts of melamine formaldehyde resin, 7-9 parts of polyisobutene, 6-7 parts of acetic acid isopropyl ester, 7-9 parts of dichloromethane, 9-14 parts of barium metaborate, 1-4 parts of sodium polyacrylate, 0.5-2 parts of antirust agents, 8-13 parts of hydroxyethyl acrylate, 6-8 parts of polyethylene glycol, 1.5-4 parts of butyl acetate, 7-10 parts of sorbitan stearate, 8-12 parts of medium-oil linseed alkyd resin, 1.2-4 parts of carboxymethyl cellulose, 8-14 parts of silicon dioxide with 75 meshes and 14-20 parts of high-level fatty alcohol. The low-cost automobile repairing paint has the advantages that the cost is low, the adhesion of the paint is high, and the acid-base resistance property of the paint can be improved well.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Method for synthesizing dibornyl oxalate by using borneol

ActiveCN103992221AExpand application channelsMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationDistillationWater vapor

The invention discloses a method for synthesizing dibornyl oxalate by using borneol. The method comprises the following steps: dissolving borneol into a certain amount of organic solvent; reacting with anhydrous oxalic acid at a certain temperature for certain time in the presence of the catalysts such as boric oxide, pyroboric acid or metaboric acid or titanium sulfate and metatitanic acid; filtering to remove the catalysts and unreacted anhydrous oxalic acid; washing with water many times; distilling the upper-layer liquid to remove the organic solvent to obtain a crude product; and performing water vapor distillation, recrystallization and the like to remove the unreacted raw material borneol, thus obtaining dibornyl oxalate. The raw material borneol comprises d-borneol, l-borneol and dl-borneol. In the reaction, the organic solvents such as aromatic hydrocarbon and branched paraffin can be used as reaction media. With a conventional heating process, the method disclosed by the invention has the advantages of mild conditions, simplicity in operation, easy separation of raw material from product, few side reactions and high product yield.

Owner:株洲松本药业有限公司

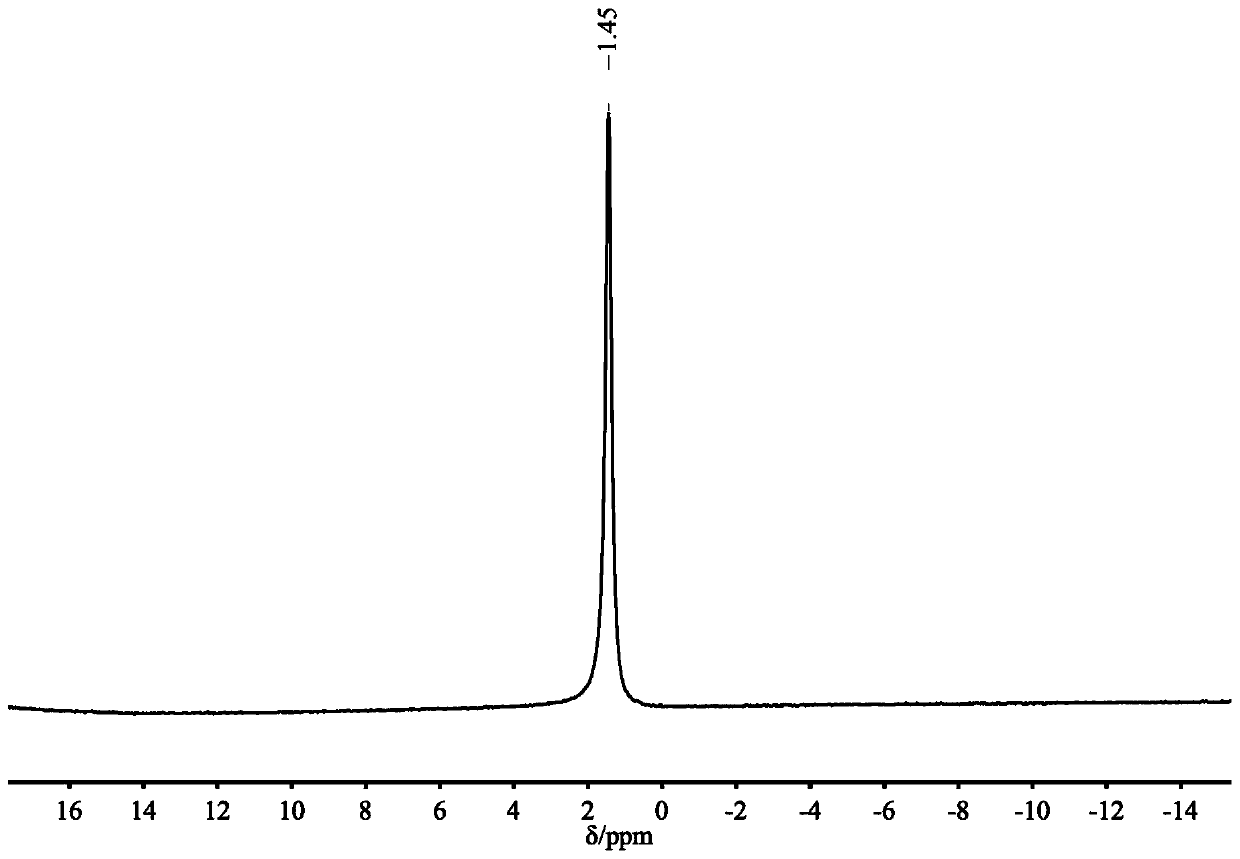

Process for preparing lithium bis (oxalato) borate

PendingCN112409393AAchieve thorough mixingReduce control difficultySecondary cellsGroup 3/13 element organic compoundsOXALIC ACID DIHYDRATELithium hydroxide

The invention discloses a process for preparing lithium bis (oxalato) borate. The process comprises the following steps: 1, uniformly mixing lithium hydroxide or lithium carbonate with oxalic acid oroxalic acid dehydrate; 2, adding ortho-boric acid or metaboric acid into the uniformly reacted raw materials in the step 1, and uniformly mixing; 3, performing dry pressing on the raw materials obtained in the step 2 under pressure to form tablets, and placing the pressed tablets in a drying box; 4, continuously adding phosphorus pentoxide into the drying box, and continuously performing drying toobtain a semi-finished product of lithium bis (oxalato) borate; 5, dissolving the semi-finished product obtained in the step 4 with anhydrous acetonitrile, filtering out insoluble substances, evaporating and concentrating until a white solid appears, recovering acetonitrile, and drying the obtained white solid in a drying oven to obtain a high-purity lithium bis (oxalato) borate product. Comparedwith the prior art, the process for preparing lithium bis (oxalato) borate has the advantages of simple operation, economy, environmental protection, low by-product content in the reaction and high reaction efficiency.

Owner:临沂小篆新材料科技有限公司

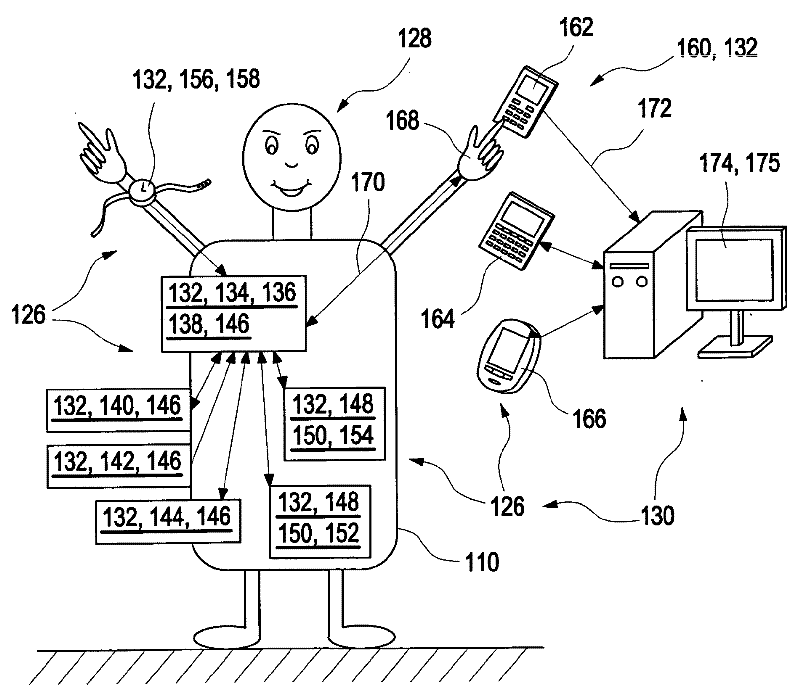

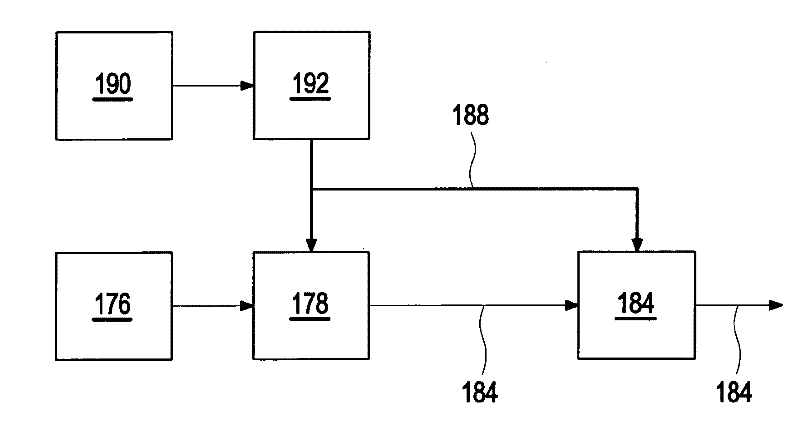

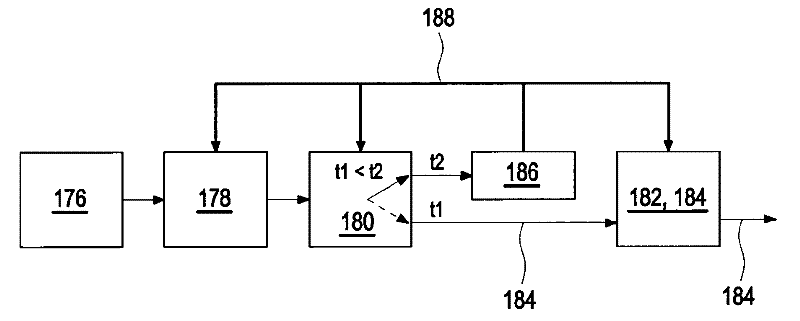

Medical Monitoring Network

InactiveCN102281813APrecise diagnostic statementConvenient treatmentSensorsMedical equipmentBlood pressureGlucose polymers

The network (126) has two different network nodes (132) connected with a body (110) of a patient (128). The two network nodes have a medical function such as diagnostic function and medication function. The network nodes are designed to directly communicate with one another via the body of the patient and exchange data and / or instructions. The network nodes include a temperature sensor (140), blood pressure sensor (142), sensor (144) for detecting glucose, lactate, carbon dioxide, boric acid and metaboric acid and another sensor (146) for detecting bodily functions i.e. kidney function. An independent claim is also included for a medical system i.e. operation system and / or intensive-medical system, including a communication device.

Owner:F HOFFMANN LA ROCHE & CO AG

Medical antibacterial EVA foam plastic and preparation method thereof

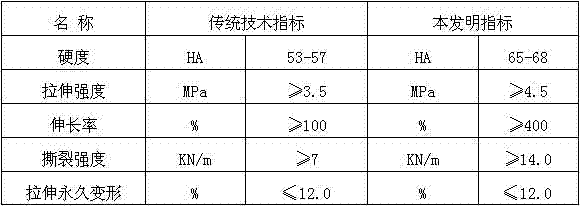

InactiveCN104448522ARelative density is smallHigh elongation at breakPolymer scienceStaphyloccocus aureus

The invention discloses a medical antibacterial EVA foam plastic and a preparation method thereof. The EVA foam plastic is prepared through the following steps: weighing the following components: EVA, PVA, nanometer activated zinc oxide, aluminum powder, POE, organic siloxane, an antioxidant, methyl phenyl silicone oil, EAA, barium metaborate, a surface treating agent, PA6, LLDPE, PA66 and talcum powder in parts by weight, uniformly mixing the weighed components, and extruding and pelleting the uniformly-mixed components so as to obtain the EVA foam plastic. The EVA foam plastic has the advantages that the relative density is reduced by 14-18%, the breaking elongation rate is increased by 50-90%, the antibacterial rate for escherichia coli is 99.5-99.9%, the antibacterial rate for golden staphylococcus is 99.5-99.9%, the tear strength is improved by 30-40%, the tensile strength is 22-28 MPa, the falling ball impact strength is 47-53 MPa / mm, and the vicat softening point is 80-100 DEG C.

Owner:SUZHOU BEC BIOLOGICAL TECH

Wear-resistant and high-toughness material for 3D printing ceramic

InactiveCN110002848AImprove function and effectPromote redox reactionsAdditive manufacturing apparatusCeramic materials productionDispersityKerosene

The invention discloses a wear-resistant and high-toughness material for 3D printing ceramic, belongs to the field of ceramic materials, and solves the problem of poor wear resistance and toughness ofcommon ceramic materials at present. The ball milling efficiency can be improved by adding kerosene and absolute ethyl alcohol as ball milling media, and combustion of the kerosene can promote unoxidized metal components in a ball milling material to have a redox reaction. Aluminum oxide contained in fly ash and an Mg<2+> component in palygorskite can produce a magnesia-alumina spinel component with erosion resistance and abrasion resistance at high temperature. A boron oxide component contained in boric sludge added to aids is acid anhydride of boric acid, the acid anhydride can produce boric acid and metaboric acid with water and emit a lot of heat, a boehmite component is embedded in a hard roasted product to improve dispersity and binding force among structures, external friction canbe well scattered, quick wear can be avoided, adsorption can be formed in combination with acrylic resin, the structure compactness of a material system can be improved, and tensile strength and wearresistance can be improved.

Owner:何治伟

Heat insulation anti-sticking coating for mechanical cast steel machining and preparation method of heat insulation anti-sticking coating

InactiveCN104190862APrevent oxidationWidely producedFoundry mouldsFoundry coresXylylenePyrrolidinones

The invention discloses a heat insulation anti-sticking coating for mechanical cast steel machining and a preparation method of the heat insulation anti-sticking coating. The preparation method comprises the steps of weighing magnesia powder, meta-barium borate, water glass, N-methyl-2-pyrrolidinone, activated bentonite, dimethyl formamide, magnesium chloride, xylene, barium chloride, polytetrafluoroethylene, polyimide, ethyl acetate, aluminum paste and paint, feeding magnesia powder, activated bentonite and barium chloride into an edge runner, performing dry mixing, and adding water glass for mixed grinding; feeding polyimide, polytetrafluoroethylene, xylene, ethyl acetate and dimethyl formamide into a reaction kettle for uniform mixing to obtain a mixture, mixing the mixture with the mixed-ground raw materials, adding the rest of the raw materials, grinding the raw materials in a three-roller machine, and adjusting the viscosity. The relative density of a product is 16-18, and the product can be solidified at low temperature; the product can resist high temperature of 1,000-1,200 DEG C, cannot be separated, does not corrode metal equipment, protects steel materials from being oxidized, avoids decarbonization and can be widely produced to continuously replace the conventional material.

Owner:珠海市龙圣模具材料有限公司

Preparation method of modified nickel cobalt lithium manganate ternary positive electrode material

InactiveCN112331844AImprove cycle performanceImprove electrochemical performanceCell electrodesSecondary cellsPhysical chemistryManganate

The invention discloses a preparation method of a modified lithium nickel cobalt manganate ternary positive electrode material, which comprises the following steps: mixing and sintering the lithium nickel cobalt manganate ternary positive electrode material and metaboric acid at 690-710 DEG C for 5-7 hours to obtain the modified lithium nickel cobalt manganate ternary positive electrode material,wherein the boron content in metaboric acid is 0.10-1.00 wt% of the lithium nickel cobalt manganate ternary positive electrode material. The preparation method provided by the invention can effectively improve the cycle performance of the NCM622 ternary material.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

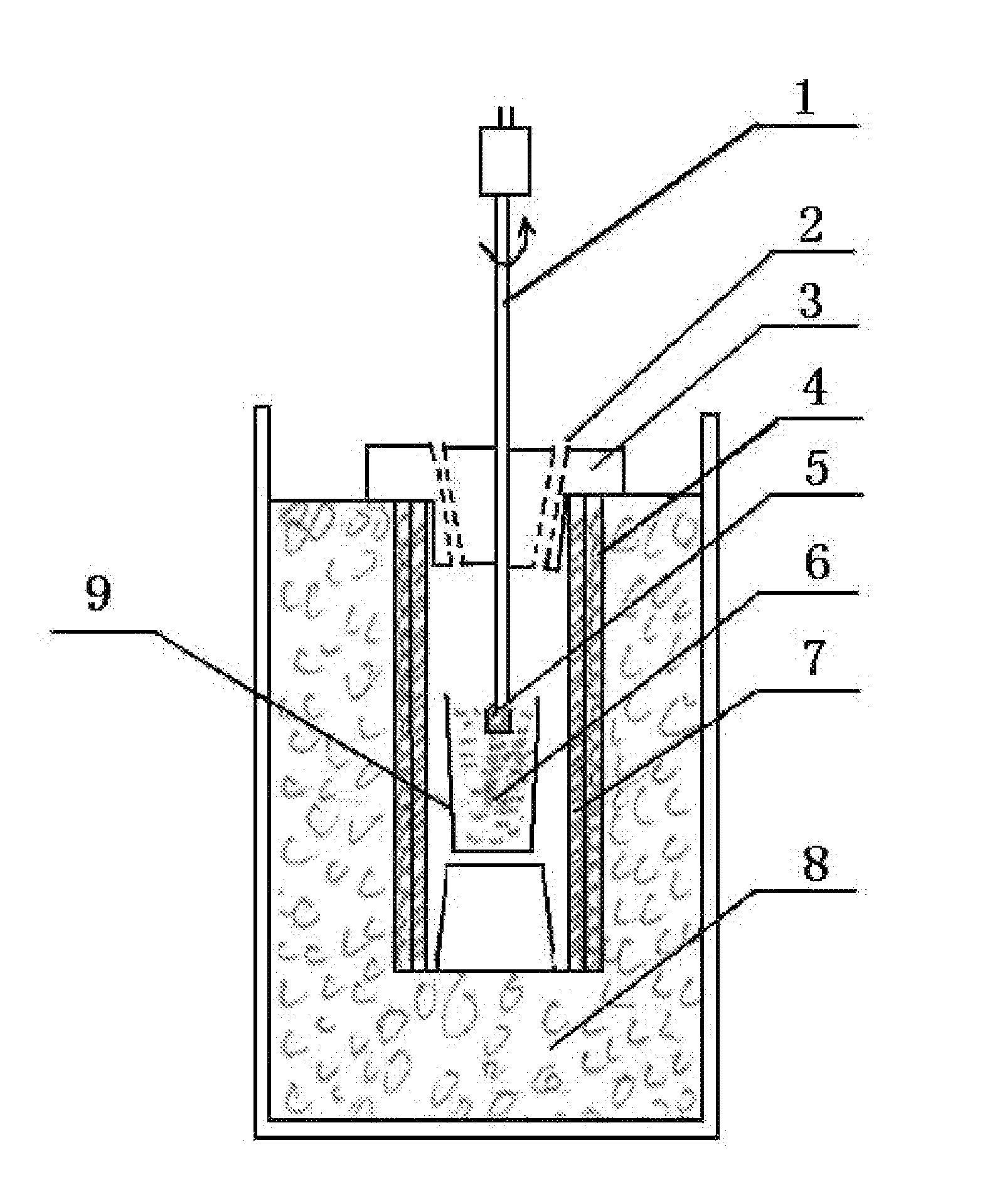

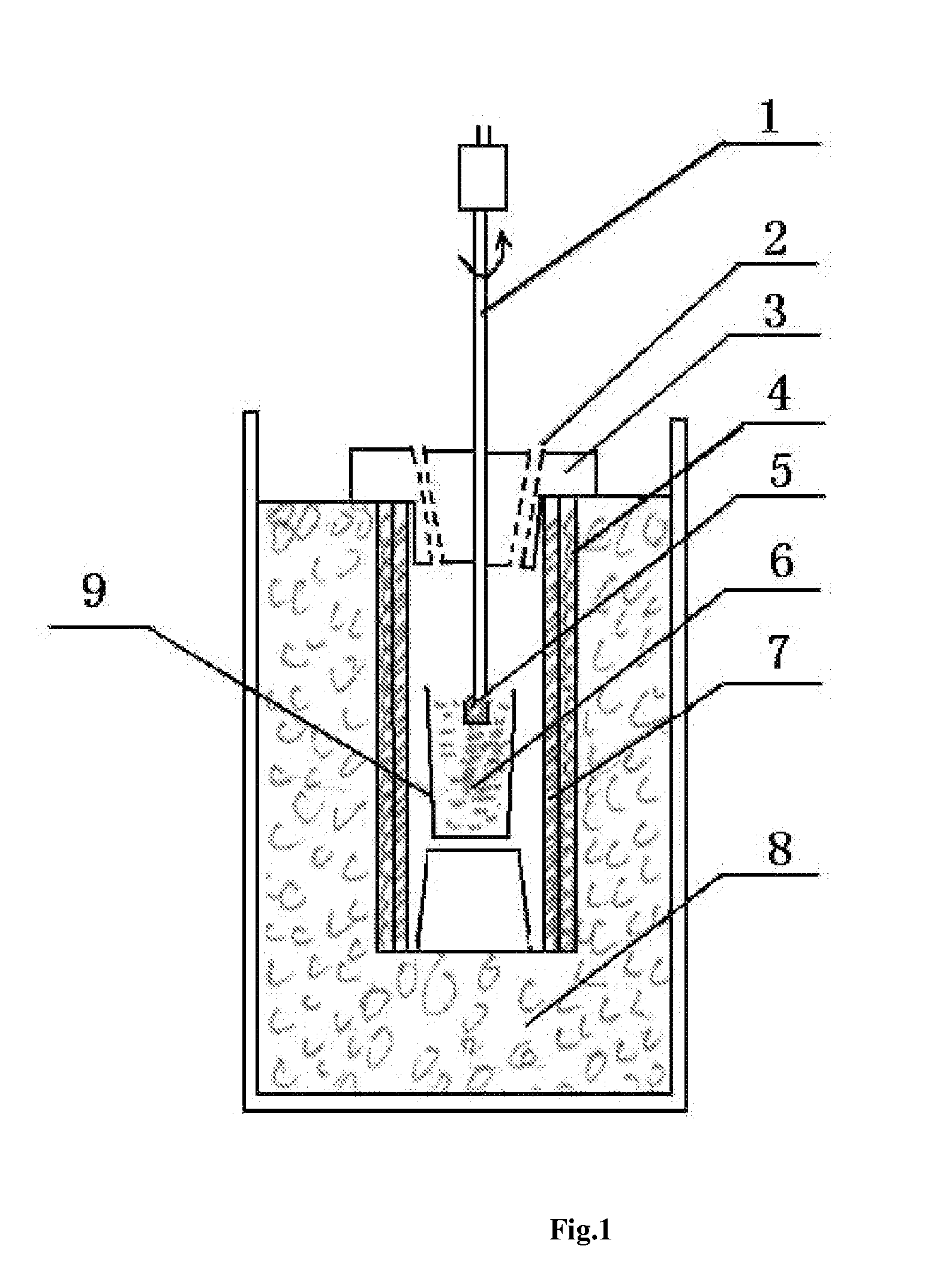

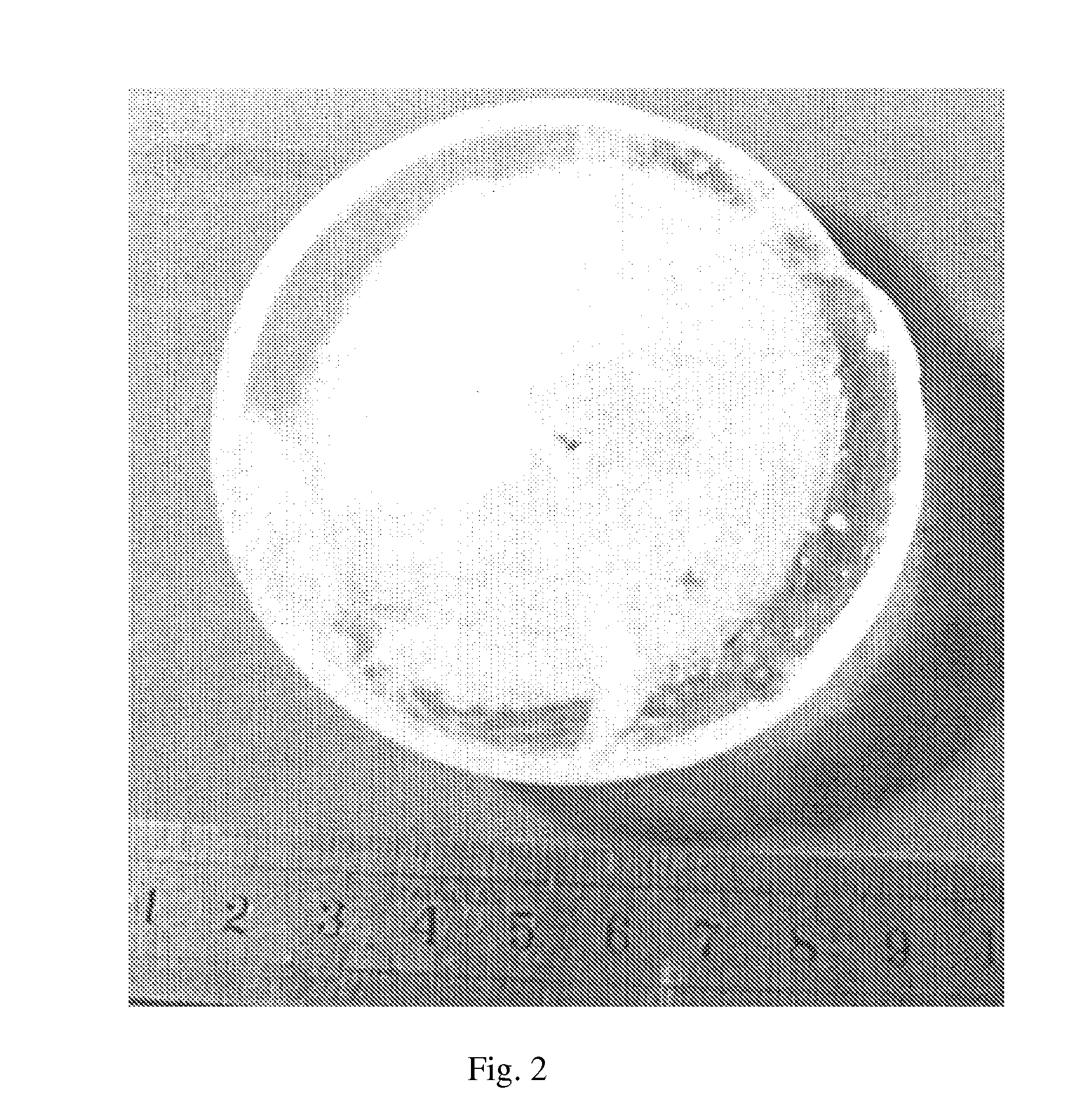

Preparation method for specimen used for measuring silicon contents in ferrosilicon by X-ray fluorometric analysis method

InactiveCN108918562AShorten production timeWill not affect other workMaterial analysis using wave/particle radiationSpectrum analyzerFerrosilicon

The invention relates to a preparation method for a specimen used for measuring silicon contents in ferrosilicon by an X-ray fluorometric analysis method. The preparation method comprises the following steps of primary burdening, pre-oxidation, secondary burdening and fusion. In primary burdening, filter paper and mixed oxidizing agent are used for coating a ferrosilicon specimen, and the specimenis coated into a sphere; in pre-oxidation, a crucible is full of graphite, the spherical specimen is put into a graphite pit, and then, the spherical specimen is oxidized in a high-temperature mufflefurnace to obtain an elliptical specimen; in secondary burdening, ammonium iodide release agent is laid in a platinum vessel, the cooled elliptical specimen is placed and is covered with lithium borate and metaboric acid mixed fusing agent; and in fusion, the platinum vessel is put in a piece fusion machine and is subjected to fusion at the temperature of 900-1050DEG C for 19min to obtain the fused piece, i.e., the specimen, and the specimen can be directly used for an X-ray spectrum analyzer for analysis. By use of the method, various specimens can be simultaneously manufactured, in addition, process controllability is simple, time consumed for experiments is short, manufacture cost is low, and an X-ray fluorometric analysis result is high in accuracy.

Owner:唐山瑞丰钢铁(集团)有限公司

Detergent and preparation method thereof

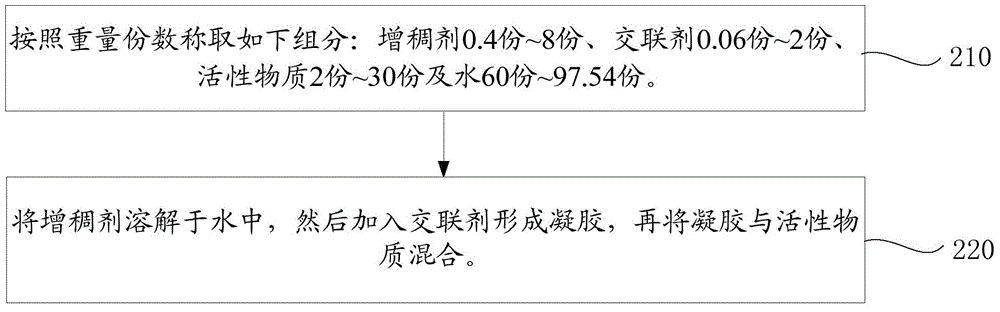

InactiveCN103981039AGood film formingEasy to wrapInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive matterHydrophile

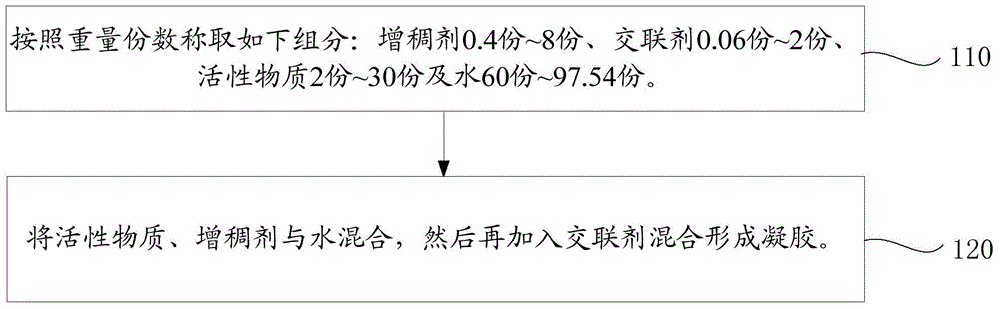

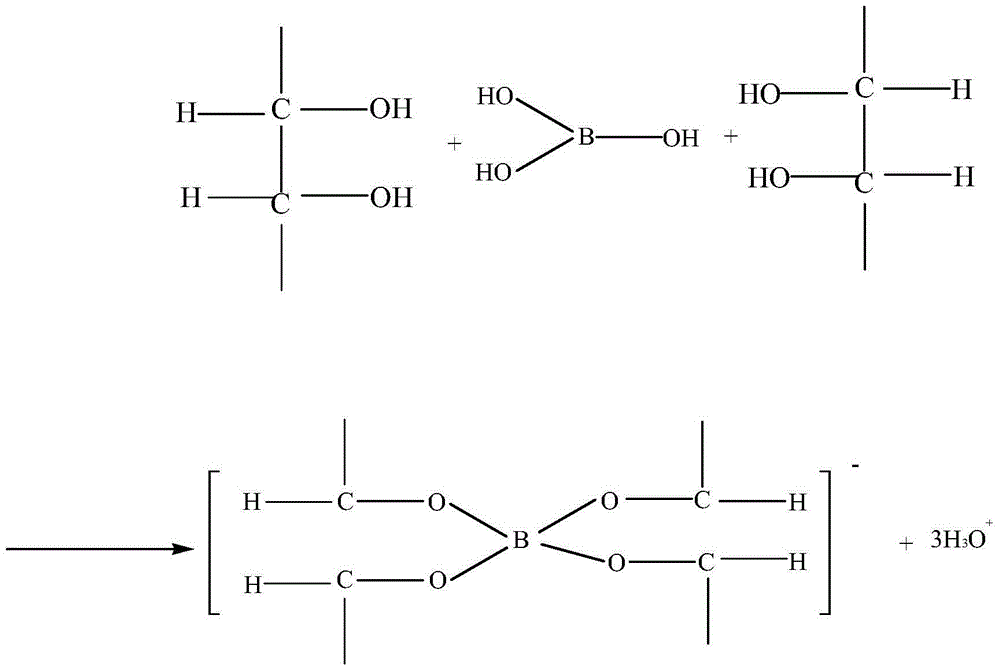

The invention provides a detergent, comprising the following components in parts by weight: 0.4-8 parts of thickener, 0.06-2 parts of cross linker, 2-30 parts of active matter and 60-97.54 parts of water, wherein the thickener is selected from at least one of galactomannan and glucomannan; the cross linker is selected from at least one of boric acid, metaboric acid, metaborate and borate; the active matter is a surfactant of which the hydrophile-lipophile balance value is more than or equal to 12. The detergent is not bonded to packages or hands. Moreover, the invention further provides a preparation method for the detergent.

Owner:SHENZHEN GREEN OUBIAO TECH

A kind of preparation method of high pressure resistant solid polymer electrolyte

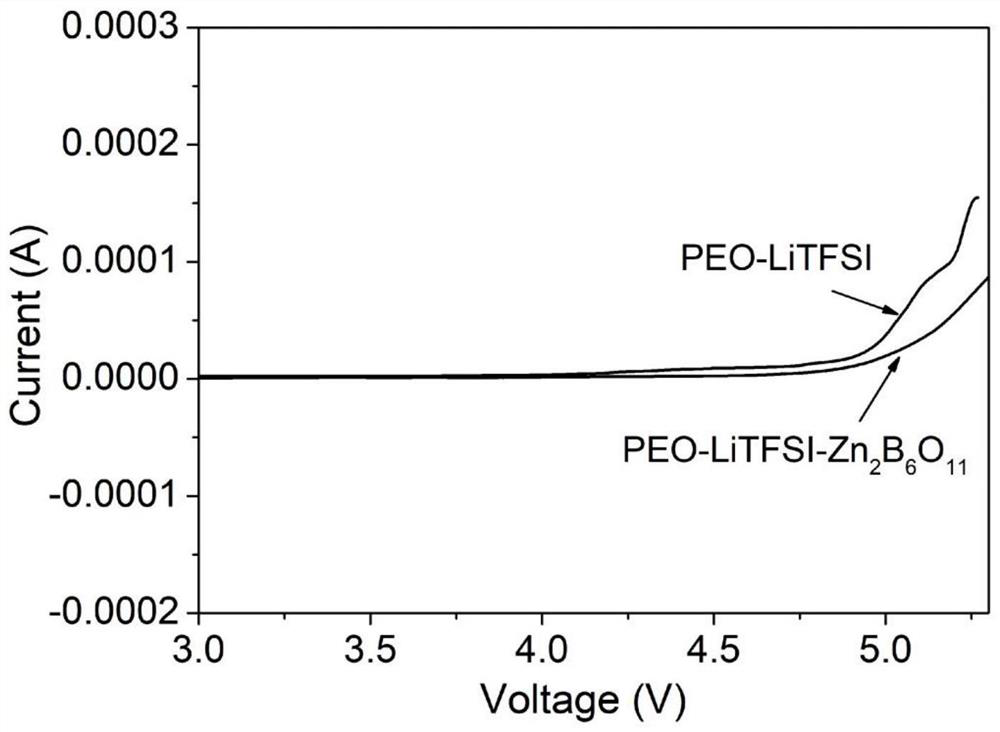

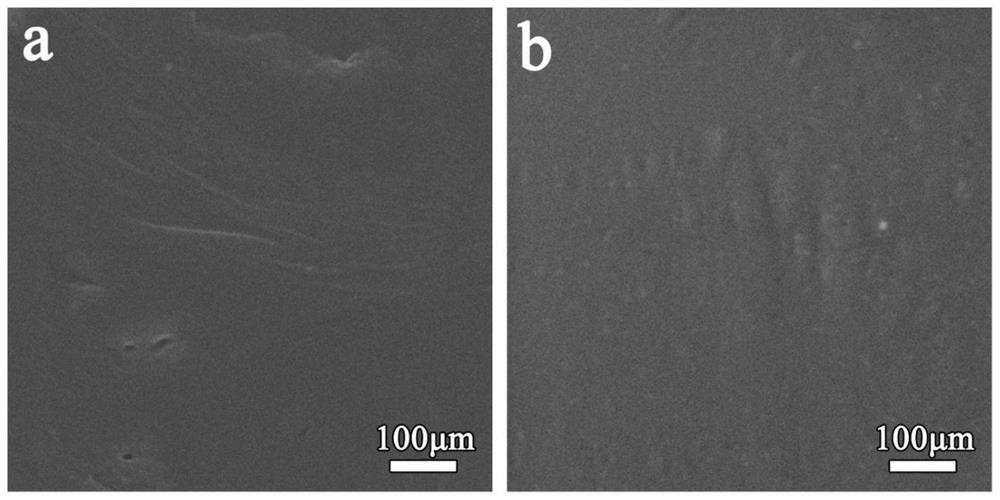

ActiveCN109301317BIncrease energy densityImprove securitySolid electrolytesLi-accumulatorsPolyethylene oxidePolytetrafluoroethylene

A preparation method of a high-voltage solid polymer electrolyte, comprising: (1) dissolving a polymer matrix, a lithium salt, and an inorganic additive in anhydrous acetonitrile in a certain proportion, and stirring at room temperature to obtain a uniform solution; the polymer matrix It is polyethylene oxide, the lithium salt is lithium bistrifluoromethanesulfonimide or lithium perchlorate, and the inorganic additive is nanowire or nanoparticle, selected from zinc borate, aluminum borate, sodium tetraborate , barium metaborate or calcium borate; The mass ratio of the polyoxyethylene and lithium salt is EO:Li + =10-20:1, the mass consumption of described inorganic additive is no more than 20% of polymer matrix and lithium salt total mass; (2) the homogeneous solution of step (1) gained is poured in the polytetrafluoroethylene mould, evaporates Let it dry completely to obtain a solid polymer electrolyte. The preparation method of the invention improves the high-voltage resistance performance of the solid polymer electrolyte, enables it to match the high-voltage ternary positive electrode material, and improves the energy density and safety of the all-solid-state battery.

Owner:ZHEJIANG UNIV OF TECH

Boron oxide and related compounds for hydrogen storage

A hydrogen storage medium is provided, where the medium is comprised of boron oxide and closely related compounds such as orthoboric acid, metaboric acid, hydrated boric acid, and disodium borohydrate. The medium is substantially an amorphous glassy network, albeit with local regions of order, pores, and networks that provide surface area. Hydrogen is adsorbed by the medium with a heat of adsorption of about 9 kJ / mol to about 13 kJ / mol, a value which is higher than that of the heat of adsorption of hydrogen on carbon. The value for the heat of adsorption of hydrogen on the inventive storage medium is provided by computation, and corroborated by experimental observation. The higher heat of adsorption of the medium provides for operation at temperatures higher temperatures higher than those provided by carbon. Further provided are methods by which the storage medium can be prepared in such a form so as to permit high capacity hydrogen storage, as well as an apparatus, with the inventive medium disposed therein, for storing hydrogen.

Owner:NANOMIX INC

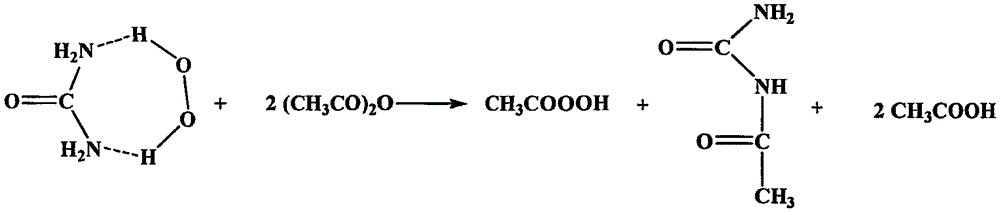

Method for synthesis of high-concentration anhydrous peracetic acid solution and co-production of acetylurea

ActiveCN105541688AEasy to manufactureWide range of usesUrea derivatives preparationOrganic compound preparationHigh concentrationAcetic anhydride

The invention discloses a method for synthesis of a high-concentration anhydrous peracetic acid solution and co-production of acetylurea. According to the method, peracetic acid and acetylurea are generated via a reaction between percarbamide and acetic anhydride under the action of a catalyst; and then the high-concentration anhydrous peracetic acid solution is separated out via vacuum distillation, the residual distillate is frozen, and the frozen residual distillate is recrystallized for preparation of acetylurea, wherein the catalyst is selected from boric acid, metaboric acid, sodium borate, sodium metaborate, sodium perborate or a corresponding hydrate. As the raw materials, percarbamide and acetic anhydride are cheap and easy to obtain; compared with a method for preparing the anhydrous peracetic acid solution via acetaldehyde oxidation, the method provided by the invention is simpler, less in equipment investment and safer; and by adoption of the method provided by the invention, both the anhydrous peracetic acid solution and acetylurea are prepared, so that the application range is broad and the added value is high.

Owner:LIMING RES INST OF CHEM IND

Oil-resistant mildew-resistant modified bituminous paint and preparation method thereof

InactiveCN104312431AImprove wear resistanceGood oil resistanceFireproof paintsConjugated diene hydrocarbon coatingsPolymer scienceMelamine formaldehyde resin

The invention discloses oil-resistant mildew-resistant modified bituminous paint. The oil-resistant mildew-resistant modified bituminous paint is prepared from 16-21 parts by weight of modified asphalt, 12-14 parts by weight of urea-formaldehyde resin, 0.5-1.0 part by weight of oxalic acid, 0.5-1.0 part by weight of aluminum phosphate, 6-8 parts by weight of modified waste sodium silicate sand, 19-22 parts by weight of terpolycyantoamino-formaldehyde resin, 4-6 parts by weight of methylene bis(cyclohexylammonium), 2-3 parts by weight of disodium sebacate, 2-4 parts by weight of cuprous thiocyanate, 1-3 parts by weight of liquid nitrile rubber, 3-4 parts by weight of nanometer diatomite, 1-2 parts by weight of nanometer calcium carbonate, 1-2 parts by weight of a silane coupling agent KH-560, 0.5-1.0 part by weight of a JWK 200 antistatic agent, 2-3 parts by weight of barium metaborate, 1-2 parts by weight of di-n-octyltin-dithioglycolate, 4-6 parts by weight of coal tar, 7-9 parts by weight of acetone and 10-13 parts by weight of xylene. The oil-resistant mildew-resistant modified bituminous paint utilizes modified asphalt as a main body. The used urea-formaldehyde resin improves paint wear resistance, oil resistance, mildew resistance and insulating properties. The used modified waste sodium silicate sand improves poor asphalt resistance to heat and improves paint resistance to heat, acids and fire. The used cuprous thiocyanate can prevent aquatic organism adhesion and reduce fuel consumption of maritime ships.

Owner:TIANCHANG JULONG TRAVEL PAINT

Cement mortar

The invention discloses cement mortar. The cement mortar is prepared from the following raw materials in parts by weight: 12 to 25 parts of perlite, 20 to 35 parts of portland cement, 4 to 8 parts of expanded vermiculite, 5 to 7 parts of latex powder, 1 to 1.5 parts of sulfomethylated phenolic resin, 2 to 4 parts of sodium sulfate, 6 to 9 parts of coke, 8 to 16 parts of tricalcium aluminate, 12 to 22 parts of lysine, 18 to 32 parts of vitrified microspheres, 10 to 17 parts of polyacrylonitrile fibers, 4 to 6 parts of sodium tripolyphosphate, 7 to 9 parts of magnesium oxide, 2 to 4 parts of barium metaborate and 3 to 7 parts of bentonite. The cement mortar disclosed by the invention has the beneficial effects of excellent dimensional stability, low elongation, improved strength, lower construction cost, and no deformation, damage or crack.

Owner:青岛千帆高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com