Method for synthesis of high-concentration anhydrous peracetic acid solution and co-production of acetylurea

A technology of anhydrous peroxyacetic acid and acetic acid solution, which is applied to the preparation of peroxygen compounds, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of high explosion risk factor, complicated production equipment, and reduced yield. The effect of simple process flow, low equipment investment and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

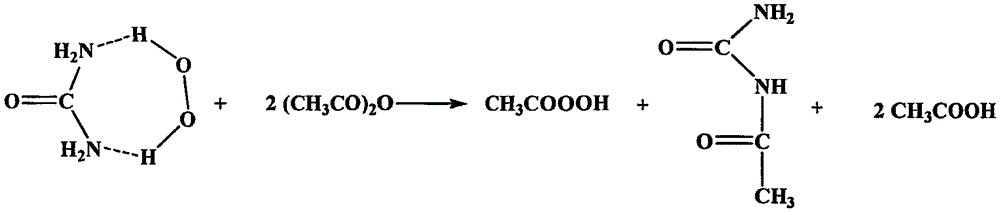

Method used

Image

Examples

Embodiment 1

[0018] Add 98.65 g of percarbamide with an active oxygen content of 16.2% into a glass reactor, add 1 g of boric acid, and then inject 51.5 g of acetic anhydride; heat the reactor to 50° C. and stir the reaction mixture until the percarbamide is completely dissolved; The remaining 154.5g of acetic anhydride was slowly dropped into the reaction solution through a constant flow device, and the reaction solution was controlled to reflux slightly during the dropping process; after the dropwise addition of acetic anhydride, the reaction solution was maintained at 50°C and stirred for 1.5h. After the reaction is over, send the mixed solution into a vacuum distillation device, first turn on the decompression device to control the absolute pressure in the device to 31.33kPa, then heat the mixed solution to 90°C, collect the distillate at 65°C, and obtain a colorless and transparent high The concentration of the acetic acid solution of anhydrous peracetic acid is about 164ml, the densit...

Embodiment 2

[0020] Add 193.75 g of percarbamide with an active oxygen content of 16.5% into a glass reactor, then add 2.85 g of sodium borate, and then inject 102.86 g of acetic anhydride; raise the temperature of the reactor to 50° C. and stir the reaction mixture until the percarbamide is completely dissolved; The remaining 309.20 g of acetic anhydride was slowly dropped into the reaction solution through a constant flow device, and the reaction solution was slightly refluxed during the dropping process; after the dropwise addition of acetic anhydride, the reaction solution was maintained at 50° C. and stirred for 1 hour. After the reaction is over, send the mixed solution into a vacuum distillation device, first turn on the decompression device to control the absolute pressure in the device to 11.33kPa, then heat the mixed solution to 70°C, collect the distillate at 60°C, and obtain a colorless and transparent high The concentration of the acetic acid solution of anhydrous peracetic aci...

Embodiment 3

[0022] Add 300.12 g of percarbamide with an active oxygen content of 16.0% into a glass reactor, then add 5.94 g of sodium perborate tetrahydrate, and then inject 155.20 g of acetic anhydride; heat the reactor to 50° C. and stir the reaction mixture to reach percarbamide All dissolved; then the remaining 465.50g of acetic anhydride was slowly dropped into the reaction solution through a constant flow device, and the dropping process was controlled to slightly reflux the reaction solution; after the dropwise addition of acetic anhydride, the reaction solution was maintained at 50°C and stirred for 0.5h. After the reaction is over, send the mixed solution into a vacuum distillation device, first open the decompression device to control the absolute pressure in the device to 6.33kPa, then heat the mixed solution to 60°C, collect the distillate at 55°C, and obtain a colorless and transparent high The concentration of the acetic acid solution of anhydrous peracetic acid is about 456...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com