Preparation method of modified nickel cobalt lithium manganate ternary positive electrode material

A technology of nickel-cobalt lithium manganate and cathode material, which is applied in the field of preparation of modified nickel-cobalt lithium manganate ternary cathode material, can solve the problems of harsh synthesis conditions, poor electrochemical performance of materials, and high oxidation potential, and achieve improved Cost-effective, improved electrochemical performance, good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

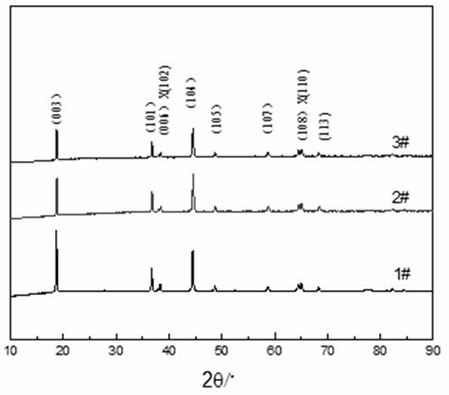

Embodiment 1

[0028] Lithium carbonate and 622 nickel-cobalt-manganese ternary precursors are used as reaction raw materials, lithium carbonate and 622 nickel-cobalt-manganese ternary precursors are mixed evenly according to the ratio of molar ratio Li / Me=1.05, put into a muffle furnace for sintering, and Oxygen flow rate is 1m 3 / h, the heating rate is 5°C / min, the sintering temperature is 900°C, and the constant temperature sintering time is 15h, to obtain the nickel-cobalt-lithium-manganese-oxide ternary positive electrode material.

[0029] Mix the nickel-cobalt lithium manganate ternary positive electrode material with metaboric acid evenly, put it into a muffle furnace for secondary sintering, the boron content in the metaboric acid is 0.50wt% of the nickel-cobalt lithium manganate ternary positive electrode material, and feed the oxygen flow 1m 3 / h, the heating rate is 5°C / min, the sintering temperature is 700°C, and the constant temperature sintering time is 6h.

Embodiment 2

[0031] Lithium carbonate and 622 nickel-cobalt-manganese ternary precursors are used as reaction raw materials, lithium carbonate and 622 nickel-cobalt-manganese ternary precursors are mixed evenly according to the ratio of molar ratio Li / Me=1.05, put into a muffle furnace for sintering, and Oxygen flow rate is 1m 3 / h, the heating rate is 5°C / min, the sintering temperature is 900°C, and the constant temperature sintering time is 15h, to obtain the nickel-cobalt-lithium-manganese-oxide ternary positive electrode material.

[0032] Mix the nickel-cobalt lithium manganate ternary positive electrode material with metaboric acid evenly, put it into a muffle furnace for secondary sintering, the boron content in the metaboric acid is 0.50wt% of the nickel-cobalt lithium manganate ternary positive electrode material, and feed the oxygen flow 1m 3 / h, the heating rate is 5°C / min, the sintering temperature is 690°C, and the constant temperature sintering time is 6.5h.

Embodiment 3

[0034] Lithium carbonate and 622 nickel-cobalt-manganese ternary precursors are used as reaction raw materials, lithium carbonate and 622 nickel-cobalt-manganese ternary precursors are mixed evenly according to the ratio of molar ratio Li / Me=1.05, put into a muffle furnace for sintering, and Oxygen flow rate is 1m 3 / h, the heating rate is 5°C / min, the sintering temperature is 900°C, and the constant temperature sintering time is 15h, to obtain the nickel-cobalt-lithium-manganese-oxide ternary positive electrode material.

[0035] Mix nickel-cobalt lithium manganate ternary positive electrode material with metaboric acid evenly, put it into muffle furnace for secondary sintering, the boron content in metaboric acid is 0.10wt% of nickel-cobalt lithium manganate ternary positive electrode material, and feed oxygen flow 1m 3 / h, the heating rate is 3°C / min, the sintering temperature is 700°C, and the constant temperature sintering time is 6h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com