Patents

Literature

276results about "Chlorine oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

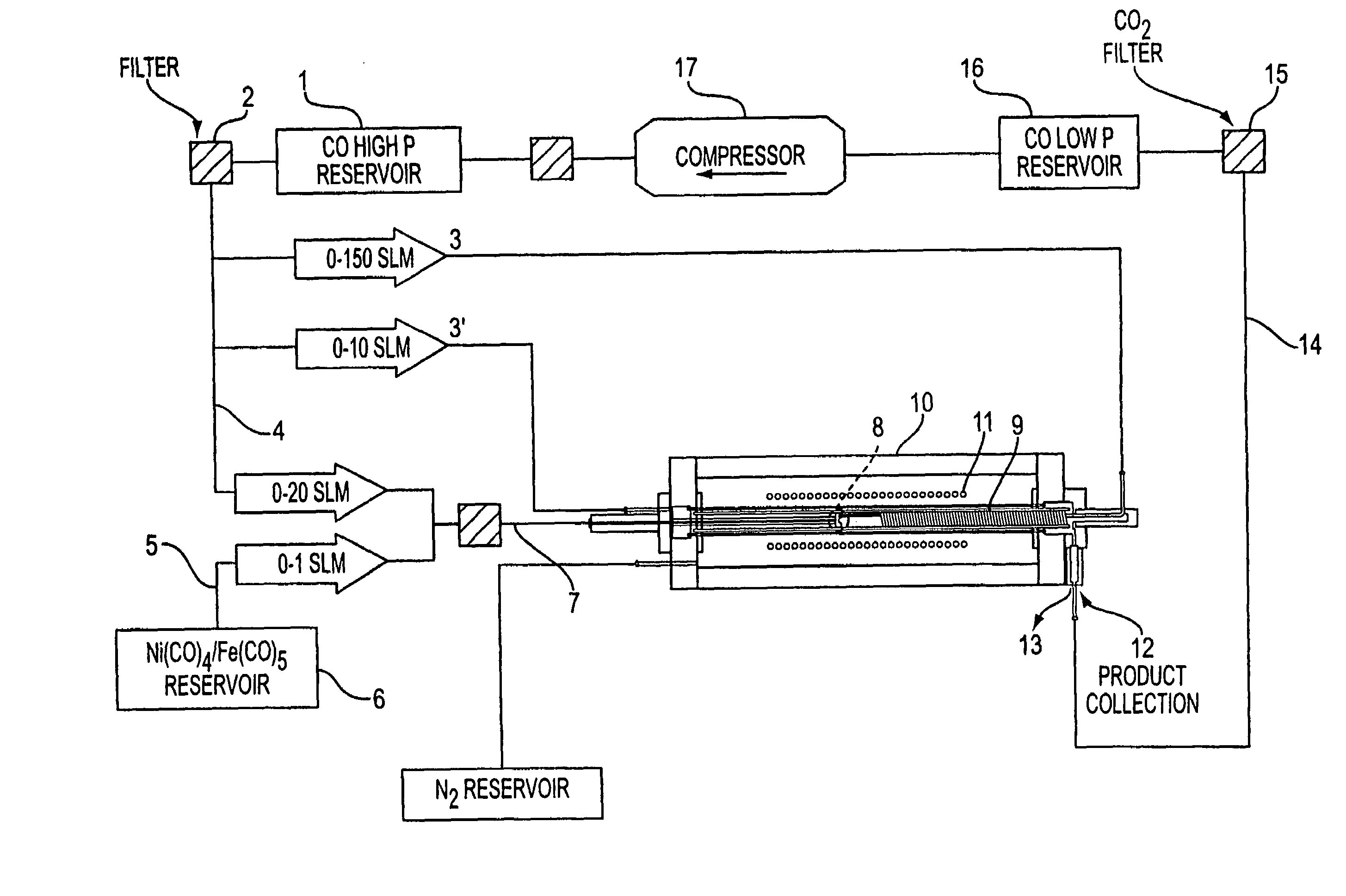

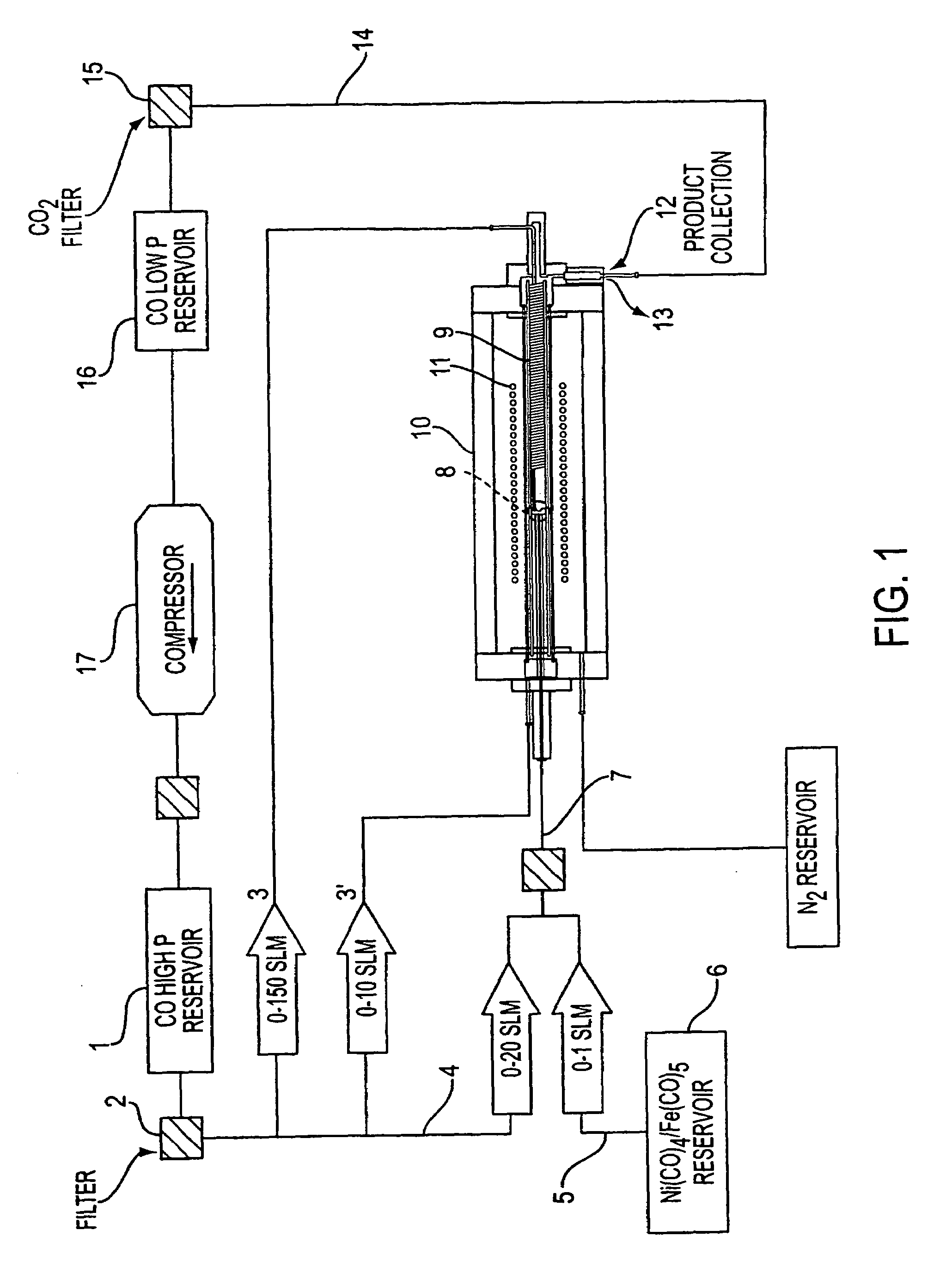

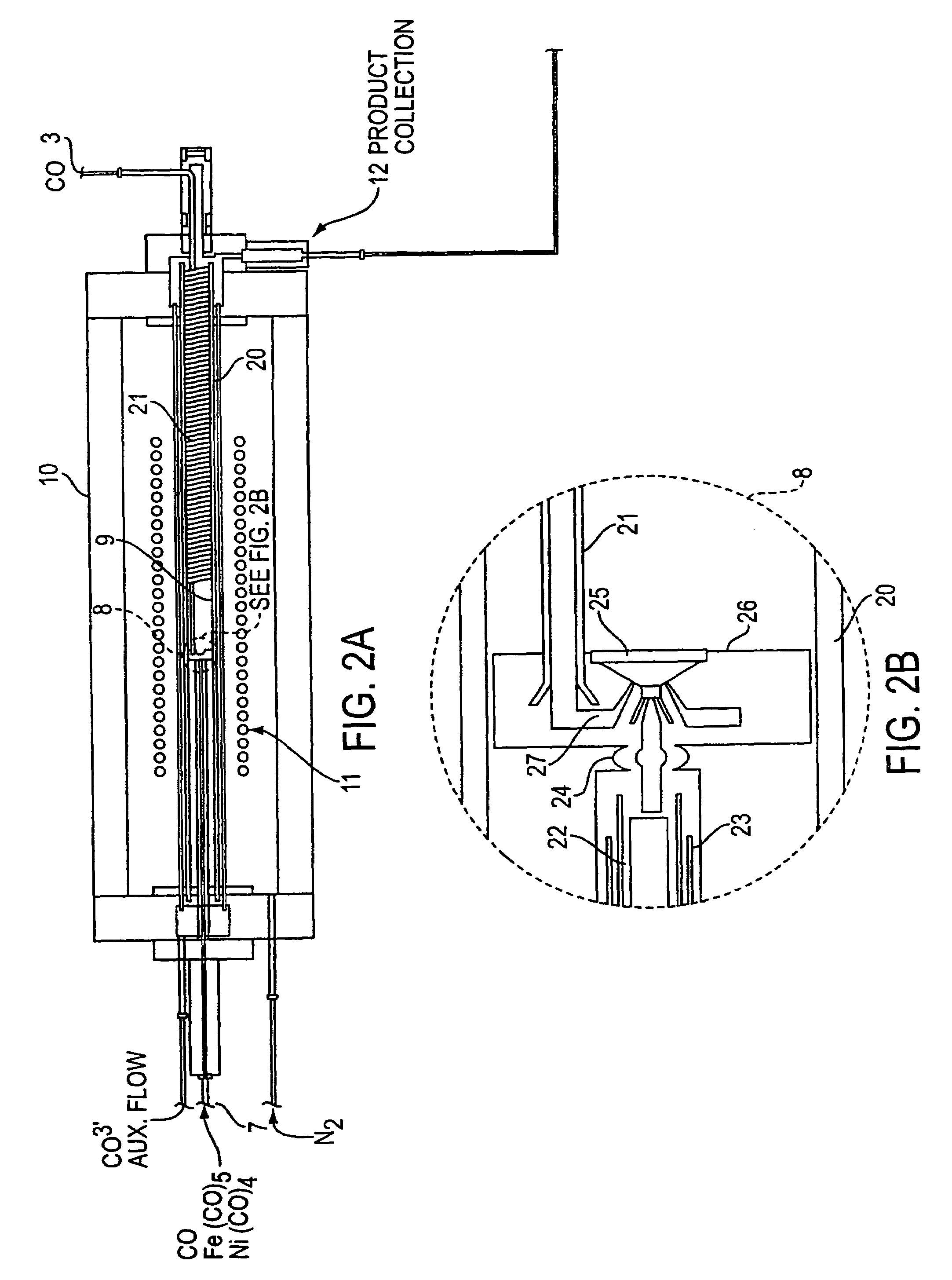

Single-wall carbon nanotubes from high pressure CO

InactiveUS7204970B2Promote rapid formationIncrease pressureMaterial nanotechnologyNanostructure manufactureDecompositionCarbon nanotube

The present invention discloses the process of supplying high pressure (e.g., 30 atmospheres) CO that has been preheated (e.g., to about 1000° C.) and a catalyst precursor gas (e.g., Fe(CO)5) in CO that is kept below the catalyst precursor decomposition temperature to a mixing zone. In this mixing zone, the catalyst precursor is rapidly heated to a temperature that results in (1) precursor decomposition, (2) formation of active catalyst metal atom clusters of the appropriate size, and (3) favorable growth of SWNTs on the catalyst clusters. Preferably a catalyst cluster nucleation agency is employed to enable rapid reaction of the catalyst precursor gas to form many small, active catalyst particles instead of a few large, inactive ones. Such nucleation agencies can include auxiliary metal precursors that cluster more rapidly than the primary catalyst, or through provision of additional energy inputs (e.g., from a pulsed or CW laser) directed precisely at the region where cluster formation is desired. Under these conditions SWNTs nucleate and grow according to the Boudouard reaction. The SWNTs thus formed may be recovered directly or passed through a growth and annealing zone maintained at an elevated temperature (e.g., 1000° C.) in which tubes may continue to grow and coalesce into ropes.

Owner:RICE UNIV

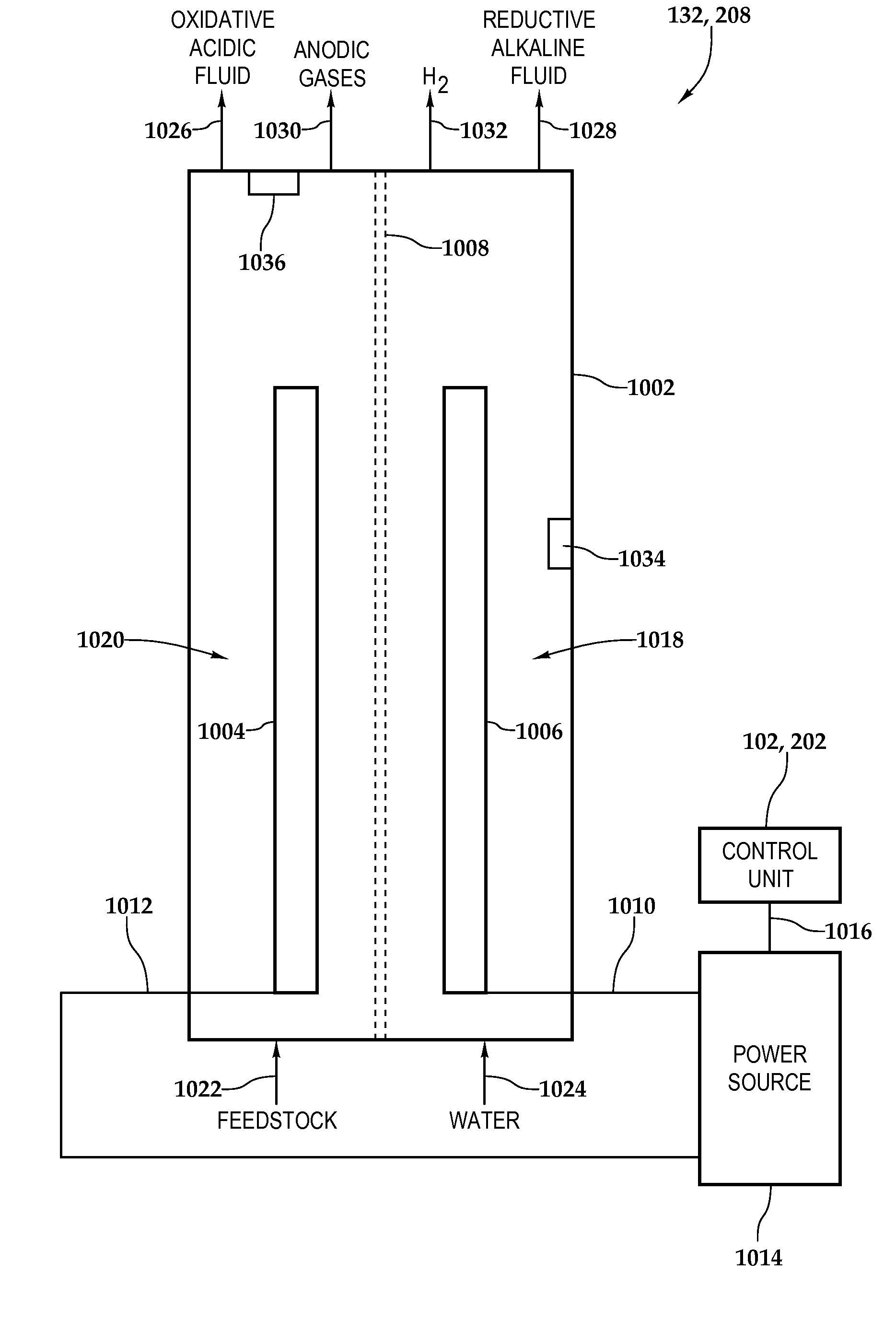

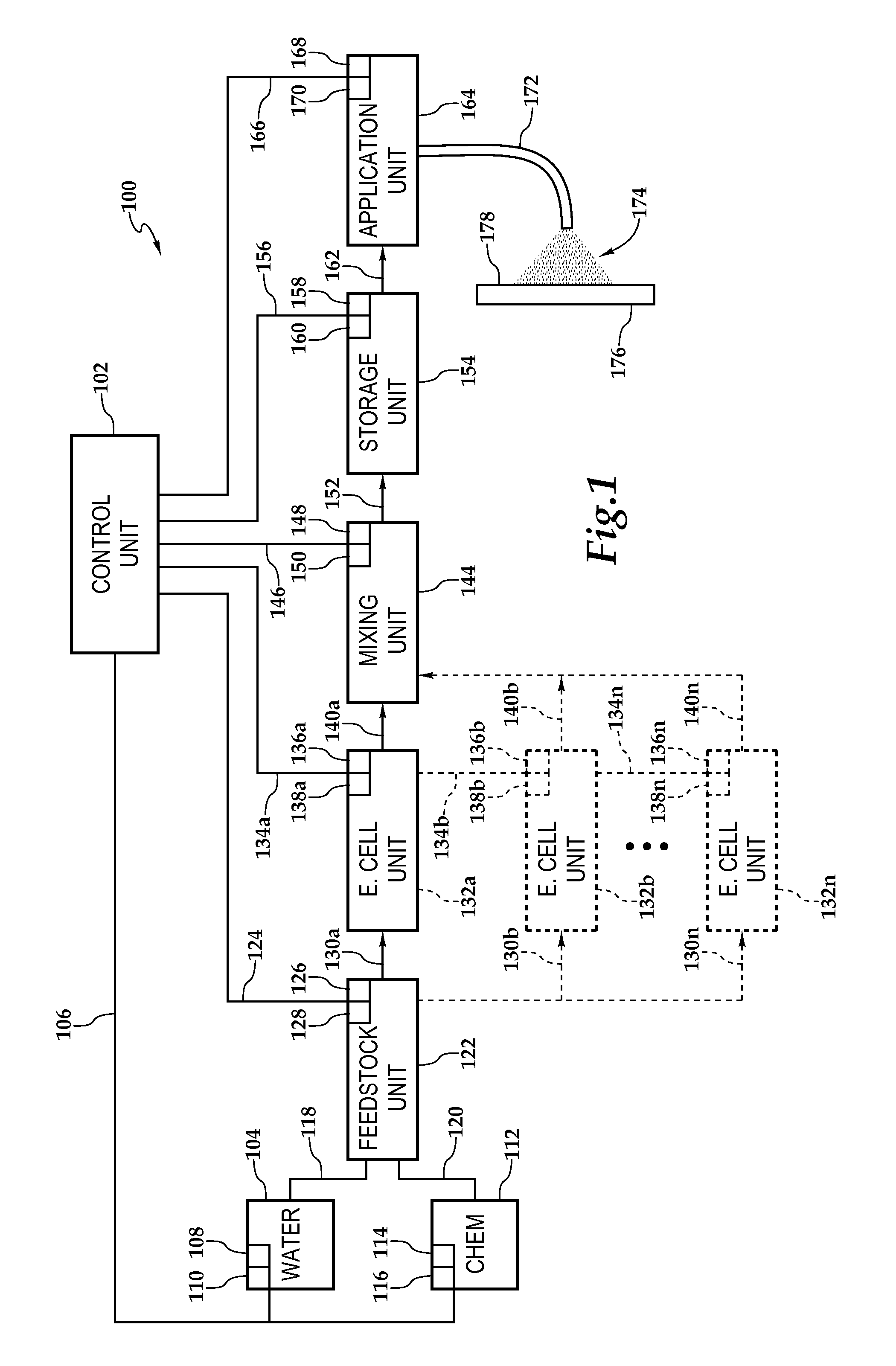

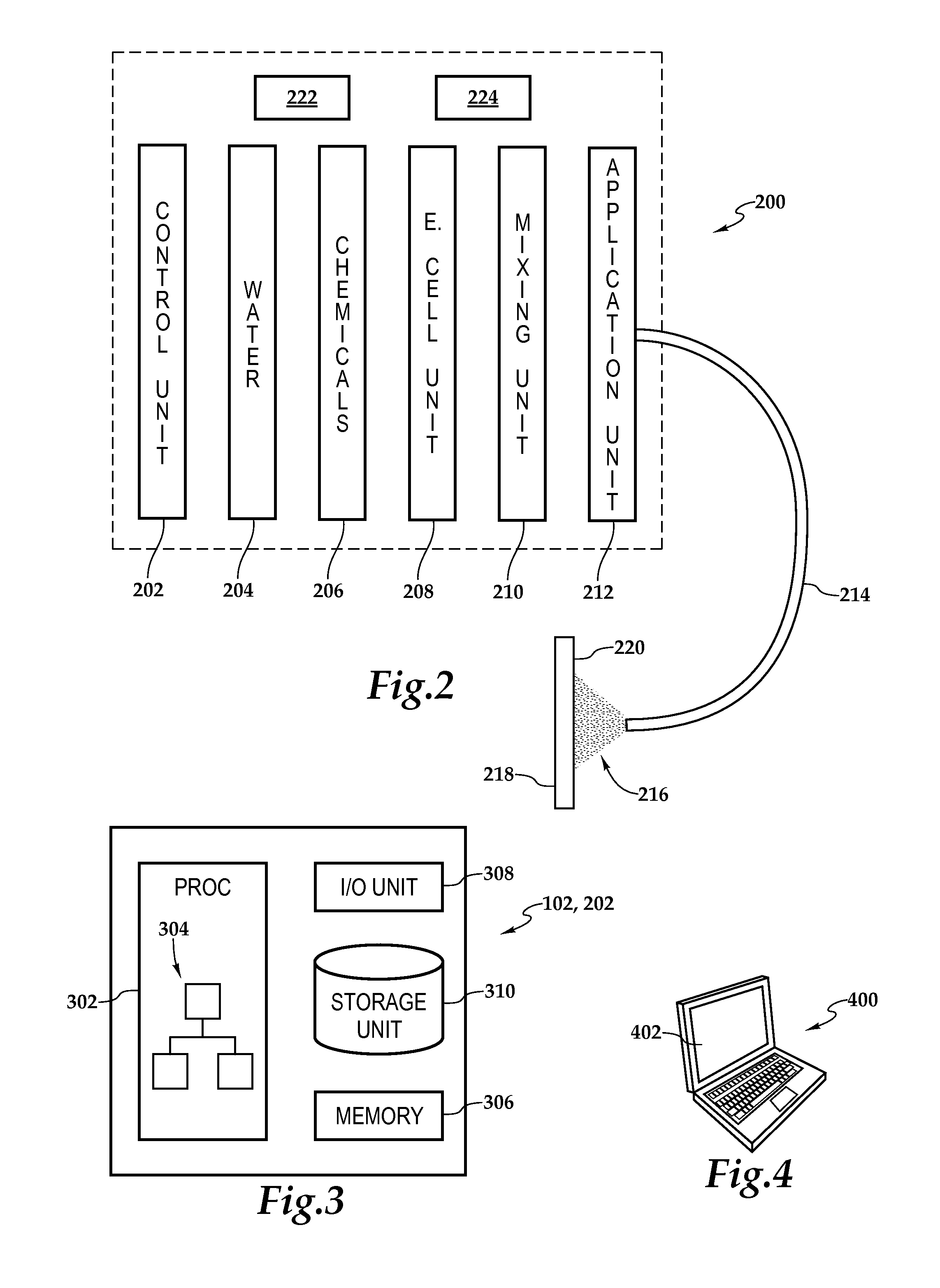

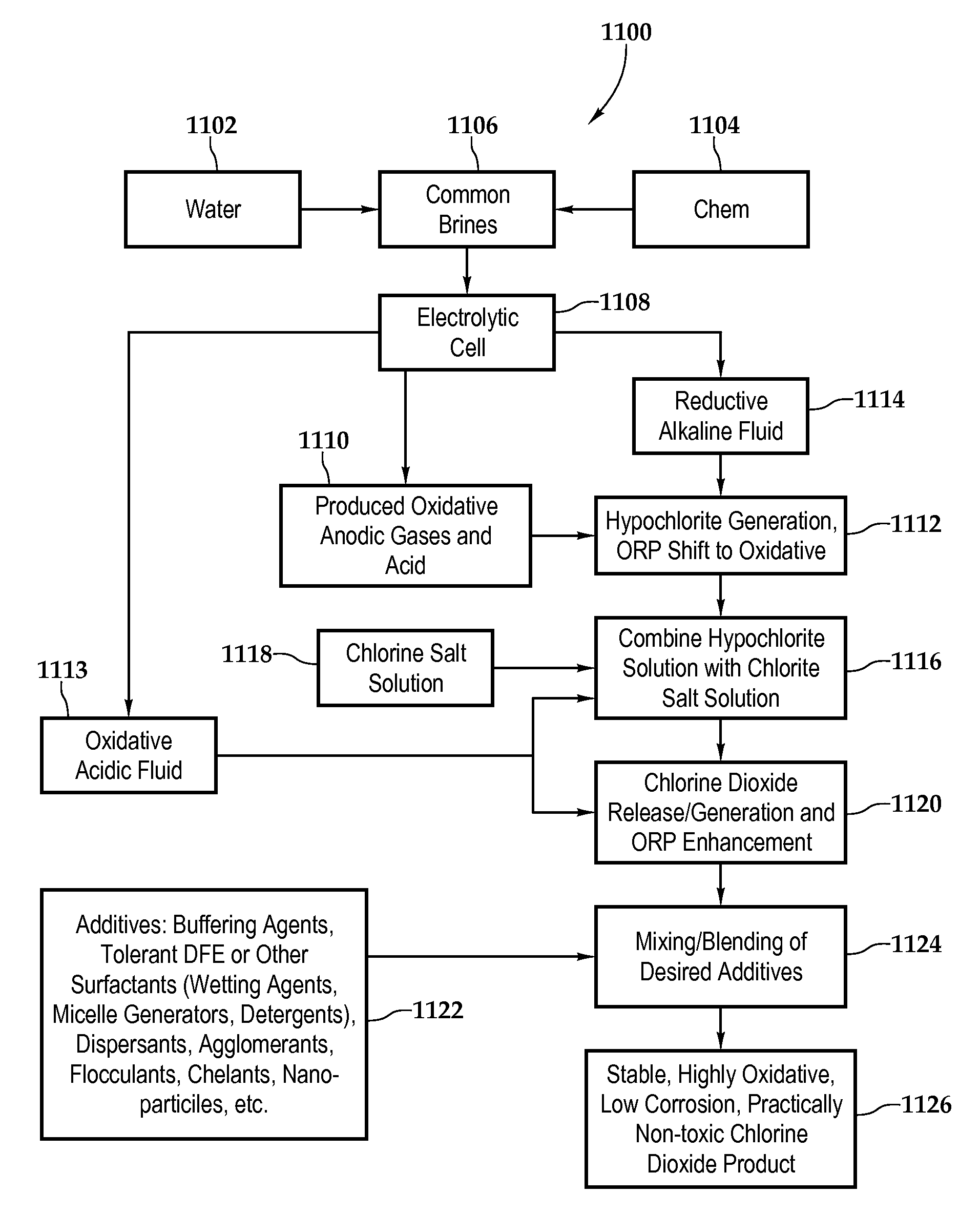

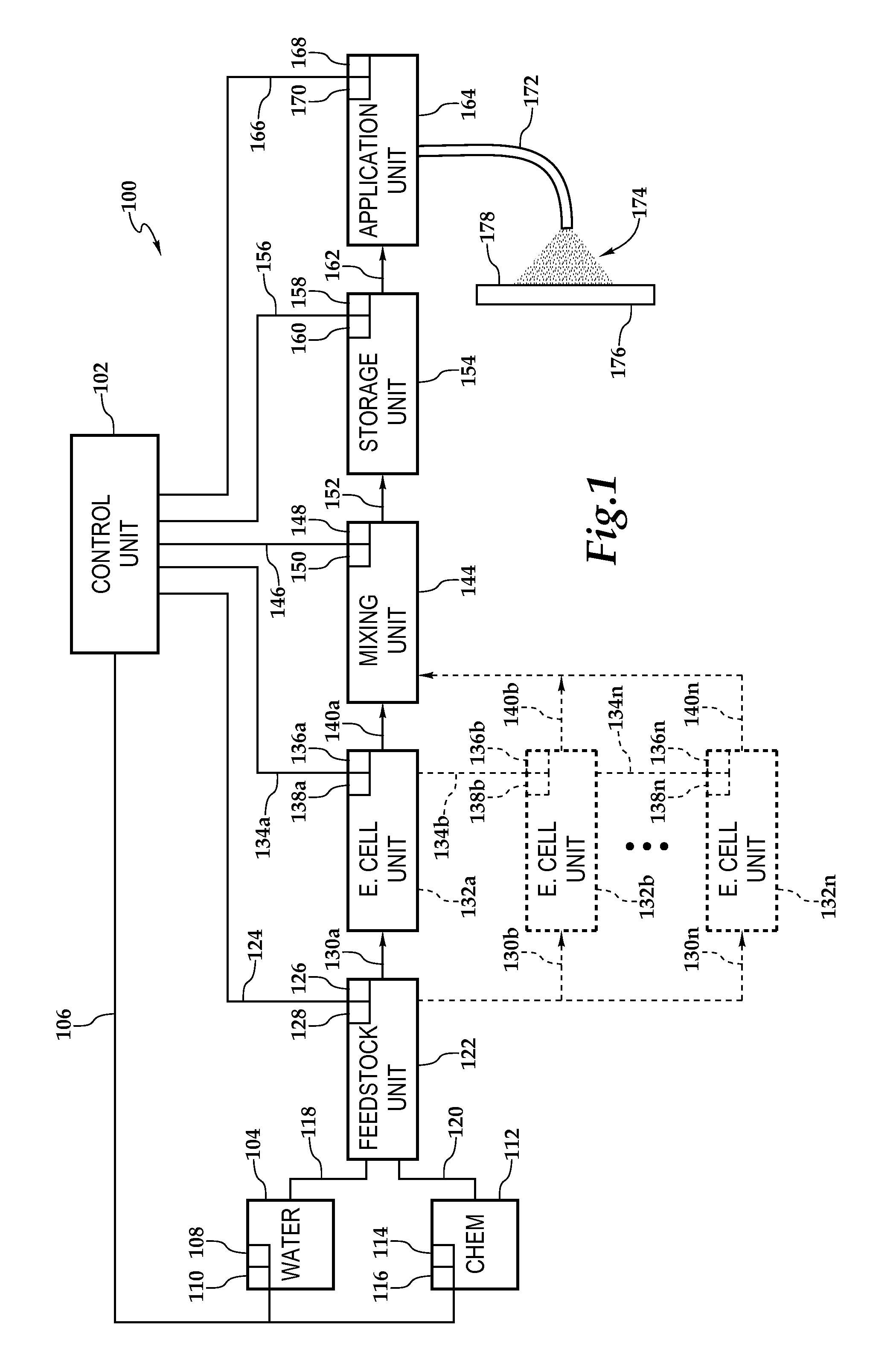

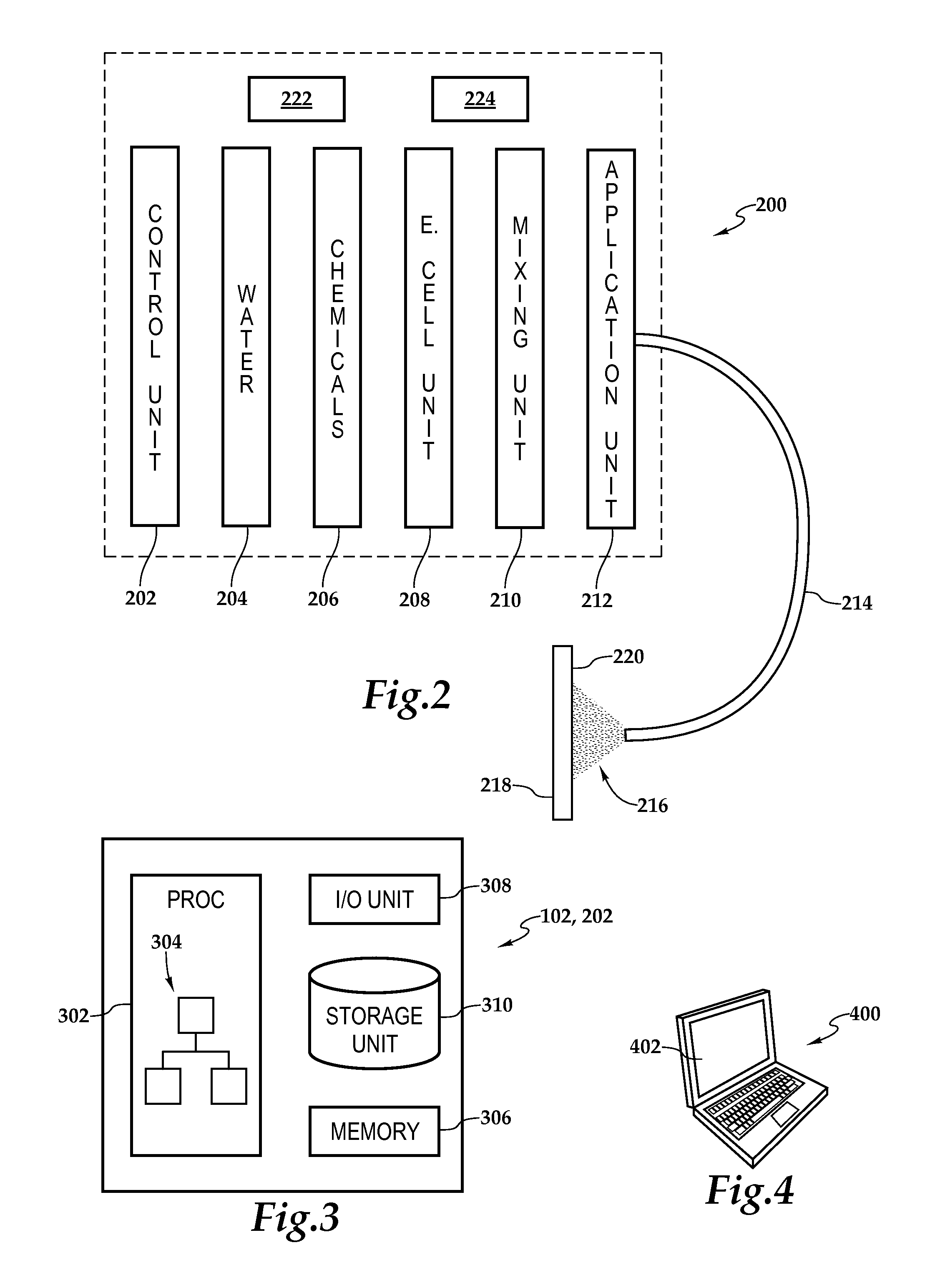

Electrolytic System and Method for Generating Biocides Having an Electron Deficient Carrier Fluid and Chlorine Dioxide

ActiveUS20120121731A1Decreases logistical burdenRapid disruptionBiocideElectrolysis componentsElectrolysisChlorine dioxide

A method for electrolytically generating a biocide having an electron deficient carrier fluid and chlorine dioxide, including providing a carrier fluid; providing a pair of electrodes interposed by a semi-permeable membrane within a vessel for creating a first passageway and a second passageway, an anode electrode of the pair of electrodes disposed in the first passageway, cathode electrode of the pair of electrodes disposed in the second passageway; flowing the carrier fluid through the vessel; applying an electric potential to the pair of electrodes to produce an oxidative acidic fluid, a reductive alkaline fluid, and anodic gases in the container; removing the fluids and gases from the vessel; mixing a portion of the anodic gases with the reductive alkaline fluid to produce a hypochlorite solution; and mixing a chlorite brine with the hypochlorite solution, followed by the introduction of additional oxidative acidic fluid to release the biocide.

Owner:STRATEGIC RESOURCE OPTIMIZATION

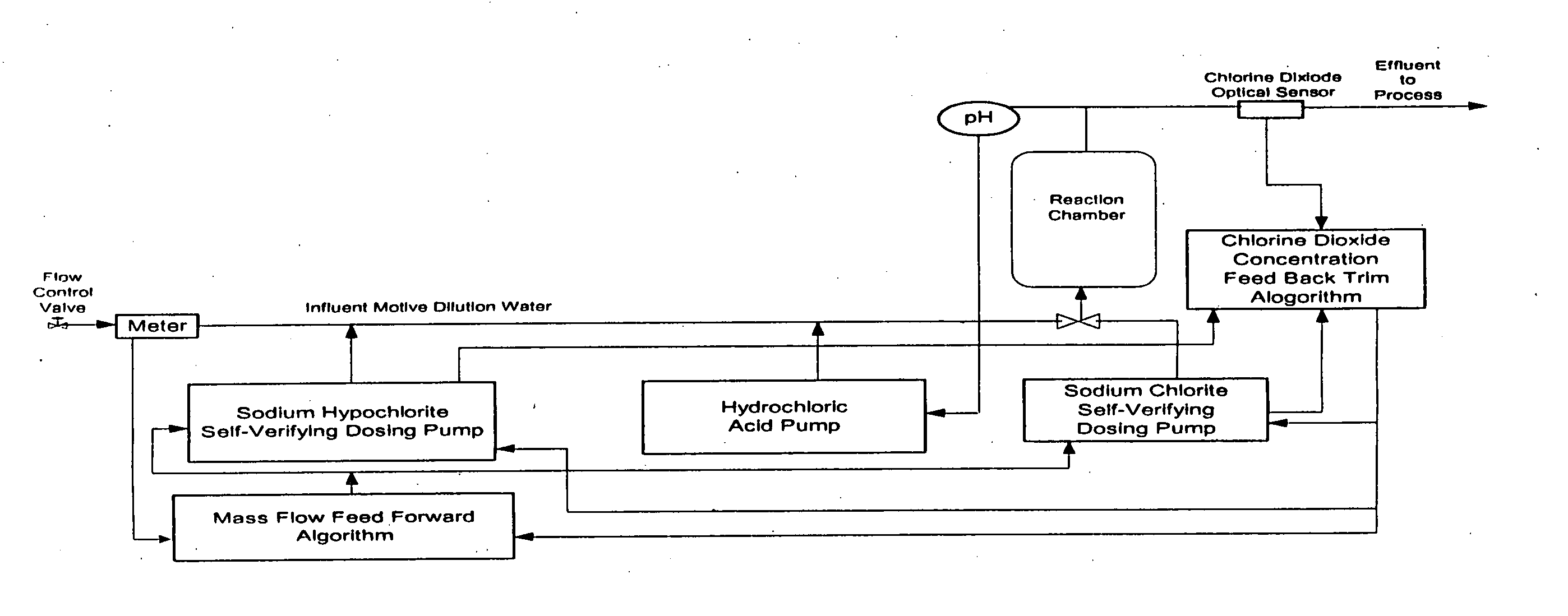

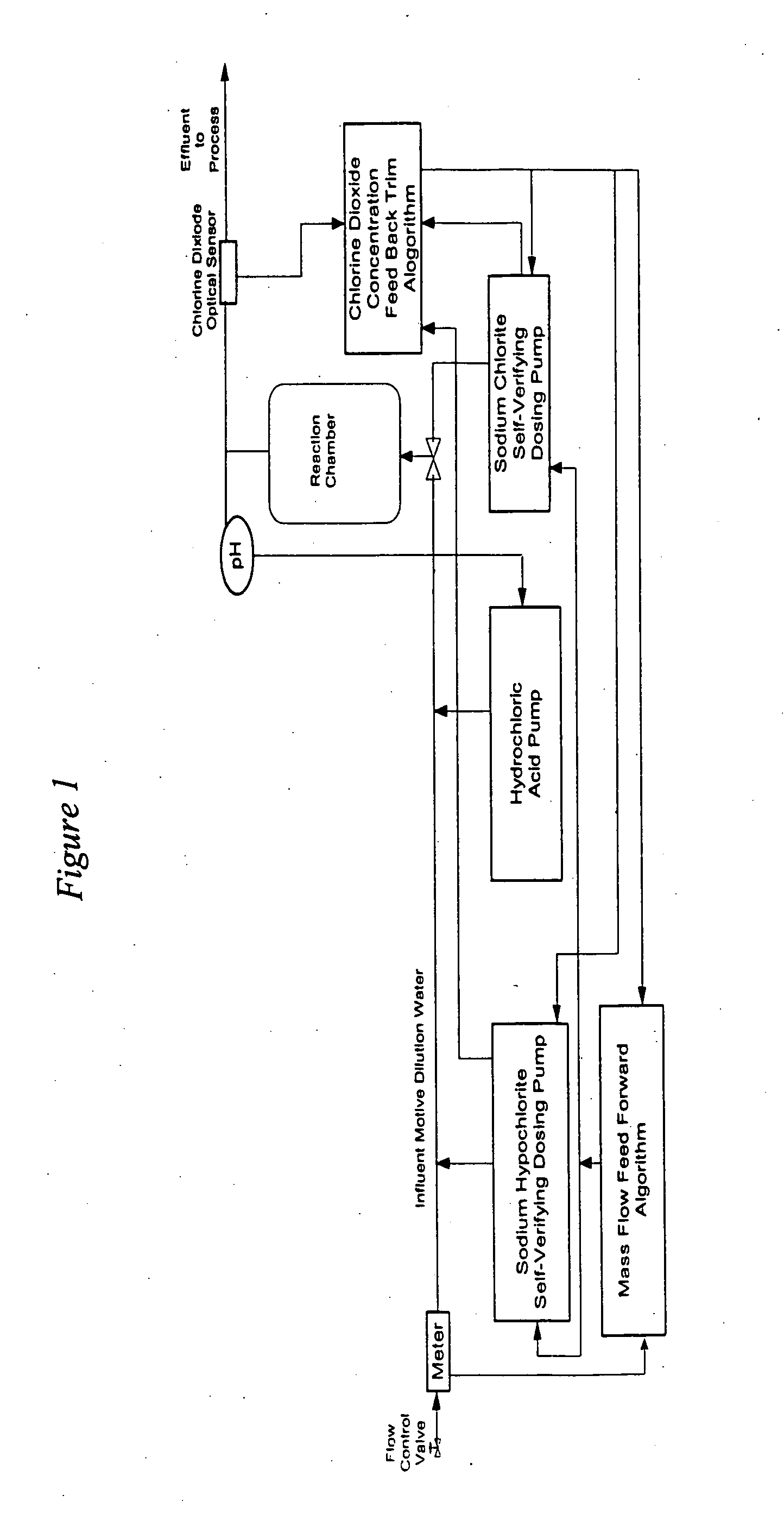

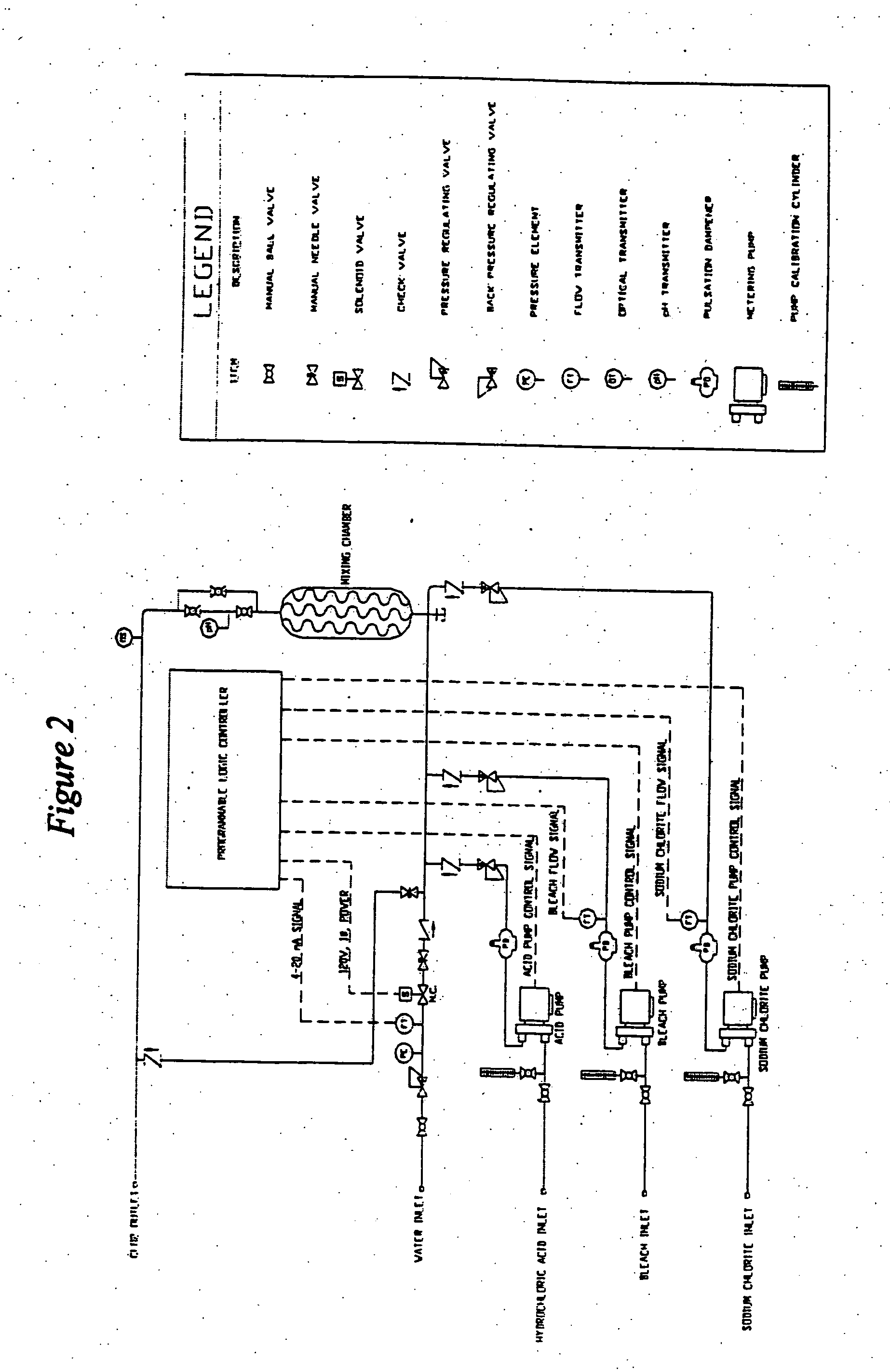

Process for treating an aqueous system with chlorine dioxide

ActiveUS20060096930A1High efficiency yieldReduce wasteWater treatment parameter controlChlorine oxidesChlorine dioxideCompound (substance)

This invention relates to an automated process for efficiently treating an aqueous system with chlorine dioxide. The process results in high efficiency yields of chlorine dioxide on a continuous basis by minimizing the waste of precursor chemicals. Additionally, the process creates less environmental stress because the formation of unwanted by-products is minimized. The level of chlorine dioxide in the aqueous system treated and other parameters of the process are monitored and adjusted automatically to maintain them within acceptable levels.

Owner:SOLENIS TECH CAYMAN

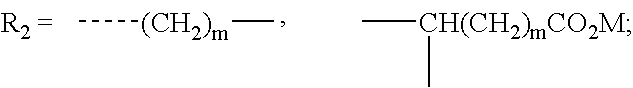

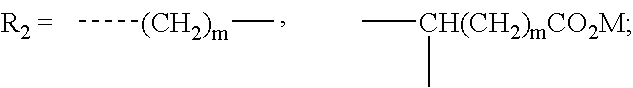

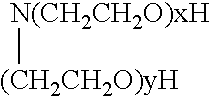

Acidified chlorite disinfectant compositions with olefin stabilizers

InactiveUS20050184273A1Reducing chlorine dioxide generationReduce drynessBiocideCosmetic preparationsDisinfectantCompound (substance)

A two-part disinfecting systems, as well as disinfecting compositions and methods for making and using the same. The two-part disinfecting system contains a first part and a second part adapted to be mixed to yield an aqueous disinfecting composition, wherein the first part comprises a chlorite and the second part comprises an acid, and wherein the first part, the second part, or both the first and second parts comprise an olefin compound.

Owner:ECOLAB USA INC

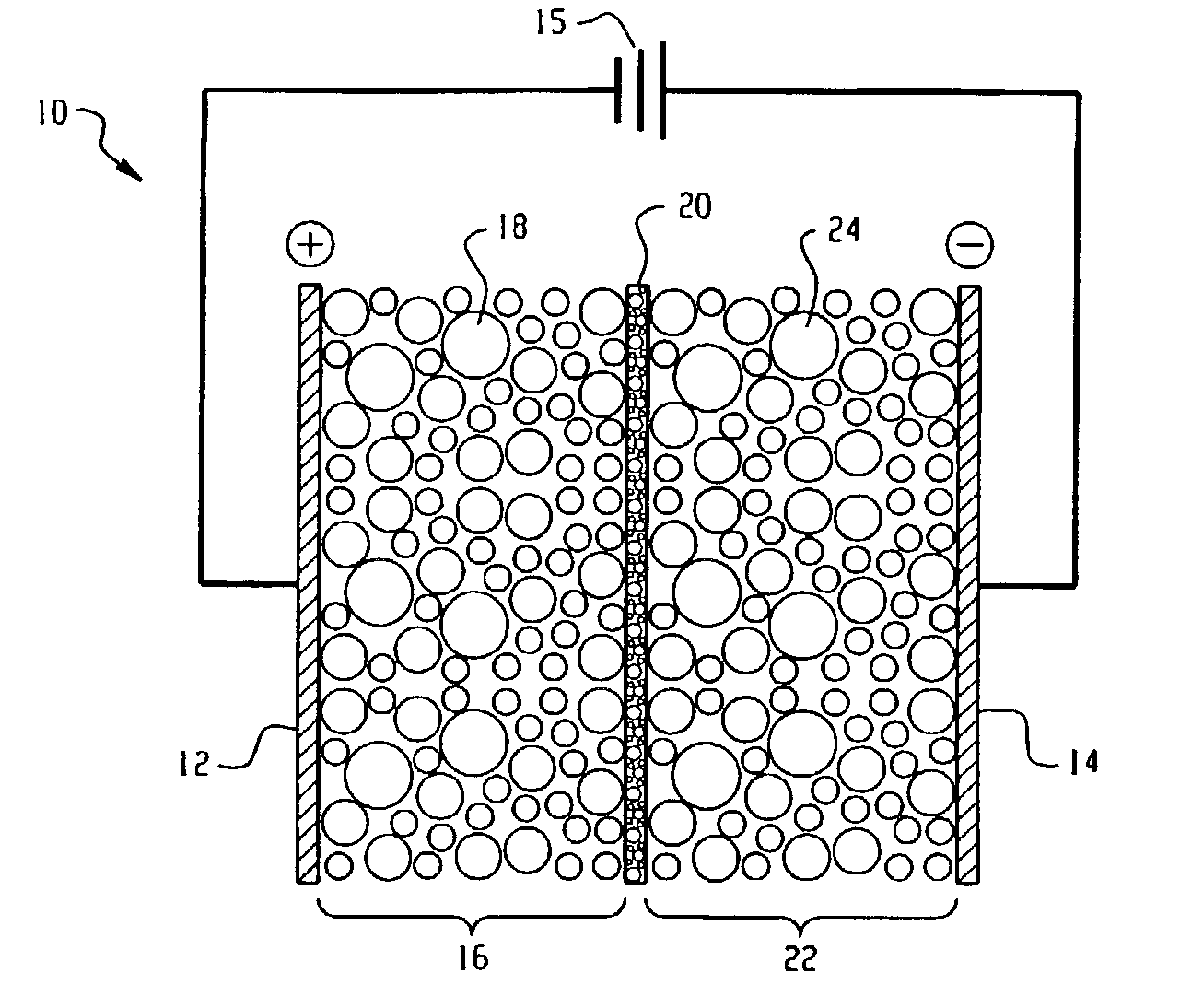

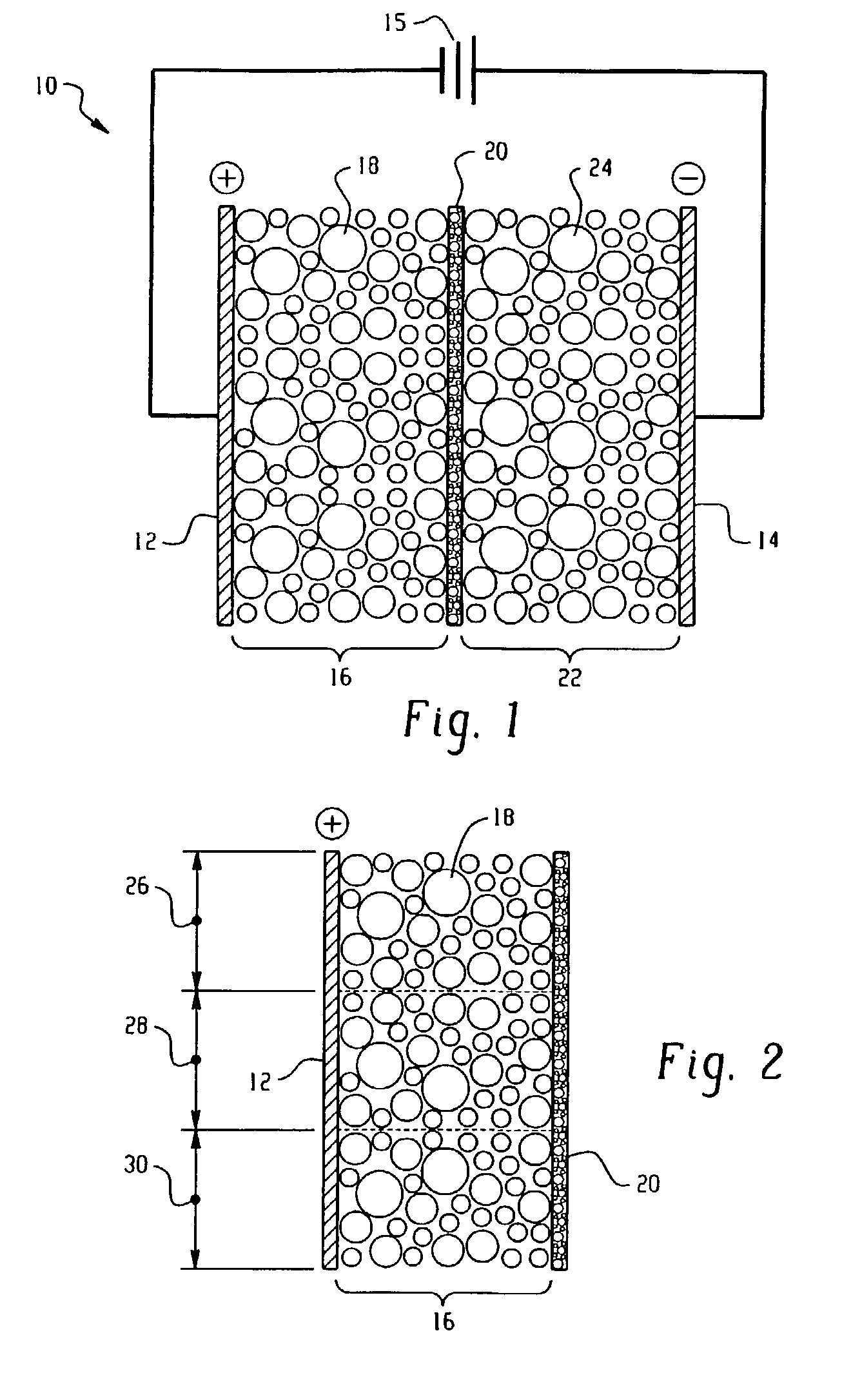

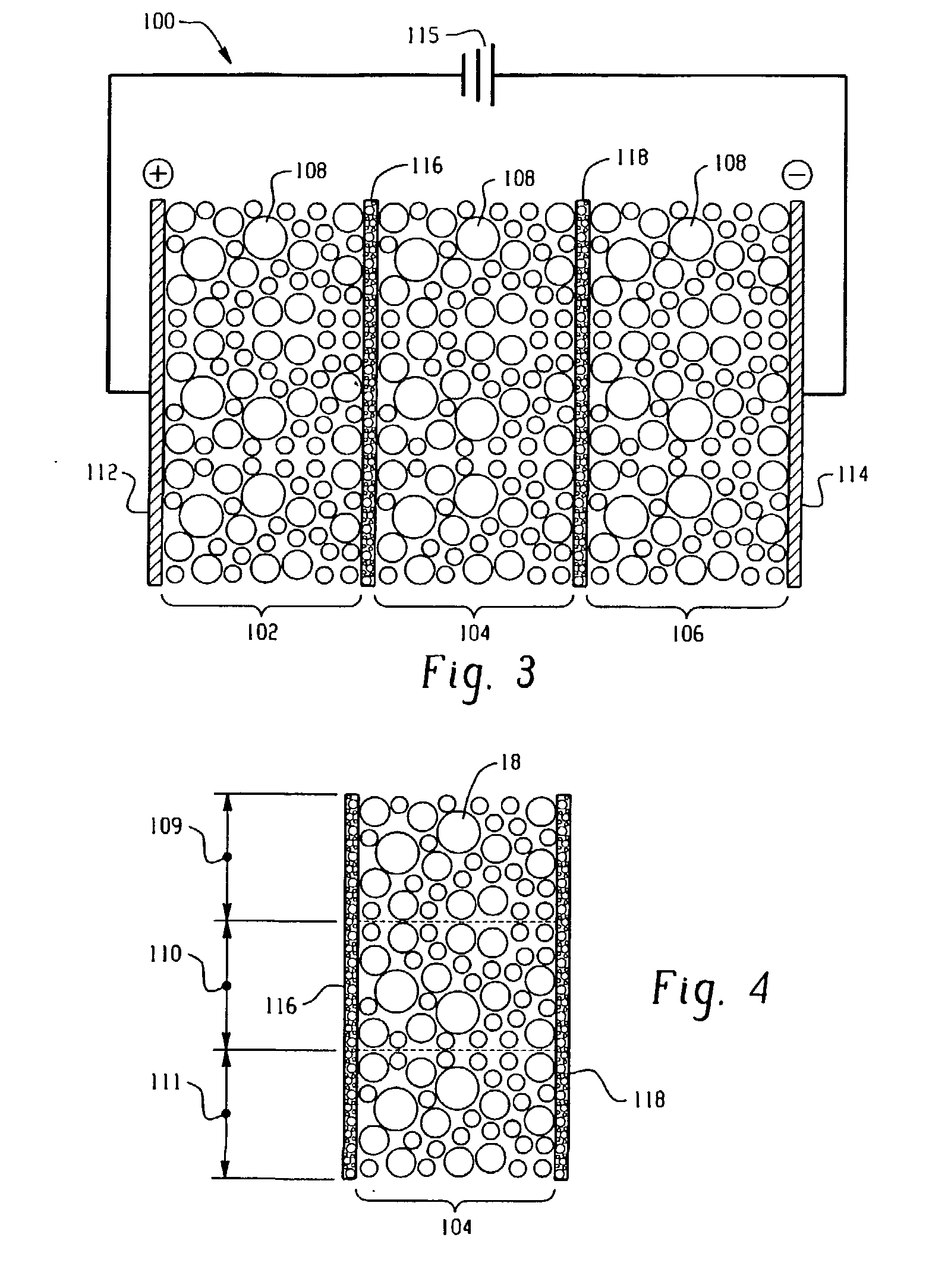

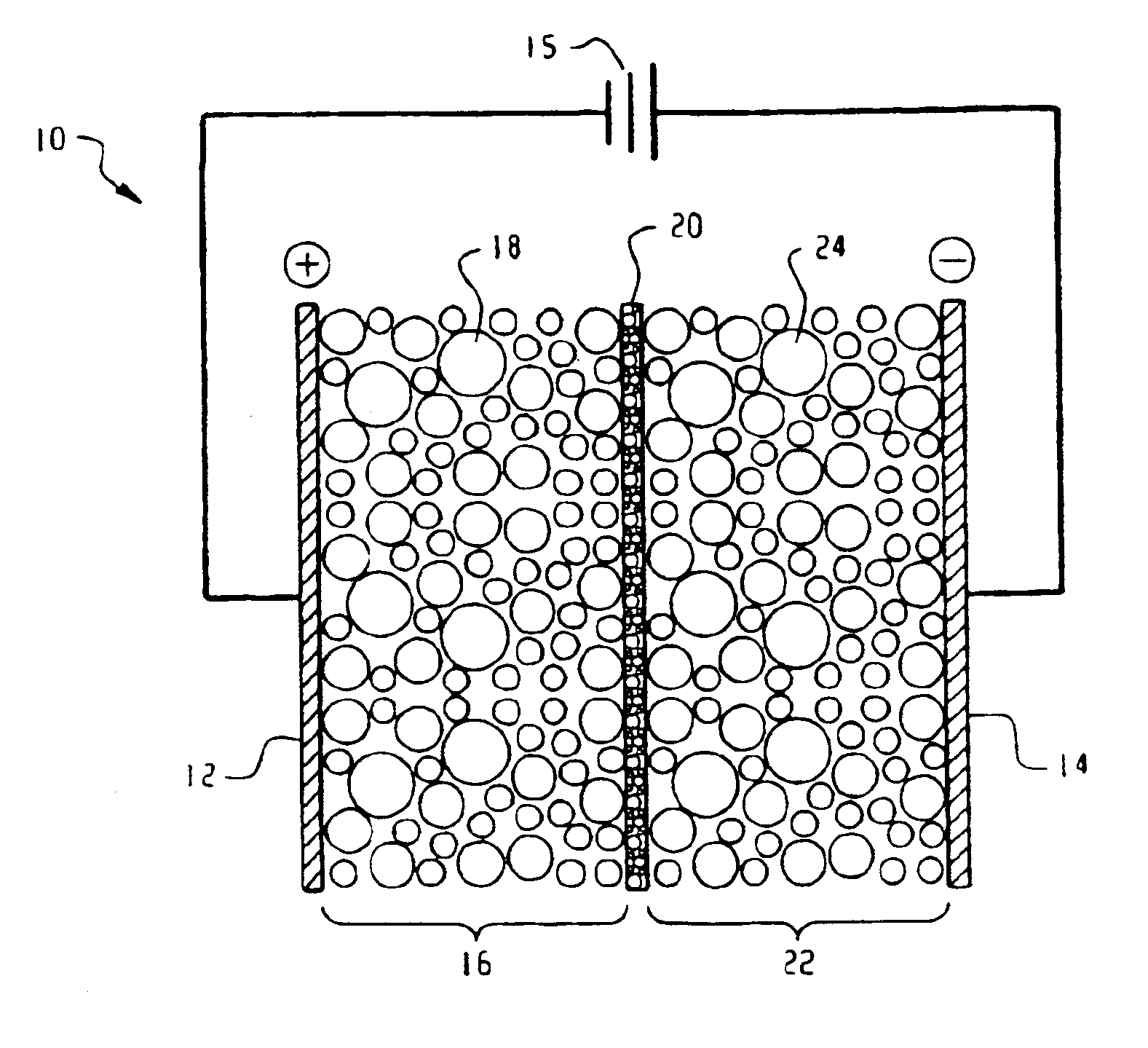

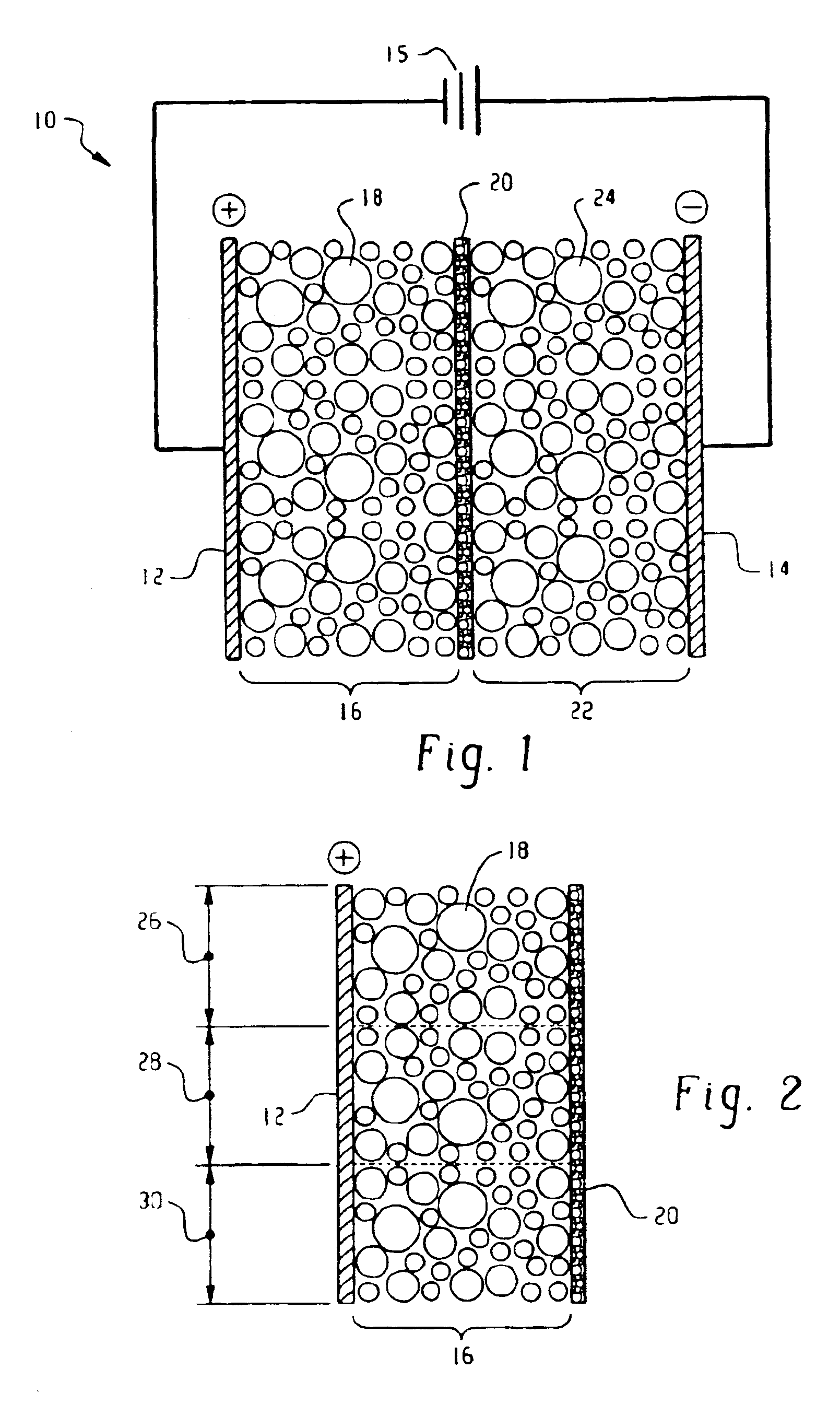

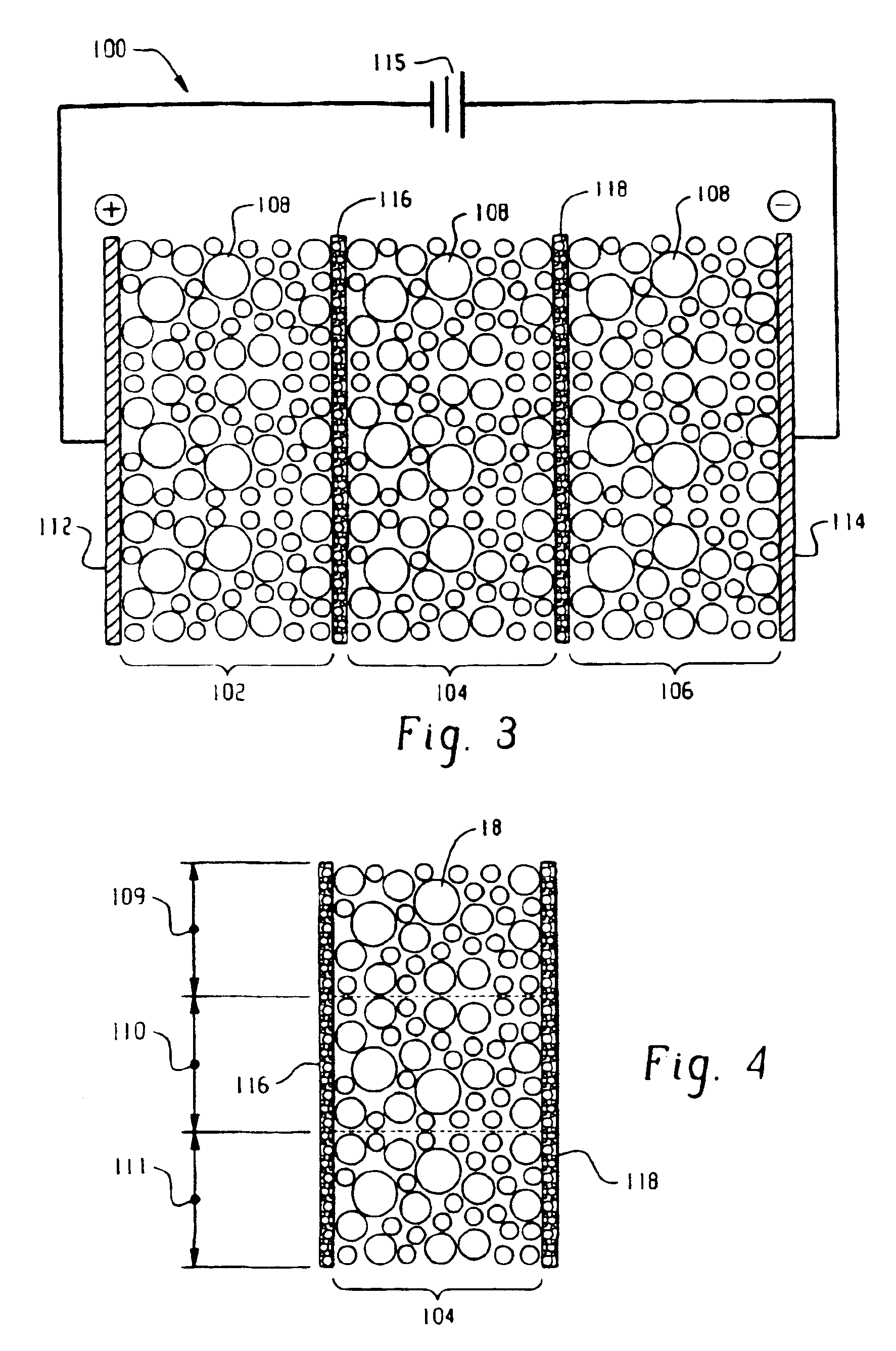

Electrolytic process and apparatus

InactiveUS20030082095A1Minimize diffusionMinimizes free movementCellsChlorine oxidesElectrolysisOrganic matter

An electrolytic process and apparatus for oxidizing inorganic or organic species is disclosed. The process and apparatus includes contacting a solution containing the inorganic or organic species with an electrocatalytic material disposed in an electrolytic reactor. Also disclosed are processes for fabricating a catalyst material for use in the electrolytic reactors and processes.

Owner:ECOLAB USA INC +1

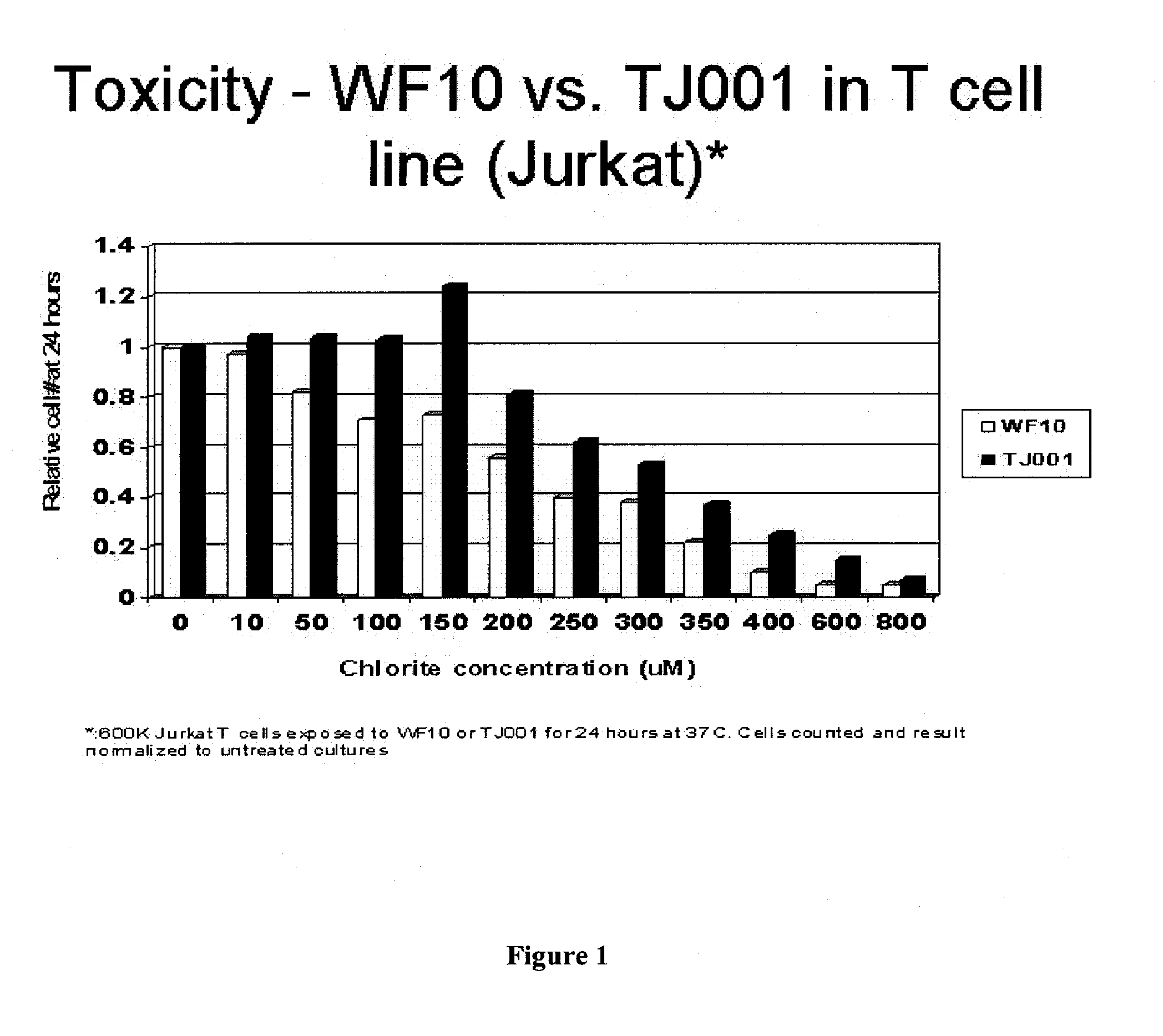

Chlorite Formulations, and Methods of Preparation and Use Thereof

Described herein are chlorite formulations having a pH between about 7 and about 8.5, wherein the chlorite formulations are substantially free of deleterious non-chlorite components. Described herein are chlorite formulations, including pharmaceutical formulations, which are formulated for systemic, parenteral, or intravenous administration. Described herein are methods of preparing and methods of using the chlorite formulations described herein.

Owner:NEUVIVO INC

Synthesis method of cadmium sulfide nano rod

A process for synthesizing the cadmium sulfide nanorods which can emit blue light under irradiation of ultraviolet lamp includes sufficiently mixing cadmium chloride with thioacetamine in the aqueous solution of the micelles of amine trimethyl hexadecanebromide, dripping the solution of sodium hydroxide to make S ions released by thioacetamine and cadmium chloride take part in reaction to generate nuclei, and gradual growing to become nanorods.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

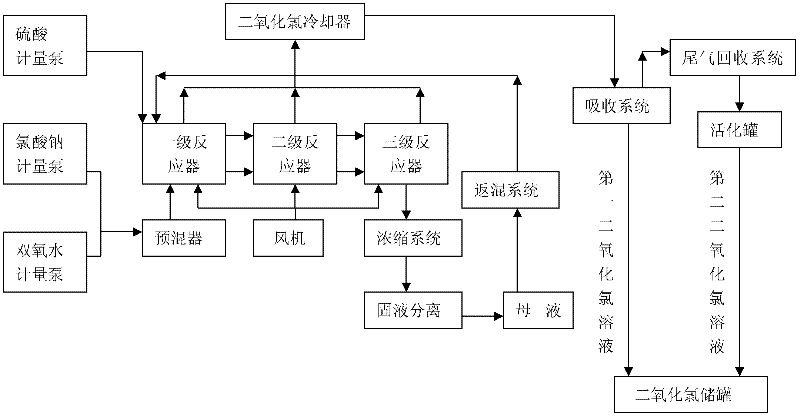

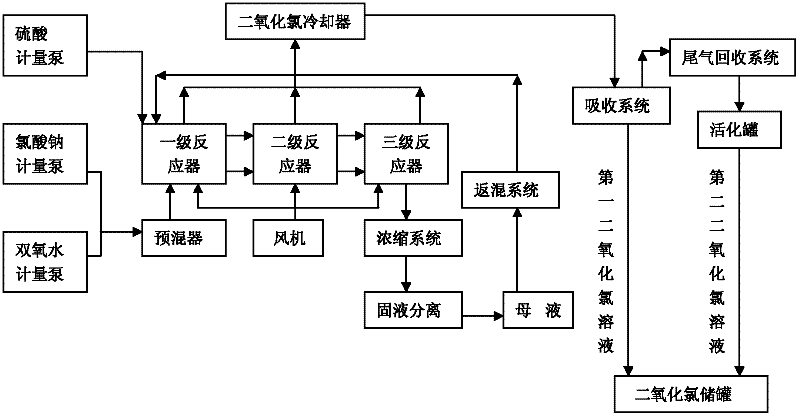

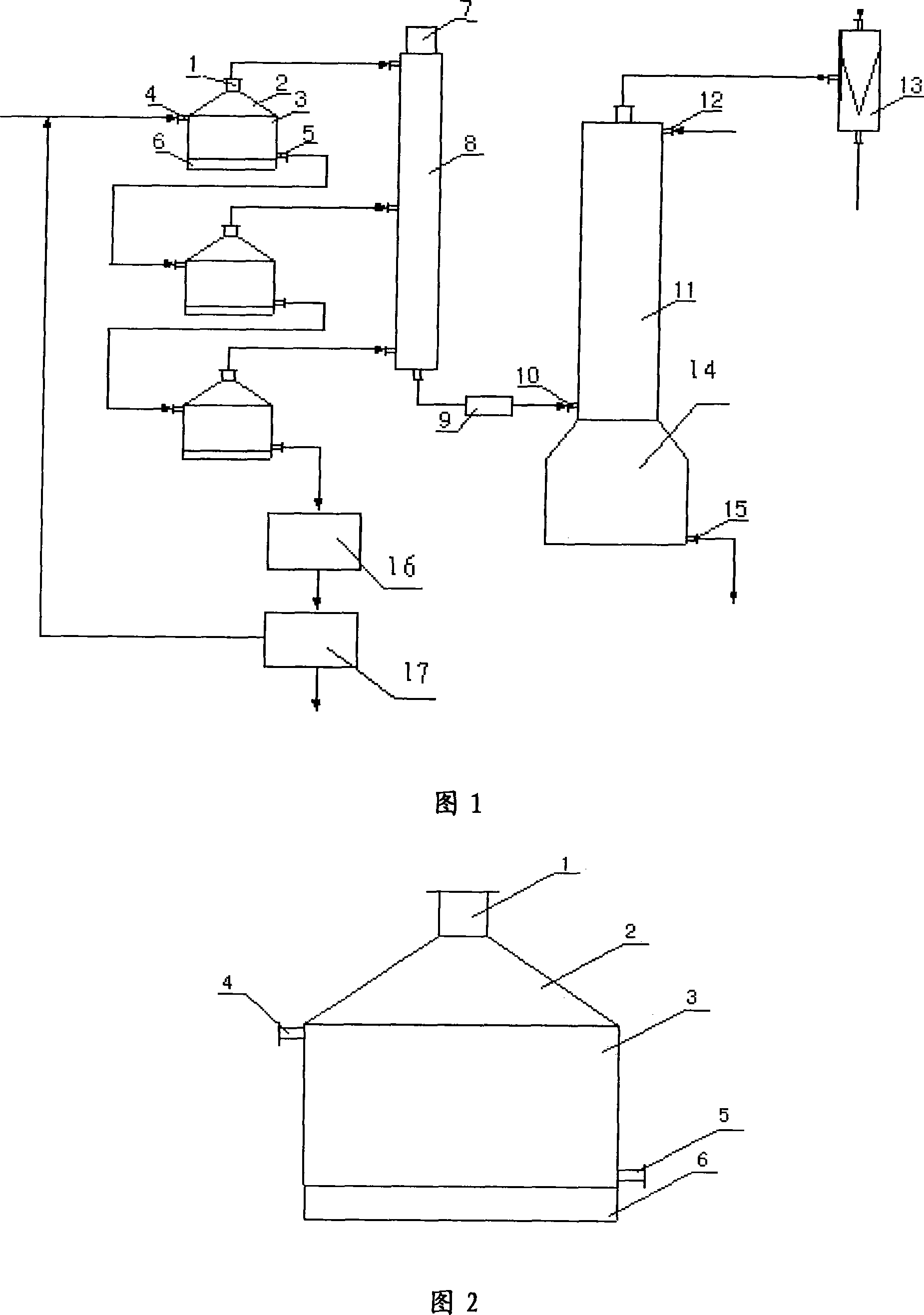

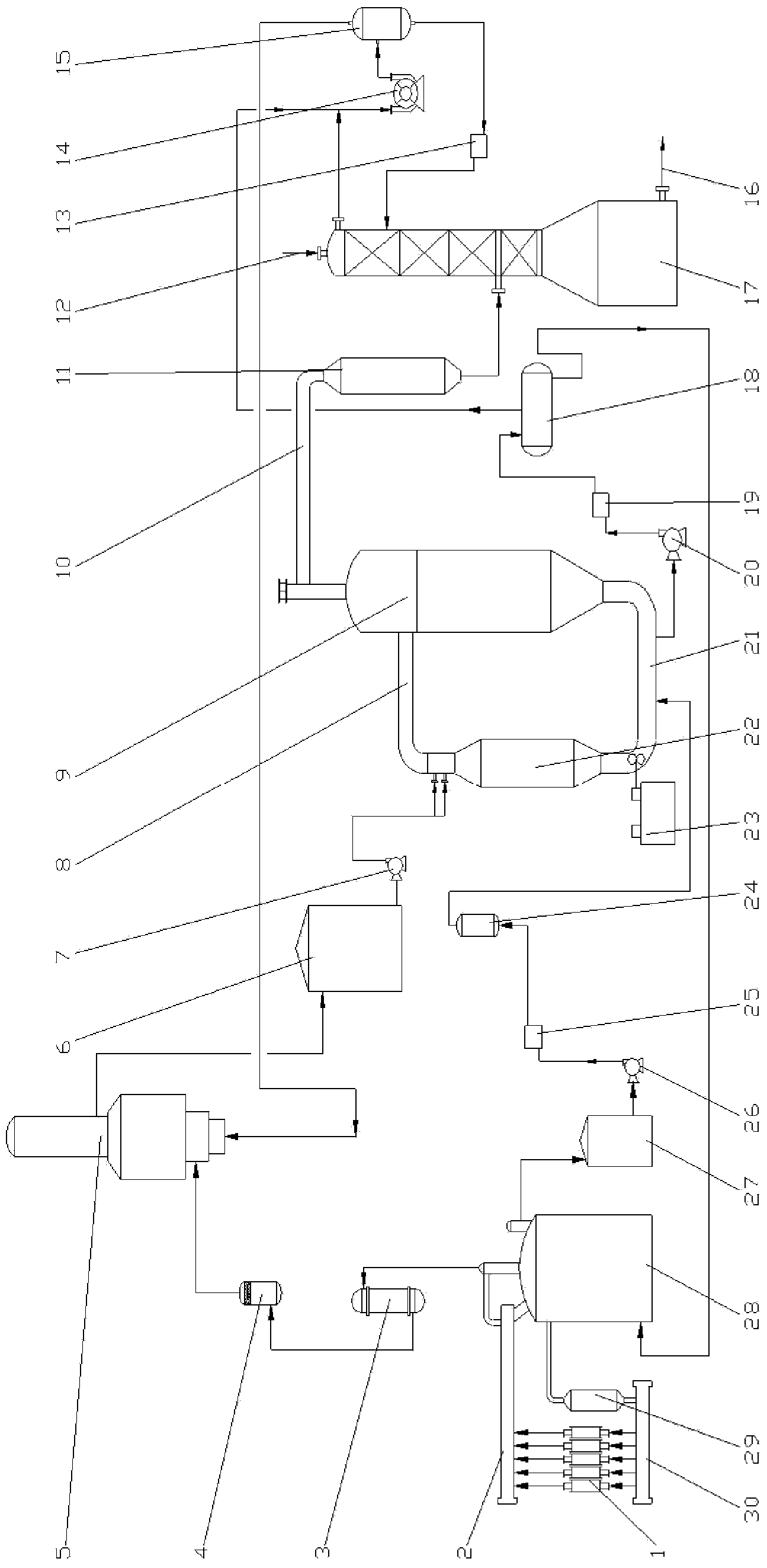

Preparation device and technology for chlorine dioxide

The invention discloses a preparation device and a preparation technology for chlorine dioxide. The preparation device comprises reactors and a chlorine dioxide cooler, wherein the reactors are at least divided into three levels, namely a primary reactor, a secondary reactor and a tertiary reactor; the tops of the primary reactor, the secondary reactor and the tertiary reactor are communicated through a gas pipeline, and the bottoms of the primary reactor, the secondary reactor and the tertiary reactor are communicated through a liquid pipeline; the primary reactor is also connected with a pre-mixer; the secondary reactor is also connected with a fan; the tertiary reactor is sequentially connected with a concentration system, a solid-liquid separator, a mother solution tank and a mixture return system and connected with the primary reactor after being connected with the mixture return system; and the primary reactor, the secondary reactor and the tertiary reactor are connected with the chlorine dioxide cooler. Compared with the prior art of China, the invention has the advantages of simple process flow, high production capacity and reaction efficiency, low consumption of raw materials, high yield change adaptability, high chlorine dioxide purity, low chlorine content and environment friendliness.

Owner:成都齐力水处理科技有限公司

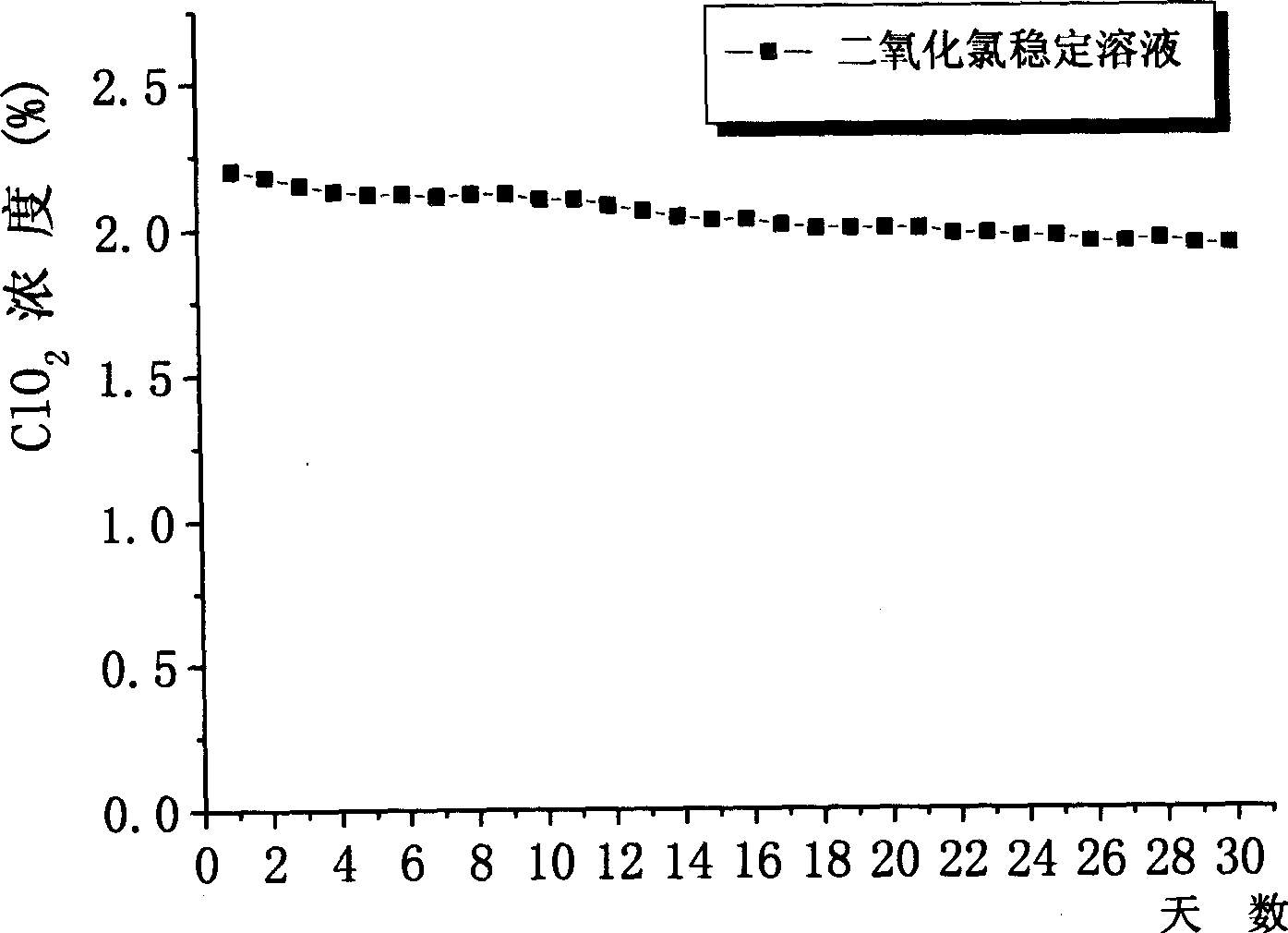

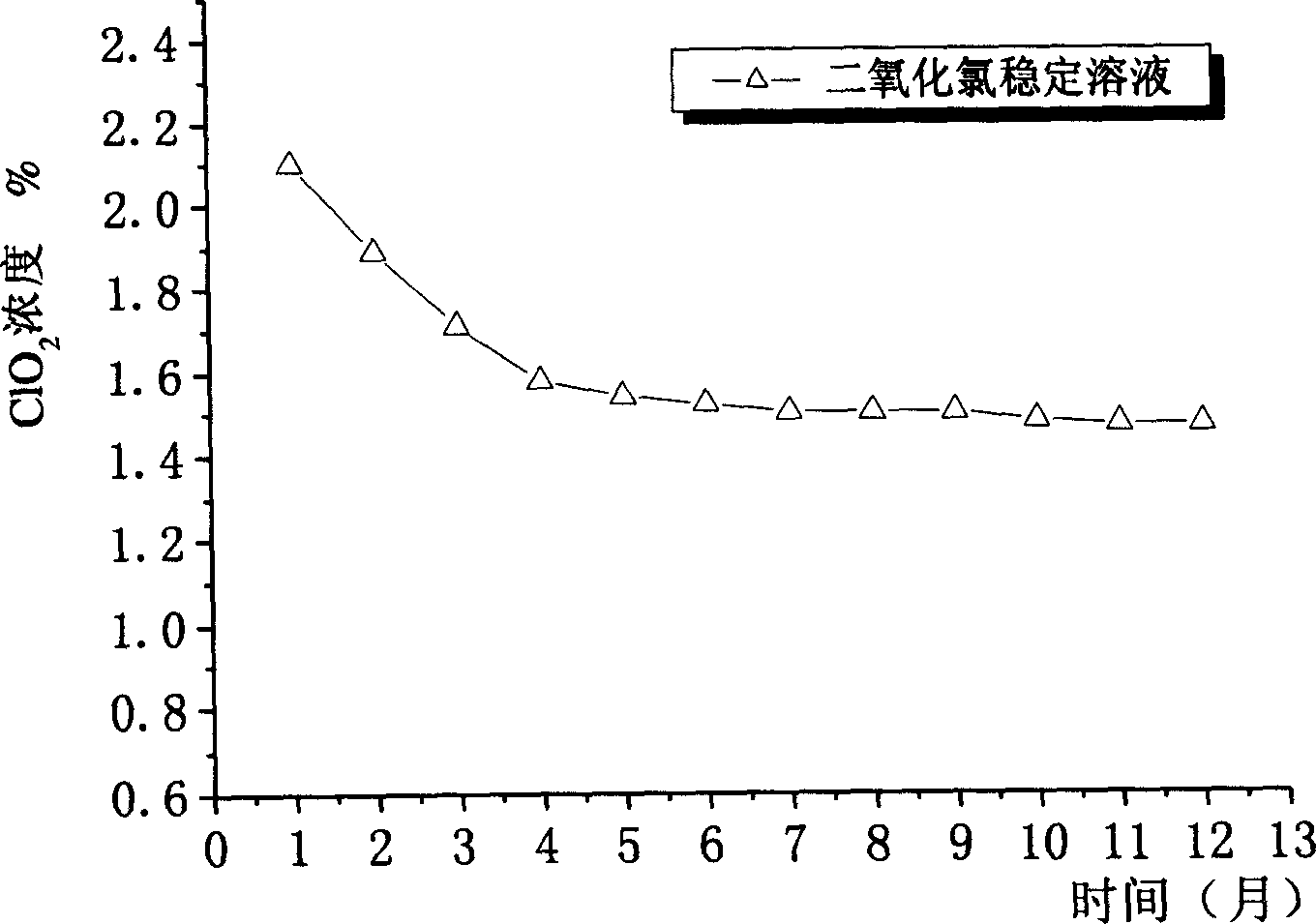

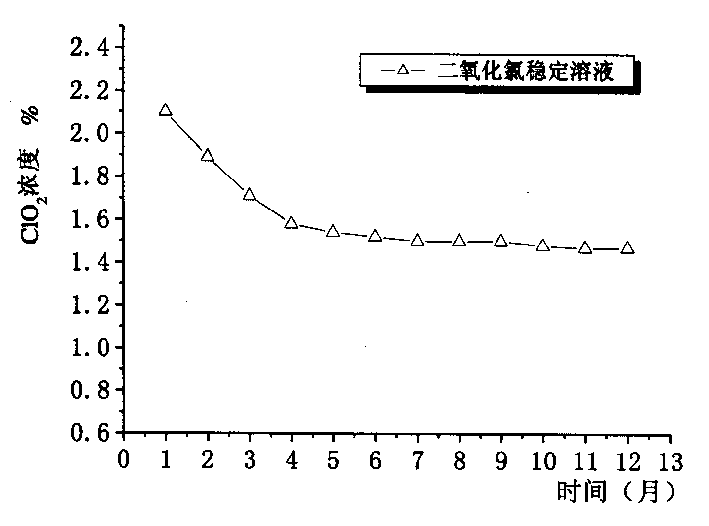

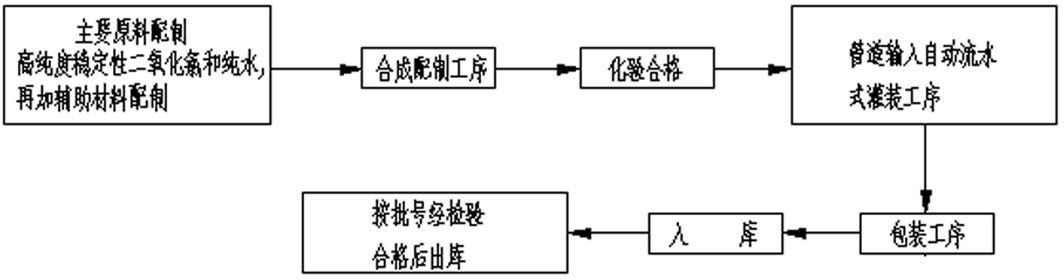

Method of preparing stable chloride dioxide

The present invention provides a new method for preparing stable chlorinedioxide, which can prepare stable chlorinedioxide solution which has good stability and can be stored for a long period by using chlorinedioxide gas, at the same time it can prepare stable chloride solution system. When it is used, the acid-like activating agent is added to the stable system, the chlorinedioxide gas can be produced. Said invention adopts the sodium carbonate and hydrogen peroxide as basic component for stability of chlorinedioxide, and adds a series of stabilizing agents to obtain the stable chlorinedioxide solution or in the chlorite solution uses sodium carbonate to regulate pH value of the solution of 7-8 and adds the hydrogen peroxide and stabilizing agent to obtain the stable chlorite solution.

Owner:GUIZHOU UNIV

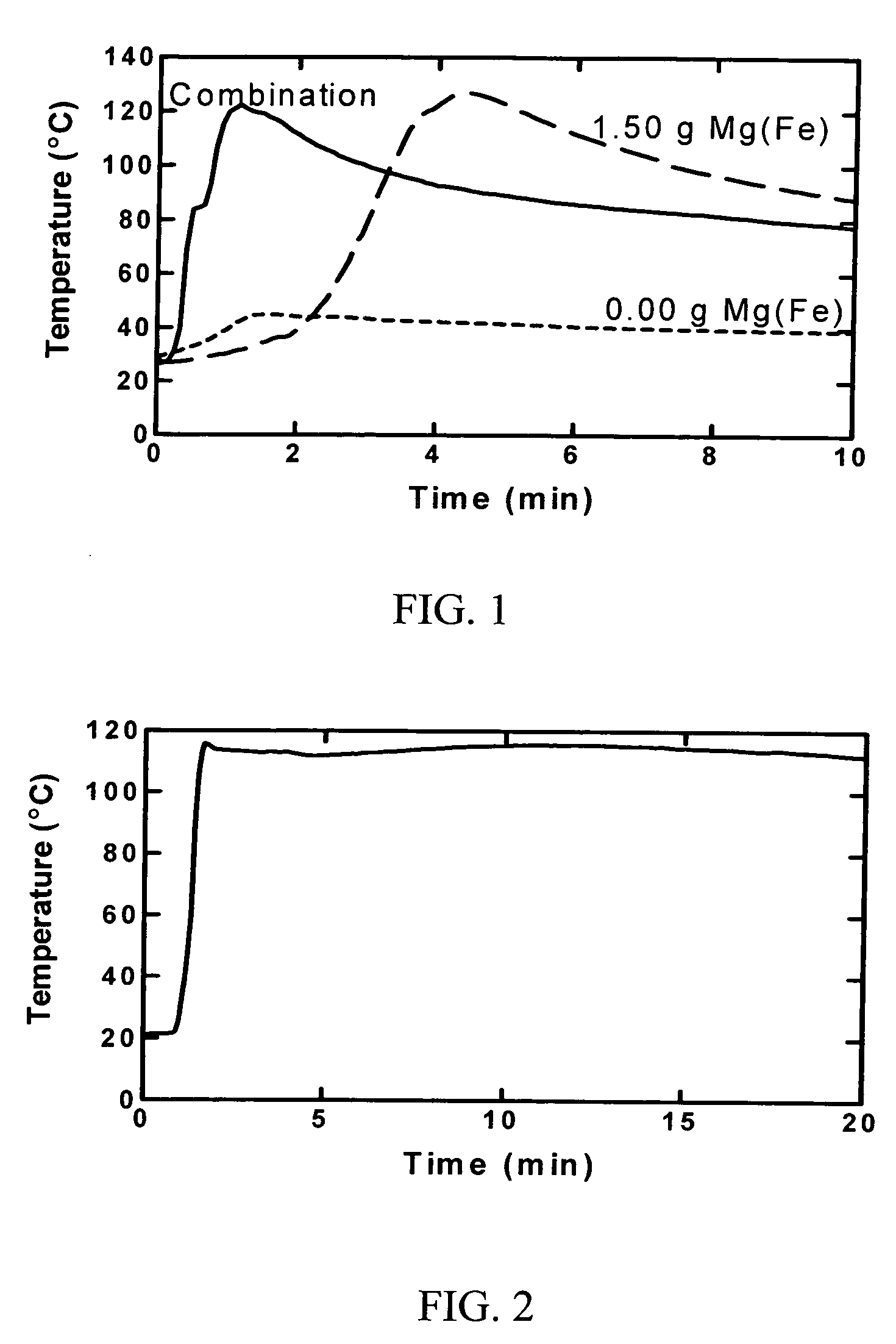

Chemical combination for generation of disinfectant and heat

InactiveUS20060097222A1Eliminate the problemExothermal chemical reaction heat productionLiquid degasificationChlorine dioxideDisinfectant

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

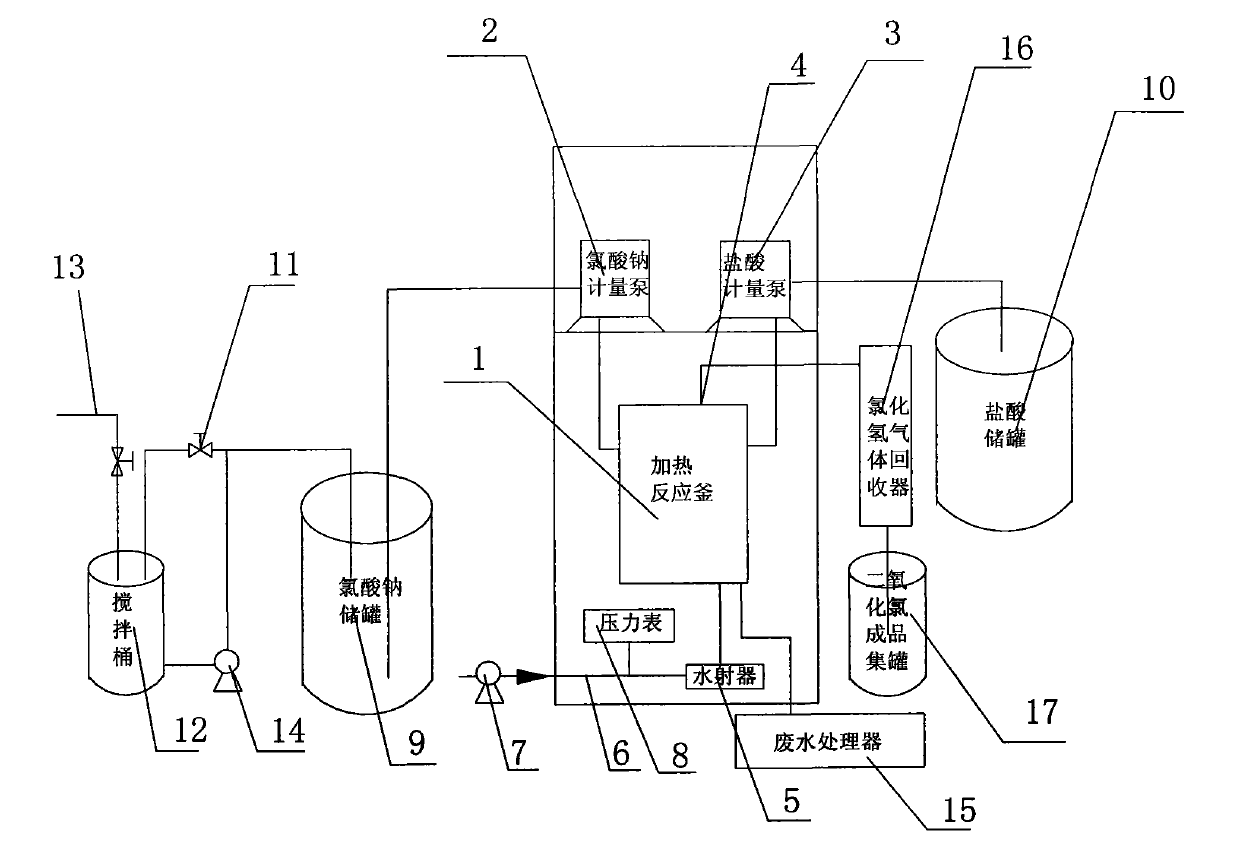

Chlorine dioxide generating system

InactiveCN102701156ANo pollution in the processSave resourcesChlorine/hydrogen-chlorideChlorine oxidesChlorine dioxideSodium chlorate

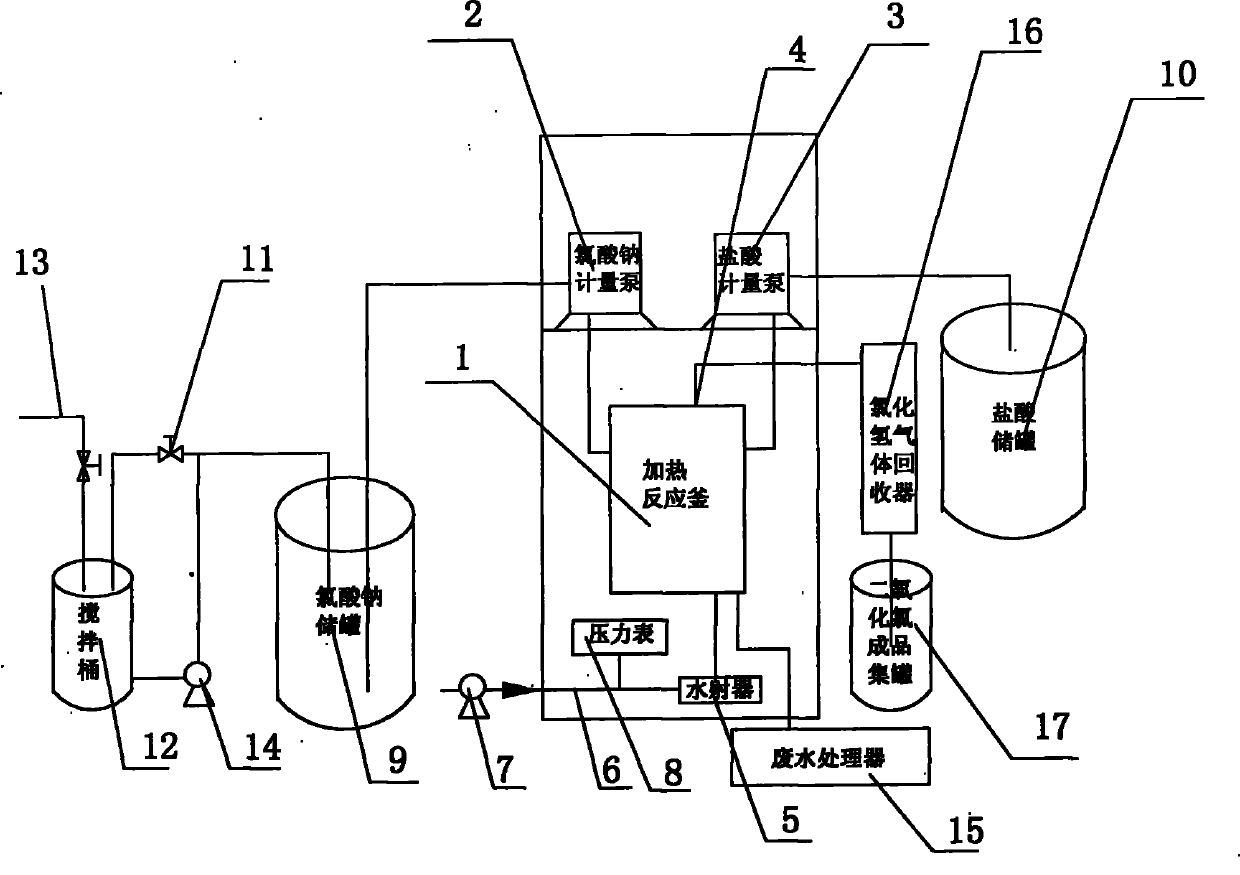

The invention relates to a chlorine dioxide generating system, comprising a heating reactor. One end of the heating reactor is connected with a sodium chlorate metering pump and the other end of the heating reactor is connected with a hydrochloric acid metering pump. The top of the heating reactor is provided with a reaction product outlet. The bottom of the heating reactor is connected with a water injector. The water injector is connected with a system water inlet circulation pump through a pipeline which is provided with a pressure gauge. The sodium chlorate metering pump is connected with a sodium chlorate storage tank. The hydrochloric acid metering pump is connected with a hydrochloric acid storage tank. A sodium chlorate storage tank is connected with an agitation vat through a manual valve. The upper end of the agitation vat is connected with a tap water pipeline. The bottom of the agitation vat is connected with a circulating pump of the agitation vat. The beneficial effects of the invention are that the chlorine dioxide from the reaction product outlet is mixed with wet hydrogen chloride gas which can be recycled to save resources; and the bottom of the heating reactor is connected with a wastewater processor to process a certain amount of harmful substances generated from the reactions so as not to pollute the environment.

Owner:陆敏慧

Product capable of delaying generation and releasing of chlorine dioxide and preparation method thereof

The invention relates to a product capable of delaying generation and releasing of chlorine dioxide and a manufacture method thereof. The product comprises a porous carrier, chlorite adhered onto the porous carrier and alkaline matters adhered onto the porous carrier. The invention further discloses the method for manufacturing stabilized chlorine dioxide products. The method includes steps of: (a) preparing aqueous solution containing the chlorine dioxide and the alkaline matters; (b) preparing aqueous suspension containing organic hydrocarbon, wherein the aqueous suspension containing the organic hydrocarbon can be prepared independently or be prepared together with the chlorine dioxide and the alkaline matters in solution obtained in the step (a); (c) adding the solution obtained in the step (a) and the step (b) (if the solution is prepared in the step (b)) into the porous carrier, and evenly mixing the solution so as to enable the porous carrier to absorb the chlorine dioxide, the alkaline matters and optional organic hydrocarbon and alkaline salt in the solution.; and (d) drying the mixture obtained in the step (c) to enable the water content to be lower than 10%, and packaging in sealing mode to obtain the product.

Owner:SHENZHEN WANHE PHARMA

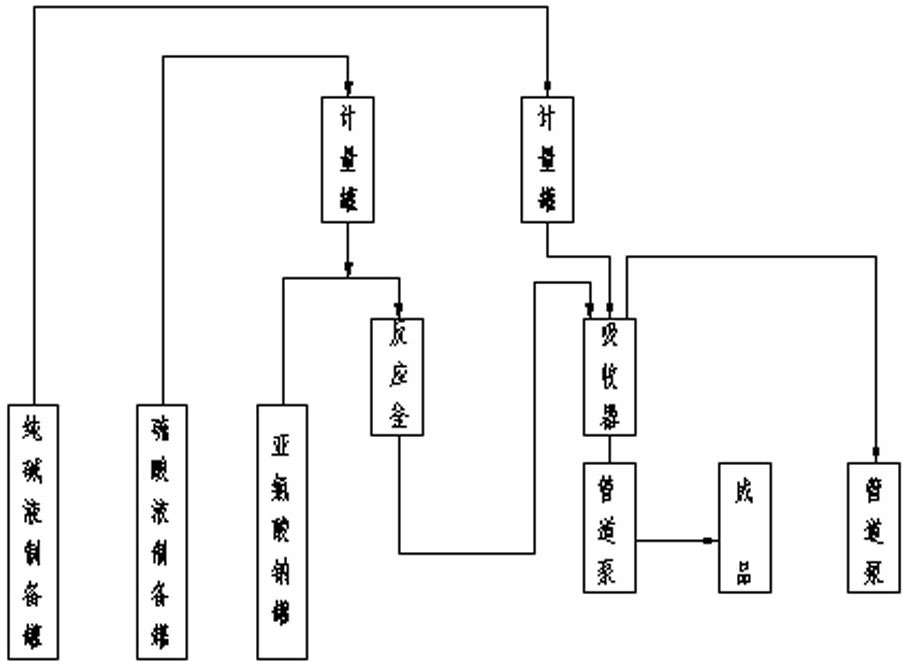

Chlorine dioxide oxidizing agent supply system for boiler flue gas denitration and technology thereof

ActiveCN105169913AAchieve continuous supplyRealize regulationChlorine oxidesDispersed particle separationLiquid wasteChlorine dioxide

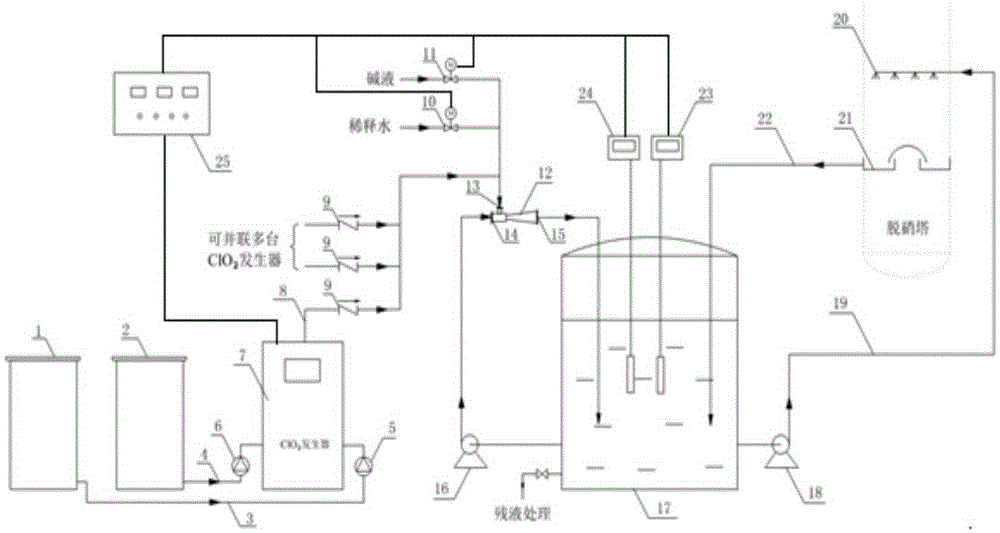

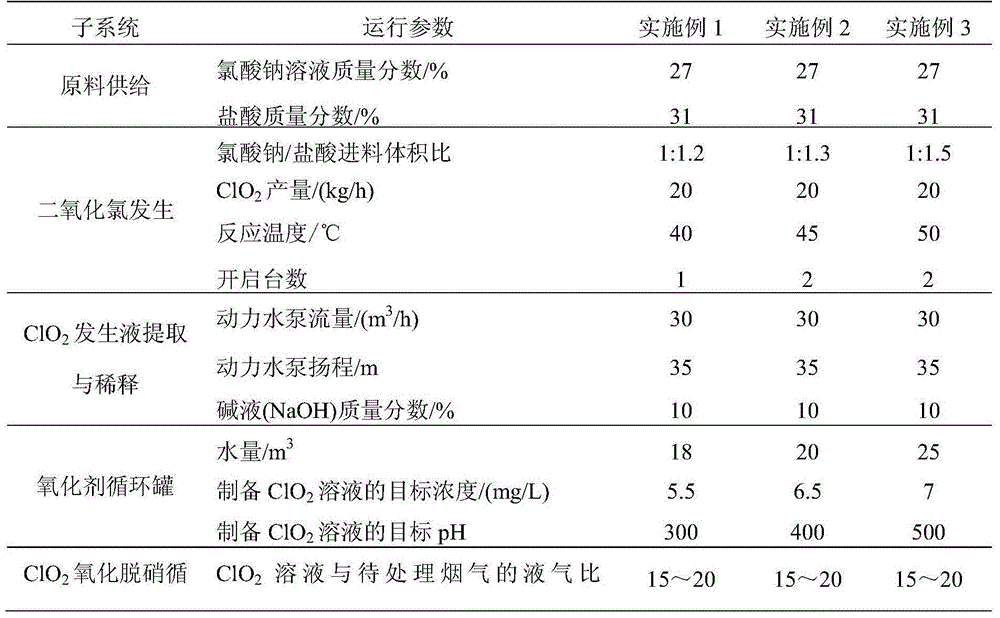

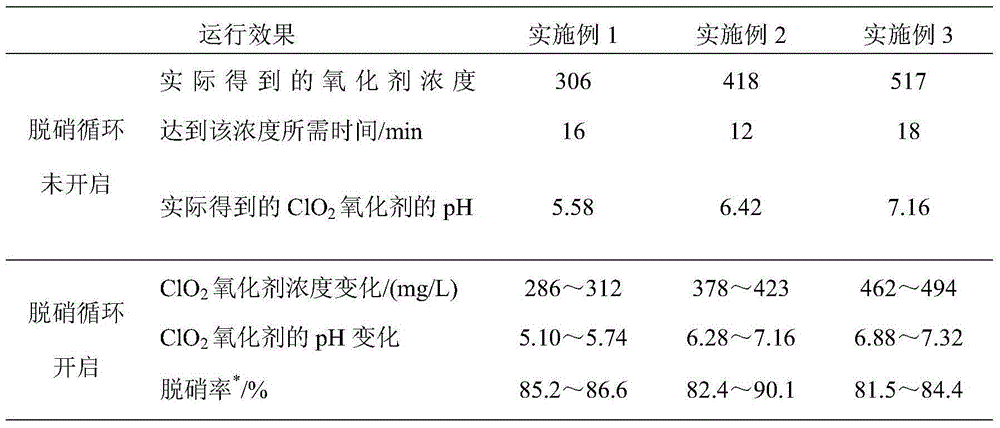

The invention provides a chlorine dioxide oxidizing agent supply system for boiler flue gas denitration and a technology thereof. The supply system comprises a raw material supply sub-system, a CIO2 generation sub-system, a CIO2 generation liquid extraction and dilution sub-system, an oxidizing agent circulation sub-system, a CIO2 solution denitration circulation sub-system and a detection and control sub-system. In the CIO2 generation sub-system, a ClO2 generation liquid is generated sodium chlorate and hydrochloric acid provided by the raw material supply sub-system. the CIO2 generation liquid extraction and dilution sub-system achieves adjustment of a concentration and a pH value of a CIO2 oxidizing agent solution in the oxidizing agent circulation sub-system according to control of the detection and control sub-system. The CIO2 solution denitration circulation sub-system extracts the CIO2 oxidizing agent solution from the oxidizing agent circulation sub-system and inputting a waste liquid to the oxidizing agent circulation sub-system after oxidation denitration and flue gas absorption. The provided system achieves continuous supply, concentration automatic adjustment and recycling of the CIO2 oxidizing agent during the denitration process, and the system is advantaged by small occupation space and low energy consumption.

Owner:NANJING UNIV OF SCI & TECH

Calcium hypochlorite composition

Calcium hypochlorite compositions that are classified as a Packing Group III Division 5.1 oxidizer material or as a non-Division 5.1 oxidizer material are described. In one embodiment, the compositions comprise an admixture of particulate calcium hypochlorite and particulate metaboric acid. The calcium hypochlorite is present in the composition in an amount and is of a concentration such that the composition would be classified as a Packing Group II Division 5.1 oxidizer in the absence of said particulate metaboric acid. Other embodiments described are solid shaped articles, e.g., tablets, comprising the described calcium hypochlorite-metaboric acid composition.

Owner:AXIALL OHIO

Method of treating with chlorine dioxide

Owner:SABRE IP ACQUISITIONCO LLC

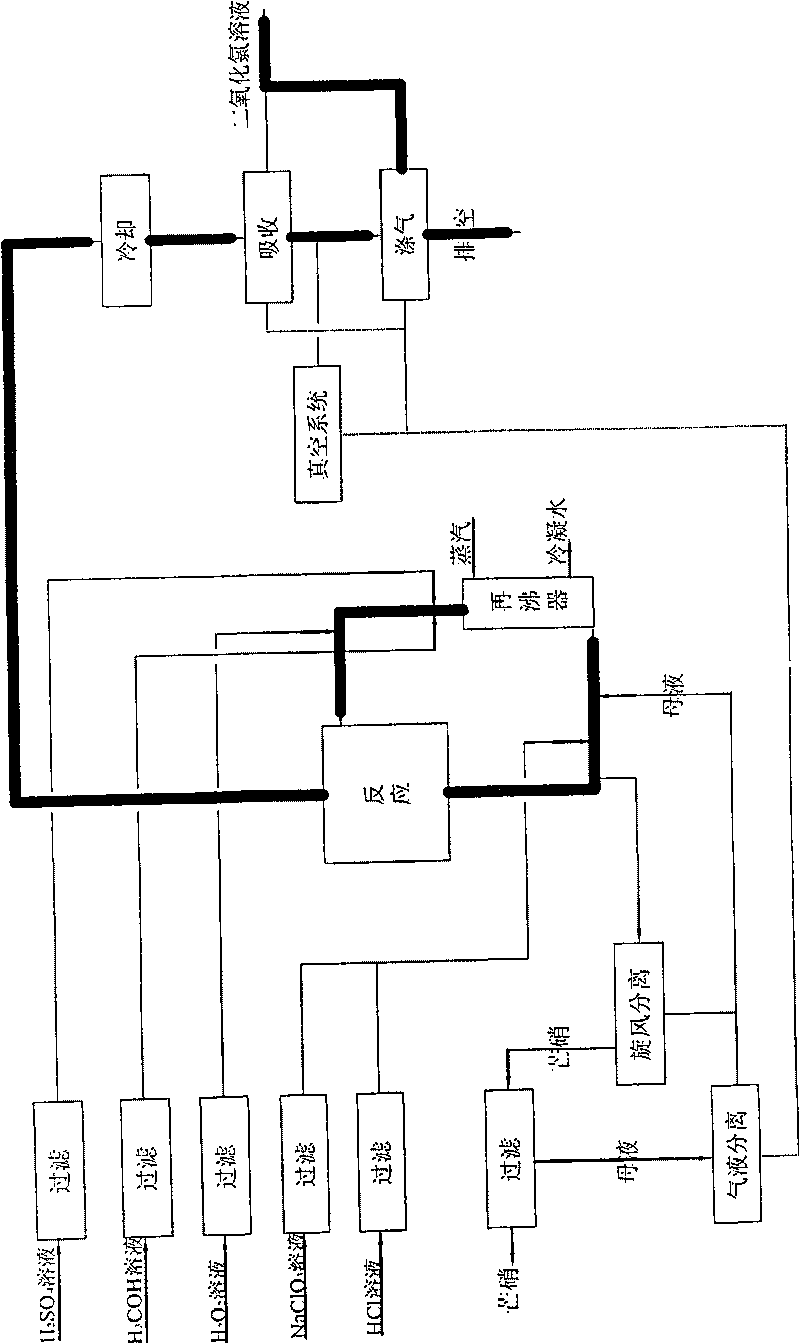

Method for producing chlorine dioxide with high purity by adopting combined reducing agent

ActiveCN101746731AImprove conversion rateReduce contentChlorine oxidesNaCl - Sodium chlorideHydrogen peroxide

The invention relates to a method for producing chlorine dioxide with high purity by adopting a combined reducing agent. The method comprises the following steps of: injecting concentrated sulfuric acid and a sodium chlorate solution into a generator to form a reacting mother solution; maintaining the reacting mother solution to a certain acidity, temperature and the content of sodium chlorate; then adding a combined reducing agent formed by mixing methanol, hydrogen peroxide, hydrochloric acid or sodium chlorate to react for generating chlorine dioxide gas and a byproduct namely acid mirabilite; cooling and then absorbing the chlorine dioxide gas by using low temperature frozen water to obtain a water solution of chlorine dioxide; and simultaneously recovering the byproduct. The conversion rate of the chlorine dioxide produced by the method is improved by 3-6 percent as comparison with that of the chlorine dioxide produced by a single reducing agent, the stability of chemical reaction is improved, the production cost is reduced, and the chlorine amount in the chlorine dioxide solution and tail gas exhausted from a chlorine dioxide absorbing tower is remarkably reduced.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Method of treating with chlorine dioxide

An aqueous chlorine dioxide solution which comprises dissolved chlorine dioxide in a concentration of about 10 to 3000 mg / l, pH in the range of about 1 to 6, and a chlorine scavenging means such as sodium chlorite in a ratio in the range of about 1:4 to 1:15 (w / w) sodium chlorite to chlorine dioxide. The chlorine dioxide solution may be stored for use over a period of several days to several months.

Owner:SABRE IP ACQUISITIONCO LLC

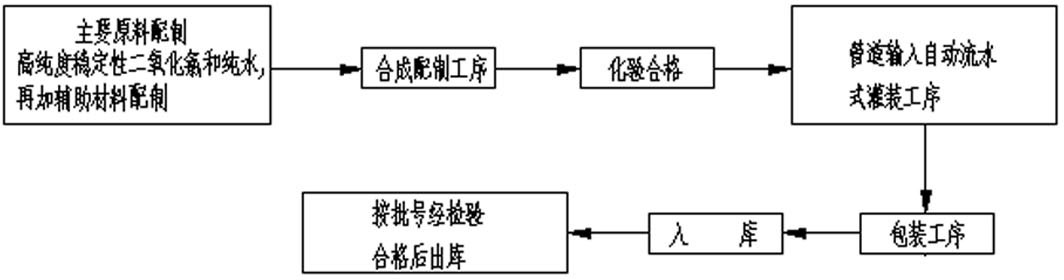

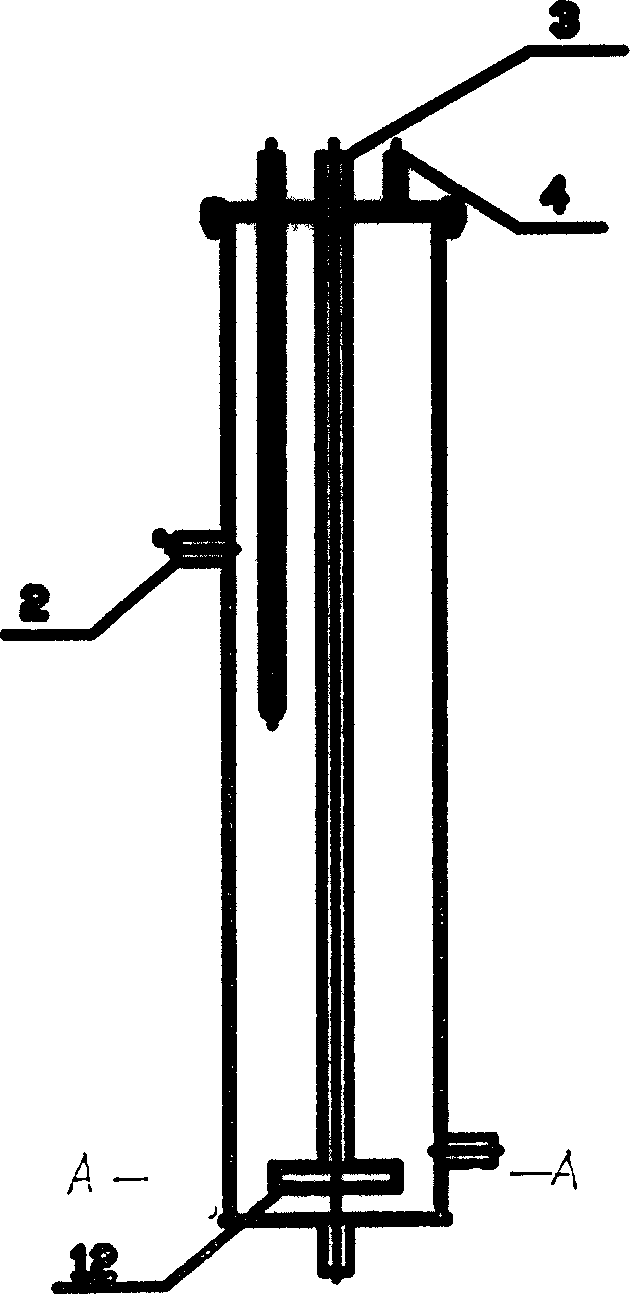

Raw liquid for preparing chlorine dioxide, method and device for preparing chlorine dioxide

The present invention relates to sterilizing and bleaching agent technology, and is especially process, apparatus and material liquid for preparing chlorine dioxide. The material liquid consists of chlorate 10-65 wt%, urea 0.5-10 wt%, hydrogen peroxide or cane sugar 0.5-8 wt% and water for the rest. The preparation process of chlorine dioxide includes the reaction of the material liquid in multiple stage serially connected reaction apparatus while heating and in negative pressure condition. The preparation process has material converting rate higher than 85 %, purity of the prepared chlorine dioxide higher than 98 %, low cost, high safety and reliability, reuse of residual liquid and no waste exhaustion.

Owner:穆超碧

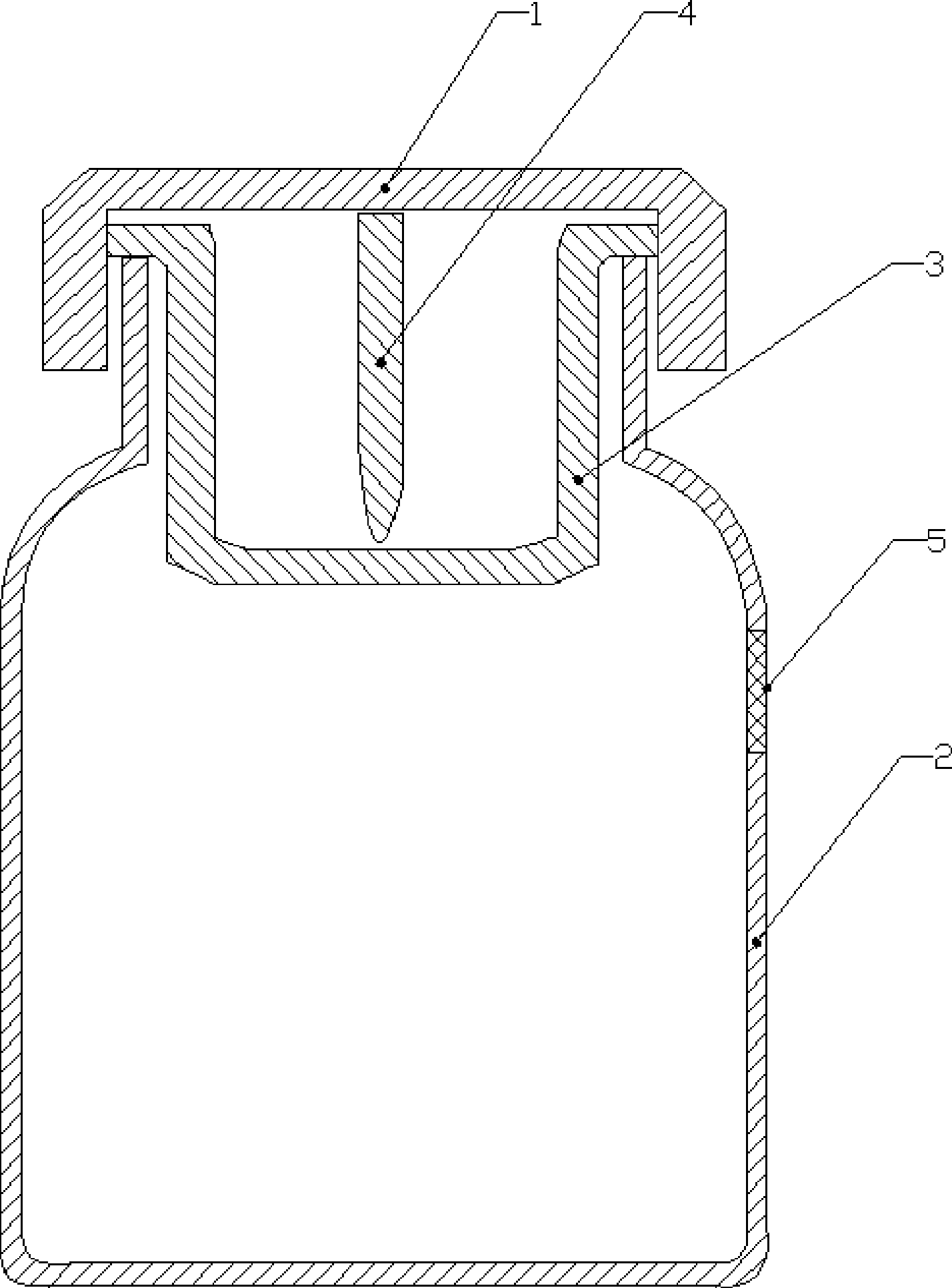

Disinfecting, deodorizing and fresh-keeping apparatus, method for preparing chlorine dioxide antistaling agent

InactiveCN101428149ALong validity periodAchieve disinfectionChlorine oxidesFood preservationPreservativeEngineering

The invention discloses a disinfection deodorization preservation device to achieve the purpose of disinfection and deodorization by utilizing chlorine dioxide and a method for preparing a chlorine dioxide preservative therefore. The device has the advantage of releasing chlorine dioxide continuously and slowly into a space to serve the purpose of the disinfection and deodorization of the space. The disinfection deodorization preservation device comprises a container cover body and a liquid storage container formed by the container body; the container cover body is connected with the container body; and a permeable material layer which allows the accommodating chamber of the container body to be communicated with the exterior atmosphere is arranged on the liquid storage container. The method of using the device to prepare the chlorine dioxide preservative comprises the follow steps: a, the container body is loaded with either sodium chlorite solution or acidic activating agent, and an inner layer liquid storage chamber is loaded with either sodium chlorite solution or acidic activating agent, except that with which the container body is loaded; and b, liquid in the inner layer liquid storage chamber reacts with liquid in the container body, and chlorine dioxide produced by the reaction is sent out through the permeable material layer. The invention can achieve the purposes of lasting and continuous disinfection and deodorization.

Owner:穆超银

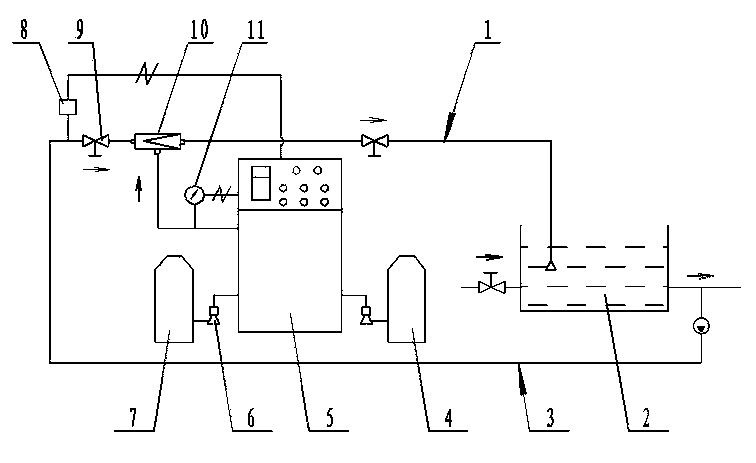

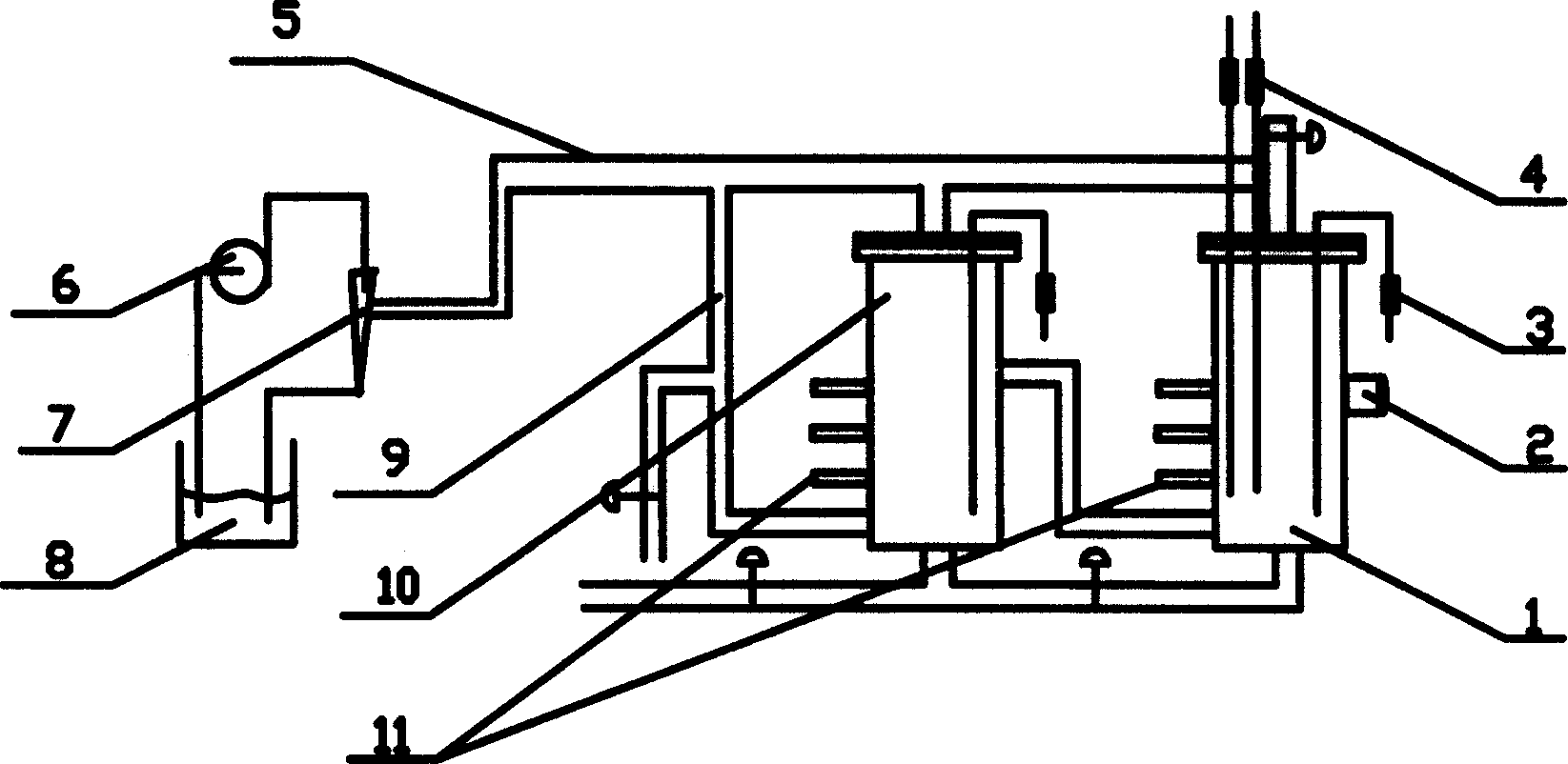

Chlorine dioxide generator improved structure

InactiveCN103922288AReduce consumption costLow running costChlorine oxidesChlorine dioxideSodium chlorate

The invention discloses a chlorine dioxide generator improved structure, which belongs to an environmental protection device for sterilizing the water, and aims at providing a water sterilizing device which is high in conversion rate and good in safety. The chlorine dioxide generator improved structure comprises a storage tank and a reactor; the storage tank comprises a sodium chlorate storage tank (7) and a hydrochloric acid storage tank (4), which are respectively communicated with the reactor (5) through a measuring pump (6), a discharging port of the reactor (5) is communicated with a processing water pond (2) through a water jet device (10) and a discharging pipe (1), and an inlet of the water jet device (10) is connected with a power water pipe (3). The chlorine dioxide generator improved structure has the advantages of simple structure, convenience in operation and application, high automation degree, safety, high efficiency and the like and is a sterilizing environmental protection device for the water treatment.

Owner:GUIZHOU YIDAO ENVIRONMENT CONSTR

Chlorine dioxide generating agent

InactiveCN101172579AEasy to carrySuitable for deodorizationBiocideChlorine oxidesMass ratioSodium chlorite

The invention relates to a compounding formula of carbon dioxide propellant, and aims at providing carbon dioxide propellant suitable for disinfection and deodorization in families and small ranges. The carbon dioxide propellant provided by the invention is produced by mixing and adding sodium chlorite and citric acid into a container according to the mass ratio of 1: 1 to 1: 20.

Owner:艾雪莉

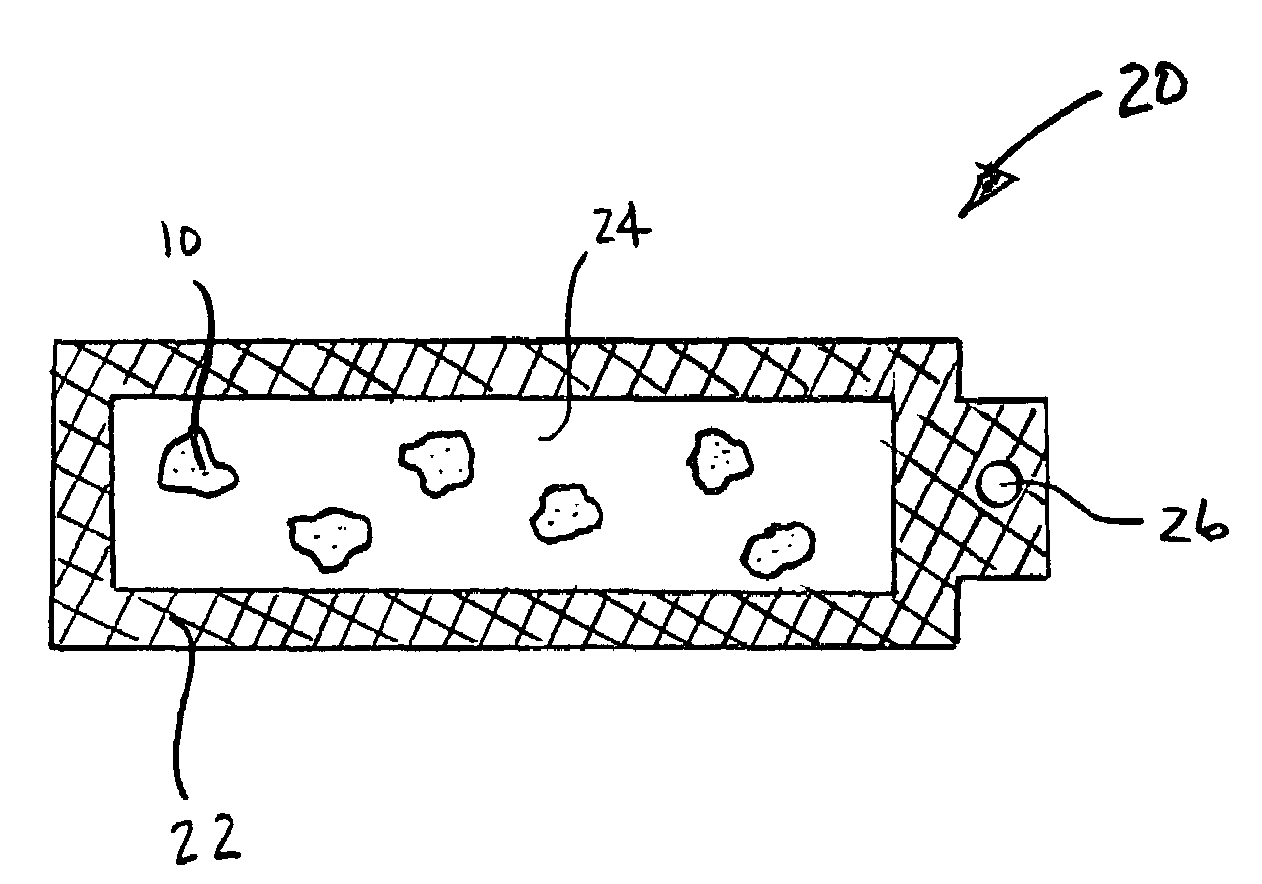

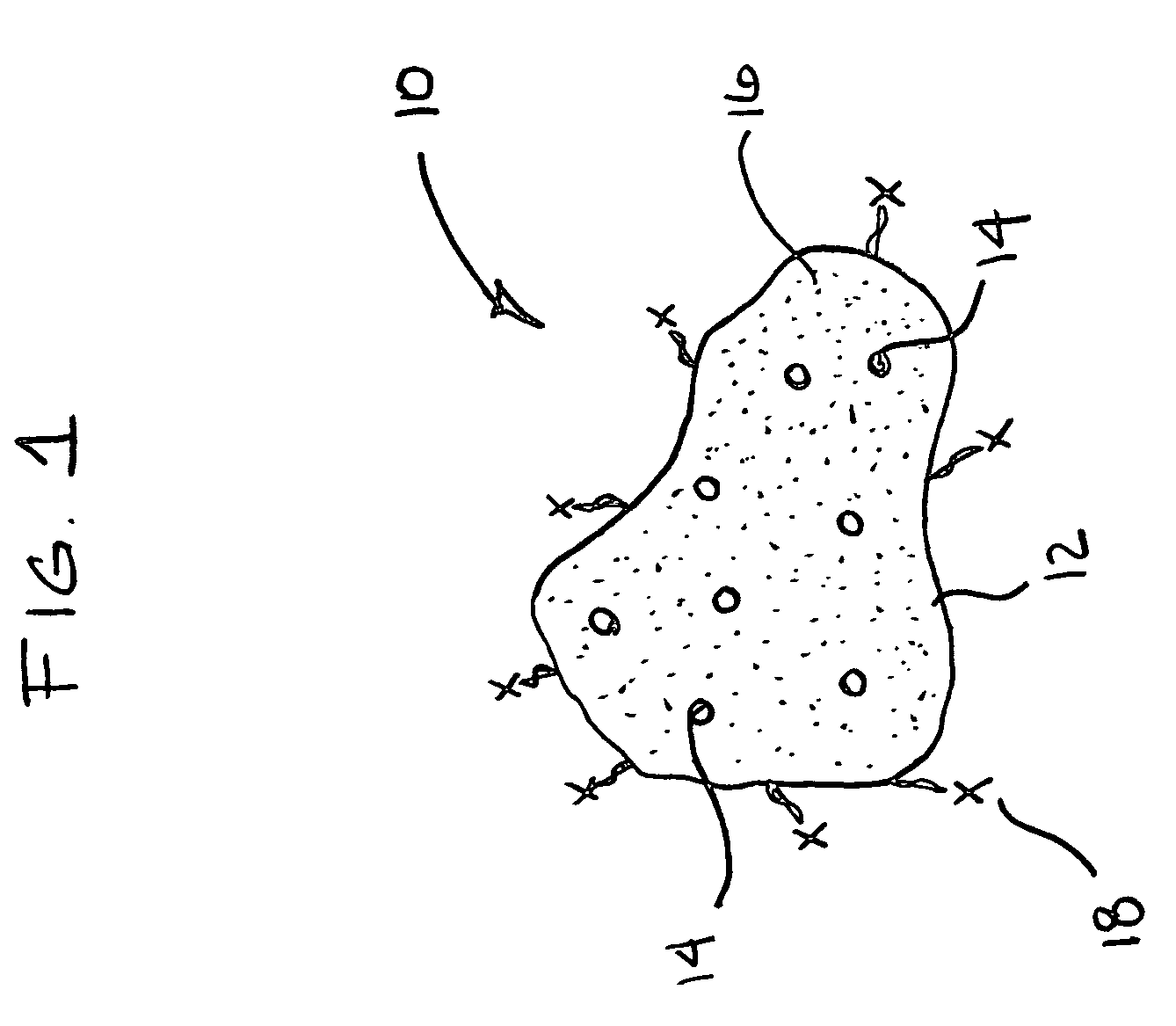

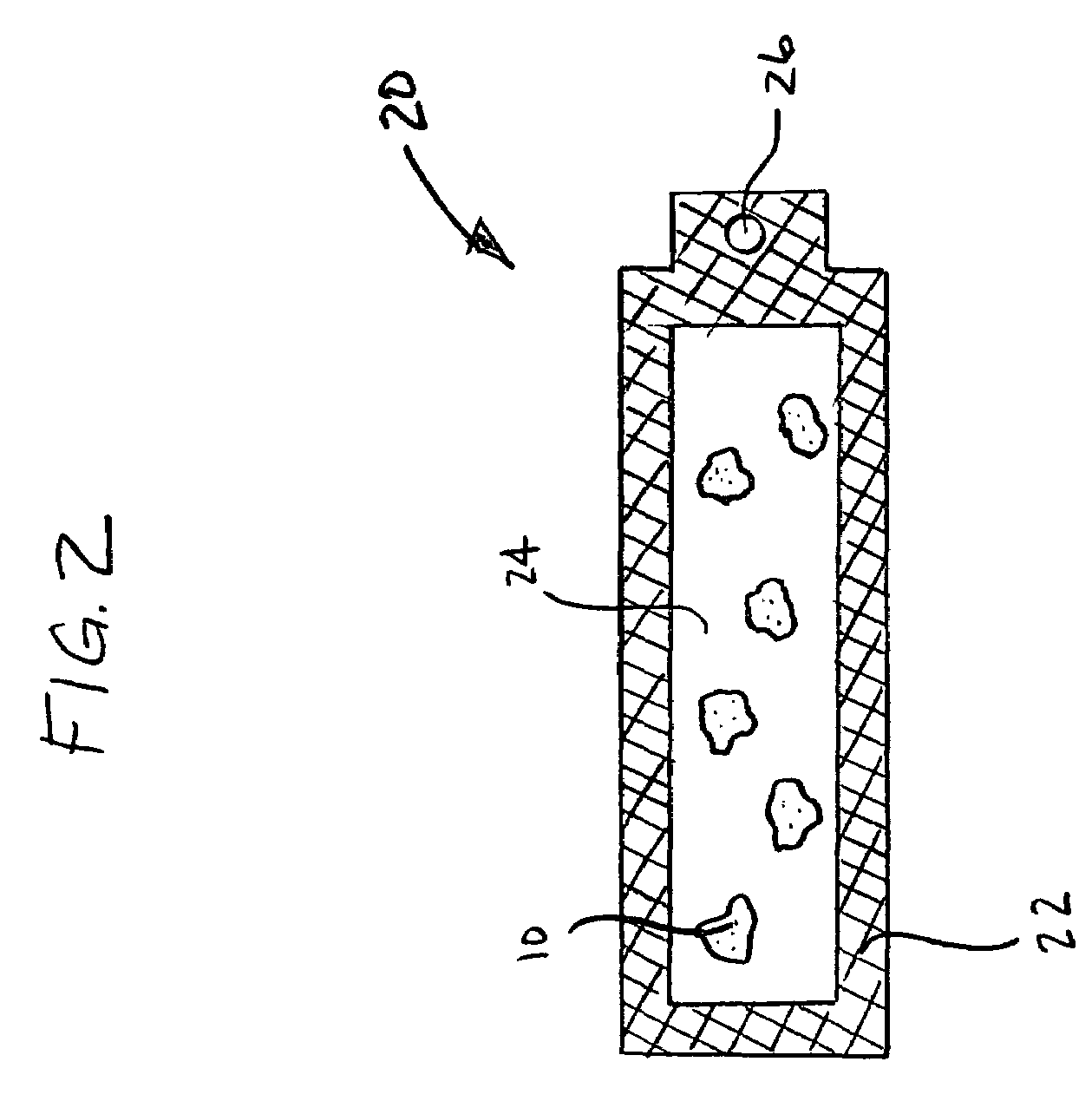

Materials for storing and releasing reactive gases

Compositions, methods, and devices are provided for use in containing and releasing a gas, particularly a reactive gas. The composition can include a reactive gas, reactive gas precursor, or combination thereof; a fluid in which the reactive gas, reactive gas precursor, or combination thereof is dissolved; and a solid material (e.g., particles or fibers) in which fluid is absorbed or adsorbed, wherein the solid material controls the formation or release of the reactive gas. The materials and methods allow rapid and safe generation, transfer, and application of high concentrations of chlorine dioxide gas in solid, liquid, and gas phase systems and are suitable for a variety of chlorine dioxide applications, such as disinfecting and sanitizing liquids, solid surfaces, and porous materials.

Owner:HUGHES KENNETH D

Preparation method of antimicrobial mouthwash

ActiveCN102008399AQuick killNo stimulationCosmetic preparationsChlorine oxidesChlorine dioxideOral ulcers

The invention relates to a preparation method of antimicrobial mouthwash, which comprises the steps of firstly preparing raw materials, then preparing stable chlorine dioxide and finally preparing an antimicrobial mouthwash product. By utilizing the produced antimicrobial mouthwash, pathogens causing periodontitis, gingivitis, oral ulcers, dental plaque, gingival bleeding and bad breath can be rapidly killed, and the antimicrobial mouthwash is a novel oral sterilization and disinfection cleaning product with safety, no toxicity, no stimulation, no side effects and no generation of drug resistance, and can also be used for denture soaking, sterilization and disinfection.

Owner:韶关蓝威消毒药业有限公司

Method for preparing solid stabilized chlorine dioxide disinfectant

The invention relates to a preparation of solid stabilized dioxide peroxide sterilization sanitizer consists of chlorite takes 0.1 percents to 65 percents weight, mixture of anhydrous calcium chloride and anhydrous sodium chloride takes 1 percents to 90 percents weight, activator includes boracic acid, acid sulfate and tartaric acid takes 5 percents to 75 percents weight,. Prepare by below steps: dry each agent; first put anhydrous calcium chloride into the mixing device, second the chlorite, third the anhydrous sodium sulfate and mix them up together or first the mixture of anhydrous calcium chloride and anhydrous sodium chloride, then solid chlorite, last mix up tartaric acid, boracic acid and acid sulfate in the device; seal and pack the mixed material as the product. The product is safe, easy to transport, of high using effect, broadly generalized, low poison, non-erode, no irritant gas, can be applied in sterilizing and disinfecting in house, hospital, restaurant and other places.

Owner:QINGDAO UNIV

Electrolytic process and apparatus

An electrolytic process and apparatus for oxidizing inorganic or organic species is disclosed. The process and apparatus includes contacting a solution containing the inorganic or organic species with an electrocatalytic material disposed in an electrolytic reactor. Also disclosed are processes for fabricating a catalyst material for use in the electrolytic reactors and processes.

Owner:ECOLAB USA INC +1

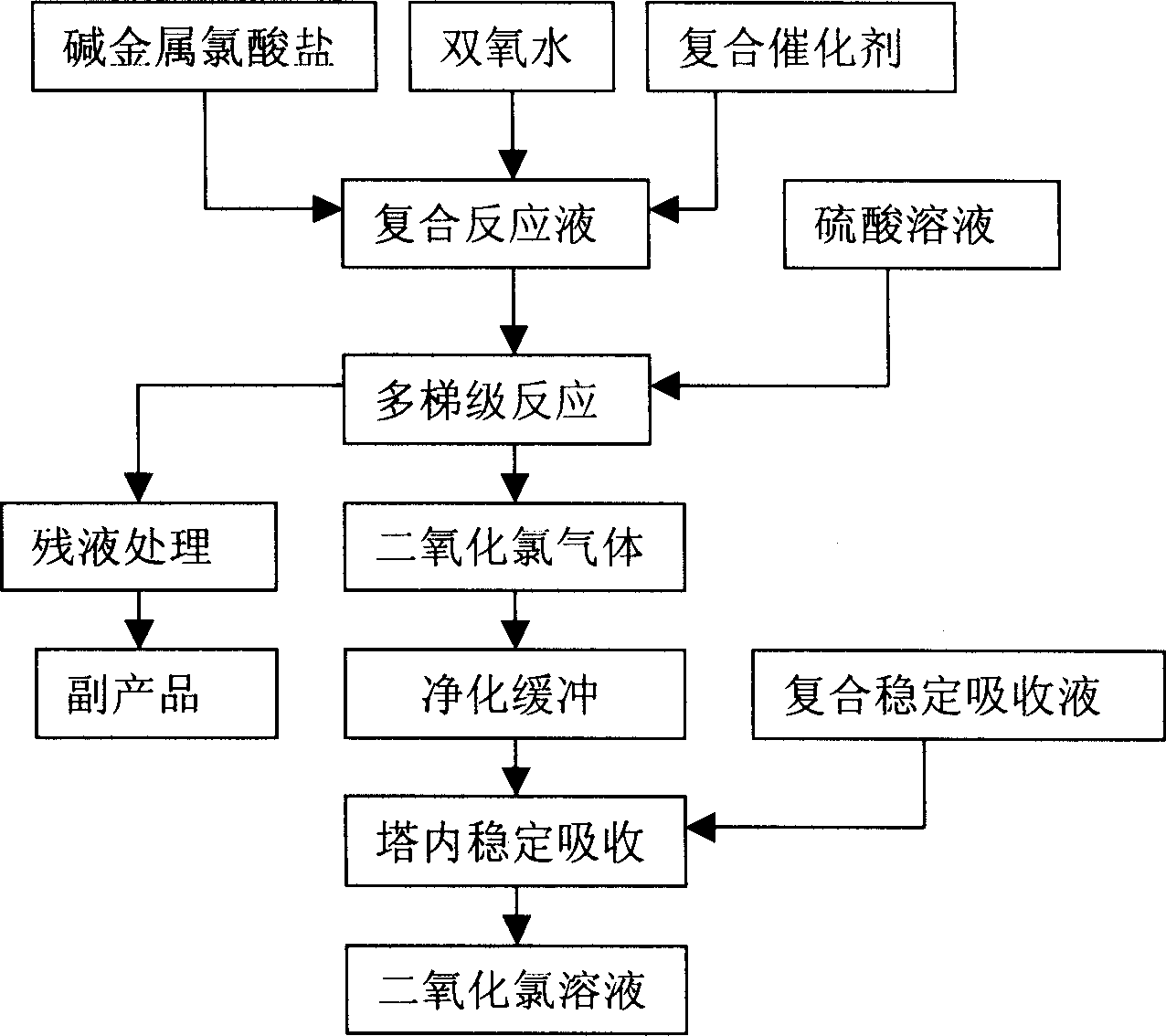

Production for stable chlorinedioxide solution

InactiveCN1439599ASolve the problem that methanol content is easy to exceed the standardAvoid instabilityChlorine oxidesAcetic acidChlorine dioxide

A process for preparing stable ClO2 solution includes such steps as preparing composite reactive liquid from H2O2 as reducer, the catalyst prepared from sodium pyrophosphate, 2-hydroxy phosphonoacetic acid and urea, and chlorate of alkali metal, staircase reacting on sulfuric acid solution to generate high-purity ClO2 gas, and absorbing by stable absorbing liquid in absorption tower. Its advantages are high productivity and stability, and low cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Chlorine dioxide generator

The present invention provides one kind of medium scale and small chlorine dioxide generator operating on chemical process and with simple operation, high conversion rate, high product purity, multiple uses and environment friendship. The chlorine dioxide generator consists of tank reactor, acid resisting ducts and water jetting vacuum machine set. The tank reactor is a two-stage or multiple-stage one, has air distributor inside its main reaction tank and balance tube inside its auxiliary reaction tank, and thus has complete reaction and residual effluent reaching the draining standard. The generated chlorine dioxide may be further prepared into water solution or other solution.

Owner:NANJING UNIV OF TECH

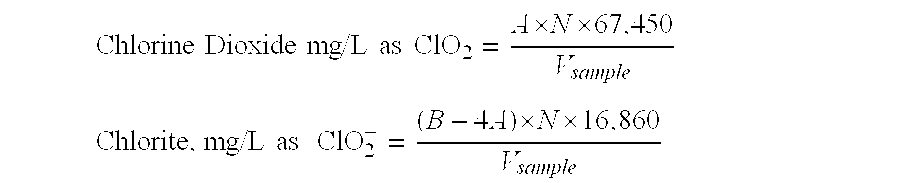

Preparation method of chlorine dioxide without production of solids

The invention discloses a preparation method of chlorine dioxide without production of solids. The method comprises the following steps: filtering a concentrated sodium chlorate solution sent from an electrolytic bath, then injecting into a generator to form a reaction mother solution, circulating in the generator and a circulating pipeline under the action of a circulating pump, maintaining the reaction mother solution at a certain density and temperature, then adding hydrochloric acid sent from a hydrochloric acid system, reacting to generate chlorine gas, chlorine dioxide gas and sodium chloride, cooling the chlorine dioxide gas, then absorbing the chlorine dioxide gas by low-temperature chilled water to obtain a chlorine dioxide water solution, sending the chlorine gas produced by reaction into a hydrochloric acid furnace to be burned with hydrogen gas produced in the electrolytic bath to prepare hydrochloric acid, and returning a dilute sodium chlorate solution after reaction into the electrolytic bath by a pump for re-preparing the concentrated sodium chlorate solution for recycling. According to the method disclosed by the invention, the production of the solids can be prevented in the whole reaction process and scaling of equipment can be avoided, so that sodium chloride and sodium dichromate can be completely recycled and do not need to be supplemented basically.

Owner:GUANGXI UNIV

Electrolytic system and method for generating biocides having an electron deficient carrier fluid and chlorine dioxide

ActiveUS8394253B2Reduce the burden onRapid disruptionBiocideWater treatment parameter controlChlorine dioxideHypochlorite

A method for electrolytically generating a biocide having an electron deficient carrier fluid and chlorine dioxide, including providing a carrier fluid; providing a pair of electrodes interposed by a semi-permeable membrane within a vessel for creating a first passageway and a second passageway, an anode electrode of the pair of electrodes disposed in the first passageway, cathode electrode of the pair of electrodes disposed in the second passageway; flowing the carrier fluid through the vessel; applying an electric potential to the pair of electrodes to produce an oxidative acidic fluid, a reductive alkaline fluid, and anodic gases in the container; removing the fluids and gases from the vessel; mixing a portion of the anodic gases with the reductive alkaline fluid to produce a hypochlorite solution; and mixing a chlorite brine with the hypochlorite solution, followed by the introduction of additional oxidative acidic fluid to release the biocide.

Owner:STRATEGIC RESOURCE OPTIMIZATION

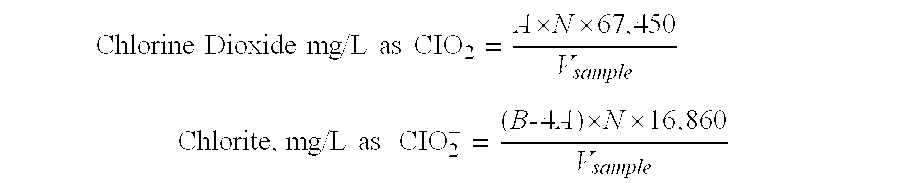

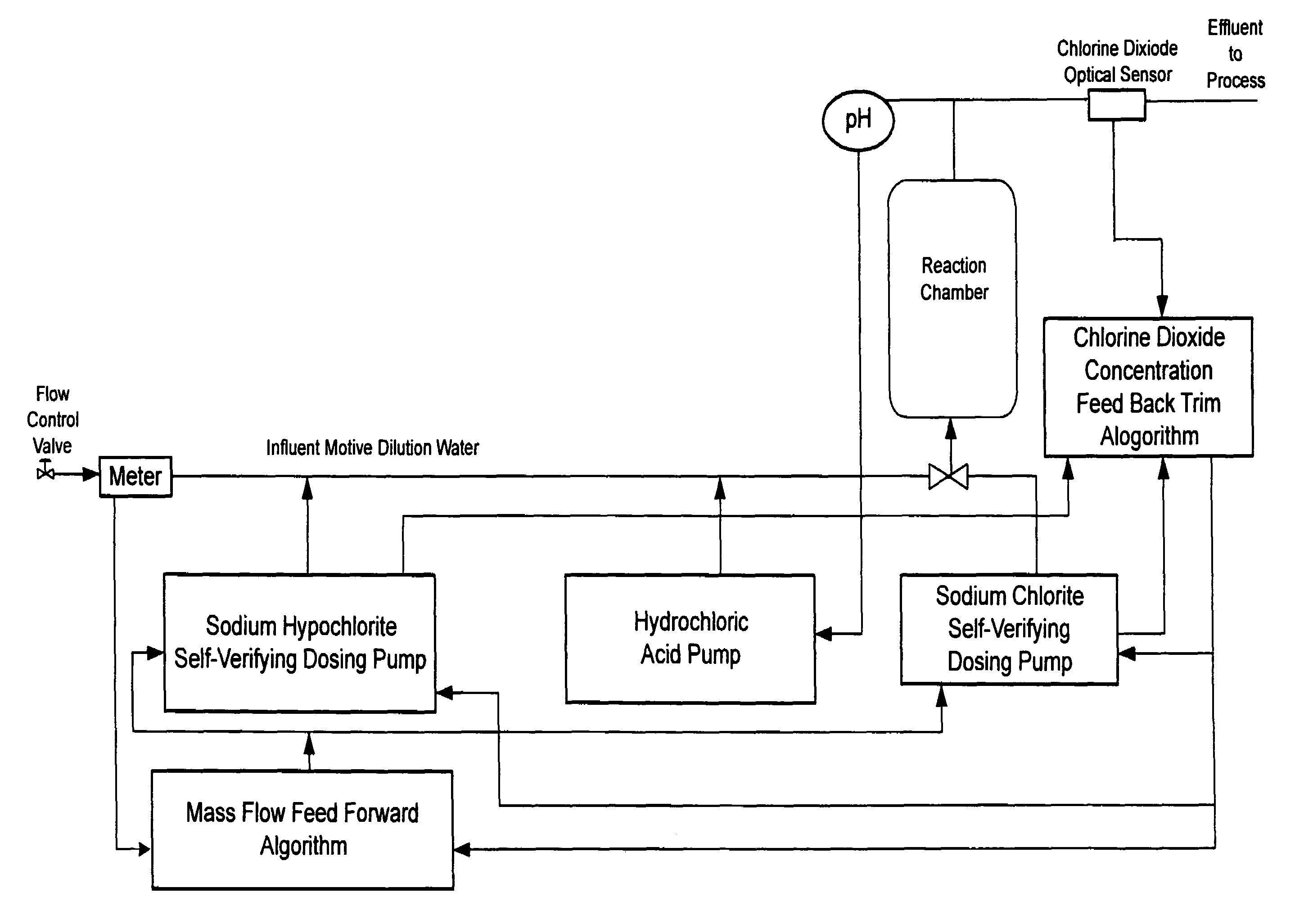

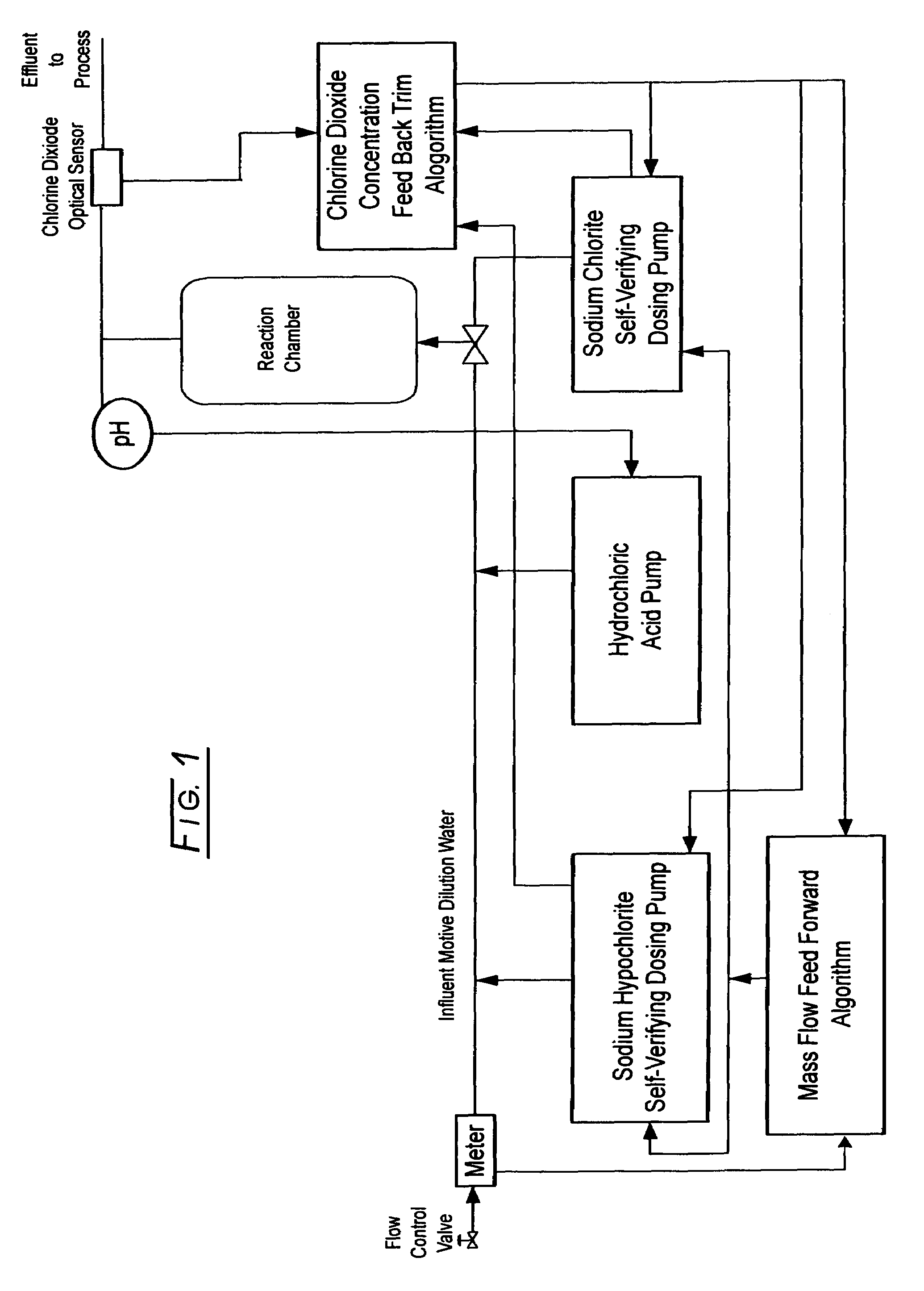

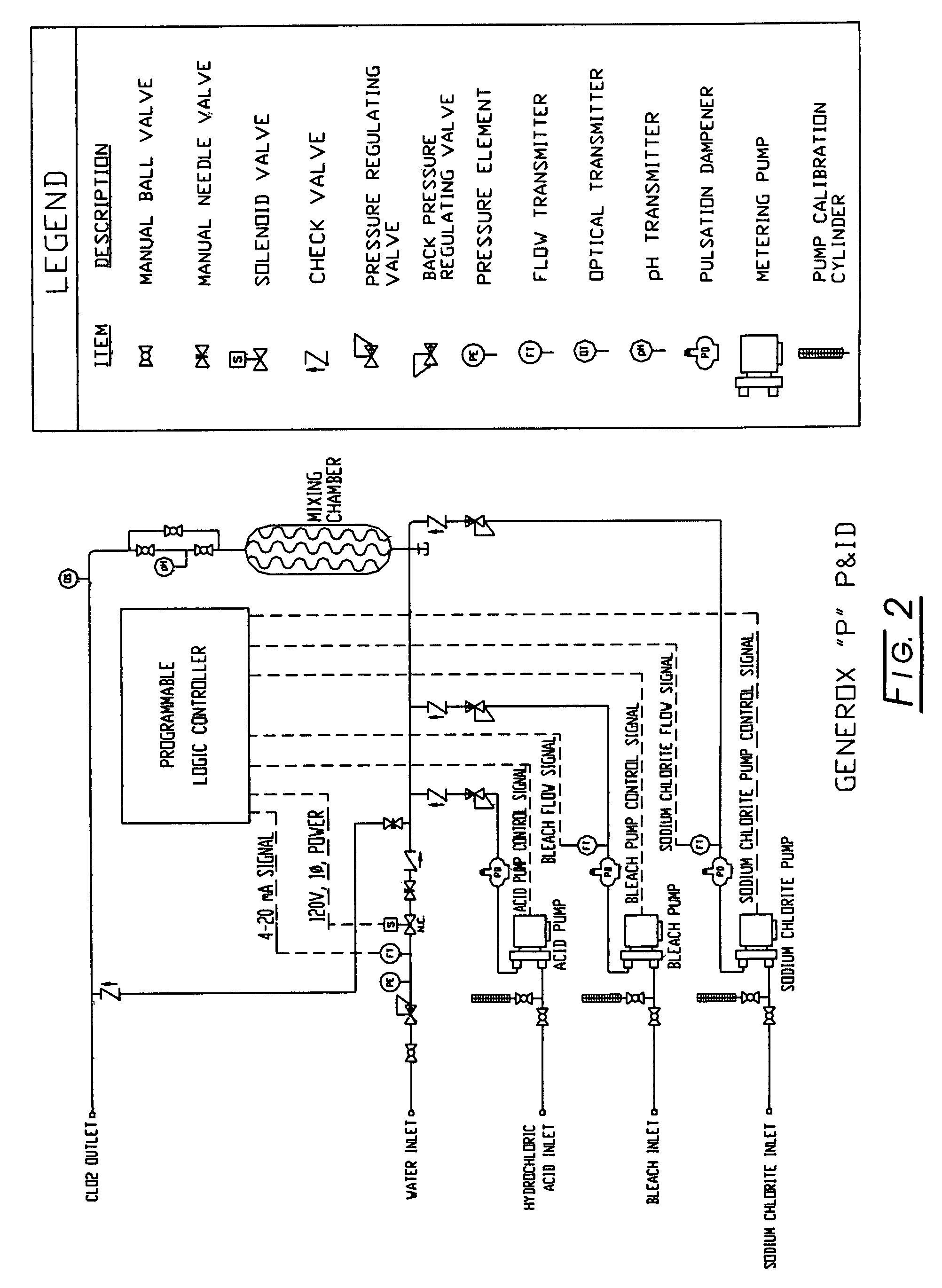

Process for treating an aqueous system with chlorine dioxide

ActiveUS7261821B2High efficiency yieldReduce wasteWater treatment parameter controlChlorine oxidesChlorine dioxideAutomated method

This invention relates to an automated process for efficiently treating an aqueous system with chlorine dioxide. The process results in high efficiency yields of chlorine dioxide on a continuous basis by minimizing the waste of precursor chemicals. Additionally, the process creates less environmental stress because the formation of unwanted by-products is minimized. The level of chlorine dioxide in the aqueous system treated and other parameters of the process are monitored and adjusted automatically to maintain them within acceptable levels.

Owner:SOLENIS TECH CAYMAN

Popular searches

Layered products Carbon preparation/purification Fibre chemical features Single-walled nanotubes Thin material handling Carbonsing rags Feed devices Pressure vessels for chemical process Chemical/physical/physico-chemical nozzle-type rreactors Energy based chemical/physical/physico-chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com