Preparation device and technology for chlorine dioxide

A chlorine dioxide and preparation device technology, applied in chlorine oxide and other directions, to achieve the effects of high purity, high production capacity and reaction efficiency, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

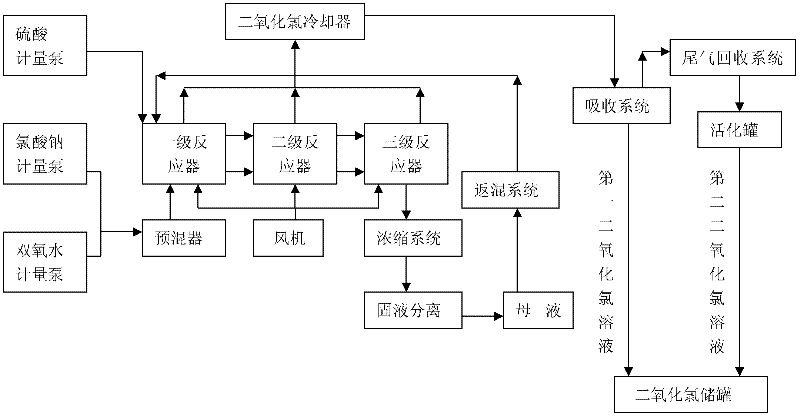

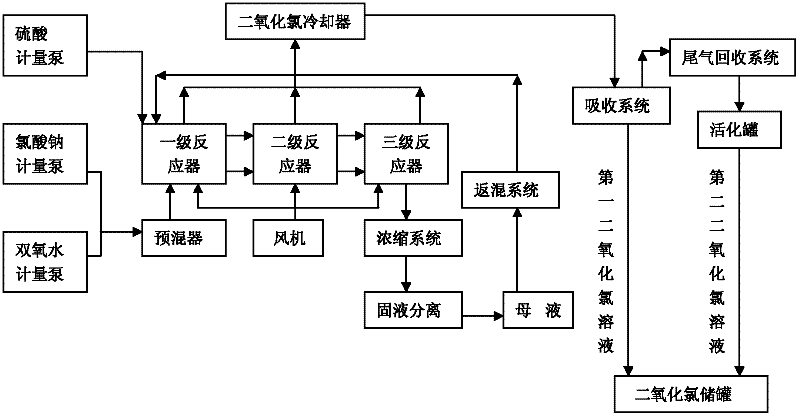

[0028] Such as figure 1 As shown, a chlorine dioxide preparation device includes a reactor and a chlorine dioxide cooler, and the reactor is at least divided into three stages, including a primary reactor, a secondary reactor and a tertiary reactor; The top between the reactor, the secondary reactor and the tertiary reactor is communicated by a gas pipeline, and the bottom is communicated by a liquid pipeline; the primary reactor is also connected with a premixer; the secondary reactor is also connected A fan is connected; the three-stage reactor is sequentially connected with a concentration system, solid-liquid separation, mother liquor tank and back-mixing system, and then connected with the first-stage reactor after the back-mixing system, the first-stage reactor, the second-stage reaction The chlorine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com