Patents

Literature

305 results about "Sodium dichromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium dichromate is the inorganic compound with the formula Na₂Cr₂O₇. Usually, however, the salt is handled as its dihydrate Na₂Cr₂O₇·2H₂O. Virtually all chromium ore is processed via conversion to sodium dichromate and virtually all compounds and materials based on chromium are prepared from this salt. In terms of reactivity and appearance, sodium dichromate and potassium dichromate are very similar. The sodium salt is, however, around twenty times more soluble in water than the potassium salt (49 g/L at 0 °C) and its equivalent weight is also lower, which is often desirable.

Stainless steel passivation process

InactiveCN101787525ALow environmental requirementsShorten the timeMetallic material coating processesRoom temperatureAcid washing

The invention relates to a surface treatment process for stainless steel, in particular to a stainless steel passivation process. The process comprises the following steps of: dipping a stainless steel workpiece in an alkali degreasing solution for 10-30 seconds under a normal temperature condition; washing the workpiece by using water at the normal temperature; acid washing: acid washing the workpiece for 50-60 seconds by using a nitric acid solution at the normal temperature; washing the workpiece by using water at the normal temperature; soaking the workpiece in a passivation solution for 40-50 seconds at the normal temperature, wherein the passivation solution contains nitric acid and sodium dichromate; washing the workpiece by using water at the normal temperature; heating purified water to be higher than 75 DEG C, and putting and soaking the passivated and cleaned workpiece into the purified water for 4-5 seconds; taking out the workpiece and airing. The invention greatly saves the time for passivating the stainless steel workpiece, reduces the production requirements of the workpiece and ensures that the process is more suitable for practical production.

Owner:SICHUAN GUANGHAN HUAWEI ALUMINUM

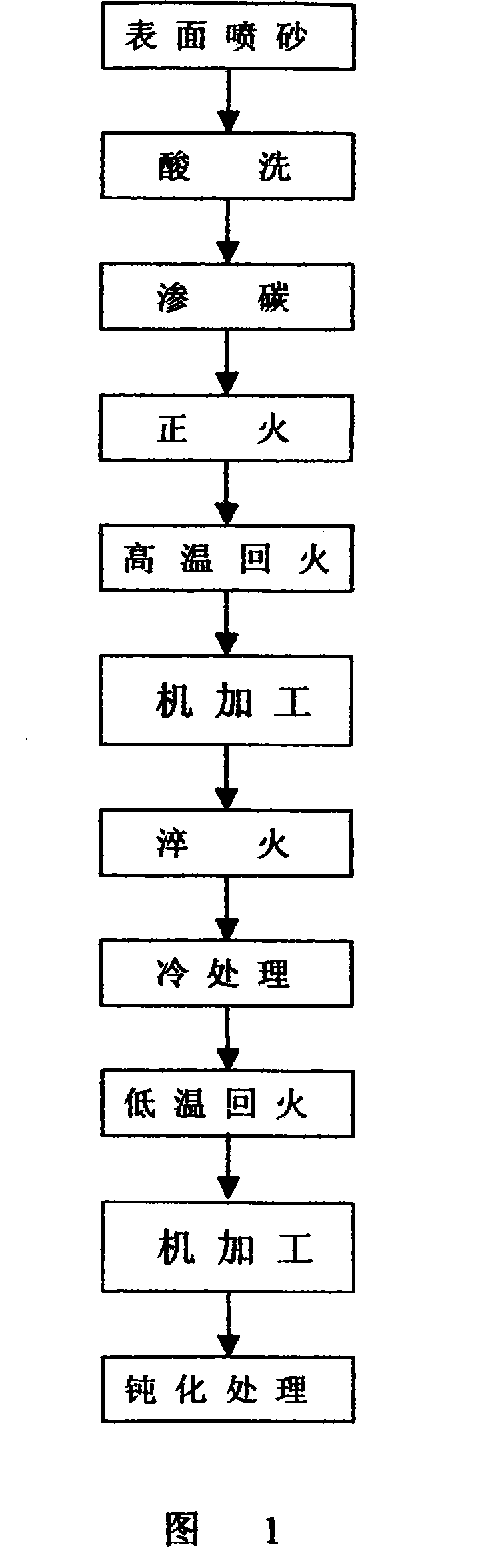

Martensitic stainless steel cementation method and product thereof

ActiveCN101139692AImprove technical performanceImprove securitySolid state diffusion coatingMartensitic stainless steelCarbide

The invention discloses a carburizing method for martensite stainless steel containing 10-19% by weight chromium, and a heat treatment method for the product after carburization. Carburization is carried out under 95-1000 DEG C in a methylbenzene atmosphere, pre treatment is carried out before carburization, oily dirt and passivation film is removed. The heat treatment procedures after the carburization are: 1. normalizing; 2. high temperature annealing; 3. tempering in vacuum under 950-1000 DEG C; 4. cold treating; 5. low-temperature annealing, then passivating 5 minutes in a passivating liquid of the following formula: 20-25% (volume) nitric acid and 3-4% (by weight) sodium dichromate. The technical indexes of the product: depth of carburized layer: 0.7-1.0 mm; surface hardness of the carburized layer: HRC>=55; surface hardness of the non-carburized layer: HRC33-45; metallographic structure: the class of carbide in the carburized layer, the residual austenite and central structure of the carburized layer are acceptable per HB5492-91; and the high-temperature annealed hardness: HRC<=30.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

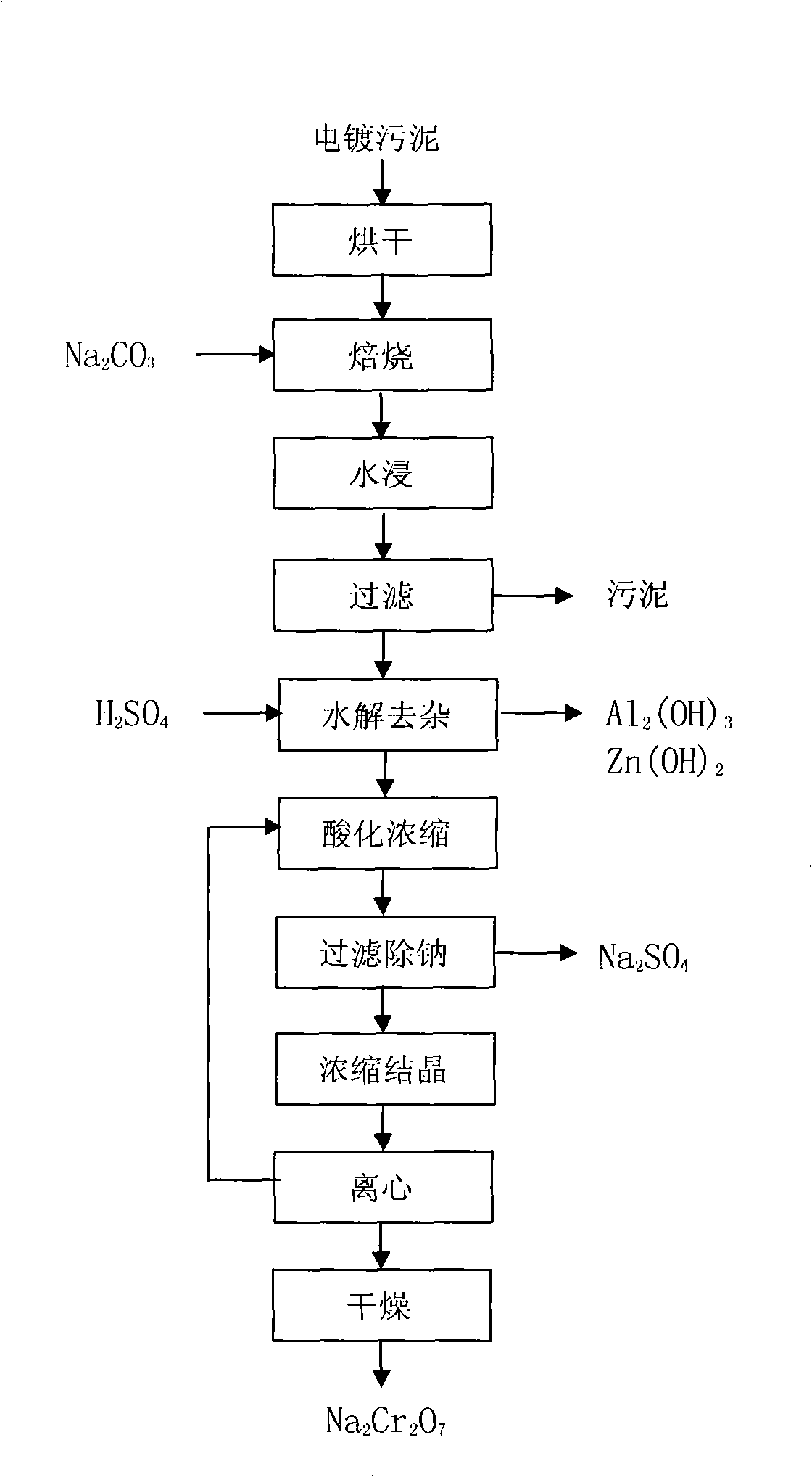

Method for recovering sodium dichromate form chromium-containing electroplating sludge

InactiveCN101333007AImprove recycling efficiencyOvercome the disadvantages of secondary pollutionSludge treatmentChromates/bichromatesResource utilizationSludge

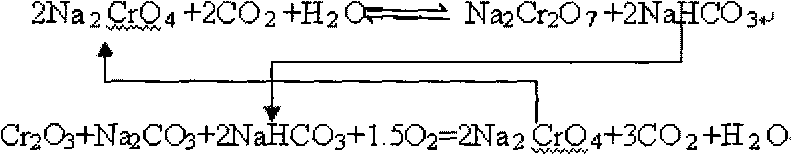

The invention discloses a method for recovering sodium acid chromate from chrome-containing electroplating sludge. The electroplating sludge is blended with Na2CO3 according to a certain proportion and is baked at a certain temperature to obtain Na2CrO4, Cr<3+> is oxidized into Cr<6+> chrome and aluminum and zinc are taken as corresponding oxides; Cr, Al and Zn are dissolved in liquid by water soaking to generate respective salt, and the solid containing the metals such as Ni, Cu, Fe, Ca, Mg, and the like, is filtered and separated; the Na2CrO4 solution is transformed by hydrolysis acidification and Al2(OH)3 and Zn(OH)2 are removed to realize the separation of Zn, Al and Cr; the chrome-containing solution is acidated into sodium acid chromate (Na2Cr2O7), cooled after being concentrated to a certain volume, and filtered to remove sodium sulfate; the sodium acid chromate solution is processed by condensation, crystallization, centrifugation and drying to obtain sodium acid chromate finished product. By adopting sodium treatment and oxidation process, the rate of recovering chrome from chrome-containing electroplating sludge can exceed 90 %, and the resource utilization of electroplating sludge can be realized.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Process for preparing chromic oxide by hydrothermal reducing sodium chromate or sodium acid chromate

InactiveCN101456588AHigh reduction conversion rateAchieve recyclingChromium oxides/hydratesSlurryHigh pressure

The invention relates to technology for preparing chromium oxide through hydrothermal reduction of sodium chromate or sodium dichromate, which comprises: preparing the sodium chromate or the sodium dichromate into an aqueous solution, placing the aqueous solution and starch or starch derivatives into a high-pressure reaction kettle for hydrothermal reduction, and obtaining chromic hydroxide slurry; filtering and separating the chromic hydroxide slurry to obtain chromic hydroxide filter cakes and a chromic hydroxide mother solution; and performing high-temperature roasting on the filter cakes to obtain chromium oxide products. The technology has short technological flow, simple operation, low cost and mild reaction conditions, and does not have overhigh requirements on equipment; not only the product quality is better than that of the prior method but also the reduction and conversion rate of sexavalent chromium reaches more than 98 percent; and the whole technology forms a closed cycle, realizes recycling of mixed alkali, the mother solution and a washing liquid, does not discharge pollutant in any form during the whole process, and fundamentally avoids pollution.

Owner:CENT SOUTH UNIV

Anticorrosion mildew inhibitor for bamboo and timber material

The present invention discloses a kind of anticorrosion mildew inhibitor for bamboo and timber material. The anticorrosion mildew inhibitor for bamboo and timber material has bamboo vinegar liquid as matrix and contains chlorthalonil, triazolone, boric acid, borax, copper sulfate, santobrite, sodium dichromate, sodium fluoride or their mixture. The anticorrosion mildew inhibitor has bamboo vinegar liquid, rather than water, as matrix, and possesses high anticorrosion and mildew inhibiting effect and less environmental pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for recycling vanadium pentoxide and sodium dichromate

ActiveCN102021345AEfficient separationRealize comprehensive utilizationSolid waste disposalProcess efficiency improvementProcess engineeringSodium dichromate

Owner:GANSU JINSHI CHEM

Fire coal combustion improver

InactiveCN102191110AImprove operational safetyExtended service lifeSolid fuelsChromium trioxideDolomite

The invention relates to an improvement of a fire coal combustion improver. The improved fire coal combustion improver is characterized by being prepared by compounding and mixing the following components: 20 to 30 weight percent of dolomite powder, 5 to 15 weight percent of dicyclopentadieny iron, 3 to 10 weight percent of chromium trioxide, 3 to 10 weight percent of manganese dioxide, 3 to 15 weight percent of magnesium nitrate, 3 to 15 weight percent of sodium dichromate and / or potassium dichromate, 3 to 18 weight percent of zinc oxide, 15 to 30 weight percent of active clay. The fire coal combustion improver has a plurality of functions of combustion acceleration, sulfur solidification, smoke abatement and the like; the thermal efficiency of a boiler can be improved by 3 to 8 percent; the coal-saving efficiency is up to 5 to 15 percent; the Ringelmann smoke blackness is less than 1; the total removal rate of SO2, NOx and the like is 25 to 60 percent, and the combustion improver has remarkable coal-saving and environmental-protection effect. Since the combustion effect is improved, the inferior coal (such as coal gangue), which is difficult to combust normally, is combusted and comes into play. After the long use, the boiler is not corroded, the scaling of the calcium sulfate in the boiler can be reduced, the operation safety of the boiler can be improved and the service life of the boiler can be prolonged.

Owner:YIXING KEQI CHEM

Method of analyzing sulfur content in fuels

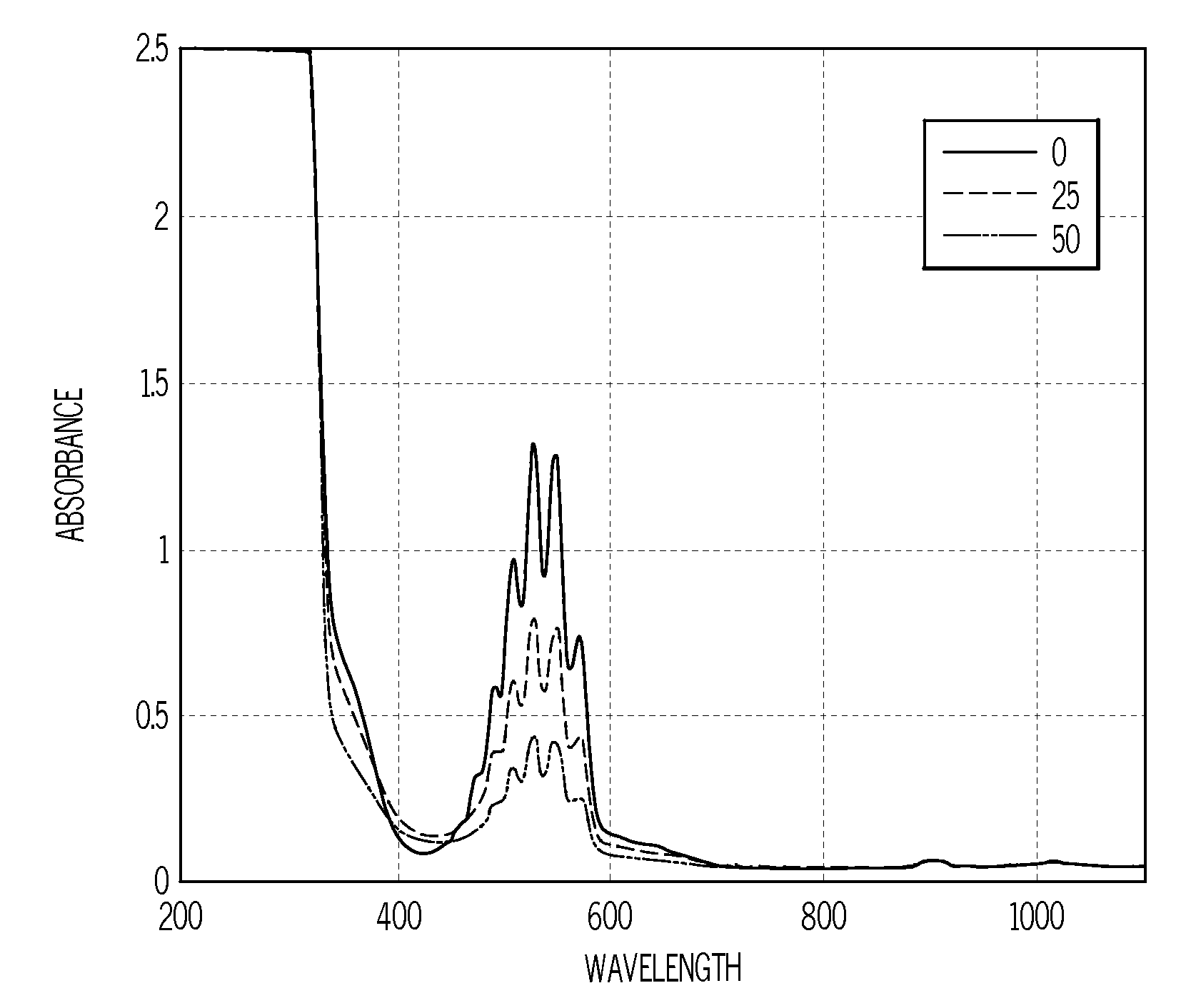

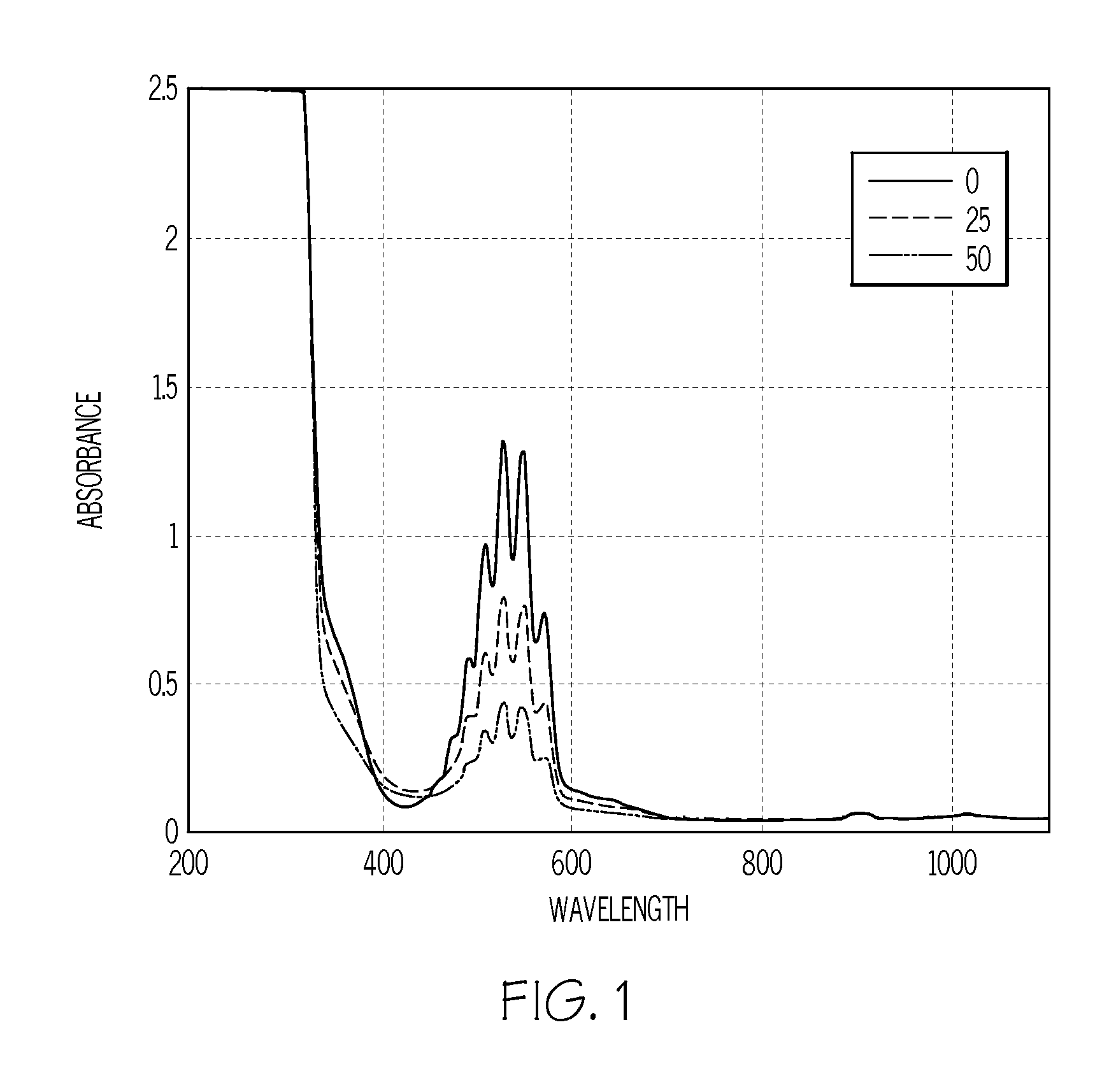

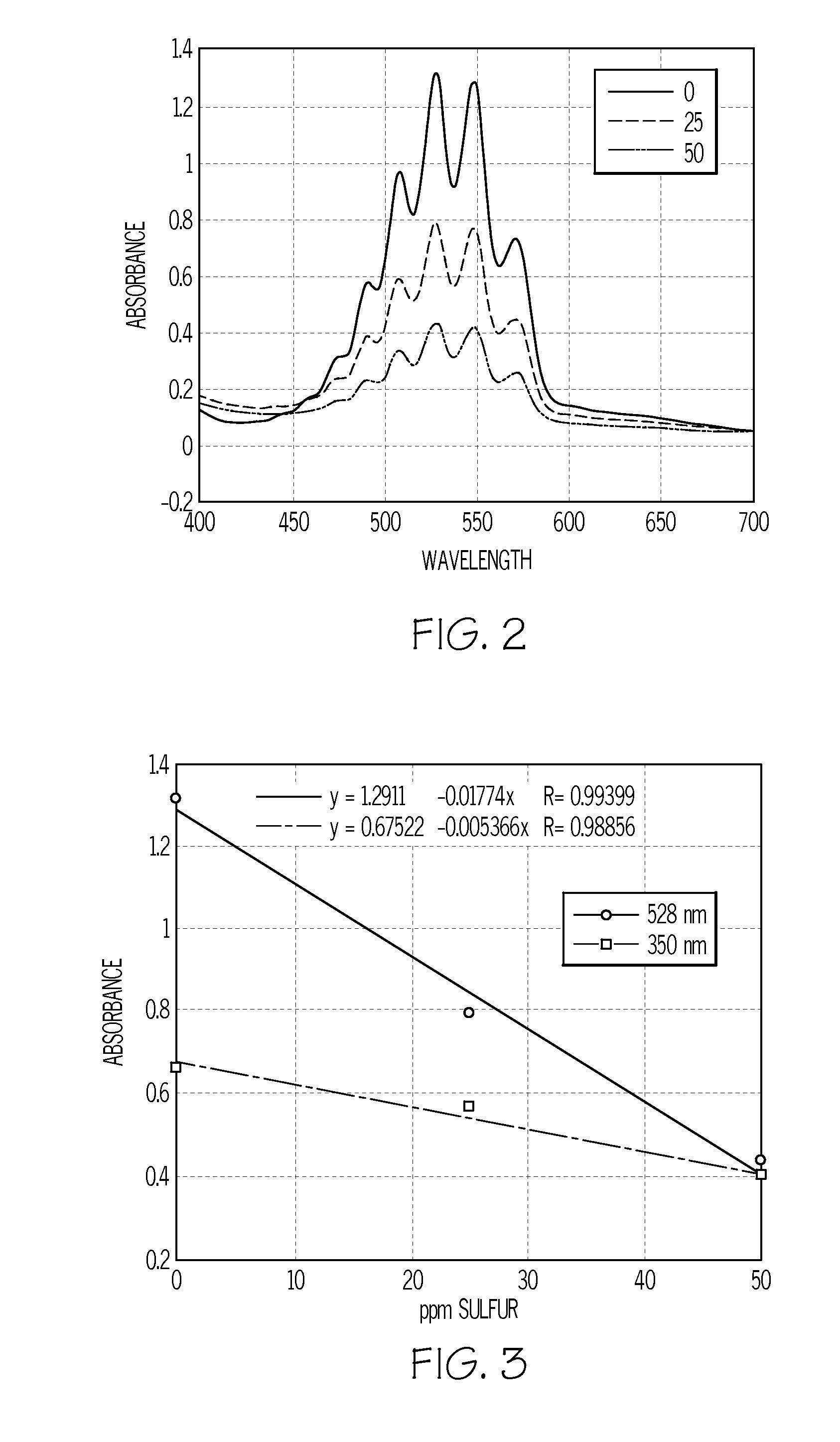

InactiveUS20080165361A1Radiation pyrometryAnalysis using chemical indicatorsSolventColorimetric analysis

A method of detecting the amount of sulfur compounds in fuels such as ultra low sulfur diesel (ULSD) fuels is provided in which a fuel sample is reacted with a solvent and an oxidizing agent to produce a reaction product which may be analyzed by visual observation and / or in combination with spectrophotometric or colorimetric analysis. The oxidizing agent may be selected from potassium permanganate, sodium dichromate, nitric acid, hydrogen peroxide, cumene hydroperoxide, and sodium hypochlorite, and may be used in combination with an acid.

Owner:UNIV OF DAYTON

Process for preparing sodium dichromate

InactiveCN101693556AReduce Chloride ContentReduce Sulfate LevelsChromates/bichromatesCarbonizationSodium dichromate

The invention provides a process for preparing sodium dichromate, namely producing the sodium dichromate through a carbonization method comprising: converting sodium chromate into the sodium dichromate via carbon dioxide under pressurizing condition; delivering sodium chromate neutral liquor with impurities removed to a carbonization tower after a cascade reaction of more than three continuous towers; obtaining carbonizing liquor by controlling different gradient parameters (concentration and temperature of the carbonizing liquor, partial pressure of the carbon dioxide, carbonizing time and the like), continuously carbonizing and separating under pressure; obtaining sodium dichromate finished products through concentrating, filtering, evaporating, crystallizing and centrifugal dehydrating.

Owner:SICHUAN YINHE CHEM

Method for producing sodium fluosilicate by utilizing waste water containing sodium sulfate

ActiveCN102020281AQuality impactLow costSilicon halogen compoundsIndustrial waste waterWater resources

The invention discloses a method for producing sodium fluosilicate by utilizing waste water containing sodium sulfate. The method is as follows: generating the sodium fluosilicate by adopting the waste water containing sodium sulfate and fluosilicic acid as a side product for producing hydrofluoric acid as a raw material; and obtaining a sodium fluosilicate product by curing, filtering, cleaning and pneumatic drying. The dilute sulphuric acid as a side product is used for a production line of sodium dichromate. The method provided by the invention has the advantages that the industrial sodium sulfate waste water is utilized to produce the sodium fluosilicate, and the materials are all industrial waste water. The industrial waste water of the sodium sulfate is from waste water obtained by washing chromium sesquioxide produced by sodium dichromate or waste water generated for producing chromium salt, the fluosilicic acid is from waste water in the process for producing the hydrofluoric acid, the produced sodium fluosilicate is used as a commodity for sales, the dilute sulphuric acid as a side product is used for the production line of the sodium dichromate. By utilizing the method, the cost for treating the waste water treatment of the industrial sodium sulfate in the chromium salt industry is reduced, and the reutilization of water resources is realized.

Owner:GANSU JINSHI CHEM

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Coal washing and desulfurizing agent composition and preparation method thereof

The invention relates to an adjuvant for coal washing and desulfurizing. The adjuvant is prepared from the following raw materials in parts by weight: 20-25 parts of sodium hypochlorite NaClO, 12-15 parts of ammonium persulfate (NH4)S2O8, 8-12 parts of sodium glycollate HOCH2COONa, 6-10 parts of sodium acetate CH3COONa, 7-12 parts of potassium citrate K3C6H5O7H2O, 5-9 parts of sodium gluconate, 5-9 parts of edetic acid, 7-12 parts of potassium permanganate KMnO4, 25-32 parts of methanol CH3OH, 22-30 parts of triethanolamine (HOCH2CH2)3N, 12-16 parts of sodium dichromate Na2Cr2O7, 3-5 parts of polyaluminum ferric chloride PAFC,1-2 parts of urea CON2H4, 1-2 parts of polyacrylamide PAM, 0.5-0.8 part of sodium dodecyl benzene sulfonate C18H29NaO3S, 0.2-0.4 part of dispersing agent JFC and 100-120 parts of water. The adjuvant disclosed by the invention is simple to use, stable in performance and free of large investment and transformation equipment; the removal rate of inorganic sulfur and organic sulfur is more than 70 percent; and the removal rate of nitric oxides is more than 70 percent.

Owner:LANZHOU XINXING NEUTRAL CLEANING TECH

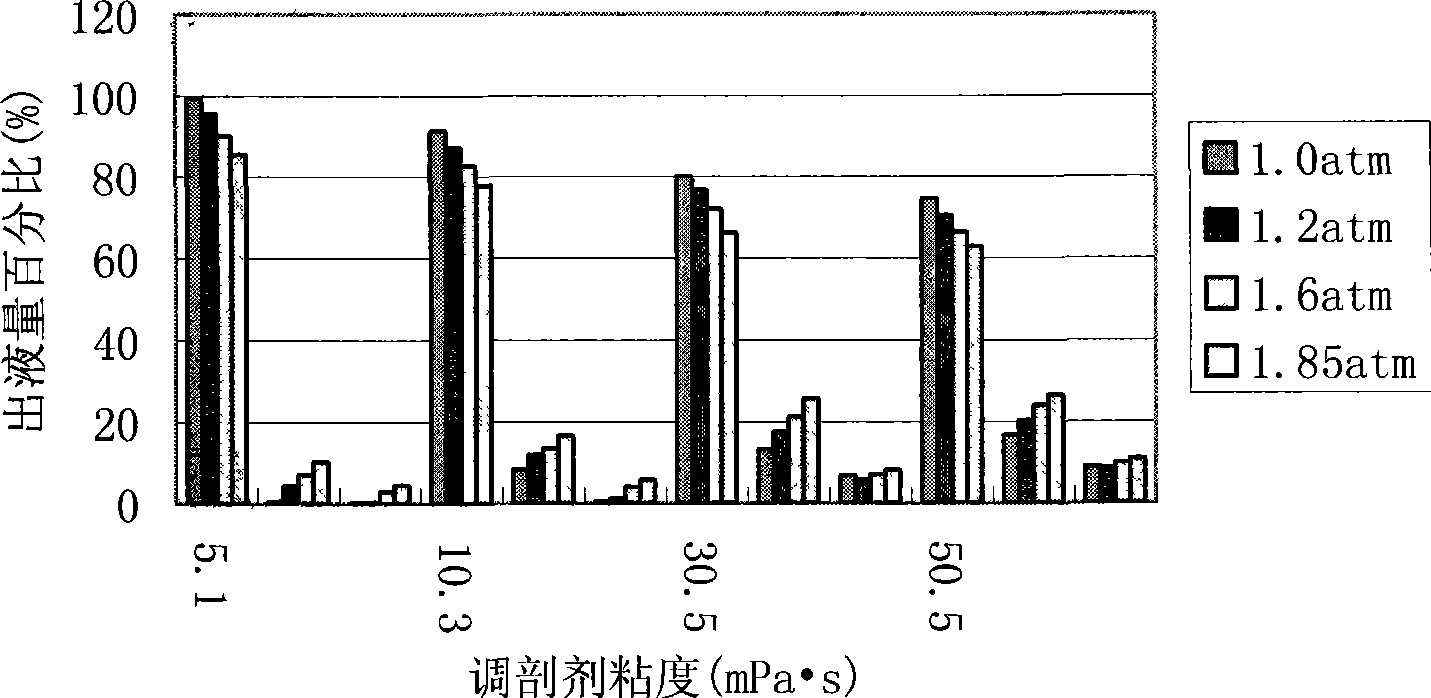

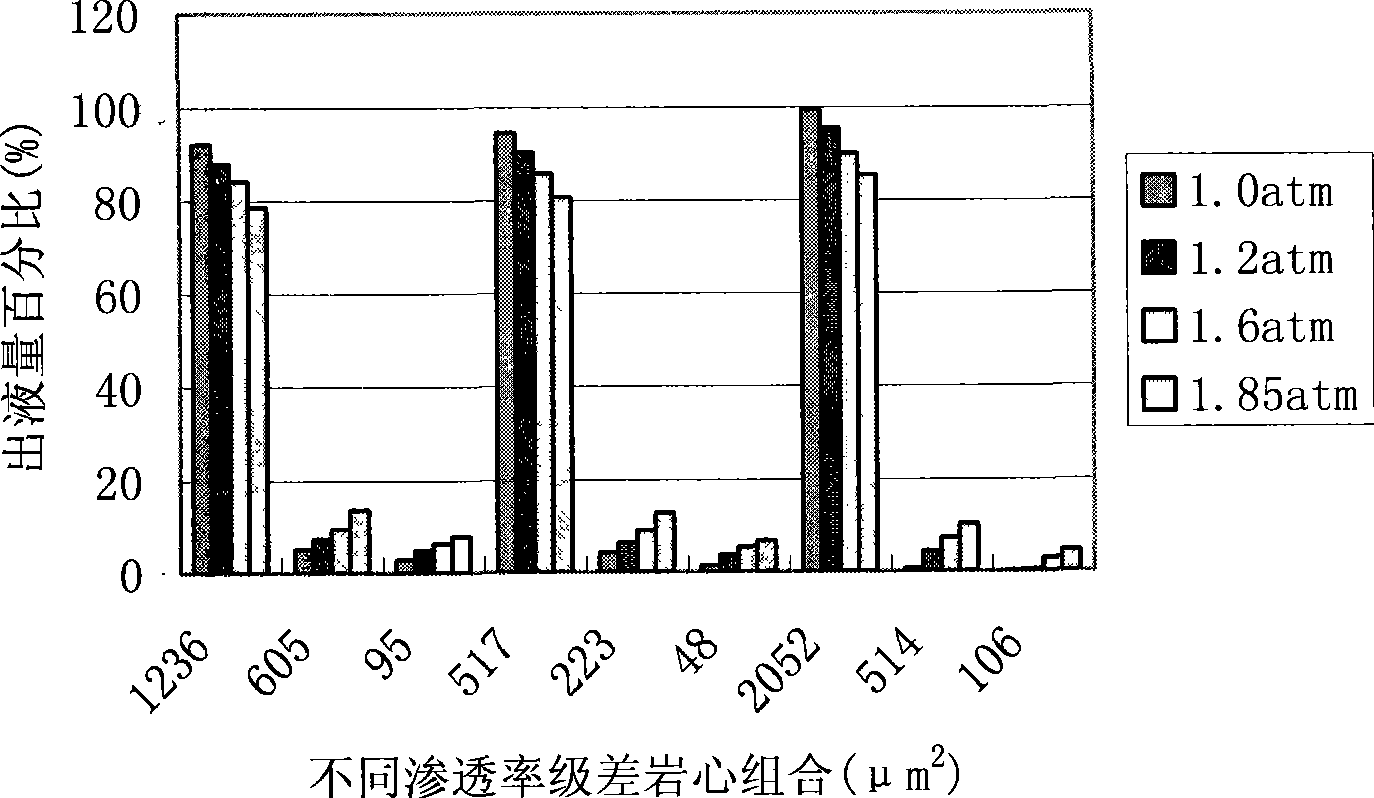

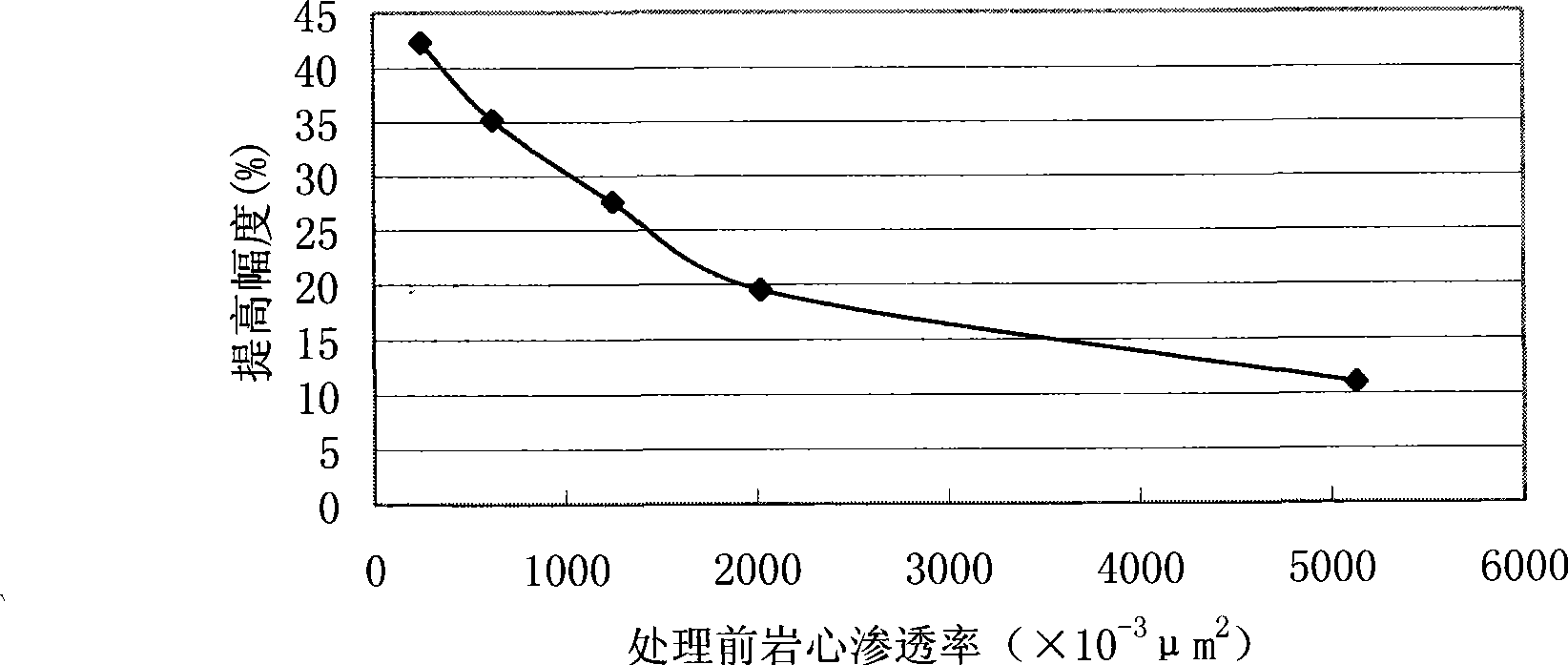

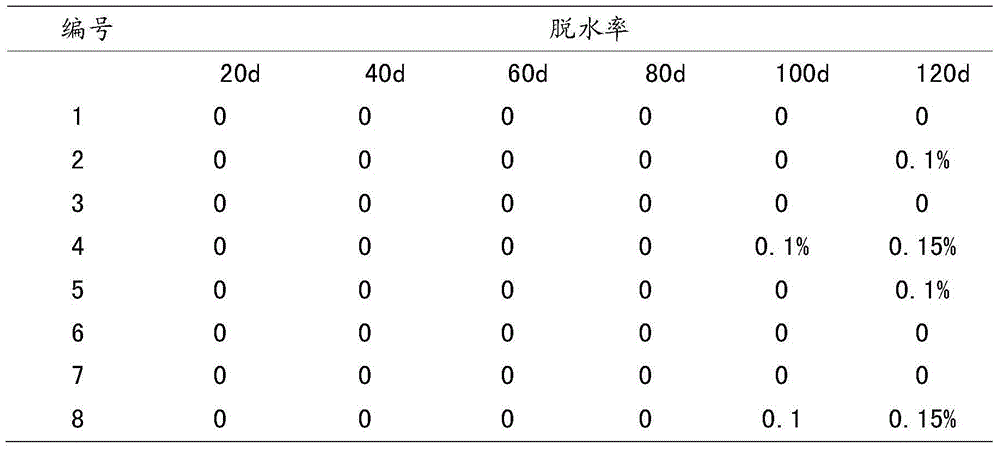

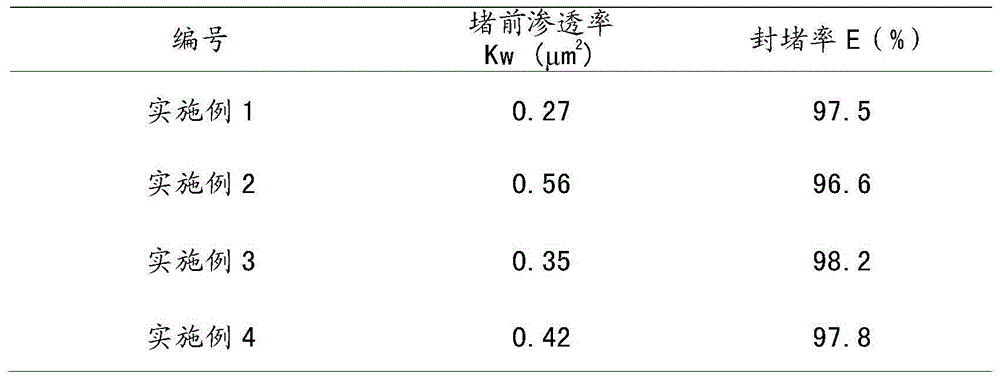

Delaying cross-linking polymer hard-gel in-depth profile controlling agent and preparation method thereof

The invention relates to a delaying cross-linking polymer hard-gel in-depth profile controlling agent and a preparation method thereof. The profile controlling agent consists of the following raw materials: anionic poly aceylanide, sodium dichromate, sodium sulfite, soldium salicylate and water. The preparation method is carried out according to the following steps of: adding the required amount of anionic poly aceylanide into the required amount of water; after the anionic poly aceylanide is sufficiently dissolved, sequentially adding the required amounts of sodium dichromate, sodium sulfiteand soldium salicylate; and sufficiently stirring to obtain the delaying cross-linking polymer hard-gel in-depth profile controlling agent. The delaying cross-linking polymer hard-gel in-depth profile controlling agent and the preparation method thereof have the beneficial effects that the delaying cross-linking polymer hard-gel in-depth profile controlling agent is simple to prepare, has stable performances, is convenient to construct, has long gelling time and has strong gel strength after being gelled; the long-term and large-dose injection is realized on site; and the delaying cross-linking polymer hard-gel in-depth profile controlling agent disclosed by the invention can enter the deep position of an oil pool to block a preferential path so as to improve the waterflooding extraction effect and improve the recovery ratio of the oil pool. The delaying cross-linking polymer hard-gel in-depth profile controlling agent is applied for over 40 well times on site and has good applicationeffect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-efficiency iron rust conversion agent

InactiveCN102618860AHas anti-rustAvoid Galvanic CorrosionMetallic material coating processesHexamethylenetetramineSodium phosphates

The utility model relates to a high-efficiency iron rust conversion agent, and belongs to the field of an antirust paint. The iron rust conversion agent comprises the following raw materials by weight: 0.1-10% of zinc oxide, 20-40% of phosphoric acid, 0.5-15% of dichromate, 0.5-10% of phosphate, 0.1-10% of corrosion inhibitor, and 50-70% of solvent, wherein the dichromate is potassium dichromate or sodium dichromate; the phosphate is sodium phosphate or potassium phosphate; the corrosion inhibitor is urotropine or urea; and the solvent is water or ethanol. The preparation method comprises the steps as follows: sequentially adding the solvent, the phosphoric acid, the dichromate, the phosphate, the corrosion inhibitor and the zinc oxide to a glass cup under persistently stirring according to the mass ratio, and dissolving for 10-20 min. The production method bases on the dissolving of the solid reactants in the phosphoric acid solution. The phosphorized film formed by iron rust conversion has the effects of preventing rust and fixing remnant rust, and the formed phosphorized layer protective film is long-acting, and stable in atmospheric environment, lubricating oil and organic solvent, has high adhesion, can be used as a primer, has dielectric properties, and can prevent electro-chemical corrosion on the metal surface.

Owner:ZHEJIANG OCEAN UNIV

Light wall partition board with addition of loofah sponge fibers

PendingCN105906295ALarge specific surface areaLarge specific surface area, high adsorption capacitySolid waste managementCeramicwarePolymer scienceSodium sulfate

The invention discloses a light wall partition board with addition of loofah sponge fibers; the light wall partition board is prepared from the following raw materials: desulphurization gypsum, calcium oleate, molasses, sodium silicate, sodium sulfate, graphene, trimethylolpropane trioleate, polyaluminum ferric chloride, sodium dichromate, loofah sponge, a silane coupling agent kh570, a nano mica powder, beta-cyclodextrin, citric acid, fly ash fibers, a quartz powder, a VAC / E latex powder, cement, oil shale residues, a naphthalene water reducing agent, a foaming agent, polystyrene and a proper amount of water. The desulphurization gypsum is used as a cementing material, so the light wall partition board has good cohesiveness, consumes a lot of desulfurization gypsum and other solid wastes, has the advantages of good water resistance, less investment and low cost, and is worthy of promotion.

Owner:安徽惠明建材科技发展有限公司

Profile modification agent for amphion jelly

InactiveCN102153999AImprove gelation performanceHigh strengthDrilling compositionSodium acetateThiourea

The invention provides a profile modification agent for amphion jelly. The profile modification agent comprises the following components by weight percent: 0.1%-0.3% of amphion polymer, 0.1%-0.3% of compound cross-linking agent and the balance of water, wherein the molecule weight of the amphion polymer is above 1500 ten thousand. The compound cross-linking agent is prepared by a method comprising the following steps: firstly, adding phenol and formaldehyde in an enamel reaction kettle with a stirrer at a mass ratio of 1:1, heating and raising the temperature to 60 DEG C, then adding triethanolamine so that the phenol and formaldehyde are reacted to generate a mixture of monohydroxymethyl phenol, dihydroxymethyl phenol and trihydroxymethyl phenol for later use; next, adding sodium dichromate and thiourea in the reaction kettle with the stirrer at a weight ratio of 1:1, adding hydrochloric acid and a mixture of sodium acetate and sodium malonate which are at a weight ratio of 1:1 to react for 12 hours for later use; and mixing the products obtained from the former two steps at an isovolumetric ratio, and adding absolute ethyl alcohol for evenly stirring so as to obtain the compound cross-linking agent. According to the invention, the glue-forming property and glue-forming strength of the jelly profile modification agent in high-hypersalinity oil field water are improved, and the validity of the profile modification of the oil field is prolonged.

Owner:XI'AN PETROLEUM UNIVERSITY

Preparation method of tin-plated plate and application of tin-plated plate prepared by preparation method

ActiveCN108950613AImprove uniformityGuaranteed corrosion resistanceChromatisationTin platingStrip steel

The invention provides a preparation method of a tin-plated plate and an application of the tin-plated plate prepared by the preparation method. The preparation method comprises the following steps that a strip steel sequentially undergoes tin plating, soft melting, passivation and oil coating to obtain a finished product, wherein in the tin plating process, the current density of the first pass and the last pass is 10-20 A / dm<2>, and the current density of the middle pass is 5-10 A / dm<2>, in the soft melting process, a pure induction soft melting process is adopted, the temperature of soft melting is 240-245 DEG C in the soft melting process, the soft melting time is 0.5-1.5 s, and in the passivation process, a sodium dichromate solution with the concentration being 27-31 g / L is used as apassivation solution. Through the preparation method, the tin-plated plate which is uniform in coating, good in welding performance, good in binding force with a PET film and extremely low in tin quantity is prepared, and the tin-plated plate can be used for replacing a chromium plated plate to be applied to the coated iron.

Owner:SHOUGANG CORPORATION

Profile control agent of injection well

ActiveCN101362940AReduce construction pressureReduce resistanceDrilling compositionThioureaSodium dichromate

The invention relates to an injection well profile modification agent which comprises polyacrylamide with the molecular weight of 1-2 million, hydrolysis degree less than 5% and consistency of 0.5%, inorganic chromium salt cementing agent sodium dichromate with the consistency of 0.15-0.5%, thiocarbamide with the consistency of 0.05-0.4% and residual quantity of water. After the profile modification agent is adopted, the permeability of high permeability layer reaches 40-60% and proportion of the profile modification agent entering the destination layer can be improved from 70% to more than 95%.

Owner:DAQING OILFIELD CO LTD +1

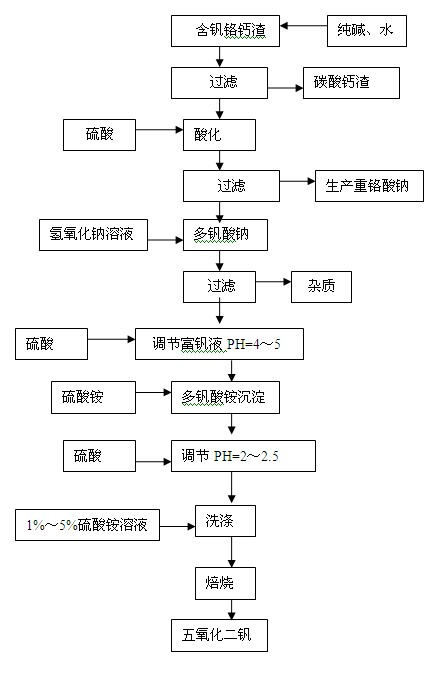

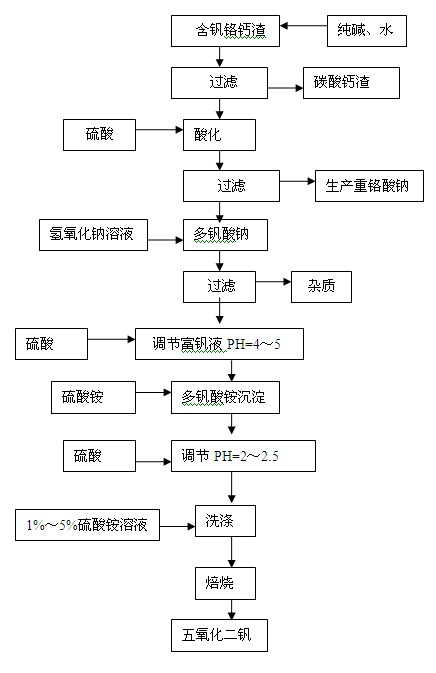

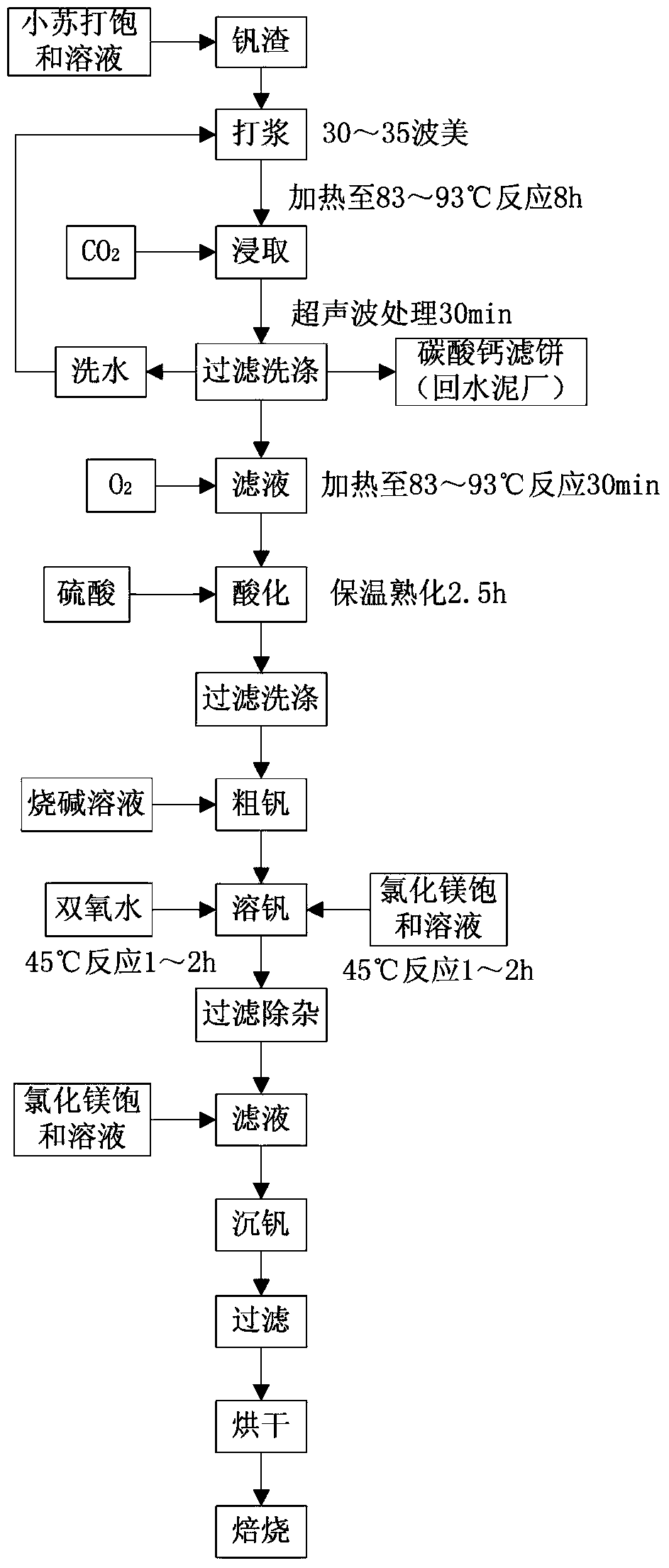

Method for producing high-purity vanadium pentoxide by using vanadium-containing waste residues

ActiveCN103924090AReduce water consumptionHigh recovery rateProcess efficiency improvementSlagFiltration

The invention discloses a method for producing high-purity vanadium pentoxide by using vanadium-containing waste residues, and the method is designed for solving the problems that in the prior art, calcium slags are long in filtration time and large in washing water amount, the recovery rate of vanadium is low, the purity of vanadium pentoxide is low, and the like. The method is implemented by taking vanadium-containing calcium slags discharged in the process of sodium dichromate production as a raw material by virtue of the steps of adding a certain amount of sodium bicarbonate solution into the raw material, stirring and leaching the obtained mixture, feeding CO2 gas for deep leaching, and filtering the obtained product for impurity removal; feeding O2 into the obtained solution so as to oxidize the obtained solution, adding a concentrated sulfuric acid for adjusting the pH value of the obtained product and acidifying the obtained product, and after the obtained product is subjected to heat preservation and curing, filtering and precipitating the obtained product so as to obtain hydrous vanadium pentoxide; heating the hydrous vanadium pentoxide so as to dissolve the hydrous vanadium pentoxide, adjusting the PH value of the dissolved hydrous vanadium pentoxide, and filtering the obtained hydrous vanadium pentoxide so as to remove impurities; adding saturated ammonium chloride into the obtained solution to carry out vanadium precipitation, and filtering, washing and roasting the obtained product so as to obtain vanadium pentoxide. Compared with original methods, the method disclosed by the invention has the advantages that the washing water amount of calcium slags is reduced by 50%, the recovery rate of vanadium is increased by about 4%, and the purity of vanadium pentoxide is increased by over 99%. The utilization rate of vanadium-containing waste residues is improved, and the market competitiveness of products is enhanced.

Owner:GANSU JINSHI CHEM

Method for preparing modified lignin poly-carboxylic-acid cement dispersant

Owner:武汉海德天物新材料有限公司

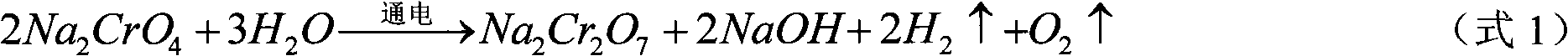

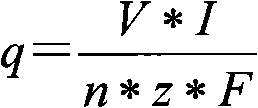

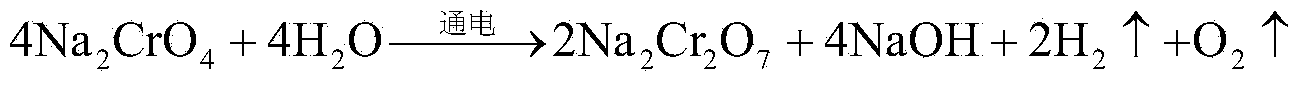

Method for continuously preparing sodium dichromate by ionic membrane electrolysis

InactiveCN101892490AHigh economic valueGood crystal morphologyElectrolysis componentsHigh concentrationEvaporation

The invention relates to a method for continuously preparing sodium dichromate by an ionic membrane electrolysis. The method comprises the following steps of: firstly, neutralizing industrial alkaline sodium chromate solution, removing impurities, and collecting filtrate serving as feed solution of electrolysis process; secondly, introducing the filtrate into an anode chamber in a one-membrane two-chamber ionic membrane electrolyzer, and introducing sodium hydroxide solution into a cathode chamber, wherein anions and cations migrate to the anode and the cathode respectively under the action of an electric field, sodium dichromate acidizing fluid is obtained in the anode chamber, high-concentration sodium hydroxide solution is obtained in the cathode chamber, and hydrogen and oxygen are produced on a positive electrode and a negative electrode respectively; and finally, performing evaporation concentration and natural cooling crystallization on the sodium dichromate acidizing fluid to separate out dehydrate sodium dichromate products. The method has the advantages of short process, low cost, high purity of the obtained sodium dichromate products, near 100 percent of raw material utilization rate, and high economic value of byproducts.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

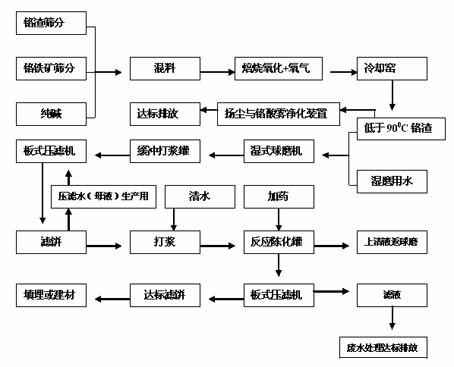

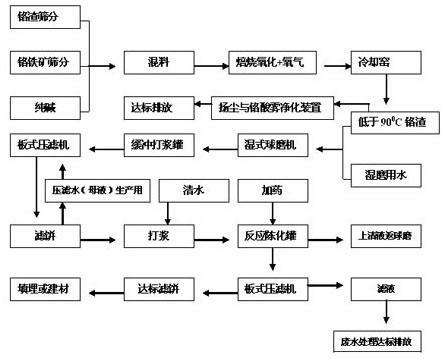

Chromium slag roasting oxidation comprehensive detoxification cleaning process

InactiveCN102285688AReduce total chromiumReduce total alkali contentSolid waste managementChromates/bichromatesSlagRaw material

The invention relates to a comprehensive detoxification and cleaning process for chromium slag by roasting and oxidation. The technical solution adopted is: a comprehensive detoxification and cleaning process of chromium slag roasting and oxidation, characterized in that: chromium slag is used as raw material, chromite and soda ash are auxiliary materials, and the material ratio is: chromium slag: chromite ore: soda ash=2:1 :0.6, at the roasting reaction temperature of 1050°C, the chromium trioxide in the mixed material is roasted and oxidized at high temperature to form sodium chromate, the conversion rate is more than 80%, and the extraction liquid is used as the mother liquor for the production of red alum sodium products. The main process flow: roasting and oxidation + ball mill leaching + plate and frame filter press dehydration + liquid production red alum sodium production + filter cake secondary beating to extract supernatant + acidification solidification + landfill or building materials. The total chromium content in the detoxification slag is low, and the comprehensive utilization rate is high, which solves the post-disposal problem existing in the traditional dry and wet chromium slag detoxification process, and the cost is low. The method is also applicable to the roasting production with calcium, less calcium and calcium-free in chromium salt production enterprises, and the effect is equally remarkable.

Owner:青海省中星化工有限公司 +1

Method for producing high-quality sodium bichromate

The invention relates to a method for producing sodium bichromate. The method comprises the following steps: 1) performing hydrothermal oxidation on slurry of chromium-containing sodium carbonate, ferrochromium and soda and water to obtain sodium chromate and carbon dioxide, and removing carbon dioxide; 2) separating the obtained reaction mixture to obtain a sodium chromate solution and iron slag; 3) concentrating the obtained sodium chromate solution to 600-1400g / L; 4) carbonizing and acidizing the sodium chromate concentrated solution by using the carbon dioxide removed in the step 1), thus obtaining a sodium dichromate solution and chromium-containing sodium bicarbonate; and 5) decomposing the obtained chromium-containing sodium bicarbonate into chromium-containing sodium carbonate and carbon dioxide, returning the chromium-containing sodium carbonate to the step 1), and returning carbon dioxide to the step 4). According to the method, the processes of preparing the sodium chromate solution and acidizing the sodium chromate are organically combined, comprehensive recycling of Na+ and CO2 is realized, no waste residues are generated in the whole production process, the discharge of three wastes is greatly reduced, the method is a low-carbon, cyclic and clean type process for production of sodium bichromate, and the purity of the produced sodium bichromate is high.

Owner:SICHUAN YINHE CHEM

Preparation method of chlorine dioxide without production of solids

The invention discloses a preparation method of chlorine dioxide without production of solids. The method comprises the following steps: filtering a concentrated sodium chlorate solution sent from an electrolytic bath, then injecting into a generator to form a reaction mother solution, circulating in the generator and a circulating pipeline under the action of a circulating pump, maintaining the reaction mother solution at a certain density and temperature, then adding hydrochloric acid sent from a hydrochloric acid system, reacting to generate chlorine gas, chlorine dioxide gas and sodium chloride, cooling the chlorine dioxide gas, then absorbing the chlorine dioxide gas by low-temperature chilled water to obtain a chlorine dioxide water solution, sending the chlorine gas produced by reaction into a hydrochloric acid furnace to be burned with hydrogen gas produced in the electrolytic bath to prepare hydrochloric acid, and returning a dilute sodium chlorate solution after reaction into the electrolytic bath by a pump for re-preparing the concentrated sodium chlorate solution for recycling. According to the method disclosed by the invention, the production of the solids can be prevented in the whole reaction process and scaling of equipment can be avoided, so that sodium chloride and sodium dichromate can be completely recycled and do not need to be supplemented basically.

Owner:GUANGXI UNIV

Anti-shearing crosslinking-delayed organic profile control agent

The invention relates to the technical field of profile control and displacement of oil field water injection wells, and in particular to an anti-shearing crosslinking-delayed organic profile control agent. The profile control agent comprises the following components with the following molar concentrations: 0.4-0.6% of anionic polyacrylamide with molecular weight of 8 million, 0.1-0.2% of sodium dichromate, 0.4-0.6% of thiourea and 0.05% of sodium hydrosulphite. The invention realizes gelation strength meeting the need of profile control of low permeability fractured reservoir after stratum shearing, and can control the gelation time by adjusting the concentration of the stabilizer, so as to meet the requirements of oil reservoir with different well spacing and raise recovery efficiency. The invention overcomes the insufficiencies that existing flooding agent, after shearing in immediate vicinity of wellbore, has greatly decreased intensity, and cannot reach the requirements of sealing cracks or meet the requirements of profile control of low permeability fractured reservoir.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

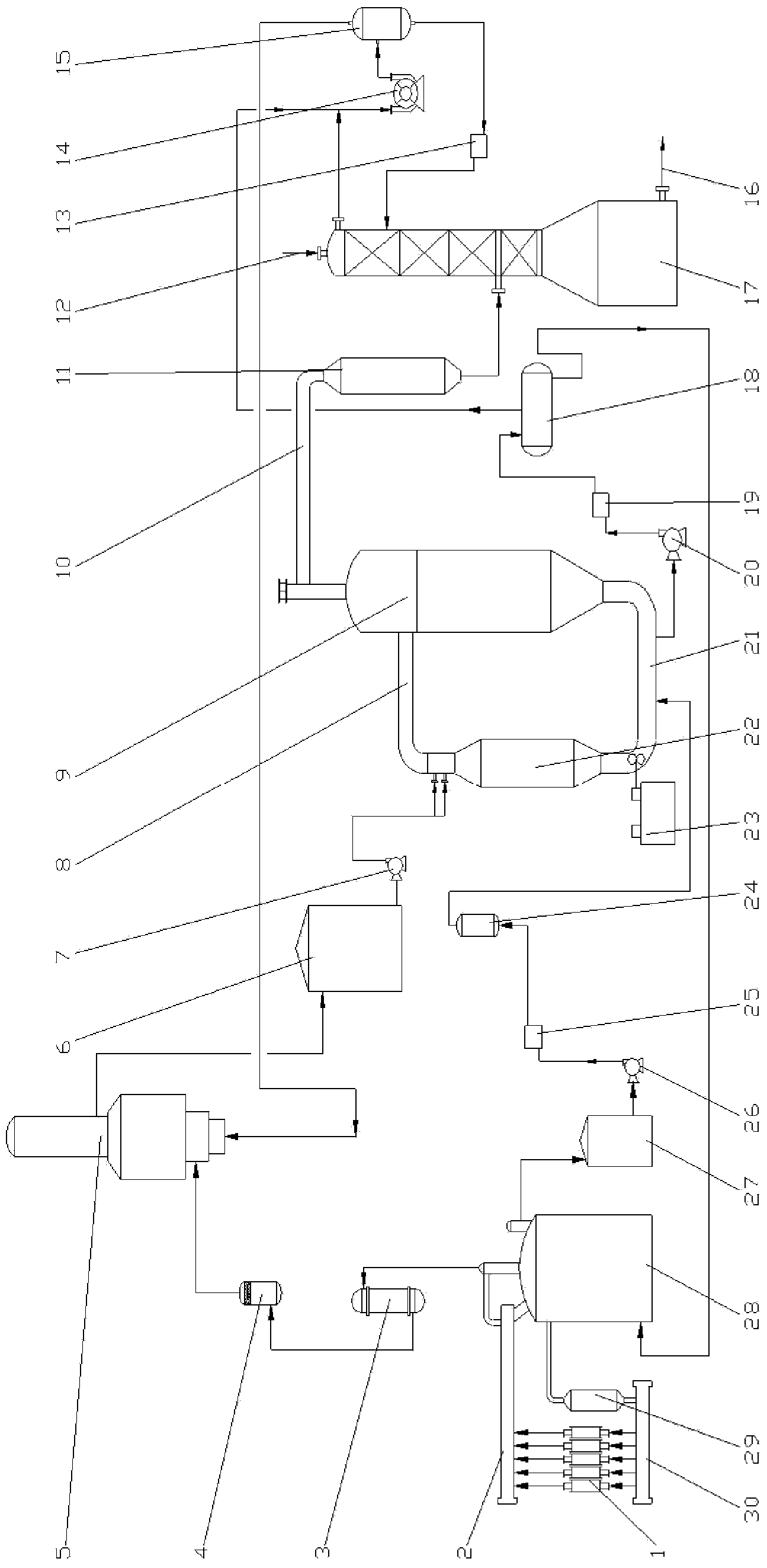

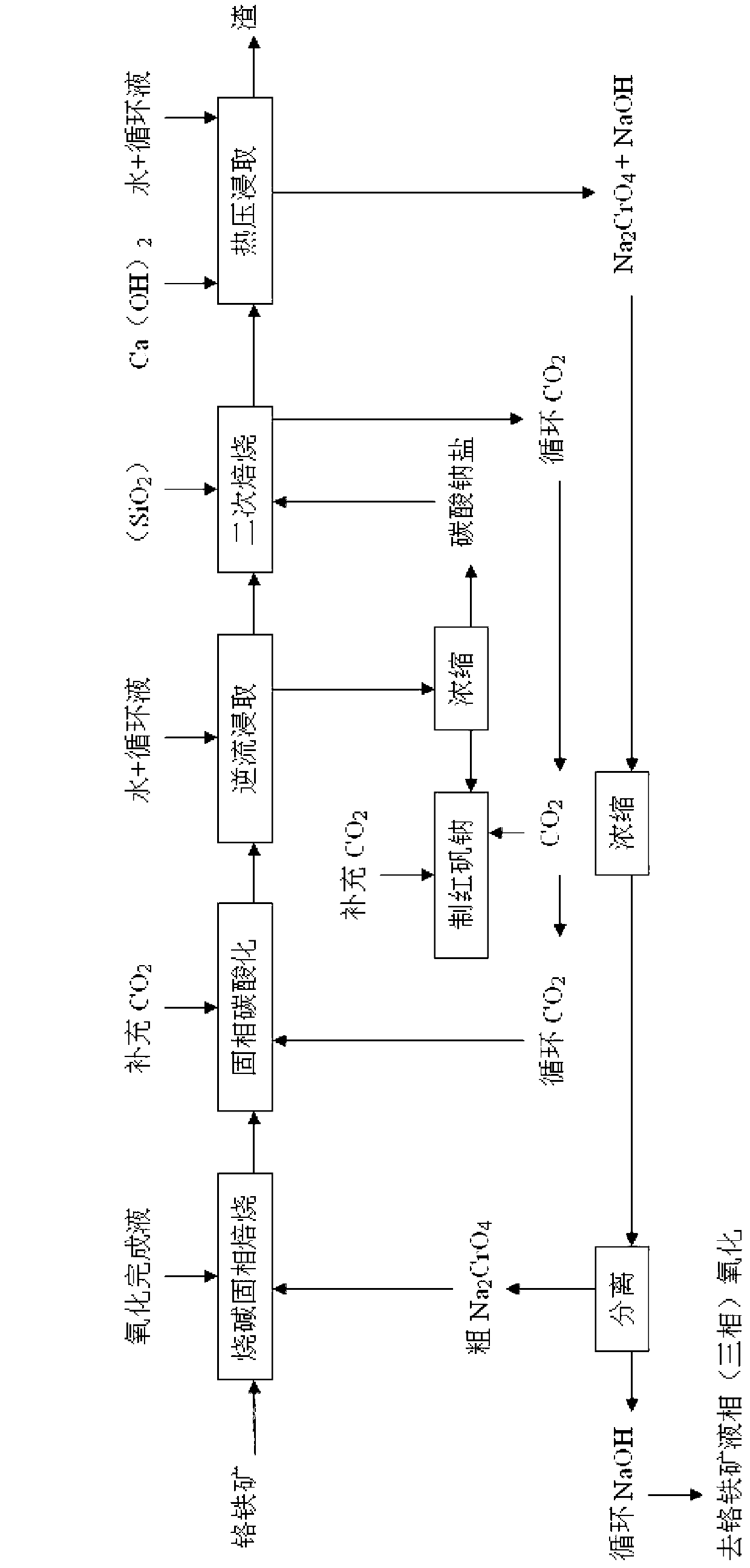

Separation method for completion liquid of caustic soda liquid-phase oxidation of chromite

The invention provides a method for separation and preparation of sodium chromate or heavy sodium chromate from completion liquid of caustic soda liquid-phase oxidation or three-phase oxidation of chromite or ferrochrome. The method comprises the following five steps: caustic soda solid-phase roasting, solid-phase carbonation, counter-current leaching, secondary roasting and hot-pressing leaching. The invention has the following advantages: 1, high recovery rates are obtained, wherein the recovery rate of chromium reaches 95 to 98%, the recovery rate of alkali is more than 80%, the cyclic utilization rate of CO2 is more than 70%, so consumption of materials is low; 2, energy consumption is substantially decreased compared to a traditional method; and 3, the amount of waste residue is only 0.9 to 1.3 ton per ton of sodium dichromate, the content of Cr<6+> (in terms of Na2Cr2O72H2O) in the waste residue is less than 0.05%, far less than the content of Cr<6+> (less than 0.2%) in a traditional calcium-free roasting method, and thus, total pollution amount of Cr<6+> in the waste residue in the invention is less than that in the traditional calcium-free roasting method.

Owner:余华强

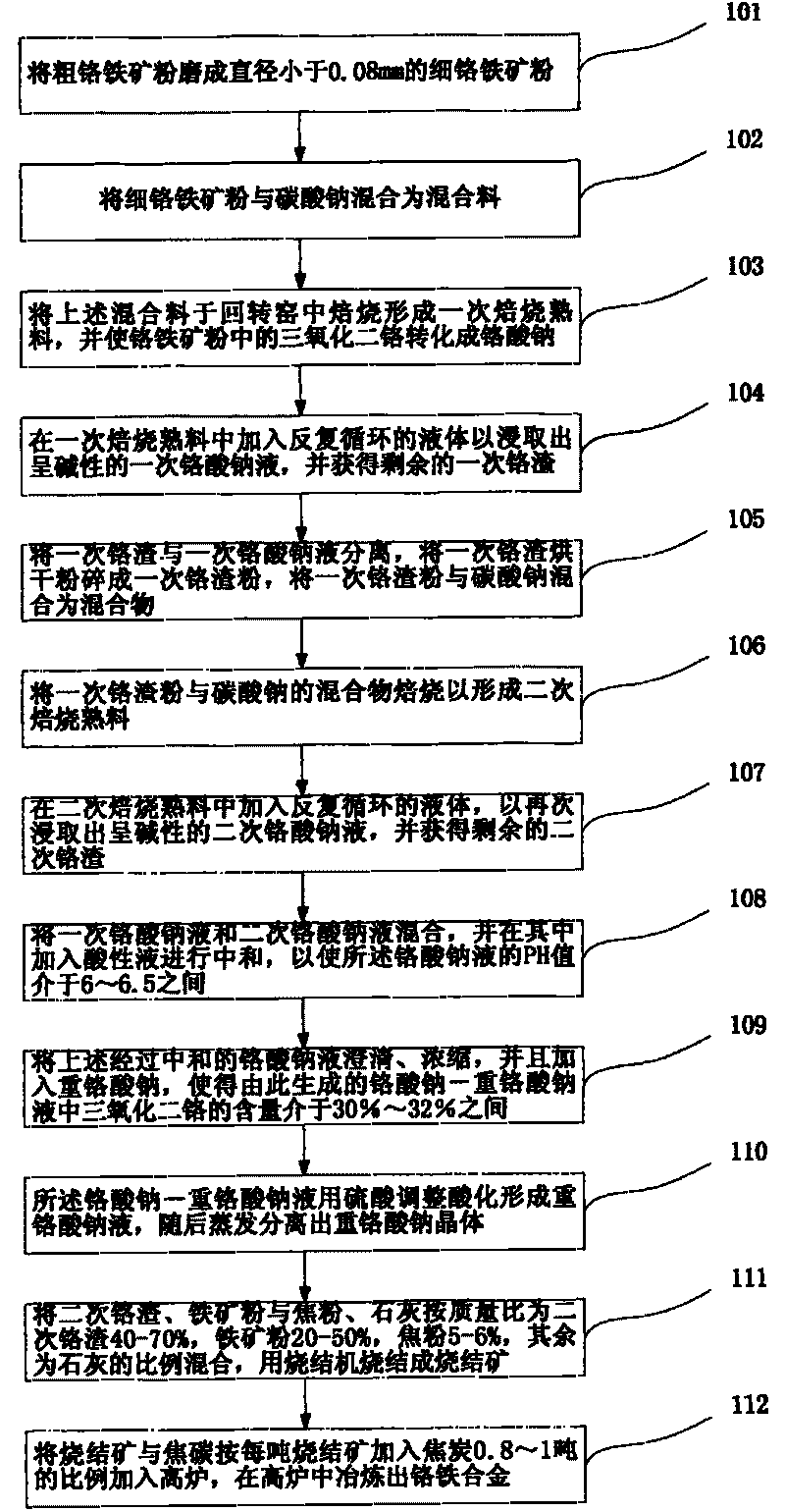

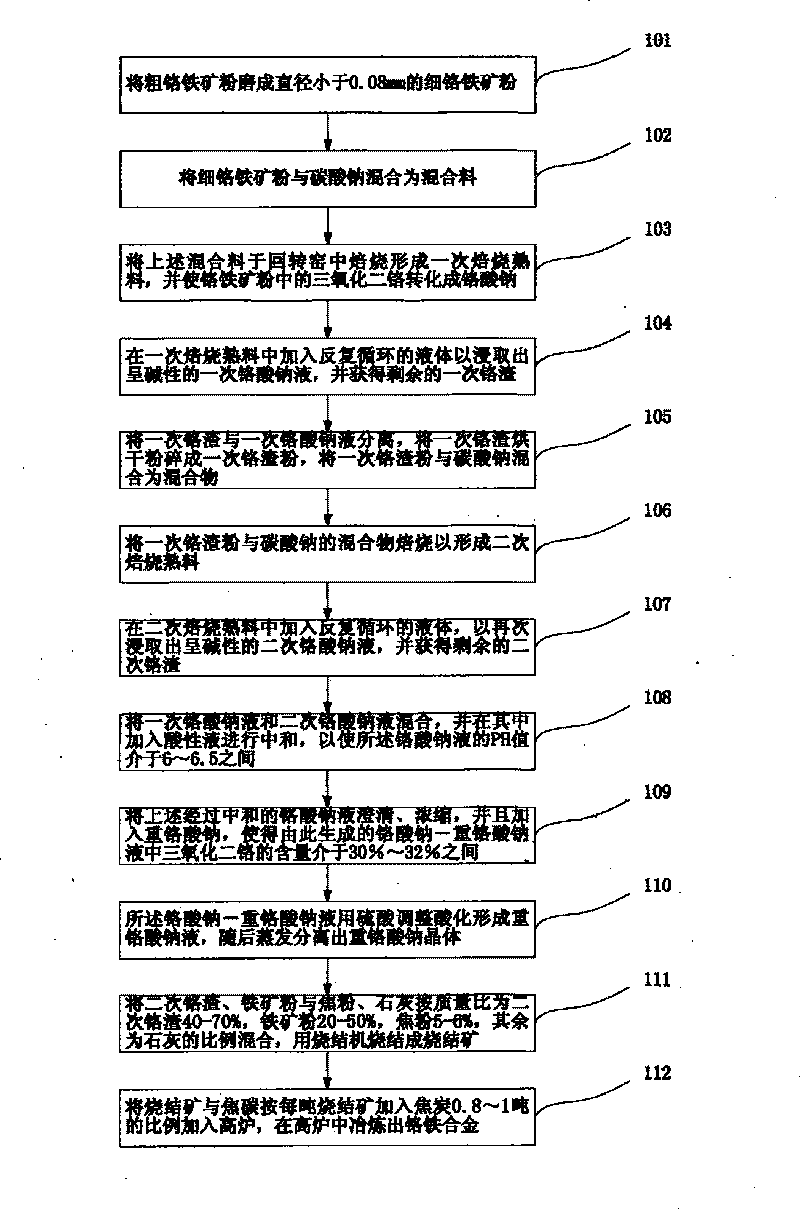

Method for jointly producing chromium salt and ferrochromium alloy by sintering with wet and fire methods

InactiveCN101709369AAchieving zero emissionsBlast furnace detailsChromium compoundsSodium dichromateFerrochrome

Owner:XINJIANG SING HORN GRP CO LTD

Delayed crosslinked chromium gel profile control plugging agent

InactiveCN104910883AHigh strengthLong gelling timeDrilling compositionPolymer scienceOxidation-Reduction Agent

The invention relates to a delayed crosslinked chromium gel profile control plugging agent, belonging to the technical field of oilfield profile control plugging. The delayed crosslinked chromium gel profile control plugging agent is formed by crosslinking partially hydrolyzed polyacrylamide and Cr<3+> generated by redox reaction. The delayed crosslinked chromium gel profile control plugging agent is composed of the following components in percentage by weight: 0.3-0.8% of partially hydrolyzed polyacrylamide, 0.02-0.20% of sodium dichromate, 0.15-0.50% of additive and the balance of water. Compared with the reported chromium gel, the delayed crosslinked chromium gel has the advantages of long gelling time, high heat stability and high gel strength. Under the optimal formula, the delayed crosslinked chromium gel has high plugging rate, favorable abrasion resistance and high practicality, and satisfies the demands for on-site construction.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Biomass fuel based on sepiolite powder combustion improver and preparation method thereof

InactiveCN105238484ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsSludgeCopper oxide

The invention discloses a biomass fuel based on a sepiolite powder combustion improver and a preparation method thereof. The biomass fuel based on the sepiolite powder combustion improver comprises the following components by dry weight: 50-65 parts of sawdust, 20-35 parts of straw, 25-35 parts of returned sludge, 5-15 parts of attapulgite clay, 1-10 parts of a fluxing agent, and 5-15 parts of the combustion improver. The combustion improver, comprises, by weight, 40-60 parts of sepiolite powder, 10-20 parts of activated carbon, 5-10 parts of magnesium oxide, 4-8 parts of lanthanum nitrate, 2-7 parts of potassium perborate, 8-15 parts of fluorite, 2-7 parts of sodium bichromate, 1-6 parts of acetone, 4-8 parts of copper oxide, 5-10 parts of magnesium oxide, and 5-10 parts of calcium permanganate. The biomass fuel provided by the has a combustion temperature up to 1410-1520DEG C, combustion efficiency increased by about 30% than ordinary biomass fuels, a calorific value up to 5100-5200 kcal / kg, combustion tail gas in line with the relevant provisions of the state, a sulfur removal rate up to 94.3%, and a nitrate removal rate up to 94.8%.

Owner:杨阳

Method for producing sodium dichromate through cationic membrane electrolysis

The invention discloses a method for producing sodium dichromate through cationic membrane electrolysis. The method comprises the following steps: mixing a 20-40% industrial sodium chromate solution and a 23-50% sodium dichromate solution to obtain a mixed feed liquid with a volume ratio of sodium dichromate to chromate being equal to (1.5:1)-(5:1); introducing the mixed feed liquid into an anode chamber and introducing a sodium hydroxide solution with mass concentration of 27-30% into a cathode chamber; switching on direct currents, wherein the current density is controlled to be 2-4kA / m<2>, the electrolysis temperature is 70-90 DEG C, the pressure difference between the cathode chamber and the anode chamber is 200-500mmH2O, the anode feed temperature is 50-85 DEG C, and the cathode feed temperature is 55-90 DEG C; and after electrolysis, obtaining sodium dichromate and oxygen gas in the anode chamber, and obtaining sodium hydroxide and hydrogen gas in the cathode chamber.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com