Method for continuously preparing sodium dichromate by ionic membrane electrolysis

A technology of ion membrane electrolysis and sodium dichromate, applied in electrolysis process, electrolysis components, etc., can solve the problems of harsh operating environment, equipment corrosion, low production efficiency, etc., and achieve the effect of high product purity and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

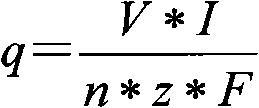

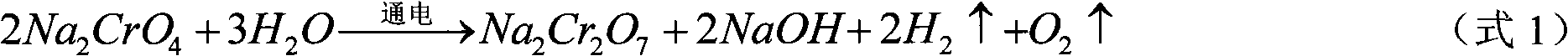

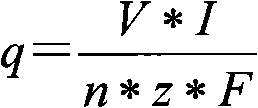

Method used

Image

Examples

Embodiment 1

[0024] Example 1 A method for continuously preparing sodium dichromate by ion-exchange membrane electrolysis, including the following steps:

[0025] (1) Neutralization and impurity removal: In an industrial alkaline sodium chromate solution with a free alkali content of 1% and a mass concentration of 10%, add an acidification rate of 80% and a mass concentration of 11% according to the amount of acid-base completely neutralized Sodium dichromate solution, that is, according to the volume ratio of industrial alkaline sodium chromate solution to sodium dichromate solution of 2.2:1, impurity elements such as aluminum and silicon in industrial alkaline sodium chromate are precipitated in the form of precipitation. After being kept and aged for 1 hour at a temperature of ℃, the precipitate was removed by filtration to obtain a neutral filtrate with a mass concentration of sodium chromate of 10.3%, and the filtrate was collected as the raw material liquid for the electrolysis process. ...

Embodiment 2

[0031] Example 2 A method for continuously preparing sodium dichromate by ion-exchange membrane electrolysis, including the following steps:

[0032] (1) Neutralization and impurity removal: In an industrial alkaline sodium chromate solution with a free alkali content of 2% and a mass concentration of 25%, add an acidification rate of 95% and a mass concentration of 30% according to the amount of acid-base completely neutralized Sodium dichromate solution, that is, according to the volume ratio of industrial alkaline sodium chromate solution to sodium dichromate solution of 3.7:1, impurity elements such as aluminum and silicon in industrial alkaline sodium chromate are precipitated in the form of precipitation. After aging for 3 hours at a temperature of ℃, the precipitate was removed by filtration to obtain a neutral filtrate with a mass concentration of sodium chromate of 26%, and the filtrate was collected as the raw material liquid for the electrolysis process.

[0033] (2) Ele...

Embodiment 3

[0036] Example 3 A method for continuously preparing sodium dichromate by ion-exchange membrane electrolysis, including the following steps:

[0037] (1) Neutralization and impurity removal: In an industrial alkaline sodium chromate solution with a free alkali content of 3% and a mass concentration of 40%, add an acidification rate of 105% and a mass concentration of 55% according to the amount of acid-base completely neutralized Sodium dichromate solution, that is, according to the volume ratio of industrial alkaline sodium chromate solution to sodium dichromate solution of 5.2:1, impurity elements such as aluminum and silicon in industrial alkaline sodium chromate are precipitated in the form of precipitation. After aging at a temperature of ℃ for 5 hours, the precipitate was removed by filtration to obtain a neutral filtrate with a mass concentration of sodium chromate of 42%, and the filtrate was collected as the raw material liquid for the electrolysis process.

[0038] (2) El...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com