Patents

Literature

36results about How to "Good crystal morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for recovering zinc from hot-dip coating zinc ash

InactiveCN101979684AReduce energy consumptionHigh purityProcess efficiency improvementBound waterFerrosilicon

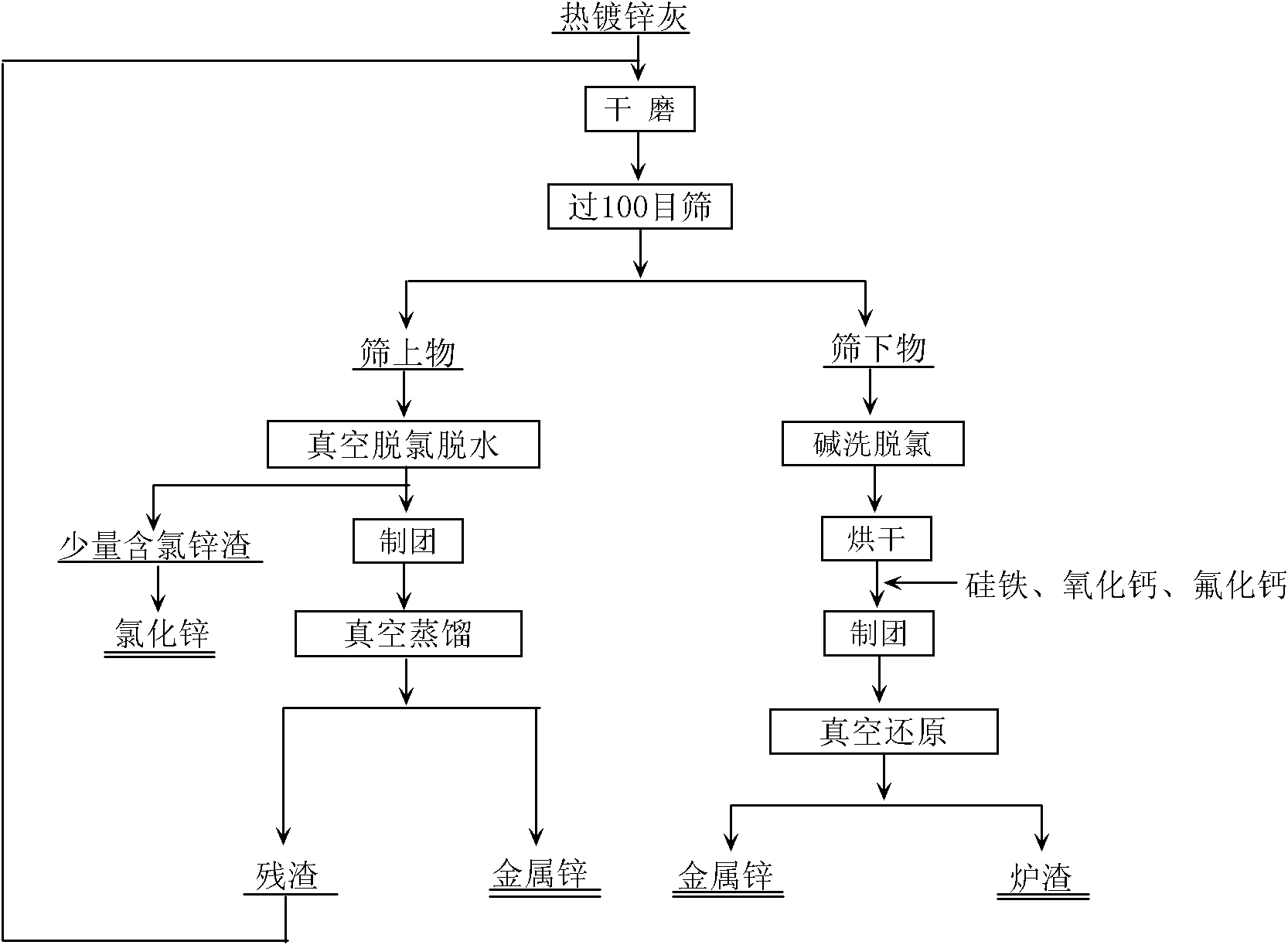

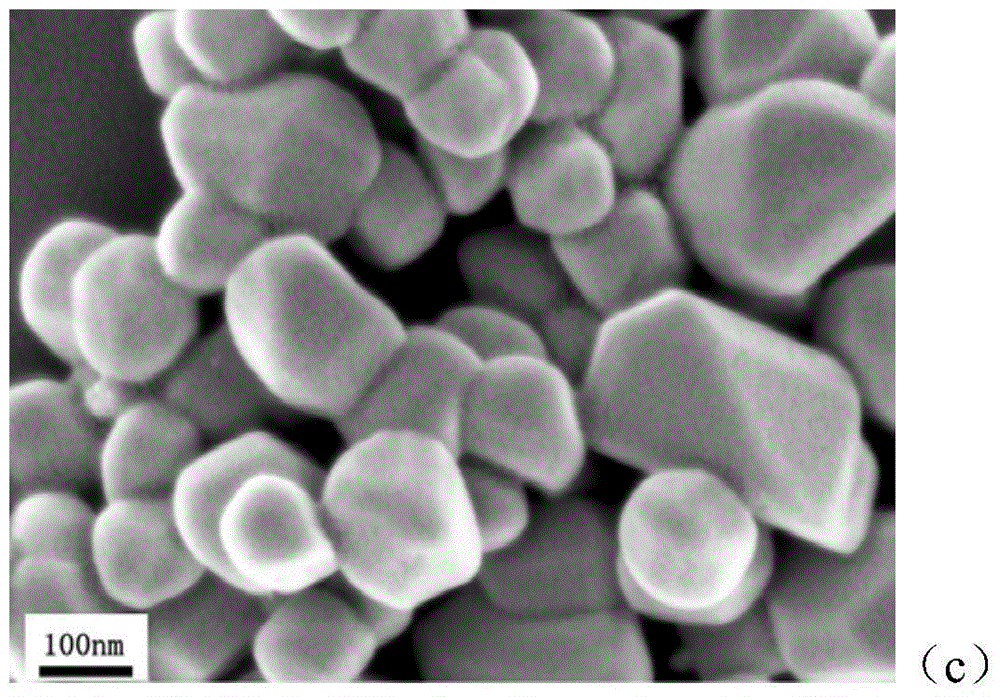

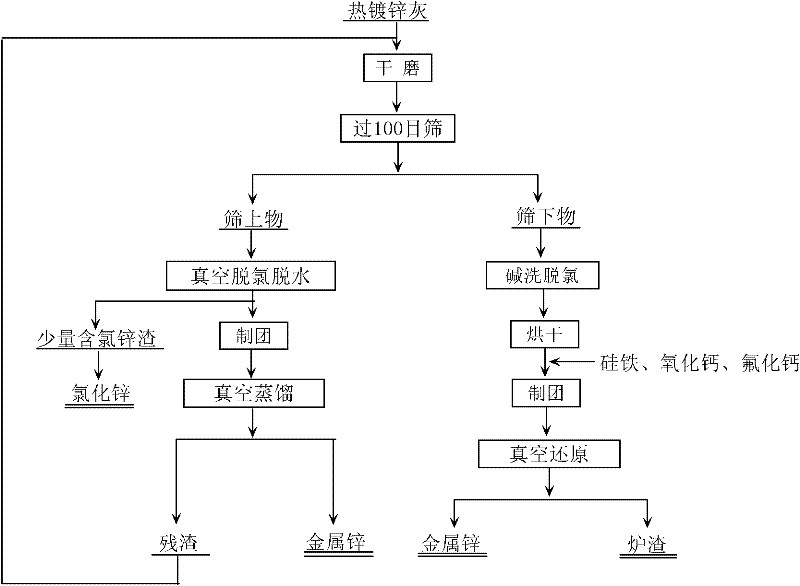

The invention relates to a process for recovering zinc from hot-dip coating zinc ash. The process comprises the following steps of: separating the hot-dip coating zinc ash after dry grinding and screening to obtain an oversize product and an undersize product; removing bound water and a small amount of zinc chloride from the oversize product under the condition that the temperature is between 400 and 500 DEG C and the vacuum degree is 10 to 50 Pa; performing vacuum distillation on the oversize product under the condition that the temperature is between 650 and 800 DEG C and the vacuum degree is 10 to 30 Pa to obtain zinc; and performing alkali cleaning on the undersize product to remove chlorine, and then performing vacuum thermal reduction on the undersize product to obtain the zinc from zinc oxide by using ferrosilicon as a reducing agent and calcium oxide as a slagging agent under the condition that the vacuum degree is 10 to 30 Pa and the temperature is between 1,050 and 1,200 DEG C. The process has a high recovery rate for recovering the zinc from the hot-dip coating zinc ash, and the obtained zinc has a good crystallized shape.

Owner:CENT SOUTH UNIV

High-temperature-resistant and high-humidity-resistant fluoride red fluorescent powder and preparation method thereof

ActiveCN106479485AGood crystal morphologyIncrease brightnessLuminescent compositionsSodium carboxymethylcelluloseRed light

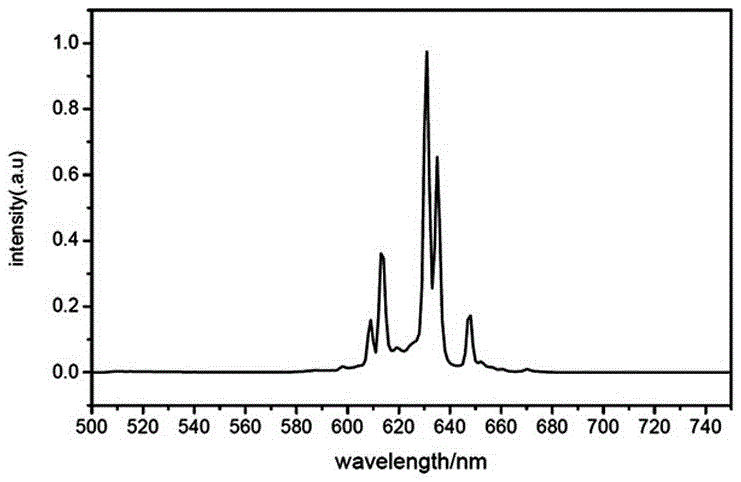

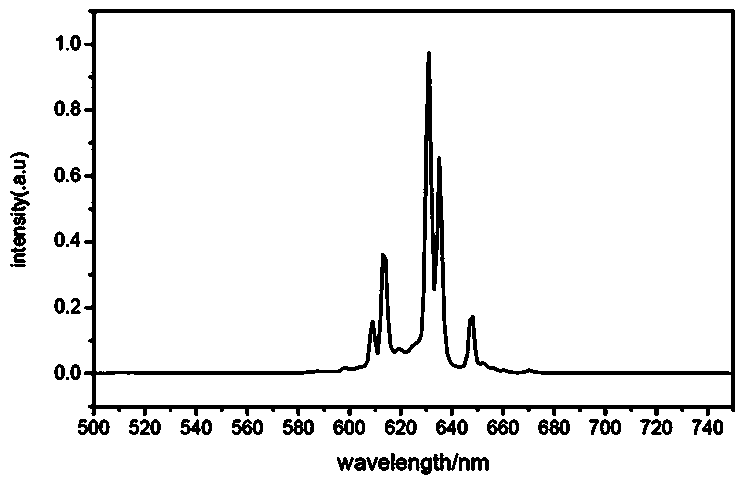

The invention provides a high-temperature-resistant and high-humidity-resistant fluoride red fluorescent powder and a preparation method thereof. The fluorescent powder has a general chemical formula of KmAnM1-xF6: xMn<4+>. In the general chemical formula, A is one or two selected from the group consisting of Cu, Ba and Zn; M is at least one selected from the group consisting of Ti, Si and Ge; m + 2n are equal to 2; n is no less than 0.05 and no more than 0.2; m is no less than 1.6 and no more than 1.9; x is more than 0 and less than 0.2; and the surface of the fluorescent powder is coated with a mixture of potassium silicate, carboxymethyl cellulose sodium and polyethylene glycol. The fluorescent powder provided by the invention can be effectively excited by light with the excitation wavelength being in a range of 300 to 500 nm, so red light with a peak wavelength of 610 to 650 nm and a half-peak breadth of only 2 to 9 nm is generated, and high color purity is obtained. The preparation method provided by the invention has simple flow, can prepare target products at low temperature and under normal pressure, and facilitates to large-scale industrial production; and a special coating technology is adopted in the invention, and a coating reagent is utilized to change the surface state of fluorescent powder particles, so the problem of agglomeration of solid particles can be effectively solved, and a fluorescent powder product with good dispersion properties and high-temperature-resistant and high-humidity-resistant performances can be obtained.

Owner:HEBEI LIFU CHEM TECH

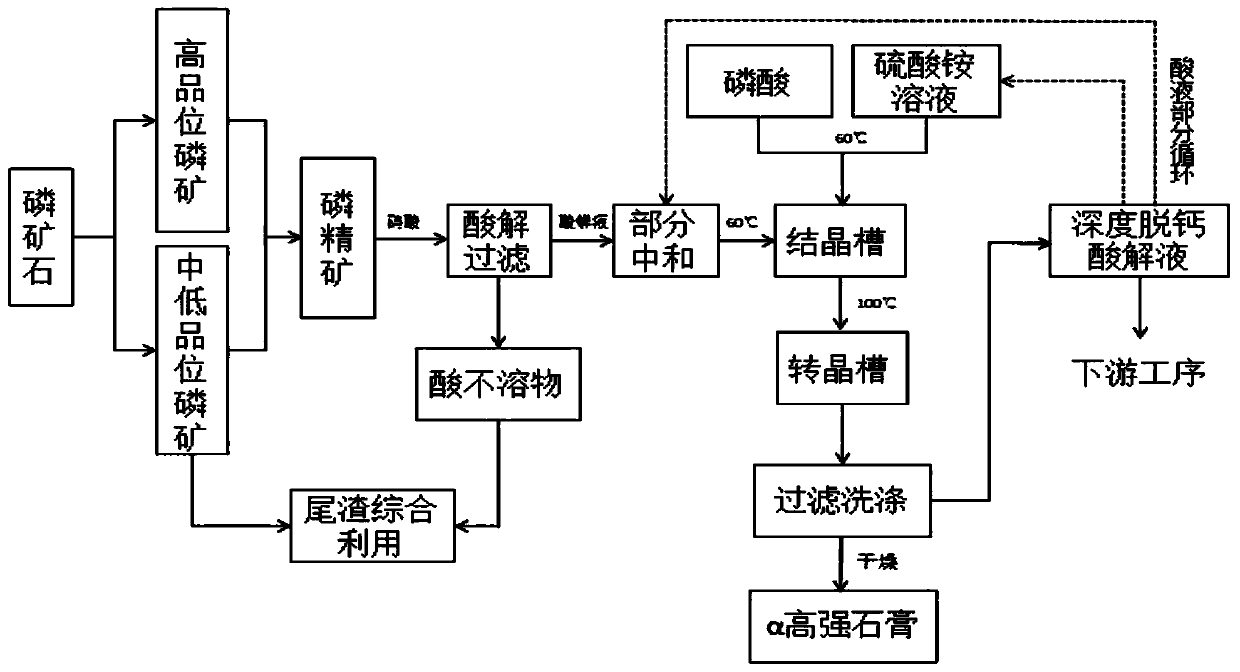

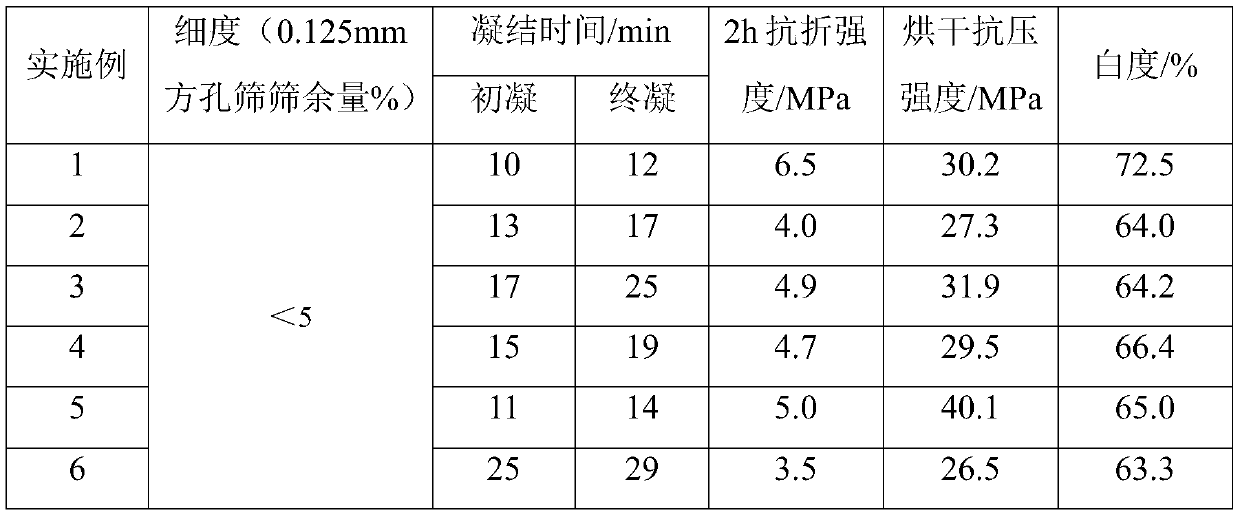

Method for preparing alpha-type high-strength gypsum from phosphogypsum

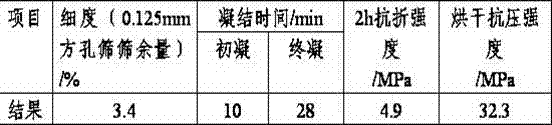

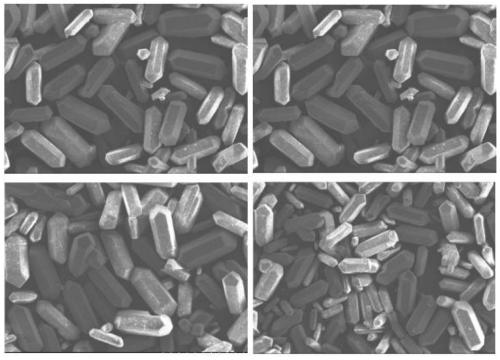

The invention relates to a method for preparing alpha-type high-strength gypsum from phosphogypsum, belonging to the technical field of building materials. The method for preparing alpha-type high-strength gypsum from phosphogypsum is characterized by employing a semi-liquid-phase process and comprising the following steps: 1) blending phosphogypsum with quicklime with an amount identical to the sum of P2O5 and F in the phosphogypsum so as to neutralize the phosphogypsum and then carrying out aging for 1 d ; 2) weighing, on the basis of the total mass of the phosphogypsum, 0.01-0.5% of ternary organic acid and 0.5-2% of hypervalent sulfate, mixing the ternary organic acid and the hypervalent sulfate, and dissolving the obtained mixture in water with a temperature of 80-90 DEG C so as to prepare a composite crystal-type control agent; 3) adding the composite crystal-type control agent and water in a solid-liquid ratio of 4: 1 to 2: 1 into the neutralized phosphogypsum so as to form thick slurry; and 4) spreading the prepared slurry in an autoclave in layers, each layer being 5-15 mm thick, carrying out constant-temperature treatment at 120-150 DEG C for 3-6h, and then carrying out drying and ball-milling so as to obtain alpha-type high-strength gypsum powder. With the method in the invention, the prepared alpha-type high-strength gypsum is in the form of a short-column-like crystal with stable quality, and has 2-hour flexural strength of 4.9 MPa and drying compressive strength of 32.3 MPa; and obvious social, environmental and economic benefits are obtained.

Owner:湖北远固新型建材科技股份有限公司

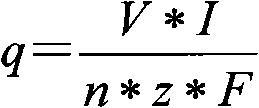

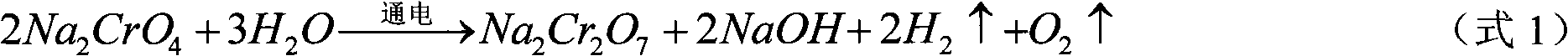

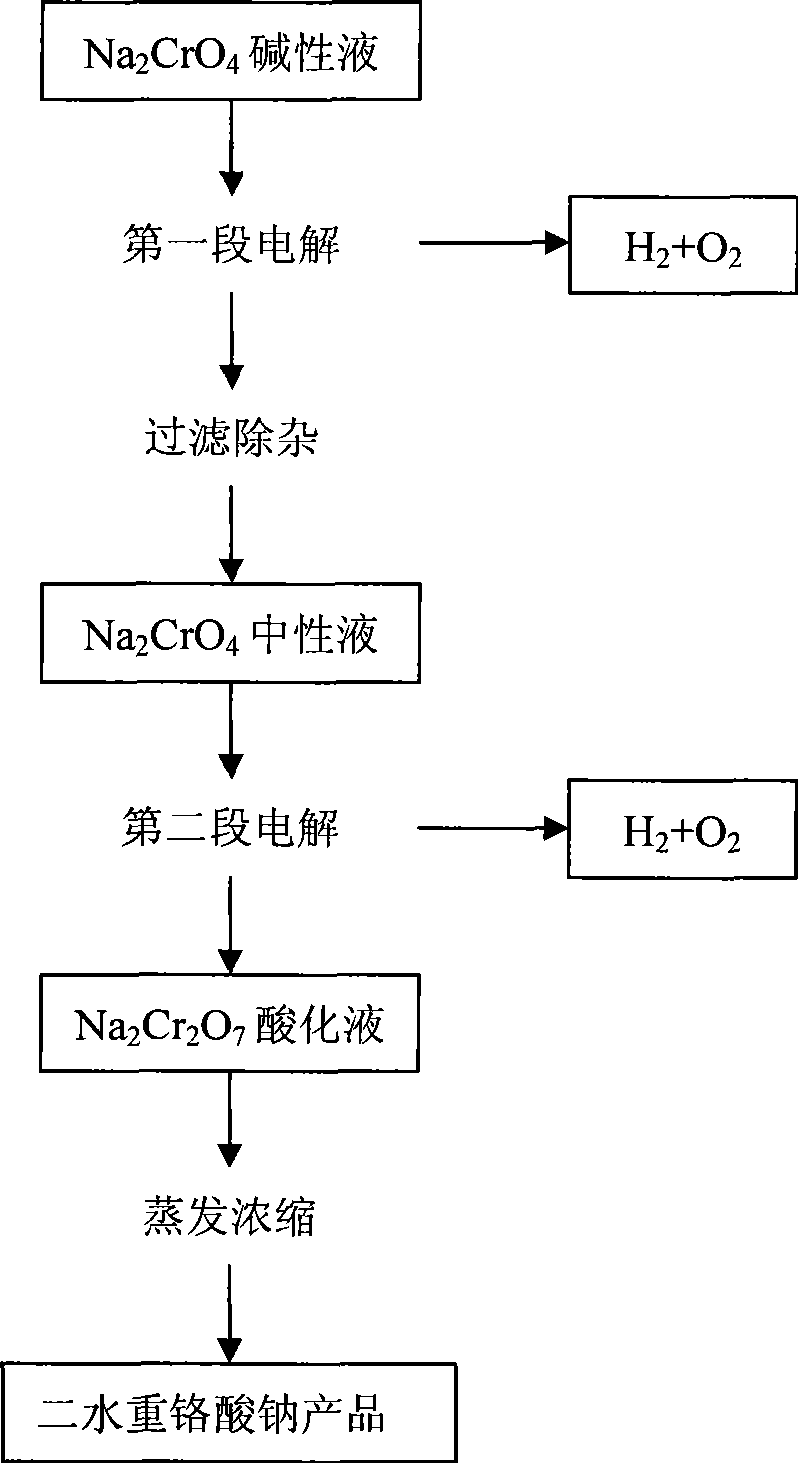

Method for continuously preparing sodium dichromate by ionic membrane electrolysis

InactiveCN101892490AHigh economic valueGood crystal morphologyElectrolysis componentsHigh concentrationEvaporation

The invention relates to a method for continuously preparing sodium dichromate by an ionic membrane electrolysis. The method comprises the following steps of: firstly, neutralizing industrial alkaline sodium chromate solution, removing impurities, and collecting filtrate serving as feed solution of electrolysis process; secondly, introducing the filtrate into an anode chamber in a one-membrane two-chamber ionic membrane electrolyzer, and introducing sodium hydroxide solution into a cathode chamber, wherein anions and cations migrate to the anode and the cathode respectively under the action of an electric field, sodium dichromate acidizing fluid is obtained in the anode chamber, high-concentration sodium hydroxide solution is obtained in the cathode chamber, and hydrogen and oxygen are produced on a positive electrode and a negative electrode respectively; and finally, performing evaporation concentration and natural cooling crystallization on the sodium dichromate acidizing fluid to separate out dehydrate sodium dichromate products. The method has the advantages of short process, low cost, high purity of the obtained sodium dichromate products, near 100 percent of raw material utilization rate, and high economic value of byproducts.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

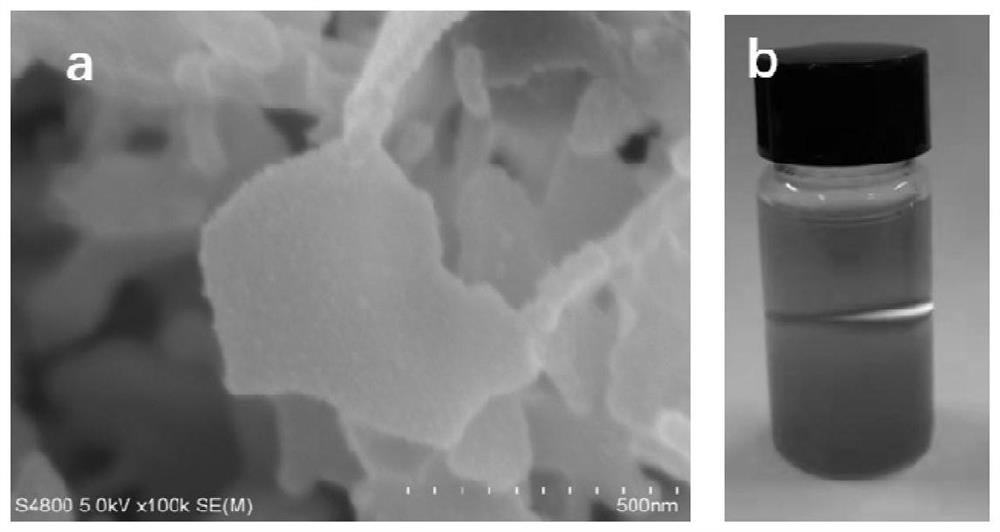

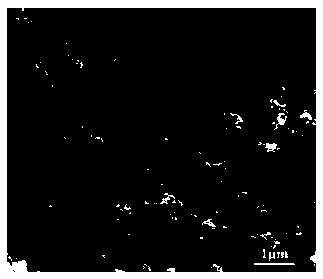

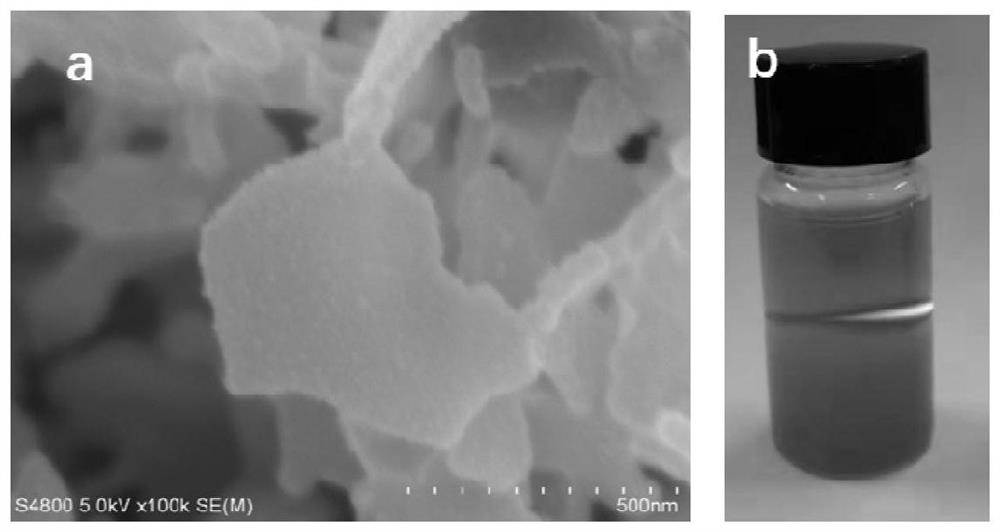

Preparation method of M-site doped vanadium MXene

ActiveCN111634914AImprove liquid phase stripping abilityHigh purityOxy/sulfo carbidesAluminium powderMolten salt

The invention discloses a preparation method of M-site doped vanadium MXene. The preparation method comprises the following steps: mixing metal powder, aluminum powder, carbon powder and fused salt according to a certain proportion to prepare powder; then putting the powder into a mortar, adding a grinding fluid, and grinding for 3-8 minutes under an air condition so that the powder is primarily mixed; transferring into a ball milling tank and carrying out ball milling for 3-6 hours to obtain powder; then putting the powder into a magnetic boat for high-temperature atmosphere sintering to obtain M-site doped MAX-phase powder; and mixing the M-site doped MAX-phase powder with an etching agent according to a certain ratio, then magnetically stirring at 20-35 DEG C for 12-36 hours, cleaning,centrifugally separating and drying to obtain M-site doped V2CTxMXene. The MXene powder material prepared by the method has the characteristics of high purity, multiple hybrid sites and the like, canbe subjected to structure fine adjustment according to working condition requirements, and has a wide application prospect in the field of electrochemistry.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing sodium dichromate dehydrate by ionic membrane electrolysis method

ActiveCN101481802AHigh economic valueIncrease concentrationElectrolysis componentsChromates/bichromatesOxygenWaste material

The invention provides a method for preparing sodium bichromate dihydrate (Na2Cr2O7.2H2O) by using an ion-membrane electrolytic method. The method is as follows: a one-membrane two-room electrolytic cell assembly is formed by using a cation-exchange membrane, a negative electrode and a positive electrode; sodium chromate alkali solution is introduced into an anode chamber. Dilute sodium hydroxide solution is introduced into a cathode chamber; after direct current is connected, negative ions and positive ions respectively move to the anode chamber and the cathode chamber under the action of an electric field; the positive ions enters into the cathode chamber by a positive ion membrane, thus obtaining alkali liquor in the cathode chamber; sodium acid chromate solution is obtained in the anode chamber; simultaneously, the negative electrode and the positive respectively output hydrogen and oxygen; sodium bichromate dihydrate products are dissolved out by evaporating and cooling off the sodium acid chromate solution. The Sodium bichromate dihydrate products prepared by the method has high purity; the utilization rate of the raw materials is close to 100%; byproduct sodium hydroxide has high economic value; no waste materials containing chromium are recycled or discharged in the production process; therefore, the method is safe and environment friendly.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

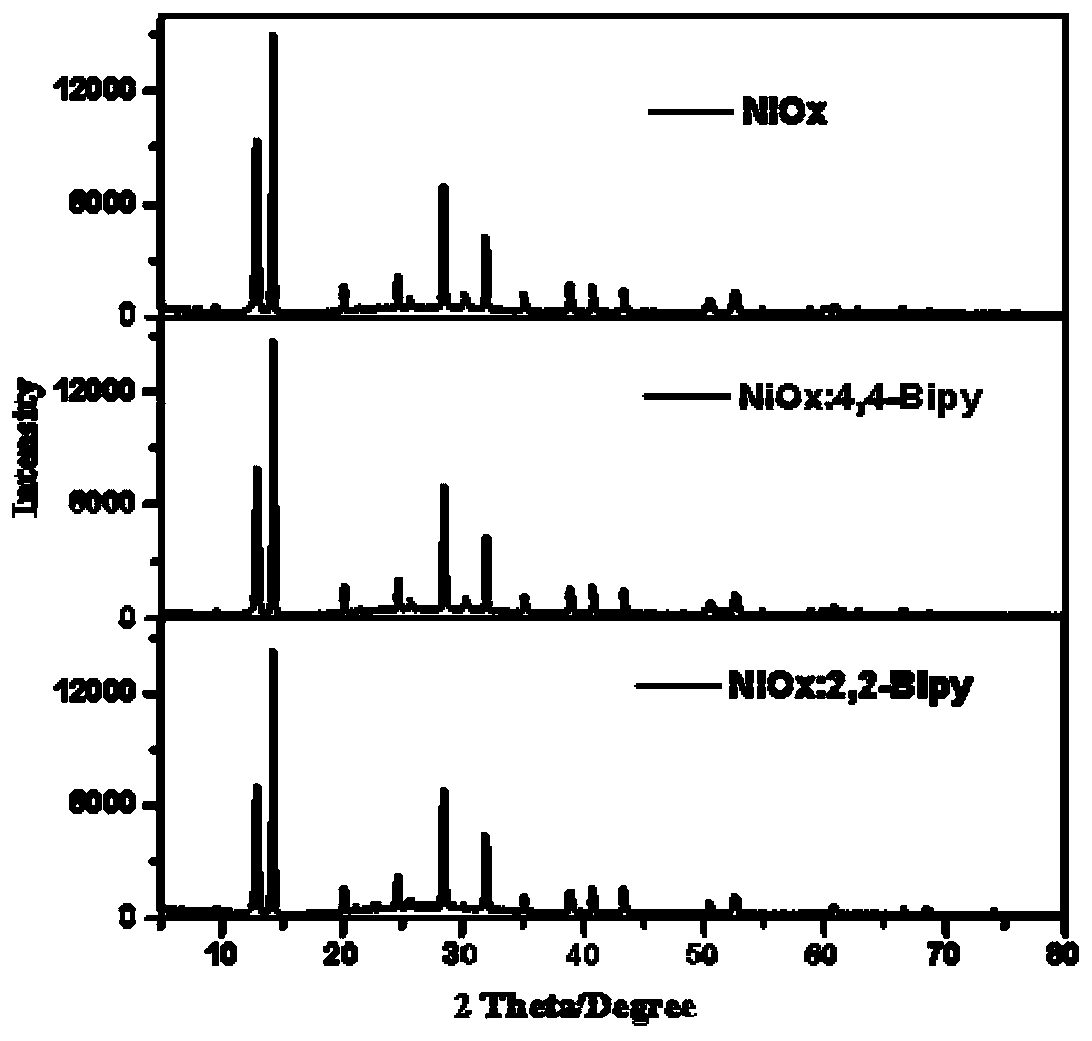

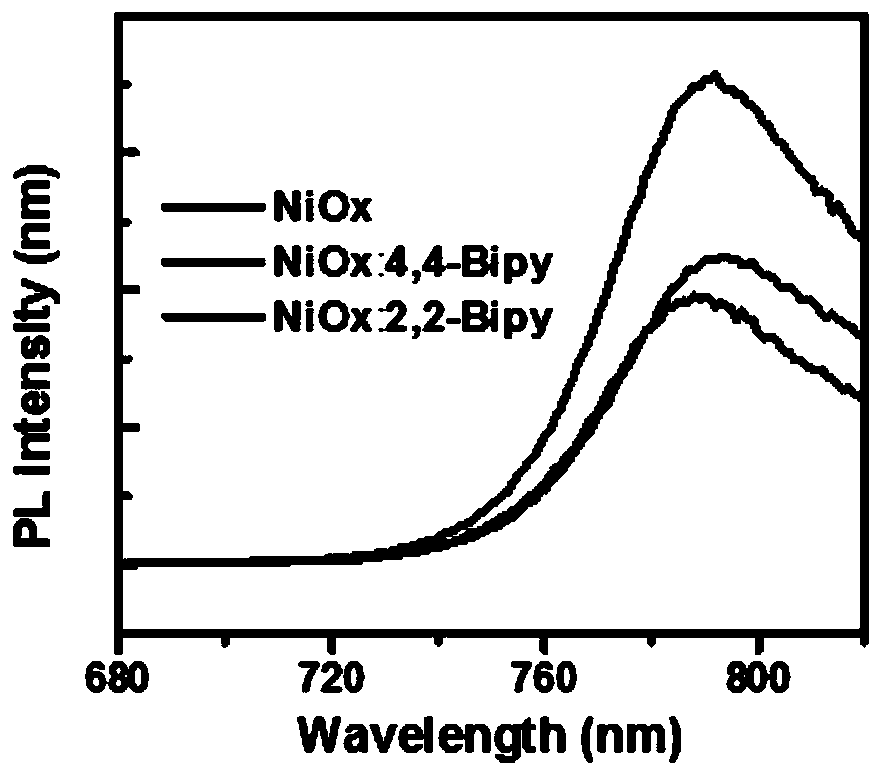

Method for regulating crystal growth of perovskite layer and application of perovskite layer in solar cell

PendingCN110112301AHigh fluorescence intensityPhotovoltaic characteristics improvedSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellComputational chemistry

The invention discloses a method for regulating the crystal growth of a perovskite layer. A modified layer is prepared on the surface of an anode interface layer, and then a perovskite layer is prepared on the surface of the modified layer. The modified layer is one or more in a group consisting of 2, 2' -bipyridine, 4, 4'-bipyridine, 1,10-phenanthroline and ethylenediamine tetraacetic acid. The method is easy to combine with the methods of introducing additives, mixing a solvent system and using an anti-solvent, a uniform film with a high coverage rate can be effectively obtained, the furtherimprovement of the efficiency of an inverted perovskite solar cell is helped, and the method has great significance to promote the commercialization process of perovskite solar cells.

Owner:GUANGDONG UNIV OF TECH

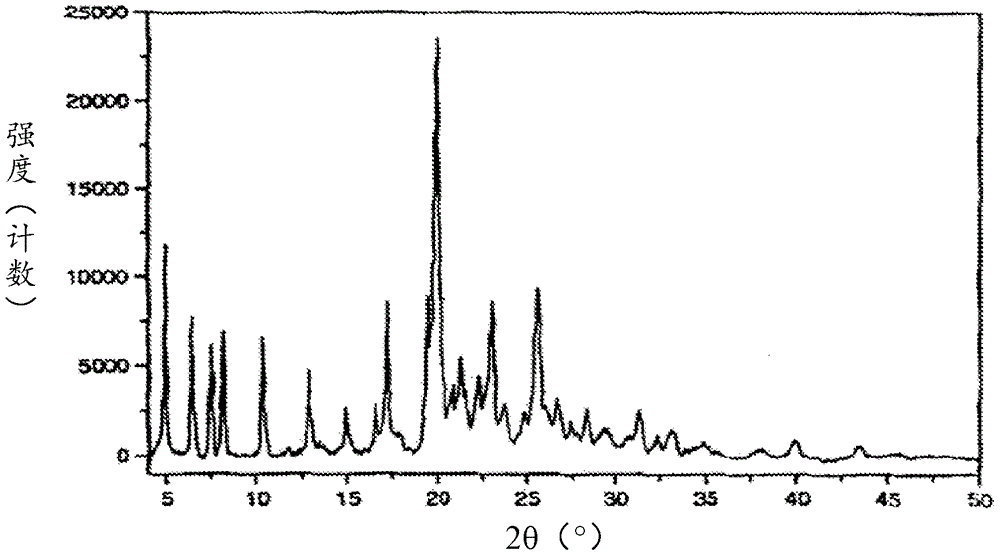

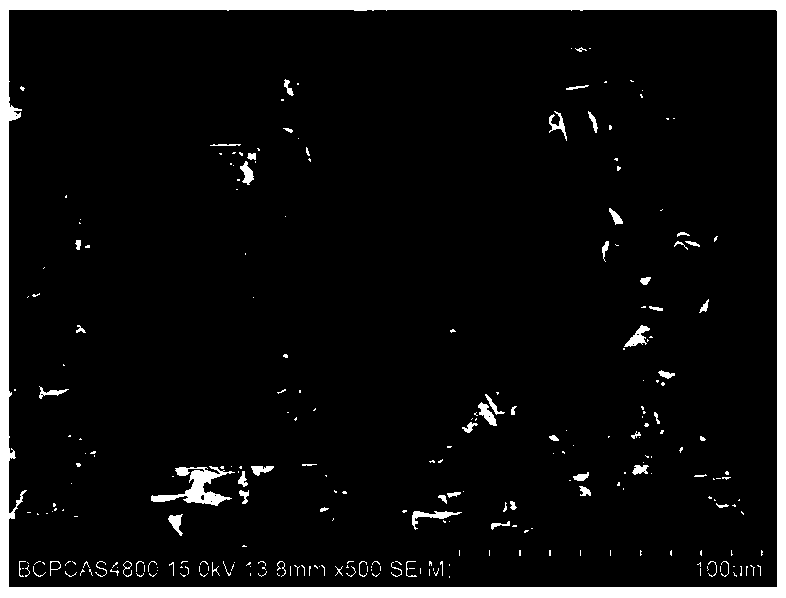

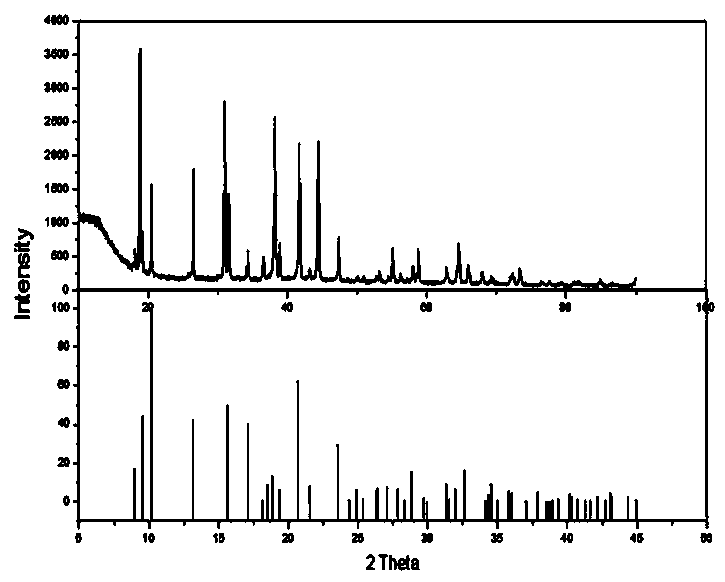

Method for preparing multi-stage pore SAPO-34 molecular sieve by mixing tetrahydrofuran with organic amine as template agent

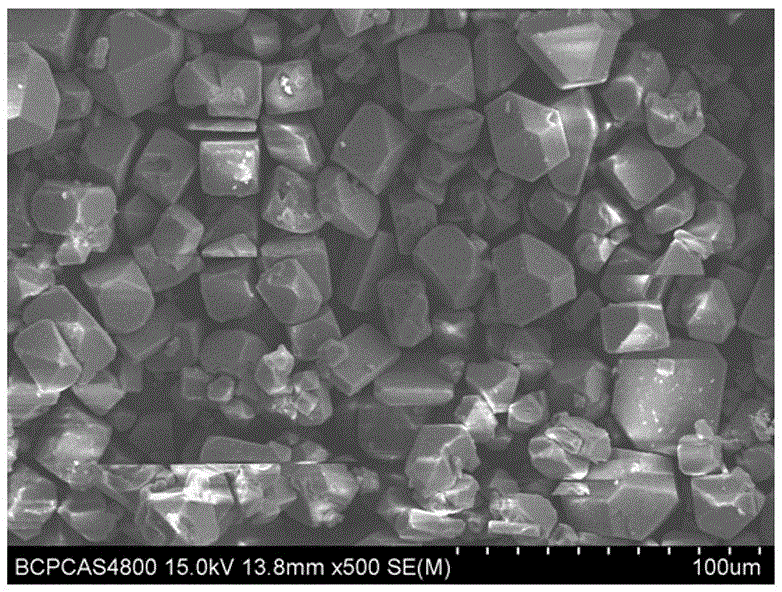

InactiveCN108298550AHigh solid phase yieldGood crystal morphologyMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesSolid phasesCrystal morphology

The invention discloses a method for preparing multi-stage pore SAPO-34 molecular sieve by mixing tetrahydrofuran with organic amine as a template agent. Firstly, the tetrahydrofuran and the organic amine are mixed as the mixed template agent, the template agent is added into deionized water and stirred sufficiently to form a mixed solution, then a silicon source and an aluminum source are sequentially added into the mixed solution and stirred for a while to form a homogeneous mixture, phosphoric acid is added dropwisely and stirred continuously until a uniform gel mixture is formed, the gel mixture is transferred to an autoclave, crystallized at a certain temperature for a while and then cooled at room temperature after completion of crystallization, and the solid phase product is washedwith deionized water, dried and then calcined at 580 DEG C in the air to obtain the SAPO-34 molecular sieve. The synthesized SAPO-34 molecular sieve is of a multi-stage pore structure, and has good crystal morphology, high solid phase yield and great significance for industrial application of the SAPO-34 molecular sieve.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

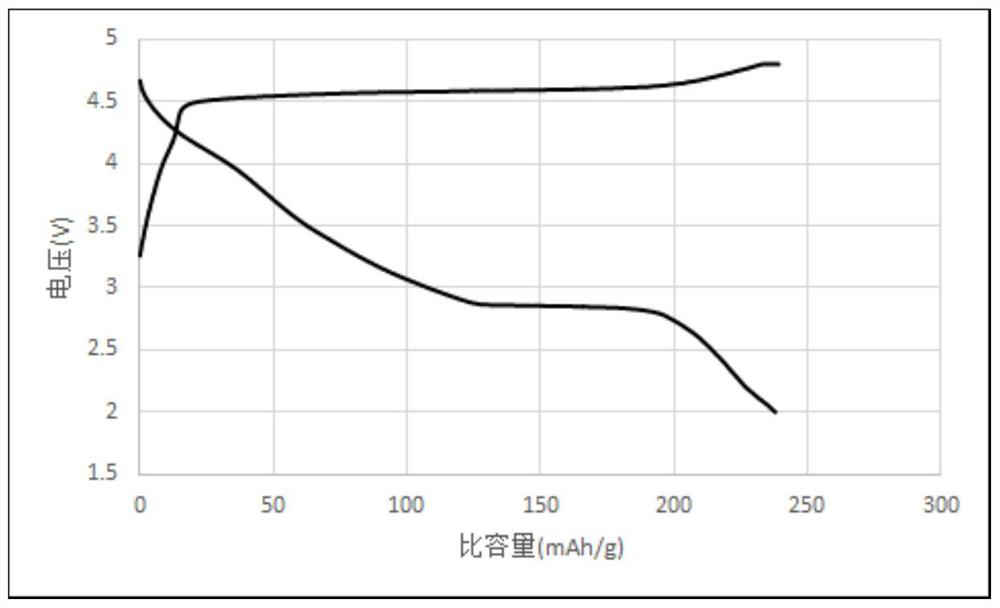

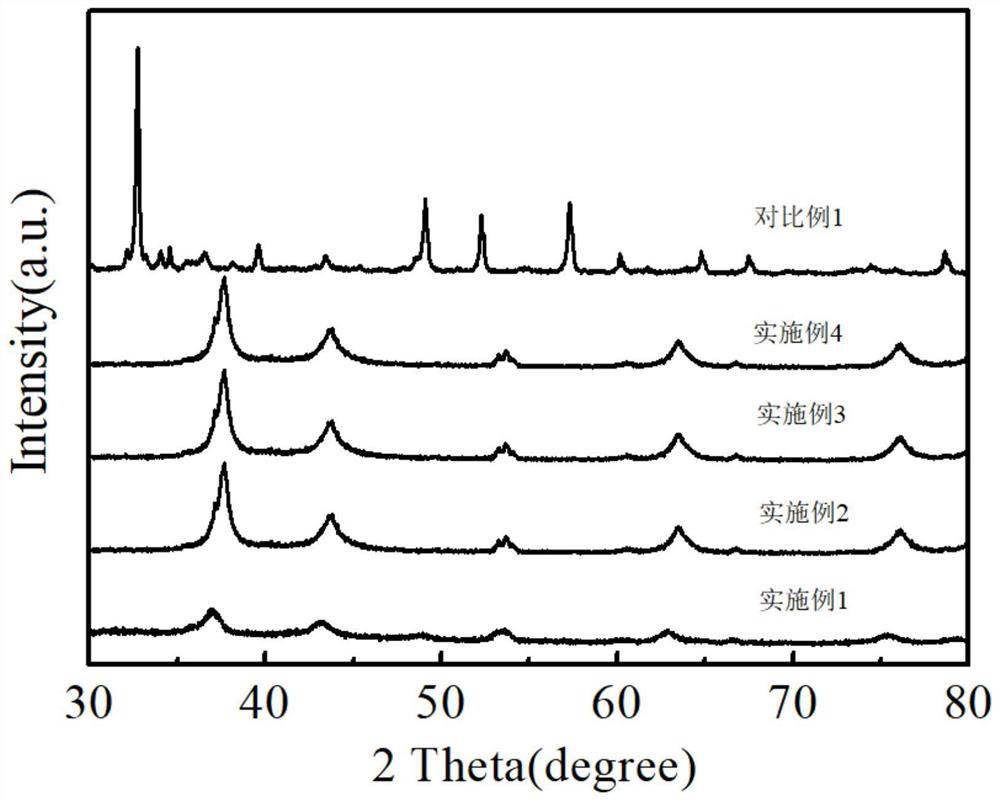

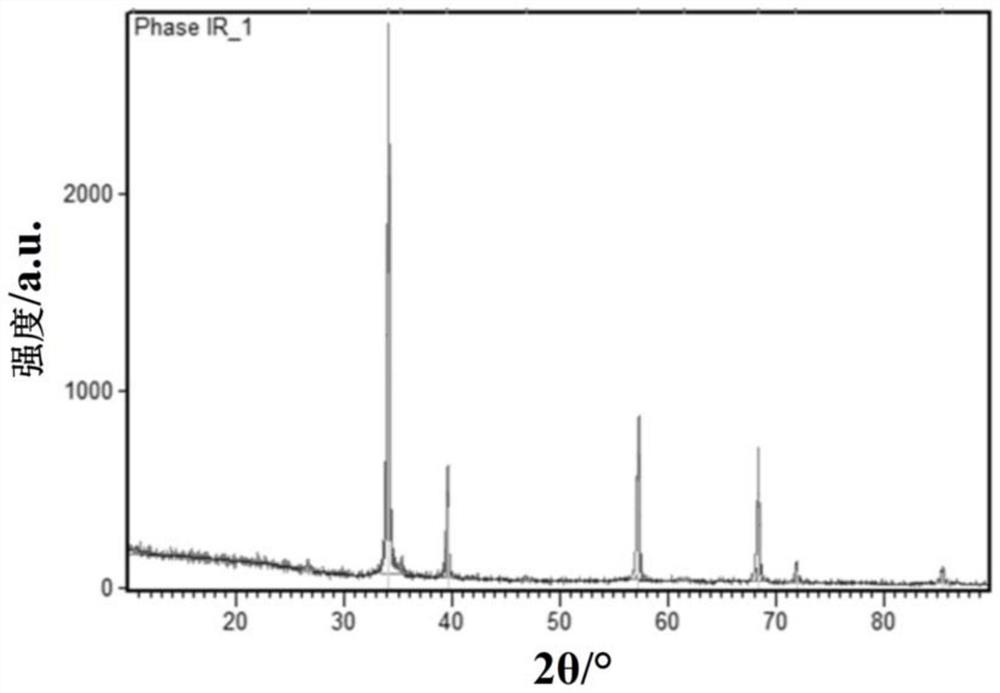

Positive electrode material and preparation method and application thereof

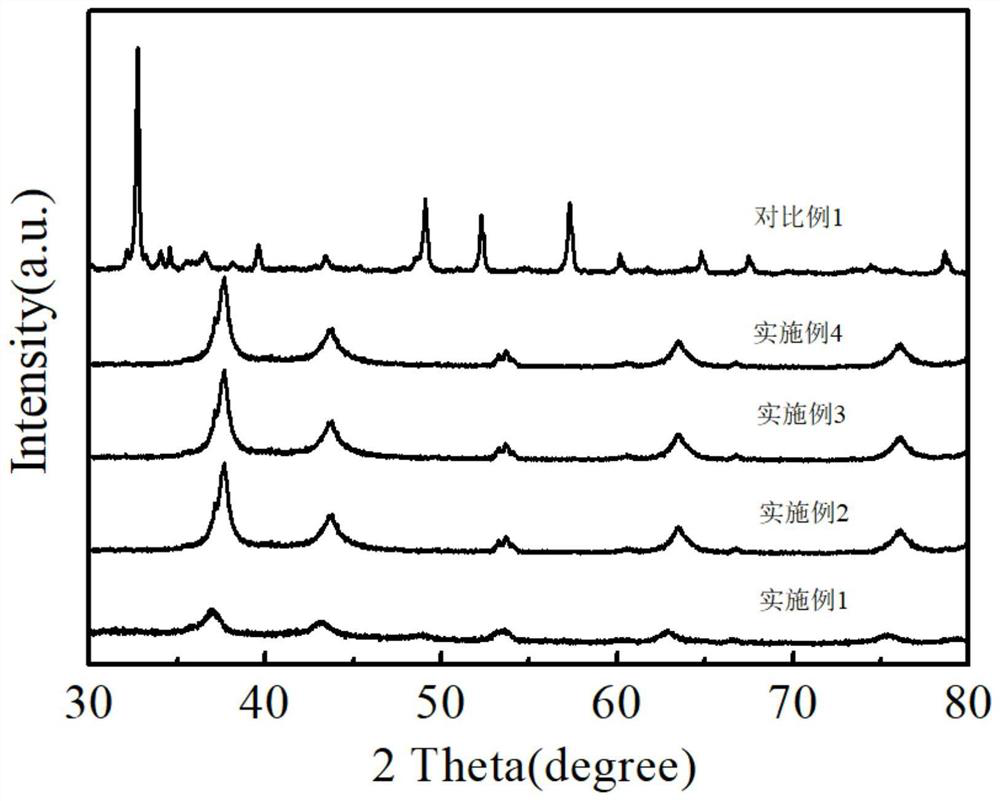

PendingCN113036118AUniform chemical compositionGood crystal morphologySecondary cellsPositive electrodesPhysical chemistryManganese

The invention provides a positive electrode material and a preparation method and application thereof. The chemical formula of the positive electrode material is LixMnyO2, x / y is greater than or equal to 0.9 and less than or equal to 1.6, x is greater than 0, and y is greater than 0. The preparation method comprises the following steps of (1) mixing a fused salt, a manganese salt and a first lithium salt, and carrying out primary sintering to obtain a base material, and (2) mixing the base material obtained in the step (1) with a second lithium salt, and carrying out secondary sintering to obtain the positive electrode material. In the step (2), the molar ratio of all the lithium elements to all the manganese elements is 0.9-1.6. The positive electrode material provided by the invention is free of cobalt and nickel, the cost is greatly reduced, relatively high capacity can still be maintained, and meanwhile, a molten salt heating method is adopted, so that the production efficiency is further improved on the basis of further reducing the cost.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

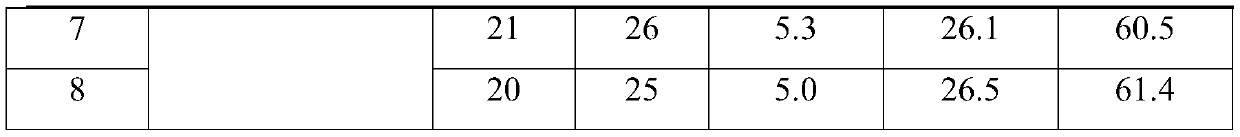

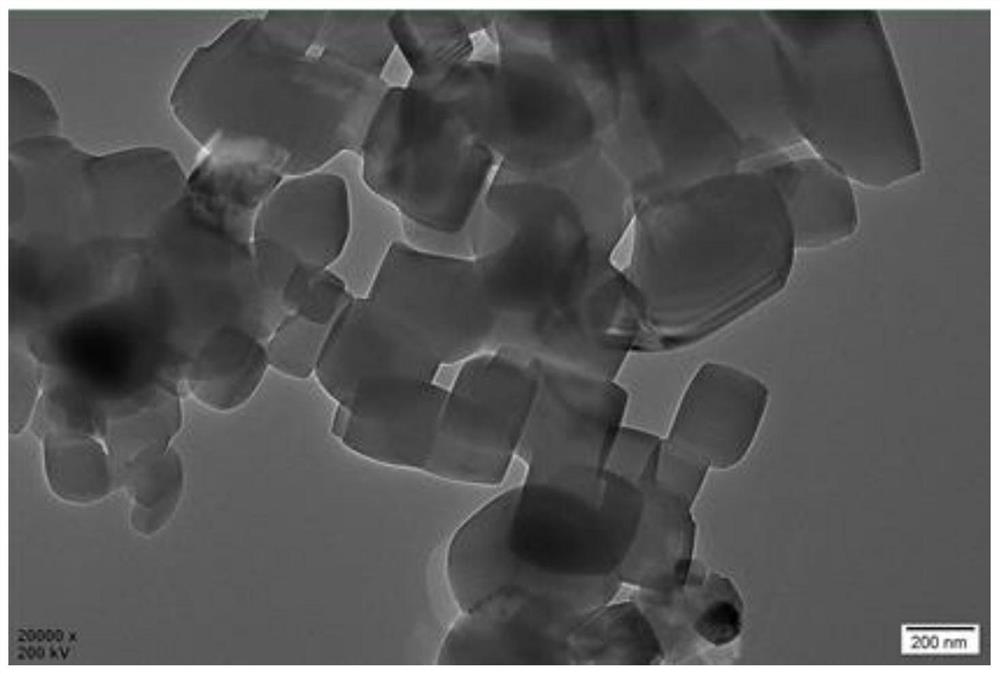

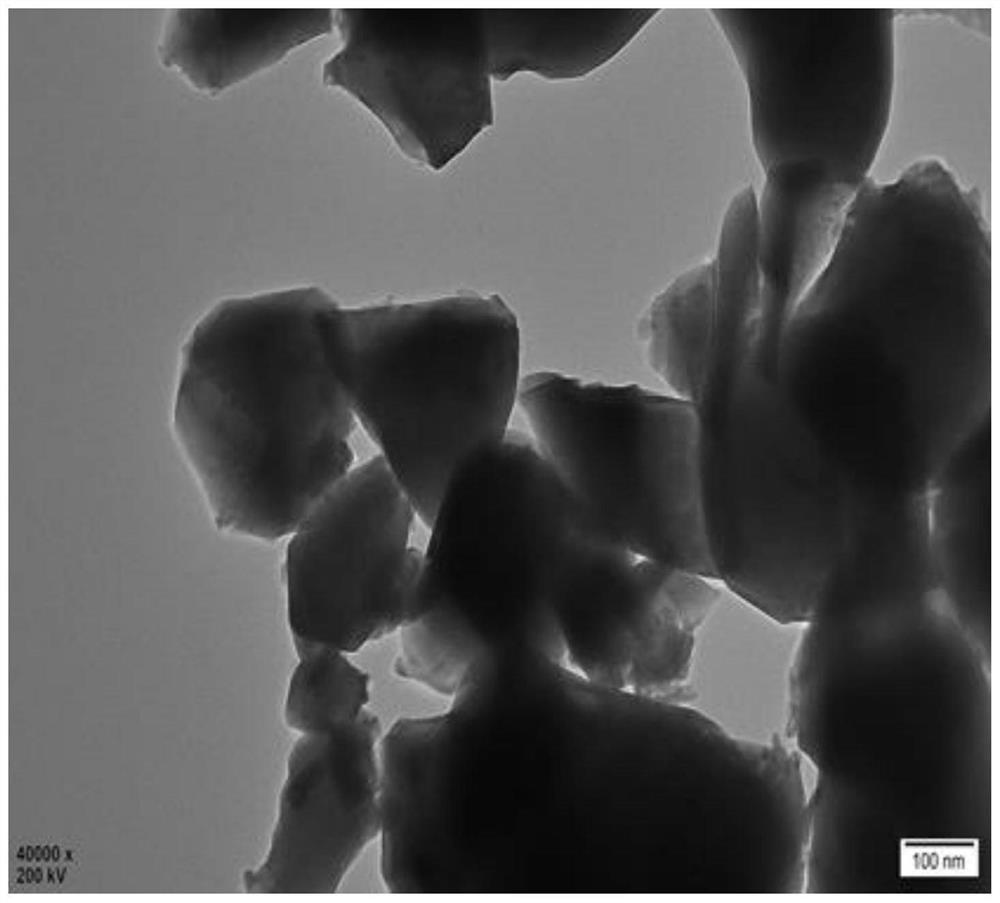

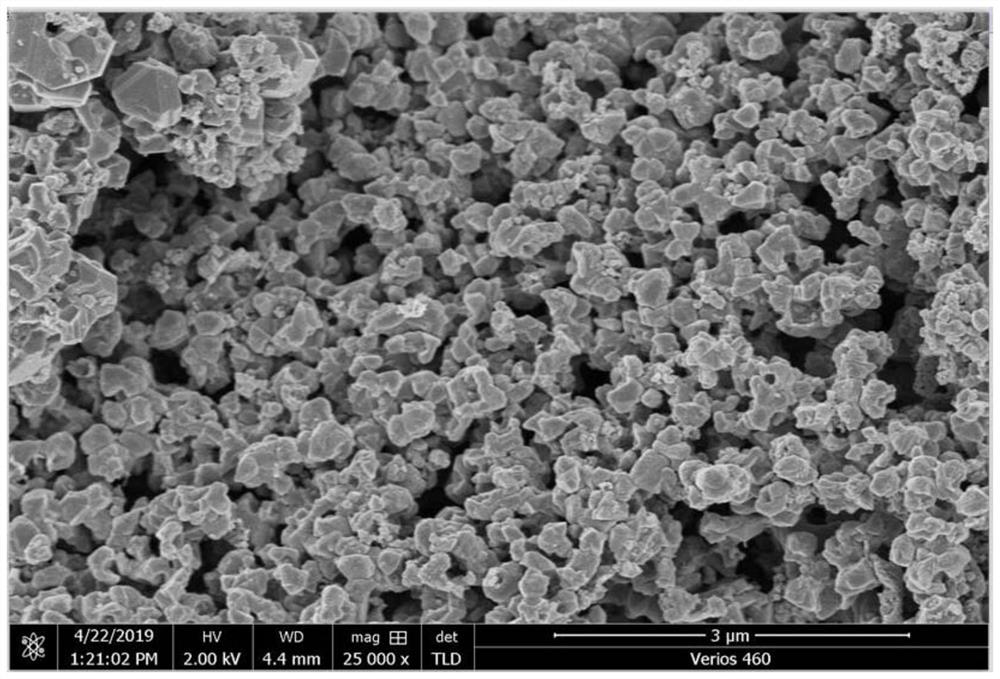

Preparation method and application of cubic molybdenum nitride

ActiveCN113321192AReduced growth rateReduce crystallizationNitrogen-metal/silicon/boron binary compoundsSecondary cellsFreeze-dryingNitrogen gas

The invention discloses a preparation method and application of cubic molybdenum nitride, and belongs to the field of lithium ion battery electrode materials. The preparation method comprises the following steps: S1, mixing an ethanol solution of urea, an ethanol solution of melamine and an ethanol solution of ammonium molybdate tetrahydrate, and stirring to obtain a mixed solution, wherein the mass ratio of ammonium molybdate tetrahydrate to urea to melamine in the mixed solution is (5-11): 100: (3-6); S2, aging the mixed solution at room temperature to form sol / gel, and freeze-drying to form a solid; S3, pre-sintering the obtained solid, and then carrying out heat treatment to obtain precursor powder; and S4, roasting the obtained precursor powder in a nitrogen atmosphere, and cooling to room temperature to obtain the molybdenum nitride electrode material. The nanoscale molybdenum nitride powder product is obtained through a simple process, has a cubic structure, is small in grain size and uniform in granularity, and has excellent cycle performance and relatively high specific capacity when being used as a lithium ion battery negative electrode material.

Owner:HUBEI ENG UNIV

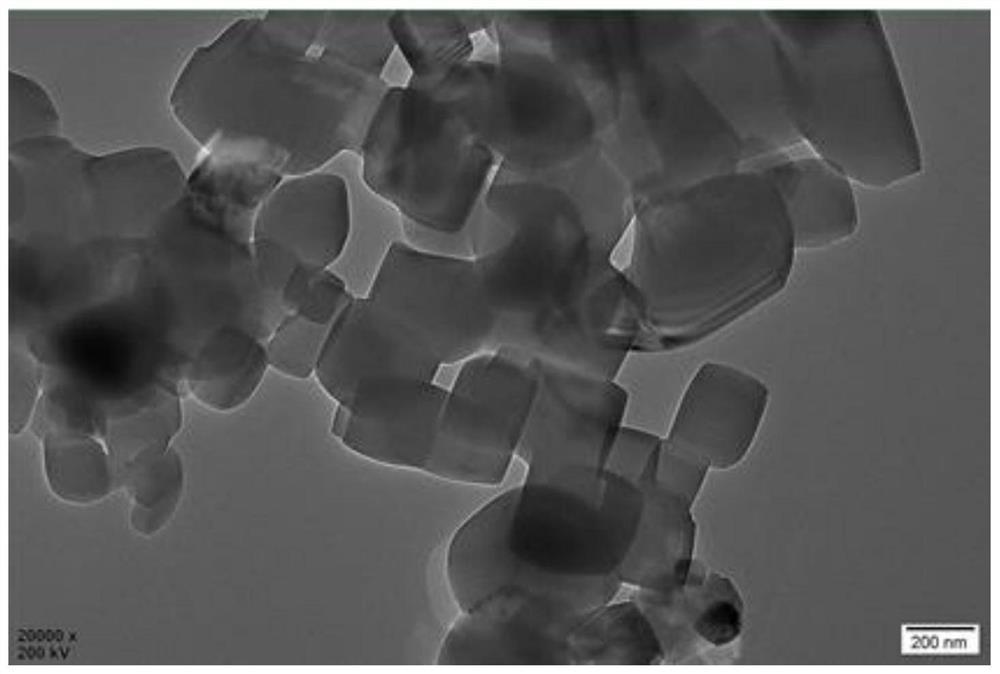

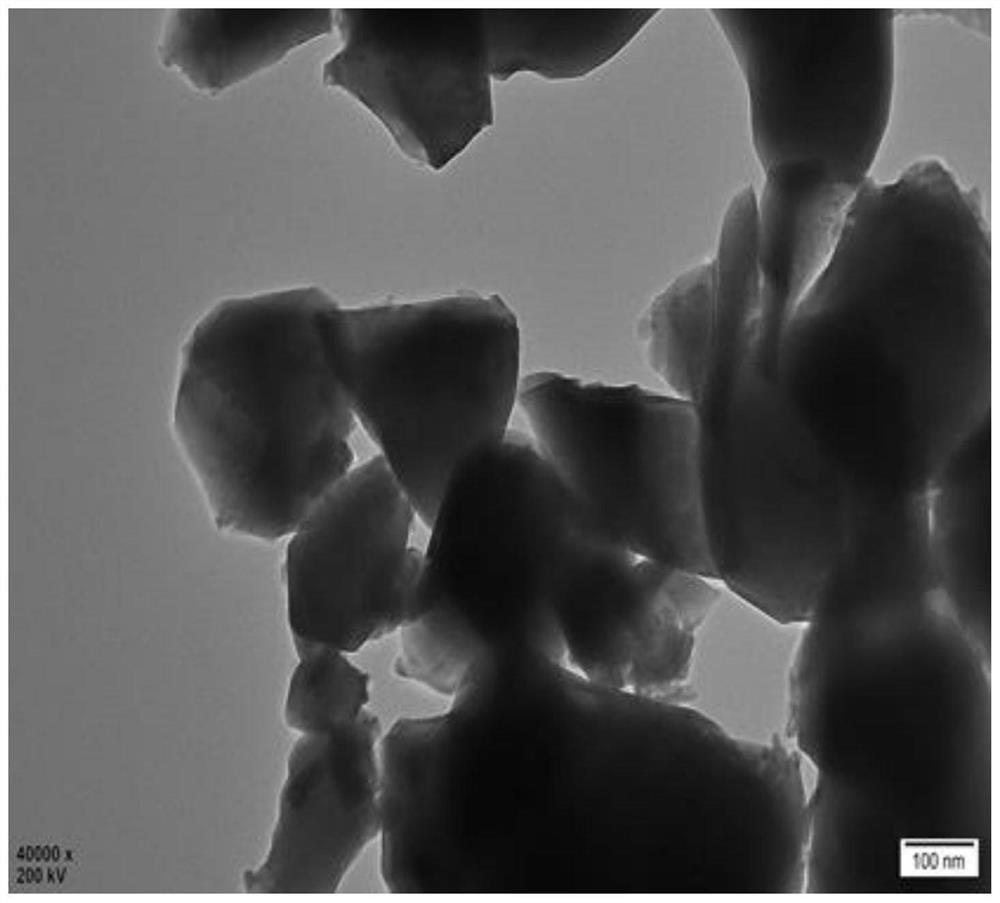

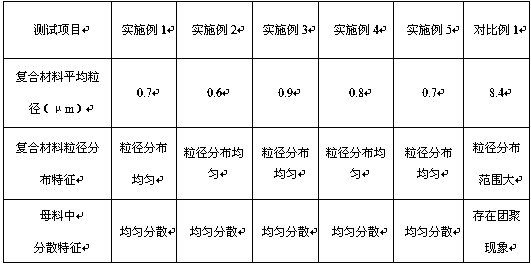

Preparation method of high dispersion barium sulfate composite material for plastic masterbatch

The invention discloses a preparation method of a high dispersion barium sulfate composite material for a plastic masterbatch. The preparation method comprises the following steps: a, impregnating barium sulfate by using a low-concentration titanium sulfate solution; b, mixing the impregnated barium sulfate, a dispersing agent with a urea solution and stirring, dropwise adding a high-concentrationtitanium sulfate solution and reacting to prepare nano-BaSO4 / TiO2 composite powder; c, carrying out ball milling on the composite powder, decontaminated water and carboxylic polybutadiene to obtain slurry; d, carrying out filter pressing and drying on the slurry to obtain a composite material coating BaSO4 / TiO2 with the carboxylic polybutadiene. According to the preparation method of the high dispersion barium sulfate composite material for the plastic masterbatch, disclosed by the invention, by utilizing good dispersion and weathering resistance of nanotitanium dioxide, the prepared BaSO4 / TiO2 composite powder has the advantages of smaller particle size, uniform particle size distribution and excellent anti-ultraviolet ability; the dispersion of the composite material in non-polar solvents is effectively improved; the prepared composite material has good dispersion and crystal appearance morphology, as well as good dispersion and processing property when being used in the plastic masterbatch.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for decomposing phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum

ActiveCN111533154AReduce manufacturing costTake advantage ofCalcium/strontium/barium sulfatesPhosphoric acidChemical industryO-Phosphoric Acid

The invention discloses a method for decomposing a phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum. The method comprises: decomposing phosphoriteby nitric acid, filtering out acid insoluble substances, partially neutralizing the acidolysis liquid, regulating and controlling the concentration of calcium ions in the acidolysis liquid, adding the acidolysis liquid into a crystallization tank containing a mixed solution of additional phosphoric acid and ammonium sulfate, controlling the reaction temperature to be 50-70 DEG C and the reactiontime to be 0.5-2 hours to firstly generate dihydrate gypsum, then, making the reaction slurry flow into a crystal transformation tank, and raising the temperature to 95 to 110 DEG C for reacting for aperiod of time so that an alpha-type high-strength gypsum product can be produced as a byproduct. According to the invention, the acidolysis liquid can be used for producing products such as fine phosphate, high-water-solubility phosphate fertilizer and the like, meanwhile, calcium resources in the acidolysis liquid are converted into an alpha high-strength gypsum product, solid waste phosphogypsum is changed into product phosphogypsum, environmental risks caused by the fact that a large amount of solid waste phosphogypsum is produced as a byproduct in the ammonium phosphate industry are eliminated, the phosphorus compound fertilizer industry is promoted to adjust the product structure, solid waste emission is reduced, and sustainable development of the phosphorus chemical industry is promoted.

Owner:GUIZHOU UNIV

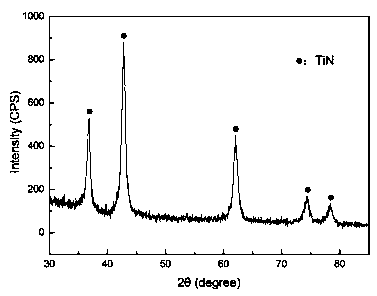

Titanium nitride powder based on low temperature liquid polymerization process and preparation method of titanium nitride powder

InactiveCN105502316AEasy to separateImprove liquidityNitrogen compoundsInorganic saltsTitanium nitride

The invention relates to titanium nitride powder based on a low temperature liquid polymerization process and a preparation method of the titanium nitride powder. According to the technical scheme, the method comprises the following steps: mixing metal magnesium powder, alkali metal inorganic salts and titanium dioxide powder according to a molar ratio of 1:(1.5-2.0):(0.25-0.50); or mixing metal magnesium powder, alkali metal inorganic salts and sodium titanate powder according to a molar ratio of 1:(1.5-2.0):(0.06-0.08); respectively maintaining the temperature of respectively mixed powder for 2-6 hours in a nitrogen atmosphere and under the condition of 900-1300 DEG C, and naturally cooling; adding the fired product into a hydrochloric acid solution for soaking for 5-6 hours, washing 3-5 times by using distilled water, and drying for 8-12 hours under the condition of 90-110 DEG C, so as to obtain the titanium nitride powder based on the low temperature liquid polymerization process. The titanium nitride powder disclosed by the invention has the characteristics of rich raw materials, low production cost and simplicity in industrial production. The titanium nitride powder prepared by the method is high in purity and excellent in morphology characteristics.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing high-strength gypsum from phosphogypsum

InactiveCN110040993AGood crystal morphologyStandard consistency requires little waterWater contentResource utilization

The invention provides a method for preparing high-strength gypsum from phosphogypsum, belonging to the technical field of building materials. The preparation method adopts a pressurized aqueous solution method and comprises the following steps: 1) phosphogypsum pretreatment, namely, taking a proper amount of the phosphogypsum, after adding tap water with a proper proportion for cleaning or washing with water for a plurality of times, adding quicklime for neutralization water washing for pretreatment until the pH value is neutral; 2) preparation of phosphogypsum slurry, namely, adding appropriate types and amounts of crystal transfer agents, and preparing the phosphogypsum slurry with appropriate water content; 3) autoclaved treatment, namely, autoclaving at an appropriate temperature (orpressure) for a certain period of time; and 4) drying and grinding of autoclaved materials. According to the invention, the high-strength gypsum with strength grades of alpha 25 and alpha 30 and whiteness of not less than 60 percent is prepared. Therefore, the preparation of the high-strength gypsum from the phosphogypsum solves the problem of massive accumulation of the phosphogypsum, develops the resource utilization of the phosphogypsum, but also save resources, improves the environment, and has important social and economic benefits.

Owner:CHINA THREE GORGES UNIV +1

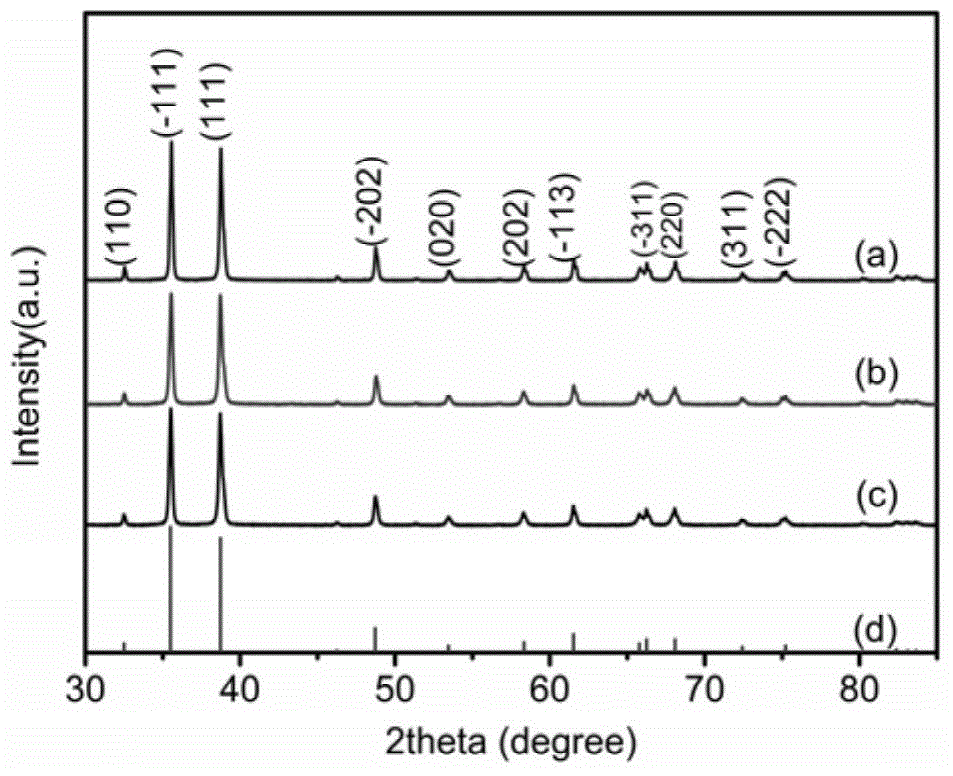

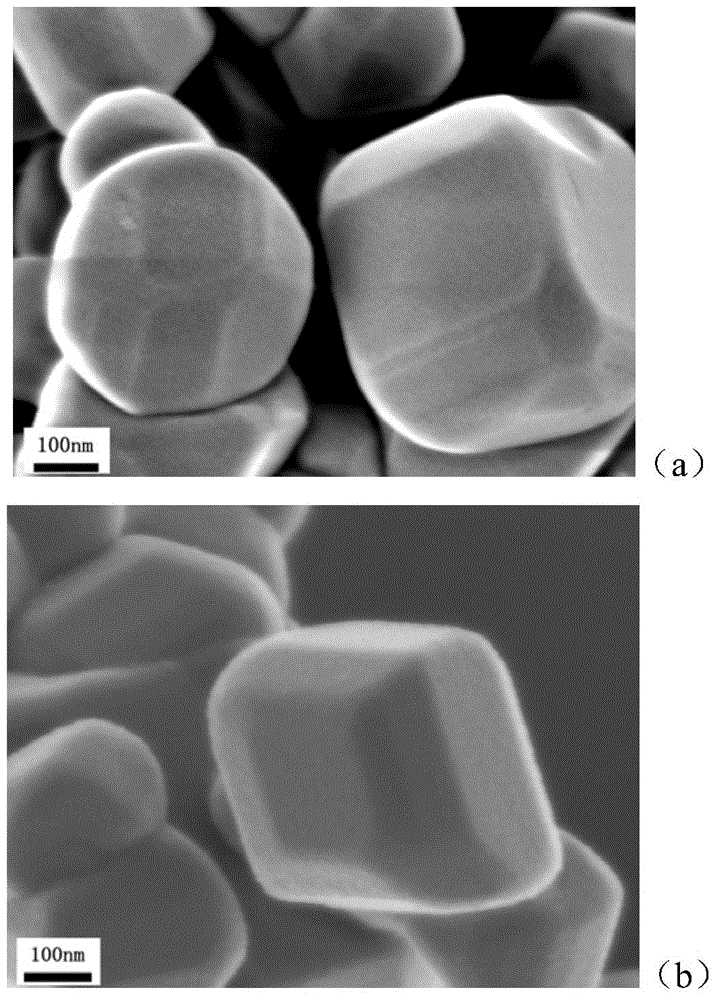

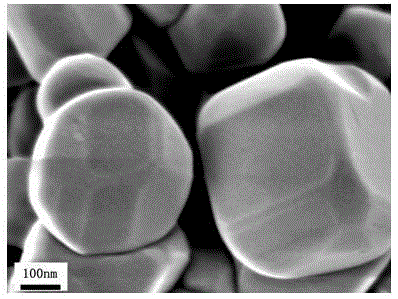

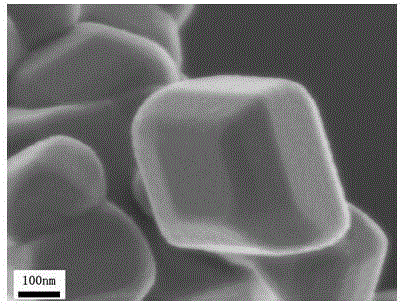

Preparation method of polyhedral nano oxide for catalyzing

ActiveCN104307521AIncrease the diffusion coefficientBlock associationMetal/metal-oxides/metal-hydroxide catalystsPotassiumCopper oxide

The invention relates to a preparation method of polyhedral nano oxide for catalyzing. The preparation method comprises the following steps: preparing nano polyhedral copper oxide powder by a salt melting method taking a potassium source and a sodium source as melted salt; dissolving copper salt into water to prepare a solution; dropping an alkali source into the solution until the pH of the solution is 6-8; putting the solution into a constant-temperature magnetic stirrer to be stirred at constant temperature of 60 DEG C; filtering and washing for two to three times after sediment is generated and putting the product into a drying oven to be dried; putting a dried precursor, sodium salt and potassium salt into a ball milling tank to be milled; drying the milled mixed solution and transferring the solution into a crucible to be calcined; then cooling in the air to room temperature; and filtering, washing and drying to prepare the nano polyhedral copper oxide powder. The preparation method has the advantages of low synthesis temperature, simplicity in operation, uniform chemical components of the synthesized powder, good crystal appearance and the like; and a Rhodamine B degrading experiment shows that compared with commodity nano copper oxide, the catalyzing performance is greatly improved.

Owner:上海泛翌新材料有限公司

Method for preparing red alumina powder

The invention relates to a method for preparing red aluminum oxide powder, relating to a method for preparing aluminum oxide powder to be added into the paint, characterized in that the preparing course in turn includes: a. adding fluoride and / or boride in 0.5%-2% into aluminum hydroxide, mixing, burning and then crushing the mixture into aluminum oxide powder; b. adding one or several ones of the colorizing agents: manganese oxide, iron oxide, copper oxide, and chrome oxide into the aluminum oxide powder, then adding in one of fluoride, and boride or their mixture to mix uniformly and then drying, burning 2-6 hours at 1050 deg.C-1550 deg.C, and grinding into the red aluminum oxide. The invention obtains the uniformly mixed particles of aluminum oxide and colorizing agents and fully uses the characters of solid phase reaction and gas phase reaction. And the prepared red aluminum oxide powder is uniform-colored, nontoxic and harmless, and has good crystal appearance.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS +1

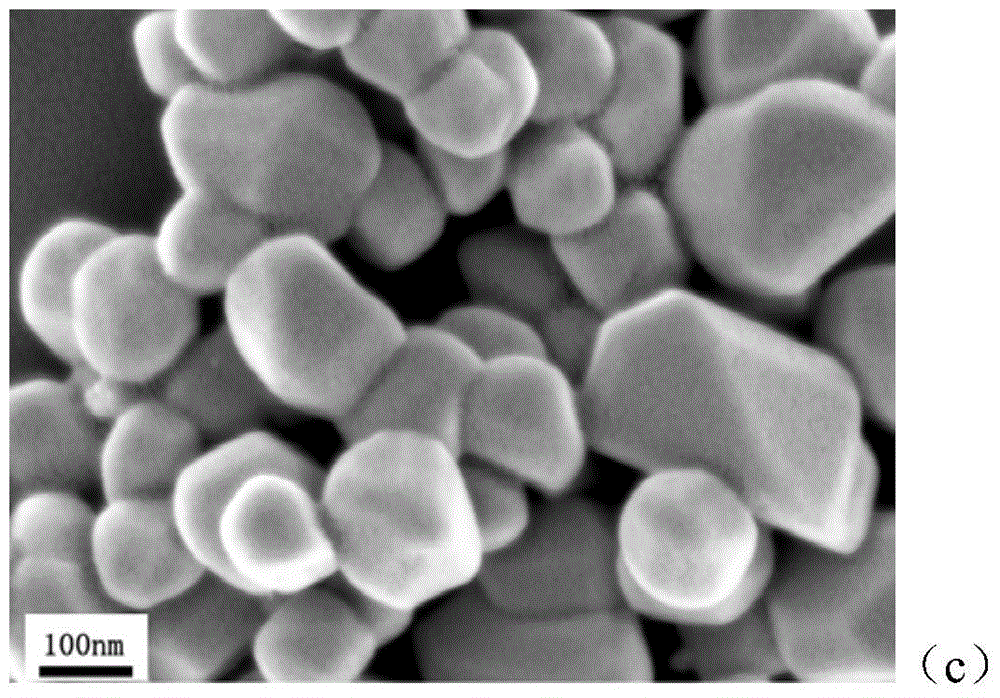

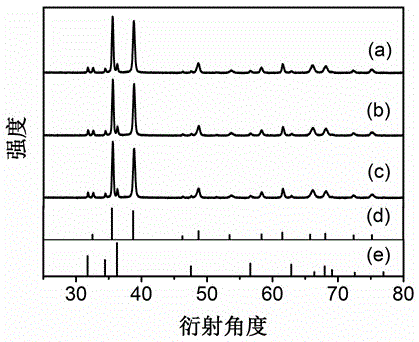

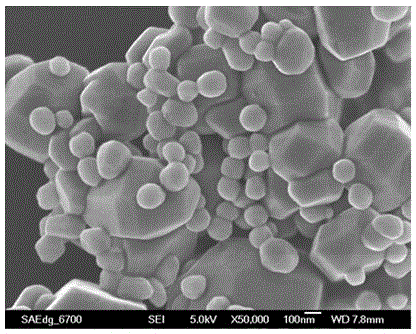

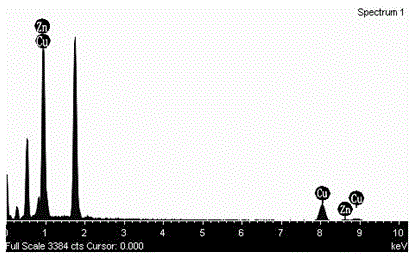

Preparation method of polyhedron nano copper oxide of loaded spherical zinc oxide nano particles

InactiveCN105013493ABlock associationReduce the degree of reunionWater contaminantsCatalyst activation/preparationCopper oxideChemical engineering

The invention discloses a preparation method of polyhedron nano copper oxide of loaded spherical zinc oxide nano particles, which is characterized in that a molten salt method is employed, calcining temperature is controlled at temperature of 450-650 DEG C for calcining to obtain the nano polyhedron copper oxide powder; then the nano polyhedron copper oxide powder is taken as a carrier, a solution evaporation method-calcining process is employed, under room temperature condition, the nano polyhedron copper oxide powder is dispersed to a zinc salt aqueous solution, and is stirred and evaporated, and is calcimined at temperature of 350-500 DEG C to obtain the polyhedron nano copper oxide of loaded spherical zinc oxide nano particles. The preparation method has the advantages of low synthesis temperature, simple operation, uniform chemical component of synthesis powder, good crystal morphology and uniform loading. Through rhodamine B degradation experiment, compared with single nano copper oxide, the catalysis performance is obviously increased.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

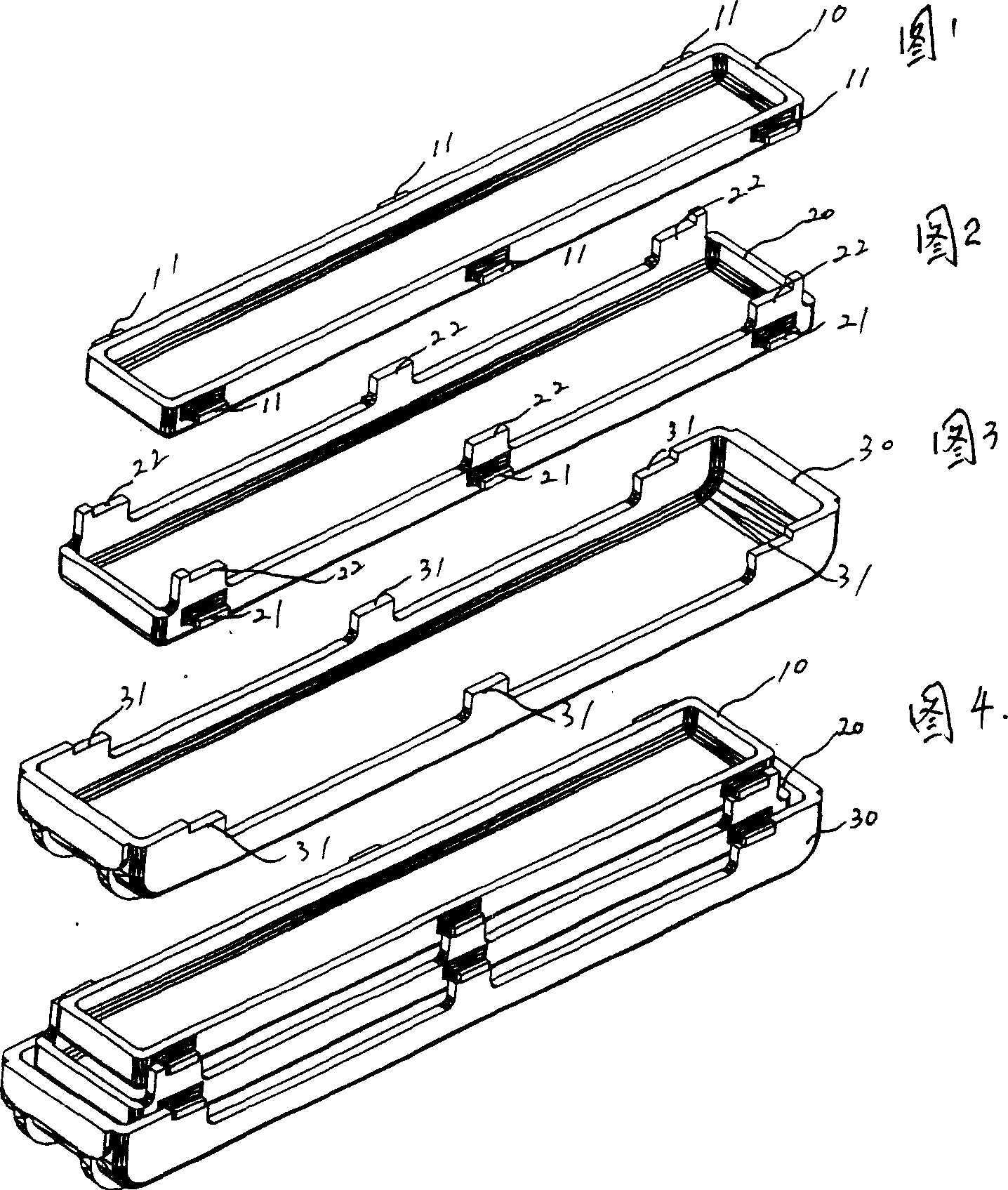

Technological method for preparing high purity nanometer grade powder

The technological process of preparing high purity nanometer level powder features that three-layer laminated boat with filled material is made to enter to the head of the multiple tube furnace, pass through the reduction area and discharge from the tail after cooling while hydrogen is made to enter to the furnace from the tail, react to the material in the reduction area and discharge through the head of the furnace to the hydrogen treating device. The present invention has specially designed three-layer laminated boat and controlled material thickness in the boat, and has been used in producing high purity tungsten powder of 30-80 nm size and with crystal form, excellent granularity distribution. Compared with available technology, the present invention has the advantage of lowered cost.

Owner:上海伟良企业发展有限公司

A kind of preparation method of silicon nitride or silicon nitride/silicon carbide composite powder

InactiveCN104496485BReduce manufacturing costSimple processNitrogen compoundsCarbide siliconInorganic salts

The present invention involves a method of preparing a silicon nainer or silicon nitride / silicon carbide composite powder.Technical solution 1: Two -~ 30wt%single silicon and 70 ~ 80WT%alkaline metal inorganic salt are used as the raw material, and then the raw material 0 ~ 3WT%catalyst is mixed, dry; then in the nitrogen atmosphere and 1200 ~ 1400 ℃In the conditions, heat preservation of 2 ~ 5h, natural cooling, washing, and silicon powder.Technical solution 2: 5 ~ 15WT%of the substances containing silicon sources, 70 ~ 80WT%alkaline metal inorganic salts, and 5 ~ 15WT%charcoal black as the raw material, plus the catalyst of 0 ~ 3WT%of the raw material, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing, mixing,Dry; then heat thermal insulation under the condition of nitrogen at the atmosphere of nitrogen and 1200 ~ 1400 ° C, naturally cool, wash, and obtain silicon nainer / silicon carbide composite powder.The present invention has the characteristics of low production costs, simple craftsmanship, and easy industrialized production; the prepared silicon nitride or silicon nitrite / silicon carbide composite powder is uniform, good crystal appearance, and high purity purity.

Owner:WUHAN UNIV OF SCI & TECH

Octagonal zeolite synthesizing method

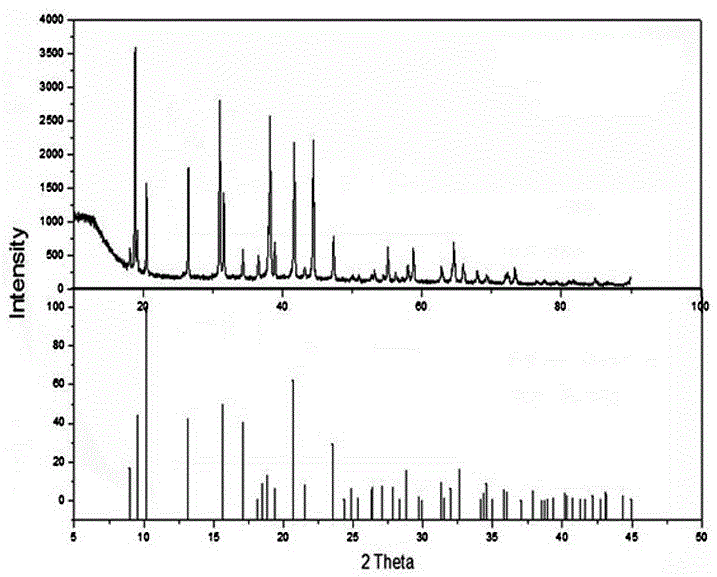

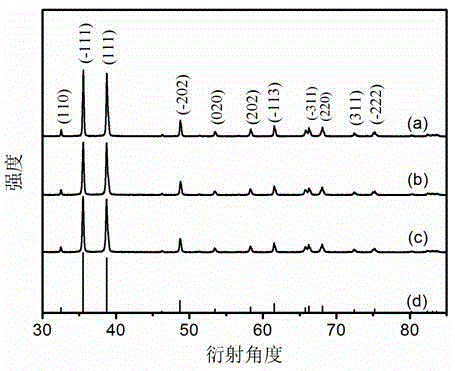

ActiveCN100431960CHigh ratio of silicon to aluminumHigh crystallinityFaujasite aluminosilicate zeoliteSiliconCrystallization

The invention discloses a synthesizing method of high-silicon aluminium rate octahedra zeolite, which is characterized by the following: synthesizing under alkaline condition to do hydrothermal crystallization; adopting low-molecular polyalcohol compound as moulding agent without zeolite seed; synthesizing the product in the hydrothermal condition directly.

Owner:CHINA PETROLEUM & CHEM CORP +1

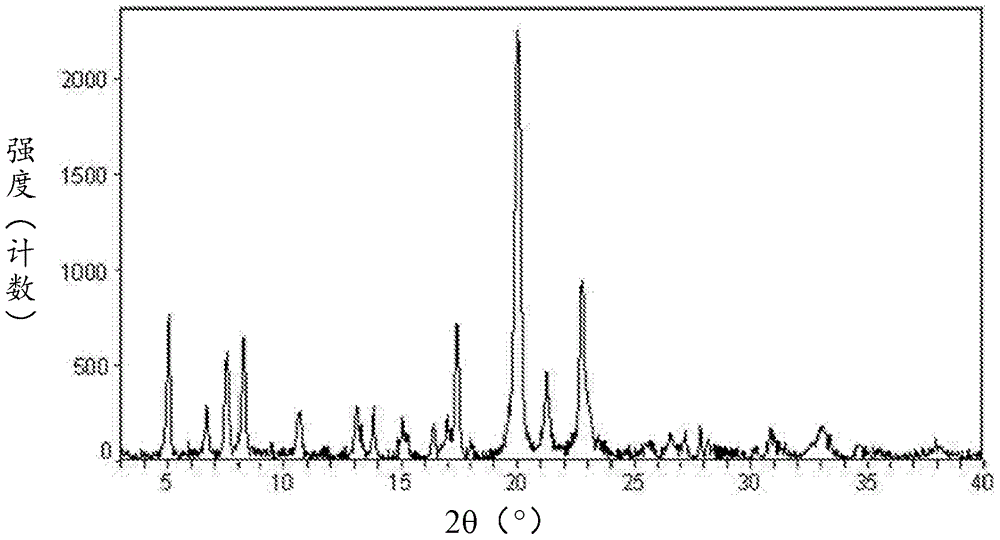

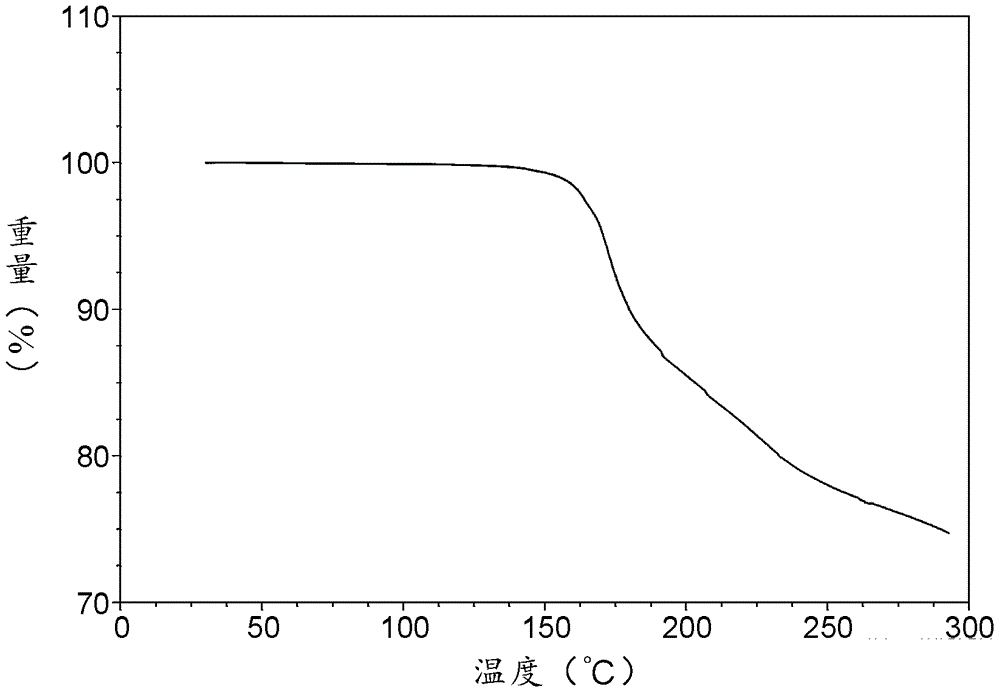

Acid addition salt of afatinib and its crystal form, its preparation method and pharmaceutical composition

ActiveCN104540820BGood application effectGood crystal morphologyOrganic active ingredientsOrganic chemistry methodsDrugAfatinib

The present invention relates to novel afatinib acid addition salts and crystal forms thereof. Compared with the prior art, the afatinib acid addition salts and crystal forms thereof of the present invention have one or more improved properties. The present invention also relates to a preparation method of the novel afatinib acid addition salts and crystal forms thereof, a pharmaceutical composition thereof, and the use thereof in preparing drugs for treating and / or preventing advanced non-small cell lung cancer and HER2-positive advanced breast cancer.

Owner:倪云

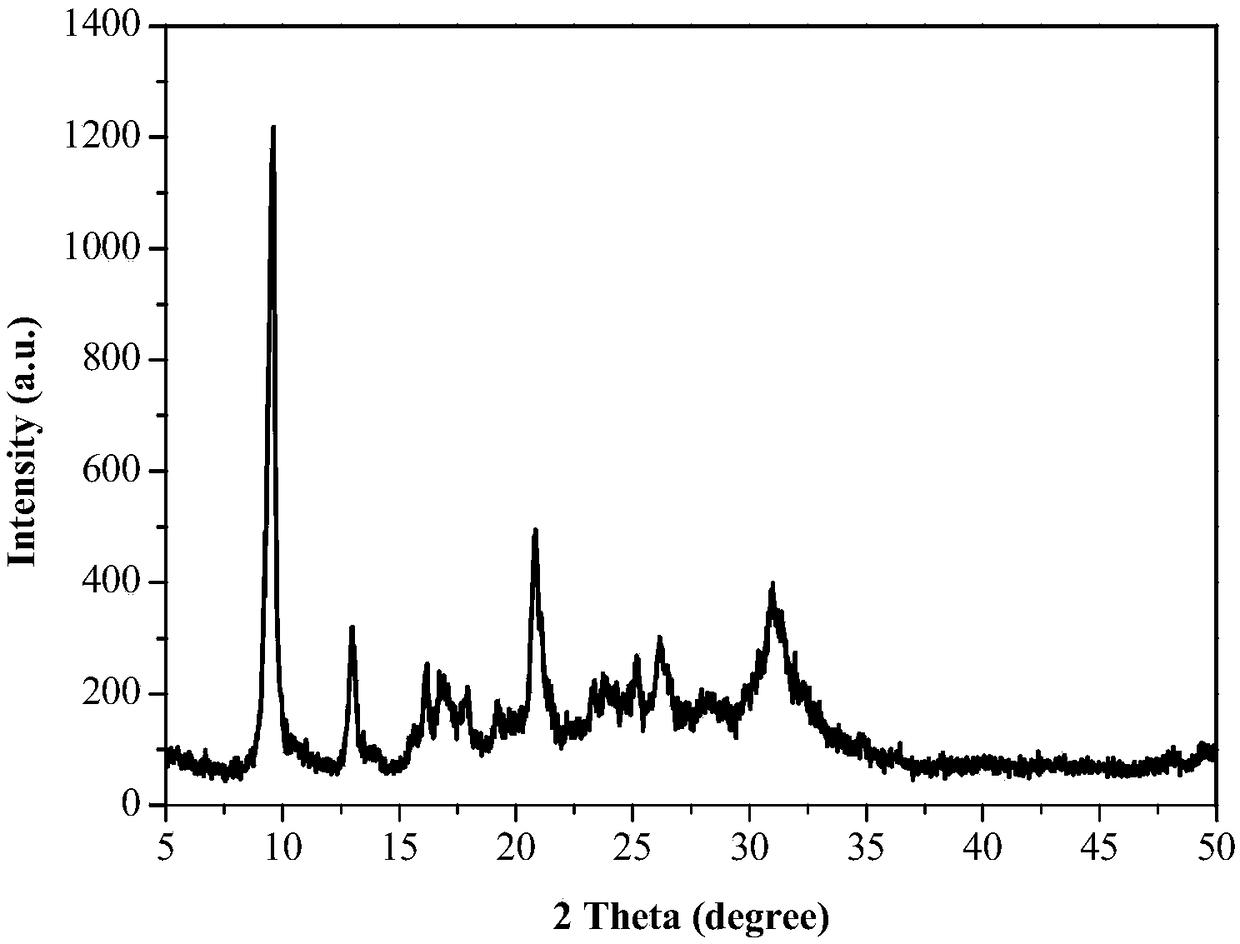

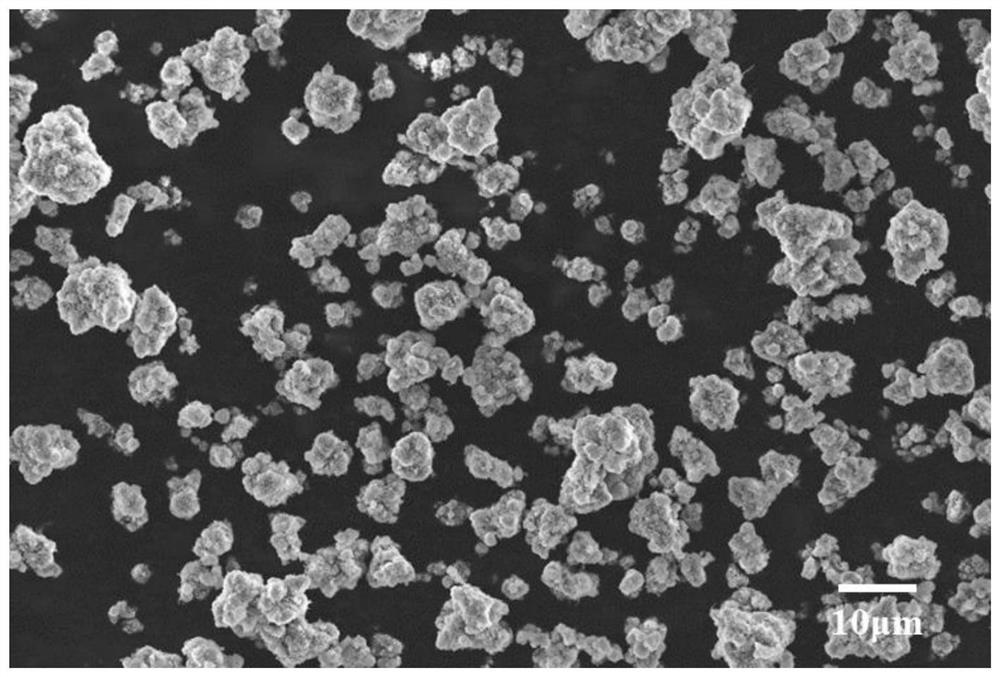

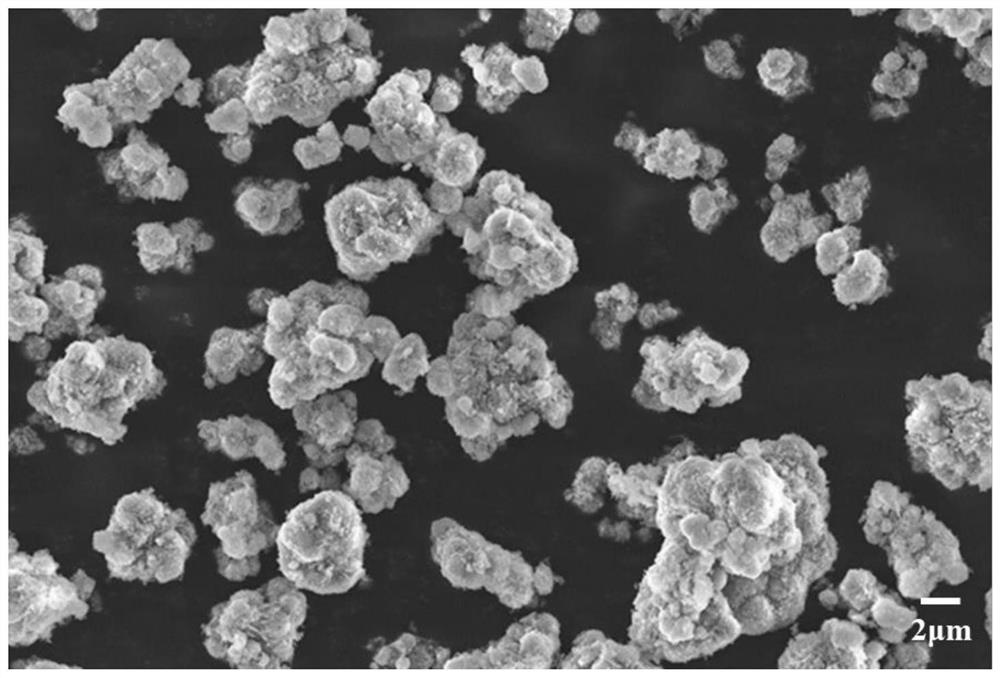

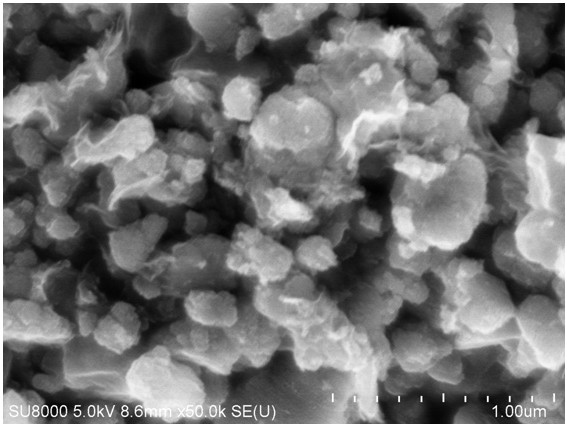

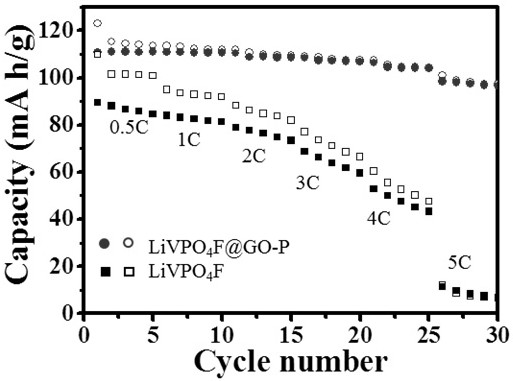

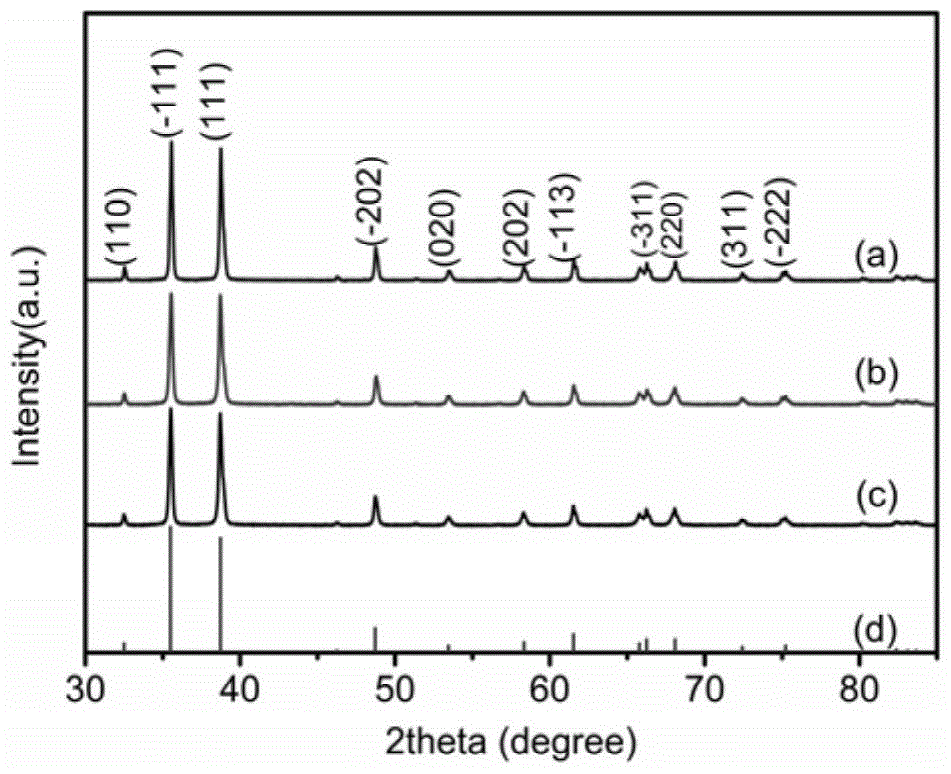

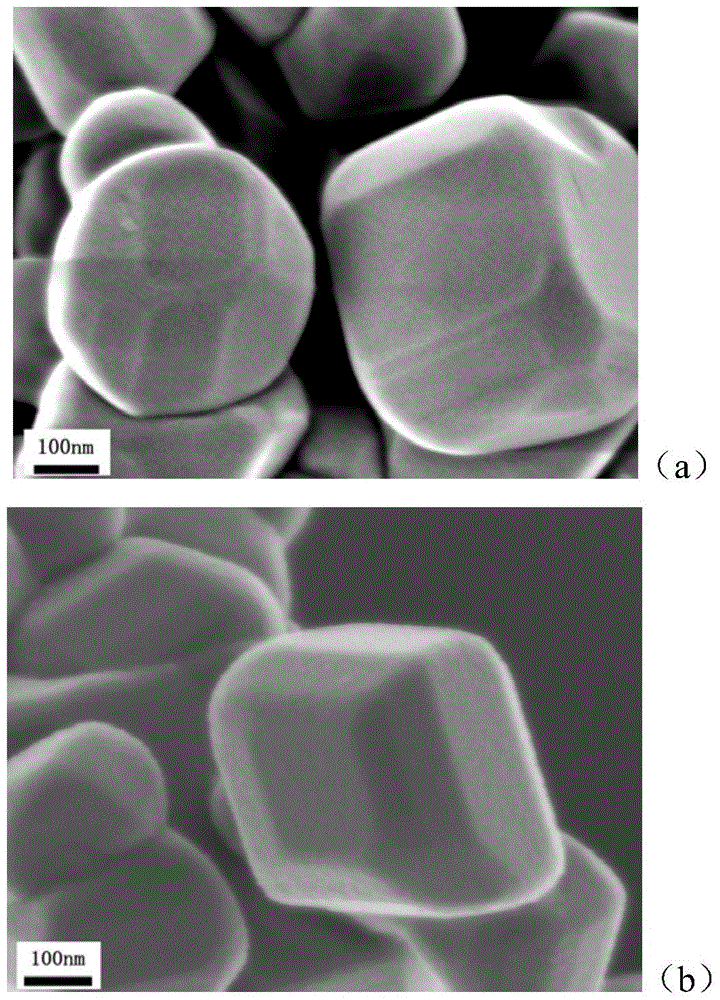

Aluminum-doped lithium vanadium fluorophosphate/phosphatized graphene oxide composite material and preparation method thereof, and application in lithium ion battery

PendingCN112018365AImprove conductivitySimple processSecondary cellsPositive electrodesGraphene coatingFreeze-drying

The invention discloses an aluminum-doped lithium vanadium fluorophosphate / phosphatized graphene oxide composite material and a preparation method thereof, and application in a lithium ion battery. The preparation method adopts a step-by-step process and comprises the following steps: (1) preparing a lithium vanadium phosphate / graphene composite material precursor by a microwave solvothermal method; (2) preparing an aluminum-doped lithium vanadium fluorophosphate / phosphatized graphene oxide composite material by a molten salt method; and (3) washing the sample, and carrying out freeze drying to obtain the pure-phase aluminum-doped lithium vanadium fluorophosphate / phosphatized graphene oxide composite material. According to the invention, the composite material can be obtained through one-time sintering, the used process is simple, the sample purity is high, graphene coating is uniform, the ionic and electronic conductivity of the composite material is obviously improved, and the assembled lithium ion battery has excellent electrochemical performance.

Owner:福建巨电新能源股份有限公司

A method for preparing α-type high-strength gypsum from phosphogypsum

The invention relates to a method for preparing alpha-type high-strength gypsum from phosphogypsum, belonging to the technical field of building materials. The method for preparing alpha-type high-strength gypsum from phosphogypsum is characterized by employing a semi-liquid-phase process and comprising the following steps: 1) blending phosphogypsum with quicklime with an amount identical to the sum of P2O5 and F in the phosphogypsum so as to neutralize the phosphogypsum and then carrying out aging for 1 d ; 2) weighing, on the basis of the total mass of the phosphogypsum, 0.01-0.5% of ternary organic acid and 0.5-2% of hypervalent sulfate, mixing the ternary organic acid and the hypervalent sulfate, and dissolving the obtained mixture in water with a temperature of 80-90 DEG C so as to prepare a composite crystal-type control agent; 3) adding the composite crystal-type control agent and water in a solid-liquid ratio of 4: 1 to 2: 1 into the neutralized phosphogypsum so as to form thick slurry; and 4) spreading the prepared slurry in an autoclave in layers, each layer being 5-15 mm thick, carrying out constant-temperature treatment at 120-150 DEG C for 3-6h, and then carrying out drying and ball-milling so as to obtain alpha-type high-strength gypsum powder. With the method in the invention, the prepared alpha-type high-strength gypsum is in the form of a short-column-like crystal with stable quality, and has 2-hour flexural strength of 4.9 MPa and drying compressive strength of 32.3 MPa; and obvious social, environmental and economic benefits are obtained.

Owner:湖北远固新型建材科技股份有限公司

A kind of preparation method of polyhedral nano-oxide for catalysis

ActiveCN104307521BIncrease the diffusion coefficientBlock associationMetal/metal-oxides/metal-hydroxide catalystsPotassiumCopper oxide

The present invention relates to a method for preparing a catalytic polyhedral nano oxide, were prepared to give a powder of copper oxide nano polyhedral sodium source and potassium source is a molten salt Method molten salt, copper salt dissolved in water into a solution configured to alkaline source added dropwise until the pH of the solution between 6 and 8, the solution was put in a constant temperature 60 deg.] C temperature with a magnetic stirrer was stirred until a precipitate after filtration was washed generate two to three times, dried in an oven ; dried precursor with sodium and potassium salts together into a ball mill jar milling; milling the dried mixture is transferred into the crucible is calcined, and then cooled in air to room temperature, filtered, washed, dried, preparation to obtain nano-copper oxide powder polyhedral shape. Preparation process of the invention has a lower synthesis temperature, simple, uniform powder synthetic chemical components, good crystal morphology, etc., rhodamine B experiments showed degraded, compared to copper oxide nano goods, a substantial catalytic performance improve.

Owner:上海泛翌新材料有限公司

Process for recovering zinc from hot-dip coating zinc ash

InactiveCN101979684BReduce energy consumptionHigh purityProcess efficiency improvementBound waterFerrosilicon

The invention relates to a process for recovering zinc from hot-dip coating zinc ash. The process comprises the following steps of: separating the hot-dip coating zinc ash after dry grinding and screening to obtain an oversize product and an undersize product; removing bound water and a small amount of zinc chloride from the oversize product under the condition that the temperature is between 400and 500 DEG C and the vacuum degree is 10 to 50 Pa; performing vacuum distillation on the oversize product under the condition that the temperature is between 650 and 800 DEG C and the vacuum degree is 10 to 30 Pa to obtain zinc; and performing alkali cleaning on the undersize product to remove chlorine, and then performing vacuum thermal reduction on the undersize product to obtain the zinc fromzinc oxide by using ferrosilicon as a reducing agent and calcium oxide as a slagging agent under the condition that the vacuum degree is 10 to 30 Pa and the temperature is between 1,050 and 1,200 DEGC. The process has a high recovery rate for recovering the zinc from the hot-dip coating zinc ash, and the obtained zinc has a good crystallized shape.

Owner:CENT SOUTH UNIV

A kind of high temperature and high humidity resistant fluoride red phosphor and preparation method thereof

ActiveCN106479485BPromote crystallizationGood dispersionLuminescent compositionsPolyethylene glycolSolid particle

The invention provides a high-temperature-resistant and high-humidity-resistant fluoride red fluorescent powder and a preparation method thereof. The fluorescent powder has a general chemical formula of KmAnM1-xF6: xMn<4+>. In the general chemical formula, A is one or two selected from the group consisting of Cu, Ba and Zn; M is at least one selected from the group consisting of Ti, Si and Ge; m + 2n are equal to 2; n is no less than 0.05 and no more than 0.2; m is no less than 1.6 and no more than 1.9; x is more than 0 and less than 0.2; and the surface of the fluorescent powder is coated with a mixture of potassium silicate, carboxymethyl cellulose sodium and polyethylene glycol. The fluorescent powder provided by the invention can be effectively excited by light with the excitation wavelength being in a range of 300 to 500 nm, so red light with a peak wavelength of 610 to 650 nm and a half-peak breadth of only 2 to 9 nm is generated, and high color purity is obtained. The preparation method provided by the invention has simple flow, can prepare target products at low temperature and under normal pressure, and facilitates to large-scale industrial production; and a special coating technology is adopted in the invention, and a coating reagent is utilized to change the surface state of fluorescent powder particles, so the problem of agglomeration of solid particles can be effectively solved, and a fluorescent powder product with good dispersion properties and high-temperature-resistant and high-humidity-resistant performances can be obtained.

Owner:HEBEI LIFU CHEM TECH

A kind of preparation method and application of cubic molybdenum nitride

ActiveCN113321192BReduced growth rateReduce crystallizationNitrogen-metal/silicon/boron binary compoundsSecondary cellsElectrical batteryFreeze-drying

The invention discloses a preparation method and application of cubic molybdenum nitride, belonging to the field of lithium-ion battery electrode materials. The preparation method is as follows: S1, the ethanol solution of urea, the ethanol solution of melamine and ammonium molybdate tetrahydrate The ethanol solution is mixed, stirred to obtain a mixed solution; the mass ratio of ammonium molybdate tetrahydrate, urea, and melamine in the mixed solution is 5-11:100:3-6; S2, aging the mixed solution at room temperature, Forming a sol / gel, then freeze-drying to form a solid; S3, pre-calcining the obtained solid, and then performing heat treatment to obtain a precursor powder; S4, roasting the obtained precursor powder under a nitrogen atmosphere, After cooling to room temperature, the molybdenum nitride electrode material is obtained; the present invention obtains nano-scale molybdenum nitride powder products through a simple process. Excellent cycle performance and high specific capacity.

Owner:HUBEI ENG UNIV

A kind of preparation method of m-site doped vanadium series mxene

ActiveCN111634914BImprove liquid phase stripping abilityHigh purityOxy/sulfo carbidesAluminium powderMolten salt

Owner:西安科多多信息技术有限公司

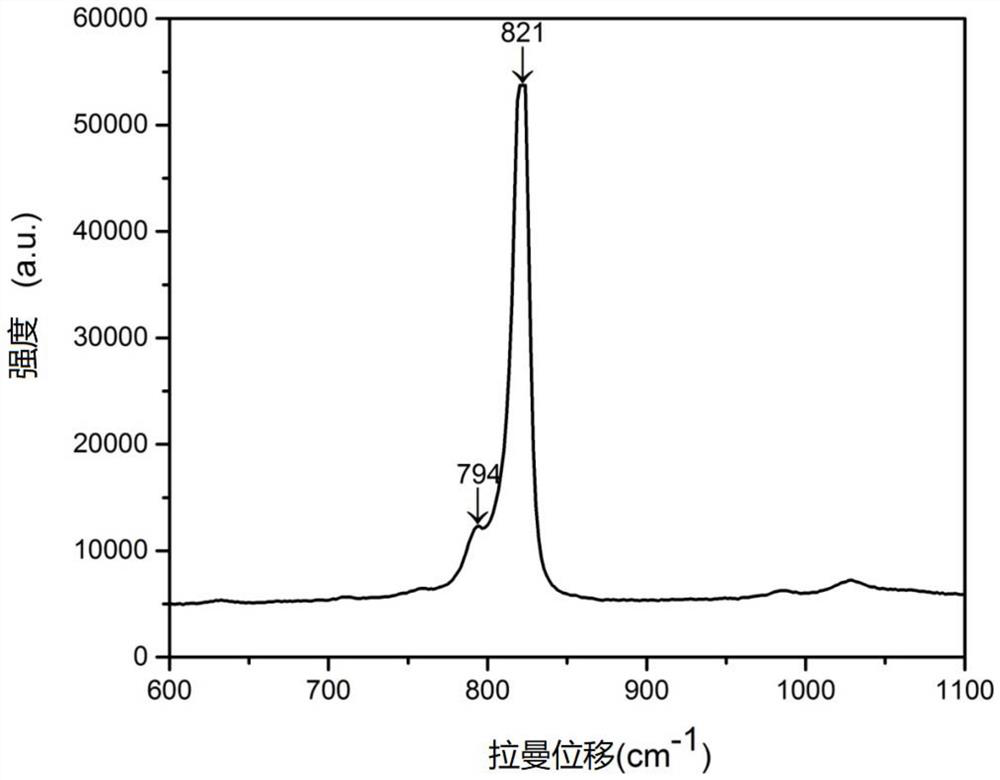

A kind of method for preparing boron phosphide with high thermal conductivity by molten salt method

ActiveCN110723740BIncreased diffusion rateReduce the temperatureHeat-exchange elementsBoron compoundsCrystal morphologyCrucible

The invention discloses a method for preparing boron phosphide with high thermal conductivity by a molten salt method; step 1: cleaning the crucible, performing ultrasonic treatment on the crucible and drying it for standby; mixing magnesium powder, boron phosphate and molten salt medium evenly, and placing the crucible in the crucible ; Step 2: Put the crucible into the reaction furnace, pass through the protective gas to raise the temperature to 750°C-850°C and keep it warm for 1h; Step 3: Soak the sample obtained in Step 2 with concentrated hydrochloric acid at room temperature, and heat it in a water bath heat preservation, then wash with deionized water to neutrality, and obtain BP after drying; this method has the advantages of simple process, low synthesis temperature, short heat preservation time, good crystal morphology of synthesized BP powder, and high phase purity; The preparation method is easy to operate, does not require complex process conditions, the process is relatively simple and safe, the cycle is short, and the boron phosphide produced has good quality and high yield.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method of nano polyhedral copper oxide powder for catalysis

InactiveCN104477966BIncrease the diffusion coefficientPromote growthMaterial nanotechnologyCopper oxides/halidesCopper oxideSaline solutions

The present invention discloses a method of catalytic nano-noodle-sized copper powder. It is about to dissolve copper salt in water, with a copper saline solution with a concentration of 0.5 mol / L.The control temperature of the copper saline solution with a pH of 6-8 is 60 ° C, and the speed is 450R / min to stir 1.5h. After the sedimentation is generated, the filter cake is washed 2-3 times with exfoliating cake, and then controlled by controlling, and then controlled.The temperature is dry at 60 ° C to get the front -drive body; then put the sodium salt, potassium salt and the front -wheel drive in the ball mill for ball grinding.Burning for 450-650 ° C, and then cooled to room temperature with the furnace, that is, the catalytic catalytic with a uniform chemical component and a good crystal appearance is obtained.The preparation method has the advantages of low synthetic temperature, simple operation, and other advantages.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com