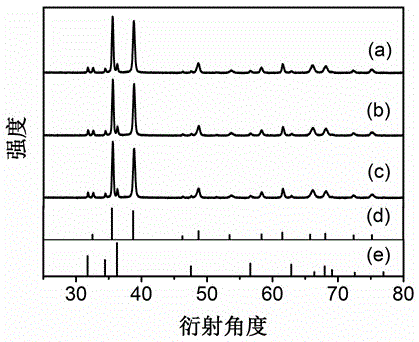

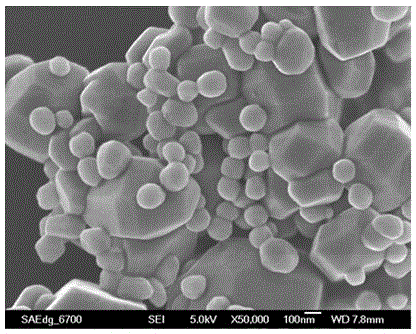

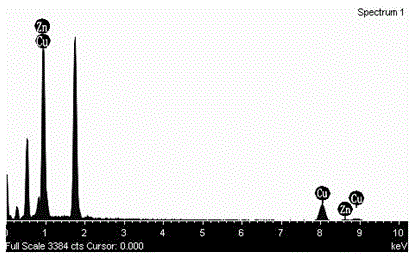

Preparation method of polyhedron nano copper oxide of loaded spherical zinc oxide nano particles

A nano-copper oxide and zinc oxide nano-technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of heterogeneous catalyst morphology and insufficient catalytic activity , low crystallinity and other problems, to achieve the effect of uniform chemical composition of the powder, good crystal morphology, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing polyhedral nano-copper oxide loaded with spherical zinc oxide nanoparticles, specifically comprising the following steps:

[0039] (1) Dissolve 15.1g of copper salt in 125ml of deionized water to make a copper salt aqueous solution with a concentration of 0.5mol / l, then adjust the pH to 6-8 with alkali, and then control the temperature in a constant temperature magnetic stirrer to 60 Stir at constant temperature for 1.5 hours at ℃, then suction filter, wash the obtained filter cake with deionized water for 2-3 times, and then control the temperature at 60℃ for drying to obtain polyhedral nano-copper oxide

[0040] Described copper salt is copper nitrate trihydrate;

[0041] Described alkali is ammoniacal liquor;

[0042](2) Put the polyhedral nano-copper oxide precursor obtained in step (1) together with the molten salt into a ball mill jar, then add alcohol for ball milling for 2 hours to obtain a mixture;

[0043] Described molten sal...

Embodiment 2

[0057] A method for preparing polyhedral nano-copper oxide loaded with spherical zinc oxide nanoparticles, specifically comprising the following steps:

[0058] (1) Dissolve 15.1g of copper salt in 125ml of deionized water to make a copper salt aqueous solution with a concentration of 0.5mol / l, then adjust the pH to 6-8 with alkali, and then control the temperature in a constant temperature magnetic stirrer to 60 ℃ constant temperature stirring for 1.5h, then suction filtration, the obtained filter cake was washed 2-3 times with deionized water, and then dried at a controlled temperature of 60 ℃ to obtain a polyhedral nano-copper oxide precursor.

[0059] Described copper salt is copper nitrate trihydrate;

[0060] Described alkali is ammoniacal liquor;

[0061] (2) Put the polyhedral nano-copper oxide precursor obtained in step (1) together with the molten salt into a ball mill jar, then add alcohol for ball milling for 2 hours to obtain a mixture;

[0062] Describ...

Embodiment 3

[0070] A method for preparing polyhedral nano-copper oxide loaded with spherical zinc oxide nanoparticles, specifically comprising the following steps:

[0071] (1) Dissolve 15.1g of copper salt in 125ml of deionized water to make a copper salt aqueous solution with a concentration of 0.5mol / l, then adjust the pH to 6-8 with alkali, and then control the temperature in a constant temperature magnetic stirrer to 60 Stir at a constant temperature of ℃ for 1.5h, then suction filter, wash the obtained filter cake with deionized water for 2-3 times, and then control the temperature at 60℃ for drying to obtain polyhedral nano-copper oxide;

[0072] Described copper salt is copper nitrate trihydrate;

[0073] Described alkali is ammoniacal liquor;

[0074] (2) Put the polyhedral nano-copper oxide precursor obtained in step (1) together with the molten salt into a ball mill jar, then add alcohol for ball milling for 2 hours to obtain a mixture;

[0075] Described molten salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com