Patents

Literature

80results about How to "Increase the spread distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

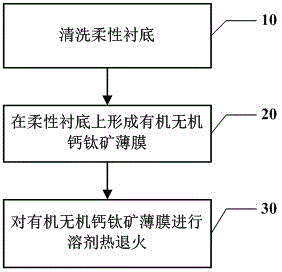

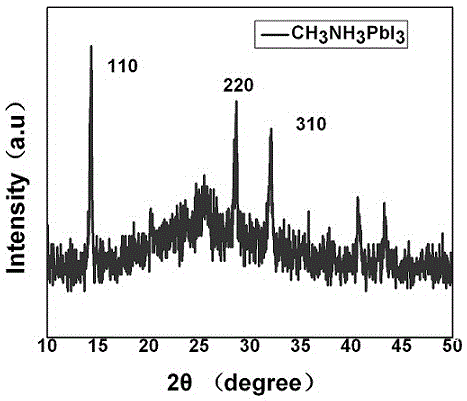

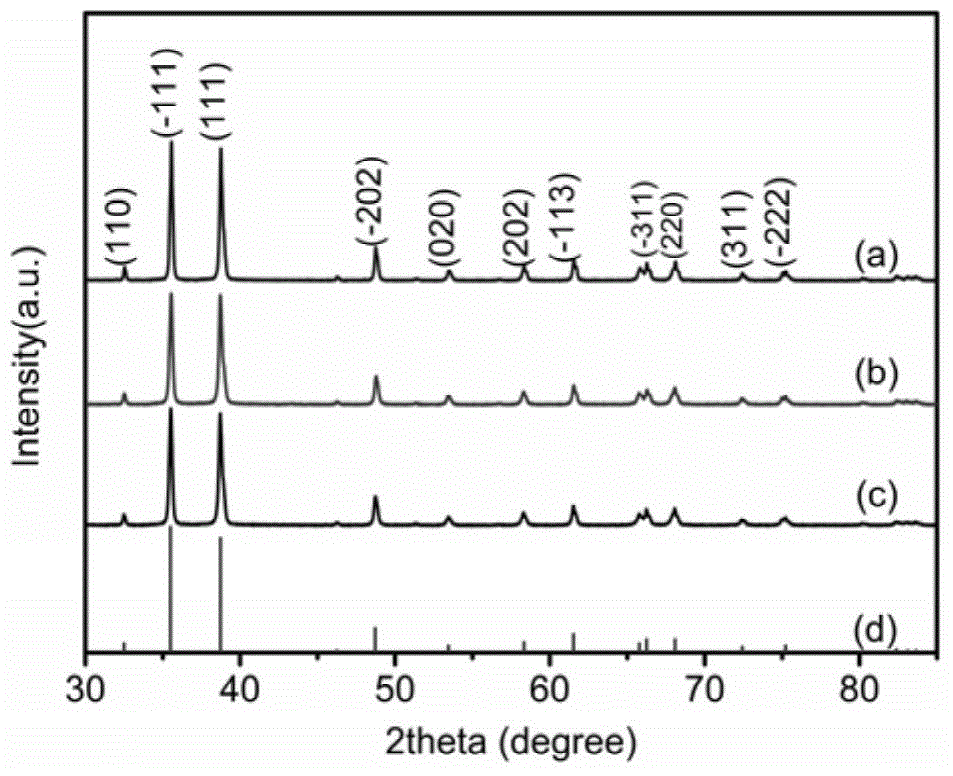

Method for manufacturing organic and inorganic perovskite crystal film

InactiveCN105098080AImprove migration speedIncrease the spread distanceFinal product manufactureSolid-state devicesPerovskite solar cellOptoelectronics

The embodiments of the invention disclose a method for manufacturing an organic and inorganic perovskite crystal film. The method comprises: cleaning a flexible substrate; forming an organic and inorganic perovskite film on the flexible substrate; and annealing the organic and inorganic perovskite film in a steam atmosphere of N, N-dimethyl formamide (DMF) or dimethyl sulfoxide (DMSO). In the embodiments of the invention, in the solvothermal annealing process of the DMF or DMSO steam atmosphere, small crystal grains are continually reduced, while large crystal grains are continually grown, so that the average grain size of the organic and inorganic perovskite crystal film is continually increased, more crystal grains in the [220] direction can be obtained, the service life of current carriers can be prolonged, the growth of the crystal grains is accelerated, the crystal grains are larger, grain boundary recombination can be reduced, and the photoelectric conversion efficiency of an organic and inorganic perovskite solar cell can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

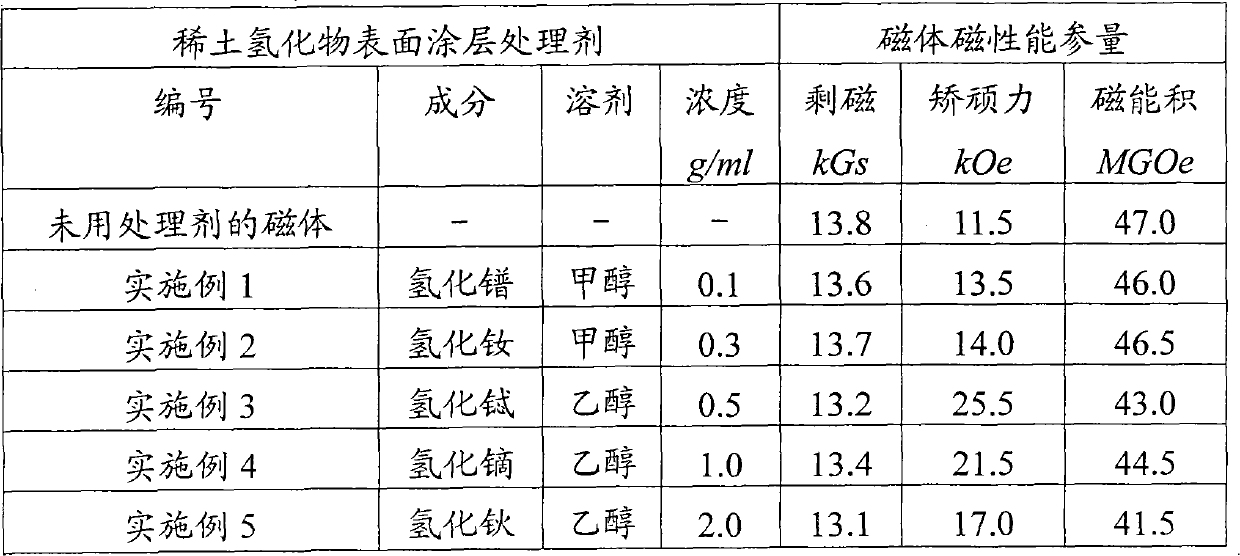

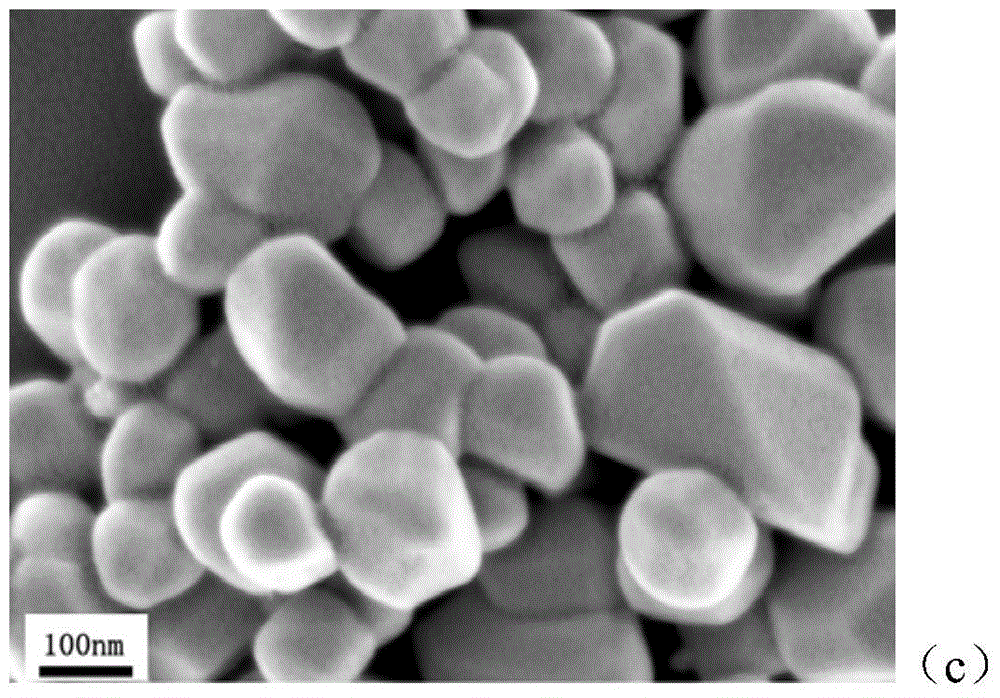

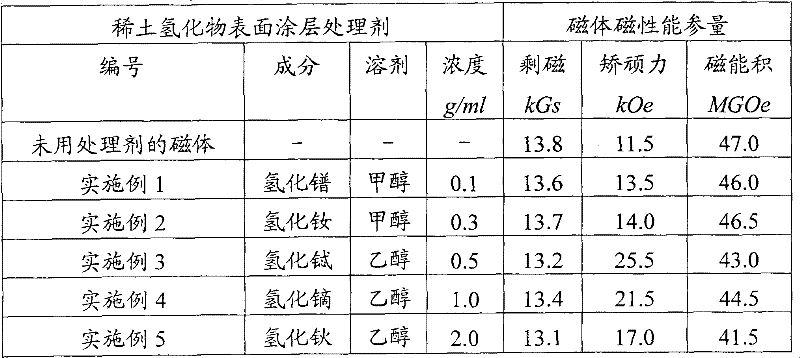

Rare earth hydride surface coating treating agent, application thereof and method for forming rare earth hydride surface coating

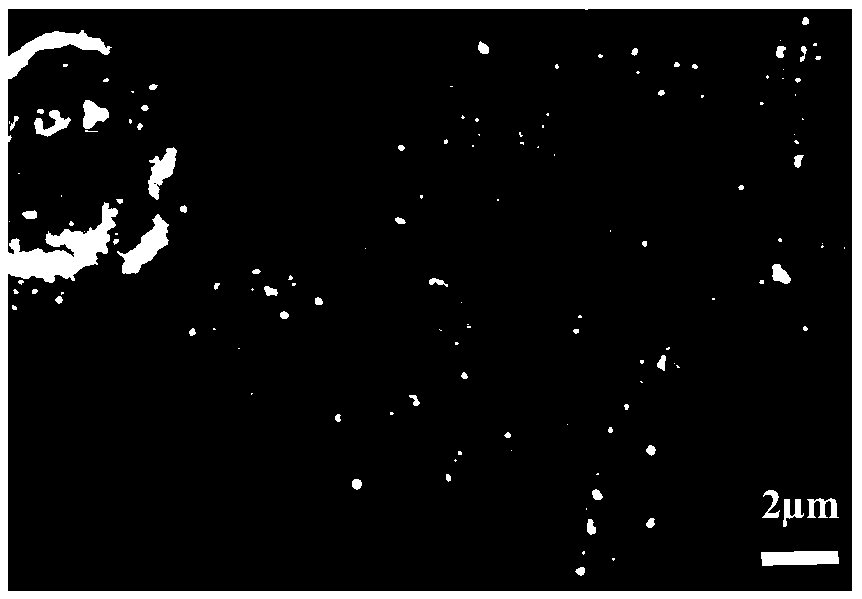

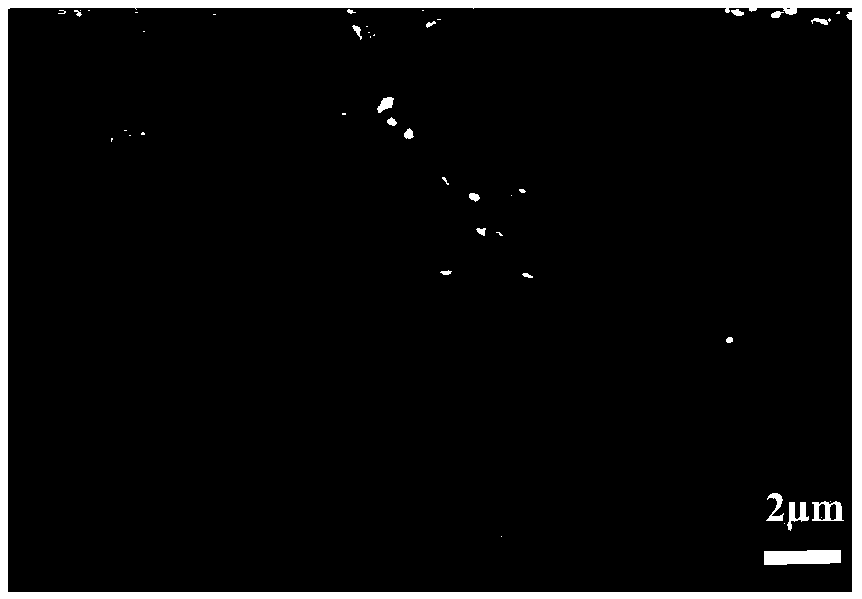

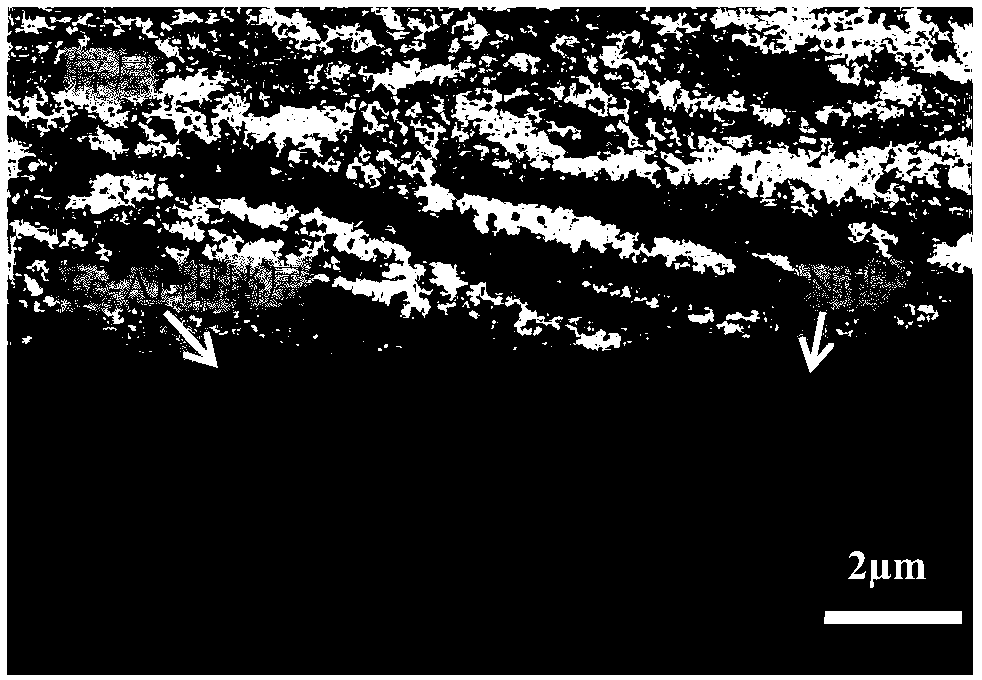

InactiveCN101908397AImprove magnetic propertiesImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureRare earthSolvent

The invention discloses a rare earth hydride surface coating treating agent, a method for forming a rare earth hydride surface coating and application of the rare earth hydride surface coating treating agent, which are used for improving the coercive force of a sintering NdFeB magnet and belong to the technical field of magnetic materials. The coating treating agent is a colloid solution formed by dispersing rare earth hydride into a methanol or ethanol solvent. The method for forming the rare earth hydride surface coating comprises the following steps of: injecting the treating agent into glassware and soaking a magnet into a solution; carrying out ultrasonic processing on the treating agent containing the magnet so that rare earth hydride in the treating agent is uniformly coated on the surface of the magnet to form a surface coating with even thickness; taking the magnet provided with the rare earth hydride surface coating out of the solution and volatilizing the solvent in the magnet surface coating in an air drying way to form a coating; and placing the air dried magnet into a vacuum heat treatment furnace and carrying out heat treatment for 0.5-2 hours in a temperature range of 500-950 DEG C. The invention can obviously improve the magnetic performance of the magnet, especially the coercive force of the magnet.

Owner:BEIJING UNIV OF TECH

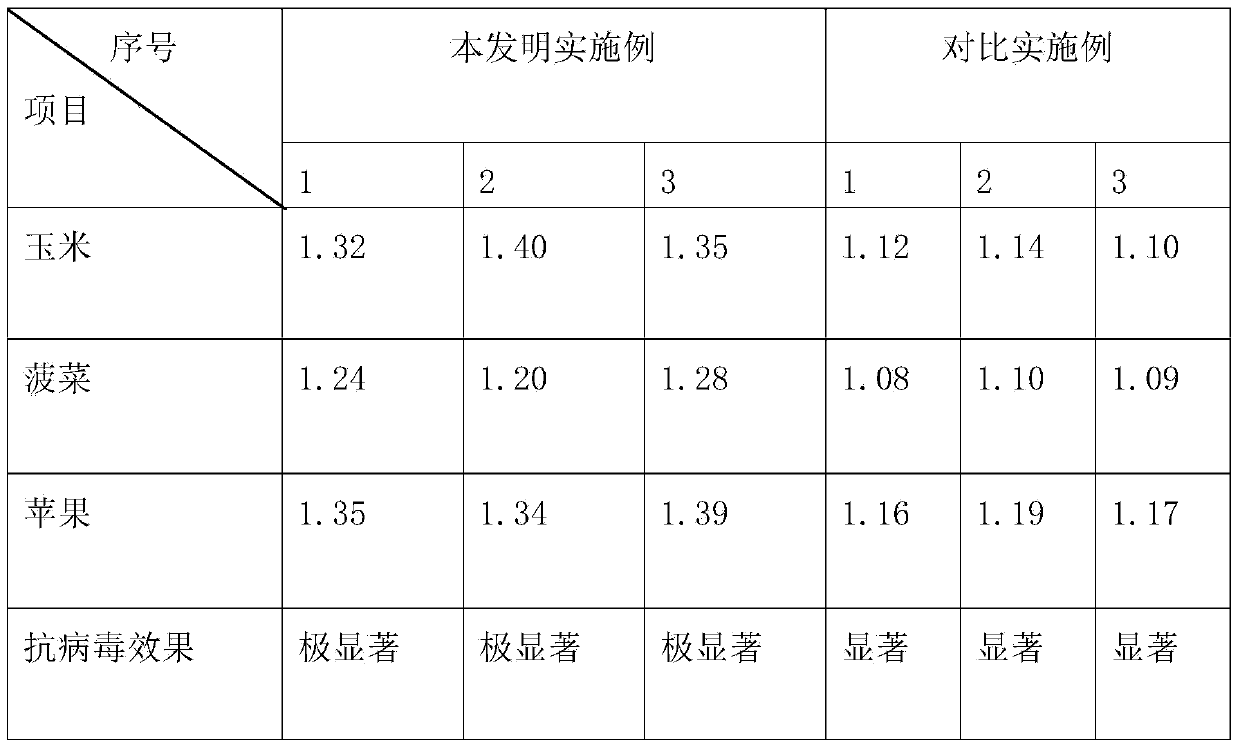

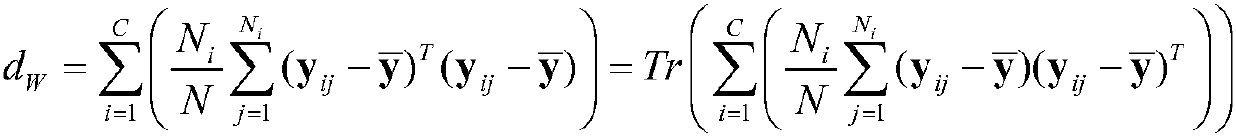

Fertilizer containing anti-plant virus fertilizer additive

ActiveCN103804097AImprove breathabilityIncrease moisture contentFertilizer mixturesOrganic acidTrace element

The invention relates to an anti-plant virus fertilizer additive and a fertilizer containing the additive. The anti-plant virus additive contains a medium trace element-containing fertilizer, organic acid, an anti-plant viral agent and a trace element additive. The fertilizer containing the additive is composed of an elemental fertilizer or a compound fertilizer and the anti-plant virus fertilizer additive, and the content of the additive accounts for 0.1-5% of the total fertilizer weight. The method has the advantages that by adopting the anti-plant virus additive or fertilizer, the yield-increasing effect is obvious, and moreover plant viruses can be prevented.

Owner:刘成才

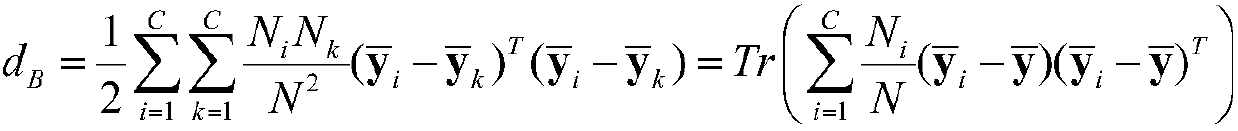

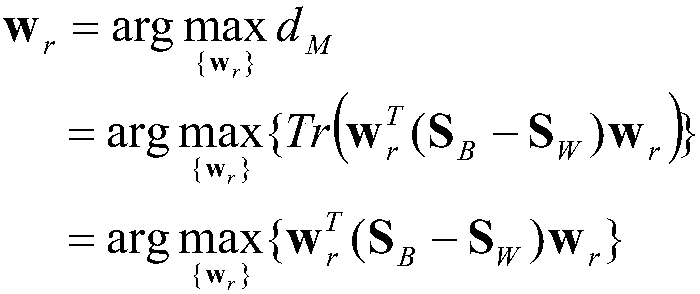

Method for extracting features of one-dimensional range profile of radar true/false target in maximum margin subspace

InactiveCN107678006AIncrease the spread distanceReduce overlapWave based measurement systemsFeature vectorFeature Dimension

The invention discloses a method for extracting the features of the one-dimensional range profile of a radar true / false target in a maximum margin subspace, which belongs to the technical field of radar target recognition. First, a maximum margin subspace matrix W is trained based on a training sample set about the one-dimensional range profile of a radar target. Then, during training, an objective equation for solving W is constructed based on a between-class scatter matrix SB and a within-class scatter matrix SW of a training sample xij. Finally, based on the trained matrix W, the one-dimensional range profile of a radar true / false target of which the sub image features are to be extracted is mapped to the matrix W to get sub image features. By increasing the between-class scatter distance and reducing the within-class scatter distance, the between-class separation interval reaches the maximum, and between-class overlap is reduced. Moreover, the dimension of the feature vector obtained by the method is not restricted by the number of classes, a more favorable feature dimension can be obtained, and therefore, the efficiency of target recognition is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Water-soluble chemical fertilizer

InactiveCN102010273AImprove breathabilityImprove water holdingFertilizer mixturesPlant rootsPotassium

The invention relates to a water-soluble chemical fertilizer. The water-soluble chemical fertilizer comprises the following components in part by weight: 20 to 45 parts of urea, 20 to 79 parts of phosphate compound, 20.5 to 48 parts of sulfate, 0.1 to 1.5 parts of borax, 0.1 to 2 parts of ammonium molybdate heptahydrate and 0.5 to 15 parts of polypropylene compound. As the water-soluble chemical fertilizer is formed by constructing major element in full-instant powder, a stable soil agglomerated particle structure can be formed after the water-soluble chemical fertilizer is applied, so that air permeability of soil, chemical and physical environments of every nutritive element in the soil, adsorption quantity of the surface of soil particles, and adduction of every nutritive element can be improved; and after the water-soluble chemical fertilizer is applied, a nutrition protecting area can be quickly formed at plant roots, so that the diffusion velocity and migration distance of nutrients such as nitrogen, phosphorus, potassium and the like in the soil are increased so as to promote root systems to uptake and use water and the nutrients.

Owner:周志勇

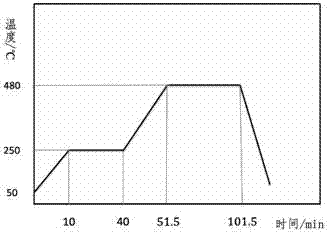

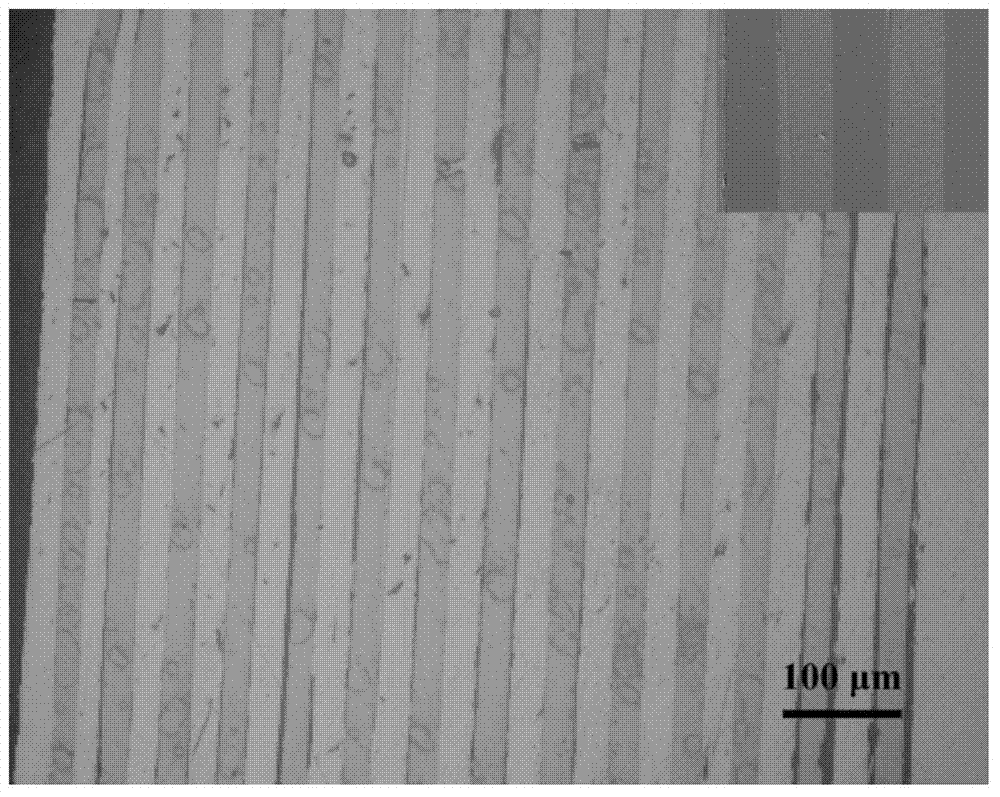

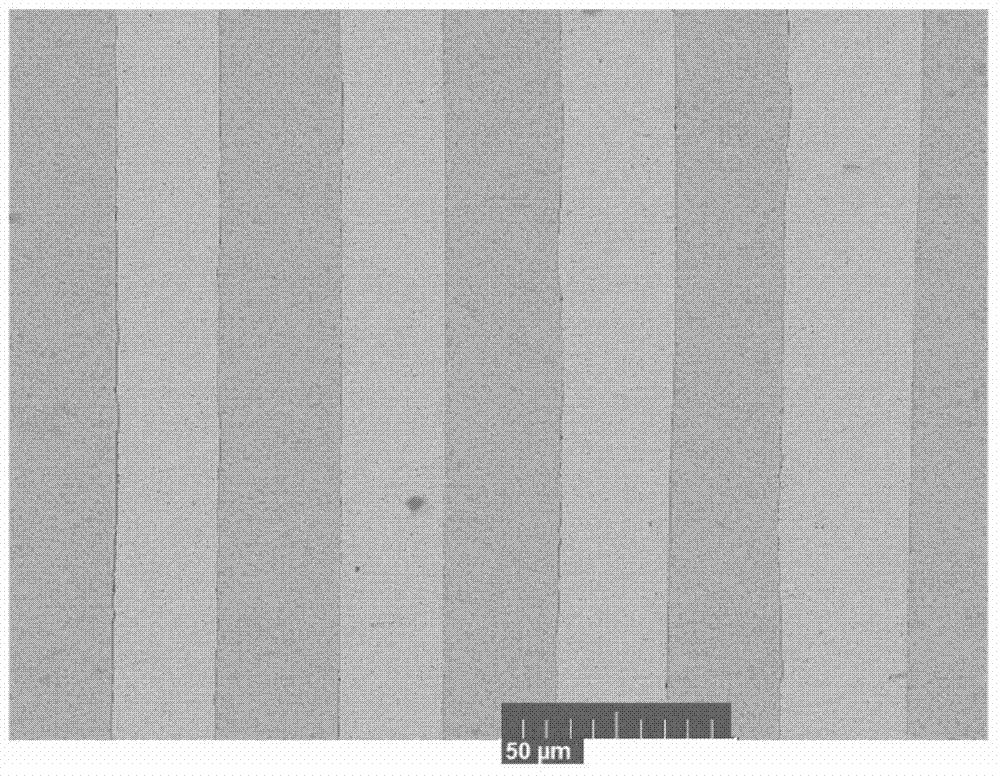

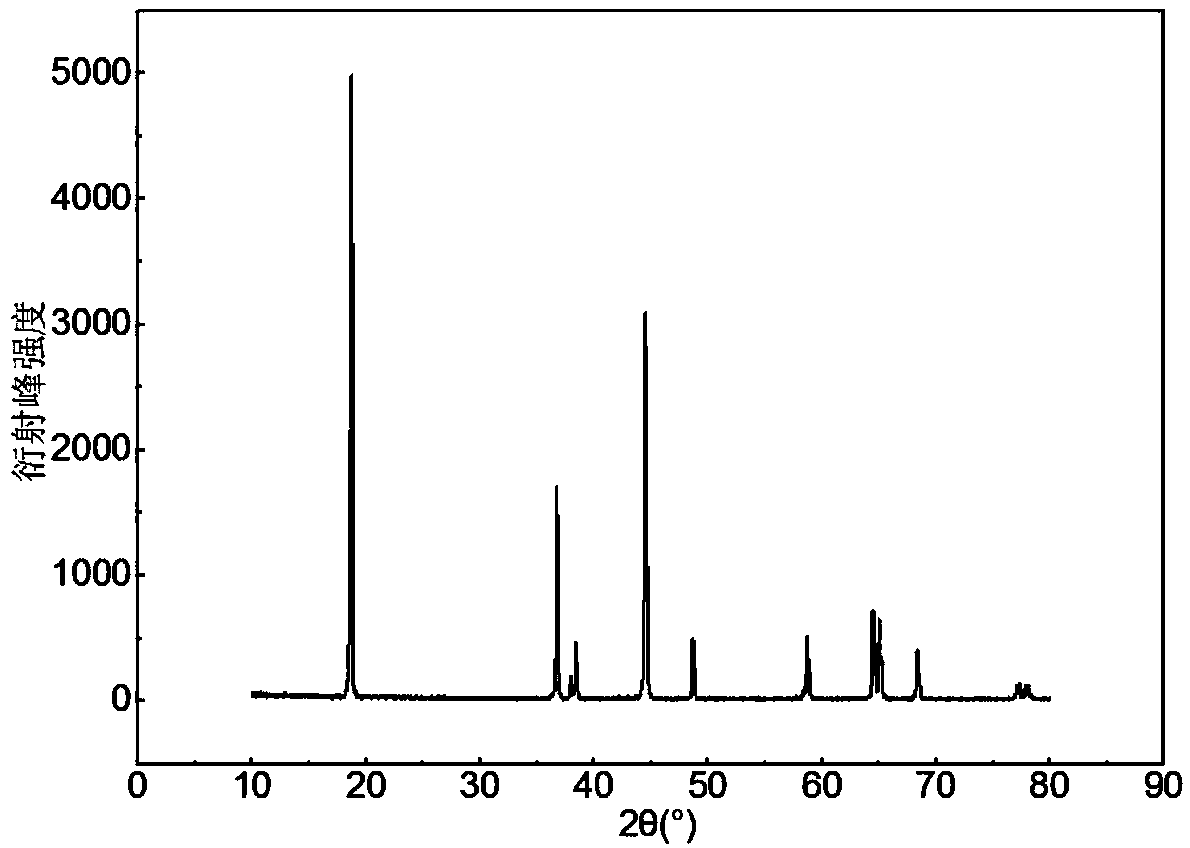

Preparation method of iron-based amorphous alloy-copper multilayer composite plate

ActiveCN103895313AAchieve preparationFlexible and efficient preparation methodLaminationLamination apparatusComposite plateAmorphous metal

The invention discloses a preparation method of an iron-based amorphous alloy-copper multilayer composite plate. By combining a vacuum diffusion bonding technology and a hot rolling bonding technology, the multilayer composite plate is prepared; in processes of vacuum diffusion bonding and hot rolling bonding, processing temperatures are selected to be in an amorphous alloy super-cooled liquid region; by adopting the characteristics of low viscosity, small flow stress and element diffusion acceleration of the amorphous alloy in the super-cooled liquid region, the iron-based amorphous alloy and the copper can be effectively connected, thus the iron-based amorphous alloy-copper multilayer composite plate can be successfully prepared. In a hot rolling process, a thin-layer surface is stressed by shearing force, so that fresh metals in the thin-layer surface are exposed in a short time and contacted and bonded with each other in the presence of pressure, thus effective welding is formed at an interface; in a vacuum annealing process, the element diffusion distance in the interface can be further increased, so that the metallurgy bonding strength can be improved, and the rolling stress can be released.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

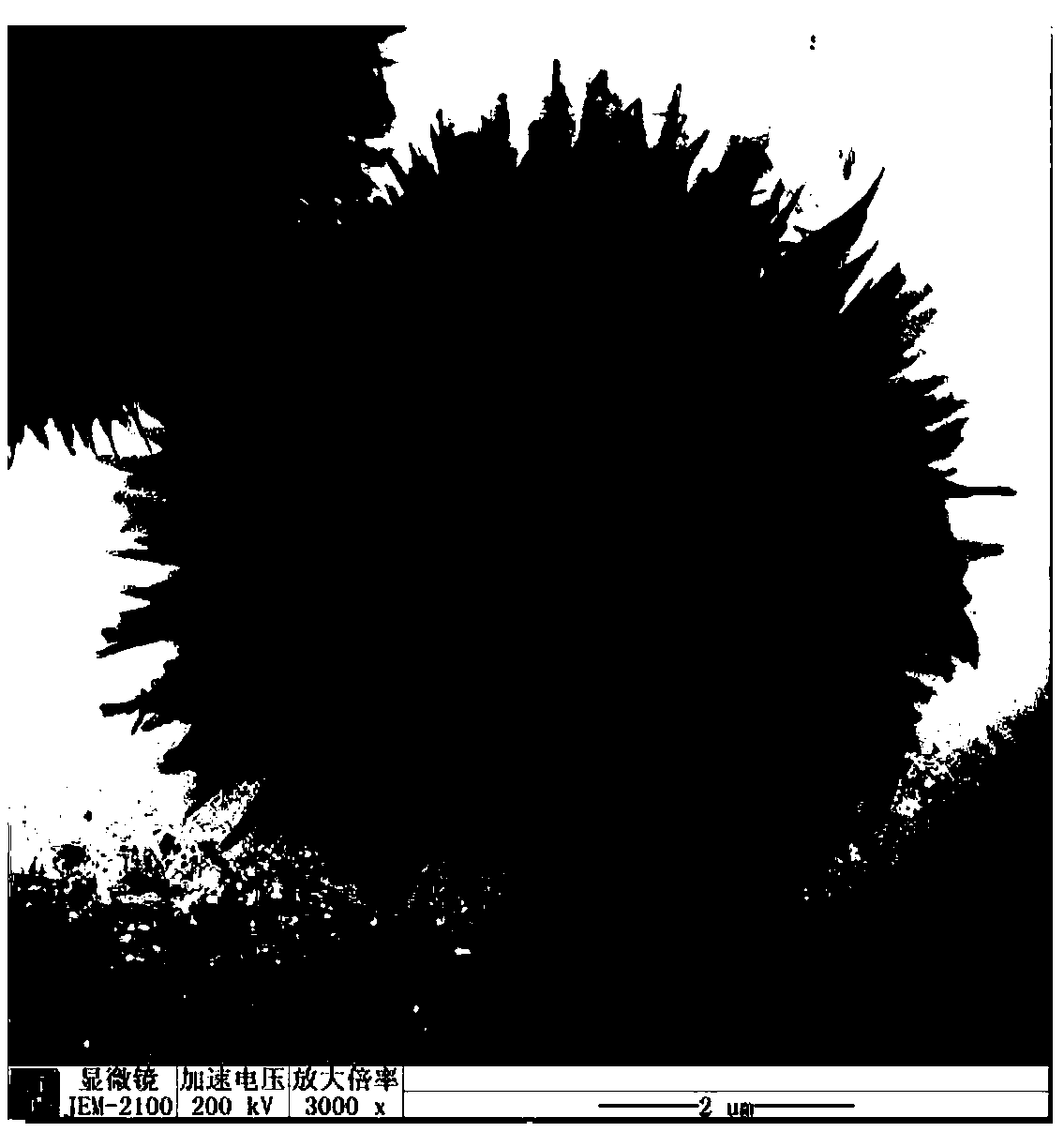

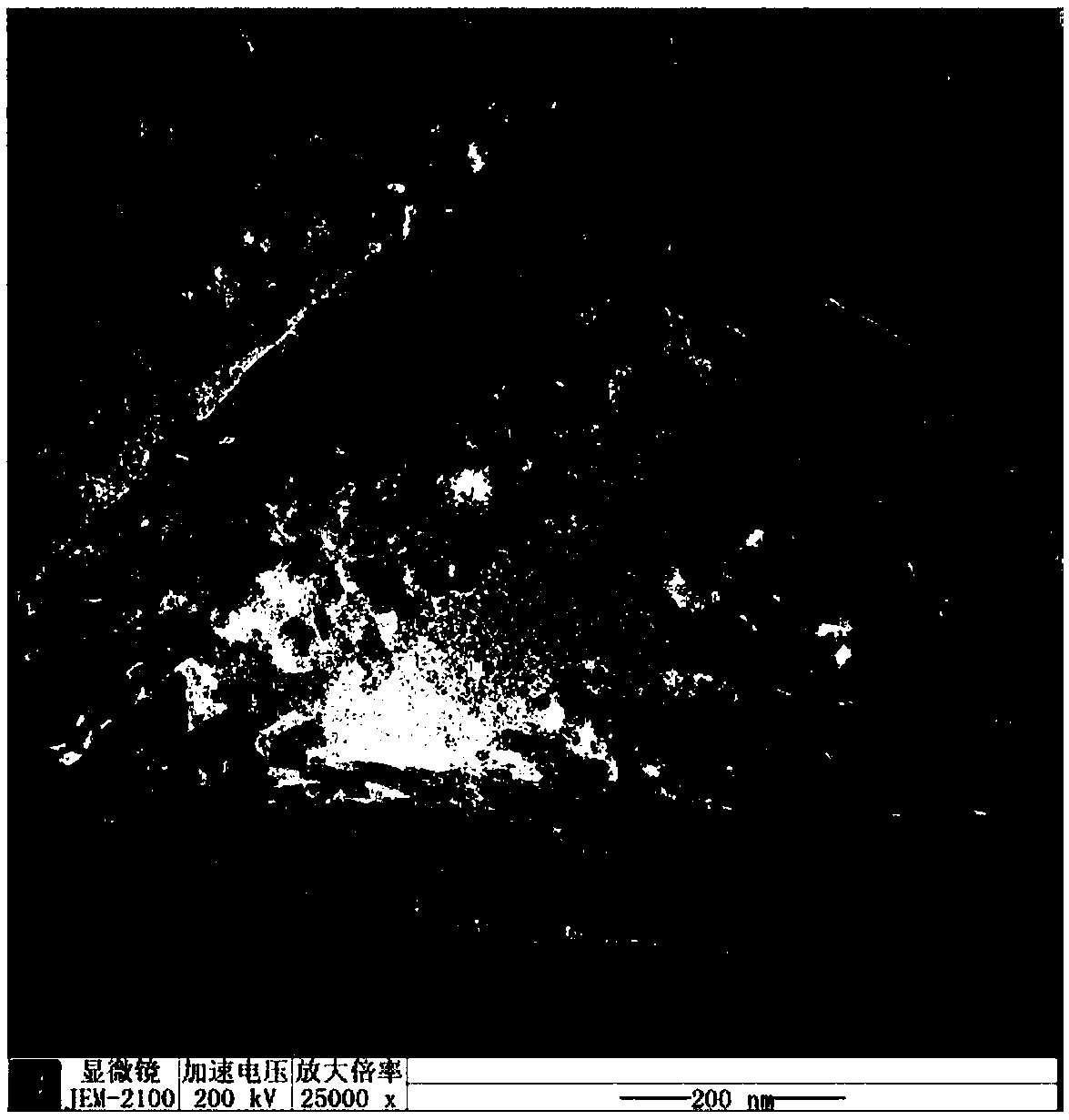

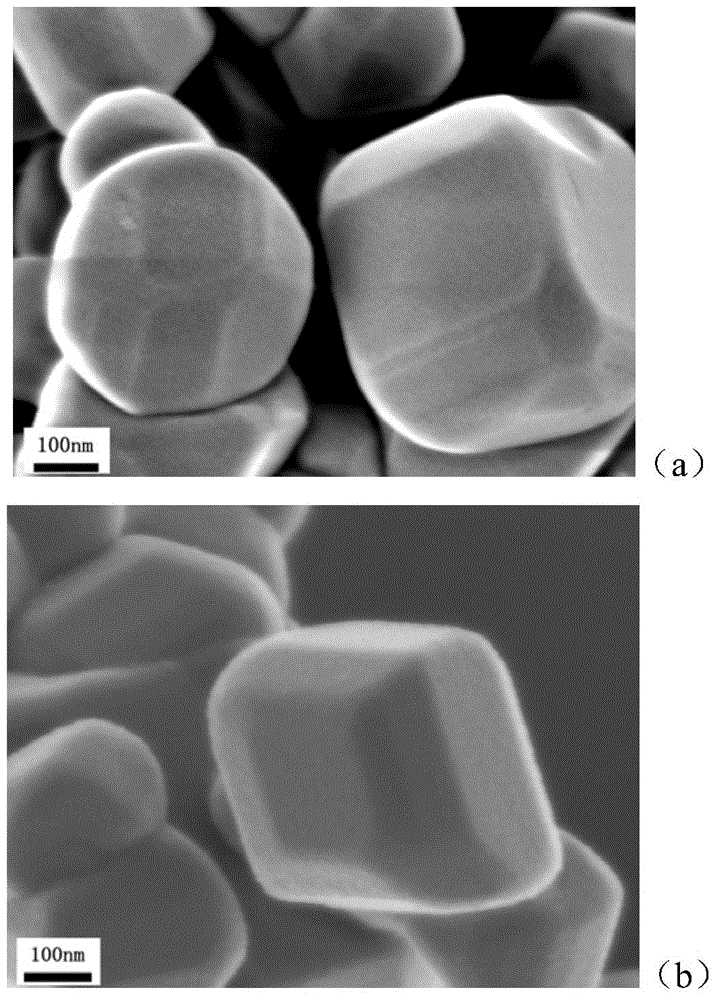

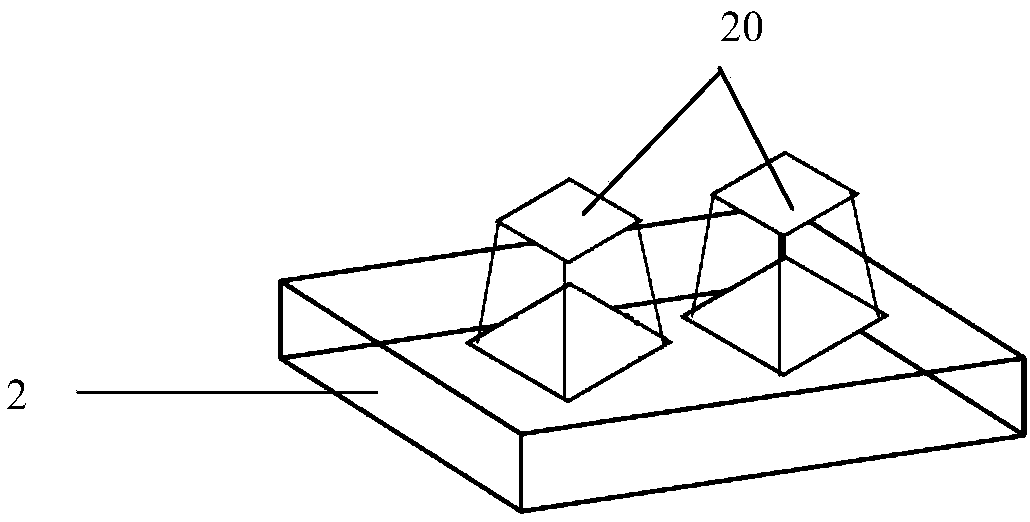

NCM ternary cathode material with gradient structure for lithium ion battery, manufacturing method and application

ActiveCN108878869AAchieve continuous declineStable gradient structureSecondary cellsPositive electrodesHigh rateLithium-ion battery

The invention provides a NCM ternary cathode material with gradient structure for lithium ion battery, a manufacturing method and an application. The molecular formula of NCM ternary cathode materialwith gradient structure is LiNixCoyMnzO2, wherein, 0.6<=x<=0.9,0.1<=y+z<=0.4,x+y+z=1. The NCM ternary positive electrode material comprises spherical particles formed by a plurality of strip-shaped primary particles diverging from the center to the periphery. The material has a gradient structure with content of Mn unchanged, content of Ni gradually decreasing and content of Co gradually increasing from the center to the outer layer. The ternary cathode material with gradient structure has simple preparation process and good processing performance, and the lithium ion battery prepared from thematerial has high capacity, high rate performance, cycle stability and safety performance.

Owner:湖南桑瑞新材料有限公司

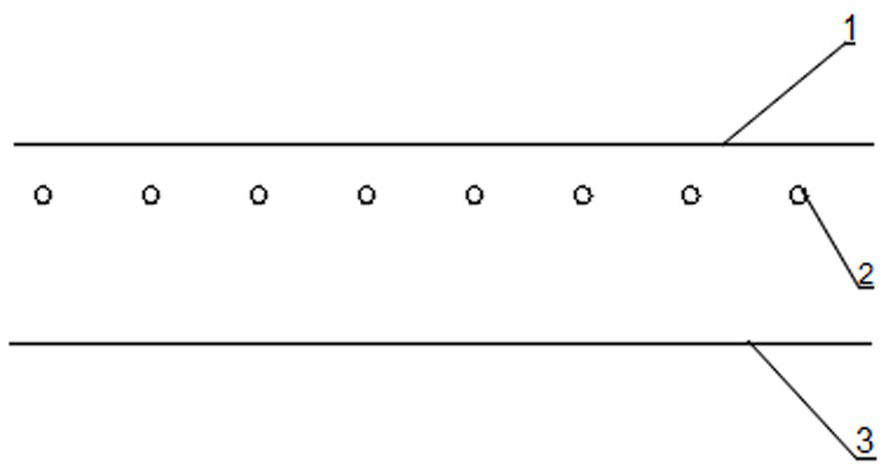

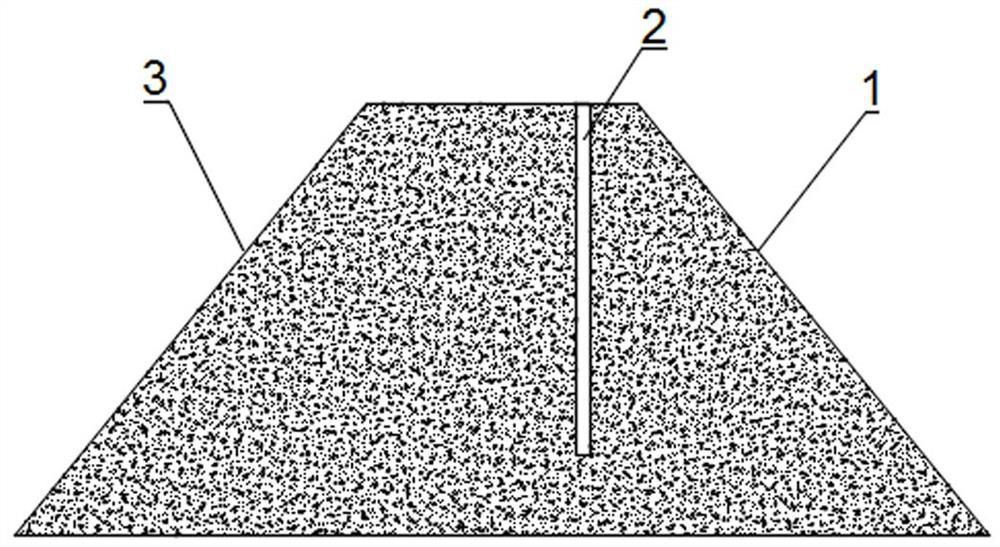

Grouting method of waterproof curtain of burnt rock covering on working surface to be mined of coal mine

ActiveCN108843343AImprove anti-seepage performanceImprove anti-seepage effectUnderground chambersDrainageGeomorphologySlurry

The invention belongs to the technical field of water control of mine shafts, and particularly relates to a grouting method of a waterproof curtain of burnt rock covering on a working surface to be mined of a coal mine so as to solve the problems existing in the prior art that slurry between grouting holes is difficult to sufficiently diffuse and overlap, the leakproof effect of a grouting curtainof the burnt rock is poor, and the water shutoff rate is not high. The technical scheme adopted by the invention lies in that the grouting method comprises the steps of (1) performing hole drilling arrangement on the curtain; (2) grouting inner-row curtain holes; and (3) grouting outer-row curtain holes.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP +1

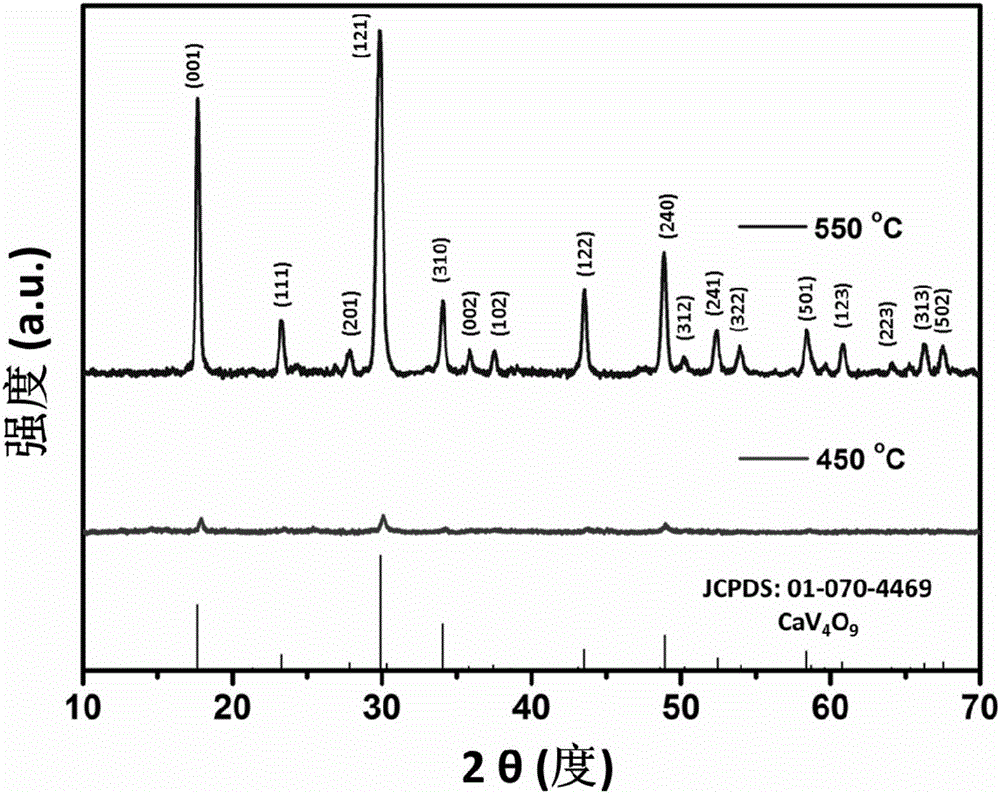

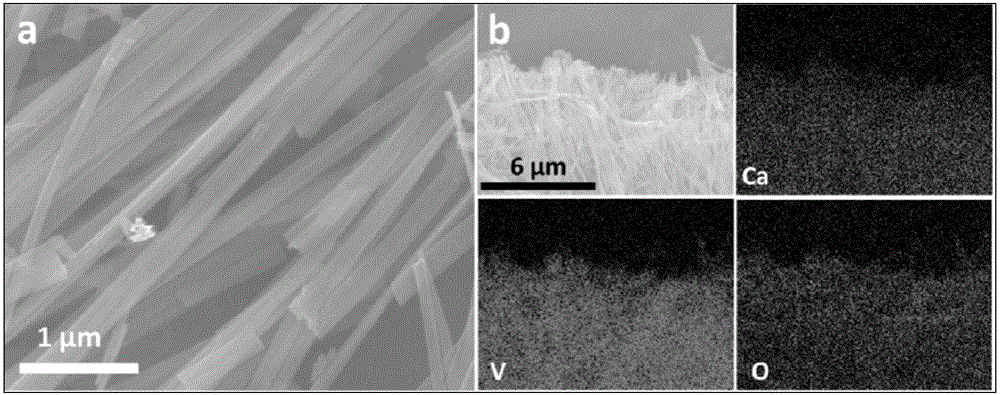

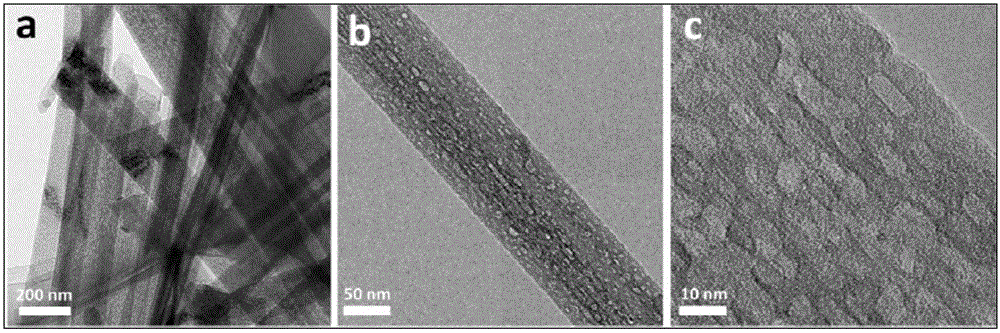

Calcium vanadate mesoporous nanowire and preparation method and application thereof

ActiveCN105680042AShorten the diffusion distanceIncrease the spread distanceMaterial nanotechnologyNon-aqueous electrolyte accumulatorsEnvironmental resistanceNanowire

The invention relates to a calcium vanadate mesoporous nanowire material and a preparation method thereof. The material can be used as a sodium-ion battery anode active material. The calcium vanadate mesoporous nanowire is obtained in combination with post heat treatment by using a hydrothermal process, the molecular formula of calcium vanadate is CaV4O9, the diameter of the nanowire is 100-200 nm, the length of the nanowire is 5-10 microns, a large number of mesopores are uniformly formed in the surface of the nanowire, and the pore diameters of the mesopores are 20-50 nm. The calcium vanadate mesoporous nanowire material has the beneficial effects that the calcium vanadate mesoporous nanowire material has relatively high specific capacity, good cycling stability and extremely excellent rate capacity when being used as the sodium-ion battery anode active material, and is a potential high-performance sodium-ion battery anode material; and moreover, the preparation method is simple in technology, and the calcium vanadate mesoporous nanowire can be obtained through the simple hydrothermal process and subsequent heat treatment, so that the method is green and environmentally-friendly and relatively low in energy consumption.

Owner:WUHAN UNIV OF TECH

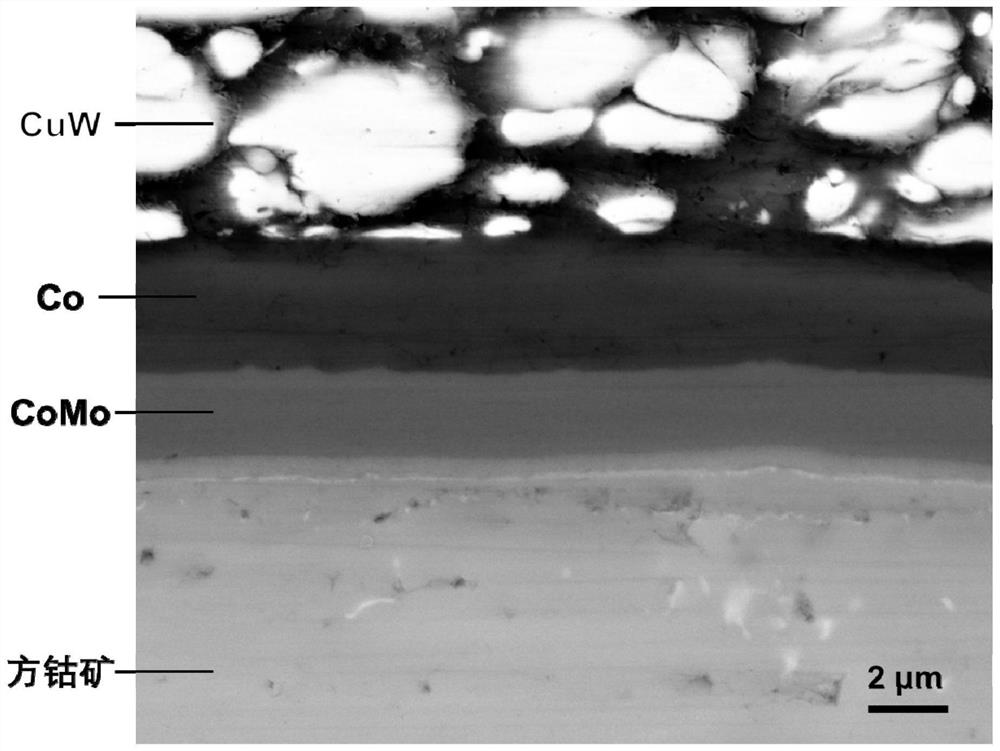

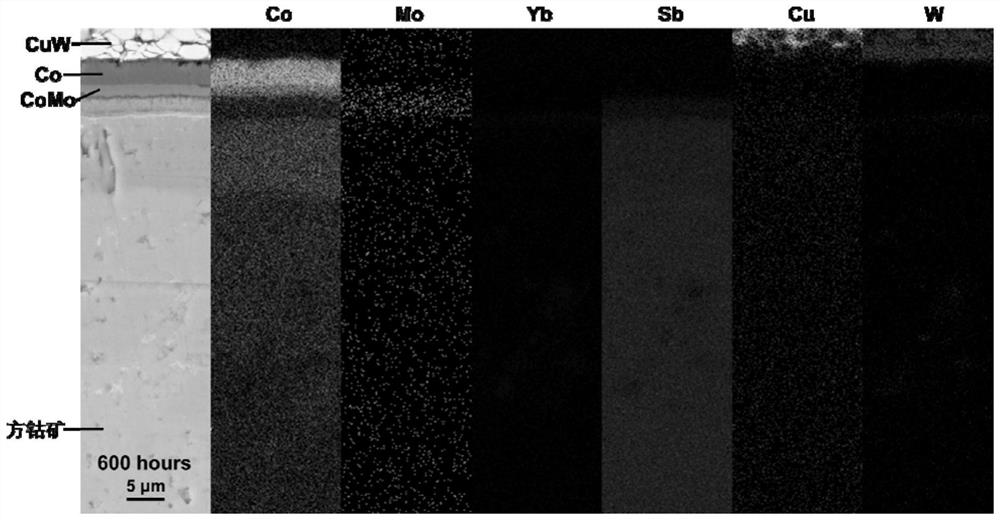

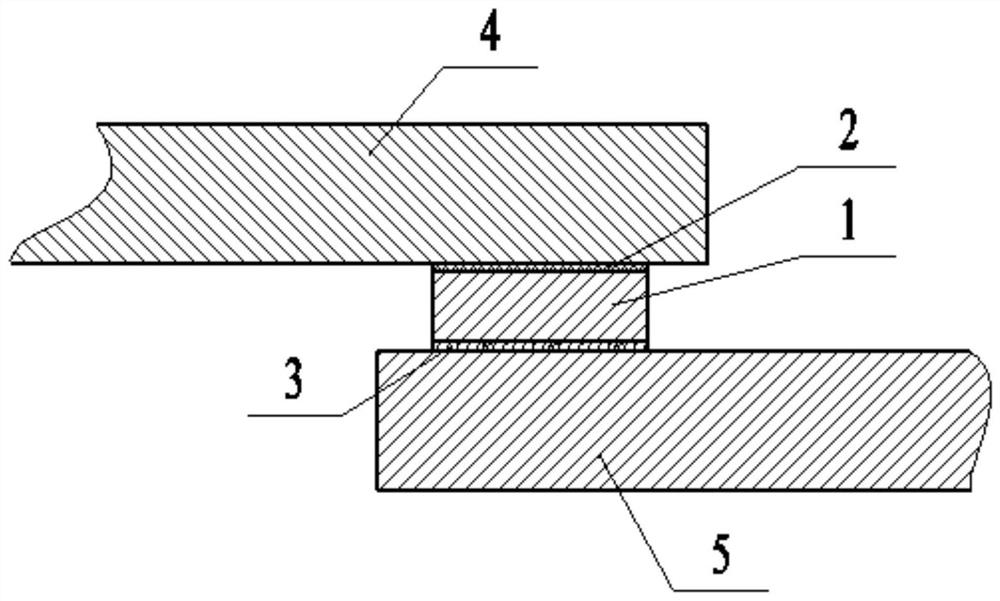

Method for connecting skutterudite thermoelectric material and electrode by using high-thermal-stability alloy composite intermediate layer

ActiveCN112276275ABarrier interdiffusionReduce contact resistivityThermoelectric device manufacture/treatmentSoldering apparatusHeat stabilityAlloy composite

The invention relates to a method for connecting a skutterudite thermoelectric material and an electrode by using a high-thermal-stability alloy composite intermediate layer, in particular to the method for connecting the skutterudite thermoelectric material and the electrode. The method aims to solve the problems of poor thermal stability and large contact resistance of a joint obtained by the existing skutterudite thermoelectric material welding method. The method comprises the following steps of 1, cleaning the skutterudite thermoelectric material and the electrode; and 2, preparing the intermediate connecting layer and a diffusion barrier layer by using an electroplating or physical vapor deposition method, and carrying out diffusion welding, wherein the intermediate connecting layer is made of Co, Fe or Ni, and the diffusion barrier layer is made of CoMo, CoW, FeMo or FeW. According to the method, the joint obtained by utilizing the intermediate connecting layer and the diffusionbarrier layer has low contact resistivity, and the thermal stability of the joint is high. The method is suitable for connecting the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

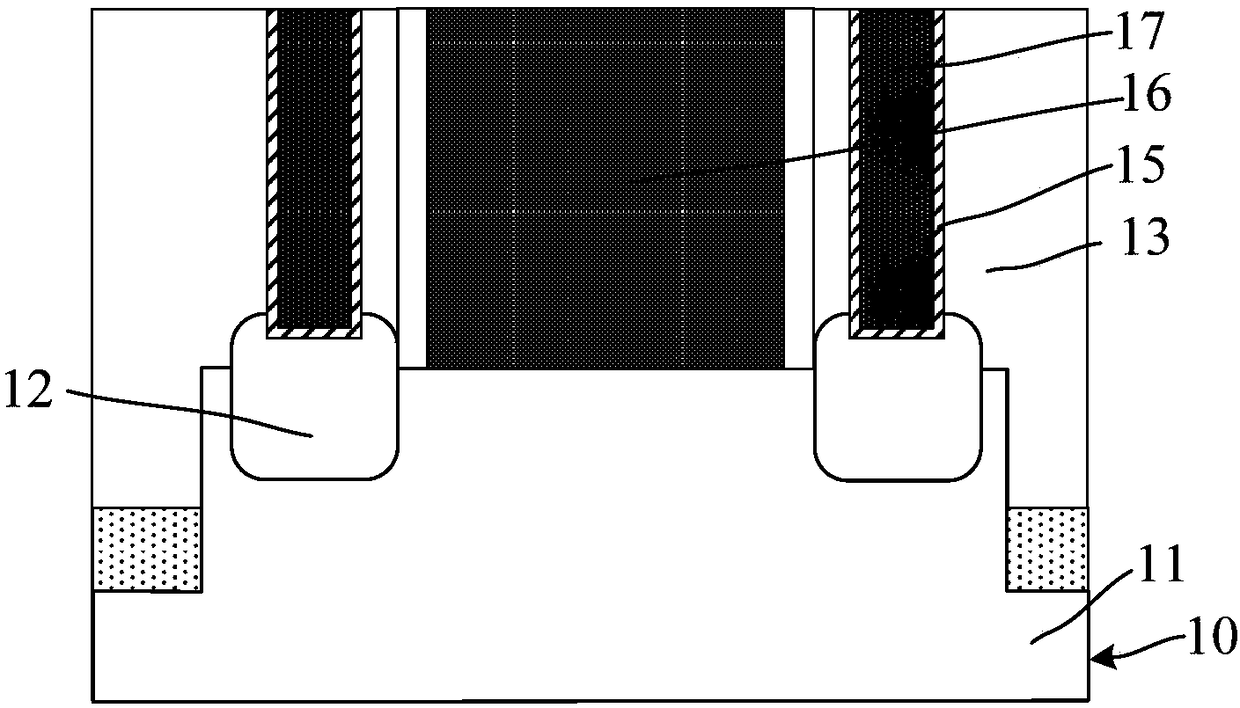

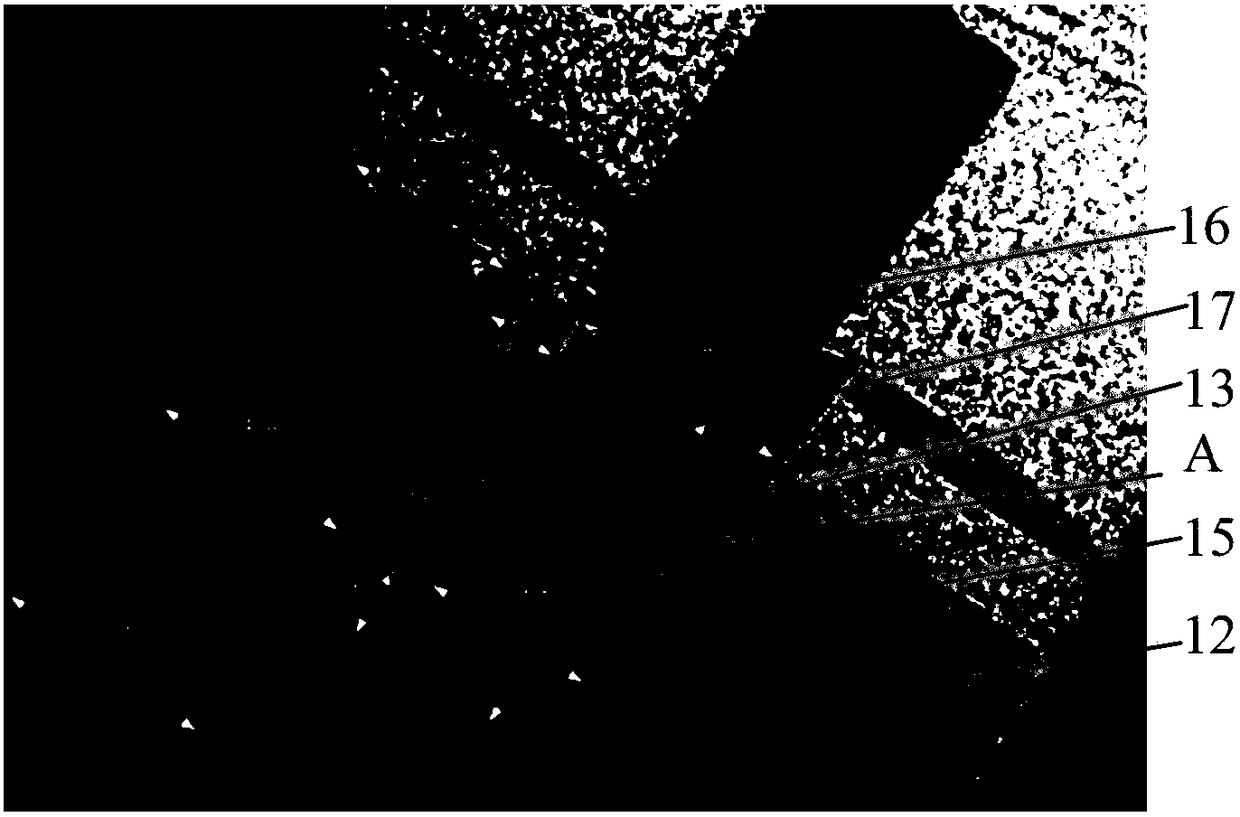

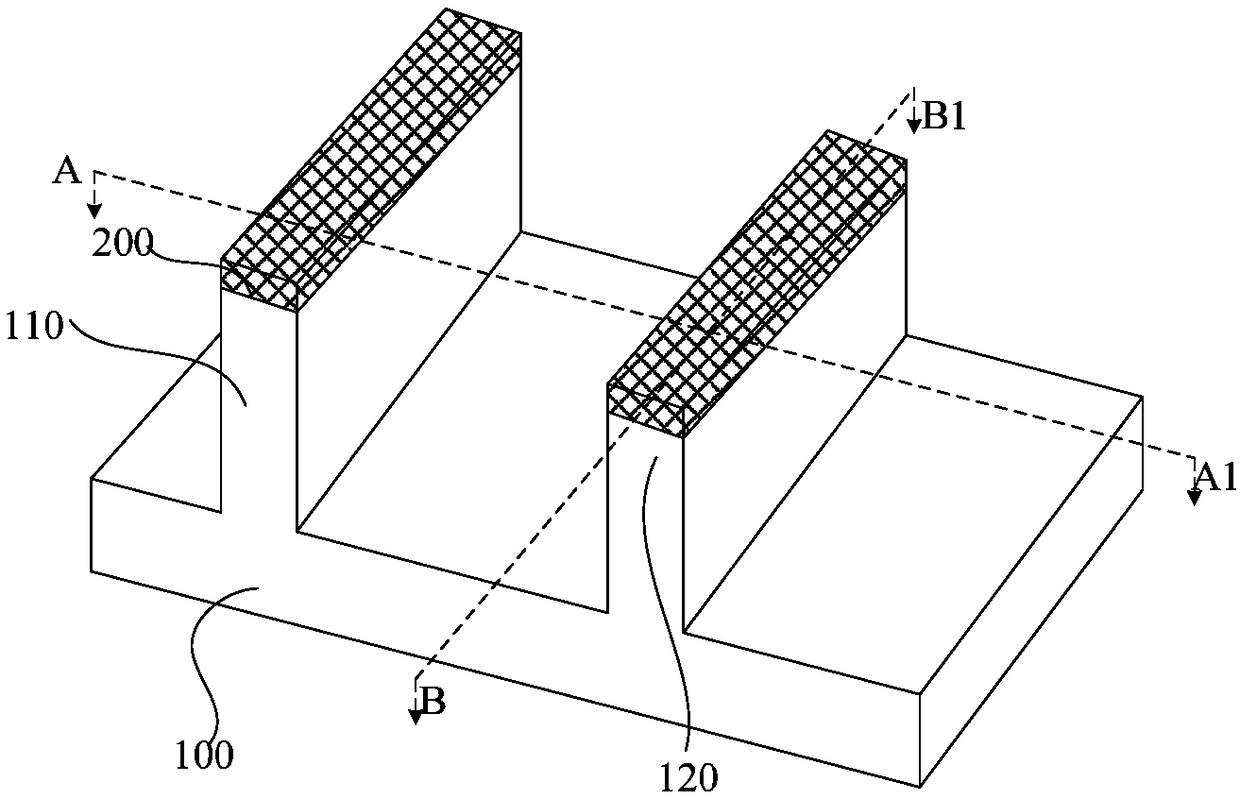

Semiconductor structure and forming method thereof

InactiveCN108074813AReduced body leakage currentAvoid conductionTransistorSemiconductor/solid-state device manufacturingSemiconductor structureMetal silicide

The invention discloses a semiconductor structure and a forming method thereof. The method comprises the steps of forming a substrate, wherein the substrate comprises a substrate, a gate structure located on the substrate, source-drain doped regions located in the substrate at two sides of the gate structure, and a dielectric layer located on the substrate from which the gate structure is exposed;forming contact openings for exposing the source-drain doped regions in two sides of the gate structure, wherein each contact opening comprises a through hole penetrating through the substrate with the thickness of the dielectric layer, and a groove penetrating through the substrate with the thickness of the part corresponding to each source-drain doped region, and the bottom size of each grooveis smaller than the top size in the direction vertical to the extension direction of the gate structure; covering the surfaces of the grooves with a metal silicide layer in a conformal manner; and forming the metal silicide layer and then forming contact hole plugs in the contact openings. The bottom size of each groove is smaller than the top size, so that, compared with a scheme that side wallsof the grooves are vertical to the substrate, the semiconductor structure has the advantages that the diffusion distance from metal atoms to a channel region in the process of forming the metal silicide layer can be increased, and the possibility that the metal atoms are diffused to a bulk region of the substrate is reduced, thereby reducing bulk leakage current.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

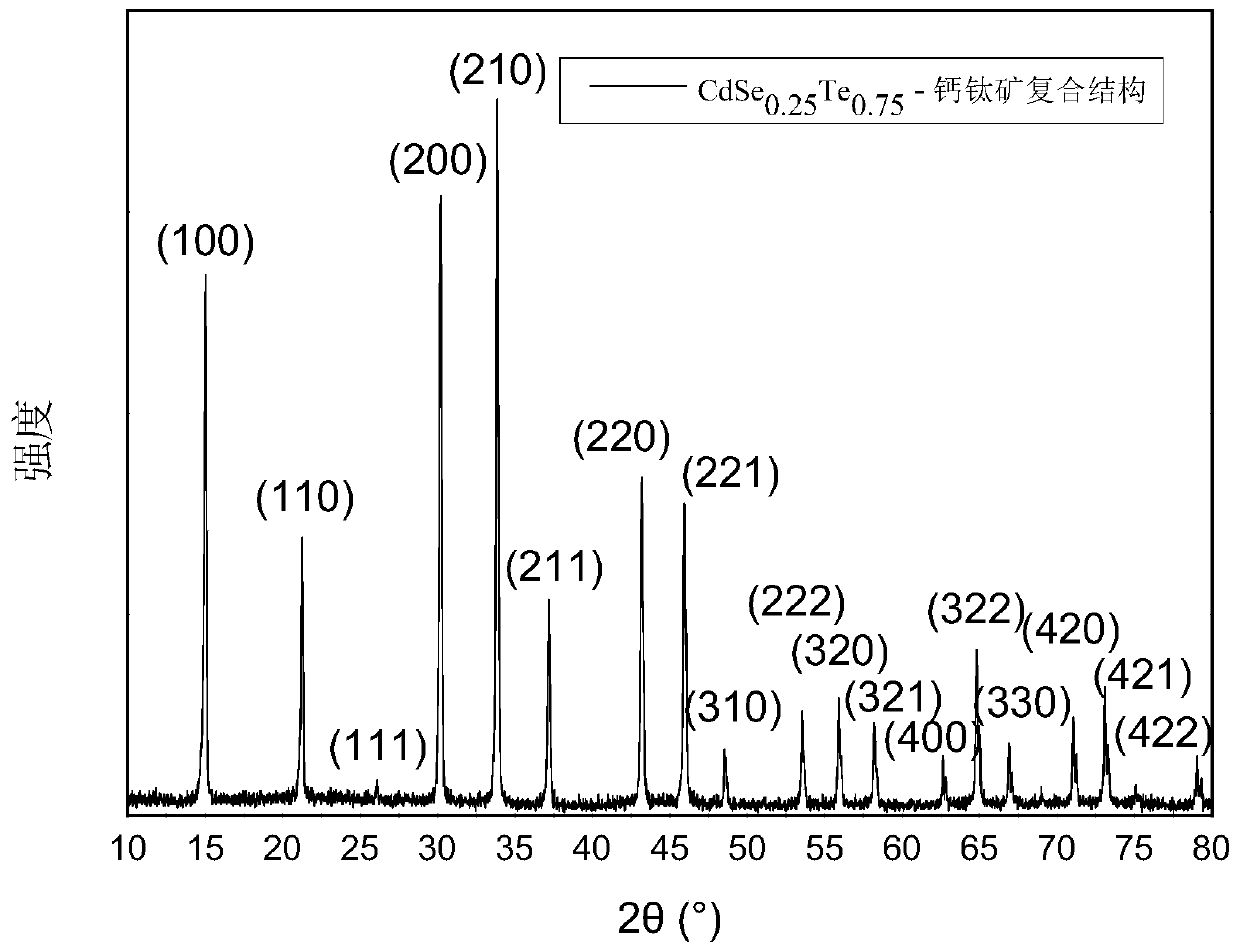

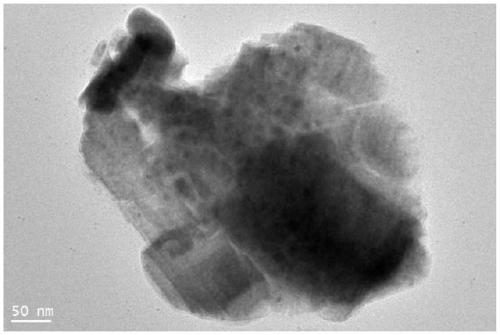

Composite nanometer structure and production method thereof

ActiveCN110184044AInhibitory complexEfficient separationMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsSolar cellSolvent

The invention discloses a composite nanometer structure and a production method thereof. The composite nanometer structure comprises organic-inorganic hybrid perovskite nanocrystallines and semiconductor quantum dots which are embedded into the organic-inorganic hybrid perovskite nanocrystallines; and a structural formula of the organic-inorganic hybrid perovskite nanocrystallines is CH3NH3PbX3, and X is selected from Cl, Br and I. The production method comprises the steps of evenly mixing lead halide and an organic solvent A to obtain a solution I; evenly mixing methyl ammonium halide and anorganic solvent B to obtain a solution II; adding the semiconductor quantum dots into the solution II, then adding a ligand, and evenly dispersing an obtained mixture to obtain a mixed solution; and then mixing the mixed solution and the solution I, and carrying out a reaction to obtain the composite nanometer structure. The composite nanometer structure produced through technology optimization can increase diffusion distance of photo-induced electrons and holes, can inhibit compounding of semiconductor quantum dot surfaces of the electrons and the holes, and can be used for a wide variety offields of solar cells, photocatalysis and the like.

Owner:ZHEJIANG UNIV

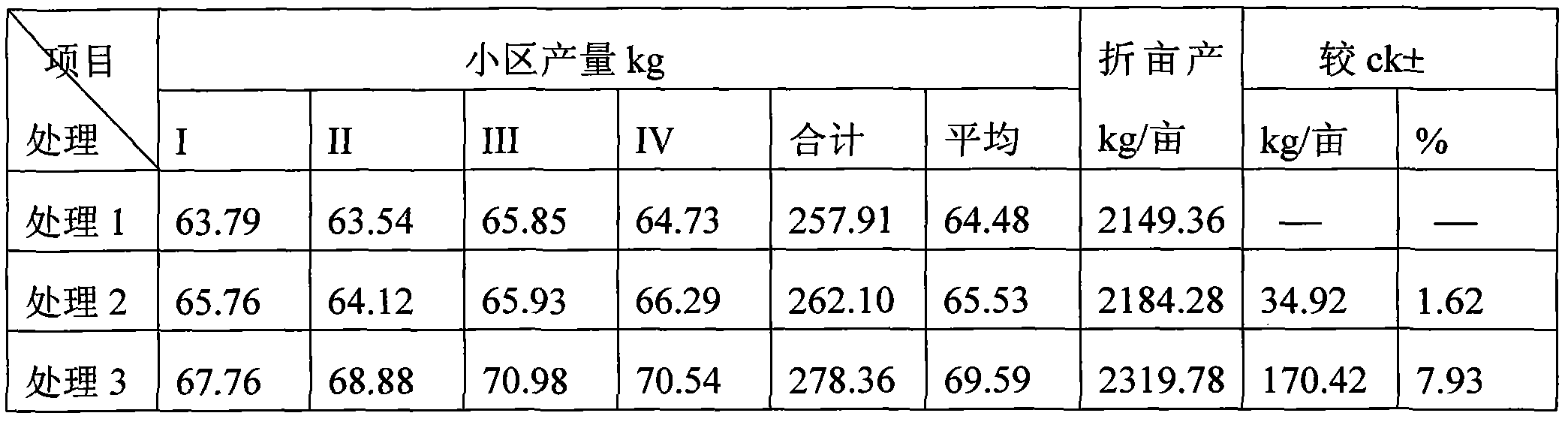

Macroelement water-soluble fertilizer

InactiveCN101759479AIncrease the speed of diffusionIncrease the spread distanceFertilizer mixturesPotassiumNitrogen

The invention relates to a fertilizer, in particular to a macroelement water-soluble fertilizer. The macroelement water-soluble fertilizer comprises many kinds of macroelements with the following contents: not less than 25% of N, not less than 10% of P2O5 and not less than 15% of K2O; the microelements have the following weight contents: not less than 0.14% of Mn, not less than 0.18% of Zn, not less than 0.18% of B and not less than 0.15% of Mg; and the weight content of the organic matter is 42%. The invention has the advantages that the high range of nitrogen, phosphorus, potassium and the microelements can completely substitute the compound fertilizer and the carbamide of the traditional base fertilizer; the products have scientific formulas, various kinds of elements, no constraint and no pollution to the soil after application; the nutrient protection region is rapidly formed at the roots of the plants; the diffusion speed and the migration distance of the nutrients such as nitrogen, phosphorus and potassium in soil are improved; the absorption and the utilization of water and nutrients to the roots are prompted. The produced fruits have smooth surface, bright color and good taste. Compared with the traditional fertilizer, the invention has remarkable increment effect.

Owner:江苏心实肥业集团有限公司

Hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and manufacturing method thereof

ActiveCN110760773AIncrease contactIncreasing the thicknessHot-dipping/immersion processesSuperimposed coating processChemical compositionUltimate tensile strength

The invention discloses a hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and a manufacturing method thereof. The hot galvanized high-strength steel plate sequentially comprises a substrate, a pre-metallization layer and Fe-Al barrier layer and a galvanized layer from bottom to top, wherein the chemical composition of the substrate comprises the following chemical components of, in percentage by weight, 0.15 wt% to 0.25wt% of C, 1.00 wt% to 2.00 wt% of Si, 1.50 wt% to 3.00 wt% of Mn, less than or equal to 0. 015 wt% of P, less than or equalto 0.012 wt% of S, 0.03 wt% to 0.06 wt% of Al and the balance Fe and inevitable impurities, and the pre-metallization layer is a metal Ni layer. The hot galvanized high-strength steel plate is good in surface quality, uniform and complete in plating layer, and better in corrosion resistance compared with a conventional hot galvanized product; and the yield strength of the hot galvanized steel plate is 600-900 MPa, the tensile strength is 980 MPa or above, the elongation is 15-22%, the surface quality and corrosion resistance are superior to those of conventional hot galvanized high-strength steel, and the hot galvanized teel plate is suitable for automobile structural parts and outer plates with higher requirements on surface quality, corrosion resistance and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

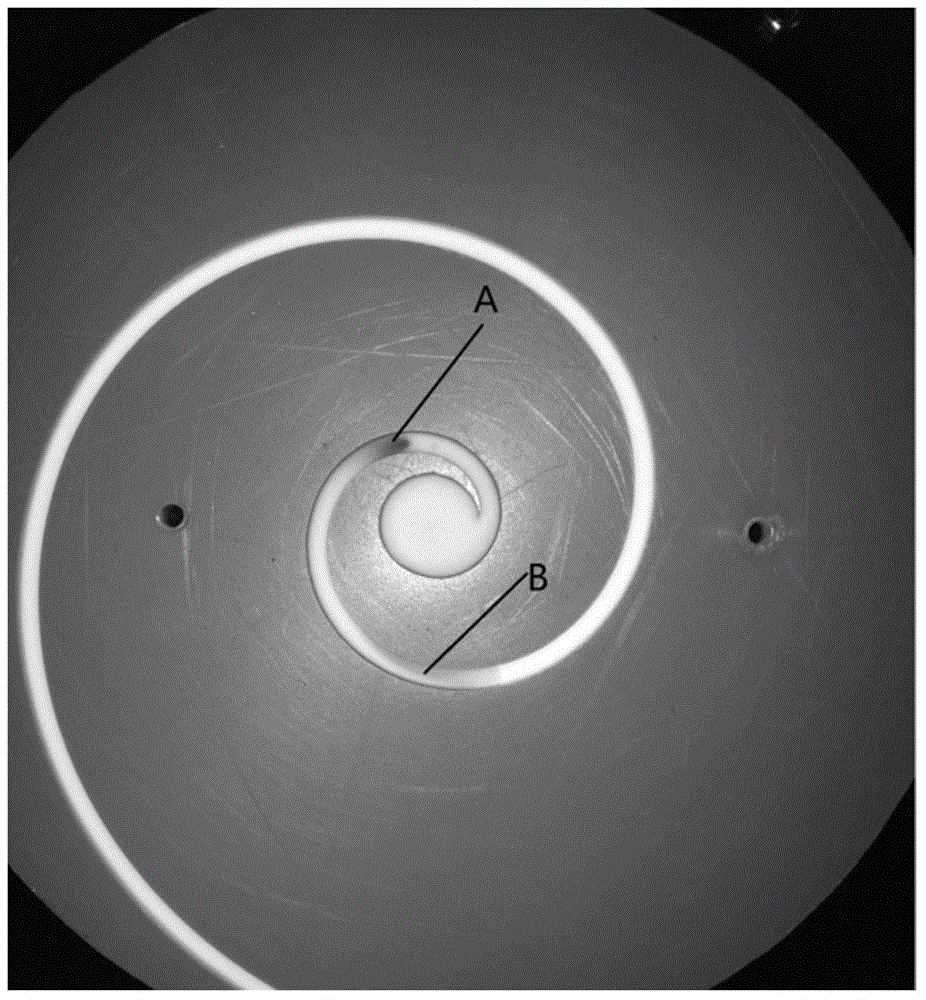

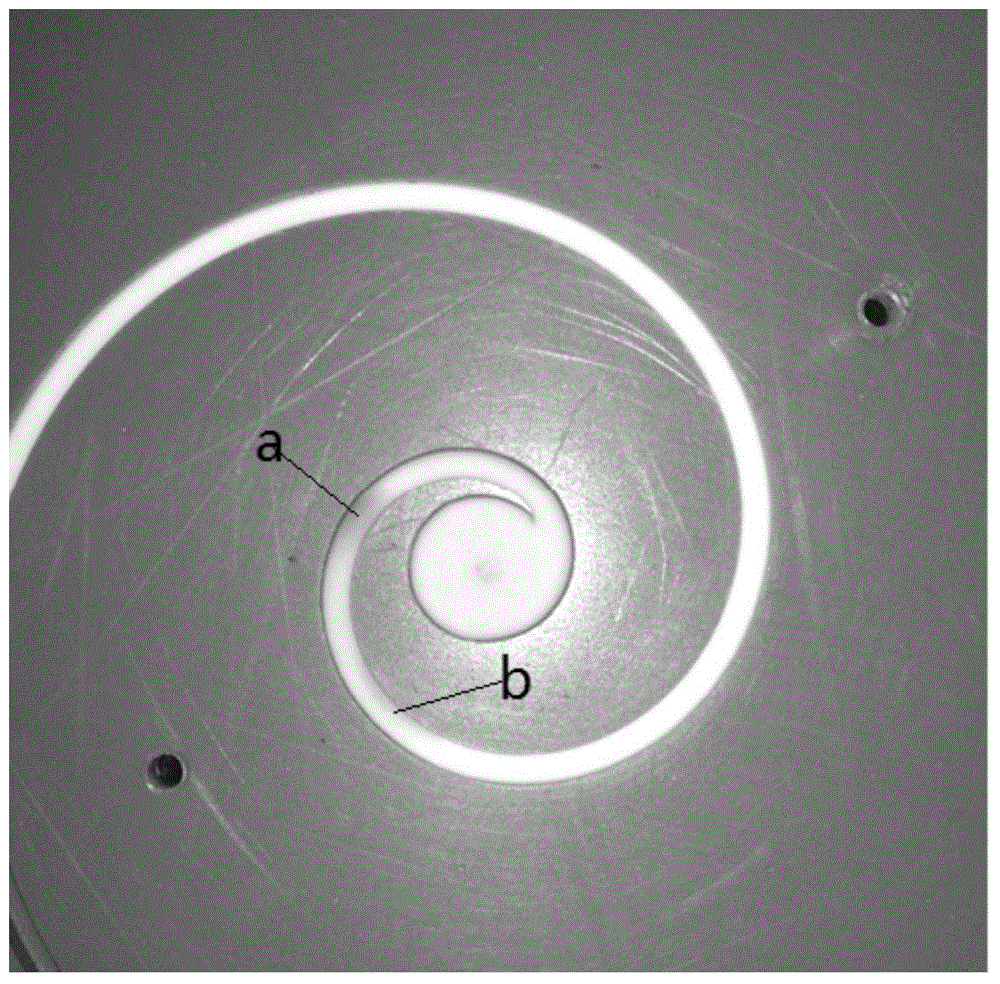

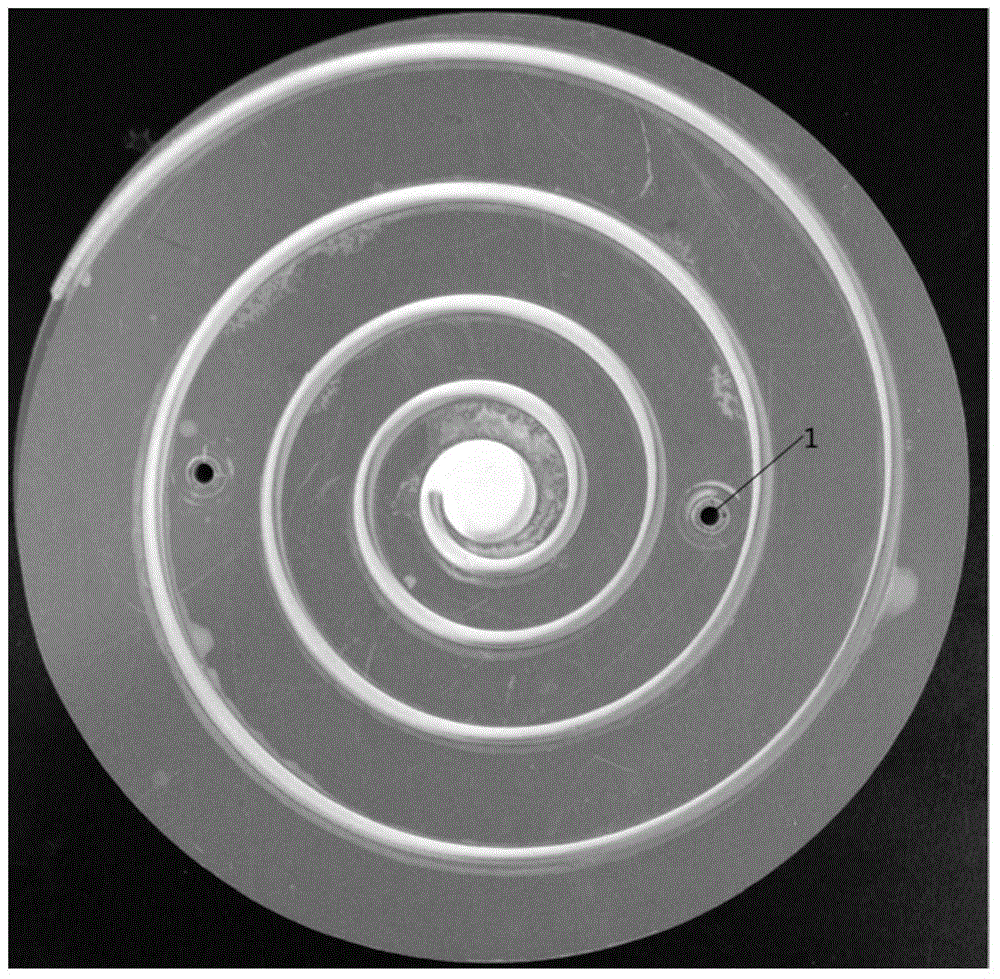

Narrow-band spiral chromatographic sheet and preparation method thereof

InactiveCN104655787AIncrease the spread distanceEasy to move forwardComponent separationStationary phaseCentrifugal force

The invention provides a narrow-band spiral chromatographic sheet and a preparation method of the narrow-band spiral chromatographic sheet. The narrow-band spiral chromatographic sheet comprises a substrate, wherein a spiral-line-shaped groove is formed at one side of the substrate, the starting end of the groove is positioned at the position of the geometric center of the substrate, and a stationary phase is arranged in the groove; according to the narrow-band spiral chromatographic sheet, the open range is increased, the difference of the retardation factors of the mixtures is increased under the action of the centrifugal force when the mixture is separated, and the separating efficiency is improved.

Owner:PEKING UNIV

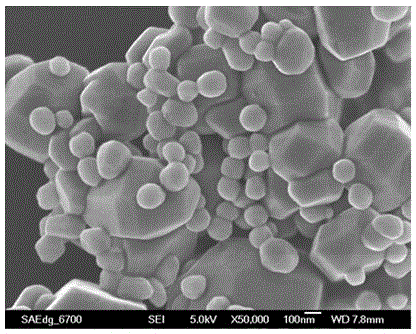

Preparation method of polyhedral nano oxide for catalyzing

ActiveCN104307521AIncrease the diffusion coefficientBlock associationMetal/metal-oxides/metal-hydroxide catalystsPotassiumCopper oxide

The invention relates to a preparation method of polyhedral nano oxide for catalyzing. The preparation method comprises the following steps: preparing nano polyhedral copper oxide powder by a salt melting method taking a potassium source and a sodium source as melted salt; dissolving copper salt into water to prepare a solution; dropping an alkali source into the solution until the pH of the solution is 6-8; putting the solution into a constant-temperature magnetic stirrer to be stirred at constant temperature of 60 DEG C; filtering and washing for two to three times after sediment is generated and putting the product into a drying oven to be dried; putting a dried precursor, sodium salt and potassium salt into a ball milling tank to be milled; drying the milled mixed solution and transferring the solution into a crucible to be calcined; then cooling in the air to room temperature; and filtering, washing and drying to prepare the nano polyhedral copper oxide powder. The preparation method has the advantages of low synthesis temperature, simplicity in operation, uniform chemical components of the synthesized powder, good crystal appearance and the like; and a Rhodamine B degrading experiment shows that compared with commodity nano copper oxide, the catalyzing performance is greatly improved.

Owner:上海泛翌新材料有限公司

Slow-dissolving-type fertilizer

InactiveCN104355811AImprove the chemical and physical environmentLarge adsorption capacityOrganic fertilisersUrea compound fertilisersPotassiumGluconic acid

The invention relates to a slow-dissolving-type fertilizer. The slow-dissolving-type fertilizer comprises the following raw materials in parts by weight: 60 to 100 parts of urea, 20 to 30 parts of sulfate, 20 to 30 parts of phosphate esterification starch, 10 to 20 parts of nitro humic acid ammonium, and 2 to 5 parts of gluconic acid. According to the slow-dissolving-type fertilizer, the chemical and physical environments of various nutritional elements in soil can be improved; the dispersing speed and the migration distance of the nutrients, such as nitrogen, phosphorus and potassium, in the soil are increased; the absorption and utilization to water and the nutrients by a root system are promoted.

Owner:重庆市盛馨种业有限公司

Rare earth hydride surface coating treating agent, application thereof and method for forming rare earth hydride surface coating

InactiveCN101908397BImprove magnetic propertiesImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureRare earthSolvent

The invention discloses a rare earth hydride surface coating treating agent, a method for forming a rare earth hydride surface coating and application of the rare earth hydride surface coating treating agent, which are used for improving the coercive force of a sintering NdFeB magnet and belong to the technical field of magnetic materials. The coating treating agent is a colloid solution formed by dispersing rare earth hydride into a methanol or ethanol solvent. The method for forming the rare earth hydride surface coating comprises the following steps of: injecting the treating agent into glassware and soaking a magnet into a solution; carrying out ultrasonic processing on the treating agent containing the magnet so that rare earth hydride in the treating agent is uniformly coated on thesurface of the magnet to form a surface coating with even thickness; taking the magnet provided with the rare earth hydride surface coating out of the solution and volatilizing the solvent in the magnet surface coating in an air drying way to form a coating; and placing the air dried magnet into a vacuum heat treatment furnace and carrying out heat treatment for 0.5-2 hours in a temperature rangeof 500-950 DEG C. The invention can obviously improve the magnetic performance of the magnet, especially the coercive force of the magnet.

Owner:BEIJING UNIV OF TECH

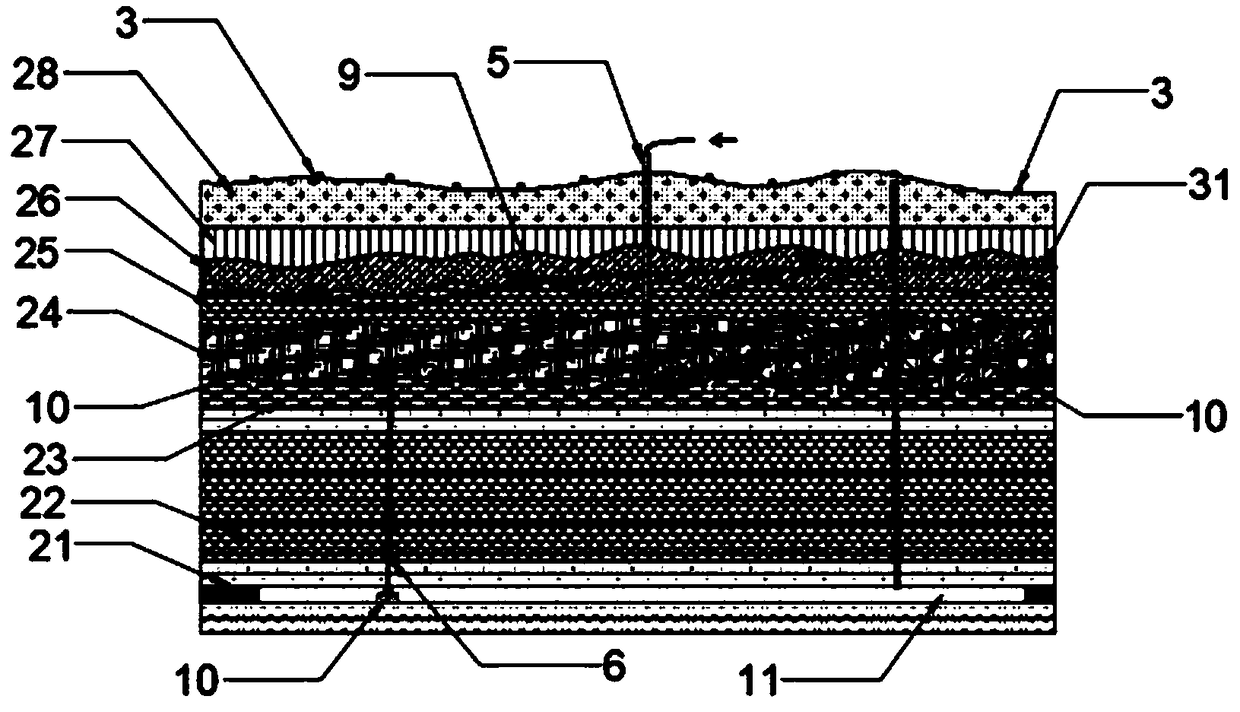

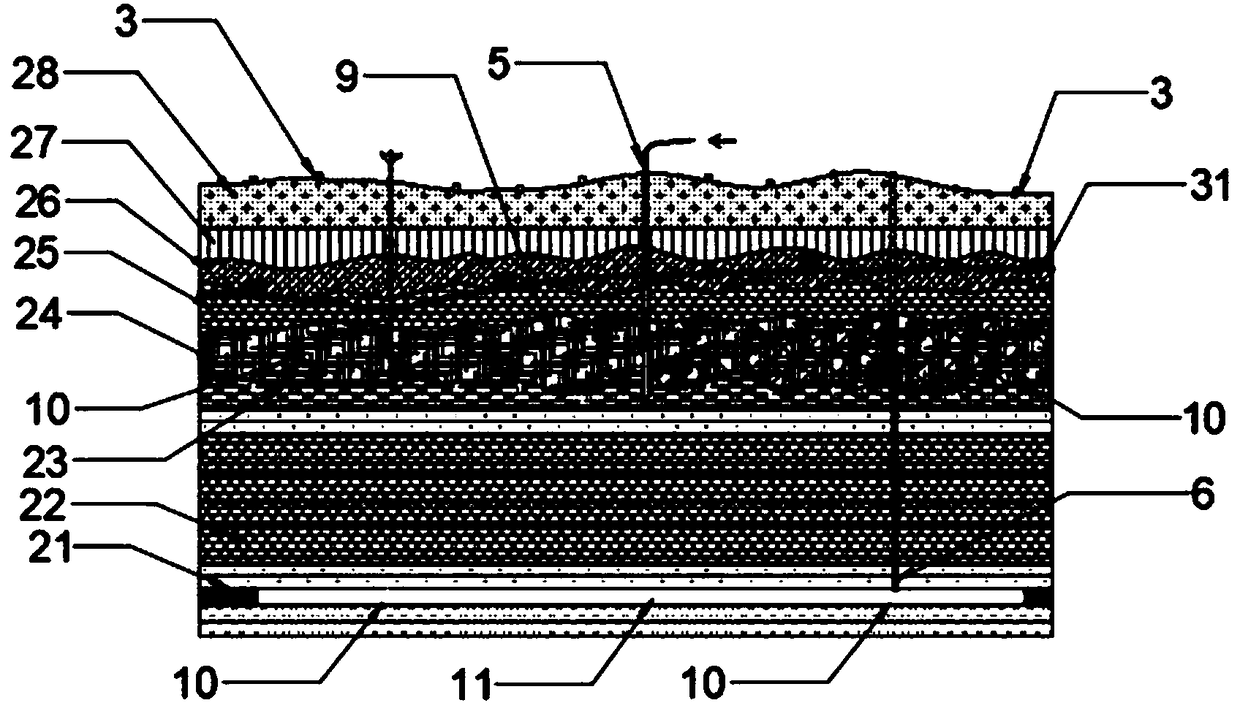

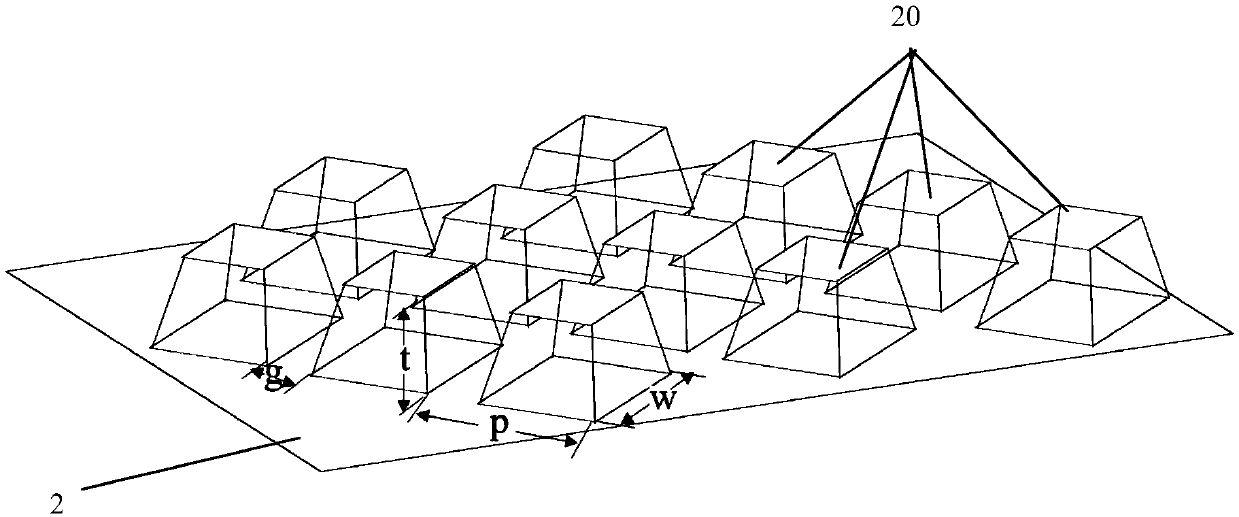

Color adjustable perovskite LED based on micro-nano structure and preparation method thereof

ActiveCN109599497AResonant enoughAvoid lossSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoIndium

The invention discloses a color adjustable perovskite LED based on a micro-nano structure and a preparation method thereof. The overall device structure, from the bottom up, sequentially includes a tin indium oxide layer, a titanium dioxide layer, a styrene sulfonate layer, a perovskite layer, a 1,3,5-tris(1-phenyl-1H-benzimidazol-2-yl) benzene layer and a lithium / aluminum fluoride layer; the titanium dioxide layer is taken as a scattering body and includes a plurality of single-layer and periodically-arranged titanium dioxide micro-nano structures; a longitudinal section of each titanium dioxide micro-nano structure is of a trapezoid having an upper edge shorter than a lower edge; cross sections of upper and lower surfaces of each titanium dioxide micro-nano structure are of a square respectively; and the titanium dioxide micro-nano structures are arranged orderly and are formed into a clear edge. The invention further discloses a preparation method. Compared with the prior art, thestructure is simple, the preparation method is greatly simplified, the conversion efficiency is high, the energy consumption is low and thus the color adjustable perovskite LED is a novel color adjustable perovskite LED with high brightness, high sensitivity and large color adjustment range.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

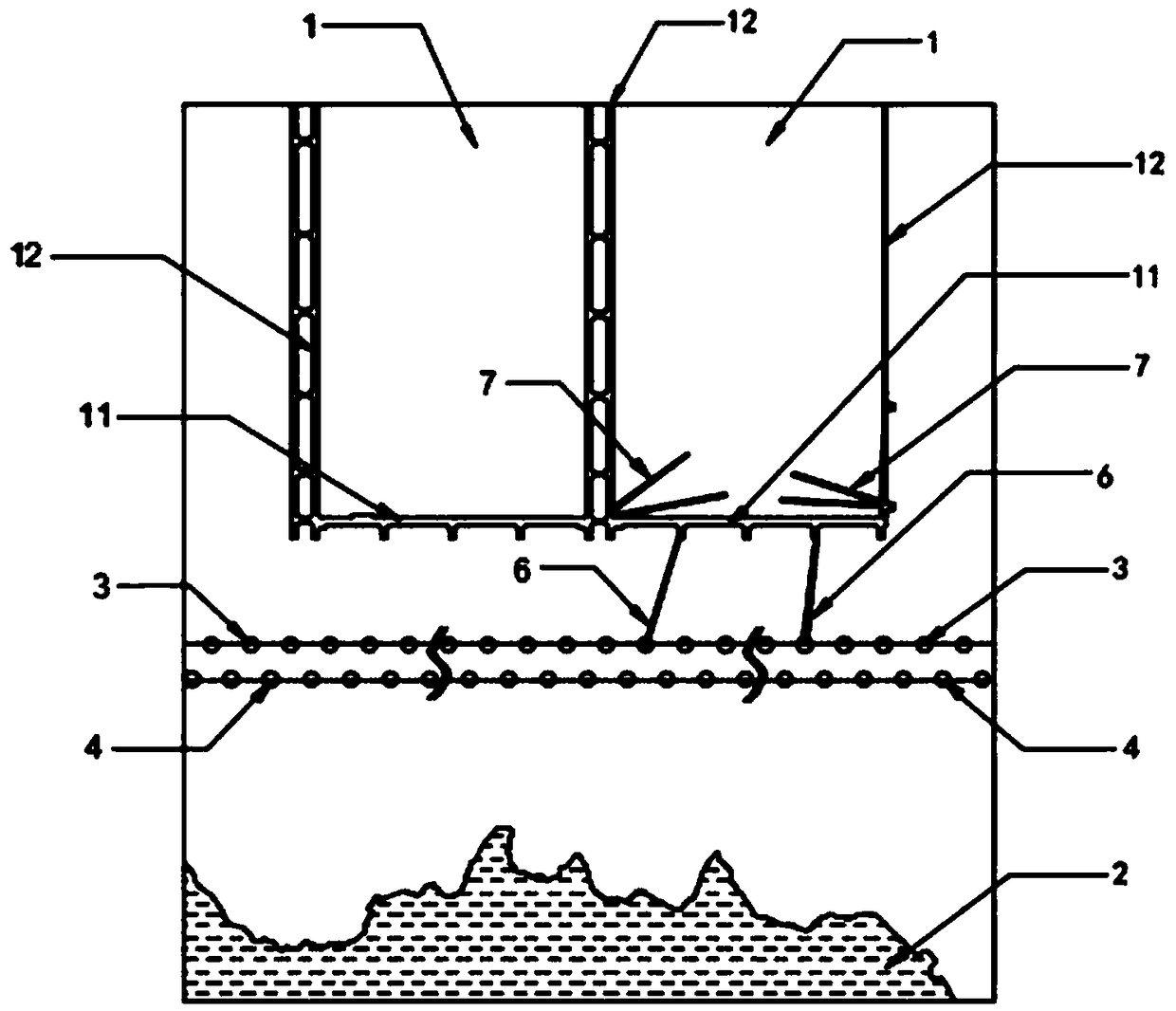

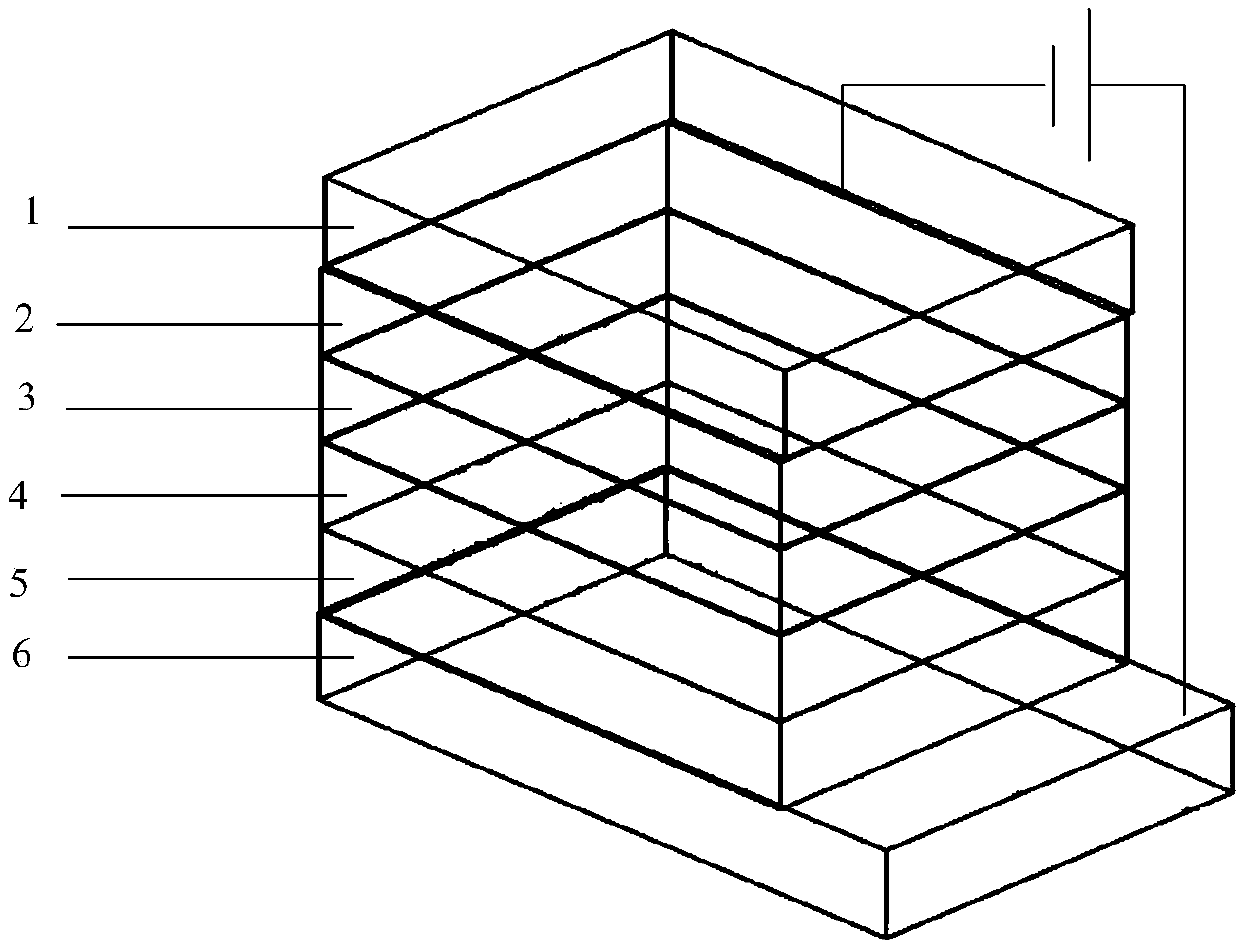

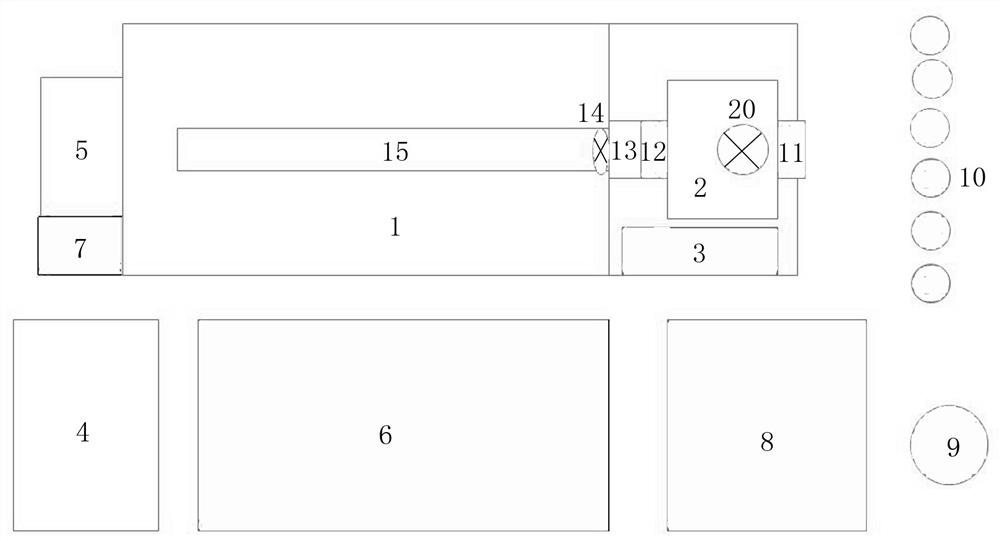

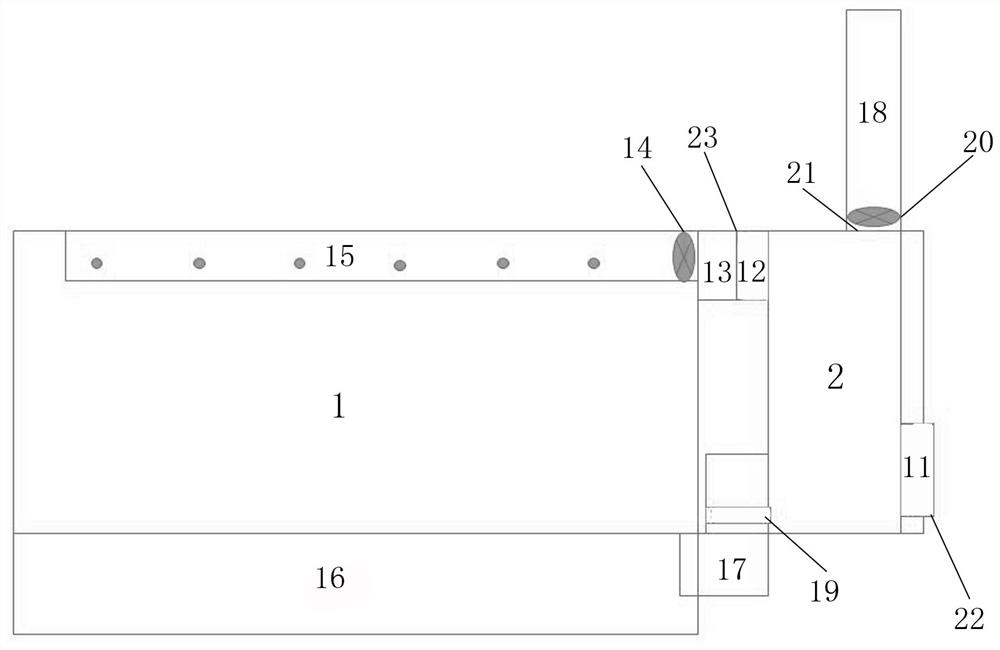

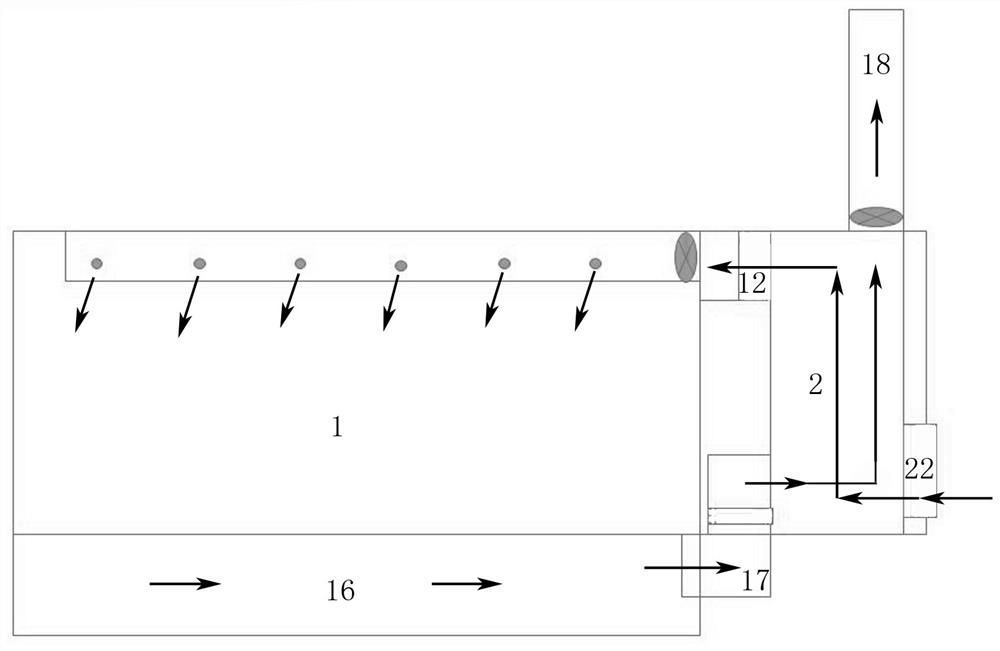

Efficient pig farm based on heat pump exchange system

PendingCN112931236AReduce the impact of production performanceReduce manufacturing costAnimal housingPig farmsWater storage

The invention discloses an efficient pig farm based on a heat pump exchange system. The efficient pig farm mainly comprises a heat-preservation closed pig house 1, a pig house tail gas heat exchange system 2, a ground source heat pump system (comprising a heat pump main machine 3, a valve system, a control system, a tail end heat exchanger 13 and the like), a pig farm staff living area 4, an office area 5, a reservoir 6, a hot water storage device 7, a feces treatment facility 8, a condensing tower 9 and a ground source well 10. The heat-preservation closed pig house 1 can be used for feeding different types of pigs by installing different facilities. The ground source heat pump system exchanges heat among different heat-producing and heat-requiring facilities and equipment; and meanwhile, the ground source well system is used for storing and taking energy, so that the energy utilization rate is increased, and the operation cost is reduced.

Owner:SHANXI CHANG RONG AGRI TECH CO LTD

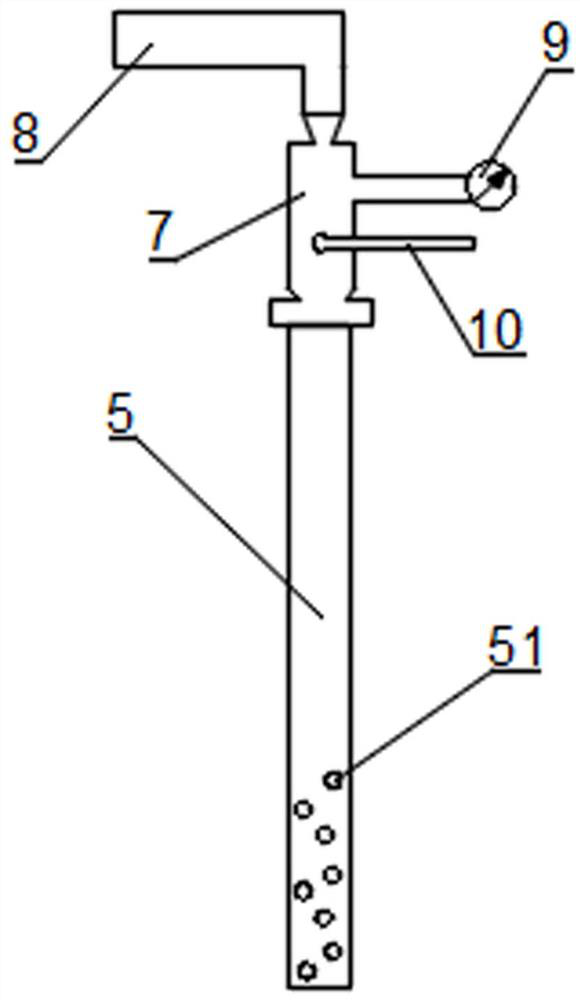

Circulating pressure-maintaining multi-turn grouting method for dam seepage-proofing reinforcement

PendingCN111851497AHigh viscosityImprove permeabilityFoundation engineeringDrinking water installationDrilling machinesGrout

The invention belongs to the technical field of seepage-proofing reinforcement of water conservancy foundations, and particularly relates to a circulating pressure-maintaining multi-turn grouting method for dam seepage-proofing reinforcement. The method comprises the following steps that the position of a permeable layer needing to be disposed is determined; holes are distributed in the position,close to the upstream face, of the top of a dam, and then a grouting hole is drilled through a drilling machine; a grouting pipe is arranged in the grouting hole, a hole sealing pipe is shorter than the grouting pipe, and an isolation block is arranged below the hole sealing pipe; an expansion material is injected into the hole sealing grouting pipe for hole sealing and pressure maintaining; and acirculating pressure-maintaining multi-turn grouting method is used for grouting of permeable high polymers, and the grouting pressure is 0.5-2Mpa. According to the method, construction is convenientand fast, the construction period is short, disturbance to the dam is small, the seepage-proofing effect is good, durability is high, full permeation and diffusion of grout are facilitated, subjectivity and experience of the grouting process can be effectively reduced, and grouting construction can be guided.

Owner:SUN YAT SEN UNIV +1

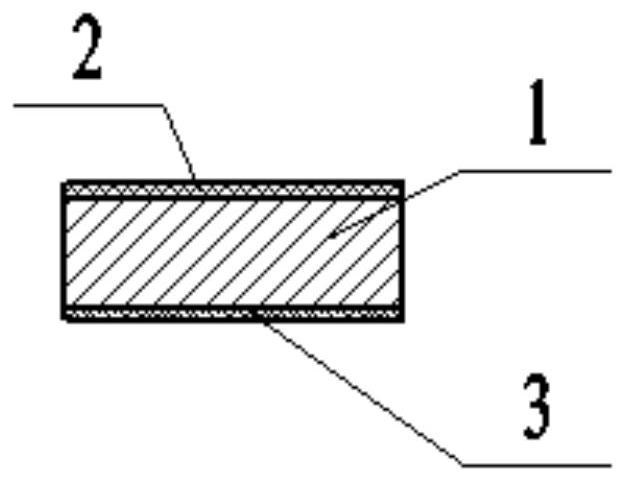

Strip-shaped brazing filler metal for lap joint brazing of copper plate and aluminum plate and preparation method thereof

ActiveCN112894191ALow melting pointImprove wettabilityWelding/cutting media/materialsSoldering mediaPolyvinyl alcoholLap joint

The invention belongs to the field of welding materials, and relates to strip-shaped brazing filler metal for lap joint brazing of a copper plate and an aluminum plate and a preparation method thereof. The strip-shaped brazing filler metal comprises a brazing filler metal body, a coating I and a coating II, the brazing filler metal body comprises the chemical components of 3.2%-4.5% of nano-zinc oxide, 6.8%-8.2% of selenium, 2.6%-4.2% of aluminum and the balance zinc, the coating I is composed of 90%-92% of surface modified nano-copper and the balance of polyvinyl alcohol, the coating II is composed of 90%-92% of surface modified nano-aluminum and the balance of polyvinyl alcohol, and the molecular weight of the polyvinyl alcohol is 8000 to 12000. According to the strip-shaped brazing filler metal for lap joint brazing of the copper plate and the aluminum plate and the preparation method thereof, the melting point of the brazing filler metal is 330 DEG C + / -10 DEG C, the wettability of the brazing filler metal is good, and due to the existence of the nano-zinc oxide, the nano-copper coating and the nano-aluminum coating, the shear strength of a copper plate and aluminum plate brazed joint is effectively improved and reaches 121 MPa or above. The preparation method is an innovation in the aspect of the strip-shaped brazing filler metal for lap joint brazing of the copper plate and the aluminum plate.

Owner:ZHENGZHOU UNIV

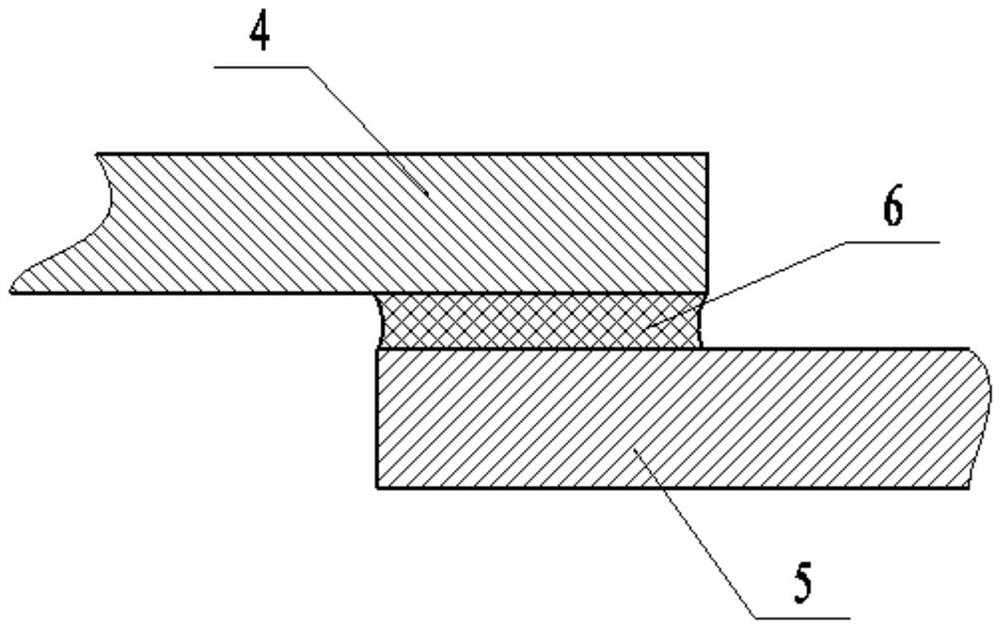

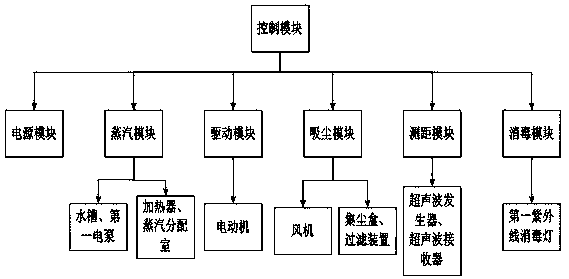

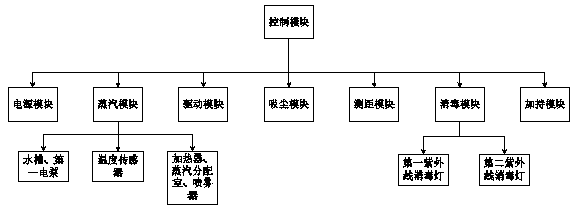

Intelligentvacuum cleaner

InactiveCN108078484AEasy to operateReasonable switch settingsElectric equipment installationEngineeringVacuum cleaner

The invention provides an intelligentvacuum cleaner. The intelligent vacuum cleaner includes a body and a charging base. The body includes a distance measuring module, a driving module, a power supplymodule, a dust collection module, a control module, a steam module and a disinfection module.The control module is connected with the distance measuring module, the driving module, the power supplymodule, the dust collection module, the steam module and the disinfection module respectively. The intelligent vacuum cleaner has simple operation, reasonable switch setting, good stain removal effect and good dust removal effect, and has a disinfection function and a drying function, the working efficiency of the ultra-intelligent vacuum cleaner is improved, and costs are saved.

Owner:东莞市极酷机电科技有限公司

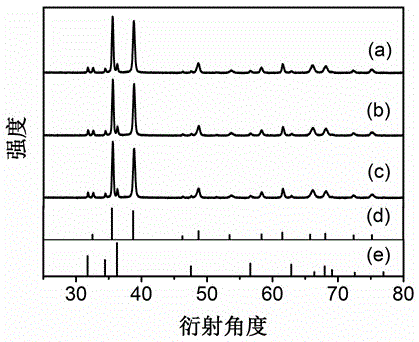

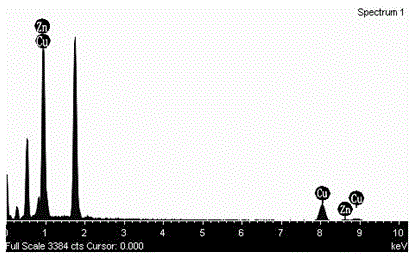

Preparation method of polyhedron nano copper oxide of loaded spherical zinc oxide nano particles

InactiveCN105013493ABlock associationReduce the degree of reunionWater contaminantsCatalyst activation/preparationCopper oxideChemical engineering

The invention discloses a preparation method of polyhedron nano copper oxide of loaded spherical zinc oxide nano particles, which is characterized in that a molten salt method is employed, calcining temperature is controlled at temperature of 450-650 DEG C for calcining to obtain the nano polyhedron copper oxide powder; then the nano polyhedron copper oxide powder is taken as a carrier, a solution evaporation method-calcining process is employed, under room temperature condition, the nano polyhedron copper oxide powder is dispersed to a zinc salt aqueous solution, and is stirred and evaporated, and is calcimined at temperature of 350-500 DEG C to obtain the polyhedron nano copper oxide of loaded spherical zinc oxide nano particles. The preparation method has the advantages of low synthesis temperature, simple operation, uniform chemical component of synthesis powder, good crystal morphology and uniform loading. Through rhodamine B degradation experiment, compared with single nano copper oxide, the catalysis performance is obviously increased.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for preparing monoolefine from diolefin through hydrogenation

ActiveCN112898111AShorten the diffusion distanceIncrease the spread distanceCatalyst carriersHydrocarbon by hydrogenationPtru catalystHydrogenation reaction

The invention relates to a method for preparing monoolefine from diolefine through hydrogenation, in particular to a method for preparing monoolefine from C10-C15 diolefine through hydrogenation. The method is characterized by comprising the following steps that in a plurality of hydrogenation reactors connected in series, an alkane olefin mixture flow containing C10-C15 monoolefine and C10-C15 diolefine makes contact with a specific hydrogenation catalyst under hydrogenation reaction conditions, hydrogen is respectively injected into each reactor, the catalyst is formed by combining an inner substance and an outer substance with different properties, the inner first-layer substance has lower porosity, the outer second-layer substance has first-type pores and second-type pores, the maximum value of the pore size distribution of the first-type pores is 4-50nm, and the maximum value of the pore size distribution of the second-type pores is 100- 1000 nm. The catalyst has relatively low permeability of the first layer of noble metal carrier and is beneficial to recovery of noble metal, and the method has outstanding selectivity and activity in a diolefin selective hydrogenation reaction process.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

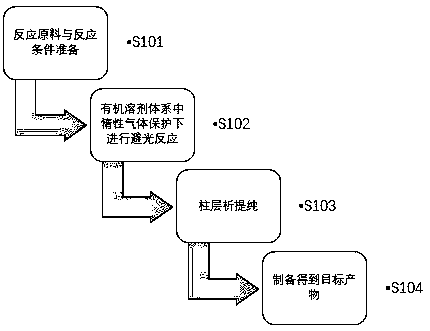

A kind of preparation method of lithium dioxalate borate

InactiveCN101602773BSimple processOvercome the disadvantages of complex processGroup 3/13 element organic compoundsOxalateSlurry

A kind of preparation method of lithium bisoxalate borate of the present invention relates to boron compound, and its process step is: the first step, raw material is mixed under the liquid phase condition and forms raw material slurry: analytically pure solid raw material ammonium oxalate, lithium iodide and The boron-containing oxygen compound is added to the aqueous ethanol solution, stirred and mixed evenly to form a raw material slurry; the second step, liquid phase reaction to prepare lithium bisoxalate borate slurry: the raw material slurry obtained in the first step is placed in an airtight container Inside, react to prepare lithium bisoxalate borate slurry; the third step, solid-phase burning to obtain lithium bisoxalate borate finished product: place the lithium bisoxalate borate slurry prepared in the second step in a vacuum oven , dried to powder, then placed in an electric furnace, heated to 200-240°C at a rate of 5-10°C / min, and then kept at this temperature for 1-6 hours to obtain the finished product of lithium bisoxalate borate. The process of the method of the invention is simple, and the obtained lithium bisoxalate borate product has high purity and high yield, and is suitable for large-scale production.

Owner:HEBEI UNIV OF TECH

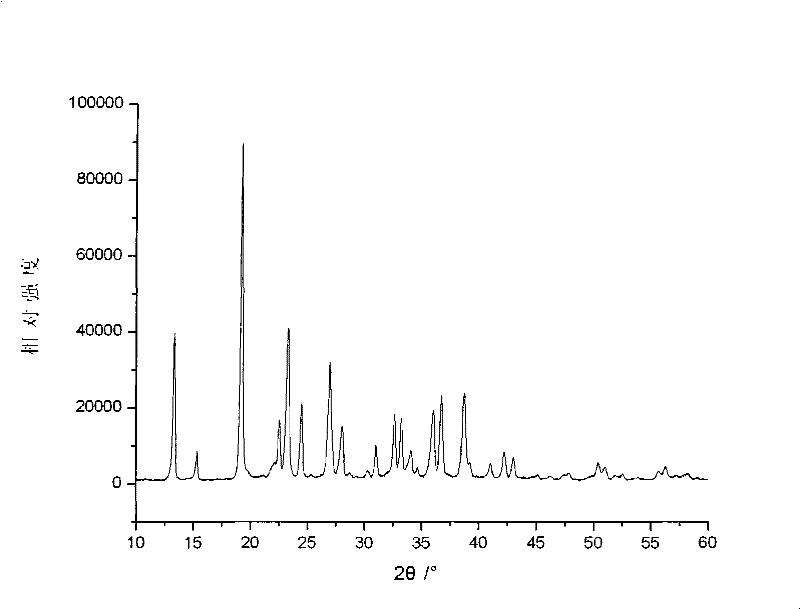

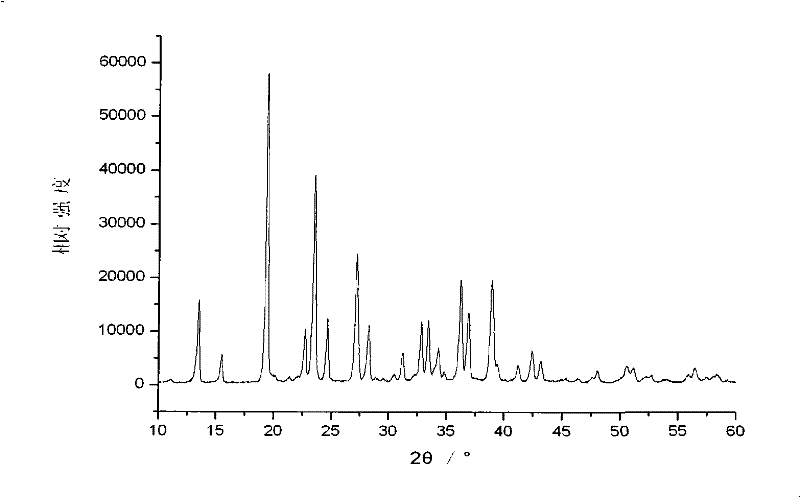

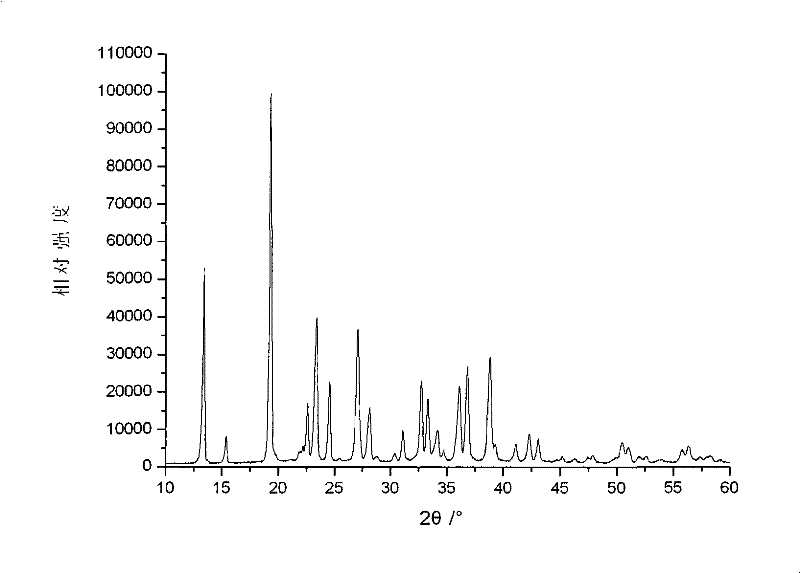

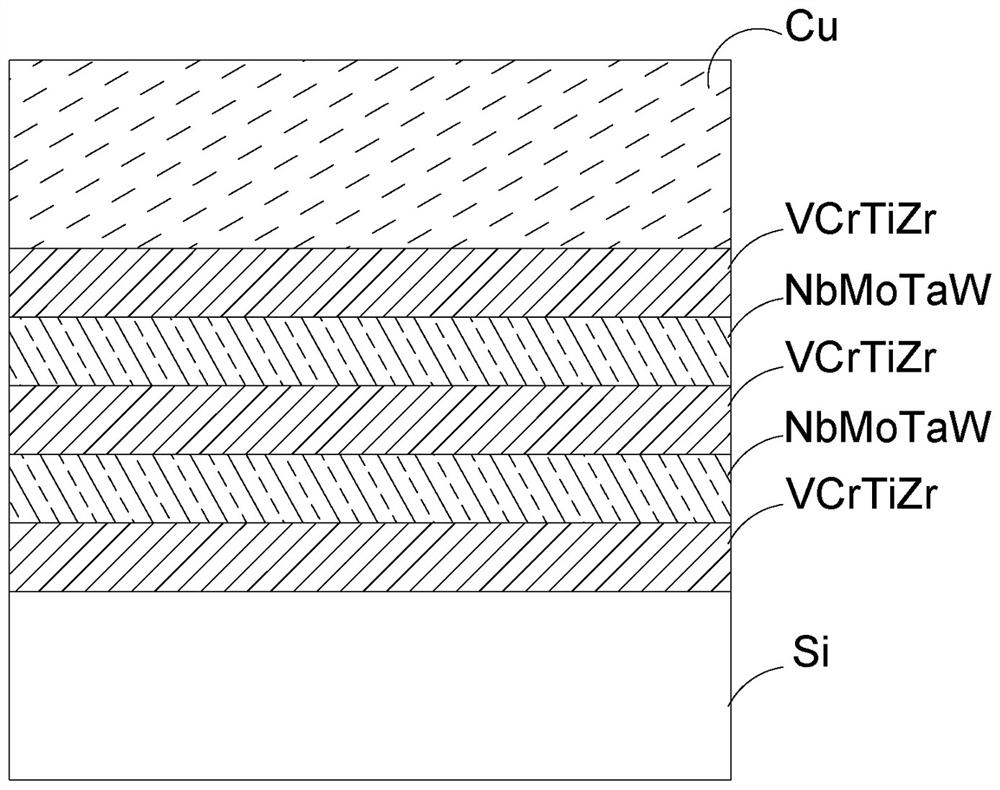

Multi-layer alloy diffusion barrier layer for Cu interconnection integrated circuit and preparation method of multi-layer alloy diffusion barrier layer

ActiveCN114783980AMeet application requirementsThe composition is uniform and denseSemiconductor/solid-state device detailsVacuum evaporation coatingHigh entropy alloysInterconnection

The invention belongs to the technical field of semiconductor integrated circuits, and particularly relates to a multi-layer alloy diffusion barrier layer for a Cu interconnection integrated circuit and a preparation method thereof, and the multi-layer alloy diffusion barrier layer sequentially comprises a Si substrate layer, a high-entropy alloy middle barrier layer and a Cu film from bottom to top; the high-entropy alloy middle barrier layer sequentially comprises a first coating, a second coating, a third coating, a fourth coating and a fifth coating from top to bottom; according to the preparation method, NbMoTaW and VCrTiZr high-entropy alloy is used as a target material, a direct-current magnetron sputtering method is adopted, and a coating is sputtered on a Si base body layer to obtain the high-entropy alloy diffusion impervious layer of a Si-VCrTiZr-NbMoTaW-VCrTiZr-NbMoTaW-VCrTiZr-Cu composite structure. The obtained Cu interconnection integrated circuit high-entropy alloy diffusion impervious layer can still keep excellent thermal stability and diffusion impervious performance after being annealed at the high temperature of 400-750 DEG C for 30 min, and has wide application prospects in Cu interconnection integrated circuits.

Owner:亚芯半导体材料(江苏)有限公司 +1

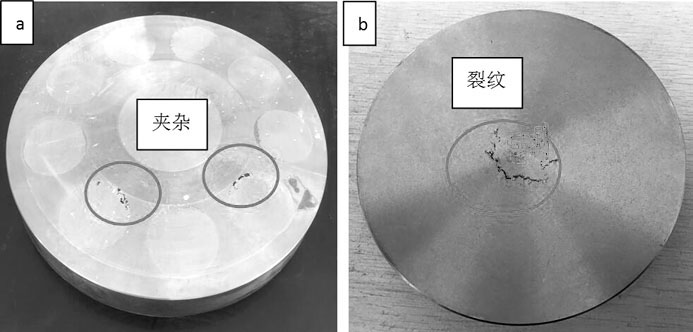

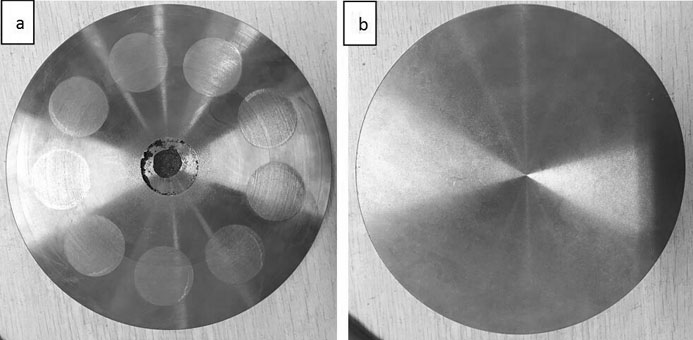

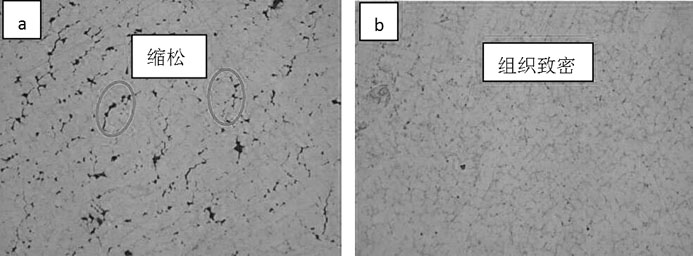

Bimetal plunger pump cylinder body extrusion casting forming method

InactiveCN113070463AImprove performance uniformityImprove the density of different positionsCylinder blockPlunger pump

The invention discloses a bimetal plunger pump cylinder body extrusion casting forming method, and relates to the technical field of bimetal extrusion forming preparation. Firstly, in the preheating stage, a steel substrate is placed in an extrusion die, an induction coil heats the steel substrate to 1130-1170 DEG C, a liquid copper alloy with the temperature being 1150-1250 DEG C is injected into the steel substrate, standing and cooling are carried out at the room temperature to 750-900 DEG C, and then in the semi-solid extrusion stage, lower and upper timed and partitioned extrusion is conducted, and a lower punch upwards conducts semi-solid extrusion so that a copper alloy valve plate copper layer at the lower end of a plunger pump cylinder body can be extruded and formed. After a valve plate of a cylinder body is formed, an upper punch begins to downwards extrude a riser at the upper end of the cylinder body, and a plunger and a kidney-shaped hole of the cylinder body are formed. The bimetal cylinder body prepared through the bimetal plunger pump cylinder body extrusion casting forming method is free of interface cracking and high in bonding strength, and the copper alloy structure is compact, fine and uniform.

Owner:ZHONGBEI UNIV

Preparation method and application of D-A BODIPY conjugated polymer

ActiveCN110041509ALower bandgapExpand the range of light collectionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellTris(dibenzylideneacetone)dipalladium

The invention provides a preparation method of a D-A BODIPY conjugated polymer. The preparation method comprises the steps of first carrying out light-shielding reaction on a compound of a structure shown in a formula I or formula II with an electron donor monomer and a catalyst under the protection of inert gas in an organic solvent system, and then purifying through column chromatography, thereby obtaining the target product, wherein the molar ratio of the compound of the structure shown in the formula I or formula II to the electron donor monomer is 1 to (1-2), the reaction temperature is 90-130 DEG C, and the reaction lasts 24-72 hours; the electron donor monomer is 5,5'-ditrimethyl tin-2,2'-bithiophene, the catalyst is any one or a mixture of copper oxide, tri(2-methylphenyl)phosphineor tri(dibenzalacetone)dipalladium, and the organic solvent is dichloromethane. The polymer prepared by the method provided by the invention has relatively good absorption and appropriate energy levels in the range of visible light, and is suitable for being donor materials in organic solar cells.

Owner:NANCHANG HANGKONG UNIVERSITY

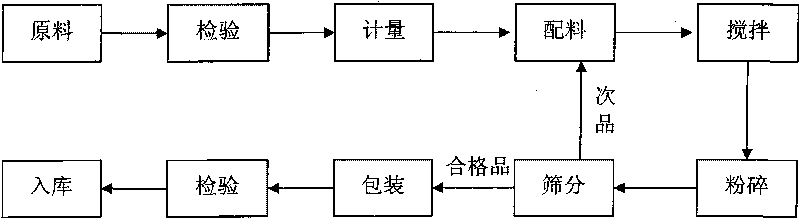

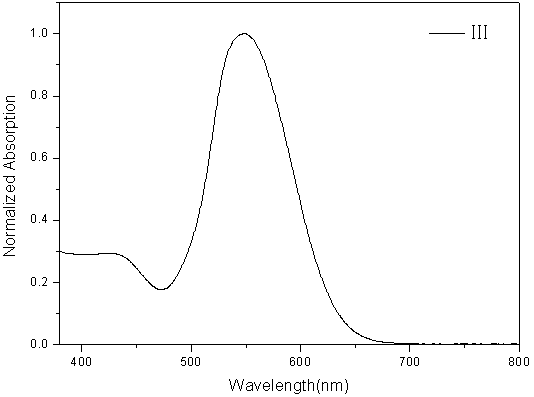

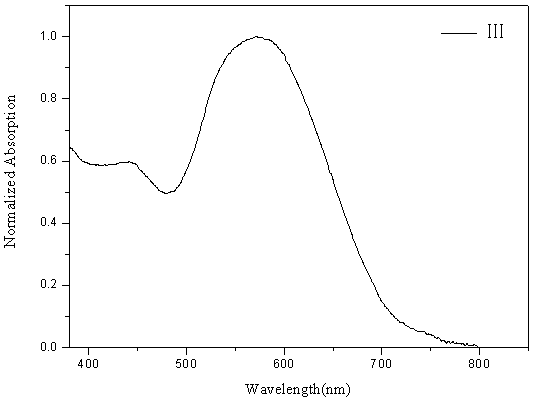

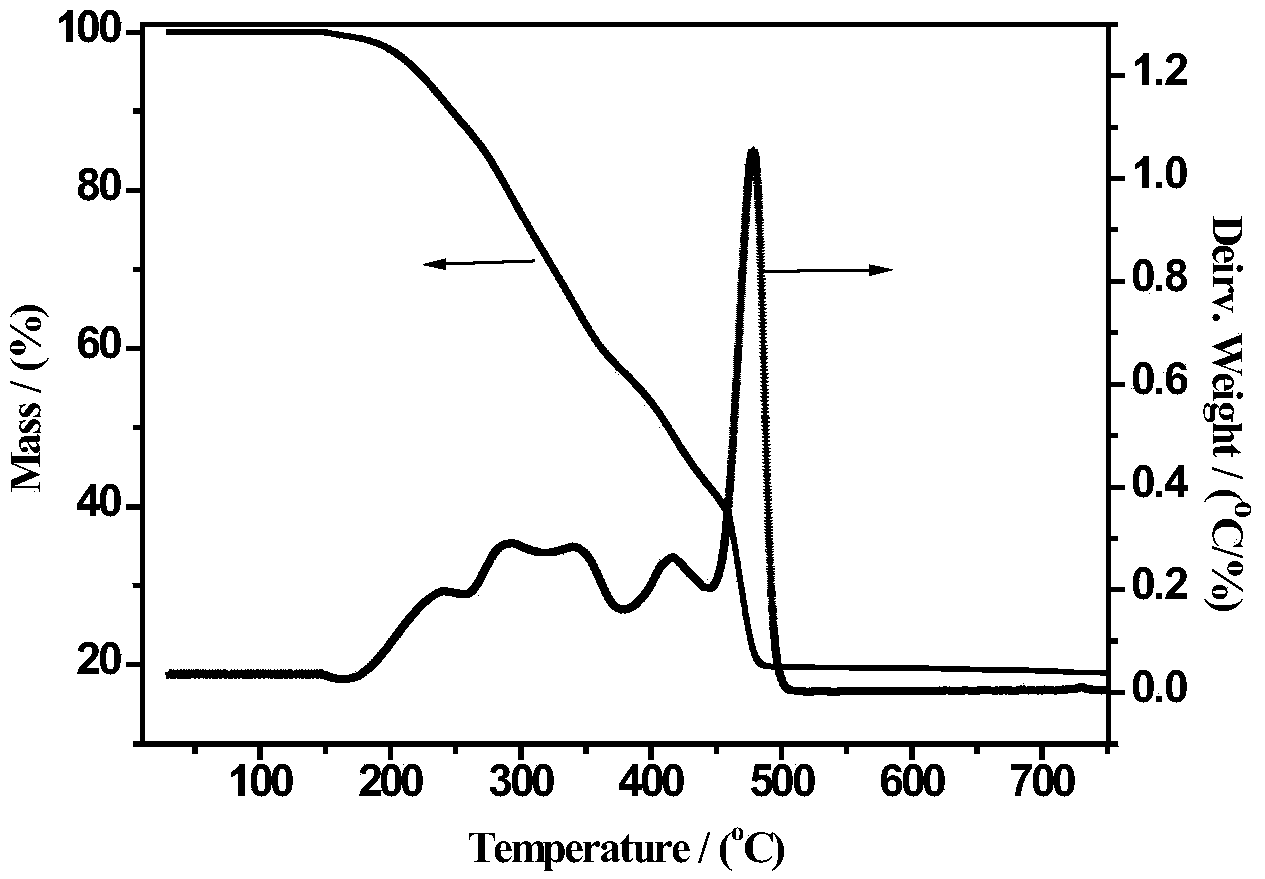

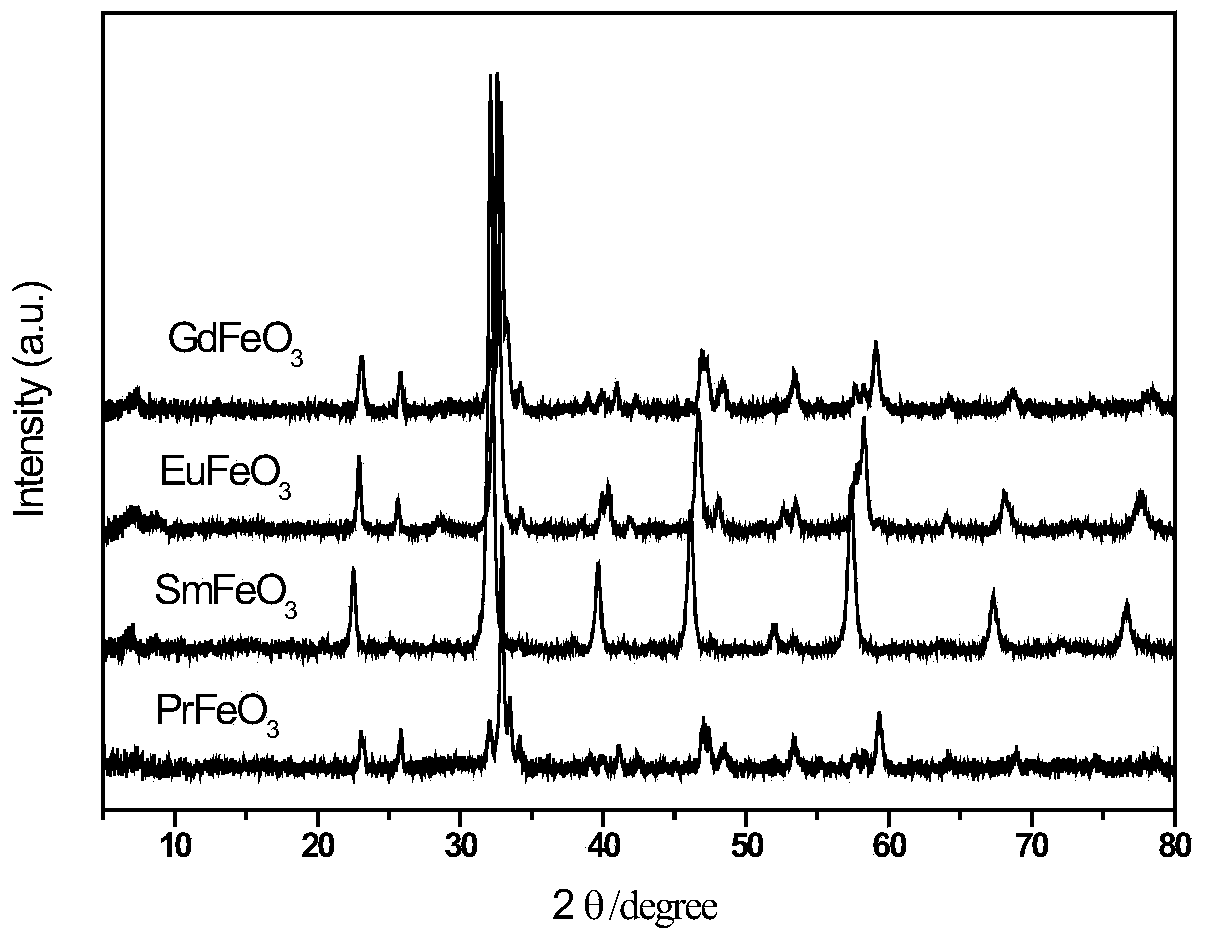

Method for preparing rare-earth magnetic ferrite through in-situ polymerization cracking process

The invention discloses a method for preparing rare-earth magnetic ferrite through an in-situ polymerization cracking process. Before a reaction begins, a stable solution is formed by dispersing metal ions in the stoichiometric ratio in an acrylic aqueous solution, various reactant metal ions are thoroughly mixed, and an initiator is added so that a polymerization reaction is aroused quickly. Lots of heat is released in the reaction, and the volume of the reactants expands sharply due to water vapor, so that a honeycombed solid-state polymer is formed. Due to volume expansion, the metal ions are dispersed more evenly, the nanocrystallization degree is high, the reaction activity among nanoparticles is increased, the diffusion distance of ions in a solid-phase reaction is reduced, the diffusibility is improved, and the nucleation and growth speed of a crystalline-state material is accelerated, and then a material uniform in dimension can be obtained through subsequent relative low heat treatment. The prepared material is good in crystallinity and few in crystal defects, and the nanoparticles are dispersed evenly. The method for preparing the rare-earth magnetic ferrite is simple in process, low in preparation temperature, short in heat-preserving time and advantageous for industrial production.

Owner:HUBEI ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com