Preparation method of polyhedral nano oxide for catalyzing

A technology of nano-oxides and polyhedrons, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve serious powder agglomeration, poor catalytic performance, and oversized particles and other problems, to achieve the effect of good crystal morphology, improved performance of catalytic degradation of organic pollutants, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

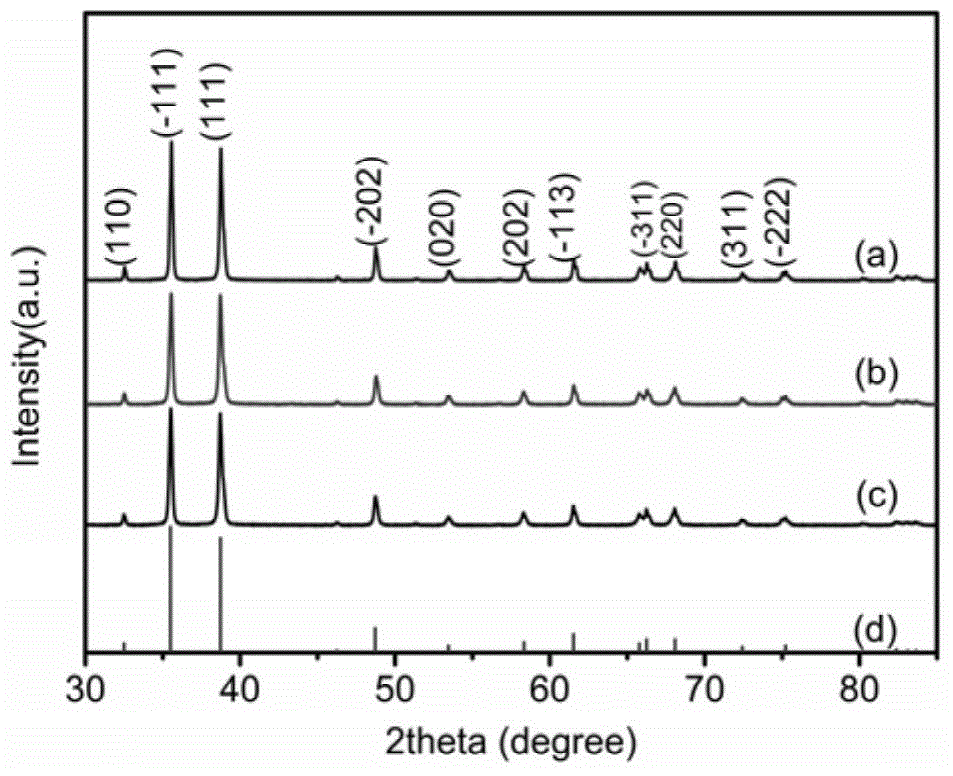

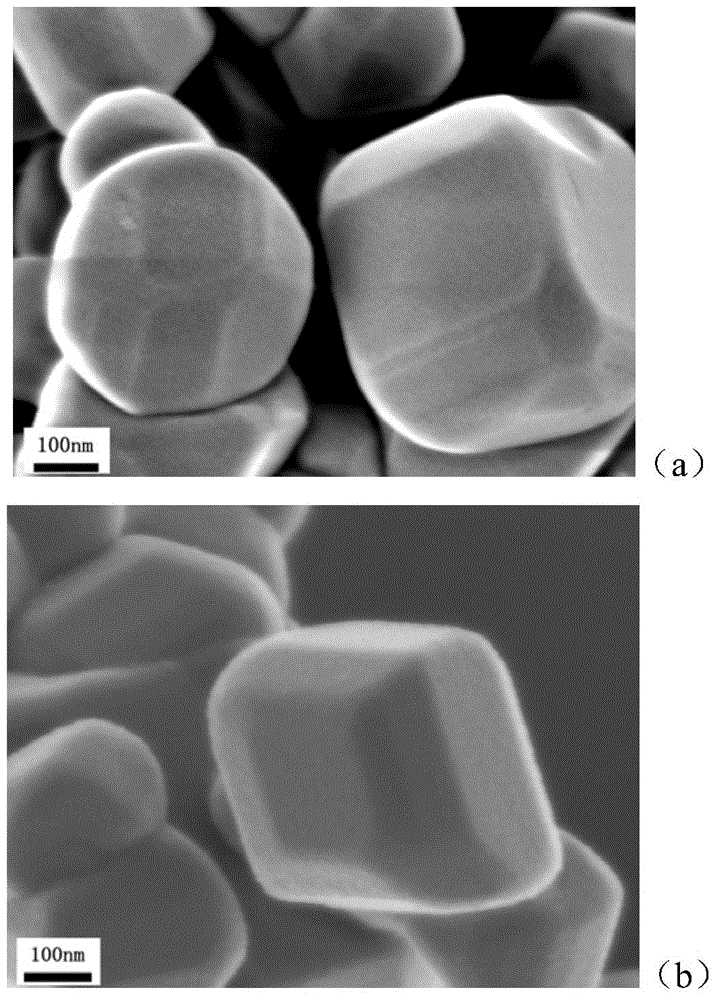

[0030] The invention discloses a preparation method of nano polyhedral oxide for catalysis, that is, nano copper oxide.

[0031] The copper salt used in the preparation is Cu(NO 3 ) 2 ·3H 2 O, the alkali source used is NH 3 ·H 2 O, the molten salt used is KNO 3 , NaNO 3 .

[0032] Weigh 15.1gCu(NO 3 ) 2 ·3H 2 O, dissolved in 125ml deionized water to form a 0.5mol / l solution, add NH dropwise 3 ·H 2 O until the pH of the solution is between 6-8, stir on a constant temperature magnetic stirrer at 60°C for 1.5h at a constant temperature, filter and wash two to three times after a precipitate is formed, and put it in an oven to dry. Weigh the dried precursor and take a certain amount of KNO 3 and NaNO 3 , and put them together into a ball mill jar for ball milling for 2h.

[0033] KNO used above 3 and NaNO 3 The molar ratio of the substance is 1:1, the mass ratio of the dried product to the molten salt is 45:55, and the ball:material:alcohol in the ball mill tank is...

Embodiment 2

[0037] The invention discloses a preparation method of nano polyhedral oxide for catalysis, that is, nano copper oxide.

[0038] The copper salt used in the preparation is CuCl 2 2H 2 O, the alkali source used is NH 3 ·H 2 O, the molten salt used is KNO 3 , NaNO 3 .

[0039] Weigh 10.655g CuCl 2 2H 2 O, dissolved in 125ml deionized water to form a 0.5mol / l solution, add NH dropwise 3 ·H 2O until the pH of the solution is between 6-8, stir on a constant temperature magnetic stirrer at 60°C for 1.5h at a constant temperature, filter and wash two to three times after a precipitate is formed, and put it in an oven to dry. Weigh the dried precursor and take a certain amount of KNO 3 and NaNO 3 , and put them together into a ball mill jar for ball milling for 2h.

[0040] KNO used above 3 and NaNO 3 The molar ratio of the substance is 1:1, the mass ratio of the dried product to the molten salt is 45:55, and the ball:material:alcohol in the ball mill tank is 2:1:0.6.

...

Embodiment 3

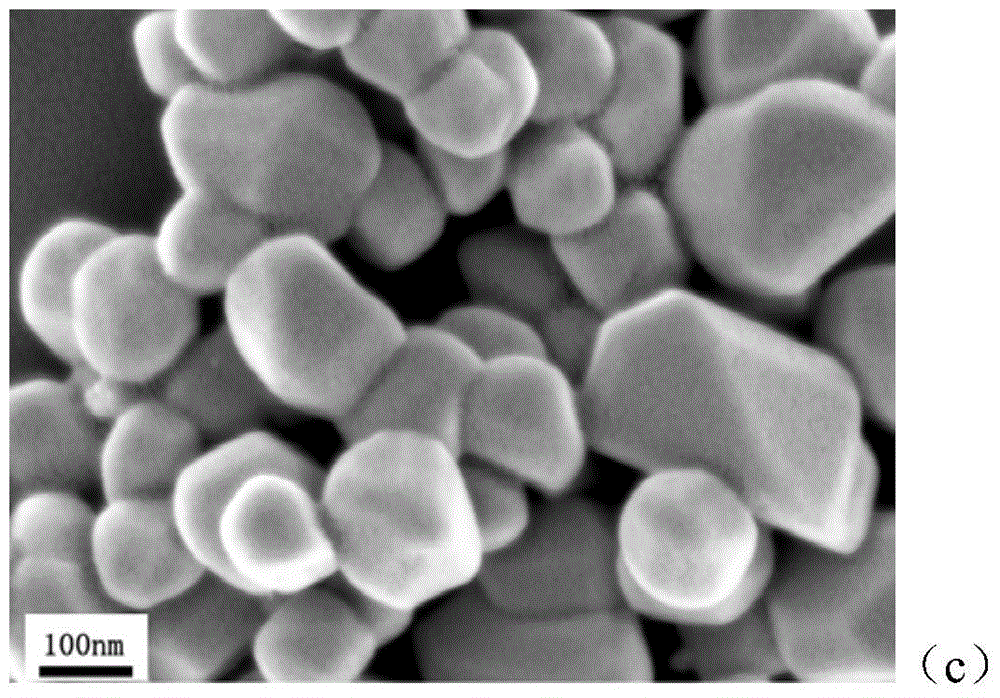

[0043] The invention discloses a preparation method of nano polyhedral oxide for catalysis, that is, nano copper oxide.

[0044] The copper salt used in the preparation is Cu(NO 3 ) 2 ·3H 2 O, the alkali source used is NaOH, and the molten salt used is KNO 3 , NaNO 3 .

[0045] Weigh 15.1gCu(NO 3 ) 2 ·3H 2 O, dissolve in 125ml deionized water to form a 0.5mol / l solution, add NaOH dropwise until the pH of the solution is between 6-8, then stir on a constant temperature magnetic stirrer at 60°C for 1.5h, and filter with suction after precipitation is formed Wash two to three times and place in the oven to dry. Weigh the dried precursor and take a certain amount of KNO 3 and NaNO 3 , and put them together into a ball mill jar for ball milling for 2h.

[0046] KNO used above 3 and NaNO 3 The molar ratio of the substance is 1:1, the mass ratio of the dried product to the molten salt is 45:55, and the ball:material:alcohol in the ball mill tank is 2:1:0.6.

[0047] Dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com