Lithium manganese nickel oxide cathode material having nickel manganese concentration gradient and preparation method thereof

A lithium-nickel-manganese oxide and cathode material technology, which is applied in battery electrodes, electrochemical generators, electrical components, etc., can solve restriction screening and optimization, comprehensive chemical performance limitations of high-voltage lithium-nickel-manganese oxide cathode materials, interface Impedance increase and other problems can be eliminated to eliminate volume change mismatch, reduce lithium ion migration resistance, and improve chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

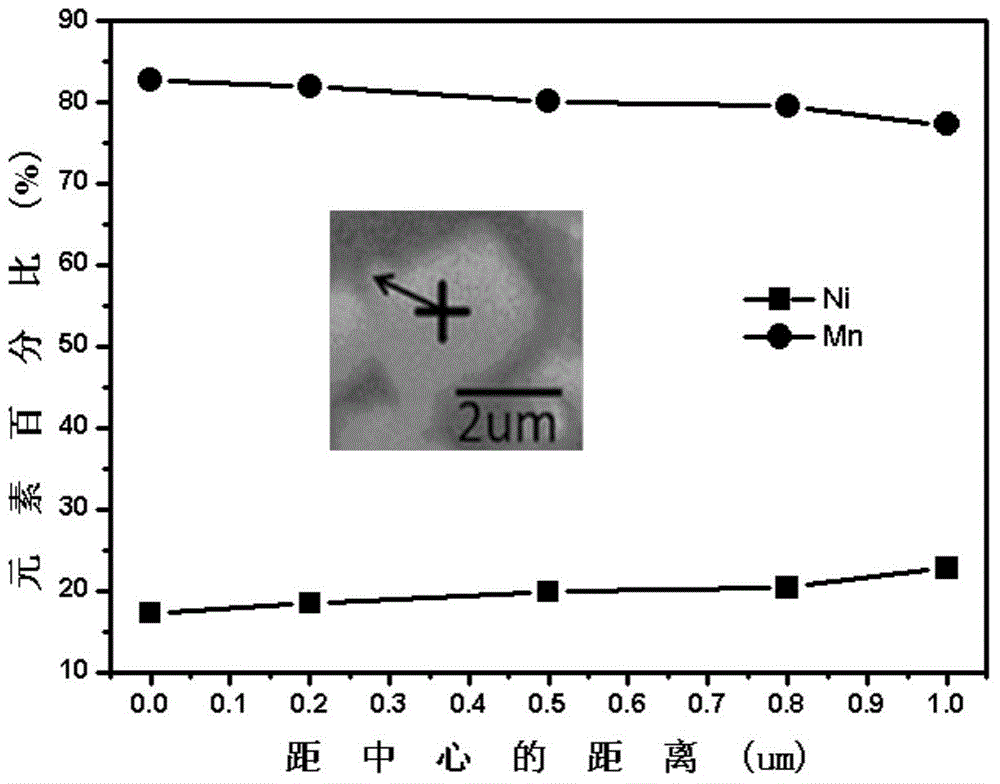

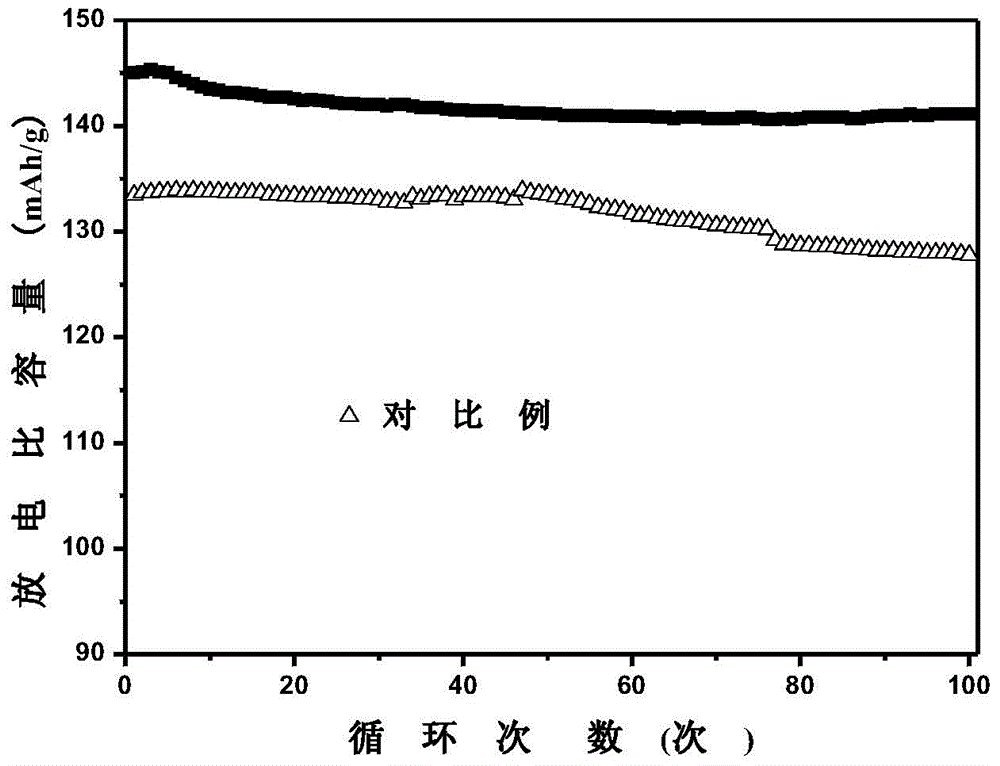

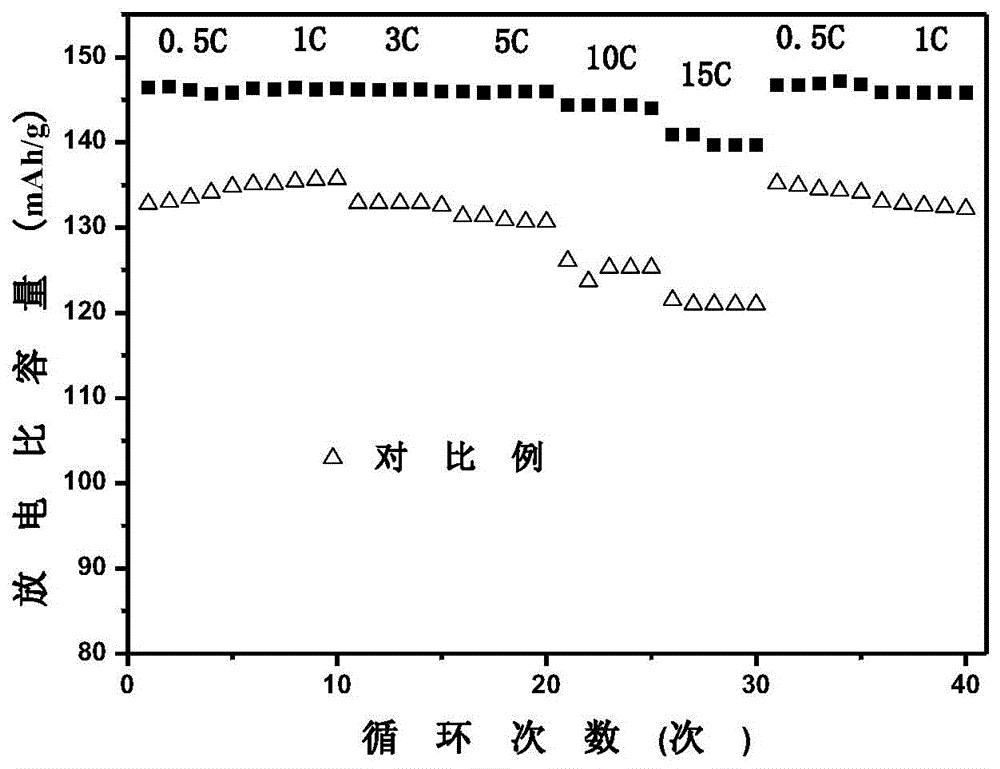

[0039] MnSO 4 ·H 2 O and NiSO 4 ·6H 2 O is dissolved in pure water according to the molar ratio of 1.65:0.35, and the total concentration is 1.33mol / L mixed solution I, the MnSO 4 ·H 2 O and NiSO 4 ·6H 2 O is dissolved in pure water at a molar ratio of 3:1 to form a mixed solution II with a total concentration of 0.67mol / L; NaOH and NH 3 ·H 2 O was dissolved in pure water respectively to form a mixed solution of sodium hydroxide-ammonia water, in which NaOH and NH 3 ·H 2 The concentration of O in the mixed solution is 2mol / L and 0.24mol / L respectively;

[0040] Take solution Ⅰ, solution Ⅱ and sodium hydroxide-ammonia water mixed solution with a volume ratio of 1:1:2, respectively. Pump the mixed solution of sodium hydroxide-ammonia water into the reactor at a constant speed of 0.7ml / min. The temperature of the reactor is 60°C and the stirring speed is 1000r / min. Pump solution I into the kettle, and control the pH value of the solution in the reaction kettle by adjus...

Embodiment 2

[0050] MnSO 4 ·H 2 O and NiSO 4 ·6H 2 O is dissolved in deionized water according to the molar ratio of 1.8:0.2, and the total concentration is 1.5mol / L mixed solution I, and the MnSO 4 ·H 2 O and NiSO 4 ·6H 2 O was dissolved in deionized water at a molar ratio of 3:1 to form a mixed solution II with a total concentration of 0.7mol / L; NaOH and NH 3 ·H 2 O was dissolved in deionized water respectively to form a mixed solution of sodium hydroxide-ammonia water, in which NaOH and NH 3 ·H 2 The concentration of O in the mixed solution is 2mol / L and 0.24mol / L respectively;

[0051] Take solution Ⅰ, solution Ⅱ and sodium hydroxide-ammonia water mixed solution with a volume ratio of 1:1:2, respectively. Pump the mixed solution of sodium hydroxide-ammonia water into the reactor at a constant speed of 9.5ml / min. The temperature of the reactor is 60°C and the stirring speed is 1000r / min. Pump solution Ⅰ into the kettle, and control the pH value of the solution in the reaction...

Embodiment 3

[0056] MnSO 4 ·H 2 O was dissolved in deionized water to prepare a solution I with a concentration of 1.4mol / L, and the MnSO 4 ·H 2 O and NiSO 4 ·6H 2 O was dissolved in deionized water at a molar ratio of 3:1 to form a mixed solution II with a total concentration of 0.6mol / L; NaOH and NH 3 ·H 2 O was dissolved in deionized water respectively to form a mixed solution of sodium hydroxide-ammonia water, in which NaOH and NH 3 ·H 2 The concentration of O in the mixed solution is 2mol / L and 0.24mol / L respectively;

[0057] Take solution Ⅰ, solution Ⅱ and sodium hydroxide-ammonia water mixed solution with a volume ratio of 1:1:2, respectively. Pump the mixed solution of sodium hydroxide-ammonia water into the reactor at a constant speed of 2ml / min. The temperature of the reactor is 60°C and the stirring speed is 1000r / min. Pump solution Ⅰ in the middle, and control the pH value of the solution in the reaction kettle by adjusting the pumping speed of solution Ⅰ to keep it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com