Preparation method of SiC nanowire toughened chemical gas codeposited HfC-SiC compound phase coating

A technology of nanowire toughening and chemical vapor phase, which is applied in the field of preparation of nanowire toughened multiphase coatings, can solve the problems of limited coating resistance to oxidation, long diffusion free path, and decreased mechanical properties, and achieve excellent anti-burning corrosion performance, short reaction cycle, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

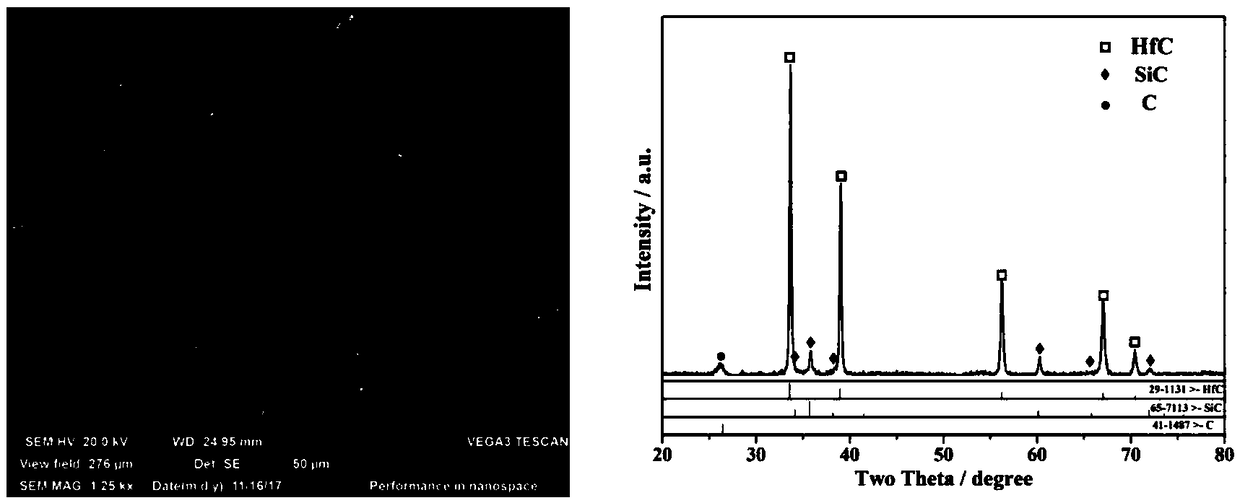

[0027] Preparation method steps of SiC nanowire toughened chemical vapor co-deposition HfC-SiC composite coating:

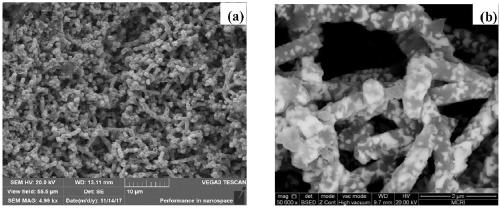

[0028] (1) Before the coating preparation, the surface of the C / C composite material sample was polished and cleaned, and dried in an oven for use. SiO 2 , Si, C three kinds of powders with a particle size of 300 mesh are mixed evenly in the ratio of 6:1:2 and dried for use;

[0029] (2) Use a bunch of carbon fiber ropes to hang the C / C composite material in step 1 in the graphite crucible with prepared powder at the bottom, and put the crucible in the constant temperature zone of the argon protective atmosphere electric furnace, press 5°C Heat at a rate of 1 / min to 1600°C, keep the temperature constant for 2 hours, and then cool down with the furnace.

[0030] (3) Hang the C / C sample with SiC nanowires on the surface obtained in step 2 with a bundle of carbon fibers in an isothermal chemical vapor deposition (CVD) furnace. 4 The powder is placed in the powder ...

Embodiment 1

[0038] The selected density is 1.70g / cm 3 The C / C sample was ground with 320-mesh SiC water sandpaper and dried at 80°C for 4 hours for later use; the particle size was minus 300-mesh SiO 2 , Si, and C are put into a planetary ball mill and stirred for 3 hours according to the ratio of about 6:1:2, and dried for later use. Choose HfCl 4 , SiCl 3 CH 3 , CH 4 As a precursor, H 2 As a reducing gas, Ar as a protective gas.

[0039] Suspend the prepared C / C matrix with carbon fiber and install the prepared SiO 2 , Si, C mixed powder graphite crucible, heated to 1500 ° C, heat preservation 2h, to obtain the surface of the C / C matrix with SiC nanowires, and then suspended in the chemical vapor deposition furnace (isothermal vertical vacuum furnace) isothermal zone . Under the protection of the Ar gas flow rate of 600ml / min, the temperature was raised at 7°C / min, and the pressure of the furnace body was kept at about 30kpa. After the temperature was raised to 1300°C, the pow...

Embodiment 2

[0041] The selected density is 1.70g / cm 3 The C / C sample was ground with 320-mesh SiC water sandpaper and dried at 80°C for 4 hours for later use; the particle size was minus 300-mesh SiO 2 , Si, and C are put into a planetary ball mill and stirred for 3 hours according to the ratio of about 6:1:2, and dried for later use. Choose HfCl 4 , SiCl 3 CH 3 , CH 4 As a precursor, H 2 As a reducing gas, Ar as a protective gas.

[0042] Suspend the prepared C / C matrix with carbon fiber and install the prepared SiO 2 , Si, C mixed powder graphite crucible, heated up to 1600 ° C, and kept for 2 hours to obtain a C / C matrix with SiC nanowires on the surface, and then hung it in the isothermal zone of a chemical vapor deposition furnace (isothermal vertical vacuum furnace) . Under the protection of the Ar gas flow rate of 600ml / min, the temperature was raised at 7°C / min, and the pressure of the furnace body was kept at about 30kpa. After the temperature was raised to 1400°C, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com