Nitride near infrared fluorescent material and light emitting device containing same

A technology of fluorescent materials and light-emitting devices, applied in the direction of light-emitting materials, chemical instruments and methods, electrical components, etc., can solve the problems of poor stability and low luminous efficiency, and achieve good stability, high luminous efficiency, and good chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, an embodiment of the present invention provides a method for preparing a nitride near-infrared fluorescent material. Since there are many kinds of elements in the nitride near-infrared fluorescent material provided by the embodiment of the present invention, at least 8 kinds of elements are included. If all raw materials are added at one time for calcination, it is difficult to simultaneously dope A, B, M, R, Er, Eu, etc. and form A x m y B z Si 5 N 8 : (aEr, bEu, cR) structure, therefore, the embodiment of the present invention prepares A by two-step method x m y B z Si 5 N 8 : (aEr,bEu,cR), to ensure the stable crystal structure and high luminous efficiency. Specifically, A was prepared by a two-step method x m y B z Si 5 N 8 : (aEr,bEu,cR) includes the following steps:

[0045] S01. Provide M 2 N 3 、Si 3 N 4, the nitride of B and the nitride of Eu are mixed and processed to obtain the first mixed material, wherein the M 2 N 3 wit...

Embodiment 1

[0067] A kind of nitride near-infrared fluorescent material, chemical formula is La 0.05 Er 0.01 PR 0.03 Sr 1.77 Eu 0.08 Li 0.06 Si 5 N 8 . The preparation method of the nitride near-infrared fluorescent material comprises the following steps:

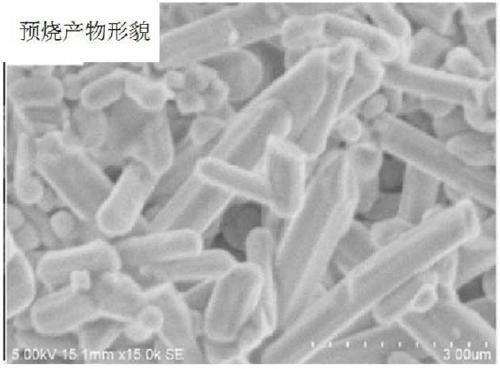

[0068] According to the stoichiometric ratio, weigh a certain amount of metal Sr nitride, Si 3 N 4 , Nitride of metal Li and nitride of europium are uniformly mixed, and the temperature is 1300°C in N 2 / H 2 Under the mixed atmosphere (volume ratio is 95% / 5%) sintering for 4h to obtain a calcined product, the obtained calcined product is crushed and post-treated as a precursor, and then the precursor is mixed with the nitride of metal La and the nitride of metal Er Fluoride, metal Pr fluoride and Si 3 N 4 According to a certain proportion of mixing, in the temperature of 1600 ℃ N 2 / H 2 The sintered intermediate was obtained by sintering for 8 hours under the mixed atmosphere (volume ratio of 95% / 5%), and the nitrided ne...

Embodiment 2~25

[0070] A kind of nitride near-infrared fluorescent material, chemical formula A x m y BYZGR 5 N 8 In (aEr, bEu, cR), A is selected from one or two elements of La, Lu, and Y, M is at least one of Ca, Sr, and Ba elements, and B is one of Li, Na, and K elements , R is a kind of Yb and Pr elements, and x, y, z, a, b, c are the amount of substances composed of each element. Specifically, the chemical formulas of the nitride near-infrared fluorescent materials described in Examples 2-25 are respectively shown in Examples 2-25 of Table 1. The preparation method of the nitride near-infrared fluorescent material is the same as that in Example 1.

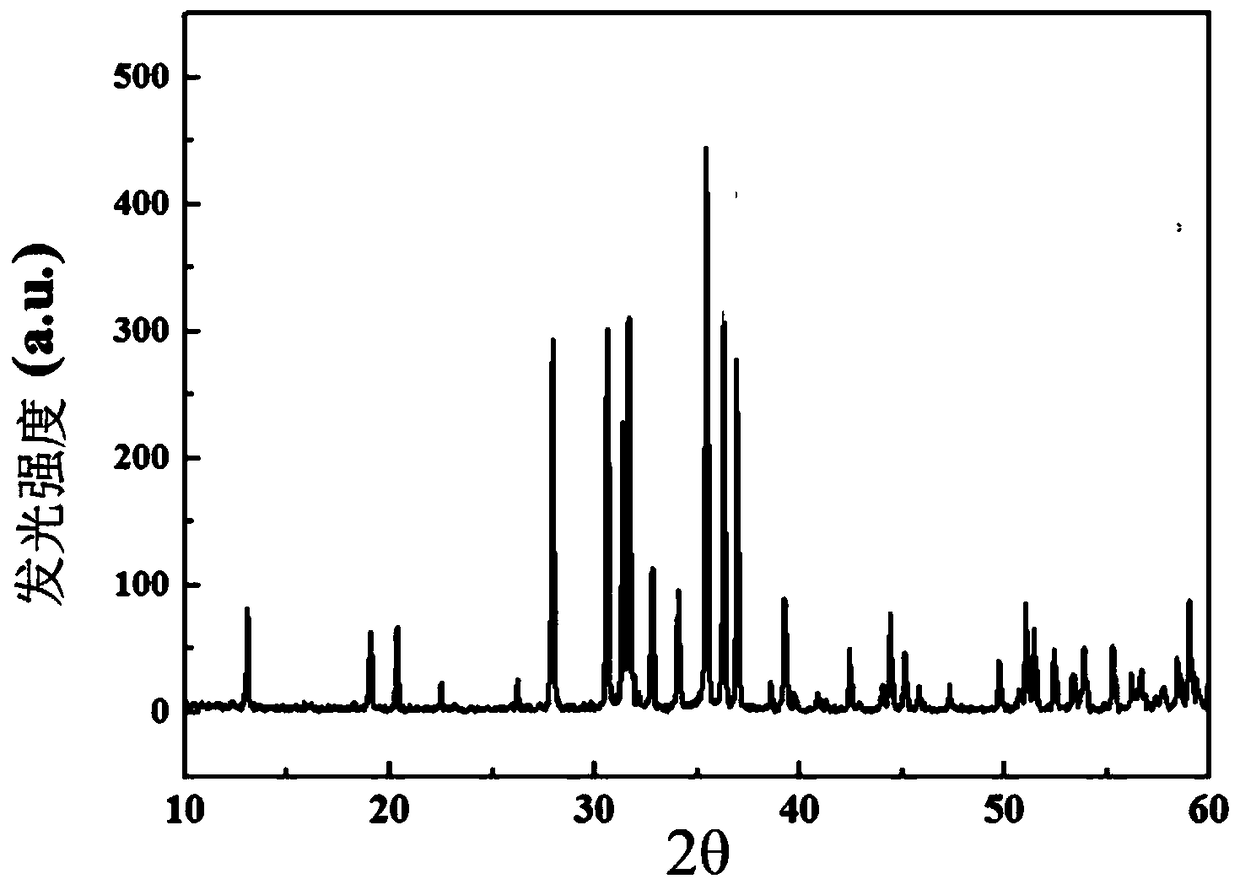

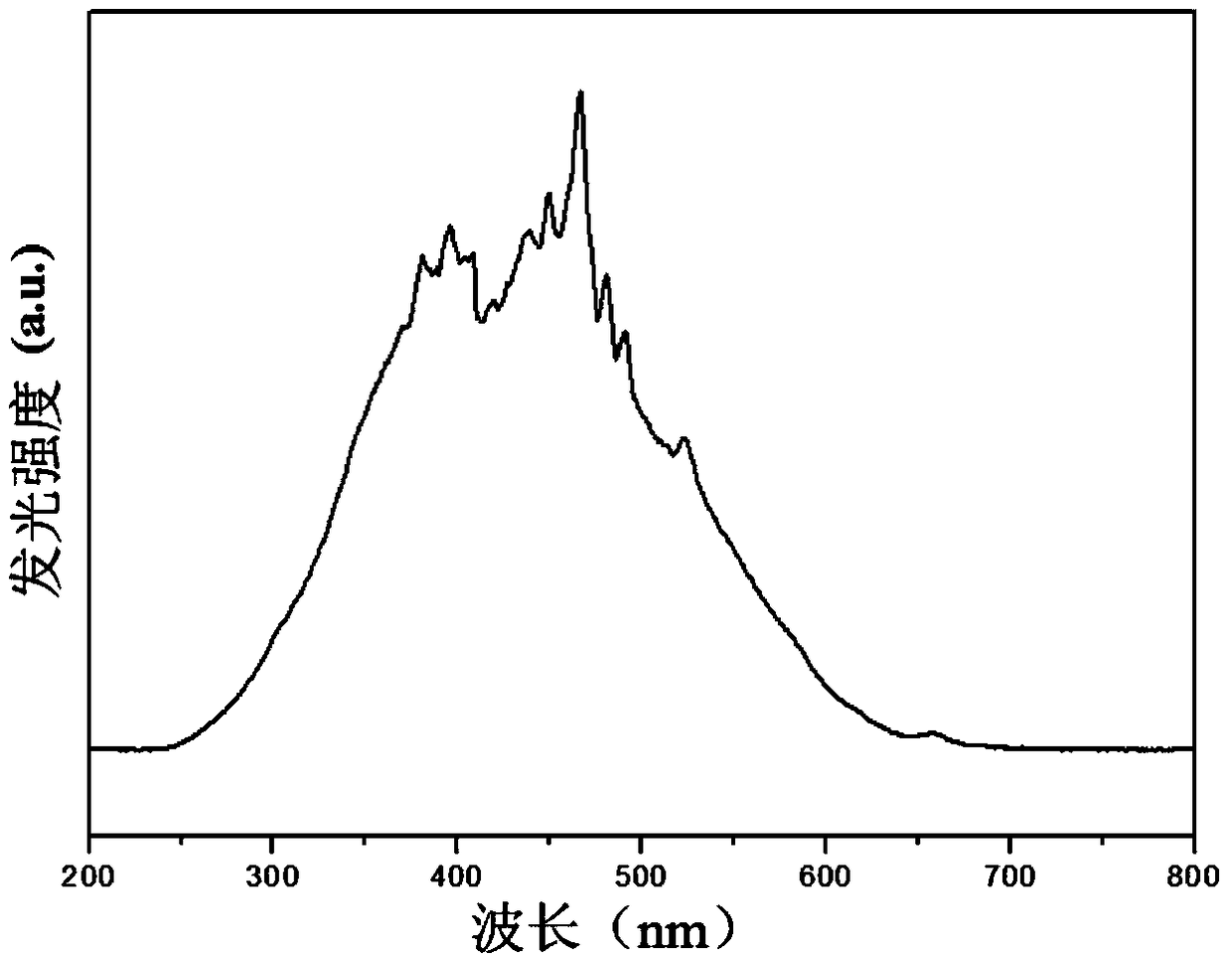

[0071] Wherein the XRD figure of the nitride near-infrared fluorescent material provided by embodiment 25 is as follows figure 1 Shown, the diffraction peak position of the material and Sr 2 Si 5 N 8 The same, indicating that after the introduction of elements such as A and B, the crystal structure of the material is still Sr 2 Si 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com