Patents

Literature

342results about How to "Stable crystal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

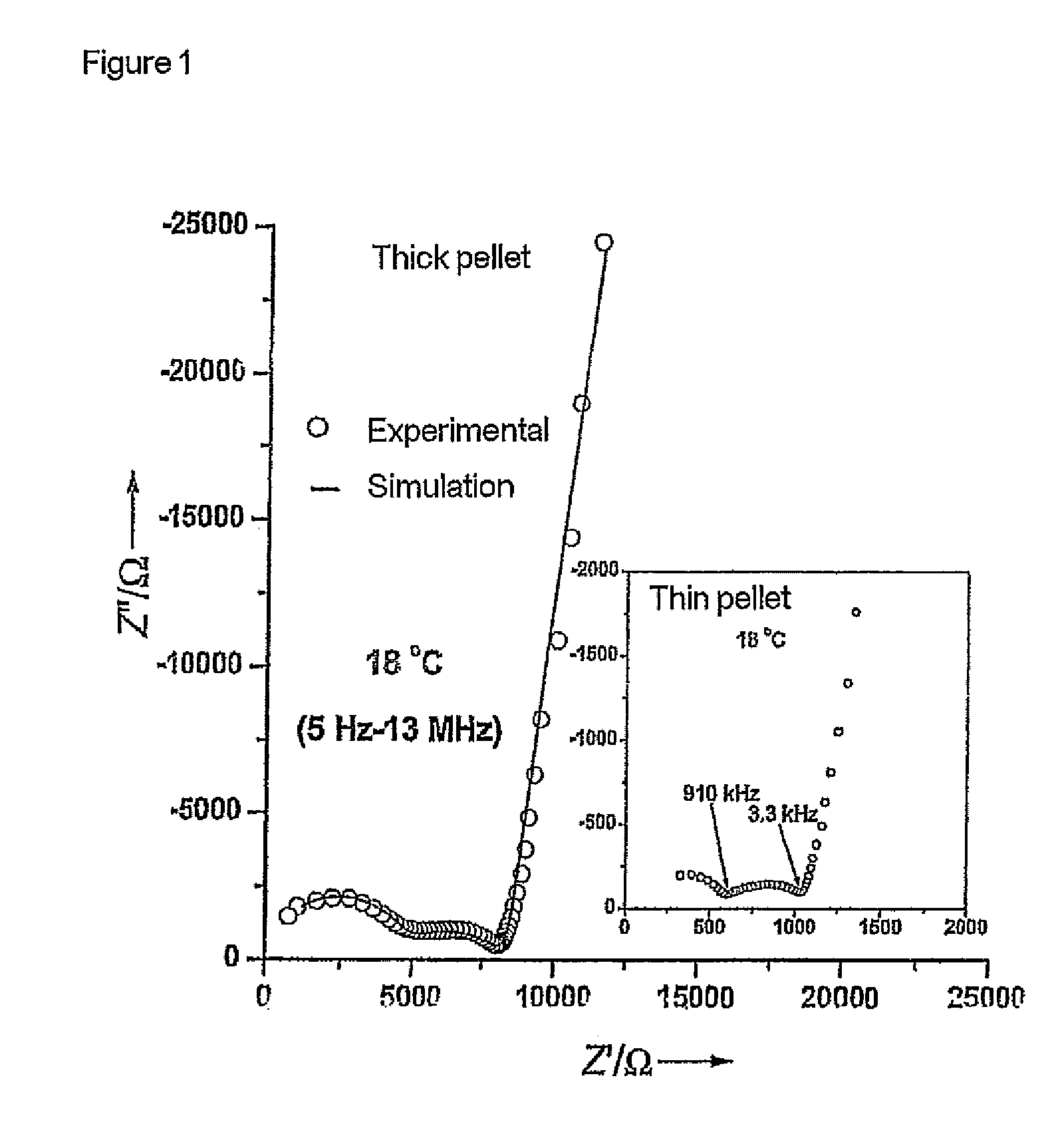

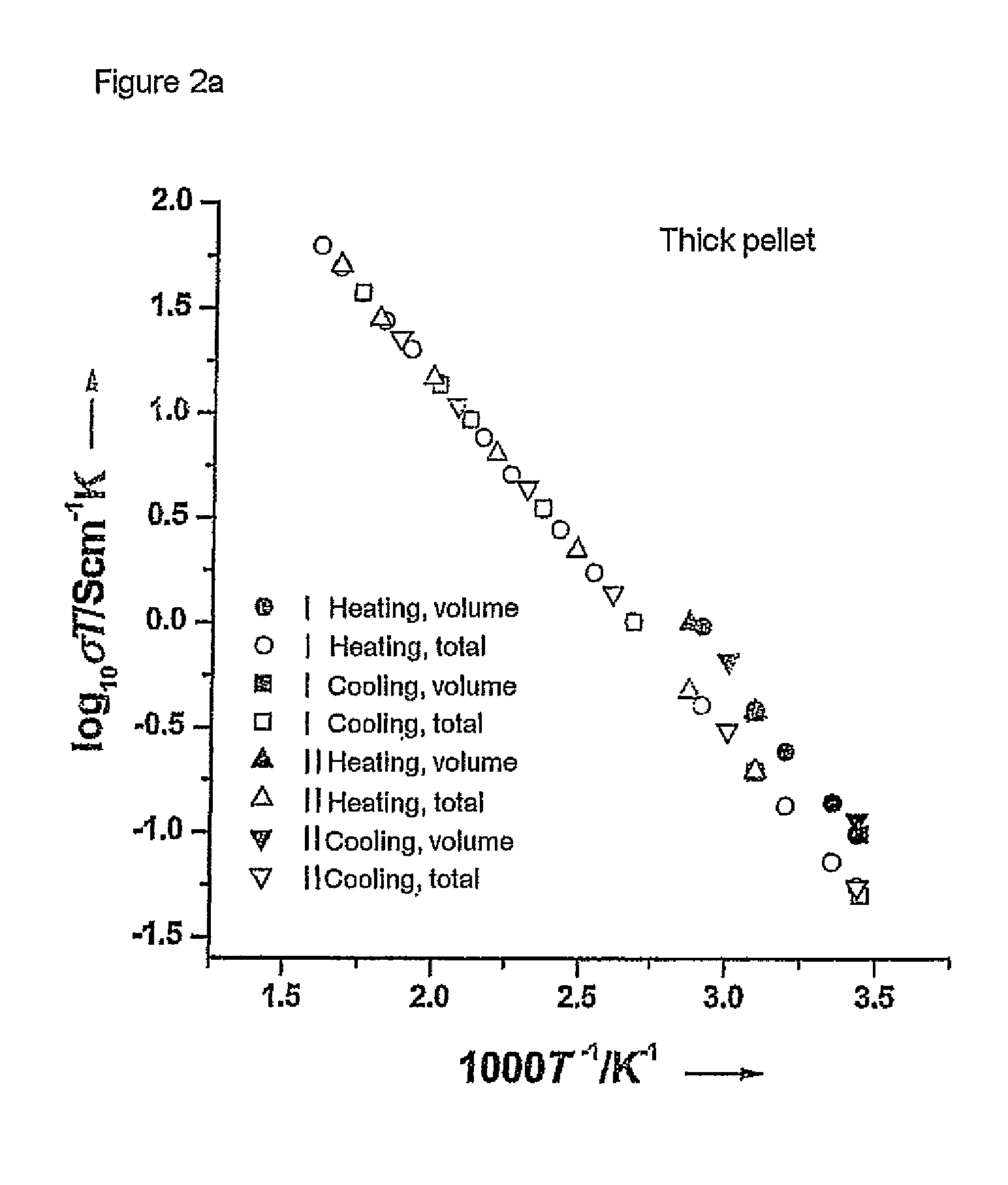

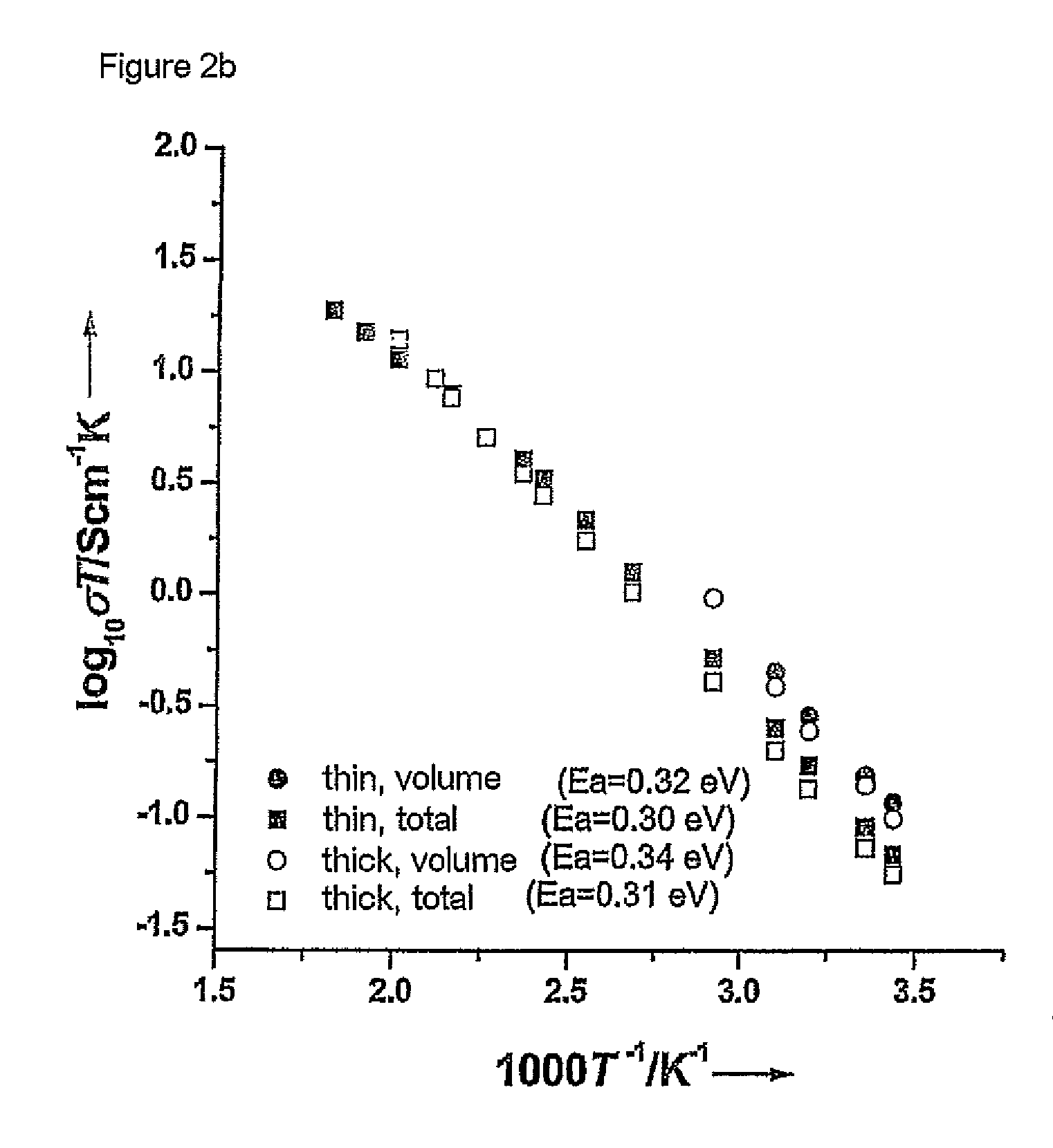

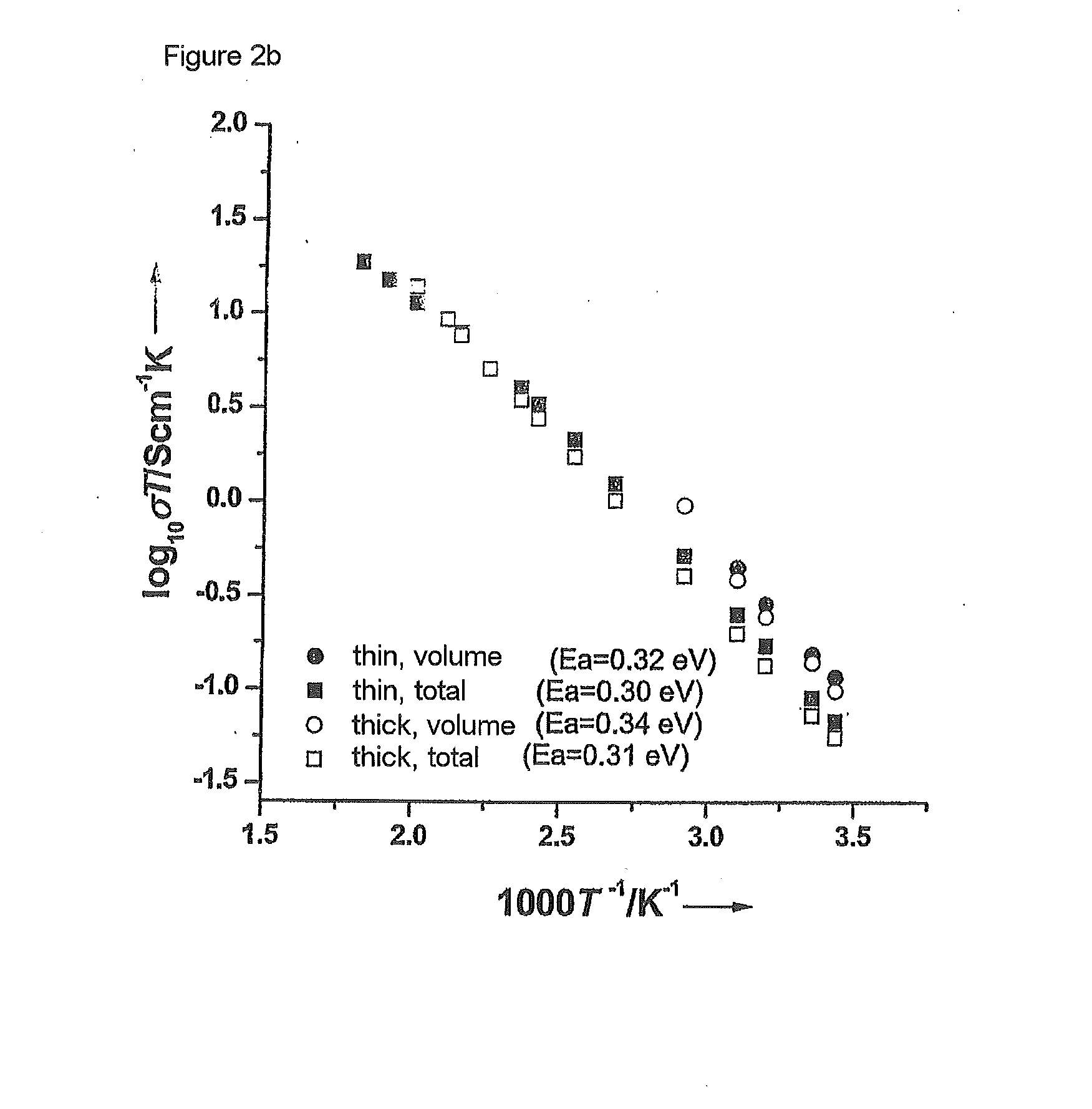

Solid ion conductor which has a garnet-like crystal structure and has the stoichiometric composition L7+XAXG3-XZr2O12

ActiveUS8658317B2Easily employedImprove ionic conductivityFinal product manufactureCell electrodesElectrical conductorCrystal structure

The invention is directed to a solid ion conductor which has a garnet-like crystal structure and has the stoichiometric composition L7+xAxG3−xZr2O12, whereinL is in each case independently a monovalent cation,A is in each case independently a divalent cation,G is in each case independently a trivalent cation,0≦x≦3 andO can be partly or completely replaced by divalent or trivalent anion.

Owner:BASF AG

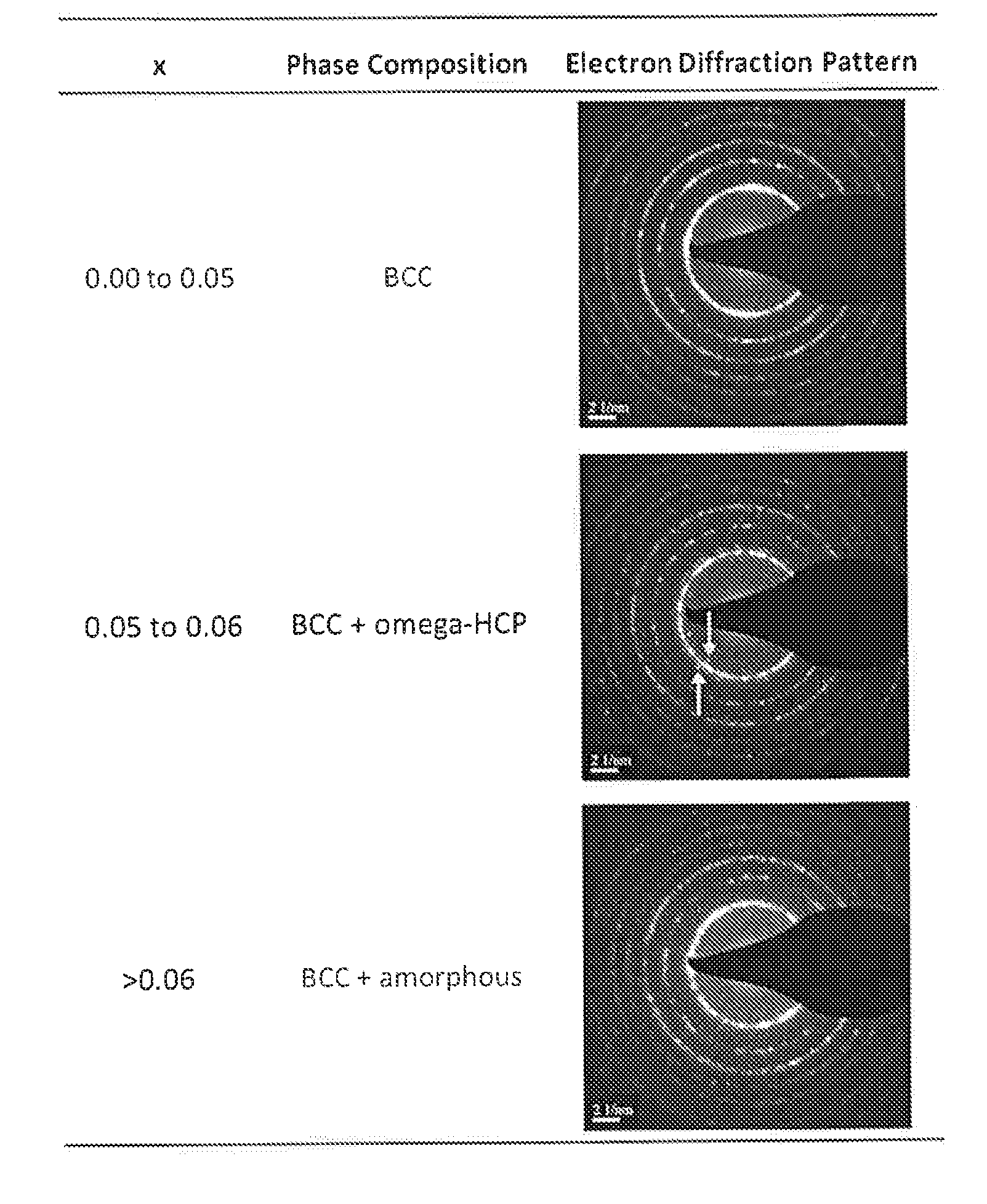

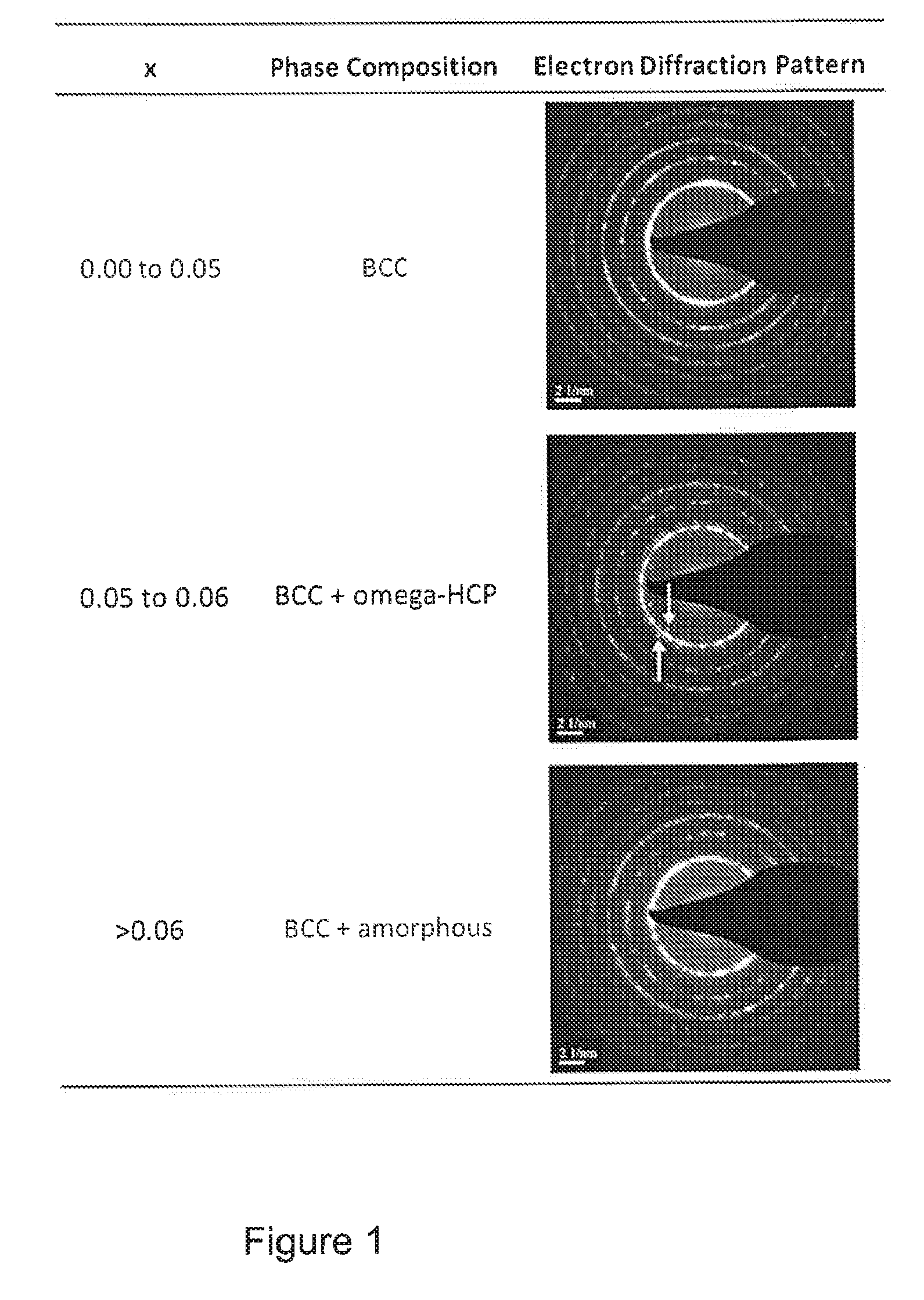

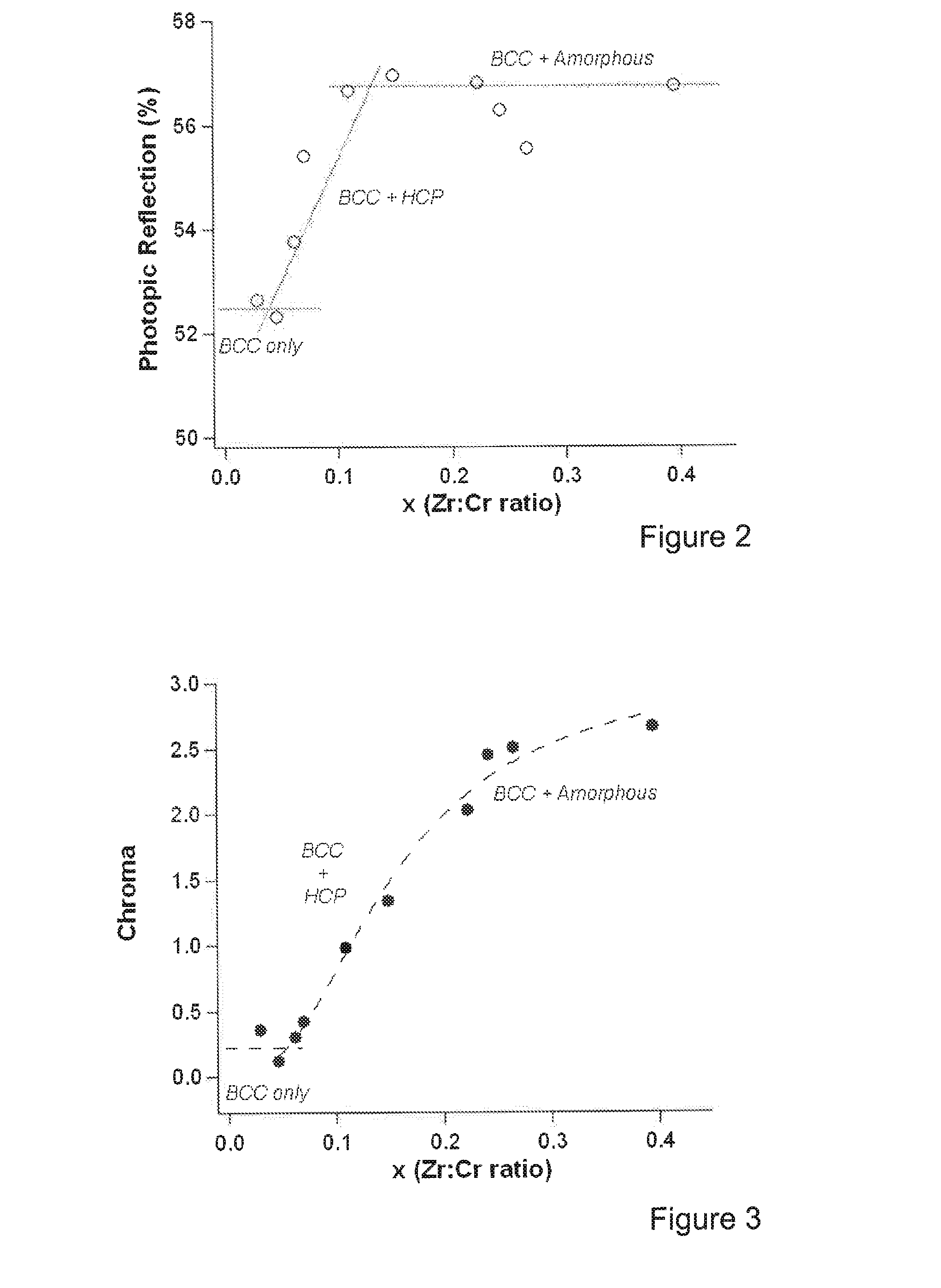

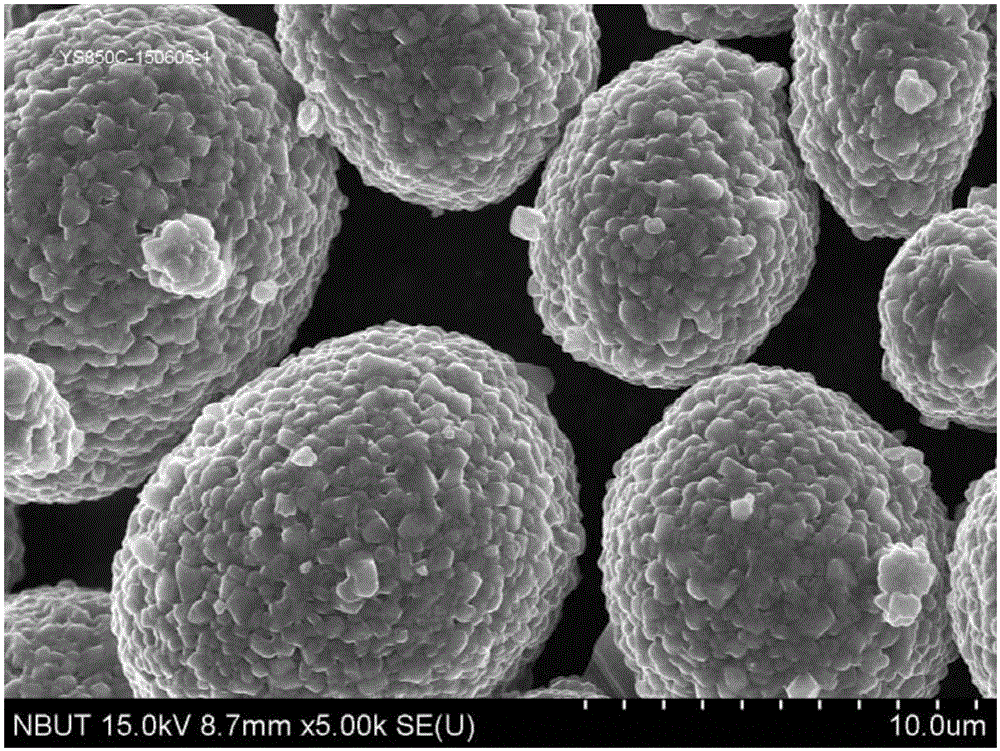

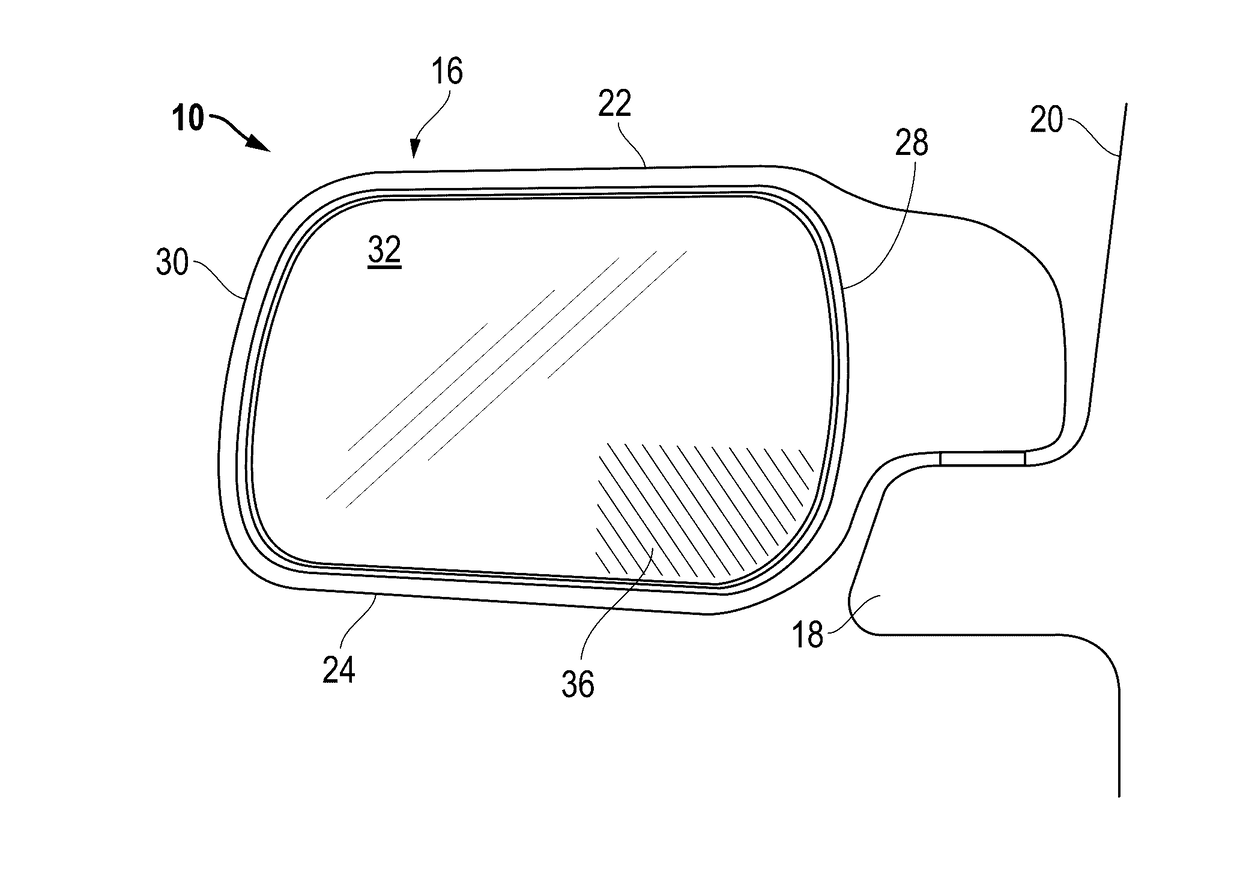

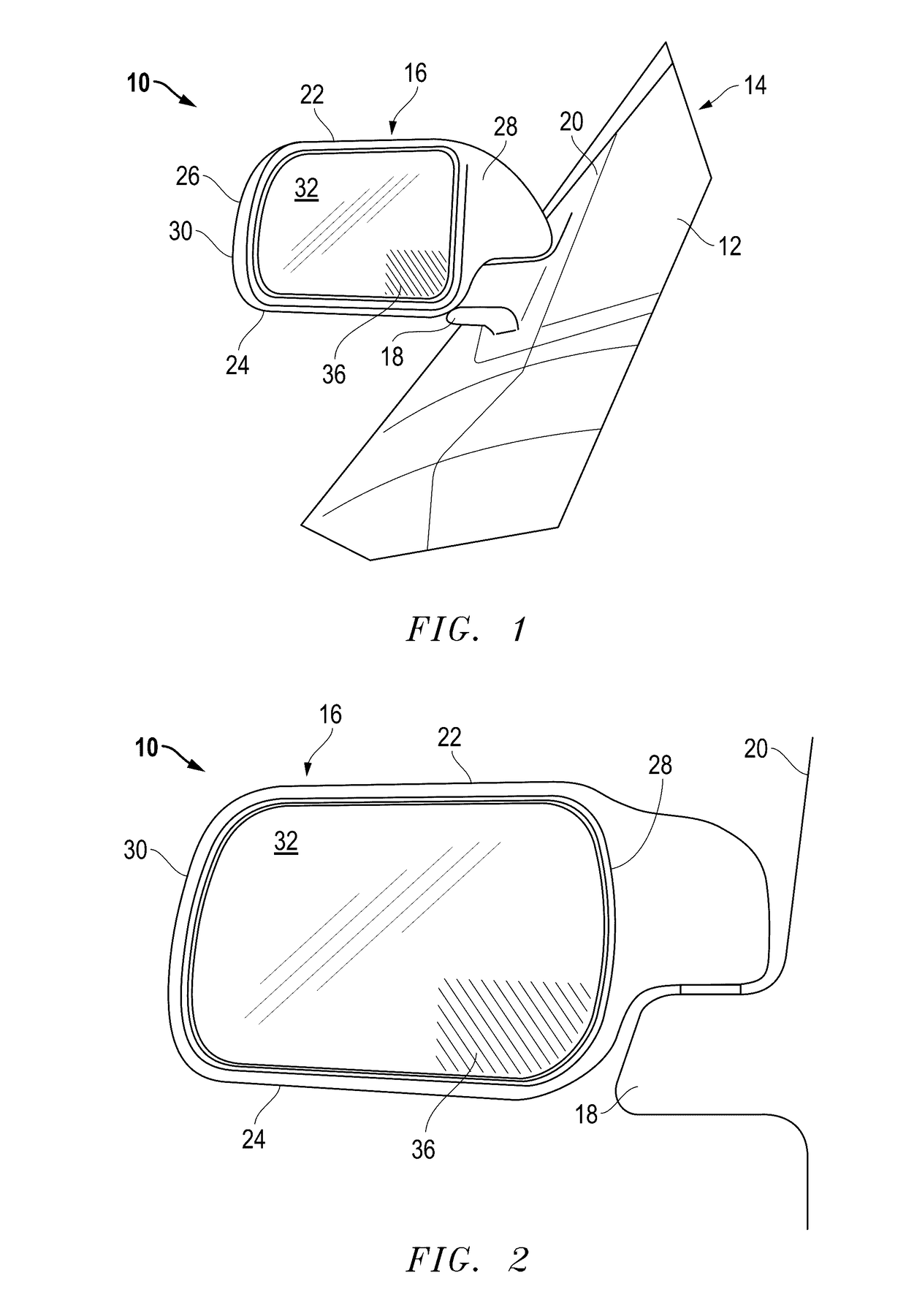

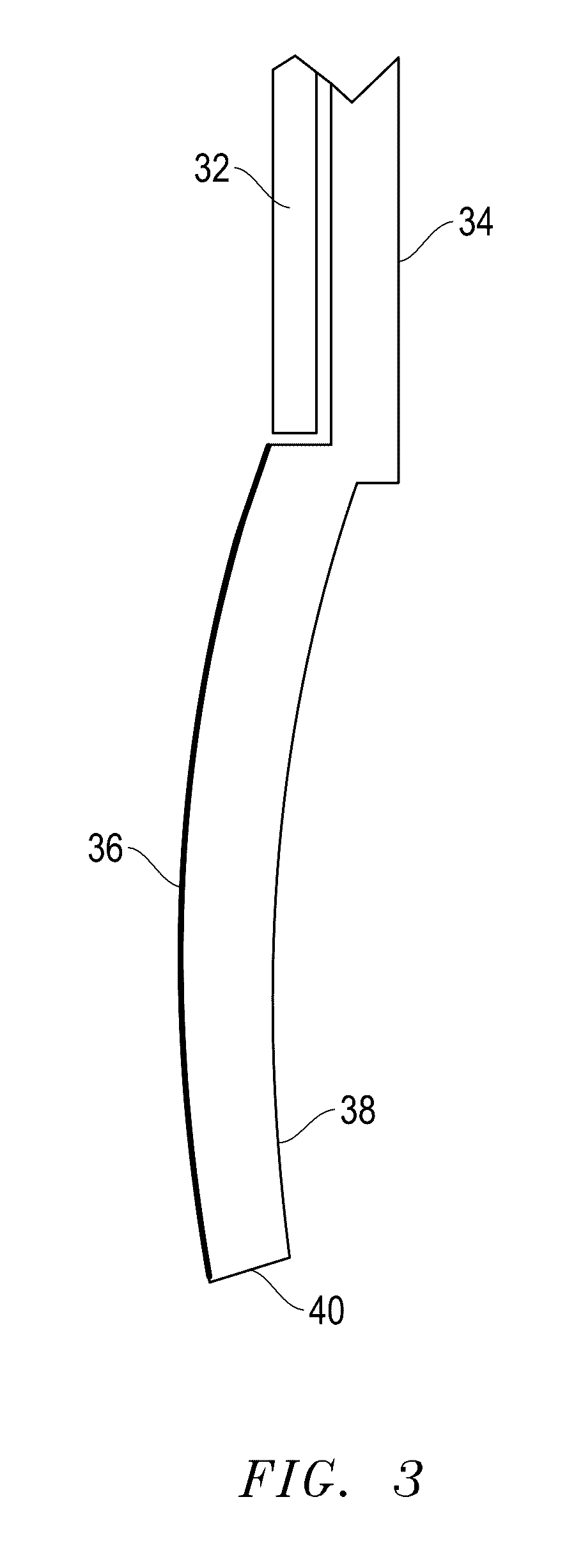

Chromium-based reflective coating

ActiveUS9181616B2High melting pointStable crystal structureMirrorsLighting and heating apparatusDopantPolymer substrate

A chromium-based reflective coating for a polymeric substrate, wherein the coating has a thickness of 200 nm or less and is an alloy of chromium and a dopant material, the dopant material being selected from the hexagonally close-packed transition metals, the alloy having a crystal structure of a primary body-centered cubic phase in coexistence with a secondary omega hexagonally close-packed phase.

Owner:SMR PATENTS S A R L +1

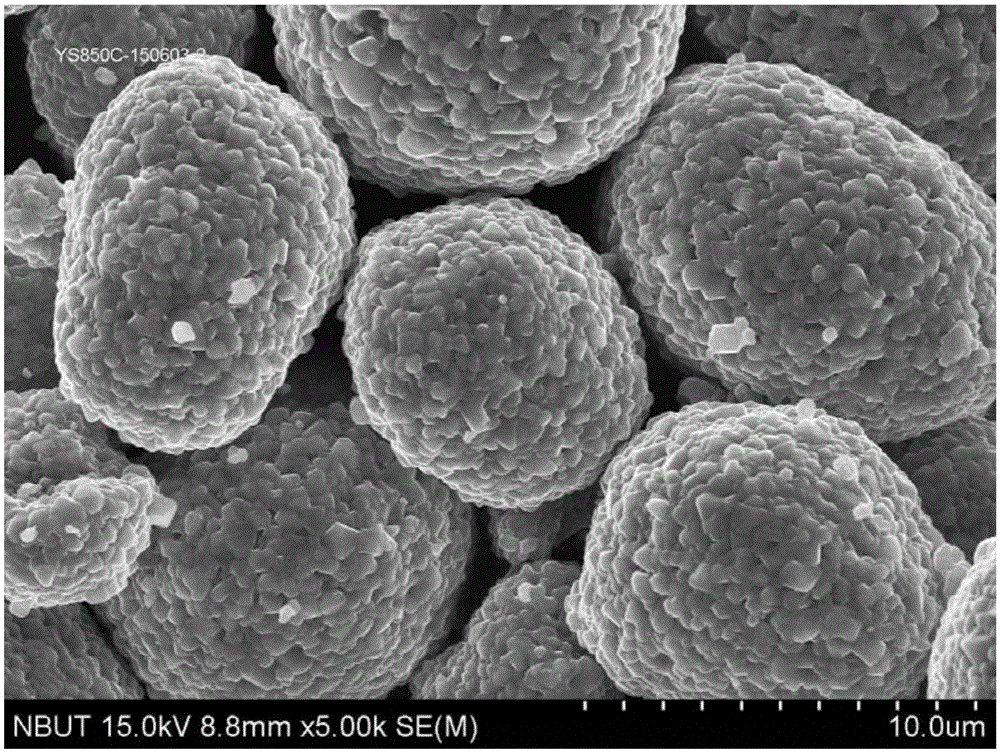

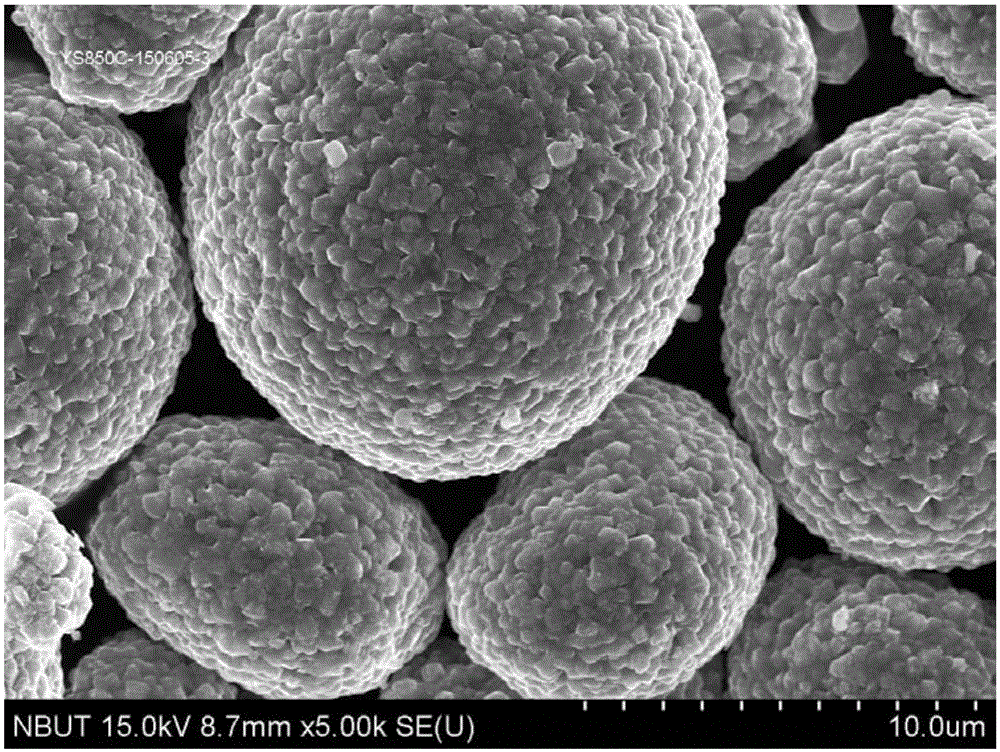

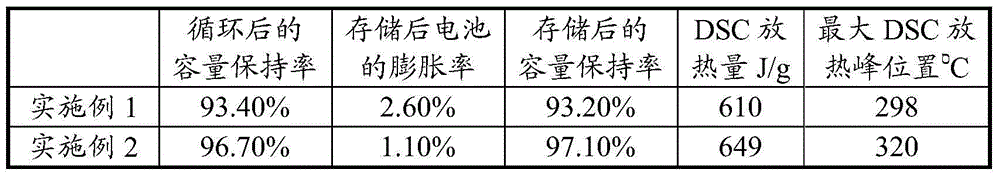

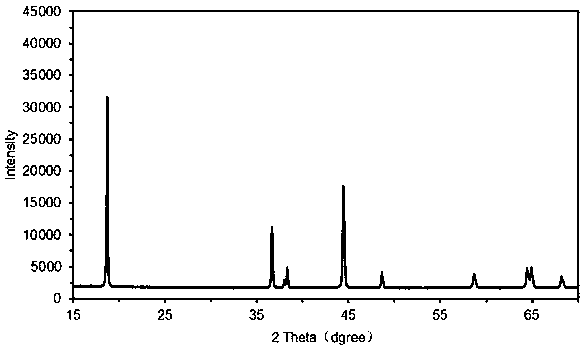

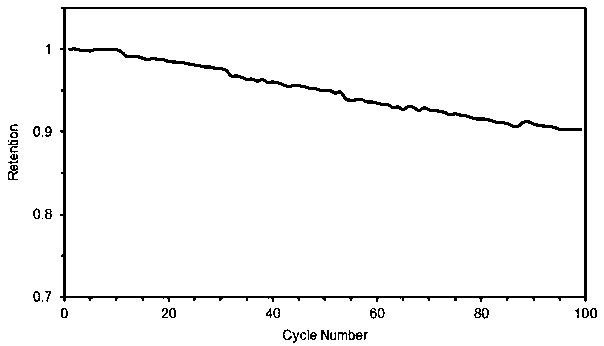

High nickel anode material, preparation method thereof and lithium ion battery

ActiveCN105070907AGood capacity and cycle performanceImproved electrochemical stability and safetyCell electrodesSecondary cellsTungstenMagnesium

The invention provides a high nickel anode material, which comprises a base body and a coating layer, wherein aluminum (Al), titanium (Ti), magnesium (Mg), zirconium (Zr), calcium (Ca), zinc (Zn), boron (B), fluorine (F), vanadium (V), strontium (Sr), barium (Ba), yttrium (Y), neodymium (Nd), caesium (Cs), tungsten (W), molybdenum (Mo), ruthenium (Ru), rubidium (Rb) or lanthanides are mingled on the surface of the base body, the coating layer is coated on the surface of the base body, and comprises one or more of the magnesium, the titanium, the zirconium, the fluorine, the boron, the aluminum and phosphate. The elements are mingled on the surface of the base body of the high nickel anode material, the mingled elements can stabilize a surface crystal structure of the base body, remit damage of washing liquid to a material surface structure of the base body, and enable capacity and cycle performance of a lithium ion battery which is prepared through the high nickel anode material to be better. Furthermore, the high nickel anode material is provided with the coating layer, and the coating layer enables the high nickel anode material to separate from an electrolyte part, and improves electrochemical stability and safety of the high nickel anode material. The invention further provides a method for preparing the high nickel anode material and a lithium ion battery.

Owner:湖北容百锂电材料有限公司

Lithium secondary battery

InactiveUS6337158B1Stable crystal structureRelieve pressureFuel cell auxillariesActive material electrodesCharge dischargeLithium-ion battery

A lithium secondary battery of this invention includes a positive electrode using, as an active material, a lithium-containing manganese composite oxide with a spinel structure having a composition, during charge and discharge, represented by a formula, Li.sub.x Mn.sub.2-y-z Ni.sub.y M.sub.z O.sub.4, in which M is at least one element selected from the group consisting of Fe, Co, Ti, V, Mg, Zn, Ga, Nb, Mo and Cu; 0.02.ltoreq..times..ltoreq.1.10, whereas x changes in accordance with occlusion and discharge of lithium ions during charge and discharge; 0.25.ltoreq.y.ltoreq.0.60; and 0<z.ltoreq.0.10. Thus, the invention provides a high-voltage lithium secondary battery exhibiting good charge-discharge cycle performance.

Owner:SANYO ELECTRIC CO LTD

Electrode Which Has Been Coated With A Solid Ion Conductor Which Has A Garnet-Like Crystal Structure And Has The Stoichiometric Composition L7+XAXG3-XZr2O12

ActiveUS20140205910A1Stable crystal structureGood chemical stabilityHybrid capacitor electrodesElectrolytic capacitorsCrystal structureStoichiometric composition

The invention is directed to an electrode which has been coated with the solid ion conductor which has a garnet-like crystal structure and has the stoichiometric composition L7+xAxG3−xZr2O12, whereinL is in each case independently a monovalent cation,A is in each case independently a divalent cation,G is in each case independently a trivalent cation,0≦x≦3 andO can be partly or completely replaced by divalent or trivalent anion.

Owner:BASF SE

Method for preparing lithium ion battery anode material doped with nanometer oxide

InactiveCN101719546AInitial reversible capacity improvement and enhancementIncreased initial reversible capacityCell electrodesCapacitanceLithium iron phosphate

The invention relates to a method for preparing a lithium ion battery anode material doped with a nanometer oxide, belonging to the technical field of manufacturing processes of lithium ion battery batteries. The method is characterized in that trace amount of nanometer oxide power is doped in the preparation process of lithium manganate, lithium cobaltoxide and lithium iron phosphate; the doping amount is 0.5-1.0 mol percent of lithium salts; and the nanometer oxide is selected from one or two of alumina, magnesia, titanium oxide, chromic oxide, nickel oxide, monox and zirconia and the nanometer oxide is subject to ball milling, drying, sieving, calcinating, crushing, grading and other processes to obtain the nanometer oxide doped or coated lithium ion battery anode material. The lithium ion battery anode material has reversible initial capacitance, and remarkably-improved attenuation property, charging-discharging properties, high-temperature circulating property and electrochemistry stability.

Owner:SHANGHAI UNIV

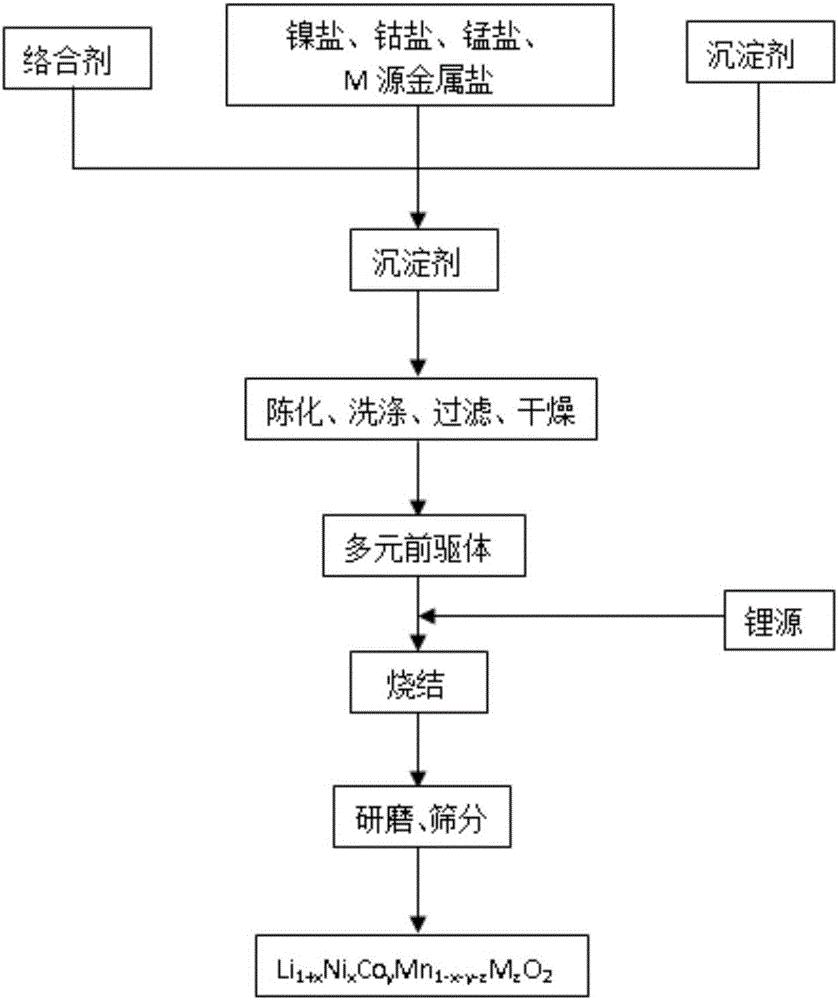

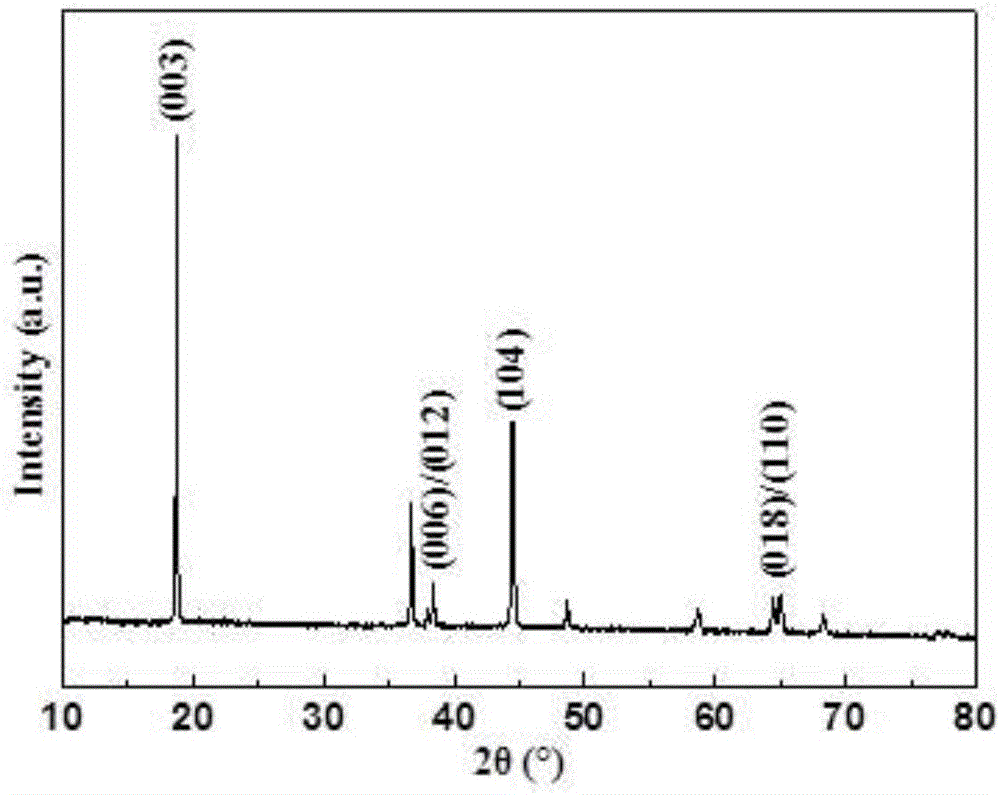

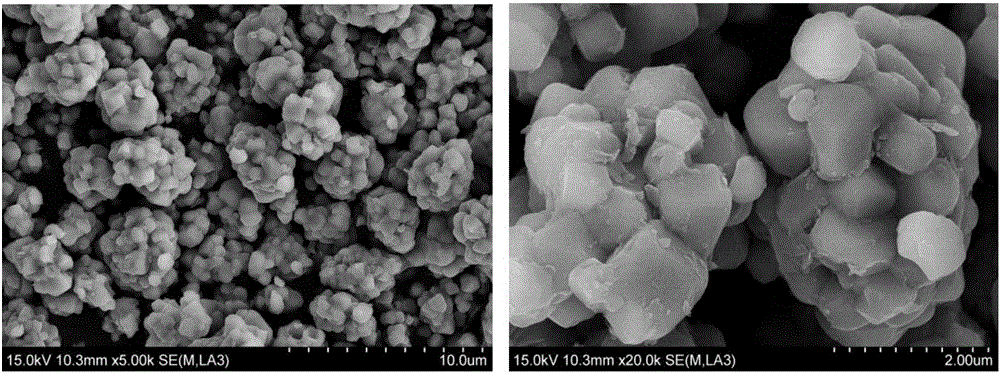

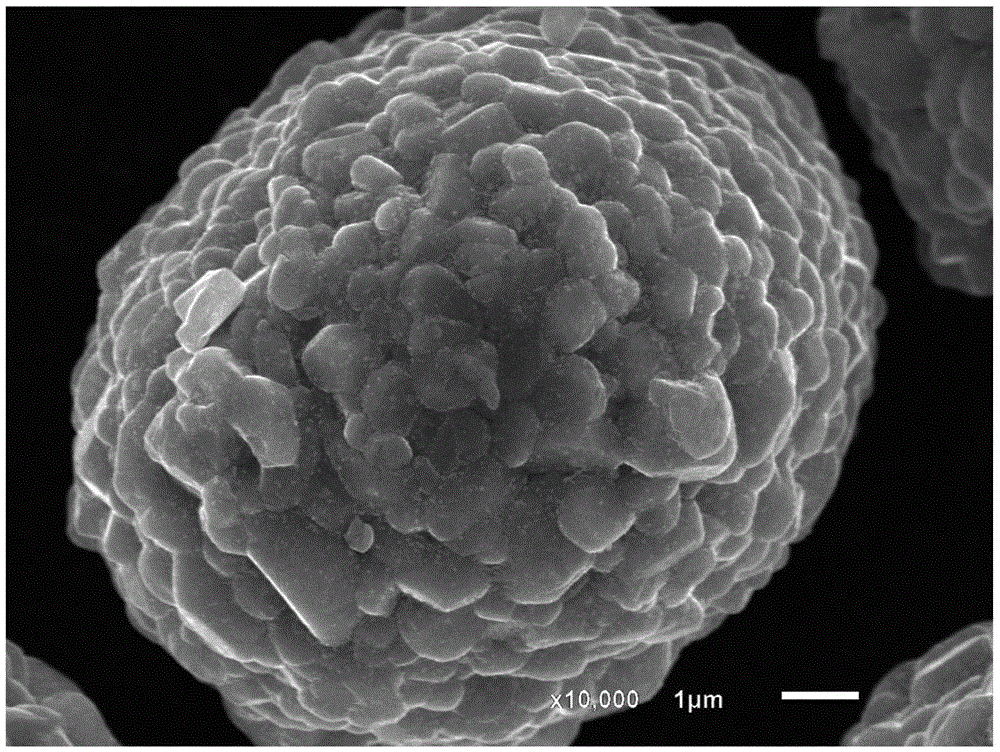

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

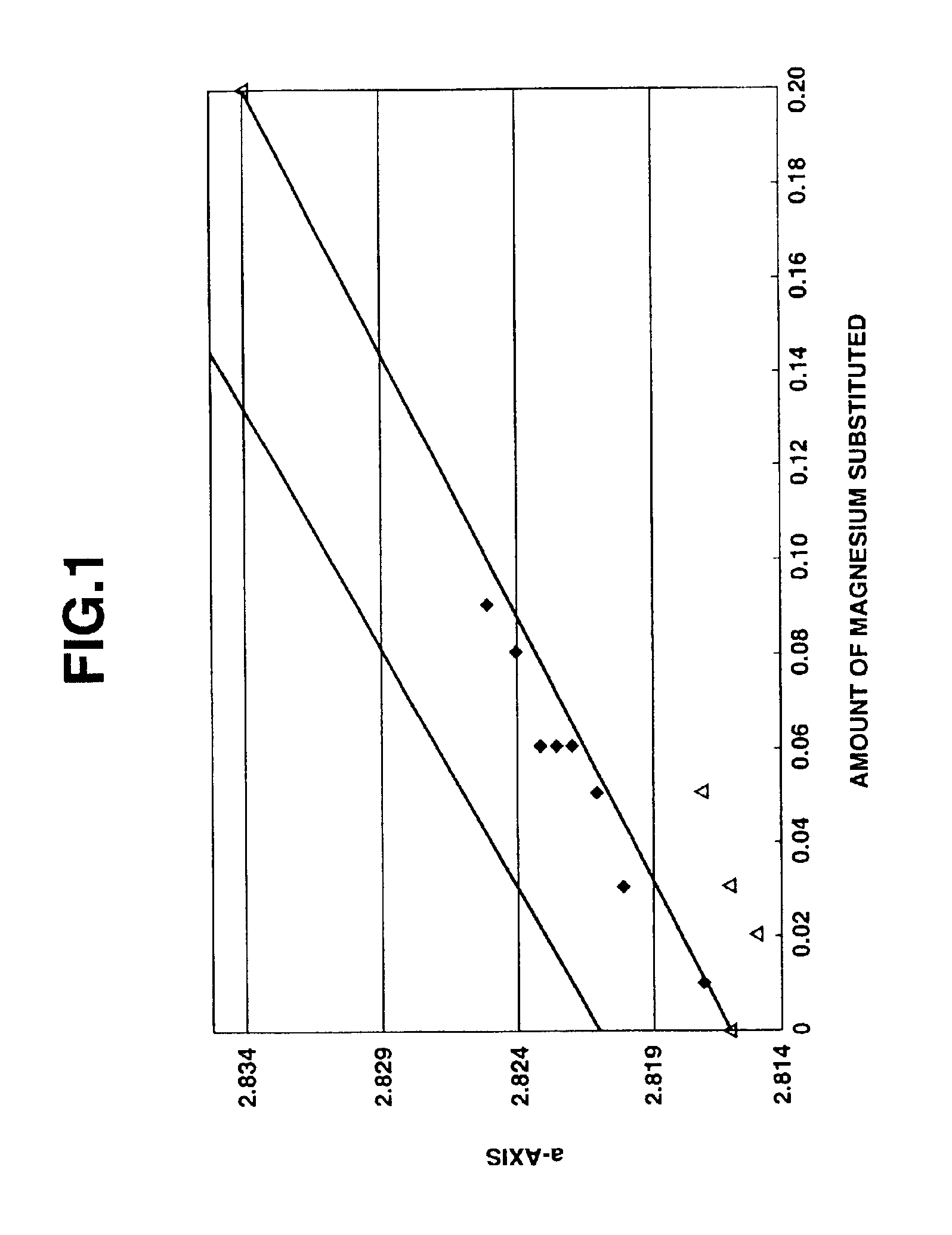

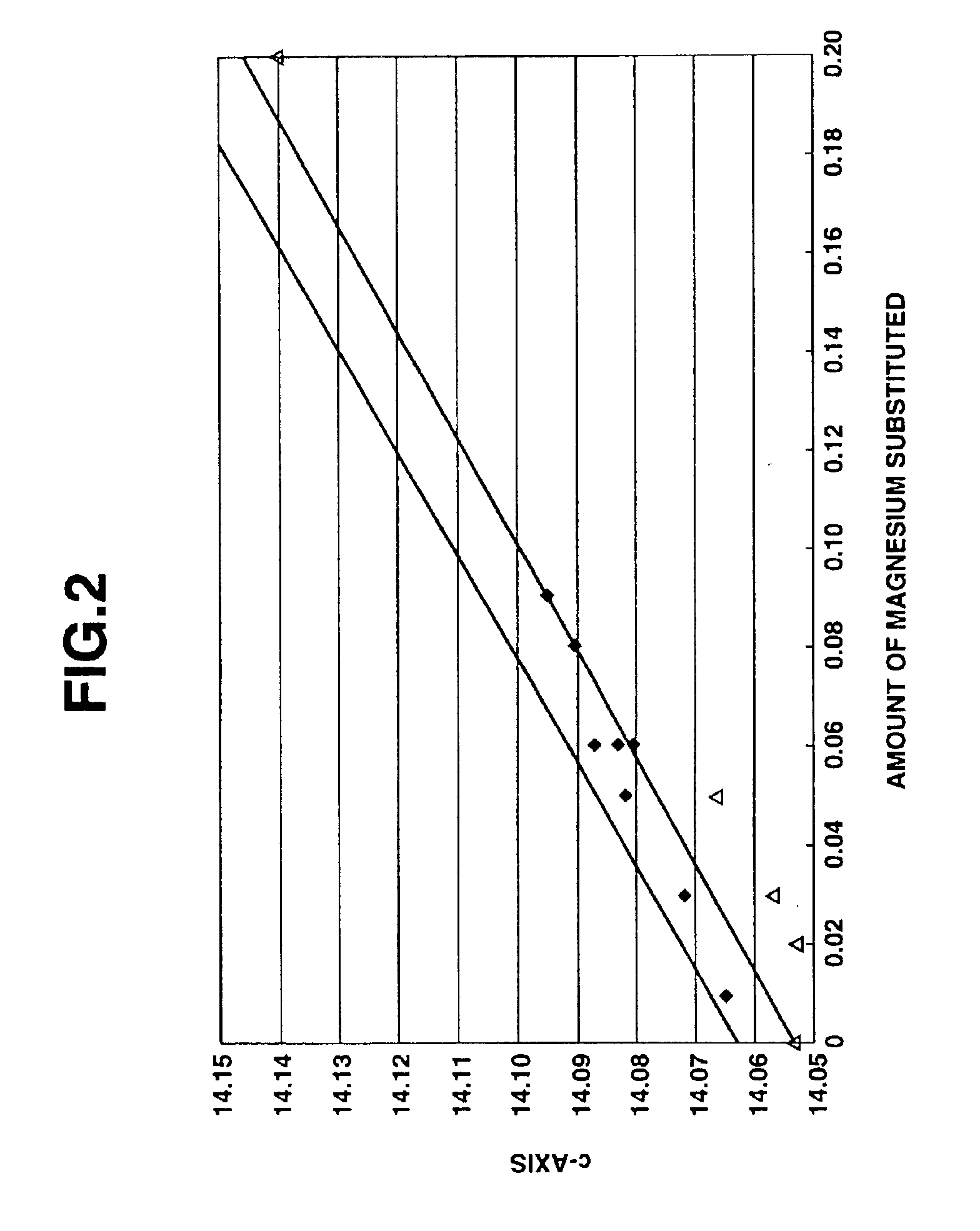

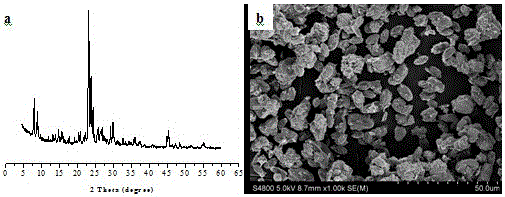

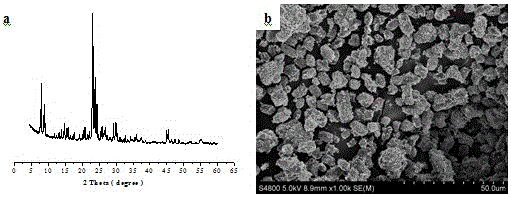

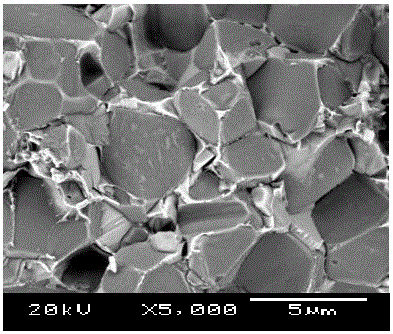

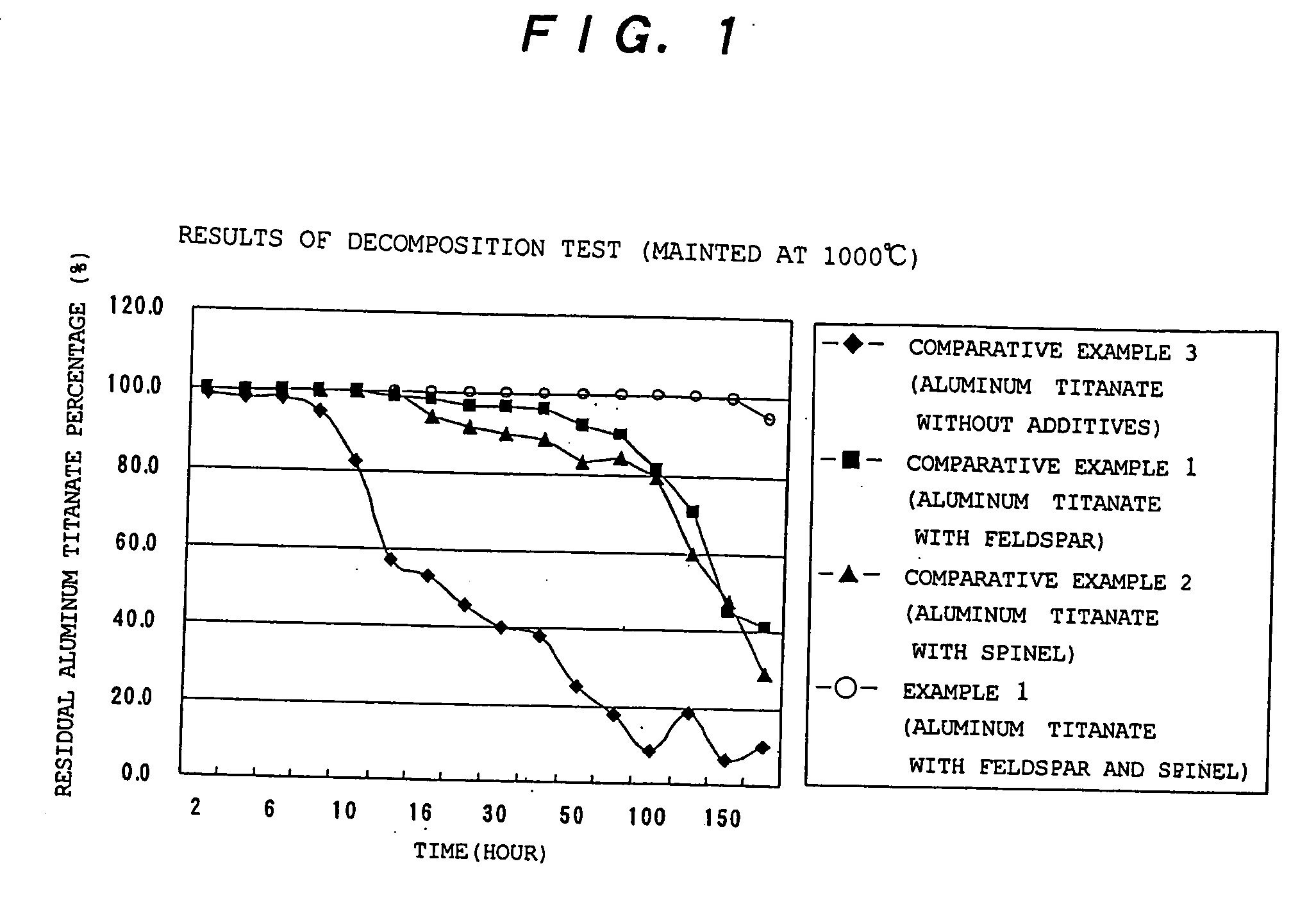

Magnesium Aluminum Titanate Crystal Structure and Method for Producing Same

InactiveUS20070224110A1Increase resistanceSmall coefficient of thermal expansionTitanium oxides/hydroxidesThermal expansionEmpirical formula

To provide an aluminum magnesium titanate crystal structure which can be used stably in variable high temperatures, because of its excellent heat resistance, thermal shock resistance, high thermal decomposition resistance and high mechanical property, and a process for its production. An aluminum magnesium titanate crystal structure, which is a solid solution wherein at least some of Al atoms in the surface layer of aluminum magnesium titanate crystal represented by the empirical formula MgxAl2(1−x)Ti(1+x)O5 (wherein 0.1≦x<1) are substituted with Si atoms, and which has a thermal expansion coefficient of from −6×10−6 (1 / K) to 6×10−6 (1 / K) in a range of from 50 is to 800° C. at a temperature raising rate of 20° C. / min, and a remaining ratio of aluminum magnesium titanate of at least 50%, when held in an atmosphere of 1,100° C. for 300 hours.

Owner:OHCERA CO LTD

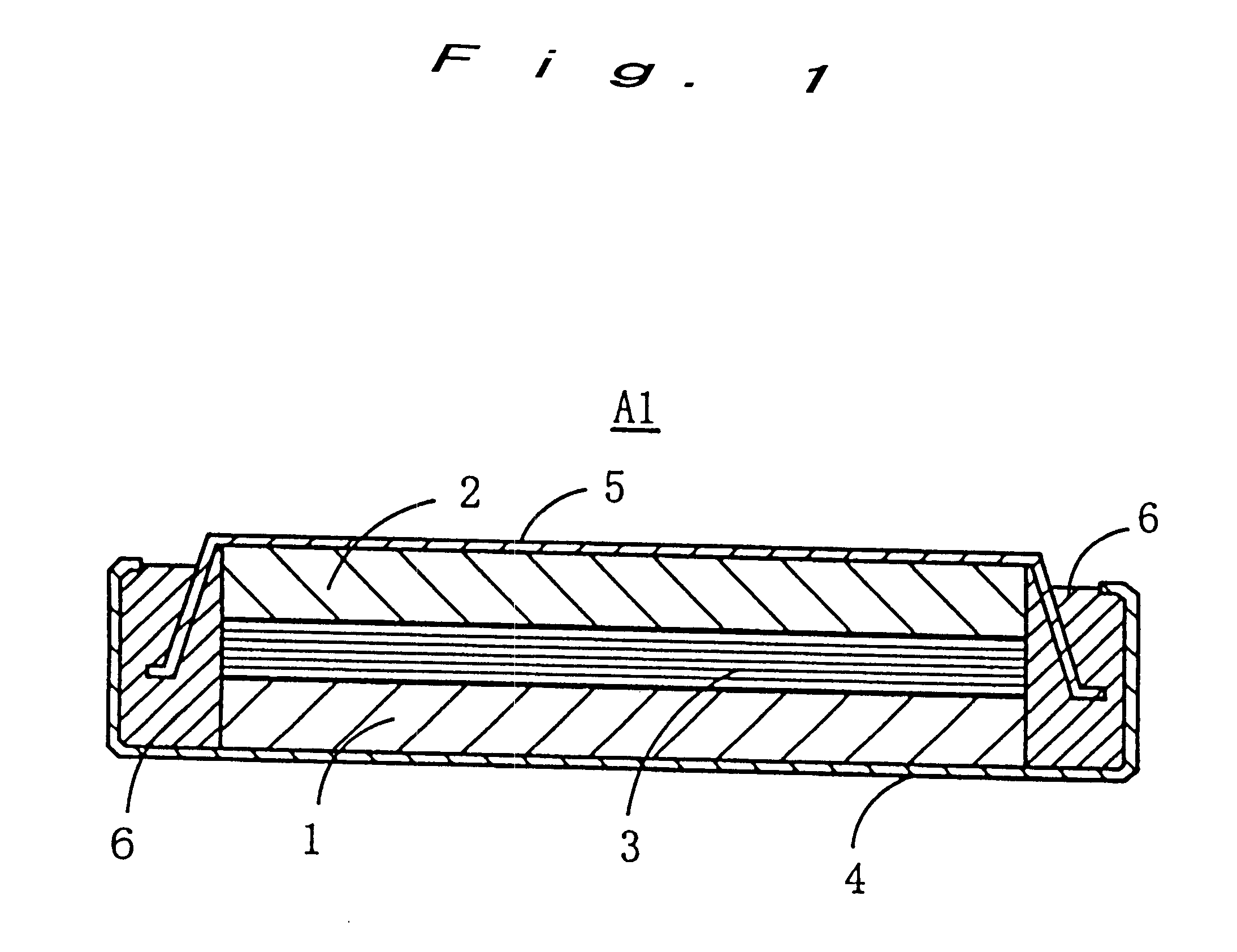

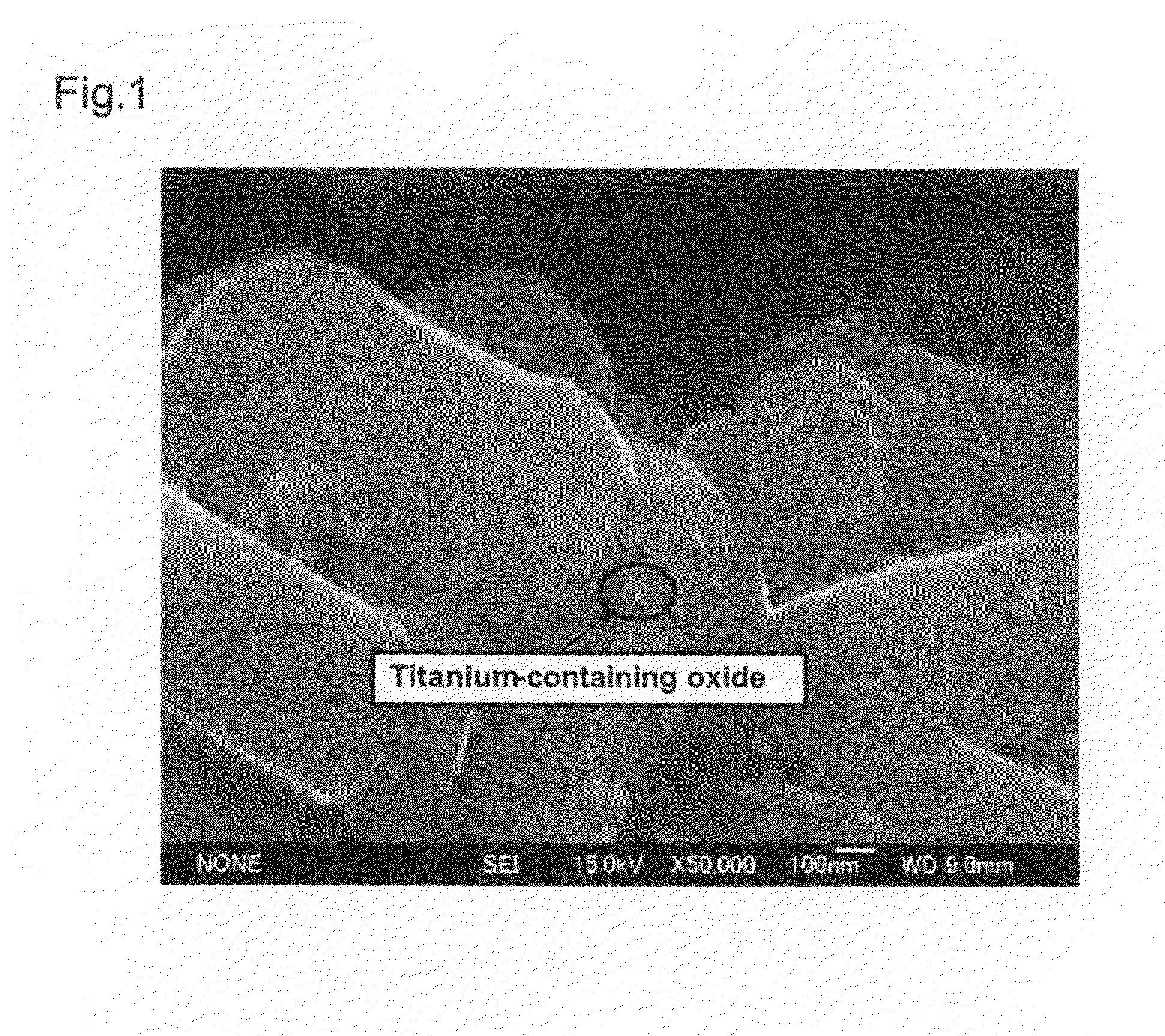

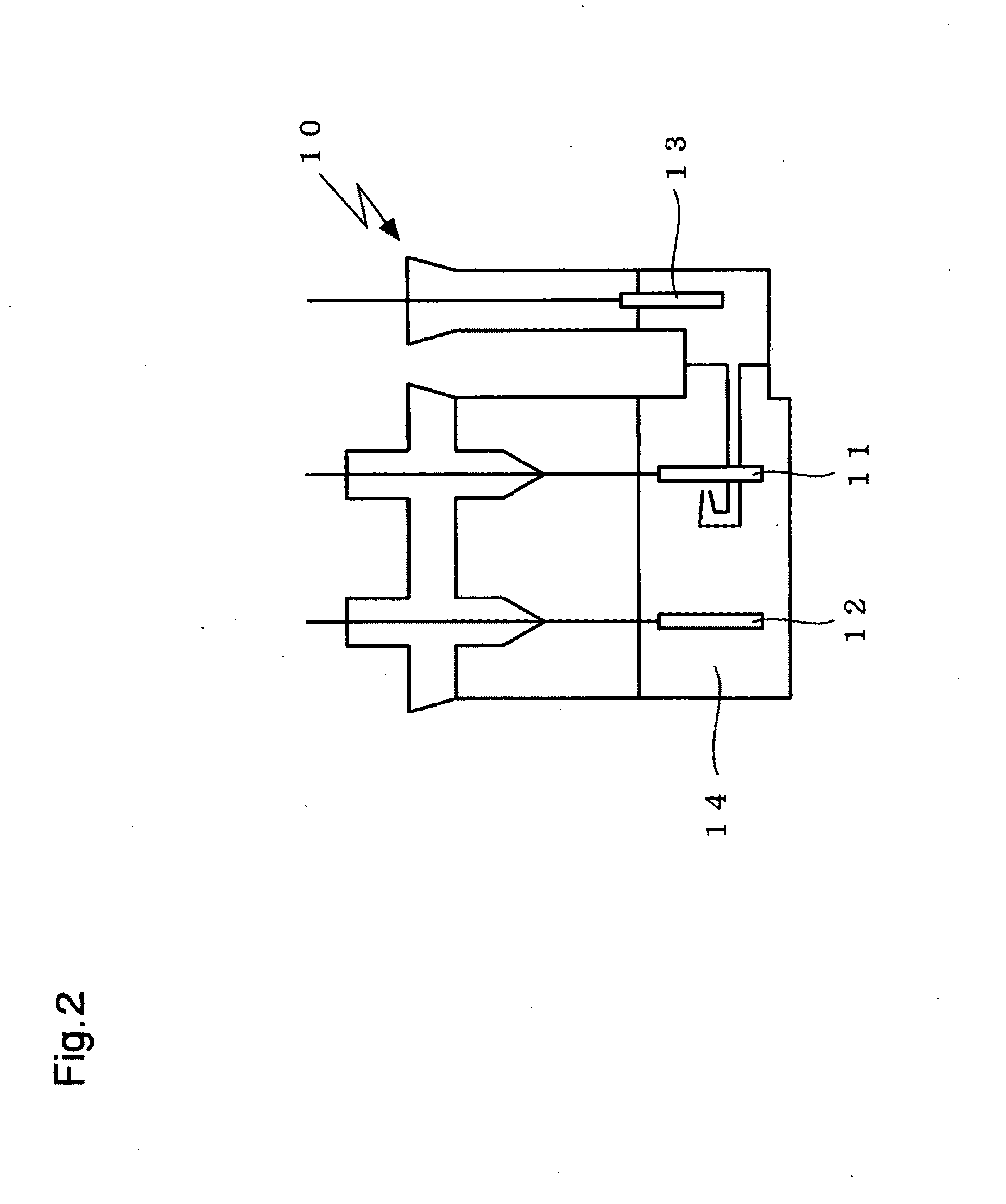

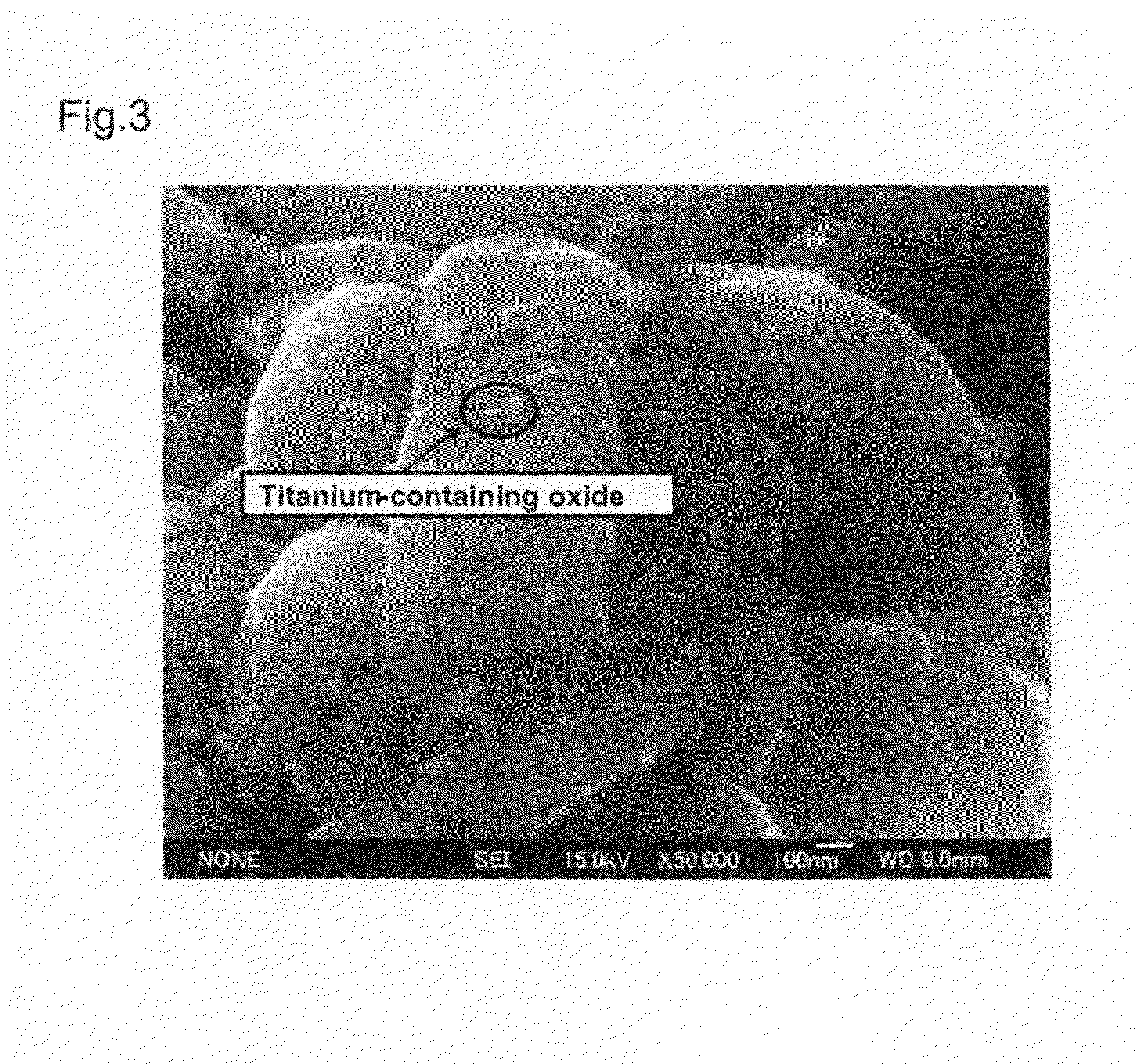

Non-aqueous electrolyte secondary battery and method of manufacturing the same

InactiveUS20090305136A1Stable crystal structureImproving high-rate charge-discharge capabilityMaterial nanotechnologyElectrode thermal treatmentPhysical chemistryTitanium

A non-aqueous electrolyte secondary battery has a positive electrode (11) containing a positive electrode active material, a negative electrode (12) containing a negative electrode active material, and a non-aqueous electrolyte solution (14) in which a solute is dissolved in a non-aqueous solvent. The positive electrode active material is obtained by sintering a titanium-containing oxide on a surface of a layered lithium-containing transition metal oxide represented by the general formula Li1+xNiaMnbCocO2+d, where x, a, b, c, and d satisfy the conditions x+a+b+c=1, 0.7≦a+b, 0≦x≦0.1, 0≦c / (a+b)<0.35, 0.7≦a / b≦2.0, and −0.1≦d≦0.1.

Owner:SANYO ELECTRIC CO LTD

Secondary lithium battery and positive electrode material thereof, and positive electrode material preparation method

ActiveCN105098177AImprove lithium ion conductivityGood chemical stabilityElectrode thermal treatmentPositive electrodesPhosphateSodium-ion battery

The present invention provides a positive active material for use in a lithium ion battery, a method for preparing the positive active material and a lithium ion battery containing the positive active material. The positive active material includes a core of lithium containing transition metal oxide represented by Formula LixMyN1-yO2-αAβ and a coating layer of lithium containing transition metal phosphate represented by Formula LiaMbN′1-bPO4-λBζ in situ formed on the core, wherein 0.9≰x≰1.2, 0.6≰y≰1.0, 0.9≰a≰1.1, 0.6≰b≰1.0, 0≰α≰0.2, 0≰β≰0.4, 0≰λ≰0.5, 0≰ζ≰0.5. The positive active material for use in a lithium ion battery according to the present invention has high capacity, desirable cycling performance and safety performance, as well as desirable thermal stability.

Owner:CONTEMPORARY AMPEREX TECH CO

Modification method of single-crystal ternary positive electrode material

InactiveCN112080800ALower internal resistanceImprove cycle stabilityPolycrystalline material growthCell electrodesSingle crystalLithium-ion battery

The invention discloses a modification method of a single crystal ternary positive electrode material. The method comprises the following steps: mixing a precursor containing nickel, cobalt and manganese elements with a dopant metal soluble salt, adding pure water, uniformly stirring, and carrying out spray drying to obtain a pretreated precursor; carrying out low-temperature sintering on the pretreated precursor in an oxidizing atmosphere to obtain a low-temperature sintered product; and uniformly mixing the low-temperature sintering product with a lithium source, and carrying out high-temperature sintering in an oxidizing atmosphere to obtain the doped and modified single-crystal ternary positive electrode material. According to the invention, the precursor and the dopant are pre-sintered at a low temperature, most of the pre-sintered dopant uniformly coats the surface of the precursor in an oxide form, and then the pre-sintered precursor and the lithium salt are sintered at a high temperature, so that the dopant is prevented from forming an oxide coating layer on the surface of the ternary positive electrode material, and the internal resistance of the ternary positive electrodematerial is reduced; and the cycling stability of the lithium-ion battery is greatly improved.

Owner:宜宾锂宝新材料有限公司

Method for preparing high-nickel cathode material for lithium secondary battery

ActiveCN110137488AReduce Lithium Nickel MixingStable crystal structureCell electrodesSecondary cells servicing/maintenanceLarge capacityLithium-ion battery

The invention discloses a method for preparing a high-nickel cathode material for a lithium secondary battery. The method comprises the steps of weighing and uniformly mixing a nickel-cobalt-manganesecompound, a lithium salt and an additive I; calcining the mixture in two stages at high temperature in an oxygen atmosphere; cooling, sieving, water-washing the mixture; and mixing the mixture with an additive II for secondary sintering so as to obtain the high-nickel ternary cathode material, wherein the lithium salt is a mixed lithium salt of lithium carbonate and lithium hydroxide, and the lithium carbonate and the lithium hydroxide can be mixed in any mixing ratio. The method can prepare a material having a large capacity and excellent cycle performance, can reduce the amount of highly-corrosive lithium hydroxide, improves the preparation environment of high-nickel materials, cancels out the impact of lithium hydroxide price fluctuation on the price of the high-nickel ternary material, and has a good application prospect.

Owner:郑州中科新兴产业技术研究院 +1

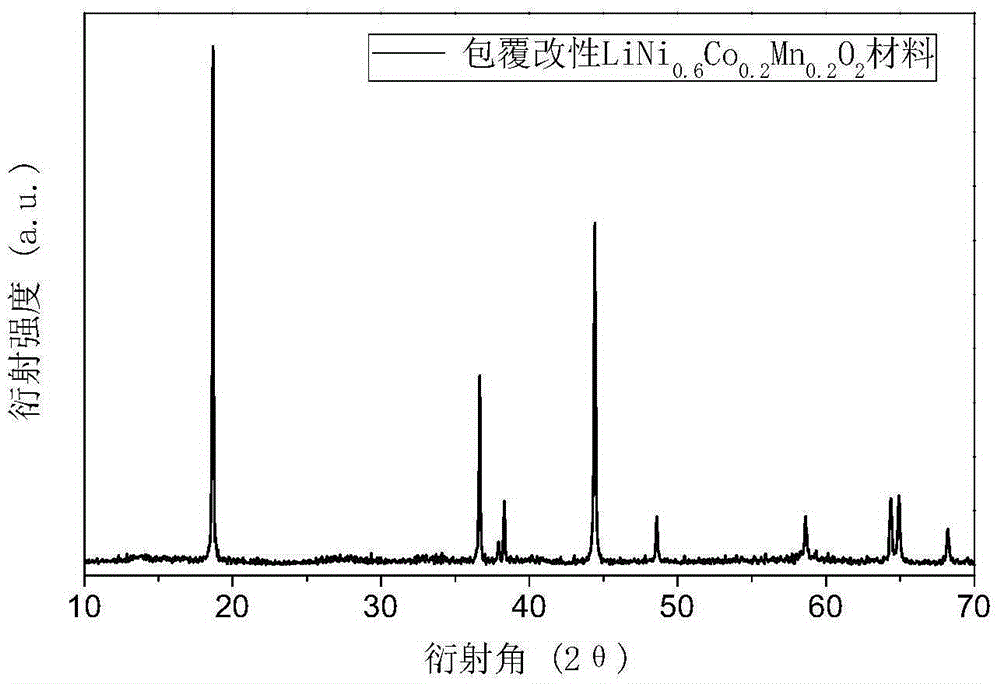

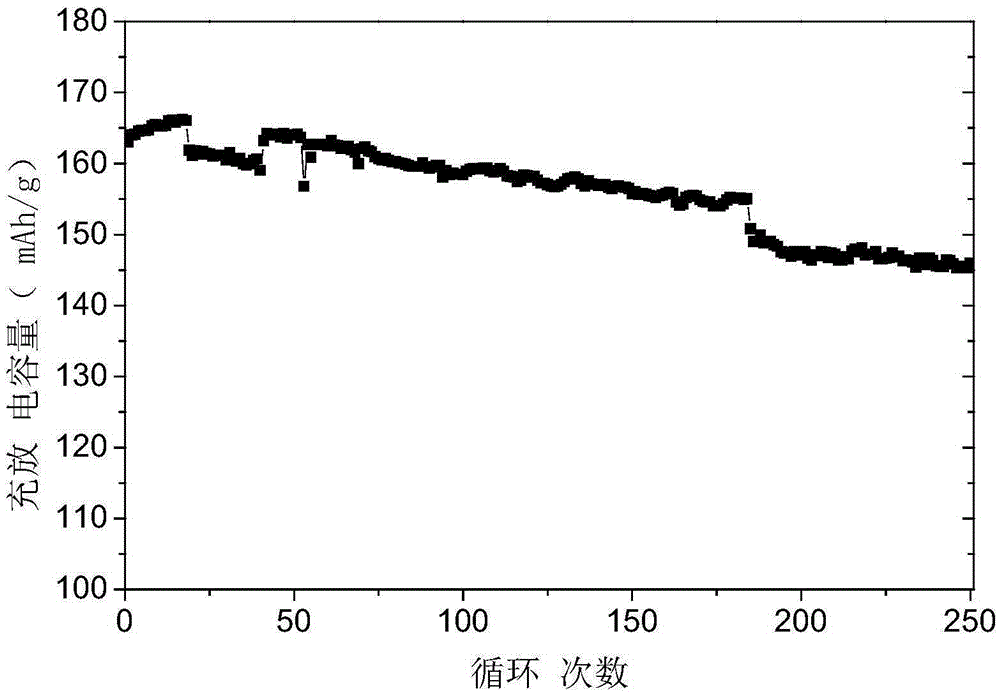

Coated and modified high-nickel ternary cathode material and preparation method thereof

ActiveCN105406040ACoated evenlyEfficient integrationCell electrodesSecondary cellsAlkalinityFree cooling

The invention discloses a coated and modified high-nickel ternary cathode material and a preparation method thereof. With a LiNi<x>Co<(1-x) / 2>Mn<(1-x) / 2>O<2> material as a matrix, wherein x is smaller than or equal to 0.9 and greater than or equal to 0.6; a coating layer coats the outside of the matrix; the coating layer contains a plurality of nano metal salts and / or nano metal oxides; and the total weight of cationic metal accounts for 0.01%-10% of weight of a ternary cathode material. The preparation method disclosed by the invention comprises the following steps: firstly, dissolving a soluble aluminum salt into deionized water to obtain an aluminum salt solution; adding the LiNi<x>Co<(1-x) / 2>Mn<(1-x) / 2>O<2> material to the aluminum salt solution for mixing evenly to obtain paste; adding an alkaline solution which is prepared from an alkaline metal compound to the paste until the pH value is greater than or equal to 7.0; and carrying out drying, sintering, natural cooling, crushing and sieving, and then obtaining the coated and modified high-nickel ternary cathode material. According to the coated and modified high-nickel ternary cathode material, the alkalinity of a high-nickel material is lowered; the coated and modified high-nickel ternary cathode material is high in processability and excellent in cycle performance and safety performance.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

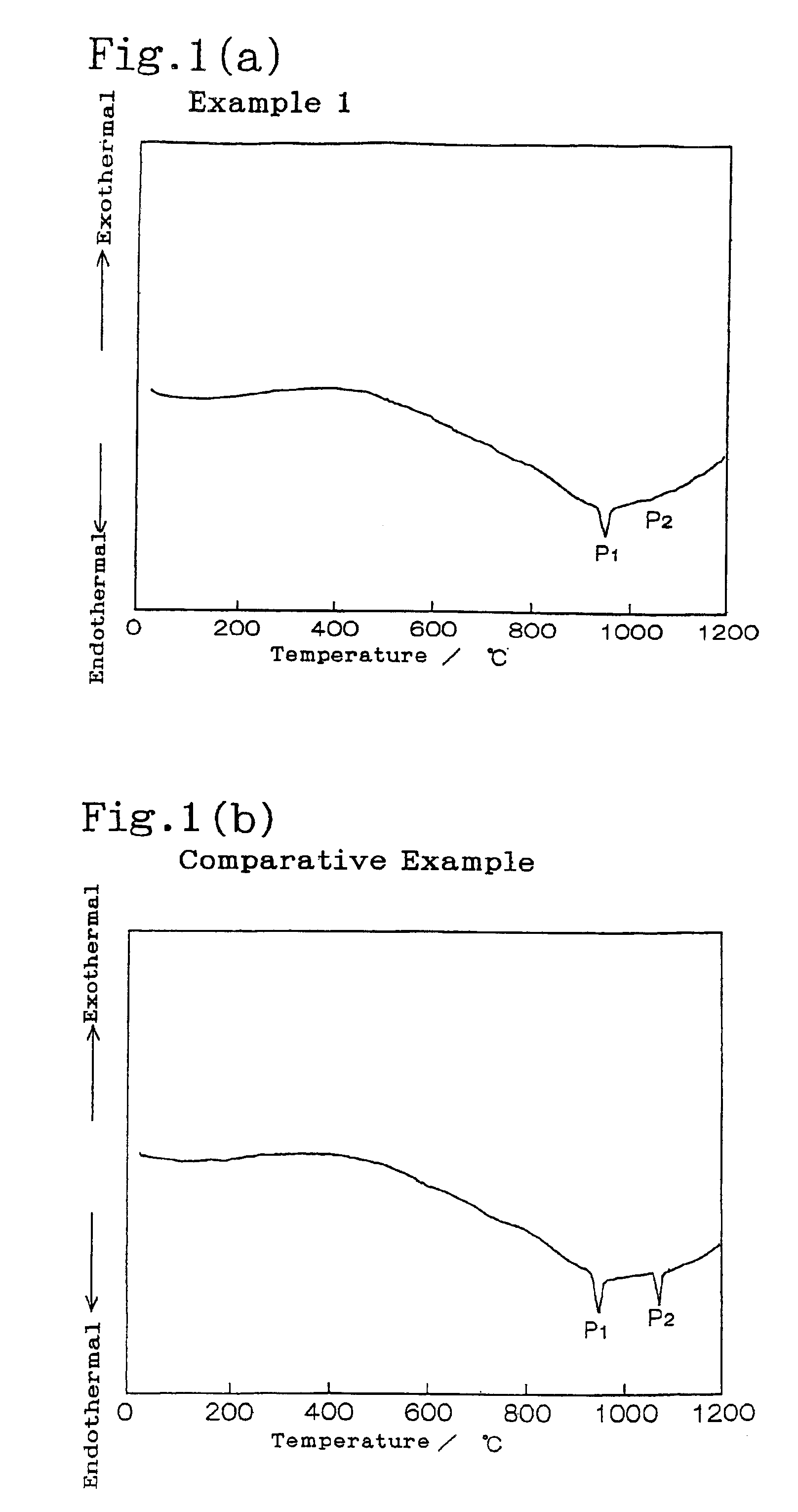

Lithium secondary battery

InactiveUS6964830B2Stable crystal structureImprove cycle performanceActive material electrodesNon-aqueous electrolyte accumulator electrodesSpinelLithium-ion battery

A lithium secondary battery using lithium manganese oxide as a positive active material and having excellent charge and discharge cycle properties.As a positive active material of a lithium secondary battery, lithium manganese oxide having a cubic spinel structure, in which the strength ratio (P2 / P1 strength ratio) of the primary endothermal peak (P1) appearing around 950° C. and the secondary endothermal peak (P2) appearing around 1100°0 C. in differential thermal analysis is under 1, is used.

Owner:NGK INSULATORS LTD

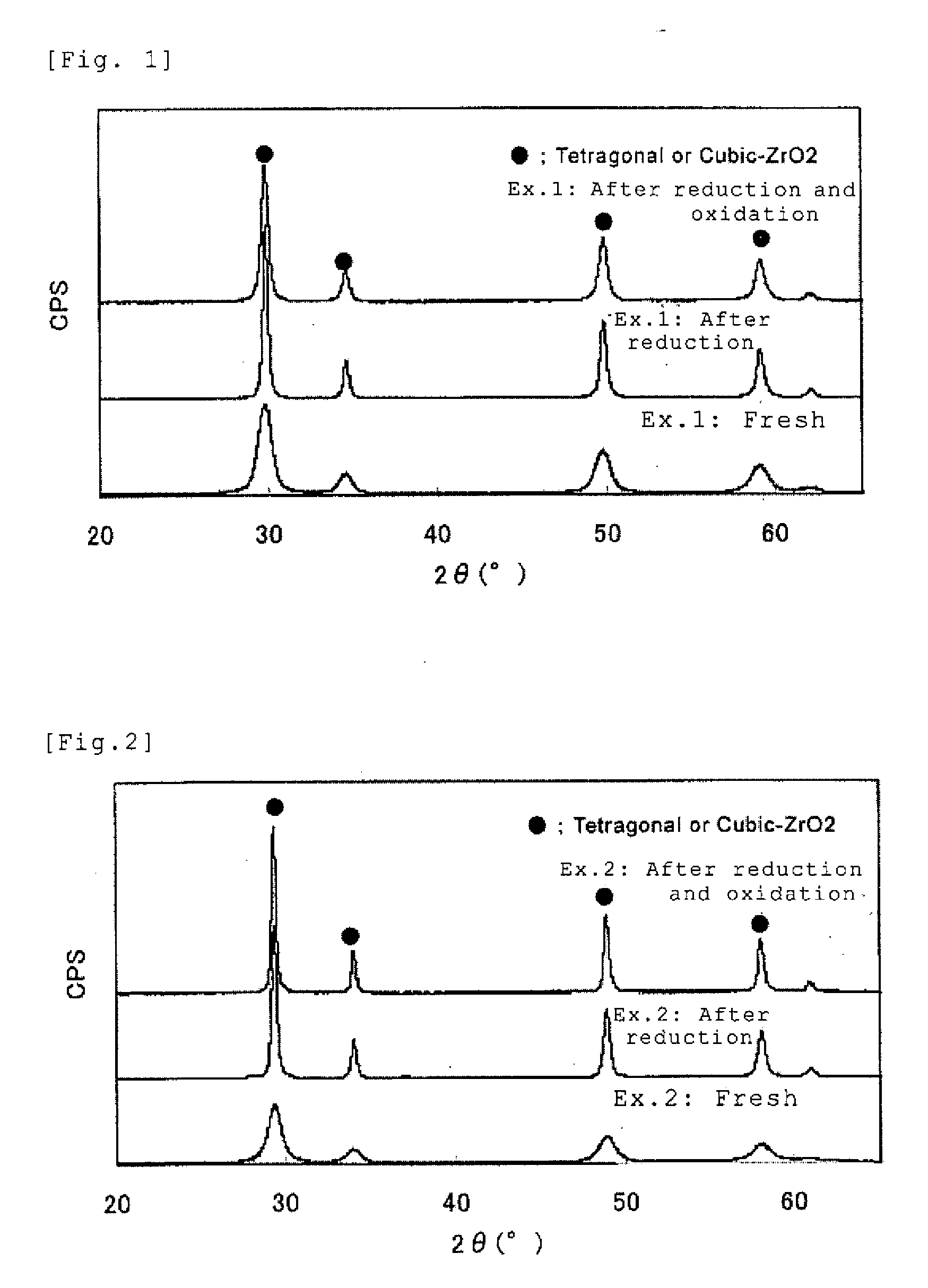

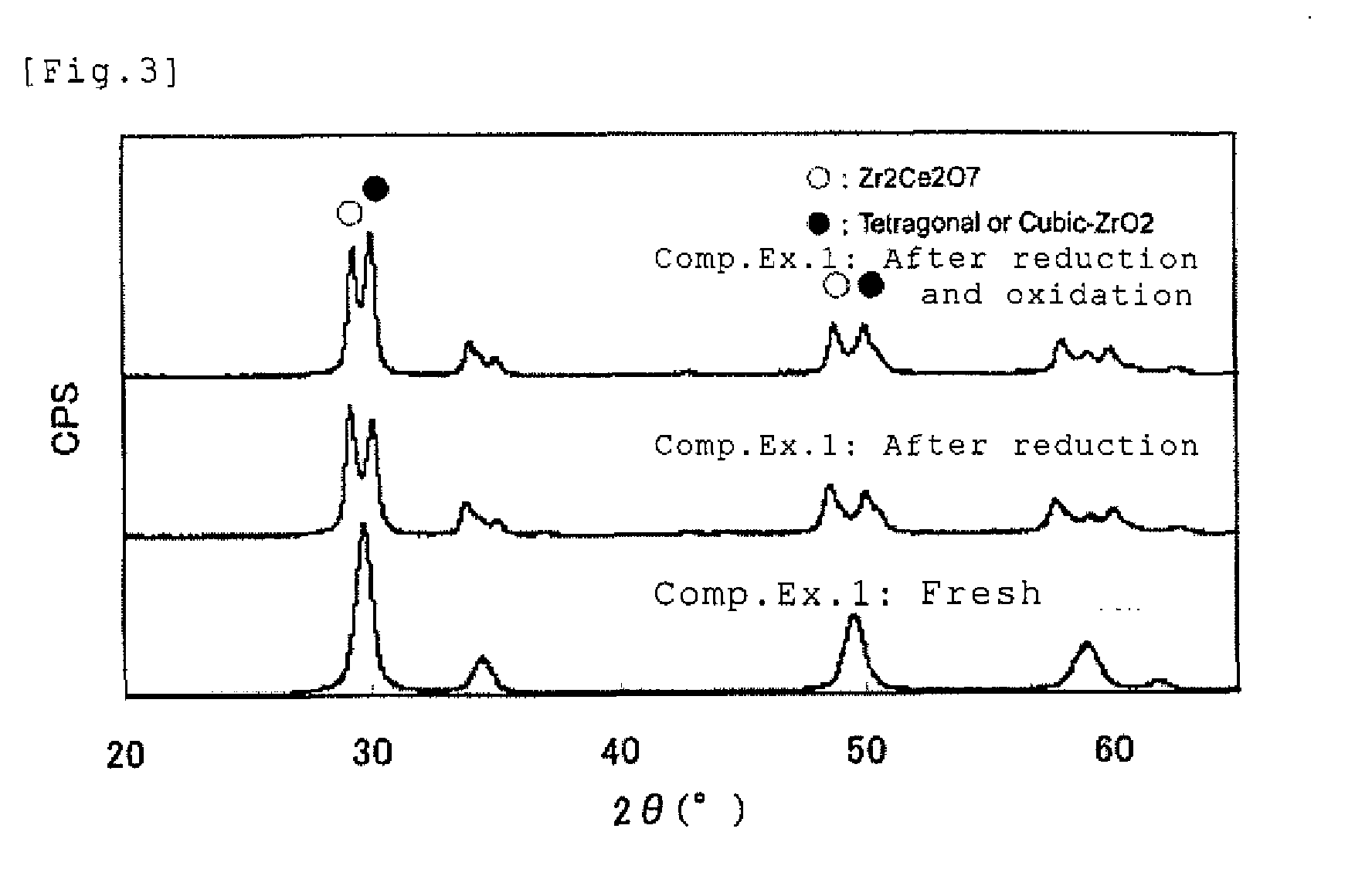

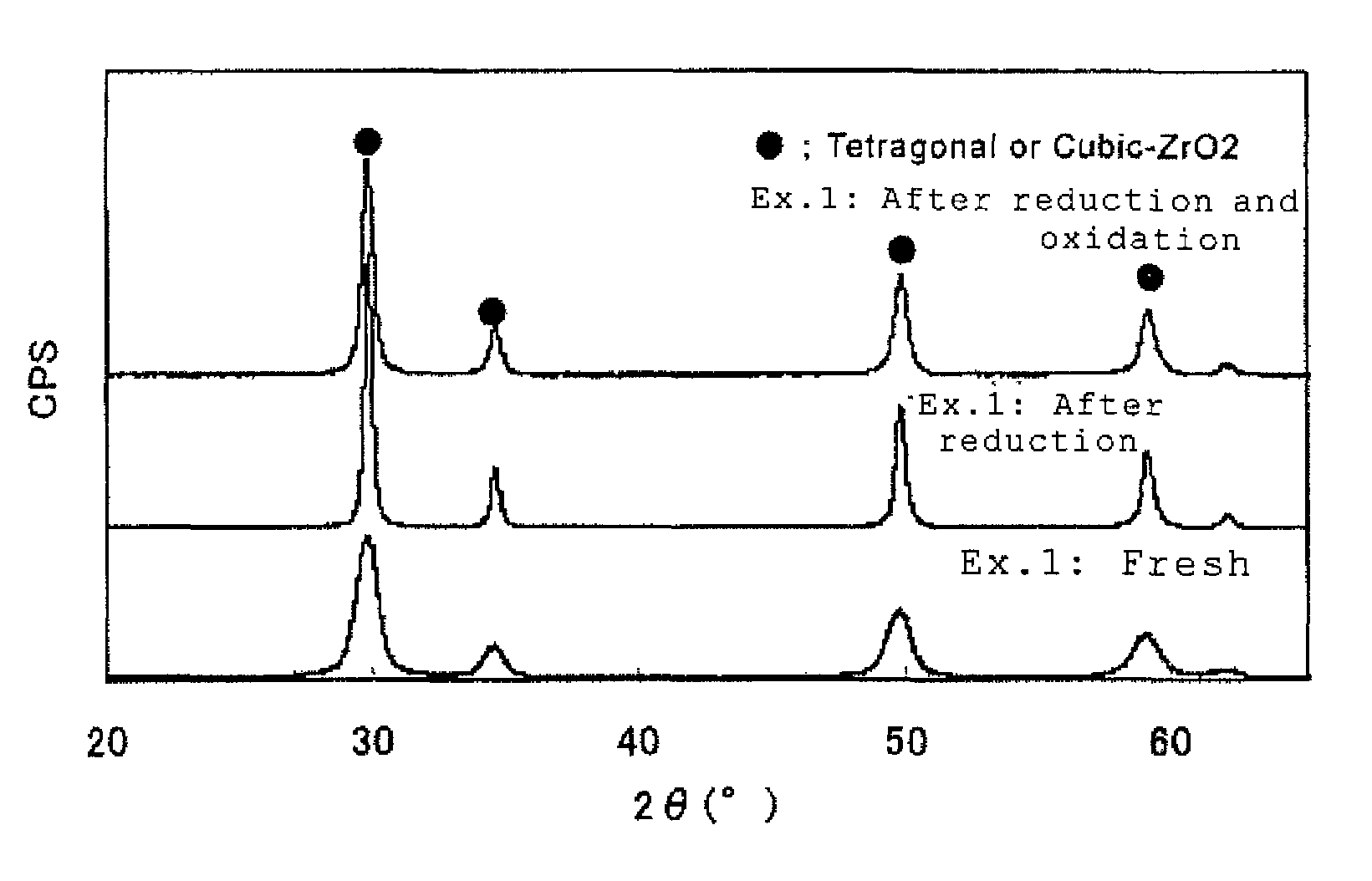

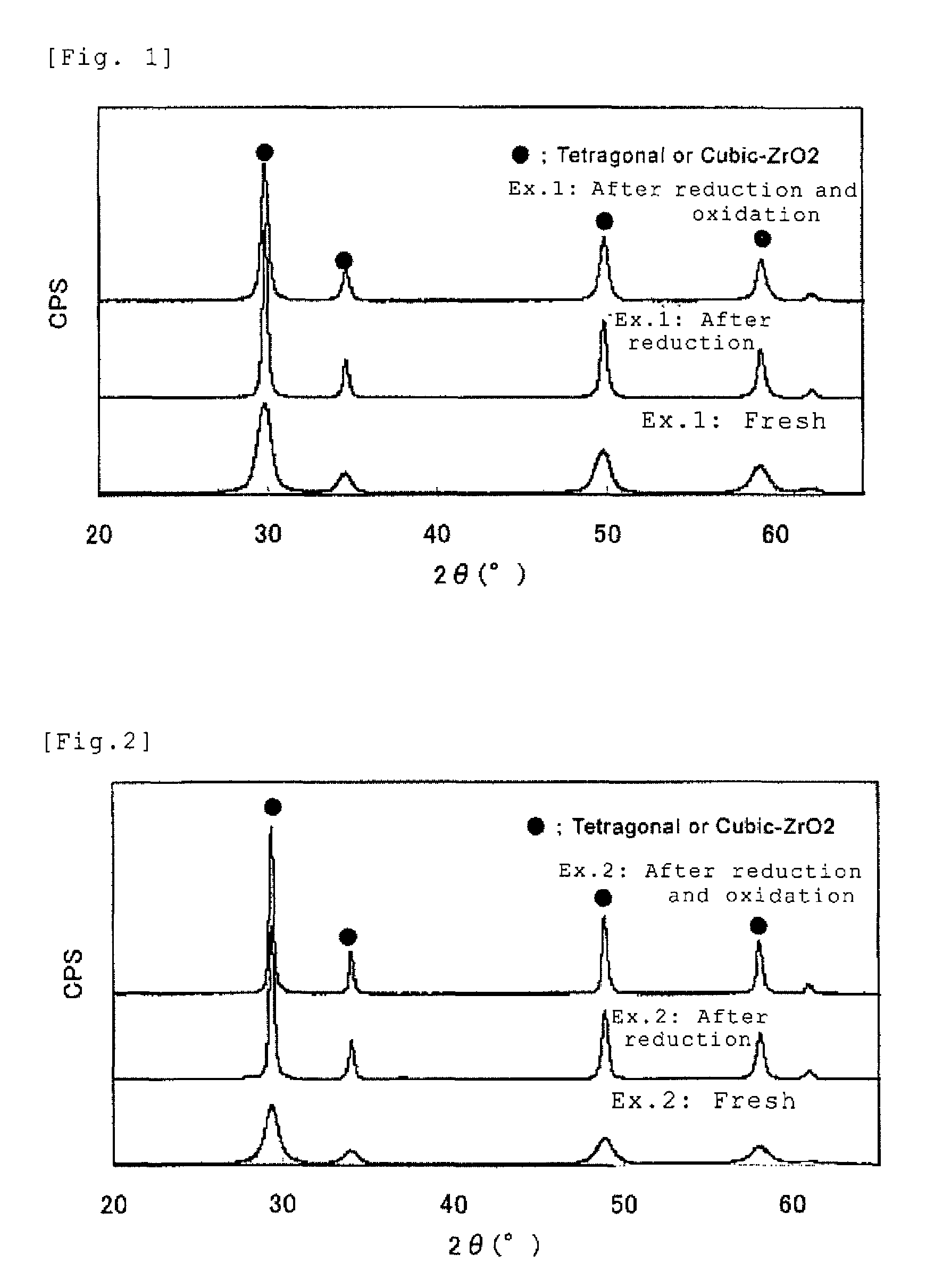

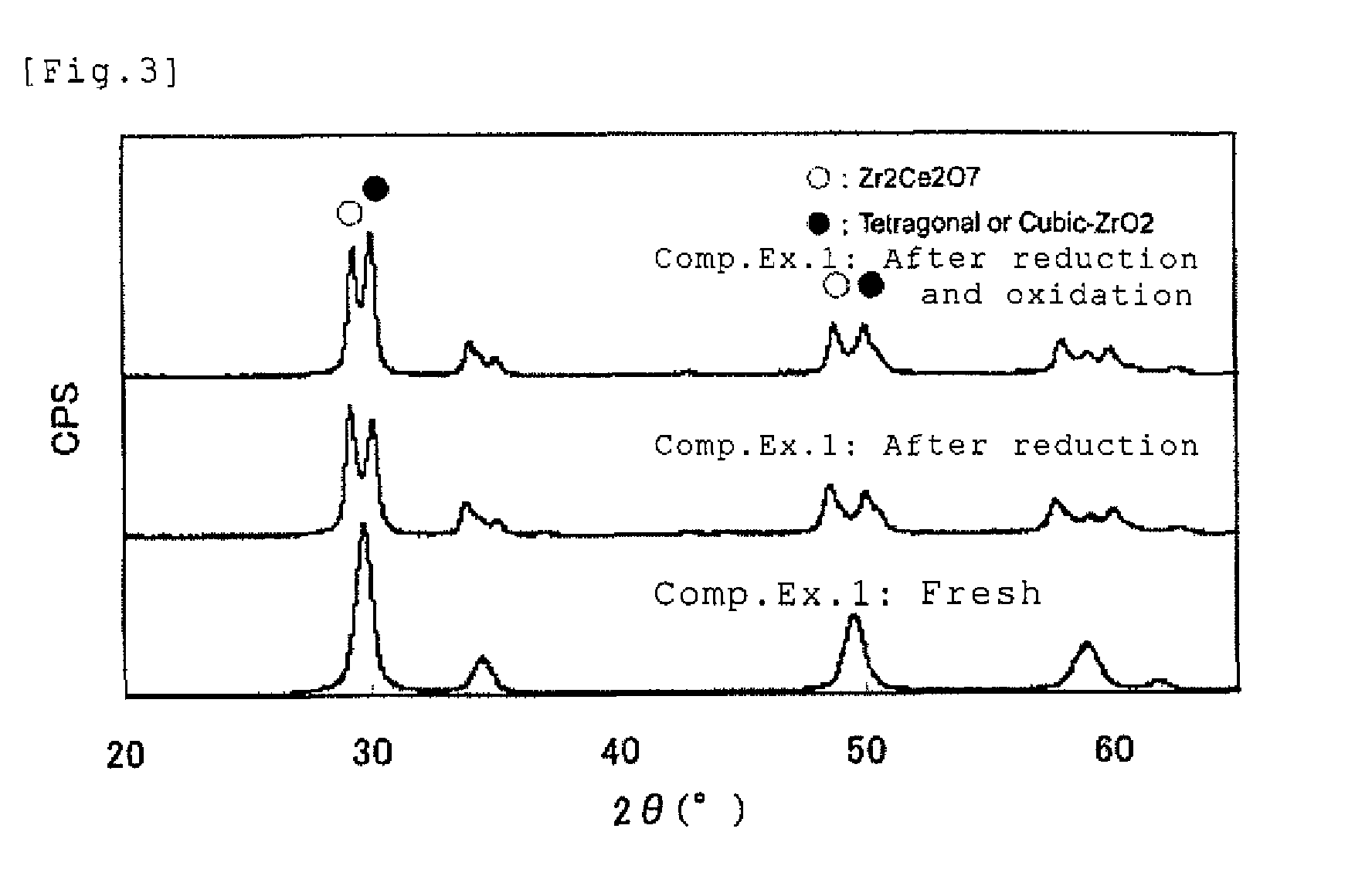

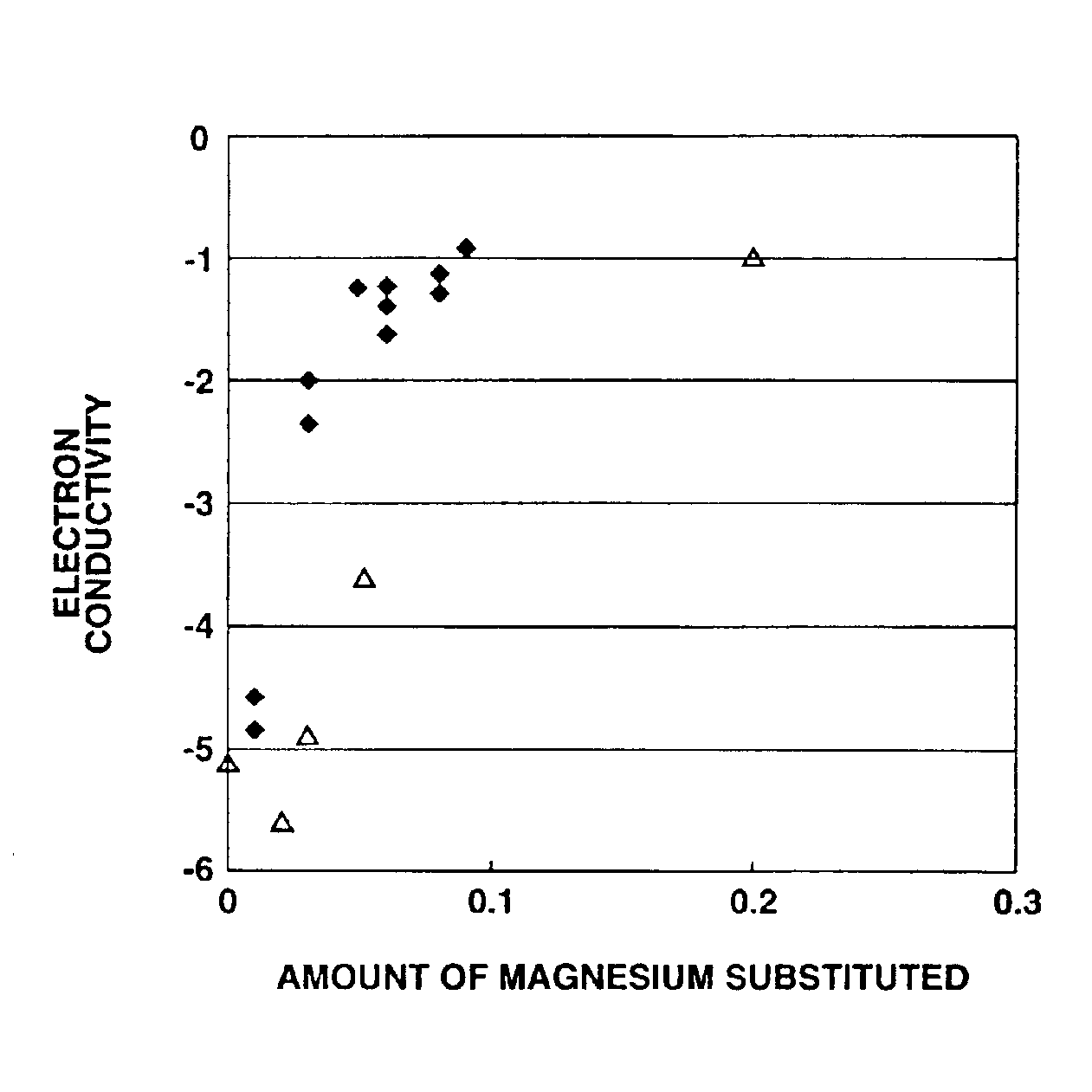

Zirconia-ceria-yttria-based mixed oxide and process for producing the same

ActiveUS20080090723A1Stable crystal structureImprove heat resistanceInternal combustion piston enginesZirconium compoundsMixed oxideCrystal structure

The present invention provides a zirconia-ceria-yttria-based mixed oxide having a stable crystal structure after 12 hours of heat treatment at 1100° C. under a reducing atmosphere, and a process for producing the mixed oxide.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

Reflective coatings and mirrors using same

ActiveUS20170158138A1High melting pointStable crystal structureMirrorsLighting and heating apparatusField of viewPolymer

The present invention relates to a mirror having a backing plate or polymeric substrate being coated with a reflective coating, for example a chromium-based reflective coating. A mirror assembly includes a mirror housing, a reflective element having a first field of view, a reflective coating having a second field of view, the second field of view being wider than the first field of view, and a multi-function backing plate supported by the mirror housing and comprising a reflective element supporting region where the reflective element is supported by the multi-function backing plate and a reflective coating supporting region where the reflective coating is applied to the backing plate.

Owner:SMR PATENTS S A R L

Zirconia-ceria-yttria-based mixed oxide and process for producing the same

ActiveUS7919429B2Stable crystal structureInternal combustion piston enginesZirconium compoundsMixed oxideCerium(IV) oxide

The present invention provides a zirconia-ceria-yttria-based mixed oxide having a stable crystal structure after 12 hours of heat treatment at 1100° C. under a reducing atmosphere, and a process for producing the mixed oxide.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

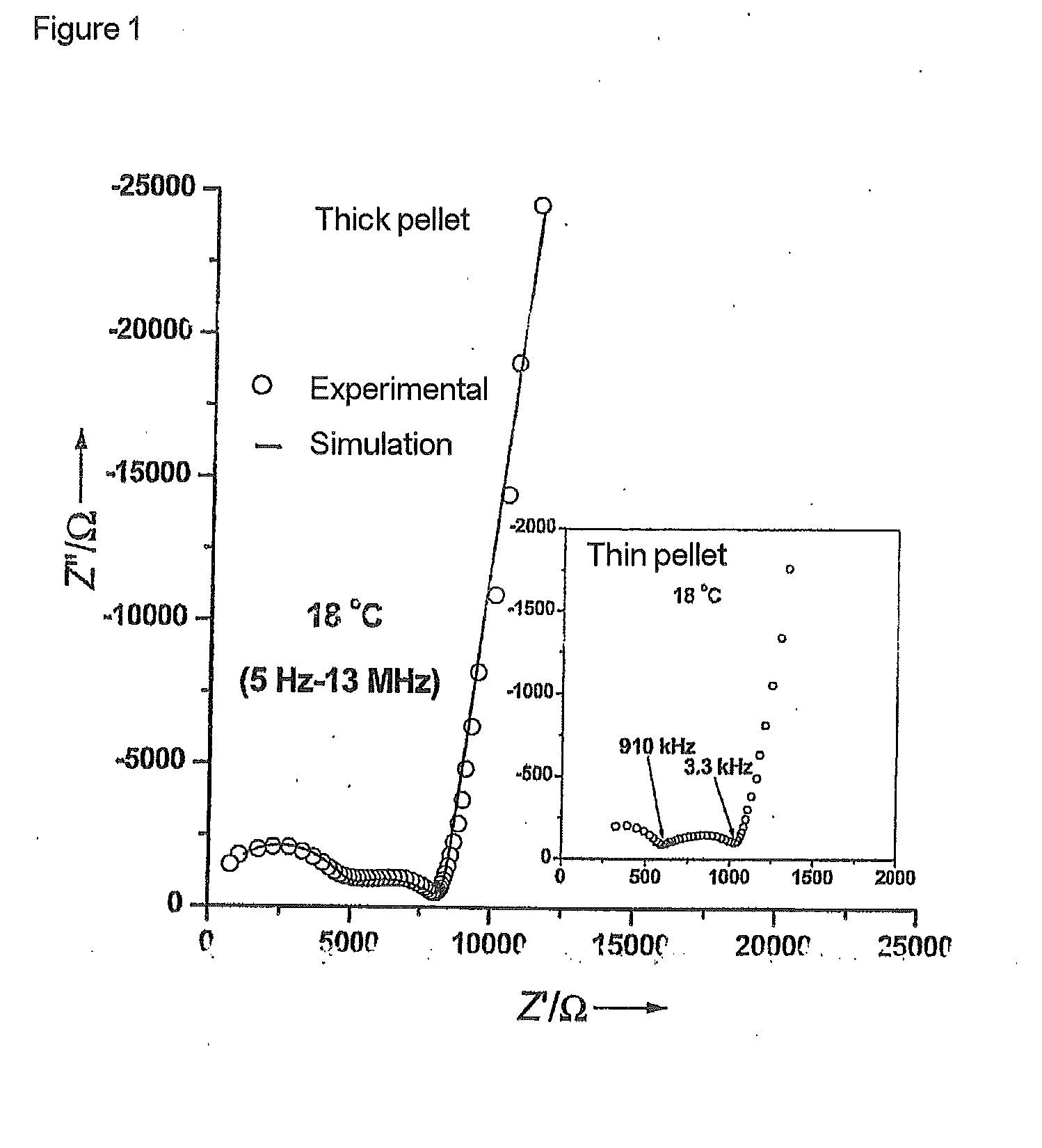

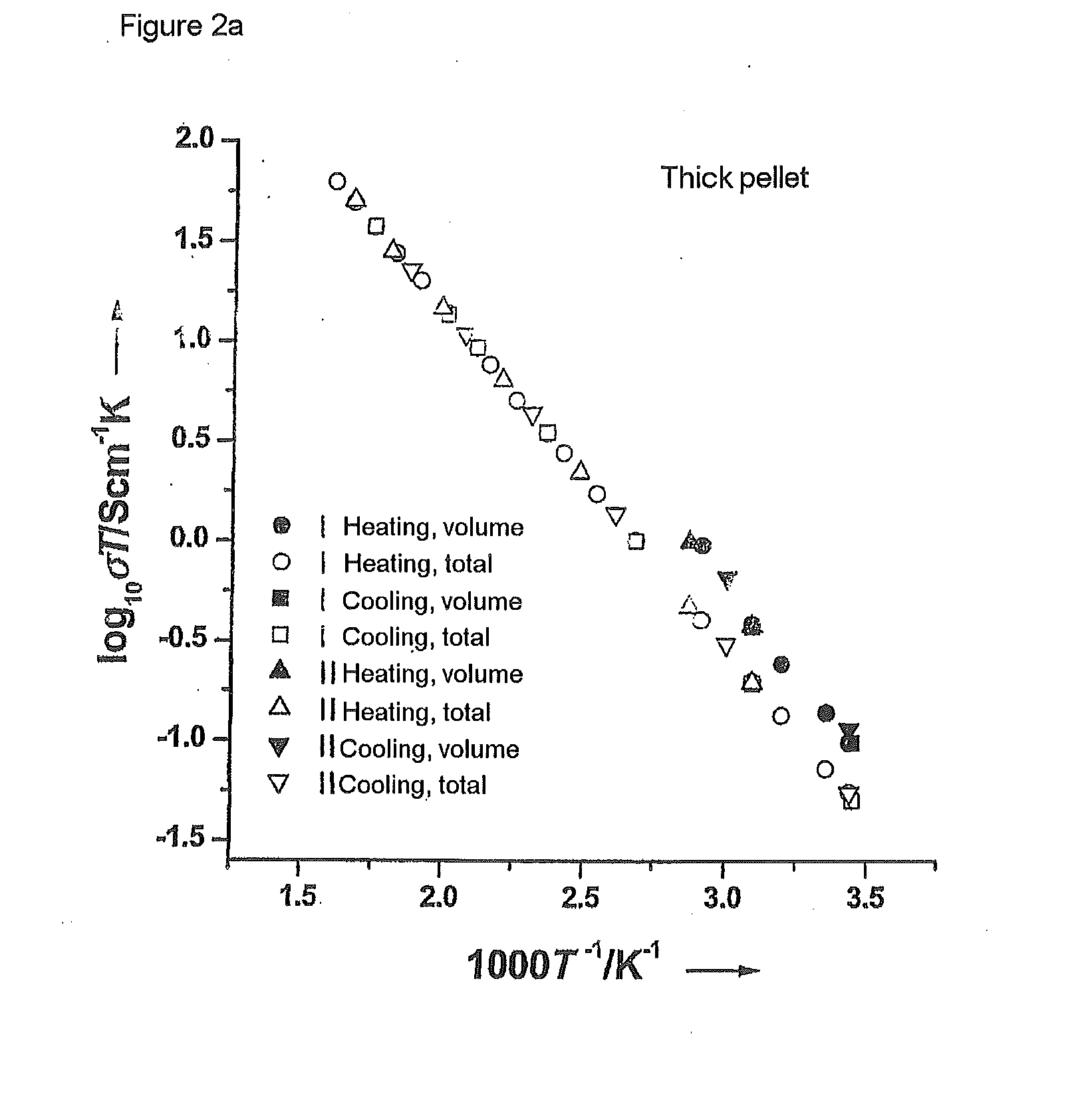

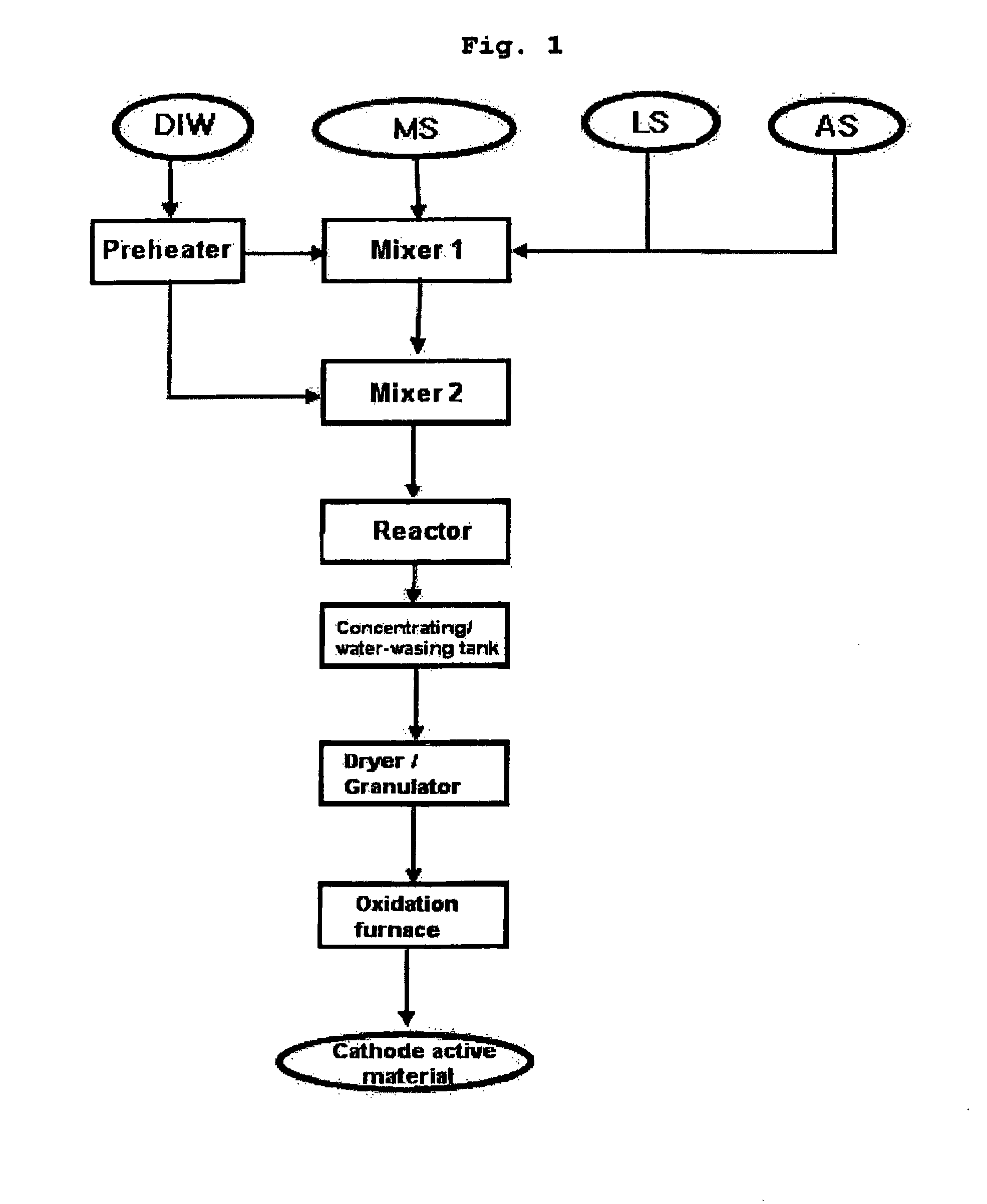

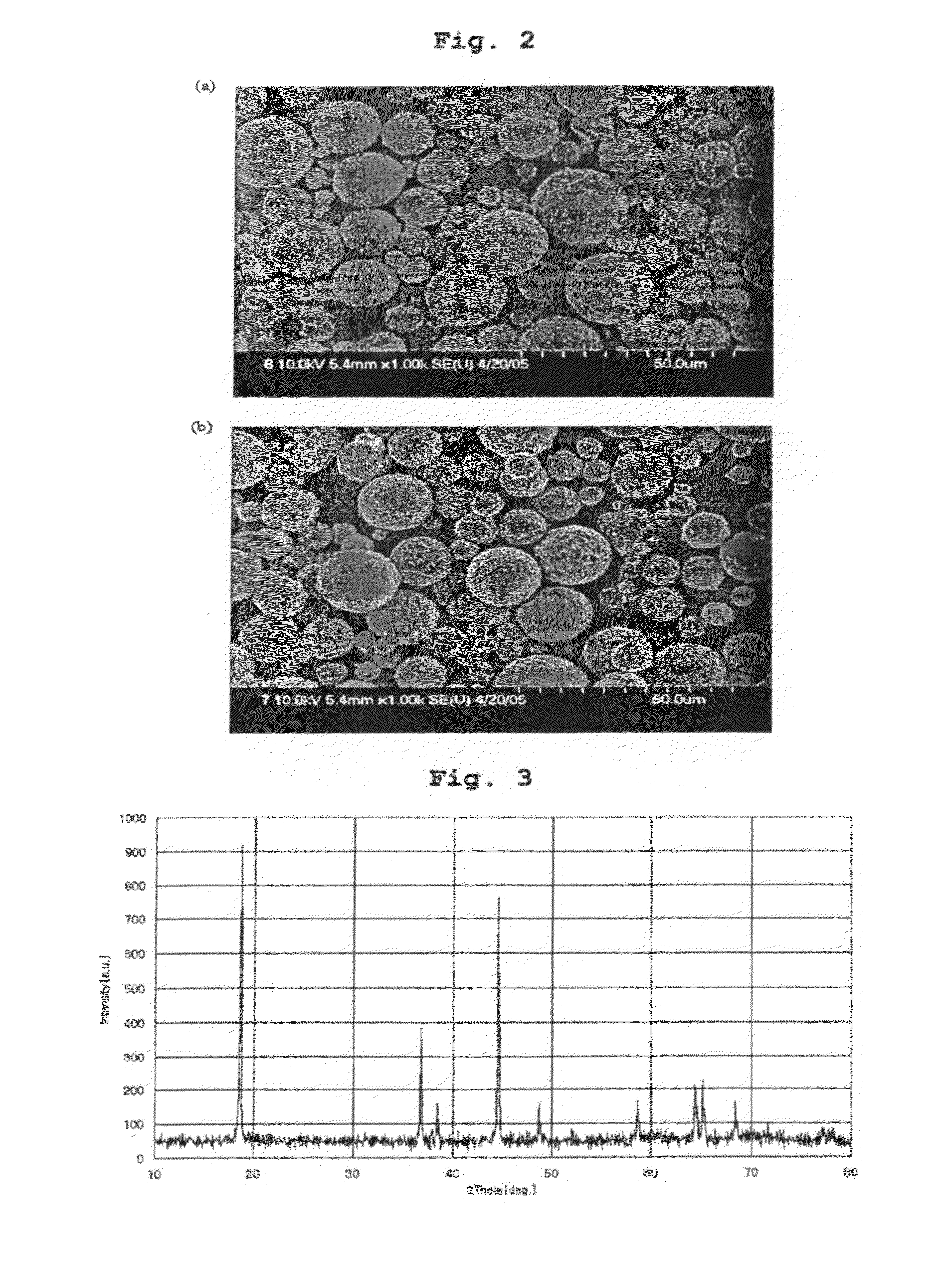

Cobalt oxide particles and process for producing the same, cathode active material for non-aqueous electrolyte secondary cell and process for producing the same, and non-aqueous electrolyte secondary cell

ActiveUS6998071B2Stable crystal structureImprove thermal stabilityMaterial nanotechnologyConductive materialElectrical batteryCrystal structure

Owner:TODA IND

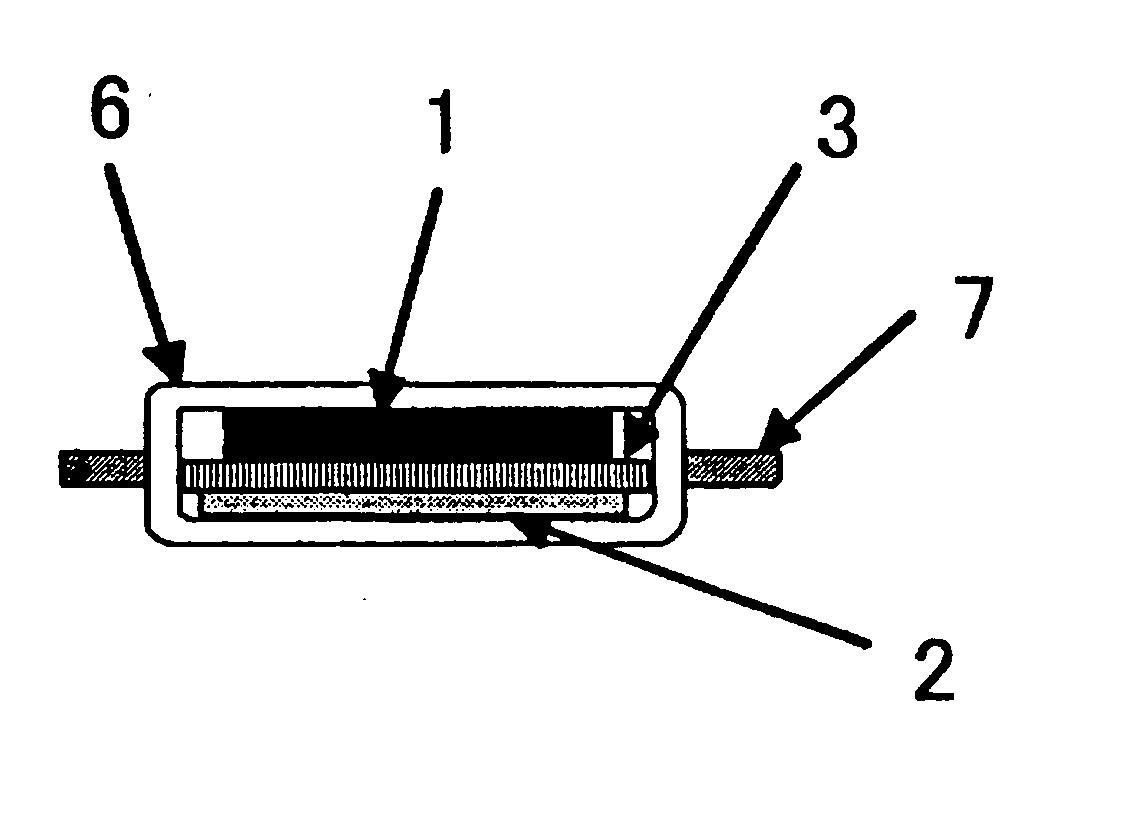

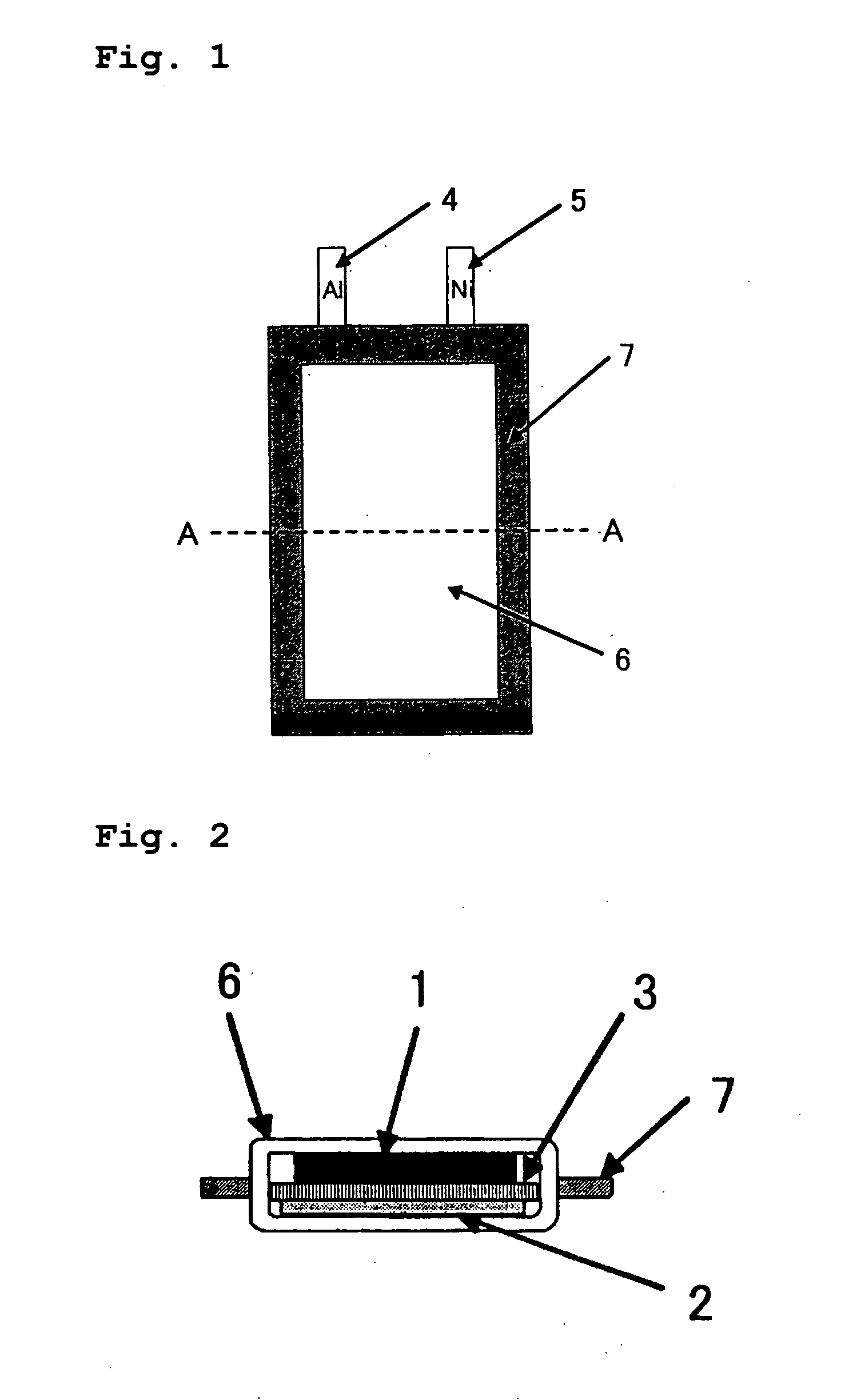

Lithium secondary battery

ActiveUS20060068290A1Stable crystal structureGood charge-discharge cycle performanceActive material electrodesElectrode collector coatingComposite oxideNickel

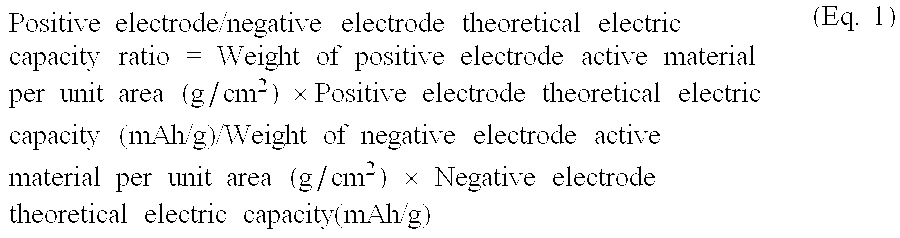

A lithium secondary battery having high capacity and good charge-discharge cycle performance is provided. The lithium secondary battery includes a negative electrode (2) containing silicon as a negative electrode active material, a positive electrode (1) containing a positive electrode active material, and a non-aqueous electrolyte. The positive electrode active material is a lithium-transition metal composite oxide including a layered structure represented by the chemical formula LiaNixMnyCOzO2, where a, x, y, and z satisfy the expressions: 0≦a≦1.3, x+y+z=1, 0<x, 0≦y≦0.5, and 0≦z.), and the theoretical electrical capacity ratio of the positive electrode to the negative electrode (positive electrode / negative electrode) is 1.2 or less.

Owner:SANYO ELECTRIC CO LTD

Li-Ni COMPOSITE OXIDE PARTICLES FOR NON-AQUEOUS ELECTROLYTE SECONDARY CELL, PROCESS FOR PRODUCING THE SAME, AND NON-AQUEOUS ELECTROLYTE SECONDARY CELL

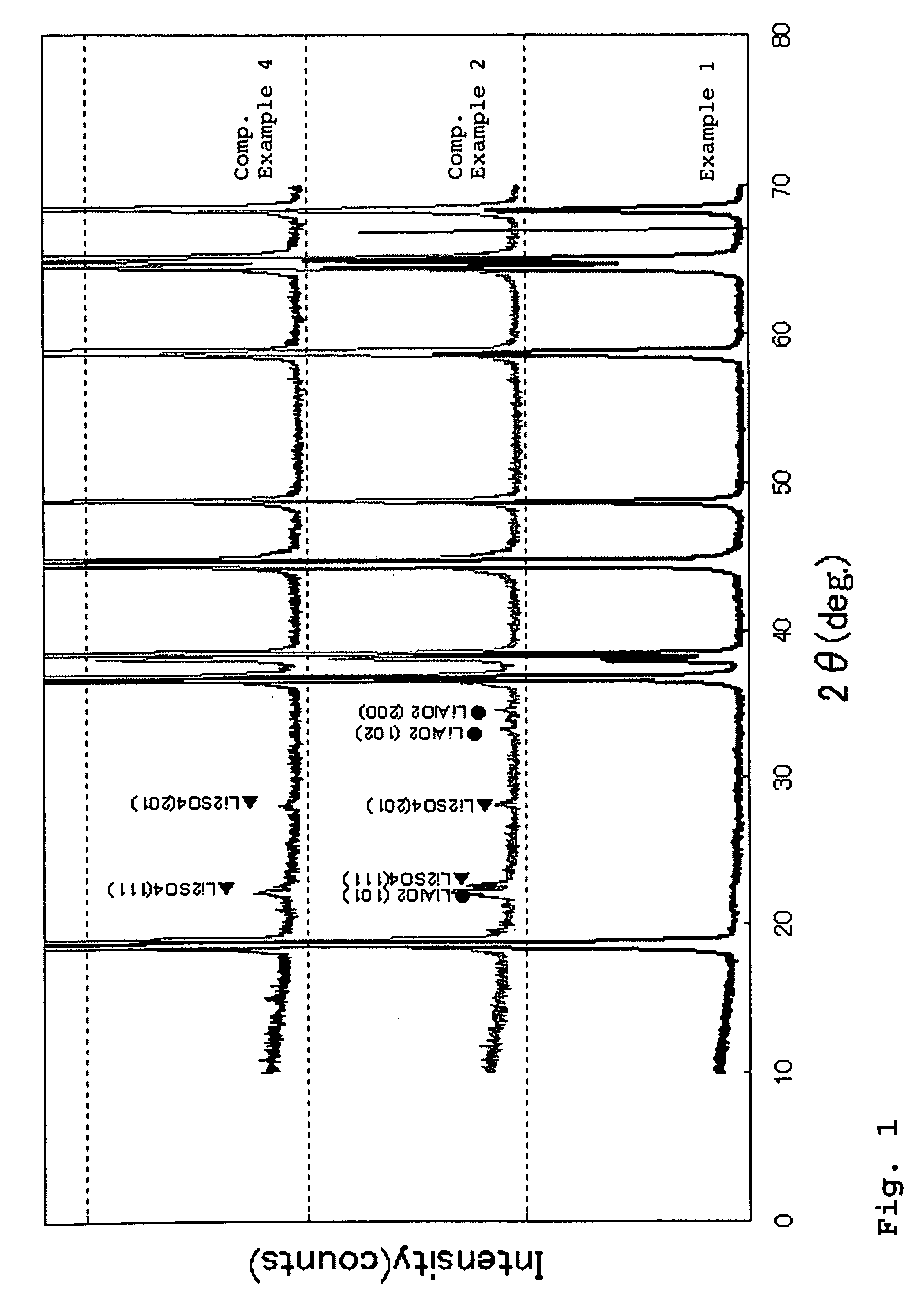

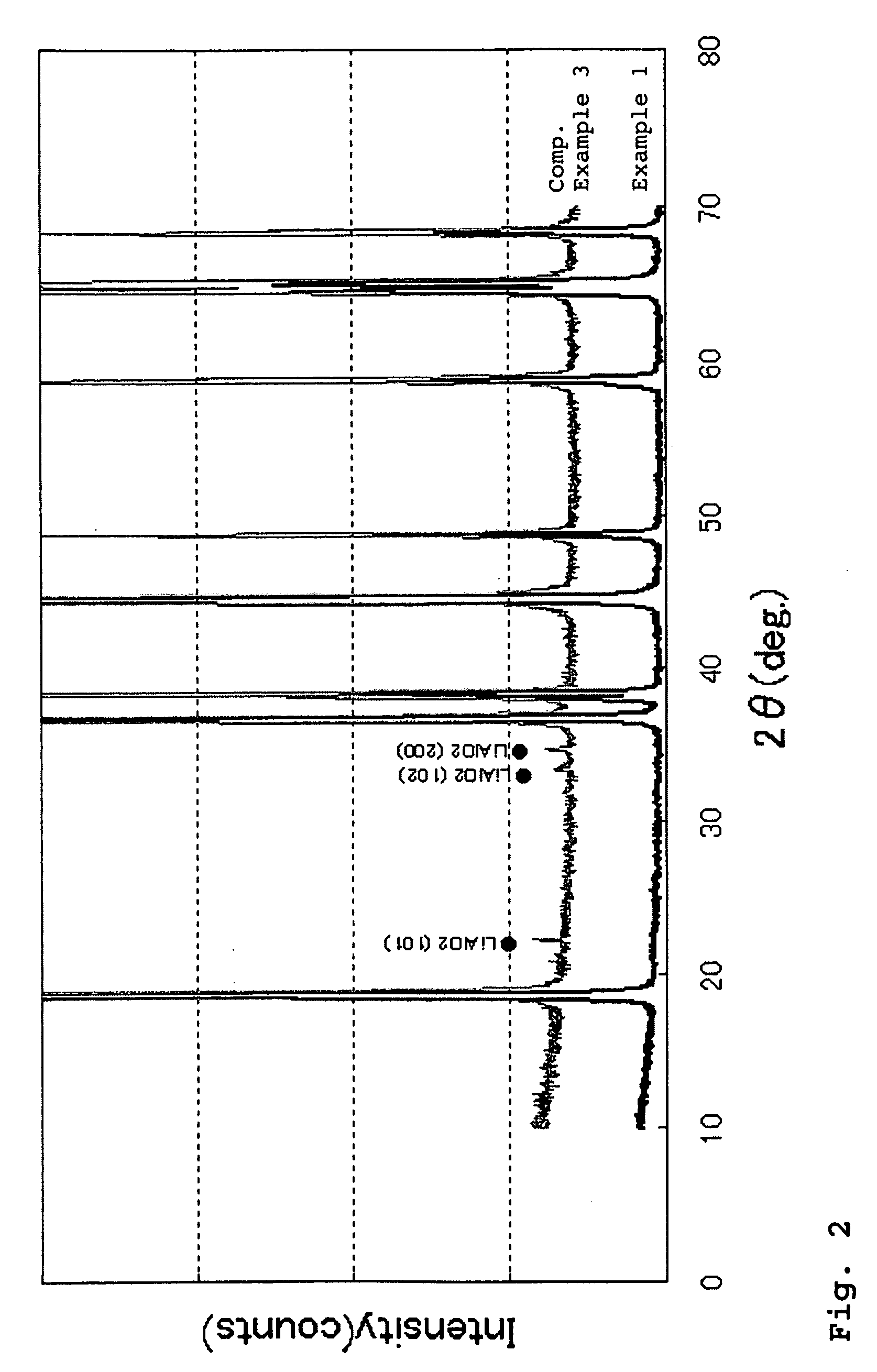

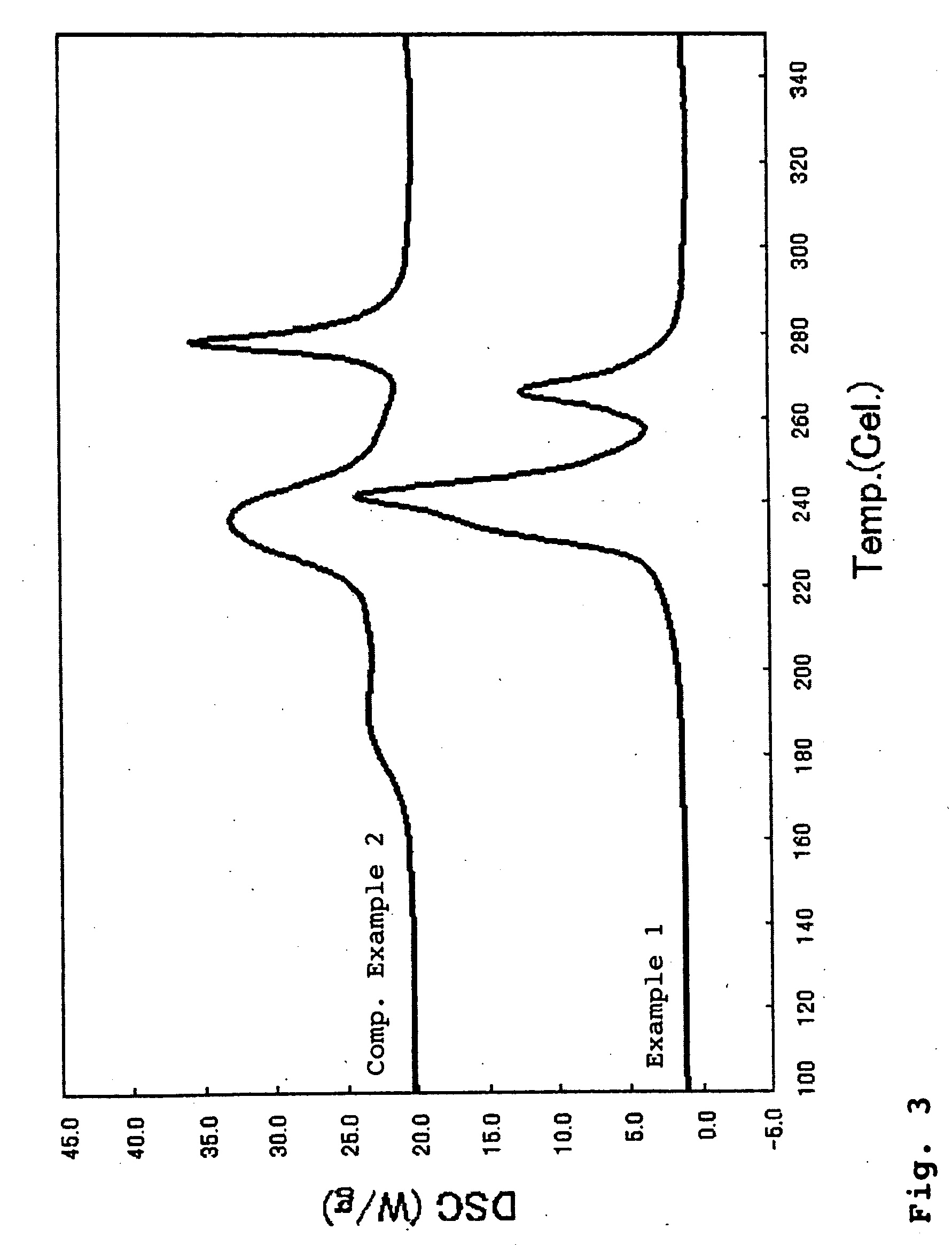

ActiveUS20090272940A1Reduce variationInhibitionElectrode manufacturing processesConductive materialPhysical chemistrySULFATE ION

The present invention relates to Li—Ni composite oxide particles for a non-aqueous electrolyte secondary cell which have a large charge / discharge capacity, an excellent packing density and excellent storage performance. The Li—Ni composite oxide particles for a non-aqueous electrolyte secondary cell which have a composition represented by the formula:LixNi1-y-zCoyAlz02 in which 0.9<x<1.3; 0.1<y<0.3; and 0<z<0.3, wherein the composite oxide particles have a rate of change in specific surface area of not more than 10% as measured between before and after applying a pressure of 1 t / cm2 thereto, and a sulfate ion content of not more than 1.0%, can be produced by mixing Ni—Co hydroxide particles having a sulfate ion content of not more than 1.0% whose surface is coated with an Al compound having a primary particle diameter of not more than 1 μm, with a lithium compound; and calcining the resulting mixture.

Owner:TODA IND

Sodium ion battery anode material and sodium iron battery comprising anode material

InactiveCN103985851AEmbedded firmlyStable prolapseNon-aqueous electrolyte accumulatorsCell electrodesElectrical batteryHigh energy

The invention discloses a sodium ion battery anode material and a sodium iron battery comprising the anode material, and belongs to the technical field of energy source materials. The sodium ion battery anode material comprises a conductive additive and Na3-xM2LO6, wherein x is greater than or equal to 0 and smaller than 2; M is one or more of Fe, Co, Ni, Cu, Zn, Mg, V and Cr; L is one or more of Sb, Te, Nb, Bi and P. The preparation method comprises the steps of mixing sodium carbonate, M oxide and L oxide according to a stoichiometric proportion, ball-milling, calcining and ball-milling so as to obtain the sodium ion battery anode material. The sodium ion battery anode material has the advantages of high sodium storage capacity, good stability and excellent rate capability, and has extremely high energy density and power density; the assembled sodium iron battery has extremely good cycling stability, is green and clean, safe and environmentally friendly and low in cost, and is an extremely excellent electrochemical energy storage system; moreover, the preparation method of the anode material is extremely simple, and raw materials are low in price and easily available.

Owner:WUHAN UNIV

Lithium-metal composite oxides and electrochemical device using the same

ActiveUS8206852B2Improve economyStable crystal structureManganese oxides/hydroxidesNon-aqueous electrolyte accumulator electrodesLithium metalElectrochemical cell

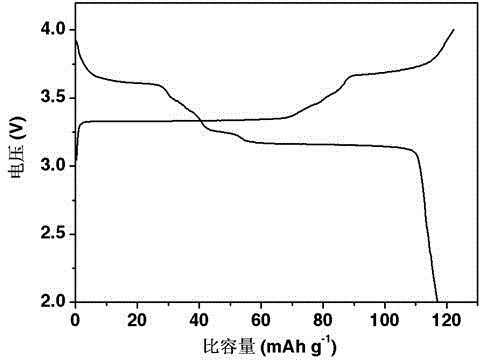

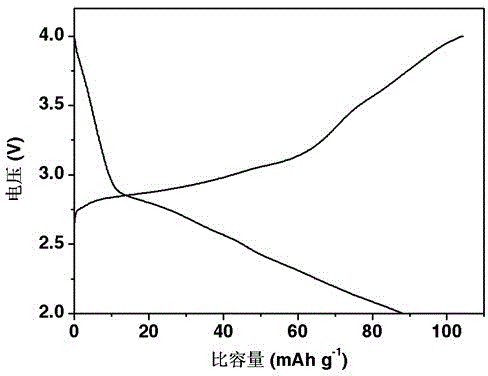

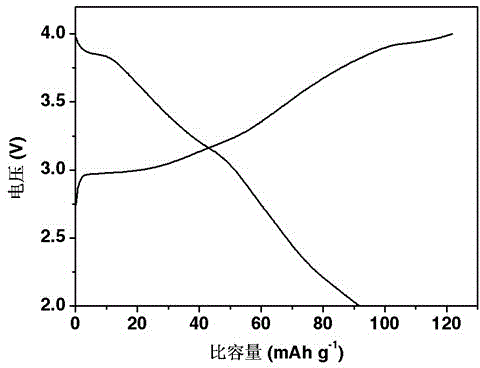

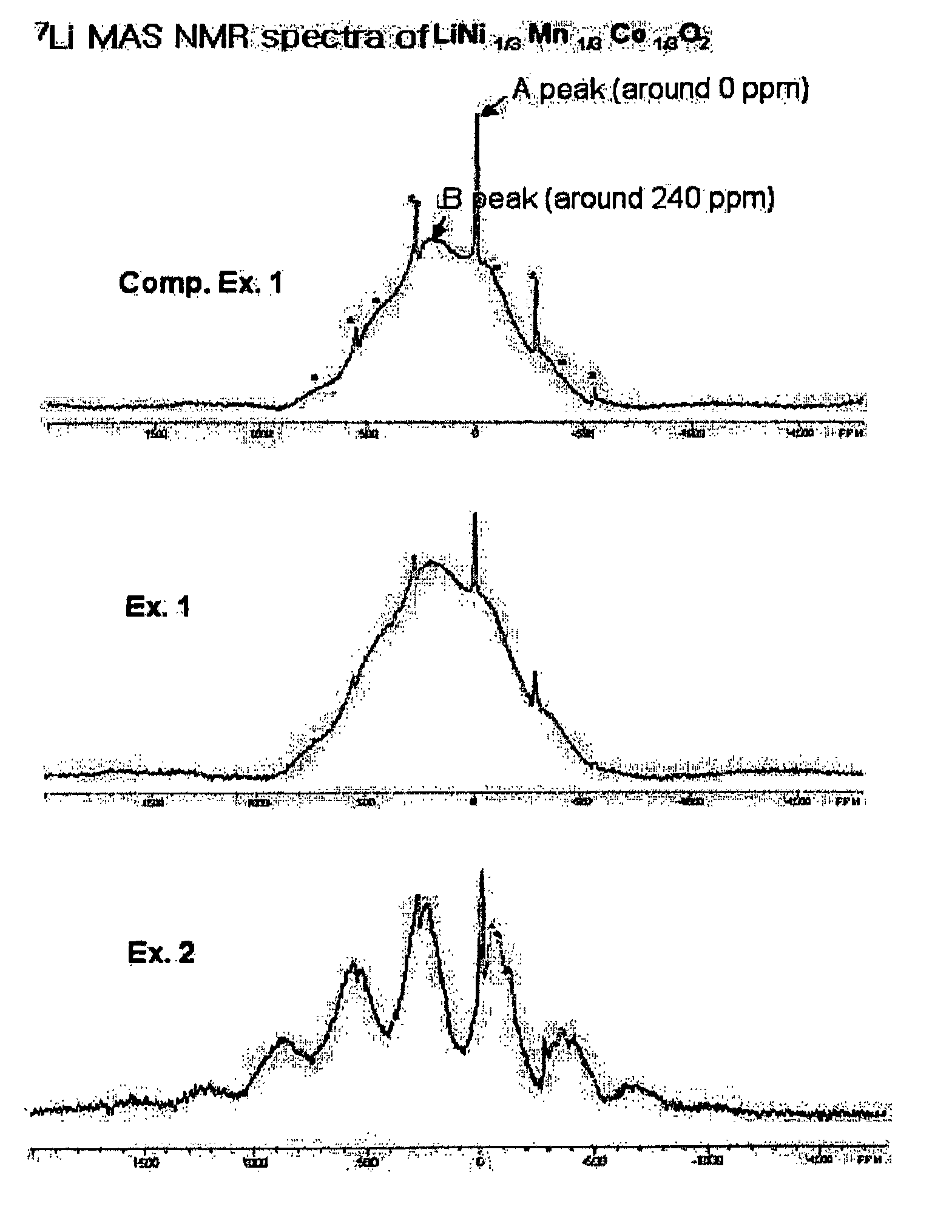

The present invention relates to a lithium-containing metal composite oxide comprising paramagnetic and diamagnetic metals, which satisfies any one of the following conditions: (a) the ratio of intensity between a main peak of 0±10 ppm (I0ppm) and a main peak of 240±140 ppm (I240ppm), (I0ppm / I240ppm), is less than 0.117·Z wherein z is the ratio of moles of the diamagnetic metal to moles of lithium; (b) the ratio of line width between the main peak of 0±10 ppm (I0ppm) and the main peak of 240±140 ppm (I240ppm), (W240ppm / W0ppm), is less than 21.45; and (c) both the conditions (a) and (b). The peaks of the lithium-containing metal composite oxide are obtained according to the 7Li—NMR measurement conditions and means disclosed herein.

Owner:HANWHA CHEMICAL CORPORATION +1

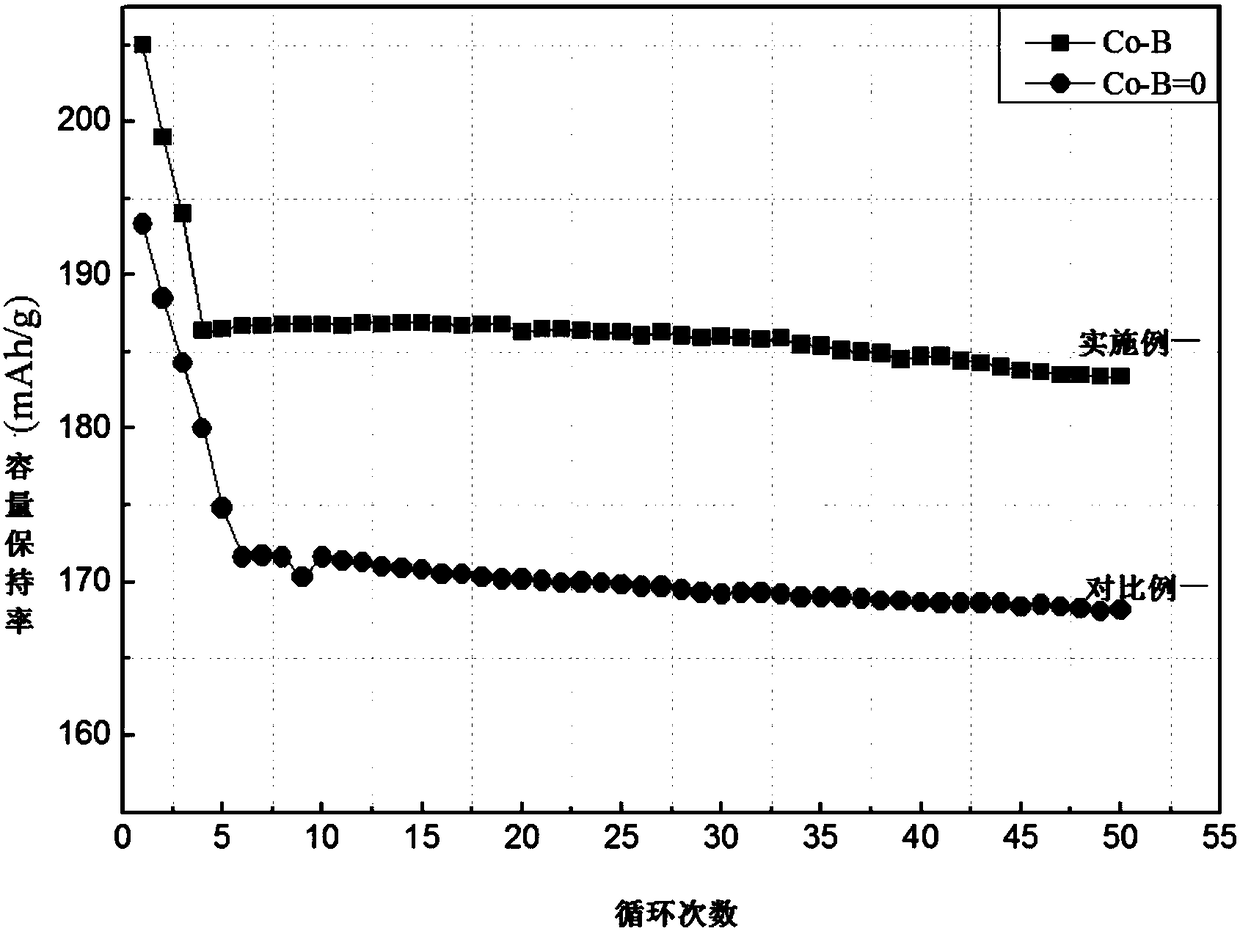

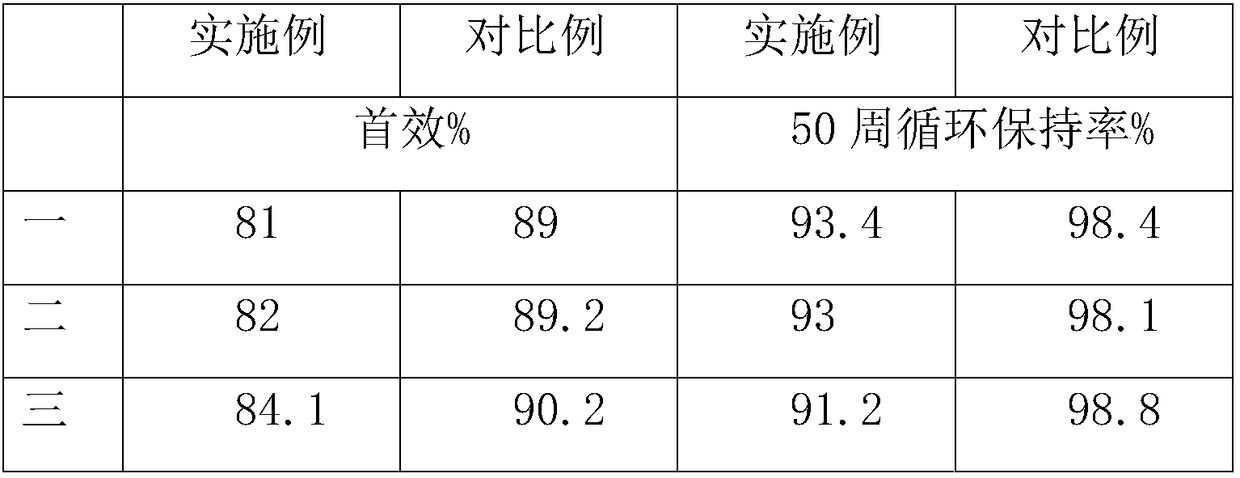

Y/La-doped Co/B co-coated nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

ActiveCN108550802AImprove cycle lifeImprove securityCell electrodesSecondary cellsManganeseSide reaction

The invention belongs to the technical field of lithium batteries, and provides a Y / La-doped Co / B co-coated nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof. According to the present invention, the cycle performance and the safety performance are improved by doping a small amount of Y<3+> ions and La<3+> ions, wherein Y<3+> / La<3+> and Ni<3+> have the same valence state, the doped Y<3+> / La<3+> can enter the metal Ni<3+> position, the Y<3+> / La<3+> does not produce the valence change during the charge and discharge, is electrochemically inert, and doesnot produce the valence state change during the charge and discharge so as not to produce the volume change, such that the Y<3+> / La<3+> can act as the skeleton, stabilize the crystal structure, and improve the cycle life and the safety performance of the material; and under the high voltage, the Co / B co-coated positive electrode material can effectively improve the cycle performance and the electronic conductivity of the battery, reduce the residual alkali, and reduce the flatulence, such that the co-coated nickel-cobalt-manganese ternary positive electrode material can effectively prevent theoccurrence of side reactions so as to improve the cycle performance and the electrochemical performance of the lithium battery.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Positive electrode active material, lithium secondary battery, and manufacture methods therefore

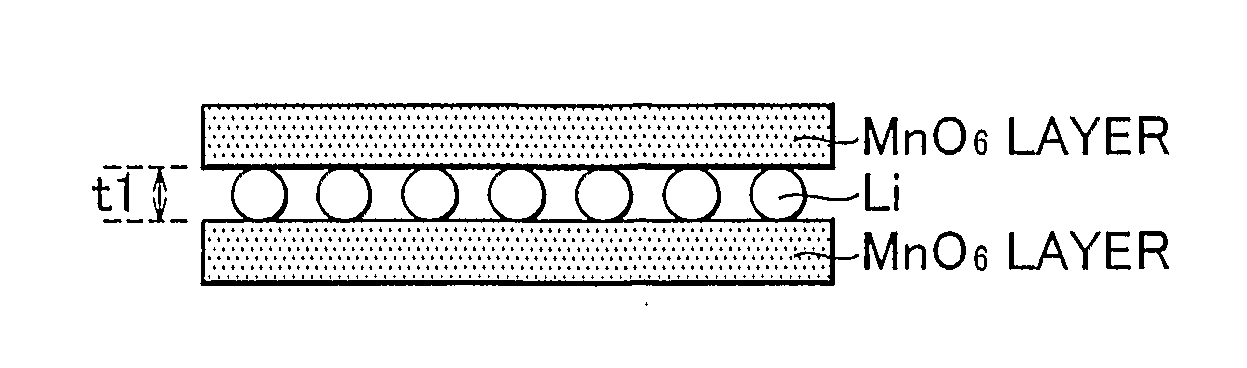

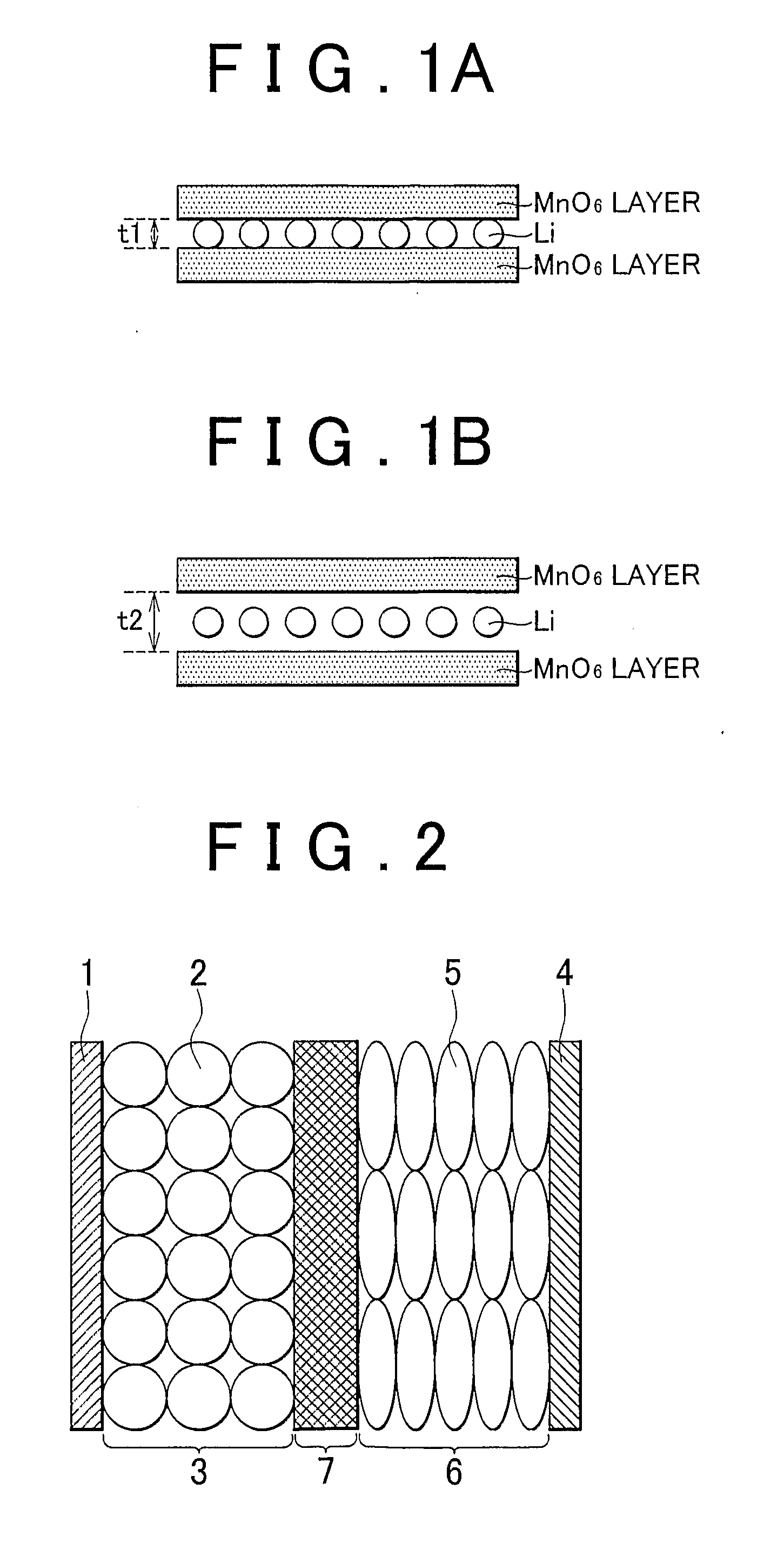

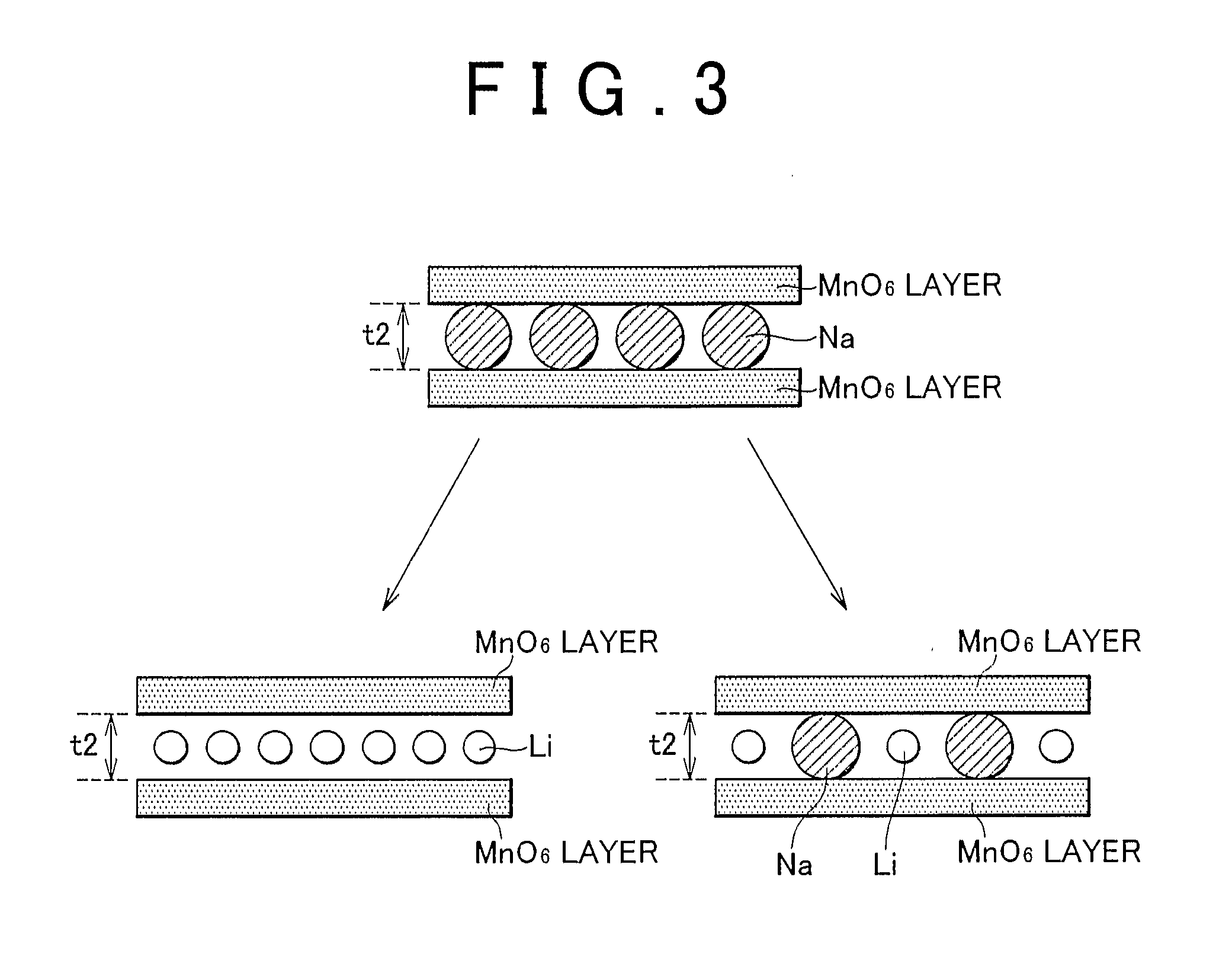

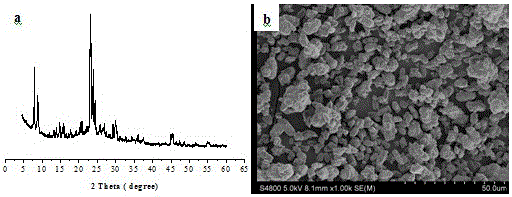

InactiveUS20100203389A1Improve lithium ion diffusion performanceLower internal resistanceFinal product manufacturePrimary cellsLithiumInter layer

The positive electrode active material of the invention has an olivine structure, and is represented by LixM1-xMnPO4 (where 0<x≦1, and M is an alkali metal element that is larger in ion radius than Li), and has a construction in which the inter-layer interval of MnO6 layers in the LixM1-xMnPO4 is larger than the inter-layer interval of the MnO6 layers contained in LiMnPO4 as a reference substance.

Owner:TOYOTA JIDOSHA KK

Method for low-cost synthesis of ZSM-5 molecular sieve

InactiveCN105776246AHigh in silicaHigh reactivityPentasil aluminosilicate zeoliteCrystallinityNatural mineral

The invention belongs to the technical fields of molecular sieve and preparation method thereof, and specifically relates to a process for synthesis of a ZSM-5 molecular sieve by using a hydrothermal method and taking natural minerals diatomite and kaolin as raw materials for providing all aluminum sources and silicon sources required for synthesis of the ZSM-5, and particularly, relates to a method for low-cost synthesis of the ZSM-5-5 molecular sieve. The natural minerals diatomite and kaolin as the raw materials provide all the silicon sources and aluminum sources required for synthesis of the ZSM-5 molecular sieve, the use of any chemical silicon or aluminum products are not required, the ways of diatomite low temperature liquid alkali dissolving and kaolin low temperature solid alkali melting are provided for achieving low temperature high-efficiency activation of natural mineral silicon and aluminum 'nutrients', at the same time, inert impurities in the raw materials are removed, and crystallinity and purity of a crystallized product are improved. The method has obvious advantages in aspects of expanding the range of molecular sieve synthetic raw materials, increasing the added value of the natural mineral products, reducing the production cost of molecular sieve, reducing the environmental pollution and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Multilayer stable black phosphorene and preparation method

InactiveCN106348263AStable crystal structureStabilizers stabilize the crystal structureMaterial nanotechnologyPhosphorus preparationSulfurSuperoxide

The invention belongs to the field of novel two-dimensional materials, and in particular relates to multilayer stable black phosphorene and a preparation method. The reaction of the black phosphorene and oxygen is hindered by chelating of a chelating agent and stable modification of a stabilizer, so that superoxide anions are more difficult to generate, thereby greatly reducing the degradation of black phosphorus in an environment. Further, the multilayer stable black phosphorene is obtained by encapsulating elemental sulfur. According to the method, a stable crystal structure of the black phosphorus is guaranteed; meanwhile, service requirements are met; the thickness of the obtained black phosphorene is between 10nm and 20nm. The multilayer stable phosphorene and the preparation method have a wide important application prospect in the fields such as transistors, sensors, solar cells, switches, battery electrodes and the like.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for producing aluminum titanate sintered compact

The present invention provides a raw material composition for preparing a sintered body of aluminum titanate, the composition comprising (i) 100 parts by weight of a mixture comprising 40 to 50 mol % of TiO2 and 60 to 50 mol % of Al2O3, (ii) 1 to 10 parts by weight of an alkali feldspar represented by the formula: (NaxK1−x)AlSi3O8 (0≦x≦1), and (iii) 1 to 10 parts by weight of at least one Mg-containing component selected from the group consisting of a Mg-containing oxide with spinel structure, MgCO3 and MgO, and a process for preparing a sintered body of aluminum titanate comprising sintering a formed product prepared from the raw material composition at 1300 to 1700° C. According to the present invention, a sintered body of aluminum titanate having high mechanical strength and ability to be stably used at high temperatures, as well as its inherent properties of low coefficient of thermal expansion and high corrosion resistance, can be obtained.

Owner:OHCERA CO LTD

Aluminium alloy material, aluminium alloy shaped part, and preparation method of aluminium alloy shaped part

ActiveCN105695809AHigh thermal conductivityGood molding effectTelephone set constructions5005 aluminium alloyMechanical property

The invention provides an aluminium alloy material. The aluminium alloy material is composed of, by mass, 5.5 to 8.5% of silicon, 0.1 to 0.4% of magnesium, 0.01 to 0.2% of boron, chromium<0.05%, 0.05 to 0.5% of iron, strontium<0.1%, and aluminium and inevitable impurities, wherein the content of each impurity element is less than 0.05%. The aluminium alloy possesses high heat-conducting properties, and excellent forming properties, and mechanical properties; thermal conductivity is higher than 140W / m.k under common pressure casting conditions; thermal conductivity is even higher than 150W / m.k under gravity casting or extrusion casting conditions; the aluminium alloy can be applied to the field of mobile phone product and communication product, can be used for solving problems in the prior art that thermal conductivity properties of materials used in mobile phone products and communication products are poor, product heat dissipation performance is poor, and severe heating phenomenon is caused. The invention also provides an aluminium alloy shaped part prepared from the aluminium alloy, and a preparation method of the aluminium alloy shaped part.

Owner:HUAWEI TECH CO LTD +1

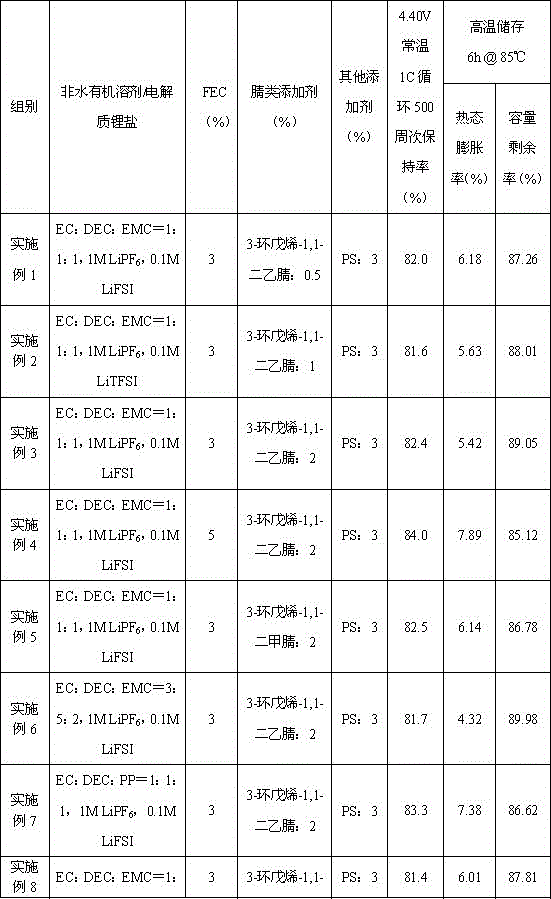

High-voltage electrolyte containing cyclopentene dinitrile and lithium-ion battery employing electrolyte

ActiveCN105742704AGood film formingImprove interface compatibilitySecondary cellsOrganic electrolytesCyclopenteneElectrolytic agent

The invention discloses a high-voltage electrolyte containing cyclopentene dinitrile and a lithium-ion battery employing the electrolyte. The high-voltage electrolyte is characterized by comprising an electrolyte lithium salt, a non-aqueous organic solvent and an additive, wherein the additive comprises fluoroethylene carbonate and a cyclopentene dinitrile compound; a nitrile functional group -CN in the cyclopentene dinitrile compound and transition metal ions in a positive active material can generate complexation; catalytic decomposition of the electrolyte is reduced; dissolution of the metal ions is inhibited; and the crystal structure of the high-voltage positive active material is stabilized, so that the cycle performance and the high-temperature performance of the high-voltage battery are improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

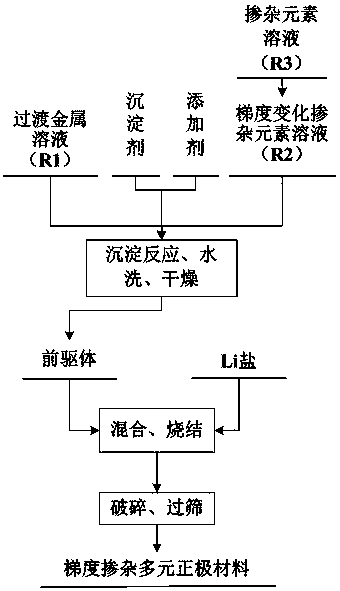

Lithium ion battery gradient anode material and preparation method thereof

ActiveCN108269997AStable crystal structureImproved magnification performanceCell electrodesSecondary cellsTransmission rateLithium electrode

The invention discloses a lithium ion battery gradient anode material and a preparation method thereof. The average composition formula of the material is Li0.3+deltaNixCoyMnzD1-x-y-zO2, delta is notsmaller than 0 and not larger than 0.9, x is not smaller than 0.3 and not larger than 1, y is not smaller than 0 and not larger than 0.4, z is not smaller than 0 and not larger than 0.4, D is one or more of Mo, Ca, Mg, Fe, Zr, Ti, Zn, Y, W, V, Nb, Sm, La, B, Al and Cr, and the content of the doping element D is continuously increased from the particle core to the surface. According to different rates of different regions in the spherical material, doping elements are optimally distributed; in the precipitation process, by changing the contents of the doping elements in different stages, the lithium ion transmission rate in the crystal structure inside the material is increased, then, the rate capability of an existing multi-element material is improved, and the cycle life of the material is prolonged; the process is continuous and controllable, operation is easy, the cost is low and the material is suitable for large-scale production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com