Coated and modified high-nickel ternary cathode material and preparation method thereof

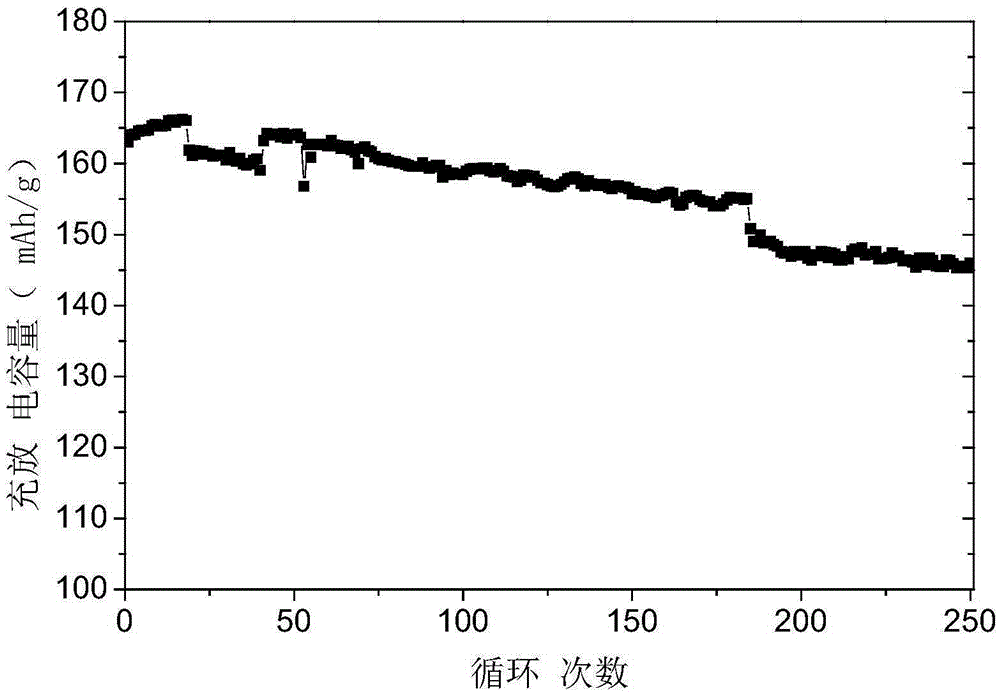

A cathode material, high nickel technology, applied in the field of high nickel ternary cathode material and its preparation, can solve the problems of increasing the difficulty of process control, high cost, complicated sintering process, etc., to improve cycle performance and safety performance, low cost. Alkalinity, effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

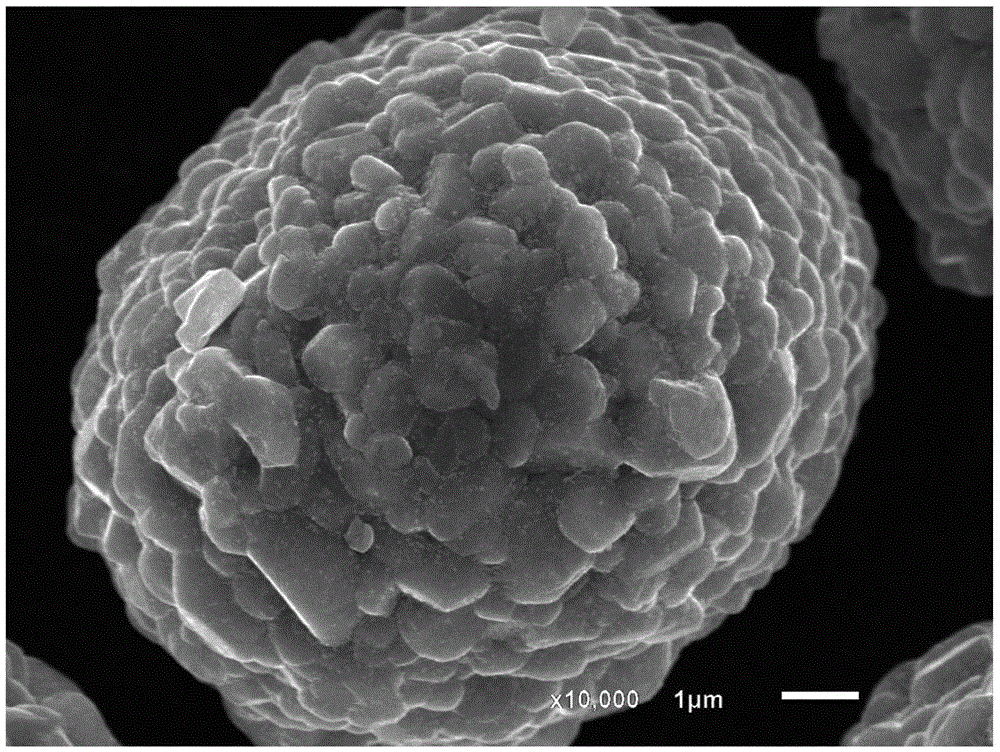

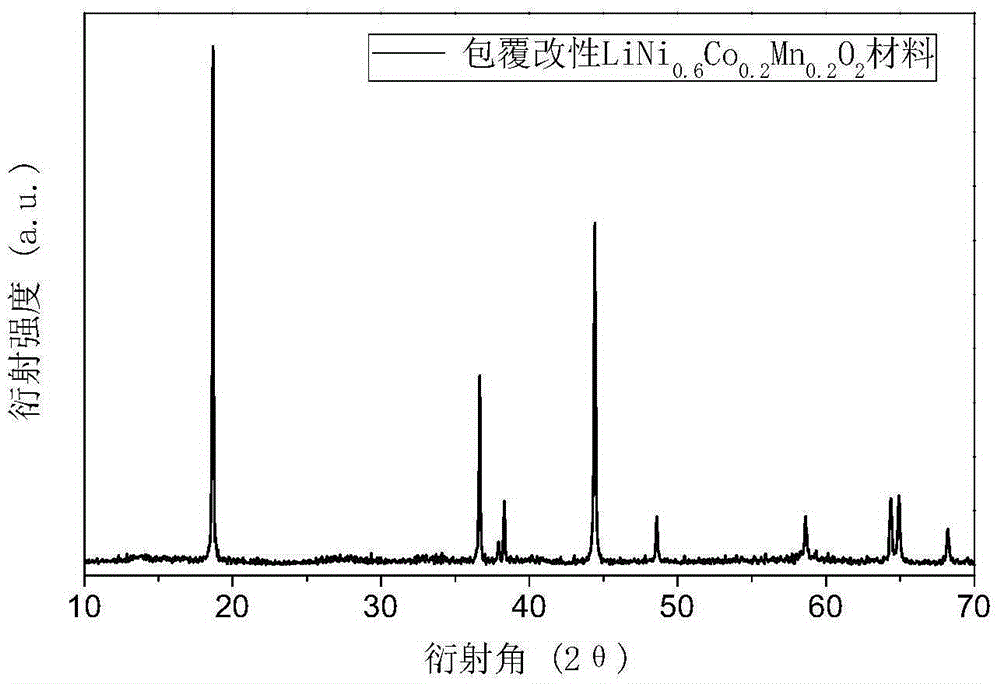

[0030] A kind of coated modified high-nickel ternary cathode material of the present invention is based on LiNi 0.6 co 0.2 mn 0.2 o 2 The material is a matrix; the matrix is coated with nano-alumina and nano-calcium; the total mass of cationic metal in the nano-alumina and nano-calcium accounts for 0.17% of the mass of the high-nickel ternary positive electrode material.

[0031] The preparation method of the above-mentioned coated modified high-nickel ternary positive electrode material in this embodiment specifically includes the following steps:

[0032] 1) Dissolve 6.5g of aluminum nitrate in 500ml of deionized water according to the added metering to obtain aluminum nitrate solution;

[0033] 2) The prepared 1000gLiNi 0.6 co 0.2 mn 0.2 o 2 The matrix material is added to the above-mentioned aluminum nitrate solution and fully mixed to obtain a slurry;

[0034] 3) Take excess calcium hydroxide and dissolve it in deionized water at 30°C to obtain 1500ml of saturat...

Embodiment 2

[0041] A kind of coated modified high-nickel ternary cathode material of the present invention is based on LiNi 0.8 co 0.1 mn 0.1 o 2 The material is a matrix; the matrix is coated with nano-aluminum fluoride and nano-potassium sulfate; the total mass of cationic metal in the nano-aluminum fluoride and nano-potassium sulfate accounts for 9.4% of the mass of the high-nickel ternary positive electrode material.

[0042] The preparation method of the above-mentioned coated modified high-nickel ternary positive electrode material in this embodiment specifically includes the following steps:

[0043] 1) Dissolve 296.5g of aluminum sulfate in 1000ml of deionized water according to the added metering to obtain aluminum sulfate solution;

[0044] 2) The prepared 2000gLiNi 0.8 co 0.1 mn 0.1 o 2 The matrix material is added to the above-mentioned aluminum sulfate solution and fully mixed to obtain a slurry;

[0045] 3) Dissolve 200.2 g of potassium fluoride in 1000 ml of deion...

Embodiment 3

[0049] A kind of coated modified high-nickel ternary cathode material of the present invention is based on LiNi 0.7 mn 0.15 co 0.15 o 2 The material is a matrix; the matrix is covered with nano-alumina, nano-strontium chloride and nano-silver chloride; the total mass of cationic metals in nano-alumina, nano-strontium chloride and nano-silver chloride accounts for the mass of high-nickel ternary cathode materials 3.5%.

[0050] The preparation method of the above-mentioned coated modified high-nickel ternary positive electrode material in this embodiment specifically includes the following steps:

[0051] 1) Dissolve 10.49g of aluminum chloride in 120ml of deionized water according to the metered addition to obtain an aluminum chloride solution;

[0052] 2) The prepared 500gLiNi 0.7 mn 0.15 co 0.15 o 2 The matrix material is added to the above-mentioned aluminum chloride solution and fully mixed to obtain a slurry;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com