Patents

Literature

40results about How to "High and stable coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

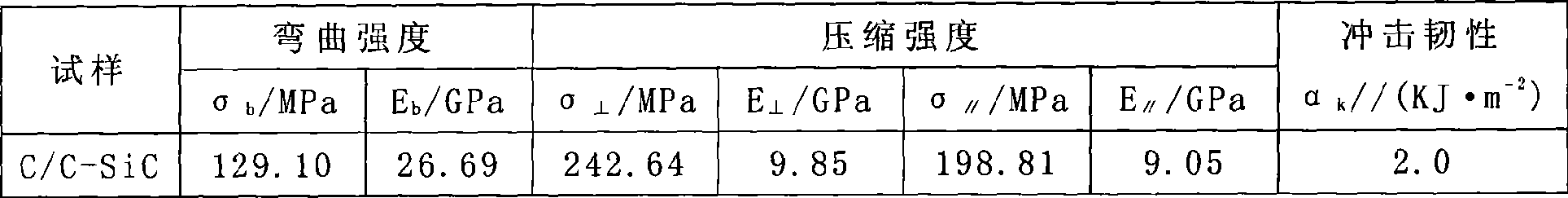

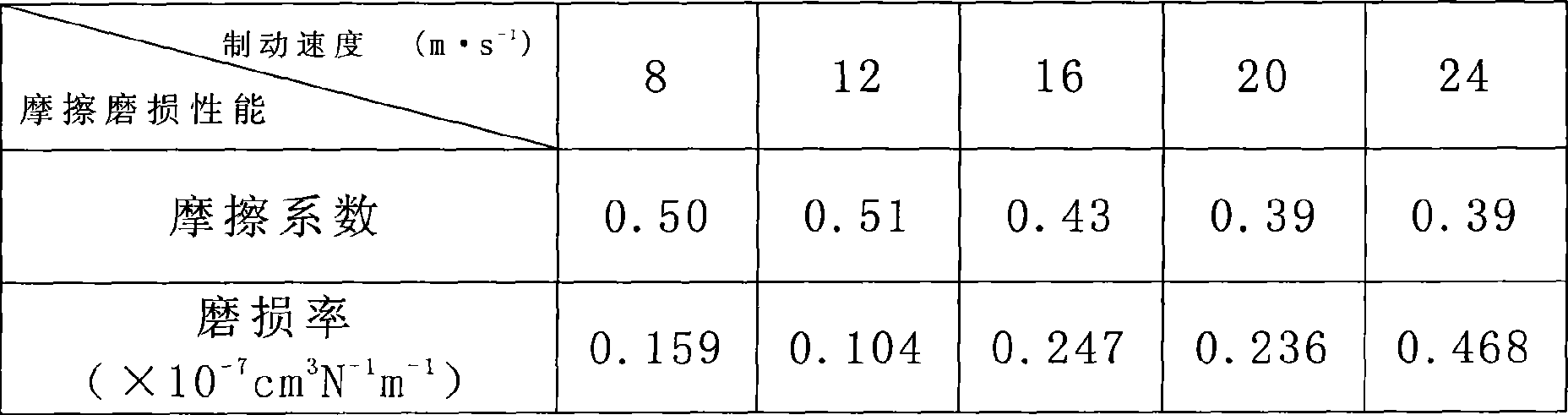

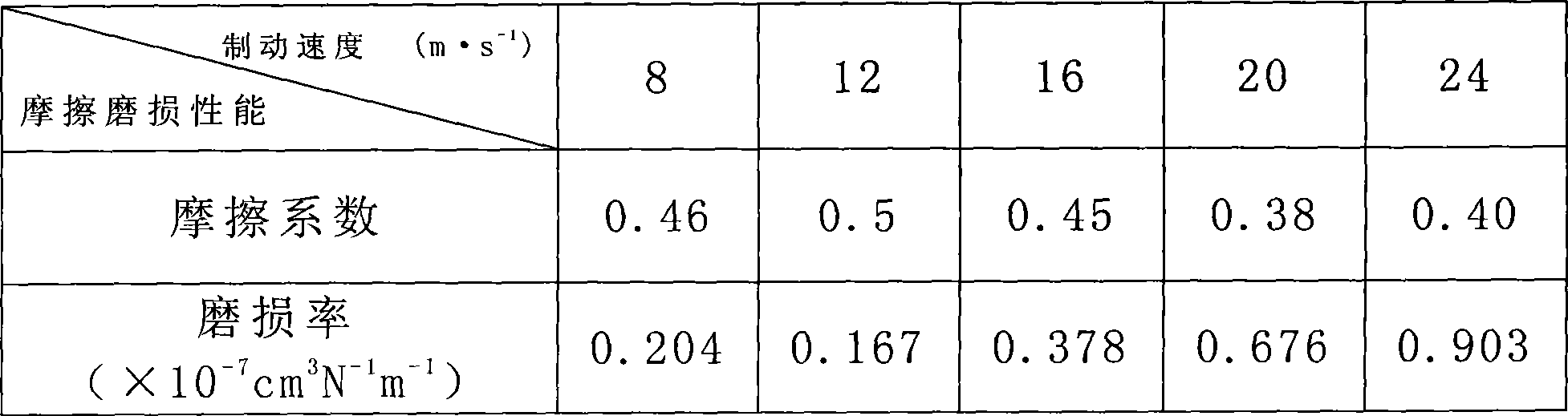

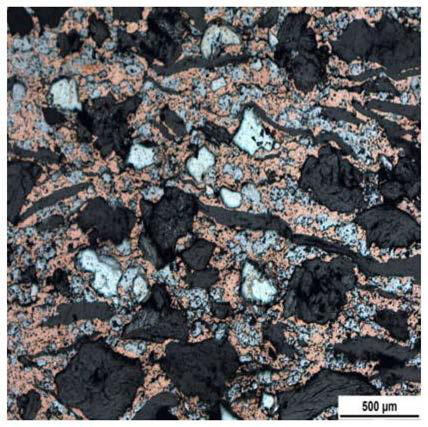

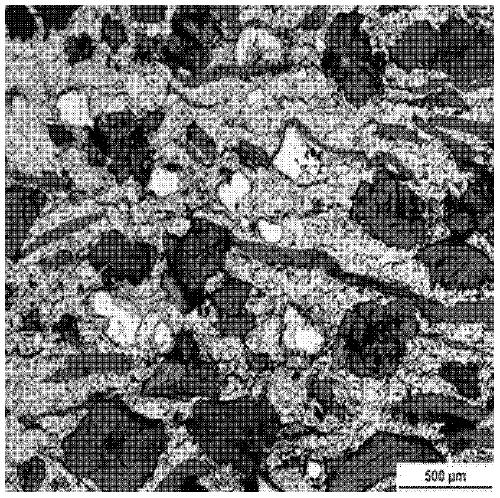

Preparation of carbon fiber reinforced carbon-silicon carbide double matrix friction material

The invention discloses a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material. Short chopped carbon fiber, graphite powder, industrial silicon powder and caking agent are employed to be pressed into the block material of carbon fiber enhanced graphite powder and silicon powder (C / C-Si) in a cooling way; then mechanical cracking and pelleting are carried out to the prepared C / C-Si block material; next, the grains are thermally pressed into a C / C-Si biscuit; and then the C / C-Si biscuit is carbonized to prepare a C / C-Si porous body; and finally non-dipping directional fused silica impregnating is carried out to the C / C-Si porous body to prepare the carbon fiber enhanced carbon-carborundum double-matrix (C / C-SiC) abrasive material. The invention relates to a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material having higher mechanical property and excellent abrasion resistance and wear performances,with the advantages of short preparation cycle, low cost, and being capable of engineering.

Owner:CENT SOUTH UNIV

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

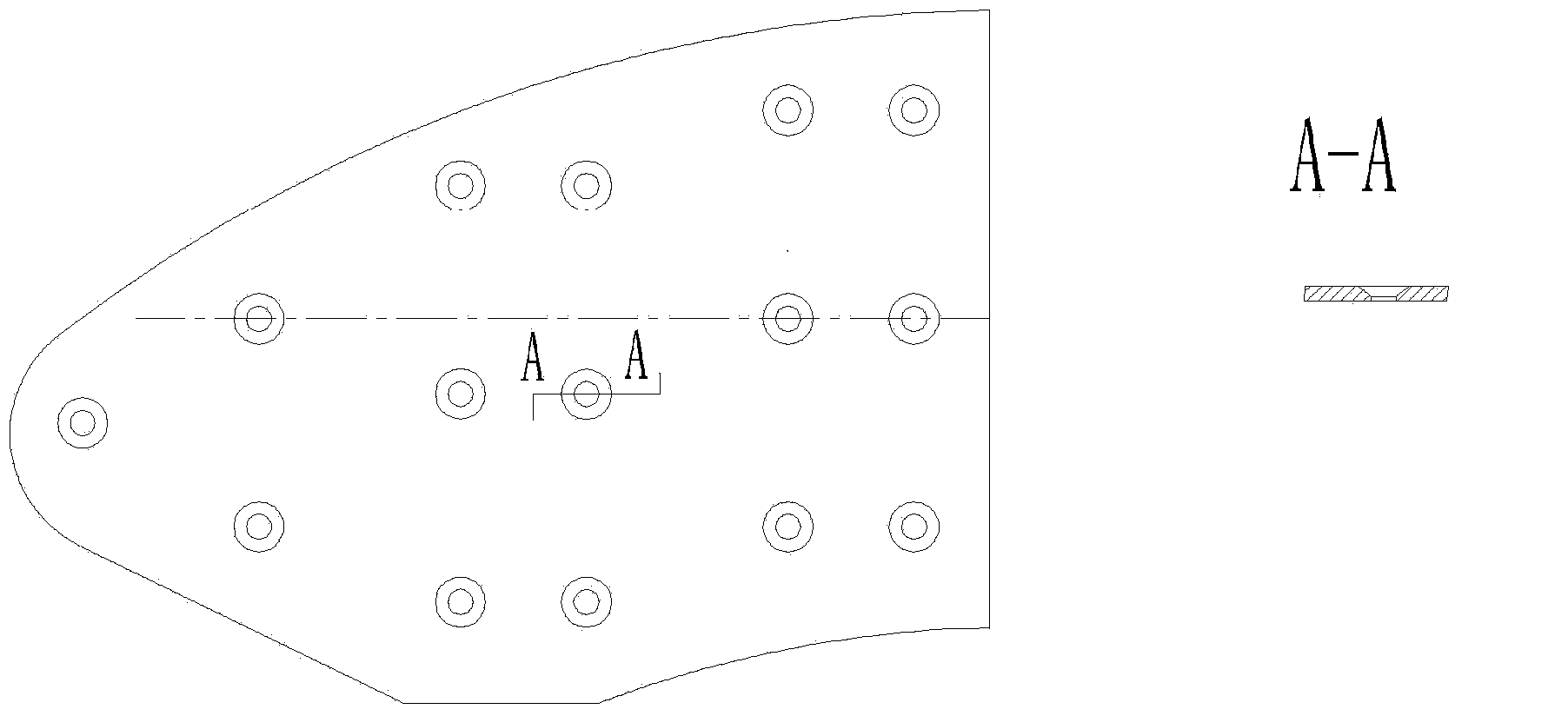

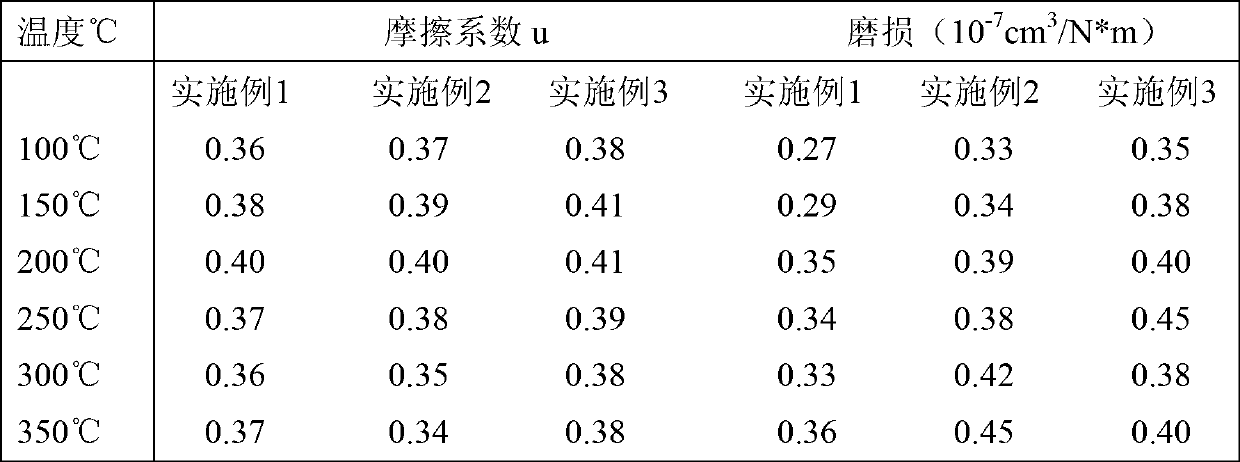

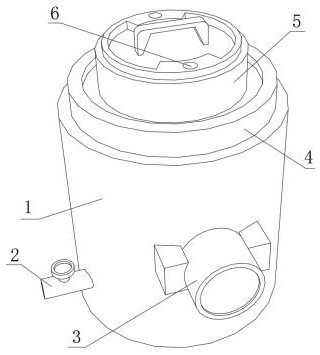

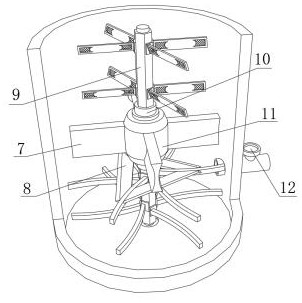

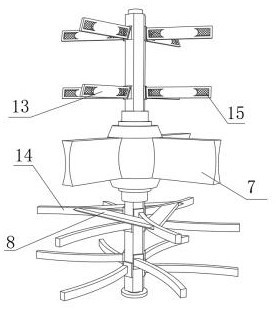

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Friction plate without asbestos and its preparation process

A non-asbestos friction disk for the brake of drilling machine, heavy machinery, etc is prepared from glass fibres, organic fibres, low-smelting-point metal powder and resin-rubber mixture. Its advantages are low hardness, high toughness, high friction coefficient, high mechanical strength, and low abrasion.

Owner:李海 +4

Preparation method and application of carbon/ceramic composite material

ActiveCN105565837AThere is no problem of large distribution gradientReduce wearBraking discsActuatorsCeramic compositeMetallurgy

The invention relates to a preparation method and application of a carbon / ceramic composite material, in particular to a preparation method and application of a carbon / ceramic composite material needed for braking a high-momentum delivery system. The preparation method includes: using a C / C composite material of 1.2-1.5 g / cm3 in density as a raw material; disposing the raw material in impregnation liquid I for impregnation, pyrolyzing in a protective atmosphere after impregnation, repeating impregnating-pyrolyzing operations until a carbon / ceramic composite material of 1.85-1.9 g / cm3 in density is obtained; treating the carbon / ceramic composite material obtained at high temperature until density of the carbon / ceramic composite material is lowered to 1.82-1.88 g / cm3 to obtain a pre-finished product; disposing the pre-finished product in impregnation liquid II, decomposing in a protective atmosphere after impregnation is completed, polishing after decomposing, and repeating impregnating-decomposing-polishing operations until a carbon / ceramic composite material finished product of 1.93-2.0 g / cm3 is obtained.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

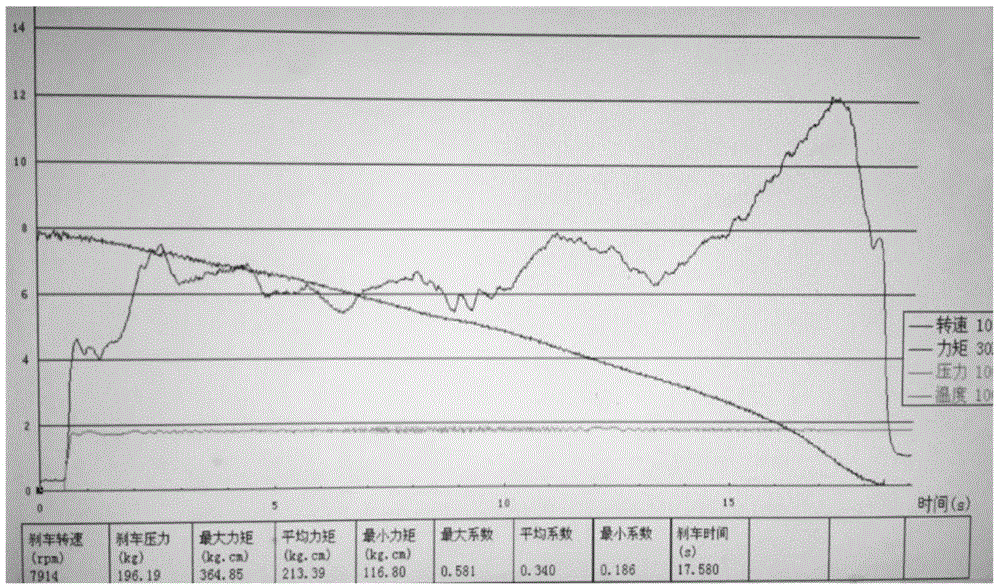

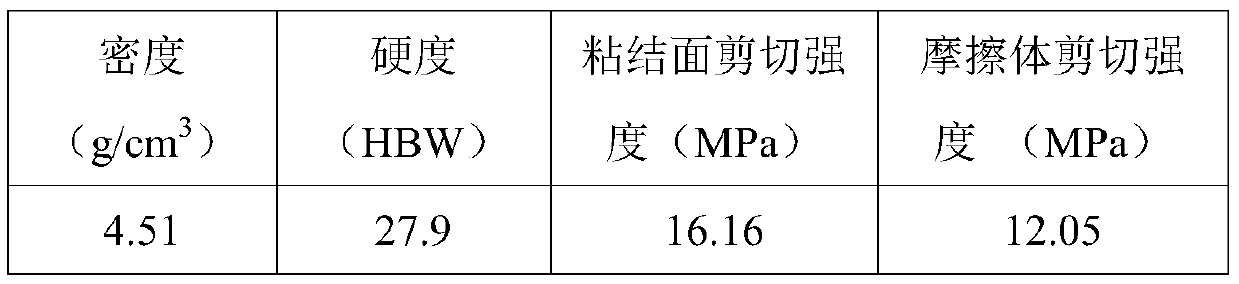

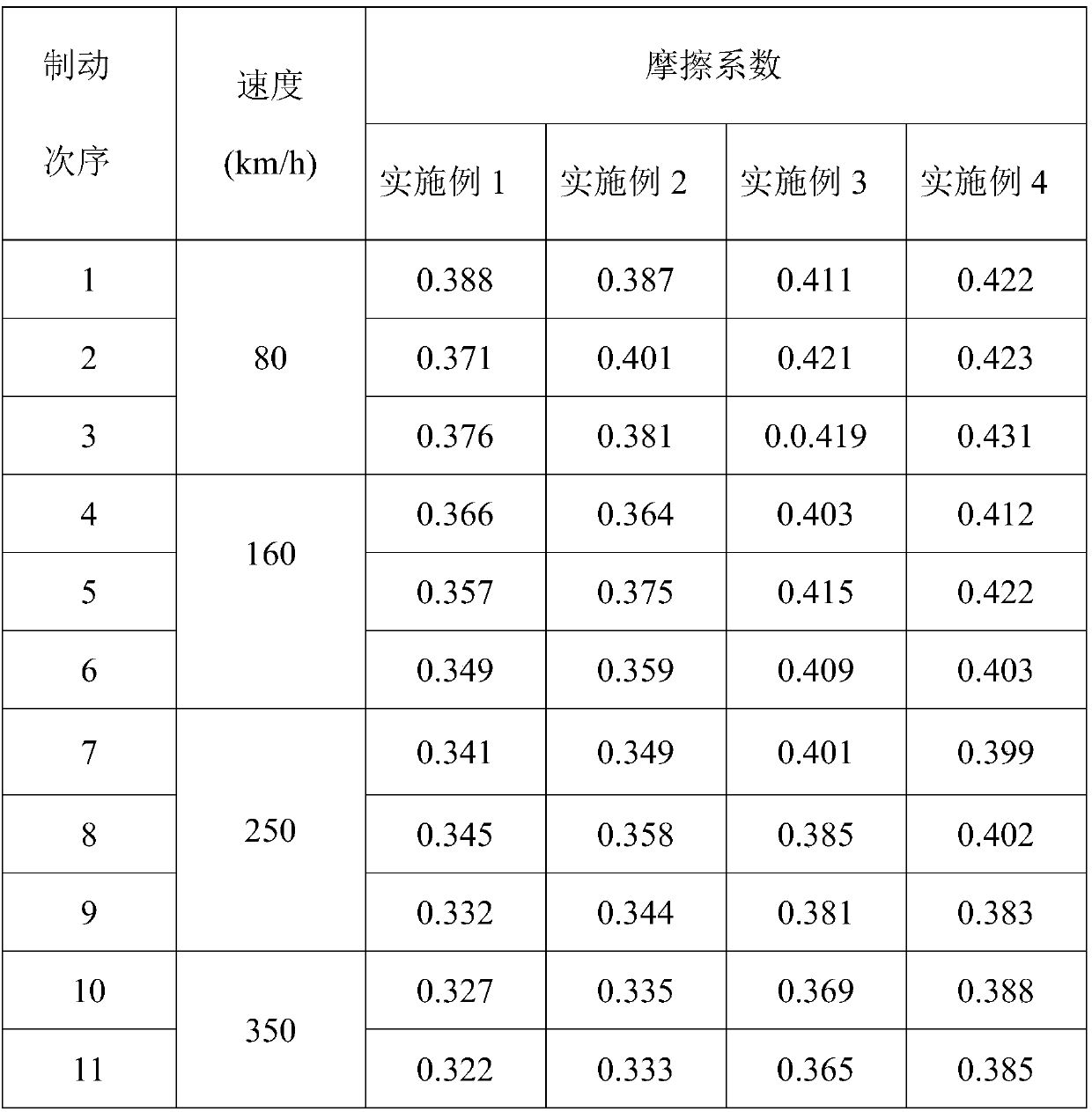

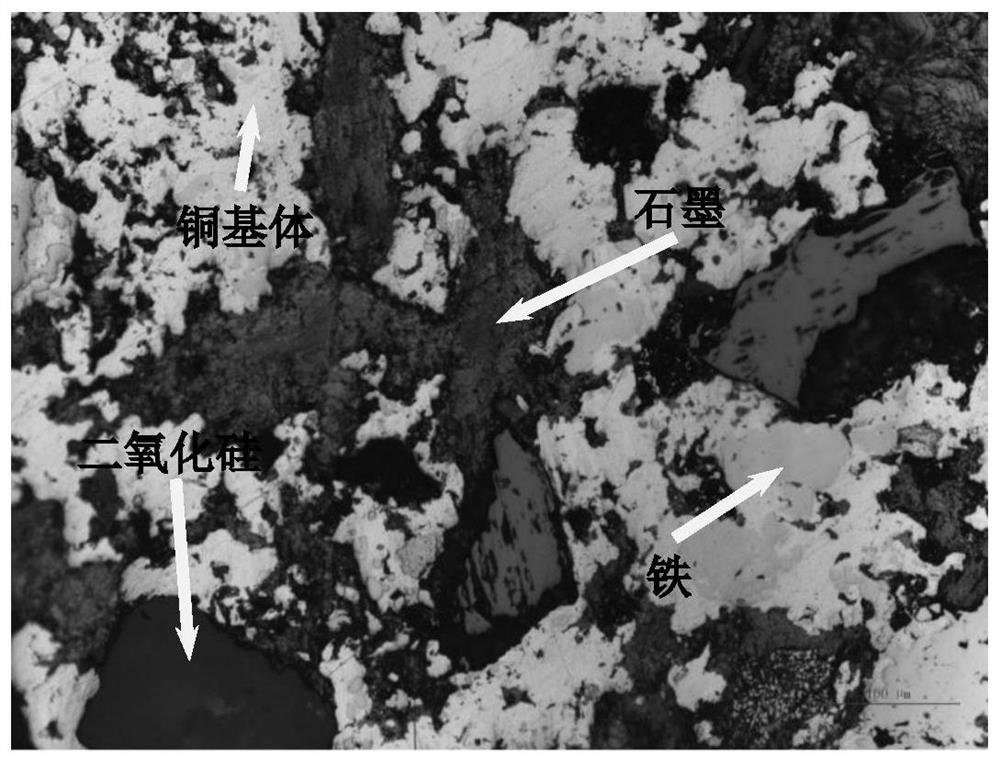

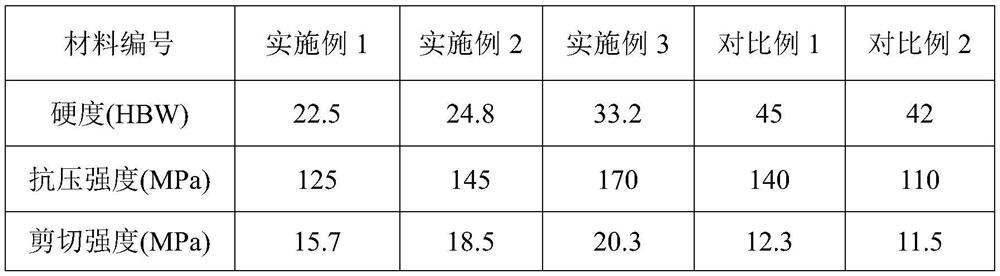

Copper-based powder metallurgy friction material for dry clutch of heavy-duty vehicle and preparation method thereof

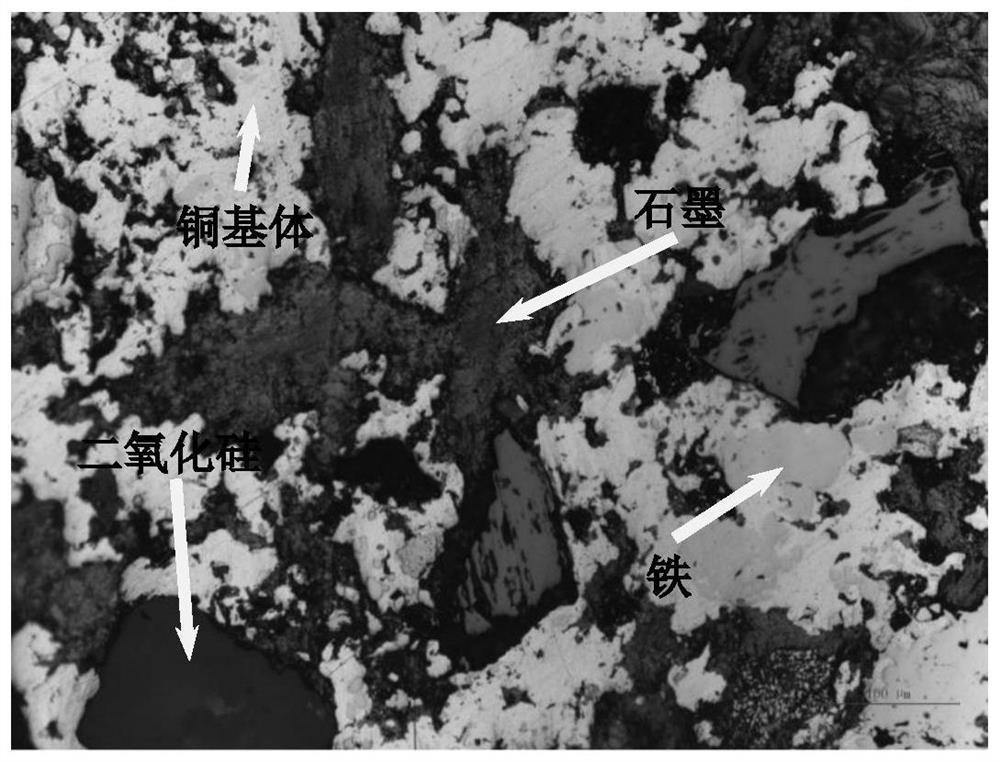

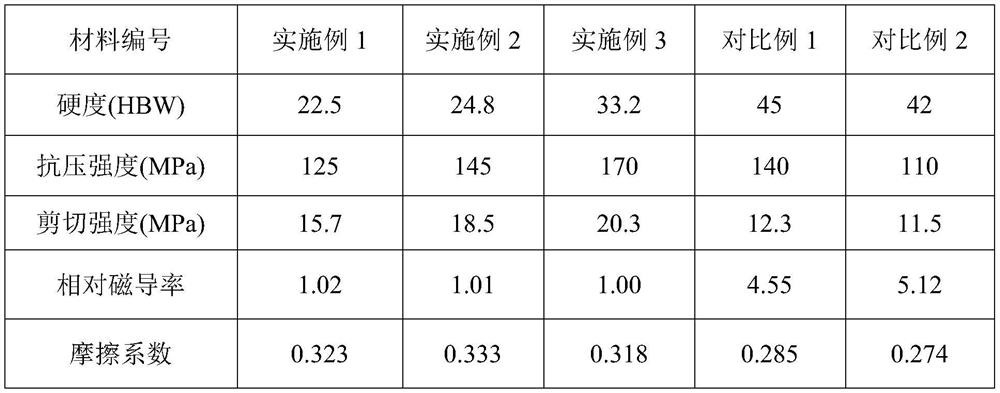

ActiveCN110102754AHigh and stable coefficient of frictionHigh coefficient of static frictionTransportation and packagingMetal-working apparatusCopper platingGraphite particle

The invention discloses a copper-based powder metallurgy friction material for a dry clutch of a heavy-duty vehicle and a preparation method thereof. The matrix component of the friction material is copper and iron; the lubricating component is graphite particles, crystalline flake graphite, molybdenum disulfide and petroleum coke; the friction component is ferrochrome, zirconia and silicon dioxide; and the strengthening component is tin. The friction material comprises the following, by weight 50%-60% of copper powders, 1%-10% of iron powders, 5%-20% of graphite particle powders, 1%-5% of flake graphite, 1%-6% of molybdenum disulfide powders, 1%-15% of petroleum coke powders, 3%-9% of ferrochrome powders, 3%-9% of the zirconia, 1%-5% of the silicon dioxide, and 1%-4% of tin powders. The preparation method of the friction material comprises the following steps of mixing a mixture according to the composition of the powder metallurgical friction material; mixing the mixture in a V-shaped mixer evenly and pressing; and then sintering together with a copper-plated steel back to obtain the copper-based powder metallurgical friction material. The copper-based powder metallurgy frictionmaterial has high and stable friction coefficients and excellent wear resistance.

Owner:CENT SOUTH UNIV

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

Method for preparing clutch facing through taking water soluble phenol-formaldehyde resin as adhesion agent

The invention discloses a method for preparing a clutch facing through taking water soluble phenol-formaldehyde resin as an adhesion agent. The method adopts the water soluble phenol-formaldehyde resin which is multiply modified by polyvinyl alcohol, nanoscale attapulgite and micron-order copper powder as the adhesion agent, the water soluble phenol-formaldehyde resin, a friction performance conditioning agent and water are mixed to produce slurry, fibers are soaked in the slurry, are dried and are wound to form a parison, the parison is then subjected to hot-press forming to form the facing, grinding and drilling are carried out after the thermal treatment, the clutch facing is obtained. The modified adhesion agent has high solubility, cohesiveness, toughness, heat resistance, thermal fading resistance and abrasion resistance; and the clutch facing which is produced through the adhesion agent is low in cost, green and environment-friendly, can bear impact force during the processing and using processes, cannot crack and has high thermal stability, high and stable friction coefficient and low abrasion resistance.

Owner:浙江科马摩擦材料股份有限公司

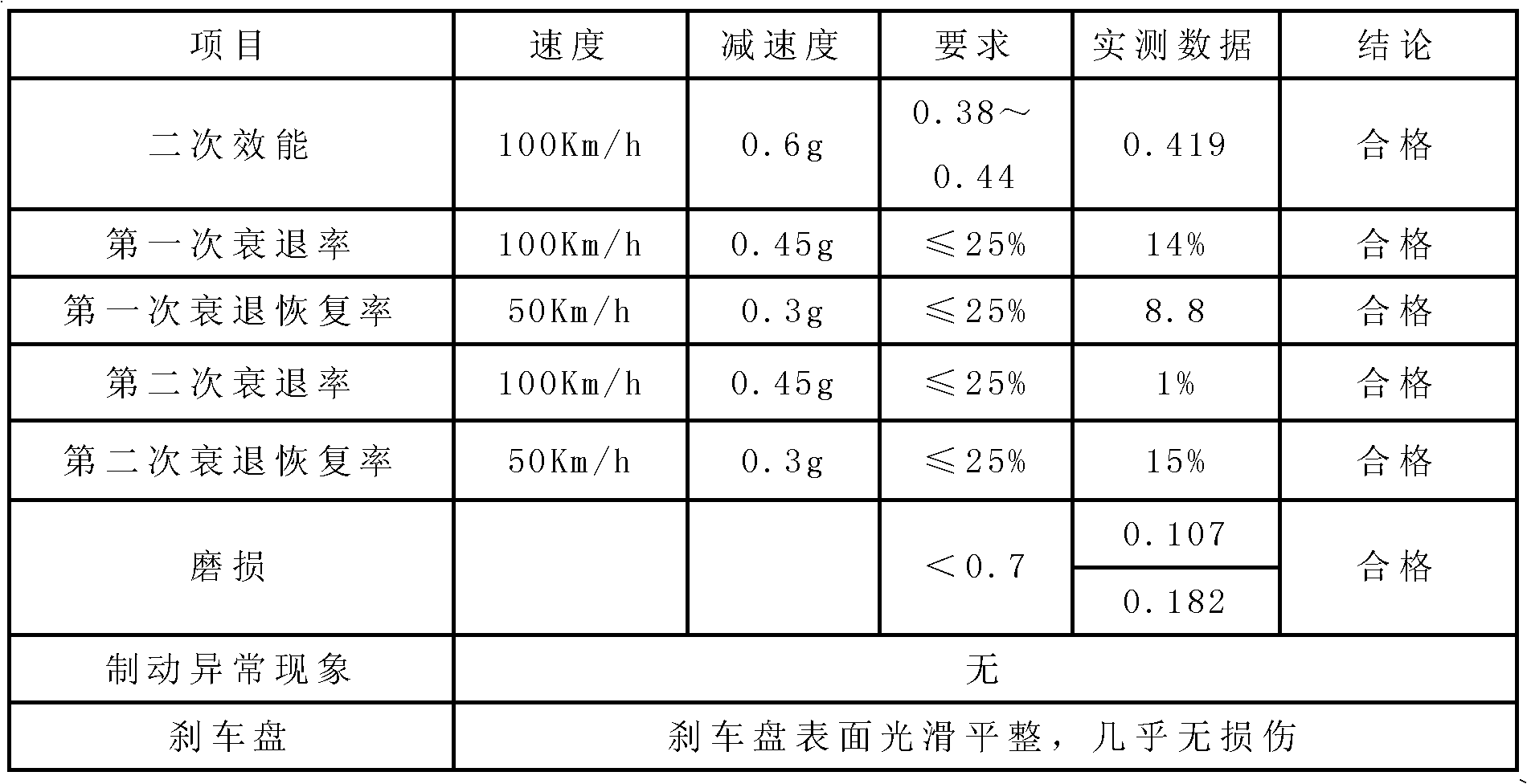

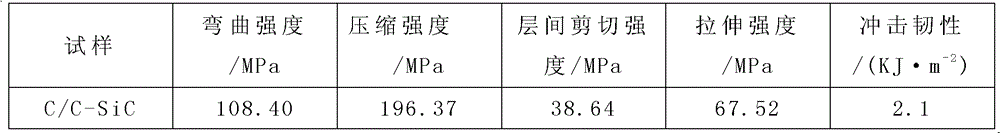

Producing method for carbon fiber reinforced ceramic matrix automobile brake pad

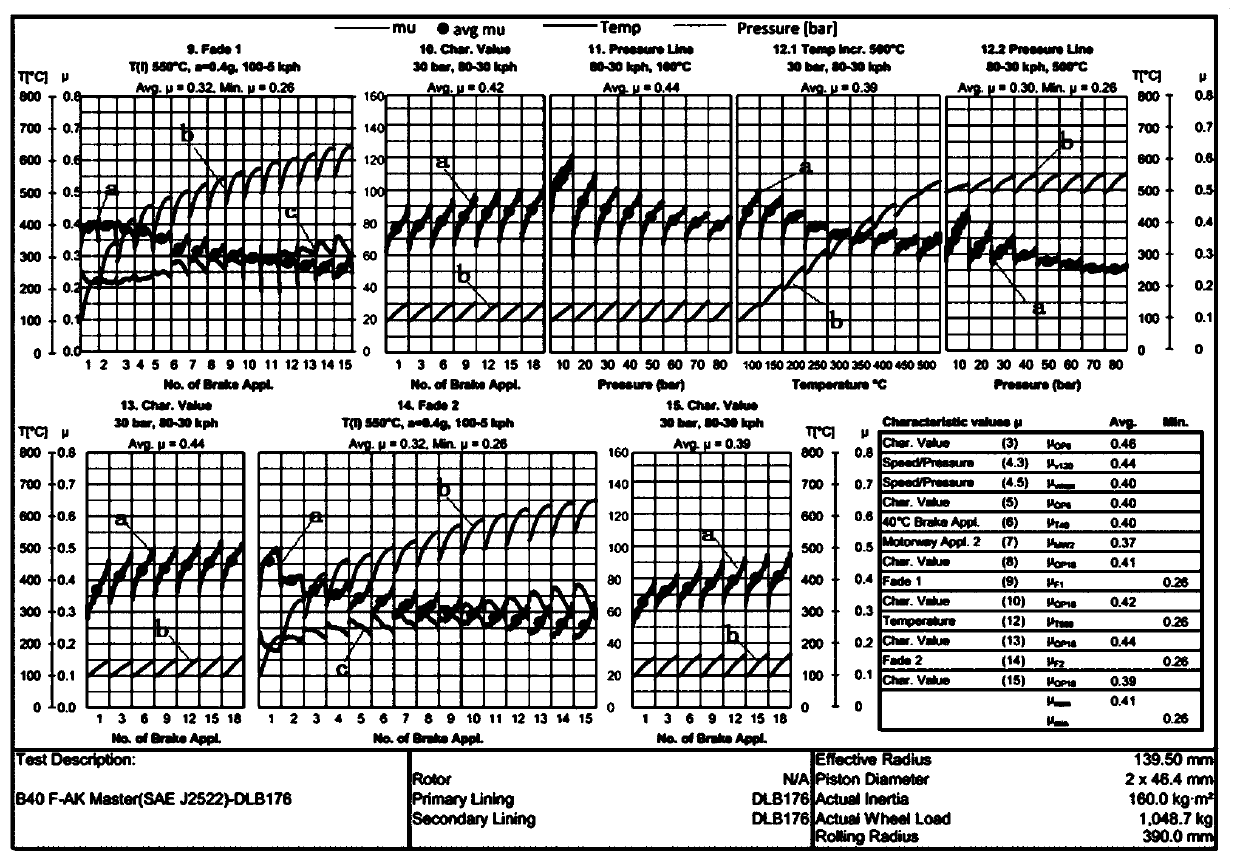

InactiveCN102661342AImproved speed/pressure correlationImprove braking effectFriction liningBrake liningChemical vapor infiltration

The invention discloses a producing method for a carbon fiber reinforced ceramic matrix automobile brake pad. The method comprises the following steps of: preparing a carbon fiber mesh tire by a needling method; performing high temperature thermal process on the prepared carbon fiber mesh tire; preparing low-intensity carbon fiber reinforced matrix carbon (C / C) composite material by adopting an isothermal chemical vapor infiltration; machining the low-intensity C / C composite material, and performing directional infiltration in a high temperature vacuum furnace to prepare C / C-SiC brake linings; and then riveting the C / C-SiC braking linings with steel back to obtain the C / C-SiC braking pad used for the automobile braking system. The method provided by the invention has the advantages that the friction coefficient of the produced automobile brake pad is high and stable; the carbon fiber reinforced ceramic matrix automobile brake pad is low in wearing and good in heat fading performance; and thus, the method is simple and feasible.

Owner:CENT SOUTH UNIV

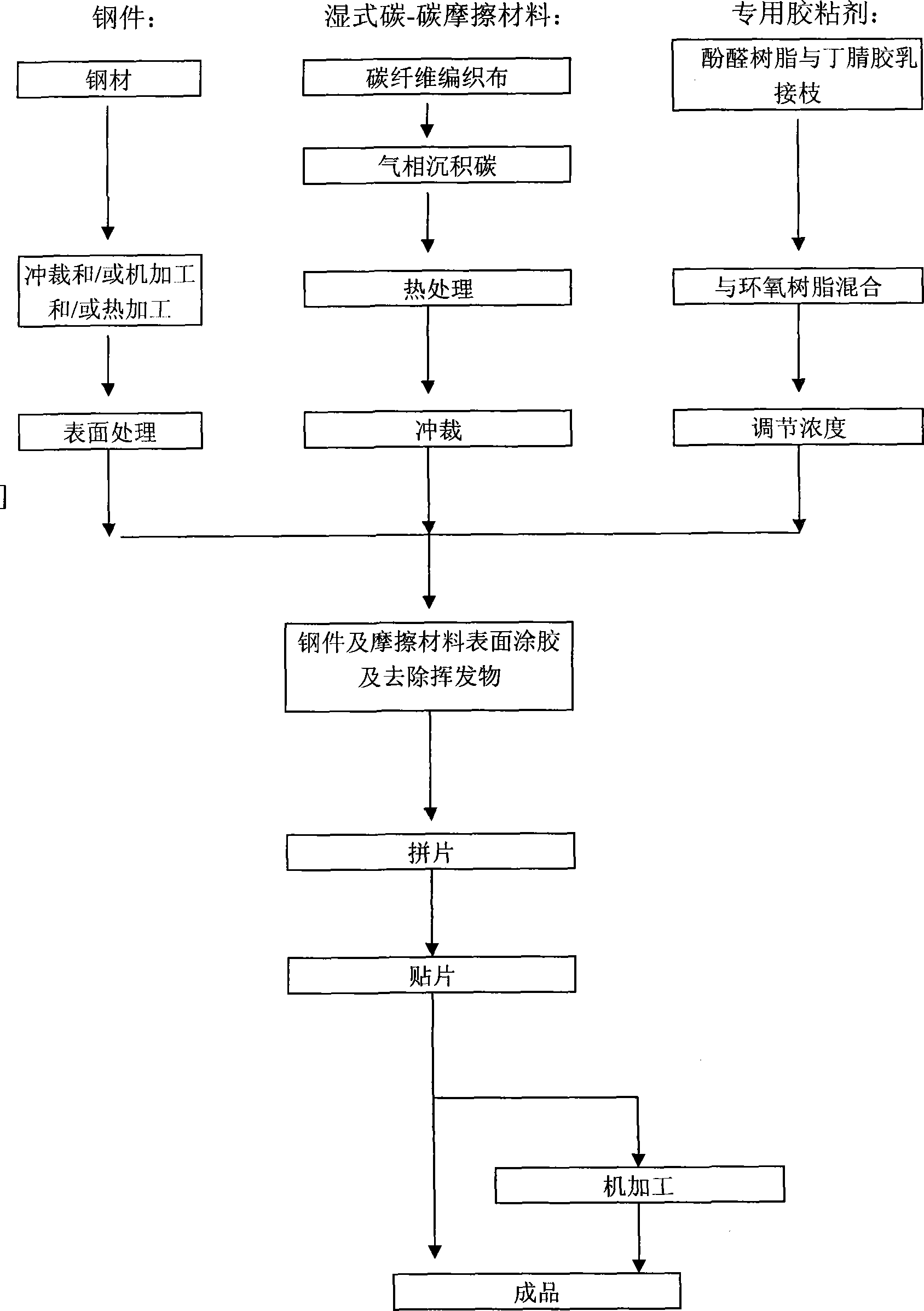

Wet-type carbon-carbon friction material, friction element and manufacturing method

InactiveCN101178105AHigh strengthImprove toughnessOther chemical processesAldehyde/ketone condensation polymer adhesivesFiberAdhesive cement

The invention provides a wet carbon-carbon friction material and a friction element and a manufacture method. The wet carbon-carbon friction material takes carbon fiber weaved cloth as a framework and is formed by changing the gaseous phase deposition carbon into gluing phase. The friction element comprises a steel part which is bonded with the wet carbon-carbon friction material by special adhesive; the manufacture method comprises (1) steel part manufacture, (2) manufacture of wet friction-friction friction material, (3) patching technique; the invention is made by the wet carbon-carbon material bonded to at least one surface of the steel part by the special adhesive. The invention has the advantages of extremely high strength and toughness, extremely good heat stability and chemical stability, extremely high energy adsorption and power adsorption capability, high and stable friction coefficient, low abrasion ratio, etc.

Owner:HANGZHOU ADVANCE GEARBOX GRP

Carbon-based friction material for automobile disc brake and preparation method thereof

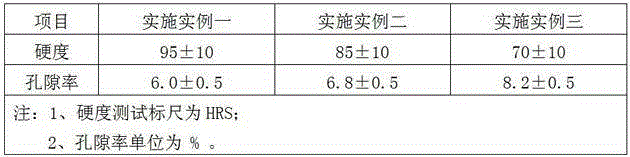

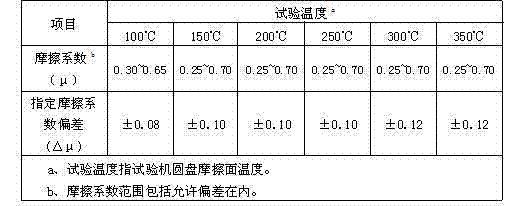

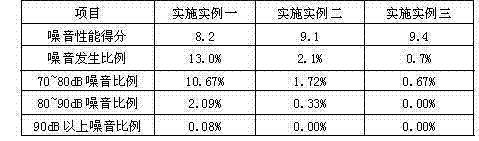

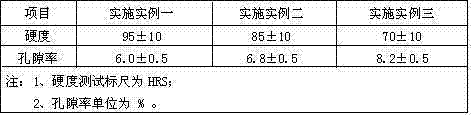

The invention relates to a composition and a preparation method of an asbestos-free friction material taking carbon fibre or other carbon materials as a main body, and in particular to a carbon-based friction material for an automobile disc brake and a preparation method of the carbon-based friction material. The friction material and the preparation method of the friction material mainly aim at solving the technical performance problems that a brake pad is high in the heat fading of friction coefficient and wear rate and is easy in the production of brake noises, and as a formulation of the brake pad often contains asbestoid fibre, the brake pad does not meet the requirement of environment-friendliness, etc. The friction material is a novel friction material with a carbon base between a carbon-carbon base and an NAO or ceramic base. The friction material mainly comprises carbon materials such as the carbon fibre and graphite, and comprises accessories such as a resin binder and a small number of inorganic or organic fillers. The friction material is produced by hot press moulding. Compared with a friction material with an NAO or ceramic base, the carbon-based friction material for the automobile disc brake disclosed by the invention has the advantages of being reliable in brake performance, low in brake noises and long in service life, and preventing friction coupling from being damaged.

Owner:杭州吉成汽车零部件有限公司

Safety type friction material having high cleaning performance and friction plate preparation method

InactiveCN105400493AGuaranteed flatnessReduce porosityOther chemical processesFriction liningFiberActivated carbon

The invention aims to provide a friction material having high cleaning performance while having high friction coefficient and safety performance and a friction plate preparation method. The friction material comprises, by weight percentage, 4-10% of resin, 6-10% of coke dust, 0.5-5% of nitrile powder, 1-8% of tire powder, 1-4% of corundum, 9-20% of graphite, 1-3% of iron black, 1-3% of activated carbon, 2-5% of friction powder, 20-30% of fiber and 30-55% of packing. The method for preparing a friction plate by utilizing the materials comprises a step (1) of mixing the materials: manufacturing a friction material mixed material; a step (2) of performing prepressing: preforming the mixed material; a step (3) of performing hot pressing: placing pressed blank in a die to undergo hot pressing, and performing interval exhaust-gas disposal; a step (4) of performing heat treatment: performing constant-speed warming and thermal insulation in a graded manner from room temperature to 185 DEG C; and a step (5) of performing size processing. The friction material is applied to the field of friction materials.

Owner:ZHUHAI HUALI FRICTION MATERIAL

Safe friction material with low noise and preparation method of friction plate

The invention aims at providing a friction material with high friction coefficient and safety performance and low noise and a preparation method of a friction plate. The friction material comprises the following components in percentage by weight: 4-10% of resin, 6-10% of coke powder, 0.5-5% of nitrile powder, 1-8% of tire powder, 1-4% of corundum, 9-20% of graphite, 1-3% of iron black, 4-5% of chromite powder, 1-3% of active carbon, 2-5% of friction powder, 20-30% of fiber and 30-55% of filler; and the preparation method of the friction plate prepared from the friction material comprises the following steps of (1) material blending, namely preparing a blended material of the friction material; (2) pre-pressing, namely pre-molding the blended material; (3) hot pressing, namely placing a pressed blank into a mould to carry out hot pressing, and then, carrying out exhaust gas disposal at intervals; (4) thermal treatment, namely heating from the room temperature to the temperature of 185 DEG C in stages at constant speed, and preserving the heat; and (5) size processing. The friction material is applied to the field of friction materials.

Owner:ZHUHAI HUALI FRICTION MATERIAL

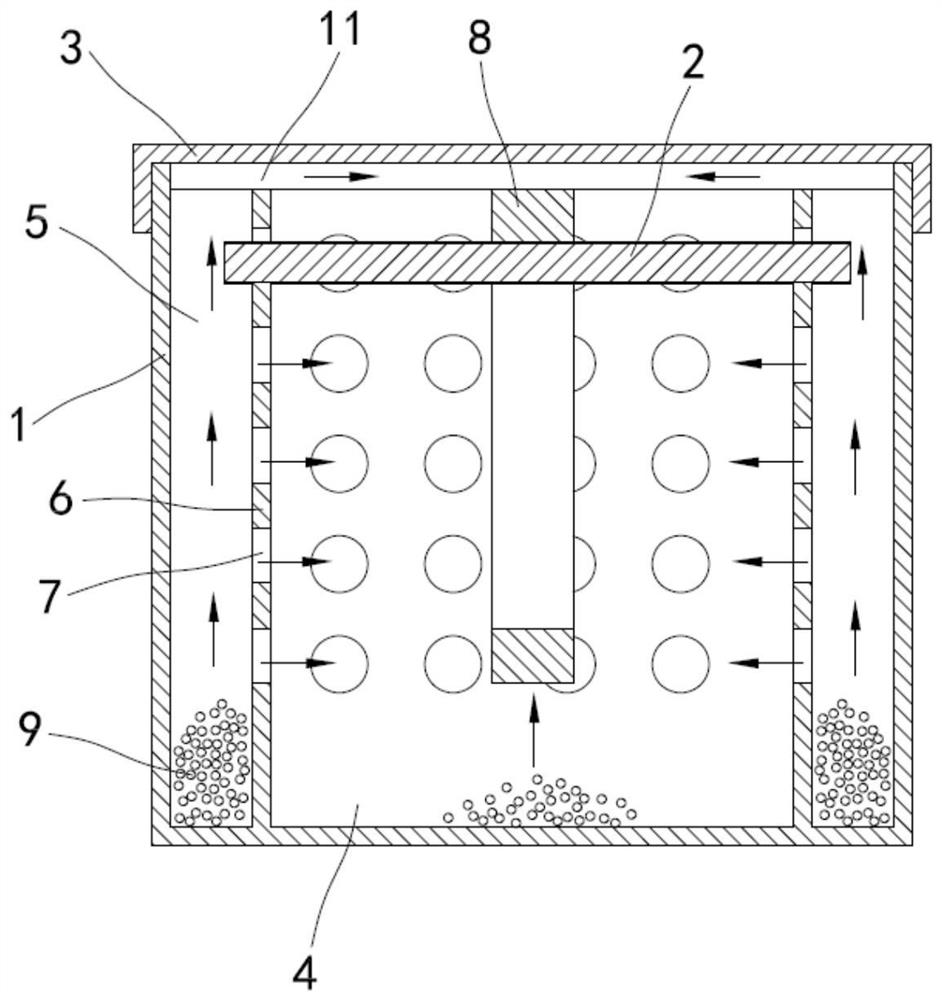

Silicon carbide ceramic used for radiators, and preparation method thereof

The invention discloses a silicon carbide ceramic used for radiators, and a preparation method thereof. The silicon carbide ceramic is prepared from following raw materials, by weight, 60 to 70 parts of silicon carbide, 4 to 5 parts of iron powder, 3 to 4 parts of bauxite, 1 to 3 parts of carboxymethyl cellulose, 2 to 3 parts of nanometer carbon black, 2 to 3 parts of sodium polyphosphate, 15 to 20 parts of absolute ethyl alcohol, 10 to 14 parts of a short carbon fiber pre-dispersed material, 2 to 4 parts of a sintering aid, and 70 to 90 parts of deionized water. According to the preparation method, short carbon fiber is added so as to improve mechanical properties of silicon carbide, improve breaking tenacity of ceramic, improve strength and compactness of ceramic biscuit, and satisfy mechanical processing requirements; the preparation method is simple; the silicon carbide ceramic is light; friction coefficient is high and stable; thermal conductivity is high; service life is long; and application prospect of the silicon carbide ceramic used for the radiators is promising.

Owner:凤阳徽亨商贸有限公司

Low noise brake pad and processing method thereof

InactiveCN108730385AImprove performanceIncrease coefficient of frictionOther chemical processesFriction liningFiberLow noise

The invention relates to the technical field of automobiles, provides a low noise brake pad, and further provides a processing method of the low noise brake pad. The low noise brake pad comprises following raw materials of adhesive-sprayed aluminum silicate fiber, glass fiber, nitrile rubber powder, tire powder, cashew nut shell oil frictional powder, tung-oil-modified phenolic resin, red copper fiber, white zi stone powder, diatomaceous earth, apocynum fiber, iron oxide green, potassium feldspar, petroleum cokes, graphite, expanded perlite, floating beads, barium sulfate, boron nitride and soft magnetic materials. The low noise brake pad and the processing method thereof have the advantages that in the research process of a formula, after a large number of experiments, a reasonable combination of various components is achieved, and the advantages of each material are fully utilized in the materials, so that the raw materials can compensate each other for deficiencies of own performance, and better performance can be generated due to mutual cooperation. The low noise brake pad has a high and stable friction coefficient and a low wear rate during use, and at the same time, low noiseis achieved during braking.

Owner:ANHUI XIANGCHI VEHICLE IND CO LTD

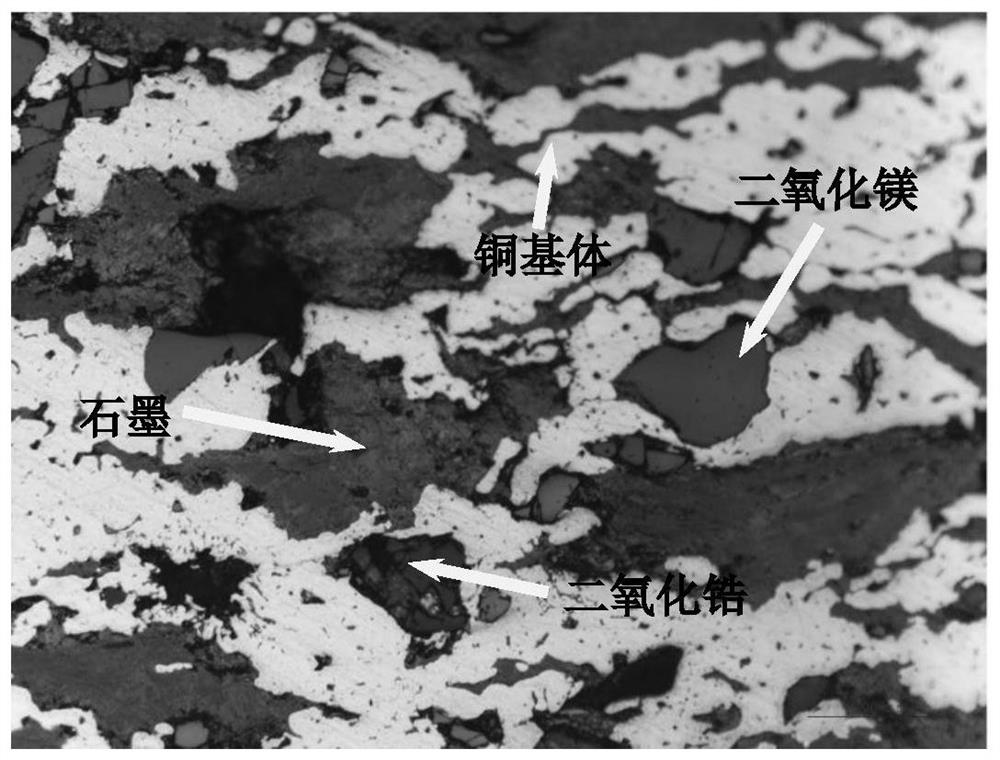

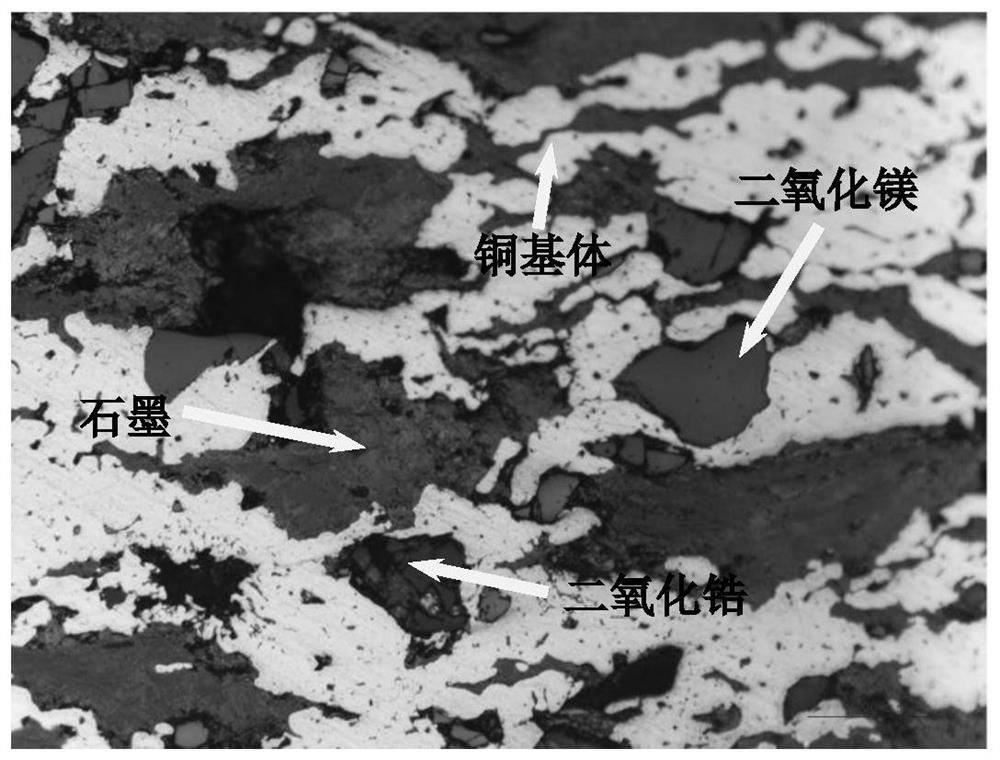

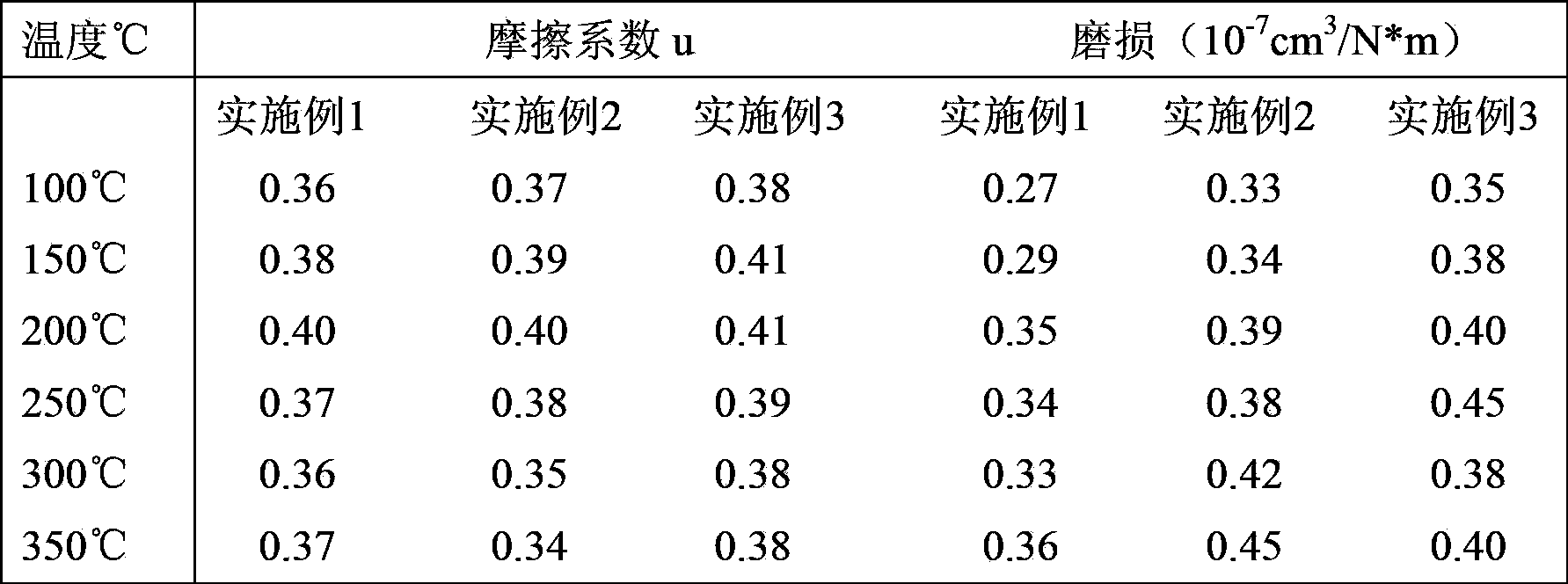

Brake material for medium-low-speed maglev train and preparation method of brake material

ActiveCN113073225AImprove thermal conductivityImprove mechanical propertiesTransportation and packagingMetal-working apparatusZirconium dioxideMaterials science

The invention discloses a brake material for a medium-low-speed maglev train and a preparation method of the brake material. The base component of the brake material is copper, the strengthening components are zinc, aluminum and molybdenum, the lubricating components are tungsten disulfide and graphite, and the friction components are magnesium oxide and zirconium dioxide. The brake material comprises the following components in percentage by weight: 50-65% of copper, 1-6% of zinc, 1-5% of aluminum, 1-4% of molybdenum, 1-4% of tungsten disulfide, 10-18% of graphite, 6-10% of magnesium oxide and 5-12% of zirconium dioxide. The invention also discloses a preparation method of the brake material. The prepared brake material for the medium-low-speed maglev train is non-magnetic, has a high and stable friction coefficient, is good in wear resistance and high in environmental adaptability, does not damage a magnetic track, and is simple in material component, simple in process and relatively low in cost.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

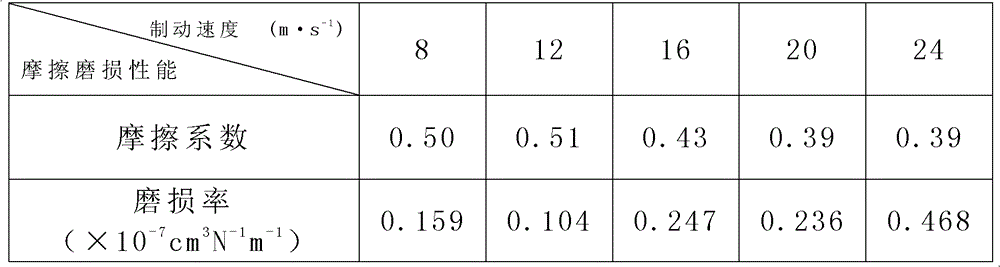

Manufacturing method of carbon/silicon carbide brake material

ActiveCN106507782BHigh and stable coefficient of frictionImprove antioxidant capacityJet aeroplaneFiber

The invention relates to a method for manufacturing a carbon / silicon carbide brake material, in particular to a method for manufacturing a low-cost chopped carbon fiber reinforced silicon carbide brake material. The method comprises: preparing phenolic resin solution, preparing carbon fiber prepreg, cutting the prepreg, forming by warm pressing, pyrolysis carbonization, and impregnating with reaction melt. Under the premise of not preparing the interface phase, the method ensures the excellent comprehensive mechanical properties of the composite material by controlling the process and designing the microstructure of the composite material, and the process is simple, the preparation cycle is short, the repeatability is good, and the cost is low. low. The carbon / silicon carbide brake material manufactured by the invention has a high and stable friction coefficient, a small wear rate, excellent friction performance, excellent mechanical properties and oxidation resistance, and can meet the requirements of high-energy load fields such as aircraft and tanks for brake materials. .

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing carbon fiber reinforced carbon and hexagonal boron nitride double-matrix friction material

ActiveCN101875562BUniform tissueThe production process is simple and easy to controlHexagonal boron nitridePyrolytic carbon

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

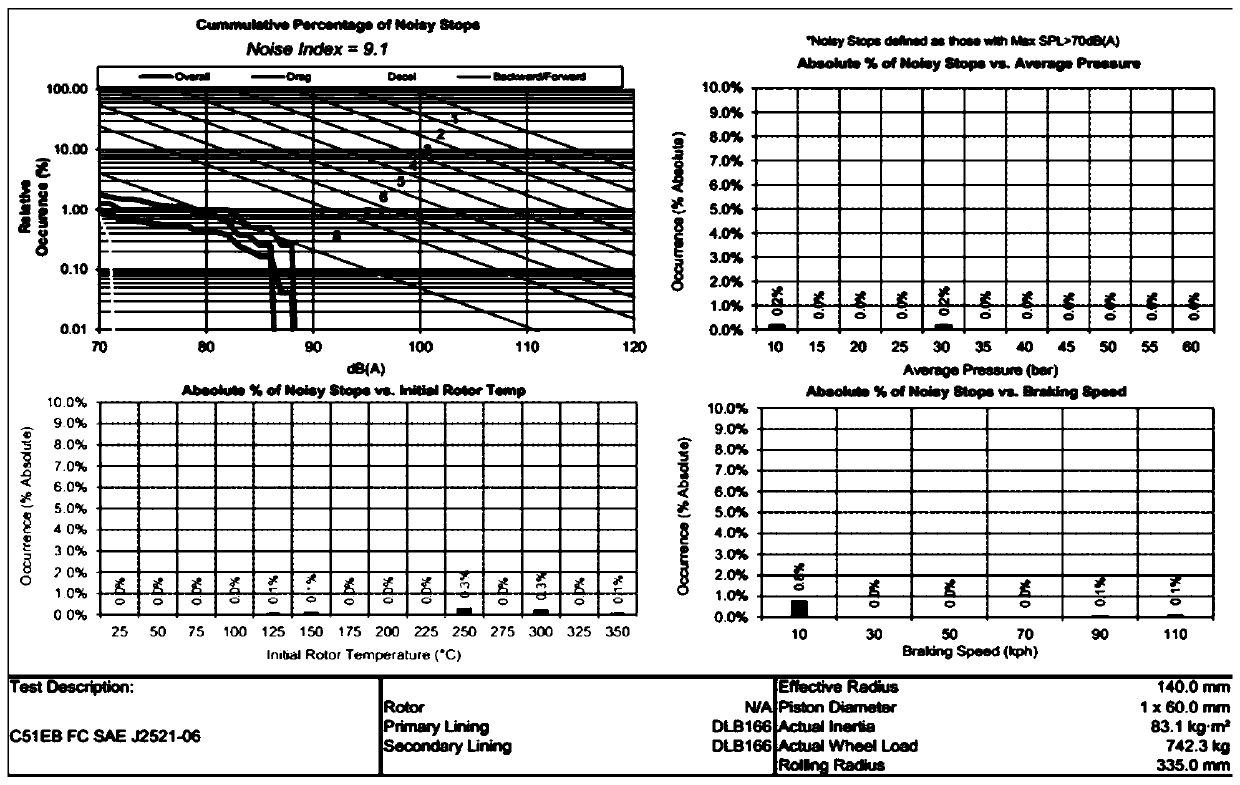

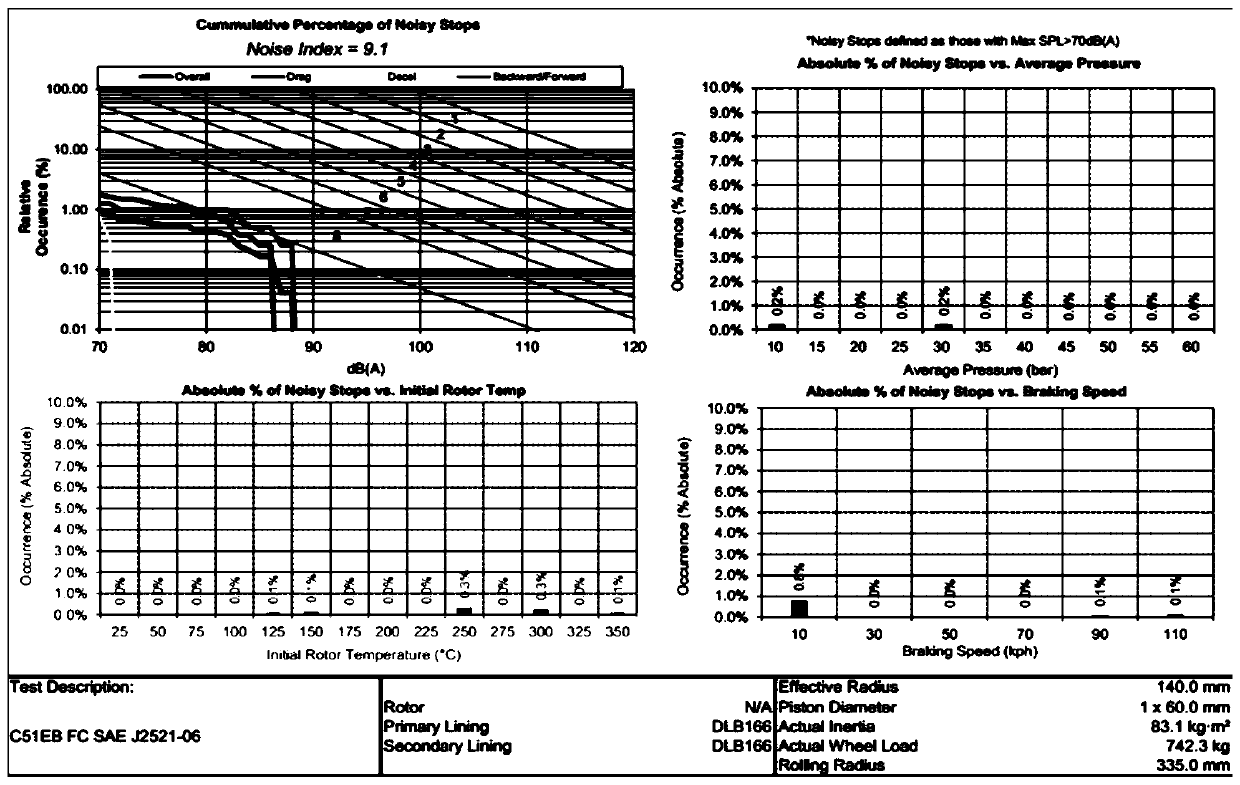

Brake disc with high friction coefficient

ActiveCN109971103AMaintain stabilityReduce high temperature thermal recessionFriction liningActuatorsMagnesiumOxide

The invention discloses a brake disc with a high friction coefficient. The brake disc is prepared from following raw materials in percentage by weight: 8 to 15% of polyacrylonitrile fibers, 10 to 20%of hybrid reinforcing fibers, 5 to 10% of zirconium silicate, 5 to 10% of magnesium oxide, 2 to 5% of antimony sulfide, 5 to 10% of graphite, 2 to 5% of molybdenum disulfide, 5 to 10% of porous iron powder, 10 to 20% of light calcium carbonate, 10 to 15% of barium sulfate, and 5 to 10 of resin. A friction material of asbestos-free low metal formula is adopted; the friction coefficient of the brakedisc is designed to be a FG grade, namely the friction coefficient is in a range of 0.40 to 0.50; the defects of a half metal formula are overcome; and the requirements of domestic automobiles and European automobiles are satisfied. The friction coefficient reaches the FG grade (0.40-0.50); the high temperature heat fade is small, the stability is high; the friction coefficient is high, the brakesensitivity is high, the safety is guaranteed, at the same time, the noise index reaches 9.1, the braking noise is reduced, the wear resistant performance is also improved, and the contradiction between the friction coefficient and wear resistant performance / comfort level is resolved.

Owner:SHANDONG DOUBLE LINK BRAKE MATERIAL

Power-transferring metal friction sheet and its machining process

The power-transferring metal friction sheet consists of Cu 62-72 wt%, Sn 3-5 wt%, Zn 3-5 wt%, SiO2 2-4 wt% and graphite 18-26 wt%. It is made through mixing the said components with small amount of light oil, and sintering at pressure of 16-24 kgf / sq cm. The present invention has the features of high base material strength, good cooling effect, high and stable friction coefficient, no copper transfer in the friction surface, no adhesion between the friction pair and good friction performance.

Owner:HANGZHOU ADVANCE GEARBOX GRP

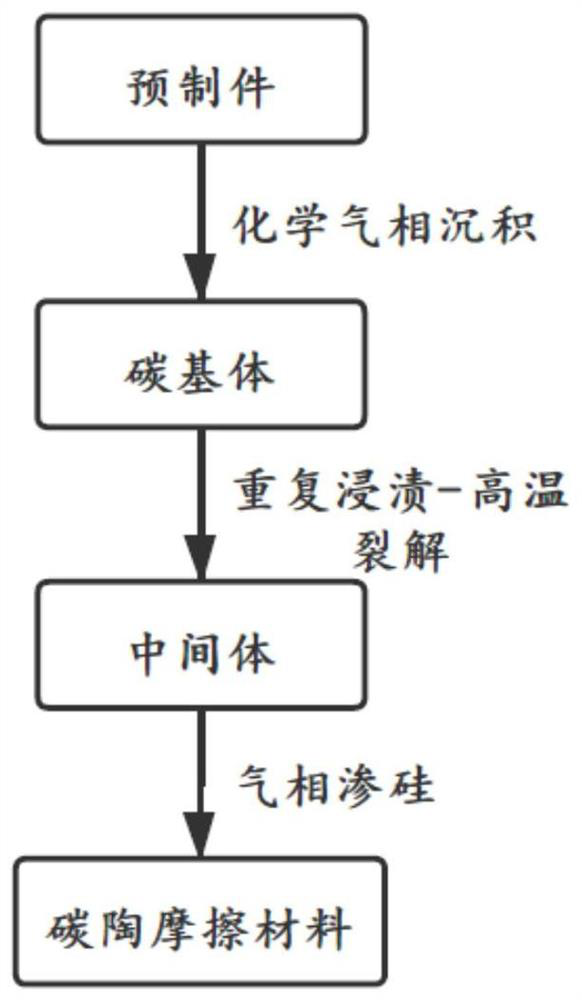

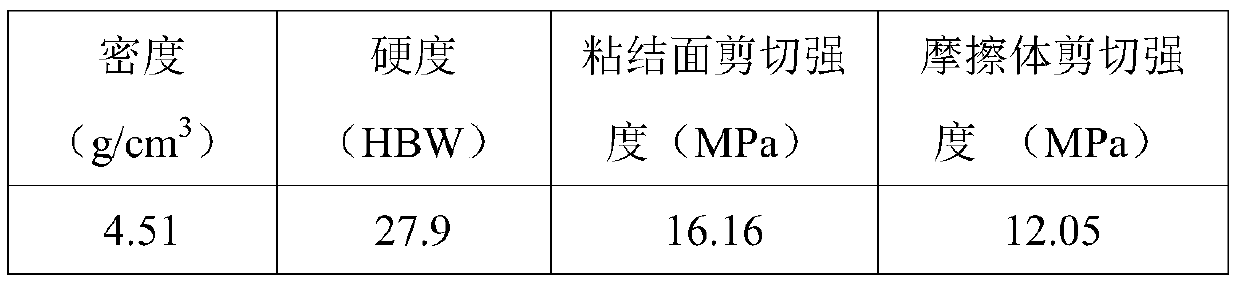

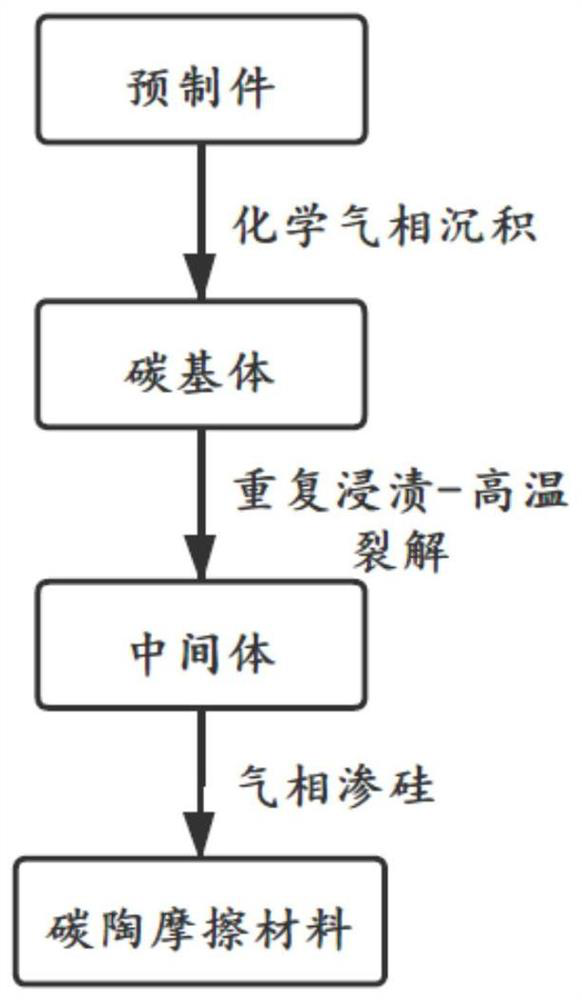

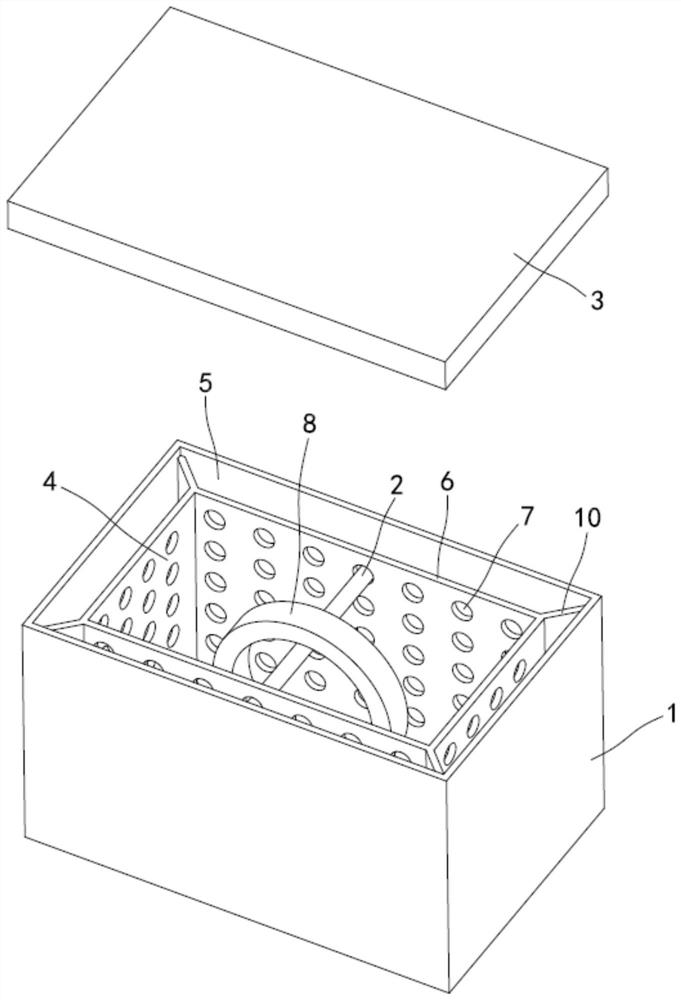

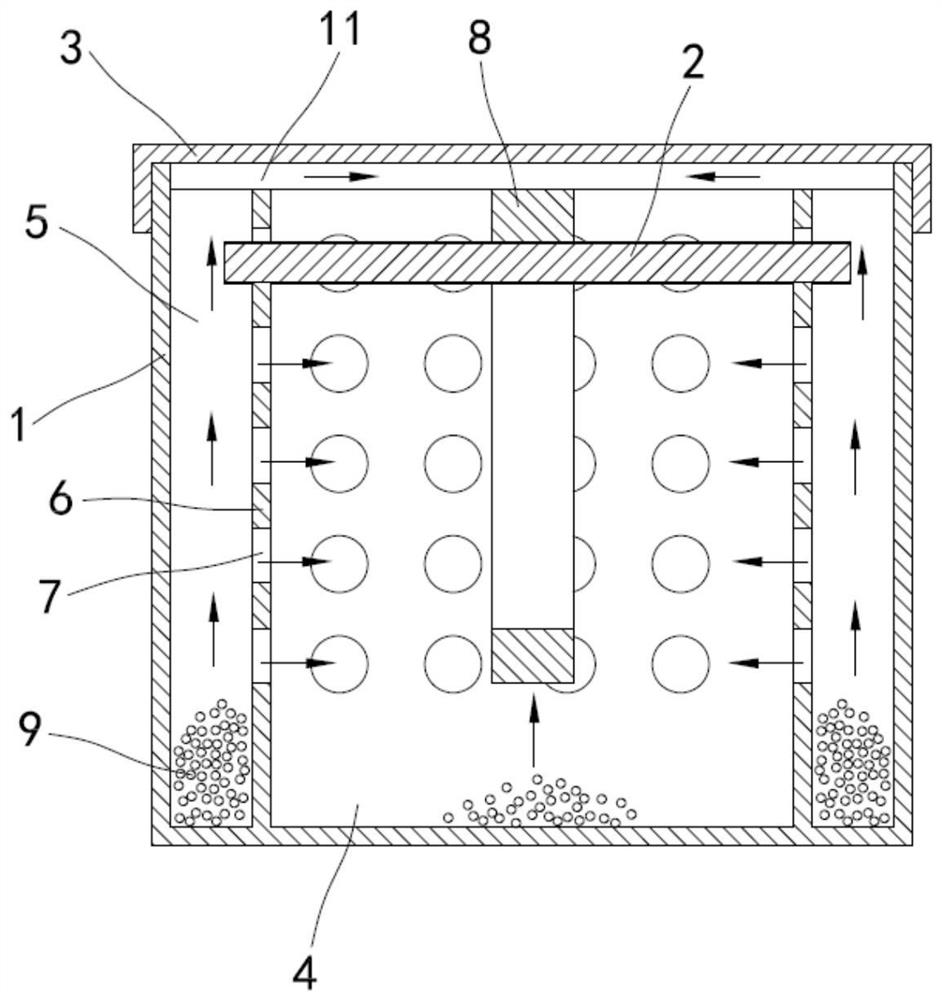

Preparation method and application of carbon-ceramic friction material

ActiveCN113248272AUniform compositionStrong penetrating powerBraking discsBraking membersCeramic compositeHigh density

The invention relates to the technical field of carbon-ceramic composite materials, and discloses a preparation method and application of a carbon-ceramic friction material. The preparation method comprises the following steps of: (A) preparing a prefabricated part; (B) performing deposition densification on the prefabricated part by adopting a chemical vapor deposition permeation process to prepare a carbon matrix; (C) preparing an impregnation liquid by taking polycarbosilane as a silicon source, introducing protective gas for high-temperature cracking, and repeating the impregnation and high-temperature cracking operations until an intermediate with a preset density is obtained; and (D) placing silicon particles in a graphite crucible, separating the intermediate from the silicon particles by using a graphite rod, heating the silicon particles to an evaporation state, guiding gaseous silicon to permeate into different side surfaces of the intermediate under a vacuum condition, and carrying out a uniform gas-phase siliconizing reaction to obtain the carbon-ceramic friction material with higher density and uniform composition. The prepared friction material can be applied to brake parts of automobiles or rail transit systems.

Owner:广州三的投资管理企业(有限合伙)

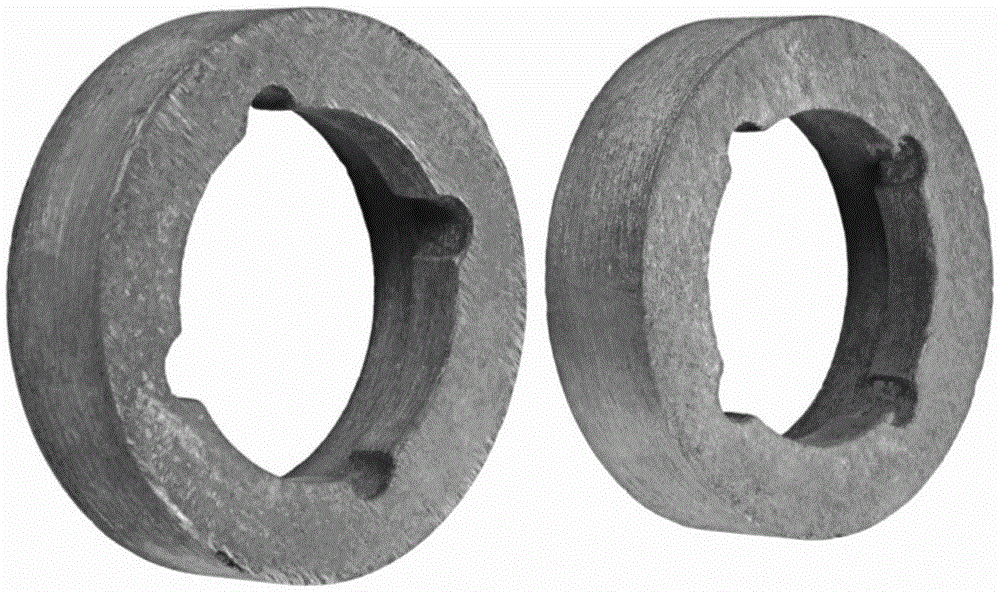

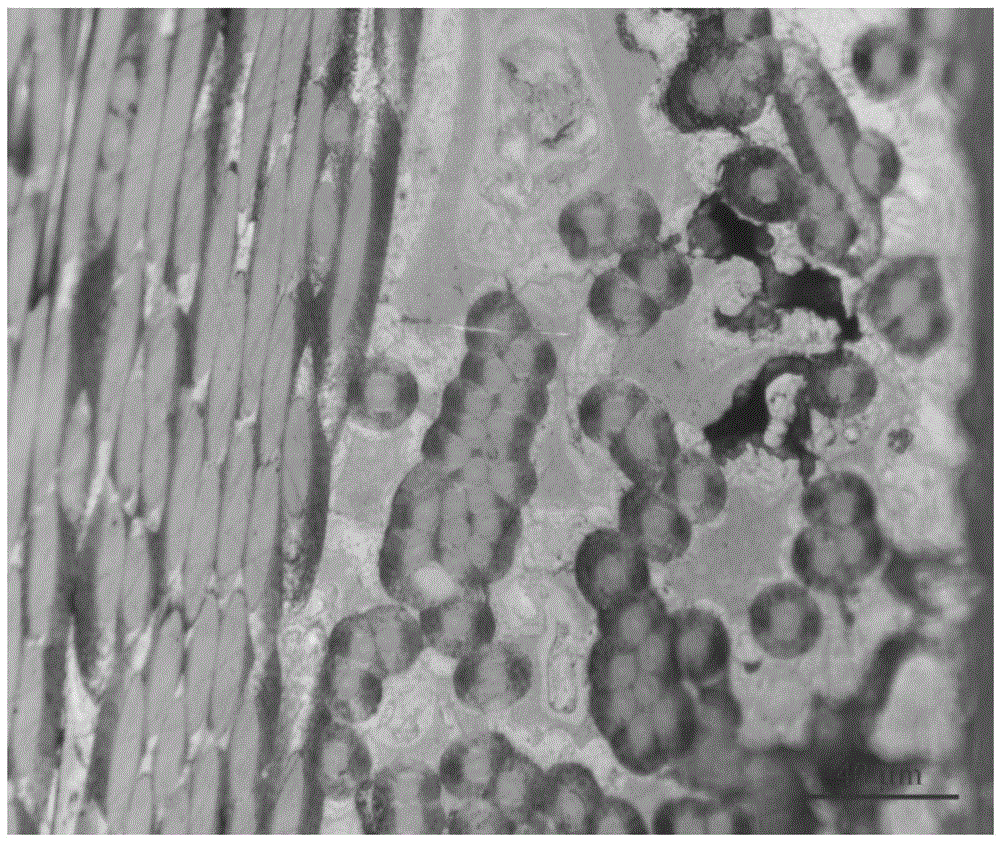

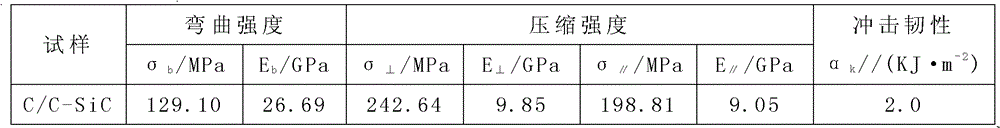

Preparation of carbon fiber reinforced carbon-silicon carbide double matrix friction material

ActiveCN101486588BImprove mechanical propertiesHigh and stable coefficient of frictionFriction liningFiberGraphite

The invention discloses a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material. Short chopped carbon fiber, graphite powder, industrial silicon powder and caking agent are employed to be pressed into the block material of carbon fiber enhanced graphite powder and silicon powder (C / C-Si) in a cooling way; then mechanical cracking and pelleting are carried out to the prepared C / C-Si block material; next, the grains are thermally pressed into a C / C-Si biscuit; and then the C / C-Si biscuit is carbonized to prepare a C / C-Si porous body; and finally non-dipping directional fused silica impregnating is carried out to the C / C-Si porous body to prepare the carbon fiber enhanced carbon-carborundum double-matrix (C / C-SiC) abrasive material. The invention relates to a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material having higher mechanical property and excellent abrasion resistance and wear performances, with the advantages of short preparation cycle, low cost, and being capable of engineering.

Owner:CENT SOUTH UNIV

Treatment method for enhancing durability of clutch friction plate

InactiveCN107654546AHigh and stable coefficient of frictionGood high temperature mechanical strengthClutchesCouplingsStatic frictionEngineering

The invention belongs to the technical field of automobile parts, in particular to a treatment method for enhancing the durability of clutch friction plates. Take out, steam treatment, take out to get the pre-treated clutch friction plate; (2) microwave the pre-treated clutch friction plate for one time, immerse it in the coating solution for 8~10min, take out, second microwave dry treatment, take out, vacuum treatment The treated clutch friction plate not only has a sufficiently high and stable friction coefficient, the difference between the static friction coefficient and the dynamic friction coefficient is reduced, and the friction coefficient basically does not change with the external conditions, and has good thermal conductivity, large heat capacity and good performance. High temperature mechanical strength, and has good wear resistance and anti-adhesion, not easy to scratch the surface of the counterpart, low noise and vibration, effectively ensuring the reliability of the clutch friction plate transmission system.

Owner:HEFEI CITY TENVER PRECISION CASTING

High-temperature-resistant ceramic brake pad and production process thereof

InactiveCN111998022ALow densityReduce hardnessOther chemical processesTransportation and packagingAluminum silicateAramid

The invention discloses a high-temperature-resistant ceramic brake pad and a production process thereof, and relates to the technical field of ceramic brake pad production to solve the problem that high temperature resistance of a brake pad cannot be estimated. The high-temperature-resistant ceramic brake pad comprises a steel backing; a noise reduction piece is arranged on the outer wall of the top of the steel backing, and a thermal insulating layer is bonded to the outer wall of the top of the noise reduction piece; and a friction material is arranged on the outer wall of the top of the thermal insulating layer and prepared from sepiolite fibers, asbestos fibers, potassium carbonate crystal whiskers, brass fibers, wollastonite, aramid fibers, aluminium silicate fibers, aluminium silicate, zirconite, cryolite, feldspar, vermiculite, graphite, antimony disulfide, talcum, mica, barite, porous iron powder, boron modified phenolic resin, open-loop polymerized phenolic resin and the like.The high-temperature-resistant ceramic brake pad has high impact-resistance strength, meanwhile the product density is low, the product hardness is low, braking noise is small, and braking duality isnot damaged.

Owner:HENGYANG MAITE BRAKE SYST CO LTD

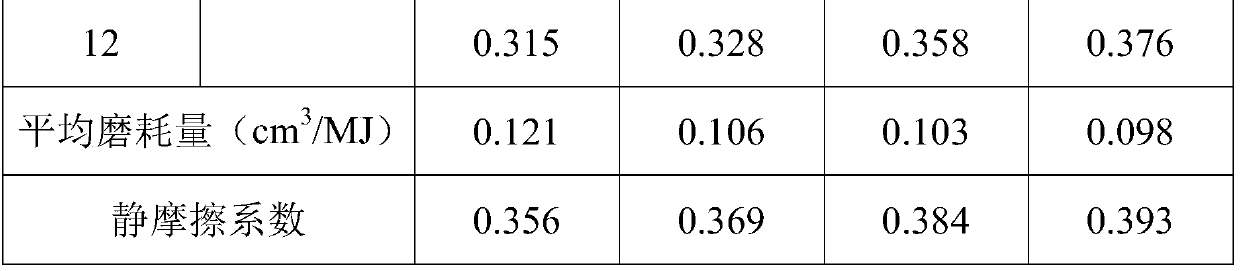

Copper-based powder metallurgy friction material for heavy-duty vehicle dry clutch and preparation method thereof

ActiveCN110102754BGood application effectGive full play to the synergistic effectTransportation and packagingMetal-working apparatusGraphite particleFerrochrome

A copper-based powder metallurgy friction material for a dry clutch of a heavy-duty vehicle and a preparation method thereof. The matrix components of the friction material are copper and iron, and the lubricating components are graphite particles, flake graphite, molybdenum disulfide and petroleum coke. The friction components are ferrochromium, zirconia and silicon dioxide, and the strengthening components are tin. The weight percent of the friction material composition is: copper powder 50%-60%, iron powder 1-10%, graphite particle powder 5-20%, flake graphite 1-5%, molybdenum disulfide powder 1-6%, petroleum Coke powder 1‑15%, ferrochrome powder 3‑9%, zirconia 3‑9%, silicon dioxide 1‑5%, tin powder 1‑4%. The preparation method of the friction material is as follows: preparing a mixture according to the composition of the powder metallurgy friction material, mixing the mixture evenly in a V-type mixer and pressing it into shape, and then sintering together with a copper-plated steel back to obtain a copper-based powder Metallurgical friction materials. The copper-based powder metallurgy friction material has a high and stable friction coefficient and excellent wear resistance.

Owner:CENT SOUTH UNIV

Heavy mechanical brake block and machining method thereof

InactiveCN108691936AImprove performanceIncrease coefficient of frictionOther chemical processesFriction liningEpoxyAramid

The invention relates to the technical field of mechanical brake, and provides a heavy mechanical brake block. The heavy mechanical brake block comprises following raw materials including aramid pulp,floating beads, nitrile rubber powder, cashew nut shell oil friction powder, epoxy resin, red copper, white Zi stone powder, white mica powder, steel wool fibers, iron oxide green, barite, petroleumcoke, graphite, barium sulfate, heavy magnesium oxide, vanadium trioxide, chromite and tire powder. The invention further provides a machining method of the heavy mechanical brake block. The heavy mechanical brake block and the machining method have the beneficial effects that in the research process of the formula, through a large amount of experiments, multiple components are subject to reasonable matching, the full exerting of advantages of all materials in the materials can be ensured, the shortcomings of the properties of the raw materials can be compensated, the better properties can begenerated through mutual cooperation, in the use process, high and stable friction coefficients are achieved, the wear rate is low, and the brake block is not prone to rusting.

Owner:ANHUI XIANGCHI VEHICLE IND CO LTD

Preparation method of powder metallurgy friction material

The invention relates to a preparation method of a powder metallurgy friction material, and belongs to the technical field of material processing. The invention is formed in the manner that copper andiron serve as matrix components, chromium and ferrochrome powder serve as friction components, graphite and silica serve as lubricating components, and three kinds of fiber materials are used for hybrid reinforcing; the three kinds of fiber materials have complementary advantages and can improve the high temperature resistance and abrasive resistance of the friction materials; in the sintering process, as the temperature gradually increases, glass fibers gradually become molten and are adhered to a ceramic fiber mesh and a boron fiber mesh, and the three kinds of fiber materials are mixed inthe friction material to form a three-dimensional network structure, and therefore the impact force borne by the friction material can be dispersed and reduced, the mechanical properties of the friction material can be improved, and the friction coefficient is more stable; and since the ceramic fibers have the characteristic of the small specific heat, the rising rate of the temperature of the friction material during braking is reduced, the volume change caused by rapid increase of temperature is avoided, and the stability of the friction material is further improved.

Owner:FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

Preparation method and application of a carbon ceramic friction material

ActiveCN113248272BUniform compositionStrong penetrating powerBraking discsBraking membersCeramic compositeSilicon particle

The invention relates to the technical field of carbon-ceramic composite materials, and discloses a preparation method and application of a carbon-ceramic friction material, comprising the following steps: A) making a prefabricated part; C) using polycarbosilane as the silicon source to make an impregnating solution, introducing a protective gas for pyrolysis, and repeating the impregnation-pyrolysis operation until an intermediate with a predetermined density is obtained; D) placing it in a graphite crucible For silicon particles, graphite rods are used to separate the intermediate from the silicon particles, and the silicon particles are heated to an evaporating state. Under vacuum conditions, gaseous silicon is guided to infiltrate into different sides of the intermediate, and a uniform gas-phase siliconization reaction is performed to obtain a dense density. Higher, uniform composition carbon ceramic friction material. The prepared friction material can be applied to braking parts of automobiles or rail transit systems.

Owner:广州三的投资管理企业(有限合伙)

Braking material for medium and low-speed maglev trains and preparation method thereof

ActiveCN113073225BImprove thermal conductivityImprove mechanical propertiesTransportation and packagingMetal-working apparatusLow speedLubrication

The invention discloses a braking material for a medium-low speed maglev train and a preparation method thereof. The base component of the braking material is copper, the strengthening component is zinc, aluminum and molybdenum, and the lubricating component is tungsten disulfide and graphite , the friction components are magnesium oxide and zirconium dioxide. The weight percent of the brake material components: 50-65% of copper, 1-6% of zinc, 1-5% of aluminum, 1-4% of molybdenum, 1-4% of tungsten disulfide, 10-18% of graphite, oxide Magnesium 6-10%, zirconium dioxide 5-12%. The invention also discloses a preparation method of the brake material. The brake material for medium and low-speed maglev trains prepared by the invention is non-magnetic, has high and stable friction coefficient, good wear resistance, strong environmental adaptability and does not damage the magnetic track. The material components of the brake material are simple, The process is simple and the cost is low.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

High-speed train brake disc and preparation method thereof

PendingCN114318121AHigh and stable coefficient of frictionEasy to brakeBraking discsCrazingManganese

A cast steel disc body of the high-speed train brake disc comprises, by mass, 0.2%-0.32% of carbon, 0.5%-0.7% of silicon, 0.4%-0.8% of manganese, 0.01%-0.02% of tungsten, 0.1%-0.9% of vanadium, 0.7%-0.9% of molybdenum, 1.0%-1.5% of nickel, 0.9%-1.2% of chromium, 0.01%-0.02% of titanium, 0.020%-0.035% of aluminum, 0.1%-0.3% of copper, 0.035%-0.050% of zirconium, 0.001%-0.003% of boron, 0.1%-0.2% of cobalt, the sum of the content of phosphorus and the content of sulfur is smaller than or equal to 0.01%, and the balance iron. The cast steel disc body of the high-speed train brake disc is prepared through a remelting method, vacuum melting and aluminum insertion deoxidation tapping, a Re-Ti-Si creep modifier is poured into a steel ladle through an in-ladle pouring method, and impurities are removed through an in-ladle argon blowing purification process, so that the high-speed train brake disc has enough strength and a high and stable friction coefficient, and the service life of the high-speed train brake disc is prolonged. The wear resistance is higher; and the thermal crack resistance is better.

Owner:JIANGSU DINGTAI ENG MATERIAL

Method for preparing clutch facing through taking water soluble phenol-formaldehyde resin as adhesion agent

The invention discloses a method for preparing a clutch facing through taking water soluble phenol-formaldehyde resin as an adhesion agent. The method adopts the water soluble phenol-formaldehyde resin which is multiply modified by polyvinyl alcohol, nanoscale attapulgite and micron-order copper powder as the adhesion agent, the water soluble phenol-formaldehyde resin, a friction performance conditioning agent and water are mixed to produce slurry, fibers are soaked in the slurry, are dried and are wound to form a parison, the parison is then subjected to hot-press forming to form the facing, grinding and drilling are carried out after the thermal treatment, the clutch facing is obtained. The modified adhesion agent has high solubility, cohesiveness, toughness, heat resistance, thermal fading resistance and abrasion resistance; and the clutch facing which is produced through the adhesion agent is low in cost, green and environment-friendly, can bear impact force during the processing and using processes, cannot crack and has high thermal stability, high and stable friction coefficient and low abrasion resistance.

Owner:浙江科马摩擦材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com