Patents

Literature

57 results about "Andiron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An andiron or firedog, fire-dog or fire dog is a bracket support, normally found in pairs, on which logs are laid for burning in an open fireplace, so that air may circulate under the firewood, allowing better burning and less smoke. They generally consist of a tall vertical element at the front, with at least two legs. This stops the logs from rolling out into the room, and may be highly decorative. The other element is one or more low horizontal pieces stretching back and serving to hold the logs off the bottom of the fireplace. An andiron is sometimes called a dog or dog-iron.

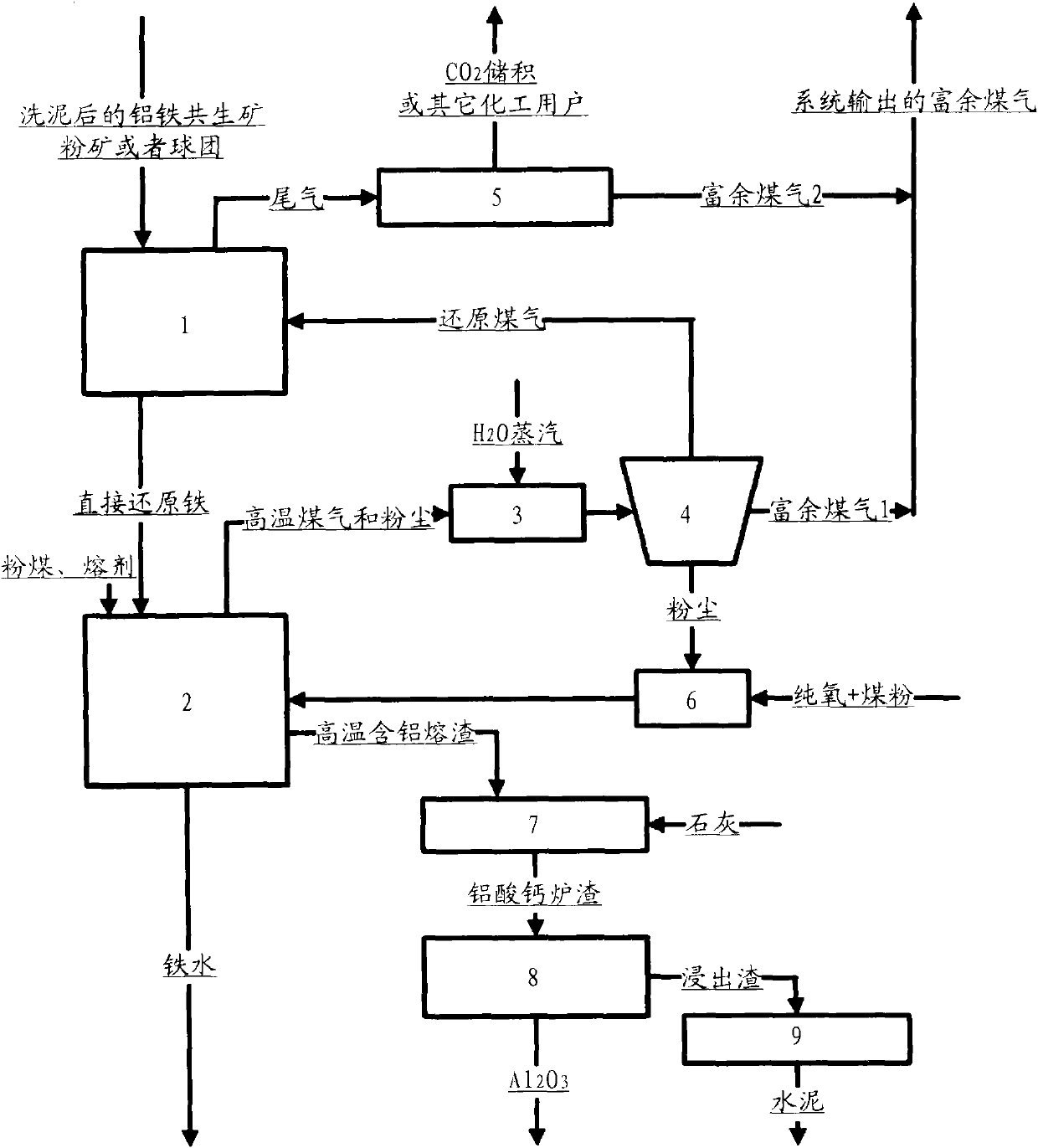

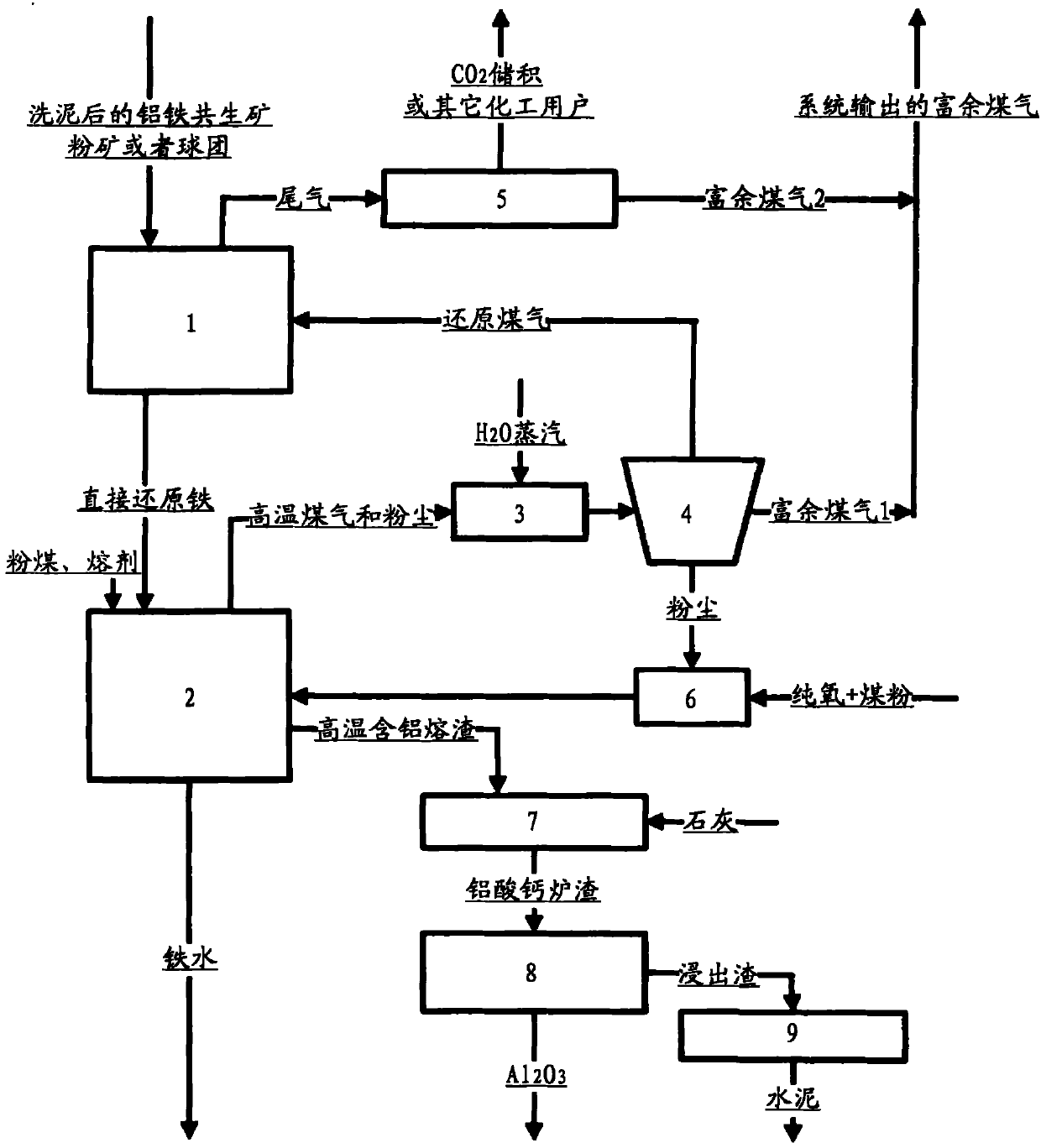

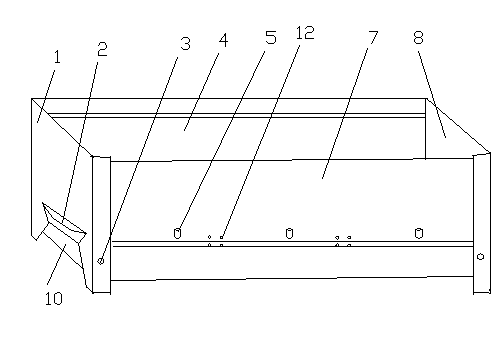

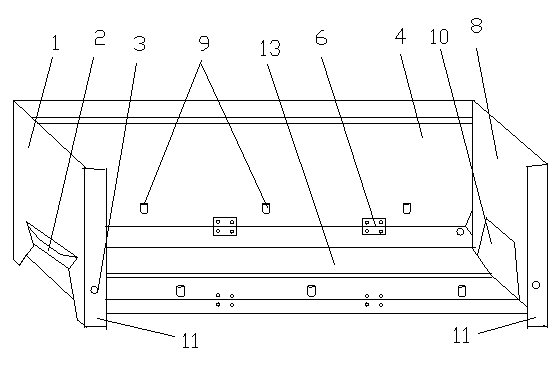

Iron and aluminum melting separation method for complicated and hard-dressing aluminum and iron intergrowth ore

The invention provides an iron and aluminum melting separation method for hard-dressing aluminum and iron intergrowth ore which is embedded in a complex way. The method comprises the following steps of: adding aluminum and iron intergrowth ore into a prereduction furnace (1), aerating carbon monoxide and / or hydrogen into the prereduction furnace (1) to partially reduce the aluminum and iron intergrowth ore, putting the partially reduced aluminum and iron intergrowth ore into a final reduction smelting and separation furnace (2), further performing final reduction on the aluminum and iron intergrowth ore through carbothermic high temperature, and tapping and deslagging respectively by utilizing the formation of an upper liquid phase and a lower liquid phase due to different specific gravities of molten iron and alumina-containing molten slag at high temperature so as to finish melting separation. By the method, the complete separation of iron and aluminum in the hard-dressing and complicated aluminum and iron intergrowth ore can be realized, and the high recovery rate of iron and aluminum is ensured and the comprehensive utilization of the complicated and hard-dressing aluminum andiron intergrowth ore is realized at the same time. Moreover, by the process, products such as iron, alumina, high-quality coal gas, cement, carbon dioxide and the like can be obtained, and exhaust gas and waste residue are not discharged; and the method has the characteristics of low energy consumption and high recovery rate.

Owner:NORTHEASTERN UNIV

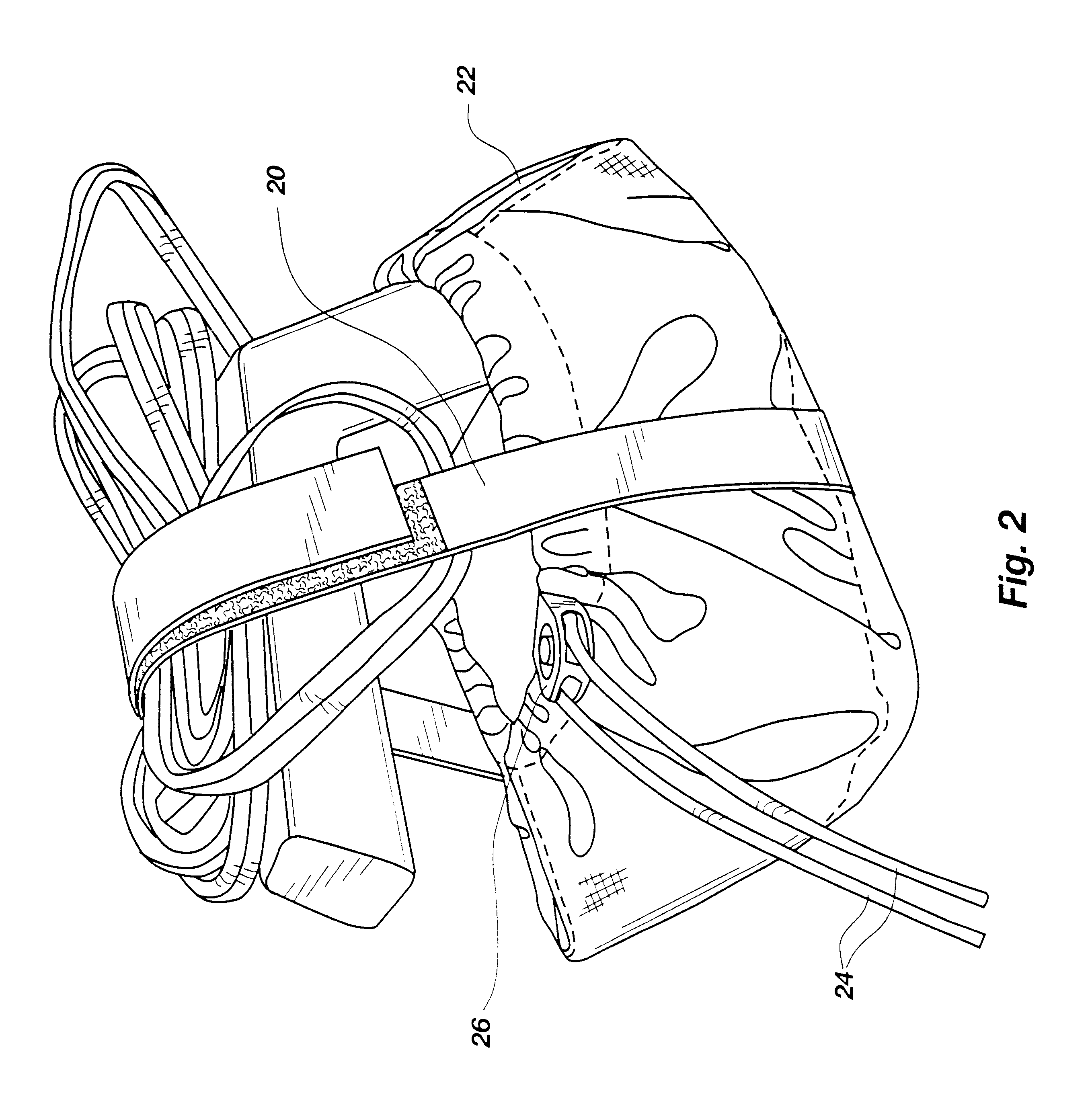

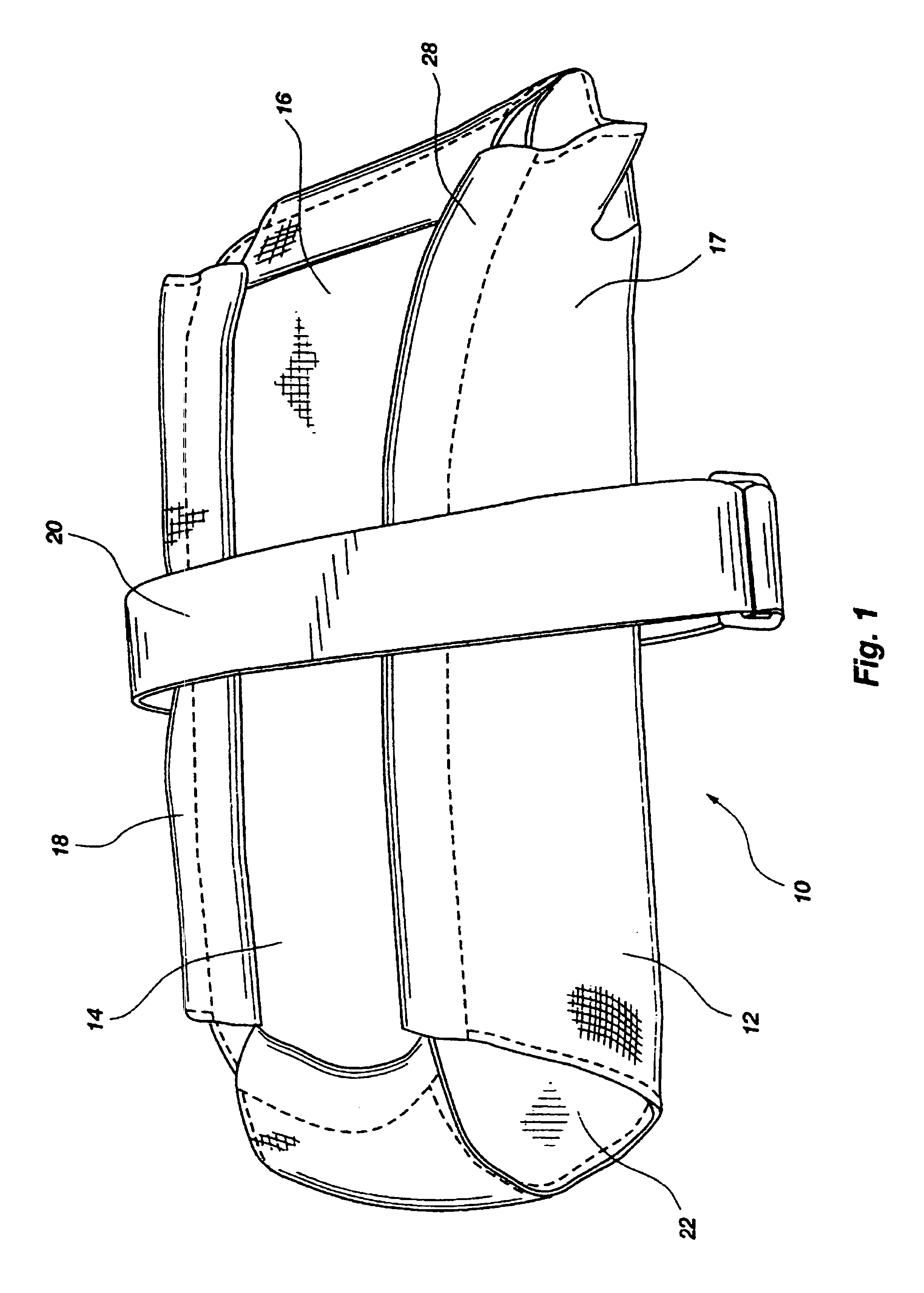

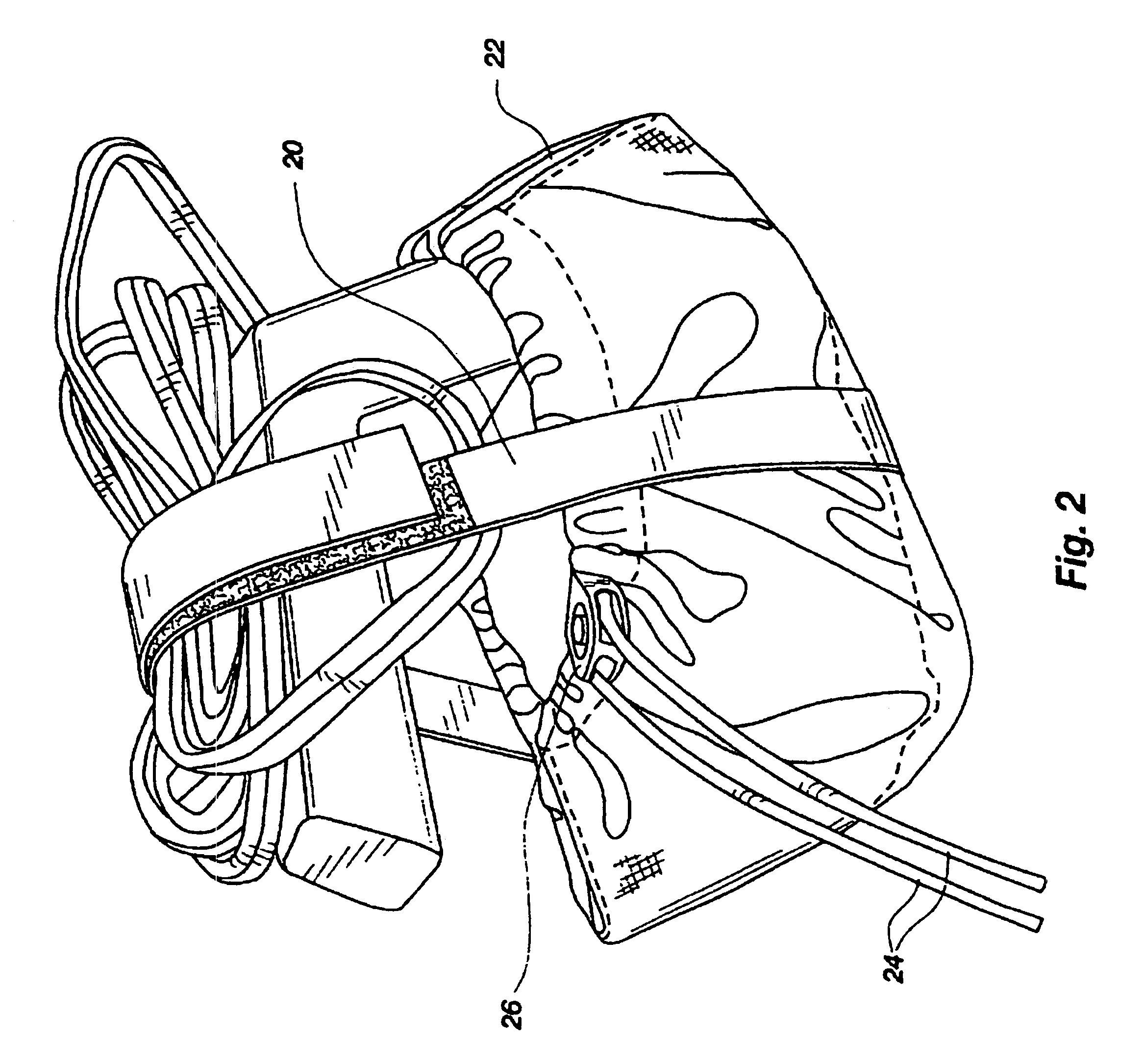

Iron cover

An iron cover for ski wax irons a heat resistant liner having a padded bottom segment shaped to cover and protect the sole of an iron and a plurality of side flaps with ends. The side flaps extend sufficiently around the sides of an iron placed within the liner, and are secured around the iron with an elastic cord associated with the side flaps. The side flaps are structured and separated to define a plurality of heat release vents to allow heat to escape from a hot iron placed in the cover for storage.

Owner:ORIGINALITY

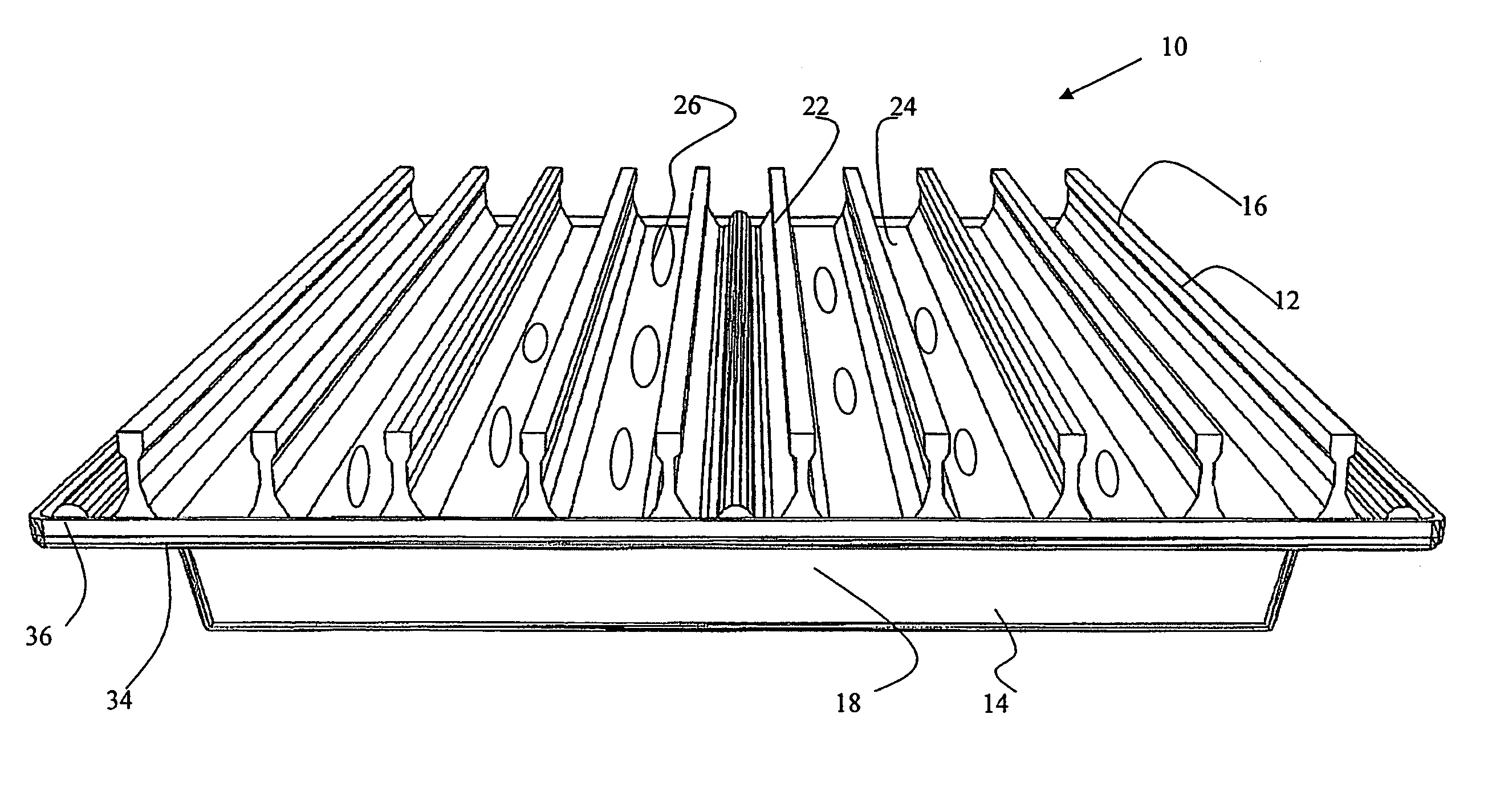

System and device for grilling foods

A system of modular, interlocking, raised-rail grate panels and a complementarily-shaped basin for supporting and peripherally-containing the base of the grate panels while continuing to allow the passage of gasses lengthwise between the raised rails and the passage of gases and liquids through the base of the grate panels, such that delivery of searing and reflective heat to a cooking food is facilitated, wherein the grate panels and basin are coated with an abrasion-resistant, high-temperature, easy-to-clean, non-stick coating for ease of use, and wherein accessory features such as integrated, stylized food branding irons and raised-rail adaptive cooking tools are optionally provided.

Owner:AHV HLDG LLC

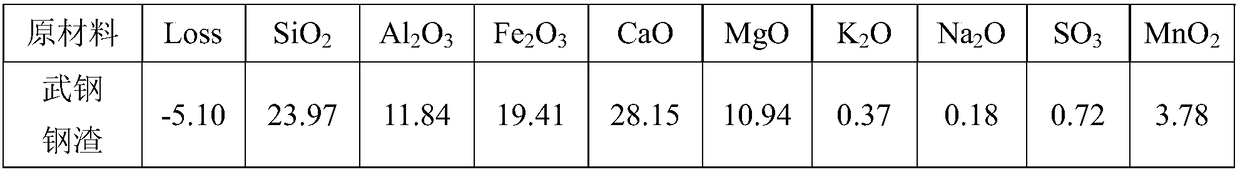

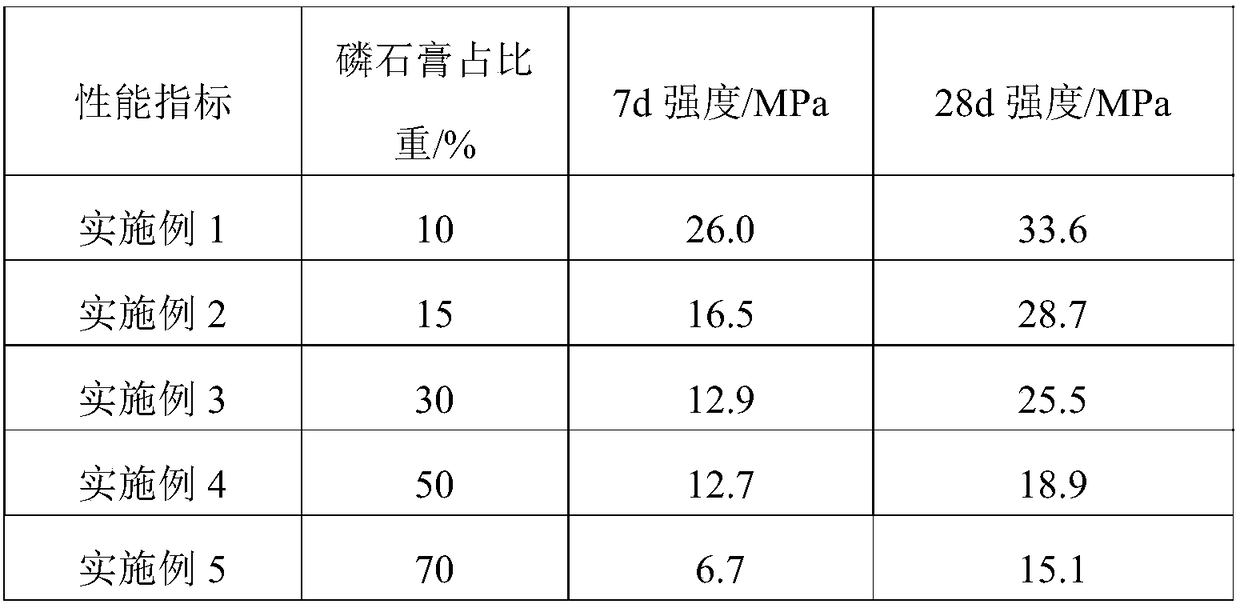

Preparation method of carbon excited slag brick

The invention relates to a preparation method of a carbon excited slag brick. The preparation method includes: mixing slag micropowder within a certain grain size range and obtained after smashing andiron separation, slag fine particle, phosphogypsum and water to form a brick blank, and preserving the brick blank in high-partial-pressure CO2 environment to obtain a high-strength slag brick product. Coal ash, silica fume, sodium sulfate and sodium carbonate can be added into raw materials of the carbon excited slag brick. The problem that a lot of slag and phosphogypsum cause emission pollution and are low in utilization rate is solved, the objective of waste reutilization is achieved, and the preparation method has good social benefit, economic benefit and environment benefit.

Owner:WUHAN UNIV OF TECH

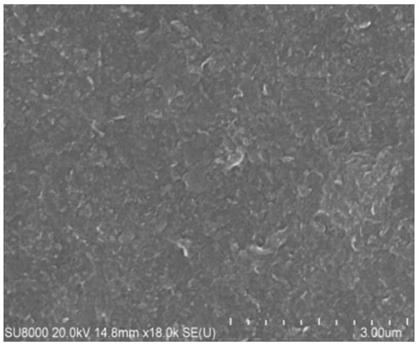

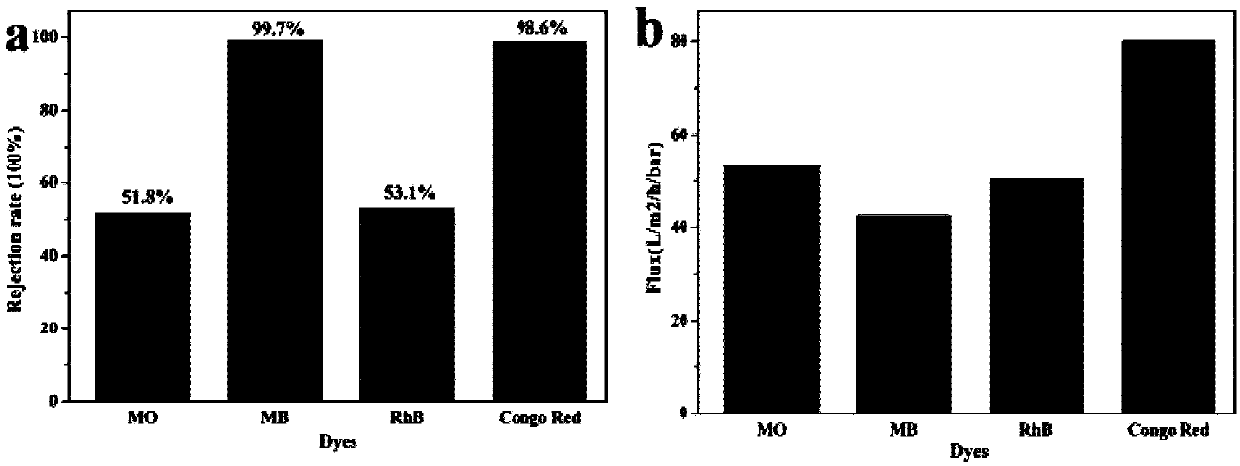

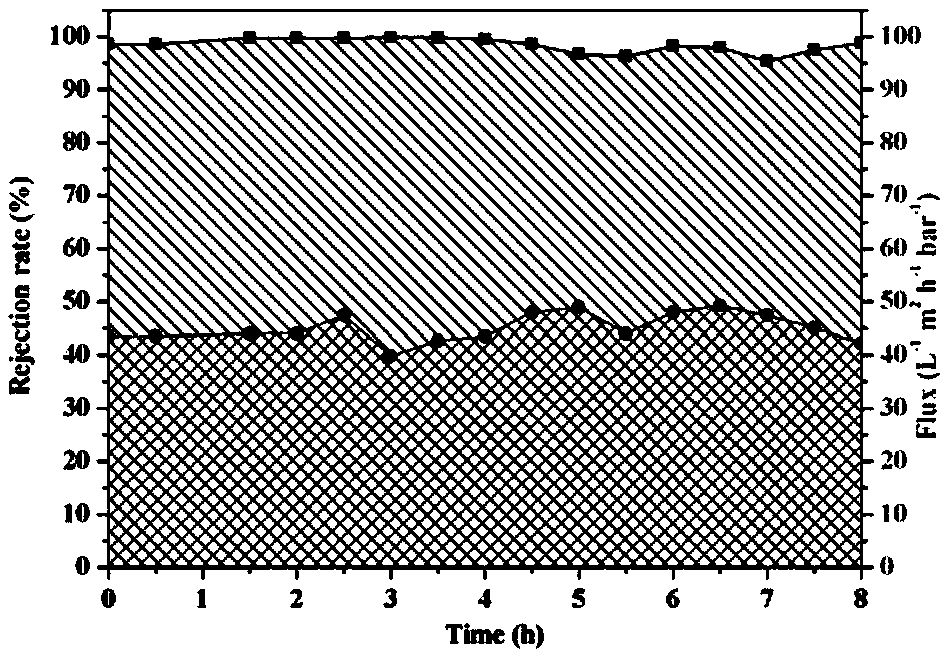

Surface self-cleaning carbon nitride Fenton-photocatalytic nanofiltration membrane and preparation method thereof

ActiveCN109569311AEfficient degradationEffective combinationMembranesSemi-permeable membranesFenton reagentWater quality

The invention discloses a surface self-cleaning carbon nitride Fenton-photocatalytic nanofiltration membrane and a preparation method thereof and belongs to the fields of water treatment membrane materials and preparation processes of the water treatment membrane materials. The method comprises selecting carbon nitride photocatalysts which integrate plasticity of polymer molecules and chemical stability of carbon materials and performing surface modification, chemical modification, Fenton-like agent compounding and the like to prepare a multifunctional water treatment membrane. On the one hand, inter-element triangular nanopores formed by carbon nitride can provide stable natural channels for rapid passage of water molecules; on the other hand, through irradiated catalytic degradation andiron-containing agent Fenton-like oxidation, in-situ degradation of nanofiltration retained pollutants can be achieved. The surface self-cleaning carbon nitride Fenton-photocatalytic nanofiltration membrane provides a new way for solving the problem of membrane contamination difficult for traditional nanofiltration membrane materials and has the advantages of being simple in preparation method, low in cost, resistant to pollution, low in water mass transfer resistance and the like, thereby being applicable to application to the field of water purification.

Owner:TSINGHUA UNIV

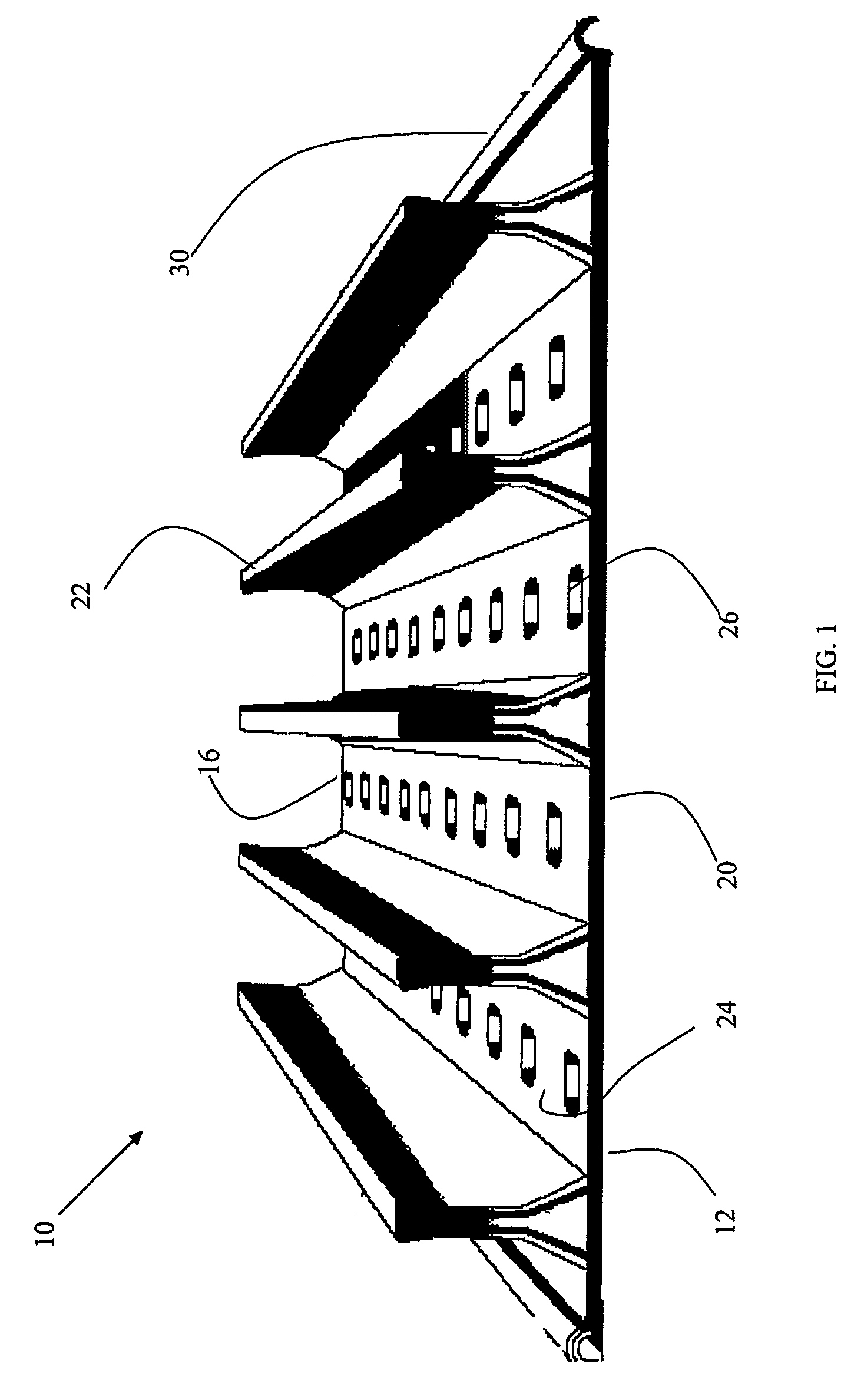

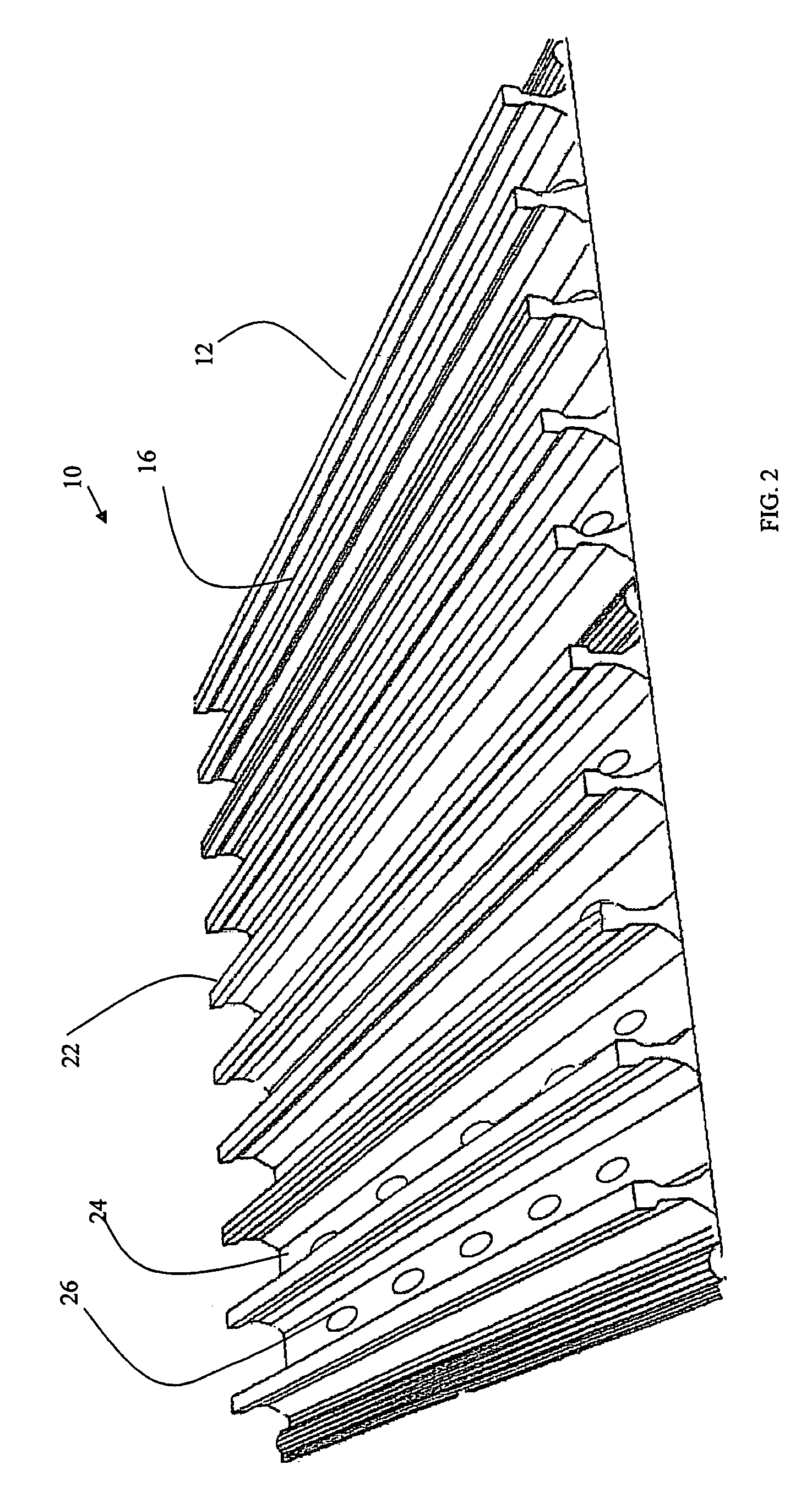

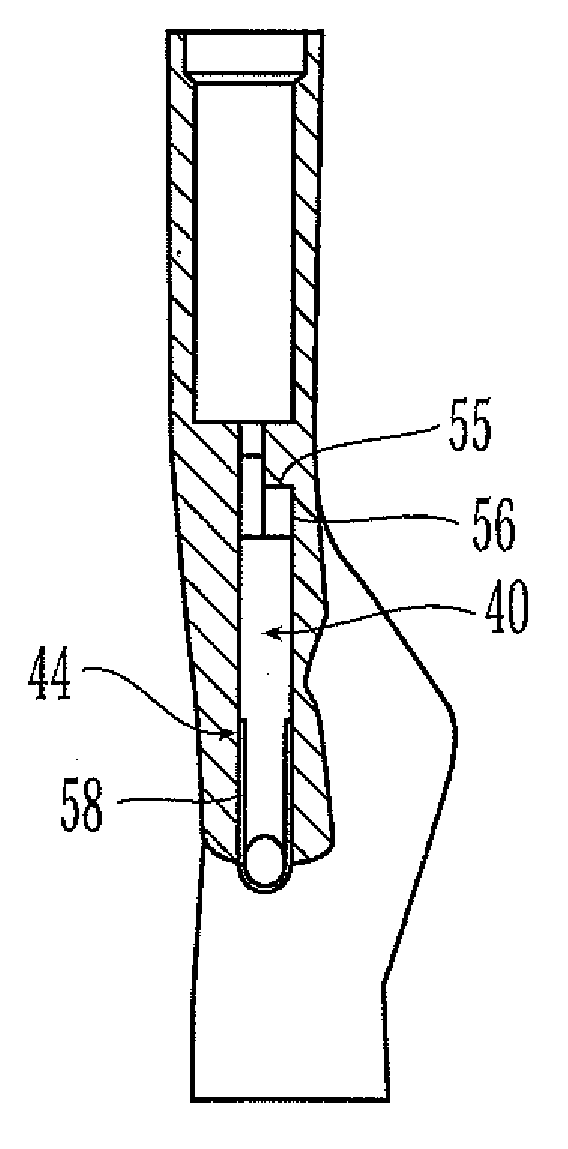

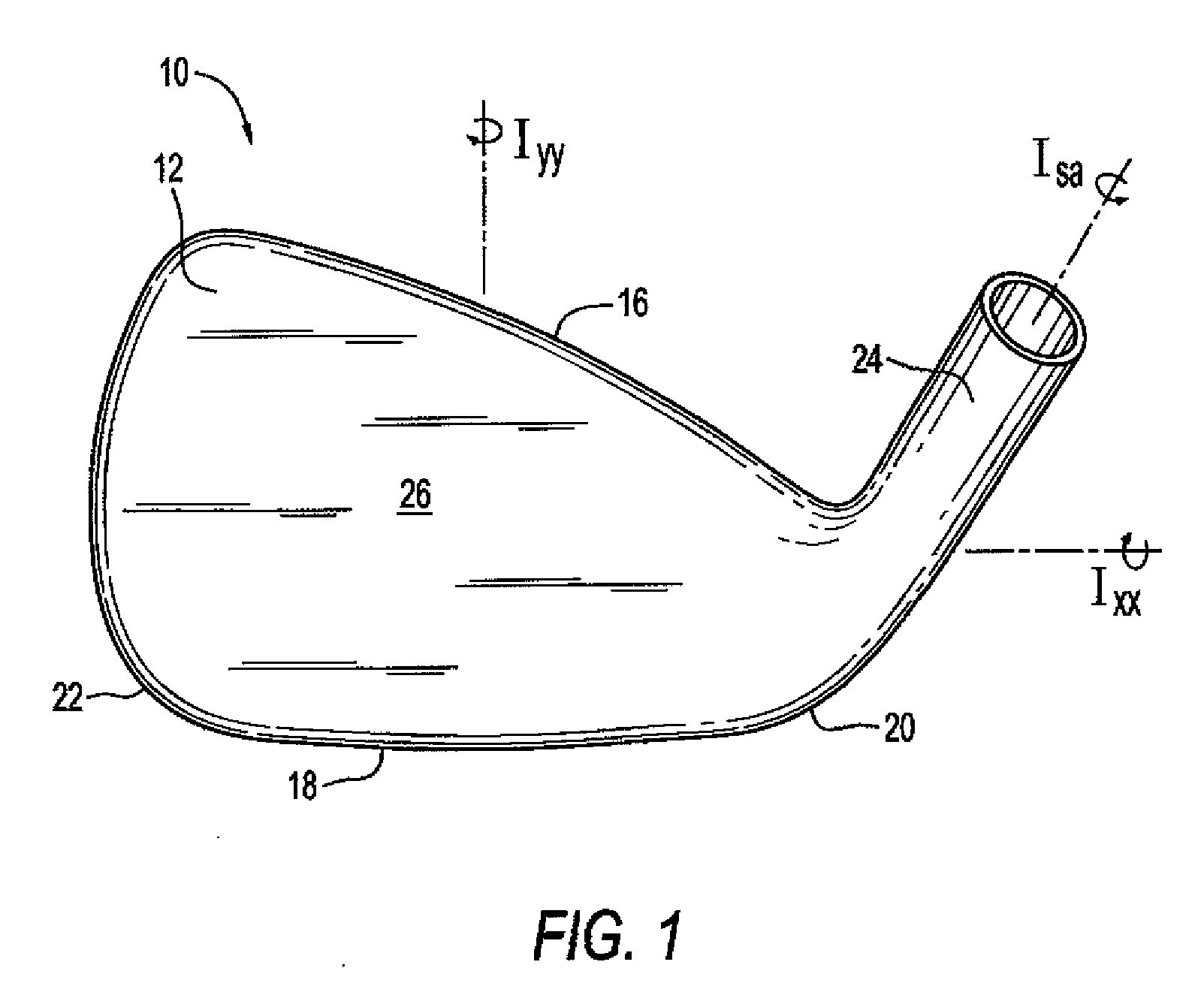

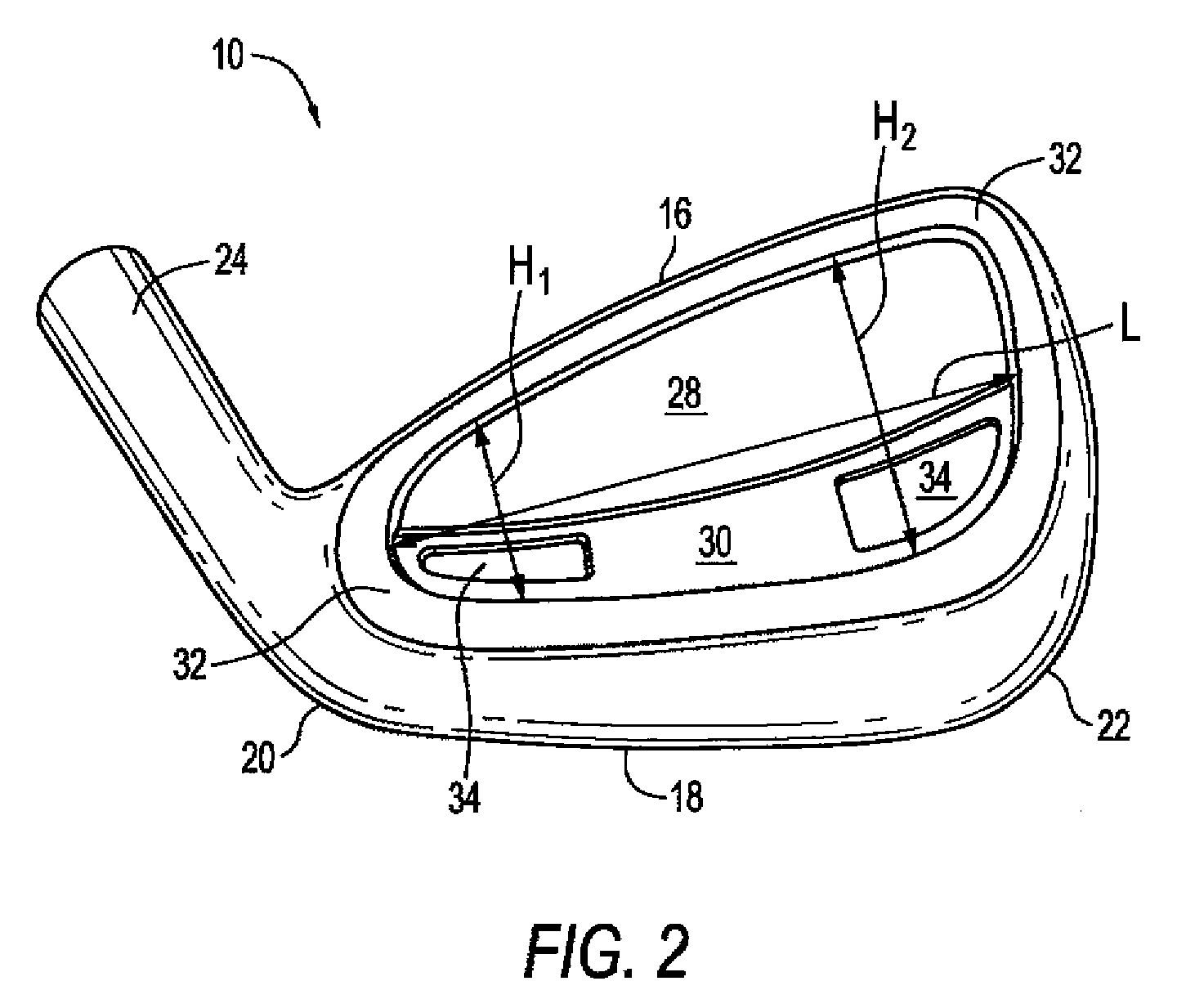

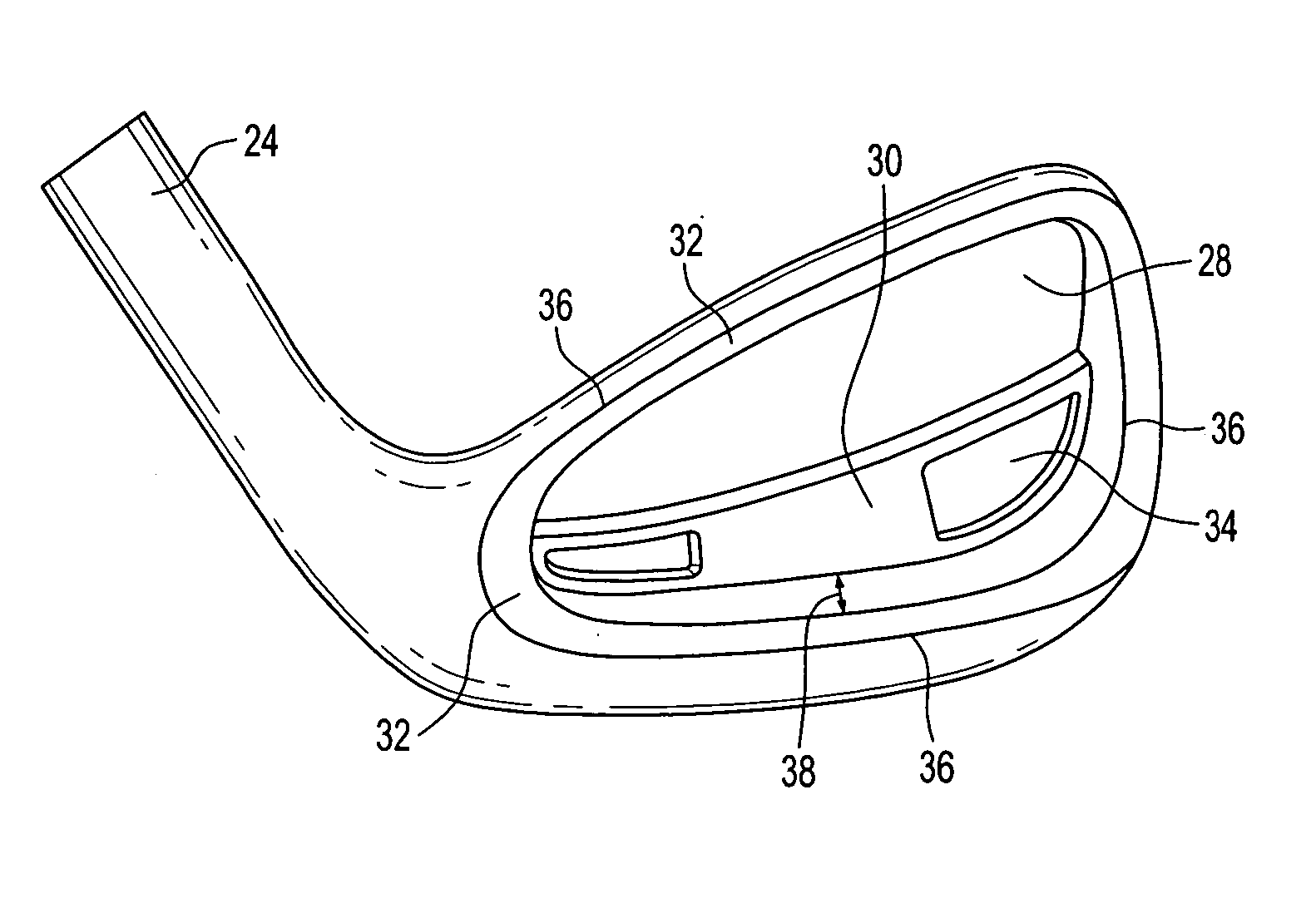

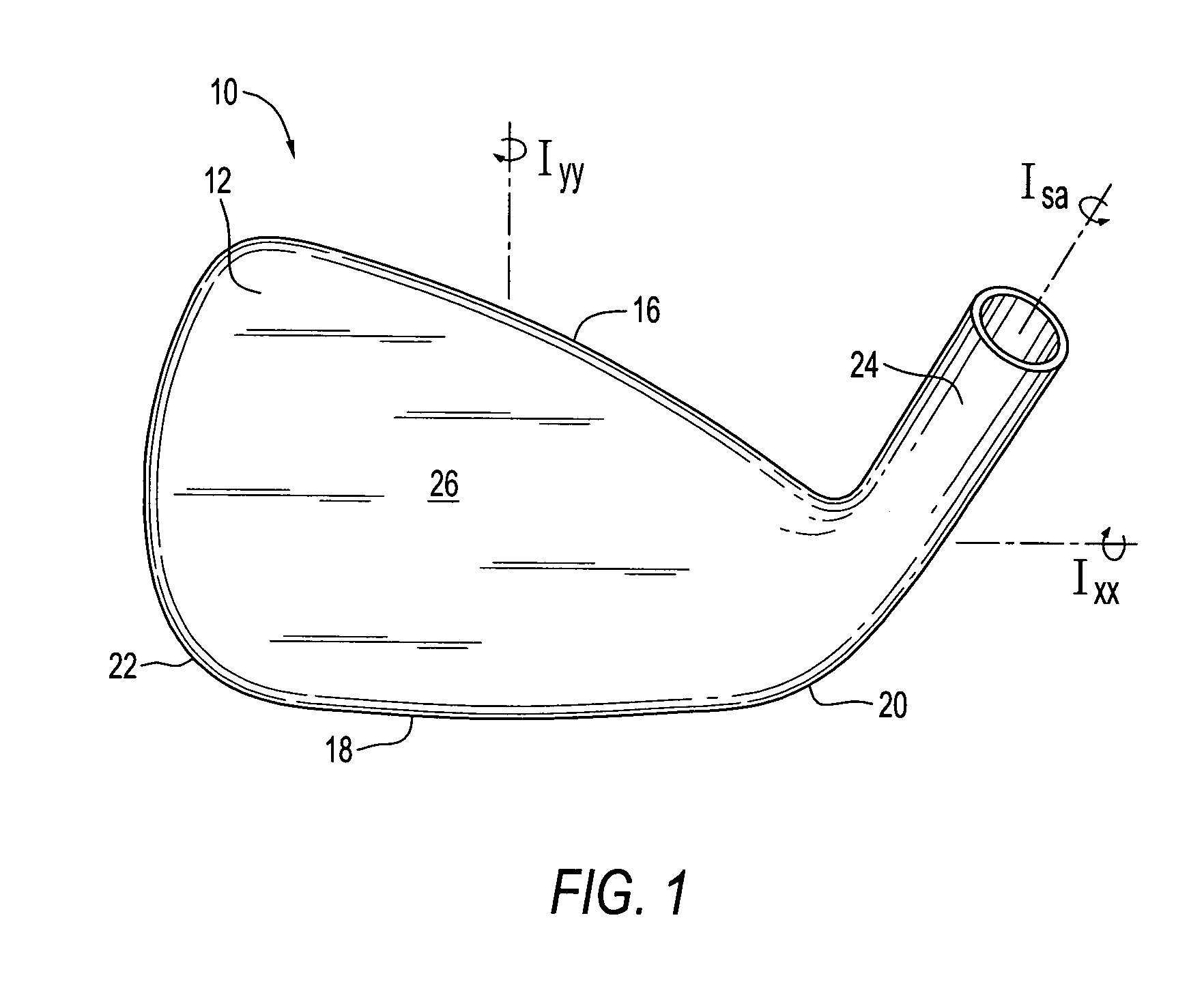

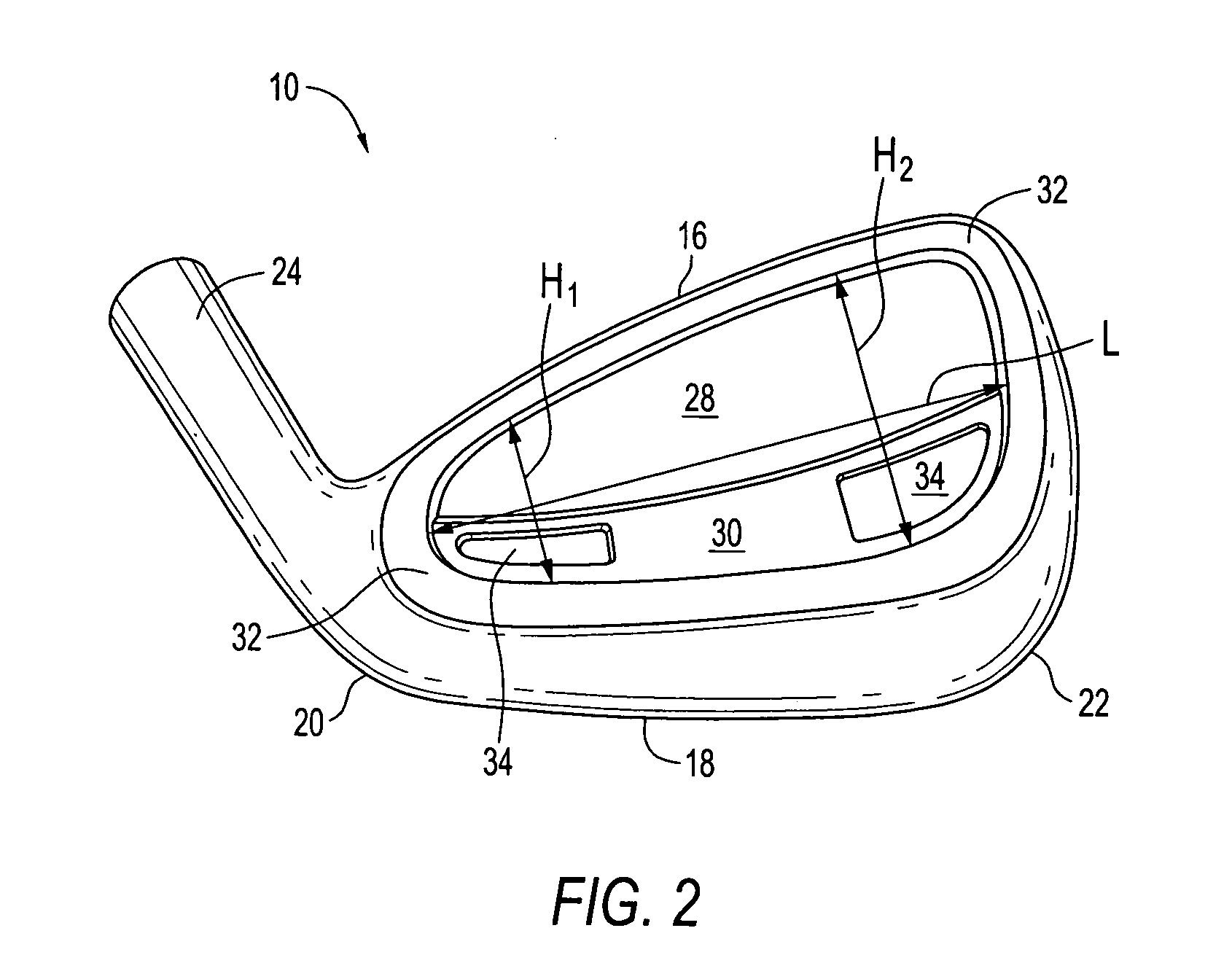

Forged iron-type golf clubs

Forged cavity back iron-type clubs and oversize clubs are disclosed. These forged clubs have thin, durable hitting face and relatively large cavity volumes. These clubs have high rotational moments of inertia to minimize distance and accuracy penalties associated with off-center hits. Long irons with hitting face of about 0.100 inch thick are achievable by the present invention. Also disclosed are forged irons made from stainless steels and annealed to achieve the desired hardness and ductility. Further, an interchangeable pin suitable for use in the manufacture of any of a set of iron-type clubs without re-tooling is disclosed. The pin is sized and configured to fit within a through-bore such that an adhesive such as a flexible epoxy may be placed within the gaps to provide a vibration dampening effect.

Owner:ACUSHNET CO

Forged iron-type golf clubs

Forged cavity back iron-type clubs and oversize clubs are disclosed. These forged clubs have thin, durable hitting face and relatively large cavity volumes. These clubs have high rotational moments of inertia to minimize distance and accuracy penalties associated with off-center hits. Long irons with hitting face of about 0.100 inch thick are achievable by the present invention. Also disclosed are forged irons made from stainless steels and annealed to achieve the desired hardness and ductility. Further, an interchangeable pin suitable for use in the manufacture of any of a set of iron-type clubs without re-tooling is disclosed. The pin is sized and configured to fit within a through-bore such that an adhesive such as a flexible epoxy may be placed within the gaps to provide a vibration dampening effect.

Owner:ACUSHNET CO

Non-polluted method for producing o-chloroaniline with ferrous powder as reducer

InactiveCN101376634AReduce energy consumptionReduce productionOrganic compound preparationAmino compound preparationO-nitrochlorobenzeneIron powder

The invention relates to an environment friendly method for reduction producing o-chloroaniline with iron powder. The method comprises adopting o-nitrochlorobenzene as the raw material and the iron powder as a reducing agent; separating o-chloroaniline, water andiron mud by vacuum distilling to obtain a coarse o-chloroaniline product; and refining by rectifying to obtain o-chloroaniline. The method solves the defects in the prior art on heavy pollution and high energy consumption, and implements the clear production of o-chloroaniline.

Owner:淮安嘉诚高新化工股份有限公司

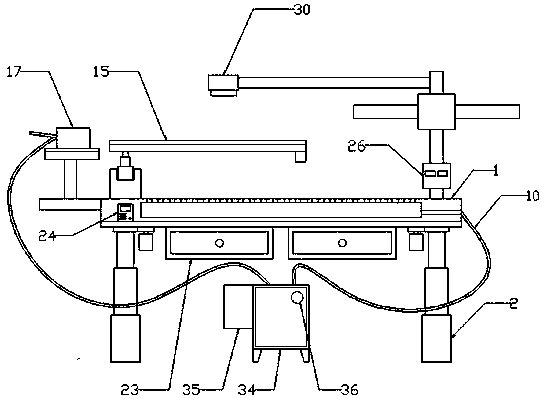

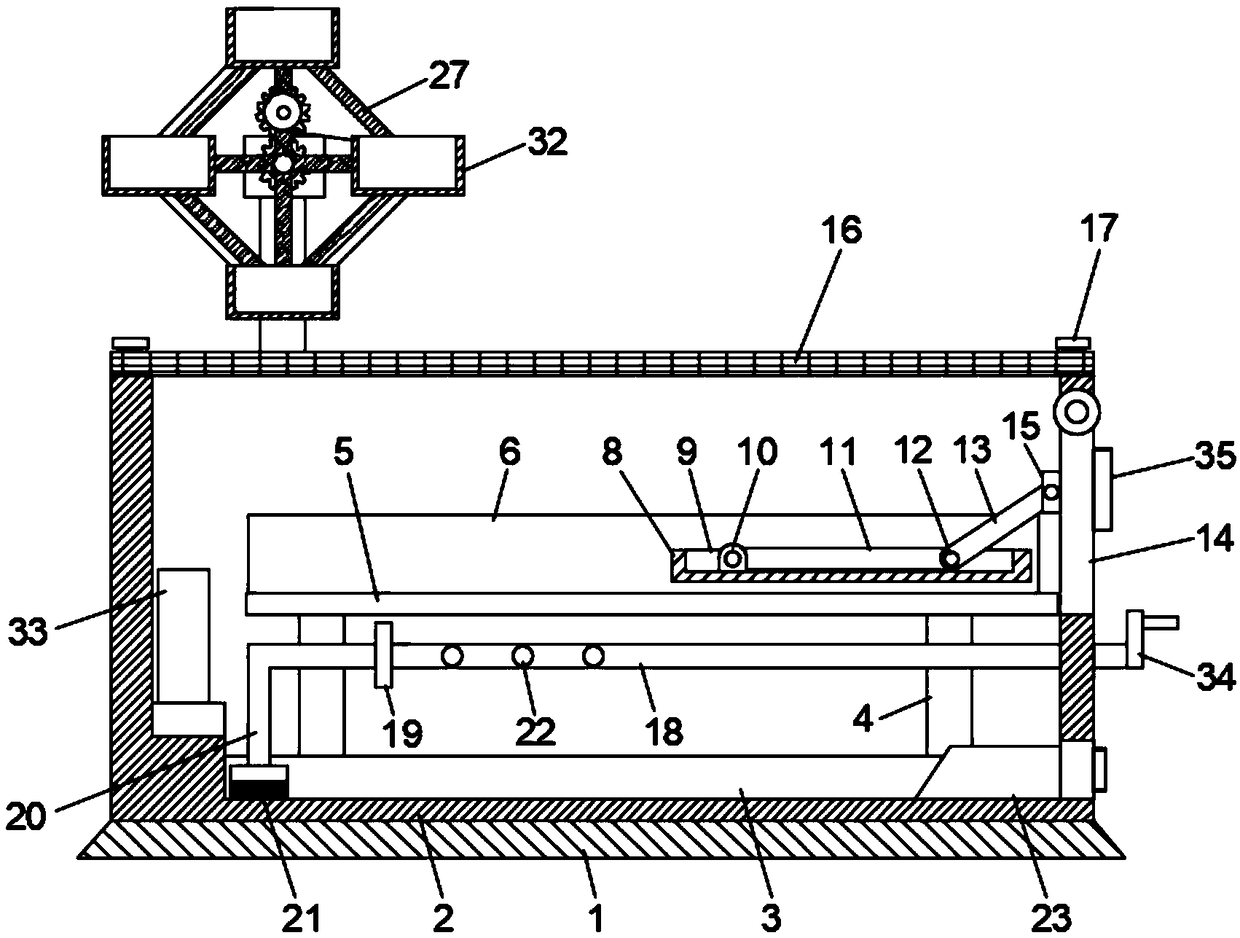

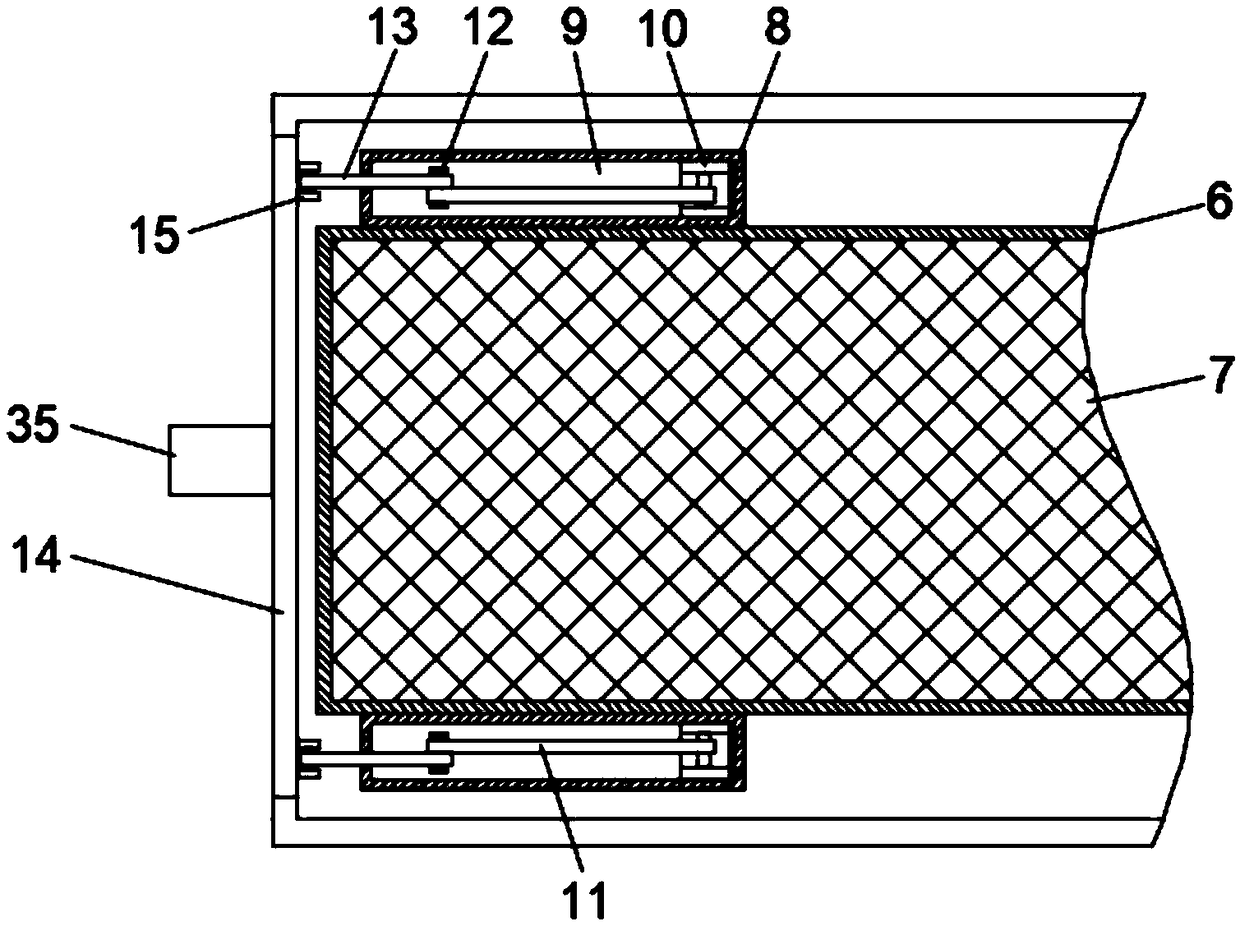

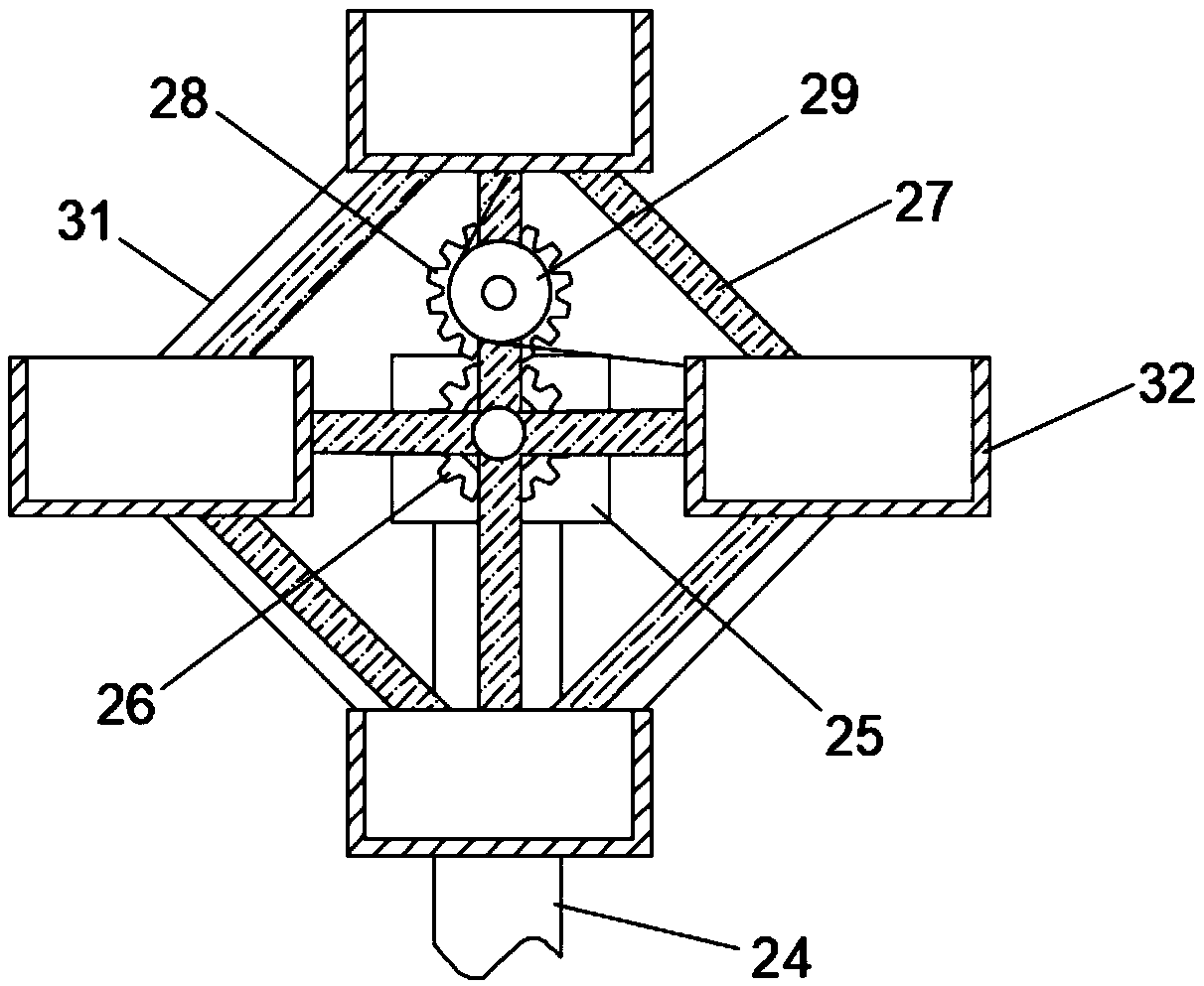

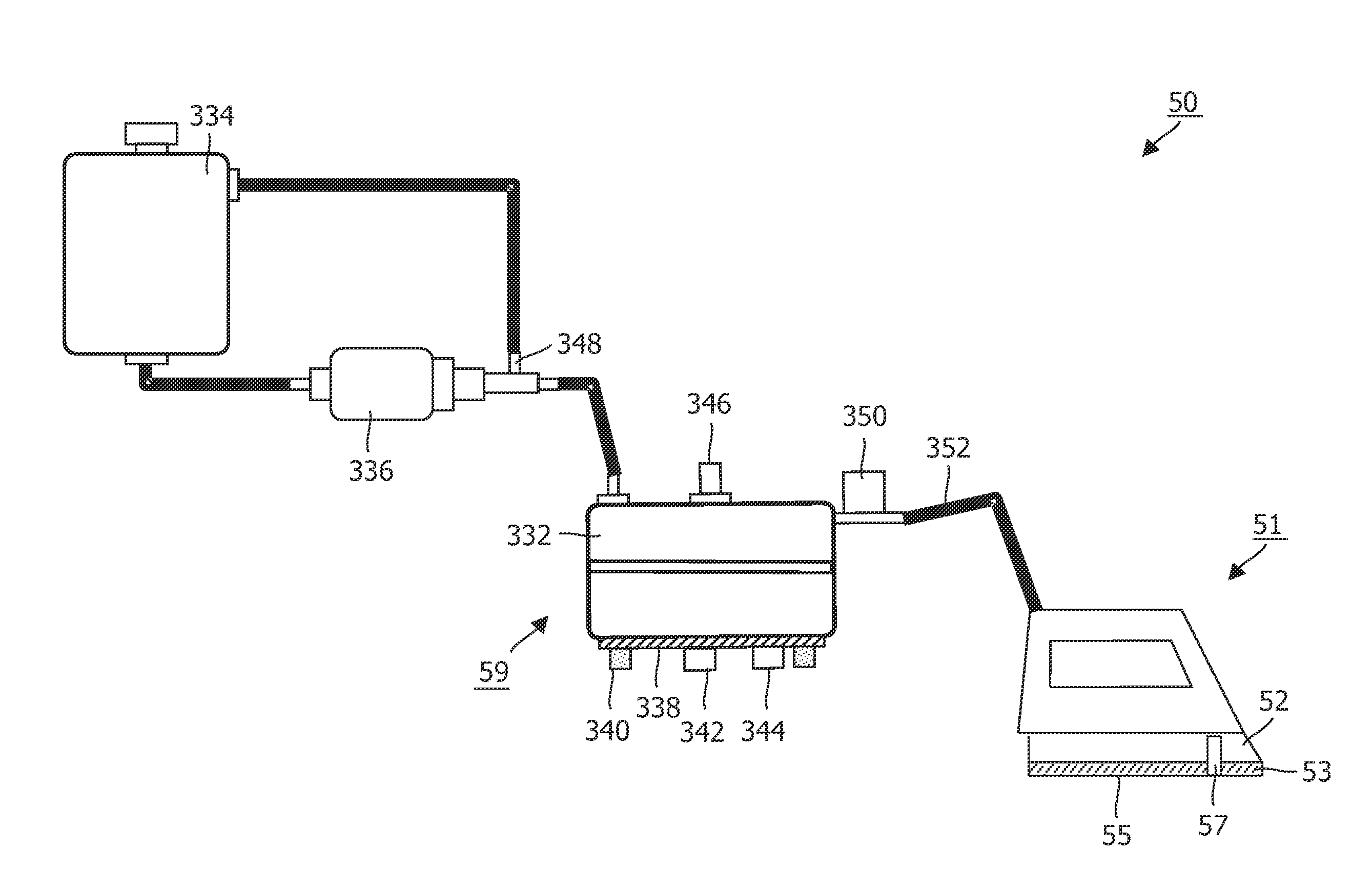

Ironing platform of which platform surface can be heated

ActiveCN107653655AReduce labor intensityIncrease productivityIroning boardsHand ironEngineeringAndiron

The invention discloses an ironing platform of which the platform surface can be heated. The ironing platform comprises an ironing workbench, the ironing workbench is fixedly installed on the ground through a supporting frame, the supporting frame is internally provided with an electric lifting device, the ironing workbench is internally provided with a steam generating device, a movable ironing plate device is arranged above the left side of the ironing workbench, a movable steam iron device is fixedly connected to one end of the left side of the ironing workbench, a fan device is arranged atone side above the right side of the ironing workbench, an illuminating device is arranged at the other side above the right side of the ironing workbench, a drawer is arranged below the ironing workbench, and a controller is arranged on the side wall of the front of the ironing workbench and is electrically connected with the electric lifting device, the steam generating device, the movable ironing plate device, the movable steam iron device, the fan device and the illuminating device separately. The ironing platform has the advantages of being simple in structure and high in practicability.

Owner:邵阳奥佳工贸有限公司

Electric steam iron

InactiveUS20090000162A1Good effectGood boiling effectHand ironTextiles and paperElectricityEngineering

Owner:ZHEJIANG YUELI ELECTRICAL

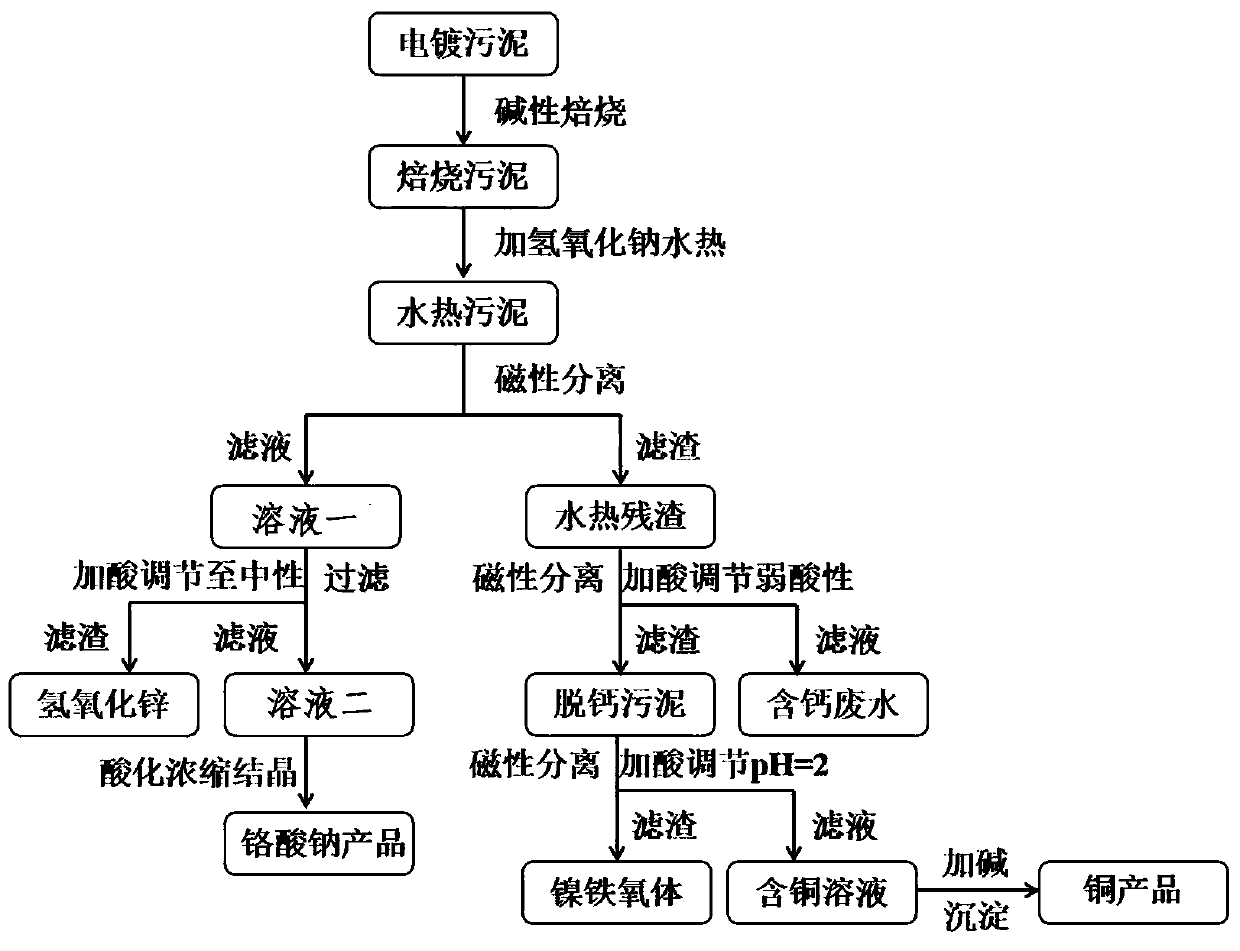

Selective separation recovery technology of heavy metal in electroplating sludge containing chromium

The invention relates to a selective separation recovery technology of heavy metal in electroplating sludge containing chromium. The selective separation recovery technology of the heavy metal in theelectroplating sludge containing the chromium specifically comprises the steps that (1) the sludge containing the chromium and carbonate are subjected to mix roasting under a certain temperature, andiron sources are supplemented appropriately; (2) hydrothermal reaction is carried out on a solid obtained in the step (1) and an alkaline mineralizing agent; (3) after solid-liquid separation is carried out on turbid liquid obtained in the step (2) by using magnetic force, a diluted acid solution (pH is 3.5-5.0) is added into the solid for calcium removal, and concentration and crystallization arecarried out for recovering the chromium after liquid dezincification; and (4) after the magnetic separation of the turbid liquid in the step (3) is carried out, mixed reaction is carried out on the solid and a concentrated acid solution (pH is 2-3.5); and after the magnetic separation of the obtained turbid liquid is carried out, the solid is a nickel ferrite product, and copper is recovered in aliquid mode. According to the selective separation recovery technology of the heavy metal in the electroplating sludge containing the chromium, doping regulation and control of metal elements in thesludge in spinel class materials (M (II) N (III) 2O4 (M=Ni, Cu, Zn, Ca; N=Cr, Fe, Al)) is realized through comprehensive regulation and control of the roasting temperature and a hydrothermal mineralizing agent, so that the selective separation recovery technology of the heavy metal is realized. Meanwhile, after the sludge is subjected to a roasting / hydrothermal combined technology, the solid has higher magnetic force, and the difficulty of solid-liquid separation in the technology is reduced.

Owner:FUZHOU UNIV +1

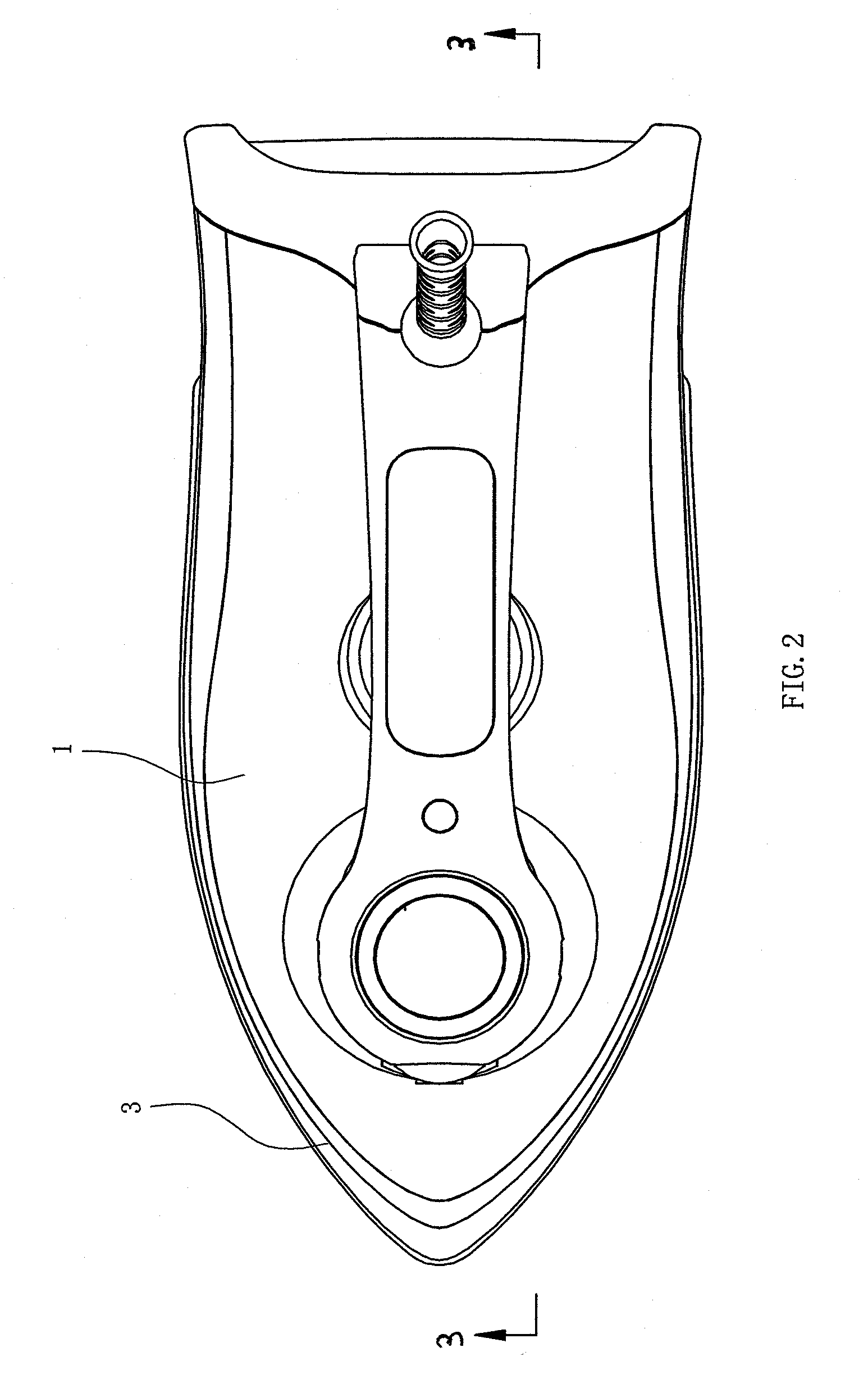

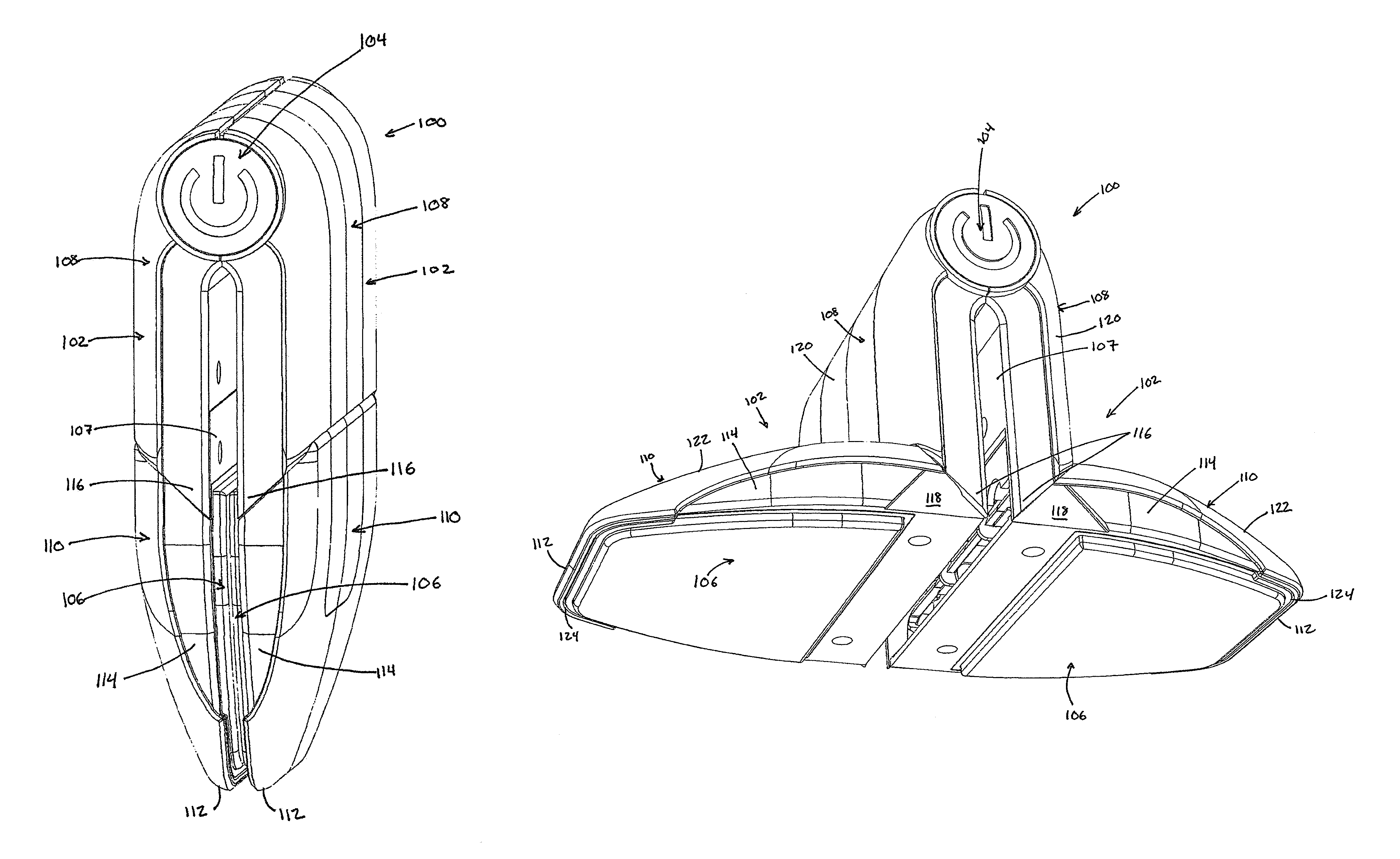

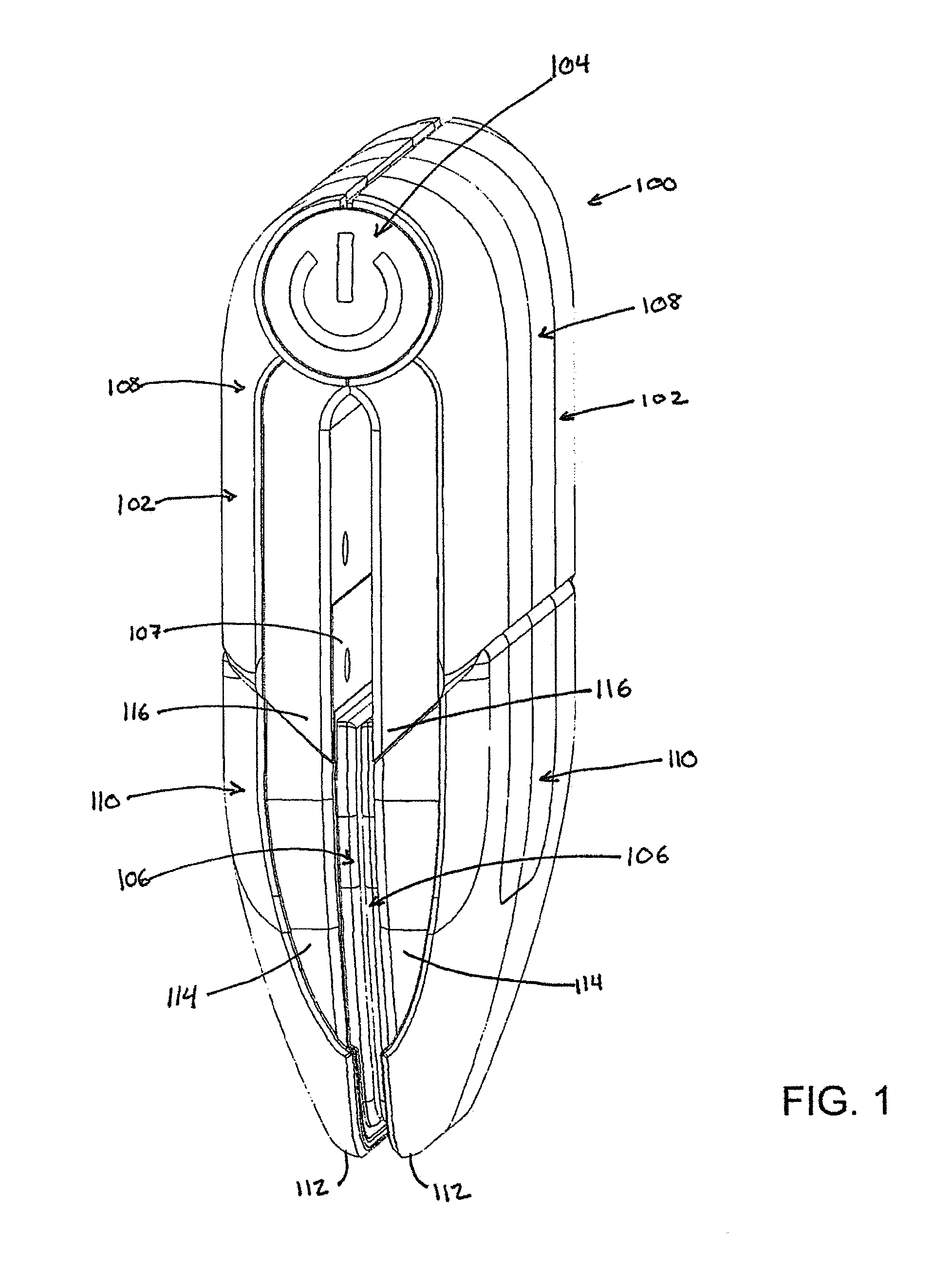

Convertible iron

Provided herein are a convertible iron and methods of manufacturing and converting the same. The iron may include a first adjustable wing and a second adjustable wing joined to a pivoting hub, such that the adjustable wings are configured to pivot about the hub with respect to each other. The iron may include a heating plate connected to at least the first adjustable wing. At least a portion of each adjustable wing may be configured to rotate between a detailing position and an ironing position. In the detailing position, the portions of each adjustable wing may be substantially parallel, such that the adjustable wings are substantially opposing one another and may be configured to receive an article therebetween for ironing. In the ironing position, the portions of each adjustable wing may be substantially coplanar and may be configured to engage a same side of a surface of an article for ironing.

Owner:DIERKER BRANDON

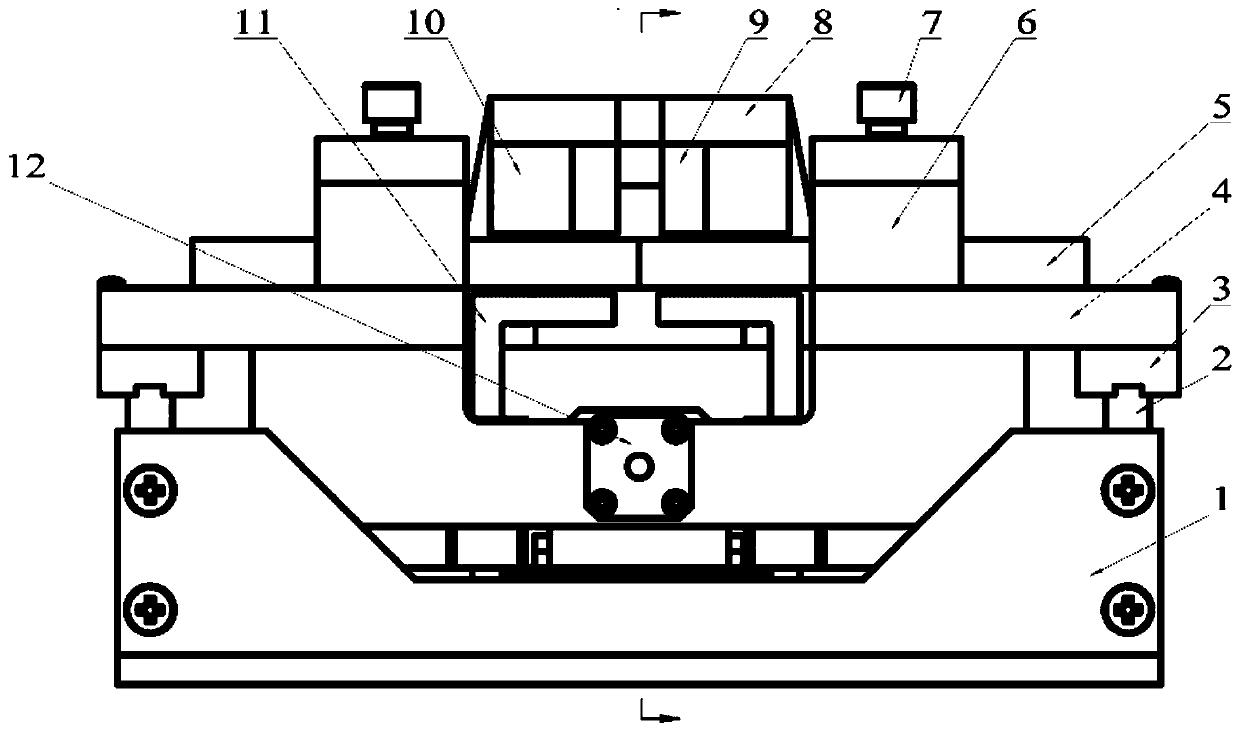

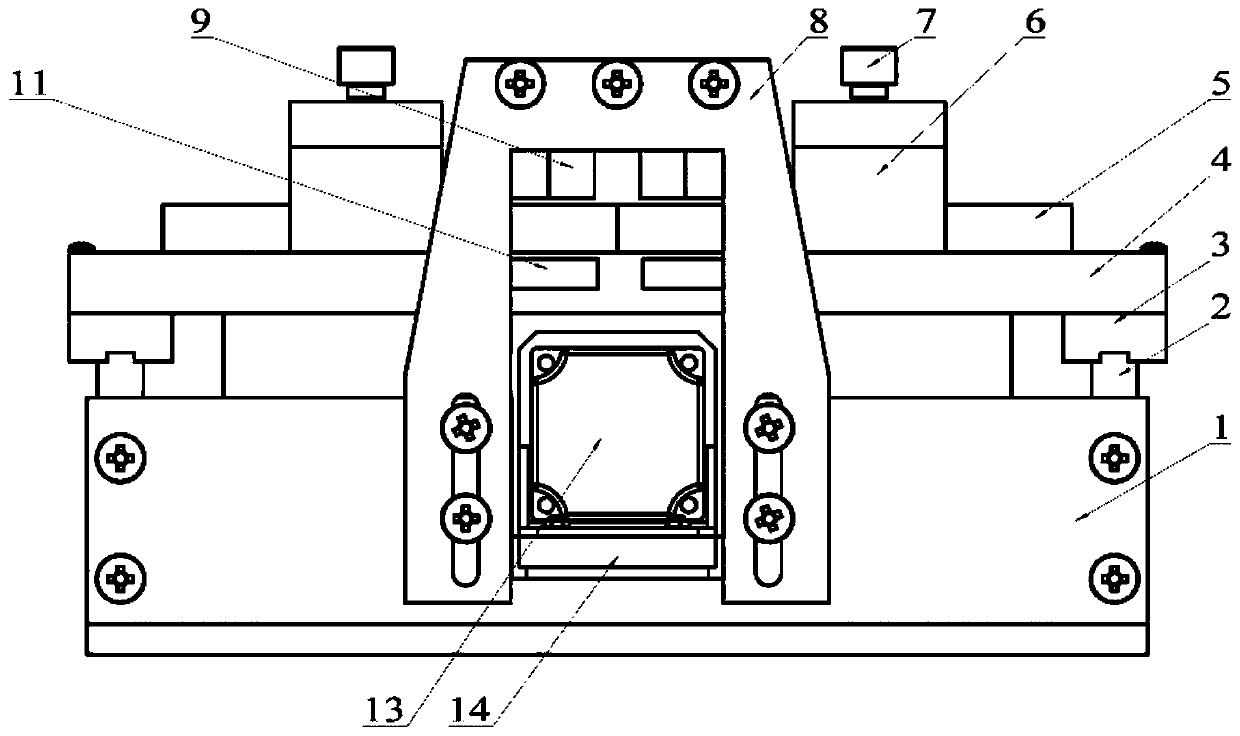

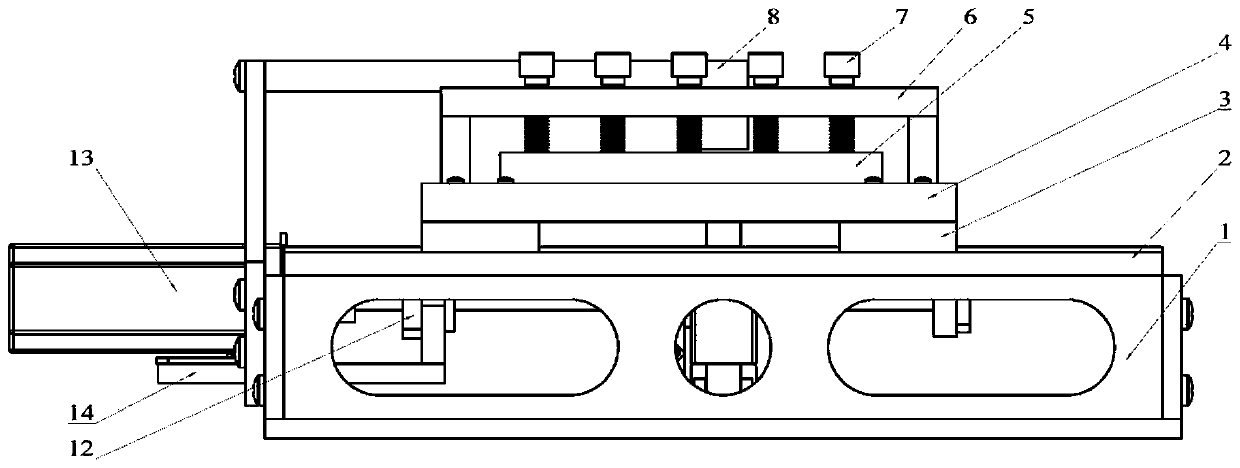

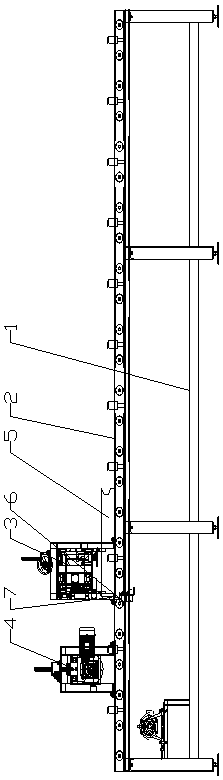

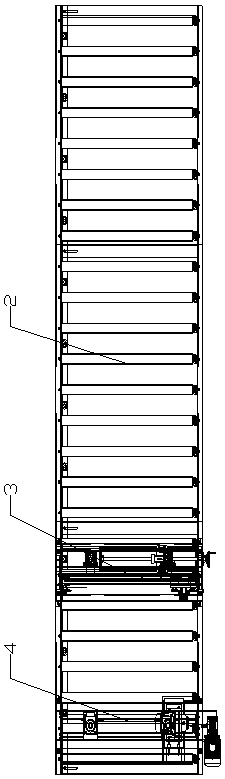

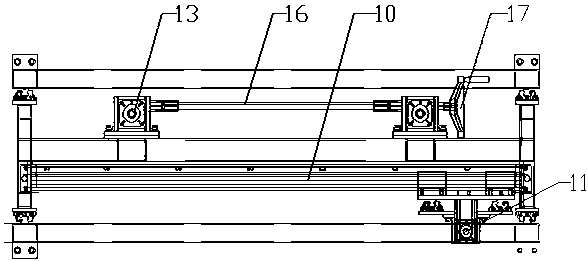

Laser welding experiment device capable of realizing magnetic field assisted molding

ActiveCN110576262AStrong penetrating powerPrevent leakageLaser beam welding apparatusWeld seamAndiron

Owner:SHANGHAI JIAO TONG UNIV

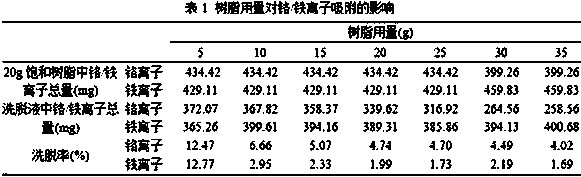

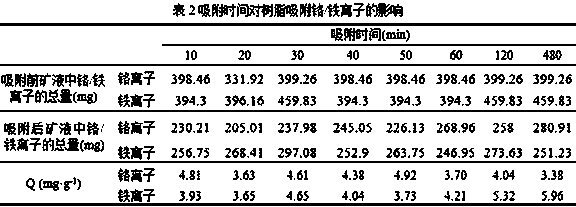

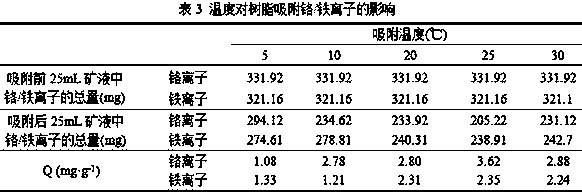

Method for adsorbing chromium and iron ions in industrial ferrochrome ore liquid through ion exchanging resin.

InactiveCN107828962ATo achieve the purpose of separating ferrochromium ionsImprove adsorption capacityProcess efficiency improvementLiquid wasteFerrochrome

The invention provides a method for adsorbing chromium and iron ions in industrial ferrochrome ore liquid through ion exchanging resin. 001x7 cation exchange resin is added into the industrial ferrochrome ore liquid, and constant temperature oscillation adsorption is performed at room temperature; centrifugal separation is performed after adsorption balance; and saturated resin uses an ammonium sulphate solution with the mass fraction being 5%-10% or water as eluant, constant temperature oscillation elution is performed at room temperature till balance is achieved, and the eluant is collected.An experiment shows that the method for adsorbing the chromium and iron ions in the industrial ferrochrome ore liquid through the ion exchanging resin can achieve high adsorption of the chromium andiron ions in the simulated industrial ferrochrome waste liquid, and a good elution effect is achieved. Thus, the method can be used for recycling of the chromium and iron ions in the industrial ferrochrome ore liquid.

Owner:LANZHOU CITY UNIV

Outdoor family barbecue grill convenient to use

The invention discloses an outdoor family barbeque grill convenient to use. The barbeque grill comprises a base, a grill body is welded to the upper end of the base, two clapboards are symmetrically and fixedly connected to the side walls of the two sides of the inner bottom of the grill body, and two supporting blocks are fixedly connected to each clapboard; two tracks are jointly supported at the portions, located at the upper edge of the same clapboard, on the two corresponding supporting blocks, andirons are jointly and slidably connected to the upper ends of the two tracks, and an iron wire net is fixedly installed at the bottom of each andiron; a door body is formed in the portion, corresponding to each andiron, of the side wall of the grill body and rotatably connected with the sidewall of the grill body, and a transmission mechanism is connected between the door body and the andirons. By means of the outdoor family barbeque grill, seasonings and tools required for barbeque areconveniently placed and classified, and are more hygienic and more convenient to take for use; the barbeque grill can avoid the situation that scaling is caused when charcoal is directly added from the portion above the andirons, is safer, and can control combustion of charcoal fire, the heat of the charcoal fire is more uniform, and the user experience is better; the outdoor family barbeque grill is convenient to clean and use next time.

Owner:广州和依德厨具有限公司

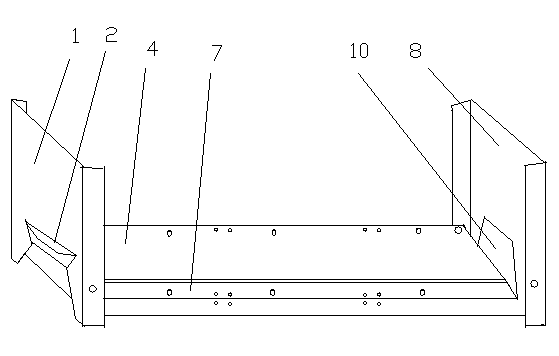

Plate burr removing device

ActiveCN108406484AAutomatic cleaningReduce labor intensityEdge grinding machinesGrinding feed controlPulp and paper industryComposite plate

Owner:山东万事达建筑钢品股份有限公司

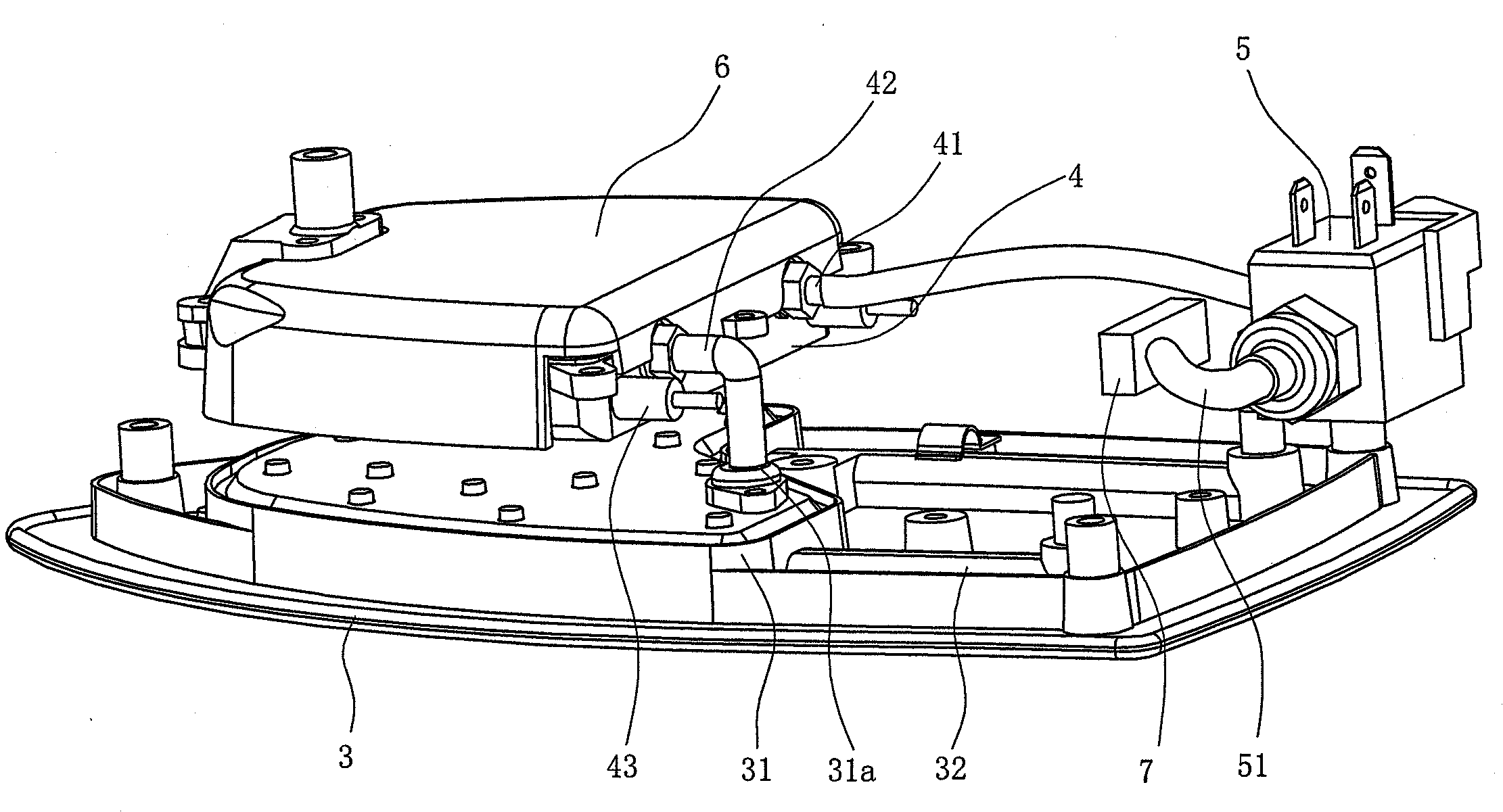

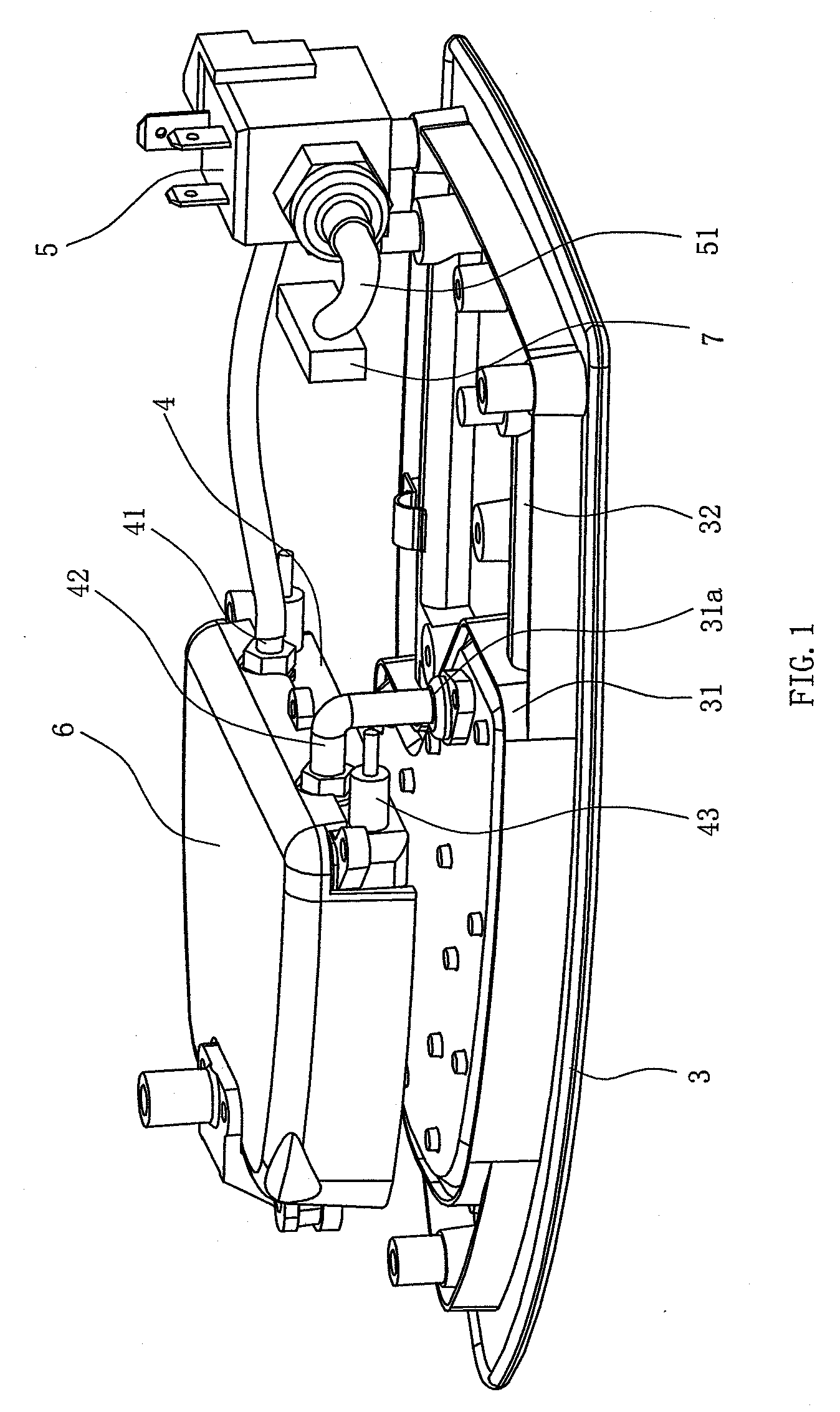

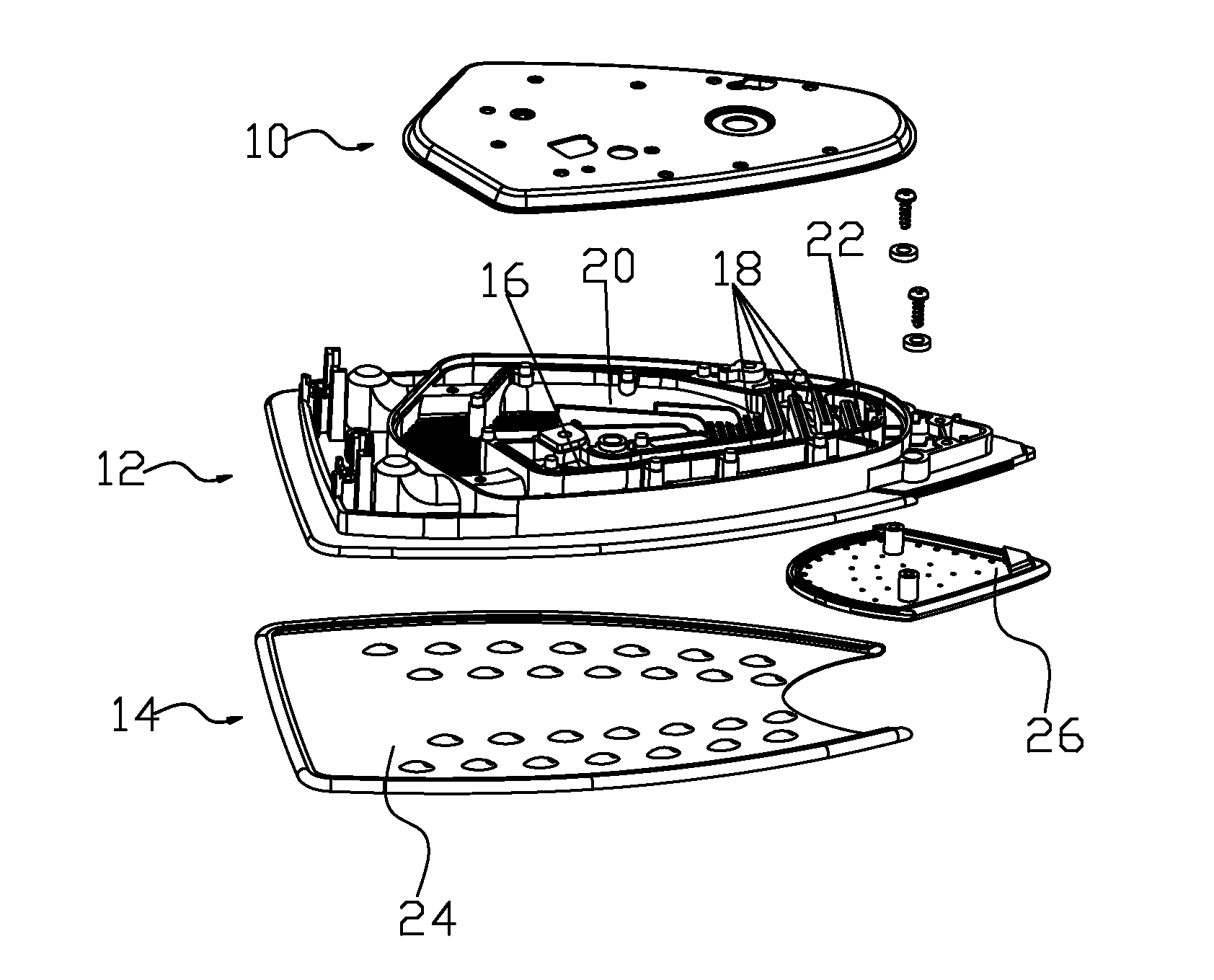

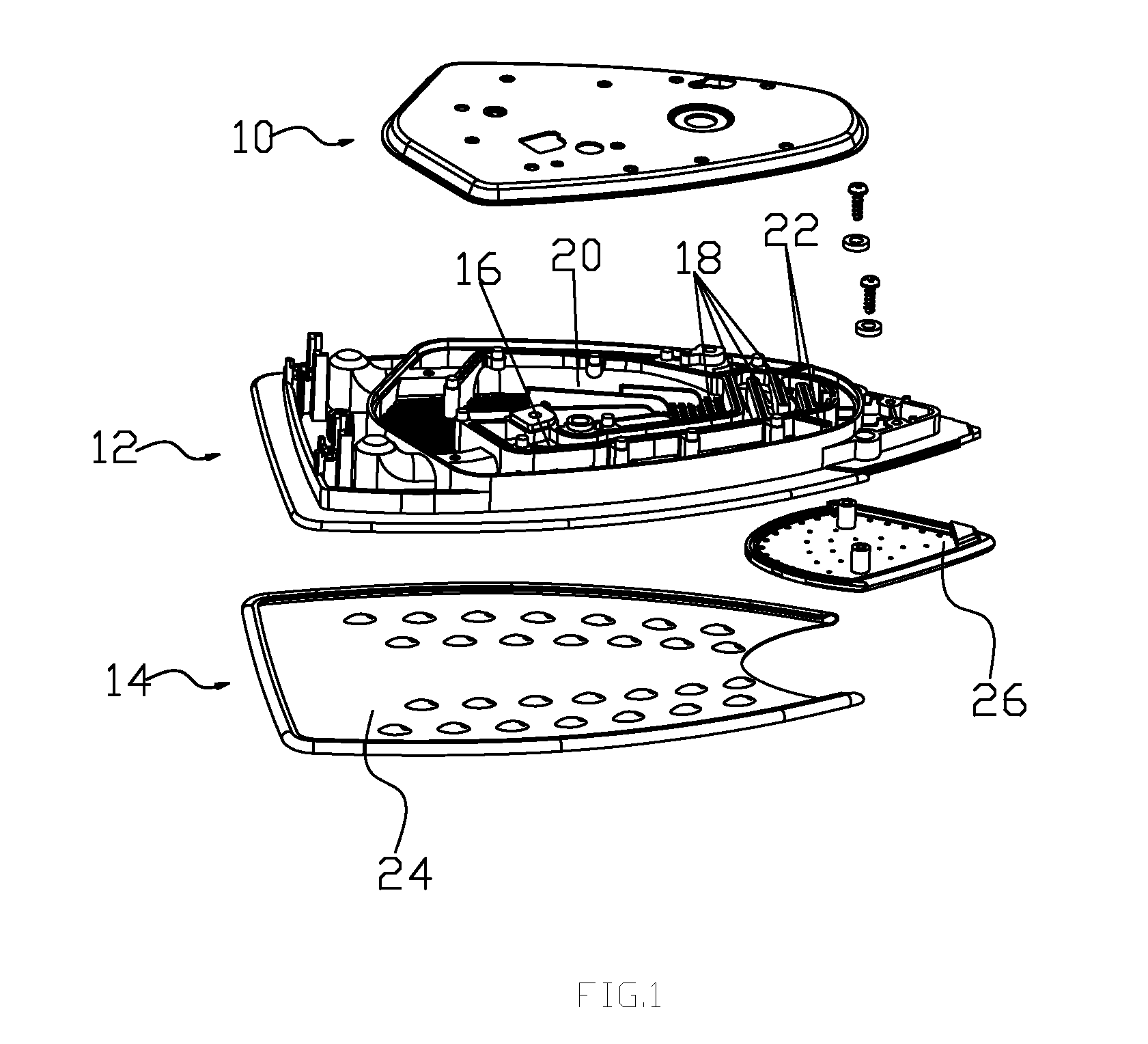

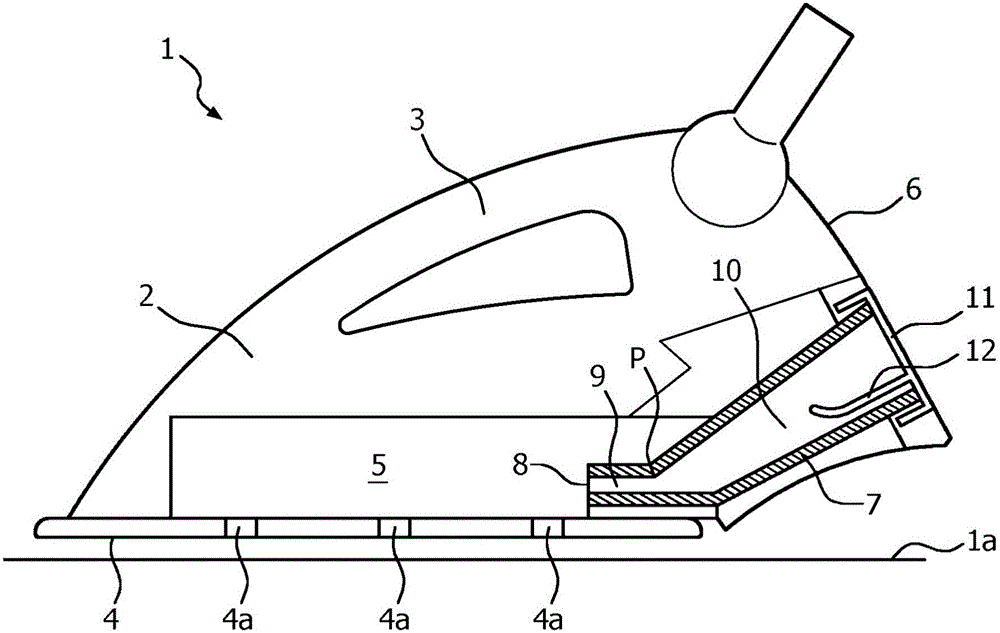

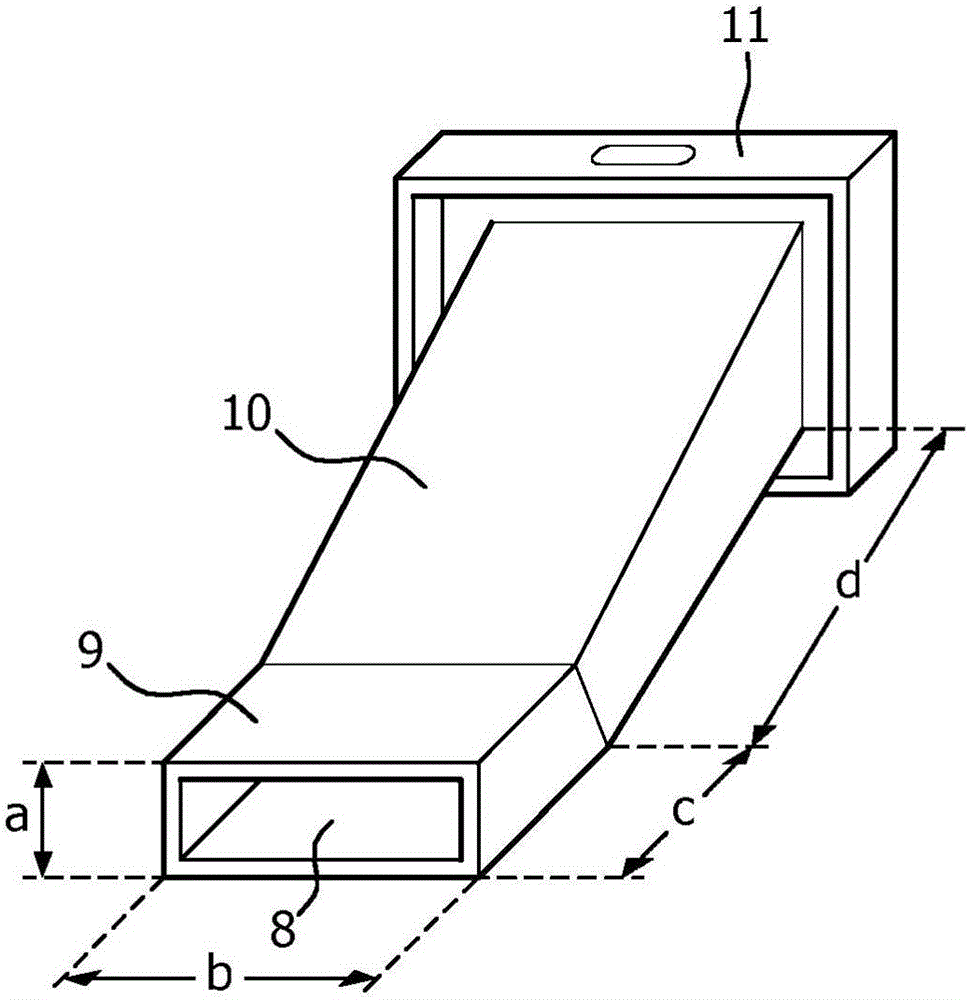

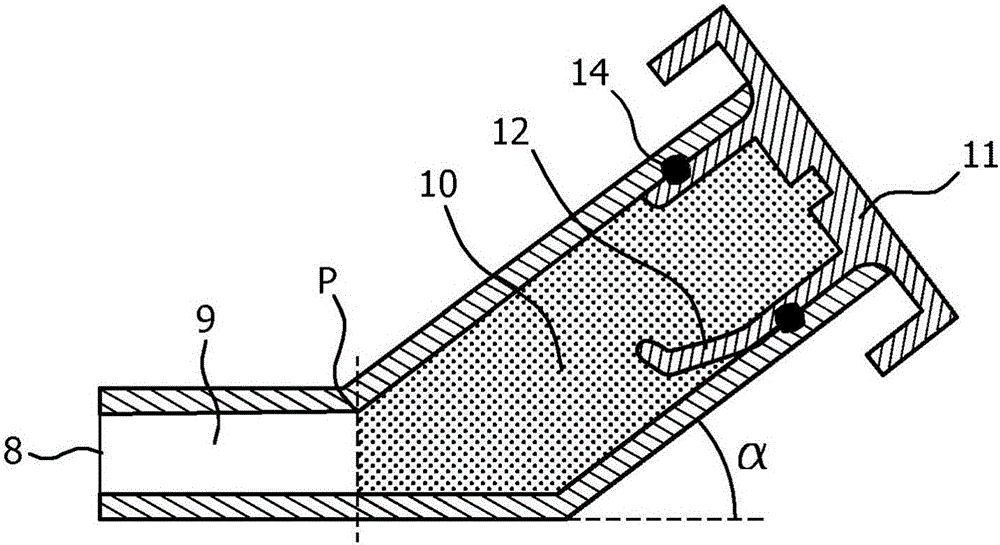

Iron

ActiveUS20110035973A1Improving blast strengthIncrease intensityHand ironTextiles and paperEngineeringAndiron

An iron comprising a water tank, a blast unit, a steam generating unit and a steam spraying unit. The blast unit has a first inlet and a first outlet, the first inlet is connected to the inlet-pipe of the inlet of the water tank, wherein the blast unit generates steam rapidly in a limited space. The steam generating unit has a second inlet and a second outlet, the second inlet being connected to the inlet-pipe of the inlet of the water tank, wherein the steam generating unit heats the water to generate steam. The steam spraying unit connects the first and second outlet, has plural steam apertures, and sprays steam. Because a blast unit is arranged for the rapid steam generation in a limited space, the iron of the present invention obviates the disadvantages in the existing irons and improves steam blast strength, intensity at a low cost.

Owner:TSANN KUEN CHINA ENTERPRISE

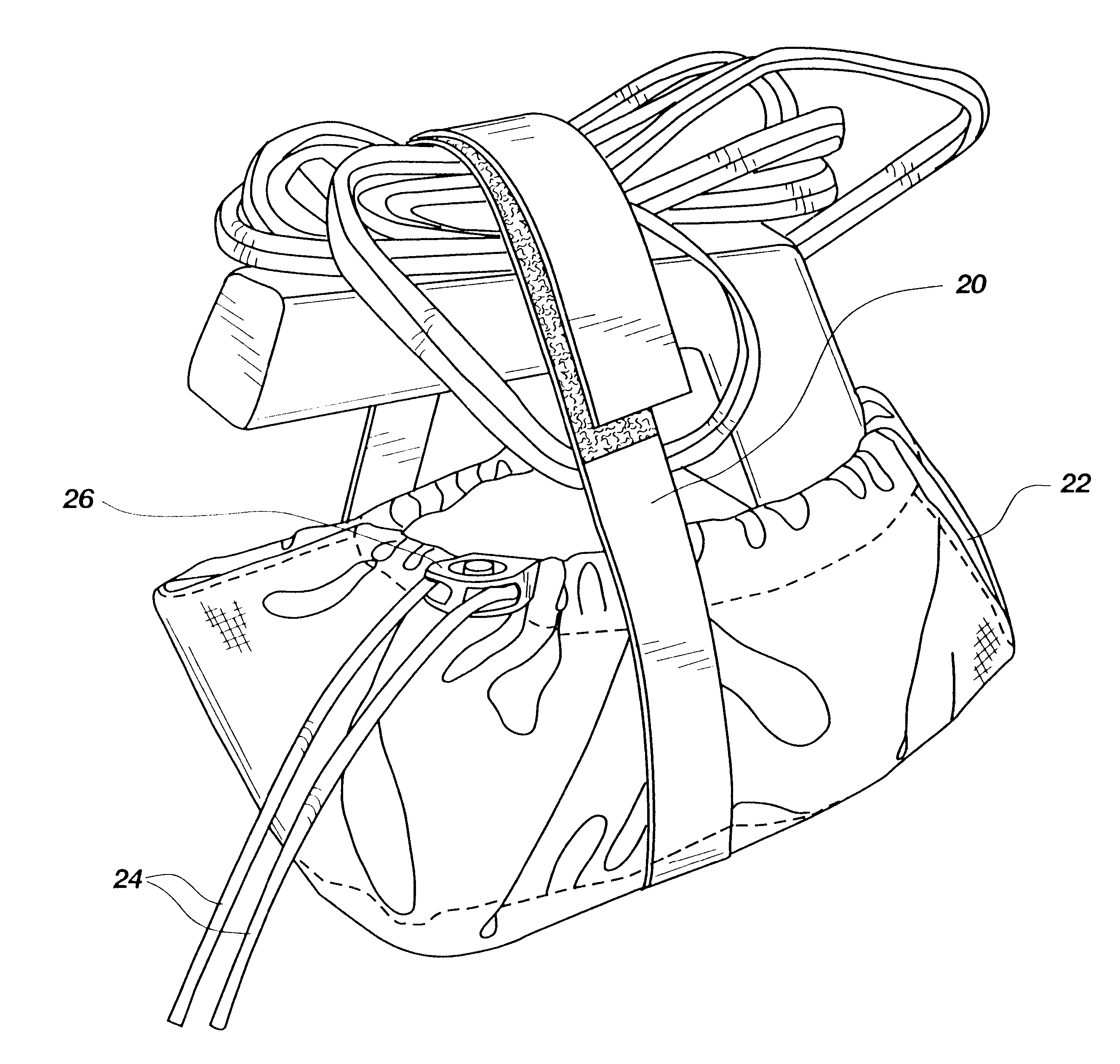

Iron cover

An iron cover for ski wax irons a heat resistant liner having a padded bottom segment shaped to cover and protect the sole of an iron and a plurality of side flaps with ends. The side flaps extend sufficiently around the sides of an iron placed within the liner, and are secured around the iron with an elastic cord associated with the side flaps. The side flaps are structured and separated to define a plurality of heat release vents to allow heat to escape from a hot iron placed in the cover for storage.

Owner:ORIGINALITY

Portable oven

The invention discloses a portable oven. The portable oven comprises a charcoal fire slot, a front hoarding, a rear hoarding, a left hoarding, a right hoarding and an andiron, wherein the front hoarding and the rear hoarding are symmetrically arranged in the forward and backward direction; the left hoarding and the right hoarding are symmetrically arranged in the left and right direction; the front hoarding and the rear hoarding are connected with the charcoal fire slot via hinges; and the left hoarding and the right hoarding are connected with the charcoal fire slot via a hinge shaft. The portable oven is simple in structure and convenient to use and carry, and the space occupied by the portable oven is only a quarter of the space occupied by a traditional oven; and a handle of the portable oven can serve as a common handle as well as can be used for sealing the andiron, so that the design is smart. After being folded, the portable oven is box-shaped so that the andiron does not slip out from the charcoal fire slot when the oven is vertically placed because the charcoal fire slot is sealed by the handle and the handle is in self-locked state.

Owner:玉田县天一户外金属制品有限公司

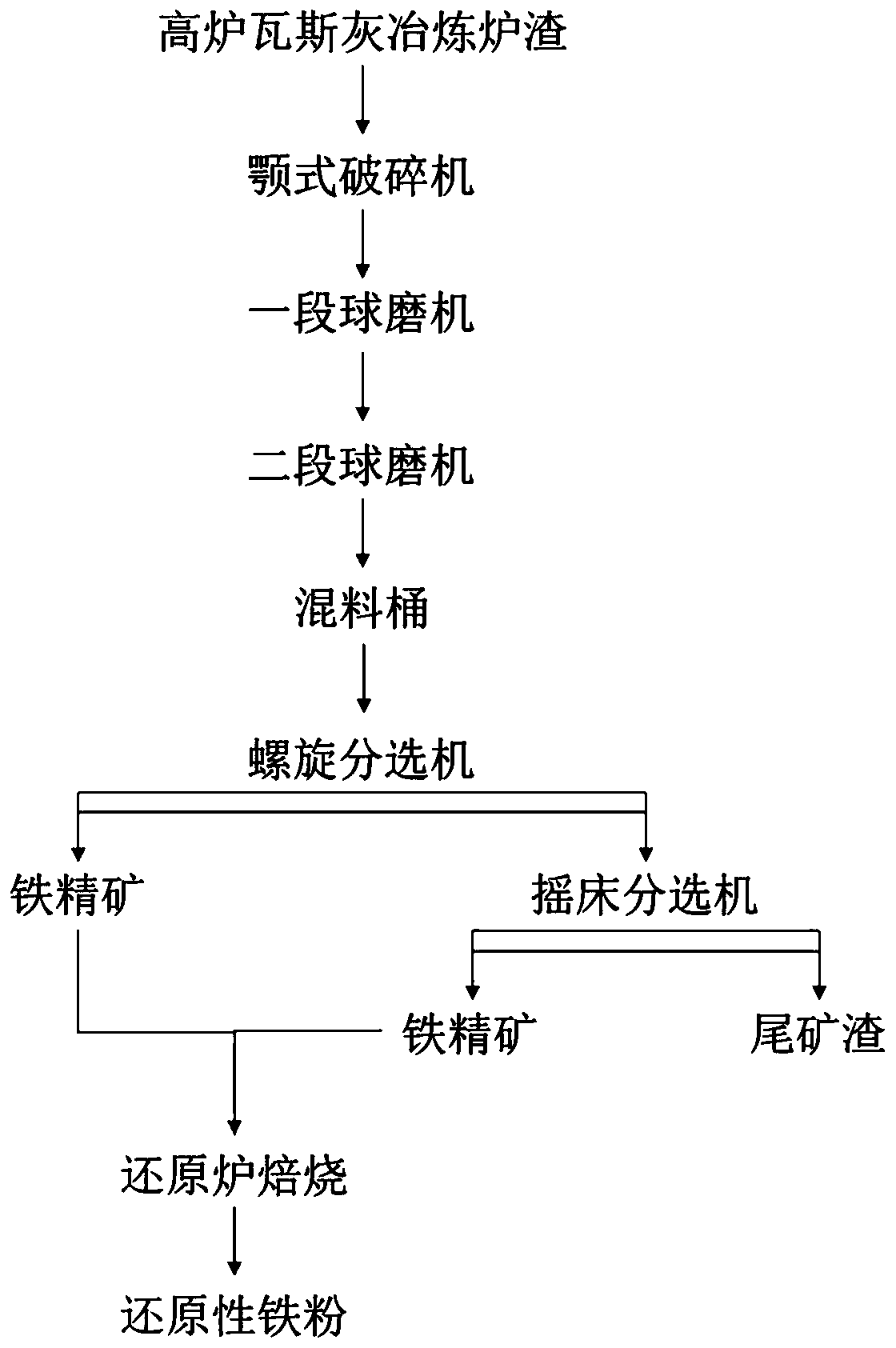

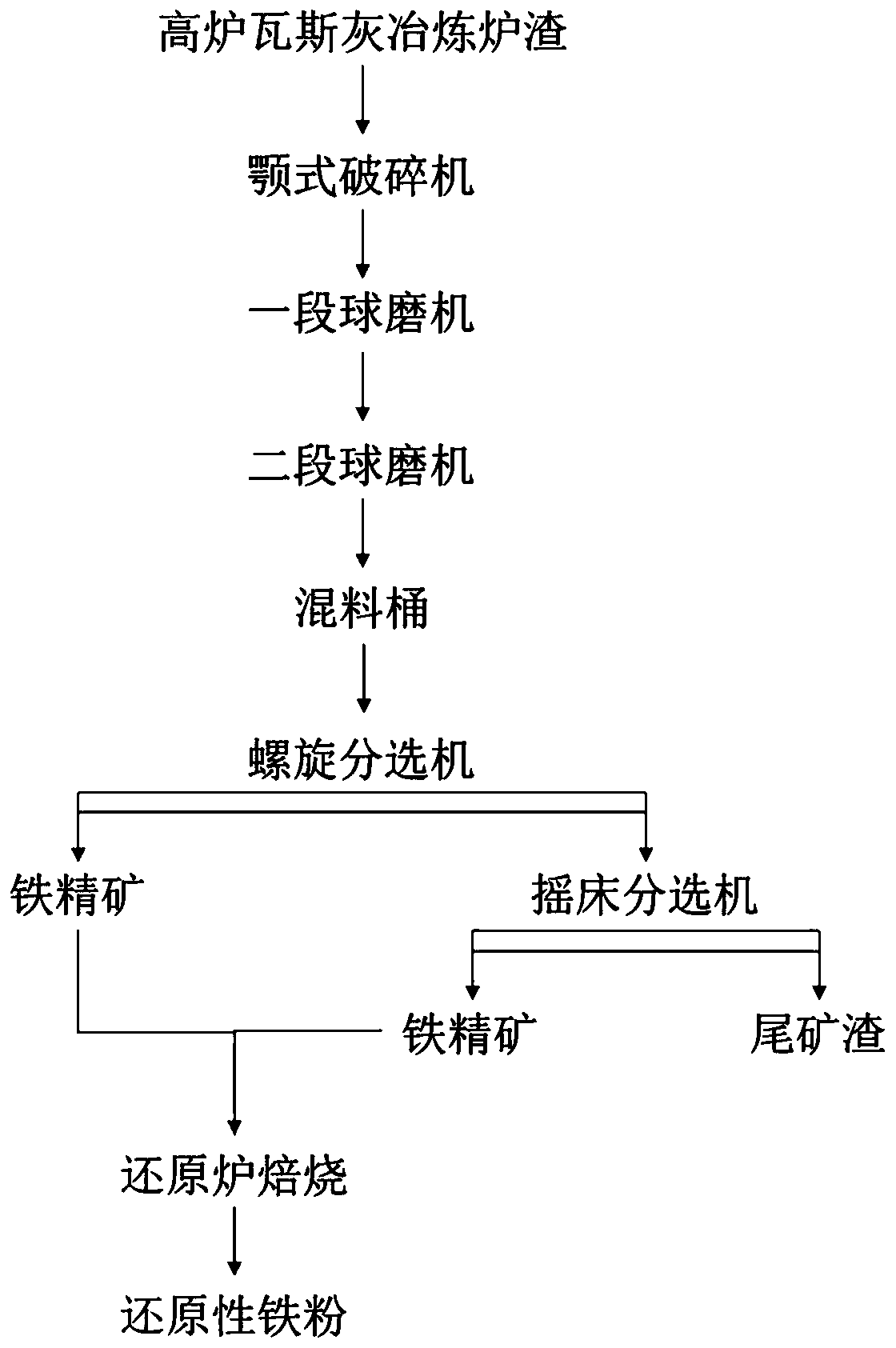

Method for preparing reduced iron powder through blast furnace gas dust smelting furnace slag

ActiveCN110039064AEfficient recyclingEasy to separateProcess efficiency improvementWet separationSlagSlurry

The invention relates to a method for preparing reduced iron powder through blast furnace gas dust smelting furnace slag. The method comprises the steps that the blast furnace gas dust smelting furnace slag is sequentially crushed and ball-milled; water is added to a material obtained after ball milling for size mixing, then slurry is put in a spiral sorting machine for sorting, and iron ore concentrate and tailings are obtained; the tailings flow out from the tangent line of the bottom spiral outer edge of the spiral sorting machine and directly enter a table sorting machine for sorting, andiron ore concentrate and tailings are obtained; and iron ore concentrates obtained at different sorting stages are mixed and then subjected to reduction roasting, and the reduced iron powder is obtained. The blast furnace gas dust smelting furnace slag is crushed and ball-milled at first, small particles are obtained, iron and carbon are completely separated, then sorting and recycling are conducted through the synergistic effect of the spiral sorting machine and a table, and finally the reduced iron powder product with the grade being 98% or above is obtained, iron elements in the blast furnace gas dust smelting furnace slag is efficiently recovered, and the method has good economic benefits and application prospects.

Owner:唐山鑫联环保科技有限公司

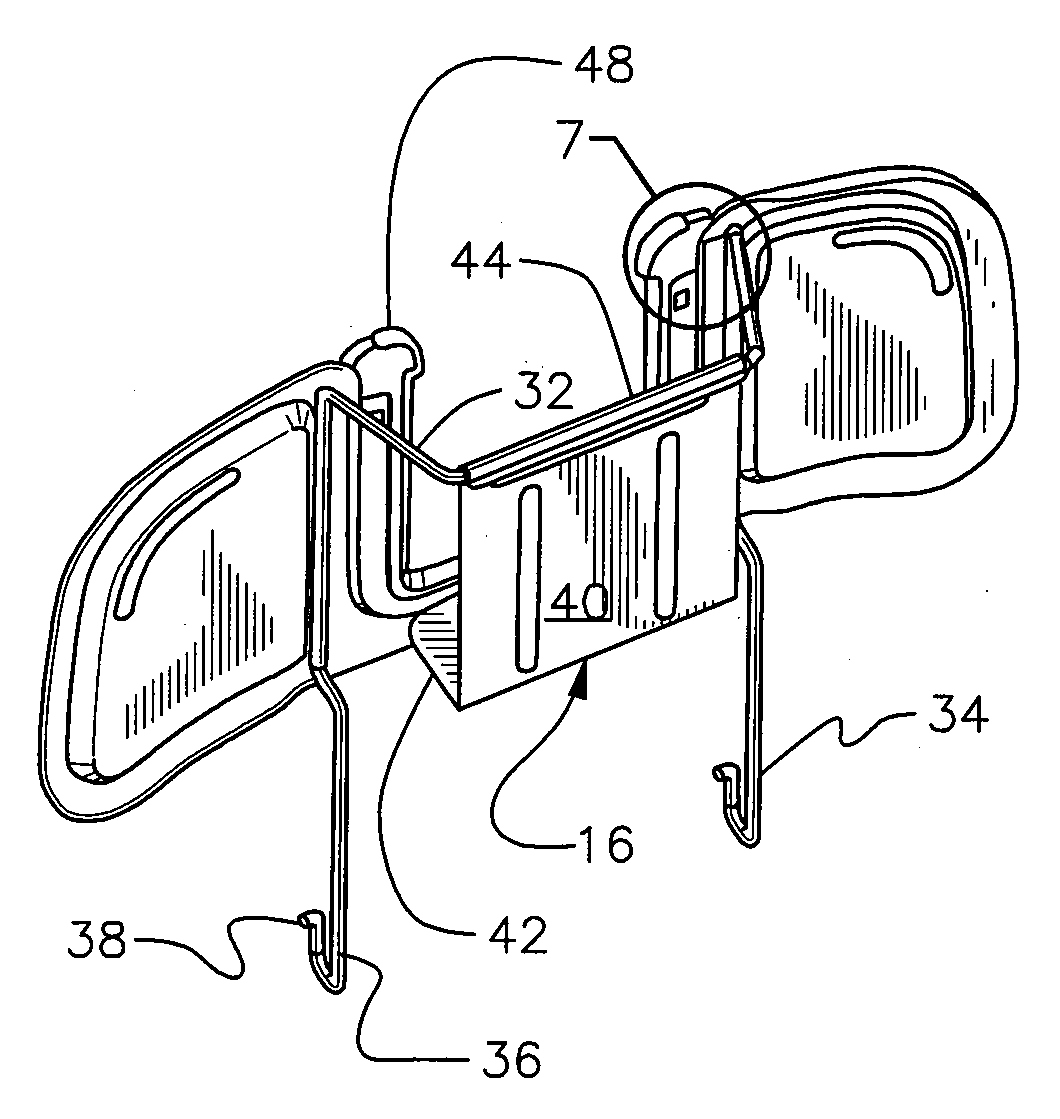

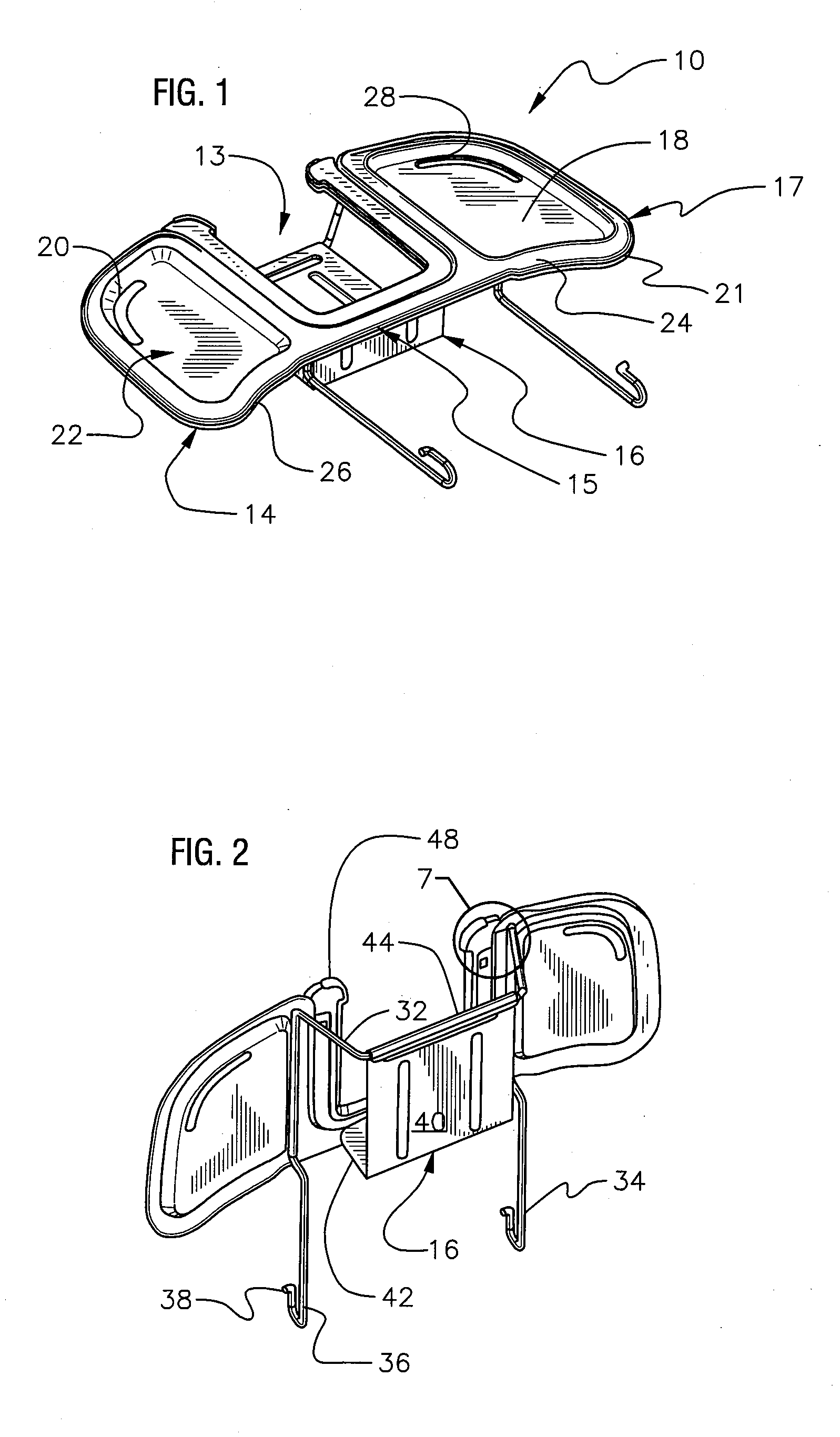

Iron rest

An iron rest assembly removably attachable to an ironing board is provided. The iron rest includes a pair of support areas with a recess area therebetween, a basket suspended below the recess area for storing an iron, and a pair of bars extending away from a back end of the iron rest assembly. The pair of bars serves to attach the iron rest assembly to the ironing board.

Owner:HOME PROD INT NORTH AMERICA INC

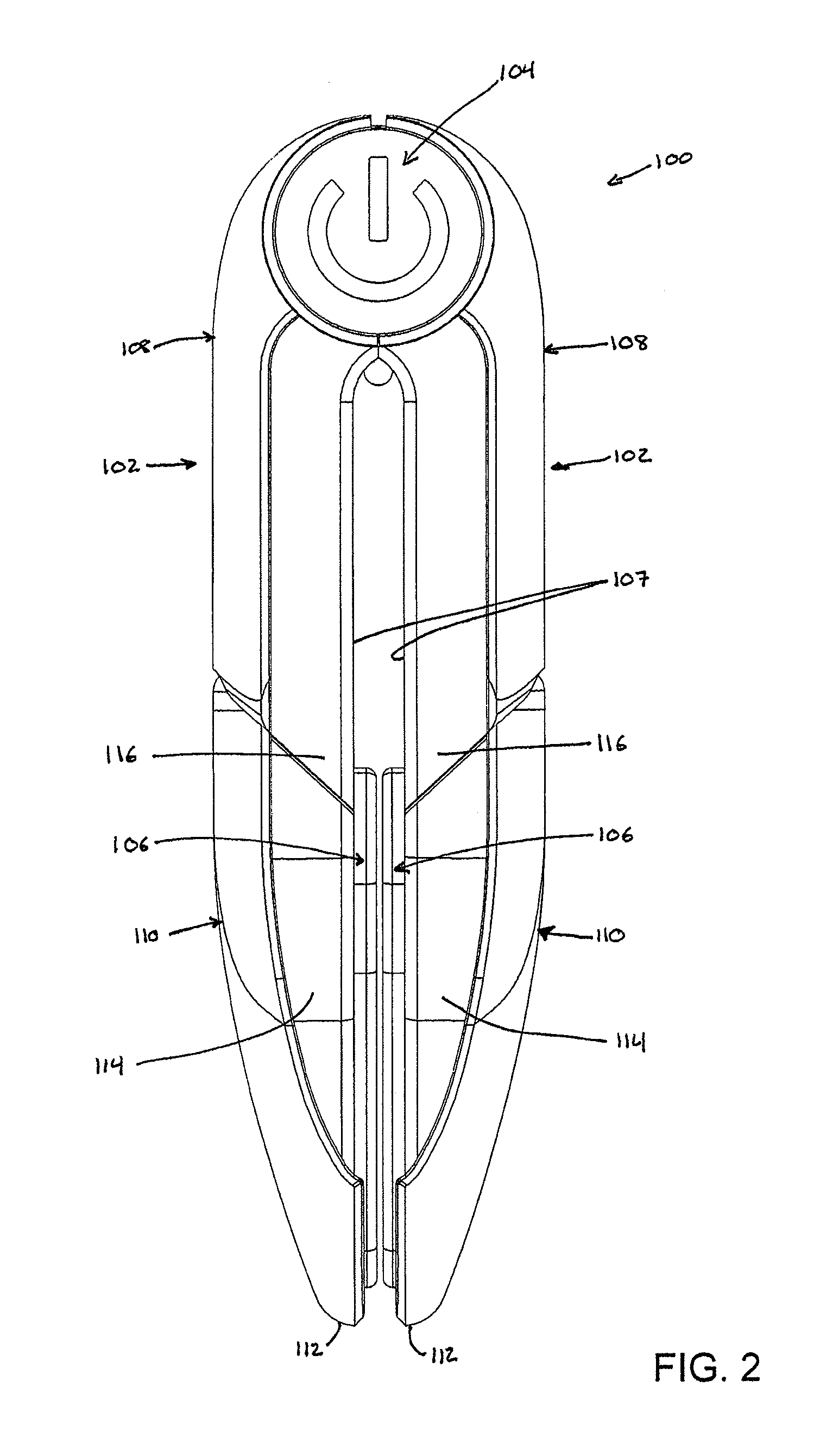

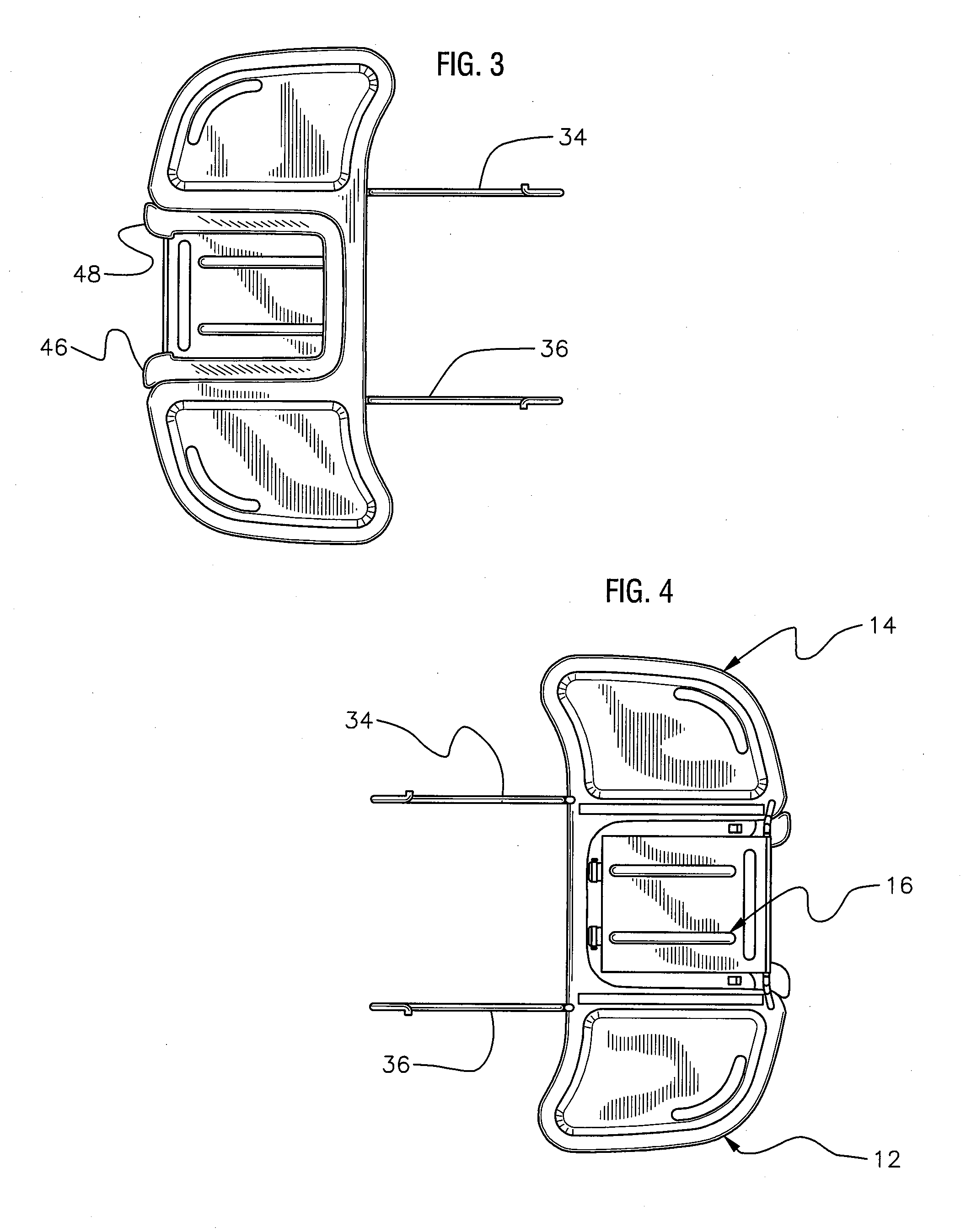

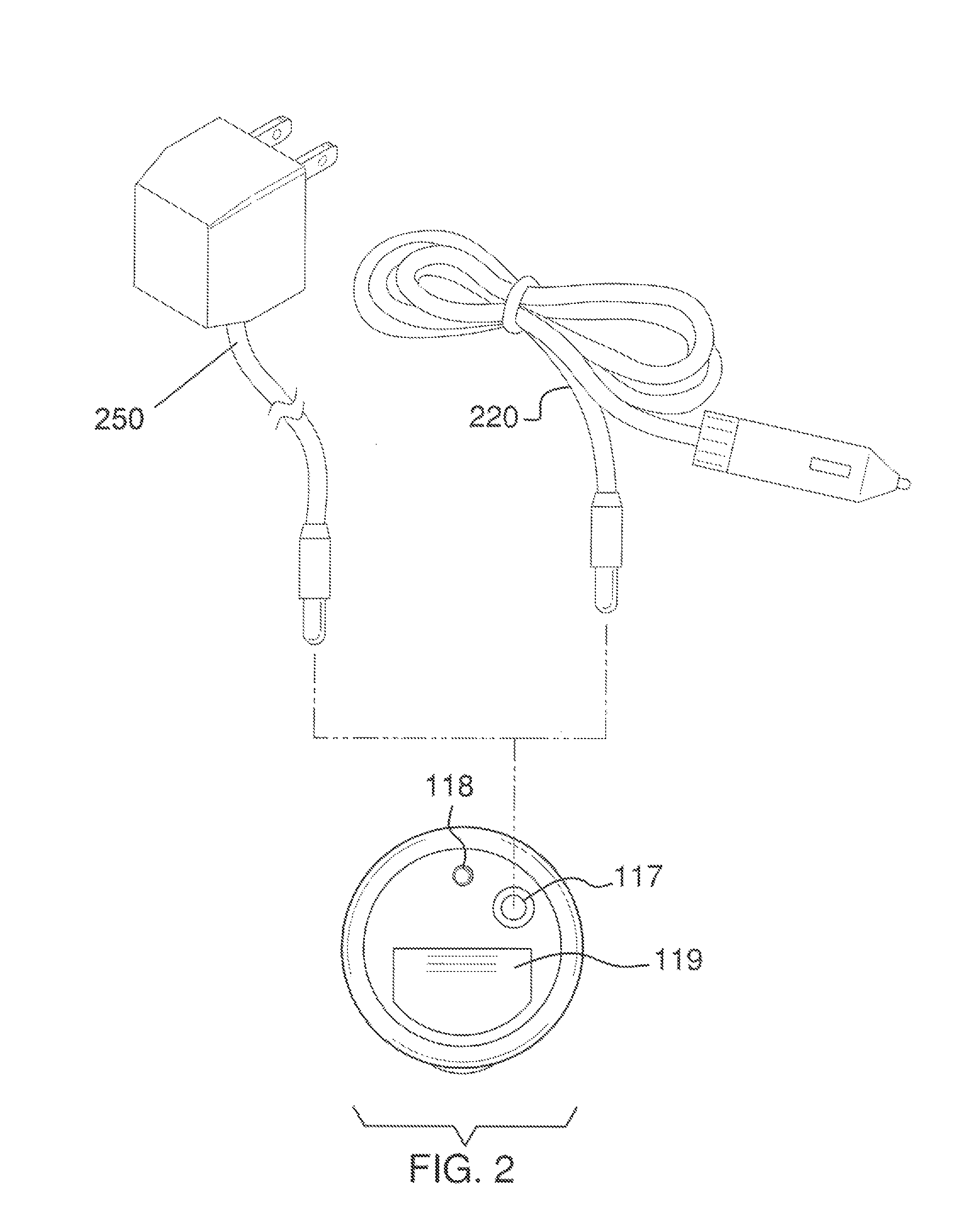

Portable branding iron

The present invention features a portable branding iron system. The system includes a handle with a handle connector, a built-in rechargeable battery, a heating coil, and a controller. A backing plate is removably connected to the handle via a threaded rod. A patterned metal, such as raised letters or logo, and an optional rotatory numbers are removably disposed on the backing plate. A power switch is disposed on the handle to turn ON or OFF the branding iron. A heat sensor is disposed on the handle connector and sends the temperature signal to the controller to power on one of a plurality of a temperature indicator LEDs.

Owner:LEVY JERONE +1

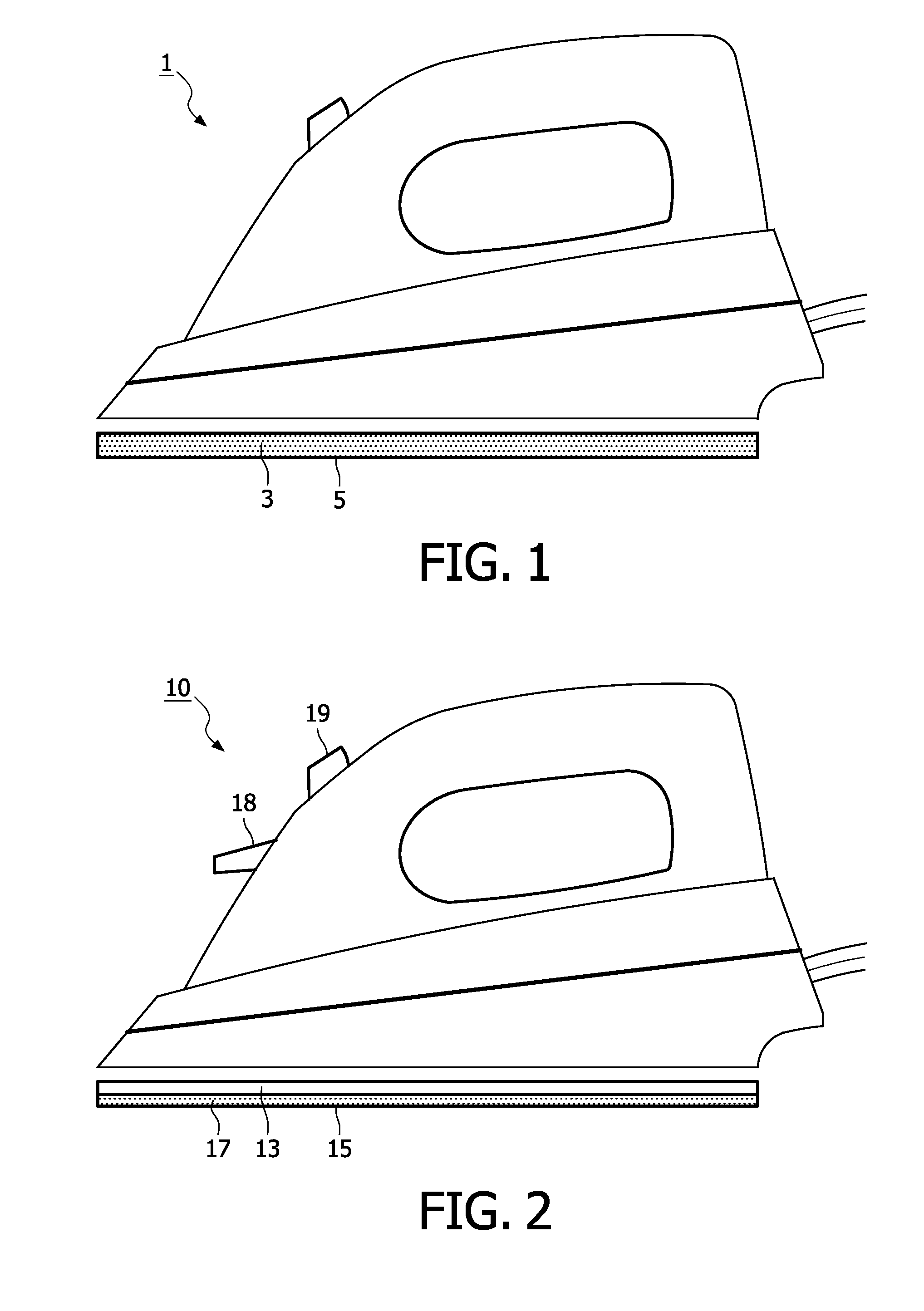

Soleplate for an iron

InactiveUS20100107457A1Easy transferIncrease resistanceHand ironTextiles and paperEngineeringAntibacterial agent

The invention relates to an iron (1) comprising a soleplate (3) having a garment-contact surface (5) and having a means for accommodating an antimicrobial agent. By contacting the garment-contact surface with the piece of garment, as is being done during ironing, the antibacterial agent is transferred to the garment. The antimicrobial agent is disposed on the garment by simply placing the iron on the garment and moving it over the garment surface. The garment stays fresher for a longer period of time. The invention further relates to a soleplate, a steam ironing device and methods of manufacturing an iron and a soleplate, respectively.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Steam iron

ActiveCN105874117APrevent flow backAvoid flowHand ironTextiles and paperEngineeringAtmospheric pressure

The present application relates to a steam iron comprising a steam generator and a sealed chamber having an inlet positioned so that calcified deposits formed in the steam generator fall under the influence of gravity through said inlet and into the chamber when the iron is moved from an ironing position into a non-ironing position. The chamber includes an inlet conduit that extends from the inlet and leads into a collection reservoir. The inlet conduit is configured so that water which flows from the steam generator into the collection reservoir through the inlet conduit when the iron is placed in said non-ironing position is trapped in the chamber when the iron is moved back into said ironing position. This occurs due to a balance of pressures between water in the collection reservoir, which acts against water that fills the inlet conduit, and atmospheric pressure that acts against water that fills the inlet conduit across the inlet.

Owner:KONINKLJIJKE PHILIPS NV

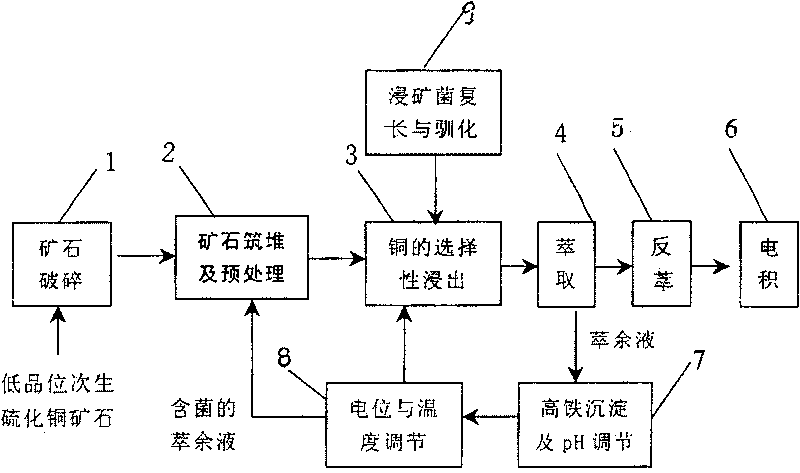

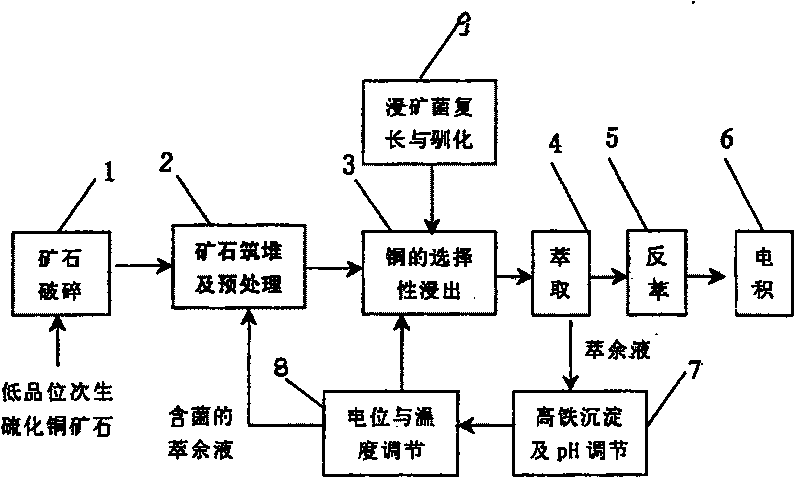

Pyrite selectivity inhibition technique for secondary copper sulfide mineral biological lixiviation process

ActiveCN101191153BControl total iron concentrationMicroorganismsProcess efficiency improvementThiobacillus ferrooxidansAndiron

The invention relates to a pyrite selective inhabitation technique for biological leaching process of secondary copper sulphide ores, wherein, a biological leaching system with low PH value and low electric potential is reached by utilization of leaching bacteria containing Thiobacillus ferrooxidans Retech III (T.F.R.III leaching bacteria for short) (has been collected in China Center for Type Culture Collection (in Wuhan University) and has a collection registration number of CCTCC No:M200033) and adoption of two spraying methods of phased intermission and continuity and reasonable matching of bacterial activity, PH value and other conditions, and high efficiency selective leaching of the copper sulphide ores is realized. Moreover, pyrites are inhibited effectively and yield of acids andirons is reduced. After extraction of qualified lixivium after leaching, aqueous phase goes back for heap leaching, and organic phase enters into stripping procedure for treatment. The invention has the advantages of short technological flow, simple equipment, low cost, no pollution, high recovery rate, capability of processing low-grade secondary copper sulphide ore resources which are difficultto process by the prior mineral smelting technique, and improvement of comprehensive utilization rate of copper resources.

Owner:有研资源环境技术研究院(北京)有限公司

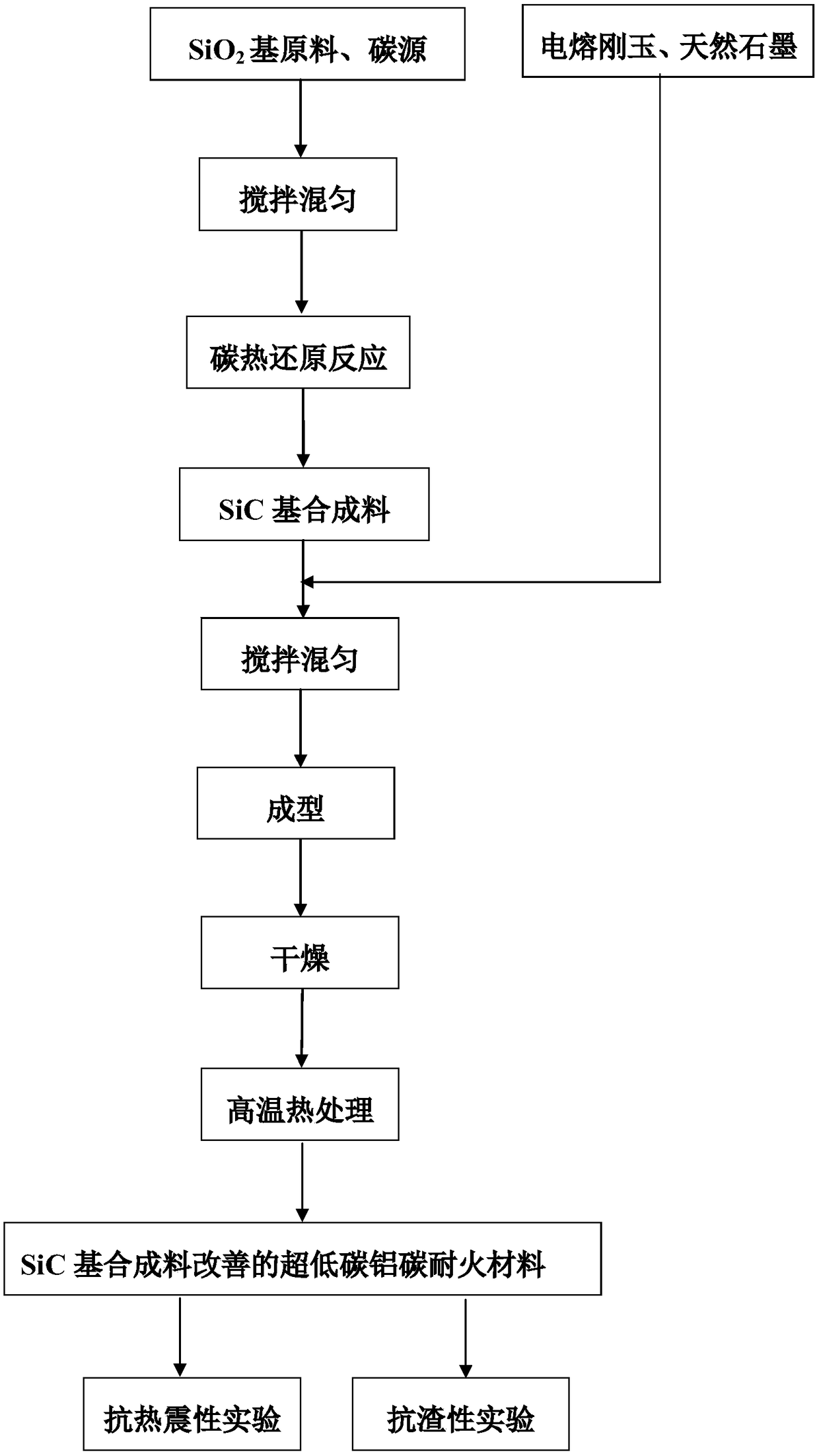

Preparation and detection method of ultralow carbon aluminum carbon fireproof material

InactiveCN109206144AReduce carbon contentImprove thermal shock resistanceMaterial analysis using wave/particle radiationMaterial heat developmentSlagAndiron

The invention relates to a preparation and detection method of an ultralow-carbon aluminum carbon fireproof material, and belongs to the technical field of fireproof material preparation for steel andiron metallurgy. SiO2-based natural ore or waste slag and a carbon source are sufficiently and uniformly mixed and are put into a high-temperature furnace for preparing a SiC-based synthesis materialin inert or reduction atmosphere; then, according to a certain proportional ratio, the SiC-based synthesis material is added into the ultralow-carbon aluminum carbon fireproof material raw materialsto be sufficiently mixed; after the shaping, drying and high-temperature heat treatment, the ultralow-carbon aluminum carbon fireproof material with the improved silicon carbide base synthesis material is obtained; finally, heat shock resistant performance and slag resistant performance experiments are performed by using a heat shock test furnace and a static crucible method. The method has the advantages that on the premise of reducing the carbon content of the aluminum carbon fireproof material, the heat shock resistant performance and the slag resistant performance are improved; the qualityrequirement of the steel and iron metallurgy process on relevant fireproof material components can be reached; the process is simple and convenient; the implementation is easy; the raw materials arecheap and can be easily obtained; the mass production can be easily realized; good economic benefits and environment-friendly benefits are realized.

Owner:苏州佳耐材料科技有限公司

Iron

An iron comprising a water tank, a blast unit, a steam generating unit and a steam spraying unit. The blast unit has a first inlet and a first outlet, the first inlet is connected to the inlet-pipe of the inlet of the water tank, wherein the blast unit generates steam rapidly in a limited space. The steam generating unit has a second inlet and a second outlet, the second inlet being connected to the inlet-pipe of the inlet of the water tank, wherein the steam generating unit heats the water to generate steam. The steam spraying unit connects the first and second outlet, has plural steam apertures, and sprays steam. Because a blast unit is arranged for the rapid steam generation in a limited space, the iron of the present invention obviates the disadvantages in the existing irons and improves steam blast strength, intensity at a low cost.

Owner:TSANN KUEN CHINA ENTERPRISE

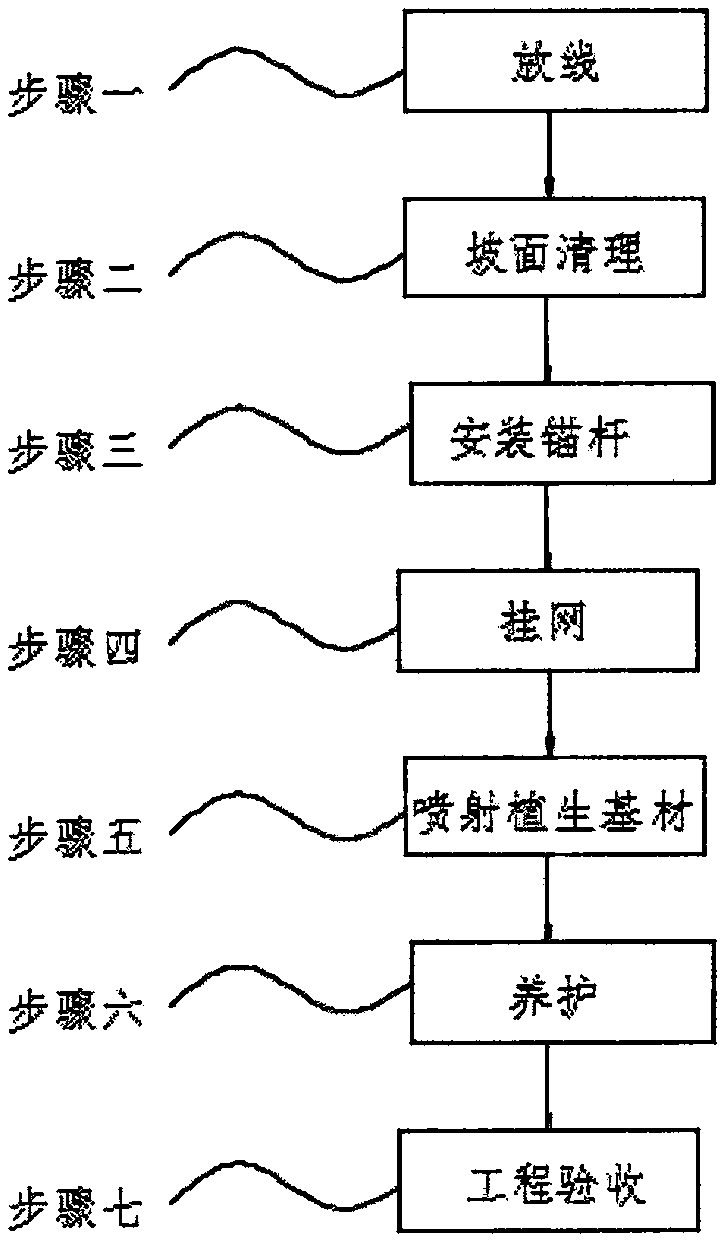

Construction method for sowing grass planting by spraying on side slopes in high-altitude areas

The invention discloses a construction method for sowing grass planting by spraying on side slopes in high-altitude areas. The construction method comprises the following steps of (1) paying off; (2)clearing slope surfaces; (3) installing anchor rods; (4) hanging nets; (5) spraying a plant growing medium; (6) curing; (7) accepting project. The construction method disclosed by the invention has the beneficial effects that by vegetation spray-sowing on the side slopes, the phenomena of washout of rainwater on the side slopes and water and soil loss are effectively prevented; due to formed near-earth microclimate, the driving environment of expressways is effectively improved, and the acceleration of the greening and beautifying processes of the environment in surrounding areas can be promoted; the mechanical degree is high, and the construction speed is fast; by stirring and spraying of a spray-sowing machine on materials such as soil, organic fertilizer, water-retaining agents, adhesives, water and the like, the uniformity of grass seeds is high, and after combination with the soil, the compact effect is achieved; after grass grows out, the coverage rate is high, and the grass andiron-wire meshes on the slope surfaces form a whole, so that the resistance to rainwater washout is greatly improved.

Owner:青海生源园林绿化工程有限公司

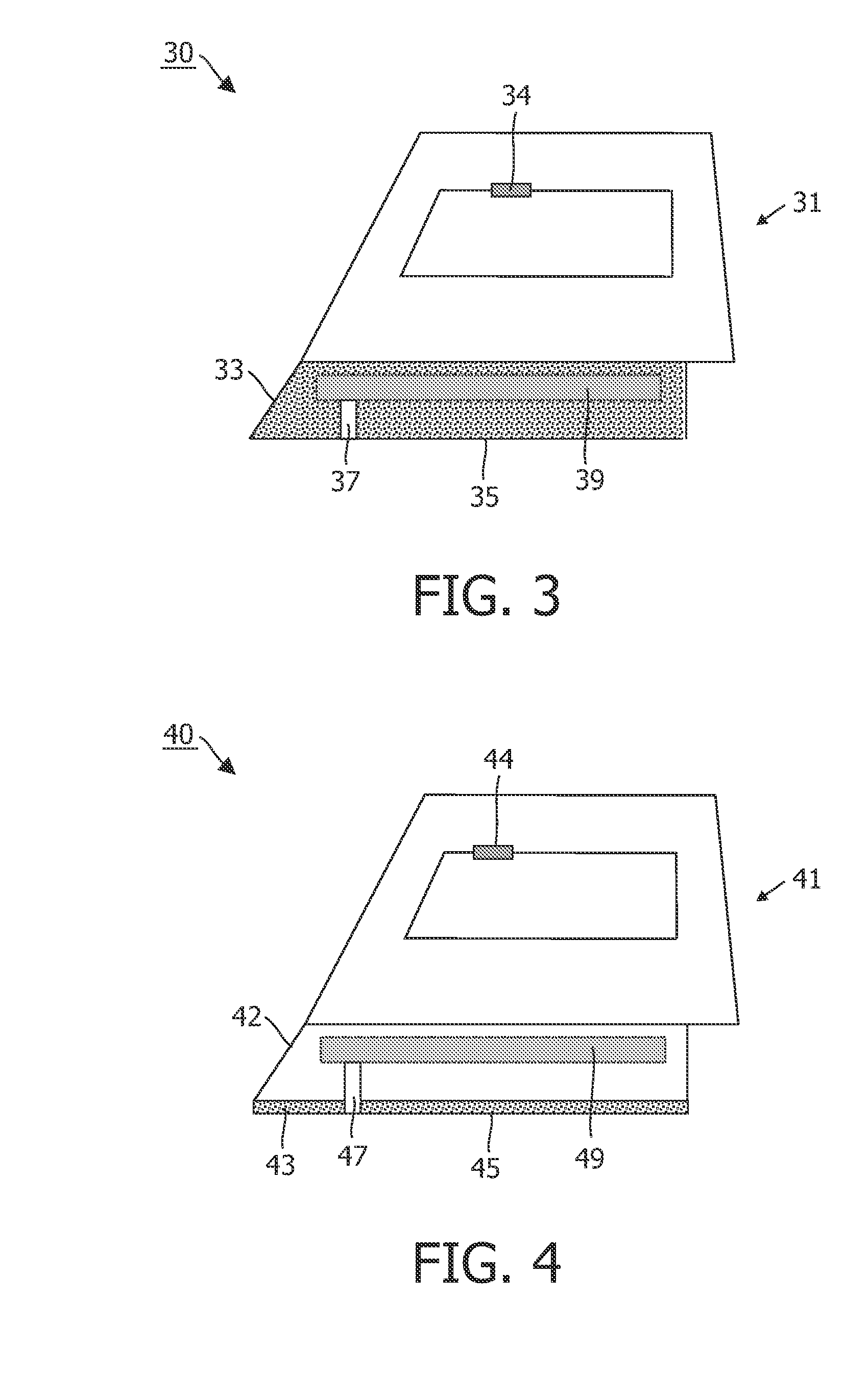

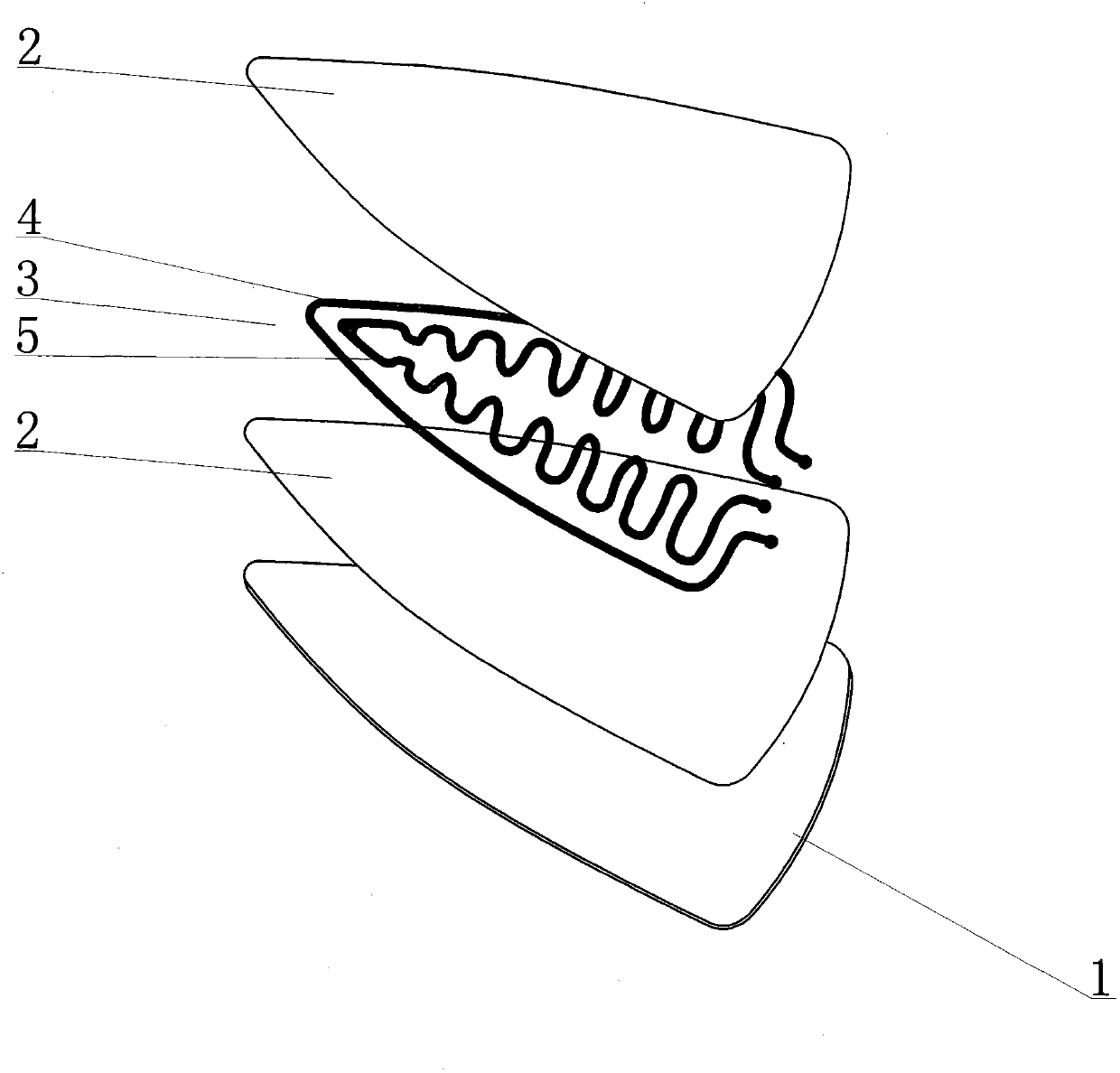

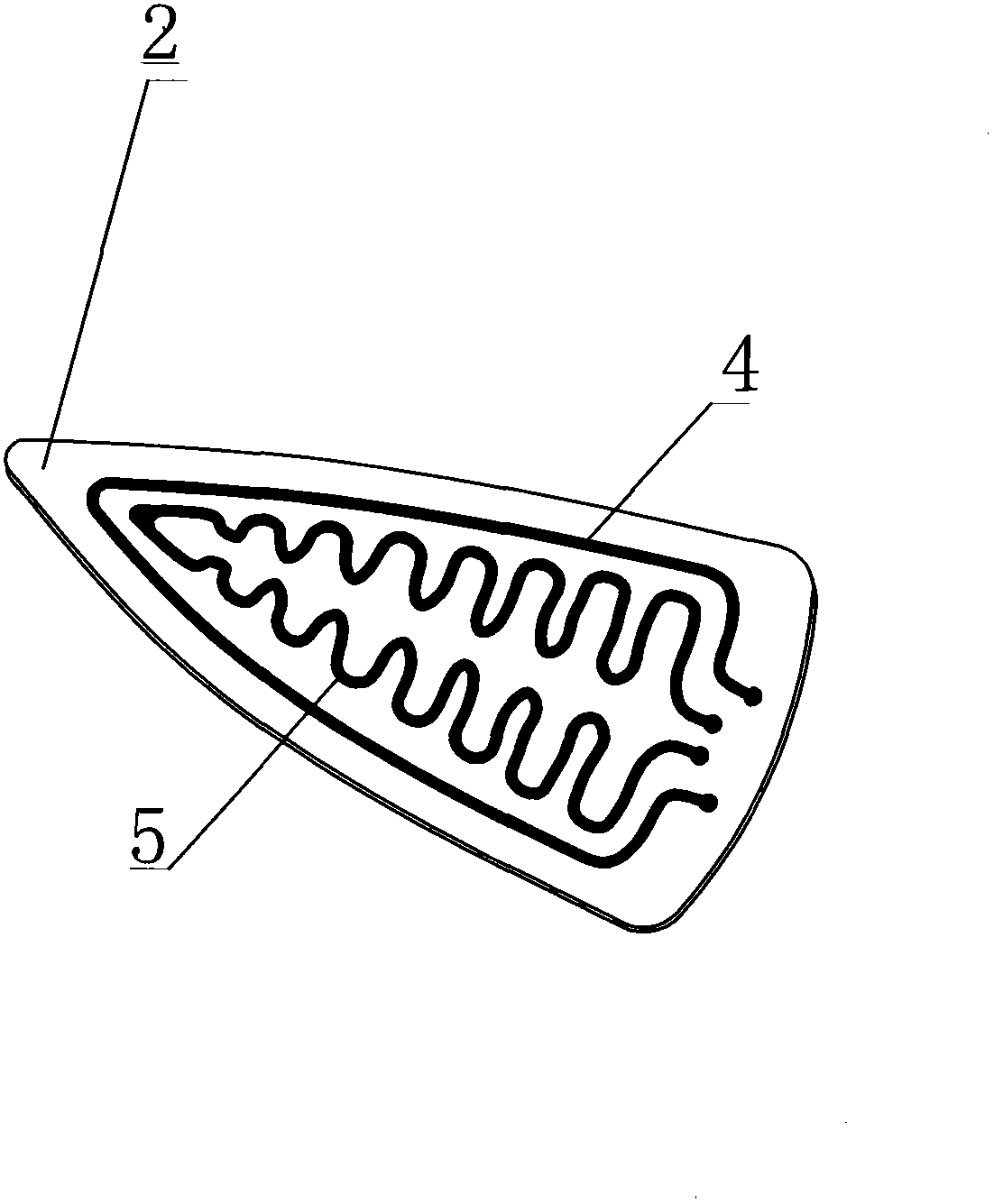

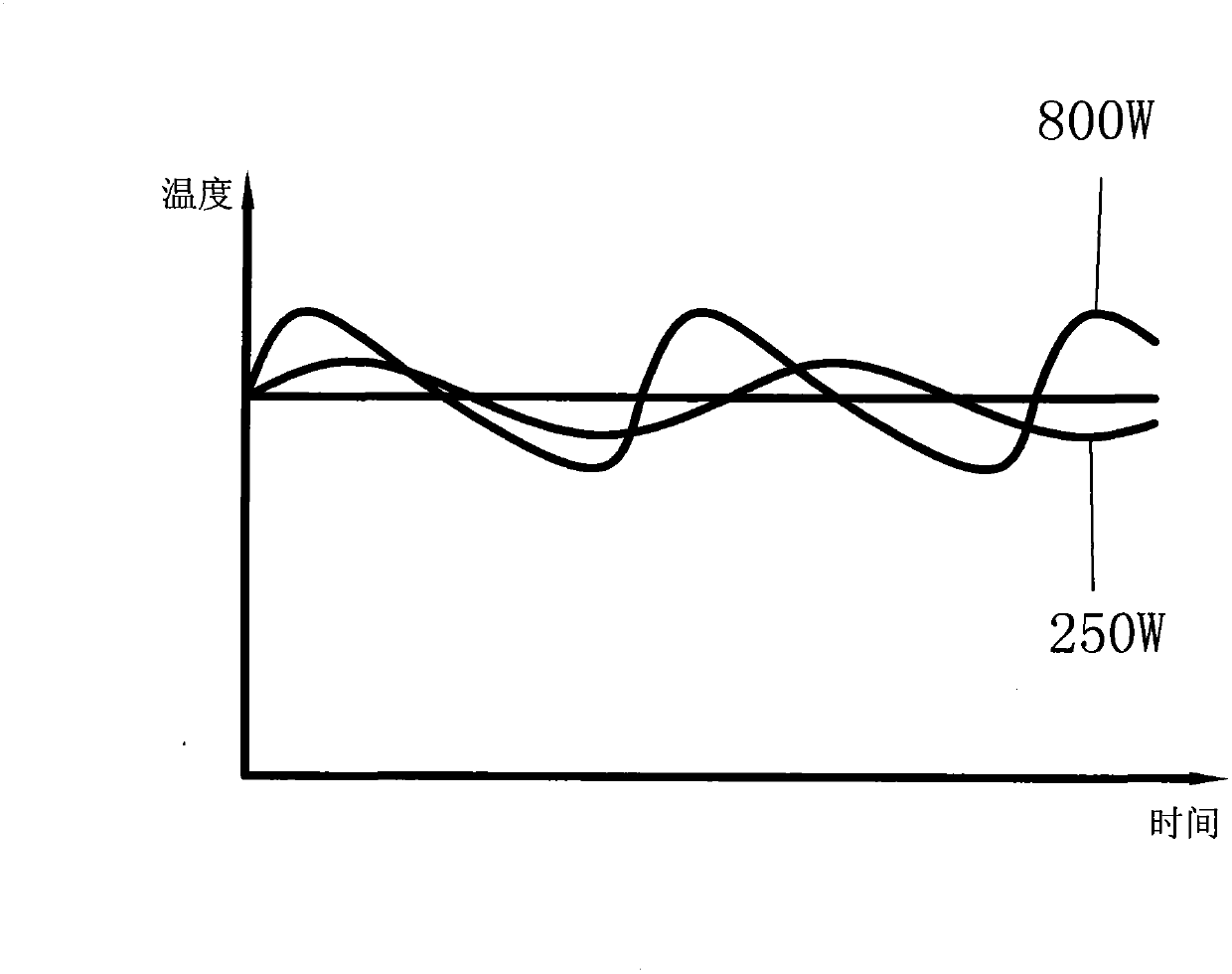

Iron bottom plate

The invention discloses an iron bottom plate which comprises a bottom plate body, an insulating material layer and a heating element, wherein the insulating material layer is sprayed on the bottom plate body, and the heating element is printed on the insulating material layer by the aid of the hot stamping technique. Another insulating material layer is sprayed on the heating element except for a conducting power connector on the heating element. The iron bottom plate has the advantages that the iron bottom plate is fast to heat and small in size, the surface is uniformly heated, the iron bottom plate can have one or a plurality of operating powers, and the probability of damage to clothing is greatly decreased.

Owner:佛山市顺德昀陶设计有限公司

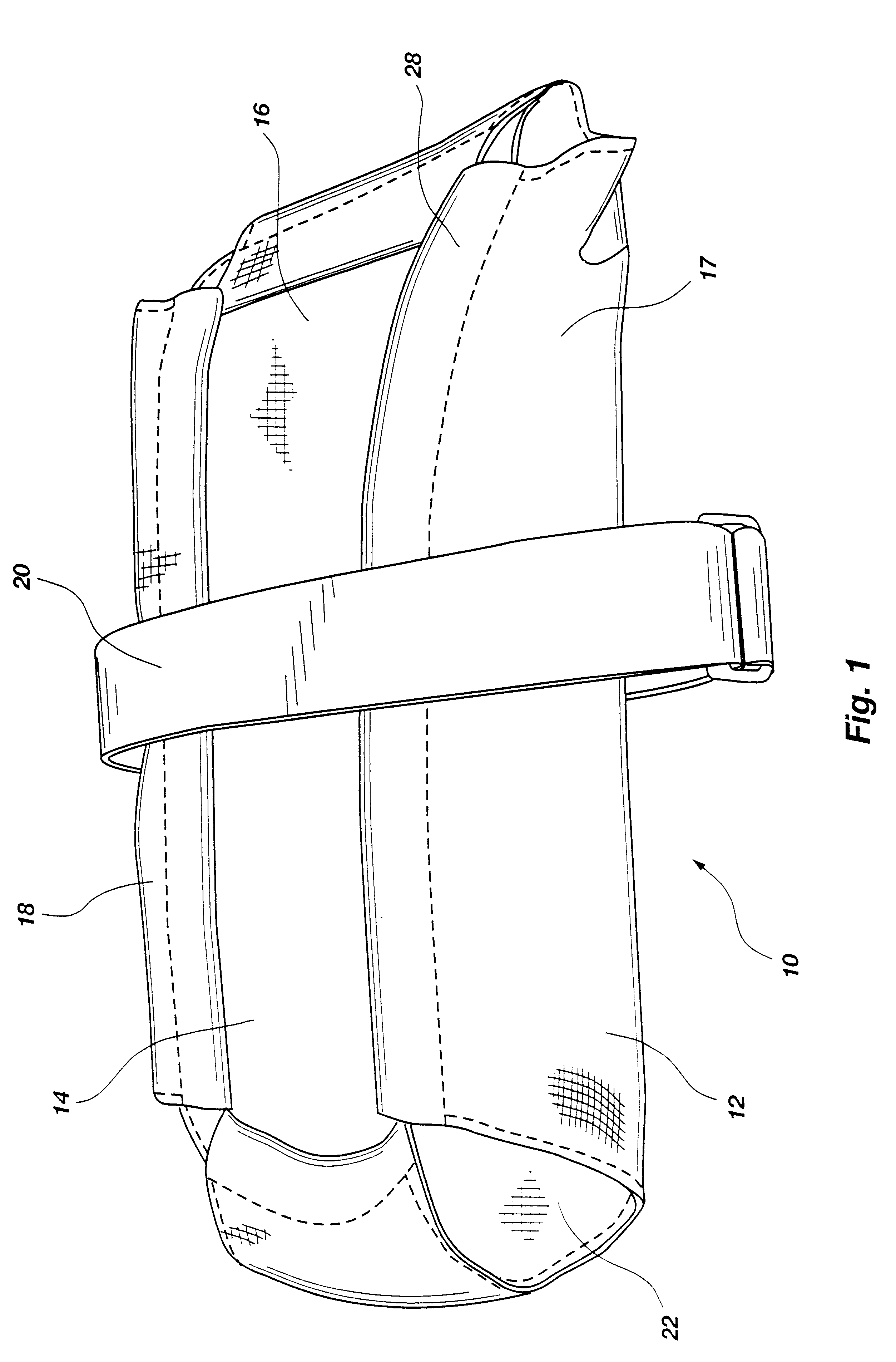

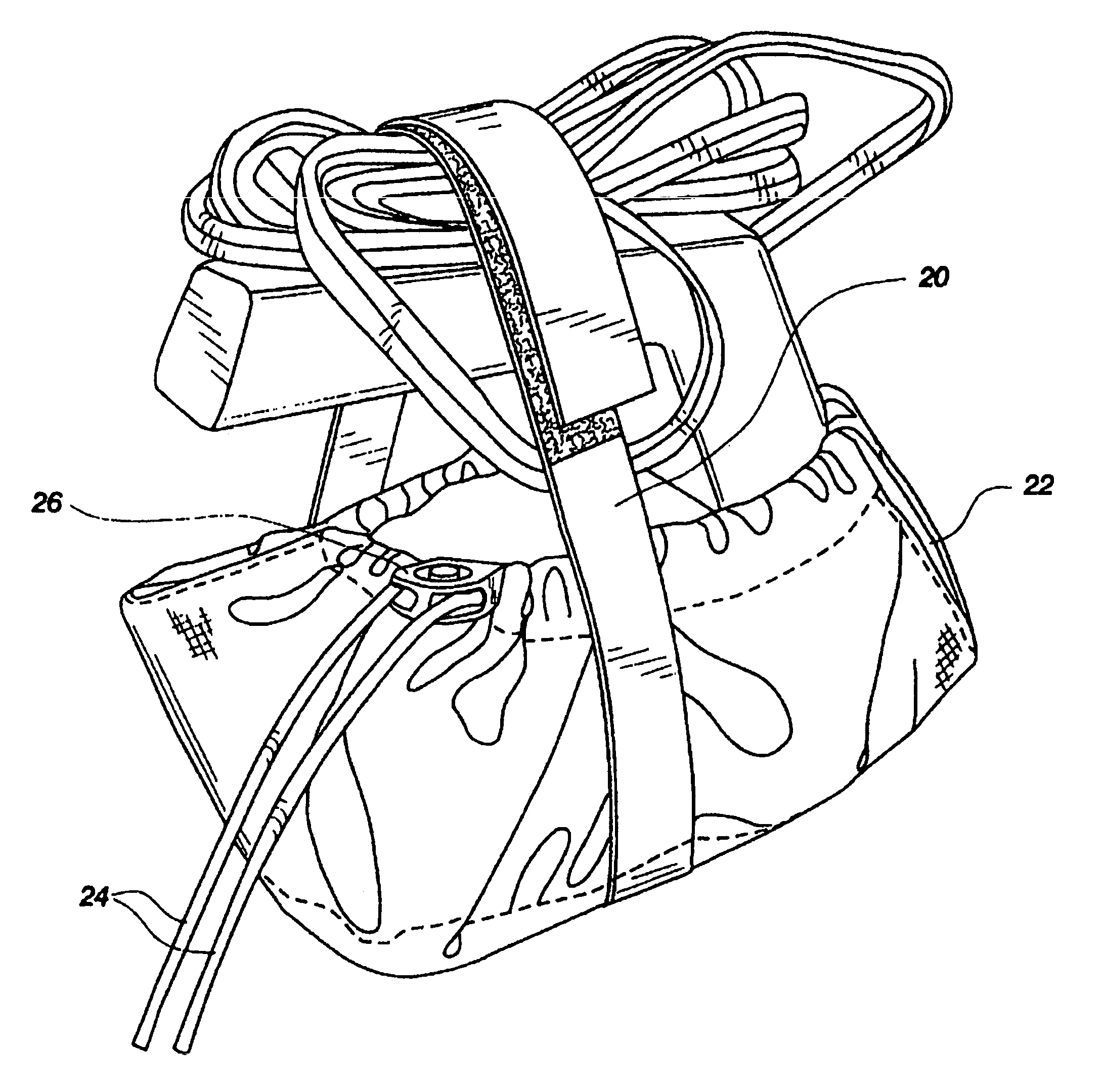

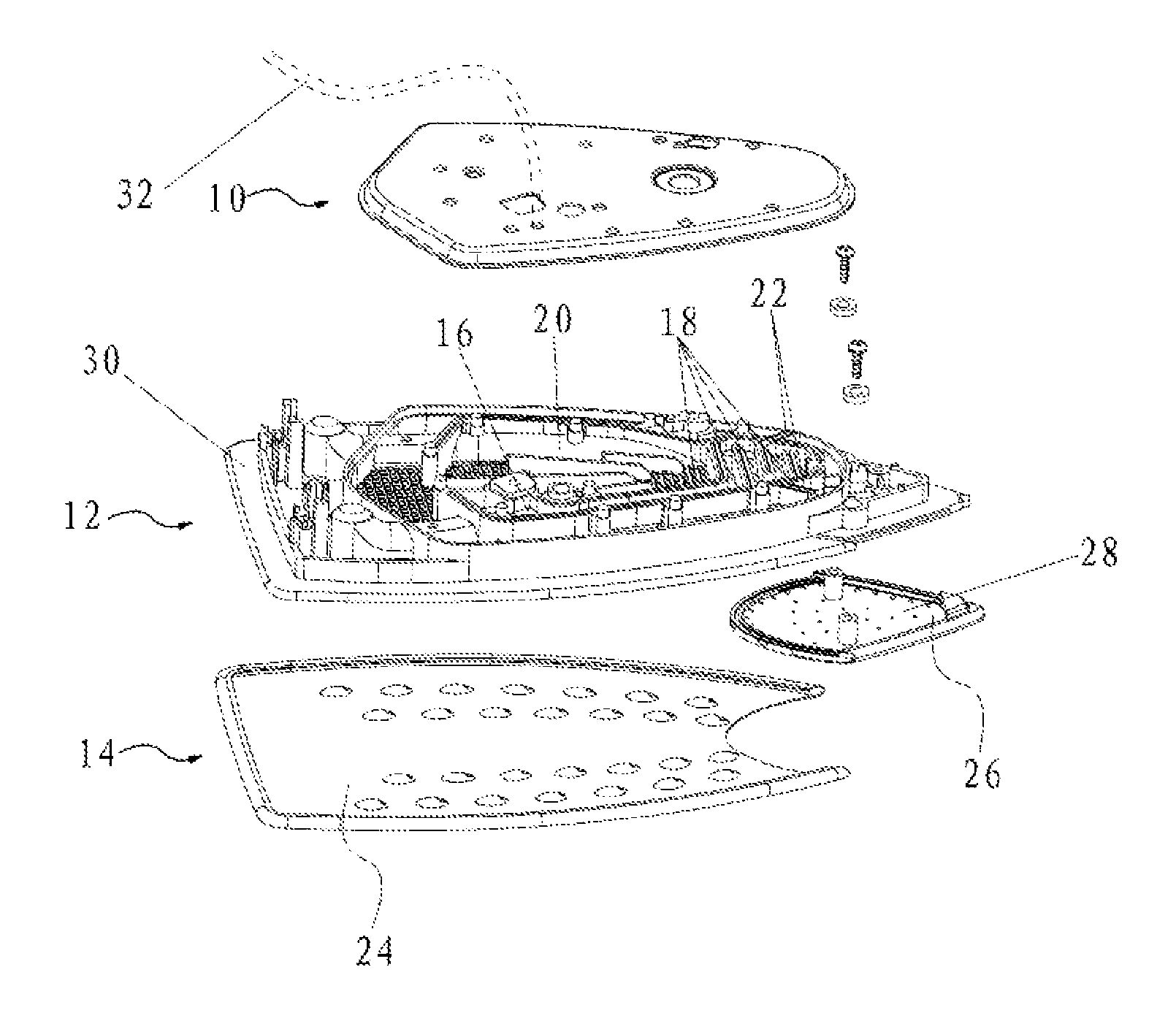

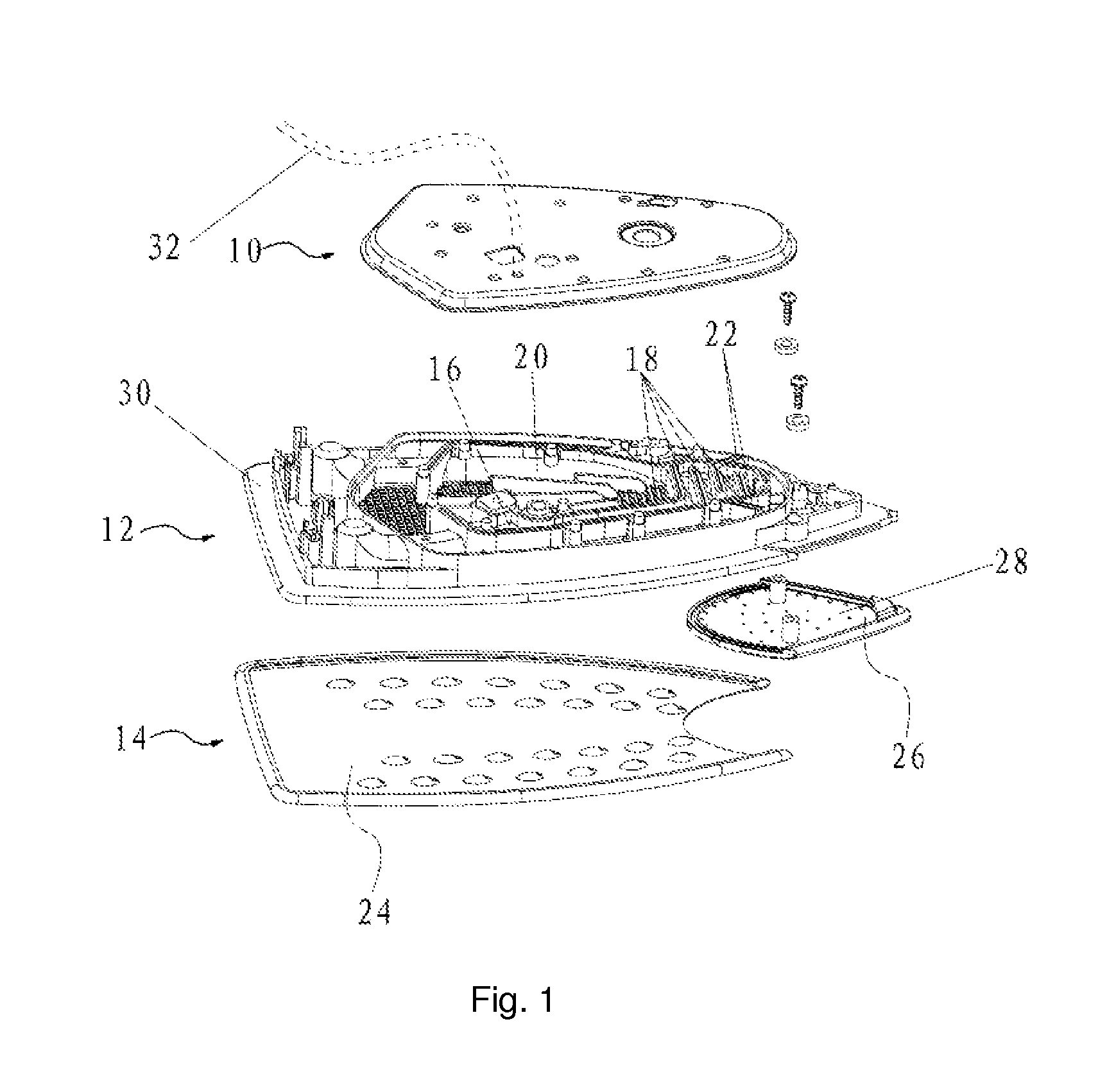

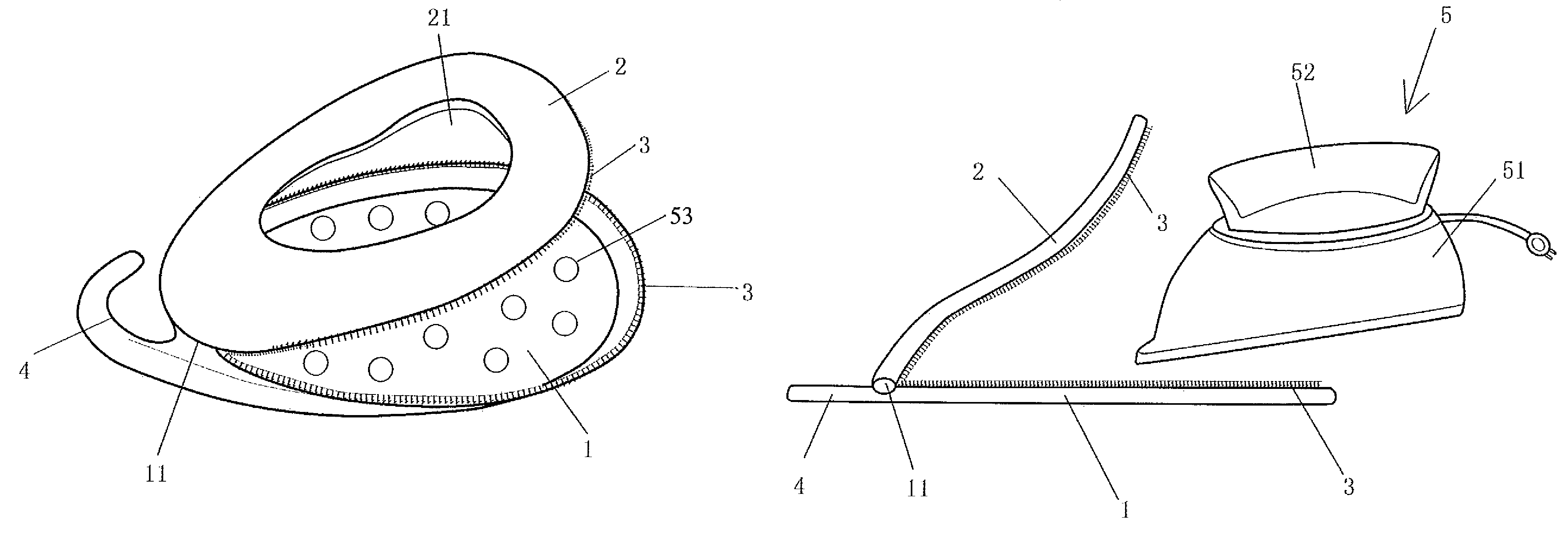

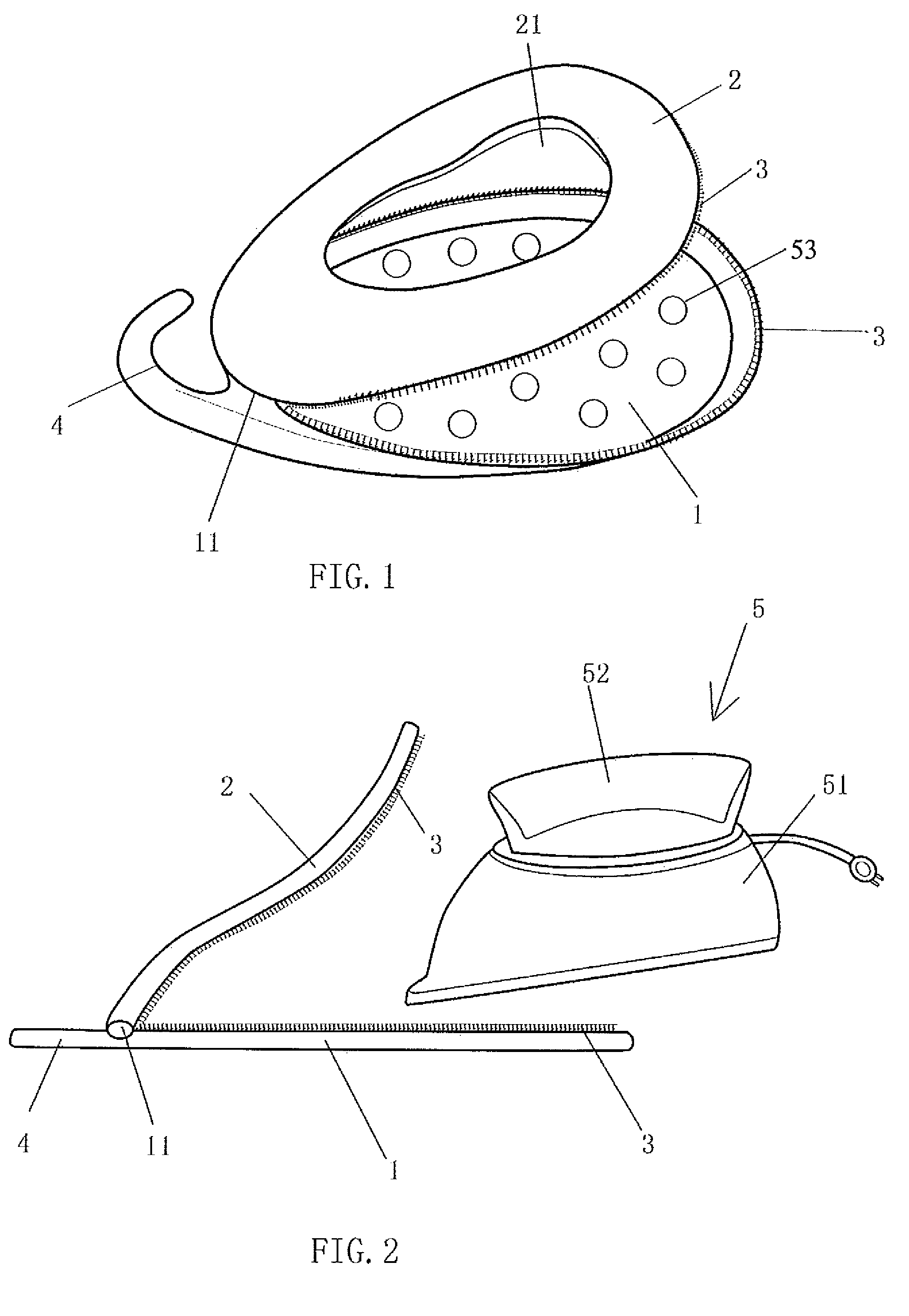

Insulation cover for iron

InactiveUS8146276B2Facilitate holding the ironImprove the heating effectFlexible coversWrappersEngineeringAndiron

An insulation cover for iron comprises a bag-shaped body for containing the iron; the body is provided with an opening which is used as an entrance for the iron; the opening of the body is provided with a zip-fastener for closing the opening; the body is provided with a hanger. After the iron being placed into the body via the opening, zip up the opening, then the iron is covered inside the insulation cover and thus it can be placed on a horizontal surface directly; or be hanged with the cover by the hanger.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com