Iron bottom plate

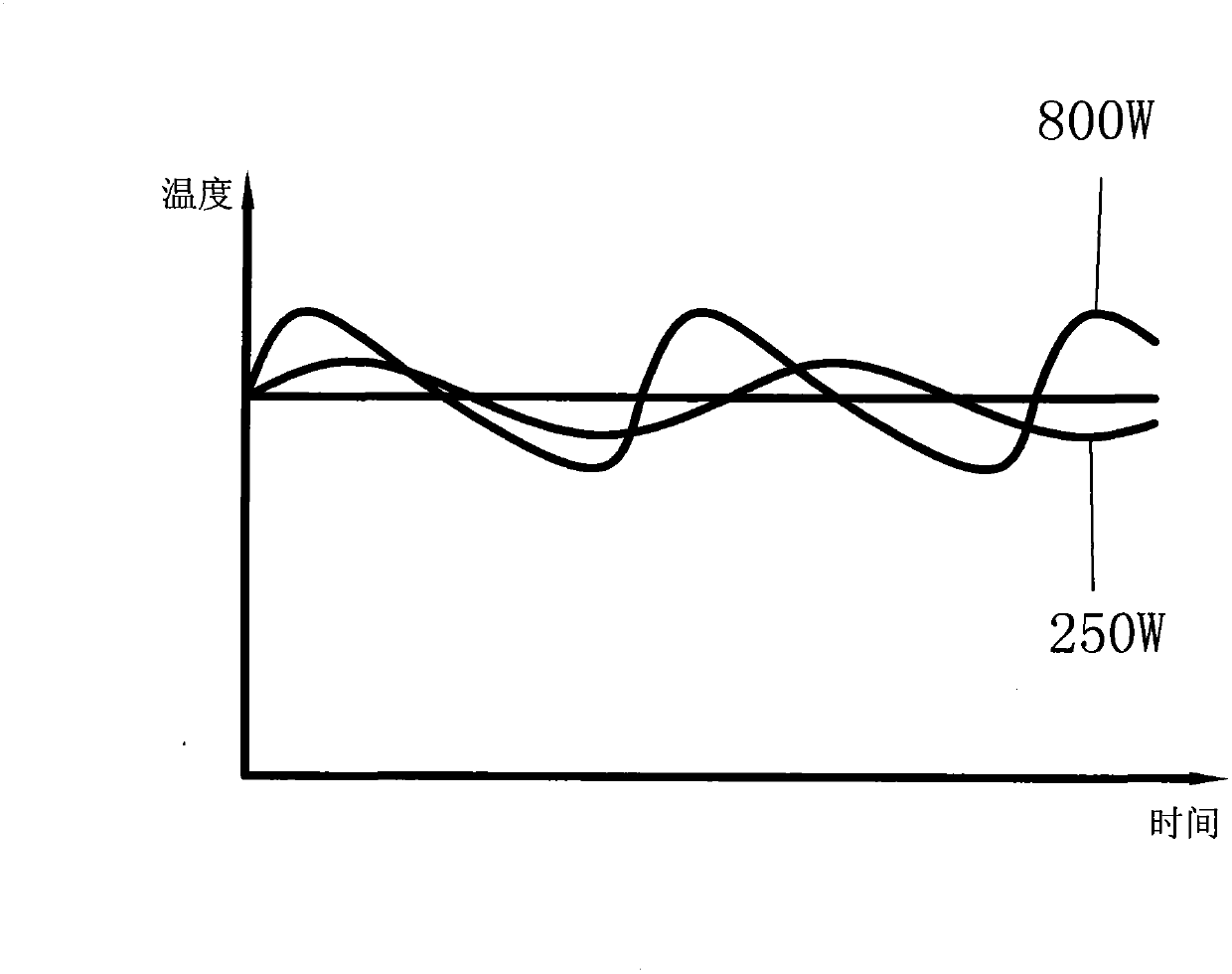

A technology of soleplate and iron, which can be used in hand irons, washing devices, textiles and papermaking, etc., can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the utility model is described in further detail.

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

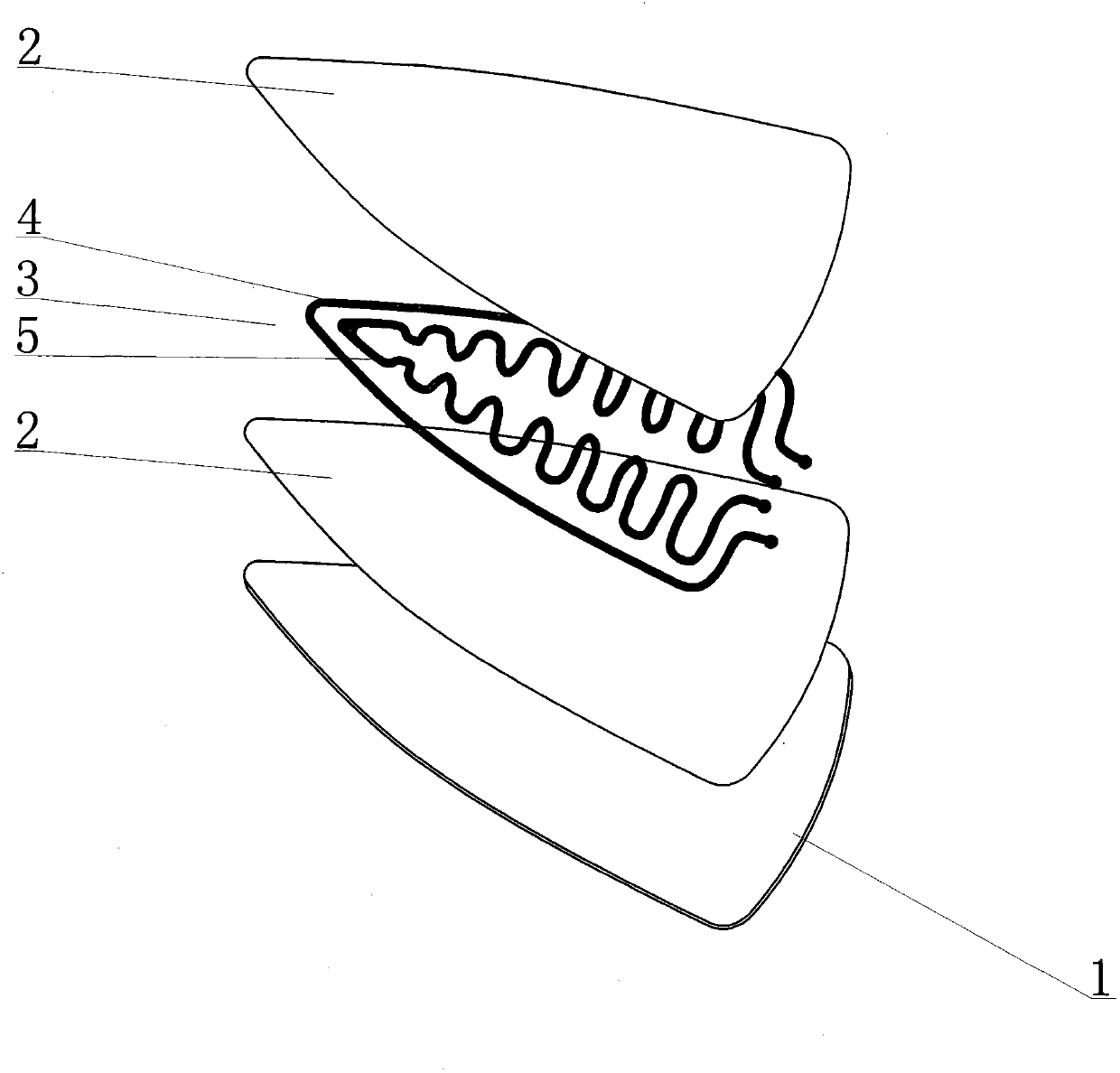

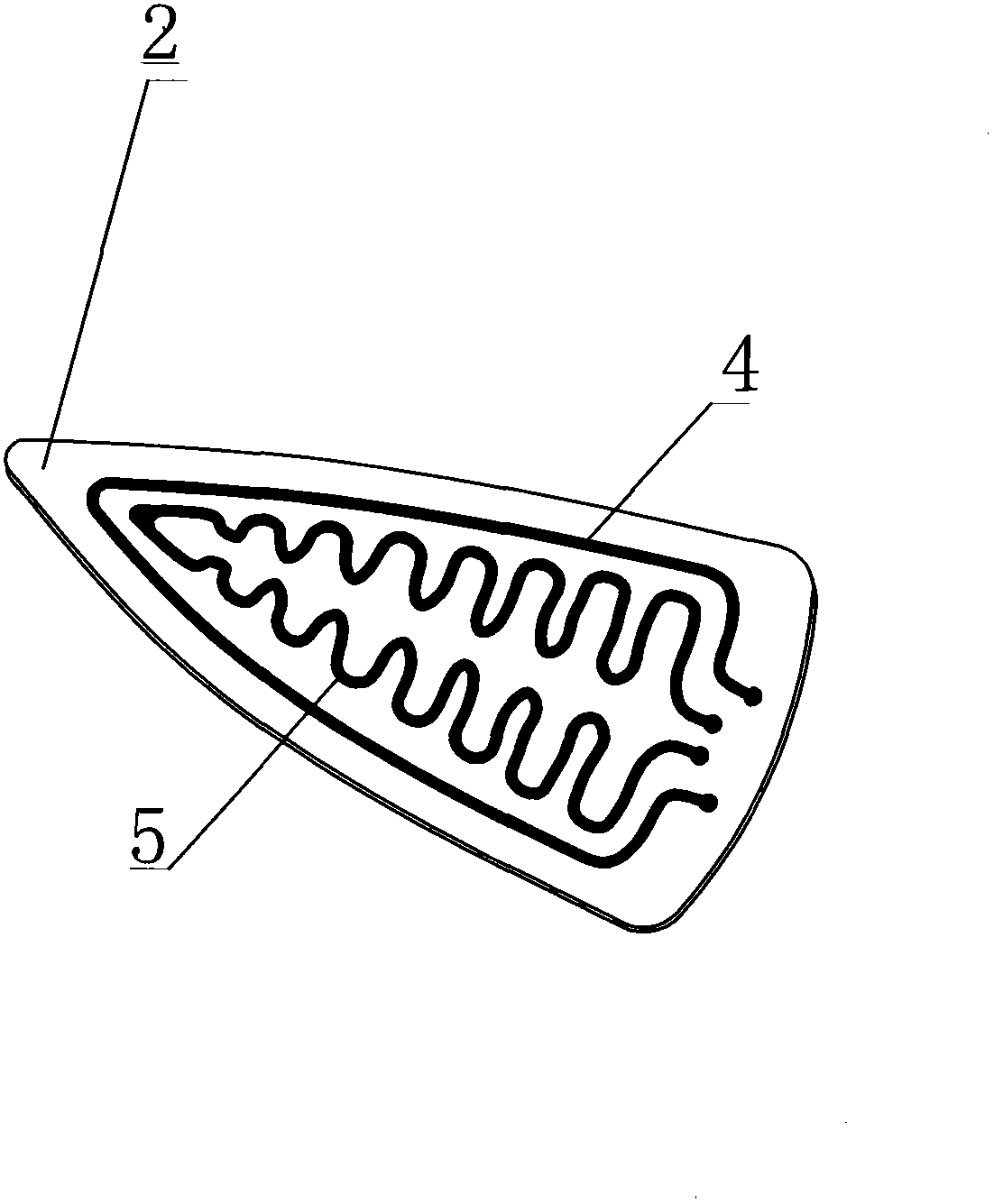

[0014] Such as Figures 1 to 2 As shown, the soleplate of the iron includes a soleplate body 1, an insulating material layer 2 sprayed on the soleplate body 1, and a heating element 3 printed on the insulating material layer 2 by hot stamping technology; The insulating material layer 2 of the power supply connection is conducted on the component 3 . The insulating material layer 2 can be insulating varnish or other insulating materials.

[0015] The shape and size of the insulating material layer 2 are consistent with the shape and size of the bottom plate body 1, the shape and size of the heating element 3 are corresponding to the shape and size of the bottom plate body 1, and the bottom plate body 1, the heating element 3 and the insulating material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com