Patents

Literature

68results about How to "Neatly packed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

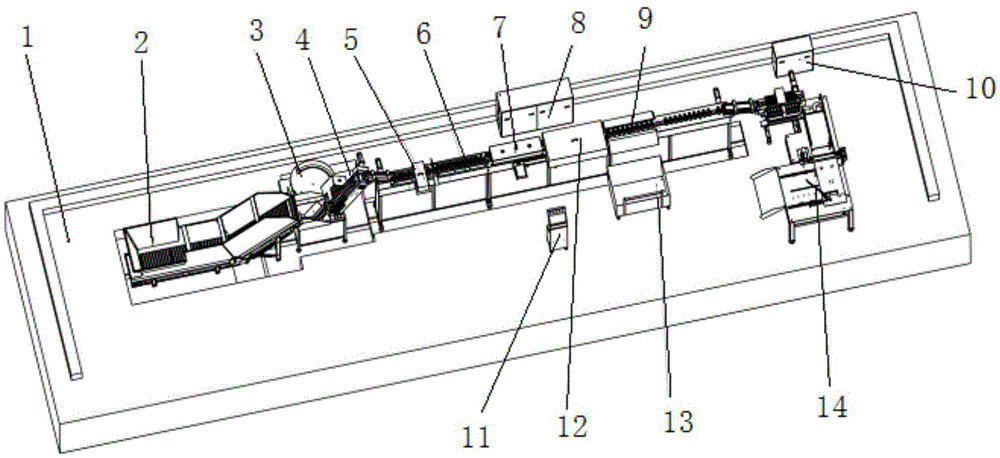

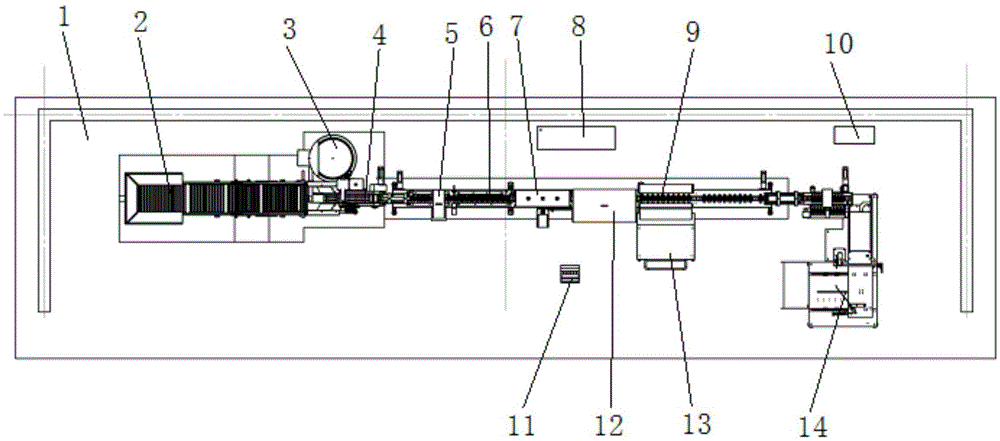

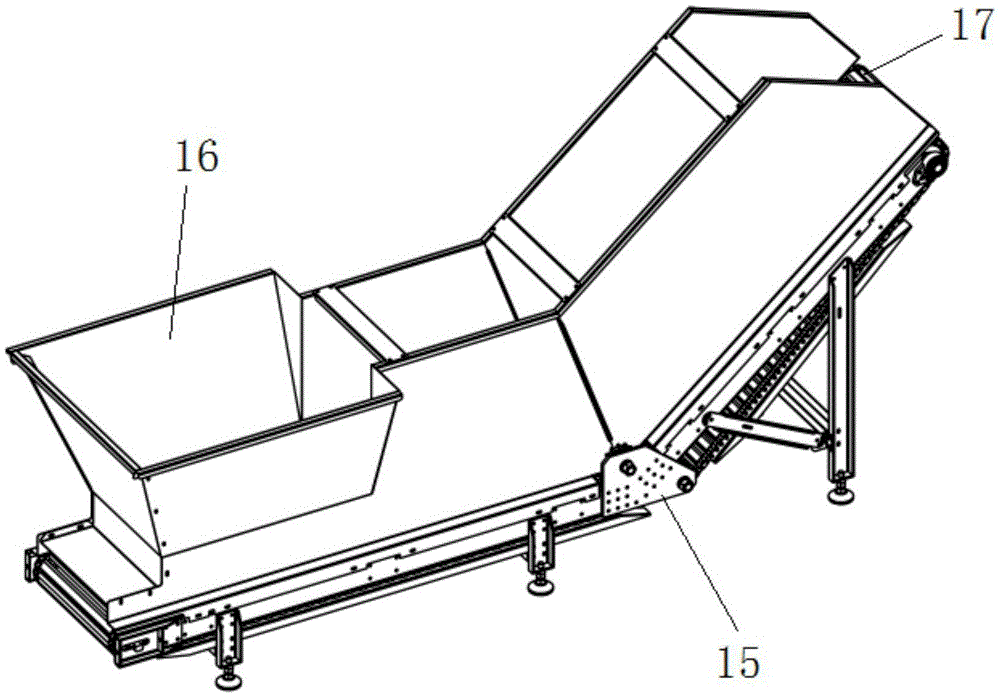

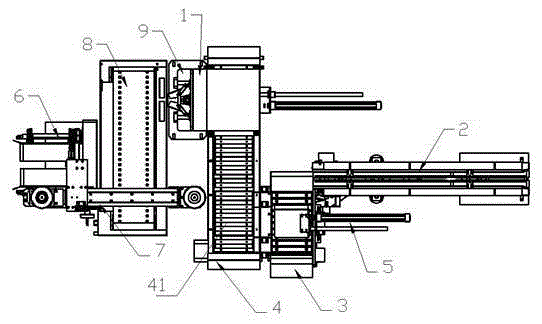

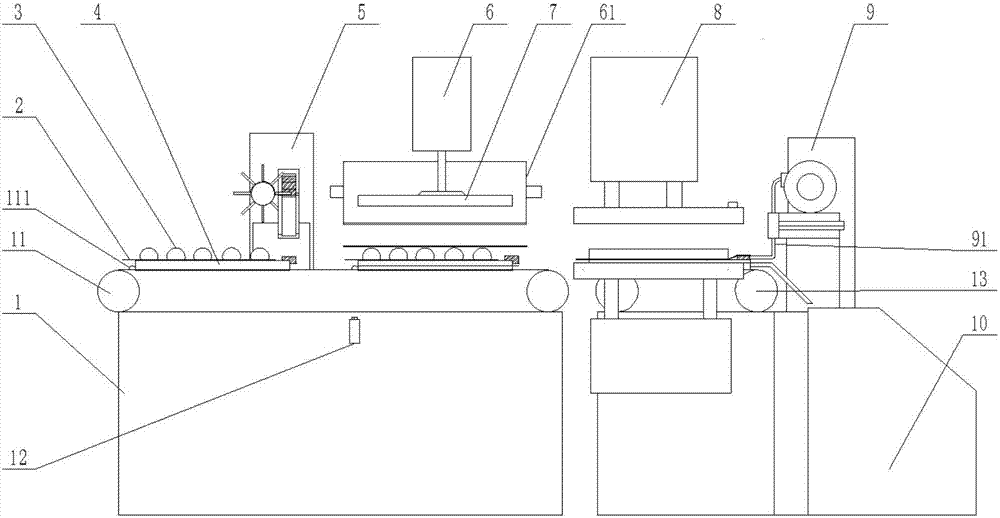

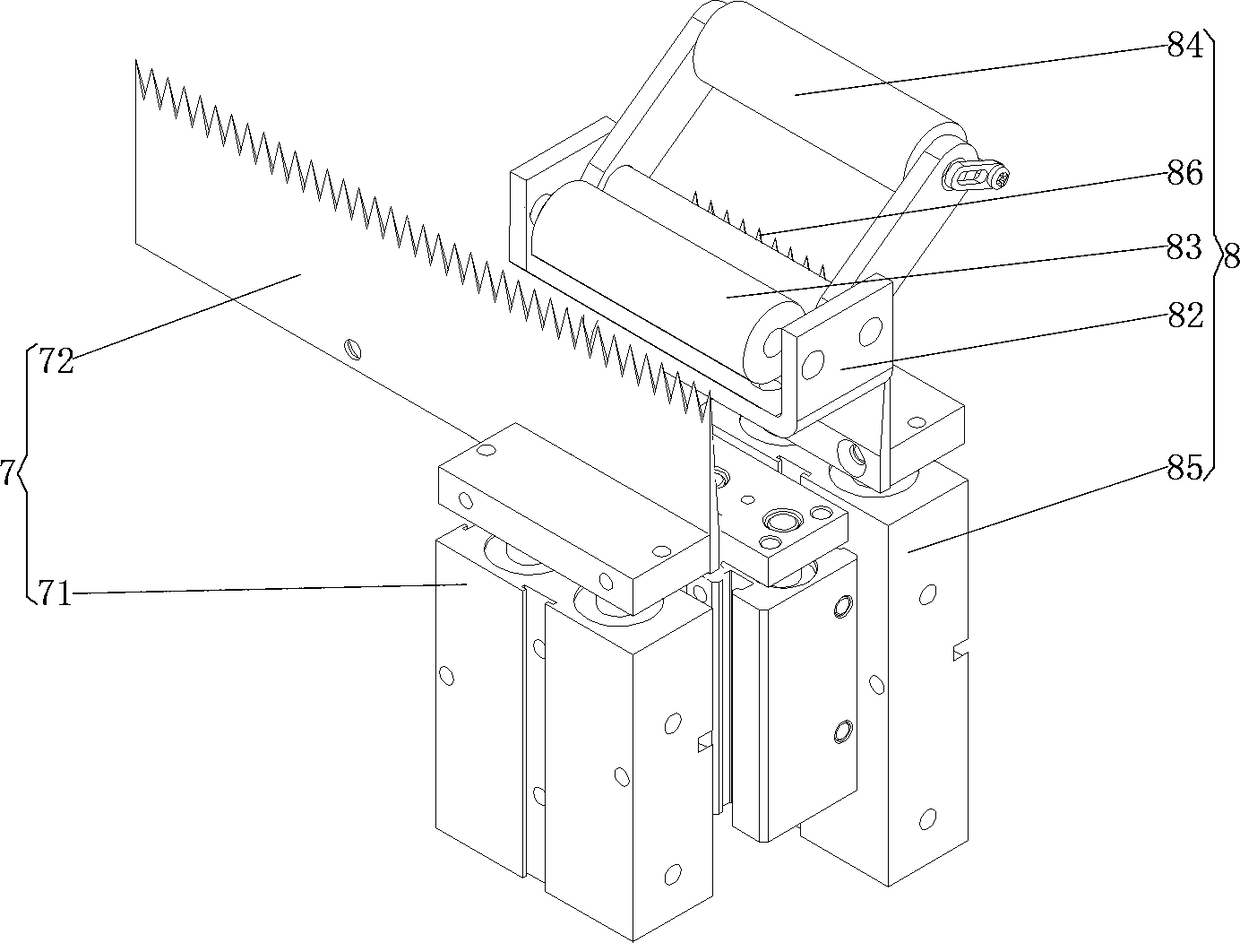

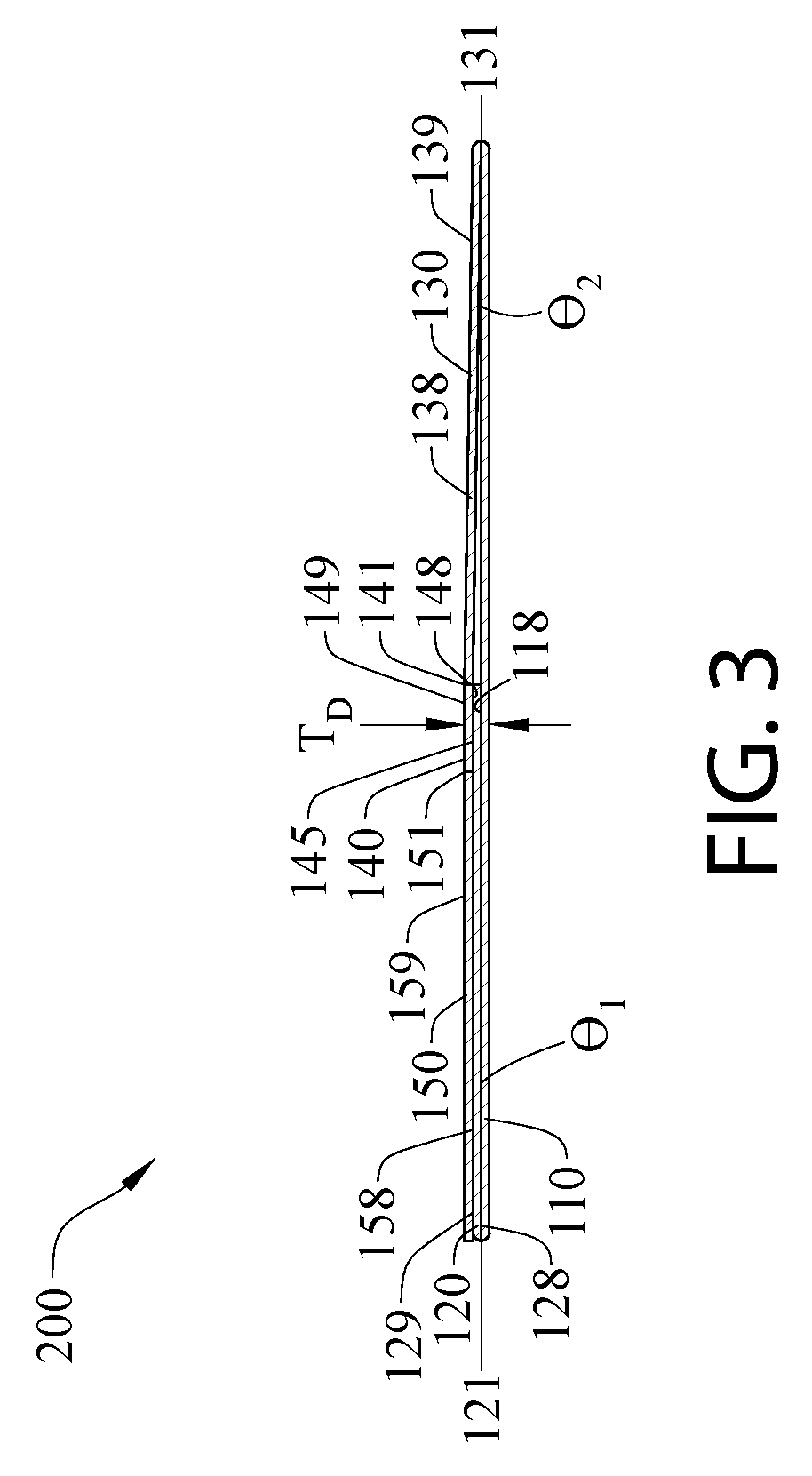

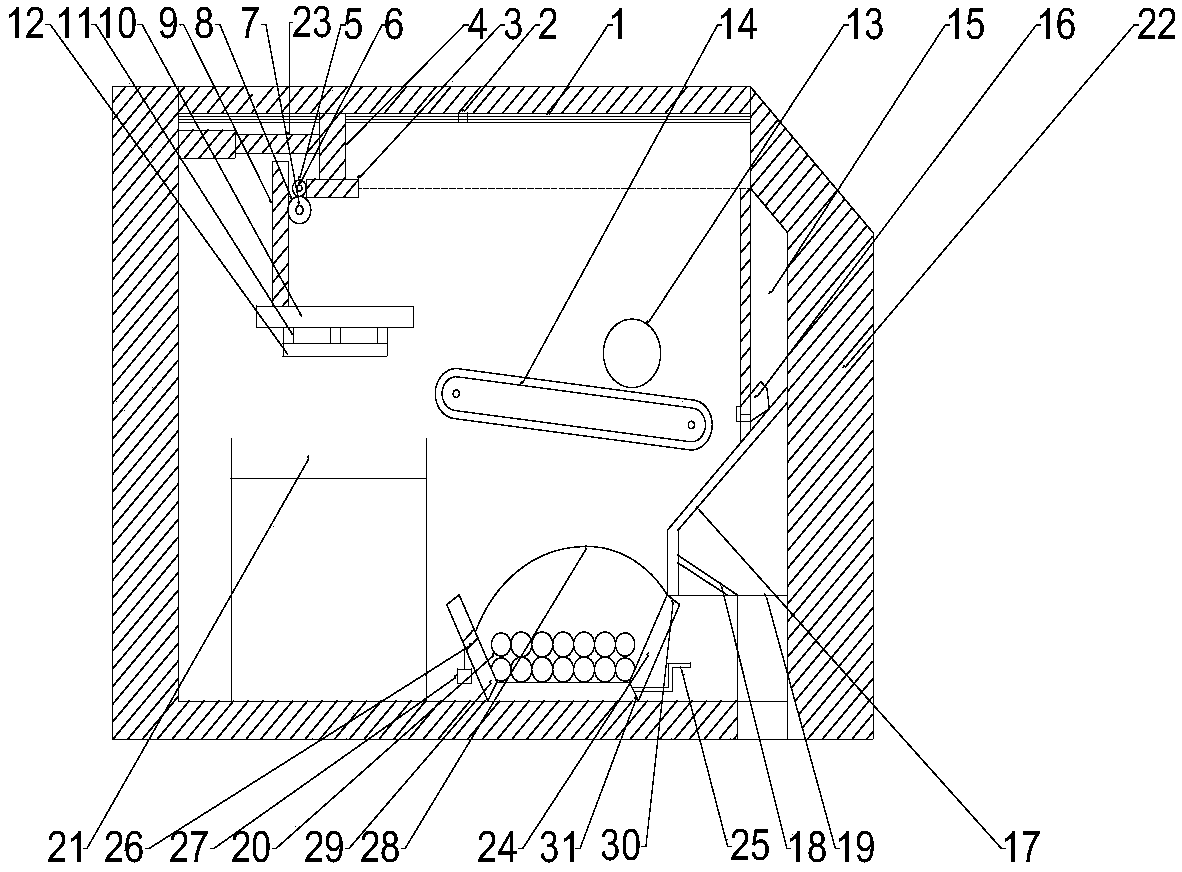

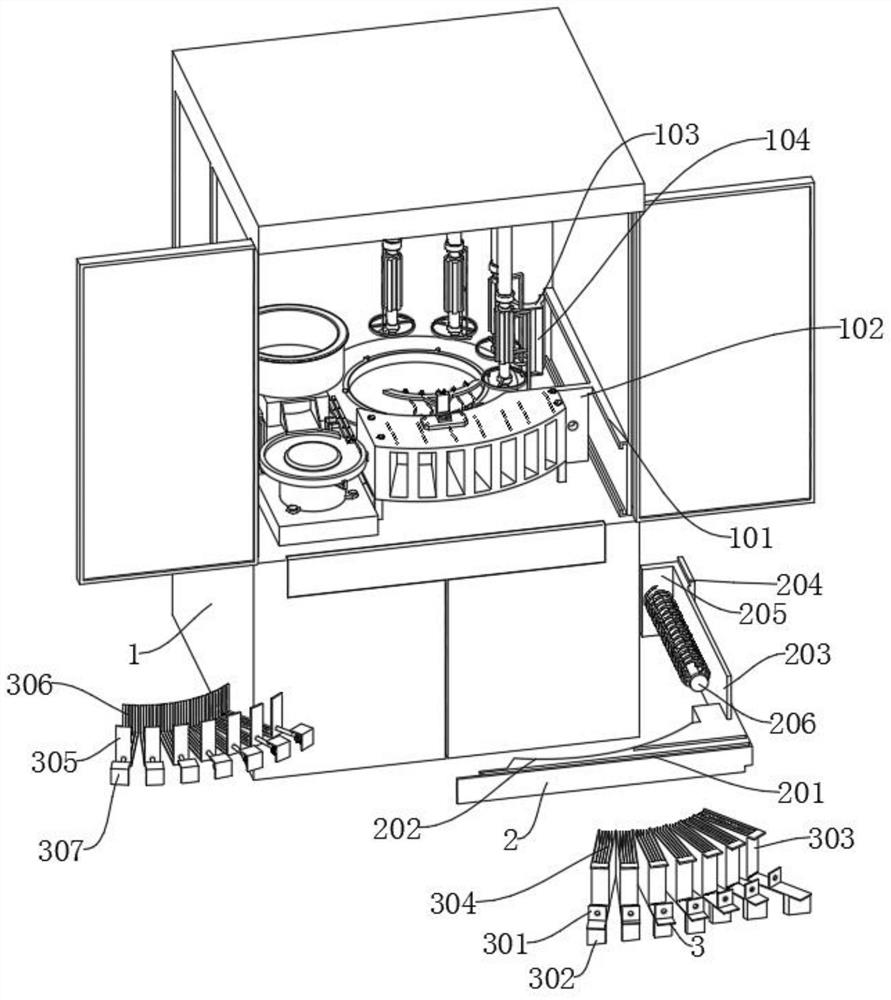

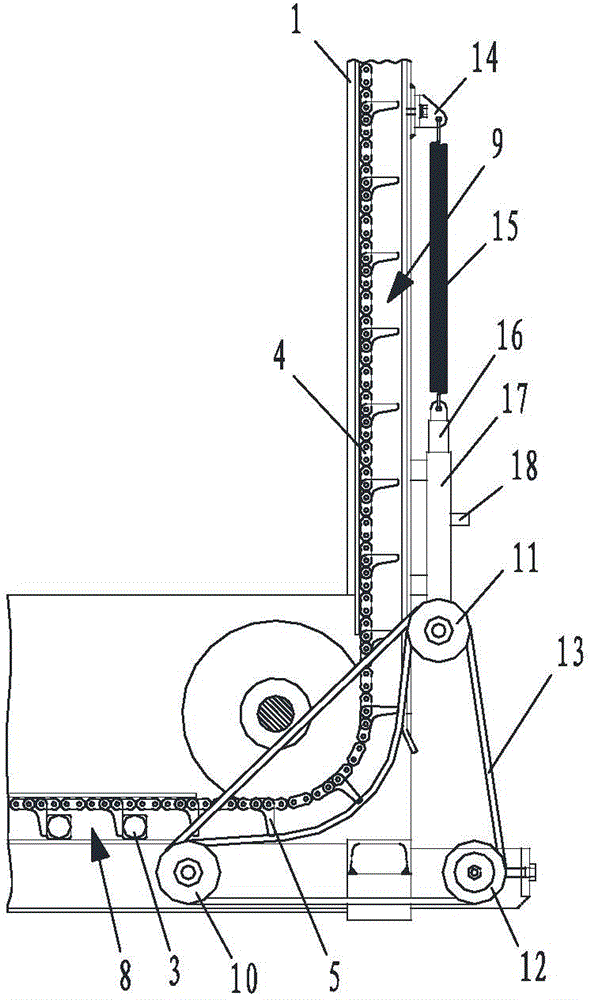

Casing pipe detection equipment and detection method thereof

InactiveCN105523369ASolve online detection problemsFully automatedConveyorsOptically investigating flaws/contaminationPetroleum engineeringVisual detection

The invention discloses casing pipe detection equipment and a detection method thereof. The casing pipe detection equipment comprises a storing and loading device, a conveying device, a pre-judging and removing device, a blow-drying device, a visual detection system, a pneumatic removing system, a material arranging device and a lifting and reversing device, wherein the conveying device is connected to the lifting and reversing device, and the pre-judging and removing device, the blow-drying device, the visual detection system and the pneumatic removing system are sequentially installed on the conveying device in the conveying direction. Casing pipes are arranged to be conveyed forwards firstly, then openings of the casing pipes are arranged towards the same side, the visual detection system detects the casing pipes, the unqualified casing pipes are removed, and the qualified casing pipes are output. According to the invention, internal shortcomings of the casing pipes can be recognized, the unqualified casing pipes can be effectively detected, the shortcomings of detecting and packaging the casing pipes manually in the prior art are overcome, the work efficiency is greatly improved, the labor intensity is lowered, the product quality is guaranteed, and the railway safety is guaranteed.

Owner:HUNAN JINGNING TECH +1

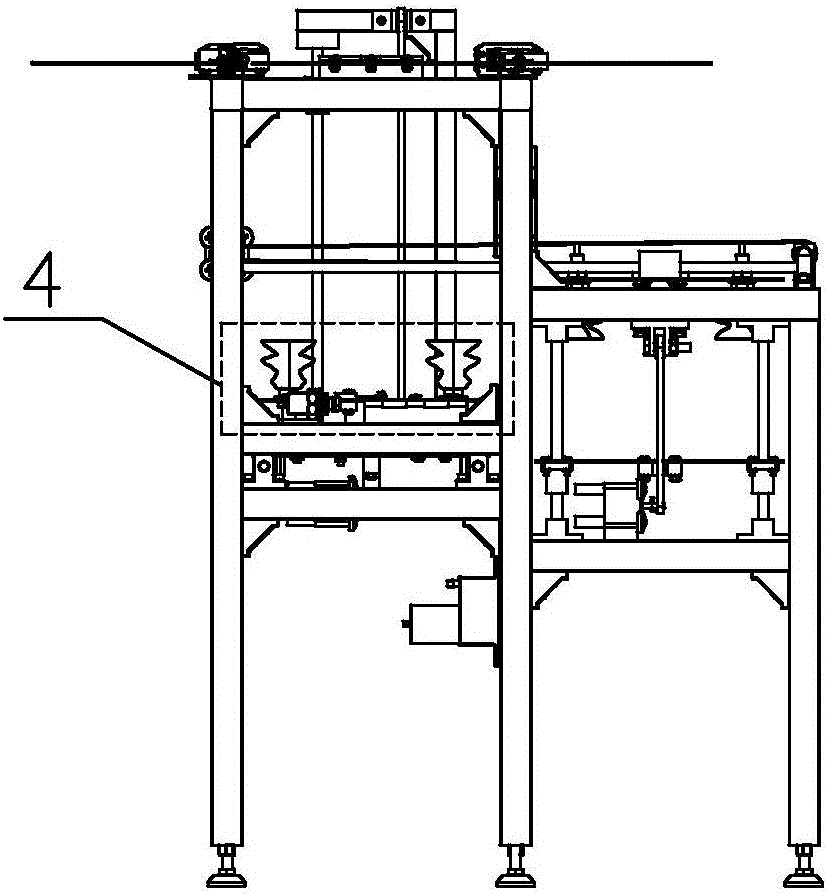

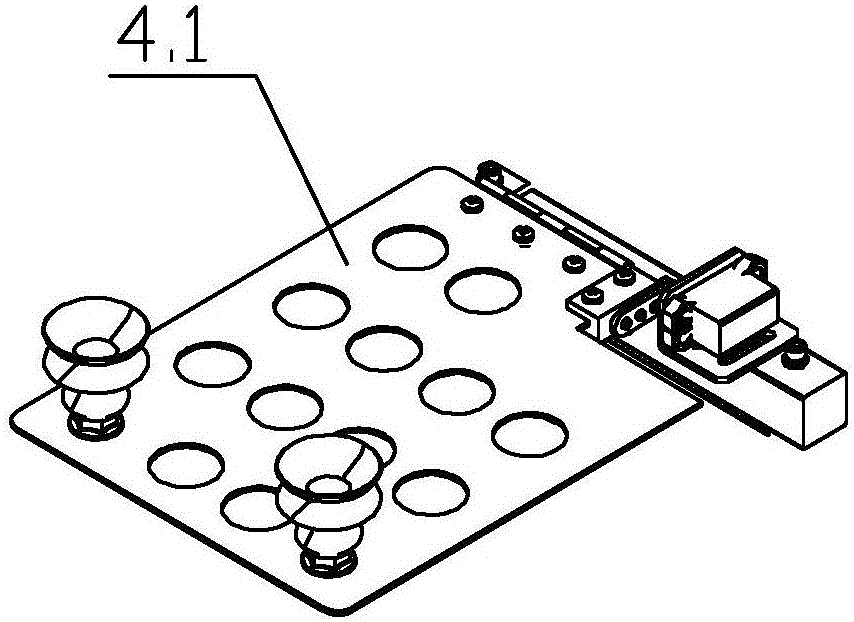

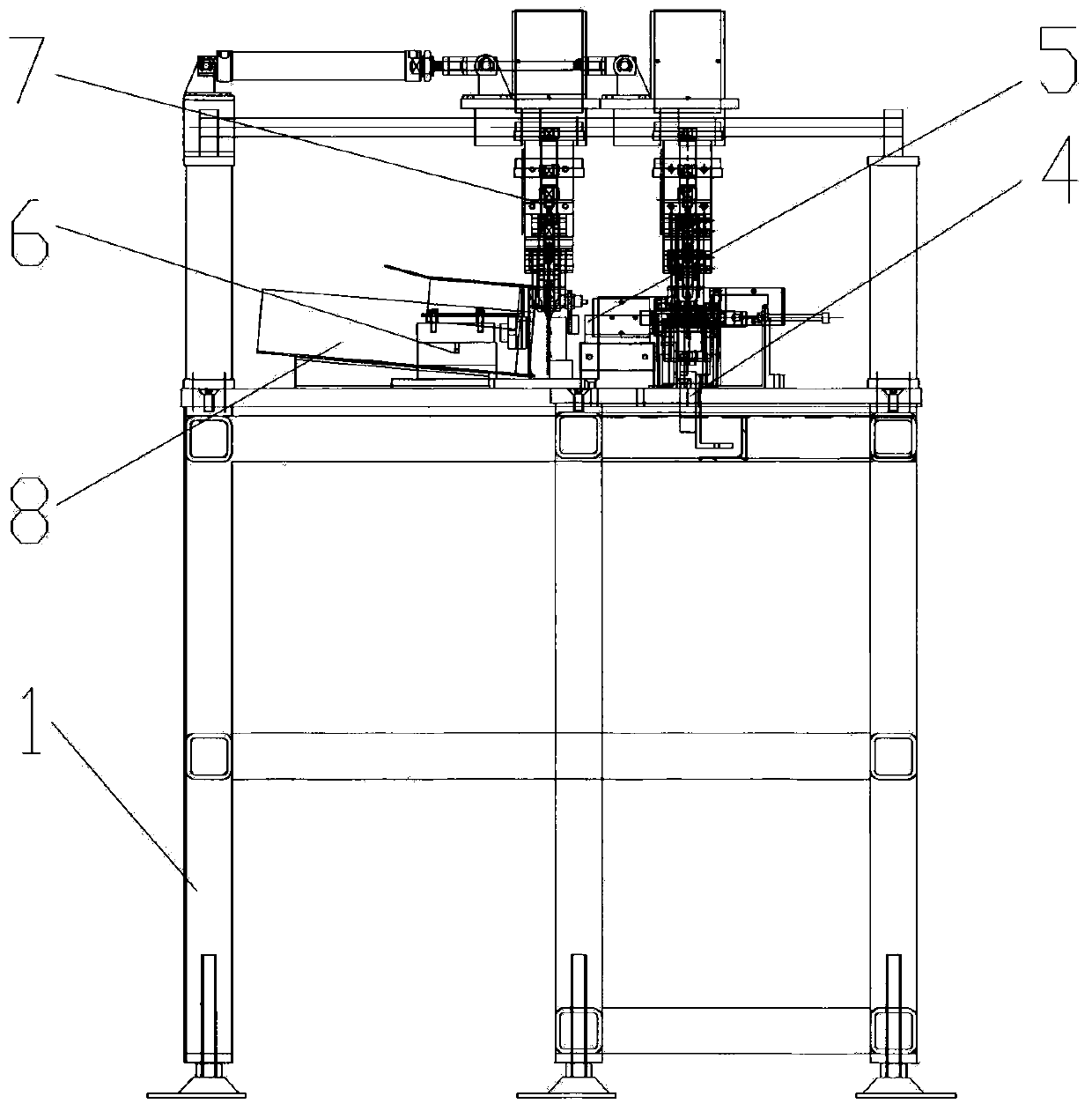

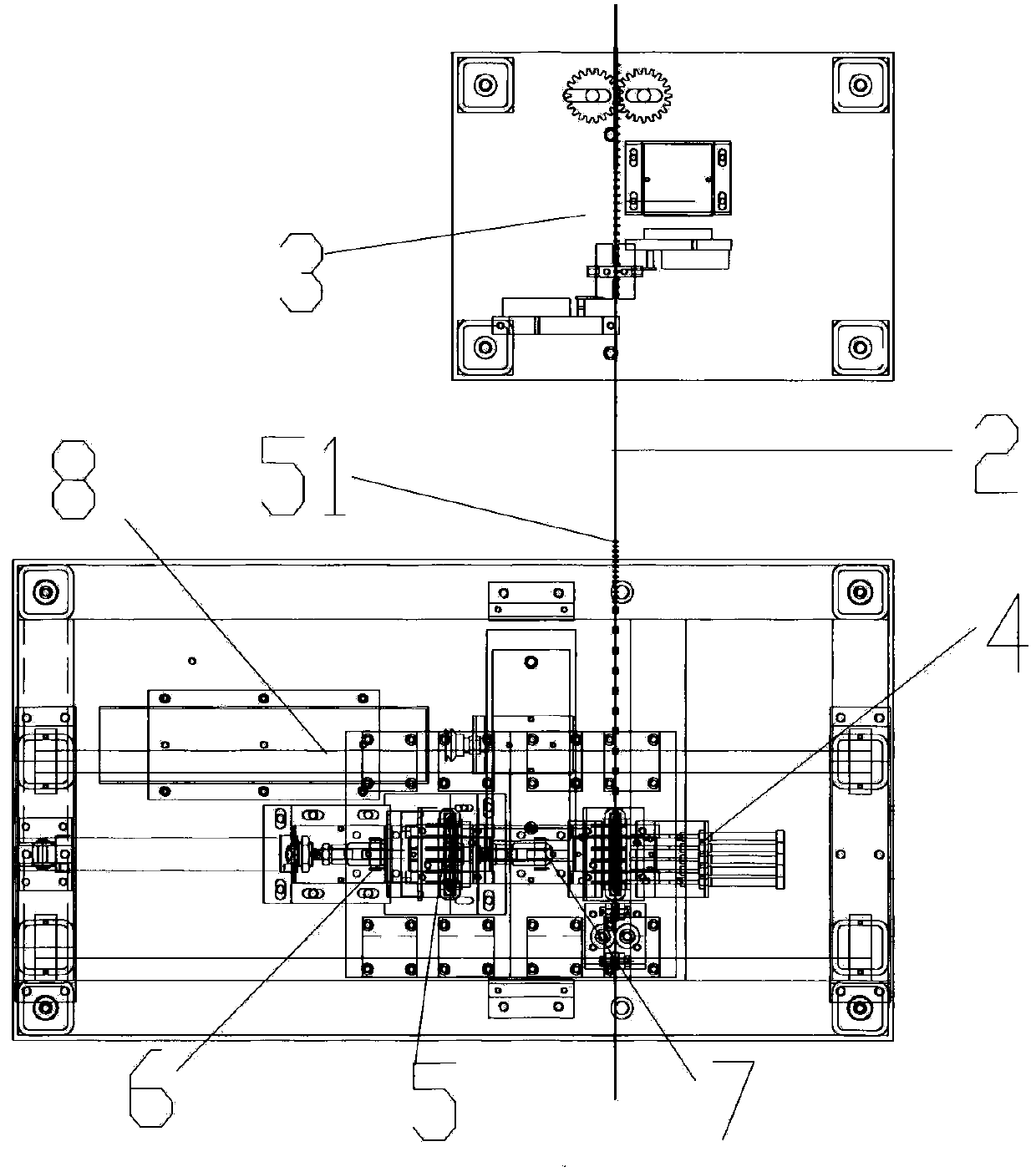

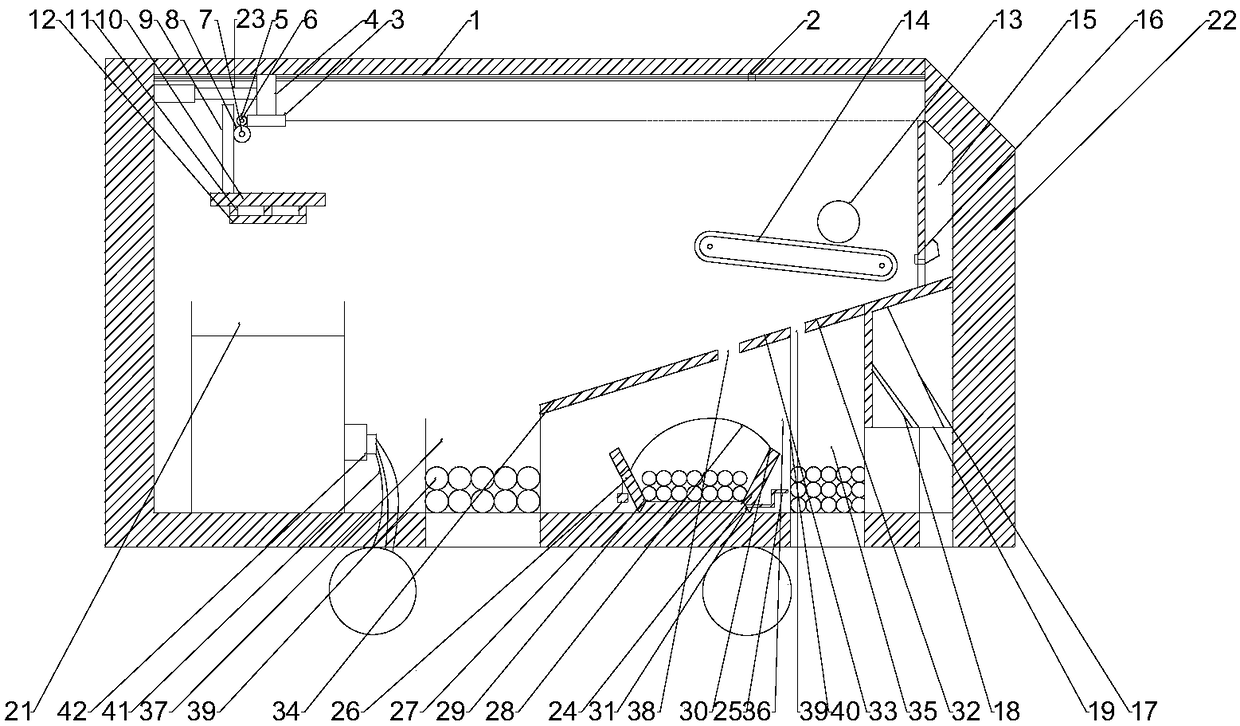

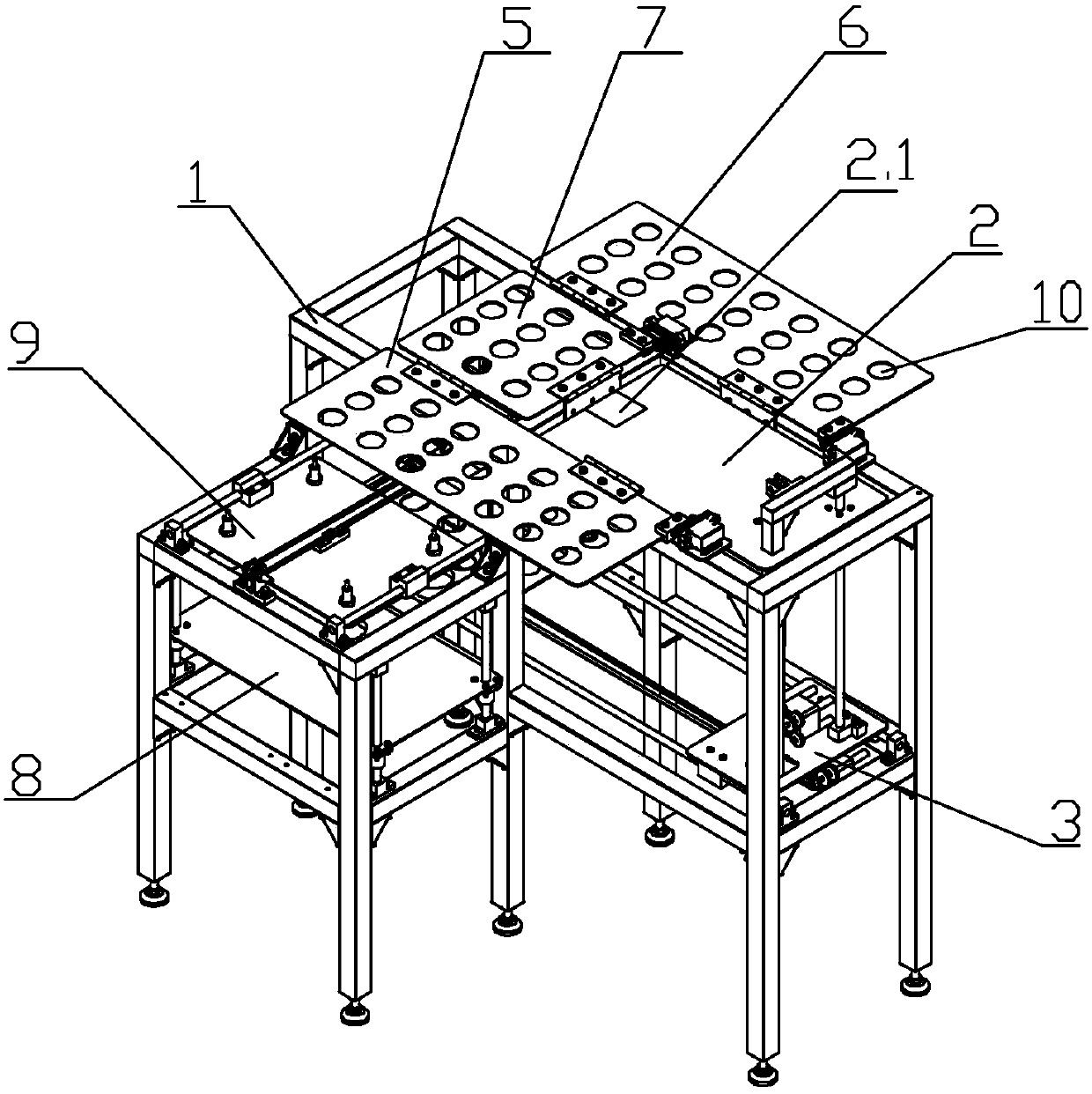

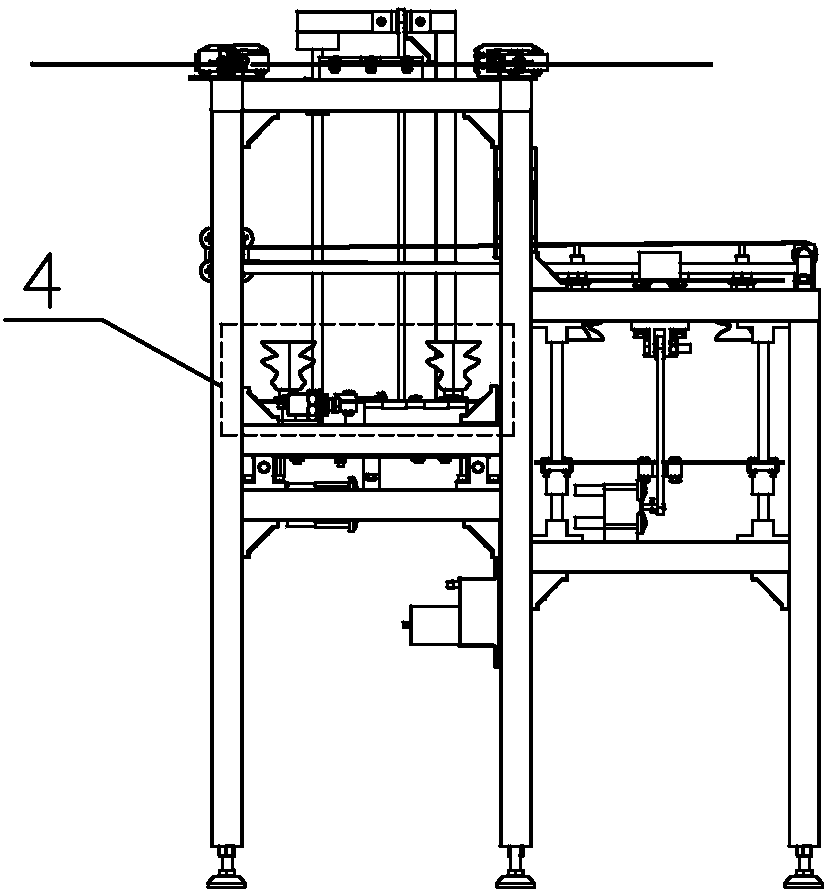

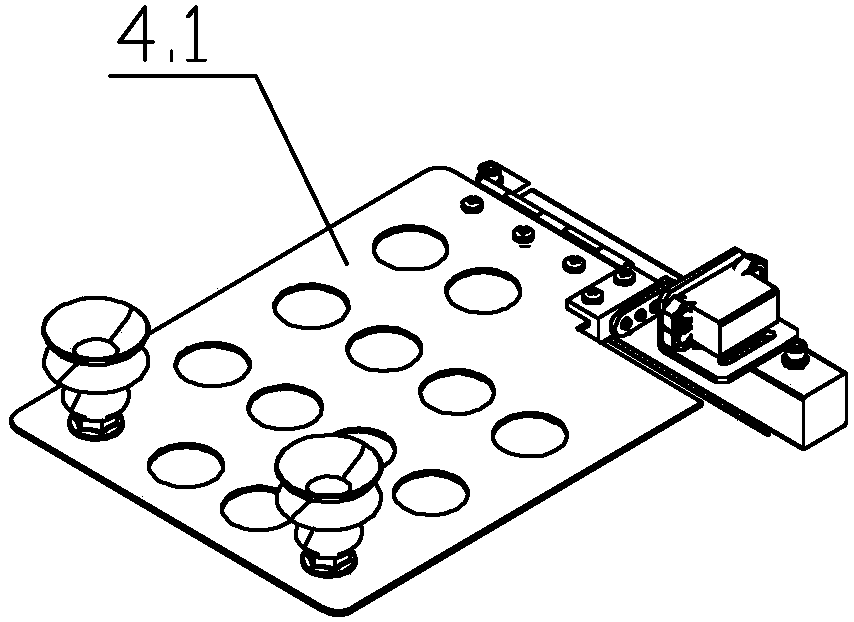

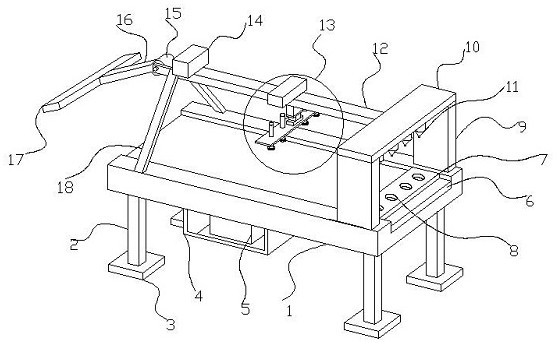

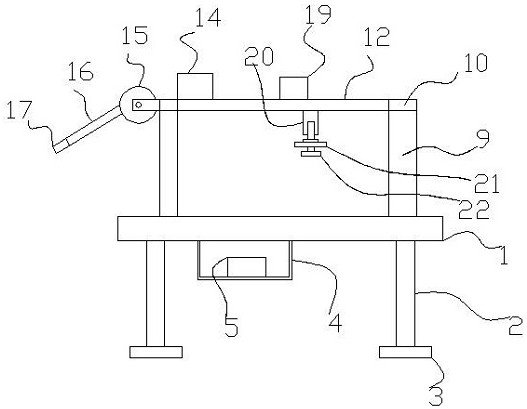

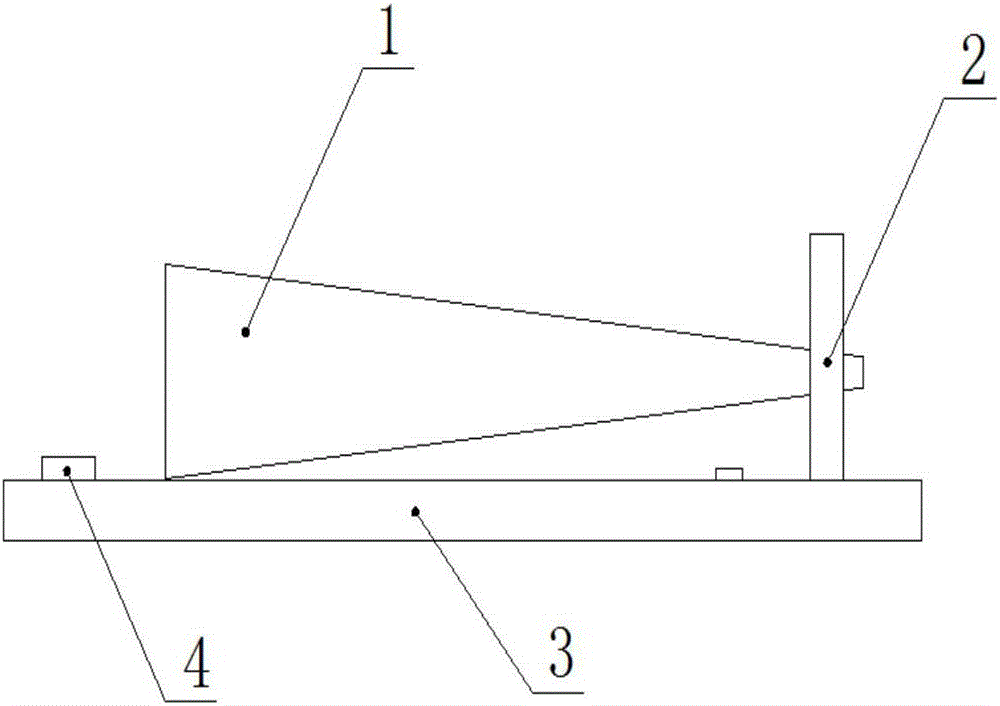

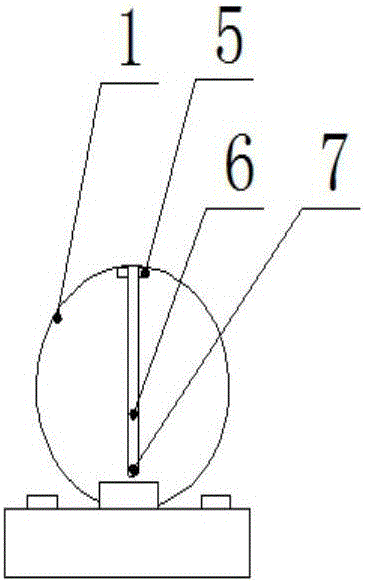

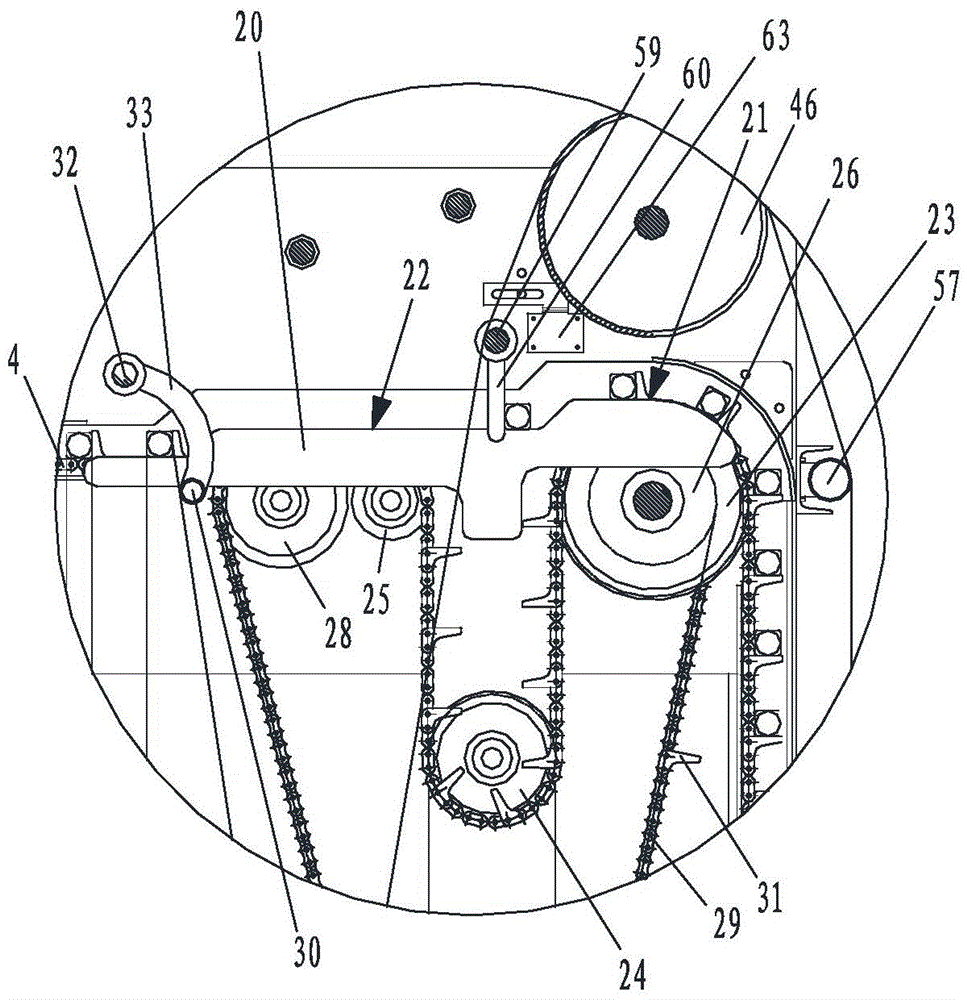

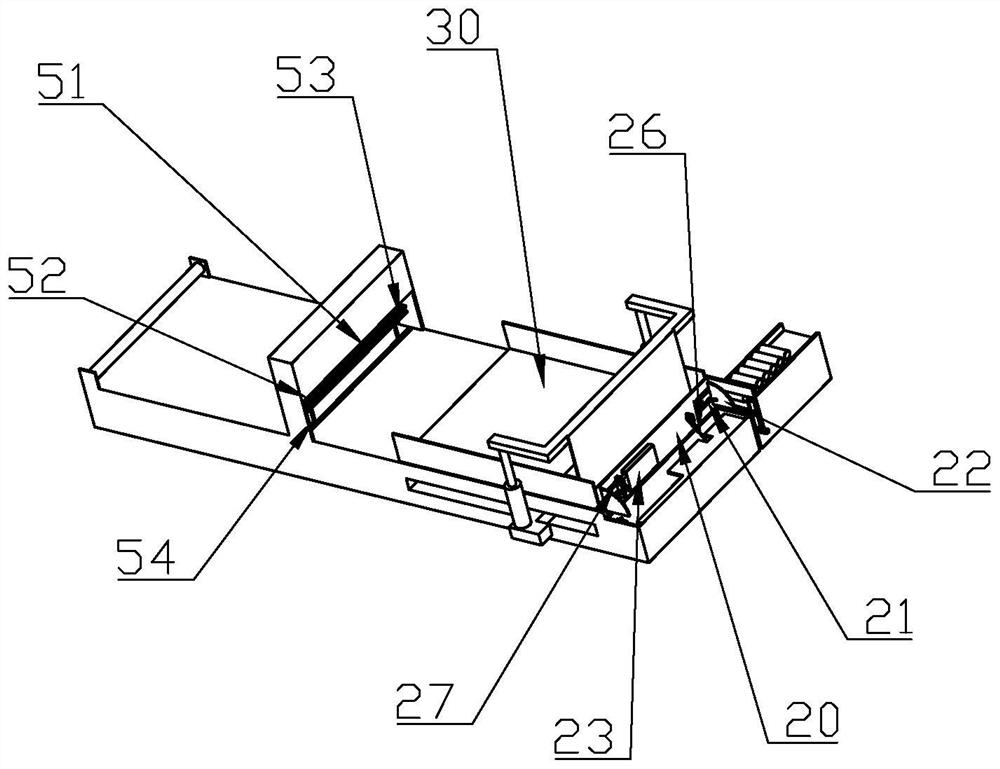

Automatic clothes folding packer and clothes folding and packing method

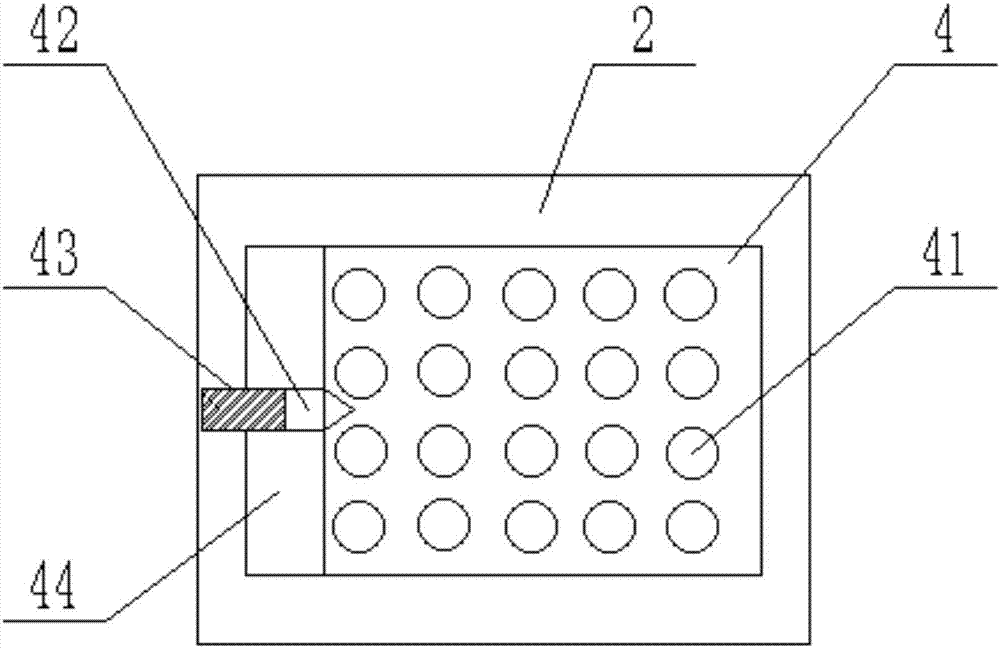

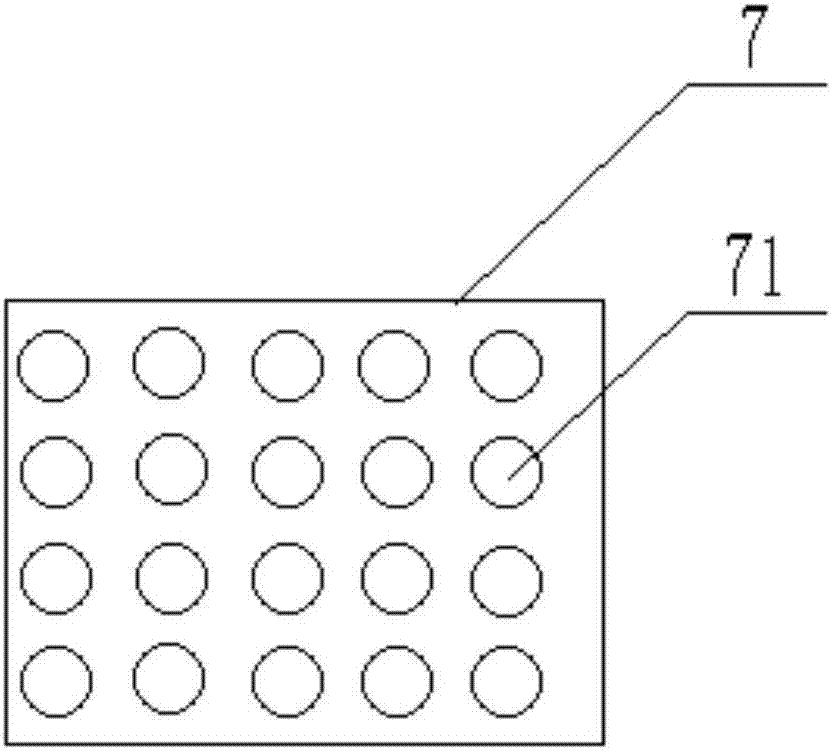

The invention discloses an automatic clothes folding packer. The automatic clothes folding packer comprises a rack and is characterized in that a main board and a folding component are arranged on the rack, the folding component is hinged to the rack (1), a transmission board (3) is arranged under the main board (2), a motor is arranged on the transmission board (3) or the rack (1), a packing station (4) and the motor used for driving the transmission board (3) to drive the main board (2) to reciprocate onto the packing station (4) are arranged on the rack (1), a transmission mechanism is arranged on the rack (1), and a clamping mechanism is arranged on the packing station (4). The invention further discloses a folding and packing method based on the automatic clothes folding packer. The automatic clothes folding packer provided by the invention can automatically finish clothes folding and packing, is high in integration performance, is motor-driven, eliminates noise, adopts a vertical structure and saves the working space.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

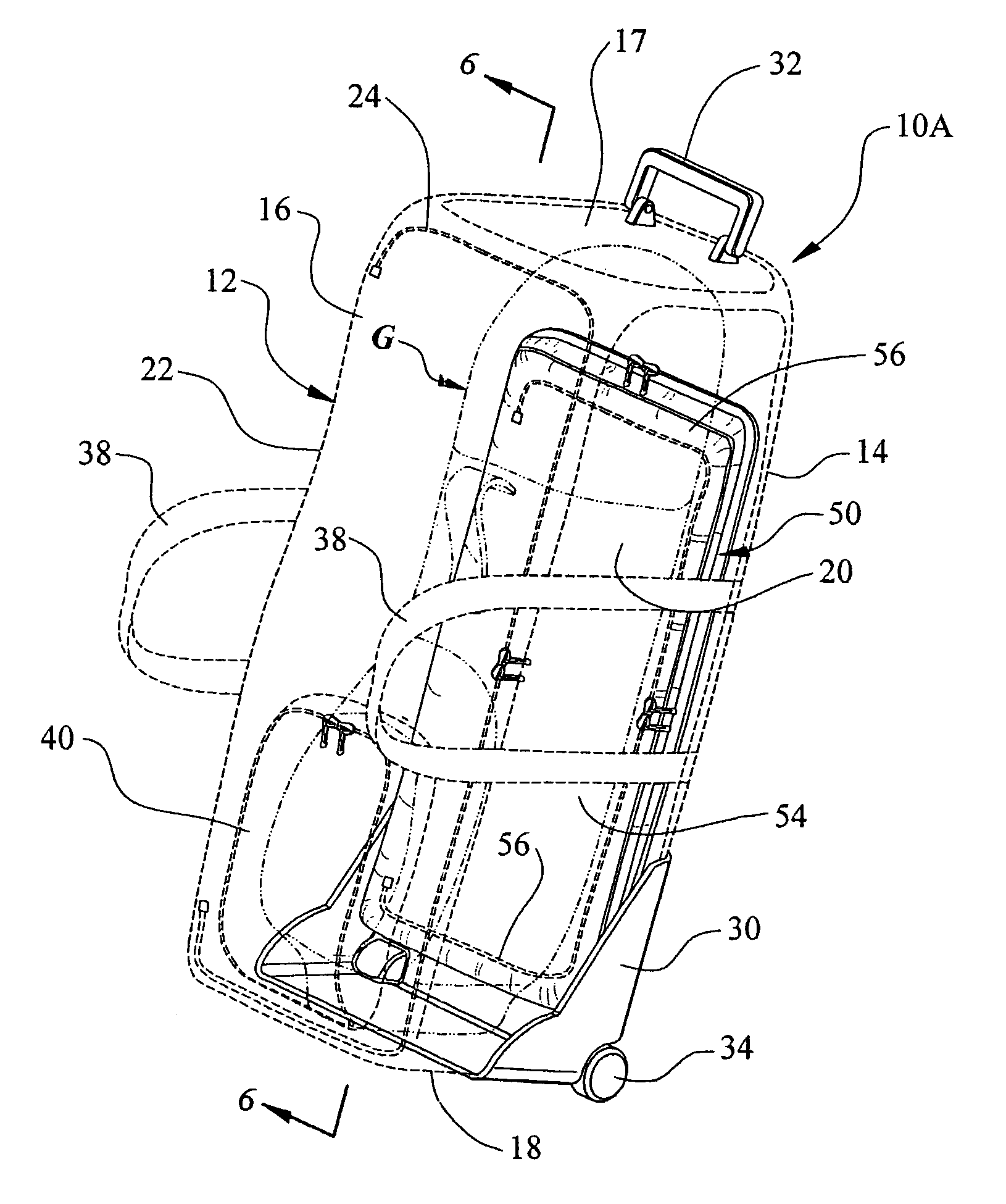

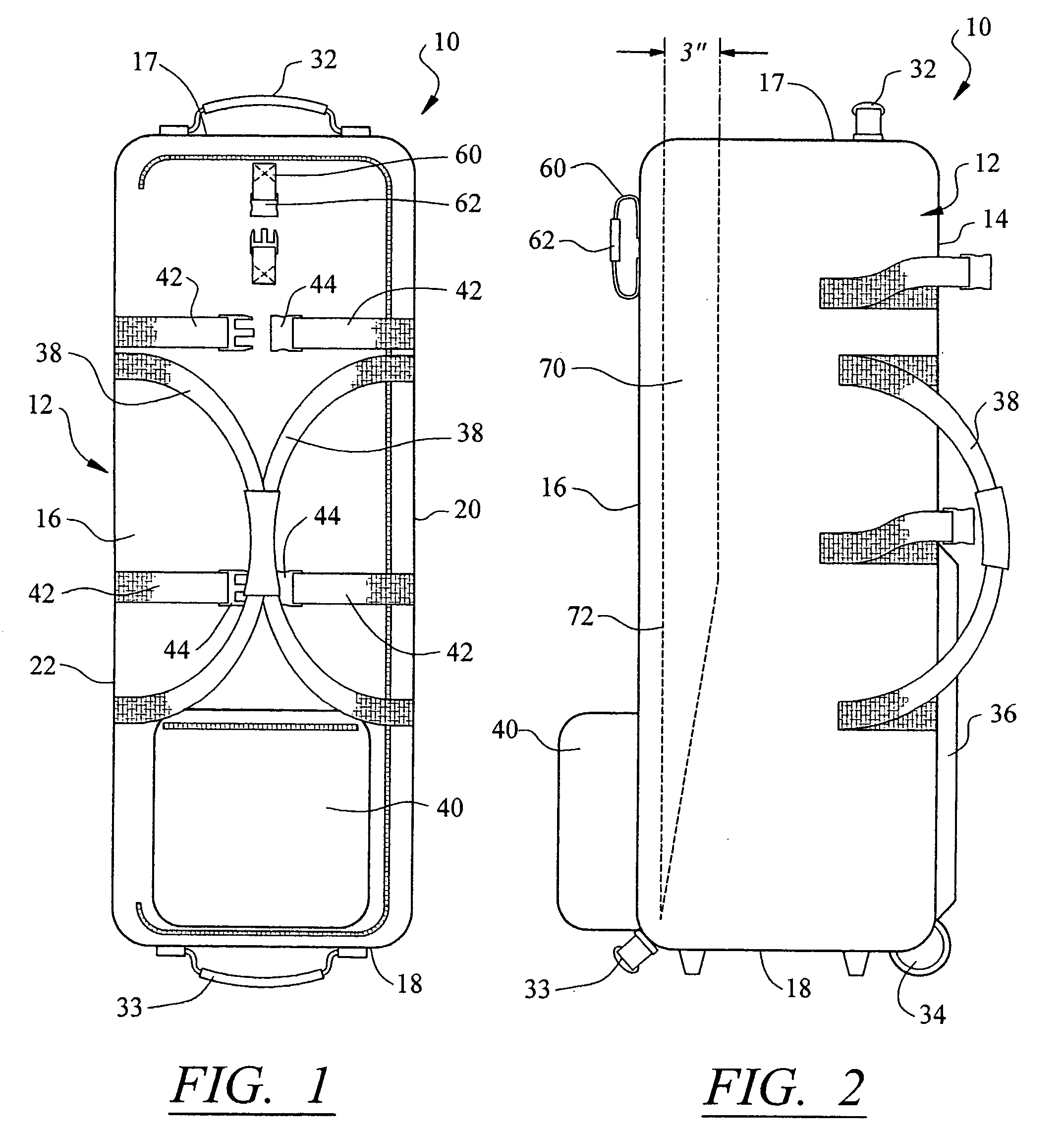

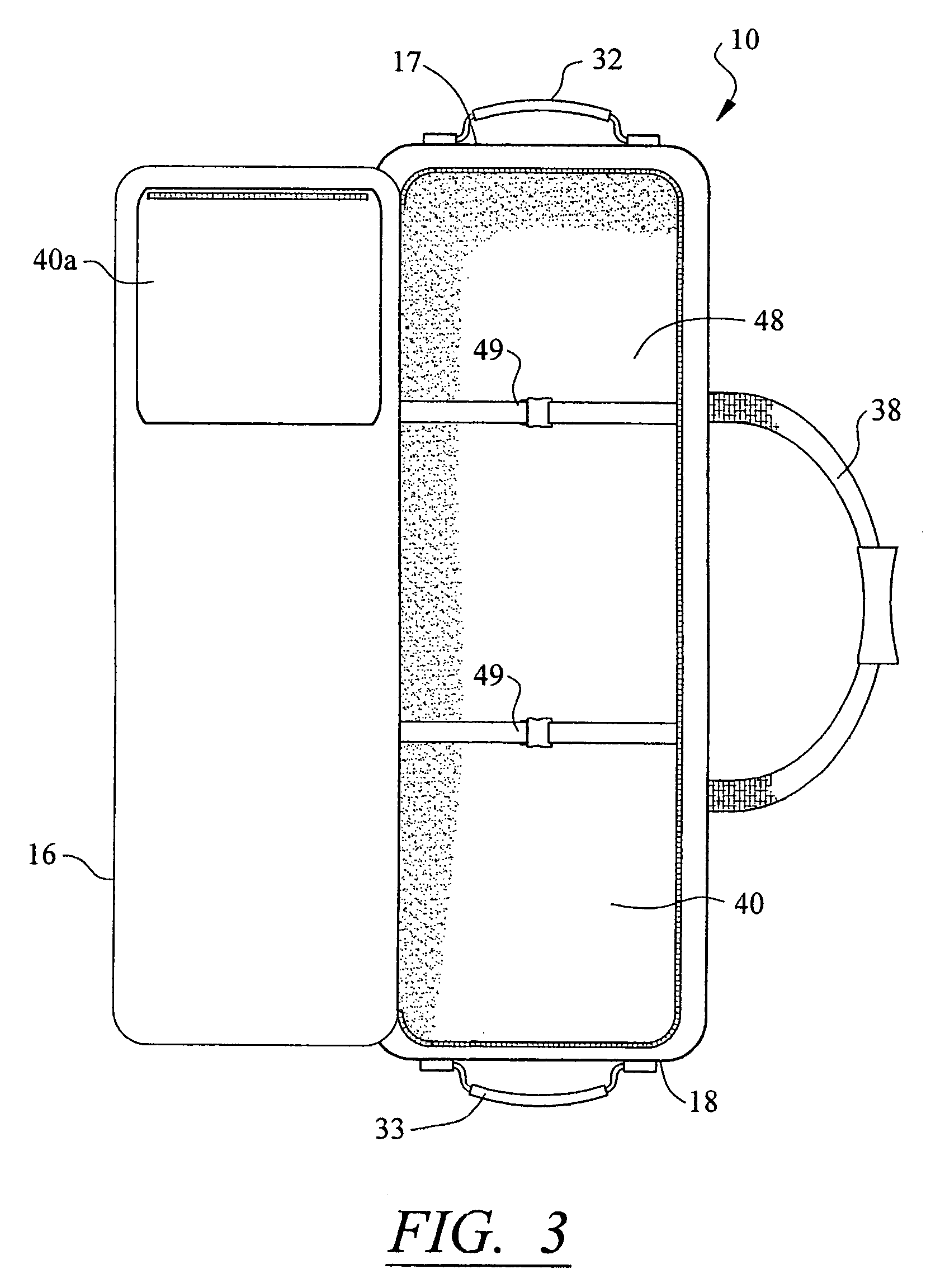

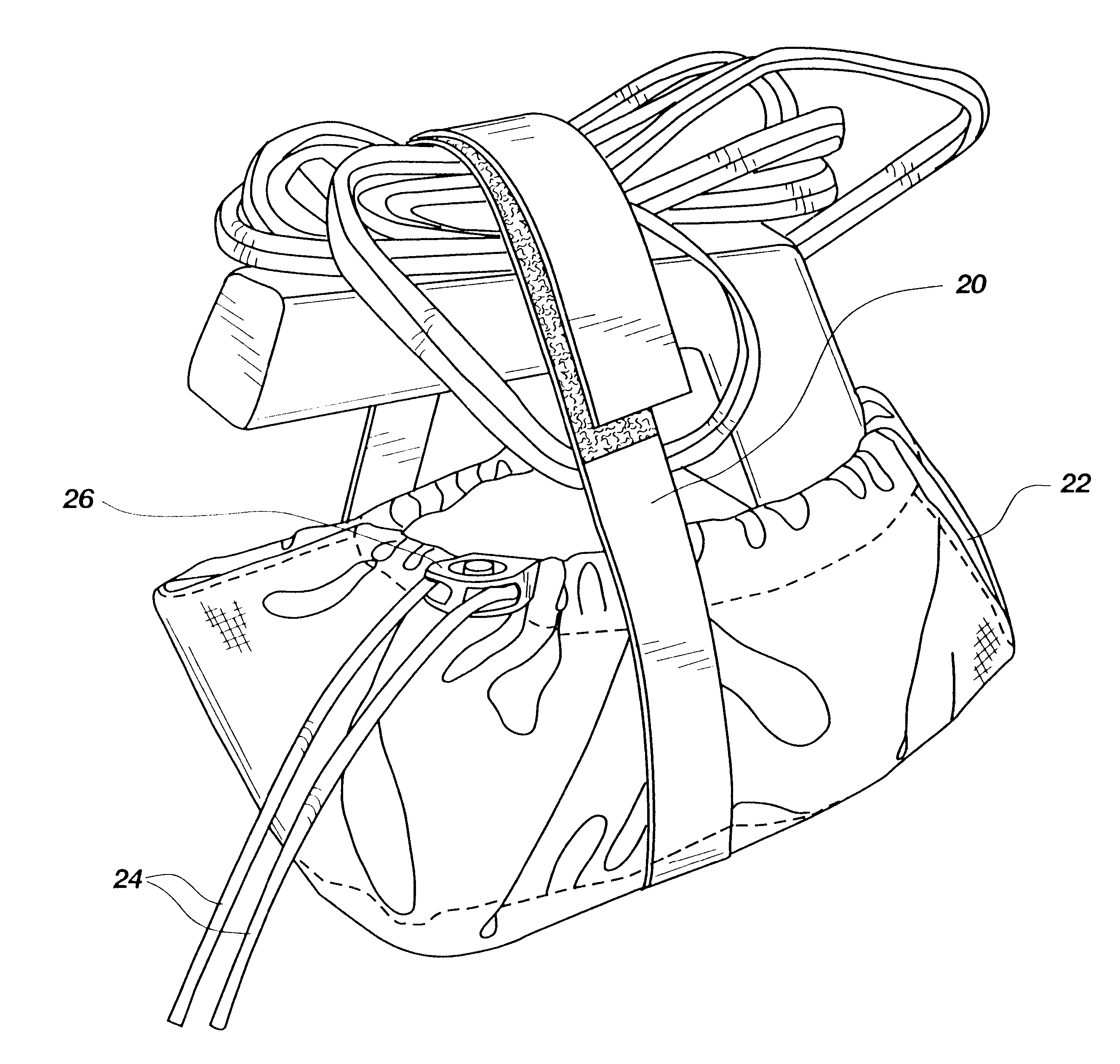

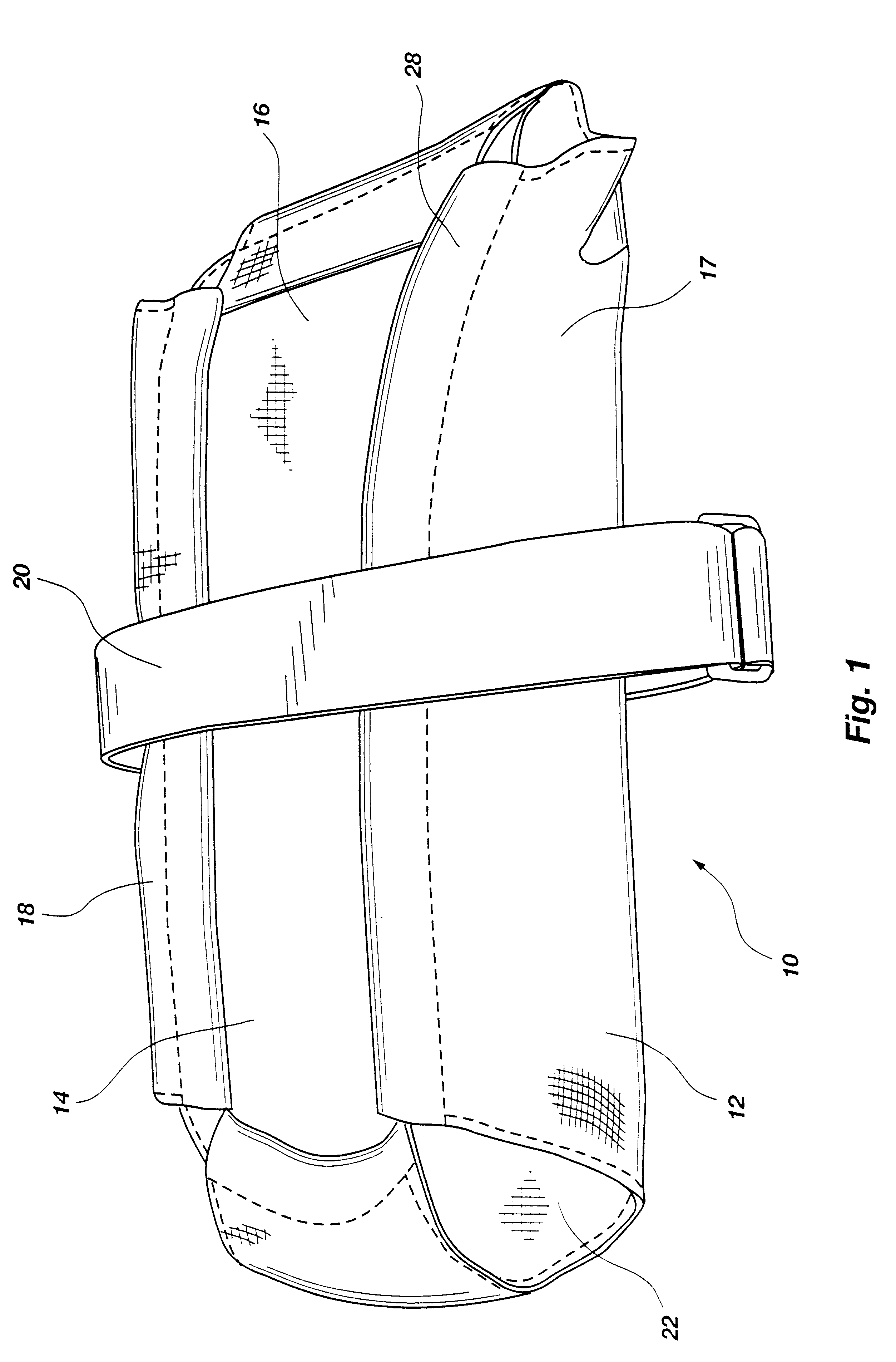

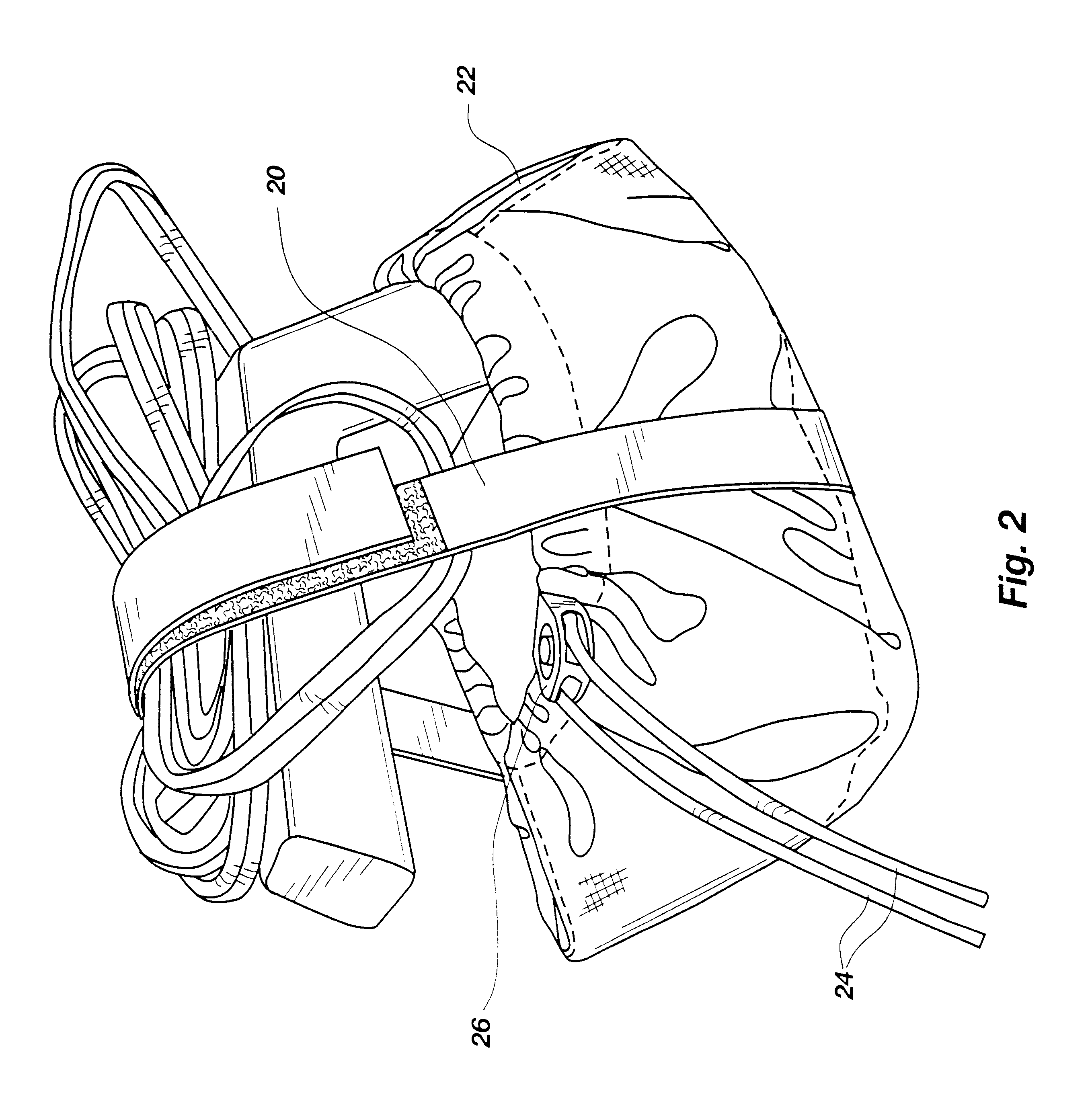

Combination golf bag travel cover and suitcase

InactiveUS7077252B2Prevents excessive wrinklingNeatly packedFlexible coversWrappersEngineeringGolf Ball

Owner:SANCHEZ RICARDO

Iron cover

An iron cover for ski wax irons a heat resistant liner having a padded bottom segment shaped to cover and protect the sole of an iron and a plurality of side flaps with ends. The side flaps extend sufficiently around the sides of an iron placed within the liner, and are secured around the iron with an elastic cord associated with the side flaps. The side flaps are structured and separated to define a plurality of heat release vents to allow heat to escape from a hot iron placed in the cover for storage.

Owner:ORIGINALITY

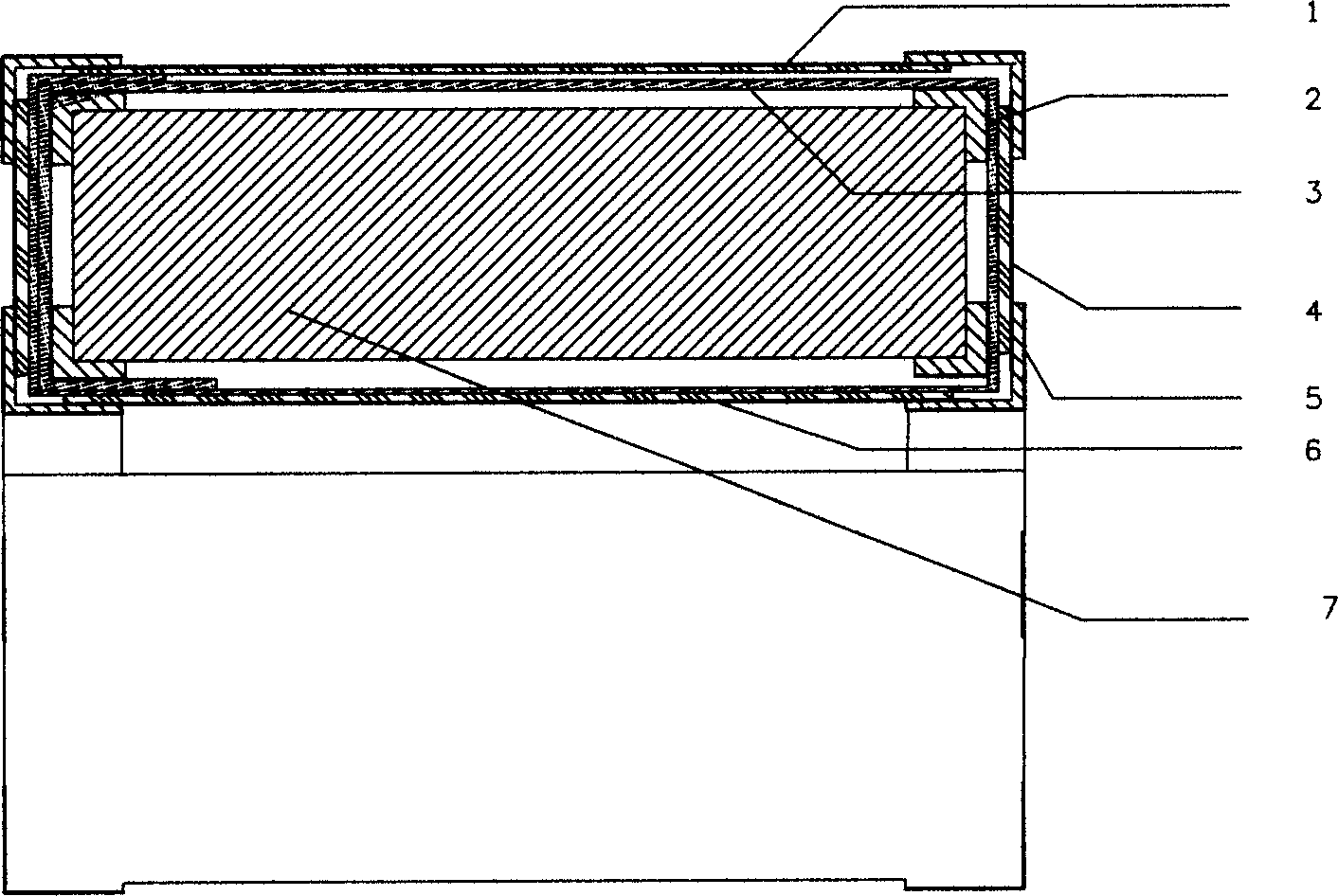

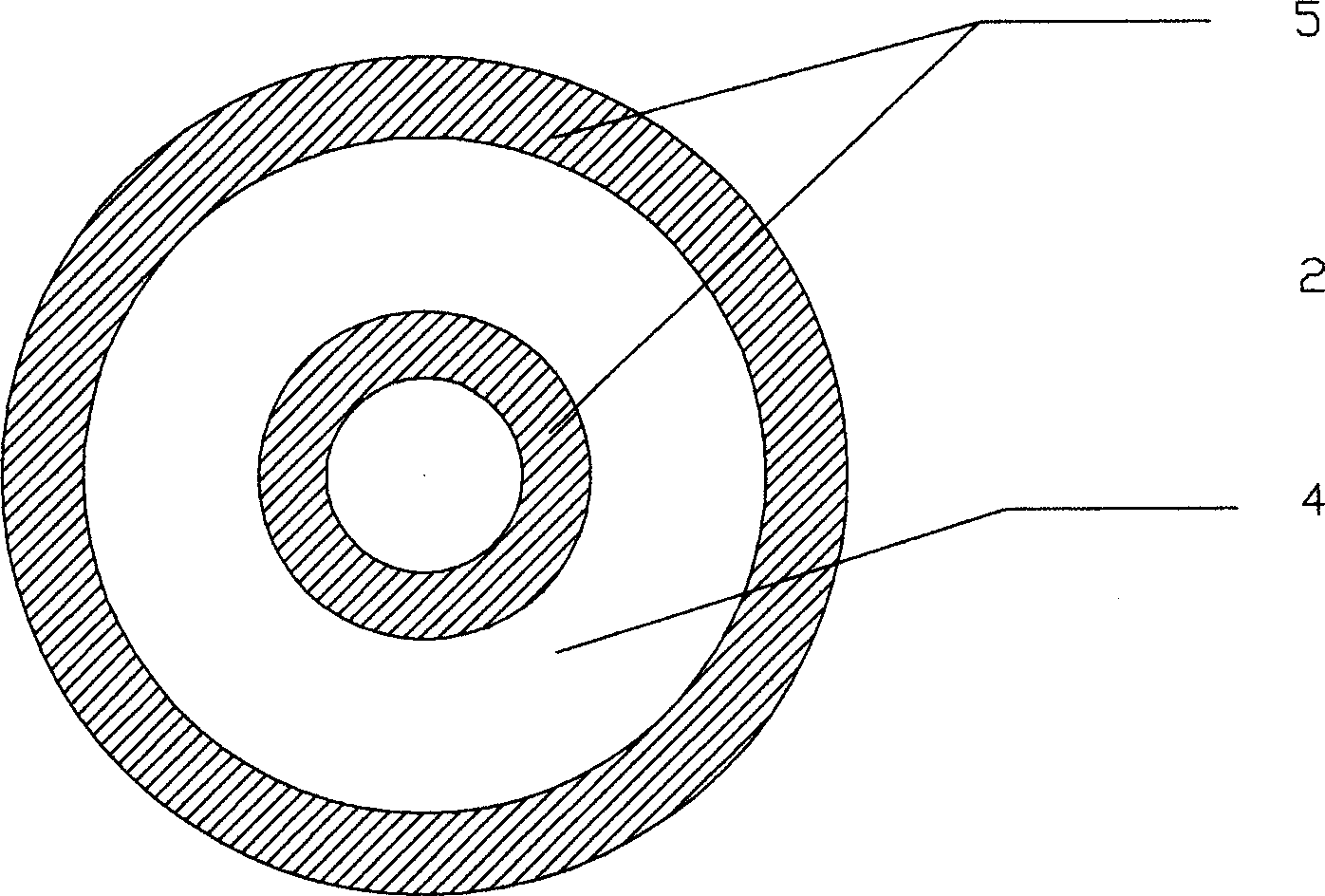

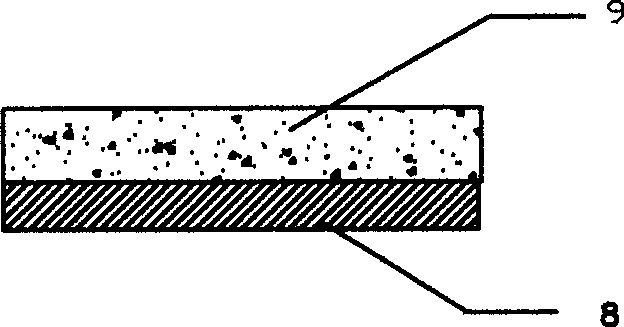

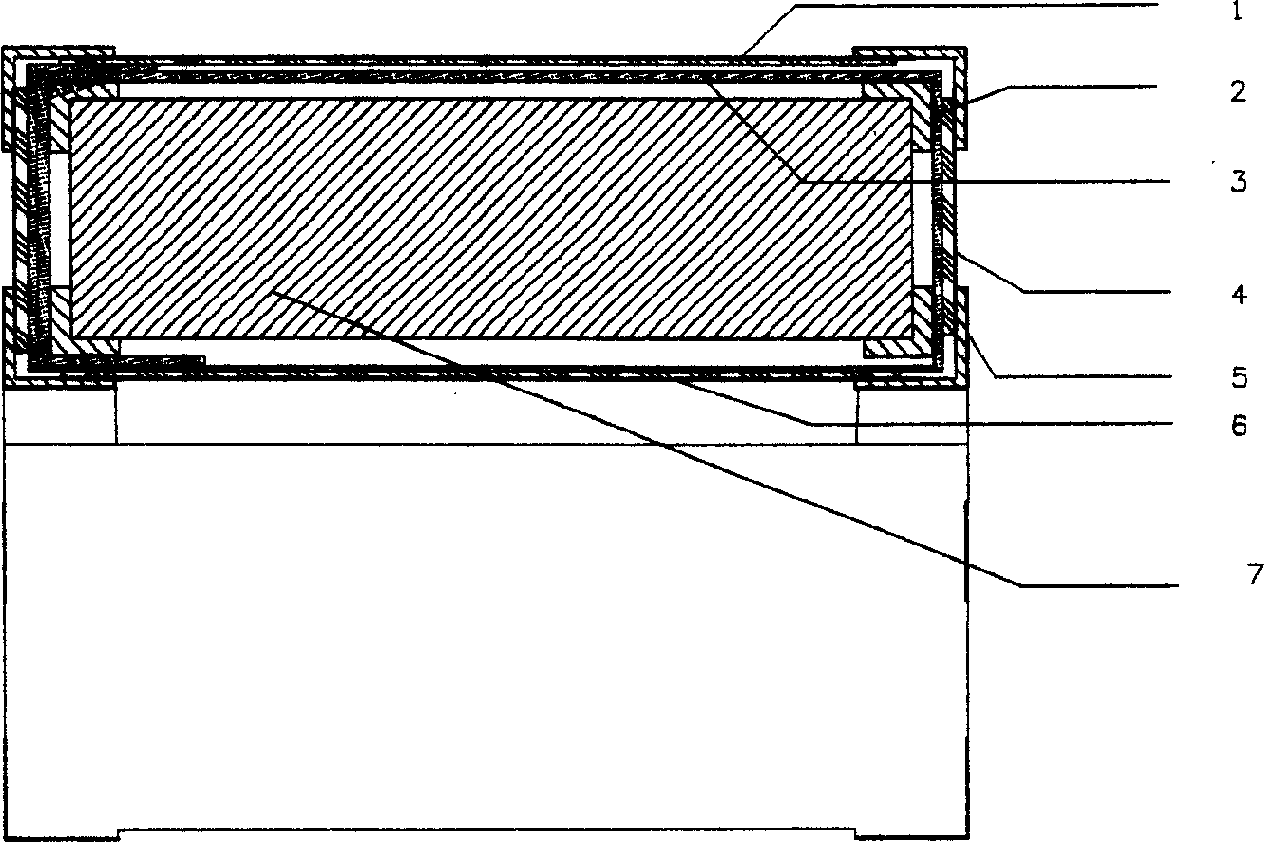

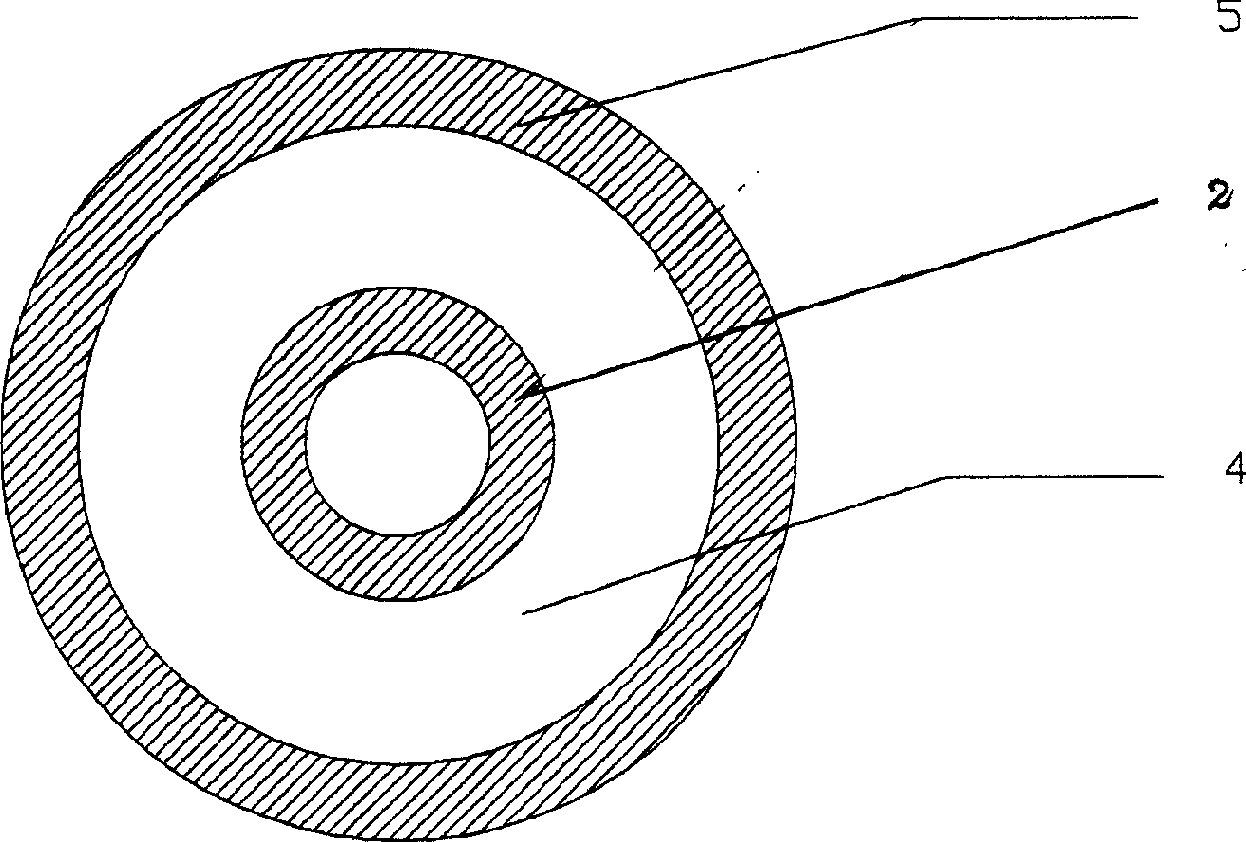

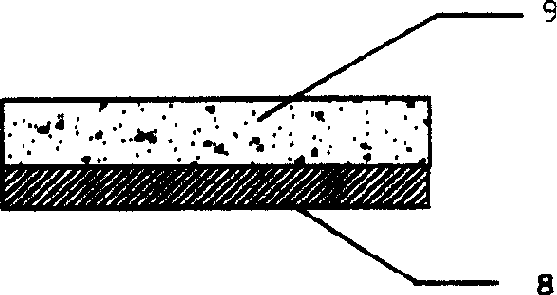

Packaging material for roll material and its packaging method

InactiveCN1380229AExcellent anti-rustImprove waterproof performancePaper article packagingFlexible coversFiberEngineering

The present invention relates to a packaging material for coiled material and its packaging method. It uses industrial composite packaging film, protection plate, end protection plate and metal protective corner as packaging material, and is characterized by that the industrial packaging film is formed from three layers of water-proofing layer, reinforcing layer and rust-proofing layer through the process of co-extrusion, its protection plate and end protection plate adopt the composite fibre packaging plate with water-proofing property. Said invention also provides the use method of these packaging material, and its packaging effect is good and solves the problem of resisting rust for coiled material.

Owner:鞍山市煜辉包装材料有限公司

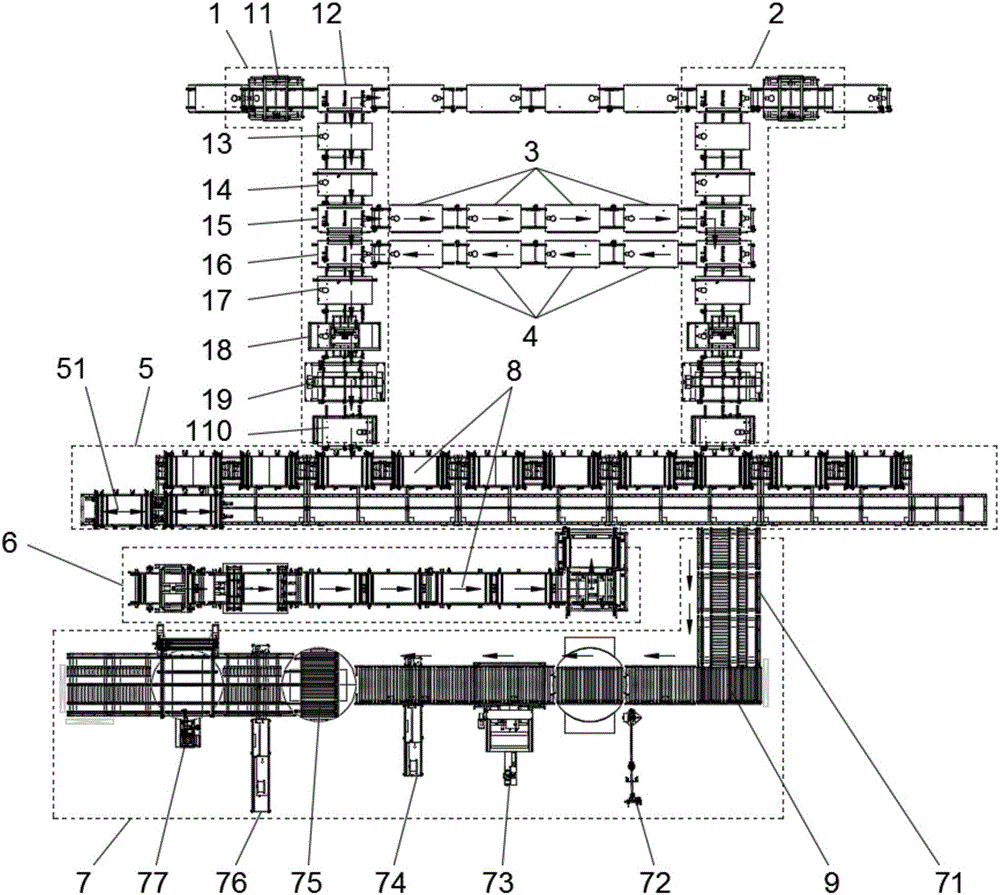

Automatic grading and encasement packaging system for solar cell modules

ActiveCN105836237AReduce work intensityNo secondary damagePackaging machinesControl systemSolar cell

The invention relates to an automatic grading and encasement packaging system for solar cell modules. The automatic grading and encasement packaging system for the solar cell modules comprises a first feeding sorting work line, a second feeding sorting work line, a first feeding-to-second feeding work line, a second feeding-to-first feeding work line, an inserting stack transportation work line, an empty stack loading work line and a full stack unloading work line. The first feeding sorting work line can be composed of a 90-degree conveying and steering unit, a first code reading and grading unit, a second code reading and grading unit, a grading and transportation unit, a confluence conveying unit, a conveying unit, a unit capable of horizontally turning by 180 degrees, a turnover unit, a restoration unit and a control system. The second feeding sorting work line and the first feeding sorting work line act as mirror images of each other. According to the automatic grading and encasement packaging system for the solar cell modules, the working intensity of workers can be reduced, the number of workers can be reduced, the labor cost can be reduced, sorting accuracy is improved, sorting encasement efficiency can be improved by 45%, encasement is more stable and more orderly, and no secondary damage is caused to products.

Owner:SUZHOU IND ROBOT TECH

Food packaging technology

ActiveCN105235946AEasy to storeEasy to transportWrapper twisting/gatheringMaterial resourcesEngineering

The invention discloses a food packaging technology and relates to the technical field of the food packaging technology. The food packaging technology includes a material conveying step, a material overturning and arranging step, a material sorting step, a bag taking step, a bag opening step and a packaging step. According to the packaging technology, after food is packaged in small bags through an outer packaging machine, the small bagged food is overturned, arranged, sorted and laminated; and finally, the small bagged food is packaged into food packaged in large bags. The whole technologic process is full automatic and mechanical, manual packaging is not needed, and a large amount of manpower and material resources are saved. The packaging technology is high in automatic and mechanical degree, packaging efficiency can be improved easily, and storage and transportation of the food packaged in bags are facilitated.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

Fruit vacuum packaging machine

ActiveCN107963257ANeatly packedOrderly rowsPackaging by pressurising/gasifyingWrapper twisting/gatheringManipulatorFilm coating

The invention relates to the technical field of packaging machinery, in particular to a fruit vacuum packaging machine. The fruit vacuum packaging machine comprises a rack body, the rack body is provided with one conveyor belt, the platform surface of the rack body is provided with a pressing conveying device, a heat-seal device, a vacuum machine and an edge cutting machine in sequence along the conveyor belt, a lower die is placed on the conveyor belt, packaging bottom film is arranged on the lower die in an attached manner, the packaging bottom film is provided with fruits placed in corresponding fruit placement holes of the lower die, the pressing conveying device is provided with an upper die and places the upper die onto the lower die below to fit into a closed block body through a mechanical arm, a packaging film conveying roller is arranged below the pressing conveying device, and the fruits are placed on the lower die which is provided with the packaging bottom film in an attached manner, under the conveying of conveyor belts, film coating, heat sealing, vacuum pumping and edge cutting will be performed in sequence at each station. By means of the fruit vacuum packaging machine, the packaged products are convenient to check and are prevented from deterioration, and the fruit vacuum packaging machine is accurate in control and good in packaging effect.

Owner:邱逸奎

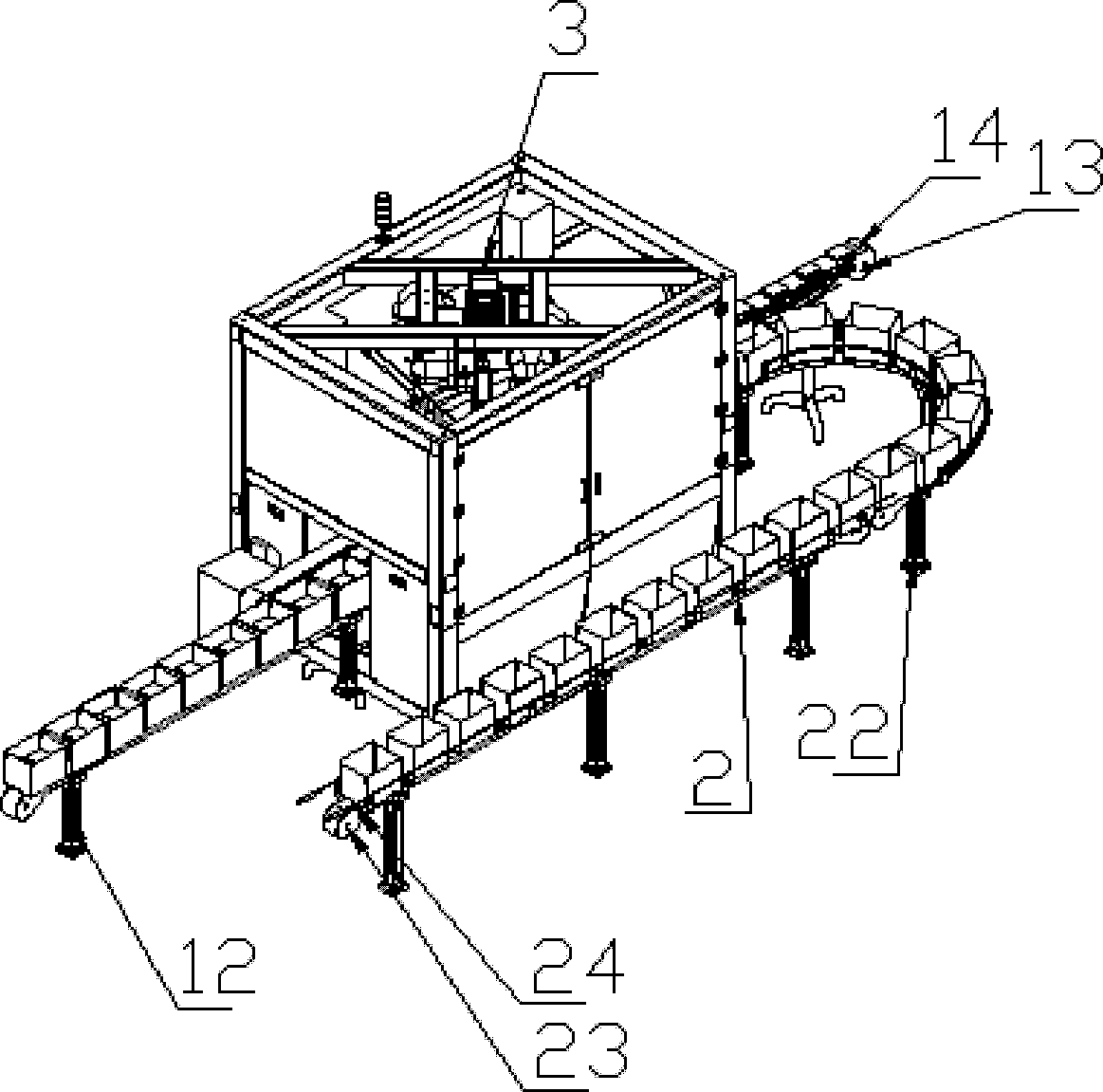

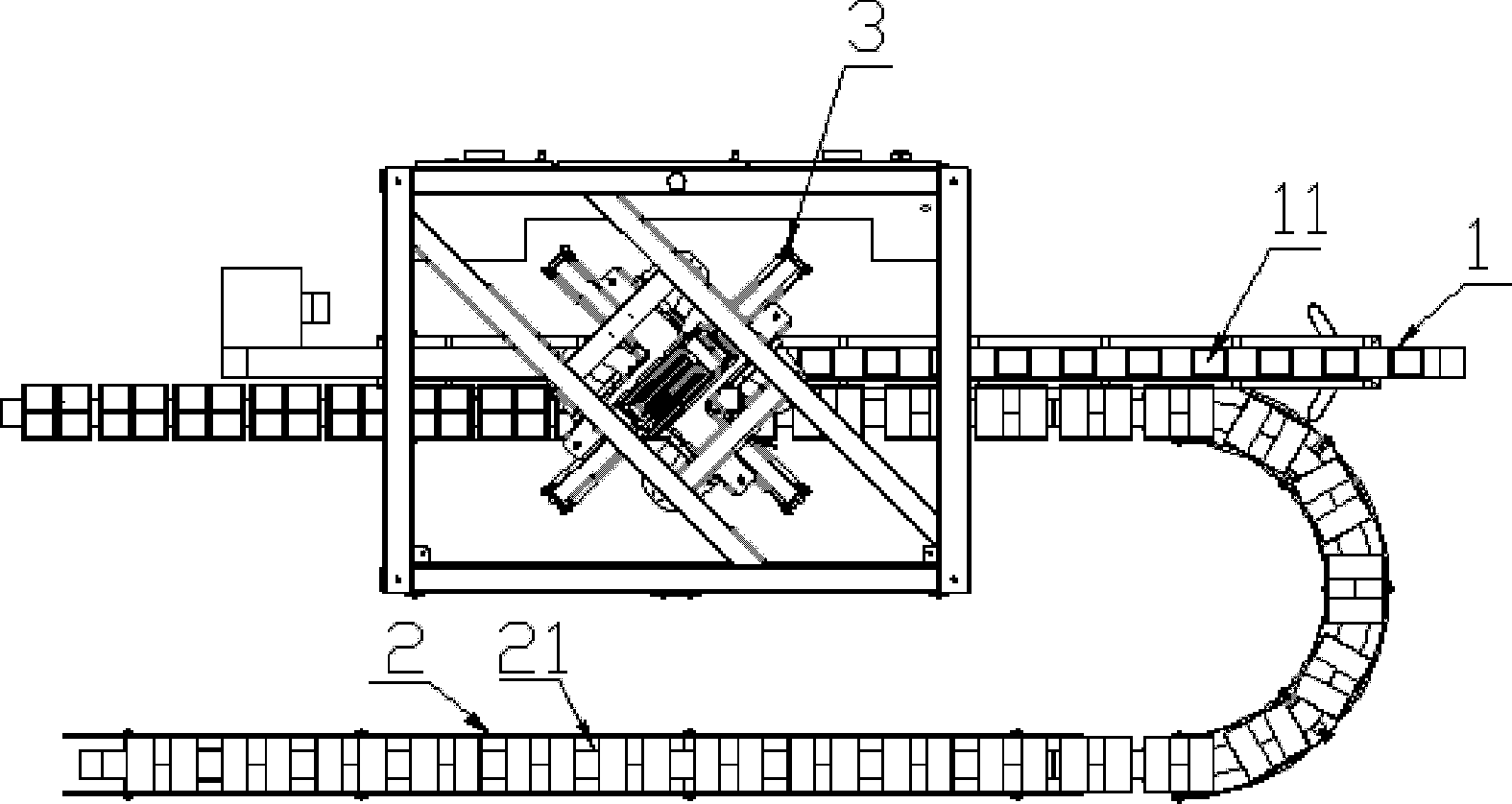

Milk bag casing system

InactiveCN102730244AReduce labor intensityFast packingPackaging automatic controlEngineeringMechanical engineering

The invention discloses a milk bag casing system which comprises a milk bag conveying line, a packing case conveying line, grabbing robots, a milk bag position sensing device, a packing case position sensing device and a controller, wherein the milk bag conveying line and the packing case conveying line can respectively drive milk bags and packing cases to move; based on the application direction, the milk bag conveying line and the packing case conveying line respectively passes through the position just below at least one grabbing robot; the milk bag position sensing device and the packing case position sensing device are respectively arranged on the milk bag conveying line and the packing case conveying line, and can respectively sense the positions of each milk bag and each packing case and transmit sensing signals to the controllers; and the controller can control the grabbing robots to grab milk bags (in a preset number) and arrange the milk bags in each packing case. The milk bag casing system disclosed by the invention is rapid in casing speed and neat in casing, causes no neglected loading and milk bag damage phenomenon, saves a lot of workers, and reduces the labor intensity of workers.

Owner:苏州澳昆智能机器人技术有限公司

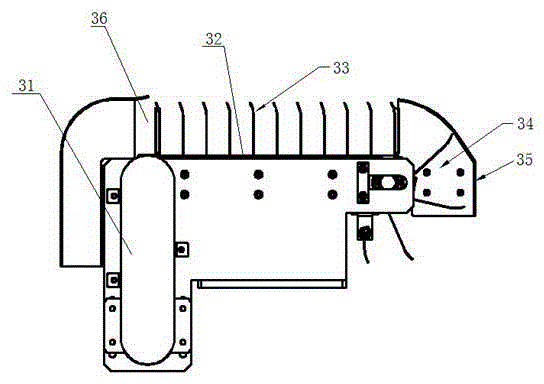

Printed product packing machine

PendingCN109178384ANeatly packedRealize automatic wrappingWrappingPulp and paper industryKraft paper

The invention discloses a printed product packing machine which comprises a rack, a loading and conveying mechanism, a paper packing mechanism, a kraft paper tailoring mechanism, an adhesive tape attaching and tailoring mechanism and an unloading and conveying mechanism. The paper packing mechanism comprises a paper feeding mechanism, a paper taking mechanism, a jacking mechanism and a clamping mechanism. The paper taking mechanism is arranged on the left side of the paper feeding mechanism, the jacking mechanism is arranged below the part between the feeding mechanism and the paper taking mechanism, and the clamping mechanism is arranged above the paper feeding mechanism, has a clamping opening formed downward and can move above the paper feeding mechanism in a reciprocating manner; and both the kraft paper tailoring mechanism and the adhesive tape attaching and tailoring mechanism are arranged between the paper feeding mechanism and the clamping mechanism, and the kraft paper tailoring mechanism is located on the left side of the adhesive tape attaching and tailoring mechanism. The printed product packing machine can feed paper automatically in a turning manner to hide sealed edges and keeps the tensity of the kraft paper all the way, so that the printed products are packaged orderly and are packed automatically.

Owner:汕头市顺鑫隆印刷机械有限公司

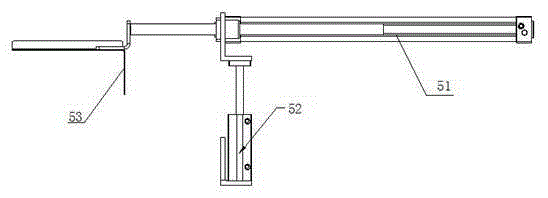

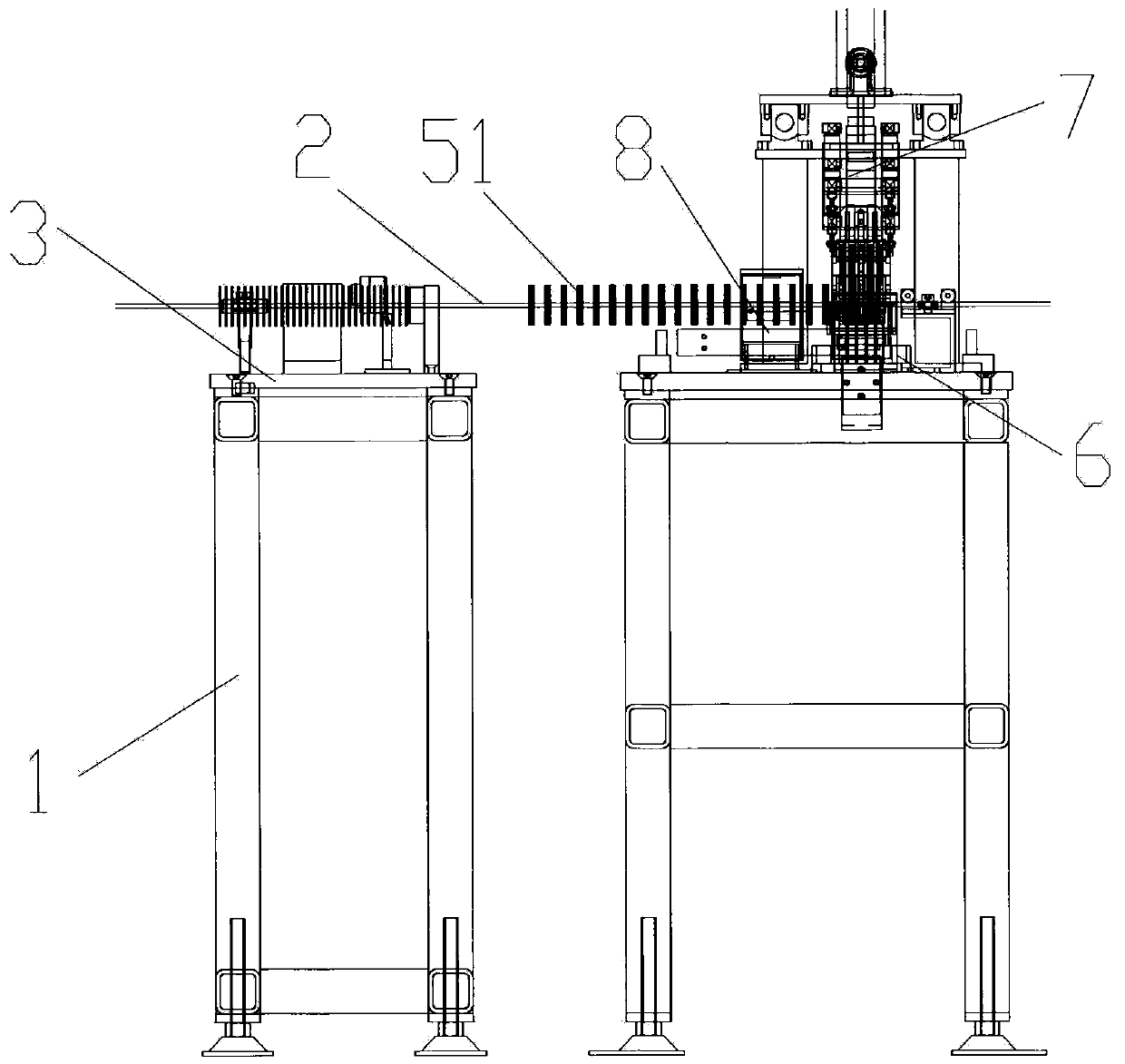

Packaging robot for steel strip assembly line

The invention relates to a packaging robot for a steel strip assembly line. The packaging robot comprises a machine frame and a steel strip, wherein the steel strip is arranged on the upper side of the machine frame and transversely penetrates through the machine frame; a counting and separating device, a queuing and collating device, a bag-taking device, a clamping device and a grabbing device are sequentially arranged on the machine frame; the machine frame is located on one side of the steel strip and a bag box is arranged in a position adjacent to the clamping device; the bag-taking device can traverse between the bag box and the clamping device; the grabbing device is arranged above the steel strip; the grabbing device can traverse between the queuing and collate device and the clamping device. According to the invention, the packaging robot is adopted to replace manual packaging; the packaging robot can automatically adapt to the speed of the steel strip assembly line; the packaging and counting are accurate and the packaging is uniform; moreover, the production efficiency of factories, the finished product ratio, as well as the accuracy of measurement can be further greatly improved. Therefore, the production development of enterprises can be promoted.

Owner:张家港市瑞昌智能机器系统有限公司

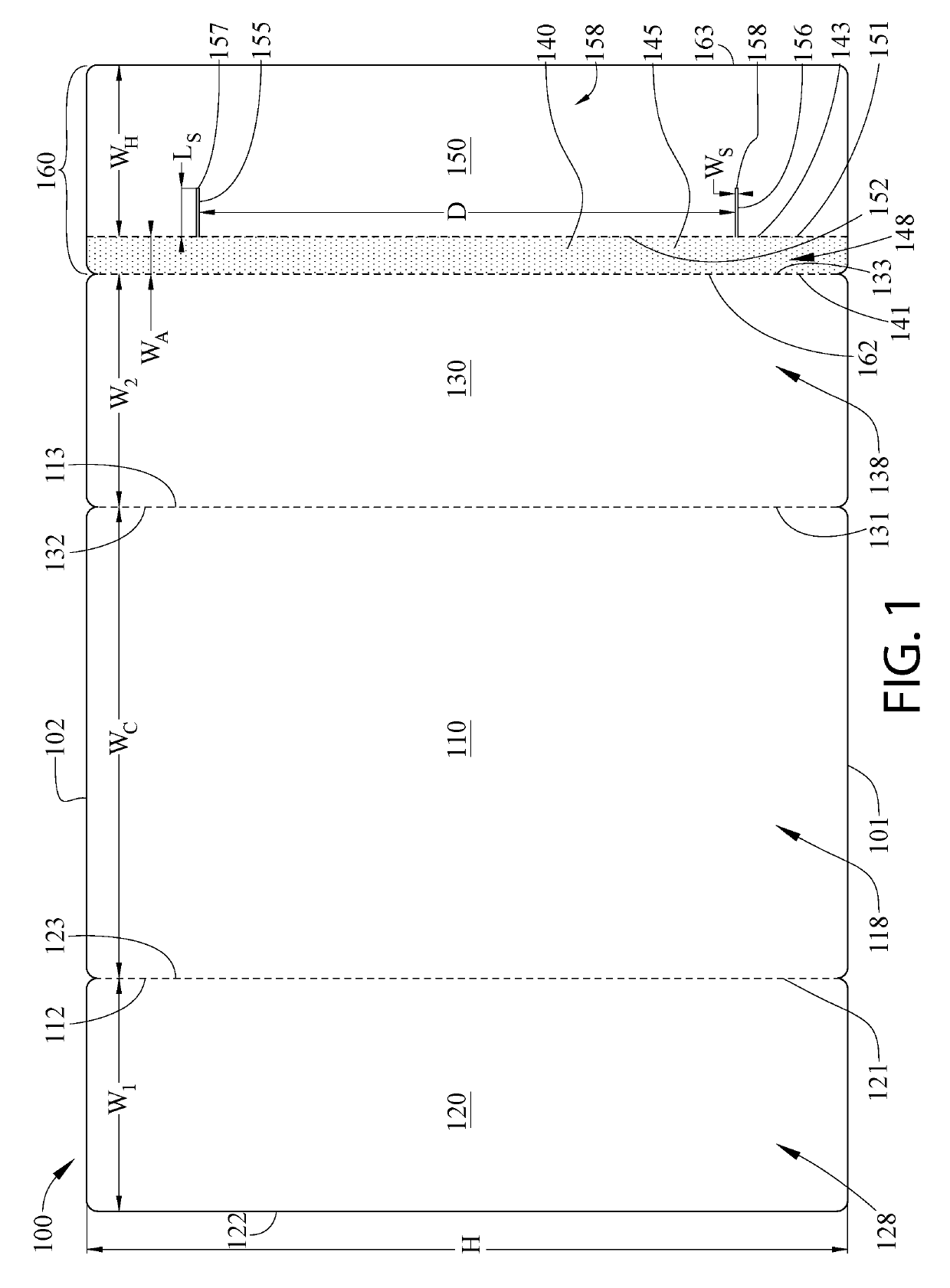

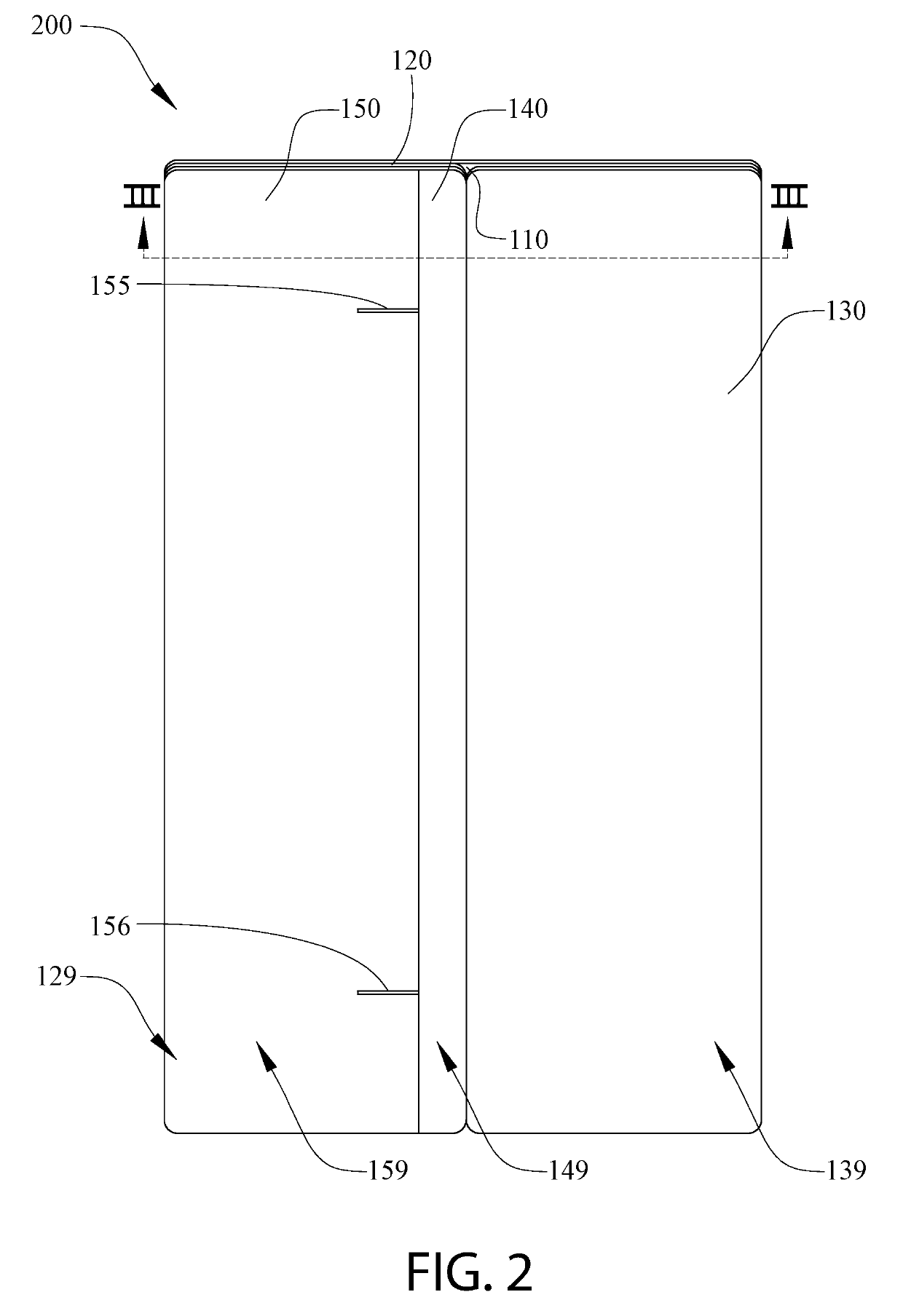

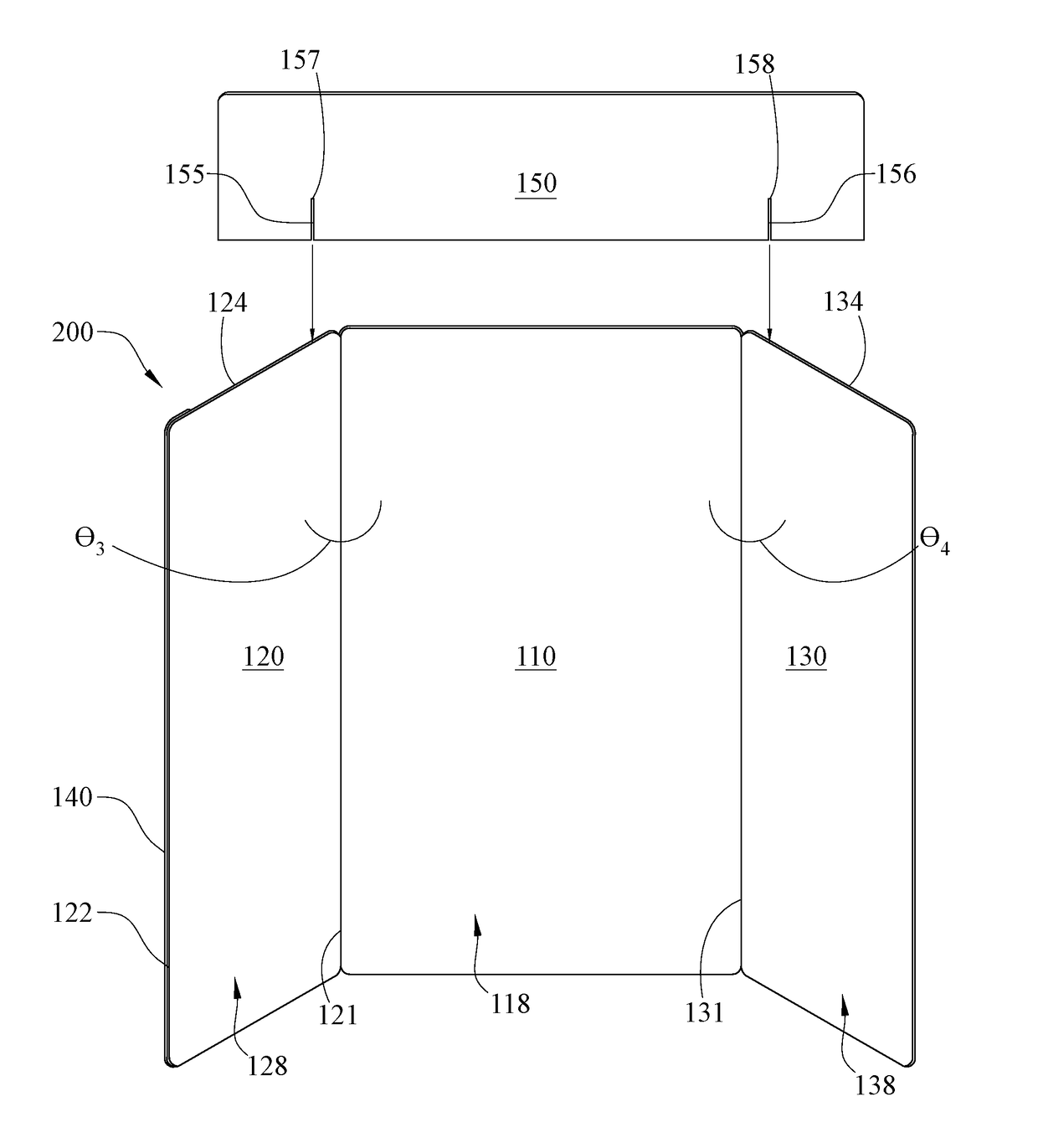

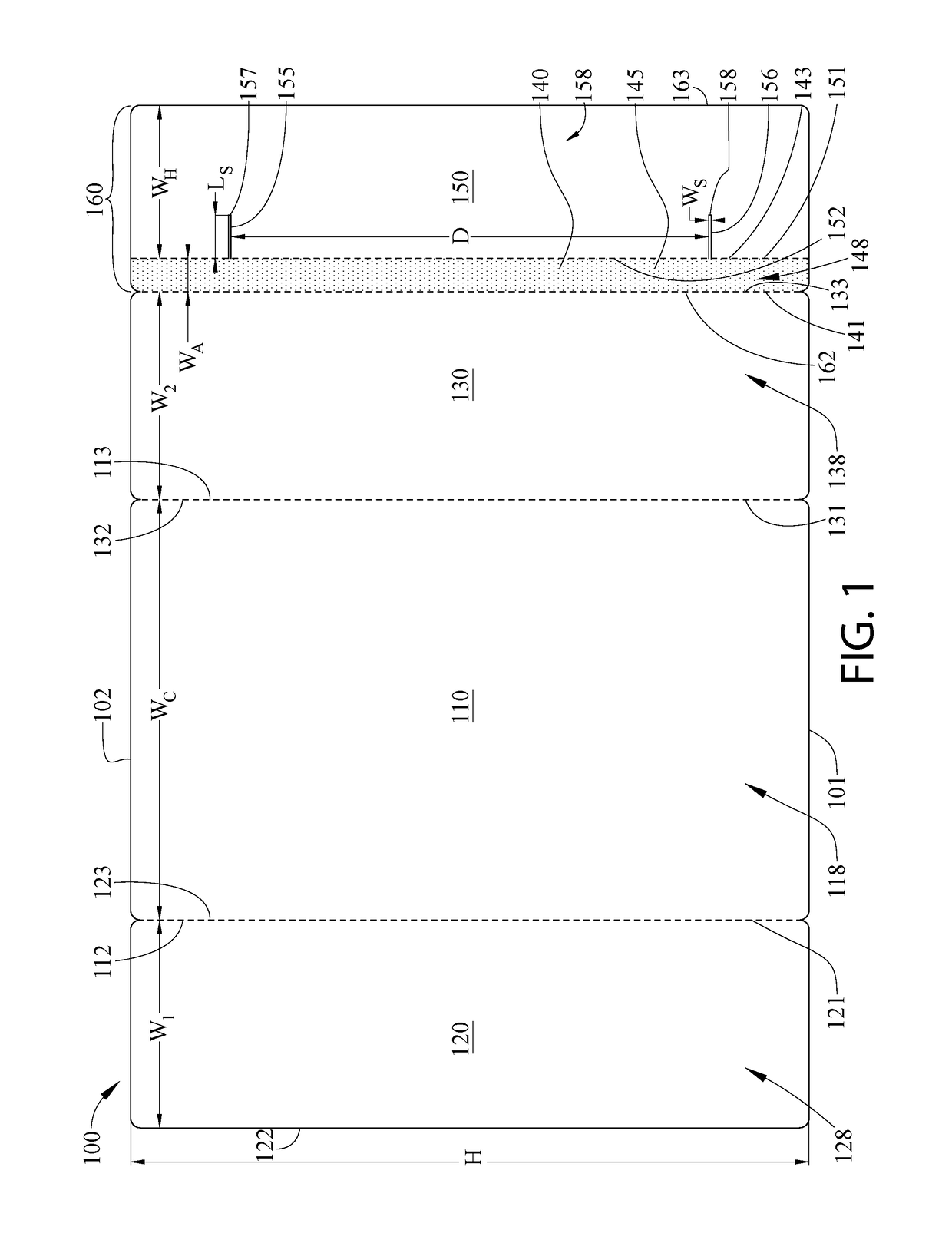

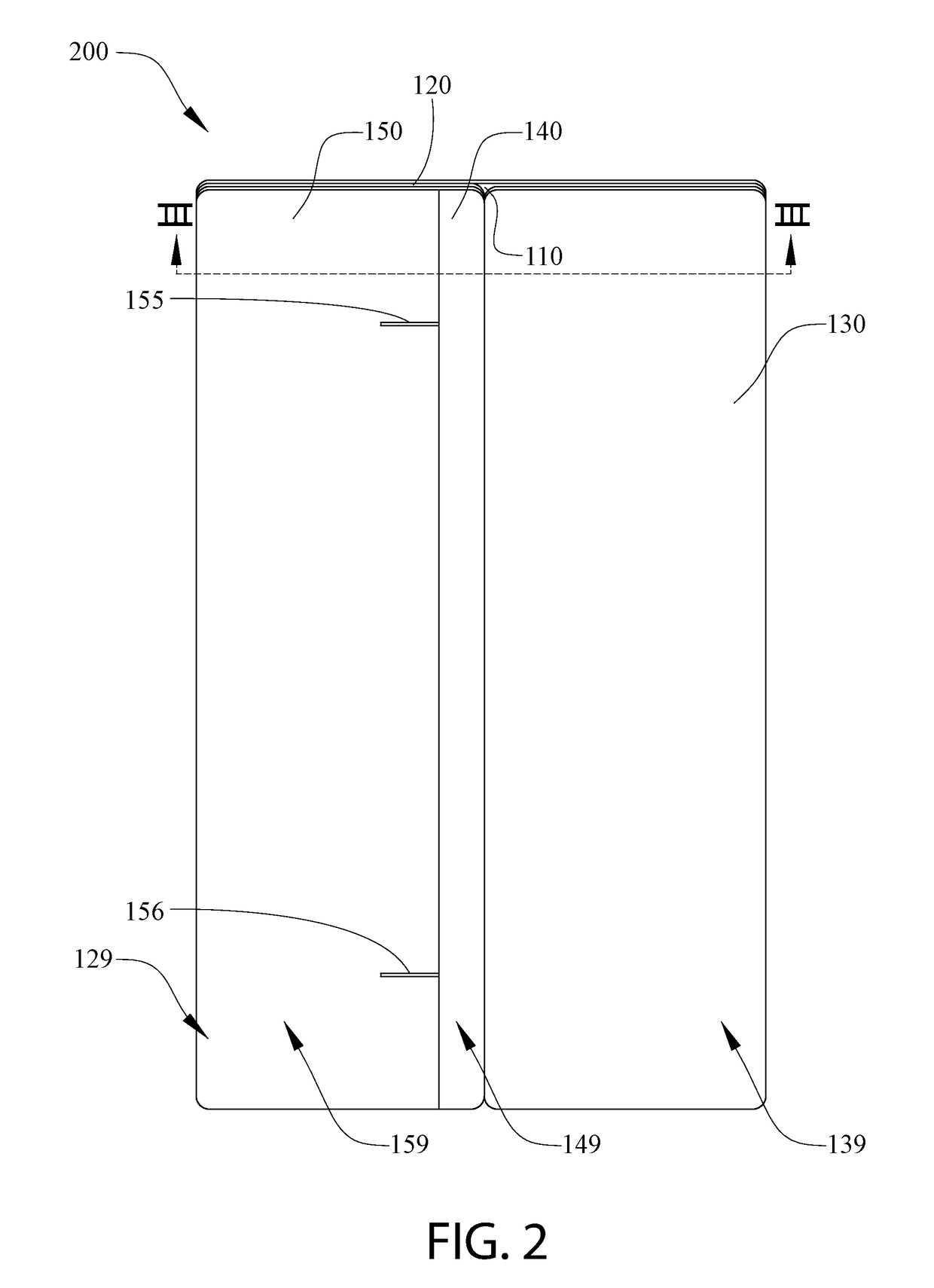

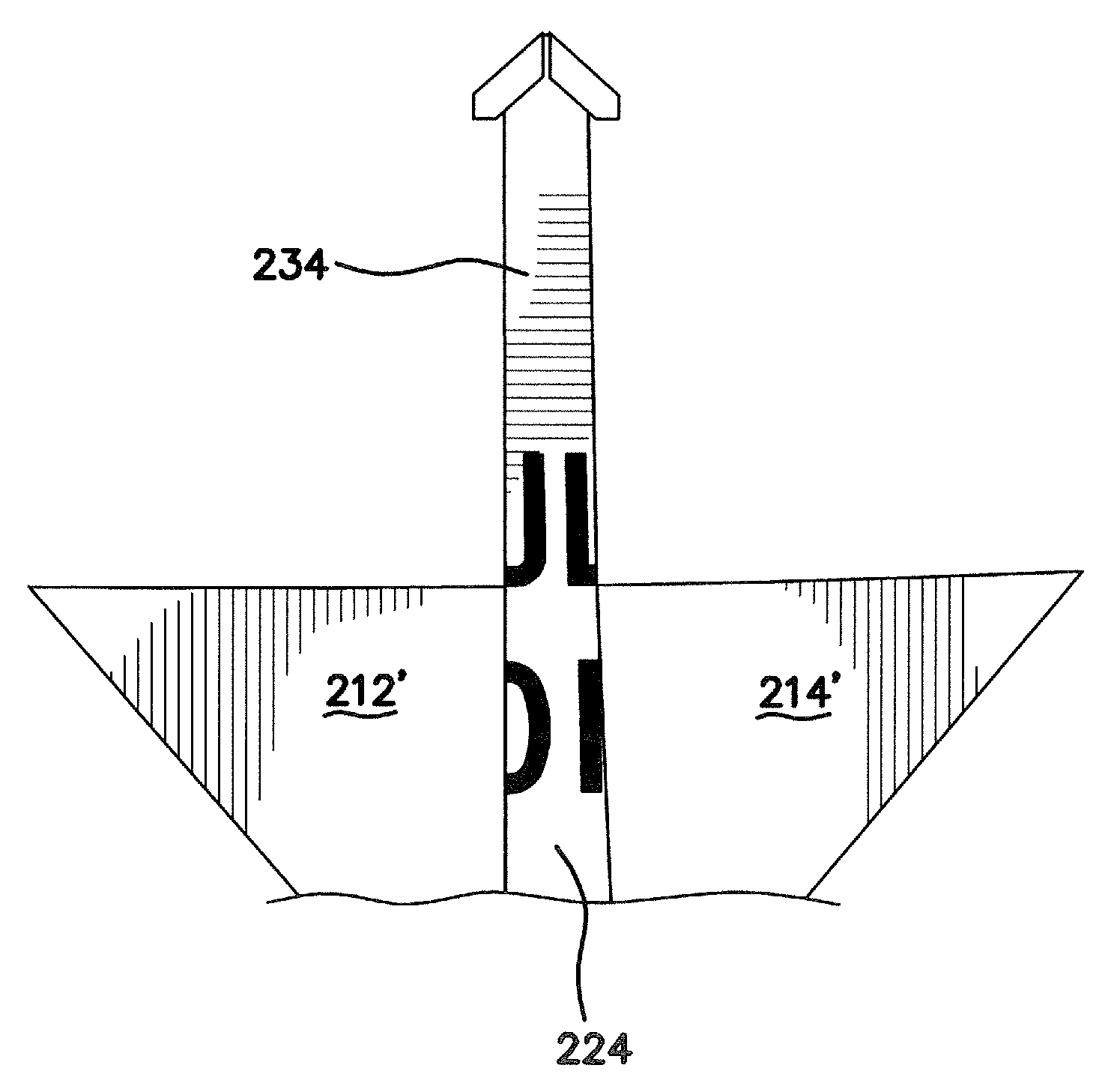

Multi-panel display kit

A multi-panel display kit that includes a multi-panel display device and a header panel. The multi-panel display device may have a center panel, a first side panel attached to the center panel on a first side thereof, and a second side panel attached to the center panel on a second side thereof, the second side of the center panel being opposite the first side of the center panel. The first and second side panels may have a combined width that is less than a width of the center panel. The header panel may have a height that is substantially equal to the difference between the width of the center panel and the sum of the widths of the first and second side panels. Thus, in a folded state, the header panel may fit within a gap between the first and second side panels.

Owner:ARTSKILLS

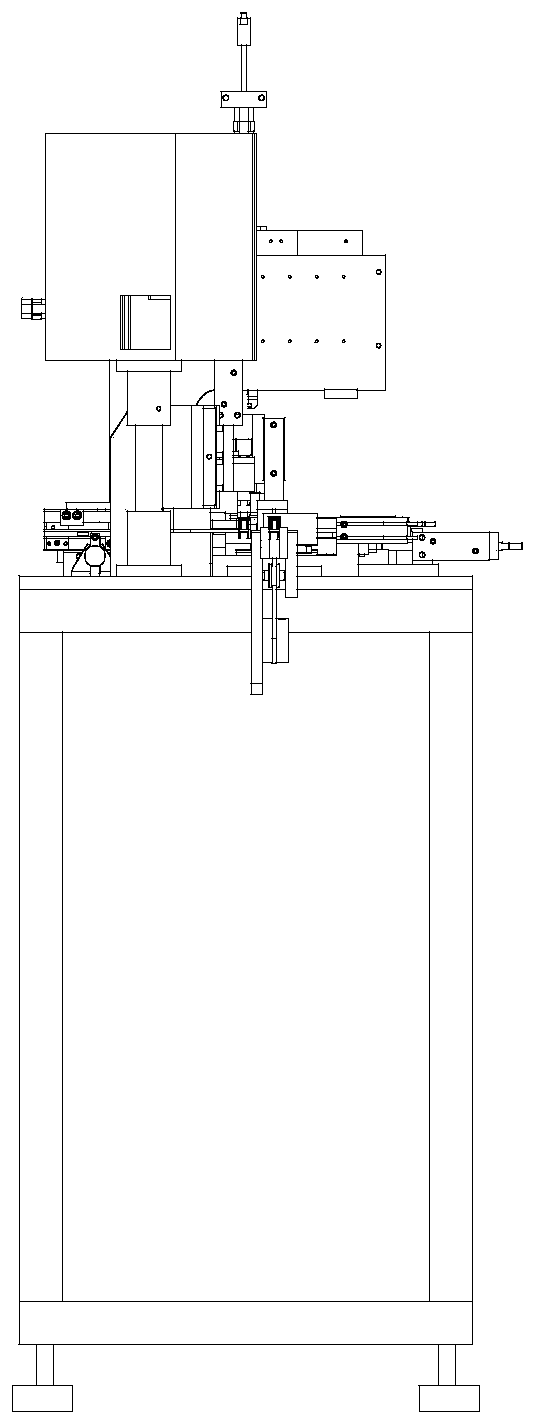

Mobile full-automatic steel pipe picking, cleaning, classification and packing device

InactiveCN108100347ANeatly packedRealize automatic packagingSievingScreeningEngineeringMechanical engineering

The invention discloses a mobile full-automatic steel pipe picking, cleaning, classification and packing device, and belongs to the field of construction. The device consists of a picking device, a cleaning device, a classifying device, a packing device and a moving device. An electromagnetic sucker picking device is used for guaranteeing stability and safety in the process of shifting steel pipesto a conveying belt; meanwhile, when a slide block touches a switch for limitation, the slide block is stopped moving; and a coil is powered off to realize demagnetization, so that the steel pipes fall down to the conveying belt. A vibration screen is arranged above a vibration plate; and a polishing wheel is arranged above the conveying belt for thoroughly removing rust on the surfaces of the steel pipes. Calibers with different lengths are used for realizing classification of the steel pipes with different diameters; and meanwhile, an inclined plate is used for driving falling and rolling of the steel pipes to improve smoothness in the classifying process. Through shrinkage of a cylinder, a rubber rope is driven to shrink, so that automatic packing of the steel pipes is realized. Wheelsand a motor are used for realizing free movement of the whole device, so that the flexibility of the device is greatly improved.

Owner:朱小英

Multi-panel display kit

A multi-panel display kit that includes a multi-panel display device and a header panel. The multi-panel display device may have a center panel, a first side panel attached to the center panel on a first side thereof, and a second side panel attached to the center panel on a second side thereof, the second side of the center panel being opposite the first side of the center panel. The first and second side panels may have a combined width that is less than a width of the center panel. The header panel may have a height that is substantially equal to the difference between the width of the center panel and the sum of the widths of the first and second side panels. Thus, in a folded state, the header panel may fit within a gap between the first and second side panels.

Owner:ARTSKILLS

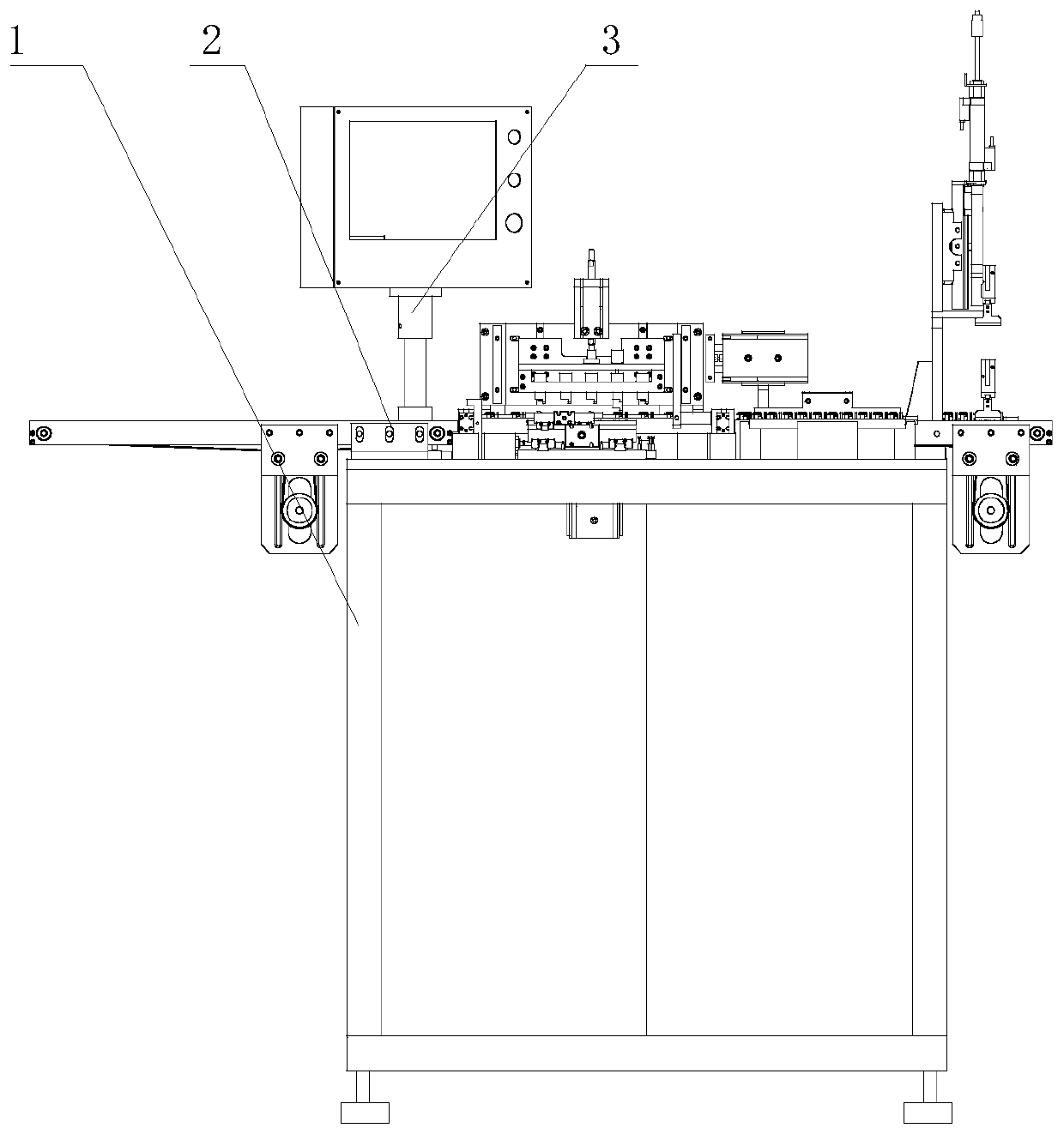

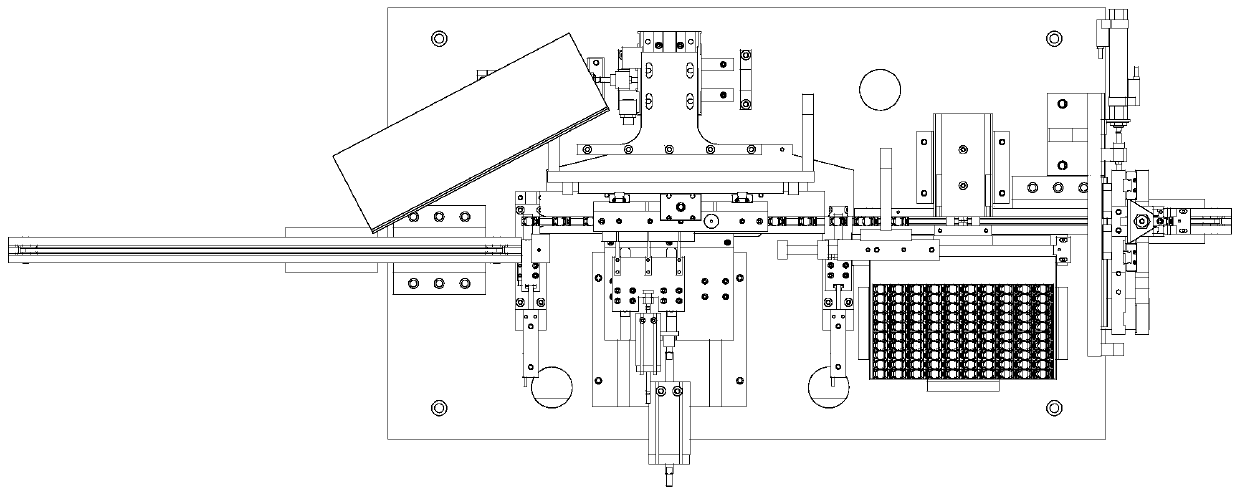

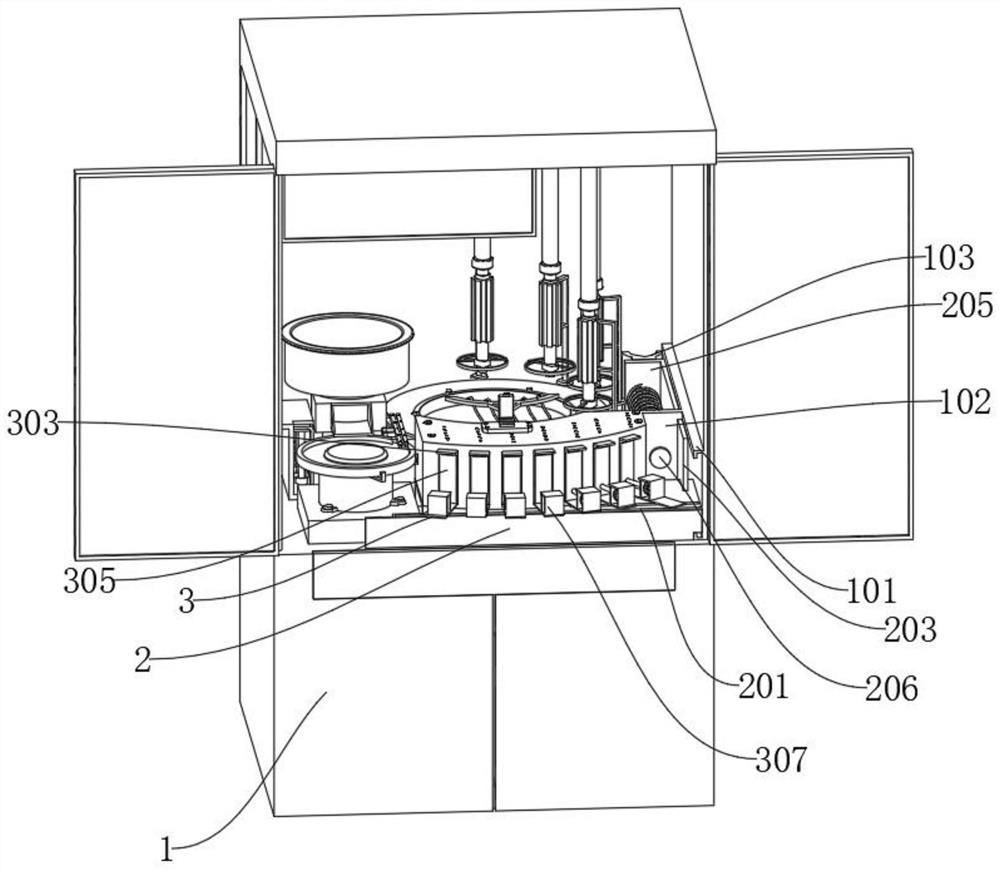

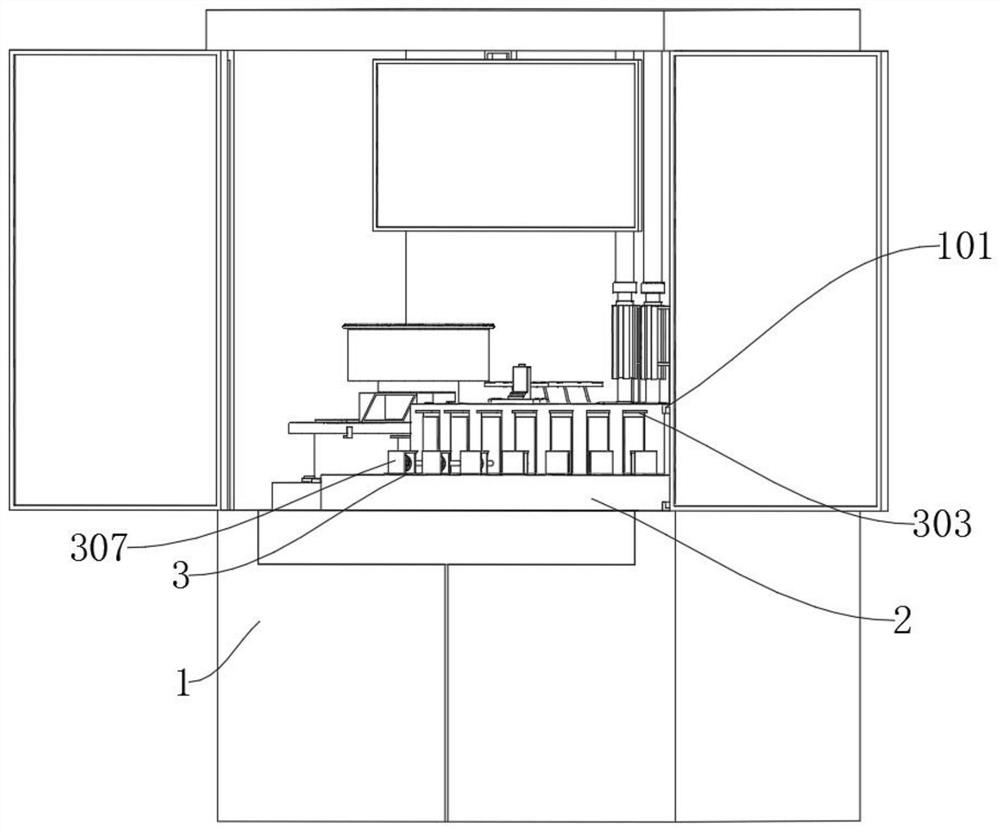

Method for testing electrical performance of relays

ActiveCN111319959AImprove classification efficiencyThe test results are accurateCircuit interrupters testingConveyor partsSystems engineeringTest equipment

The invention discloses a method for testing the electrical performance of relays based on a relay electrical performance testing equipment. The testing equipment includes a bracket, an operation box,a characteristic mechanism, and an operation box. The characteristic mechanism includes a feeding conveying assembly, a positioning mechanism, a pushing mechanism, a pushing clamping test mechanism,a plug plate mechanism, a qualified product boxing mechanism, and an unqualified product taking mechanism. Various stations required for testing the electrical performance of the relays are highly integrated, a high degree of automation in the classification of testing of the relays is realized through the cooperation between the mechanisms, while it is ensured that relay test results are accurate, the relays are tested for multiple items and the tested relays are packaged in a classified mode or taken out according to the test results, so that the work efficiency of the electrical performancetest of the relays is significantly improved.

Owner:江苏西欧电子有限公司

Full-automatic steel pipe pickup, cleaning and packaging device

InactiveCN107697336AAssurance controlNeatly packedBinding material applicationBundling machine detailsFuel tankGrinding wheel

The invention discloses a full-automatic steel pipe pickup cleaning and packaging device, and belongs to the field of building construction. The device is composed of a pickup device, a cleaning device and a packaging device, an electromagnetic suction cup pickup device is used for ensuring stability and safety of steel pipes in the process of being moved to a conveying belt, meanwhile, when a sliding block on a linear guide rail touches a switch limit, the sliding block stops running, meanwhile, an inner coil of an electromagnetic suction cup is powered off, magnetic force disappears, demagnetization is achieved, and the steel pipes fall on the conveying belt; a vibration screen is arranged above a vibration plate, a grinding wheel is arranged on the conveying belt, an oil spraying deviceis arranged on the side, close to the conveying belt, of the lower portion of an oil tank, rust on the surface of the steel pipes can be removed, and the rust removal work efficiency can be ensured.A spiral adjusting device is used for achieving control over a movable support, the steel pipes can be more in order in the packaging process, practicability is high, an air cylinder retracts, a rubber rope is driven to retract, the multiple steel pipes are bundled through the rubber rope, and the automatic packaging of the steel pipes can be achieved.

Owner:李露青

Manufacturing process of crystal diode

ActiveCN105097504AAvoid damageReduce uneven thicknessSemiconductor/solid-state device manufacturingPlastic packagingWafer dicing

The invention relates to a manufacturing process of a crystal diode. The manufacturing process comprises the following steps: (S1) wafer cutting; (S2) wafer assembly, namely putting a wafer lead on a lead track, sequentially grabbing each wafer to put into the wafer lead, and cutting the wafer lead into wafer lead segments of 216-360 products through a segmentation machine, and sequentially putting the wafer lead segments into the lead box; (S3) wire soldering, namely transferring the lead box with the wafer lead segments into a work bench of a wire soldering machine, adjusting the power of the wire soldering machine to be 30-50mW, the pressure to be 250-350mN and the temperature to be 240-320 DEG C, putting each wafer lead segment in the lead box on the wire soldering machine for wire soldering, so as to obtain the wafers with pins; (S4) injection molding; (S5) electroplating; (S6) separating; (S7) testing; and (S8) band loading, namely loading the tested and qualified crystal diodes to a stripped carrier band with a band loading mechanism, and carrying out plastic packaging to obtain the product. The manufacturing process has the advantages that transportation is facilitated in the manufacturing process; the product quality is improved; and classified transportation or storage is facilitated.

Owner:SICHUAN BLUE COLOR ELECTRONICS TECH

Automatic screening machine suitable for LED product detection

The invention provides an automatic screening machine suitable for LED product detection, relates to the field of automatic screening machines, and aims to solve the problems that when an existing automatic screening machine for LED product detection is used and products enter and are collected, guiding arrangement cannot be controlled, and passive control orderly arrangement cannot be carried out. The automatic screening machine comprises a main body, a pulling piece and a control panel, wherein the main body is an automatic screening machine body and is of a rectangular structure, and the pulling piece is installed at the bottom of the front end of the main body; the pulling piece is of an L-shaped plate-shaped structure, and the control panel is installed at the top end of the pulling piece; and the control panel comprises a leveling mechanism, and the inner end of the control panel is connected with the leveling mechanism. After all products are detected, the top ends of limiting plates are controlled to turn over slightly, so that the limiting plates can be removed from limiting, pulling plates and a pushing plate are pulled through round rods, the pushing plate can move on the side edges of partition plates, the products are pushed to move, and the products can be pushed in order again and arranged neatly.

Owner:深圳市恒工科技有限公司

Package material for roll material and packaging method

InactiveCN1167586CReduce water permeabilityHigh tensile strengthPaper article packagingFlexible coversFiberEngineering

The present invention relates to a packaging material for coiled material and its packaging method. It uses industrial composite packaging film, protection plate, end protection plate and metal protective corner as packaging material, and is characterized by that the industrial packaging film is formed from three layers of water-proofing layer, reinforcing layer and rust-proofing layer through the process of co-extrusion, its protection plate and end protection plate adopt the composite fibre packaging plate with water-proofing property. Said invention also provides the use method of these packaging material, and its packaging effect is good and solves the problem of resisting rust for coiled material.

Owner:鞍山市煜辉包装材料有限公司

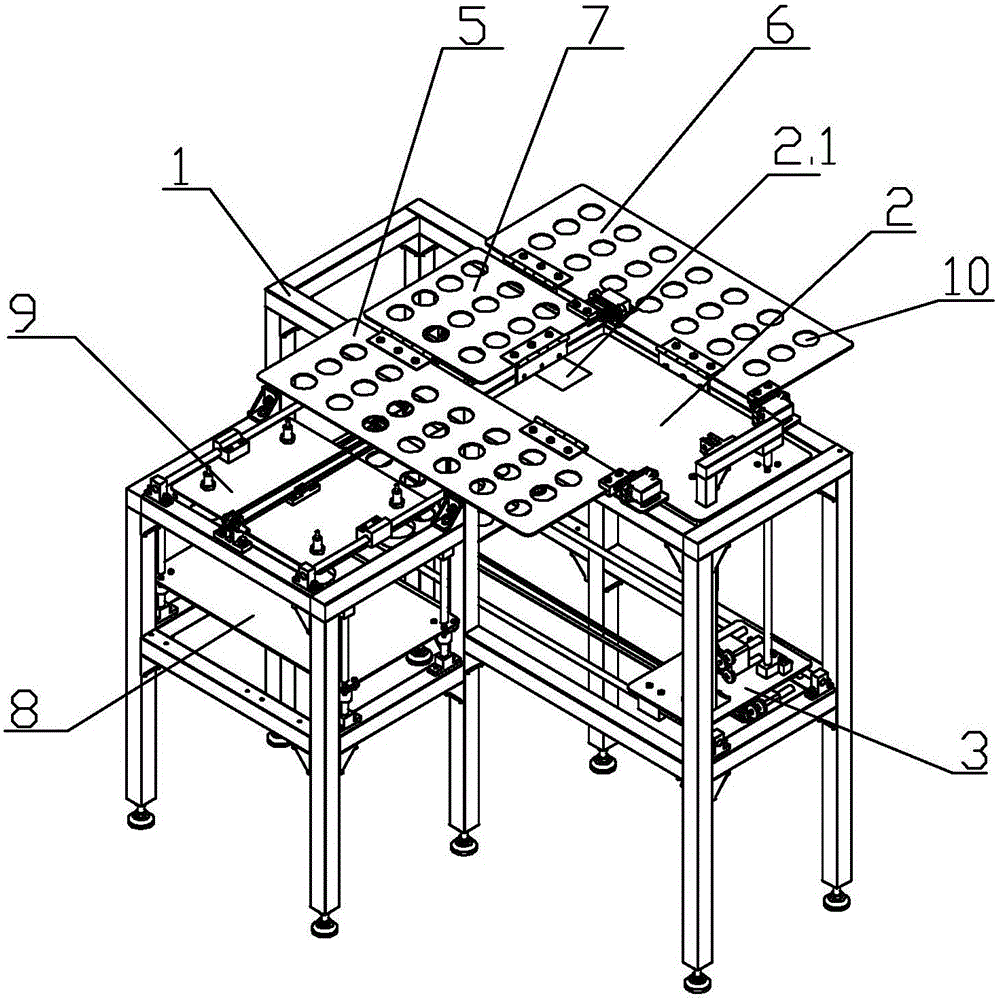

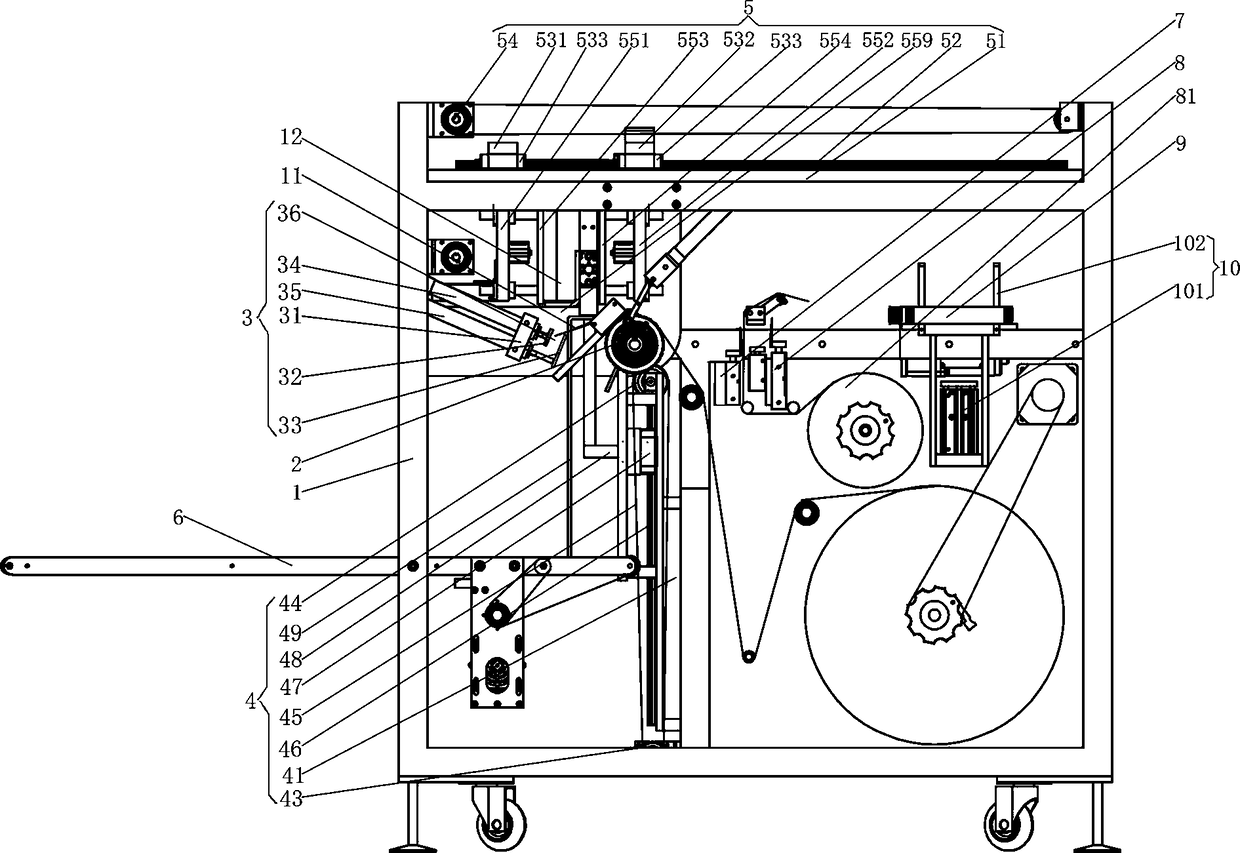

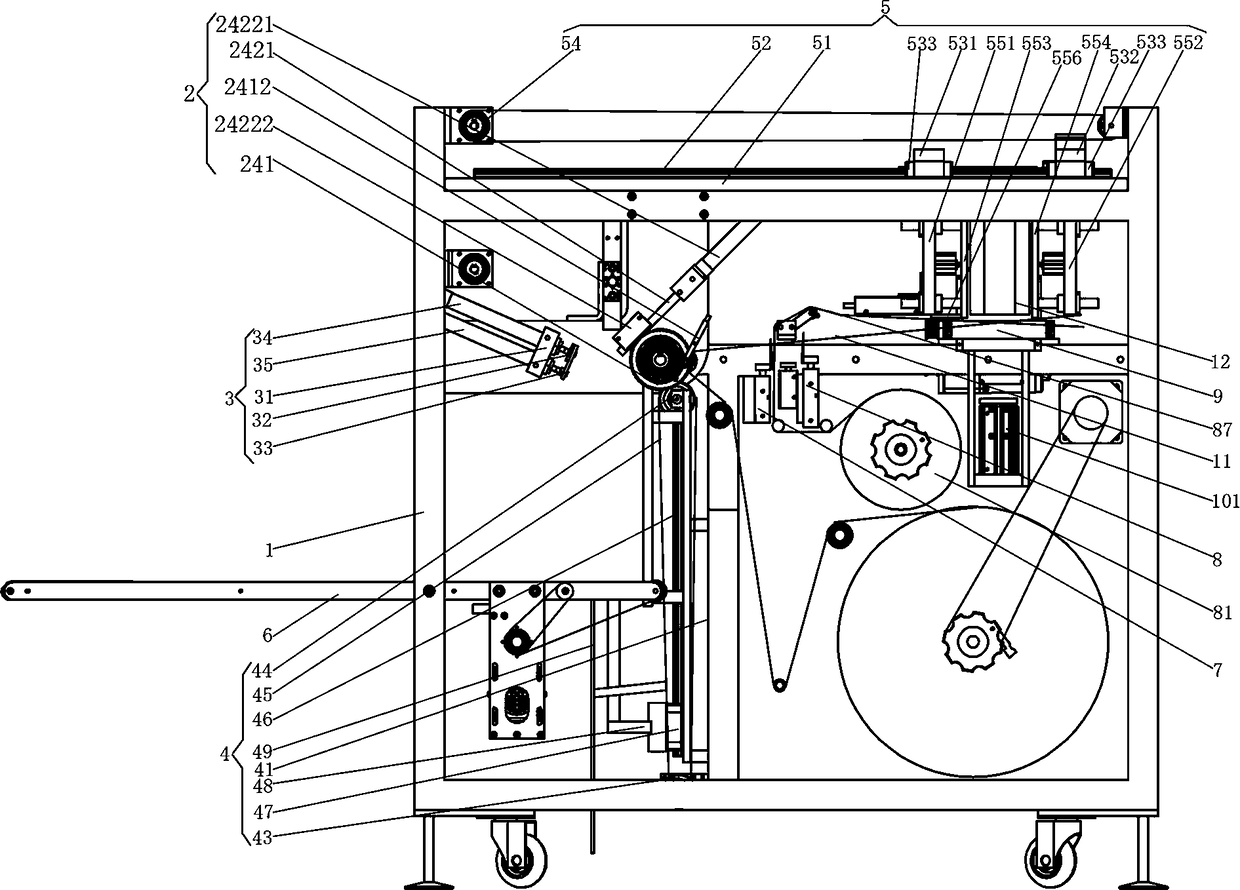

An automatic clothing folding packaging machine and a clothing folding packaging method

The invention discloses an automatic clothes folding packer. The automatic clothes folding packer comprises a rack and is characterized in that a main board and a folding component are arranged on the rack, the folding component is hinged to the rack (1), a transmission board (3) is arranged under the main board (2), a motor is arranged on the transmission board (3) or the rack (1), a packing station (4) and the motor used for driving the transmission board (3) to drive the main board (2) to reciprocate onto the packing station (4) are arranged on the rack (1), a transmission mechanism is arranged on the rack (1), and a clamping mechanism is arranged on the packing station (4). The invention further discloses a folding and packing method based on the automatic clothes folding packer. The automatic clothes folding packer provided by the invention can automatically finish clothes folding and packing, is high in integration performance, is motor-driven, eliminates noise, adopts a vertical structure and saves the working space.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

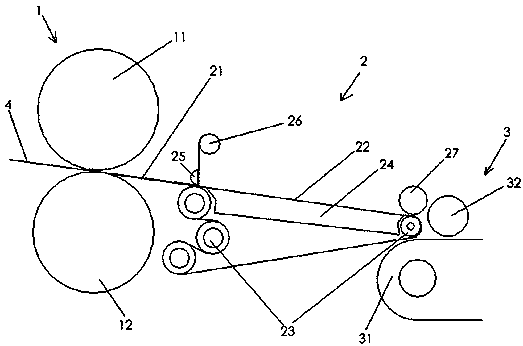

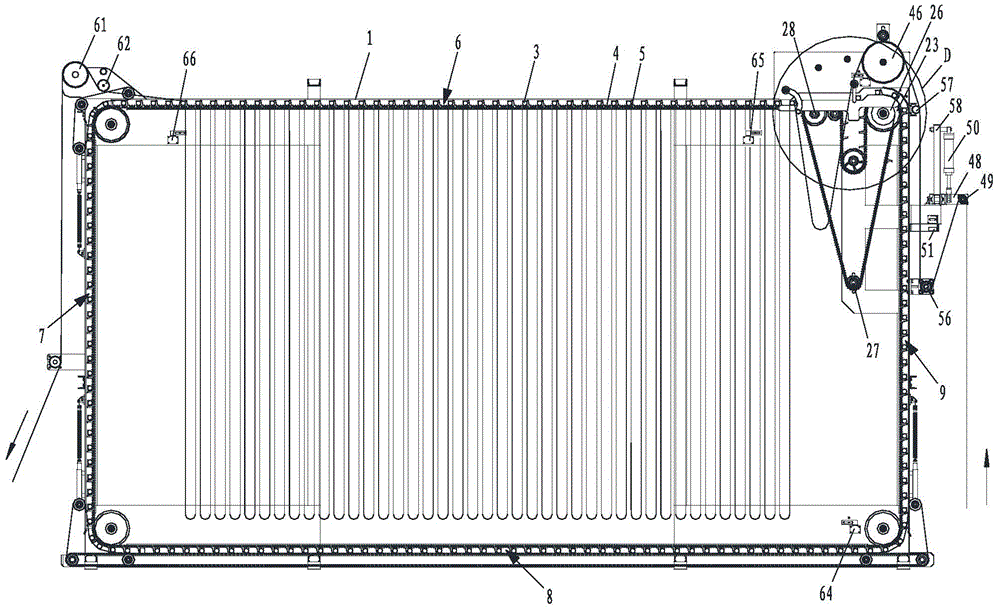

Circular die cutting and receiving machine of small tags

ActiveCN103753617ANeatly packedRealize automated productionMetal working apparatusStampingEngineering

The invention discloses a circular die cutting and receiving machine of small tags. The circular die cutting and receiving machine comprises a die cutting portion and a receiving portion which are arranged in a front and back mode; the die cutting portion comprises a die pressing plate knife roll and a bottom roll, wherein the die pressing plate knife roll is located on the upper side and rolls, and the bottom roll is located below the die pressing plate knife roll and is in clearance fit with the die pressing plate knife roll; the receiving portion comprises a receiving platform and a tag receiving wheel which is located above the receiving platform; the circular die cutting and receiving machine further comprises a conveying portion located between the die cutting portion and the receiving portion, wherein the conveying portion is composed of a supporting plate and a feeding platform, the feeding platform comprises a conveying belt and rollers at the two ends, the rollers are used for tensioning the conveying belt, a vacuum cavity is formed below the upper plane of the conveying belt, the front end of the supporting plate is connected with the position, at the gap of the die pressing plate knife roll and the bottom roll, of the bottom roll in an overlapped mode, the other end of the supporting plate is adjacently connected with the position, at the front end of the feeding platform, of the conveying belt, and the tail end of the conveying belt is located above the receiving platform. The circular die cutting and receiving machine enables the small tags to be capable of being produced automatically, production processes of flexographic printing, gold stamping, die cutting and receiving are completed on the same equipment, working efficiency is improved greatly, the number of workers is reduced, and production cost is reduced.

Owner:HUAIAN YUAN PACKAGING & PRINTING CO LTD

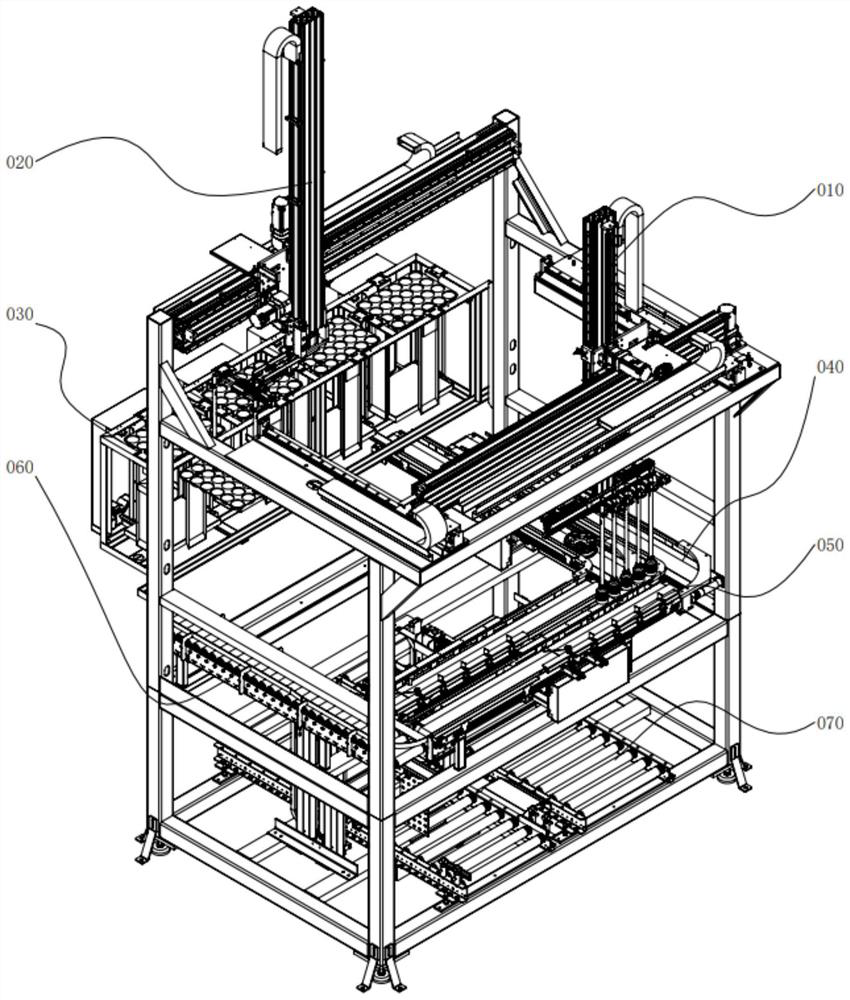

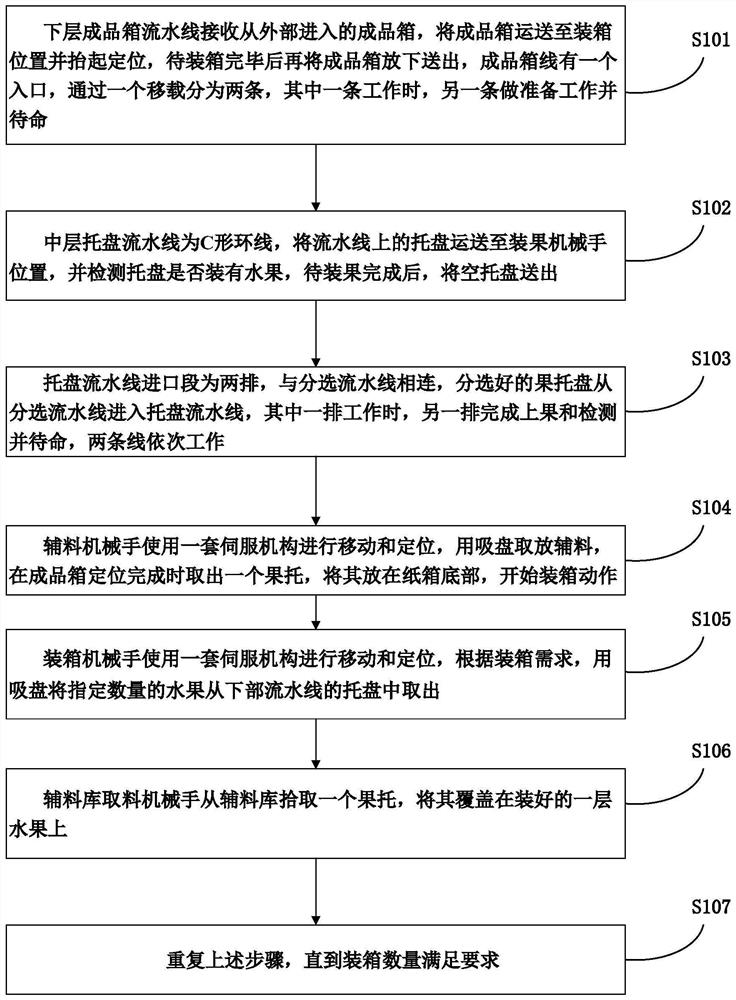

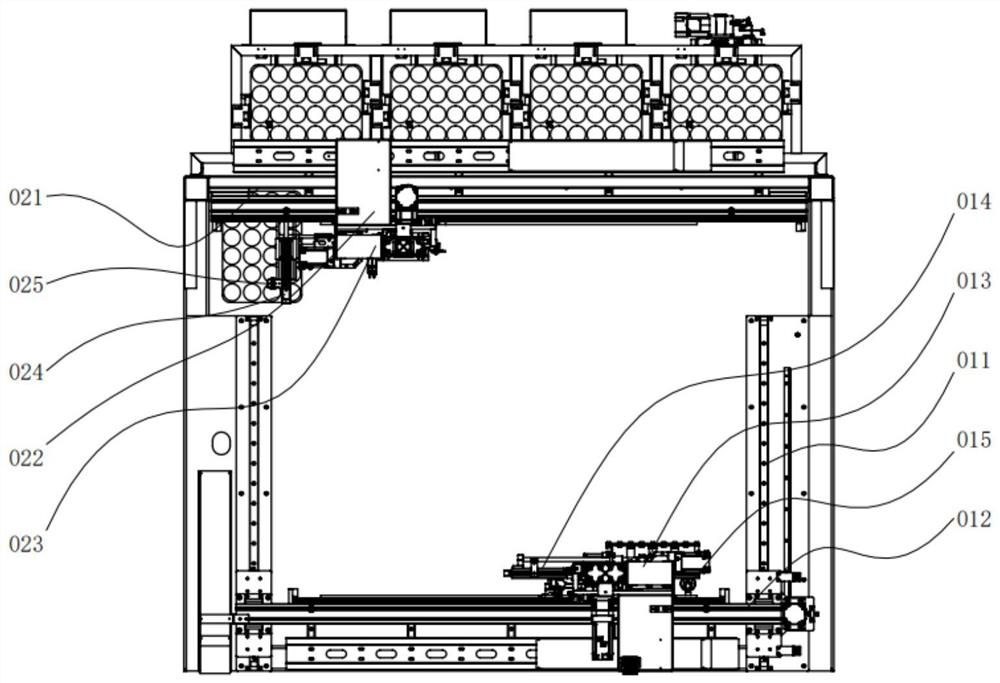

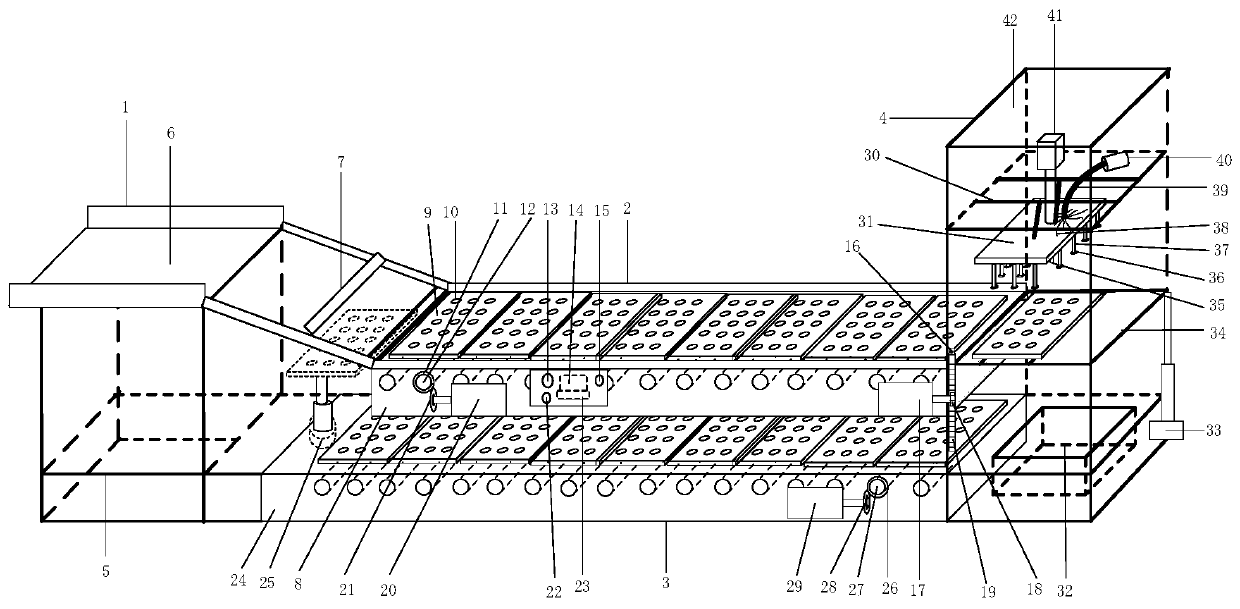

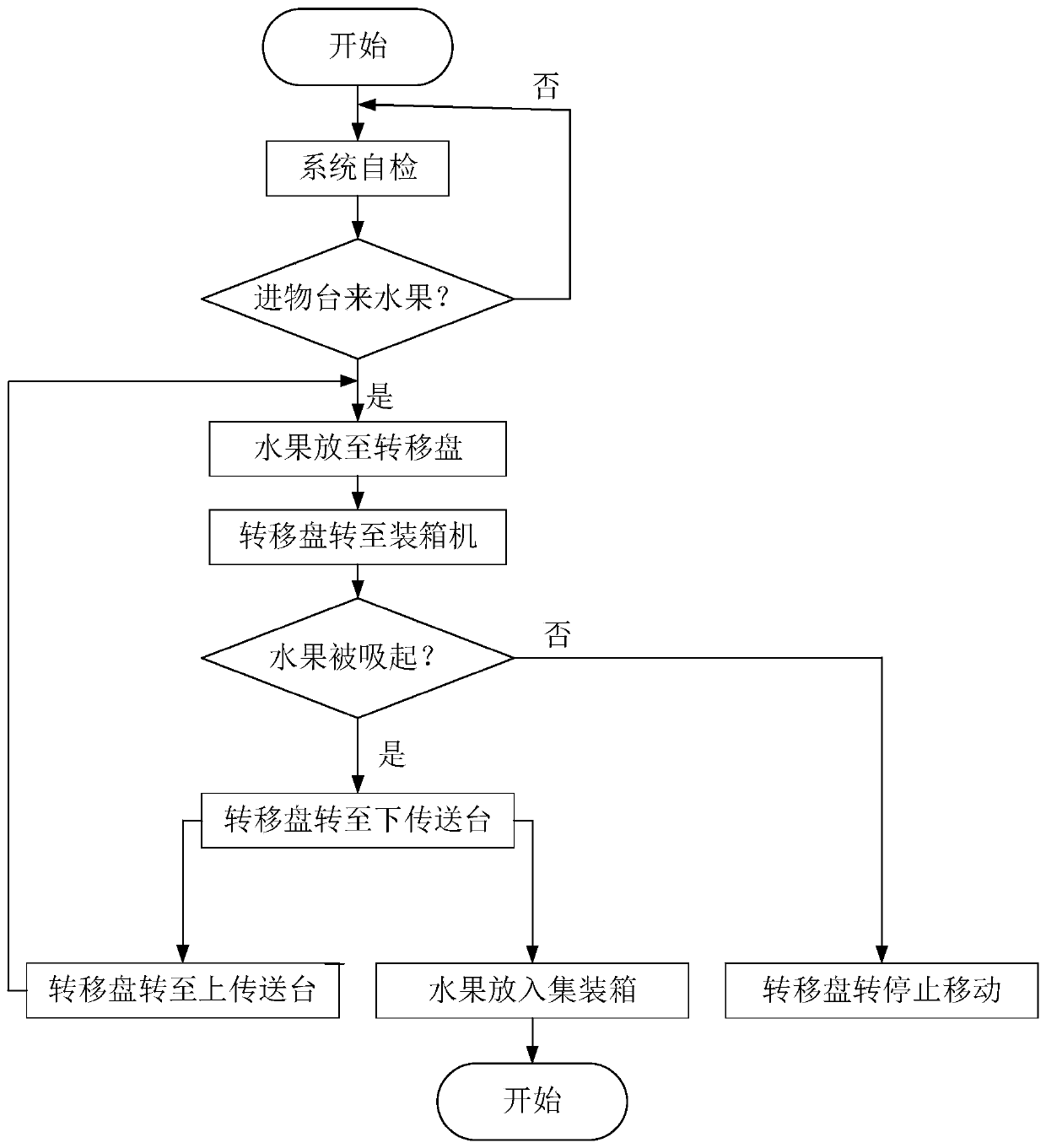

Automatic boxing method and device for fruit and vegetable sorting line

PendingCN114506507ACreativeRow by row implementationPackaging fruits/vegetablesAgricultural engineeringMechanical engineering

The invention belongs to the technical field of agricultural fruit and vegetable sorting equipment, and discloses a fruit and vegetable sorting line automatic boxing method and device, and the fruit and vegetable sorting line automatic boxing device is provided with an upper layer boxing manipulator; the upper-layer boxing manipulator is arranged on the upper layer of the automatic boxing device, and an auxiliary manipulator and an auxiliary warehouse are further arranged on the upper layer of the automatic boxing device; batch automatic boxing of the soft-shell fruits is achieved, and the fruits are prevented from being collided and scratched in the boxing process; the sucking disc used by the invention is designed and customized according to the fruit shape, and the sucking disc shape conforming to the fruit shape and an organ type buffer structure are used to realize flexible sucking and carrying of the soft-shell fruit; unmanned automatic boxing of fruits is achieved, the boxing speed is high, and the takt is uniform and determined; the soft-shell fruit boxing device can automatically box soft-shell fruits in order, auxiliary materials can be automatically placed, the fruits on all layers are prevented from making contact with one another, and the fruit packaging quality is improved.

Owner:近江度量衡设备无锡有限公司

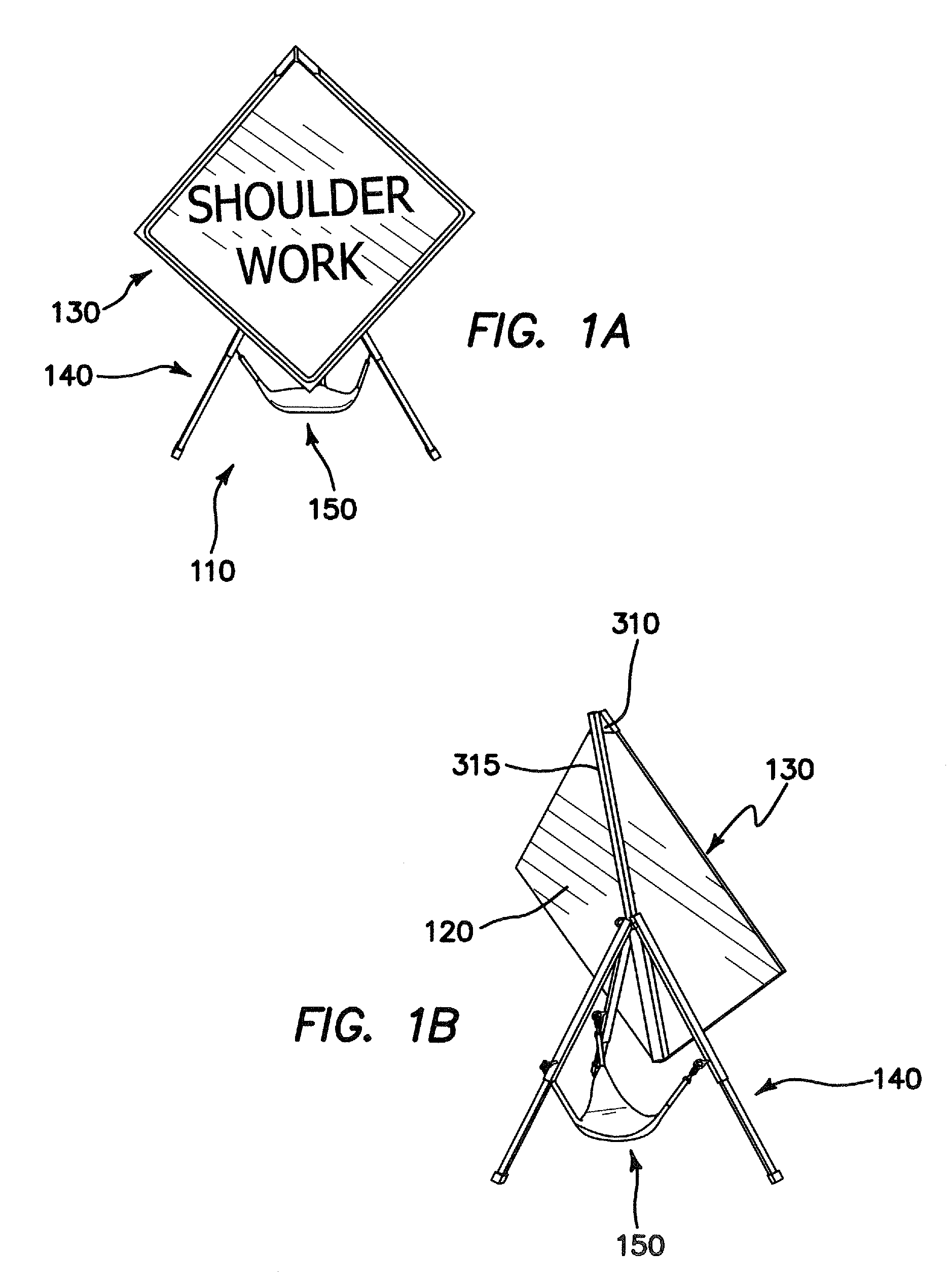

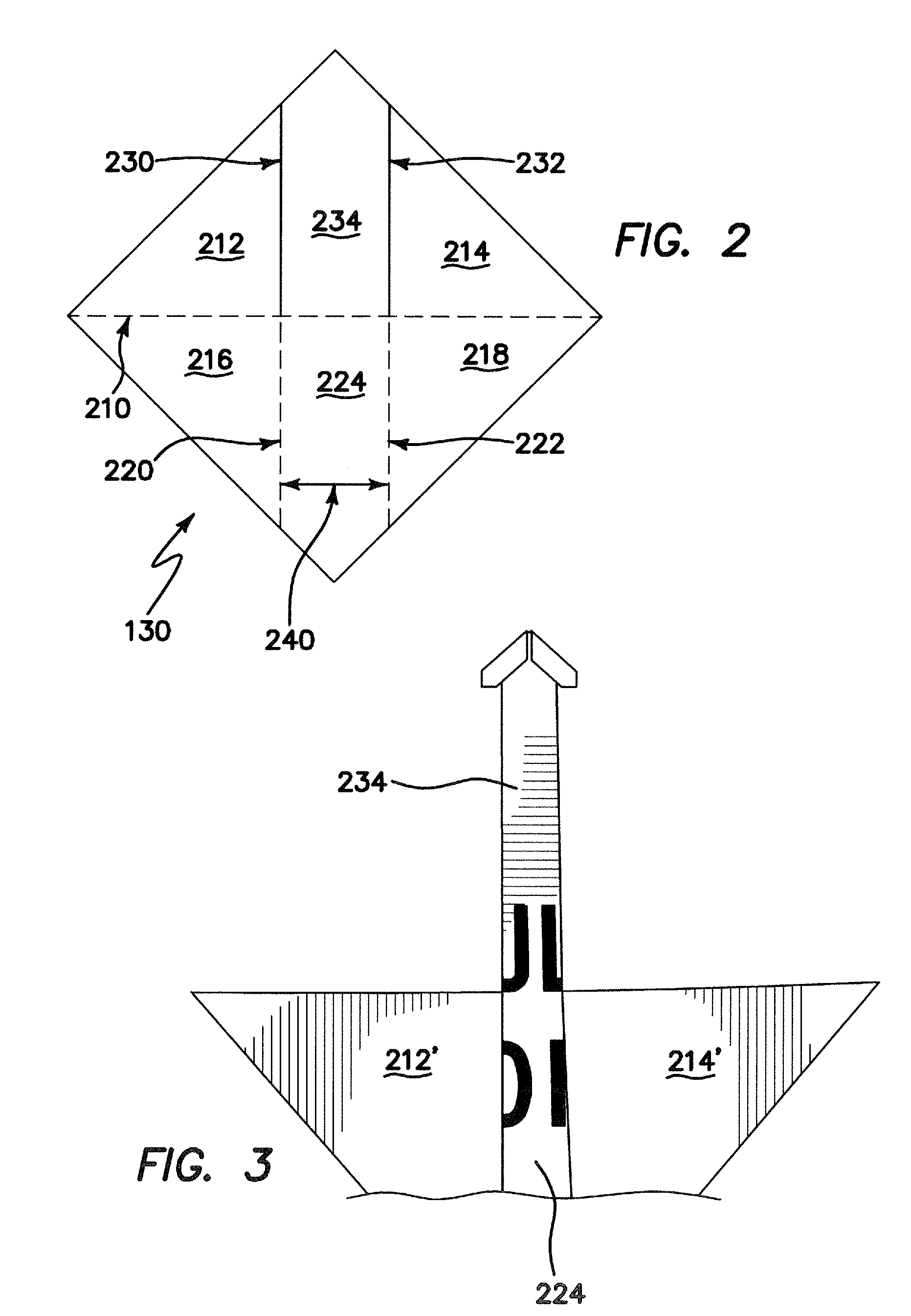

Foldable traffic sign

ActiveUS7444774B1Conveniently carried and storedNeatly packedTraffic signalsStands/trestlesEngineeringTraffic sign

A foldable traffic sign system comprises a relatively rigid sign panel and a plurality of folding lines disposed in the sign panel, for permitting ready folding of the sign panel into a substantially smaller configuration. In a preferred embodiment, at least one cut is disposed partially along a dimension of the sign panel, to further facilitate ready folding of the sign panel. One of the folding lines is disposed substantially horizontally across a center region of the sign panel, and at least one of the folding lines is disposed substantially vertically on the sign panel, and intersects with the horizontal folding line. The plurality of folding lines creates a plurality of sign sections, preferably six, defined by a combination of the folding lines and cuts in the sign panel. The sign system further comprises a folding sign stand, and a tote for containing both the sign panel and sign stand.

Owner:TRAFFIX DEVICES INC

Automatic packaging machine convenient to install for beer production

InactiveCN111675183AStable transport modeProne to dumpingFlanged caps applicationBottle-handling machinesWine bottleElectric machinery

The invention discloses an automatic packaging machine convenient to install for beer production. The automatic packaging machine convenient to install for beer production comprises an operation tableand a bottle cap container. The bottom of the operation table is connected with a base support, the bottom of the base support is connected with a base, a motor containing box is arranged at the bottom of the operation table, and a first motor is arranged in the motor containing box. A conveying device is arranged at the top of the operation table, a wine bottle fixing disc is arranged at the topof the conveying device, a fixed containing tank is arranged in the beer bottle fixing disc, a fixed side plate is arranged at the top of the operation table, and a transverse plate is connected to the top of the fixed side plate. According to the automatic packaging machine convenient to install for beer production, the beer bottle fixing disc and the fixed containing tank are arranged, the whole device body constitutes a structure capable of stabilizing the position of a beer bottle. When a beer bottle is packaged, the beer bottle is prone to toppling over due to the driving effect of the conveying belt. The wine bottle fixing disc and the fixed containing tank are arranged, it is guaranteed that the beer bottle is stably conveyed in the conveying process.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

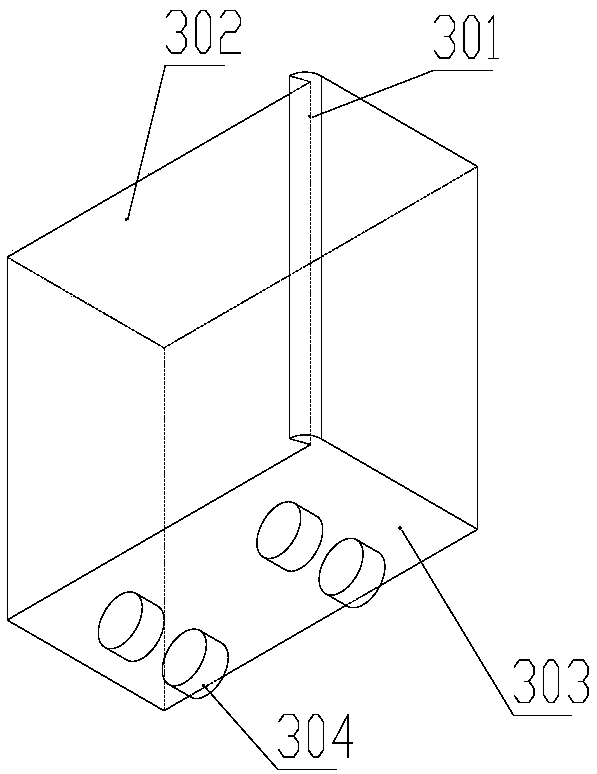

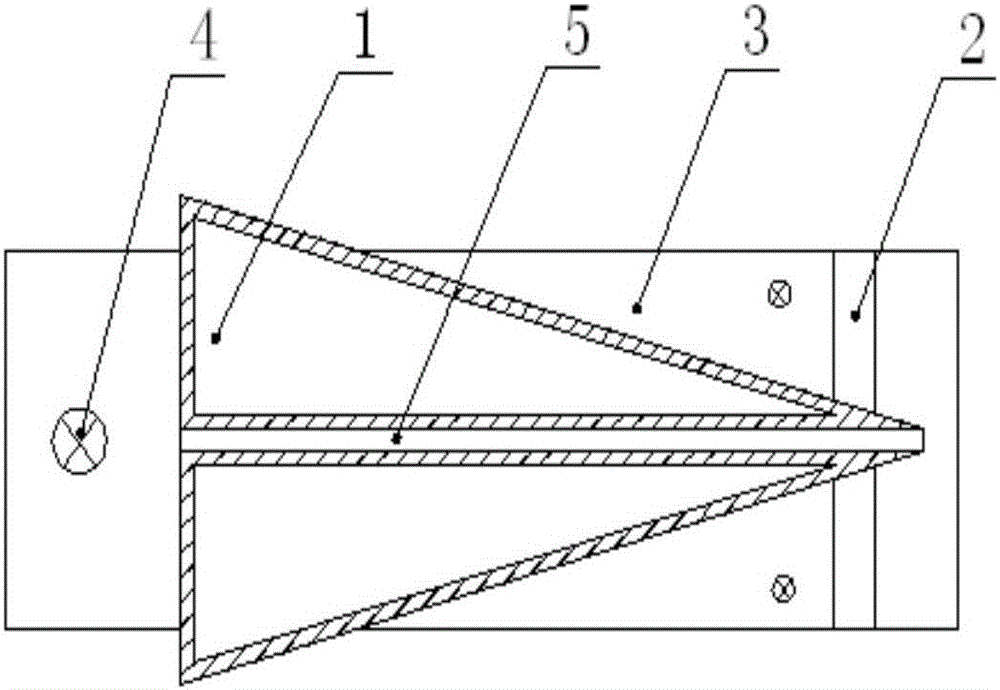

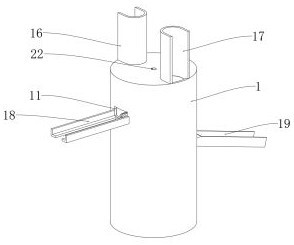

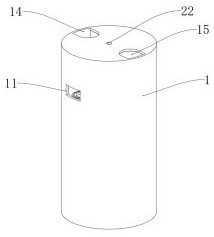

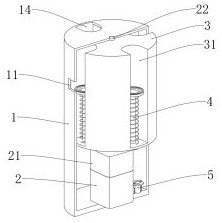

Introducing device for longitudinal wrapping and pressing technology of metal composite belt

PendingCN106199864ALimit movement directionNeatly packagedFibre mechanical structuresDislocationMechanical engineering

The invention relates to an introducing device for a longitudinal wrapping and pressing technology of a metal composite belt. The introducing device comprises a bottom plate, a pipe barrel and a cavity inserting plate; a longitudinal groove is formed in the surface of the inner wall of the pipe barrel in a penetrating mode, the cavity inserting plate is movably inserted into the longitudinal groove, and a hole groove used for allowing a cable core to pass is integrally formed in the lower end of the cavity inserting plate. The introducing device is simple in structure, reasonable in design, high in practicability, low in manufacture cost, solid and durable; the longitudinal groove is formed in the surface of the inner wall of the pipe barrel in the penetrating mode, the cavity inserting plate is movably inserted into the longitudinal groove, therefore, the technical defect that in the prior art, core and belt separation is caused due to the fact that dislocation is prone to be generated when the wrapped and pressed optical cable core and the metal composite belt are introduced is overcome, and the production efficiency and the optical cable quality are effectively improved.

Owner:天津立孚光电科技股份有限公司

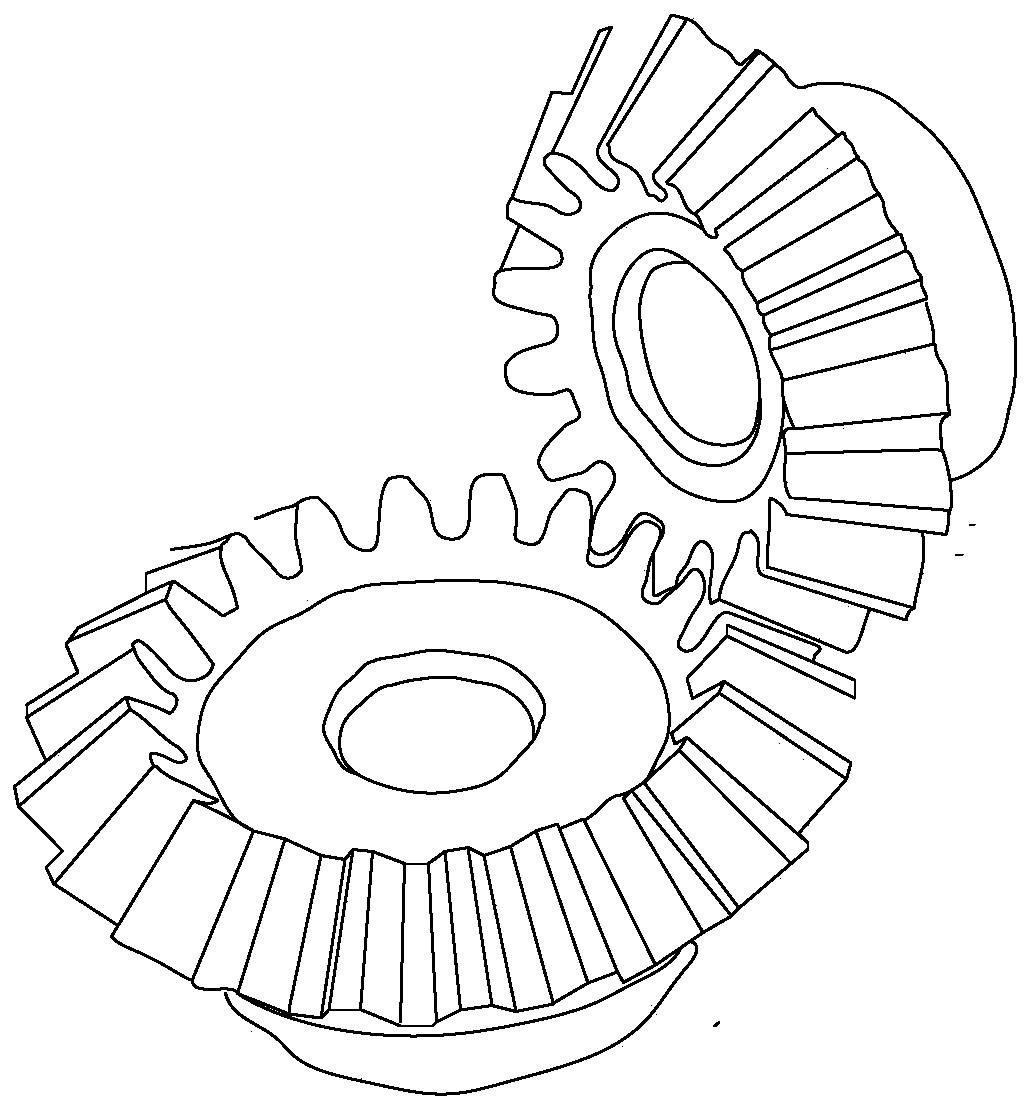

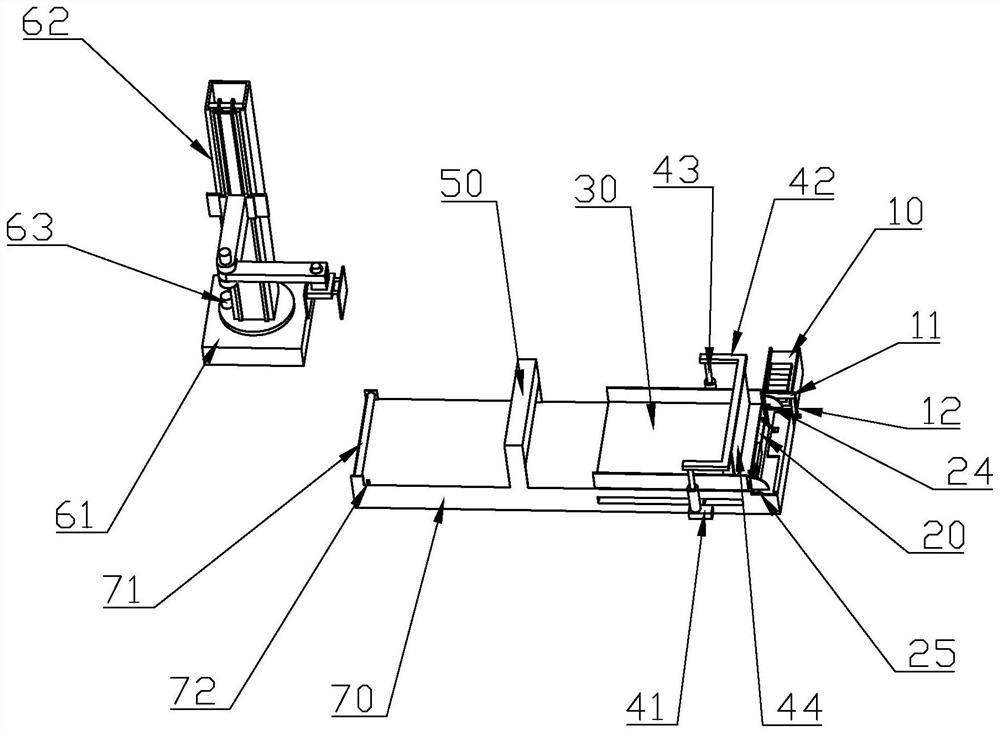

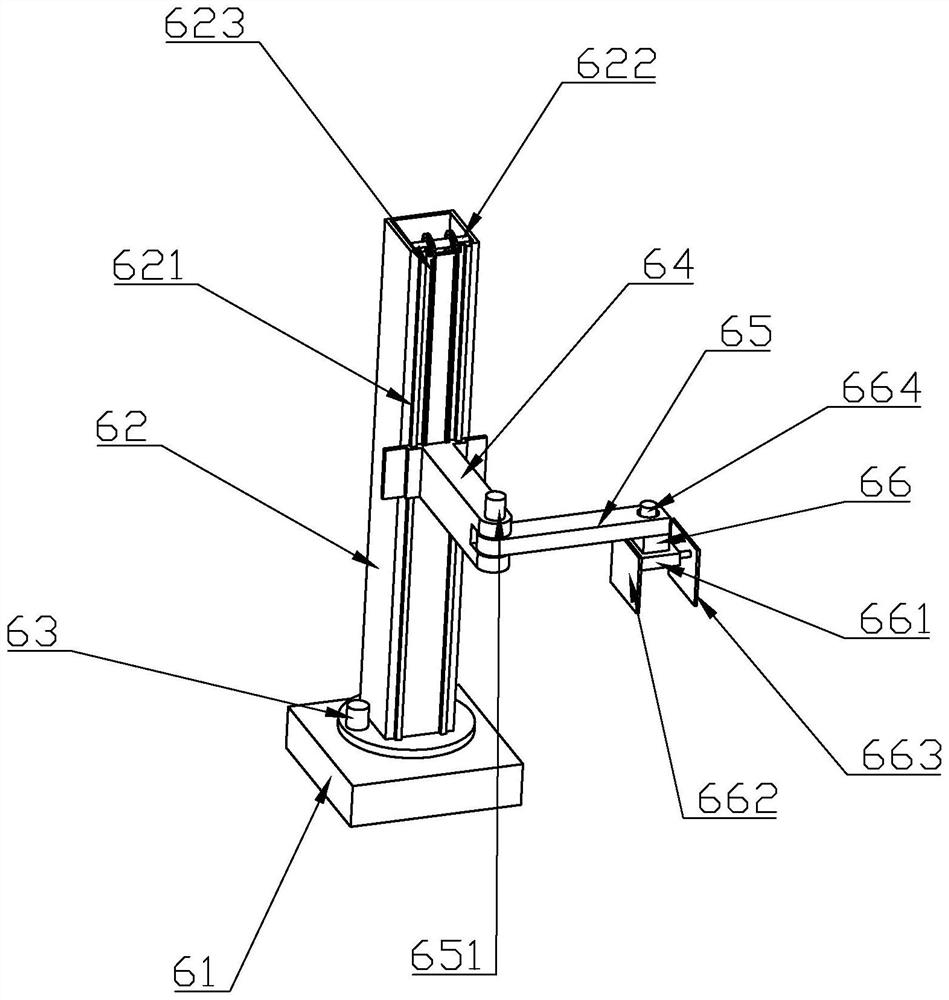

A packing machine for rotary fruit

ActiveCN108238296BReduce labor costsImprove work efficiencyPackaging automatic controlPackaging fruits/vegetablesCartoning machineAgricultural engineering

Owner:EAST CHINA JIAOTONG UNIVERSITY

Method for using cloth hanging and cooling machine

ActiveCN104370138AImprove continuityRealize deliveryFunction indicatorsWebs handlingFree coolingEngineering

The invention discloses a method for using a cloth hanging and cooling machine. The method is based on the full-automatic cloth hanging and cooling machine, various tweeds are continuously and automatically hung and conveyed by the different speeds of a cloth feeding roller, a circulated conveying chain, a cloth hanging chain and a cloth pressing roller, synchronous drive of the last process and the next process can be better achieved, and the production efficiency is improved. Cloth is in a drooping state on cloth hanging rods of the full-automatic cloth hanging and cooling machine to be naturally cooled, winkles can be removed, an original state can be better recovered, and the quality of products is guaranteed. In addition, the full-automatic cloth hanging and cooling machine is further provided with a cloth deviation correcting device, before the cloth is hung and cooled, the cloth is first subjected to deviation correcting operation through the cloth deviation correcting device, and it is better guaranteed that the cloth hanging rods are used for hanging the cloth neatly.

Owner:青岛诚利佳机械有限公司

High-efficiency paper tube packing device

PendingCN113460380ANeatly packedImprove efficiencyWrapper twisting/gatheringIndividual articlesStructural engineeringManufacturing engineering

The invention discloses a high-efficiency paper tube packing device. The device comprises a radial conveying device, an overturning device, a bagging device, a stacking device and a rack, the overturning device and the bagging device are both installed at the upper end of the rack, the radial conveying device is used for conveying polished paper tubes to the overturning device, and the bagging device comprises a pushing mechanism, a spreading mechanism and a sealing device which are sequentially arranged from right to left, the spreading mechanism is used for spreading a packaging bag of the paper tubes, the pushing mechanism is used for pushing the paper tubes into the packaging bag, the sealing device is used for sealing the packaging bag, and the stacking device comprises a clamp. The clamp is used for clamping the packaged paper tubes. According to the high-efficiency paper tube packing device, manual packing can be replaced, the paper tubes can be packed more orderly, the efficiency is higher, and the labor cost can be reduced.

Owner:桐乡市恒昌纸塑有限公司

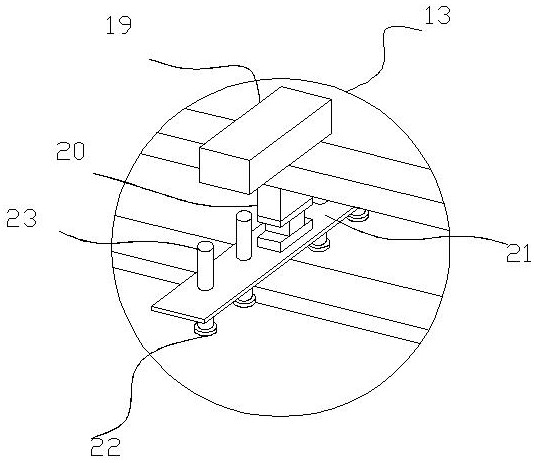

A kind of equal-volume cartoning transfer mechanism for food packaging machinery

ActiveCN114604458BThe product is neatly packagedImprove efficiencyWrapper twisting/gatheringPackaging biscuitsElectric machineryTransfer mechanism

The invention discloses an equal-quantity boxing and transporting mechanism for food packaging machinery. A drive shaft is fixedly installed on the upper end, the upper end of the drive shaft is rotatably inserted on the top wall of the body, a core column is fixedly installed on the drive shaft, and four symmetrically extending through the top wall of the core column are arranged on the side wall of the core column. Each of the blanking troughs is equipped with a gravity quantitative mechanism, and a magnetic trigger mechanism is installed on the inner bottom wall of the body. The present invention automatically arranges the products one by one by utilizing their own gravity, so that the product packaging is more tidy and can be continuously carried out. By integrating multiple packaging steps in the same body and performing sequential transport in a rotating manner, the efficiency is higher and the space occupied is small. The energy consumption is low, the structure is simpler, and the biscuits are not pressed during the whole process, which makes the product quality higher.

Owner:JIANGSU TENGTONG PACKING MACHINERY

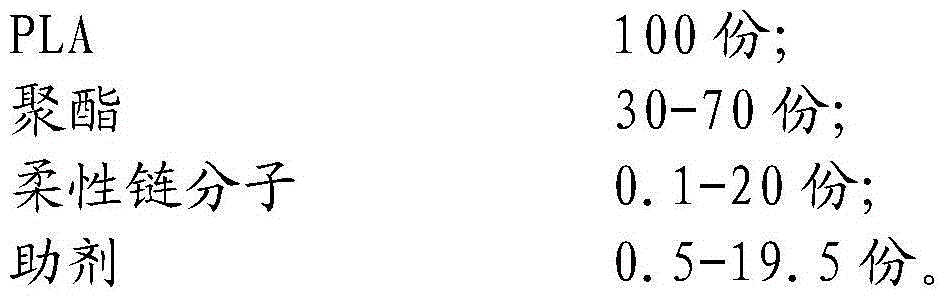

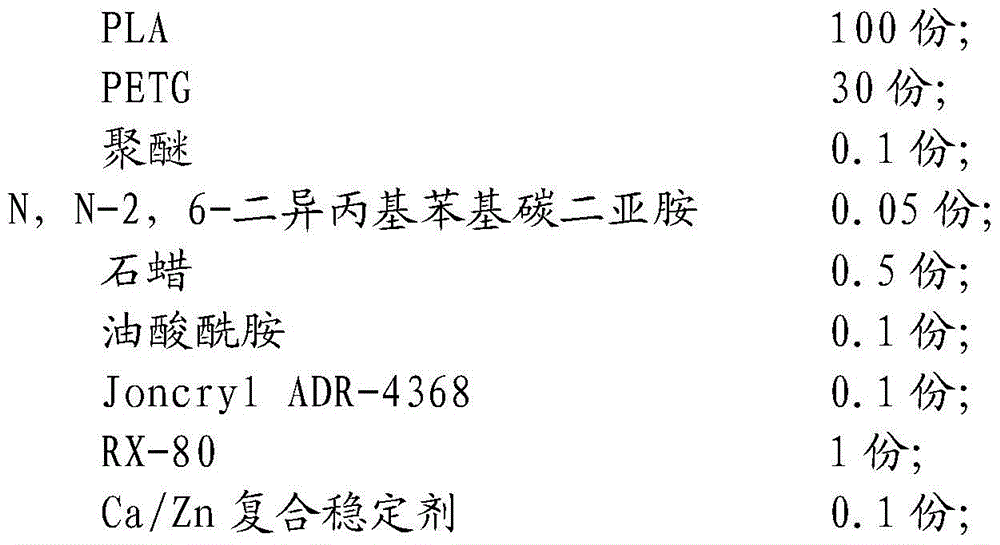

A kind of PLA modified material and its manufacture method

The invention relates to a preparation method of a PLA (poly lactic acid) modified material. The preparation method of the PLA modified material is characterized in that block polymerization is carried out on PLA resin and polyester by virtue of a double screw and flexible chain molecules are introduced in a preparation process. The preparation method of the PLA modified material has the advantages that a brand new formula is adopted, raw materials are modified, the size of a processing window is increased, free end groups are controlled, raw material stability is improved, performances of a film material are stable and a guarantee period of the film materials is at least three years; besides, by virtue of modification on the resin, softness, high tensile strength and other properties of a thin film hygienic material can be met.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com