Patents

Literature

78results about How to "Neatly collected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

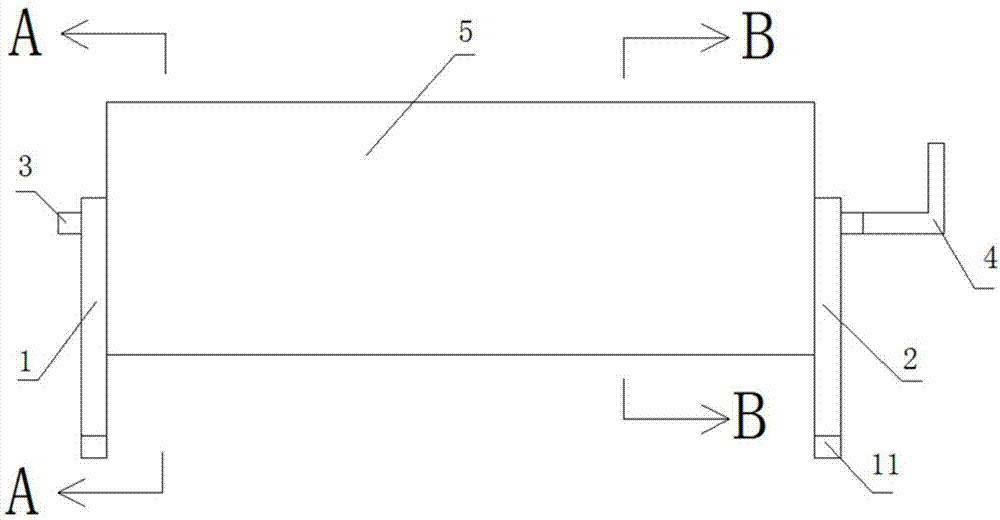

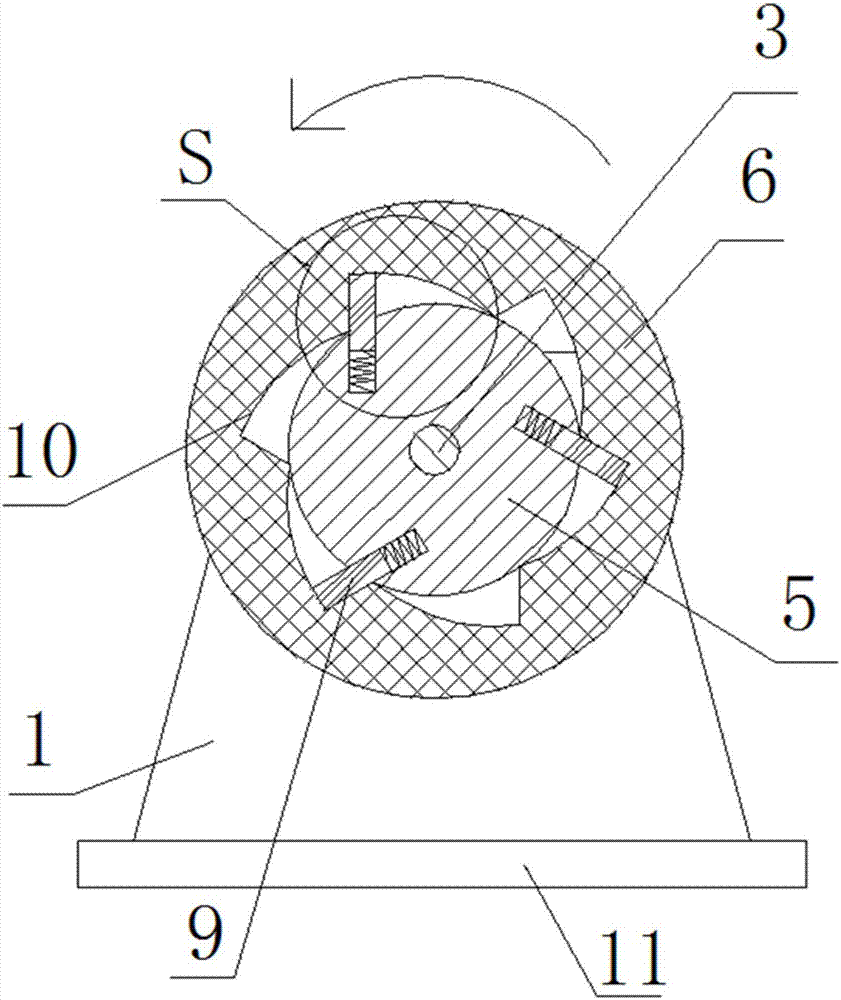

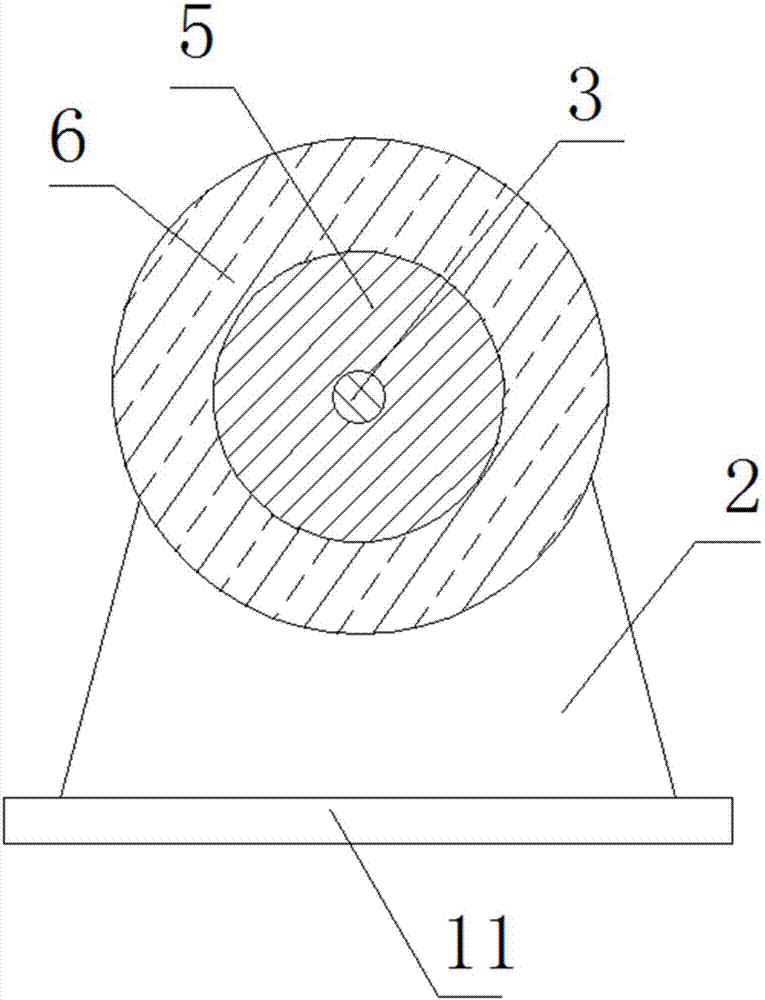

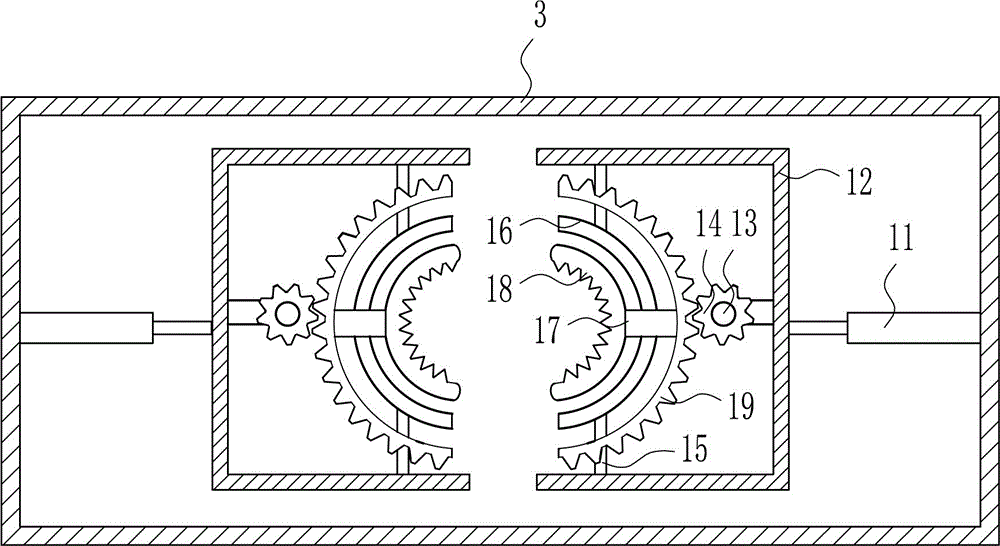

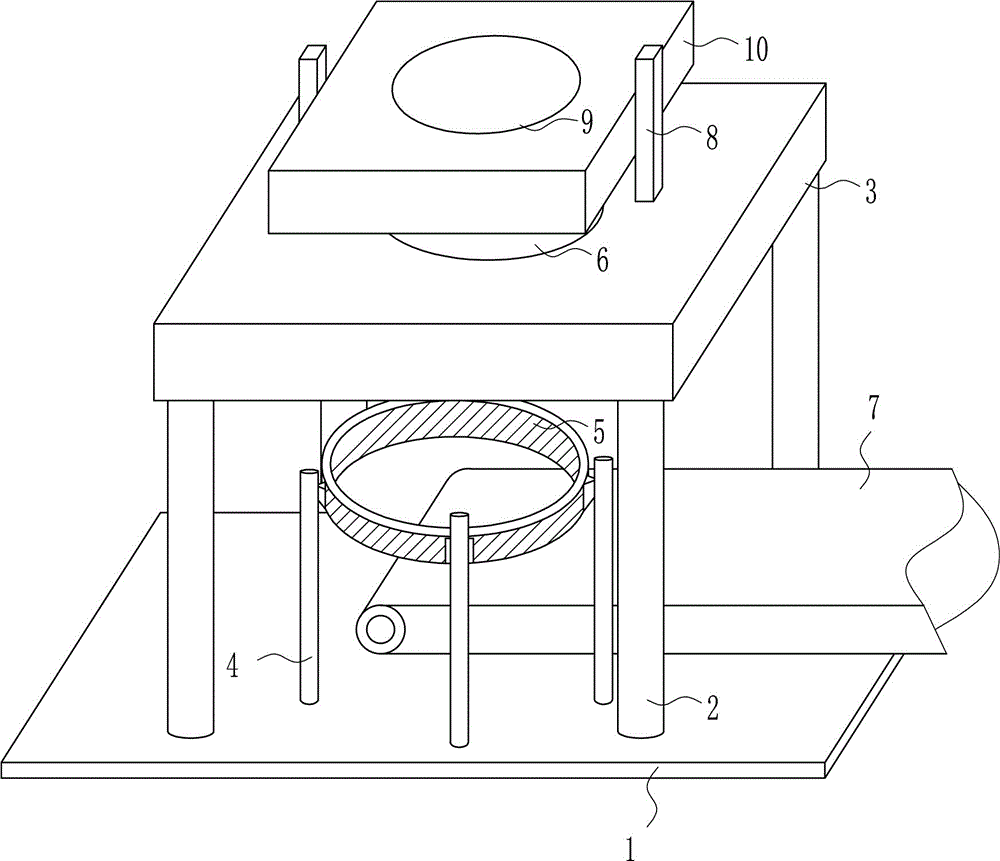

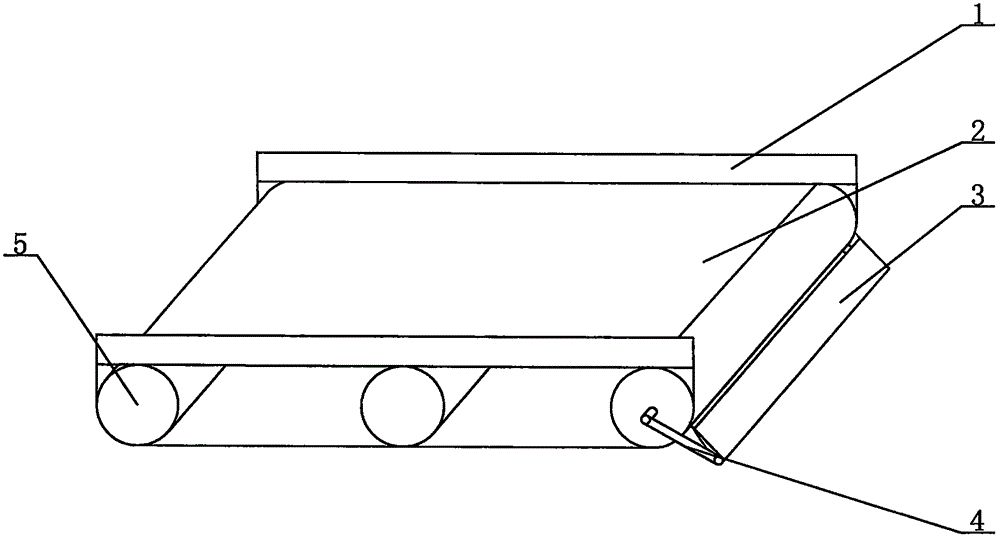

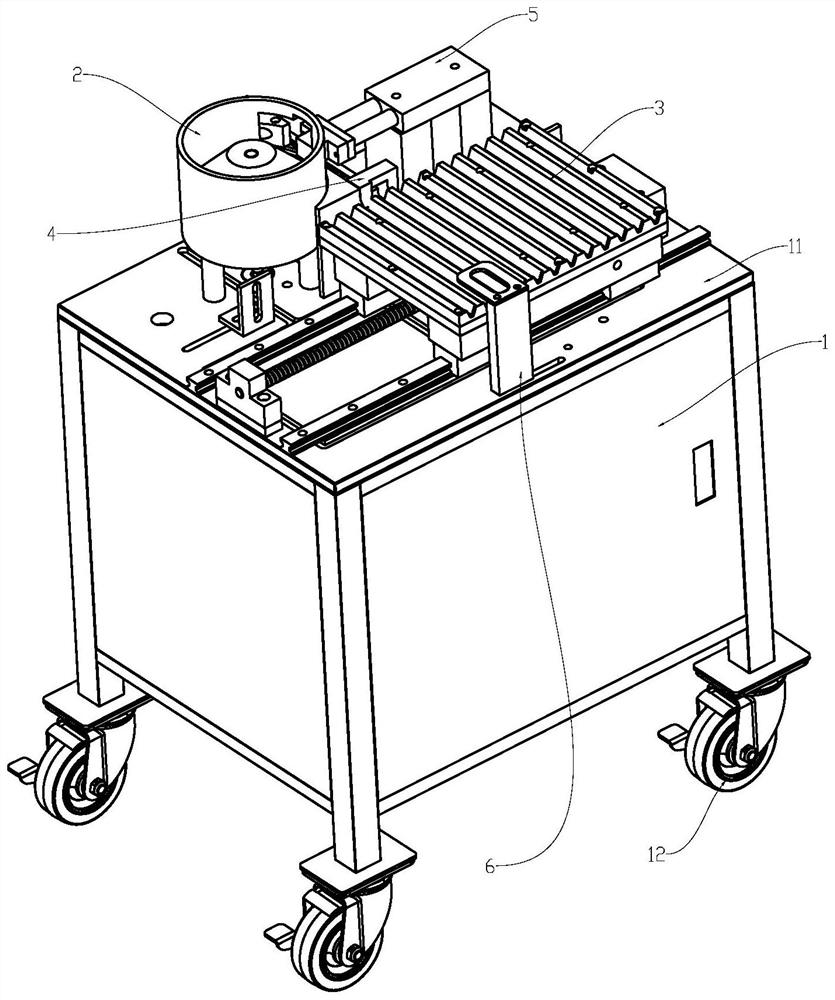

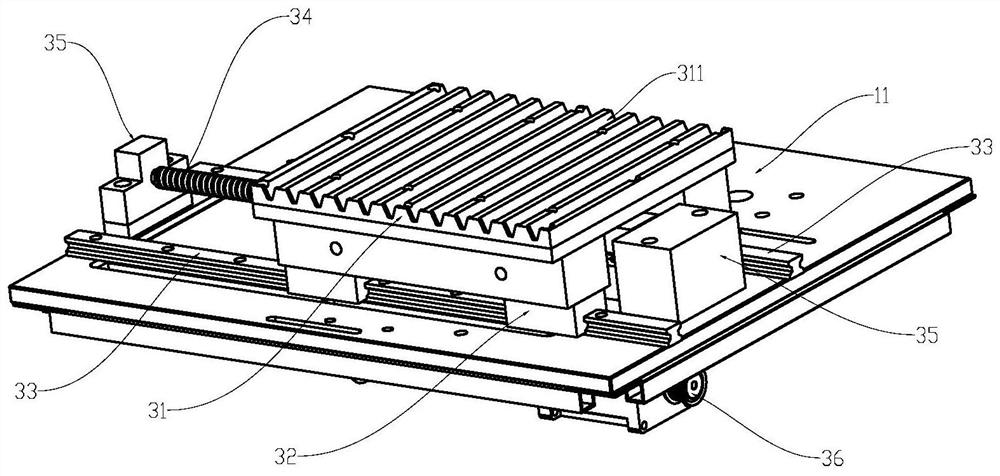

Automatic clothes folding packer and clothes folding and packing method

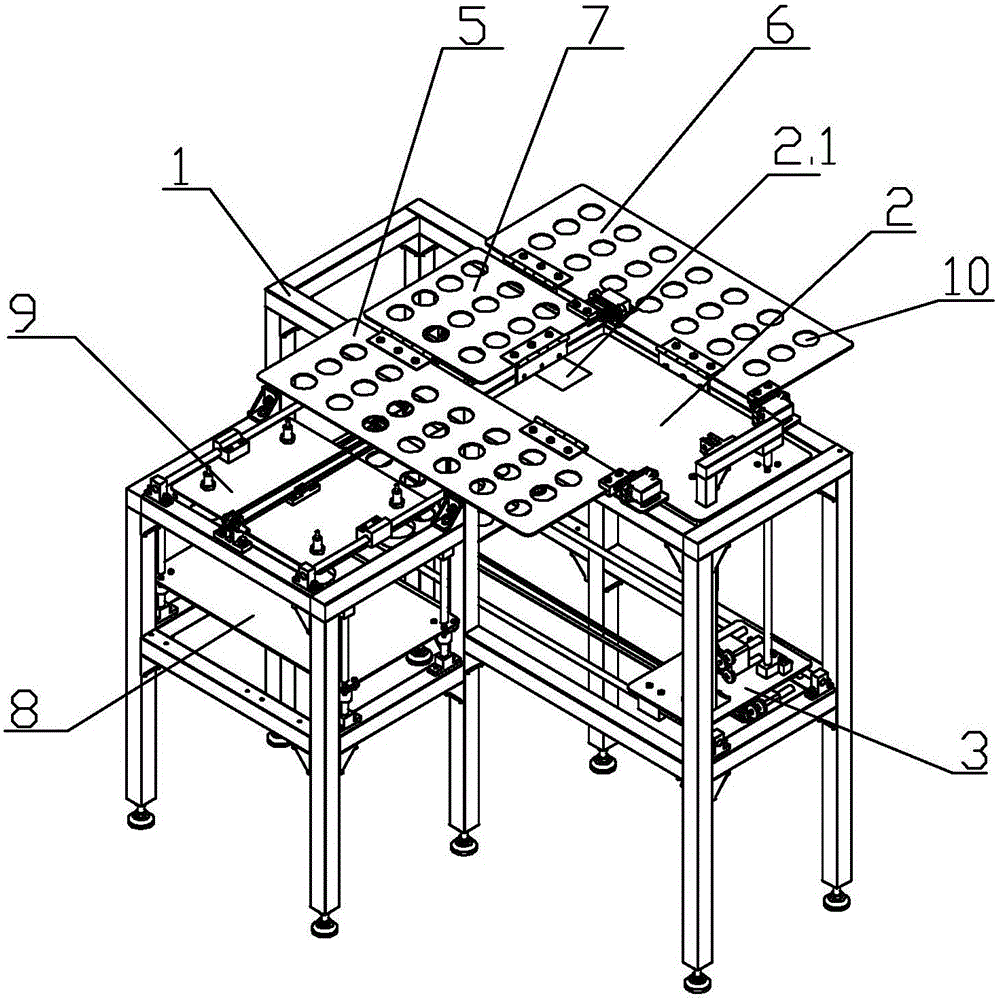

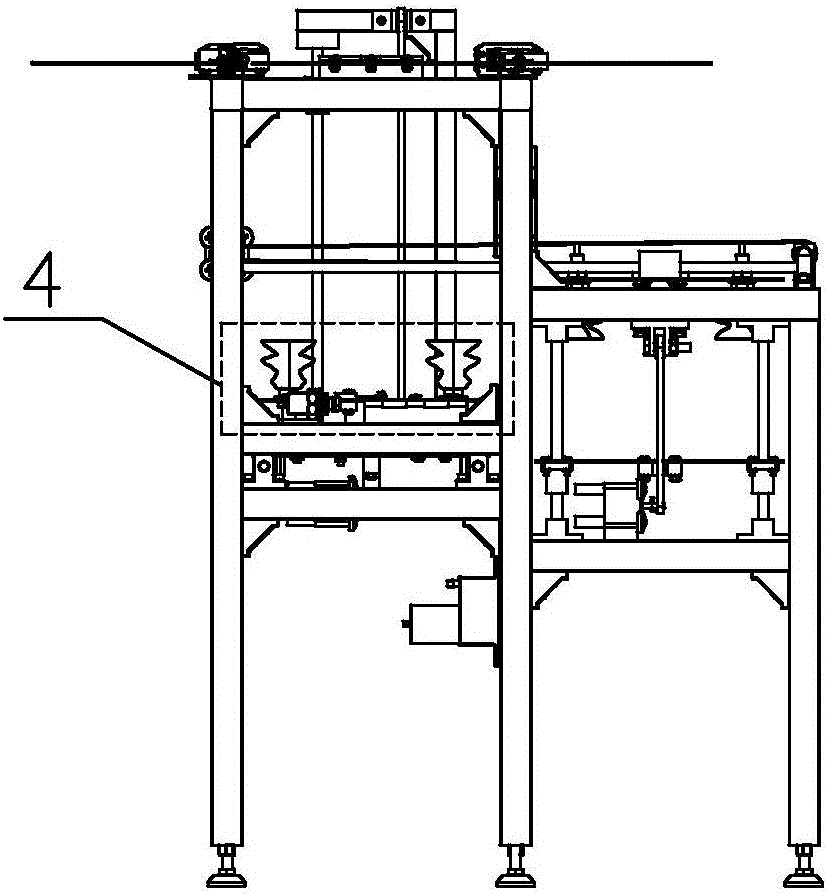

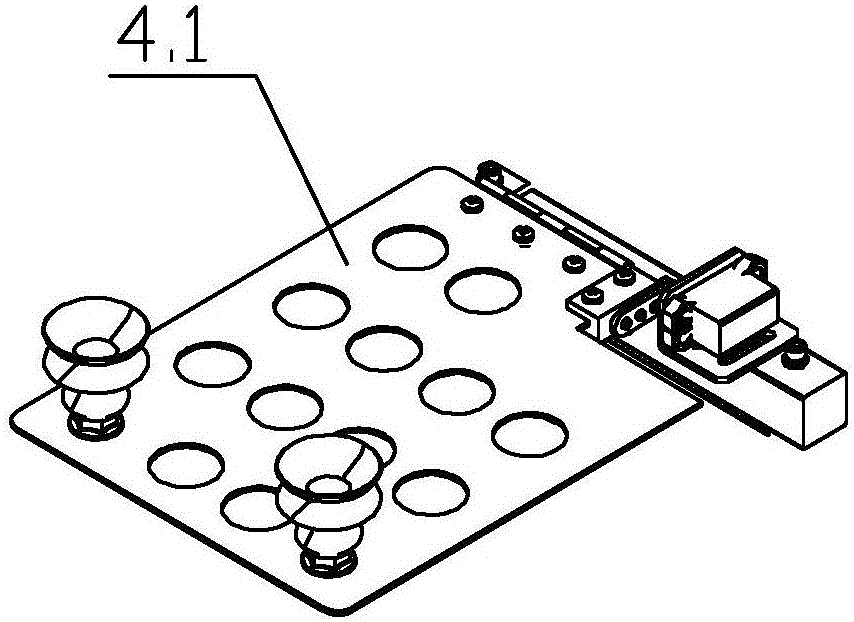

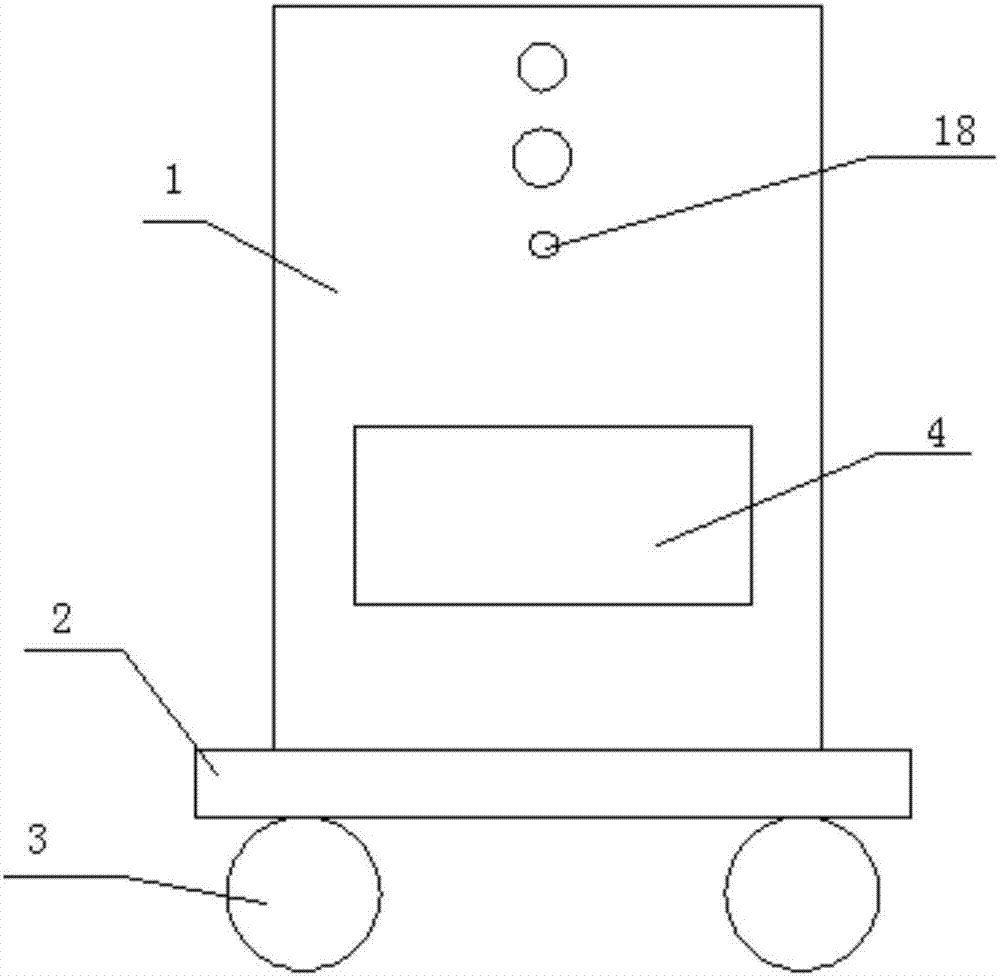

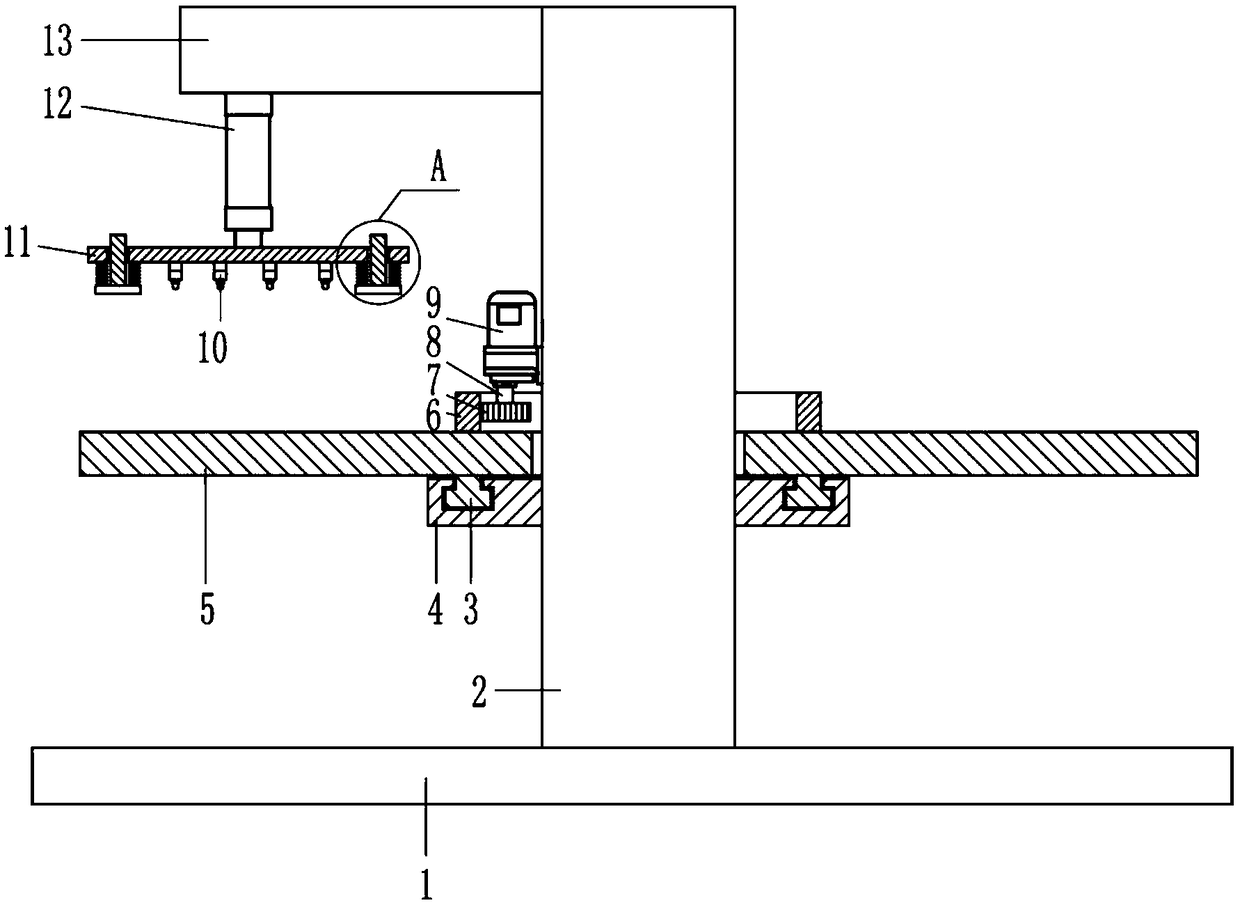

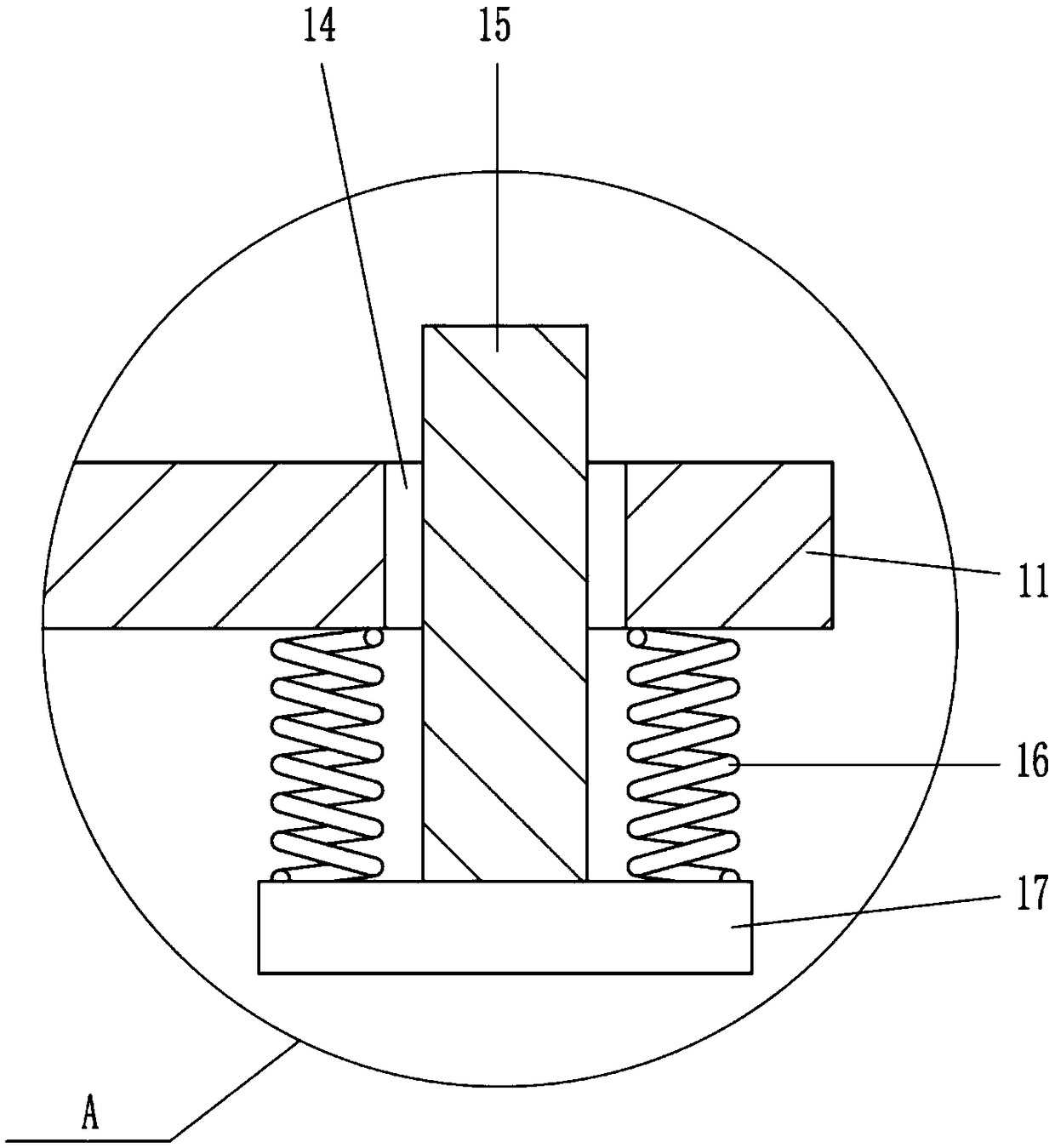

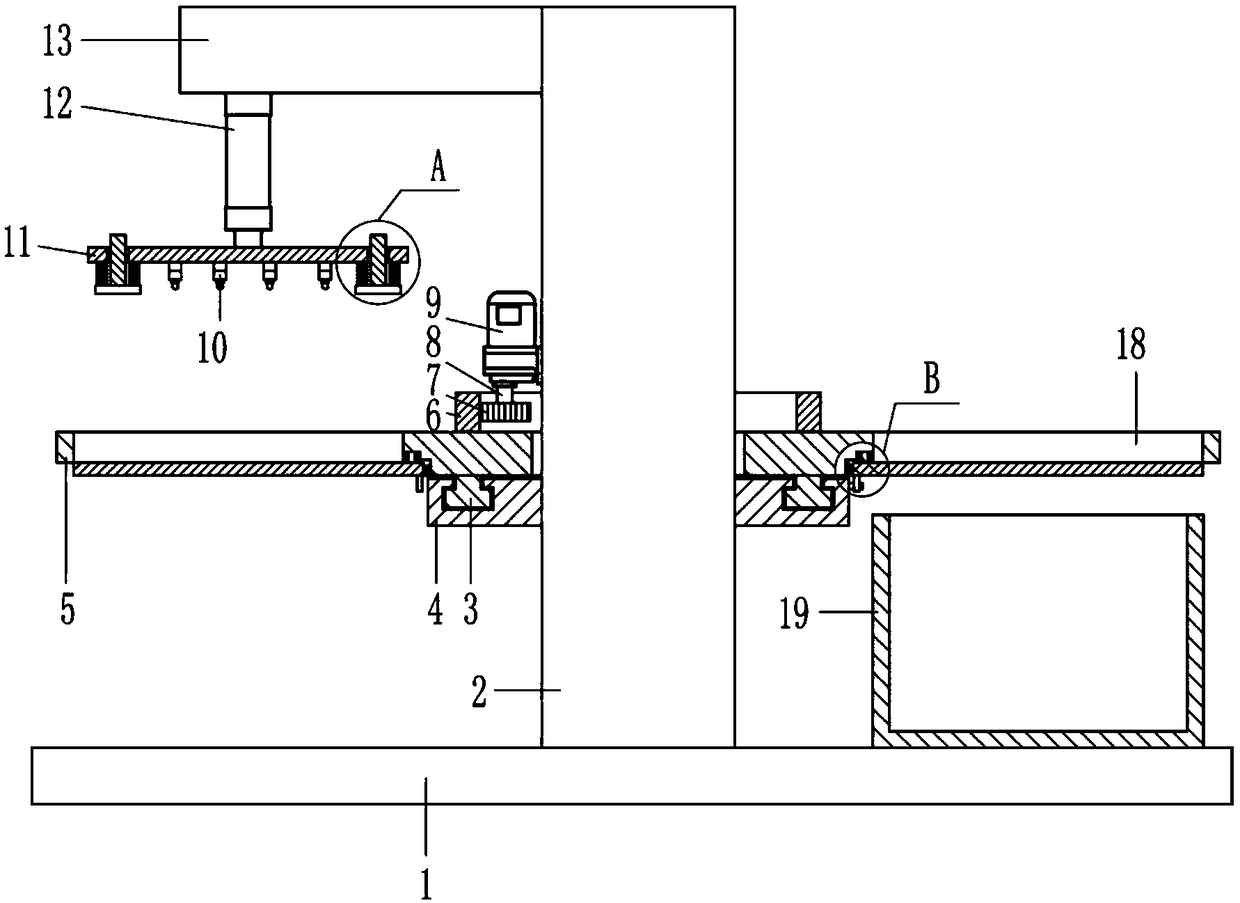

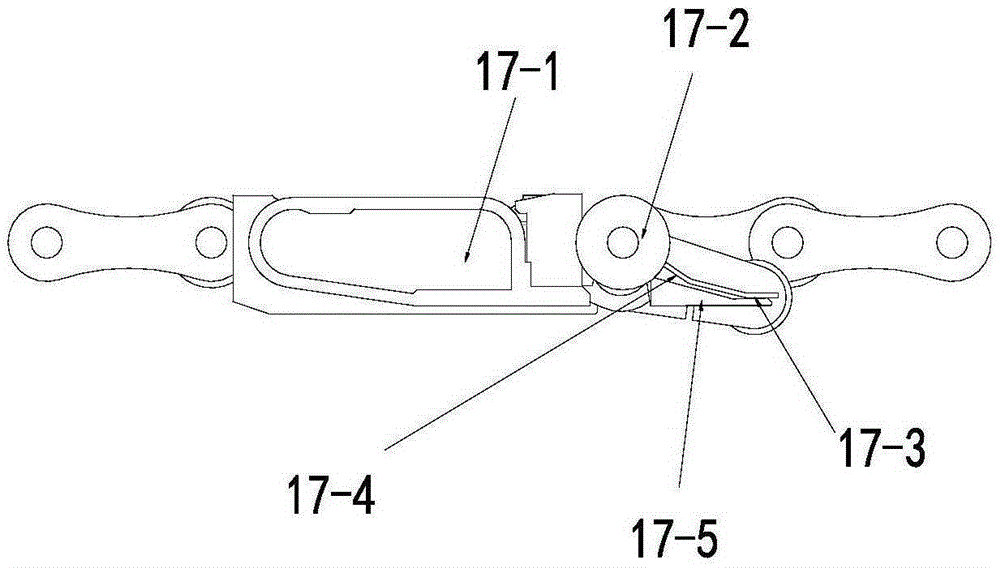

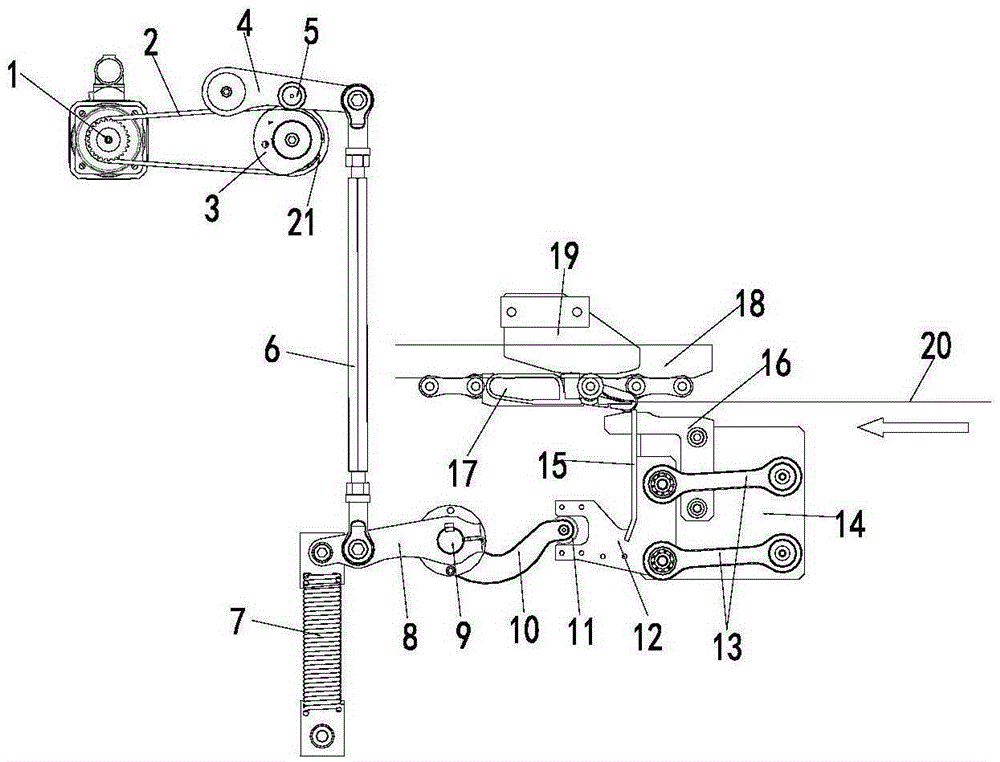

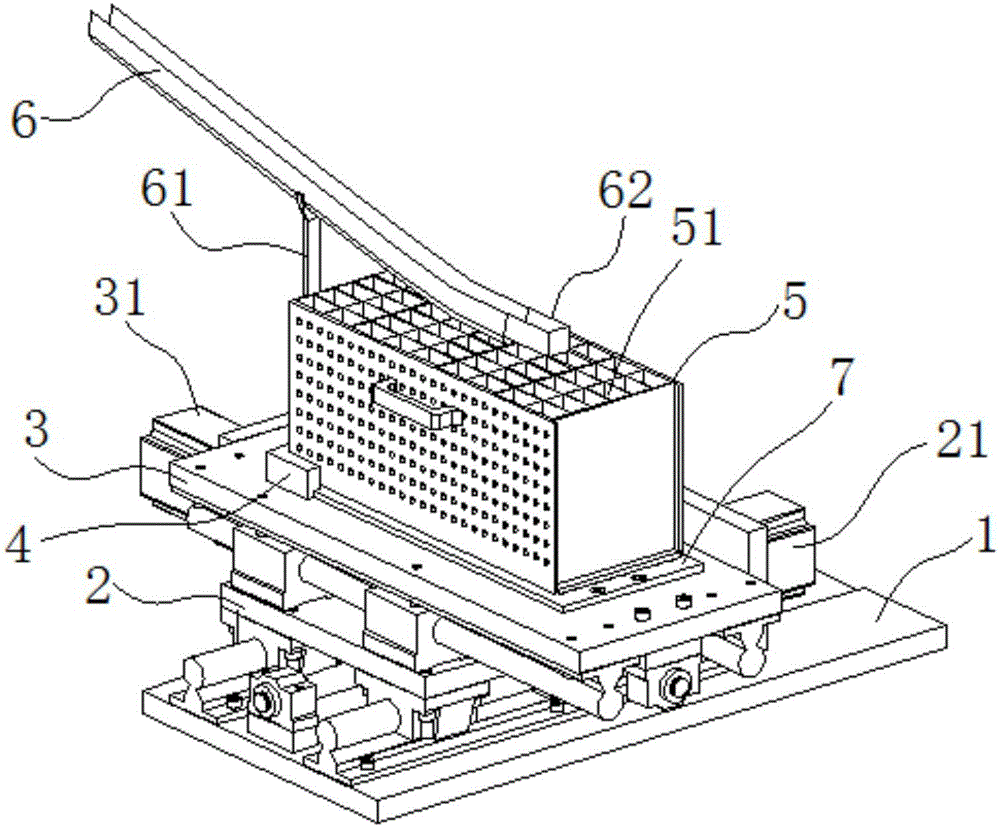

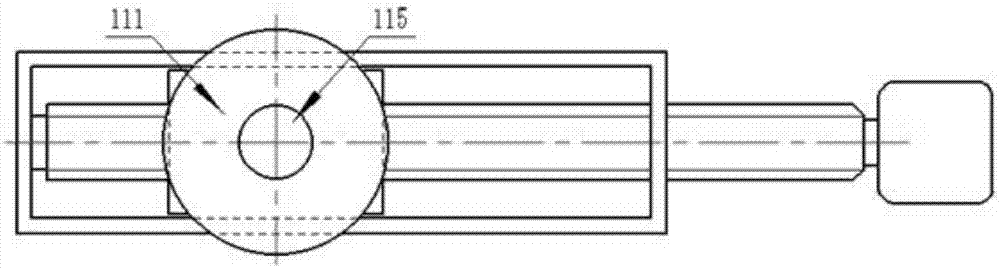

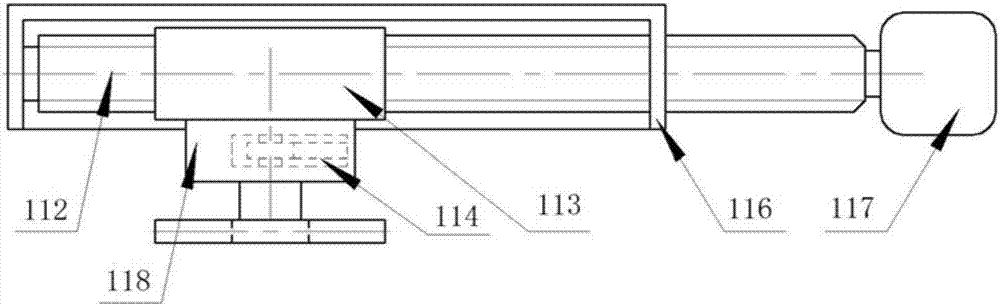

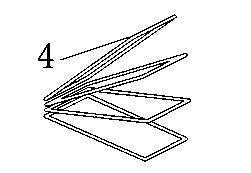

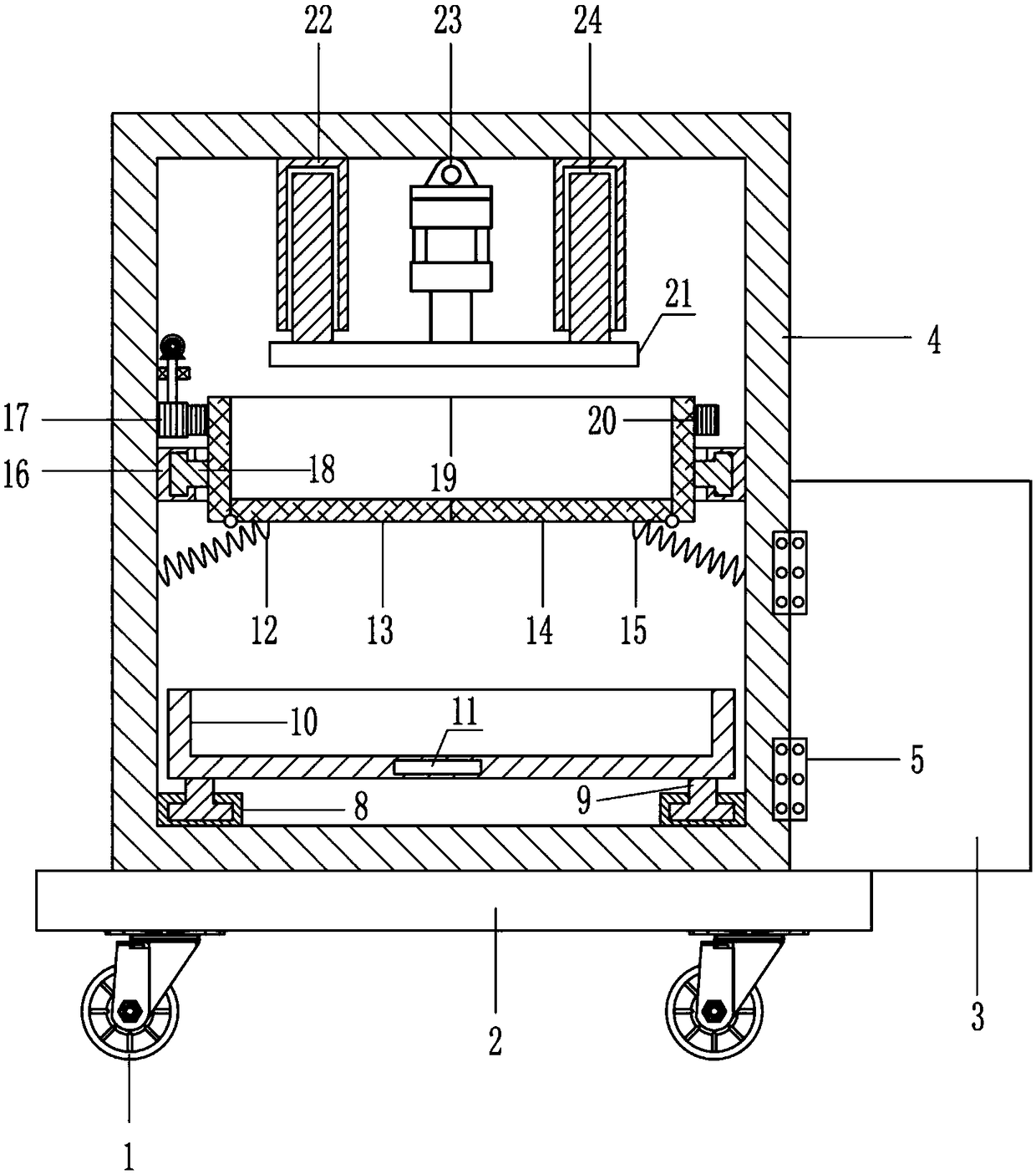

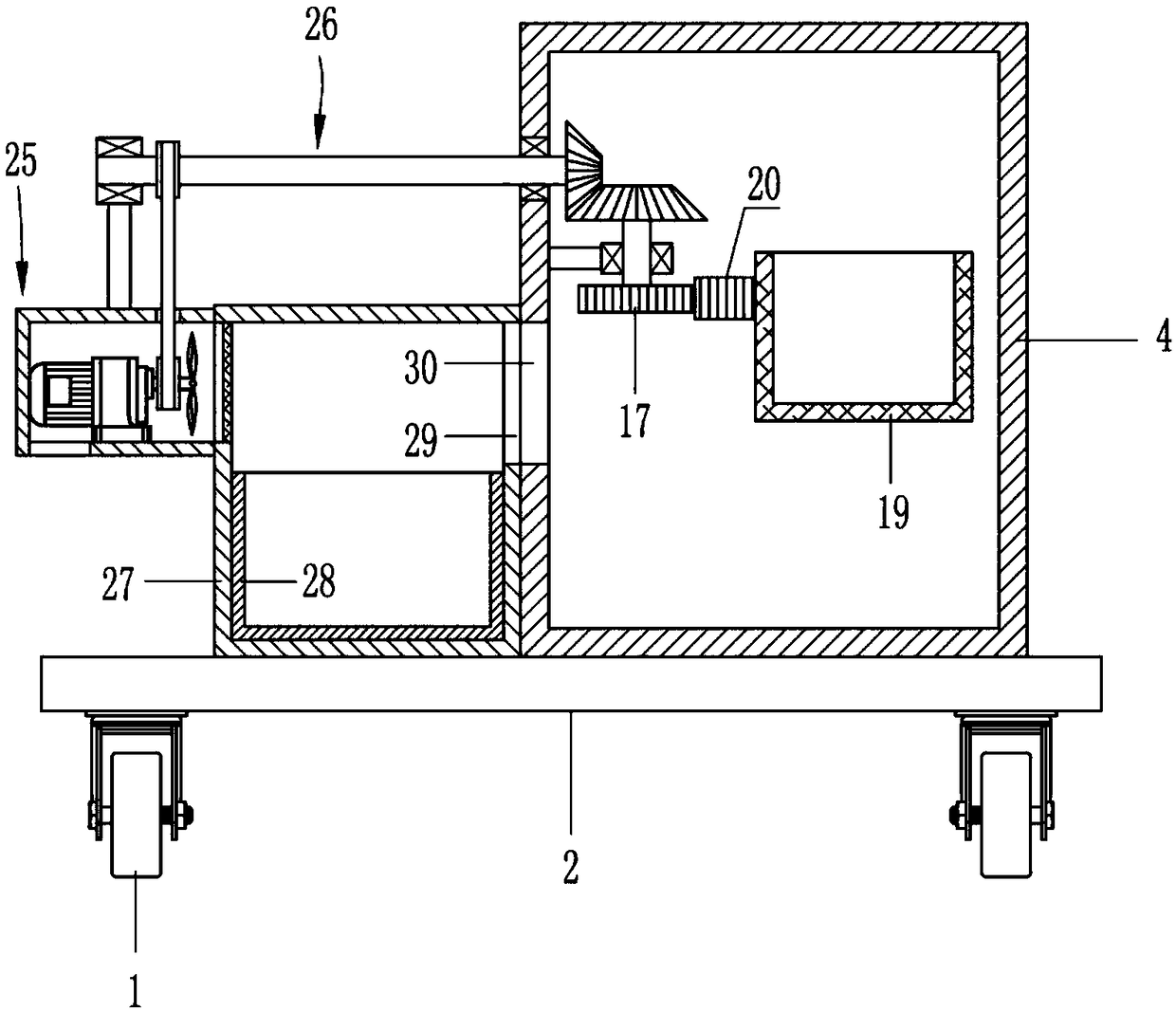

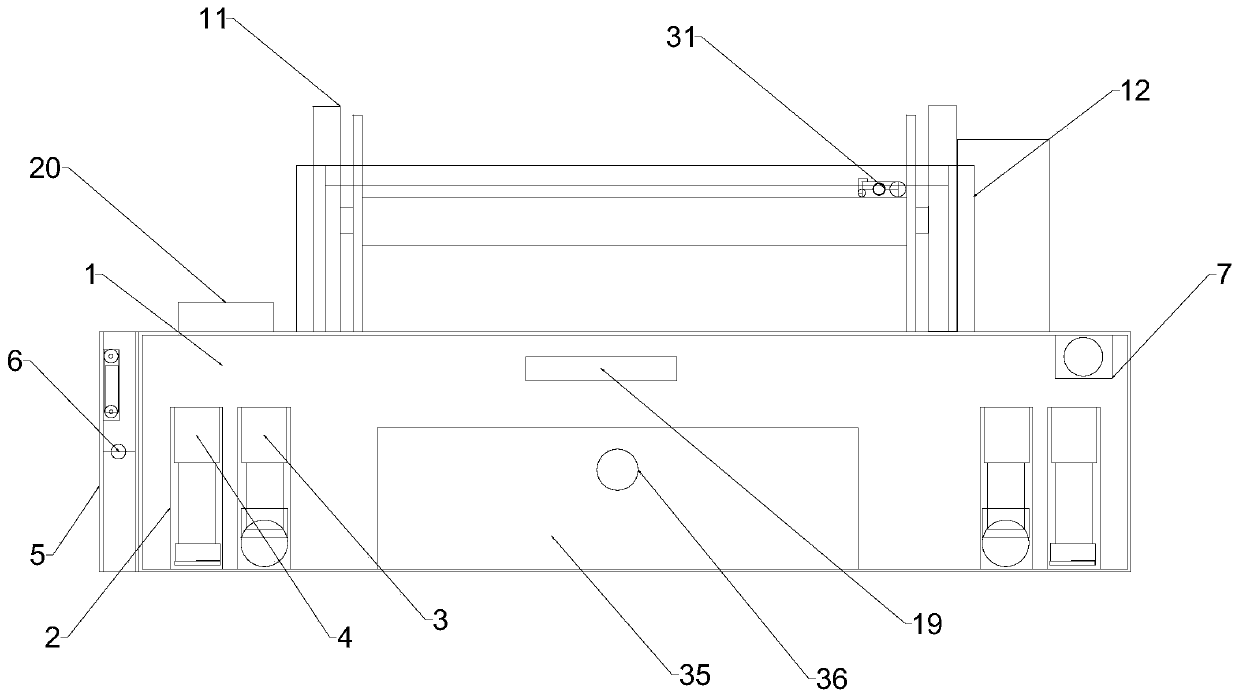

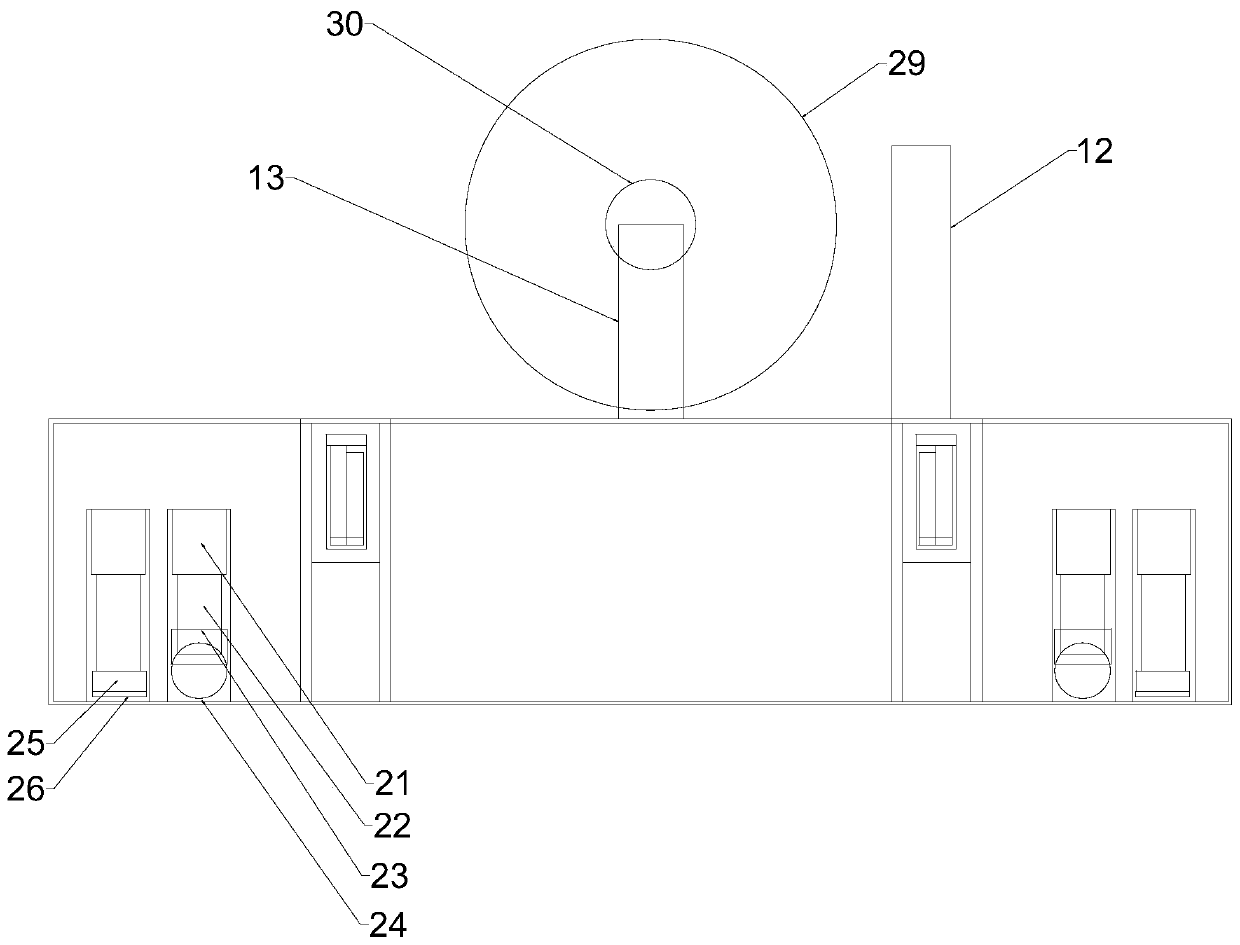

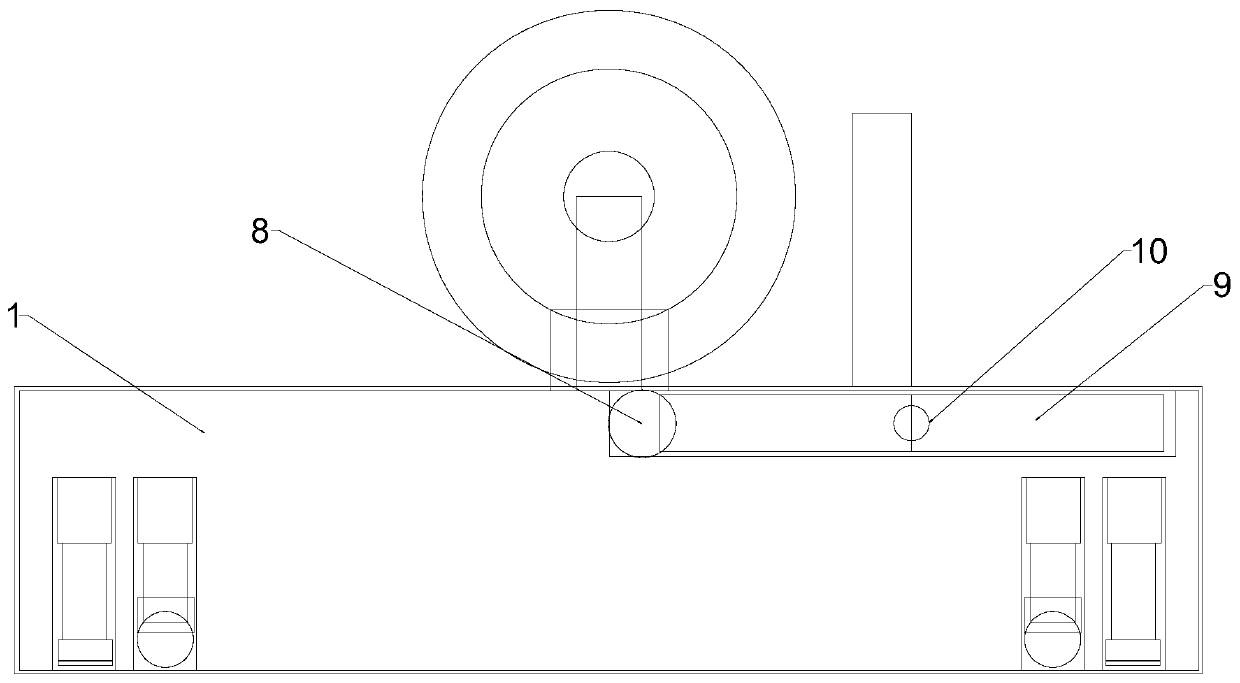

The invention discloses an automatic clothes folding packer. The automatic clothes folding packer comprises a rack and is characterized in that a main board and a folding component are arranged on the rack, the folding component is hinged to the rack (1), a transmission board (3) is arranged under the main board (2), a motor is arranged on the transmission board (3) or the rack (1), a packing station (4) and the motor used for driving the transmission board (3) to drive the main board (2) to reciprocate onto the packing station (4) are arranged on the rack (1), a transmission mechanism is arranged on the rack (1), and a clamping mechanism is arranged on the packing station (4). The invention further discloses a folding and packing method based on the automatic clothes folding packer. The automatic clothes folding packer provided by the invention can automatically finish clothes folding and packing, is high in integration performance, is motor-driven, eliminates noise, adopts a vertical structure and saves the working space.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

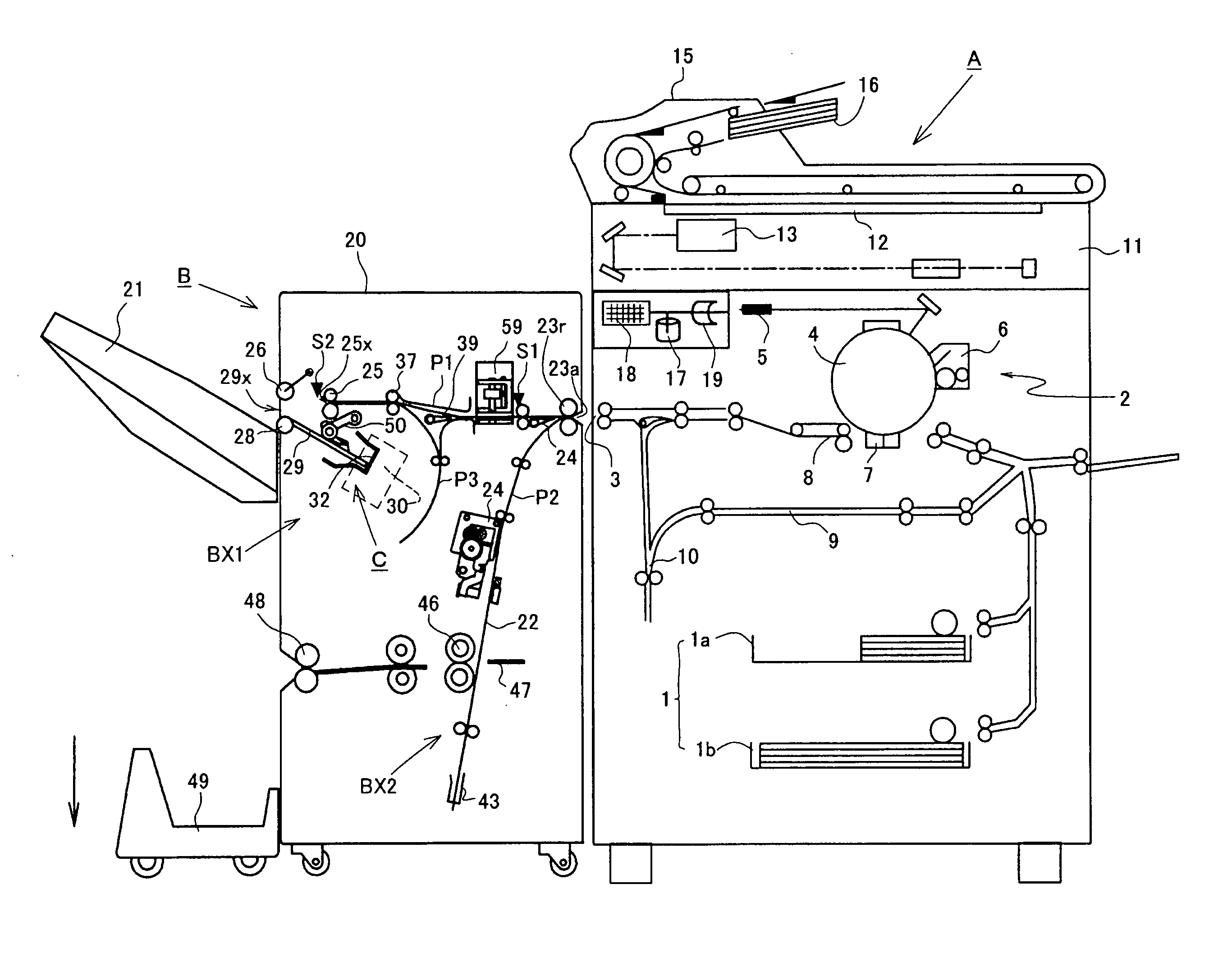

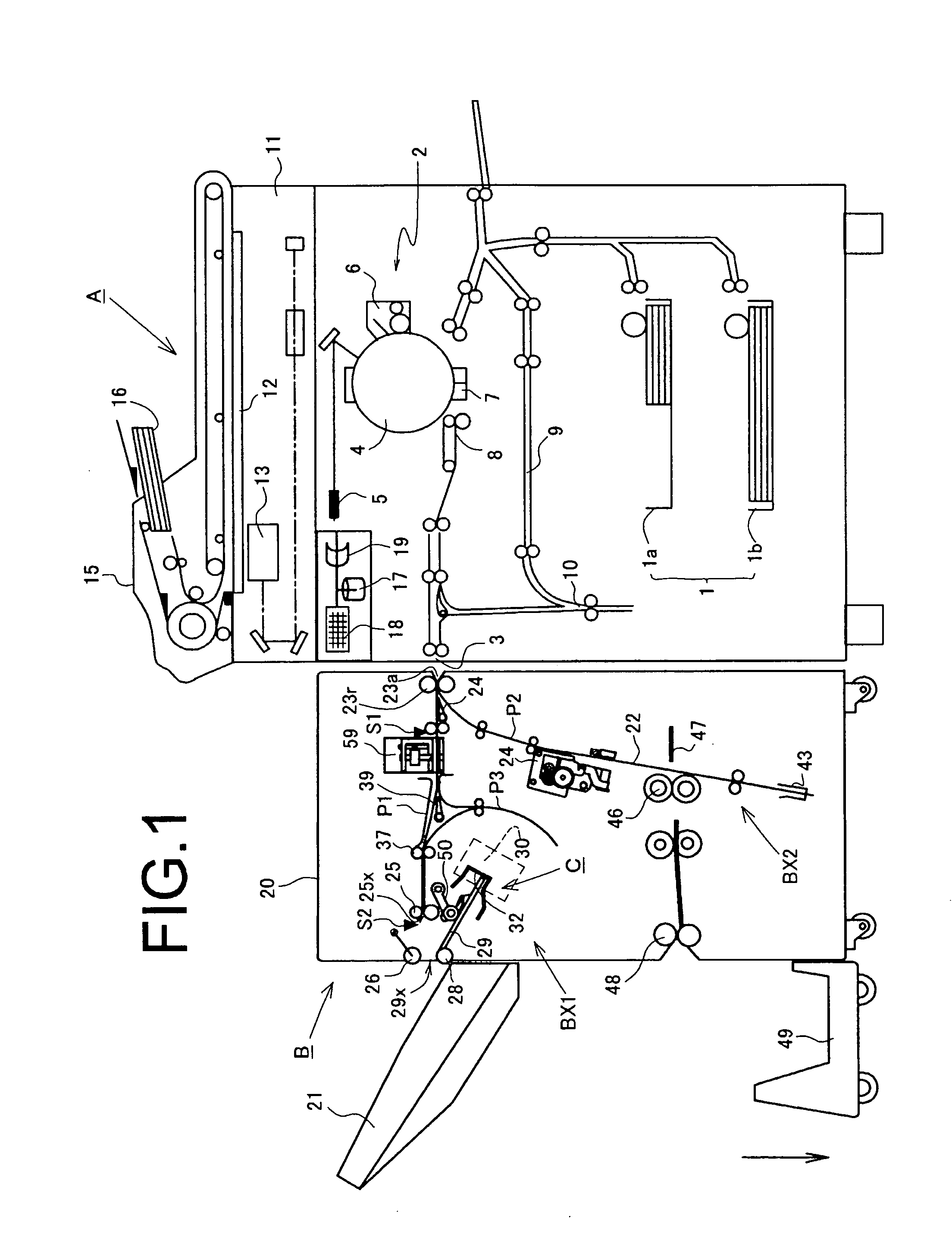

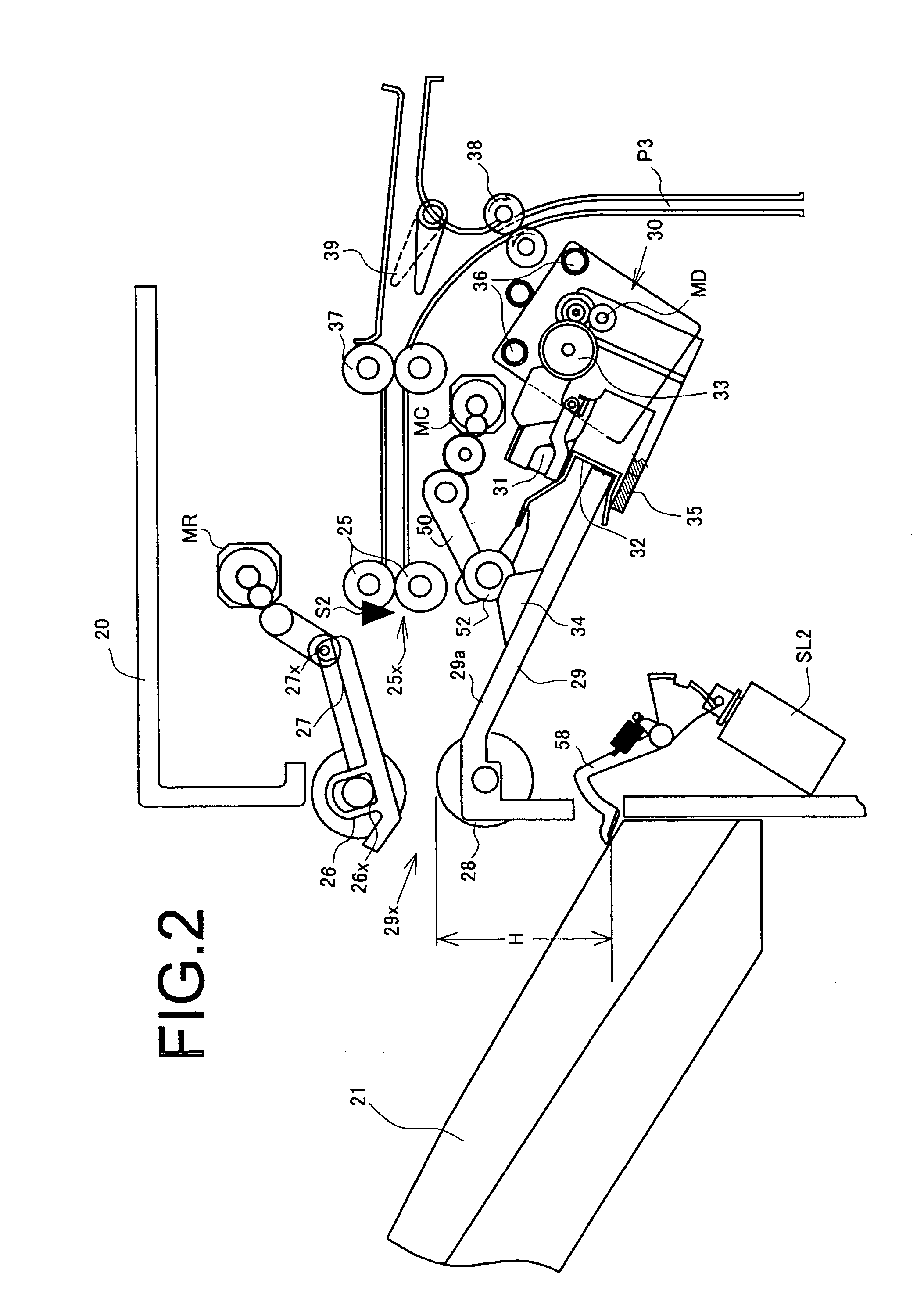

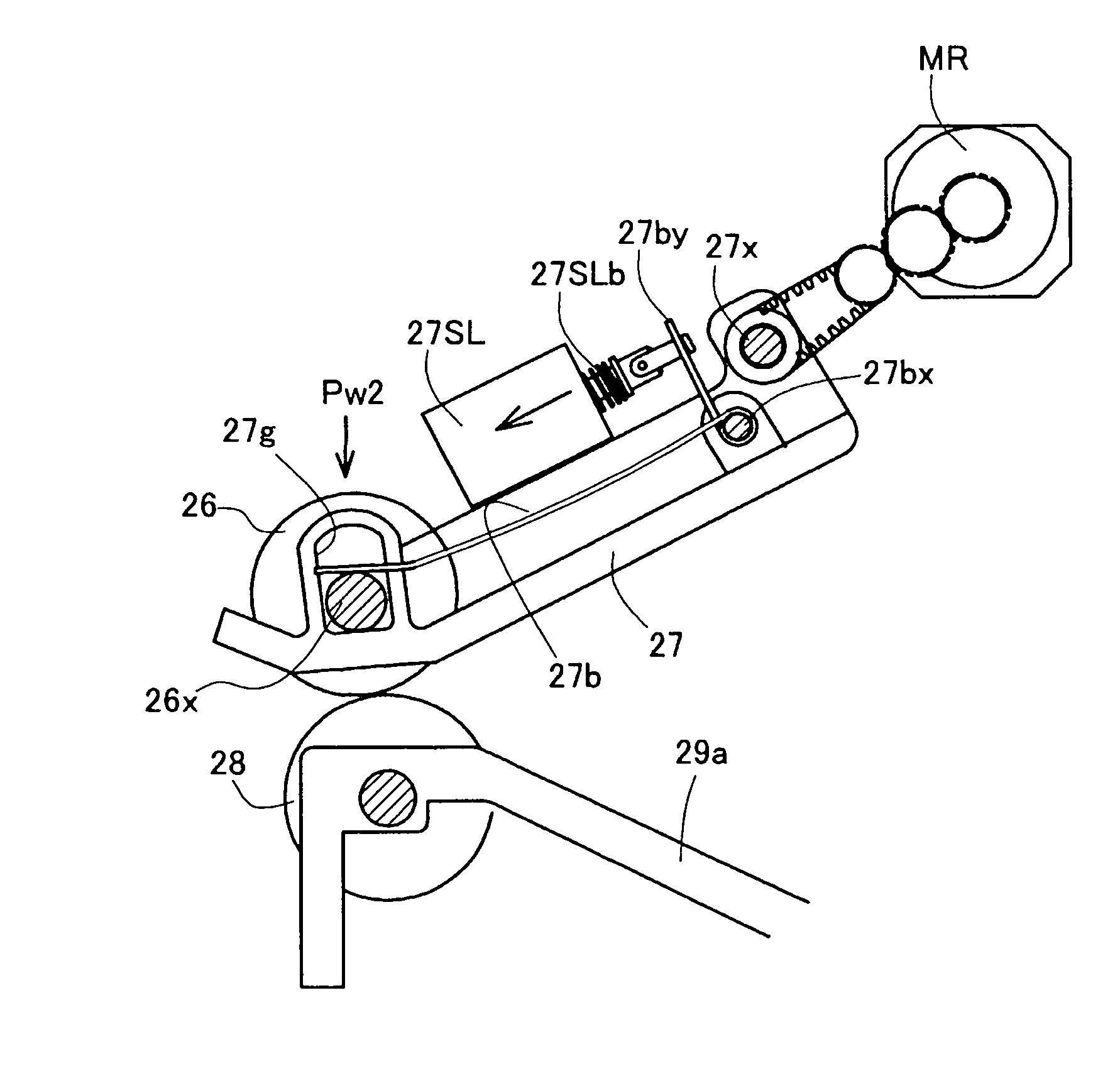

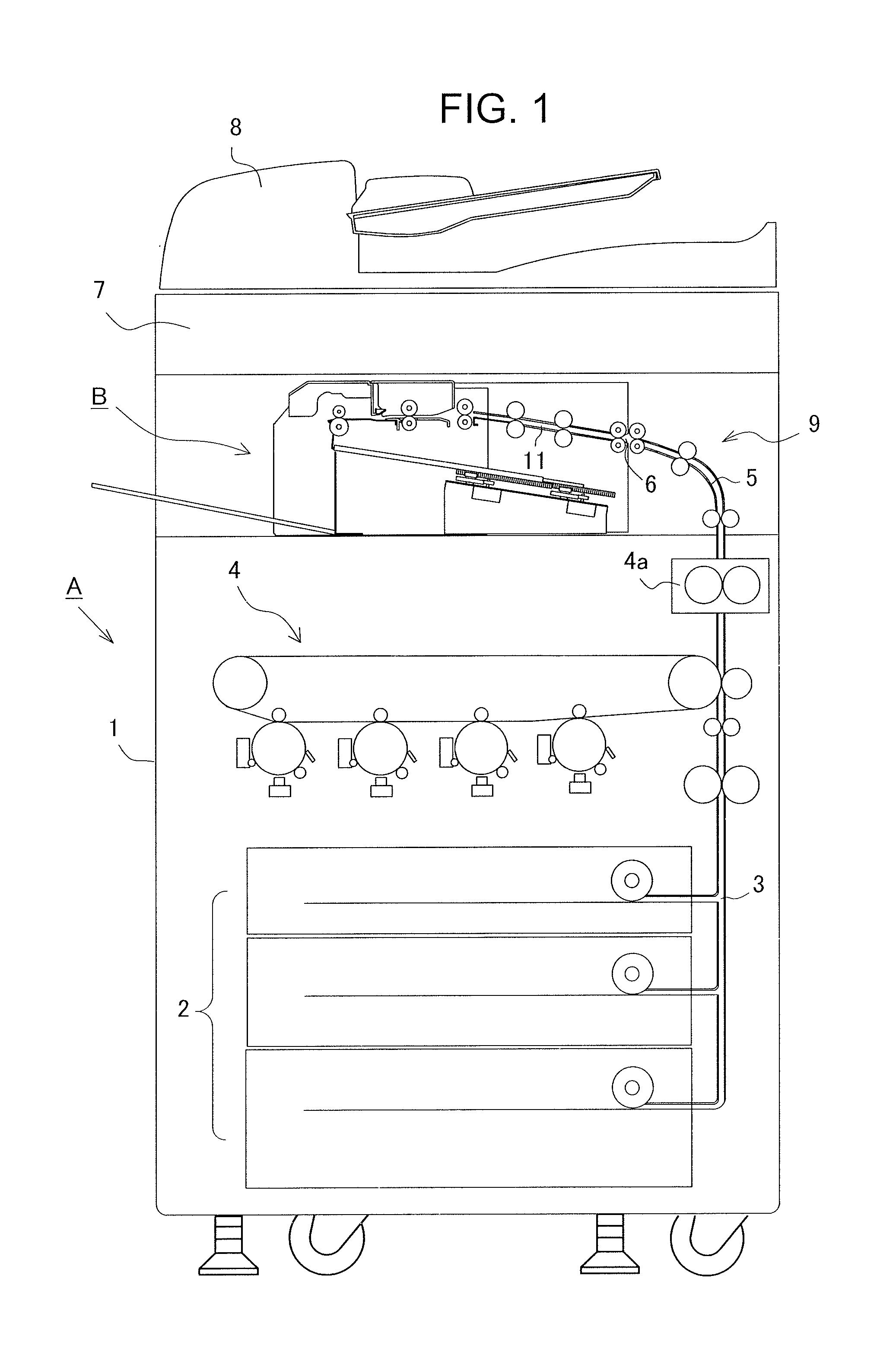

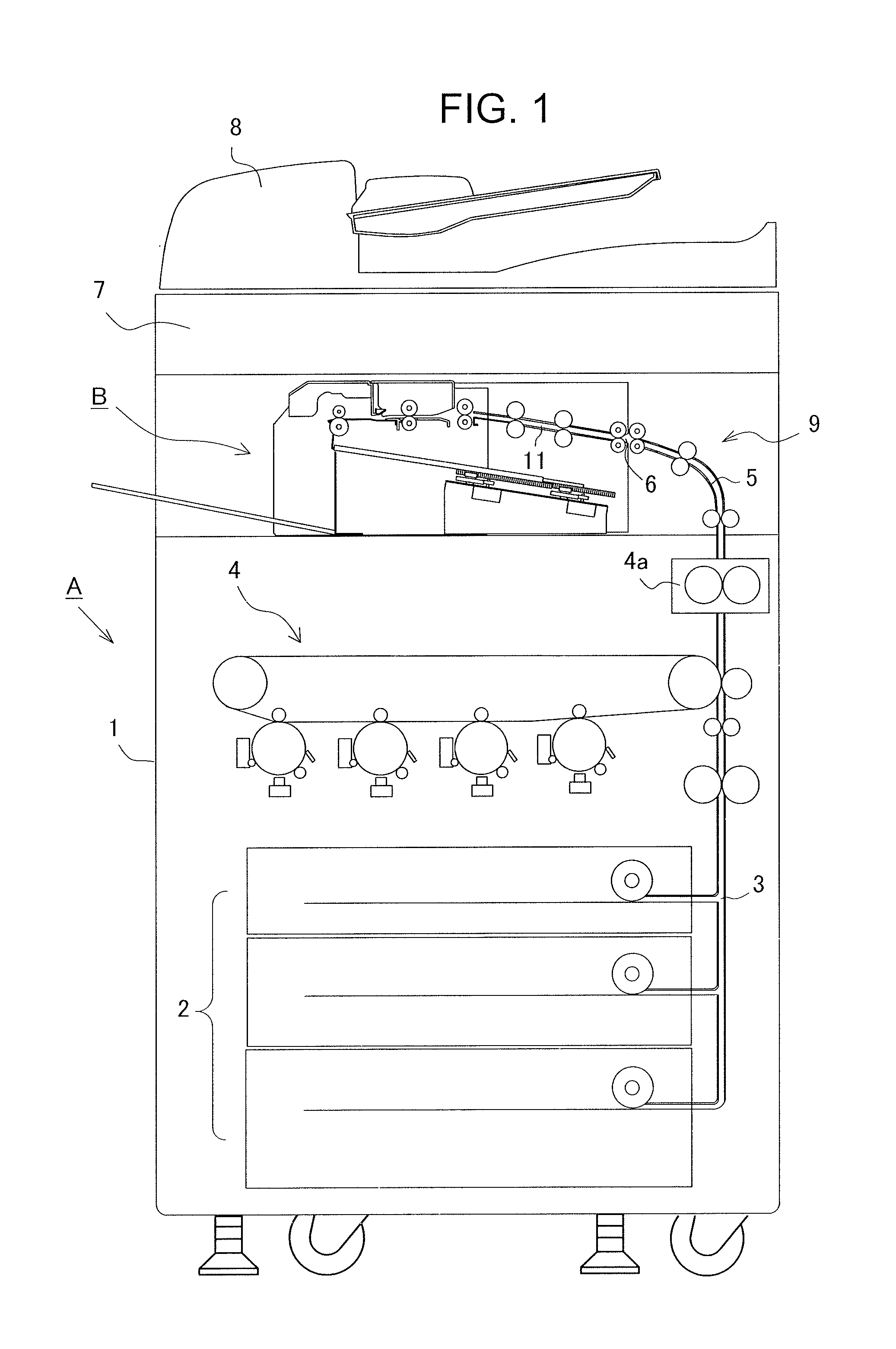

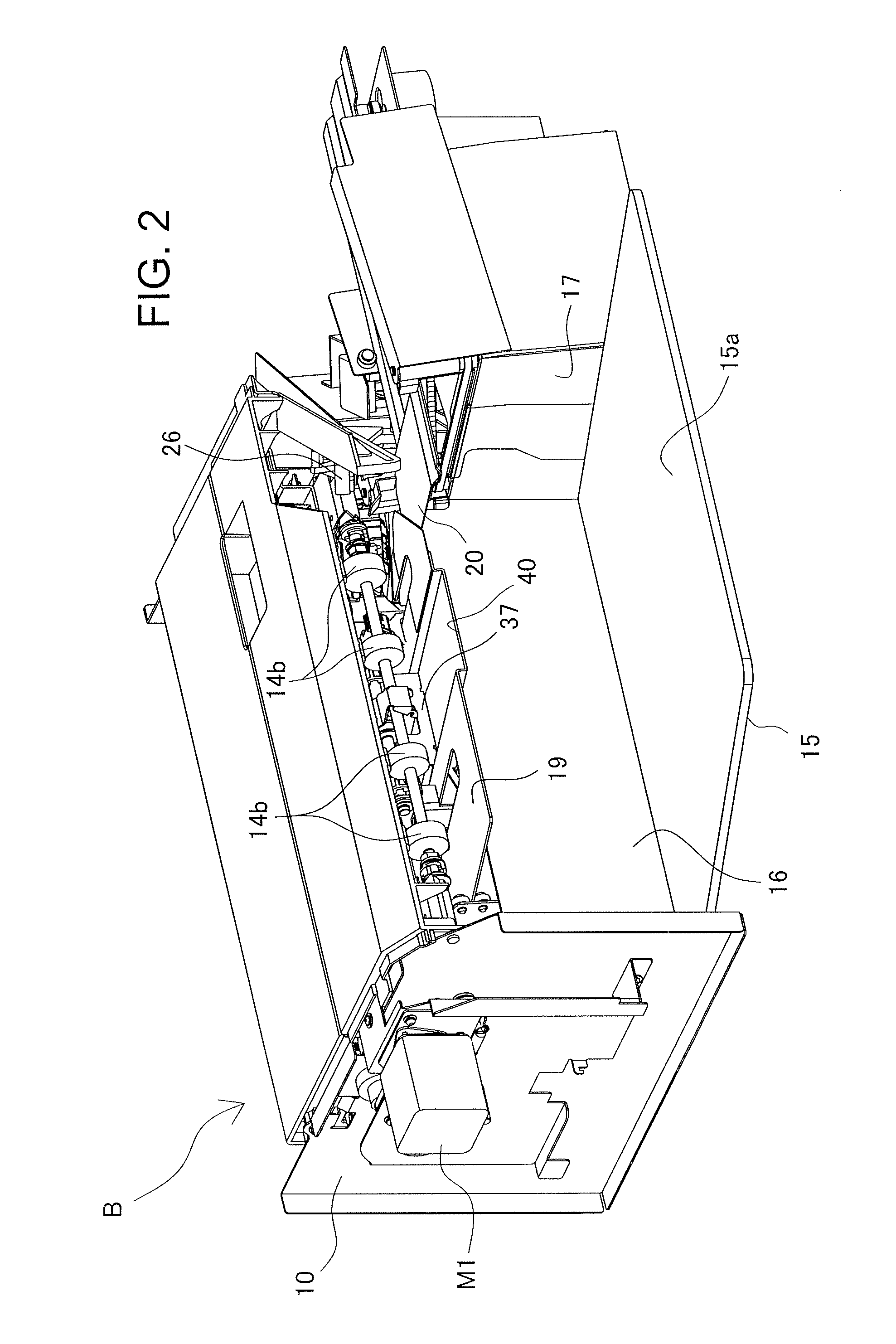

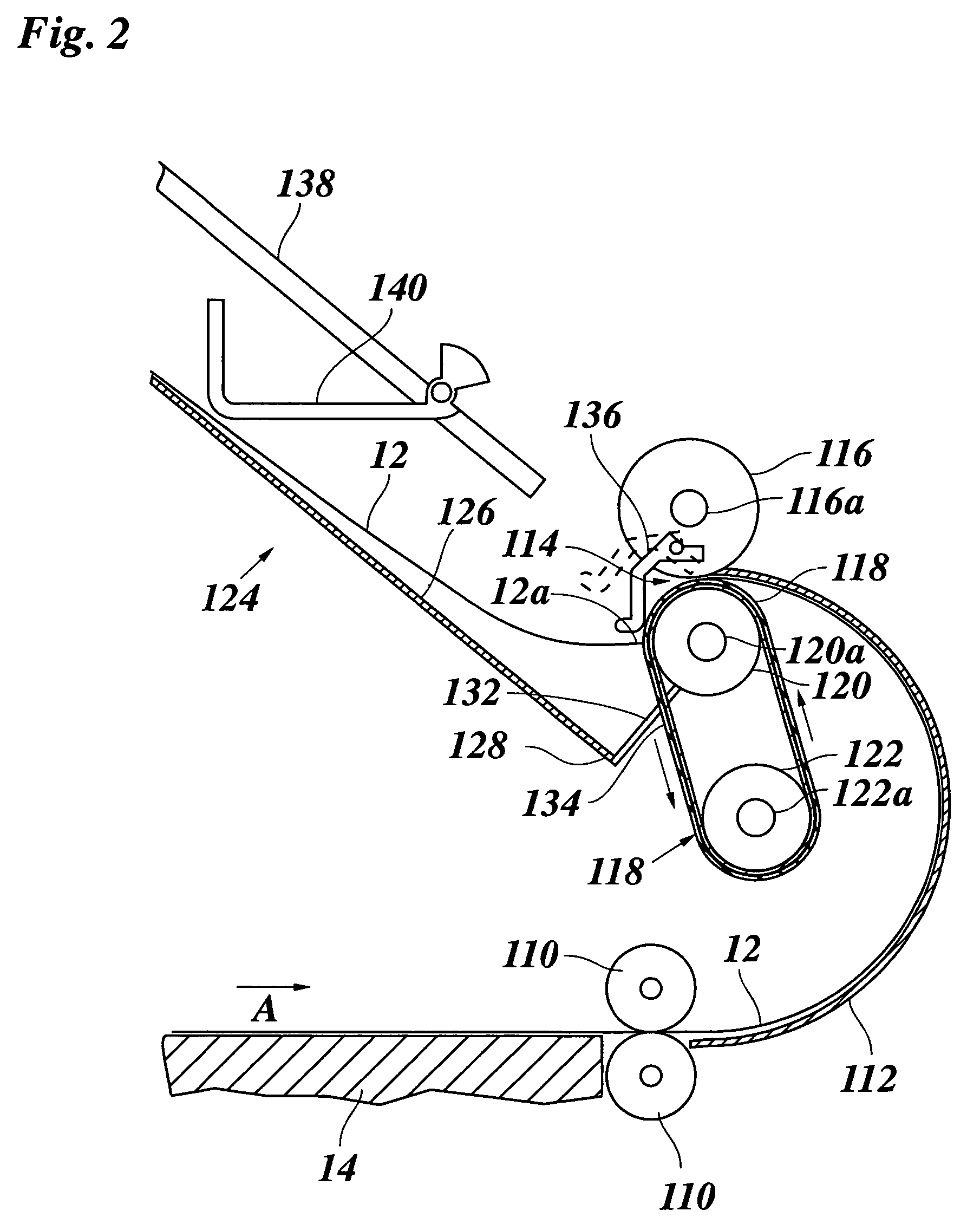

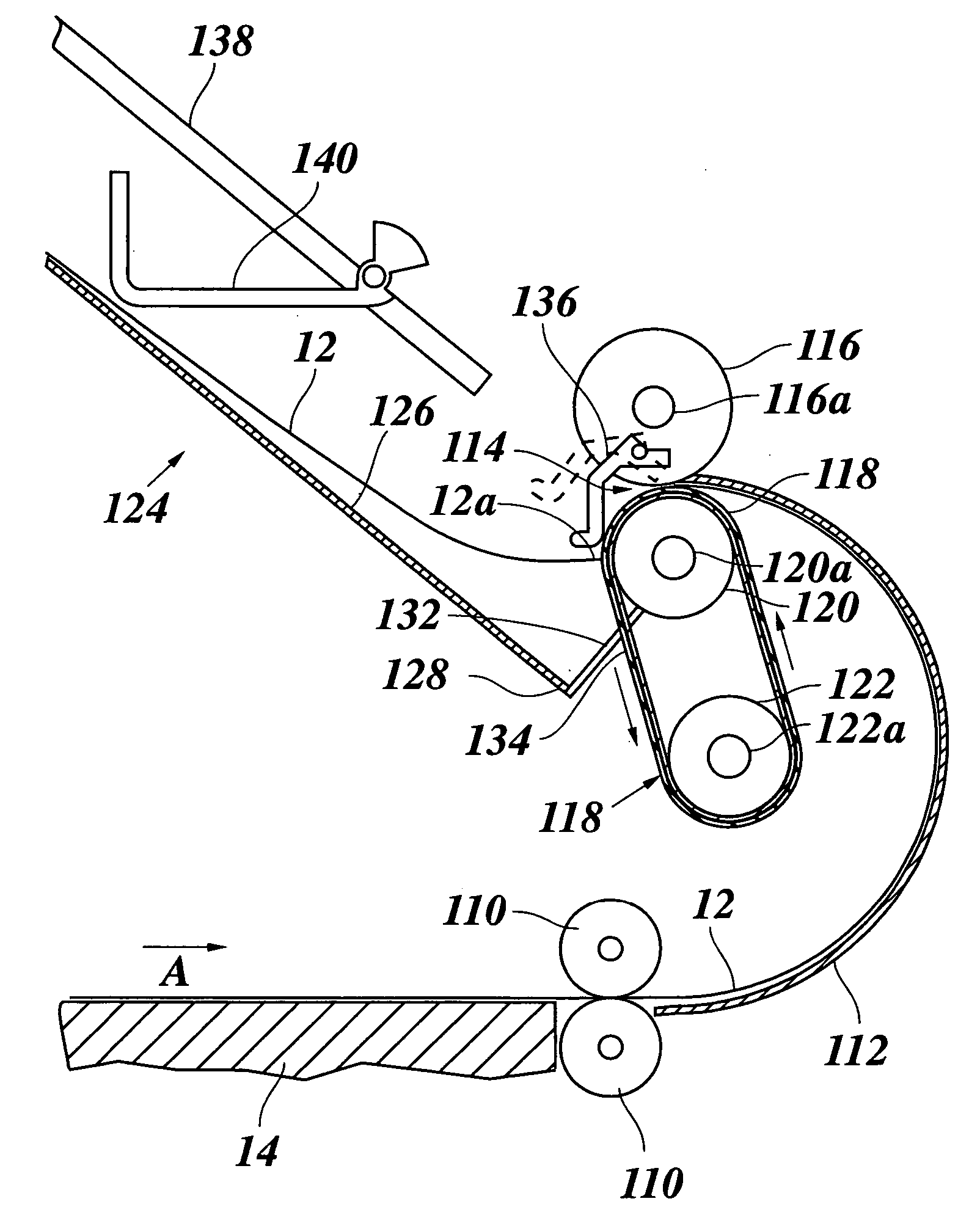

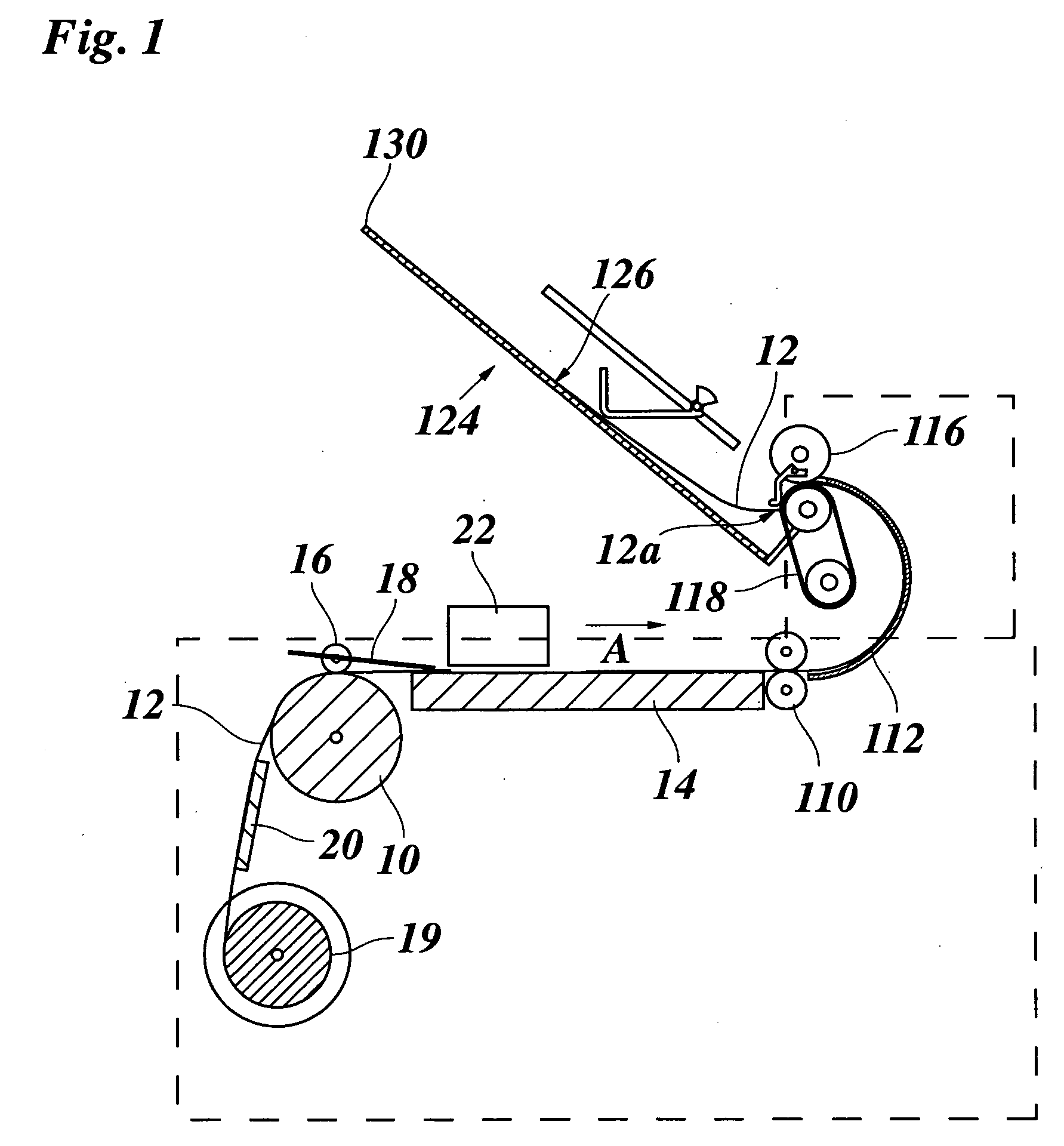

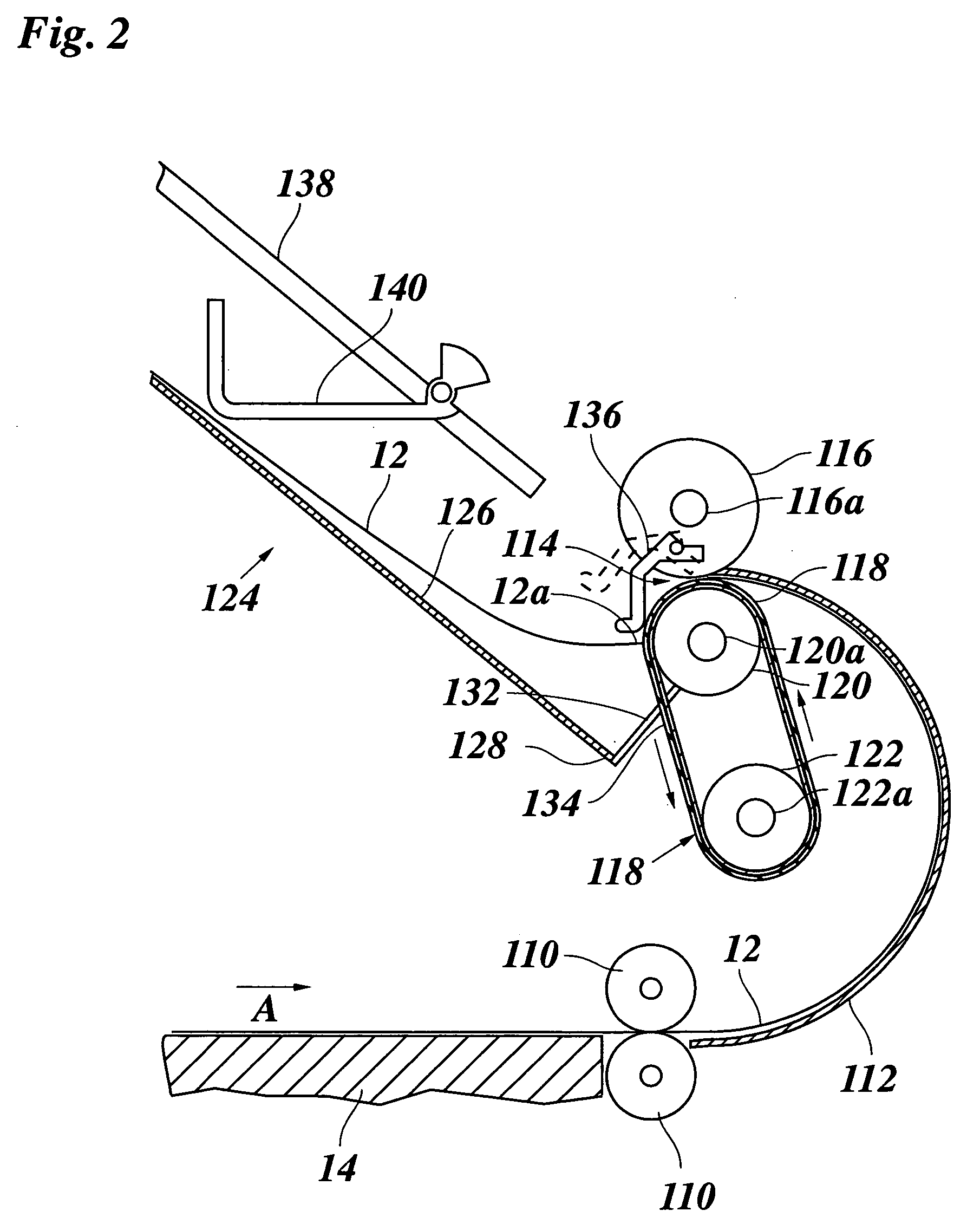

Sheet collecting apparatus, post processing apparatus and image formation system

ActiveUS20100140861A1Reduce pressing forceNeatly collectedRegistering devicesElectrographic process apparatusImage formationEngineering

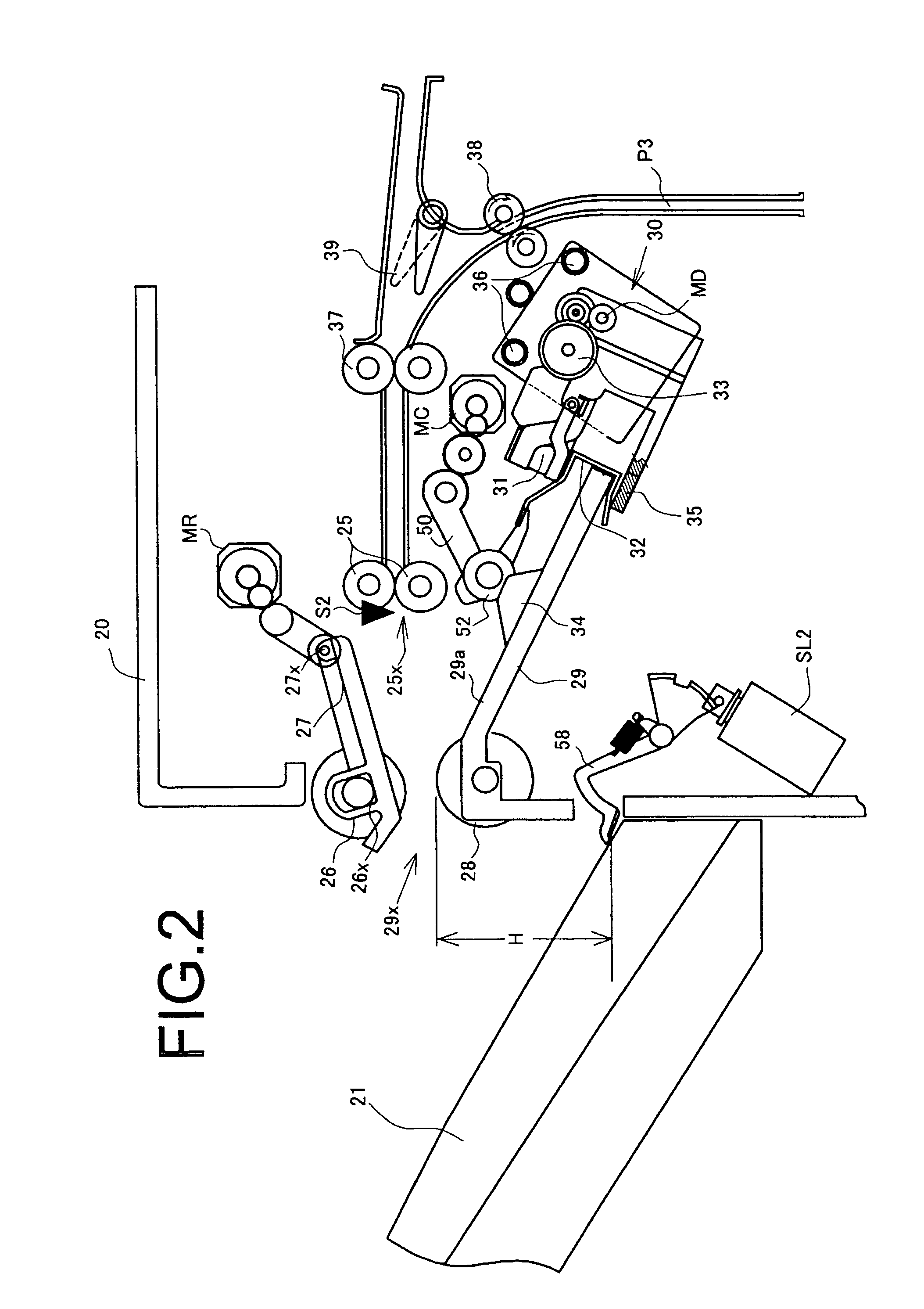

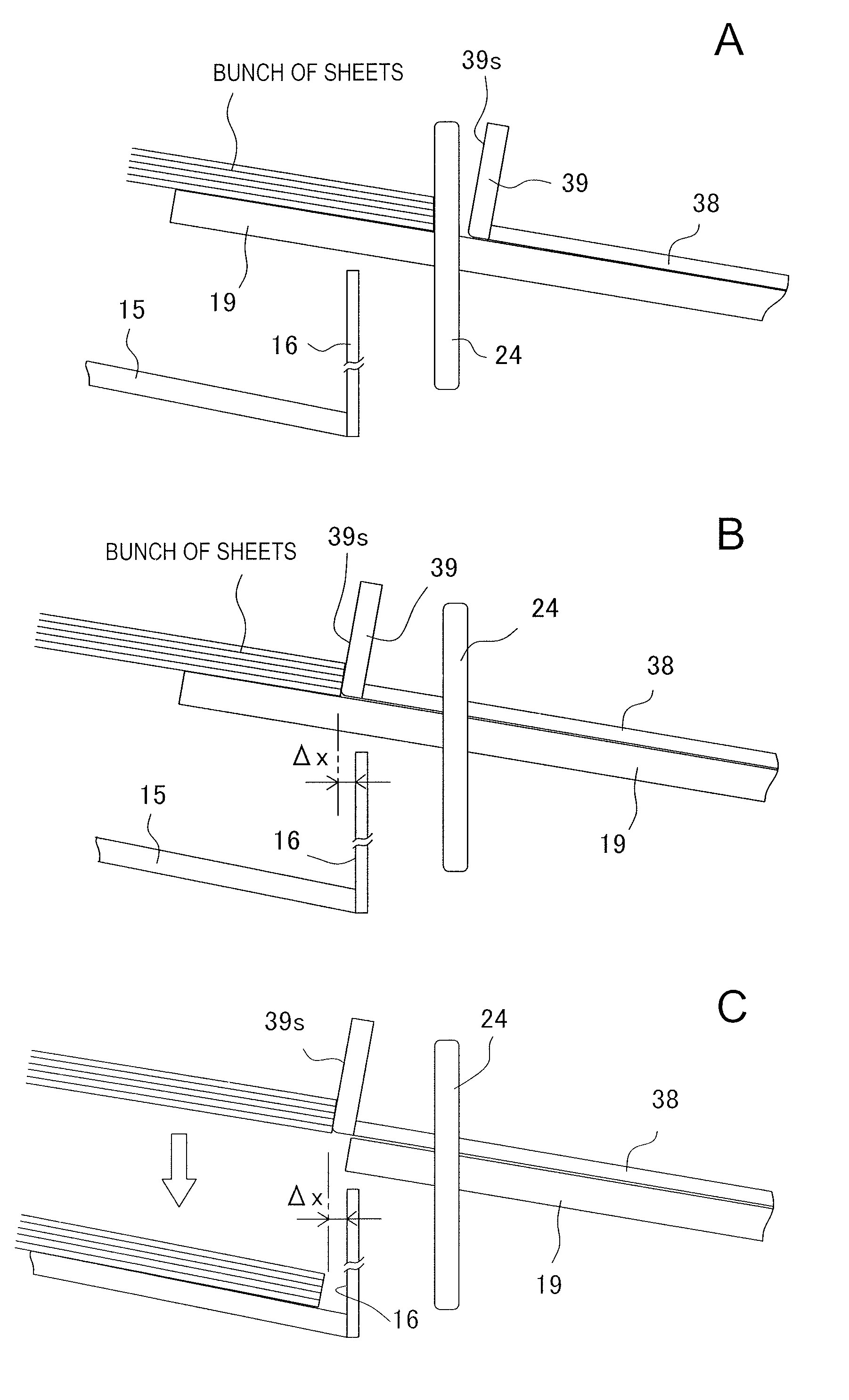

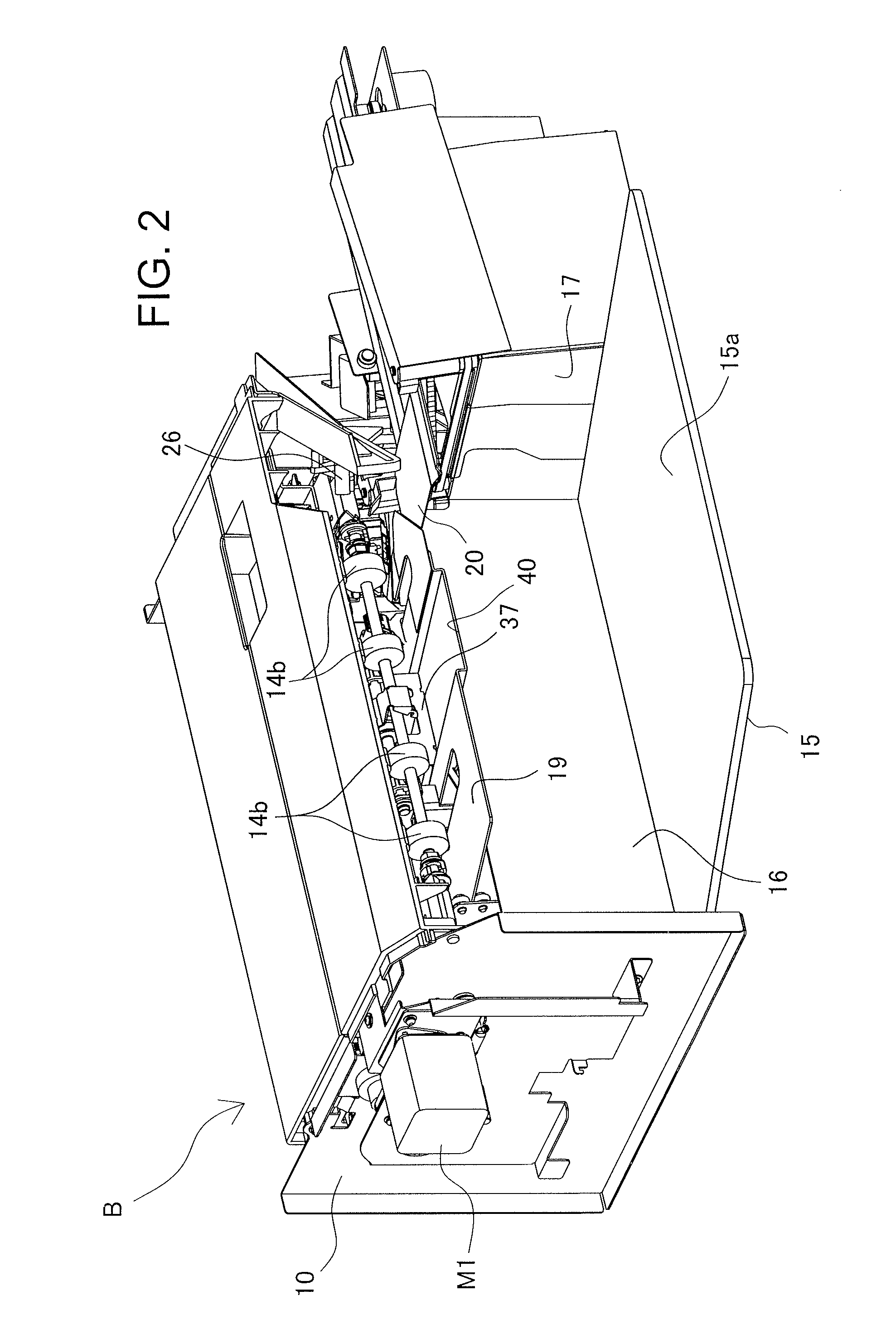

The invention is to enable sheets to be aligned neatly even when front ends of the sheets are displaced to the front and back in overlapping the front and rear sheets and transporting the sheets from a sheet discharge outlet onto the tray, and provides an apparatus having a sheet transport path for transporting a sheet from a carry-in entrance to a predetermined sheet discharge outlet, a tray means for bearing and storing sheets, a regulation stopper for regulating the sheet by an end edge of the sheet striking the stopper, a holding path for temporarily holding a sheet in the sheet transport path, an alignment roller for transporting the sheet fed from the sheet discharge outlet to the regulation stopper, and a control means for controlling transport of the sheet, where the control means controls so that in the first operation mode, the alignment roller applies a transport force to the sheet by a predetermined pressing force after the rear end of the sheet is carried into the tray means, and that in the second operation mode, for a period during which rear ends of overlapped sheets are carried into the tray means and then reach the regulation stopper, the alignment roller changes the pressing force acting on the sheets from strong to weak and thereby applies the stepwise varied transport force.

Owner:NISCA KK

Sheet collecting apparatus, post processing apparatus and image formation system

ActiveUS8172214B2Reduce pressing forceNeatly collectedElectrographic process apparatusPile receiversImage formationOperation mode

A sheet collecting apparatus has a sheet transport path for transporting a sheet, a tray device for bearing and storing sheets, a regulation stopper for regulating the sheet, a holding path to temporarily hold a sheet, an alignment roller to transport the sheet, and a control device for controlling transport of the sheet. The alignment roller adjusts a level of pressing force acting on the sheet transported onto the tray device. The control device has a first operation mode and a second operation mode. In the first operation mode, the alignment roller applies a transport force to the sheet by a predetermined pressing force after a rear end of the sheet is carried into the tray device, while in the second operation mode, changing the pressing force applied to the sheets from the alignment roller from a first pressing force to a second pressing force and applying varied transport force.

Owner:NISCA KK

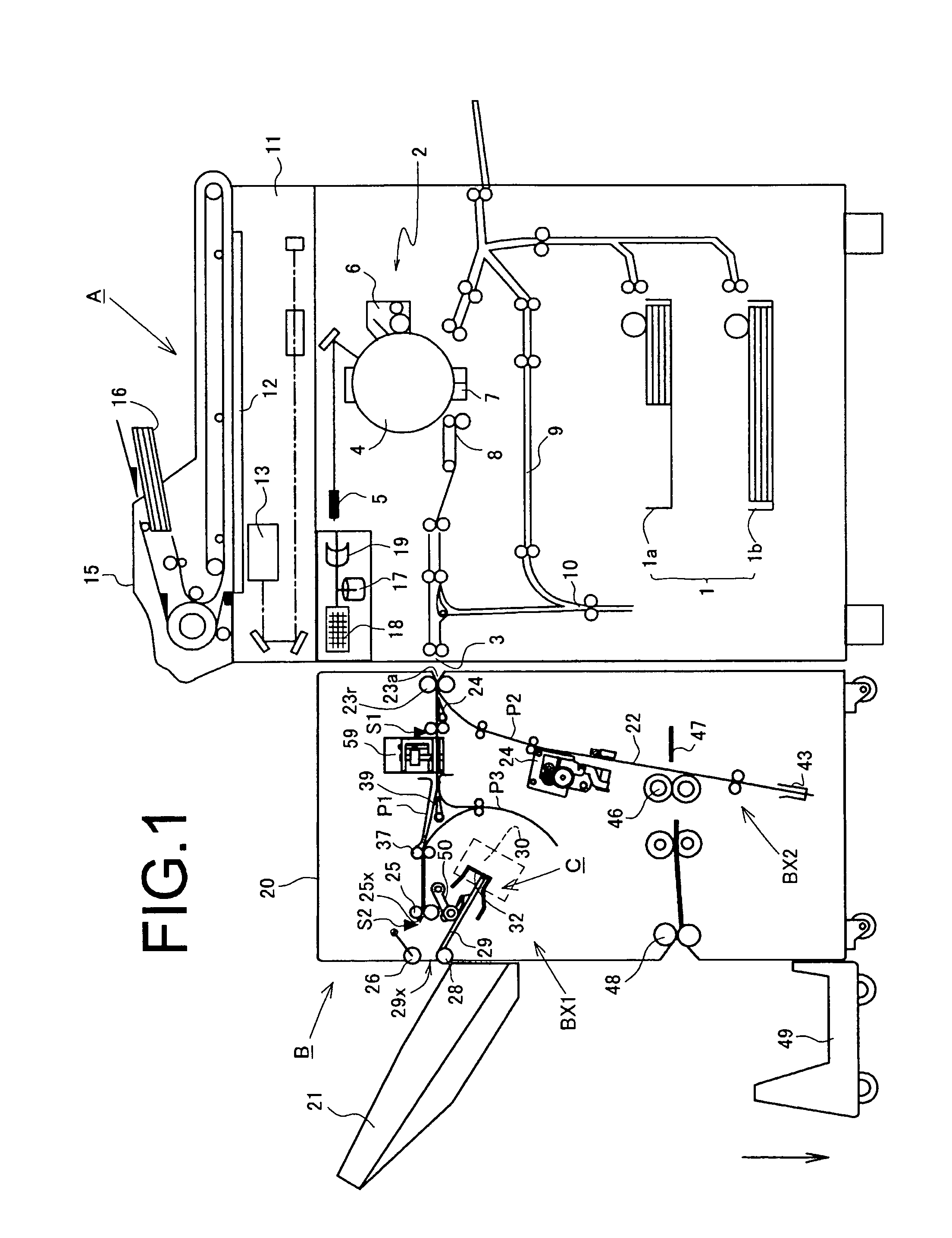

Sheet storage apparatus and image formation system using the apparatus

ActiveUS20140103604A1Increase storage capacityReduce storage capacityPile receiversArticle deliveryPaper sheetEngineering

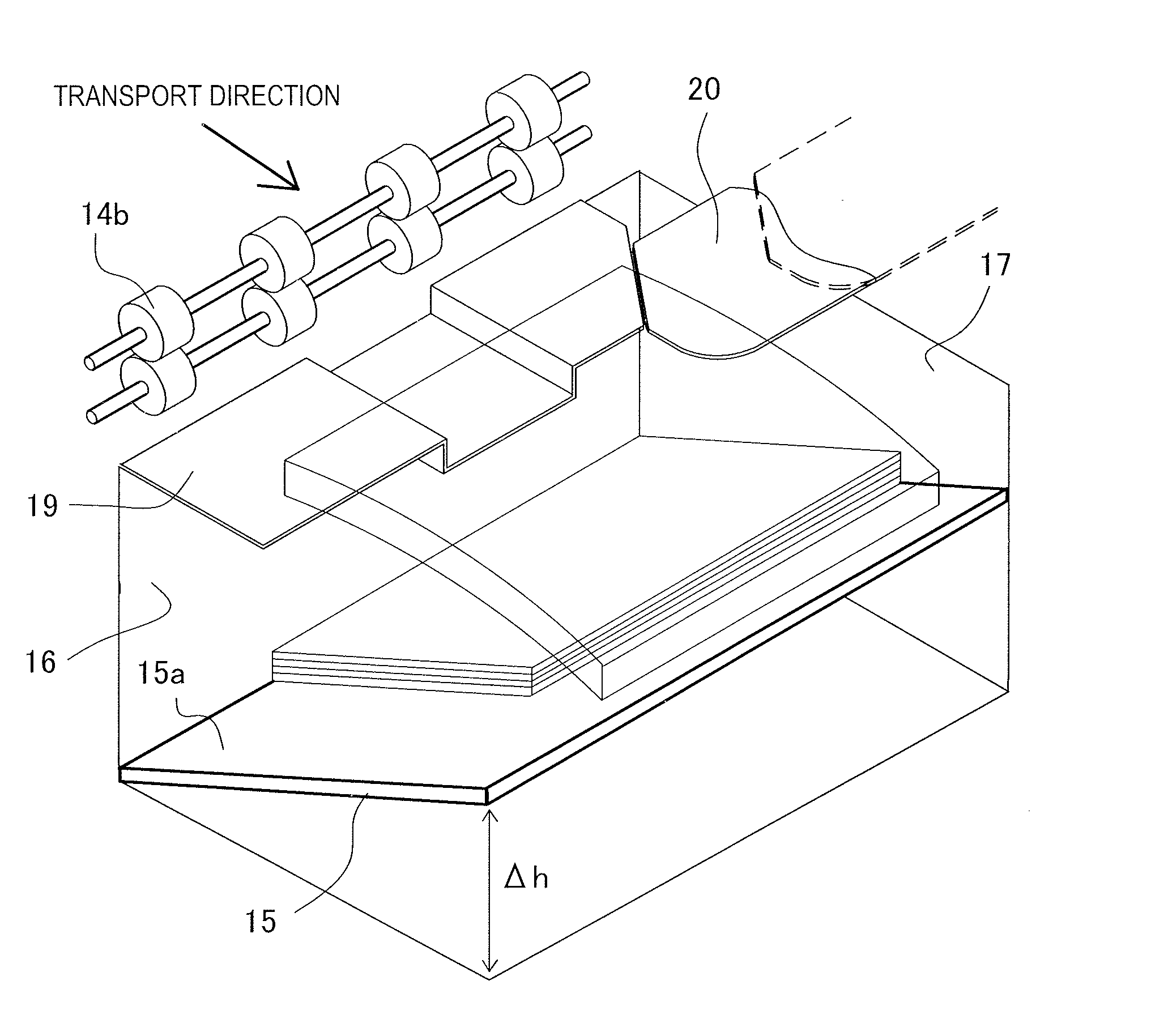

A paper mount surface is disposed while being inclined in the sheet discharge direction or sheet-discharge orthogonal direction, and first and second support members that support the sheet rear and portion in the sheet discharge direction and rear end portion are disposed to be able to shift between actuation positions inside the tray and retract positions. Then, after collecting sheets on both support members, the support member positioned in the direction orthogonal to the inclined direction of the paper mount surface is first retracted from above the tray, and next, the support member positioned in the inclined direction is retracted to the waiting position.

Owner:NISCA KK

Sheet storage apparatus and image formation system using the apparatus

ActiveUS8955838B2Increase storage capacityReduce capacityPile receiversArticle deliveryImage formationEngineering

A paper mount surface is disposed while being inclined in the sheet discharge direction or sheet-discharge orthogonal direction, and first and second support members that support the sheet rear and portion in the sheet discharge direction and rear end portion are disposed to be able to shift between actuation positions inside the tray and retract positions. Then, after collecting sheets on both support members, the support member positioned in the direction orthogonal to the inclined direction of the paper mount surface is first retracted from above the tray, and next, the support member positioned in the inclined direction is retracted to the waiting position.

Owner:NISCA KK

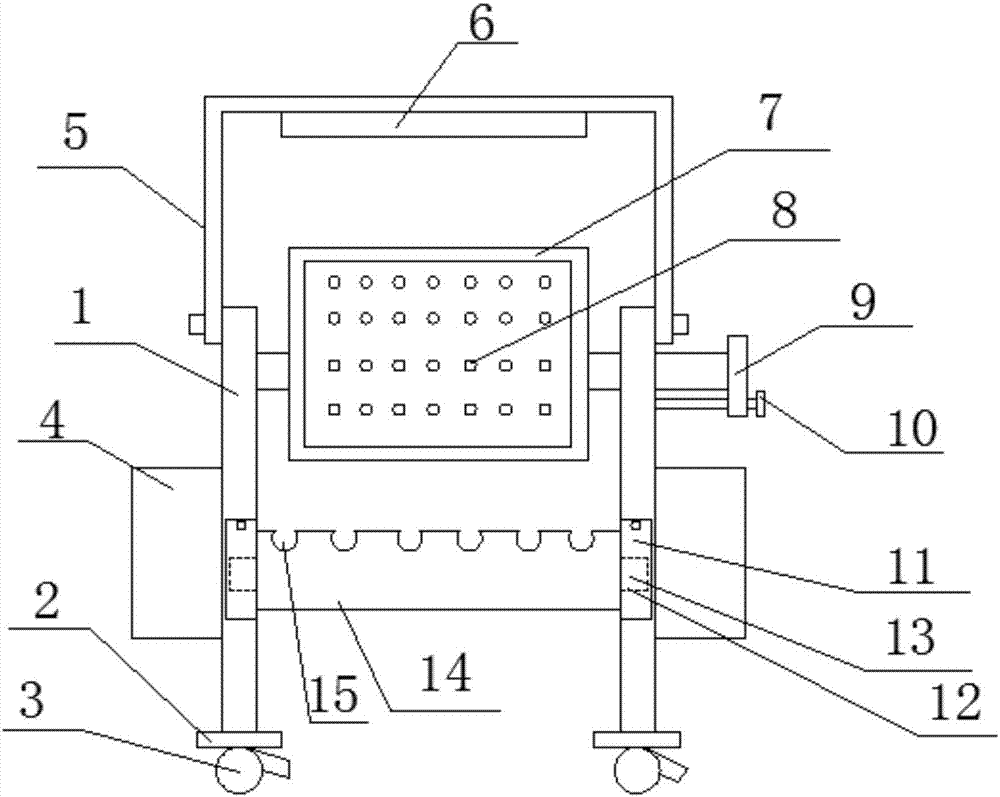

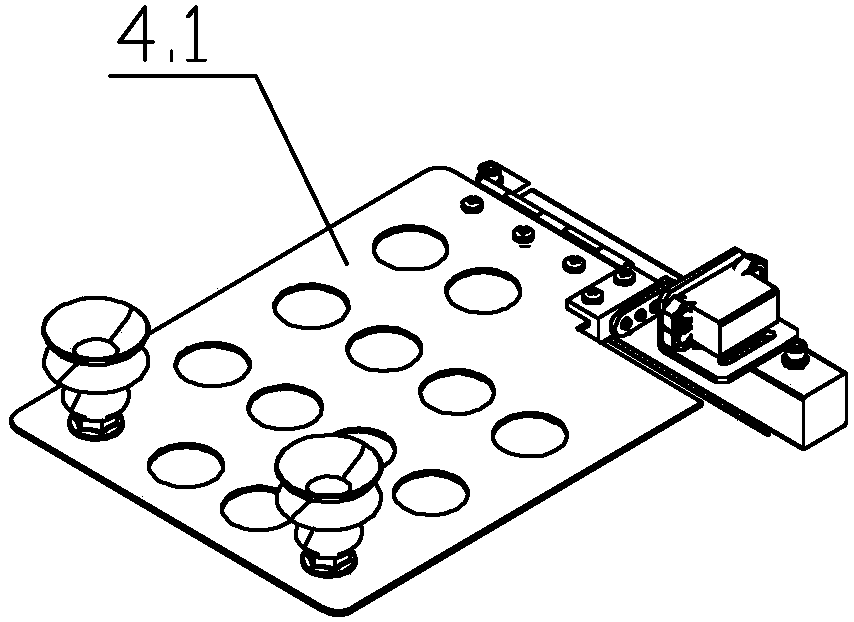

Multifunctional wiring harness tool plate jig

InactiveCN107039126ANeatly collectedEasy to storeManufacturing wire harnessesEngineeringMechanical engineering

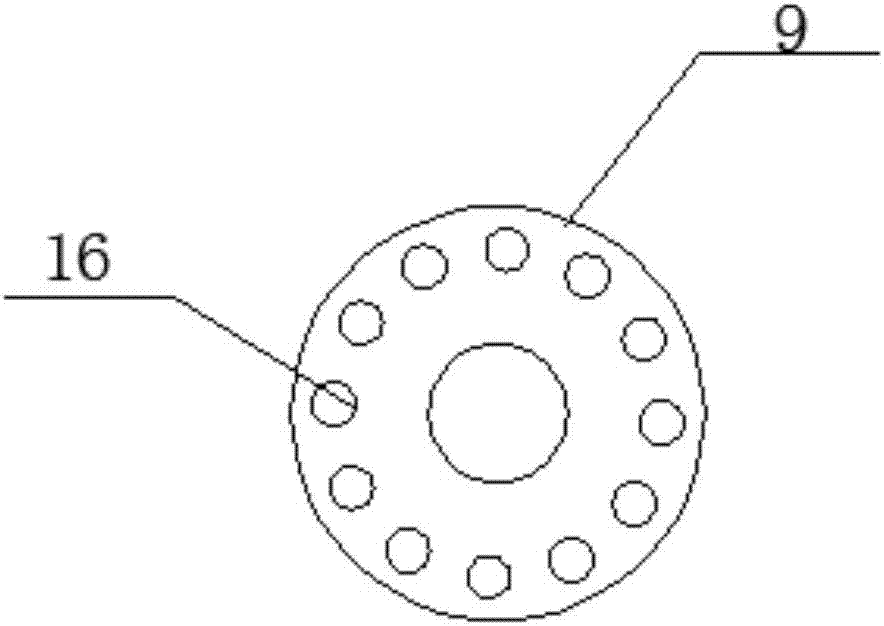

The invention discloses a multifunctional wire harness tooling board fixture, which relates to the technical field of wire harness processing, and comprises a symmetrical support plate and a wiring board. The bottom of the support plate is provided with a mounting plate, and the bottom of the mounting plate is provided with a universal The two side walls of the wiring board are provided with rotating shafts, and the wiring board is connected to the support plate through the rotating shaft. The runner is provided with several through holes along the circumferential direction of the runner, the through holes are provided with positioning pins, the support plate is provided with positioning holes, and the positioning pins are detachably connected with the positioning holes. A number of threaded holes are provided on the wiring board, and a wire harness placement device is also provided between the support plates. The support plate is also provided with a lighting device. This design has a simple and reasonable structure, multiple functions, and is convenient to use.

Owner:WUHU QIAOYUN & YOUXING ELECTRICAL IND CO LTD

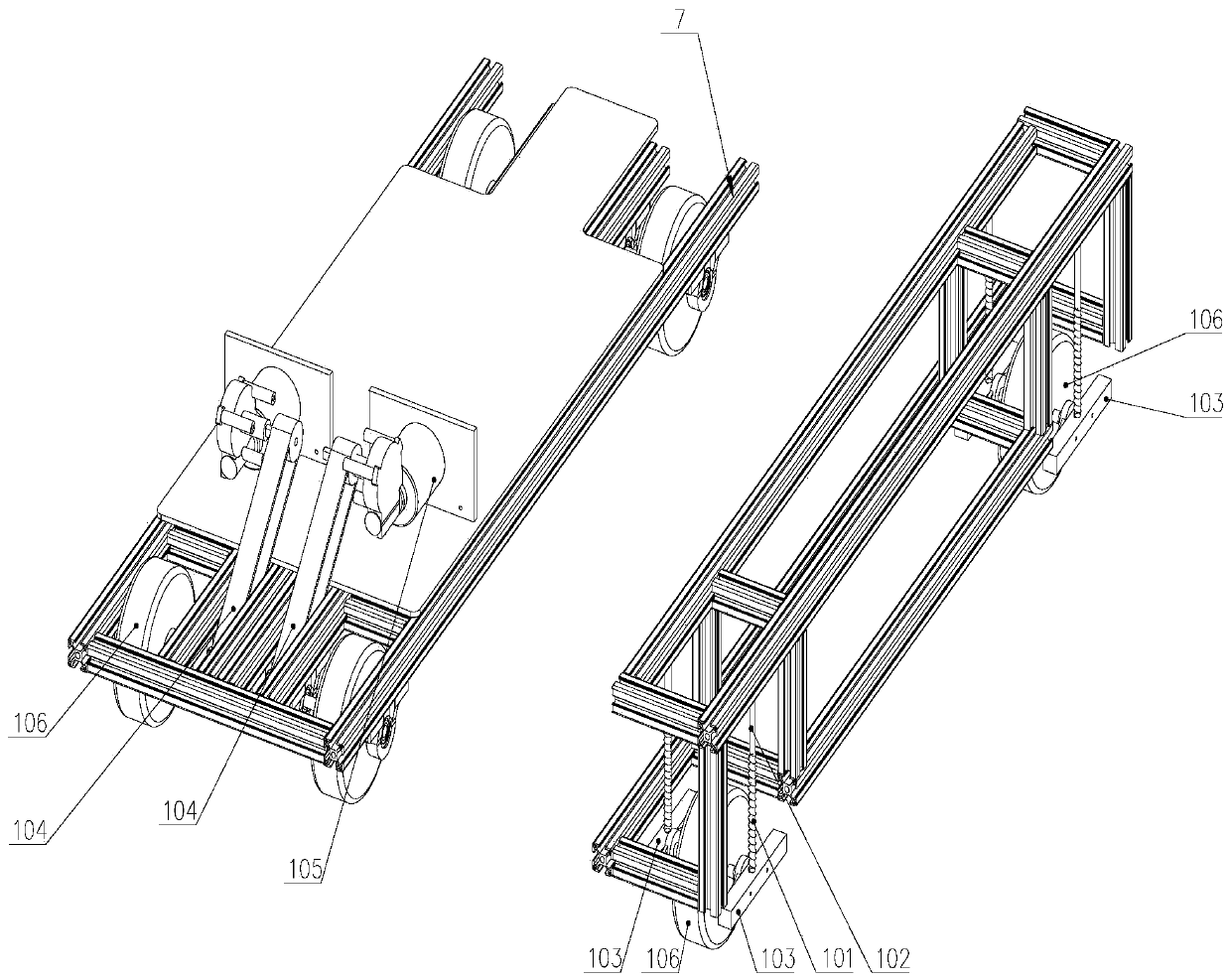

Pineapple picking machine

ActiveCN109804776AIncrease collection capacityReduce shipping costsTelevision system detailsImage analysisPineapple PlantEngineering

The invention relates to a pineapple picking machine. The pineapple picking machine comprises a frame, a travelling device, a picking device, a lifting device, and a collecting device, wherein the travelling device is installed at the bottom of the frame, and used for realizing advancing and turning of the picking machine; the picking device comprises an inference mechanism, the inference mechanism comprises a support, a swinging mechanism and a pushing plate, a pineapple channel is formed in one side of the support, the swinging mechanism is installed on the support, and the swinging direction opposites the pineapple channel, and the pushing plate is installed at the top of the swinging mechanism and opposites the tail end of the pineapple channel; the lifting device is used for lifting pineapples broken by the picking device and conveying the pineapples to the collecting device; and the collecting device is used for collecting the broken pineapples. According to the pineapple pickingmachine, the pineapples are picked by breaking stems of the pineapples to separate the pineapples from pineapple plants, and damage to seedlings is reduced in the picking process; and in the pickingprocess, the travelling device, the picking device, the lifting device, the collecting device and a camera are all continuously operated, and the picking and collecting efficiency of the pineapples isgreatly improved.

Owner:GUANGZHOU UNIVERSITY

Cable winding and unwinding device and power line repairing equipment

PendingCN108394765AAvoid physical exertionNeatly collectedCable installation apparatusEngineeringConductor Coil

The invention relates to a cable winding and unwinding device and power line repairing equipment. The cable winding and unwinding device comprises a support, a first driving mechanism, two wheel plates, a main shaft, a plurality of adjusting rods and an axial adjusting mechanism; the two wheel plates are oppositely arranged, the main shaft penetrates the centers of the two wheel plates, the multiple adjusting rods are circularly and evenly distributed between the two wheel plates to form a winding shaft, the two wheel plates are provided with a plurality of sliding grooves, the number of the sliding grooves is the same as that of the adjusting rods, the sliding grooves are evenly distributed on the wheel plates and are arranged in the axial direction of the wheel plates, and the adjustingrods can slide in the sliding grooves; the axial adjusting mechanism is located between the main shaft and the multiple adjusting rods and is used for adjusting the size of the diameter of the cross section of the winding shaft formed by the multiple adjusting rods; and a first driving mechanism is located on the support, is connected with the main shaft and is used for controlling to the main shaft to rotate so as to wind a cable to the winding shaft formed by the multiple adjusting rods.

Owner:GUANGDONG POWER GRID CO LTD +1

Cable take-up device

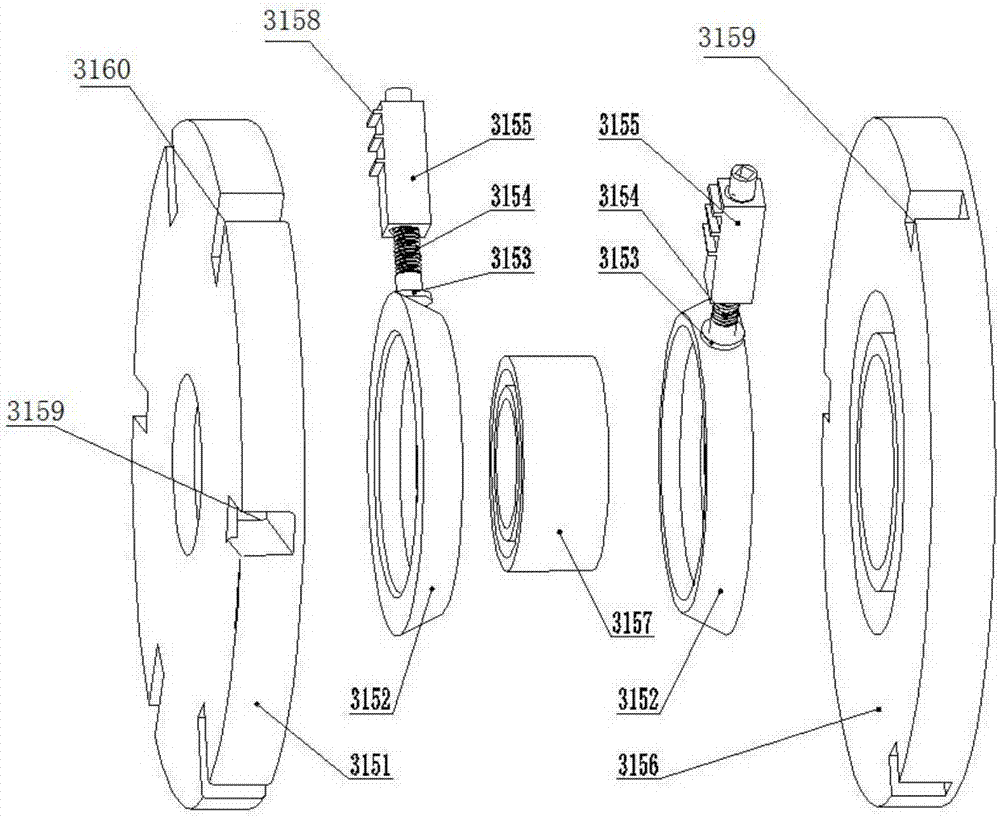

The invention provides a cable take-up device. The cable take-up device comprises a first vertical plate and a second vertical plate which are arranged oppositely; a rotating shaft is rotatably arranged between the first vertical plate and the second vertical plate; a power device connected with the rotating shaft is arranged on the outer side of the second vertical plate; a rotating cylinder rotating along with the rotating shaft is arranged outside the rotating shaft in a sleeving way; a winding reel is rotatably arranged outside the rotating cylinder in a sleeving way; three guide grooves are distributed on the outer wall of the rotating cylinder on the first vertical plate side circumferentially and uniformly; springs and pawls are arranged in the guide grooves; one end of each springis connected with the bottom wall of each guide groove and the other end of the spring is connected with the pawl; six inner ratchet wheels matched with the pawls are arranged in the winding reel; andone end of each pawl is fixedly connected with the spring and the other end of the pawl extends into each inner ratchet wheel and is matched with the inner ratchet wheel. The cable take-up device canguarantee the tidy winding effect of the cable during forward rotation winding and also can prevent reversed rotation of the winding reel and guarantee that winding is not returned, and the cost is controlled.

Owner:重庆华旗线缆有限公司

Plastic pipe cutting device capable of screening plastic pipes of proper lengths

ActiveCN106737941ANeatly collectedAchieve the effect of cutting plastic pipesMetal working apparatusEngineeringProper length

The invention relates to a plastic pipe cutting device, in particular to a plastic pipe cutting device capable of screening plastic pipes of proper lengths. The plastic pipe cutting device capable of screening the plastic pipes of the proper lengths can isometrically cut plastic pipes, is good in cutting effect, can tidily collect the well cut plastic pipes and comprises a base plate, brackets, a shell, supporting rods, a conveying device, fixing rods, a clamping device, cylinders, N-shaped frames, motors, gears, cross rods, arc slide rails and the like. One bracket is welded to each of the front side, the rear side, the left side and the right side of the top of the base plate. The tops of the brackets are provided with the shell. The top of the shell is provided with a through hole. According to the plastic cutting device, tooth-shaped blades on the left side and the right side make semi-circumferential movement to rub the plastic pipes so as to achieve the effect of cutting the plastic pipes.

Owner:徐州市华为工程机械有限公司

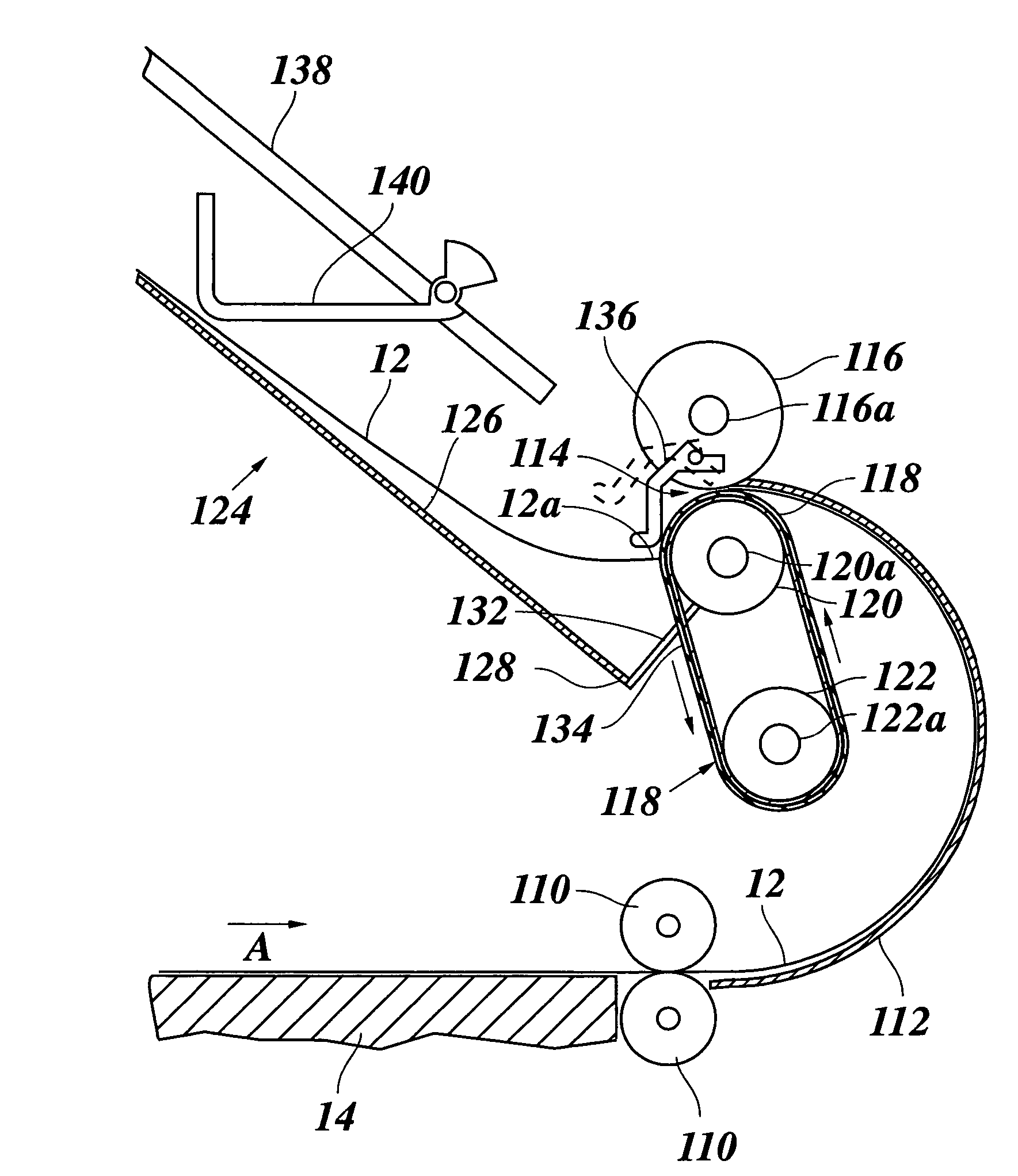

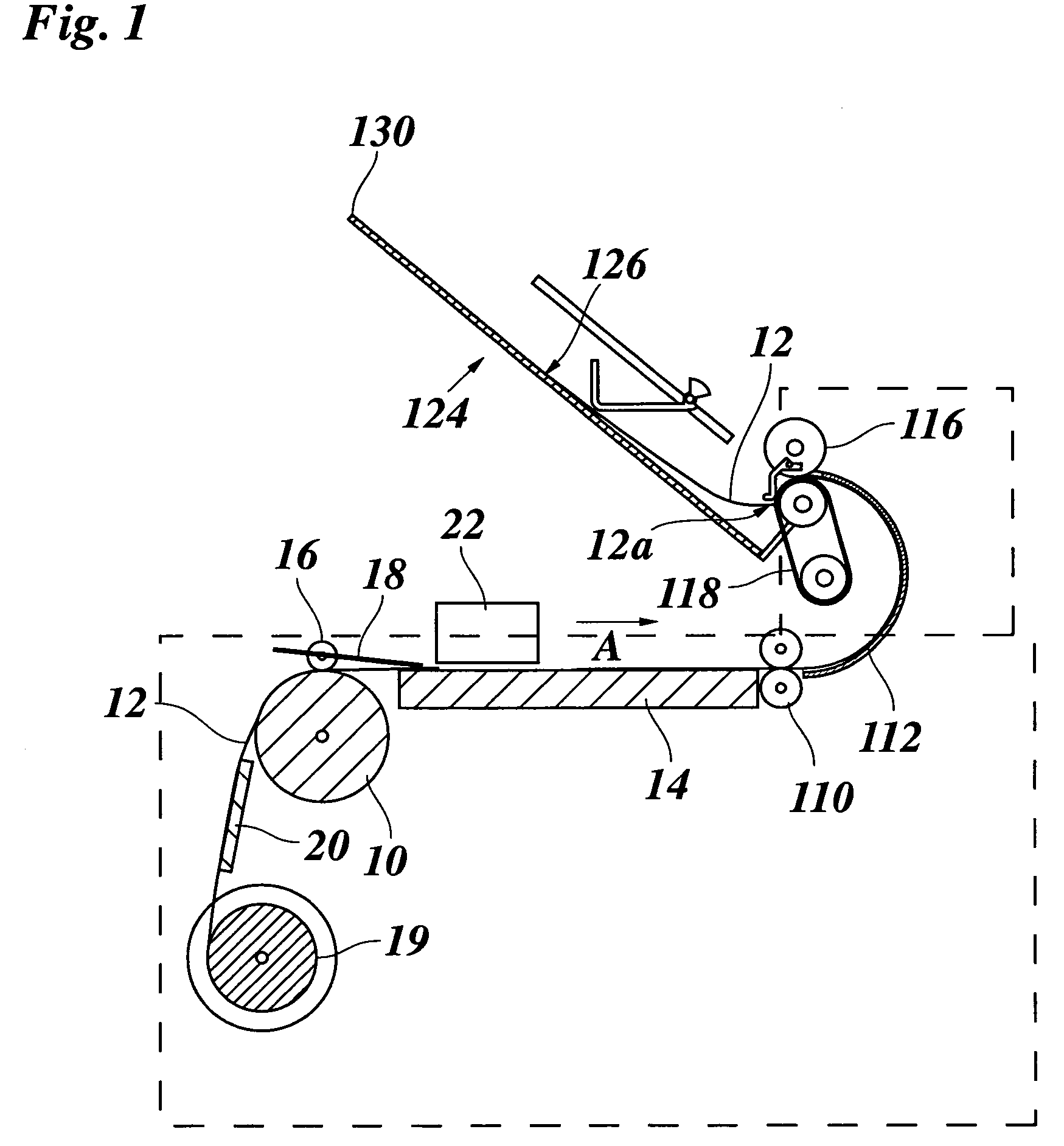

Sheet discharge system

InactiveUS7644918B2Neatly collectedNeatly stackedPile receiversArticle deliveryEngineeringTrailing edge

Owner:OCE TECH

Sheet discharge system

InactiveUS20060181017A1Neatly collectedNeatly stackedPile receiversArticle deliveryTrailing edgeEngineering

A discharge system for printed media sheets which includes a tray having a surface for supporting the media sheets; and rotating transport elements forming a discharge nip for discharging the sheets onto the tray, wherein at least one driven transport belt is arranged to engage a trailing edge of the sheet that has left the discharge nip and to exert a driving force towards the tray surface.

Owner:OCE TECH

Punching machine used for corrugated paper processing

ActiveCN109093742APrecise punchingQuick collectionMetal working apparatusPunchingPulp and paper industry

The invention belongs to the field of corrugated paper processing, and particularly relates to a punching machine used for corrugated paper processing. The invention aims to solve the technical problem that the punching machine used for corrugated paper processing is provided, the punching machine can improve the punching efficiency of the corrugated paper and can conveniently collect the punchedcorrugated paper. The punching machine used for the corrugated paper processing comprises a first installation plate, a supporting seat, first sliding blocks, an annular sliding rail, a placement plate, an inner gear ring, a gear, a first spindle, a motor, a punching device, a second installation plate, an air cylinder, a third installation plate, a first sliding rod, first elastic elements and apressing plate, wherein the supporting seat is fixedly connected to the middle of the first installation plate, the annular sliding rail is fixedly connected to the middle of the supporting seat, andthe placement plate is in sliding connection with the annular sliding rail through the first sliding block. By use of the punching machine, the corrugated paper can be quickly accurately punched, andin addition, the punched corrugated paper can be quickly collected.

Owner:日照环宇纸制品有限公司

Raw paper cutting equipment used before printing of printing machine

ActiveCN113618806ANeatly collectedEasy for post-printingMetal working apparatusPrinting pressIndustrial engineering

The invention discloses raw paper cutting equipment used before printing of a printing machine. The raw paper cutting equipment used before printing of the printing machine comprises a machine table, the upper end of the machine table is fixedly connected with an L-shaped first plate, the first plate is provided with a cutting mechanism for cutting raw paper, the cutting mechanism comprises a cutting knife, the machine table is provided with a placing mechanism for leveling and placing the cut raw paper, the placing mechanism comprises two electric push rods fixedly connected to the lower end of the machine table, the movable ends of the two electric push rods are fixedly connected with a movable frame through fixing blocks, the movable frame freely slides on the side wall of the machine table, a driving groove is formed in the inner wall of the movable frame, a driving disc is rotationally connected to the inner wall of the driving groove in a sealed mode, and a first rod is fixedly connected to the side wall of the driving disc. According to the raw paper cutting equipment used before printing of the printing machine, by arranging the placing mechanism, cut hard body paper can be placed after being adsorbed and moved; and the positions, located under the hard body paper, of the hard body paper are consistent each time, so that the hard body paper is kept tidy when collected, and later printing is facilitated.

Owner:南通星月印刷科技有限公司

Special excreta disposal device for rabbit keeping

Owner:XINAN ERLONG PLANTING FARMERS SPECIALIZED COOP

Paper collecting and shifting device and working method thereof

Owner:MASTERWORK GROUP CO LTD

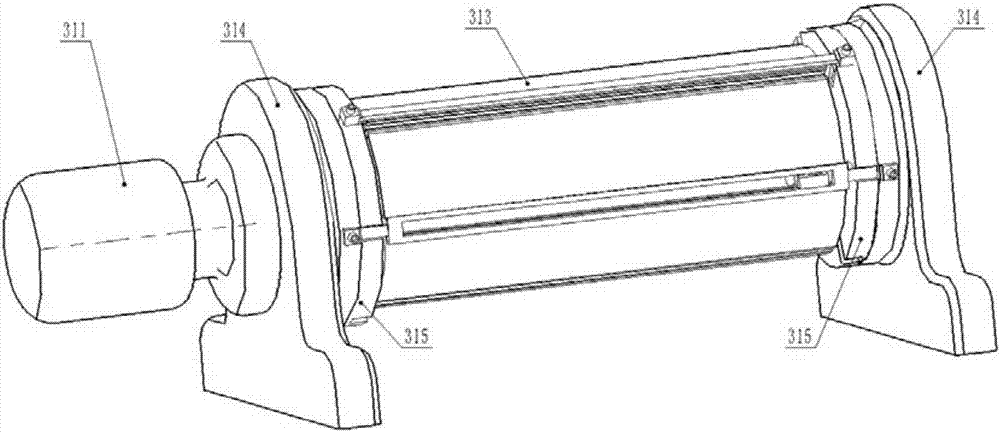

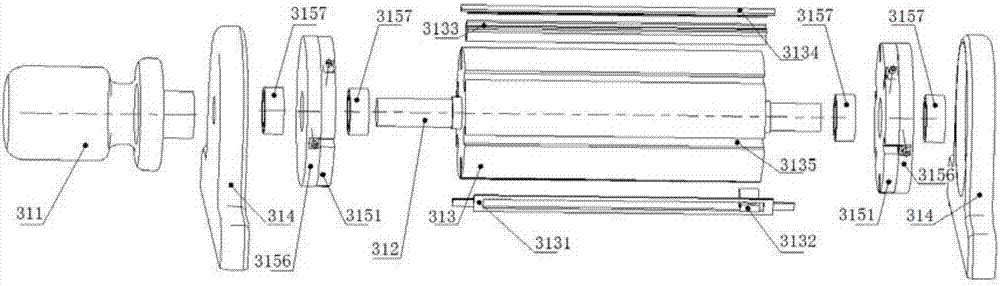

Cutting off recovery device for linear cutting molybdenum wires

ActiveCN106862688AEasy to collectNeatly collectedElectrical-based machining electrodesElectrical-based auxillary apparatusEngineeringMachine tool

The invention discloses a cutting off recovery device for linear cutting molybdenum wires. The recovery device comprises a wire cylinder, guide grooves uniformly distributed on the outer wall of the wire cylinder along the peripheral direction and cut-through axially, cutting off devices respectively disposed on the guide grooves spaced on the outer wall of the wire cylinder along a radial extending direction of the wire cylinder and wire collecting devices disposed in the guide grooves between adjacent cutting off devices; the wire collecting devices and the guide grooves are slidably matched, compressing devices for compressing cutoff electrode wires sleeve the wire collecting devices in the axial direction of the wire cylinder, and tightening devices for driving the cutting off devices and the compressing devices to move radially are symmetrically disposed on the two ends of the wire cylinder. According to the cutting off recovery device, the detaching efficiency of the molybdenum wires is greatly improved, labor intensity of operators is relieved, and the collected molybdenum wires occupy a small space and are orderly collected and convenient to store. The recovery device is simple and compact in structure design, can be mounted on any existing linear cutting machines without a need to modify circuits or other mechanical structures of the existing machines, and is convenient to mount and favorable for wide application.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

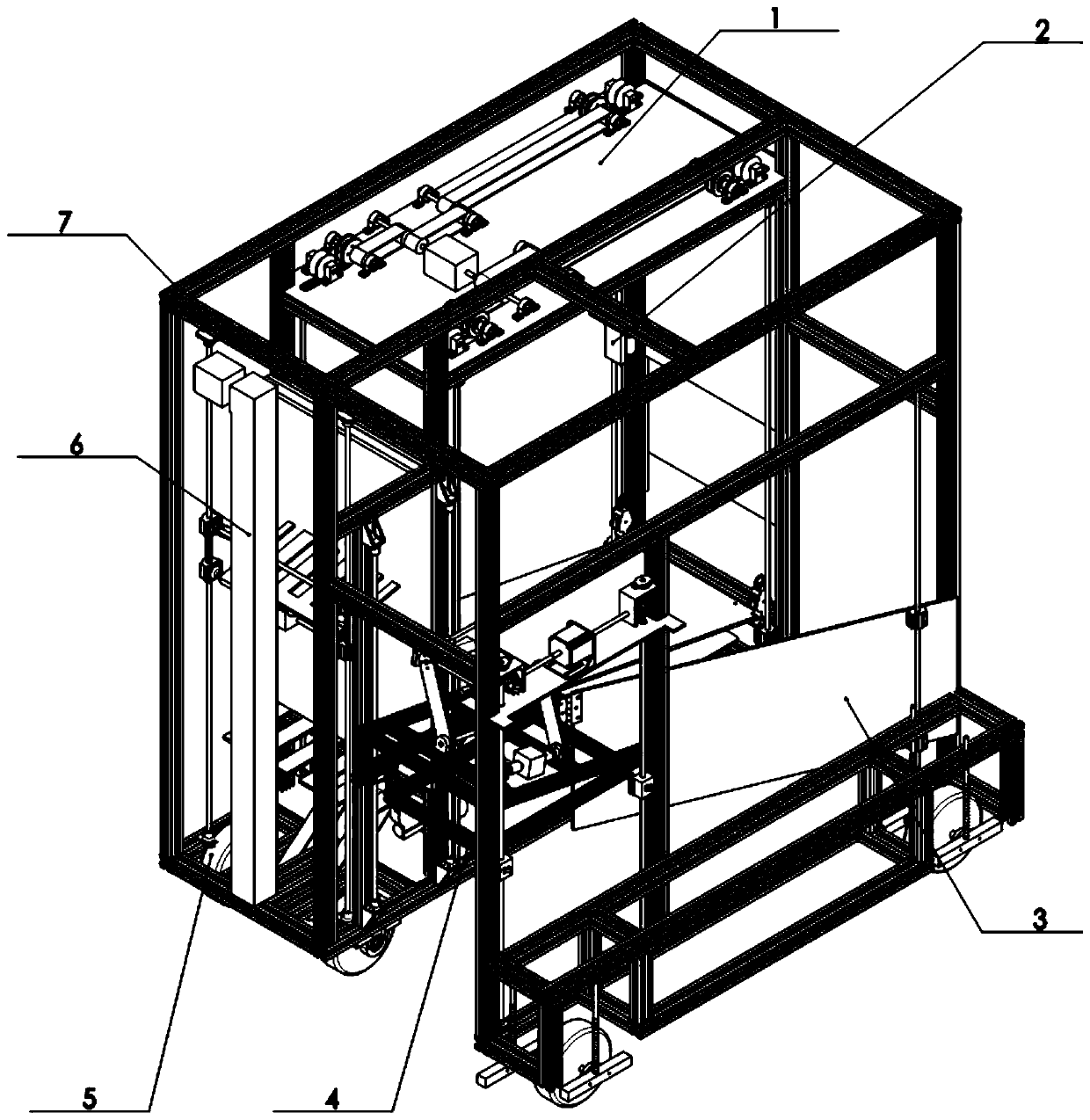

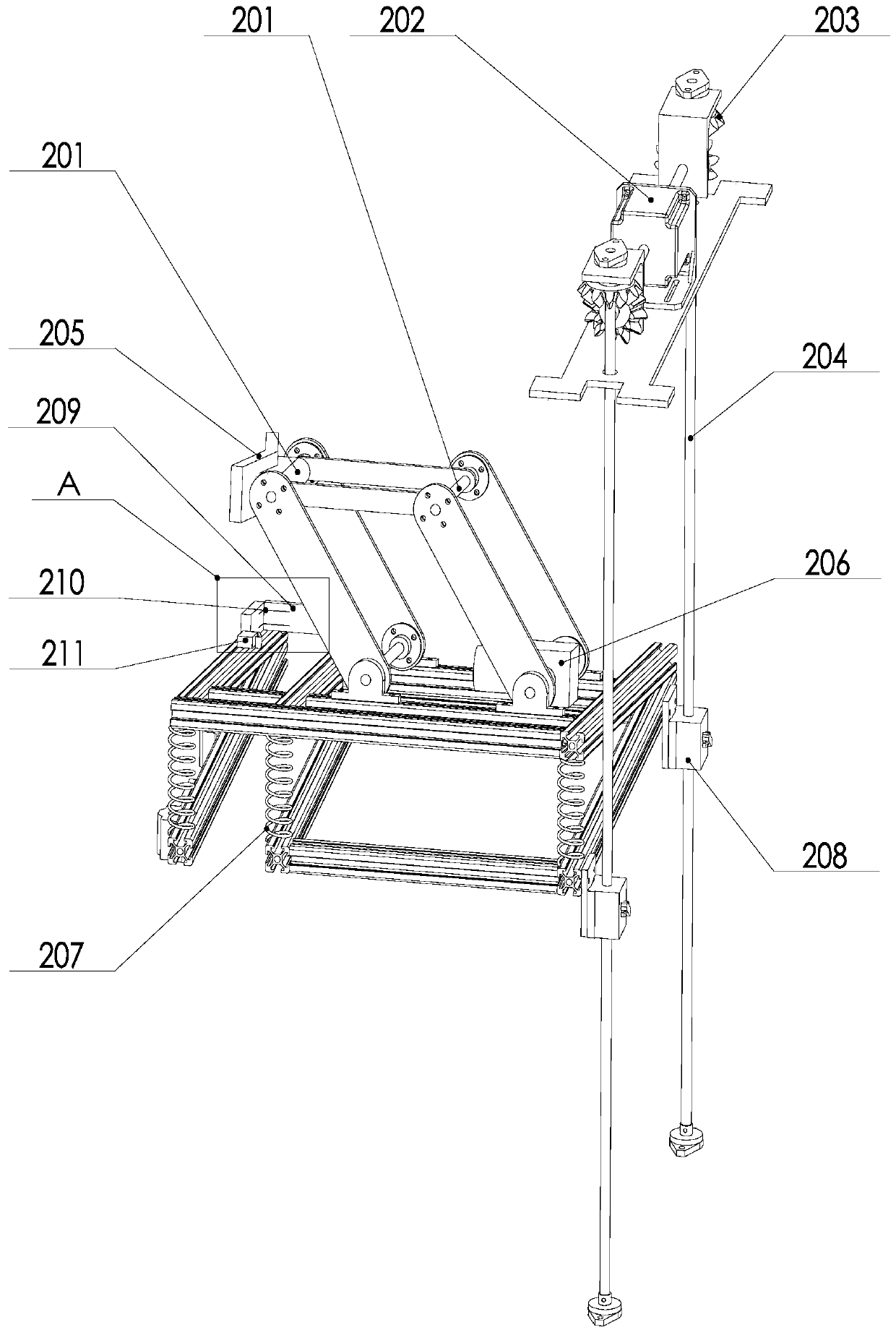

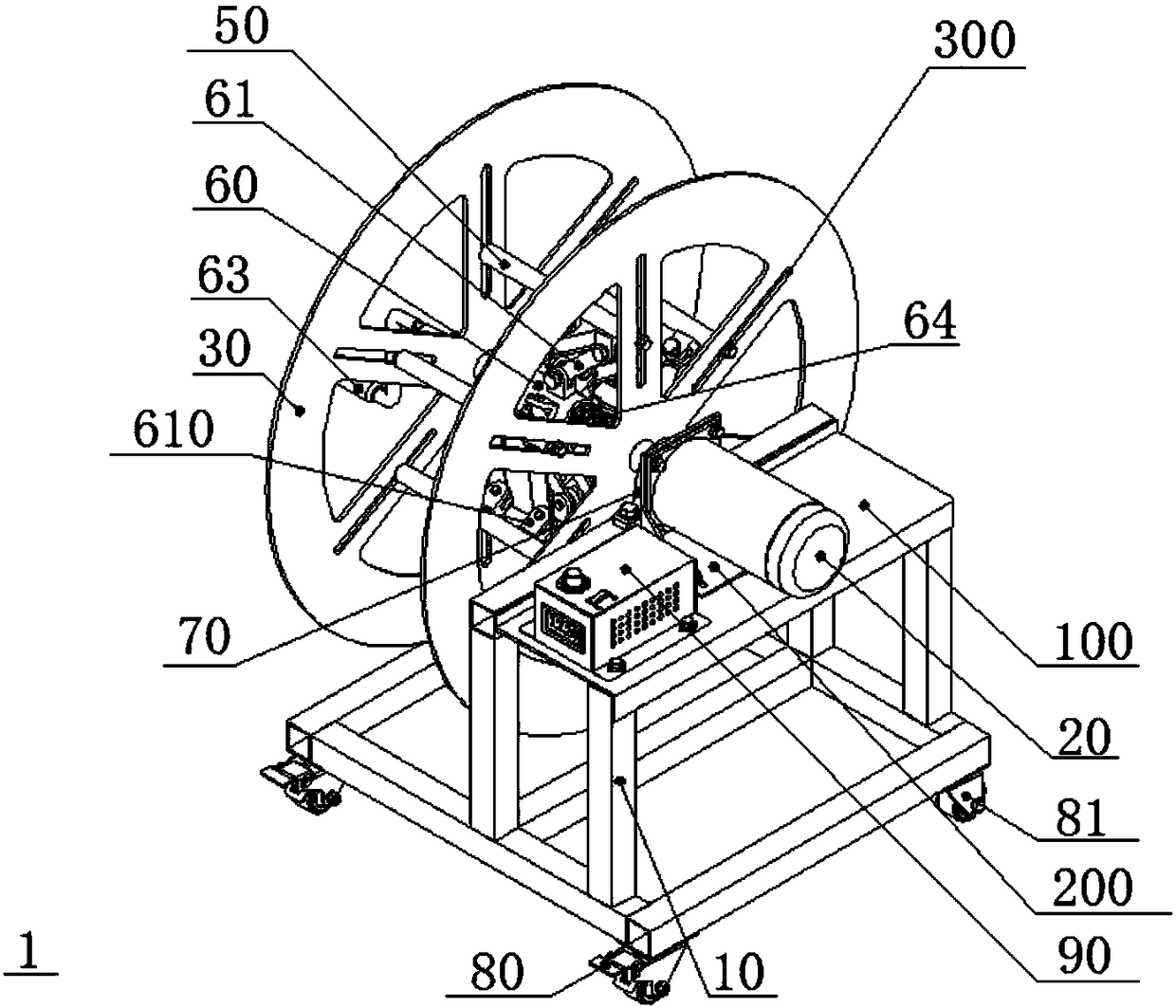

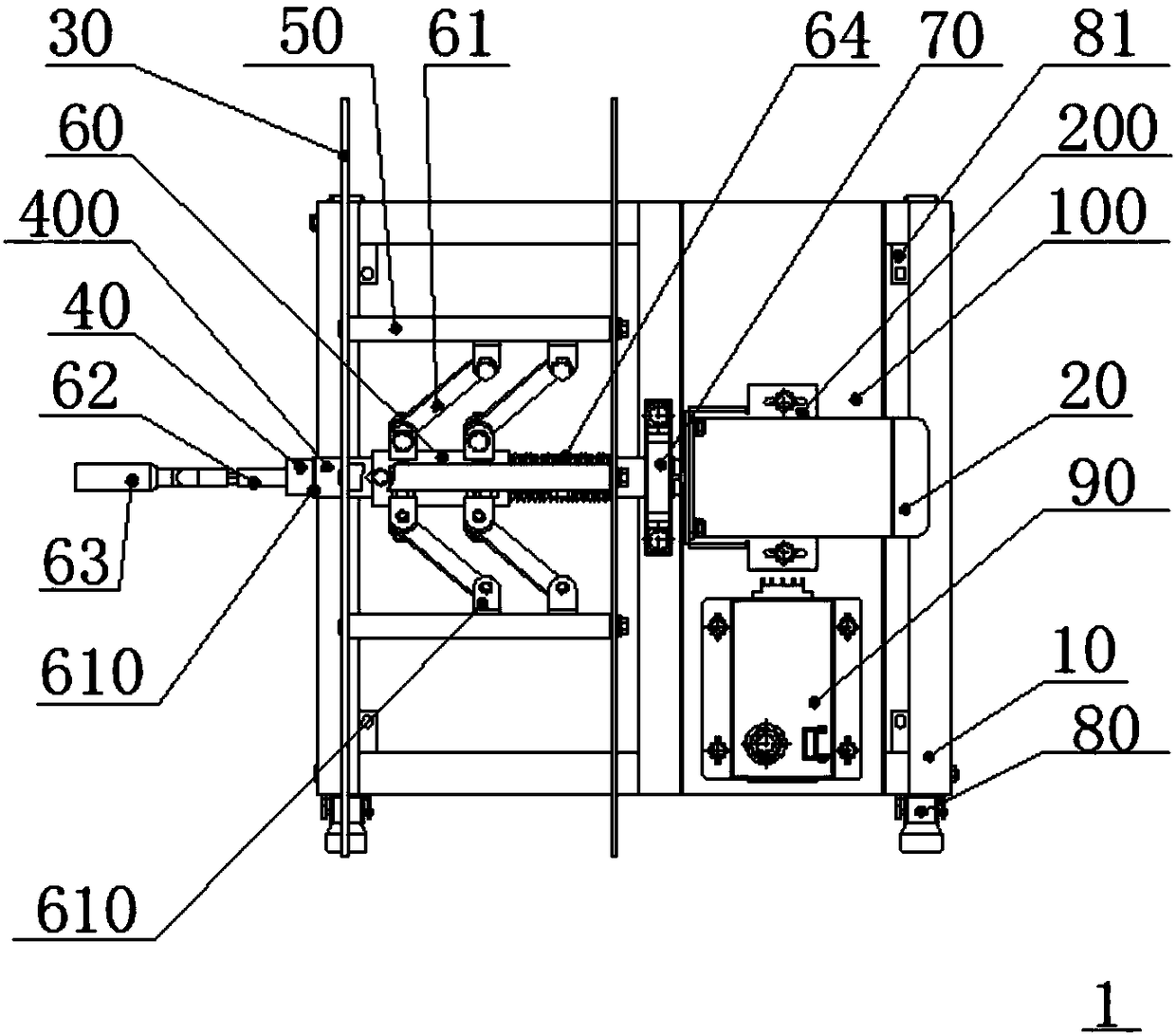

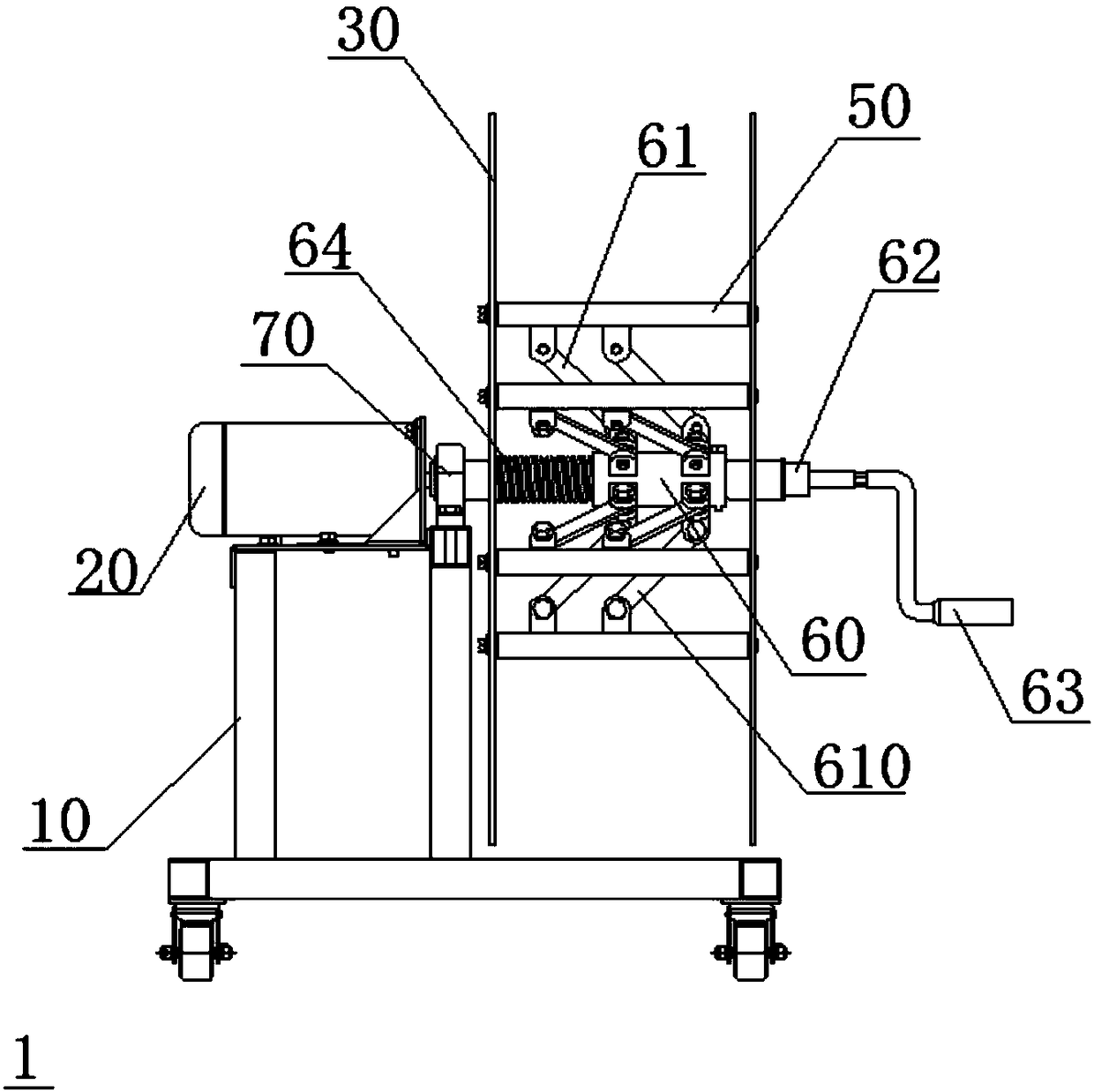

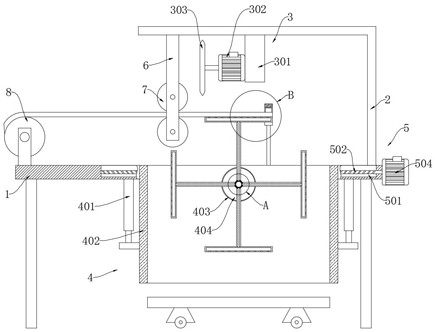

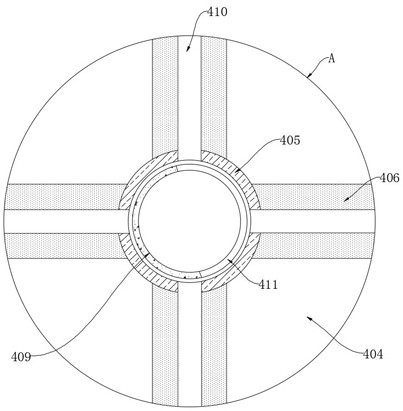

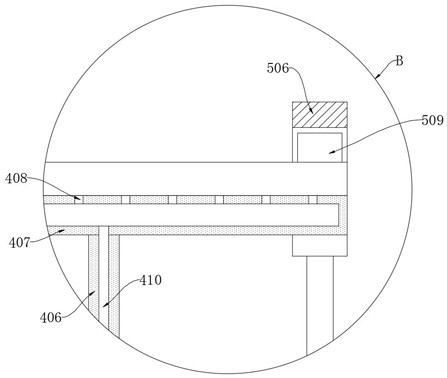

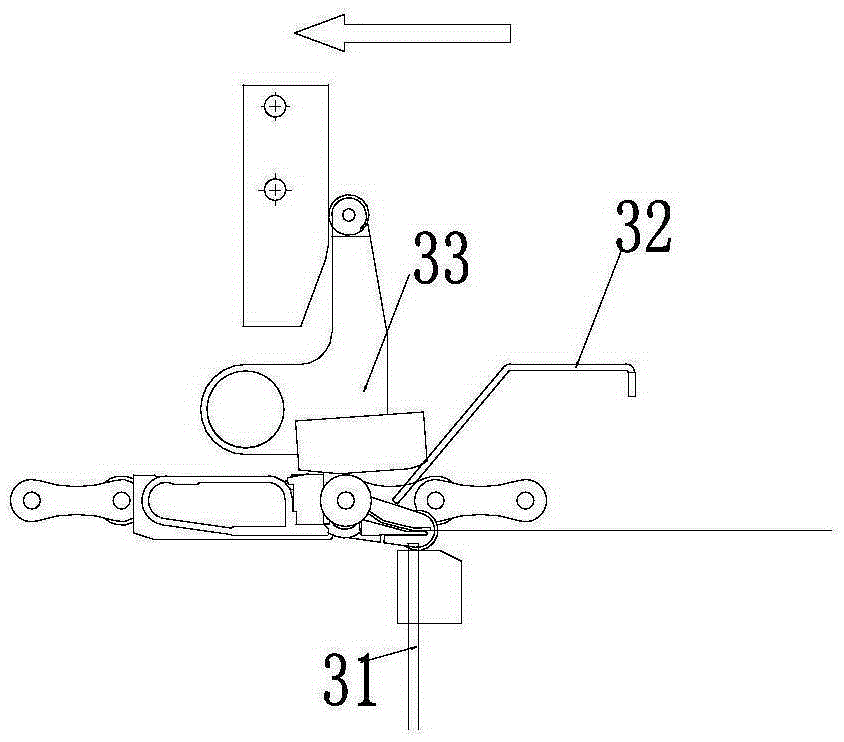

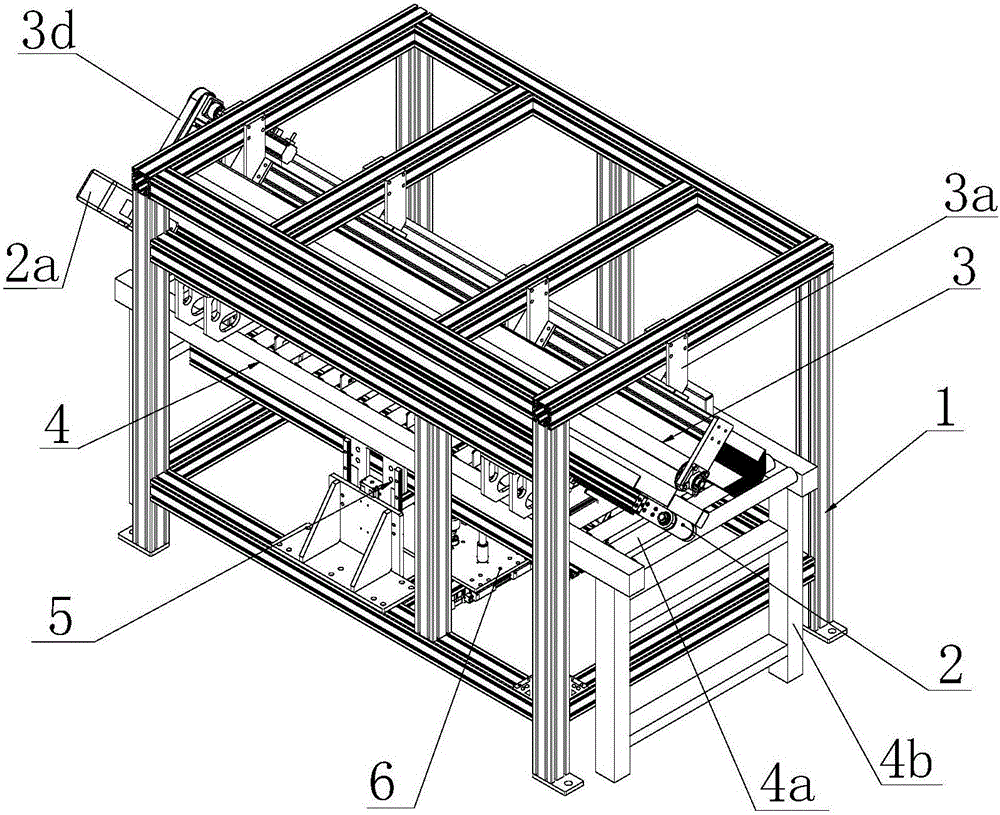

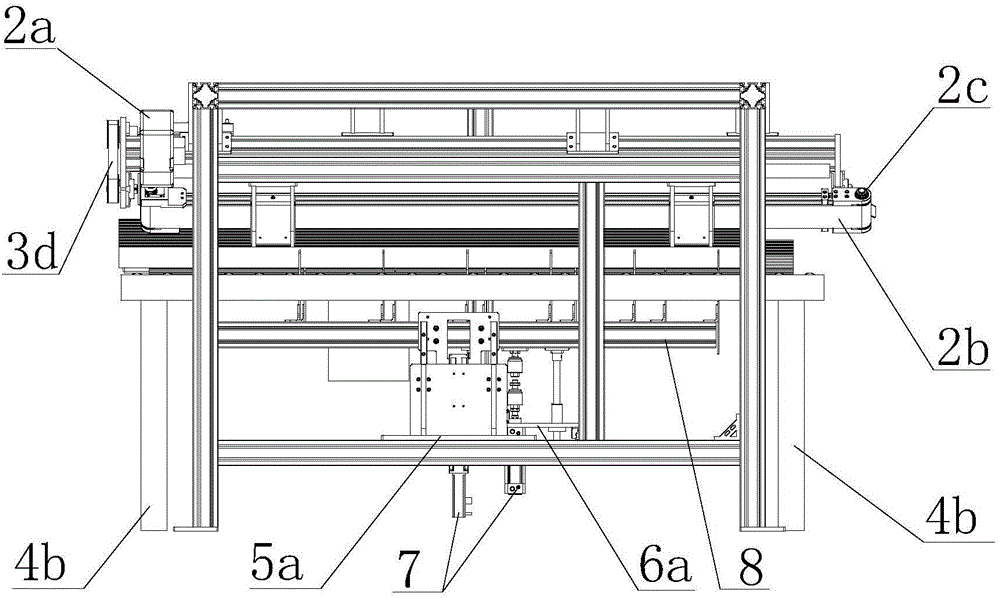

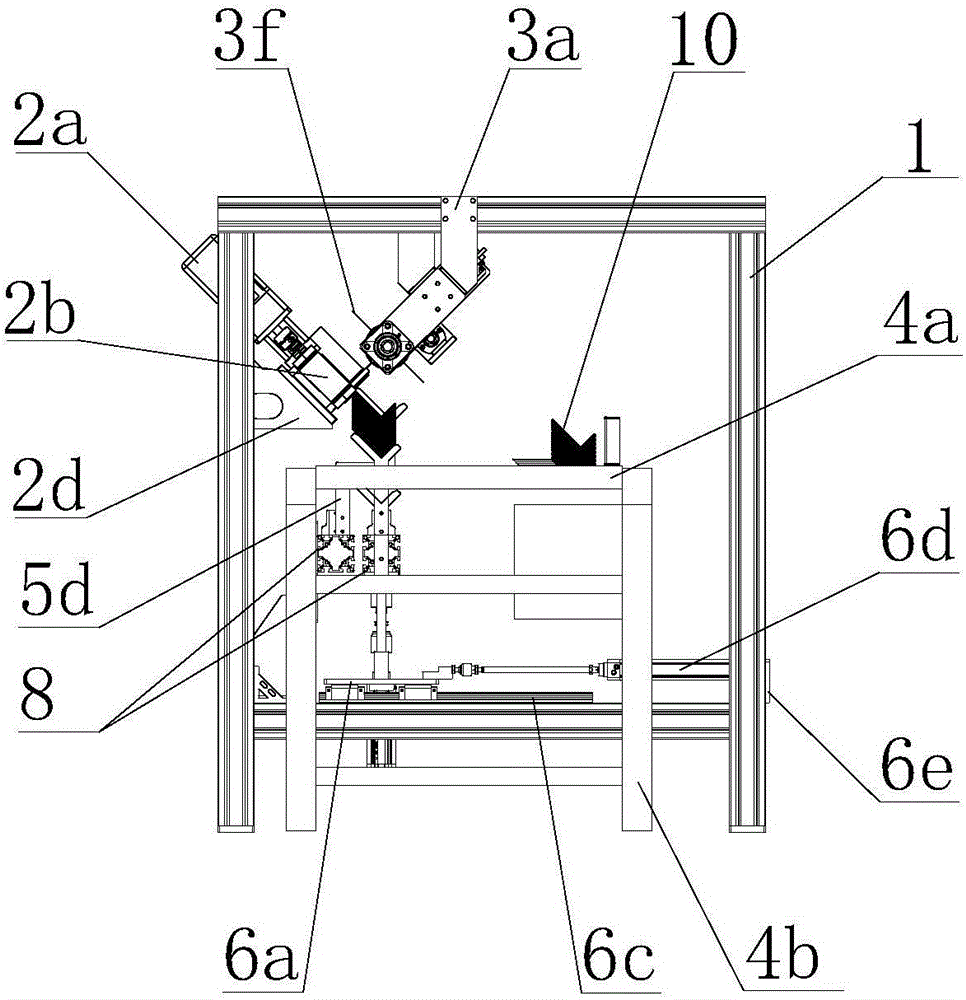

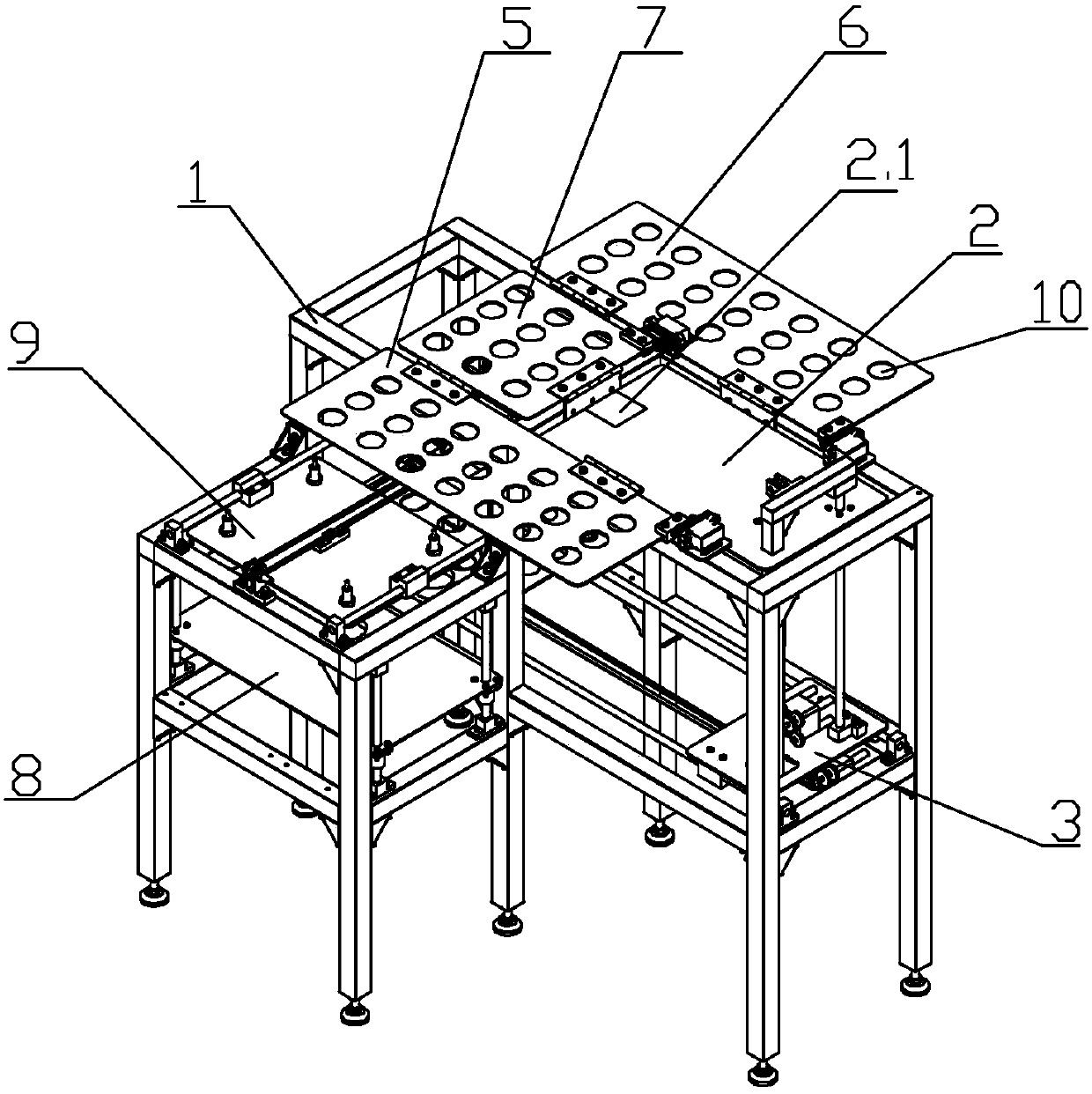

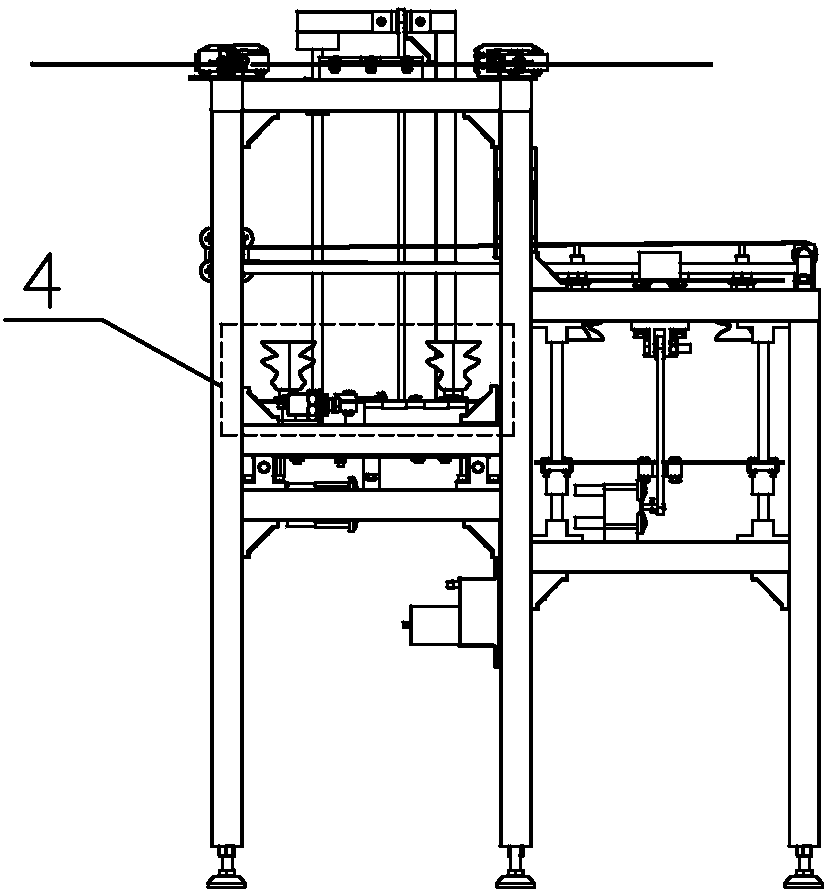

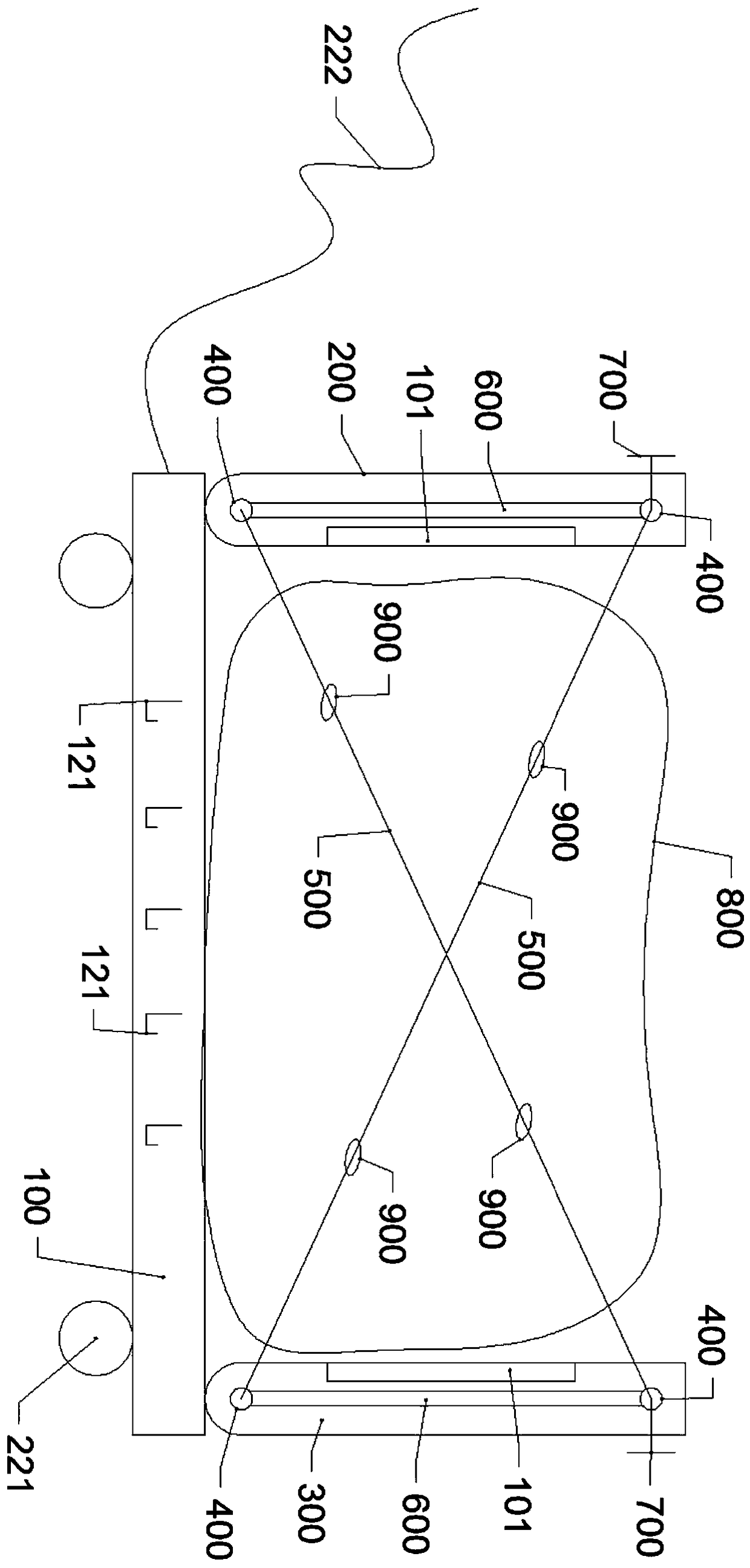

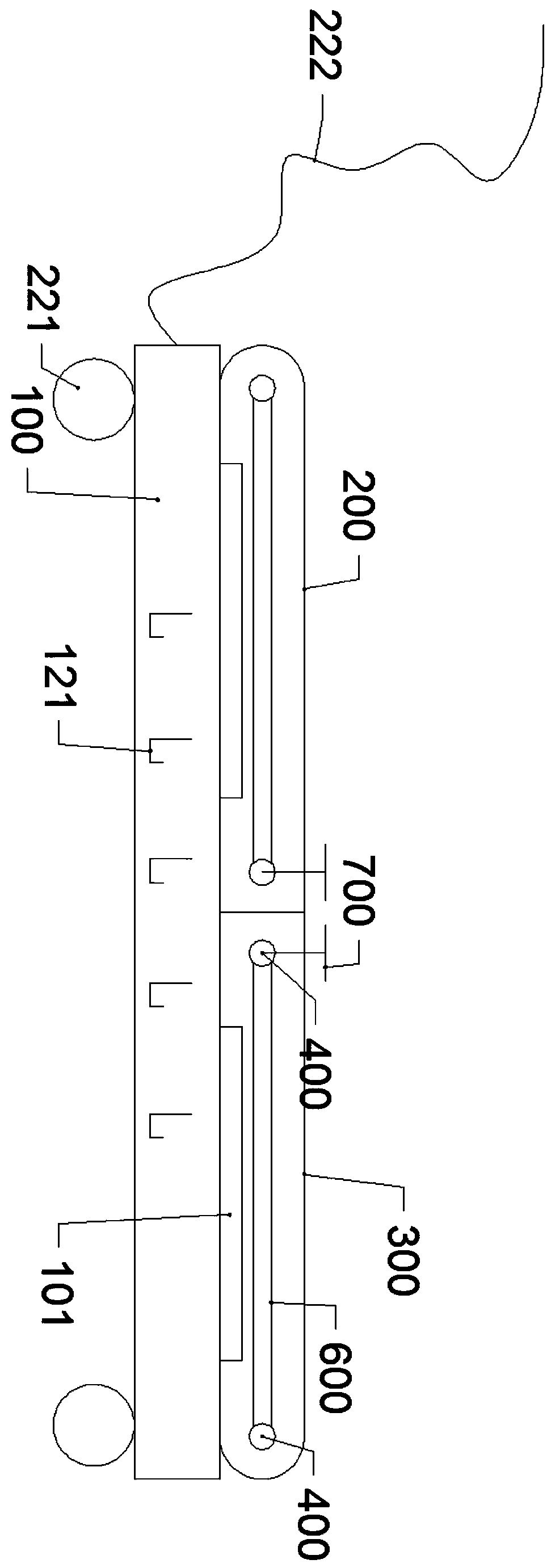

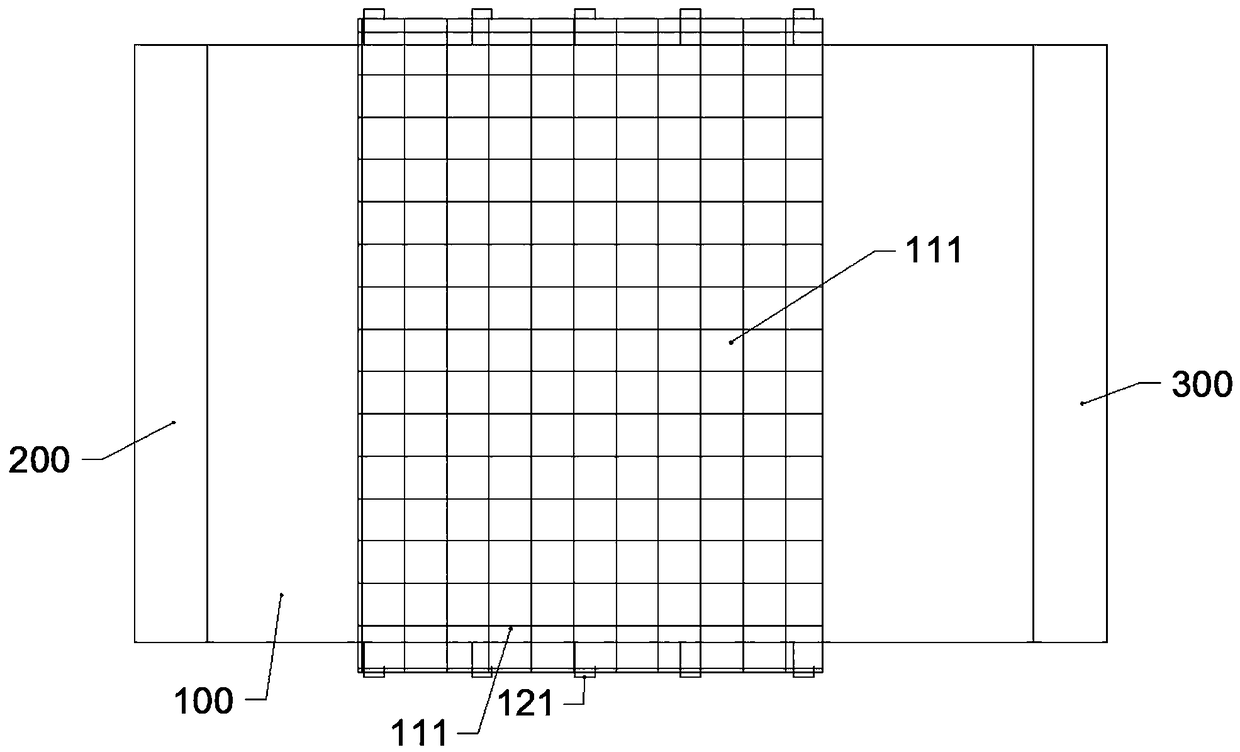

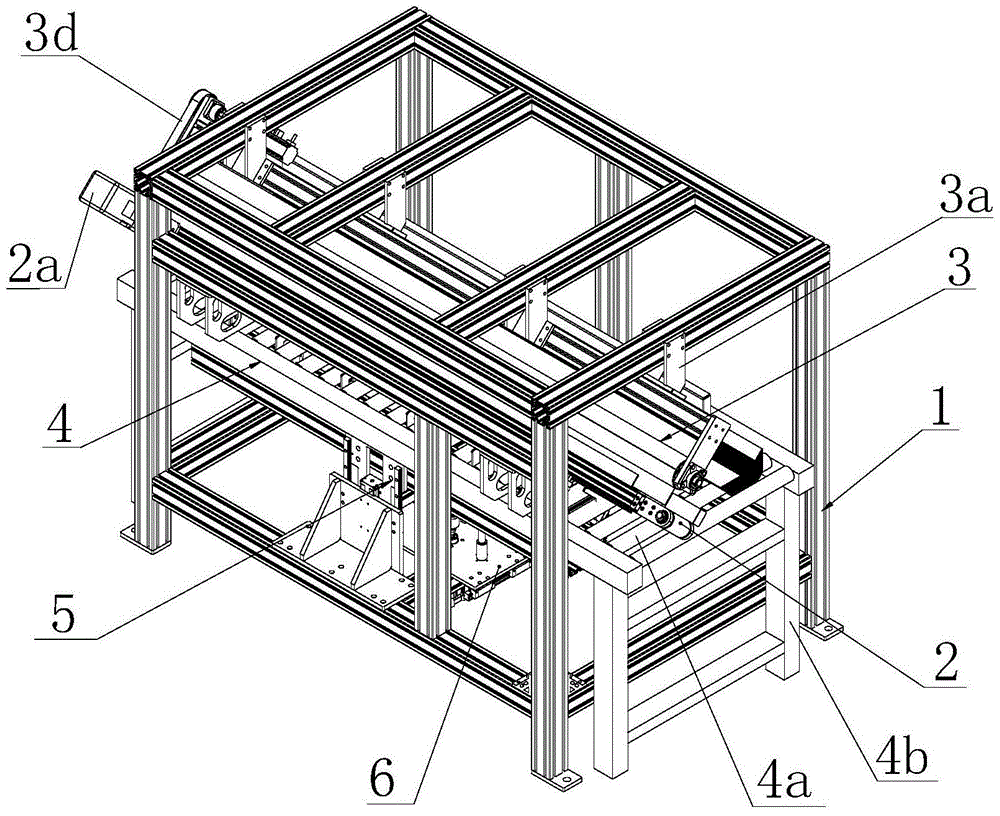

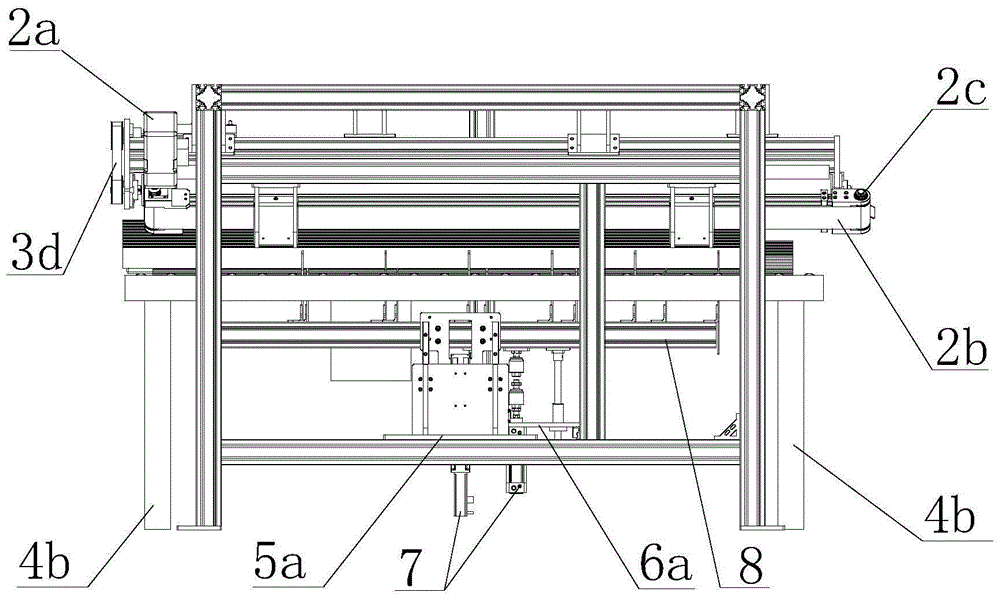

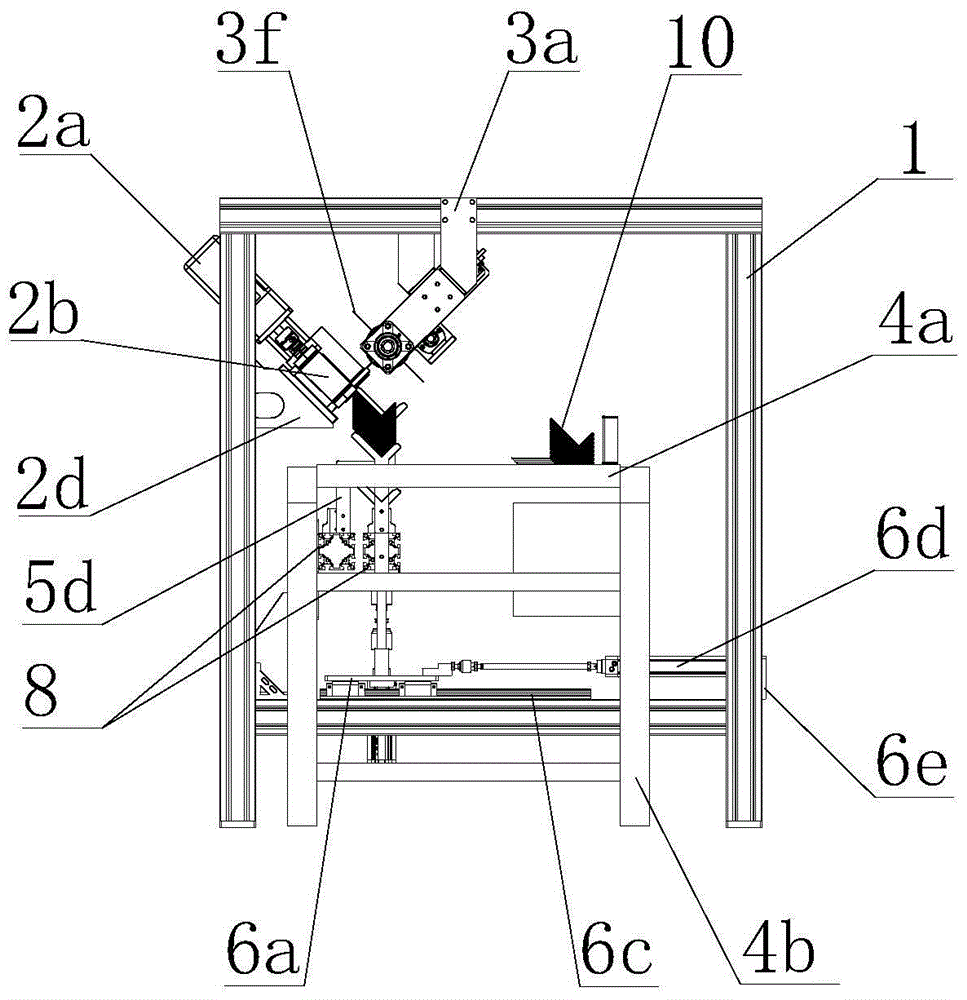

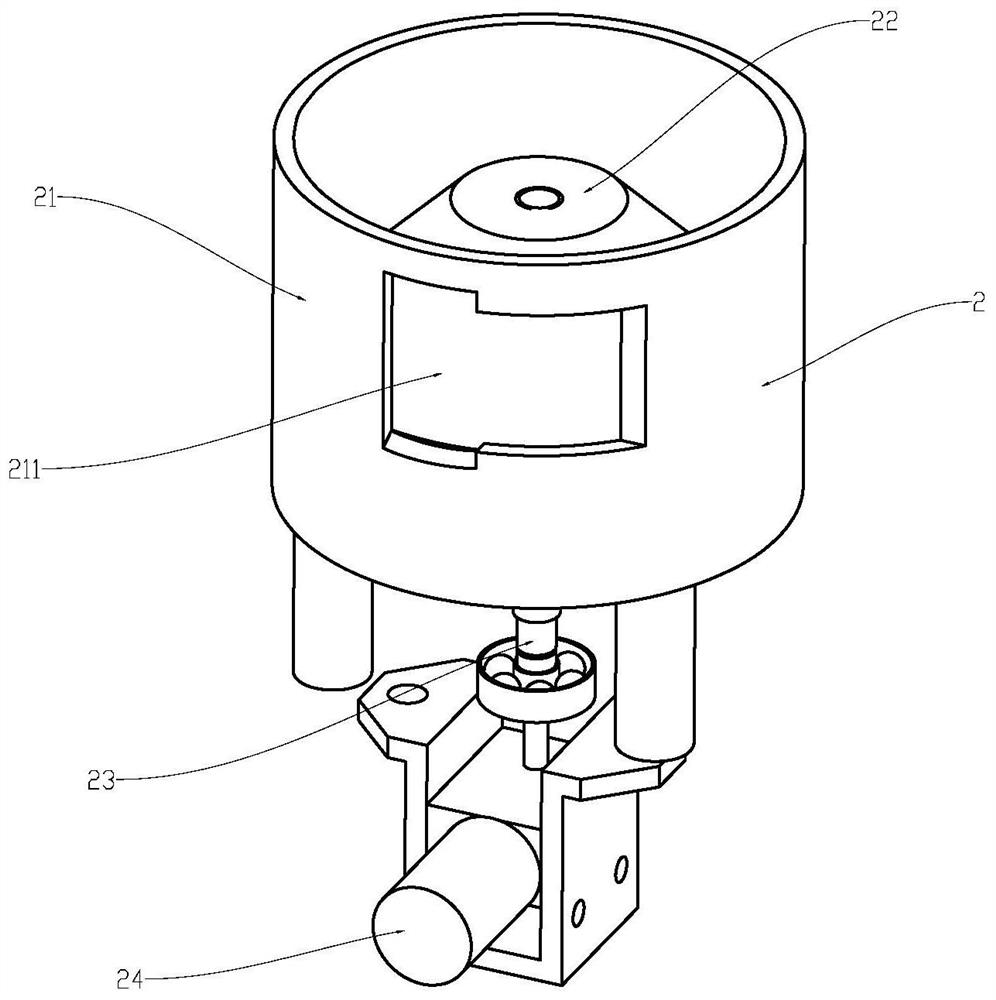

Automatic collecting device for paper angle bead strips

The invention relates to an automatic collecting device for paper angle bead strips. The automatic collecting device comprises a discharging machine frame (1), a receiving device (2), a rotating mechanism (3), a conveying device (4), a lifting mechanism (5) and a lifting transverse-moving mechanism (6). The receiving device (2) is fixedly connected to the discharging machine frame, and the conveying device (4) is located below the rotating mechanism. The paper angle bead strips which are rotationally cut are received by the receiving device; the strips are placed on a lifting bracket of the lifting mechanism through the rotating mechanism; the strips are moved to the other side of a rotating roller through a transverse-moving bracket of the lifting transverse-moving mechanism; finally, the strips are conveyed by the conveying device to the next working procedure. Compared with the prior art, the paper angle bead strips can be collected more orderly, next-step binding is facilitated, working efficiency is greatly improved, manual collection is replaced, the labor cost is reduced, and production is safer.

Owner:上海宝钢工业有限公司

Sugarcane seed collecting device

ActiveCN106688381AHigh degree of automationAvoid damage to seedlingsAgriculture tools and machinesPlantingBudCell budding

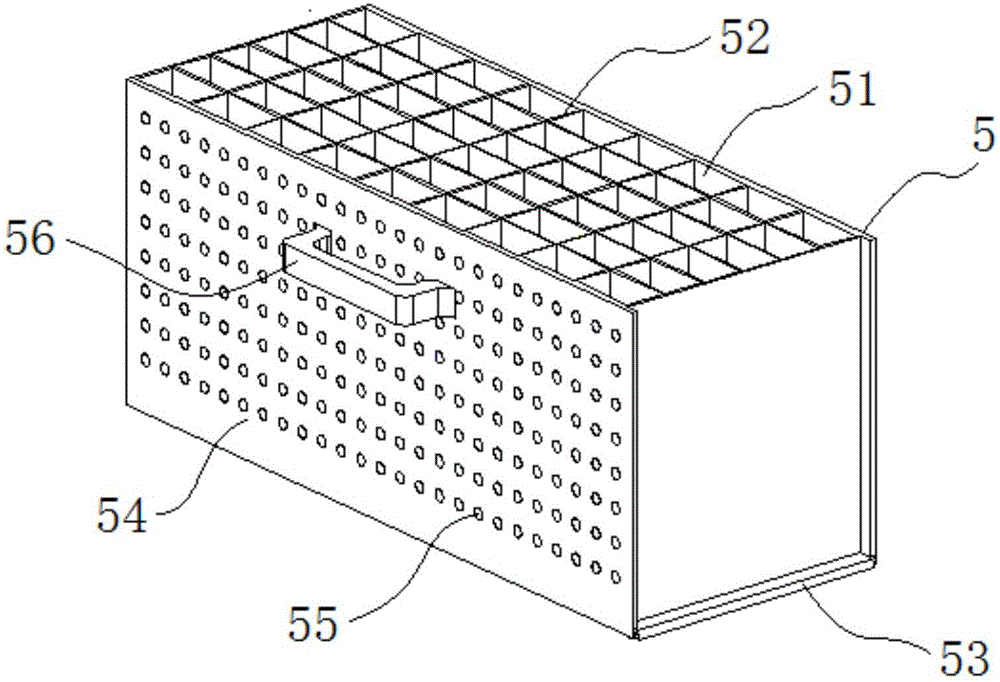

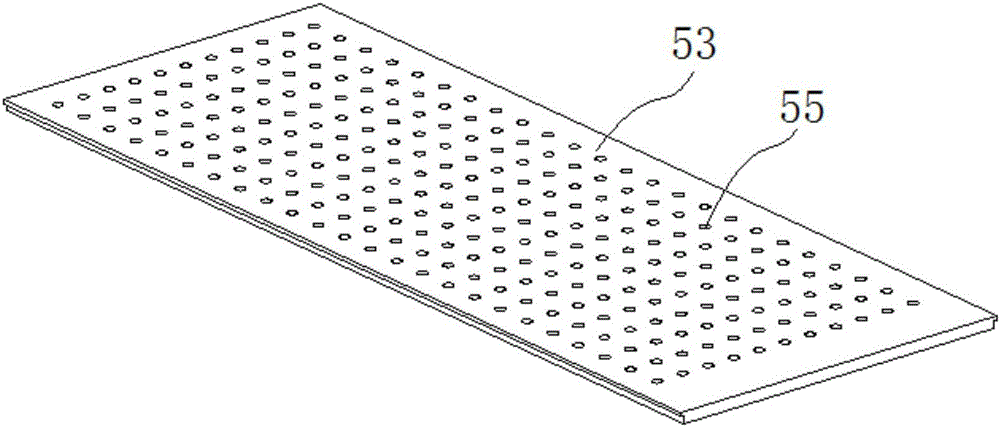

The invention discloses a sugarcane seed collecting device which comprises a base, a longitudinal moving platform, a transverse moving platform, a positioning platform, a box body and a sugarcane guide channel, wherein the longitudinal moving platform is arranged on the base in a mode of moving forwards and backwards; the transverse moving platform is arranged on the longitudinal moving platform in a mode of moving leftwards and rightwards; the positioning platform is arranged on the transverses moving platform; the box body is arranged on the positioning platform in a detachable mode; an opening is formed in the upper end of the inner cavity of the box body; the inner cavity of the box body is partitioned into a plurality of sugarcane storage chambers which are distributed in a matrix manner by a plurality of partitioning plates; the bottom wall of the box body can be dissembled; the bottom wall is of a hollowed plate structure, so that the lower end of each sugarcane chamber is communicated with the outside; the sugarcane guide channel is erected on the base through a support rack in an inclined manner; the lower end of the sugarcane guide channel is positioned above the box body. By adopting the sugarcane seed collecting device, sugarcane seeds can be automatically guided into the sugarcane seed storage chambers, the box body and the sugarcane seeds can be soaked into a medicinal pool and can be also directly put into a seed box of a planting machine for use, seed bud damage can be avoided, and the working intensity of operators can be alleviated.

Owner:GUANGXI UNIV

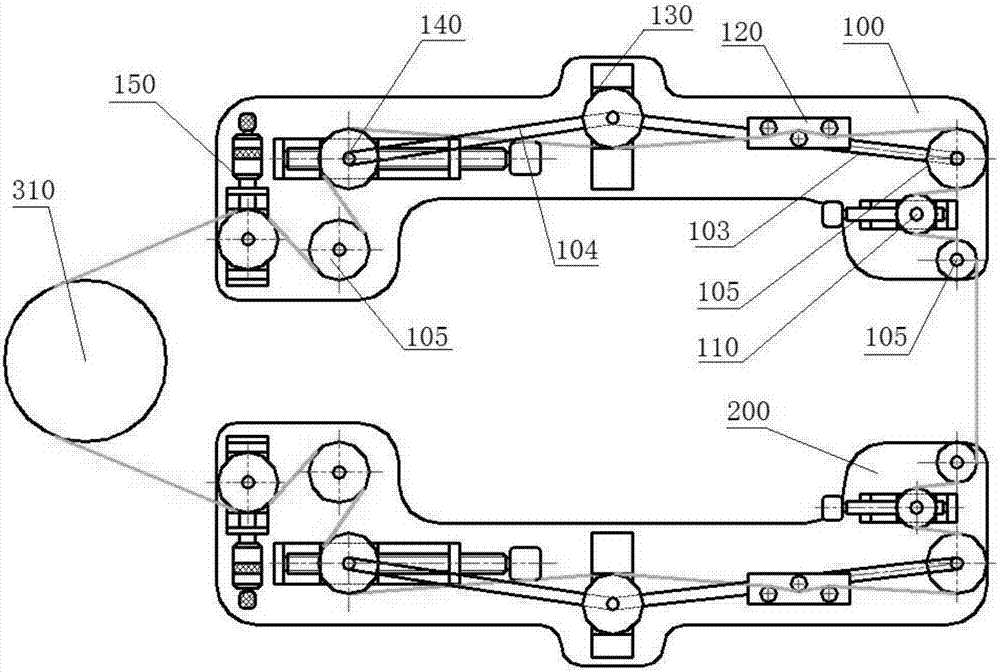

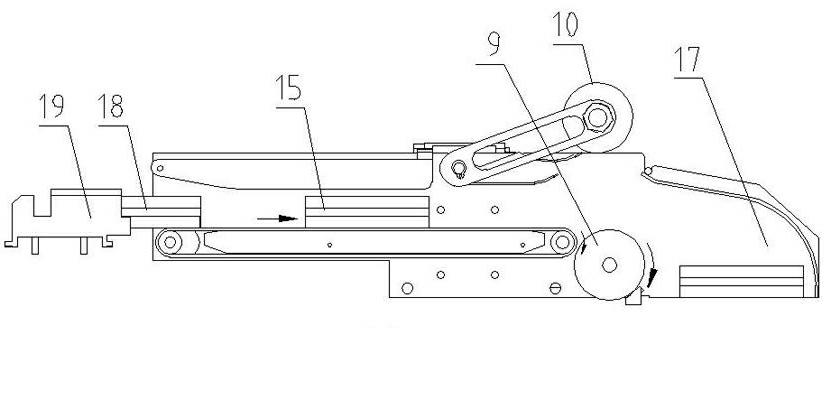

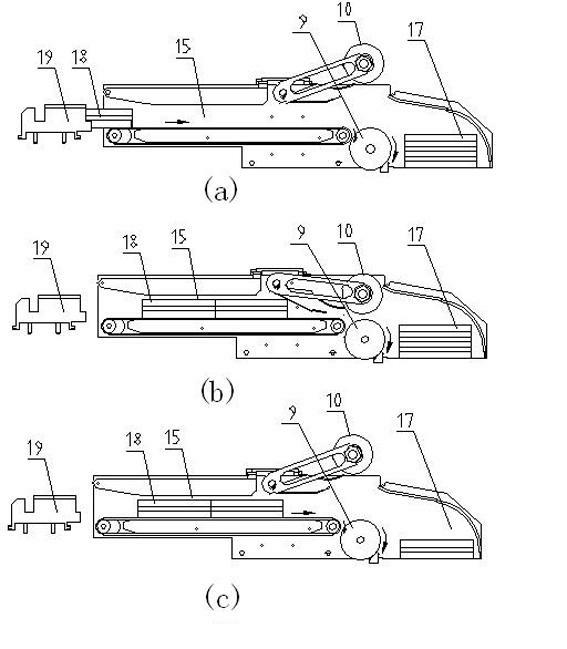

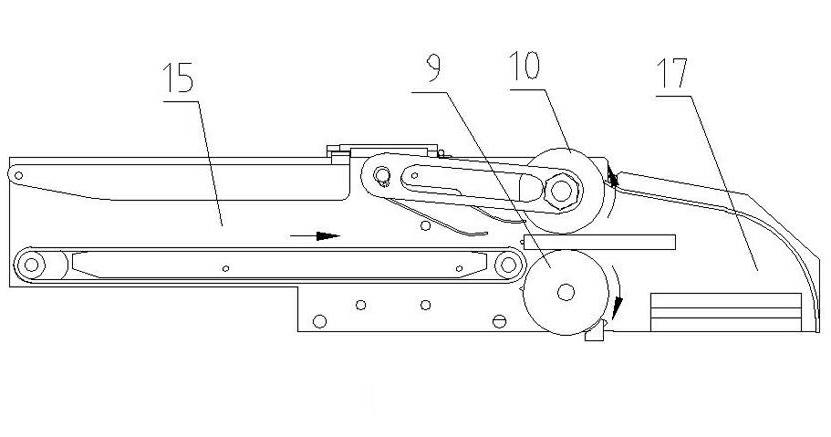

Wire cutting wire arrangement mechanism with electrode wire cutting and recovery functions

ActiveCN106944688AImprove processing efficiencyGuaranteed real-time dynamic tensionElectrical-based machining electrodesElectrical-based auxillary apparatusWire cuttingEngineering

The invention discloses a wire cutting wire arrangement mechanism with electrode wire cutting and recovery functions. The mechanism comprises a wire cylinder mechanism and a wire arrangement mechanism; the wire arrangement mechanism comprises two sets of connecting rod combination mechanisms arranged on the same one plane in a mirror image manner; the connecting rod combination mechanisms comprise manual wire tightening mechanisms, automatic wire tightening mechanisms, slide mechanisms and fixed guide wheels for changing a wire arrangement direction; the wire cylinder mechanism comprises a wire cylinder, guide grooves uniformly distributed in the peripheral direction of the outer wall of the wire cylinder, cutting devices respectively arranged in the guide grooves spaced on the outer wall of the wire cylinder in a radial extending direction of the wire cylinder, and wire collecting devices arranged in the guide grooves between the adjacent cutting devices; the wire collecting devices are sleeved with pressing devices in the axial direction of the wire cylinder; and tightening devices for driving radial movement of the cutting devices and the pressing devices are symmetrically arranged at two ends of the wire cylinder. The wire cutting wire arrangement mechanism comprises a whole set of wire cutting flow as wire penetration, wire tightening and cutting of molybdenum wires after machining, and is optimized to improve the machine tool machining efficiency.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

An automatic clothing folding packaging machine and a clothing folding packaging method

The invention discloses an automatic clothes folding packer. The automatic clothes folding packer comprises a rack and is characterized in that a main board and a folding component are arranged on the rack, the folding component is hinged to the rack (1), a transmission board (3) is arranged under the main board (2), a motor is arranged on the transmission board (3) or the rack (1), a packing station (4) and the motor used for driving the transmission board (3) to drive the main board (2) to reciprocate onto the packing station (4) are arranged on the rack (1), a transmission mechanism is arranged on the rack (1), and a clamping mechanism is arranged on the packing station (4). The invention further discloses a folding and packing method based on the automatic clothes folding packer. The automatic clothes folding packer provided by the invention can automatically finish clothes folding and packing, is high in integration performance, is motor-driven, eliminates noise, adopts a vertical structure and saves the working space.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

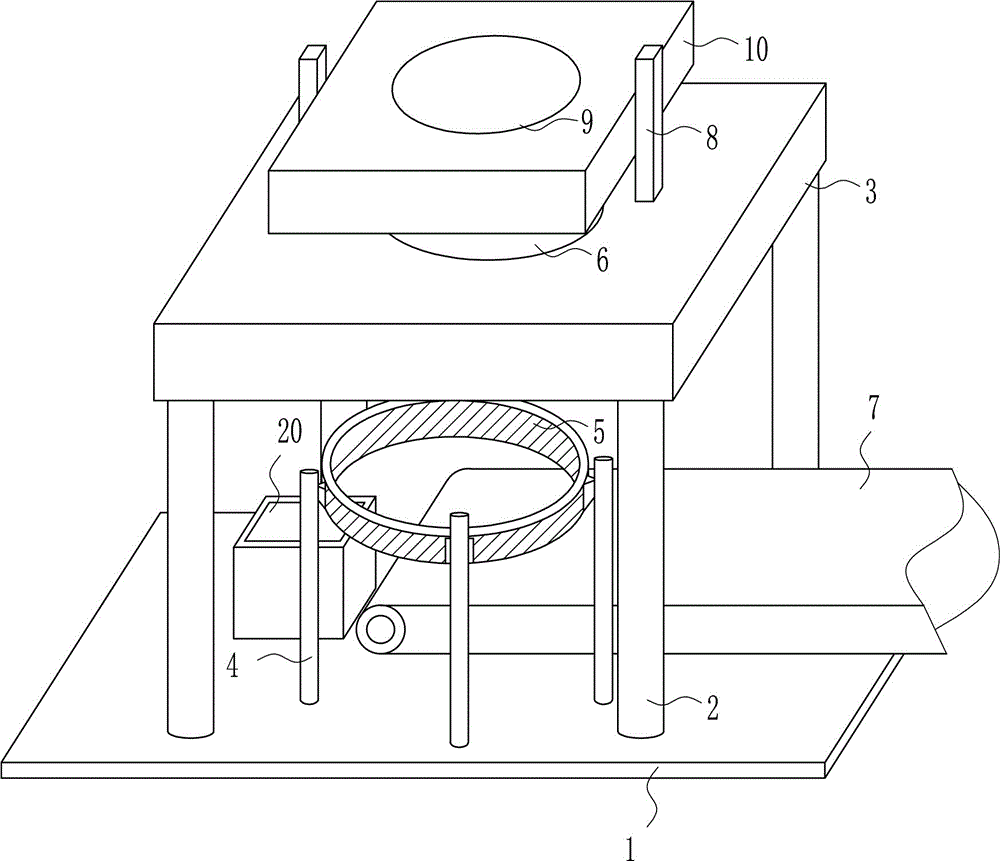

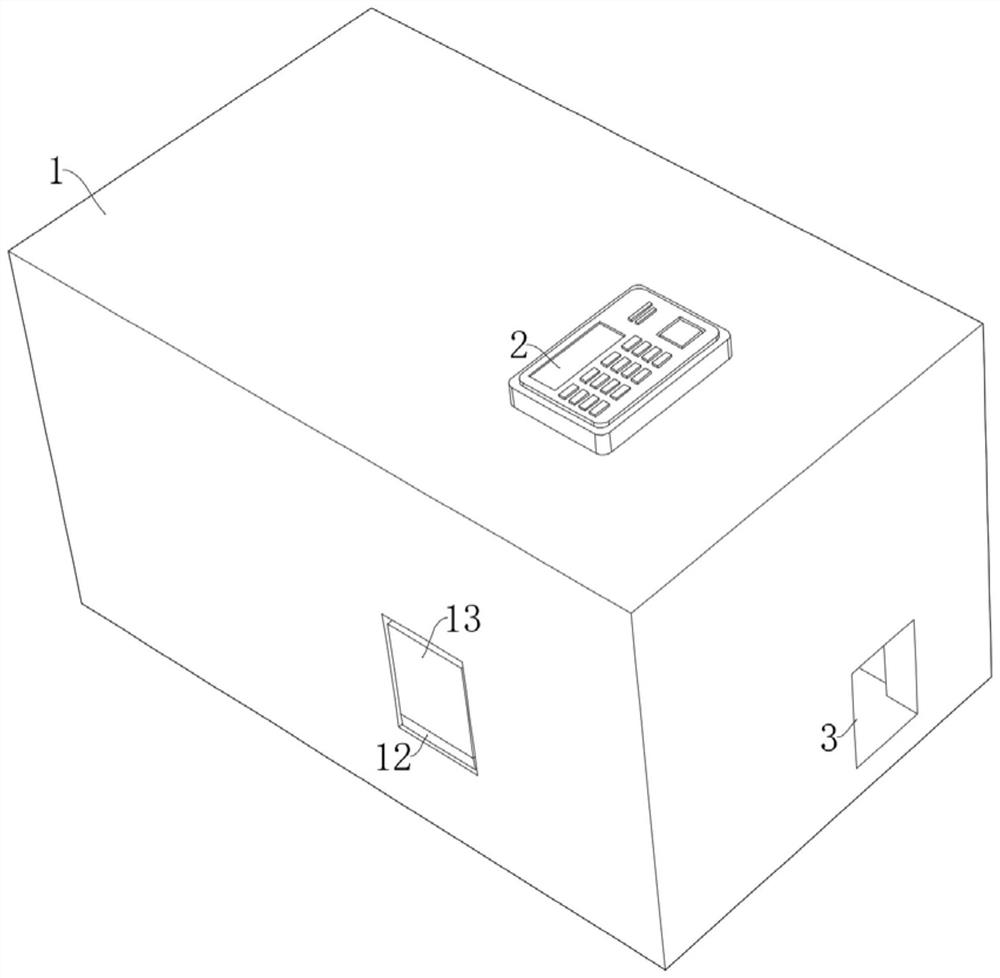

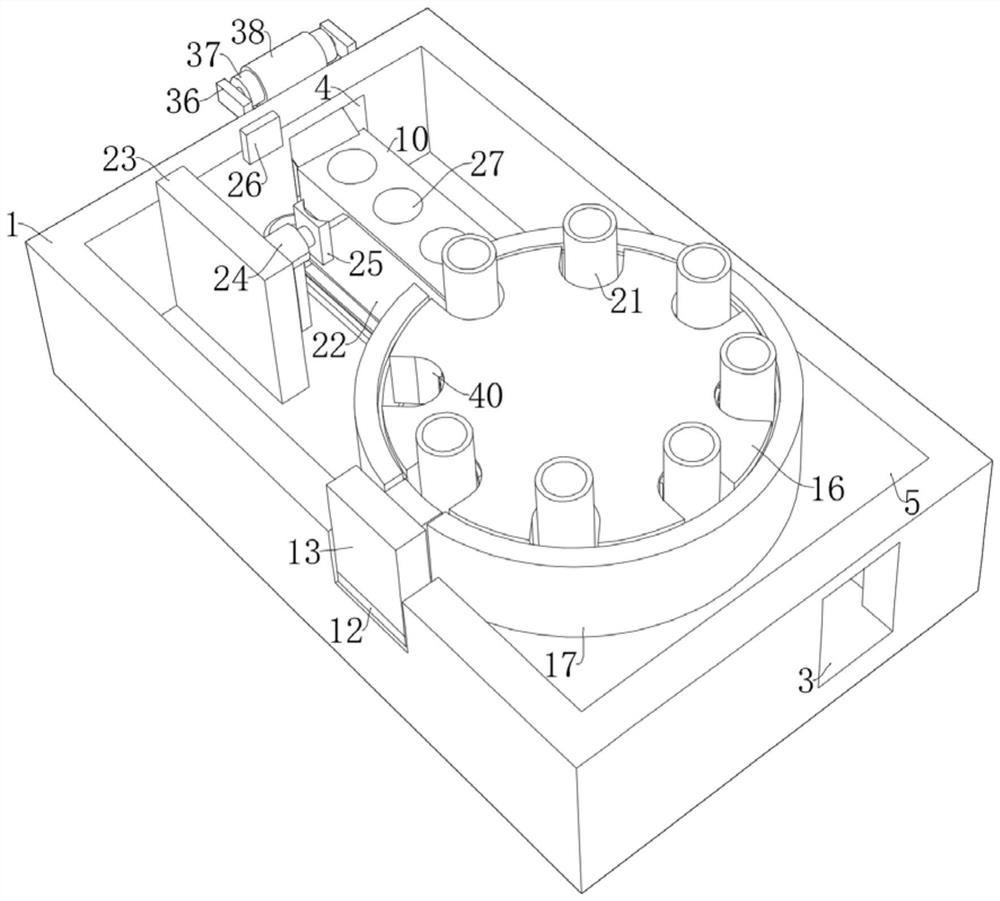

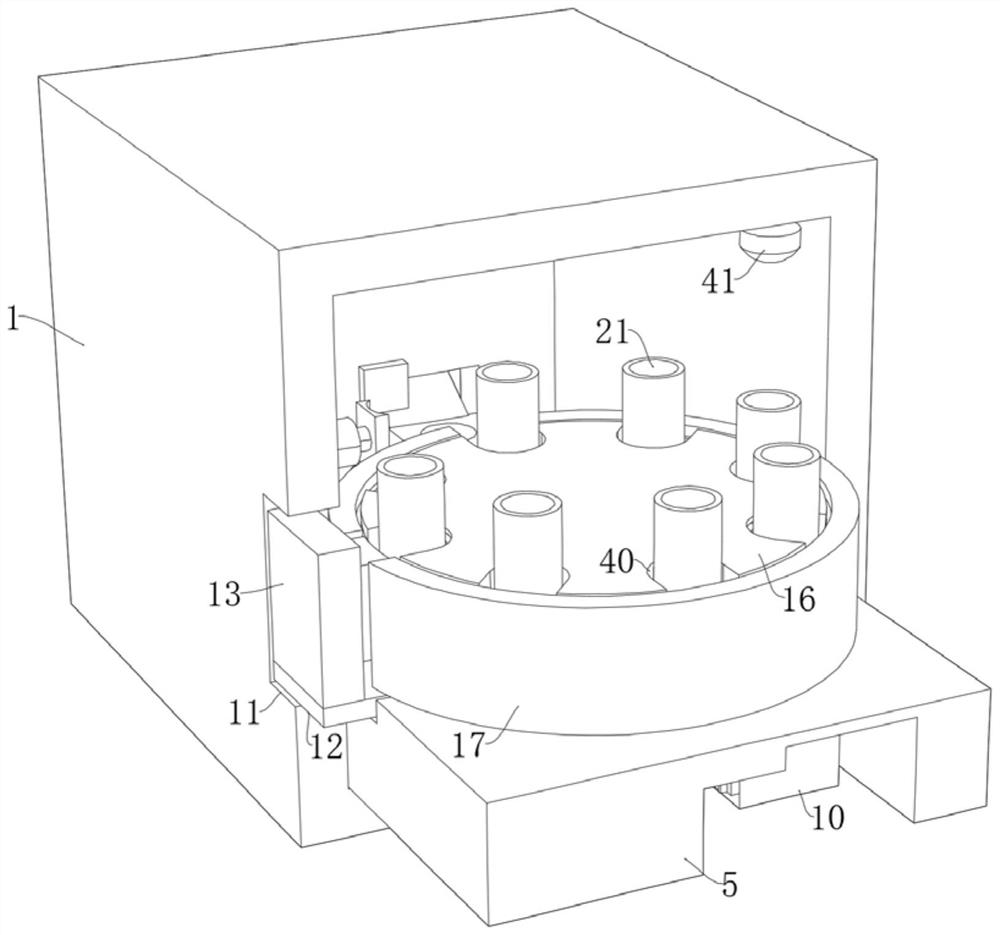

Reagent analysis system for clinical laboratory of hospital and use method of reagent analysis system

PendingCN114405342AIncrease frictionReduce frictionRotating receptacle mixersTransportation and packagingGear wheelElectric machinery

The invention discloses a reagent analysis system for a hospital clinical laboratory and a use method of the reagent analysis system, and provides the following scheme that the reagent analysis system comprises an analysis box and a plurality of reagent bottles located in the analysis box, a first through hole and a second through hole are formed in the inner walls of the sides, away from each other, of the analysis box respectively, and a control panel is fixedly connected to the top of the analysis box; the inner wall of the bottom of the analysis box is fixedly connected with a bottom plate, the top of the bottom plate is rotatably connected with a rotating shaft, the driving motor is started to drive the first gear to rotate, the first gear can drive the rotating shaft to rotate through a gear ring, and along with rotation of the rotating shaft, the rotating disc can be driven to rotate so as to convey and analyze reagent bottles; the rotating shaft can drive the collecting box to move through cooperation of a first synchronous wheel, a second synchronous wheel, a synchronous belt and a second gear, then the reagent bottles are collected and put in order after analysis is finished, and the phenomenon that the reagent bottles are lost due to the fact that the reagent bottles are placed in a mess is avoided.

Owner:郝剑南

Garden foldable tool collecting box

The invention discloses a garden foldable tool collecting box. The garden foldable tool collecting box comprises a bottom plate, wherein a left side plate and a right side plate are arranged on the left and right sides of the bottom plate correspondingly, and the left side plate and right side plate are correspondingly hinged to the bottom plate; connecting columns are arranged on the front and rear sides of upper and lower ends of the left and right side plates correspondingly, and the connecting column at the upper end of the left side plate at the front side of the collecting box is connected with the connecting column at the lower end of the right side plate by a rope; the connecting column at the lower end of the left side plate at the front side of the collecting box is connected with the connecting column at the upper end of the right side plate by a rope, and the connecting column at the upper end of the left side plate of the rear side of the collecting box is connected with the connecting column at the lower end of the right side plate by a rope; and the connecting column at the lower end of the left side plate of the rear side of the collecting box is connected with theconnecting column at the upper end of the right side plate by a rope, the ropes form an enclosure edge on the front and rear sides of the collecting box in a staggered mode, and the columns located atthe upper ends of the left side plate and the right side plate can be adjusted for up and down positions. The garden foldable tool collecting box is composed of a foldable movable plate structure anda collecting bag, and is convenient for people to carry and use.

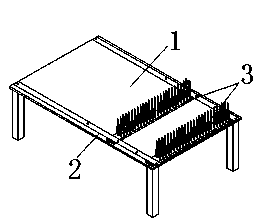

Production method facilitating orderly collection of fibers

InactiveCN103469376ANo damageImprove collection efficiencyHand tools for fibre treatmentFiber bundleCombing

The invention discloses a production method facilitating orderly collection of fibers. The production method comprises the following steps of pressing a grate on a table board by using a pressing plate; enabling teeth of the grate to be upwards; uniformly spreading beaten fiber bundles on the grate in the same direction by different layers; inserting a plurality of grates on the fiber bundles, enabling the teeth of the grates on the fiber bundles and the teeth of the grate under the fiber bundles to be inserted in the fiber bundles so that the fiber bundles are well fixed; pulling out a small quantity of fibers manually or by a multilayered clamp and collecting the fibers; and repeatedly collecting the fibers which are pulled out until all the fibers are pulled out from the fiber bundles. A large quantity of orderly fibers can be collected, and accordingly, follow-up fiber sorting such as fiber combing and fiber beating can be carried out. The production method is simple in structure and convenient to operate, and does not damage the fibers; and the fibers can be easily pulled out from the fiber bundles orderly and then can be collected orderly, so that the fiber collection efficiency is effectively improved.

Owner:XUCHANG UNIV

Cigarette receiving channel for single cigarette detecting and eliminating equipment of packaging machine

InactiveCN102476712AEfficient collectionNeatly collectedPackaging cigarettePackaging cigarsTransmission channelEngineering

The invention discloses a cigarette receiving channel for single cigarette detecting and eliminating equipment of a packaging machine, belonging to the technical field of cigarette packaging machines. The cigarette receiving channel comprises a cigarette transmission channel, a lower roller wheel, a blocking mechanism and end part baffle plates, wherein the lower roller wheel is arranged in the cigarette transmission channel; one end of a conveying belt of the cigarette transmission channel is arranged close to a cigarette inlet end; the tail end of the conveying belt is provided with a lowerroller wheel connected with a second servo motor; the highest point of the lower roller wheel and the upper surface of the conveying belt are positioned on the same plane; the blocking mechanism is arranged between two side plates of the cigarette transmission channel; and the end part baffle plates are arranged on two side plates of the cigarette transmission channel. During working, the inlet of the cigarette transmission channel is connected with the die box eliminating position of the packaging machine, and the blocking mechanism and the lower roller wheel co-act after an eliminated cigarette passes through the cigarette transmission channel, so that a cigarette which is possibly hung between the cigarette transmission channel and a cigarette falling port is conveyed to a cigarette falling port position. Due to the adoption of the cigarette receiving channel, eliminated cigarettes can be collected orderly, and the phenomena of cigarette blockage and disarrangement caused by continuous elimination are avoided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

An automatic collection device for paper corner strips

The invention relates to an automatic collecting device for paper angle bead strips. The automatic collecting device comprises a discharging machine frame (1), a receiving device (2), a rotating mechanism (3), a conveying device (4), a lifting mechanism (5) and a lifting transverse-moving mechanism (6). The receiving device (2) is fixedly connected to the discharging machine frame, and the conveying device (4) is located below the rotating mechanism. The paper angle bead strips which are rotationally cut are received by the receiving device; the strips are placed on a lifting bracket of the lifting mechanism through the rotating mechanism; the strips are moved to the other side of a rotating roller through a transverse-moving bracket of the lifting transverse-moving mechanism; finally, the strips are conveyed by the conveying device to the next working procedure. Compared with the prior art, the paper angle bead strips can be collected more orderly, next-step binding is facilitated, working efficiency is greatly improved, manual collection is replaced, the labor cost is reduced, and production is safer.

Owner:上海宝钢工业有限公司

Cement bag collecting device used for road construction

ActiveCN108974990ANeatly collectedCollect thoroughlyLoading/unloadingRoad constructionMaterials science

The invention relates to a collecting device, in particular to a cement bag collecting device used for road construction. The technical problem is solved through the cement bag collecting device, andthe cement bag collecting device can collect cement bags in order and collect residual cement powder in the cement bags for secondary utilization, and prevents the cement powder from being blown by wind into the eyes of a worker. The cement bag collecting device used for road construction comprises universal wheels, a bottom plate, a first baffle, a box, hinges, first slide rails, first sliding blocks, an extruding frame, a first pull ring, a first elastic part, a first net plate, a second net plate, a second elastic part, an annular slide rail, a cylindrical gear, a second sliding block, a net cylinder, an annular gear, an extruding block and hollow tubes. The cement bag collecting device has the advantages that through the cement bag collecting device, the cement bags can be collected inorder, the residual cement powder in the cement bags can be collected for secondary utilization, and the cement powder is prevented from being blown by wind into the eyes of the worker.

Owner:林向亮

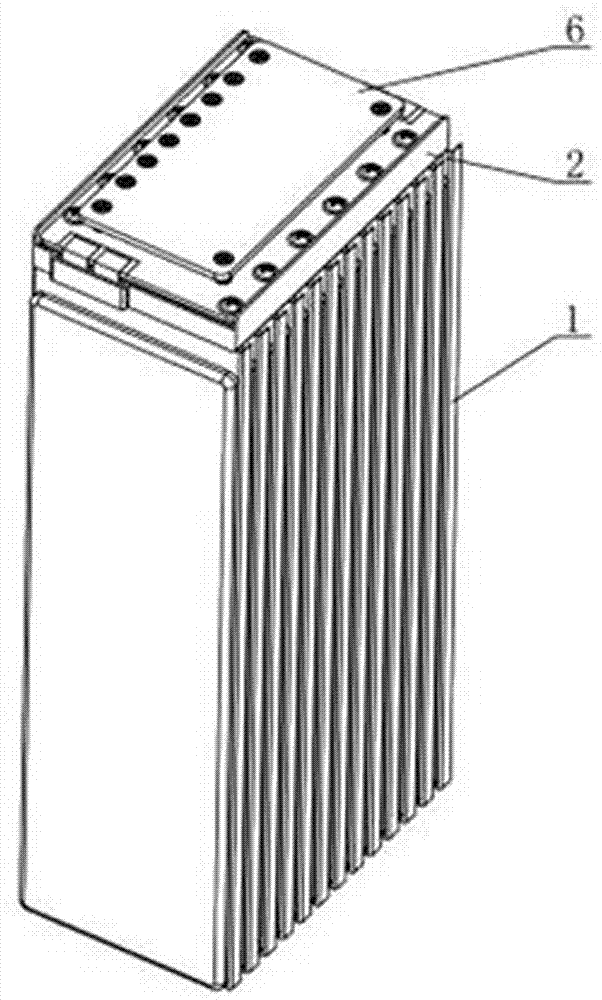

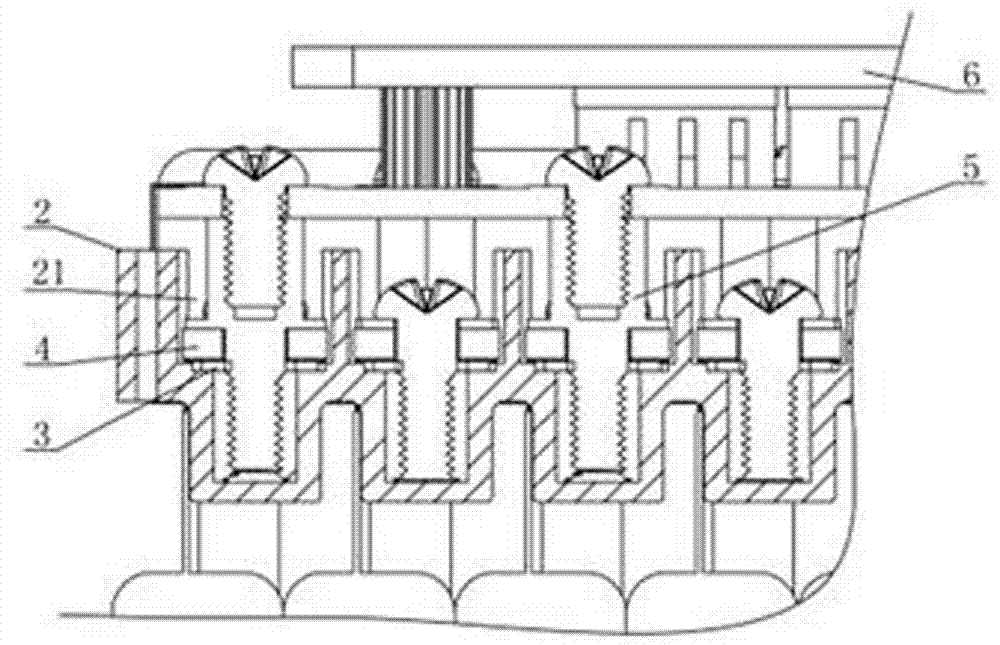

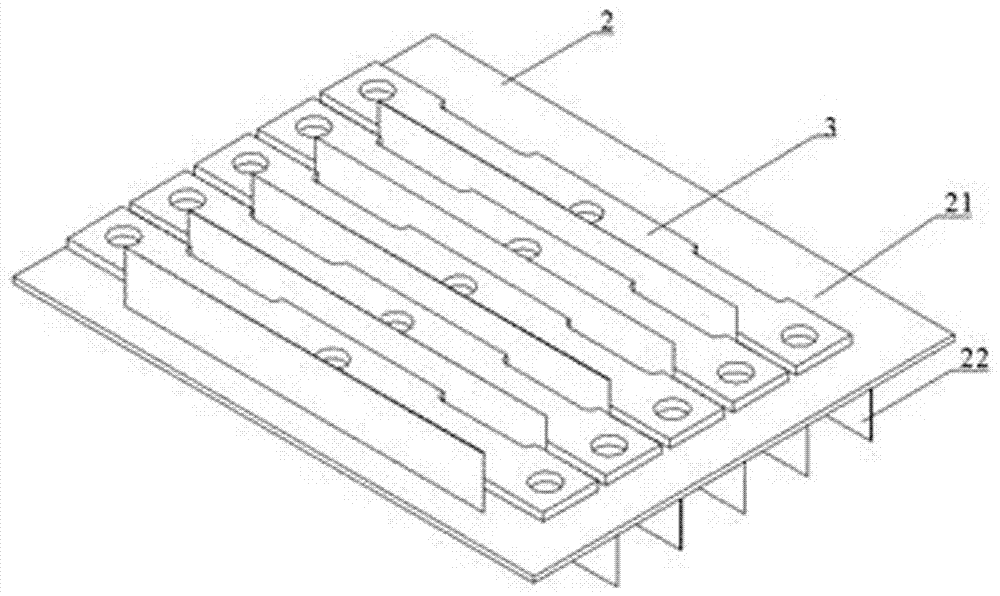

Electrode lug serial connection structure for lithium battery pack

PendingCN107302076AEasy maintenancePromote repairCurrent conducting connectionsSecondary cellsEngineeringLithium ion battery pack

The invention provides an electrode lug serial connection structure for a lithium battery pack. The electrode lug serial connection structure comprises a complex number of cells which are serially connected, wherein the cells are arranged in a same direction; anode lugs and cathode lugs of two adjacent cells form an electrode lug group in a serial connection manner; the anodes and the cathodes of two cells at an end part are power supply output ends; serial connection brackets are arranged at electrode lug ends of the cells; serial connection cavities which are arranged longitudinally are formed in the serial connection brackets corresponding to electrode lug groups; each electrode lug group penetrates through electrode lug holes formed in two sides of the inner bottom of a corresponding serial connection cavity, is bent and folded and is connected with a tabletting mechanism arranged on each serial connection cavity; detection studs are arranged on the tabletting mechanisms; connection platforms are arranged at the upper ends of the detection studs and are electrically connected with detection protection plates through screws; threads are formed in the lower ends of the detection studs and are fixed with the tabletting mechanism and the serial connection cavities; and the detection studs are arranged on two sides of the serial connection cavities. The electrode lug serial connection structure has the beneficial effects that the design is simple in structure, convenient to assemble and low in use cost and has the advantage that the use security of the lithium battery pack is improved.

Owner:山东高佳新能源有限公司

Automatic collecting device and automatic collecting method for worm tooth

PendingCN111776777ANeatly collectedEasy to organizeControl devices for conveyorsLoading/unloadingElectric machineryEngineering

The invention discloses an automatic collecting device and automatic collecting method for a worm tooth. The device comprises a material distributing component, a material passing block, a material pushing component and a material receiving component, wherein the material distribution component comprises a turntable, a turntable shaft, a fence and a turntable motor; the fence is fixed on the periphery of the turntable; one end of the turntable shaft is connected with the turntable, the other end of the turntable shaft is connected with the turntable motor, and the fence is provided with a discharge port; the material passing block is provided with a material passing groove corresponding to the position of the discharge port; the material pushing component comprises a material pushing cylinder, a material pushing sliding block, a material pushing guide rail and a material pushing hook; the material pushing guide rail is fixed on the material passing block, the material pushing slide block is slidably connected on the material pushing guide rail, the material pushing hook is fixedly connected with the material pushing sliding block, and the material pushing cylinder is connected withthe material pushing hook and can drive the material pushing hook to move in the length direction of the material pushing guide rail; the material pushing hook is provided with a hook part, and the hook part is arranged in the material passing groove; the receiving component comprises a receiving disc; and the material receiving disc is provided with a transverse groove, and the length directionof the transverse groove is the same as the length direction of the material passing groove. According to automatic collecting device and automatic collecting method for the worm tooth, the safety andthe working efficiency are improved.

Owner:华宏达精密五金制造(深圳)有限公司

Dedicated adjustable bracket for placing steel wire ropes in process of elevator mounting

The invention discloses a dedicated adjustable bracket for placing steel wire ropes in the process of elevator mounting. The dedicated adjustable bracket comprises a mounting box; a plurality of mounting grooves are symmetrically formed in the bottom of the mounting box; a moving device and a supporting device are arranged in each mounting groove; a sleeve is arranged on one side of the mounting box; a suspension device is arranged in the sleeve; a groove is formed in one side of the upper part of the mounting box; a telescopic rod is mounted in the groove by means of a rotating shaft; a set screw is arranged on the telescopic rod; a steel wire rope collection frame is arranged at the upper end of the mounting box; a steel wire rope guiding frame is arranged on one side of the steel wire rope collection frame; and handles are symmetrically arranged on two sides of the mounting box. The dedicated adjustable bracket can regularly and neatly collect the steel wire ropes automatically, andmeanwhile, the moving devices, a fixing device and the suspension device are arranged, so that using of the bracket on various mounting occasions is facilitated, and the mounting efficiency is improved; and the dedicated adjustable bracket is simple in structure, convenient to operate, and is high in practicability.

Owner:四川贤通机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com