Raw paper cutting equipment used before printing of printing machine

A technology for printing presses and base paper, which is applied in the field of cutting equipment for base paper before printing by printing presses, can solve the problems of affecting appearance, low efficiency, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

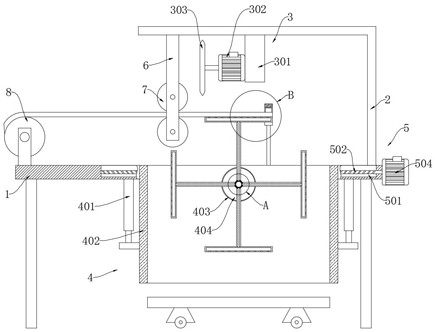

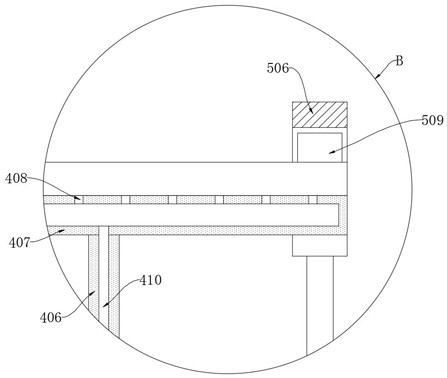

[0024] refer to Figure 1-6 , a base paper cutting device for a printing machine before printing, comprising a machine 1, an L-shaped first plate 2 is fixedly connected to the upper end of the machine 1, and a cutting device for cutting the base paper is provided on the first plate 2 Mechanism 3, the cutting mechanism 3 includes a cutting knife 303, a console 301 is installed on the first board 2, a first motor 302 is installed on the side wall of the console 301, and the movable end of the first motor 302 is fixedly connected with the cutting knife 303.

[0025] It should be noted that the console 301 can control the cutting knife 303 to move up and down and back and forth, so as to realize the cutting of the hard base paper, which is a prior art, and will not be repeated here.

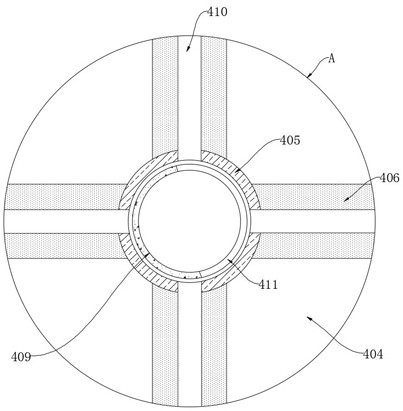

[0026] The machine 1 is provided with a placement mechanism 4 for leveling and placing the cut base paper. The placement mechanism 4 includes two electric push rods 401 fixedly connected to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com