Electrode lug serial connection structure for lithium battery pack

A lithium-ion battery pack and connection structure technology, which is applied to battery pack components, batteries, structural parts, etc., can solve problems such as unfavorable repairs, affecting yield, and signal line puncture short circuits, etc., to achieve convenient battery maintenance and repair, The effect of improving the degree of production automation and improving the insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

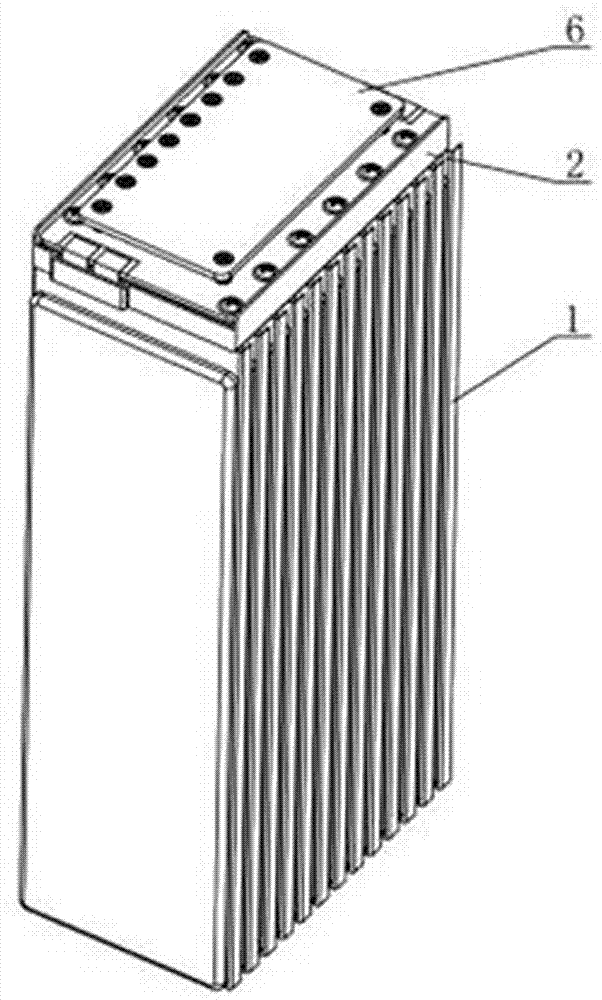

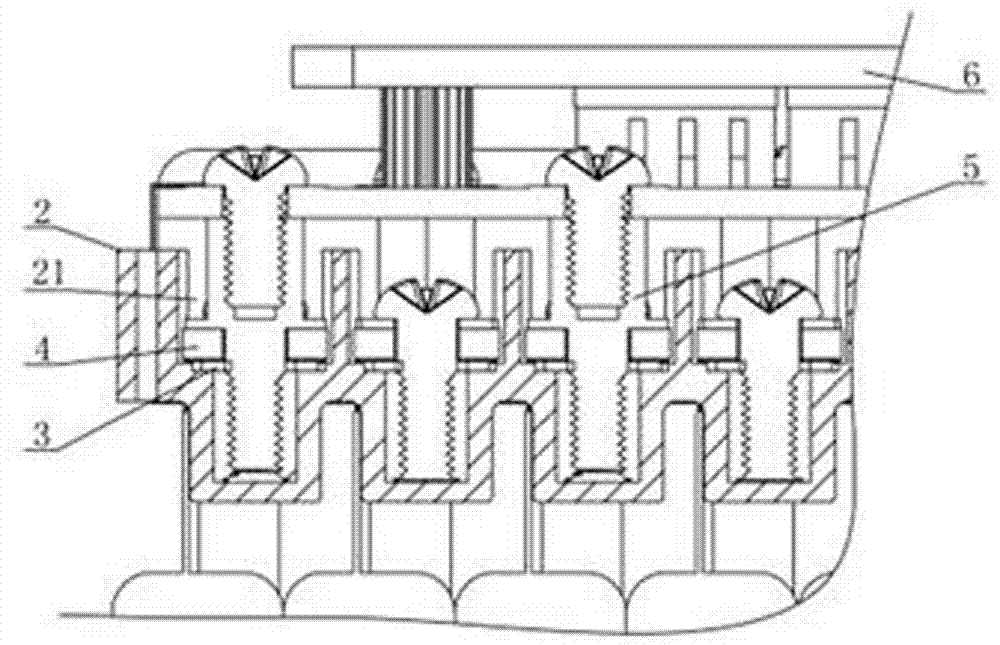

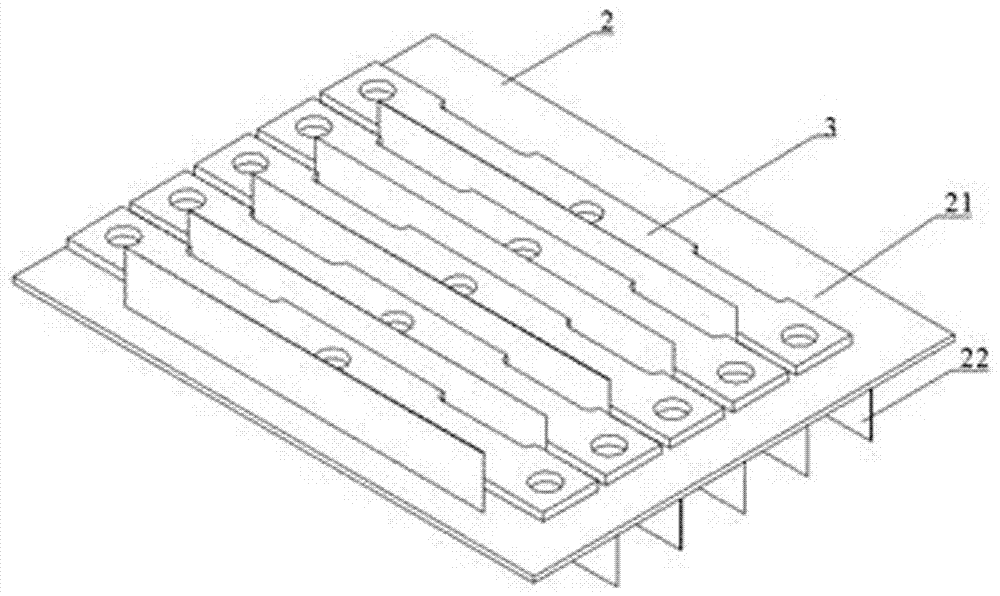

[0027] Such as Figure 1-8 As shown, a tab series structure of a lithium-ion battery pack includes a plurality of series-connected battery cells 1 arranged in sequence, the battery cells 1 are arranged in the same direction, and the positive tabs of two adjacent battery cells 1 , The negative tab is a set of tabs connected in series. In order to facilitate the electrical connection between the tab groups, the positive tab of each cell 1 is placed adjacent to the negative tab of the adjacent cell 1 . In addition, the positive and negative poles of the two cells 1 located at the ends of the lithium-ion battery pack are power output terminals, thus completing the serial connection of a lithium-ion battery pack.

[0028] This embodiment creates an excellent place for the safe connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com