Patents

Literature

54results about How to "Avoid micro-short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite solid polymer electrolyte and preparing method and application thereof

InactiveCN106299471AHigh mechanical strengthImprove thermal stabilitySolid electrolytesSecondary cellsPolymer electrolytesElectrical battery

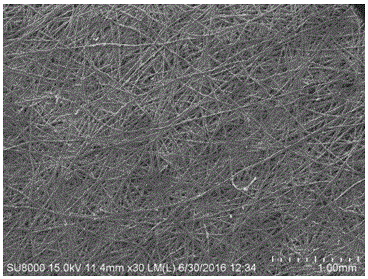

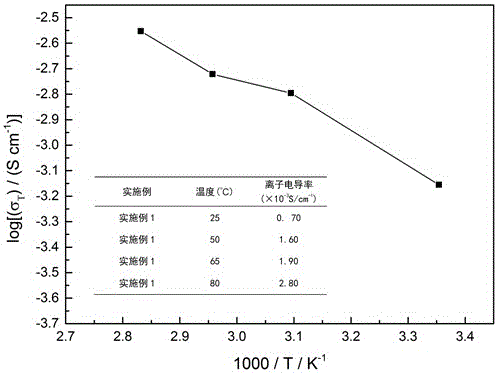

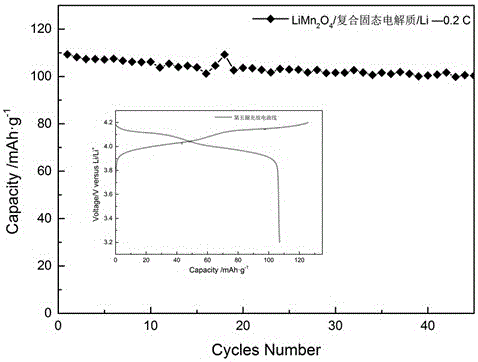

The invention discloses a composite solid polymer electrolyte and a preparing method and application thereof. The composite solid polymer electrolyte is prepared from a gadoleic acid ester monomer, a porous supporting matrix, lithium salt, an additive and an initiator, wherein the mass ratio of the gadoleic acid ester monomer to the additive is (1-10):1, the lithium salt accounts for 5-30% of the total mass of the gadoleic acid ester monomer and the additive, and the mass ratio of the initiator to the gadoleic acid ester monomer is (1-10):100. The composite solid polymer electrolyte prepared with the method has the advantages of being large in ion conductivity, high in mechanical strength, easy to form, stable in interface contact, high in electrochemical stability and easy to prepare and can be used for forming solid lithium ion secondary batteries, and the prepared solid lithium ion secondary batteries are high in safety, energy density and production efficiency.

Owner:HARBIN INST OF TECH +1

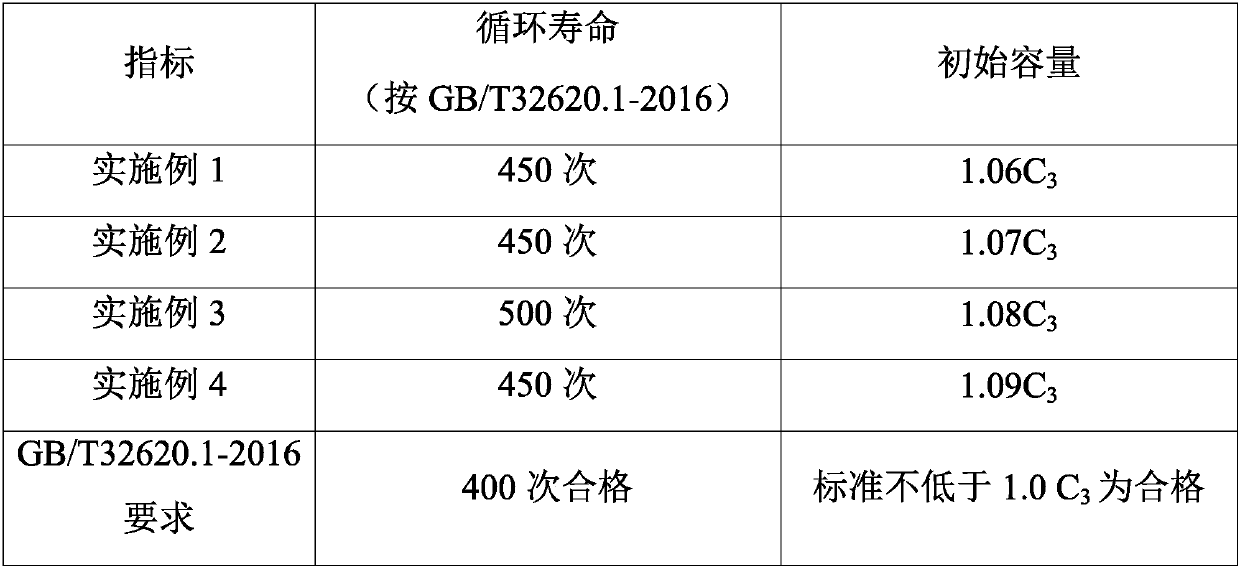

Rapid container formation charging method for lead-acid storage battery

ActiveCN105226338AImprove cycle lifeAvoid damageSecondary cells charging/dischargingNameplate capacityConcentration polarization

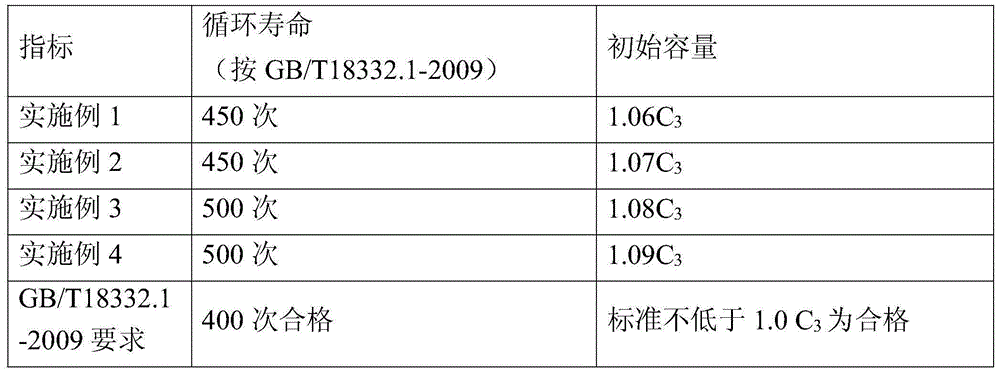

The invention discloses a rapid container formation charging method for a lead-acid storage battery. The charging method is implemented through 27 charging and discharging stages, including eight times of discharging, one time of standing and one time of capacity checking and matching, wherein a maximum charging current is 0.15C<3> to 0.20C<3>, and a minimum charging current is 0.01C<3> to 0.05C<3>. The lead-acid storage battery is charged and discharged repeatedly, and a quantity of electricity charged each time is larger than a quantity of electricity discharged subsequently. Through adoption of the method, concentration polarization phenomena can be reduced greatly, and damages to crystal structures of active substances on a pole plate are reduced, thereby prolonging the service lifecycle of the lead-acid storage battery. As indicated by a detection performed according to specifications in GB / T18332.1-2009, the service lifecycle of the lead-acid storage battery adopting the method is greater than 450 times, and an initial capacity of the lead-acid storage battery is not less than 100 percent (counted by a rated capacity)

Owner:ZHEJIANG TIANNENG POWER ENERGY

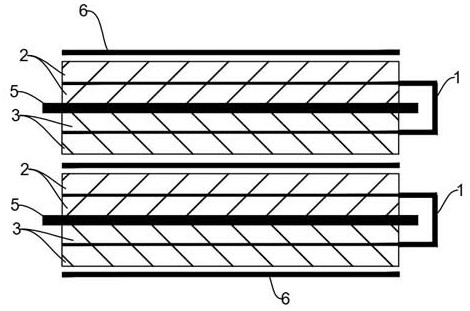

Diaphragm and preparation method thereof, and lithium ion battery

ActiveCN102623658AThe absolute value of the surface potential is largeEvenly distributedSecondary cellsCell component detailsHexafluoropropyleneLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an inorganic and organic composite multihole diaphragm. The diaphragm comprises a multihole diaphragm base material and an active coating layer attached to at least one surface of the multihole diaphragm base material, wherein the active coating layer comprises inorganic particles, vinylidene fluoride and hexafluoropropylene copolymer, cellulose based polymer with the molecular weight of 100,000 to 1,000,000 and at least one of polyacrylic acid and polyacrylate. Compared with the prior art, the diaphragm keeps relatively high air permeability and lithium ion transmission capacity; the active coating layer and the multihole diaphragm base material are well bonded; and the overheating contraction performance and the puncture strength of a diaphragm base can be improved remarkably. Furthermore, the invention also discloses a preparation method for the diaphragm and a lithium ion battery with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

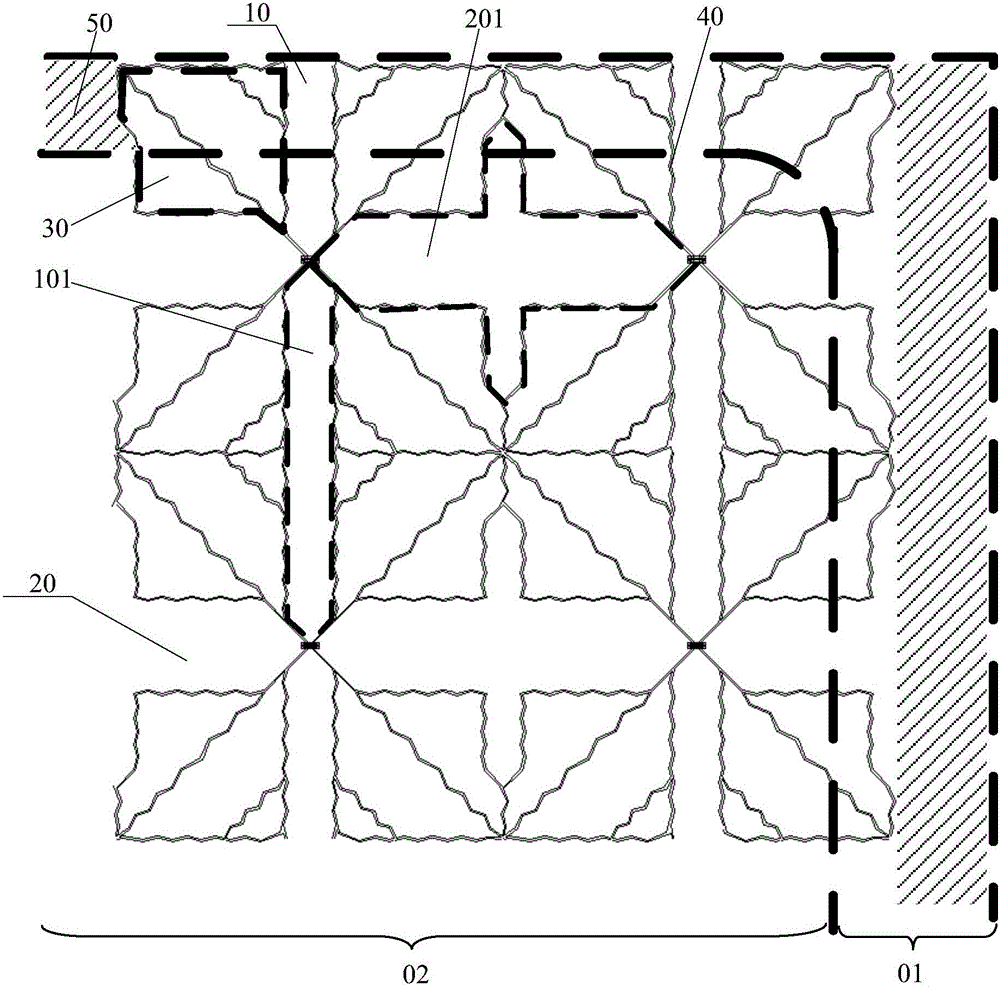

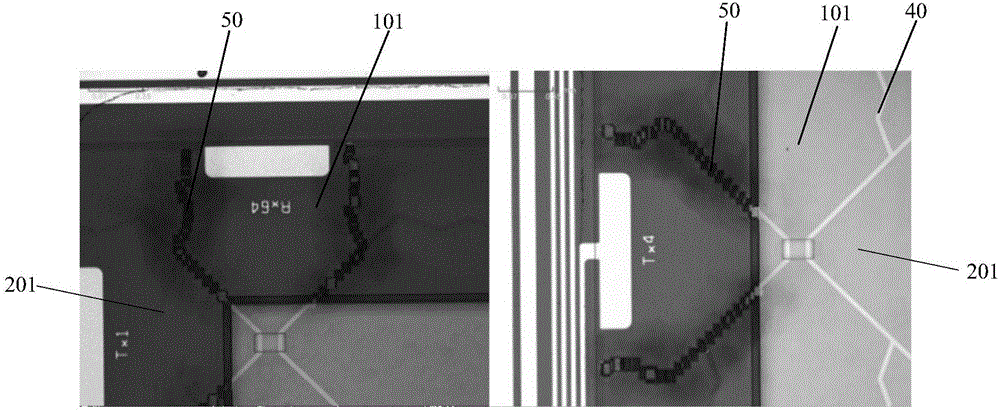

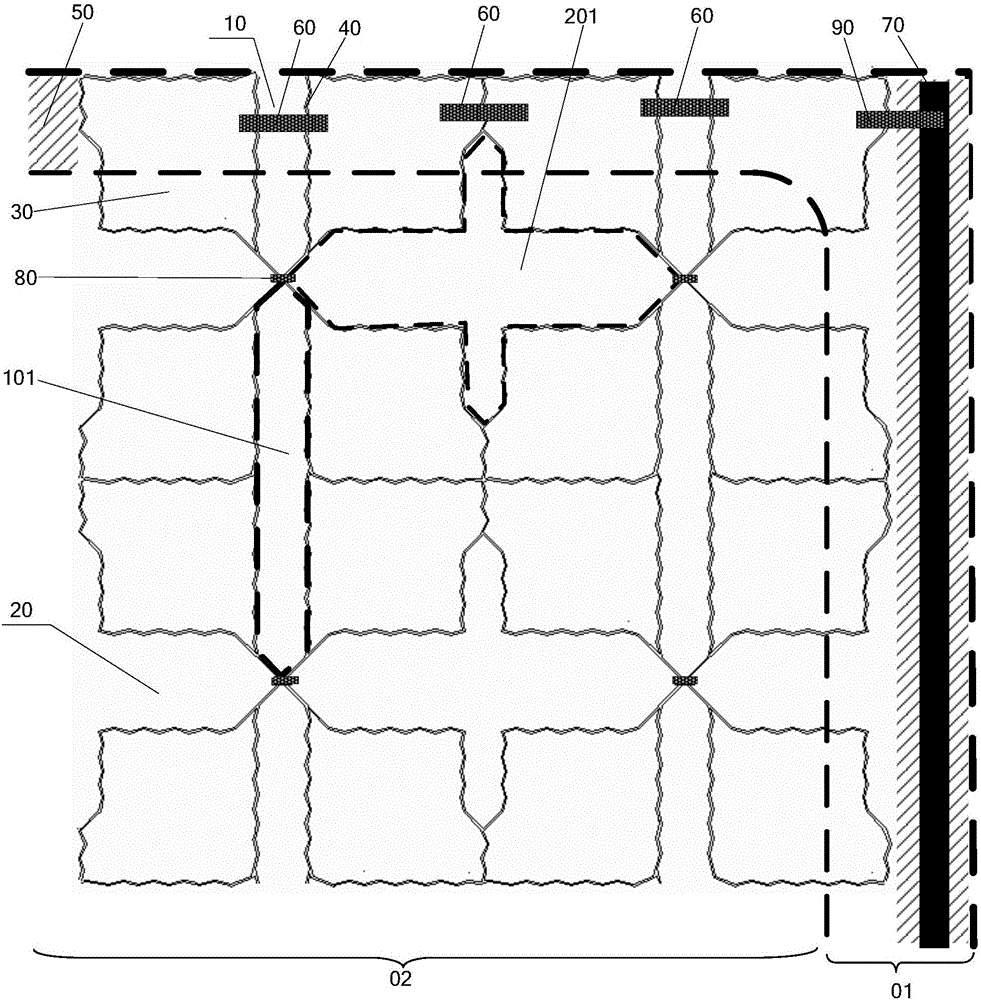

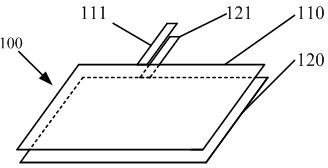

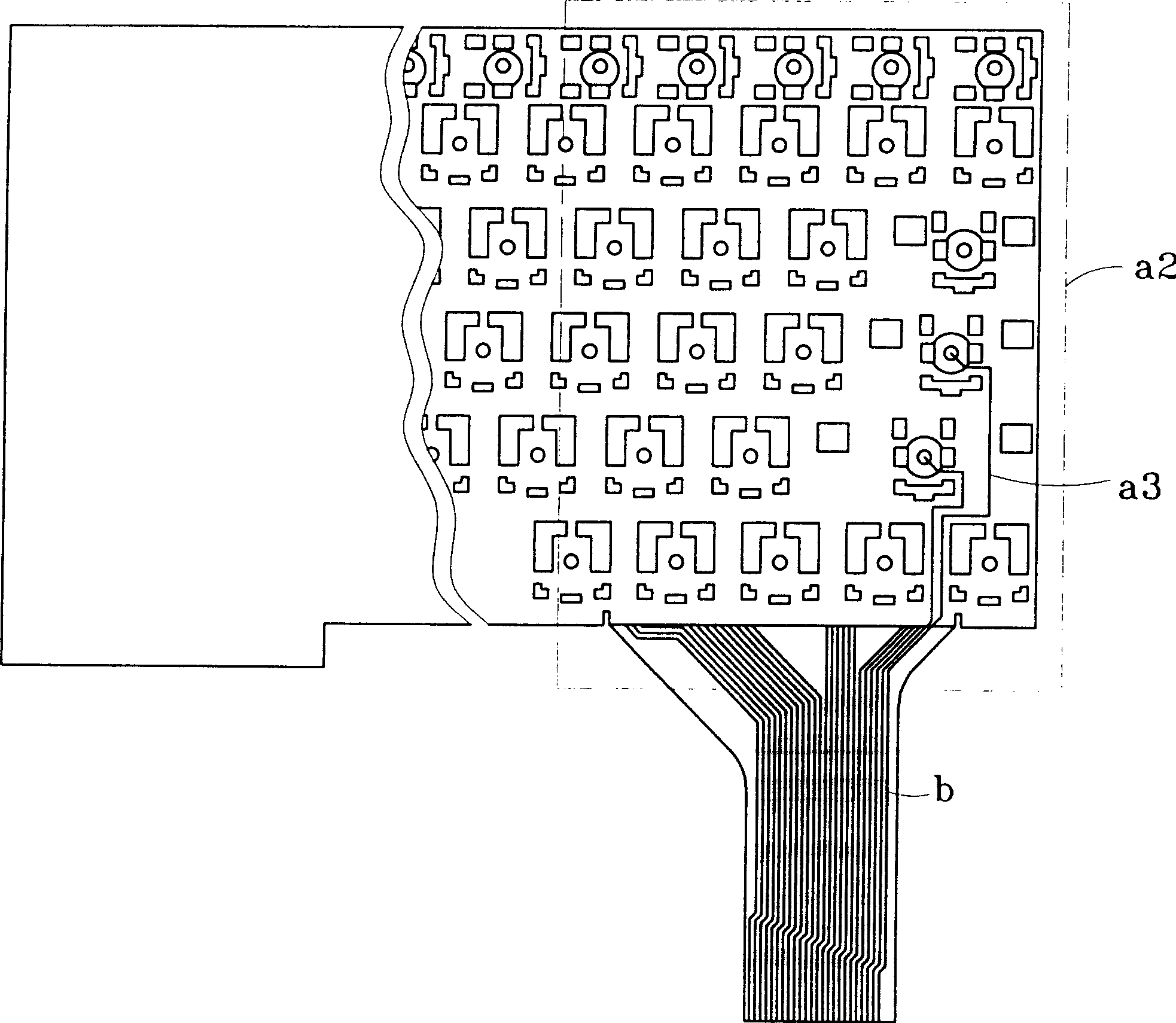

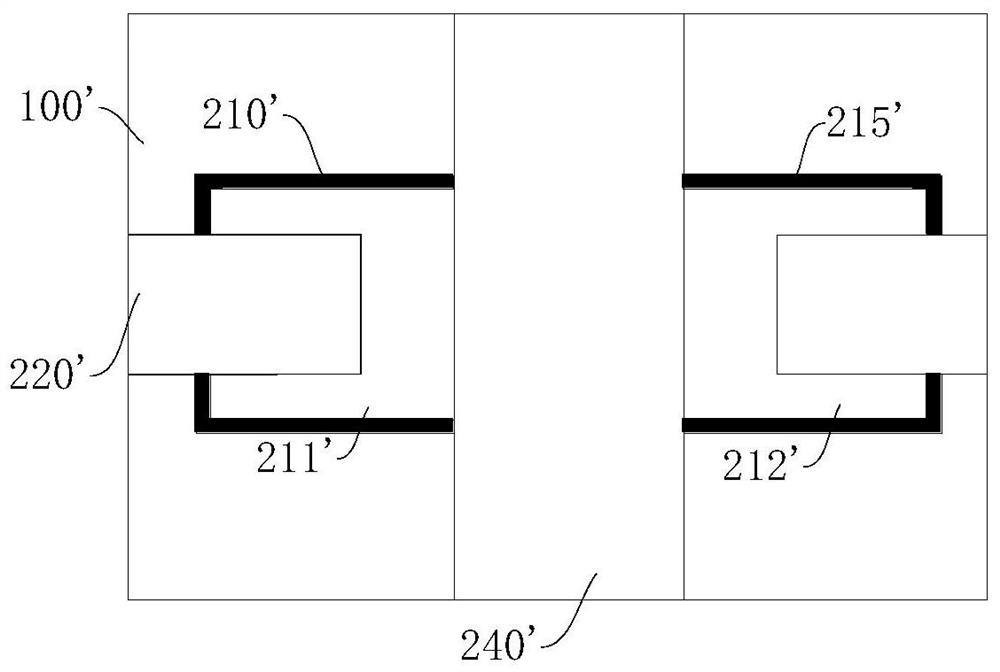

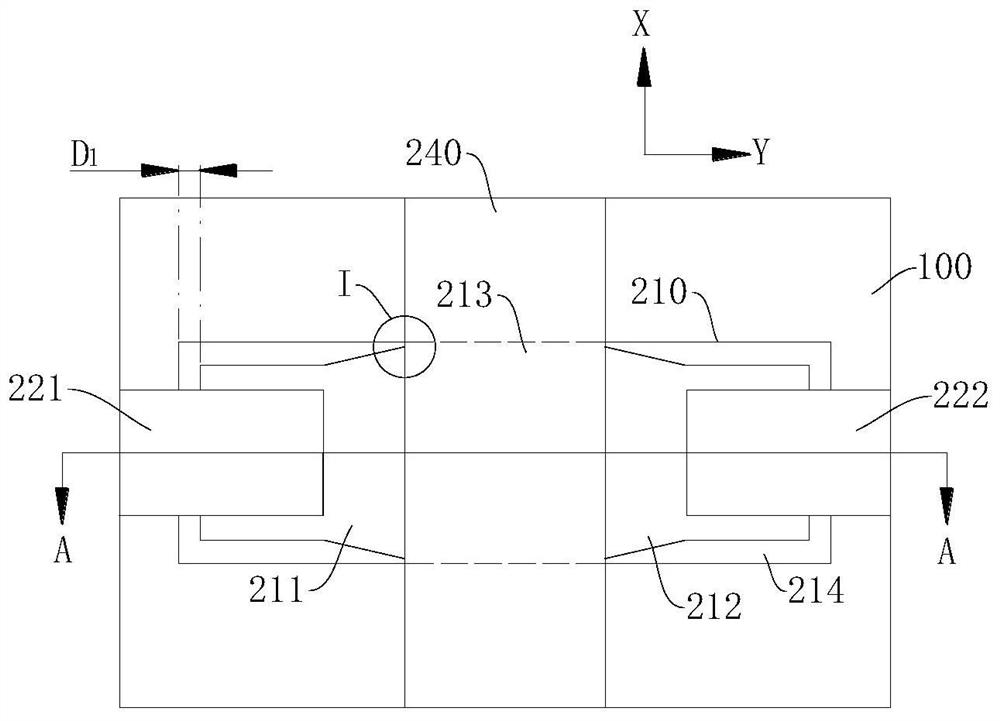

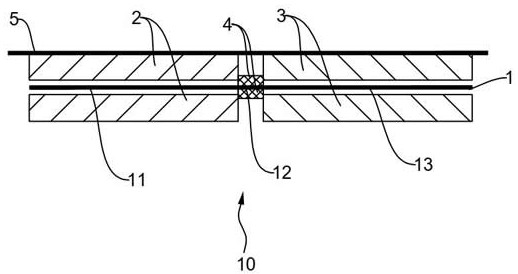

Touch substrate, preparation method thereof and touch display device

ActiveCN106354299APrevent from breakdown and conductionAvoid micro-short circuitNon-linear opticsInput/output processes for data processingDisplay deviceHuman–computer interaction

The embodiment of the invention provides a touch substrate, a preparation method thereof and a touch display device, and relates to the technical field of display. Static on virtual electrodes in a shading zone can be released, and compared with the prior art, production cost can be reduced. The touch substrate is divided into a touch zone and the shading zone encircling the touch zone, and a shading pattern is arranged in the shading zone. The touch substrate comprises first touch electrodes, second touch electrodes and the virtual electrodes, wherein the first touch electrodes and the second touch electrodes intersect and are insulated from each other, the virtual electrodes are arranged in a zone defined by the first touch electrodes and the second touch electrodes, and gaps exit between the virtual electrodes and the first touch electrodes and between the virtual electrodes and the second touch electrodes. The first touch electrodes, the second touch electrodes and the virtual electrodes make contact with the shading pattern, the parts, located in the shading zone, of the adjacent virtual electrodes are connected through first bridges, and the first bridges are insulated from the first touch electrodes and the second touch electrodes. A first ground wire is arranged in the shading zone and electrically connected with the virtual electrodes connected through the first bridges.

Owner:BOE TECH GRP CO LTD +1

High specific energy battery pack internal flame-retardant cooling method

The present invention relates to the technical field of secondary battery pack manufacturing, and provides a high specific energy battery pack internal flame-retardant cooling method. According to the method, a flame retardant agent is subjected to a microencapsulation treatment and the treated flame retardant agent is filled inside the battery pack, such that the problem that the sharp temperature change caused by the electrical core short circuit and other failures causes firing burning even explosion can be solved. According to the present invention, the method has the following effects that after the temperature in the battery pack is increased to a certain value, the shell of the microcapsule filled with the flame retardant agent is rapidly dissolved or broken to release the flame retardant agent, and oxygen is consumed or diluted through the physical pathway of the isolation film forming on the local high-temperature area and the surrounding in the battery pack and the chemical pathway of the free radical terminating so as to achieve the functions of flame retardant effect and cooling, terminate the spreading of the high temperature area, eliminate and reduce the firing risk, and improve the safety performance of the battery pack; and the method has advantages of high safety and high reliability, and with the microcapsule flame retardant agent, the installation of the larger fire extinguishing device is avoided, and the advantages of lightweight and environmental protection are provided.

Owner:江苏海四达电源有限公司 +1

Electrode sheet and lithium ion battery

InactiveCN105655540AReduce edge sheddingImprove adhesionSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryColloid

The present invention provides an electrode sheet and a lithium ion battery. The electrode sheet comprises a current collector and an active-material-containing active material layer arranged on at least a surface of the current collector, wherein the electrode sheet further comprises an insulating colloid substance coated on at least an edge of the active material layer. The lithium ion battery comprises the electrode sheet. According to the present invention, the insulating colloid substance is coated on at least an edge of the active material layer, can enhance the adhesion between the edge of the active material layer and the current collector, and can reduce the shedding of the edge of the active material layer, such that the metal exposing of the current collector due to the shedding of the edge of the active material layer can be avoided, and the battery micro-short circuit caused by burr produced during the electrode sheet cutting process can be avoided so as to improve the safety performance of the lithium ion battery using the electrode sheet.

Owner:CONTEMPORARY AMPEREX TECH CO

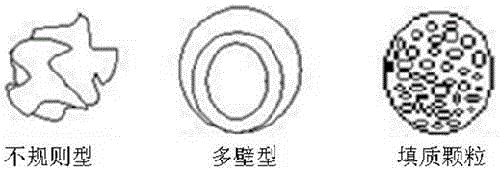

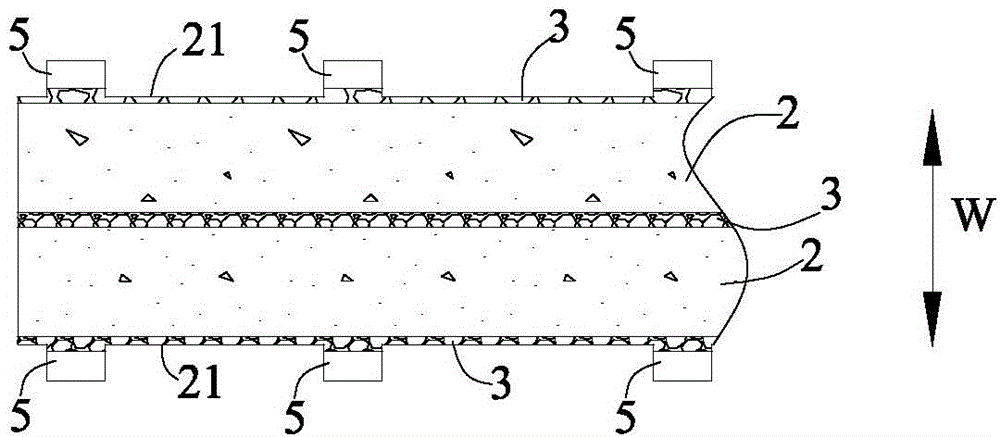

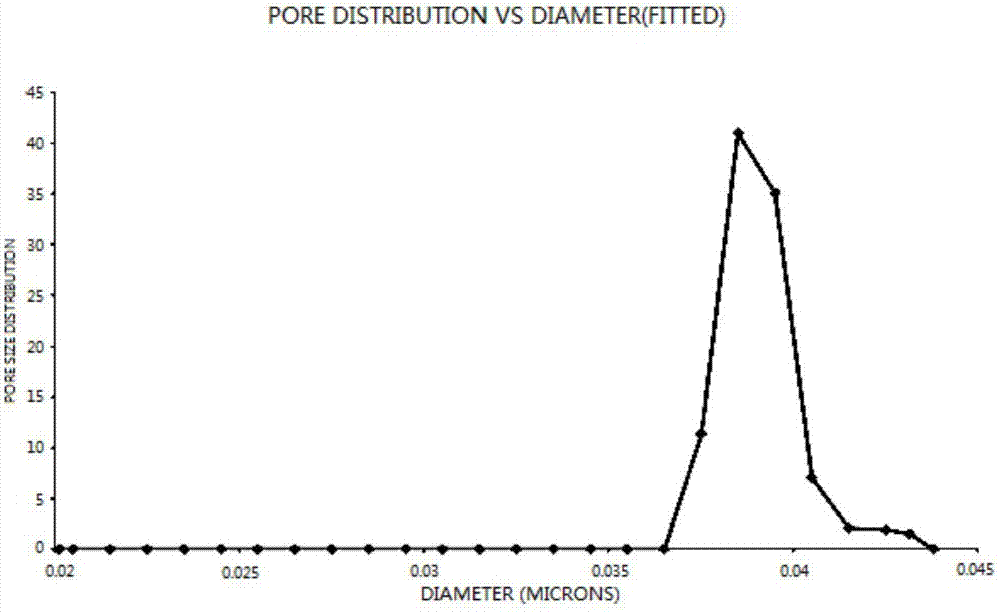

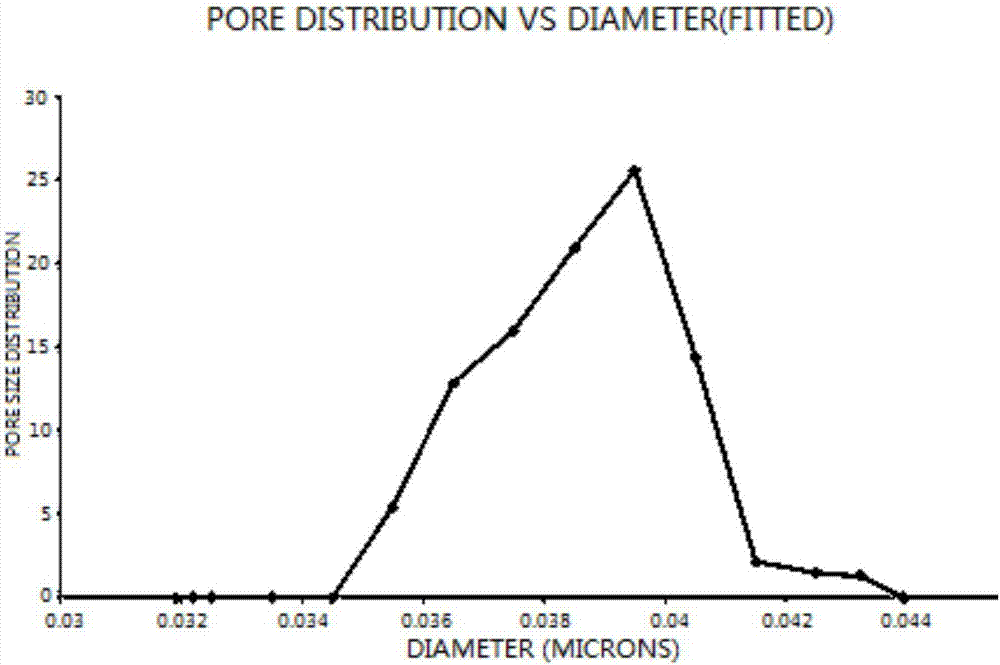

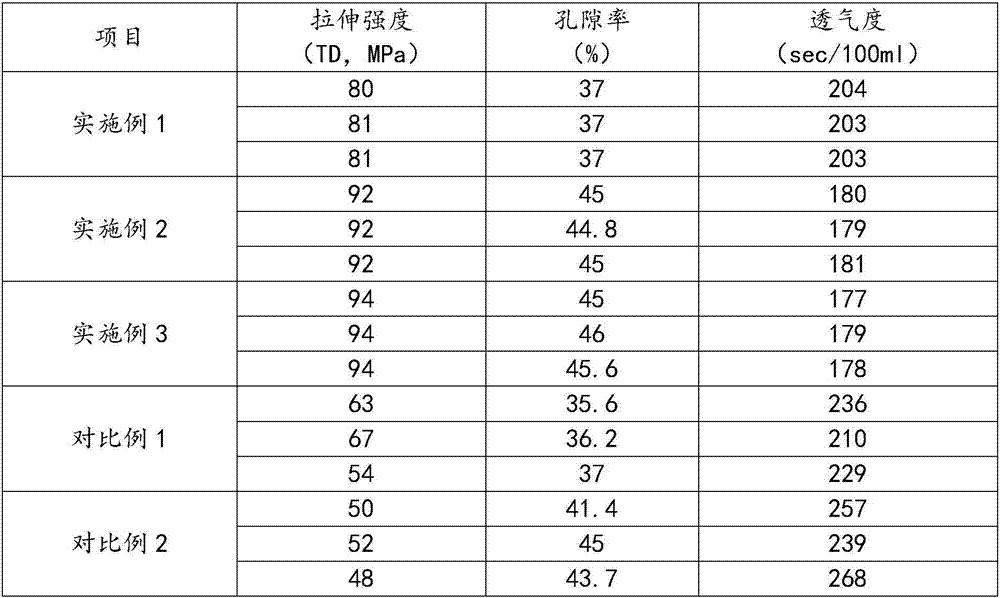

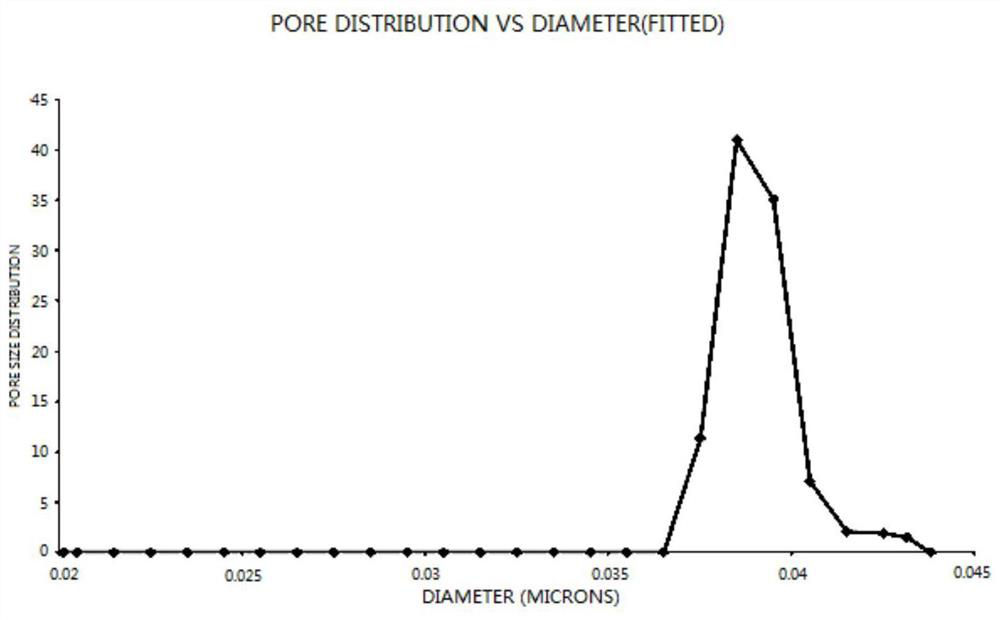

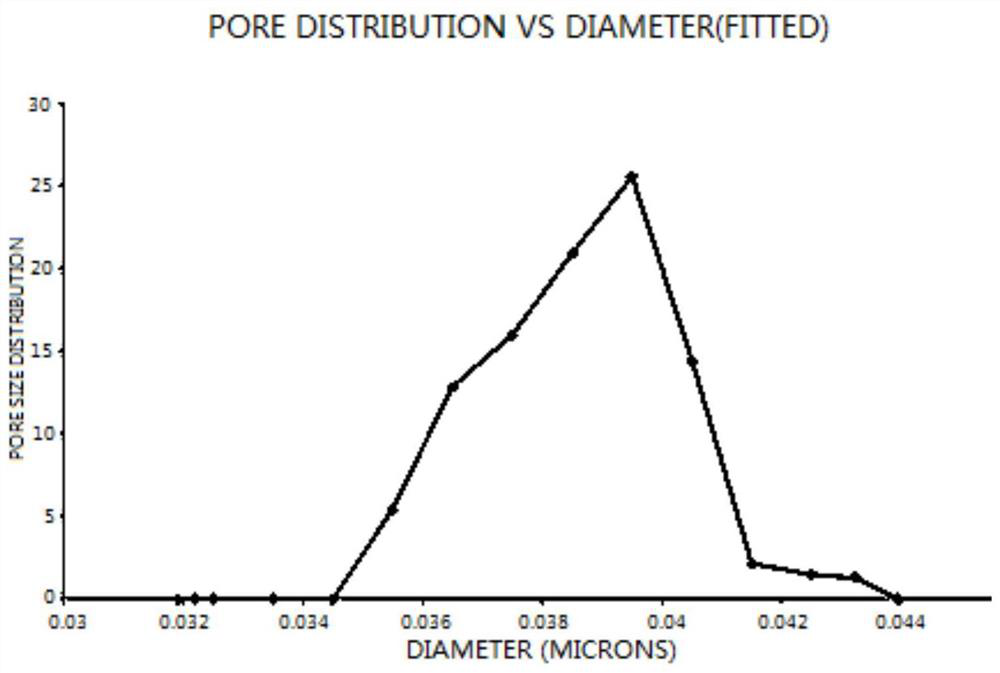

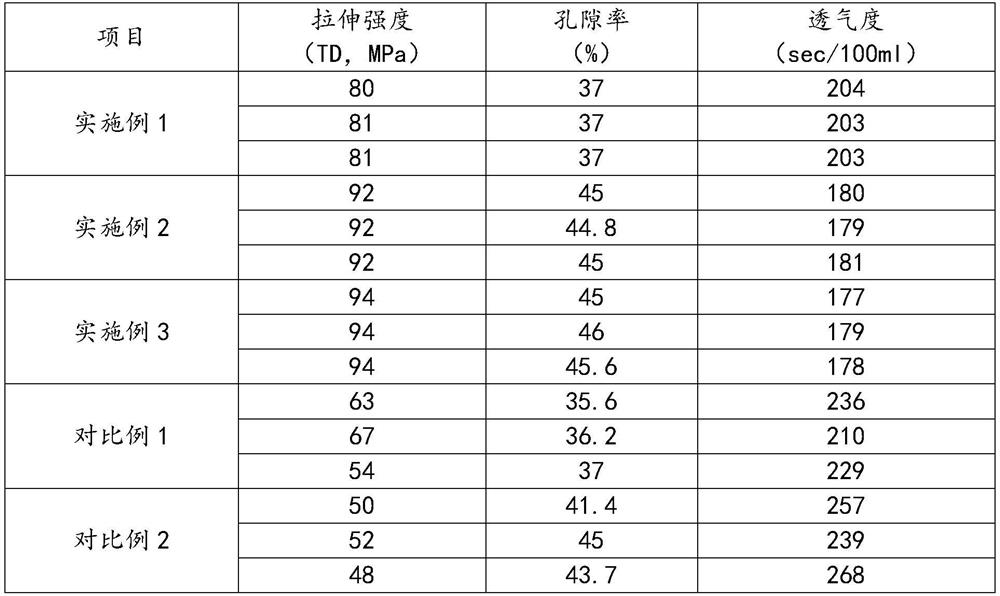

Preparation method for multilayer micro-porous membrane of lithium ion battery

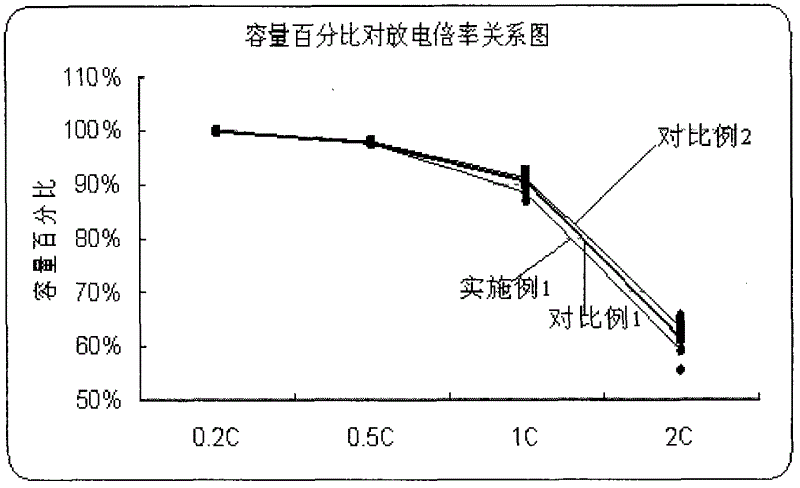

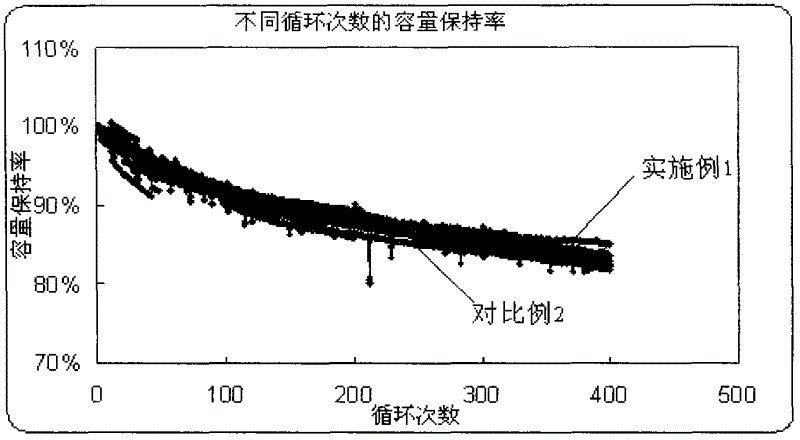

ActiveCN106981608AImprove securityImprove rate discharge performanceSecondary cellsCell component detailsPolyolefinPorous membrane

The invention provides a preparation method for a multilayer micro-porous membrane of a lithium ion battery. The method comprises the following steps: taking polyolefin resin and auxiliary additive as raw materials, fusing and plastifying, thereby acquiring a flux; extruding by a die head and performing tape casting, thereby acquiring intermediate membranes; taking multiple coils of intermediate membranes and compounding by adopting a compounding device with a horizontal stretching function, thereby acquiring a compound intermediate; and performing annealing treatment under an effect of bidirectional micro-tension and longitudinally stretching, thereby acquiring the multilayer micro-porous membrane of the lithium ion battery. According to the invention, a compounding roll is heated in a compounding process of the intermediate membranes, the inner macromolecular structure crystallization of the intermediate membranes is further perfected, and meanwhile, the intermediate membranes horizontally extend under the effect of bidirectional micro-tension and the horizontal orientation degree is increased, so that the micro-pores of the prepared micro-porous membrane are uniform, the horizontal strength is promoted, the capacity of resisting against lithium dendrite puncture is effectively promoted, the micro-short circuit phenomenon is avoided and the micro-porous membrane is suitable for large-scale production. The multilayer micro-porous membrane prepared according to the invention is high in structure uniformity and is effective in promoting the safety of the battery.

Owner:SHENZHEN SENIOR TECH MATERIAL

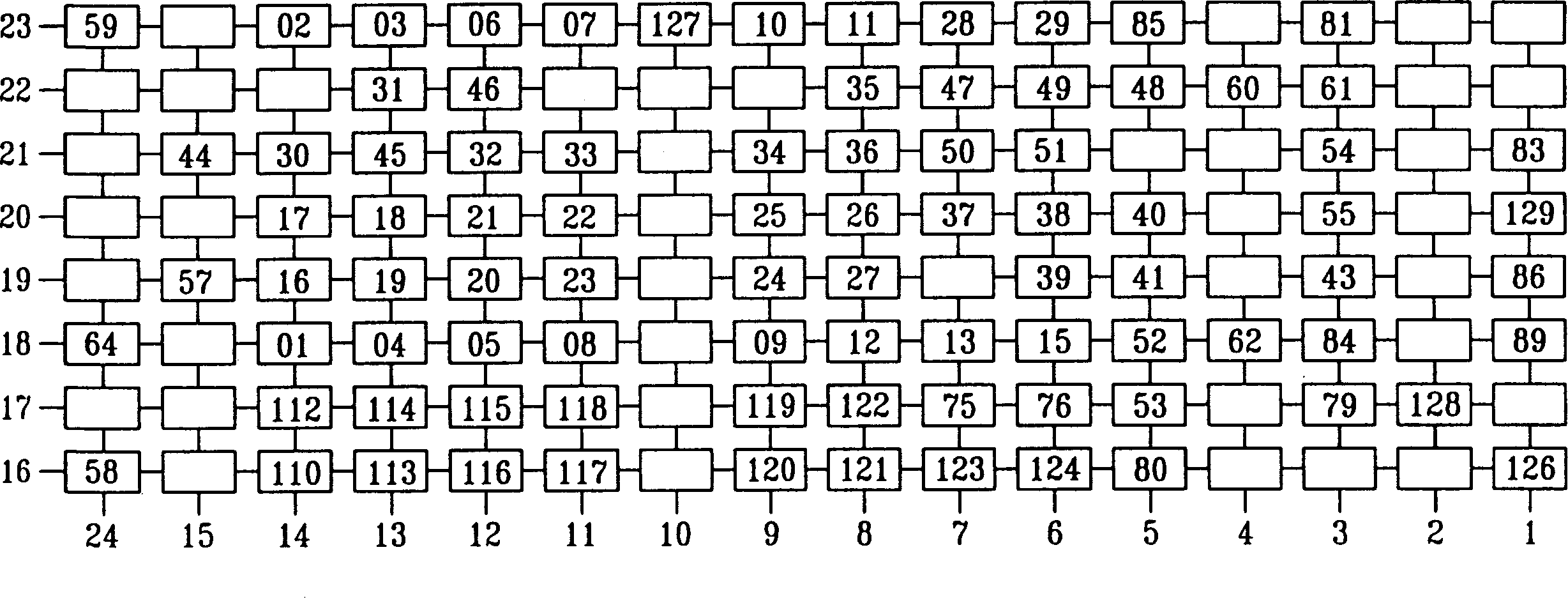

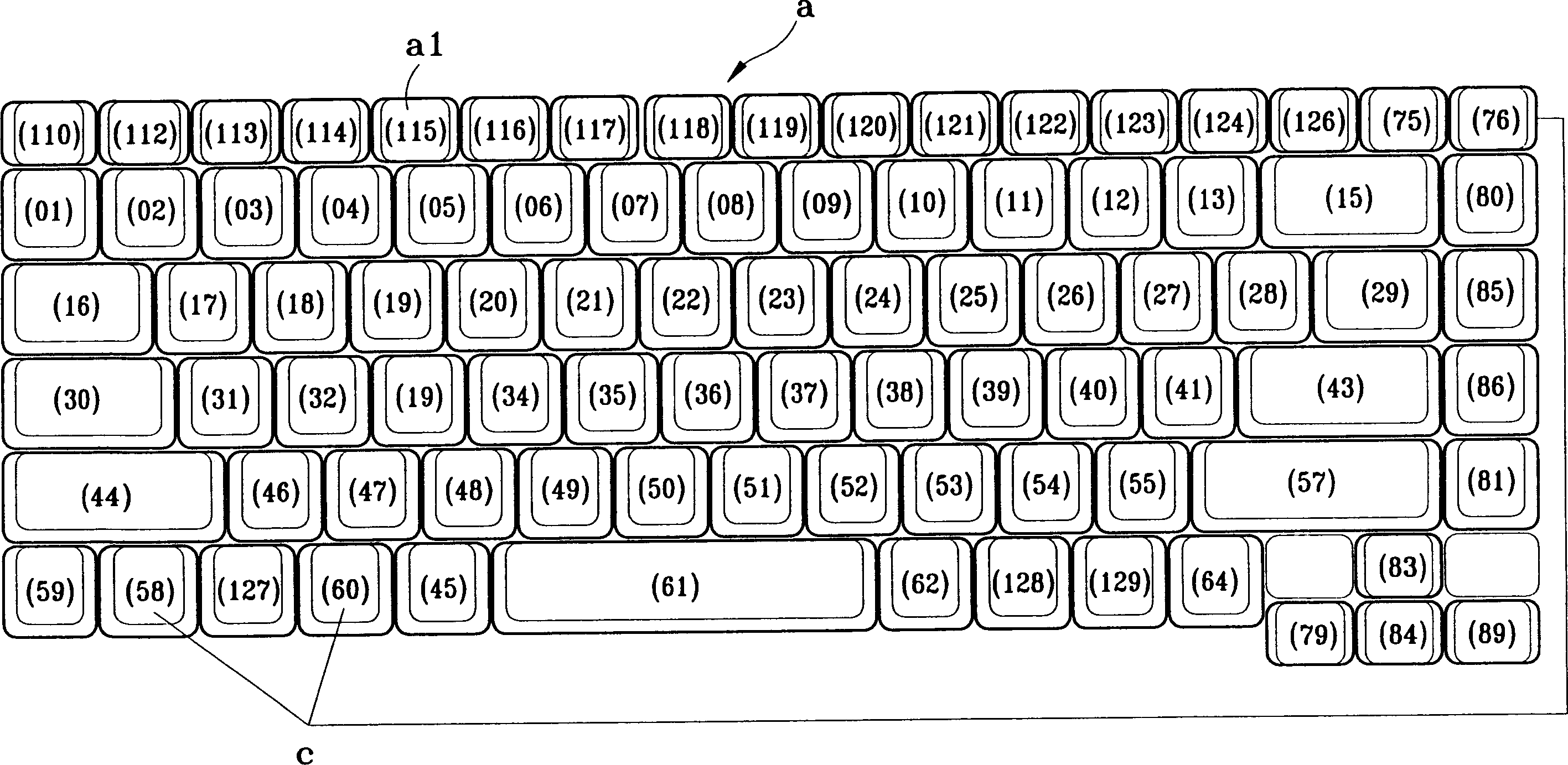

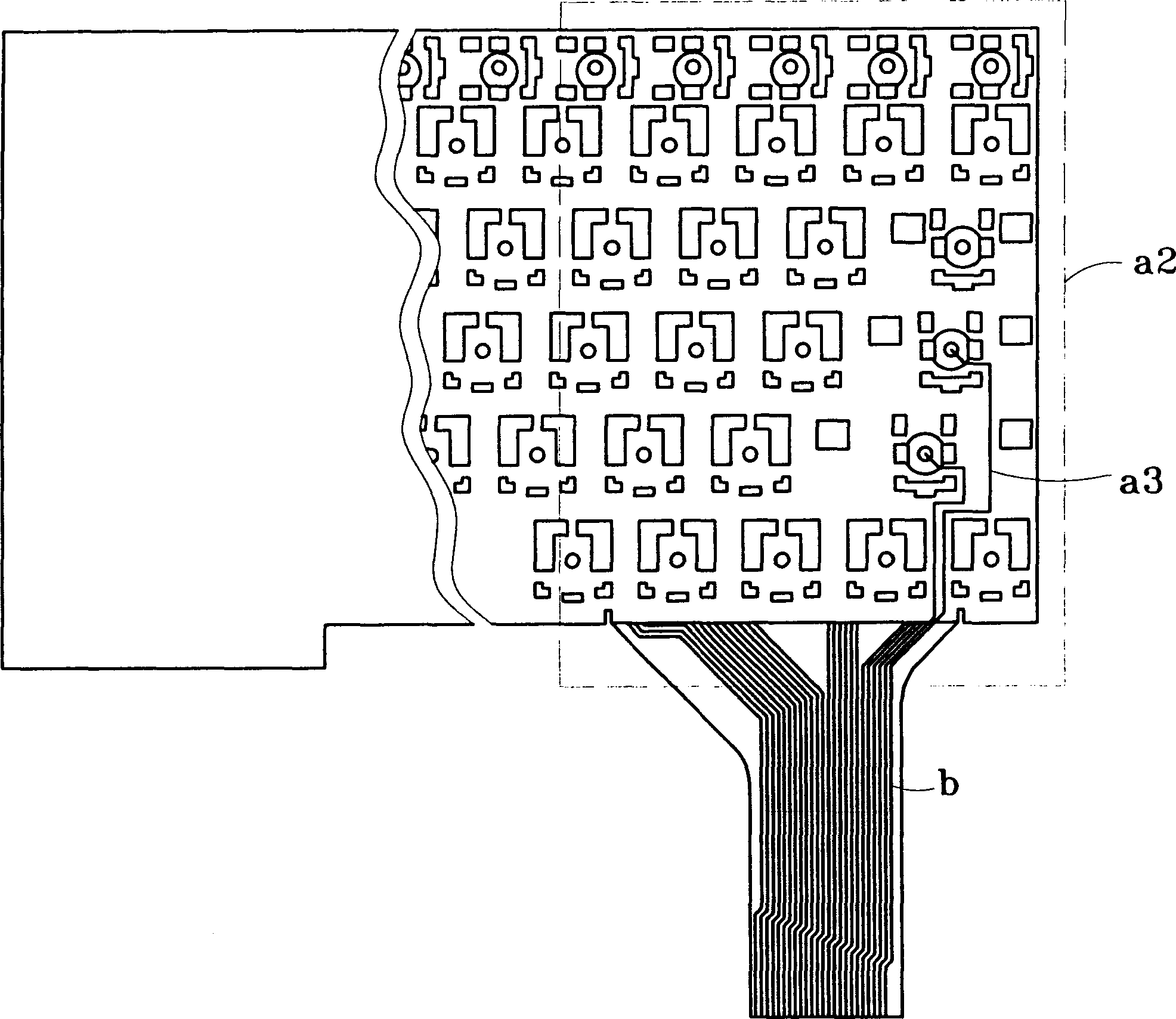

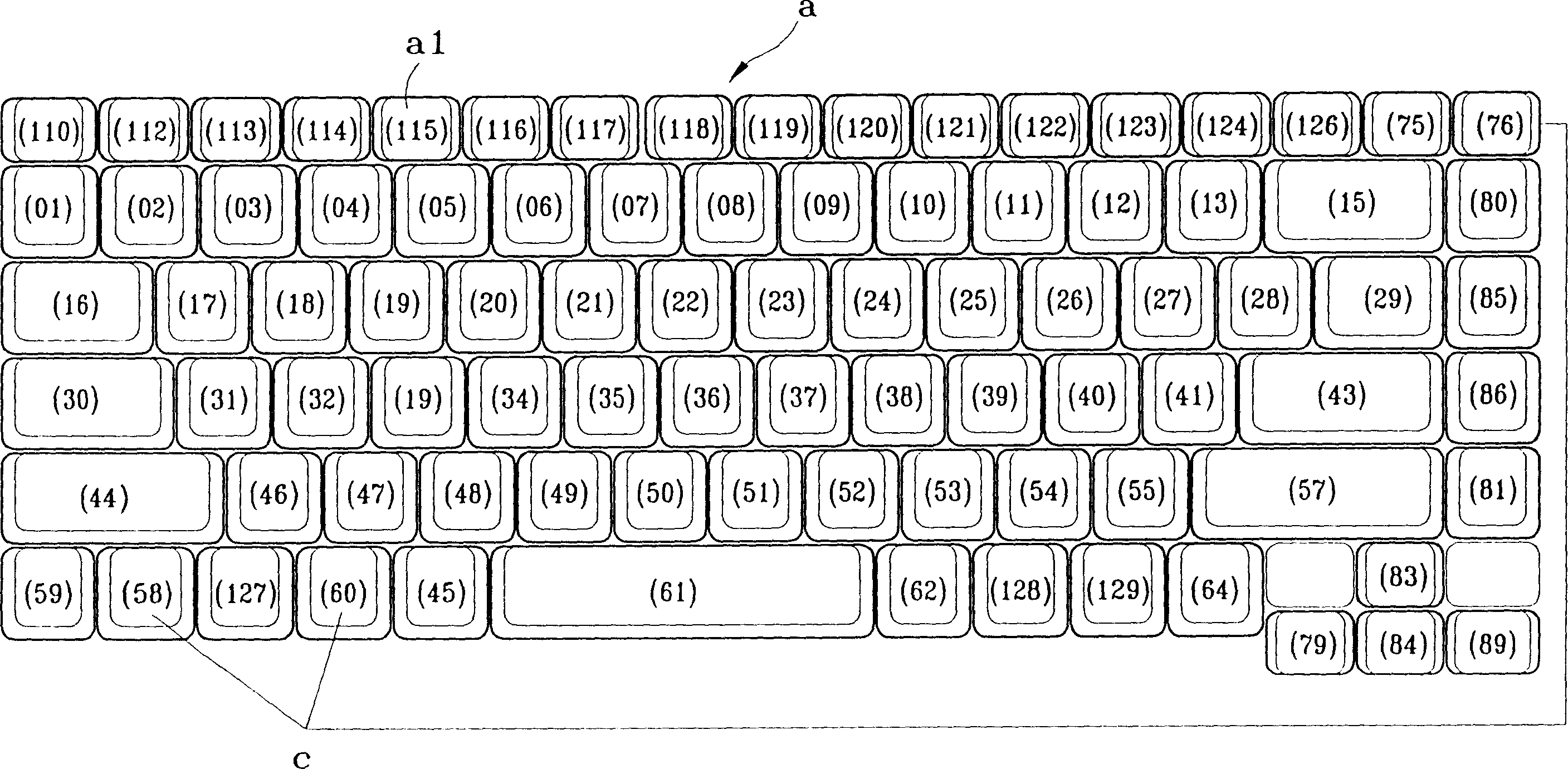

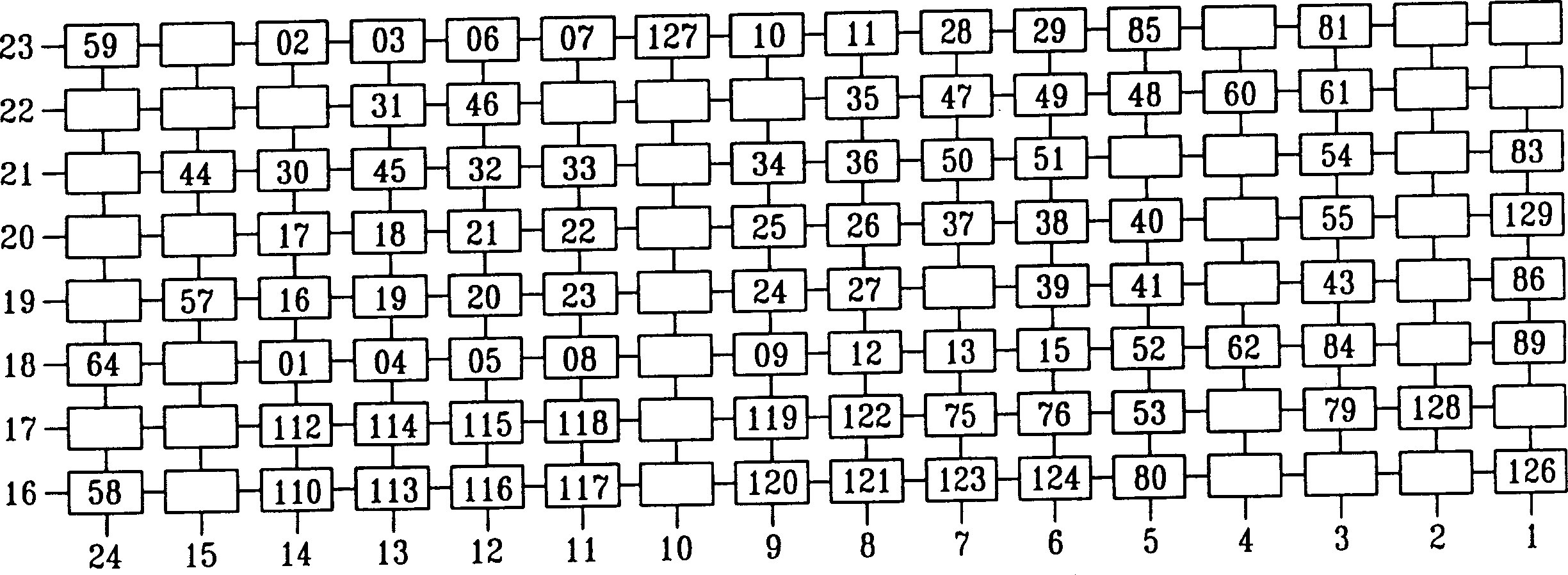

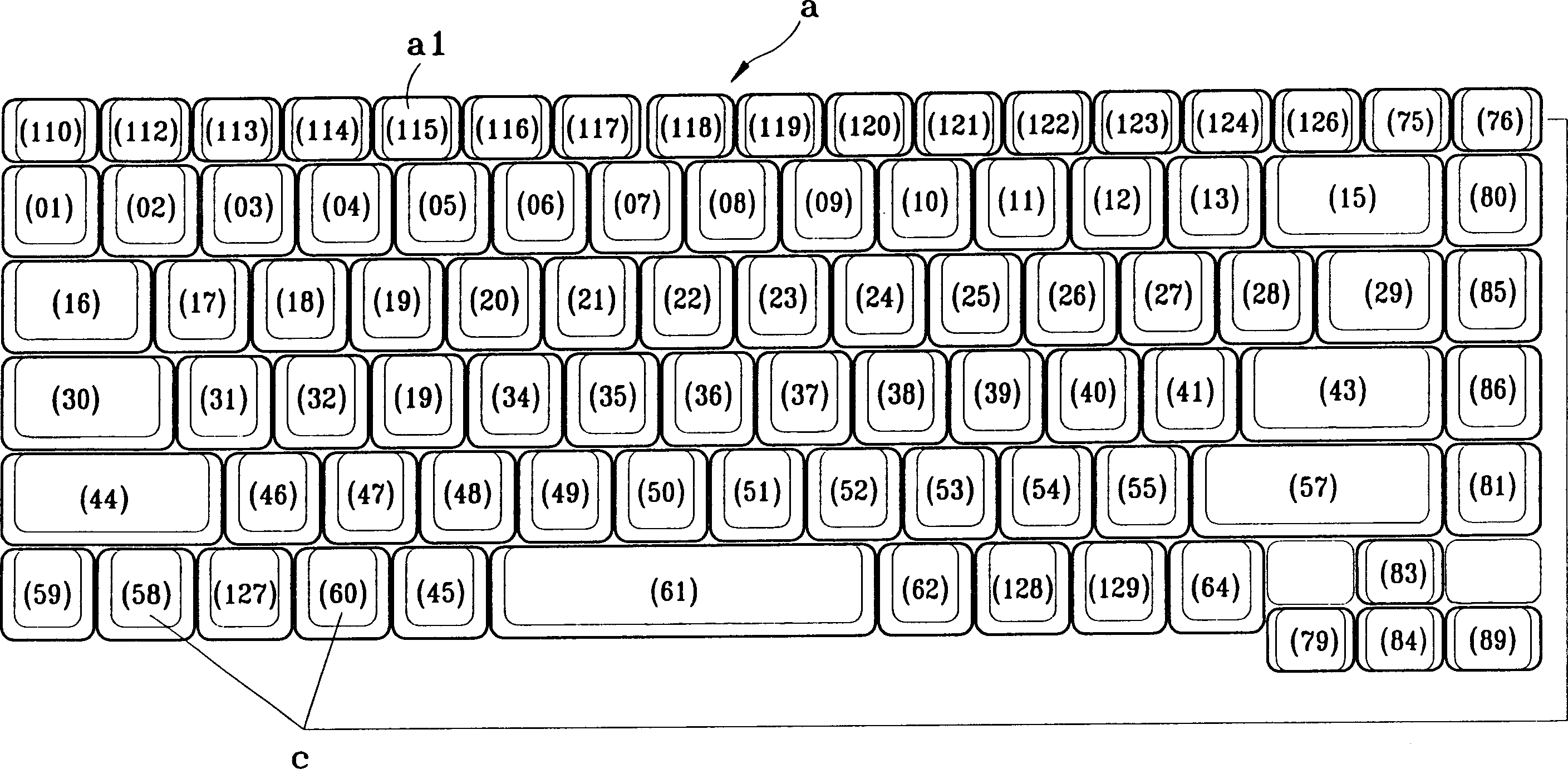

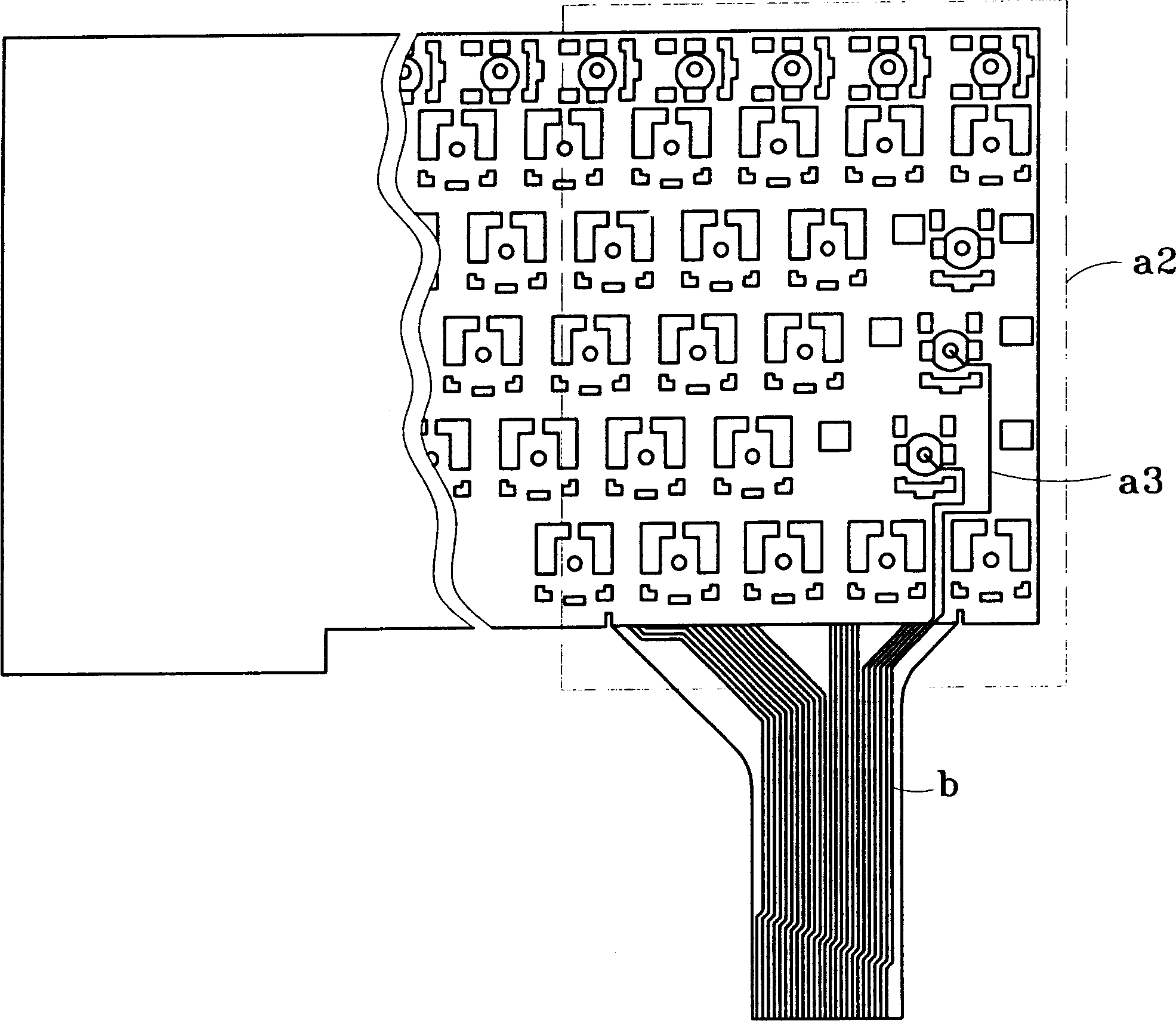

Production method of film circuit plate

InactiveCN1477920AReduce printing processAvoid affecting typingConductive pattern formationCarbon layerSlurry

The present invention relates to a method for making film circuit board. Under the condition of having no wire jumper and preventing production of unknown key signal it adopts the following steps: making key position circuit and matrix arrangement, then when the film circuit board is made, firstly making PET heating preshrinking process of film circuit board, then printing circuit silver slurry on the film circuit board, then printing insulating layer or printing carbon layer on the printed circuit silver slurry, folding the film circuit board and making ultrasonic combination, punching structure holes on the film circuit board so as to obtain the product.

Owner:ZIPPY TECH

Container formation method for lead-acid storage battery for electric road vehicle

PendingCN110797599AAvoid excessive heatFormation time is shortFinal product manufactureSecondary cells charging/dischargingAutomotive engineeringCharge and discharge

The invention discloses a container formation method for a lead-acid storage battery for an electric road vehicle. 27 charging and discharging stages are divided. The period comprises eight times of discharging, one time of standing and one time of capacity checking and matching, the maximum charging current is 0.30 C3 to 0.35 C3, and the minimum charging current is 0.05 C3 to 0.1 C3. The lead-acid storage battery is charged and discharged for multiple times, and the electric quantity charged each time is greater than the electric quantity discharged subsequently. The method provided by the invention can effectively reduce the concentration polarization phenomenon and reduce the damage to the crystal structure of the active substance on the polar plate, thereby prolonging the cyclic service life of the lead-acid storage battery. Calculated according to GB / T32620.1-2016 regulations, the cycle life of the lead-acid storage battery prepared by the method is longer than 400 times, and theinitial capacity of the lead-acid storage battery is not lower than 100% (in terms of rated capacity).

Owner:江西京九电源(九江)有限公司

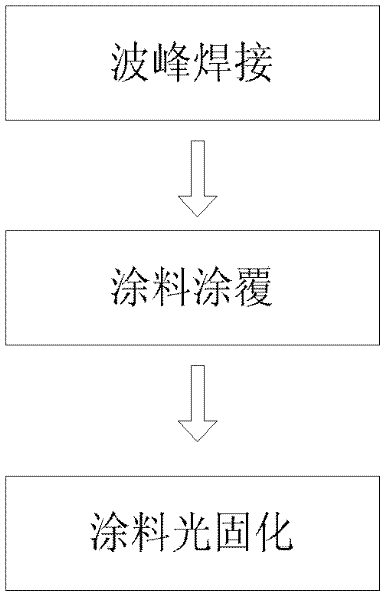

Paper base printing circuit board with protective layer and preparation method thereof

InactiveCN102595771AAvoid micro-short circuitEliminate micro-short circuit phenomenonPrinted circuit detailsCoatingsEngineeringOligomer

The invention provides a paper base printing circuit board with a protective layer and a preparation method thereof. The paper base printing circuit board with the protective layer comprises a paper base printing circuit board with electronic components and a protective layer. The protective layer is a conformal paint which mainly comprises organic silicone acrylate oligomer and low-viscosity monoacrylate oligomer. The paper base printing circuit board with the protective layer is prepared by wave soldering, painting coating and paint photocuring. The paper base printing circuit board with the protective layer provided by the invention can effectively solve the problem of micro short circuit caused by flux residue; the preparation method is simple, and quality of products is reliable.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

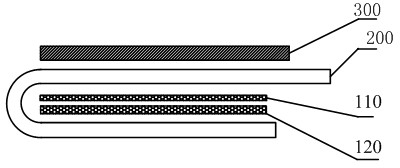

Electrode and manufacture method thereof

InactiveCN102088083AReduce thicknessGood flexibilityElectrode carriers/collectorsAlkaline accumulator electrodesInternal resistanceElectrical battery

The invention discloses an electrode and a manufacture method thereof. The electrode comprises at least two parallel electrode plates, and each electrode plate has a pore structure in which an electrode active substance is filled. The electrode has the advantages that the flexibility of the electrode plate is greatly improved; thus, in the coiling process, the electrode plate has small possibility of cracking or breaking so as to avoid low battery capability; and meanwhile, micro short circuit because of power falloff has small possibility of formation, the battery short circuit caused by that burrs pierce the membrane has small possibility of formation, and large internal resistance fluctuation of the battery can be avoided.

Owner:SHENZHEN EPT BATTERY

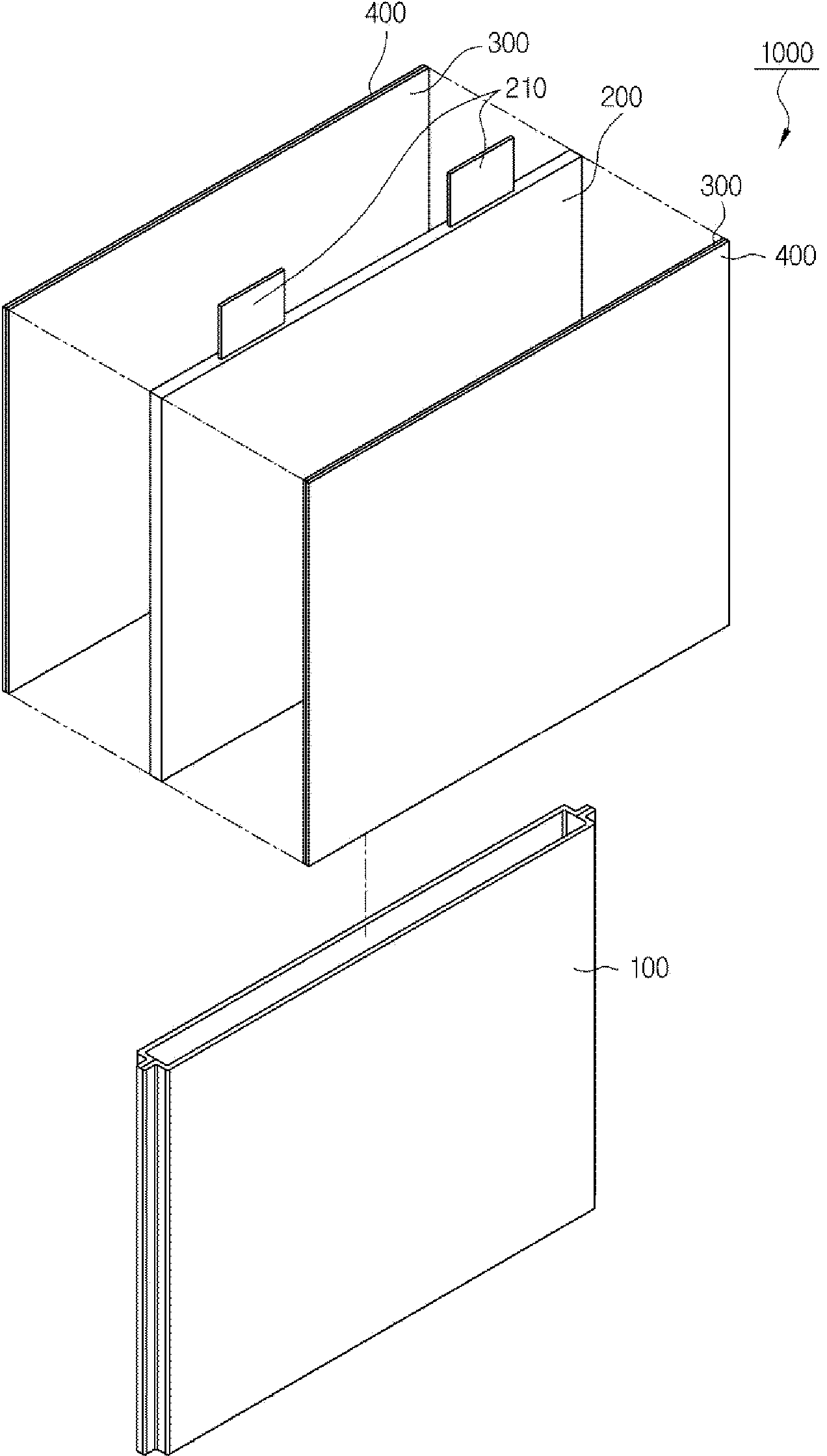

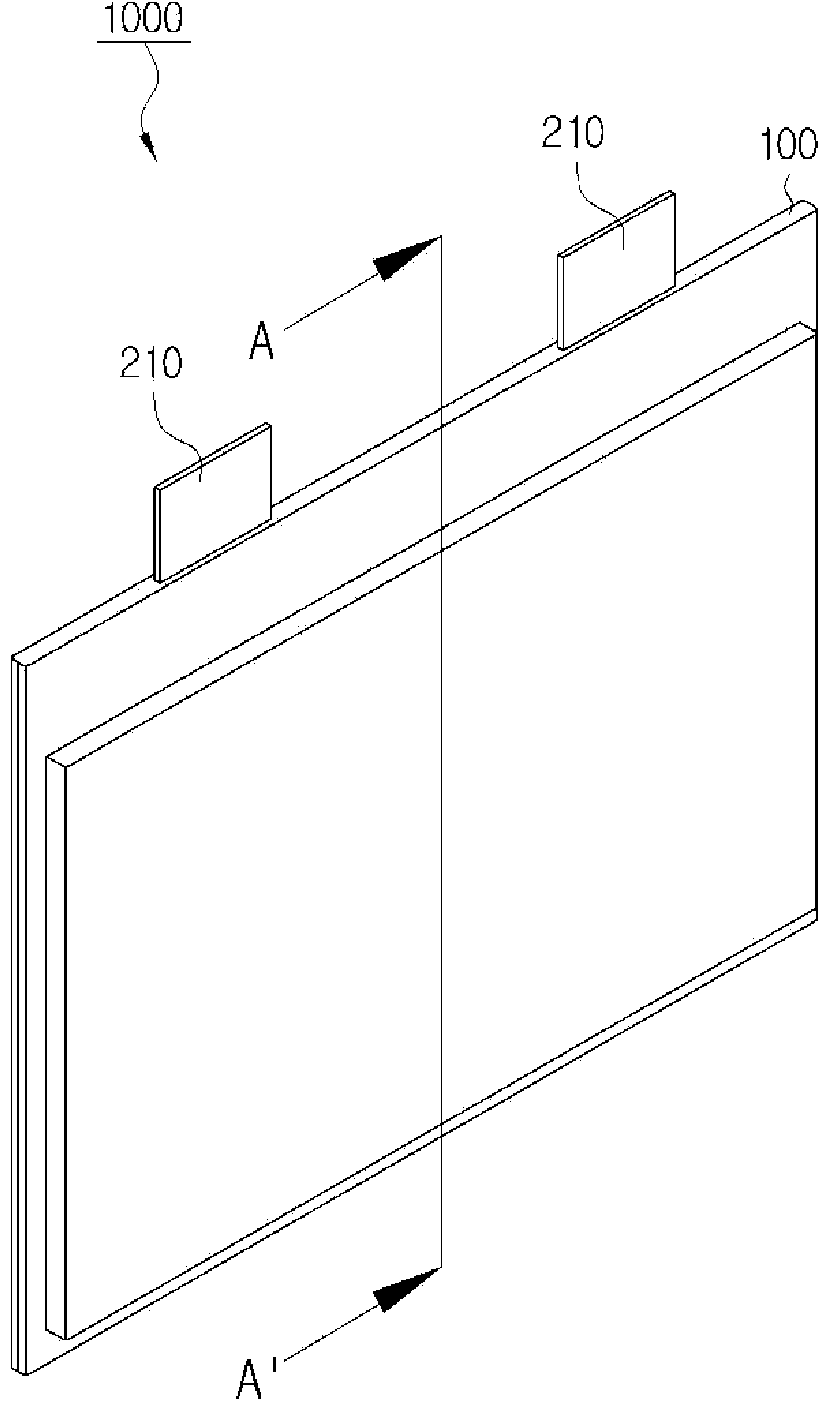

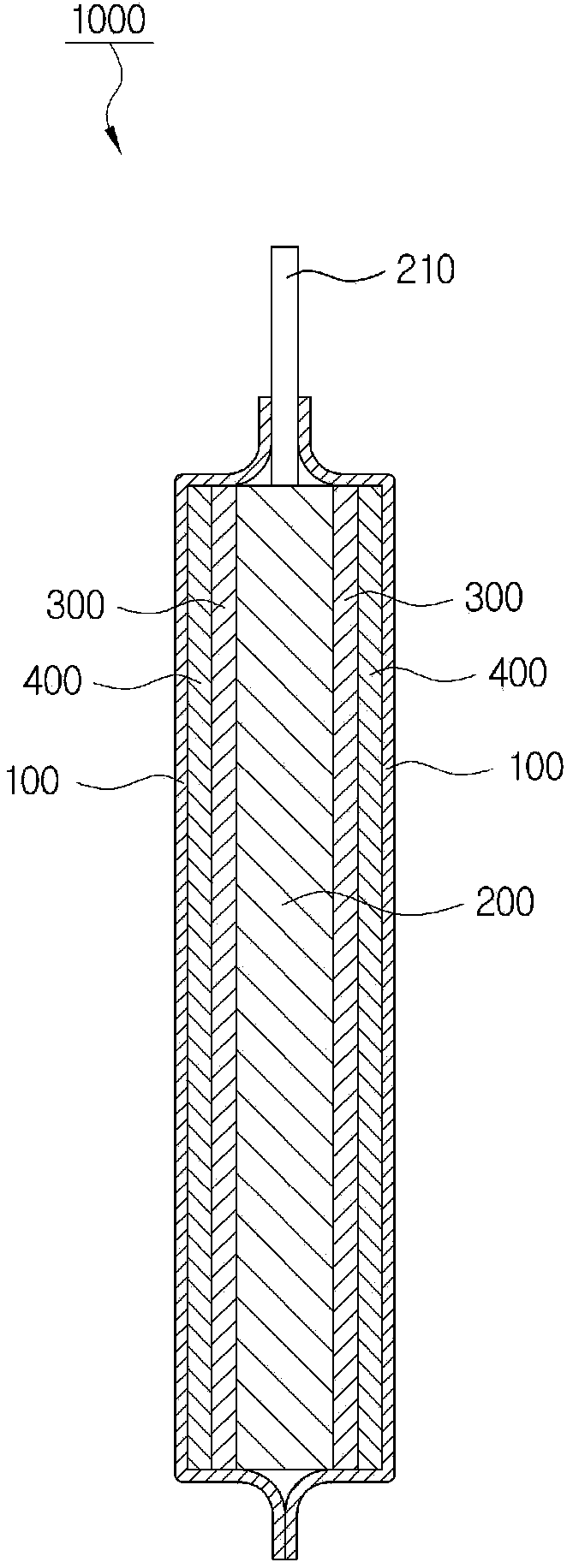

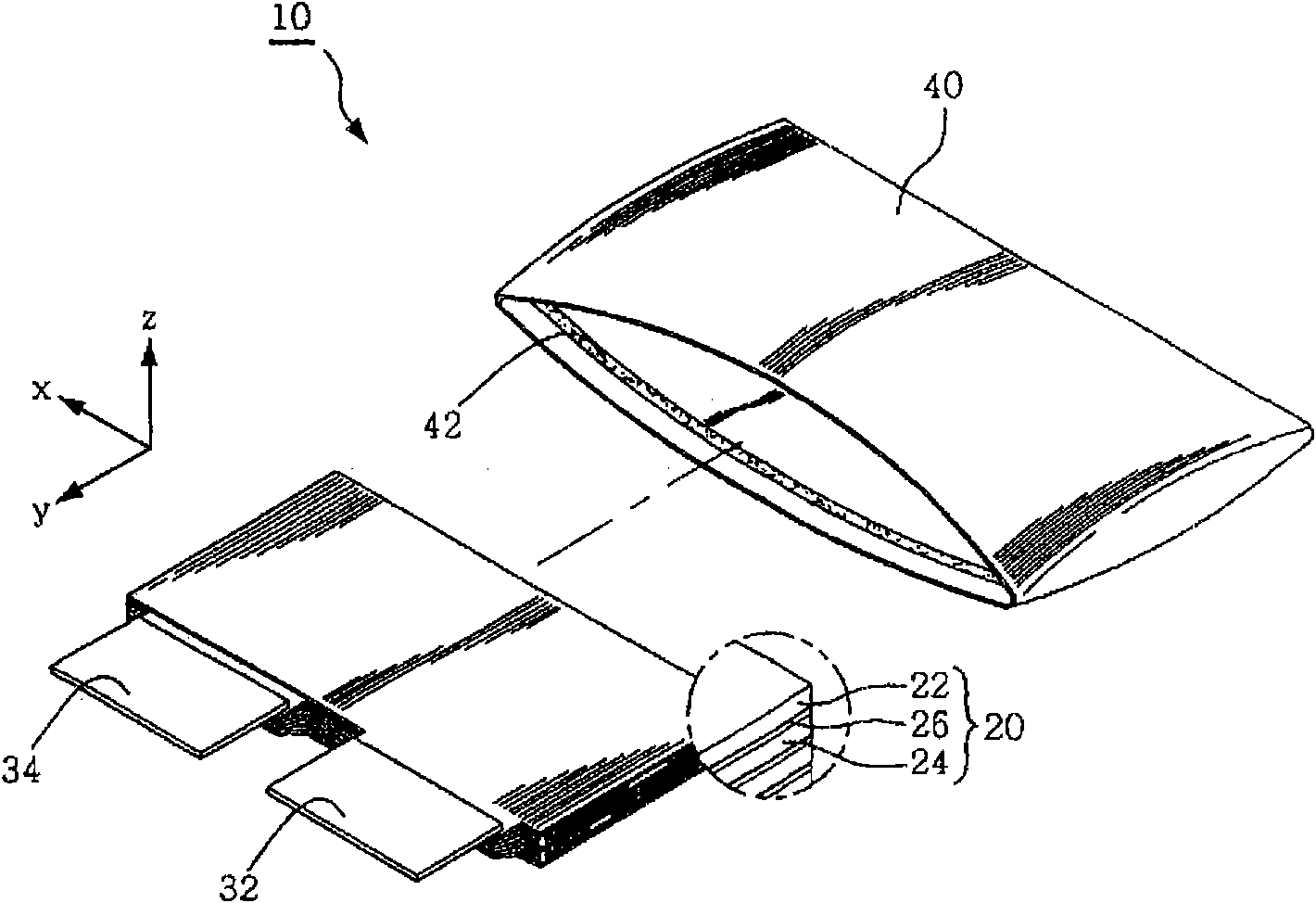

Secondary Battery and Secondary Battery Pack Having the Same

ActiveCN104241591AReduce performanceImprove interface resistanceFinal product manufactureSmall-sized cells cases/jacketsEngineeringUltimate tensile strength

Provided are a secondary battery and a secondary battery pack having the same capable of preventing performance degradation by preventing an increase in an interface resistance of an electrode body accommodated in a pouch and capable of improving stability by preventing deformation of the electrode body to thereby prevent a fine short circuit even though the pouch is swelled due to a gas generate at a high temperature, by providing first members for reinforcing rigidity and second members deformed at the high temperature and capable of adhering the electrode body to one side or both sides of the electrode body accommodated and sealed in the pouch.

Owner:SK ON CO LTD

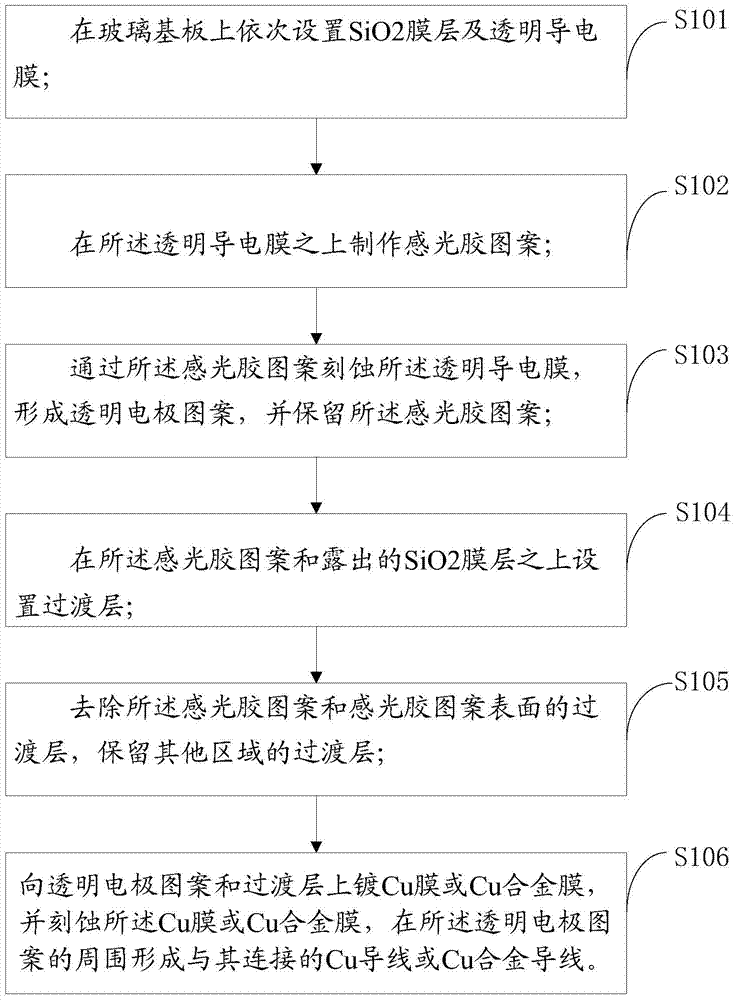

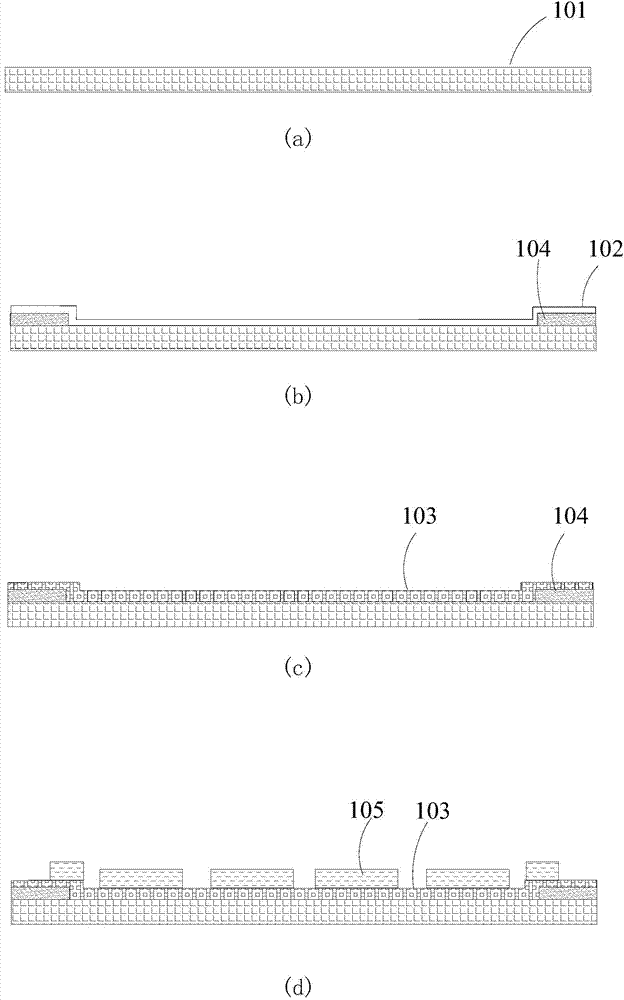

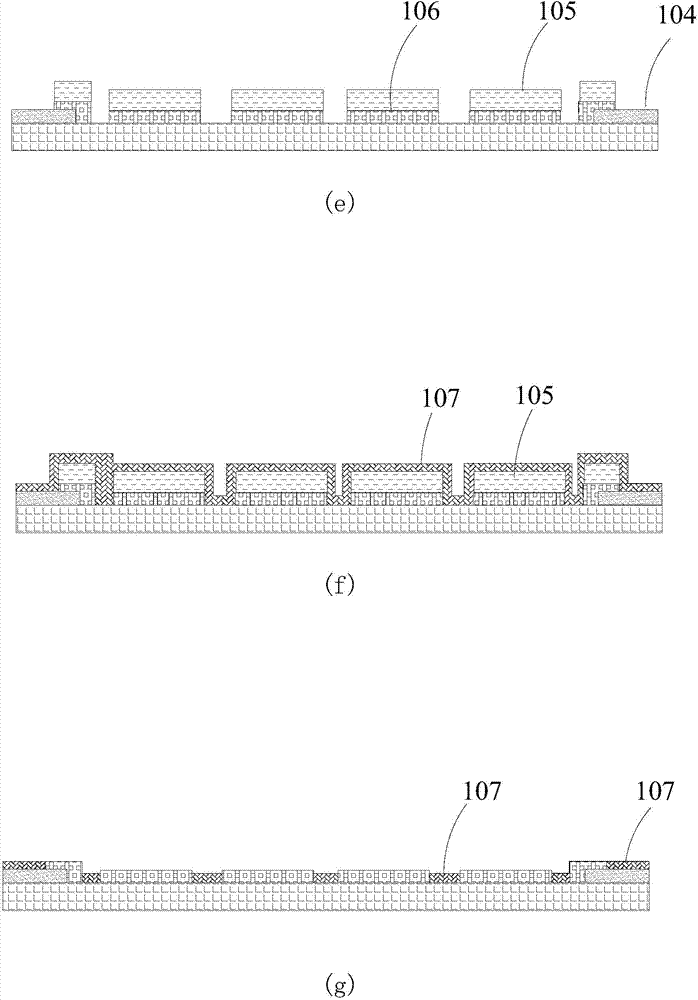

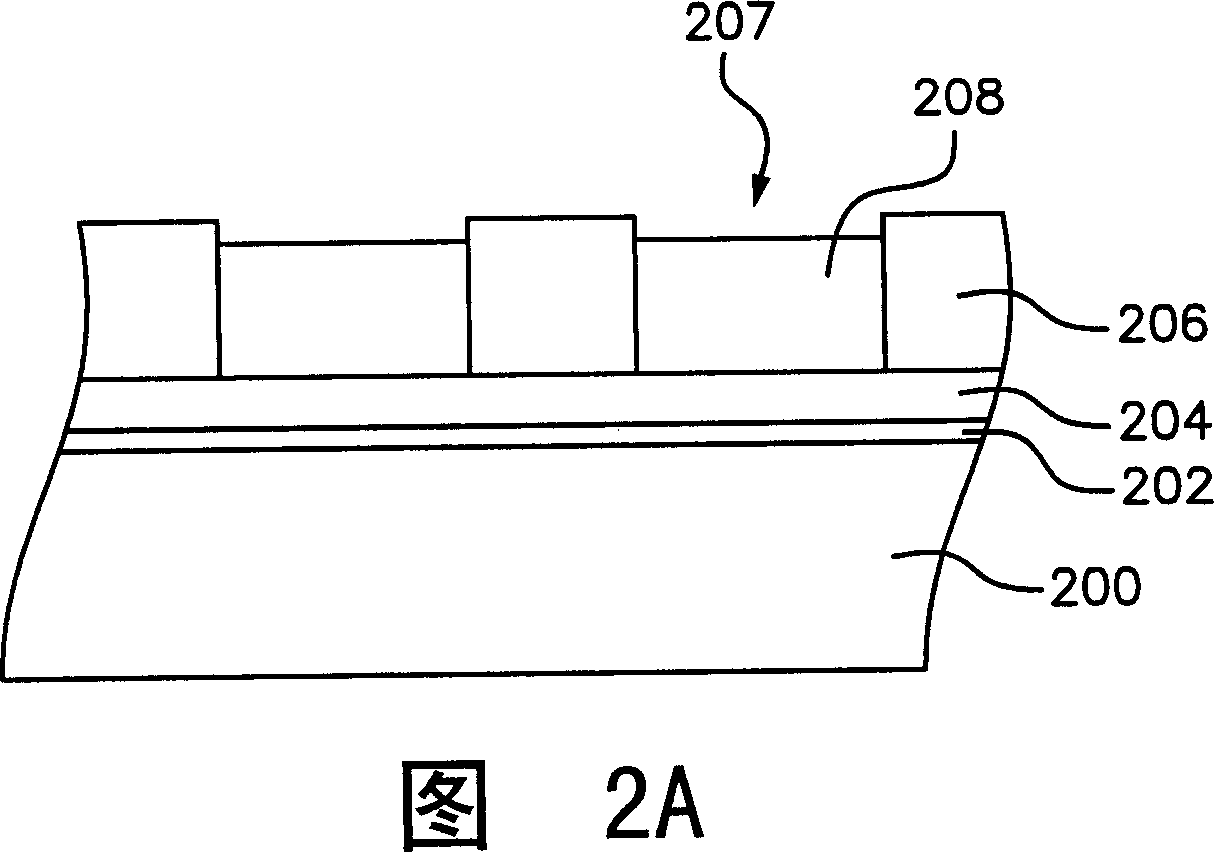

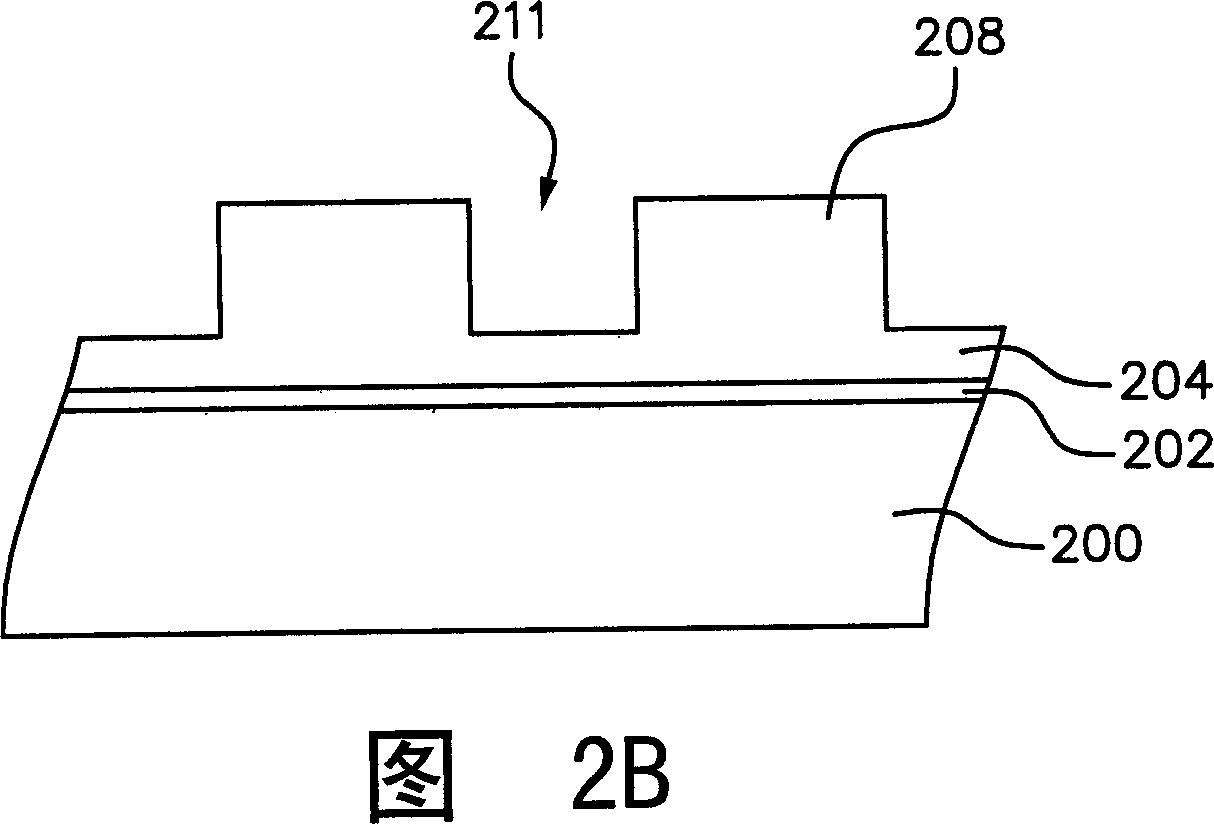

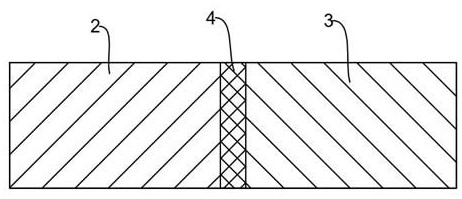

Capacitive touch panel and manufacturing method

PendingCN104503644AAvoid micro-short circuitLow costInput/output processes for data processingElectrically conductiveTouch panel

The invention applies to the technical field of touch, and provides a manufacturing method of a capacitive touch panel. The manufacturing method of the capacitive touch panel comprises the steps of sequentially arranging an SiO2 film layer and a transparent conductive film on a glass base plate; manufacturing a light sensitive glue pattern on the transparent conductive film; etching the transparent conductive film through the light sensitive glue pattern to form a transparent electrode, wherein the light sensitive glue pattern is remained; arranging a transition layer on the light sensitive glue pattern and the SiO2 film layer; removing the light sensitive glue pattern and the transition layer on the surface, and remaining the transition layer on the SiO2 film layer; coating a Cu film or a Cu alloy film on the transparent electrode pattern and the transition layer; etching the Cu film or the Cu alloy film; forming a Cu conductor around the transparent electrode pattern. The manufacturing method has the advantages that the Cu conductor and the SiO2 film layer are insulated through the transition layer, so that Cu elements are prevented from being dispersed to the SiO2 film layer, and as a result, micro short circuit of the transparent electrode can be prevented, the problem that the Cu material cannot be applied to the glass base plate can be overcome, the cost can be decreased, and the productivity and yield are improved.

Owner:SHENZHEN LEAGUER OPTRONICS

Production of flexible circuit board

InactiveCN1942056ASolve the insufficient top widthAvoid micro-short circuitConductive material chemical/electrolytical removalMetallic pattern materialsCopperMetal

The method comprises: providing a flexible baseplate made by sequentially stacking a polyamide baseplate, an alloy layer and a first copper layer; making first photo etching, and patterning the first copper layer and the alloy layer in order to form multi first conducting wire structures on the polyamide baseboard; forming second copper layer on the polyamide baseplate and the first conducting wire structures; finally, making the second photo etching to remove the second copper layer on the polyamide baseplate.

Owner:HIMAX TECH LTD

High-performance long-service life silicon-silver cell positive and negative plates and preparation method thereof

InactiveCN102468482AImprove corrosion resistanceImprove adhesionElectrode carriers/collectorsLead-acid accumulator electrodesAlloySilicon

The invention discloses high-performance long-service life silicon-silver cell positive and negative plates and a preparation method thereof. The high-performance long-service life silicon-silver cell positive and negative plates comprise positive and negative grid plates, and are characterized in that a raw material of the positive and negative grid plates is a Pb-Ag-Ca-Ce alloy. The high-performance long-service life silicon-silver cell positive and negative plates have the advantages that the single sheet capacity of the high-performance long-service life silicon-silver cell positive and negative plates is 1.38 times that of the existing common products having surfaces same as surfaces of the high-performance long-service life silicon-silver cell positive and negative plates; a cell weight-capacity ratio is greatly improved; and the high-performance long-service life silicon-silver cell positive and negative plates provide a power energy storage guarantee and an early solution scheme for electric automobile development.

Owner:陈清利 +2

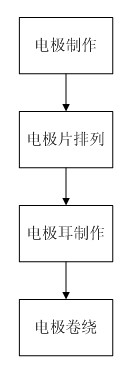

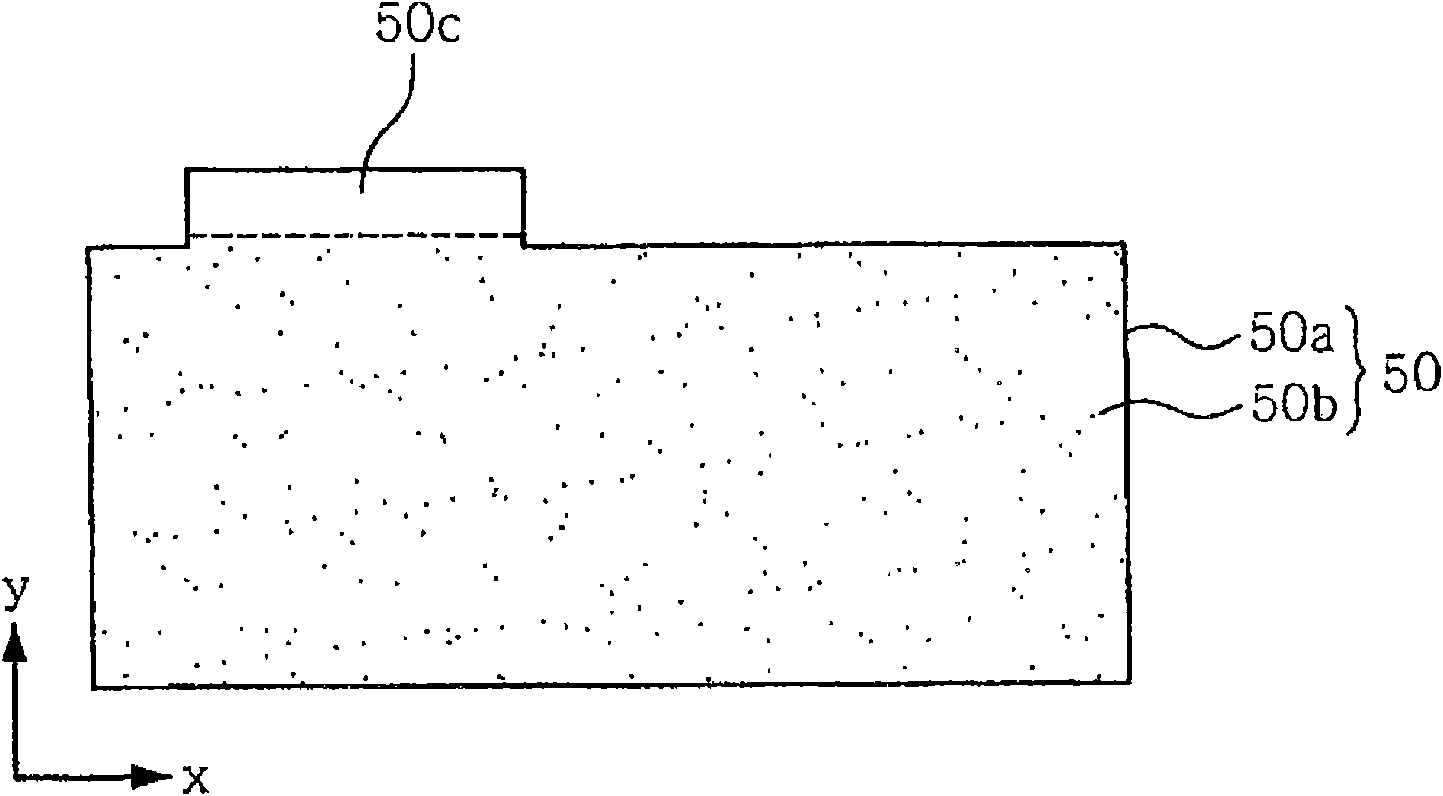

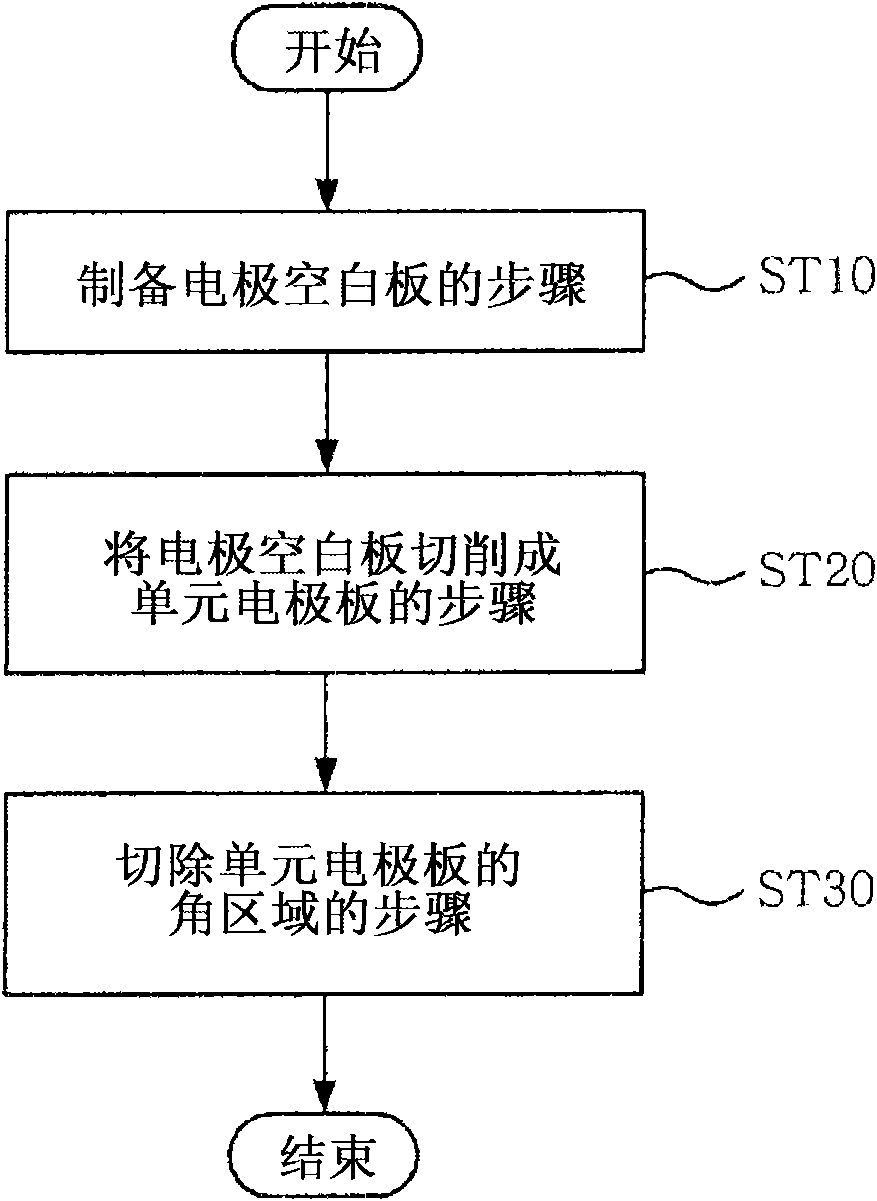

Manufacturing method of electrode for battery

ActiveCN101569032AImprove reliabilityReduce manufacturing costElectrode manufacturing processesFinal product manufactureCost savingsBiomedical engineering

This invention relates to a method of manufacturing an electrode for a secondary battery, which enables cost savings and the manufacture of products having various sizes and shapes. The method includes (A) preparing an electrode plate, (B) cutting the electrode plate to conform to the width of the electrode, thus providing a unit electrode plate, and (C) removing at least one of the corner regionsof the unit electrode plate.

Owner:SK ON CO LTD

Production method of film circuit plate

InactiveCN1247056CReduce printing processAvoid affecting typingConductive pattern formationCarbon layerEngineering

The present invention relates to a method for making film circuit board. Under the condition of having no wire jumper and preventing production of unknown key signal it adopts the following steps: making key position circuit and matrix arrangement, then when the film circuit board is made, firstly making PET heating preshrinking process of film circuit board, then printing circuit silver slurry on the film circuit board, then printing insulating layer or printing carbon layer on the printed circuit silver slurry, folding the film circuit board and making ultrasonic combination, punching structure holes on the film circuit board so as to obtain the product.

Owner:ZIPPY TECH

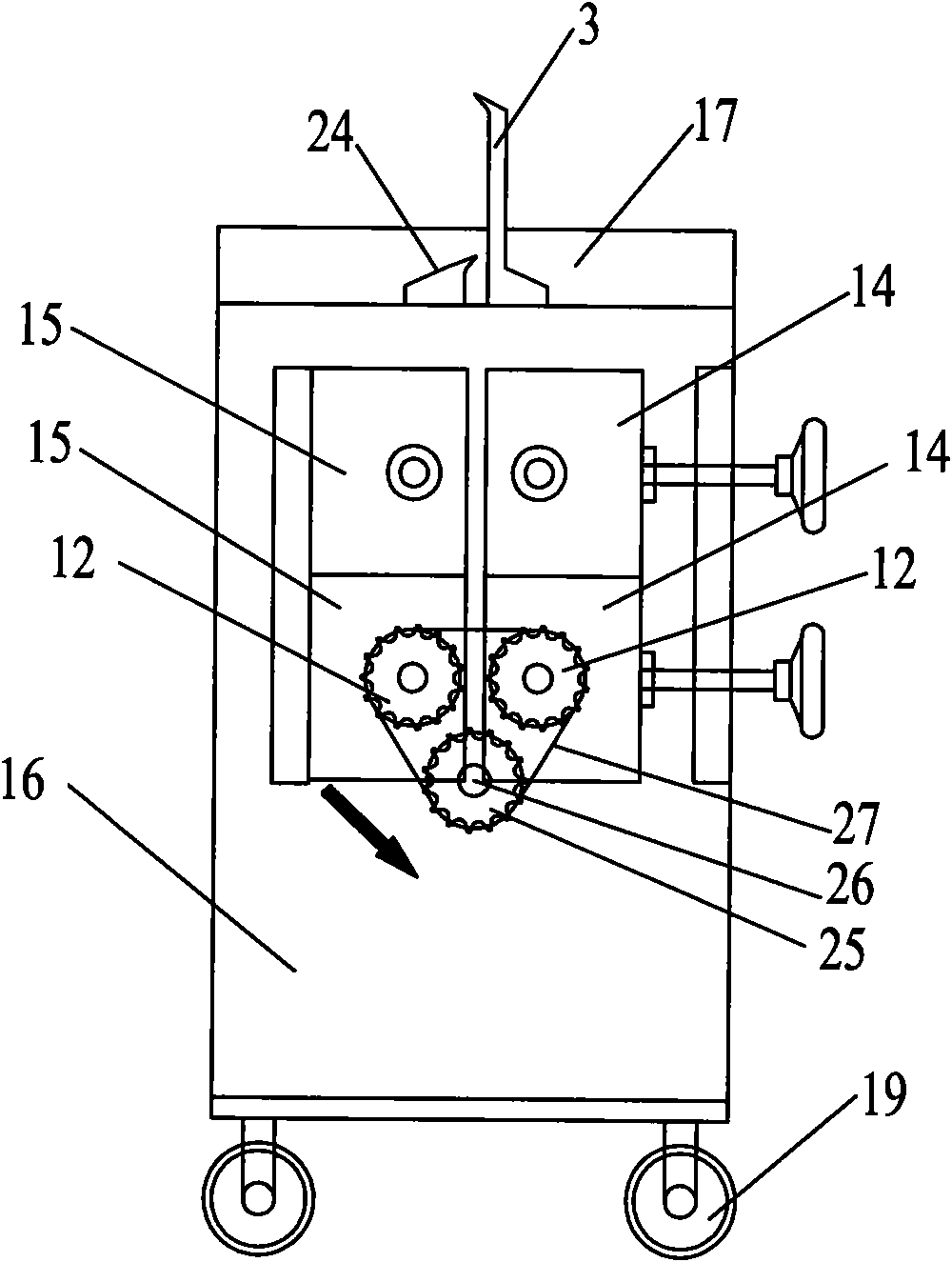

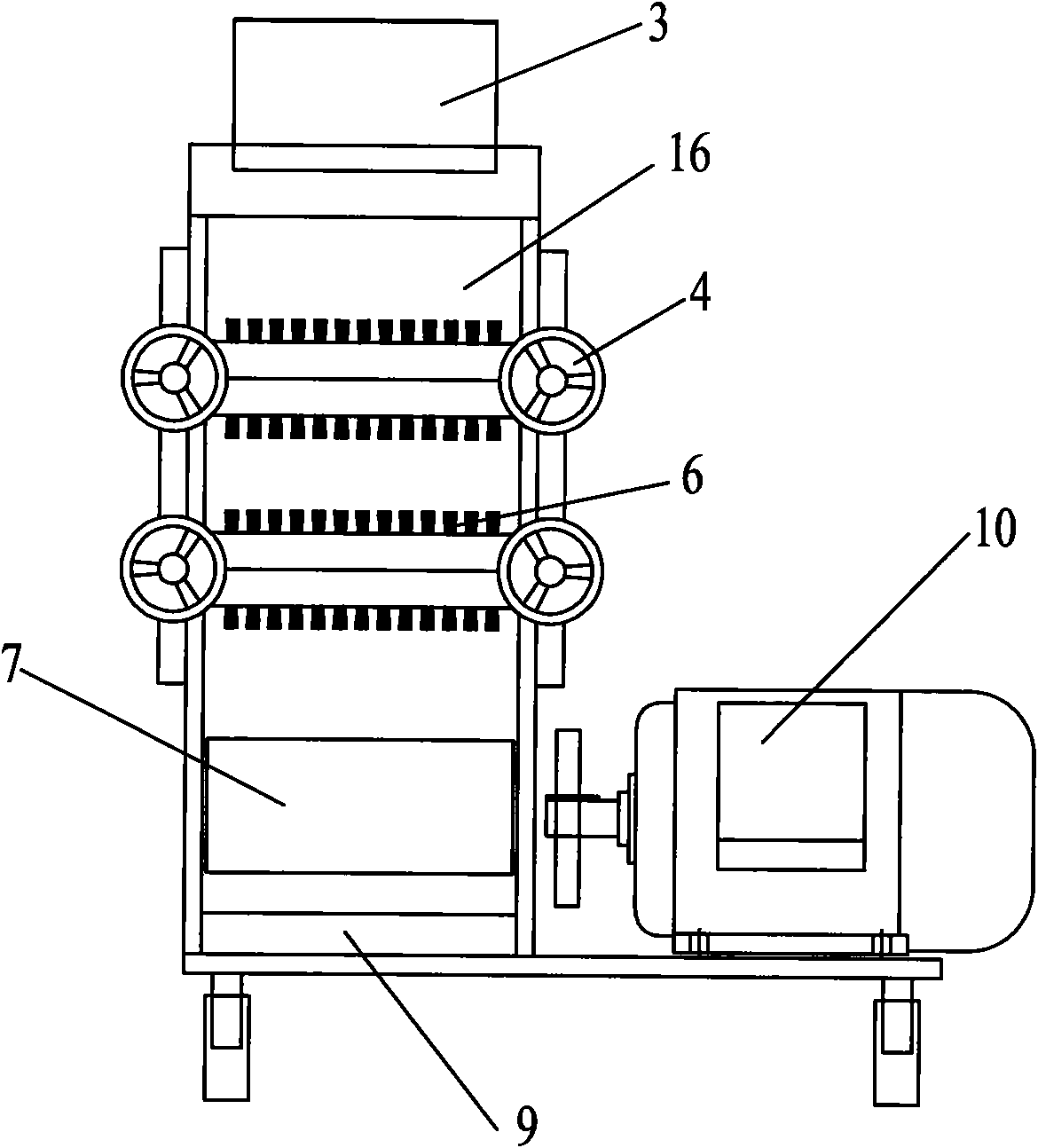

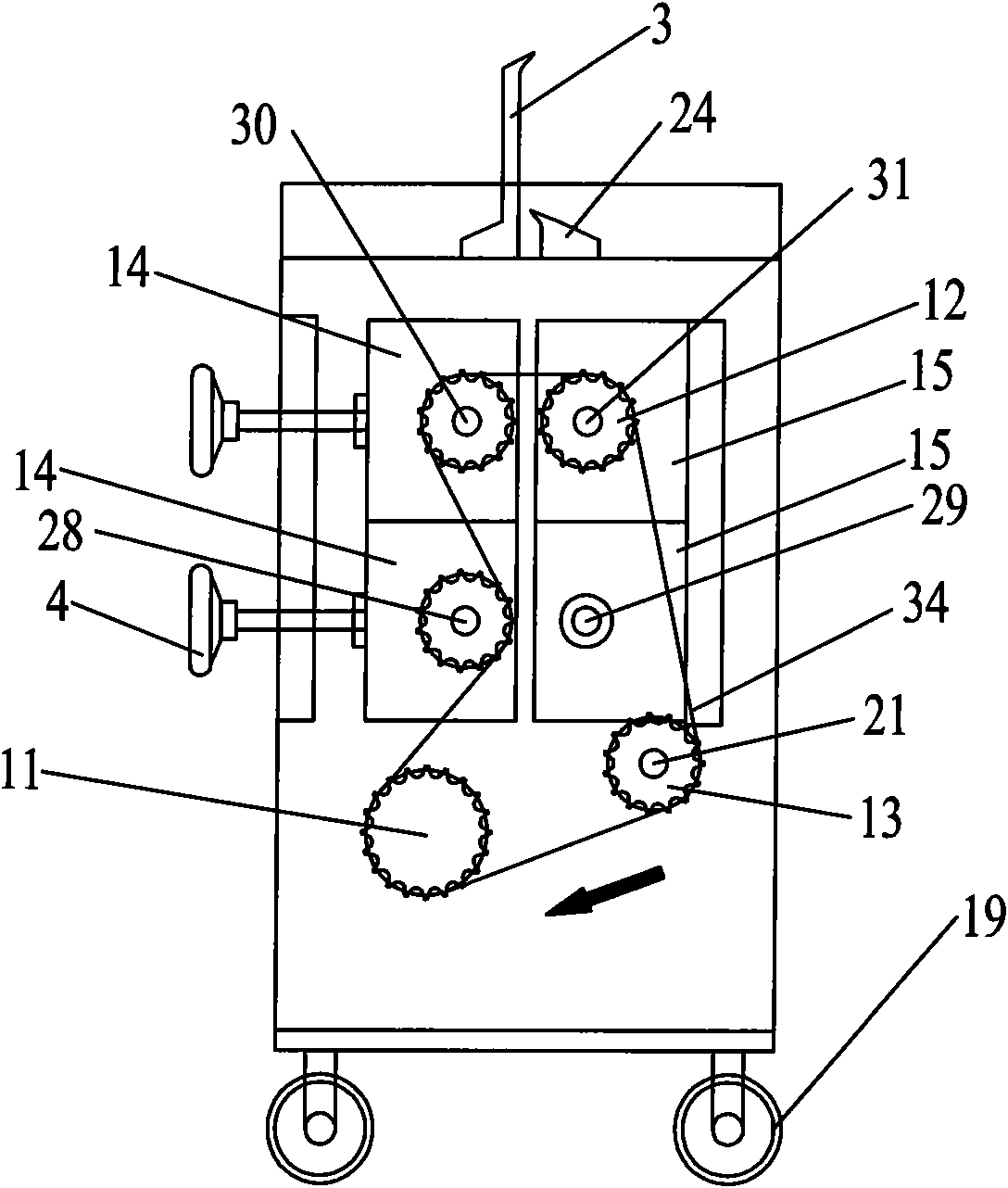

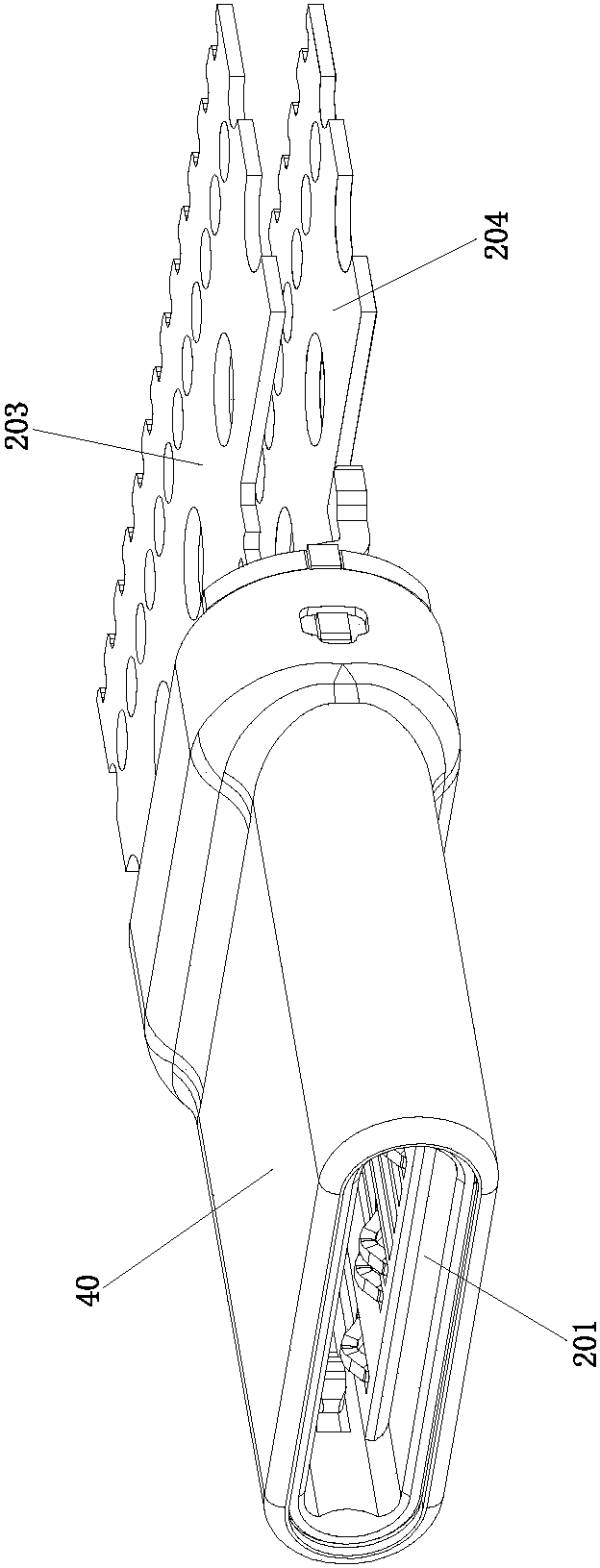

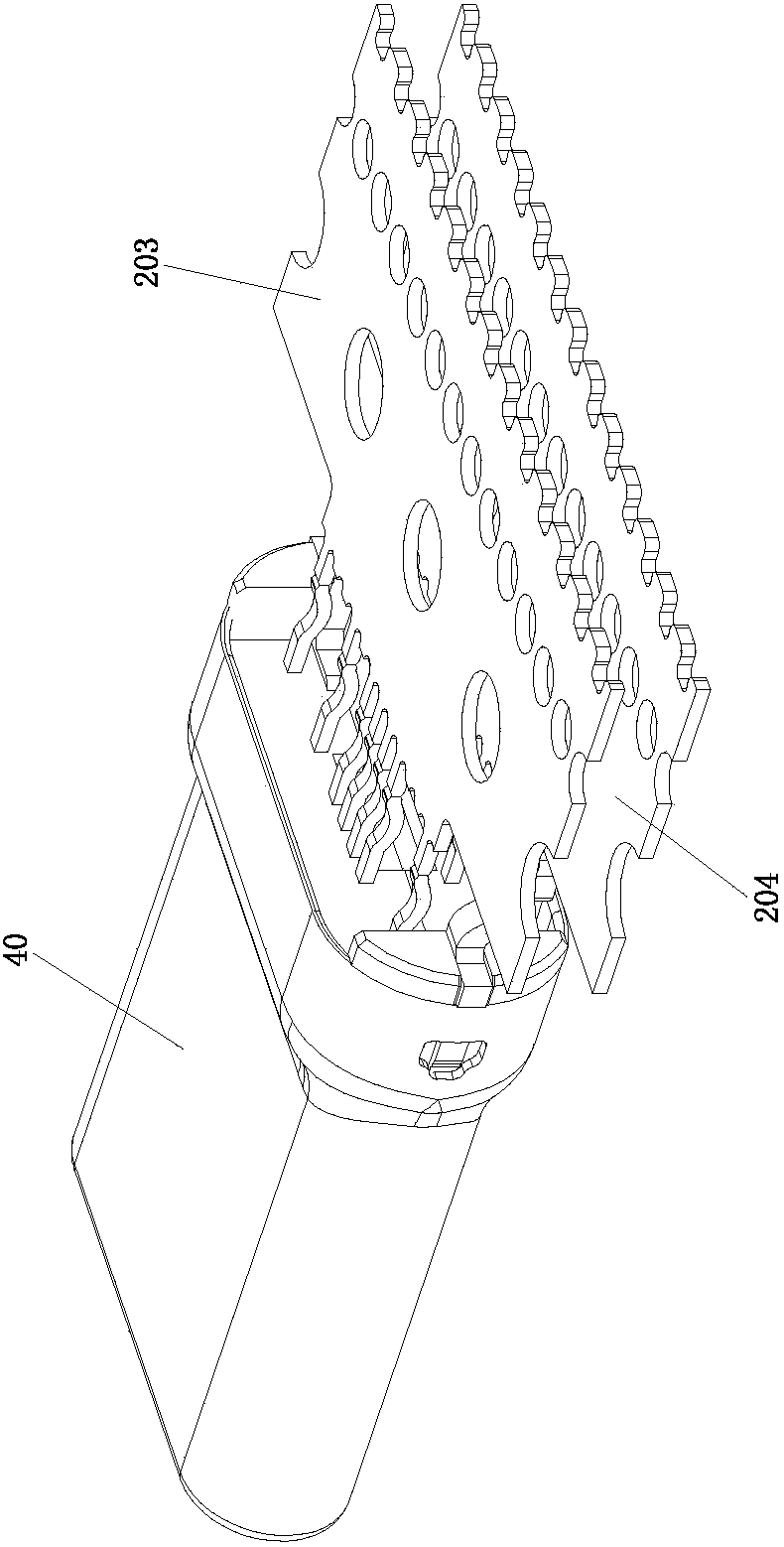

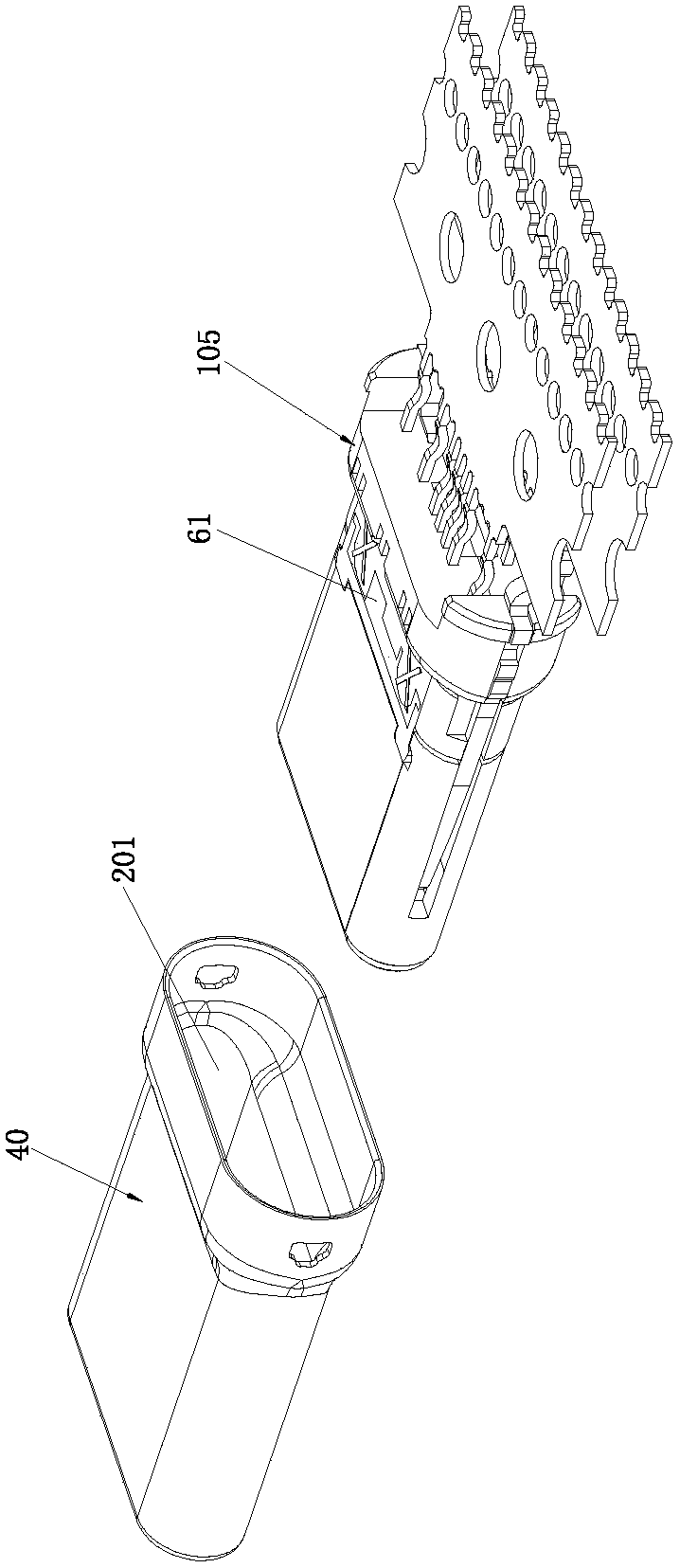

Automatic powdering box for anode of secondary battery

InactiveCN101908612AAvoid short circuitAvoid micro-short circuitElectrode manufacturing processesSprocketEngineering

The invention relates to an automatic powdering box for the anode of a secondary battery, which comprises a box body; a powder inlet box guide wheel is arranged in the box body; a first coarse coarse brush, a second coarse hard brush, a first soft brush and a second soft brush are arranged above the powder inlet box guide wheel; the end parts of a first rotating shaft, a third rotating shaft and a fourth rotating shaft are all provided with driven sprockets, and a drive sprocket and a first tension sprocket are arranged below one end of the first rotating shaft; the drive sprocket is connected with the driven sprockets corresponding to the first rotating shaft, the third rotating shaft and the fourth rotating shaft by using a first chain; and one end of a second rotating shaft away from the drive sprocket is provided with a driven sprocket, the lower part of the second rotating shaft corresponding to the driven sprocket is provided with a second tension sprocket, and the second tension sprocket is connected with the driven sprockets corresponding to the first rotating shaft and the second rotating shaft by using a second chain. The invention has simple structure, is convenient to maintain, shortens the technological process of anode film production, improves the production efficiency, and reduces the production cost.

Owner:珠海市光环自动化科技有限公司

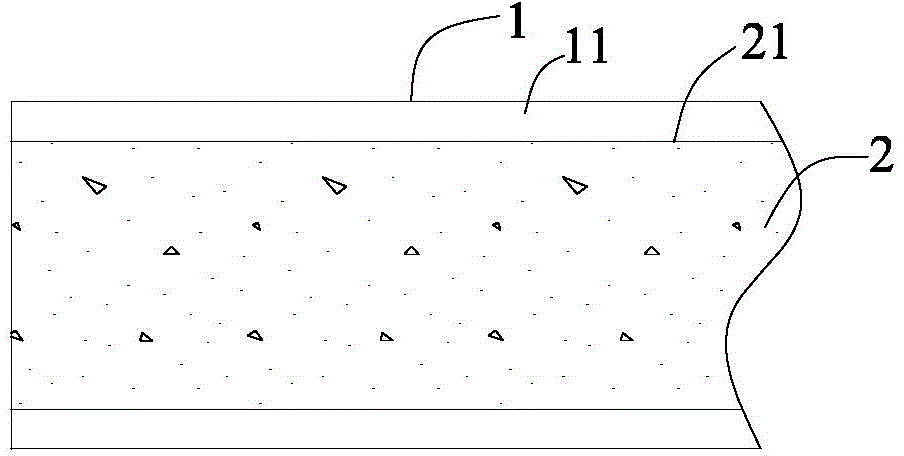

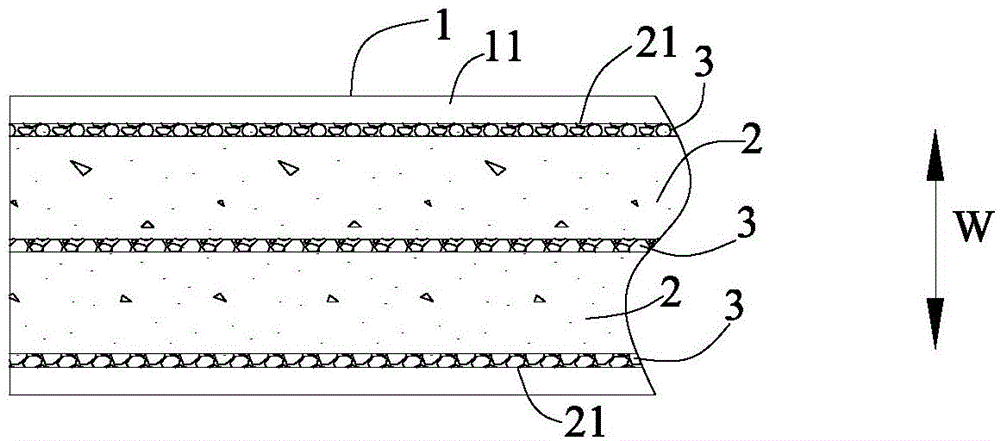

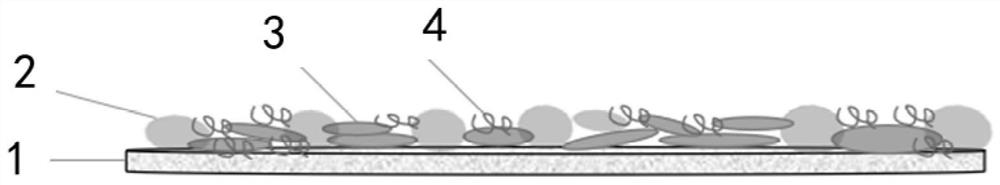

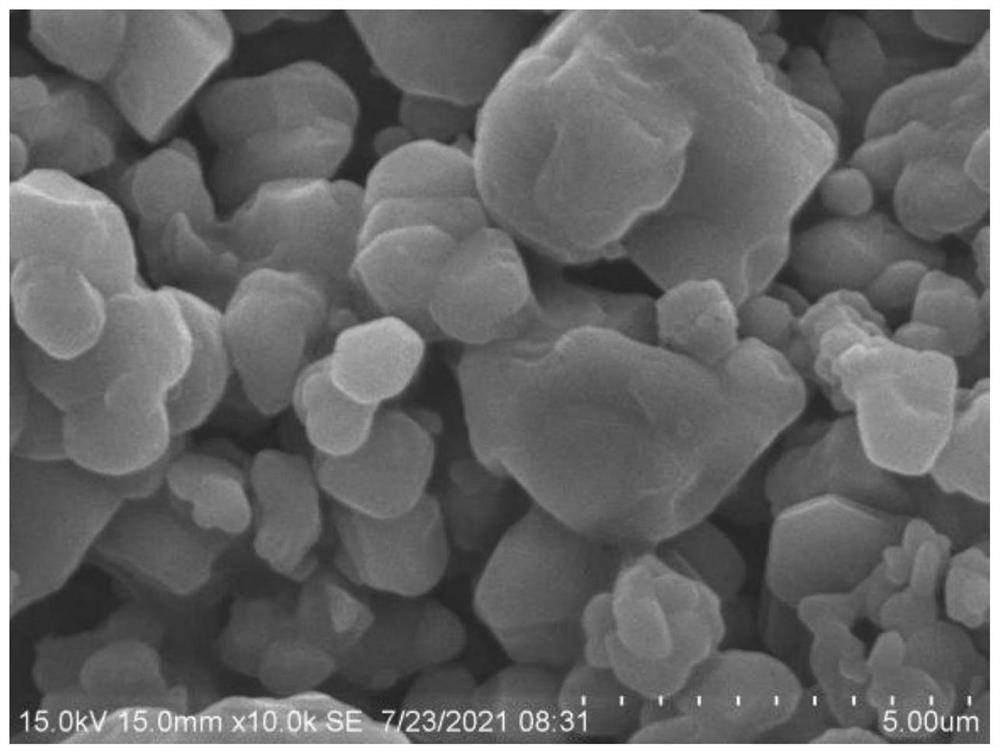

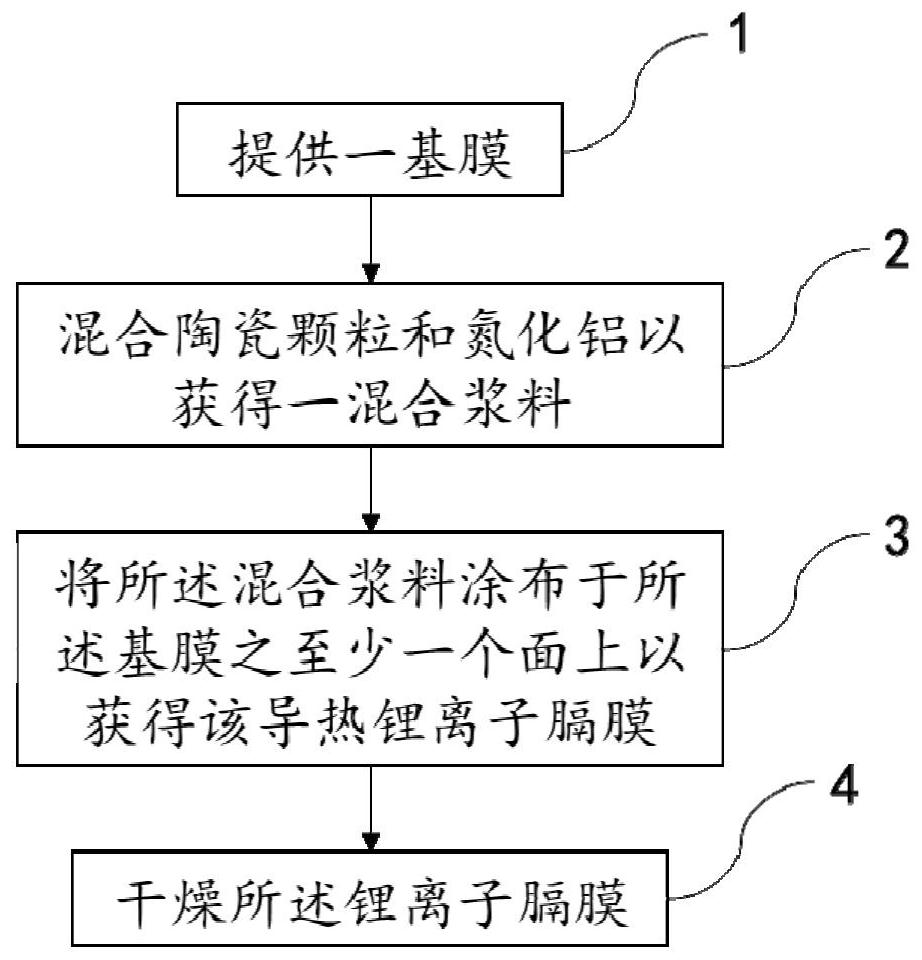

Heat-conducting lithium ion diaphragm and preparation method thereof

PendingCN114142156AGood thermal conductivityGood physical and chemical propertiesCell seperators/membranes/diaphragms/spacersBoehmiteCeramic particle

The invention discloses a heat-conducting lithium ion diaphragm and a preparation method, the heat-conducting lithium ion diaphragm comprises a wet-process base membrane and a coating, the coating provided by the invention comprises ceramic particles and aluminum nitride inorganic particles, and the ceramic particles and the aluminum nitride inorganic particles are mixed and bonded through an organic binder. Compared with a single aluminum oxide or boehmite ceramic coating, aluminum nitride particles are introduced on the basis, so that the heat conduction performance of the lithium ion diaphragm is greatly improved, and the heat conduction performance and the comprehensive performance of the diaphragm can be improved by controlling the amount of aluminum nitride; and the heat-conducting property, the battery safety performance and other electrochemical properties of the finally prepared heat-conducting diaphragm are effectively improved.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

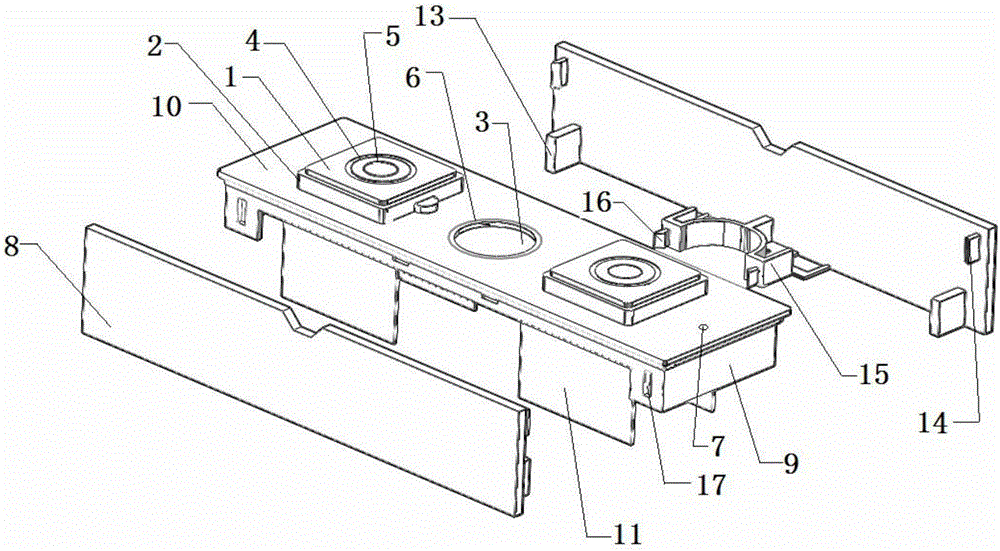

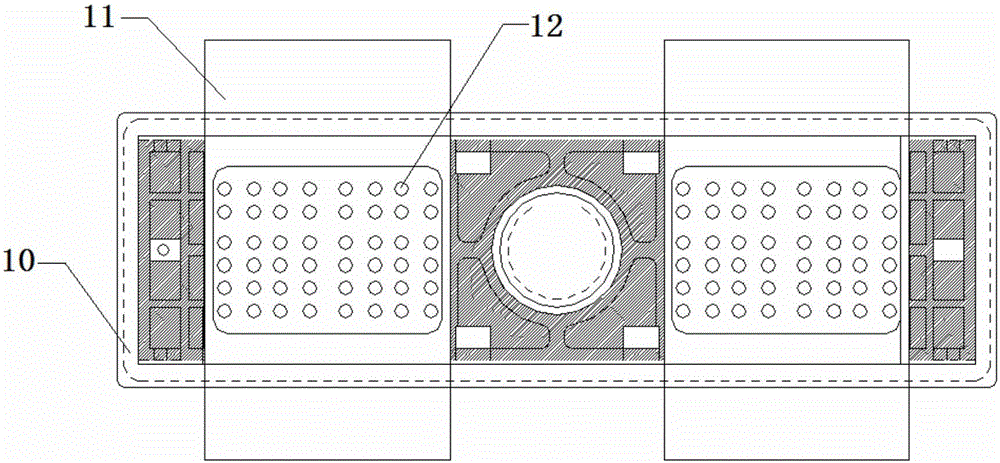

Secondary molding plug connector and manufacturing method thereof

PendingCN108288781ARealize secondary moldingAvoid prone to oxidationContact member manufacturingContact member assembly/disassemblyEngineeringCopper

The invention discloses a secondary molding plug connector and a manufacturing method thereof. The secondary molding plug connector comprises an upper row of primary molding terminal module, a lower row of primary molding terminal module, a first insulating body and a shielding case, wherein the upper row of primary molding terminal module comprises an upper row of terminal and an upper row of second insulating body; the lower row of primary molding terminal module comprises a lower row of terminal and a lower row of second insulating body; a connection part of the upper row of terminal is embedded and molded into the upper row of second insulating body to form the upper row of primary molding terminal module; the connection part of the lower row of terminal is embedded and molded into thelower row of second insulating body to form the lower row of primary molding terminal module; and the upper row of primary molding terminal module and the lower row of primary molding terminal moduleare embedded and molded into the first insulating body, thereby achieving secondary molding of the plug connector, effectively avoiding the phenomenon of oxidation caused by exposed copper in an environment test and preventing micro-short circuiting of a liquid and an iron shell and a hook when the liquid enters.

Owner:DONGGUAN TECONN ELECTRONICS TECH CO LTD

Array substrate, manufacturing method of array substrate and display device

ActiveCN112349733AReduce cut-off currentLarge flowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The embodiment of the invention provides an array substrate, a manufacturing method of the array substrate and a display device. The array substrate comprises a substrate and a plurality of thin filmtransistors located on one side of the substrate. The thin film transistor comprises an active structure which is arranged on one side of the substrate and comprises a first region and a second region, wherein the resistivity of the first region is smaller than that of the second region, the first region comprises a source region and a drain region, and the second region comprises a channel regionand an auxiliary region, the channel region being located between the source region and the drain region, and the auxiliary region surrounding at least part of the source region and / or the drain region; a source-drain electrode which comprises a source electrode and a drain electrode, wherein the source electrode is connected to the source region, and the drain electrode is connected to the drainregion; a first insulating layer arranged on one side of the active structure; and a grid electrode arranged on the side, deviating from the active structure, of the first insulating layer, wherein the orthographic projection of the grid electrode on the substrate covers the orthographic projection of at least part of the channel region on the substrate. The cut-off current of the thin film transistor can be reduced.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

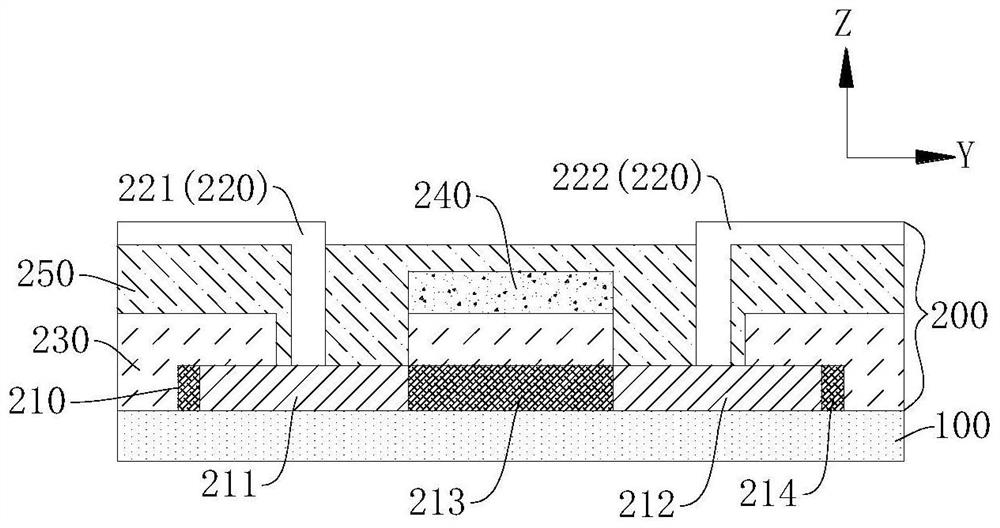

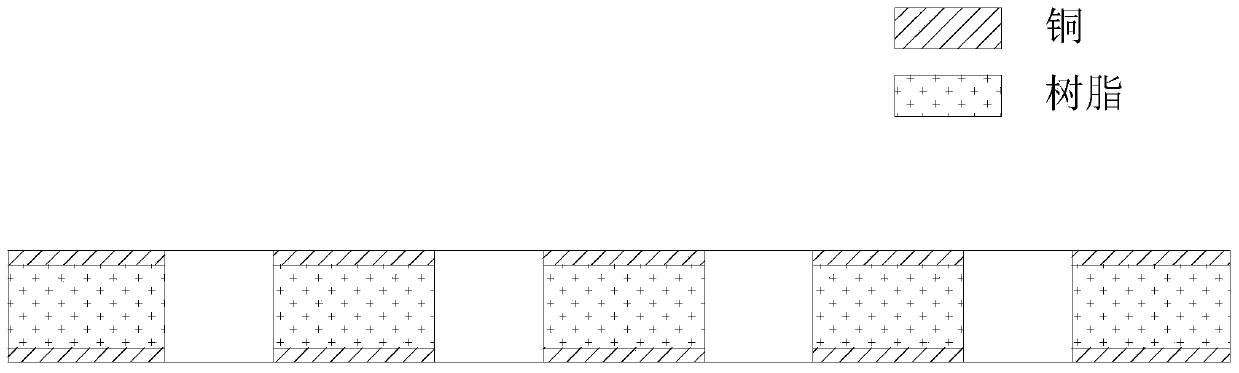

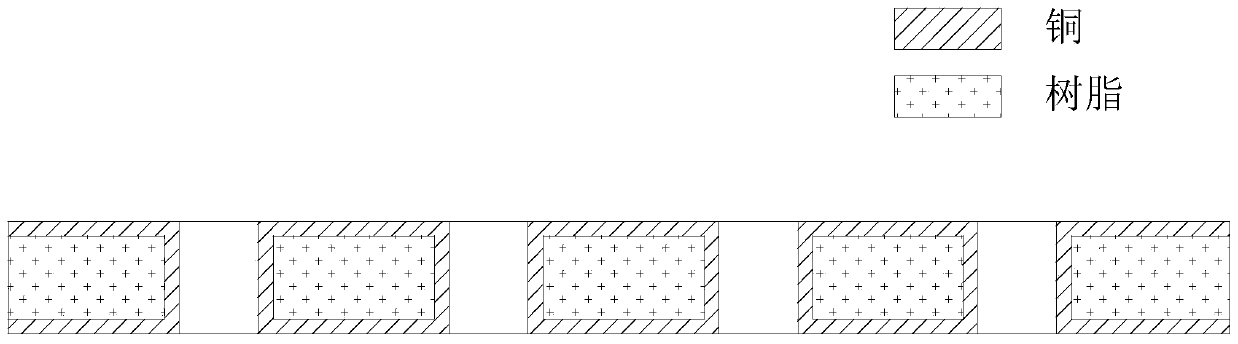

Miniled backlight substrate packaging method

ActiveCN110635017AEasy to operateAvoid micro-short circuitSemiconductor devicesMaterials preparationCopper plating

A miniled backlight substrate packaging method comprises the following steps: the step of material preparation: preparing a double-sided copper-clad plate, wherein the thickness of the double-sided copper-clad plate is 100-1000 micrometers, the thickness of a single layer of copper foil being 12-35 micrometers; the step of drilling: drilling the double-sided copper-clad plate to ensure that drilled holes run through two layers of copper foils of the double-sided copper-clad plate; the step of copper plating: plating copper on the walls of the drilled holes of the double-sided copper-clad plateto make the copper plating layers on the walls of the drilled holes connected with the copper foils on the two sides of the double-sided copper-clad plate to allow the copper foils on the two sides of the double-sided copper-clad plate to be electrically connected; and the step of hole filling: filling the drilled holes with white resin or white ink. The white resin used in the anisotropic conductive adhesive manufacturing step is melted, and the side faces of a miniled chip is wrapped due to surface tension, so that the chip is independently wrapped, a reflection cup is formed, and the reflection brightness of light is improved.

Owner:美琪电路江门有限公司

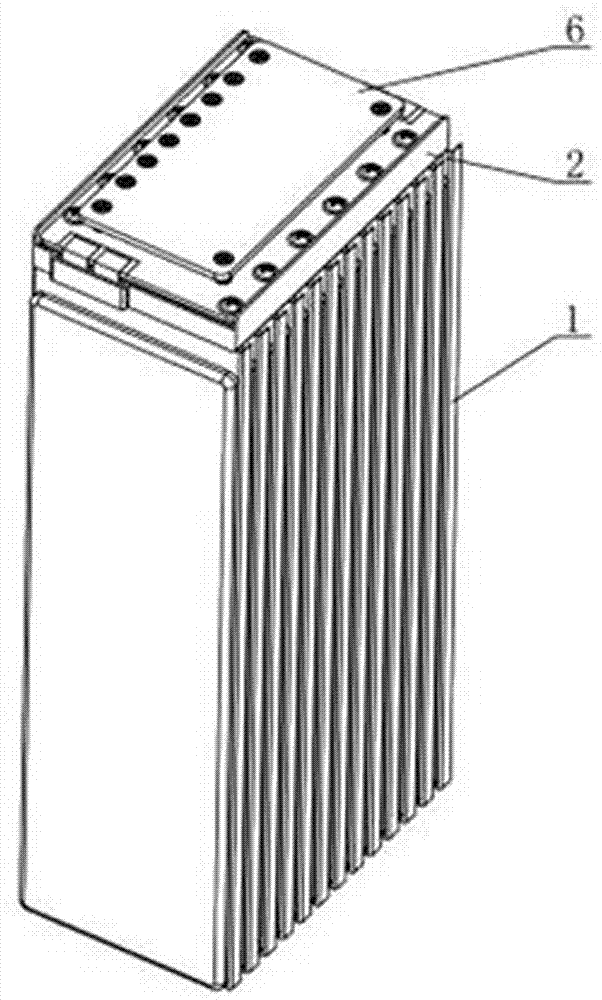

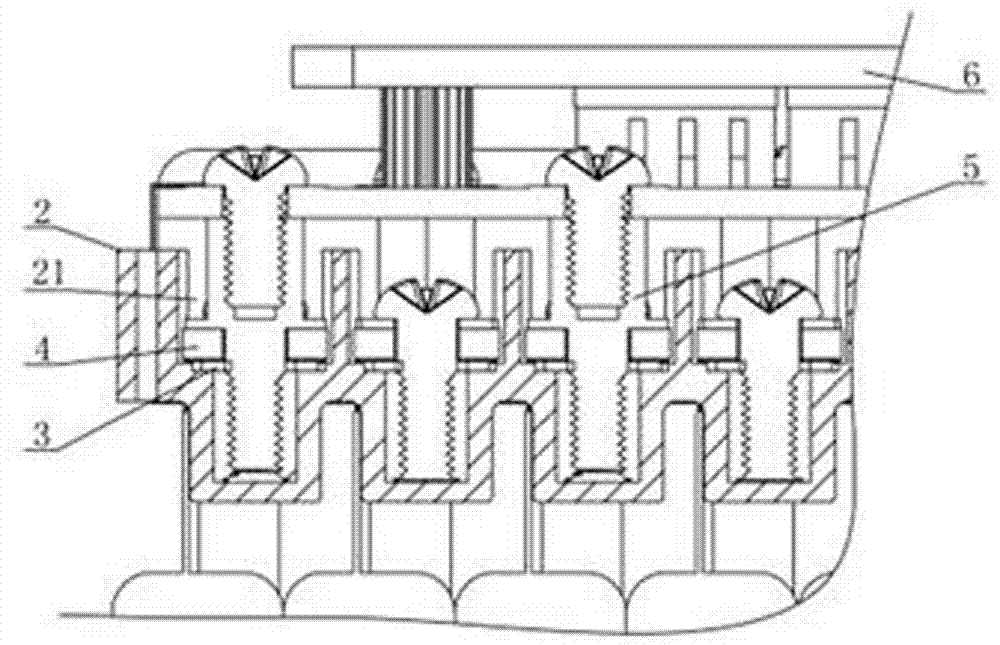

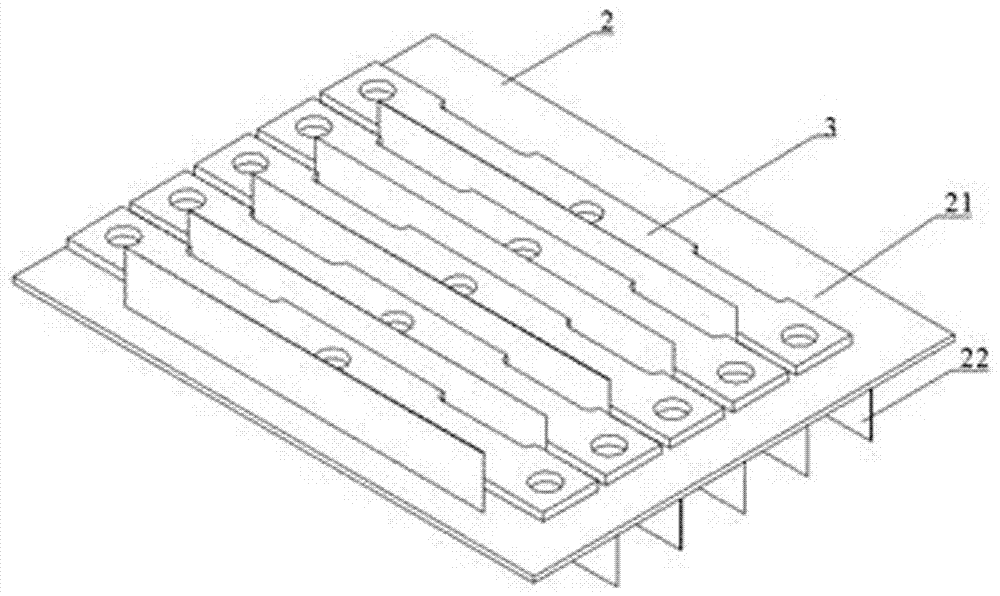

Electrode lug serial connection structure for lithium battery pack

PendingCN107302076AEasy maintenancePromote repairCurrent conducting connectionsSecondary cellsEngineeringLithium ion battery pack

The invention provides an electrode lug serial connection structure for a lithium battery pack. The electrode lug serial connection structure comprises a complex number of cells which are serially connected, wherein the cells are arranged in a same direction; anode lugs and cathode lugs of two adjacent cells form an electrode lug group in a serial connection manner; the anodes and the cathodes of two cells at an end part are power supply output ends; serial connection brackets are arranged at electrode lug ends of the cells; serial connection cavities which are arranged longitudinally are formed in the serial connection brackets corresponding to electrode lug groups; each electrode lug group penetrates through electrode lug holes formed in two sides of the inner bottom of a corresponding serial connection cavity, is bent and folded and is connected with a tabletting mechanism arranged on each serial connection cavity; detection studs are arranged on the tabletting mechanisms; connection platforms are arranged at the upper ends of the detection studs and are electrically connected with detection protection plates through screws; threads are formed in the lower ends of the detection studs and are fixed with the tabletting mechanism and the serial connection cavities; and the detection studs are arranged on two sides of the serial connection cavities. The electrode lug serial connection structure has the beneficial effects that the design is simple in structure, convenient to assemble and low in use cost and has the advantage that the use security of the lithium battery pack is improved.

Owner:山东高佳新能源有限公司

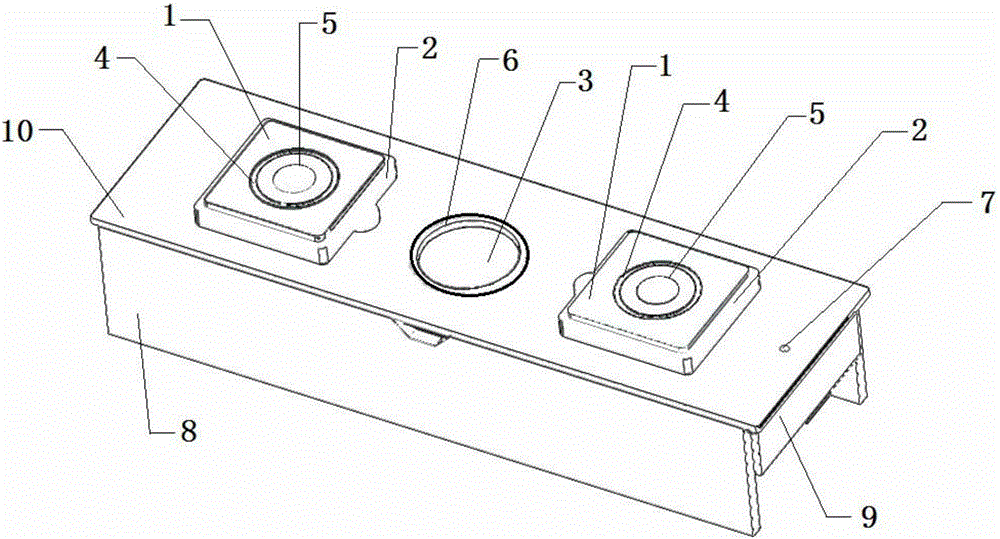

Novel square lithium ion battery cover plate

PendingCN106450048AImprove vibration resistancePrevent explosion and other hazardsSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsUltrasound attenuationElectricity

The invention discloses a novel square lithium ion battery cover plate. The novel square lithium ion battery cover plate comprises a main body cover plate, wherein a liquid filling hole and two electrode studs are formed in / on the main body cover plate; an electrode stud upper cover plate is arranged at the top of each electrode stud in a sleeving manner; two connecting pieces are arranged at the bottom of the main body cover plate and are connected with the lower parts of the corresponding electrode studs; an explosionproof membrane is arranged at the middle part of the main body cover plate and an explosionproof membrane upper film is arranged at the top of the explosionproof membrane; support upper edges are respectively arranged at two ends of the bottom of the main body cover plate along the length direction; vibration supports are respectively arranged at the two ends of the bottom of the main body cover plate along the width direction, and the bottoms of the vibration supports can support against a battery cell; the vibration supports can be in contact fixation with the support upper edges; the two vibration supports can be in contact fixation; the two electrode studs comprise a positive stud and a negative stud. According to the novel square lithium ion battery cover plate, the vibration resistance of a lithium ion battery is enhanced, and further a series of risks of short circuit, open circuit, quick attenuation of electrical performance inside the lithium ion battery and the like are avoided.

Owner:江苏海四达电源有限公司 +1

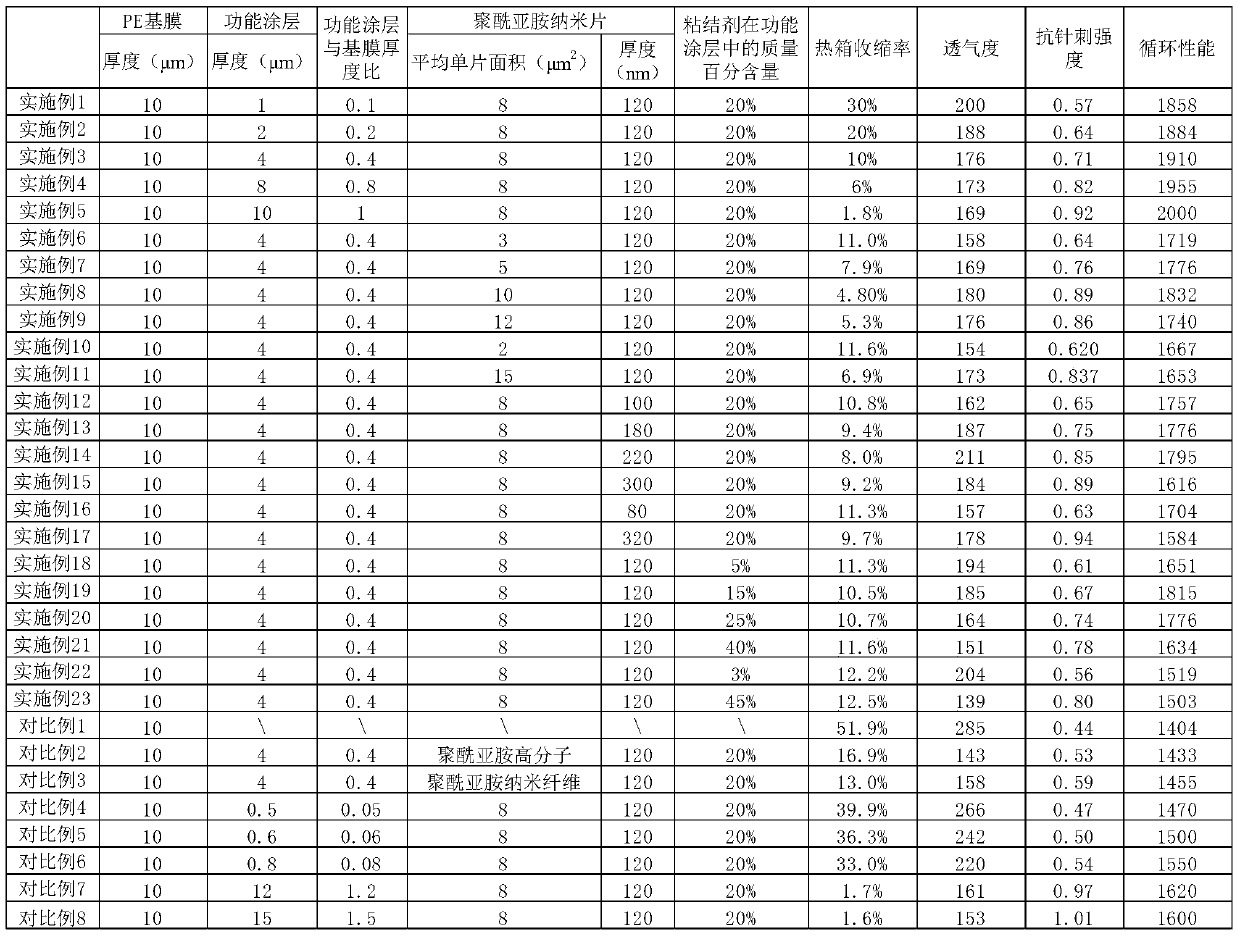

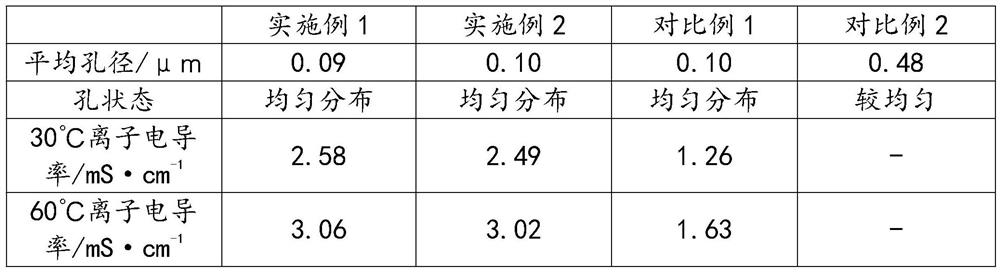

Isolating membrane, preparation method thereof, lithium ion secondary battery and device

PendingCN111063852AGood high temperature resistanceHigh thermal and chemical stabilityMaterial nanotechnologyCell seperators/membranes/diaphragms/spacersPhysicsChemistry

The invention provides an isolating membrane, a preparation method thereof, a lithium ion secondary battery and a device. The isolating membrane provided by the invention comprises a porous base membrane and a functional coating arranged on at least one surface of the porous base membrane. The functional coating comprises polyimide nanosheets, and the polyimide nanosheets are irregularly stacked to form a lamellar loose structure. The thickness ratio of the functional coating to the porous base membrane is 0.1 to 1.0. The invention further provides the preparation method of the isolating membrane, the lithium ion secondary battery comprising the isolating membrane and a device. The isolating membrane provided by the invention has relatively good thermal stability and chemical stability, can effectively resist mechanical puncture of lithium dendrites, avoids micro short circuit, and improves the cycle performance of the battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Preparation process of lithium battery diaphragm

InactiveCN111640902AImprove ionic conductivityImprove solubilityLi-accumulatorsCell component detailsFiberSpinning

The invention discloses a preparation process of a lithium battery diaphragm. The preparation process comprises the following steps of: 1, preparing a membrane casting solution; 2, carrying out electrostatic spinning on the membrane casting solution to obtain a prefabricated fiber membrane; 3, performing baking at high temperature; and 4, coating the upper surface and the lower surface of the fiber membrane with a ceramic material. According to the invention, polyimide is modified, a soft chain segment can be introduced into a polyimide molecular chain, the flexibility of the polyimide molecular chain is improved, the flexibility of the fiber membrane is improved, also polyethylene glycol is combined with a membrane matrix in a chemical bonding mode, the binding force is high, the solventresistance and the high temperature resistance of polyethylene glycol are improved, and the diaphragm has efficient and lasting ionic conductivity; besides, the surface of the polyimide fiber membraneis coated with the ceramic material, so that the pore diameter of the diaphragm can be effectively reduced, the average pore diameter of the diaphragm is about 0.1microm, the pore diameter distribution is uniform, and the use performance of the lithium battery diaphragm is improved.

Owner:淮北市吉耐新材料科技有限公司

Test method of thin-film battery micro-short circuit

InactiveCN104569722AExact searchImprovement and improvement point the wayElectrical testingImaging equipmentVoltage

The invention discloses a test method of a thin-film battery micro-short circuit. The test method comprises the following steps that firstly, a backward voltage is applied to the positive electrode and the negative electrode of a thin-film battery for 800 ms to 5 s; secondly, an infrared imaging device is used for observing the thin-film battery to which the voltage is applied; thirdly, the micro-short circuit gives off heat due to current passing, different states can be displayed in the infrared imaging device, and therefore the micro-short circuit position can be accurately found. By means of the test method, the micro-short circuit position can be quickly and accurately found when a micro-short circuit occurs, and the test method indicates directions for technology improving.

Owner:江苏武进汉能薄膜太阳能有限公司

A kind of preparation method of multi-layer microporous film for lithium ion battery

ActiveCN106981608BImprove securityImprove rate discharge performanceSecondary cellsCell component detailsPolyolefinPhysical chemistry

The invention provides a method for preparing a multilayer microporous membrane for lithium ion batteries. Polyolefin resin and auxiliary additives are used as raw materials to obtain a melt after melting and plasticizing, extruding through a die head, and tape-casting to obtain an intermediate Membrane: Take multiple rolls of the intermediate film, compound it through a composite device with transverse stretching function, obtain a composite intermediate, anneal it under bidirectional micro tension, and stretch it longitudinally to obtain a multilayer microporous membrane for lithium ion batteries . In the present invention, the compounding roll is heated during the compounding process of the intermediate film, and the crystallization of the polymer structure inside the intermediate film is further improved. At the same time, the transverse extension is carried out under slight tension, and the degree of transverse orientation is increased, so that the prepared microporous film has uniform micropores. , the lateral strength is improved, the ability to resist lithium dendrite piercing is effectively improved, and micro-short circuits are avoided, which is suitable for large-scale production. The multilayer microporous membrane prepared by the invention has high structural uniformity, and has obvious effect on improving the safety performance of the battery.

Owner:SHENZHEN SENIOR TECH MATERIAL

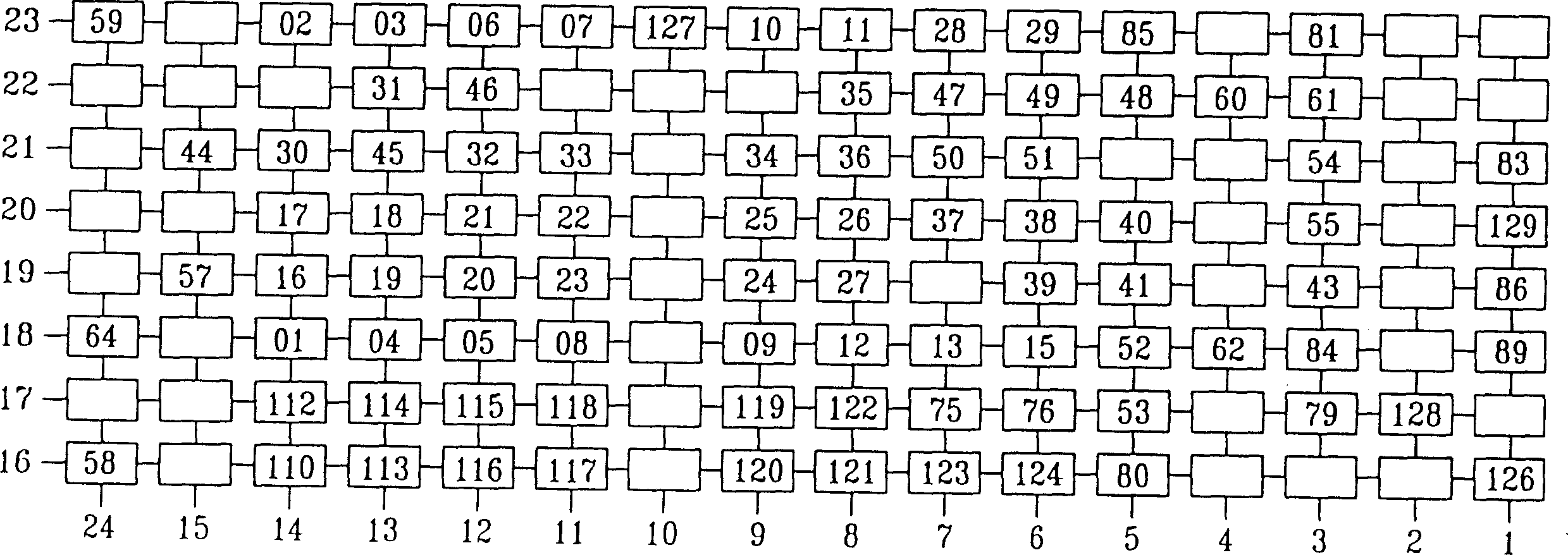

Key position arrangement method of film circuit board

InactiveCN1477482AReduce printing processReduce lossesInput/output processes for data processingEngineeringDistribution diagram

The key position arrangement method of the film circuit board is characterized by that under the condition of having no wire jumper and preventing production of unknown key signal the key position can be arranged, when the key positions are arranged, firstly, the adjacent keys can be centralized into a group, every group can be used for defining a key position distribution diagram, then the circuit of every key of every group can be connected on the row of wires of film circuit board, then the amount of every kind of composite keys can be defined, and in the composite keys the keys which can not be colinear or can be formed into cross-coline can be arranged on the matrix scanning line of X-axis or y-axis, and under the condition of having no wire jumper other adjacent keys can be arranged.

Owner:ZIPPY TECH

A kind of bipolar sodium ion battery and preparation method thereof

ActiveCN114094170BInhibit sheddingIncrease profitFinal product manufactureElectrode carriers/collectorsInsulation layerSodium phosphates

The invention relates to a bipolar sodium-ion battery and a preparation method thereof. The bipolar sodium-ion battery comprises a plurality of bipolar pole pieces, a diaphragm and an electrolyte, and a plurality of bipolar pole pieces are stacked in sequence. The bipolar pole pieces The sheet includes an aluminum foil, an insulating strip and an insulating layer. The aluminum foil has a first surface and a second surface opposite to each other. Positive electrode active layer, the negative electrode area is coated with hard carbon; the positive electrode active layer includes transition metal oxides, Prussian blue materials, polyanionic compounds or amorphous materials; the aluminum foil can be folded in half along the bending area to make the positive electrode area and negative electrode The insulating strip is arranged in the bending area; the insulating layer is interposed between the positive active layer and the hard carbon; a separator is arranged between two adjacent bipolar pole pieces; the electrolyte is used for the positive active layer and the hard carbon. Hard carbon conducts electricity, and the electrolyte includes sodium hexafluorophosphate. Bipolar sodium-ion batteries have high energy density and long service life.

Owner:深圳市睿赛新能源科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com