Rapid container formation charging method for lead-acid storage battery

A lead-acid battery and charging method technology, applied in the direction of secondary battery charging/discharging, secondary battery, electrochemical generator, etc. Differential polarization phenomenon, prolonging cycle life, reducing the effect of damage to crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

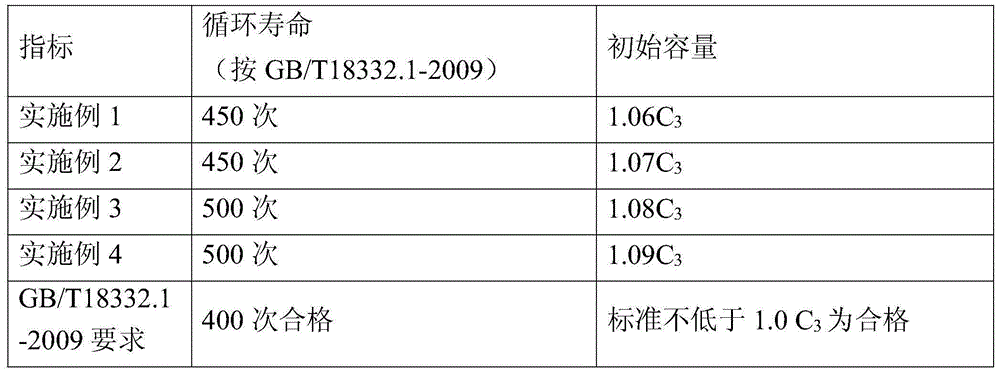

Examples

Embodiment 1

[0074] Take the 12V100Ah battery as an example, put the lead-acid battery that has been filled with vacuum acid in the circulating water bath for 10-15 minutes, and connect the charging line to prepare for charging. When the battery temperature drops to 30-40℃, turn on the charger and press Charge in the following ways:

[0075] Step (a): Precharge: at 0.06C 3 (6A; 0.06×100) charge for 0.2 hours; then charge at 0.12C 3 Discharge for 0.05 hours;

[0076] Step (b): Gradient up-current charging: 0.09C 3 Under charge for 0.2 hours; 0.1C 3 Charge for 2 hours; 0.15C 3 Charge for 3 hours; then charge at 0.12C 3 Discharge for 0.05 hours;

[0077] Step (c): Cycle charge and discharge: first cycle charge and discharge: at 0.15C 3 Charging for 4 hours: then at 0.12C 3 Discharge for 0.05 hours;

[0078]The second cycle charge and discharge: at 0.15C 3 Charge for 4 hours; then charge at 0.2C 3 Discharge for 0.5 hours;

[0079] The third cycle charge and discharge: at 0.15C 3 C...

Embodiment 2

[0088] Compared with Example 1, how to charge and discharge is implemented:

[0089] Step (a): Precharge: at 0.15C 3 Charge for 0.5 hours; then charge at 0.15C 3 Discharge for 0.1 hour;

[0090] Step (b): Gradient up-current charging: 0.1C 3 Charge for 0.2 hours; 0.15C 3 Charge for 2 hours; 0.18C 3 Charge for 3 hours; then charge at 0.12C 3 Discharge for 0.05 hours;

[0091] Step (c): Cycle charge and discharge: first cycle charge and discharge: at 0.2C 3 Charging for 5 hours: then at 0.15C 3 Discharge for 0.1 hour;

[0092] The second cycle charge and discharge: at 0.2C 3 Charge for 5 hours; then charge at 0.20C 3 Discharge for 1 hour;

[0093] The third cycle charge and discharge: at 0.2C 3 Charge for 5 hours; then charge at 0.25C 3 Discharge for 1 hour;

[0094] The fourth cycle charge and discharge: at 0.2C 3 Charging for 5 hours: then at 0.3C 3 Discharge for 1 hour;

[0095] The fifth cycle charge and discharge: at 0.2C 3 Charge for 5 hours; then charge ...

Embodiment 3

[0101] Compared with Example 1, the charging and discharging mode is implemented as follows:

[0102] Step (a): Precharge: at 0.15C 3 Charge for 0.5 hours; then charge at 0.12C 3 Discharge for 0.05 hours;

[0103] Step (b): Gradient up-current charging: 0.09C 3 Under charge for 0.5 hours; 0.15C 3 Charge for 2 hours; 0.2C 3 Charge for 3 hours; then charge at 0.15C 3 Discharge for 0.05 hours;

[0104] Step (c): cycle charge and discharge:

[0105] The first cycle charge and discharge: at 0.15C 3 Charging for 4 hours: then at 0.15C 3 Discharge for 0.05 hours;

[0106] The second cycle charge and discharge: at 0.2C 3 Charge for 4 hours; then charge at 0.2C 3 Discharge for 0.5 hours;

[0107] The third cycle charge and discharge: at 0.2C 3 Charge for 4 hours; then charge at 0.25C 3 Discharge for 1 hour;

[0108] The fourth cycle charge and discharge: at 0.2C 3 Charging for 5 hours: then at 0.3C 3 Discharge for 0.5 hours;

[0109] The fifth cycle charge and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com