Production method of film circuit plate

A technology of thin-film circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, electrical components, etc., and can solve problems such as high defective rate, complicated manufacturing steps, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

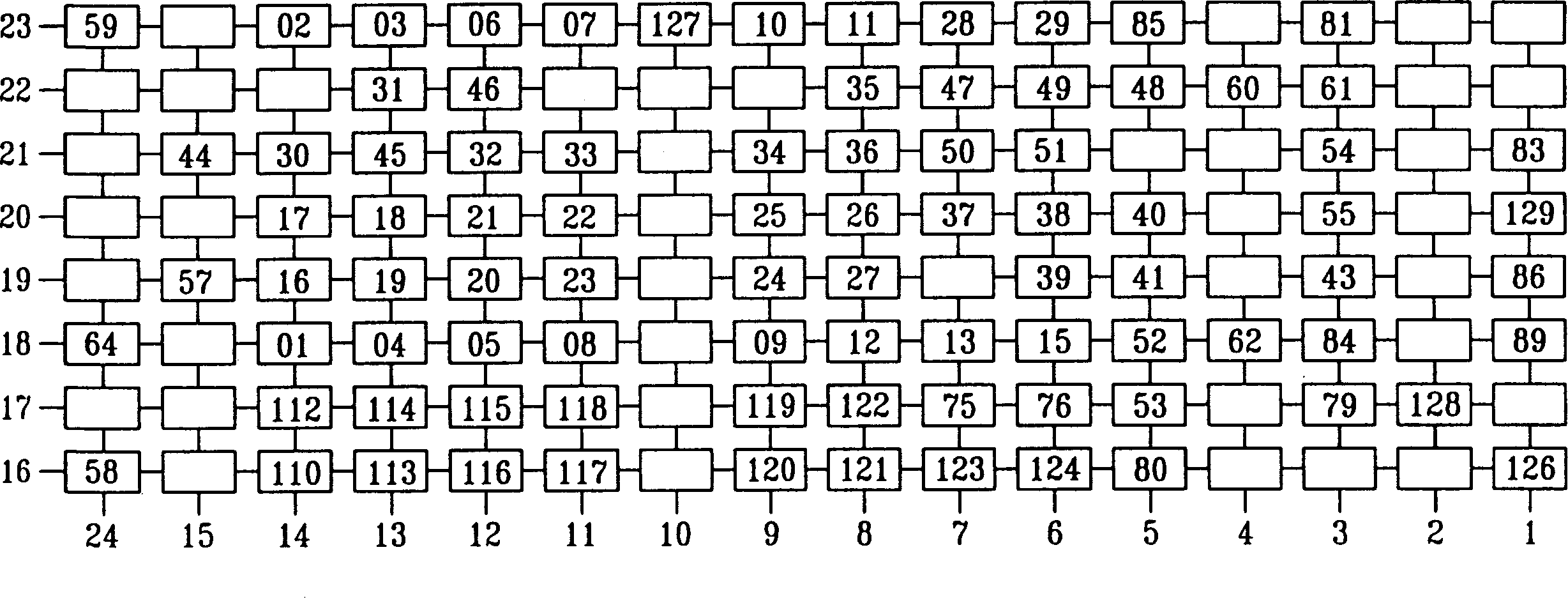

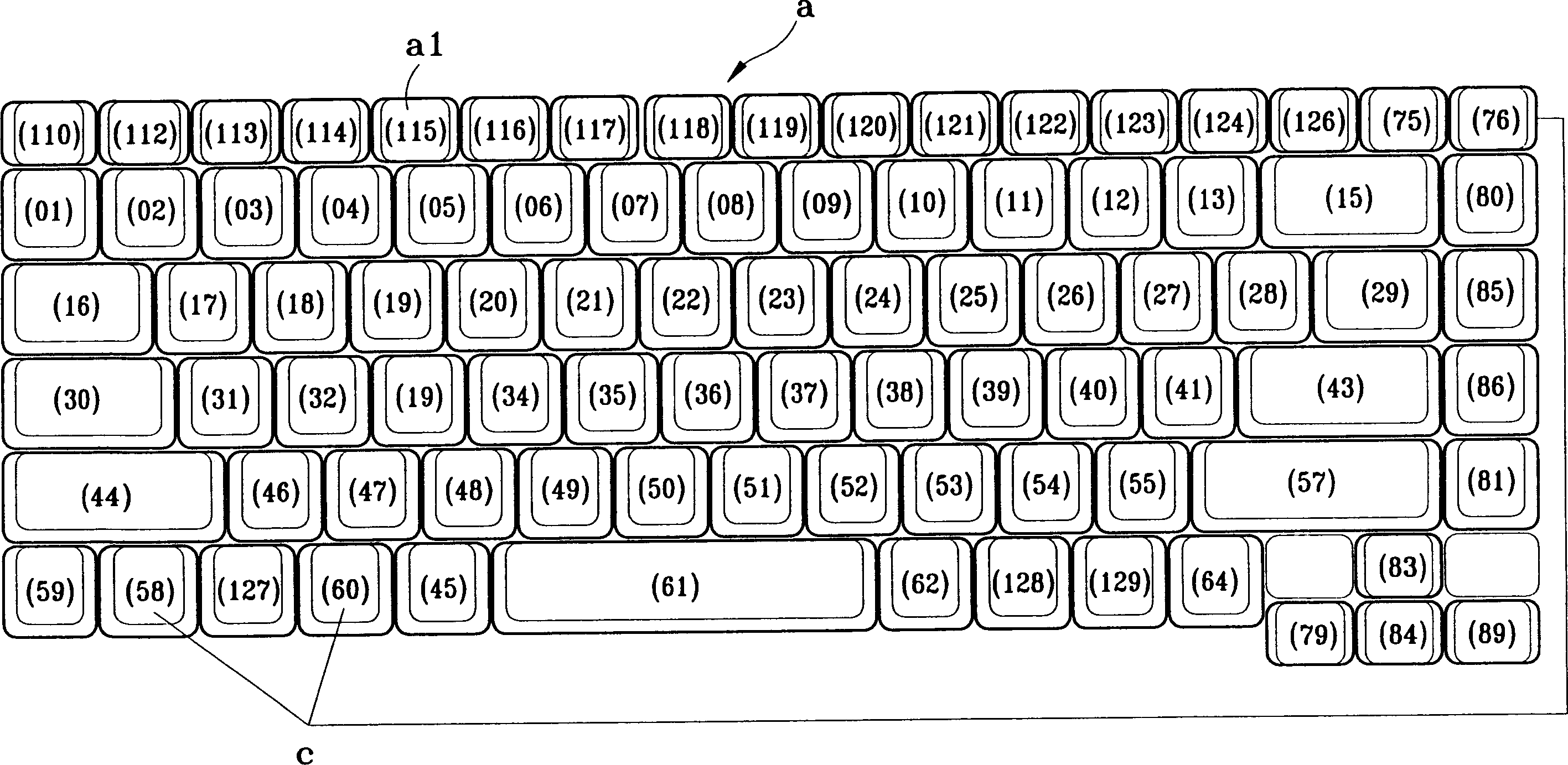

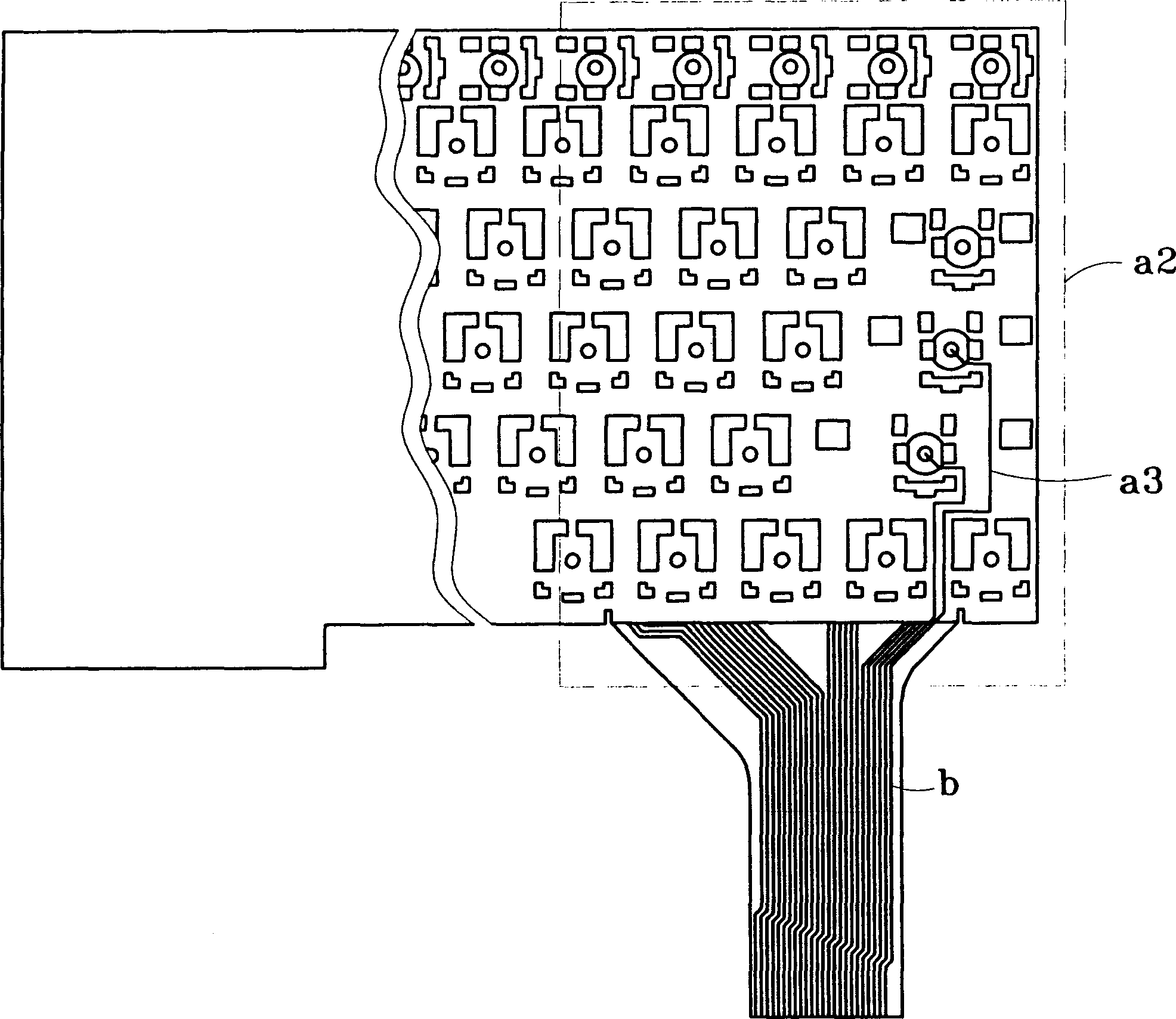

[0015] see figure 2 , 3 , is a schematic diagram of key position distribution and thin film circuit board of the present invention. As shown in the figure: the manufacturing method of the thin film circuit board of the present invention is mainly carried out under the condition that the thin film circuit board does not jump wires and avoids the generation of unknown key signals when the thin film circuit board is arranged or arranged (Membrane Layout) to make. Circuit arrangement (Layout), and then define the matrix (Matrix) arrangement, and then provide the manufacturer to fill in the code of each key position in the chip; this production method can reduce the circuit board printing process, reduce production costs, and increase production. Relatively, the production steps are also reduced, thereby reducing the loss caused by the defect rate, and at the same time, it can also avoid the micro-short circuit caused by the free circuit of the jumper part, which can improve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com