Patents

Literature

76results about How to "Reduce printing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

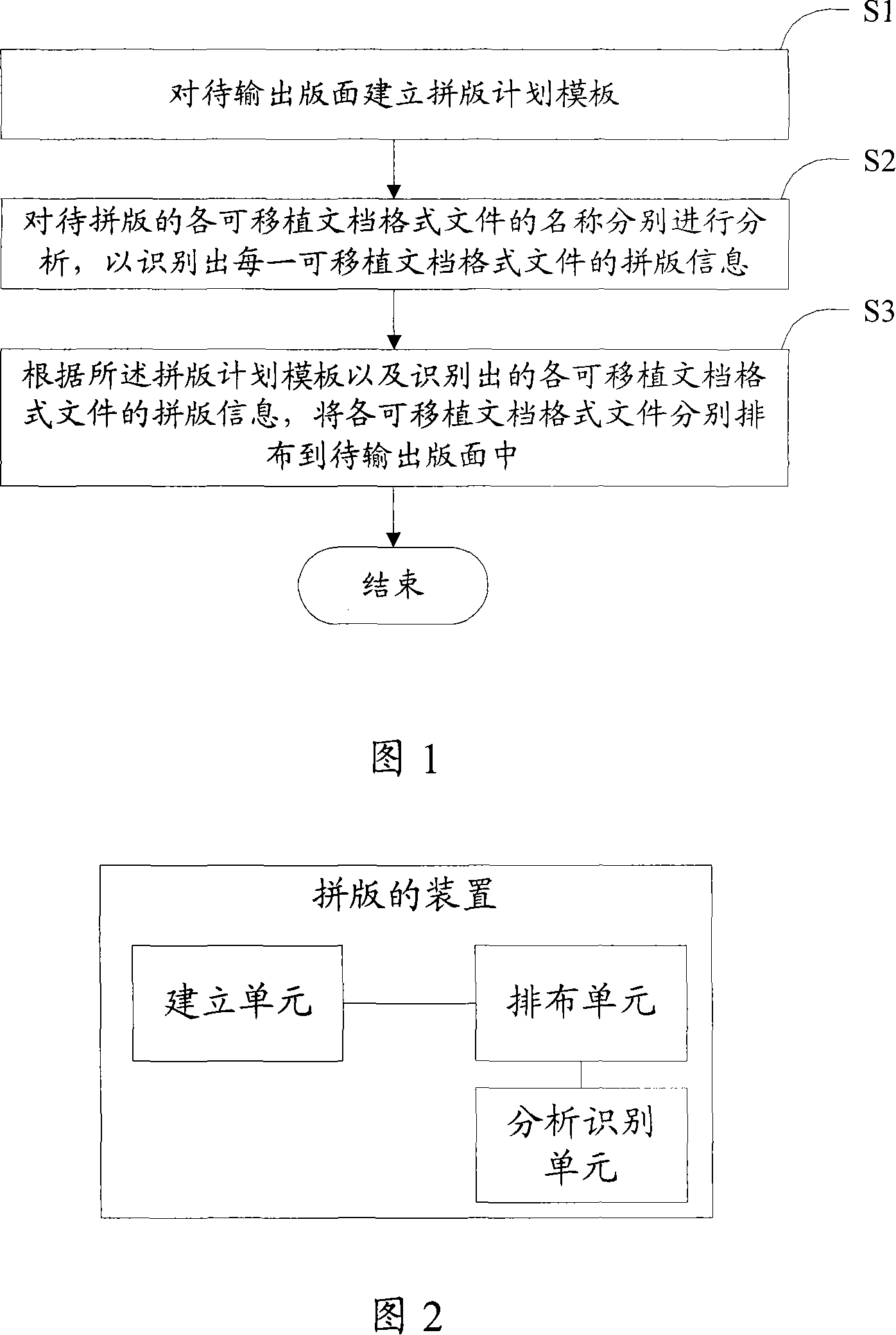

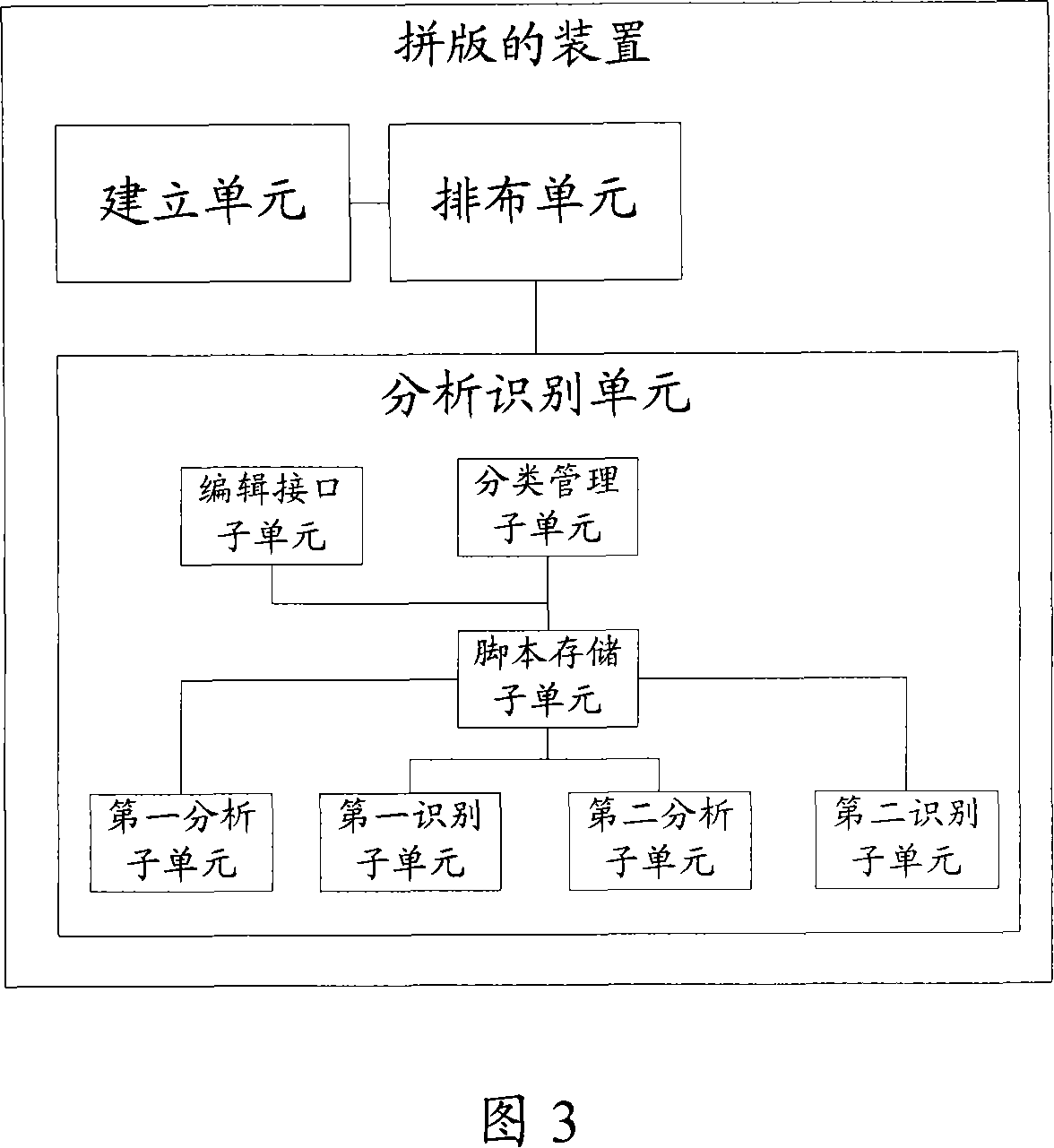

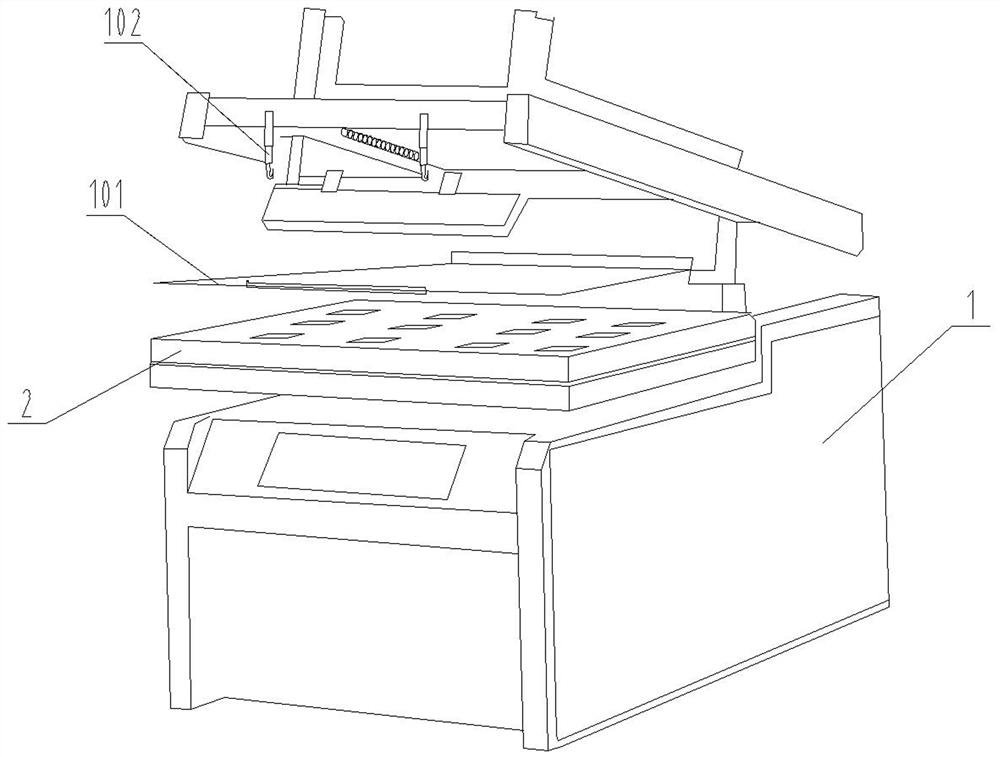

Layout splicing method and equipment

ActiveCN101122898AFully automatedSave labor inspection costSpecial data processing applicationsPortable document formatComputer software

The present invention discloses an imposition method and device, which belongs to the field of newspaper printing and computer software so as to achieve automatic imposition. The imposition method in the present invention includes the following procedures: an imposition plan template is established for the layout to print out; the name is analyzed separately to identify the imposition information of each portable document format file of the layout to impose. According to the imposition plan template and the identified imposition information in each portable document format file, each portable document format file is arranged separately to the layout to print out. The imposition device of the present invention includes: an establishment unit, an analysis identification unit and an arrangement unit. The application of the method and device described in the present invention can improve imposition accuracy and efficiency.

Owner:NEW FOUNDER HLDG DEV LLC +1

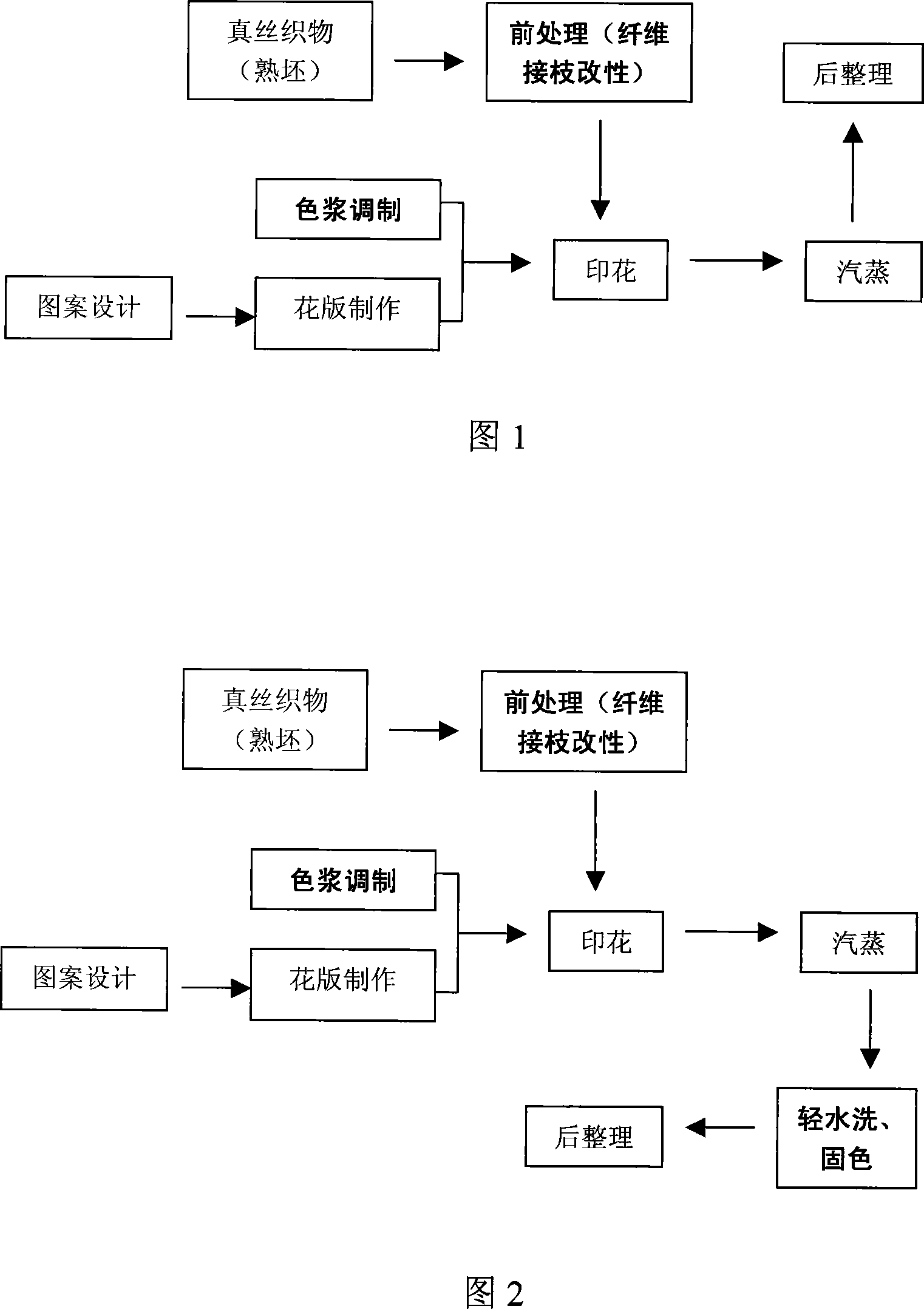

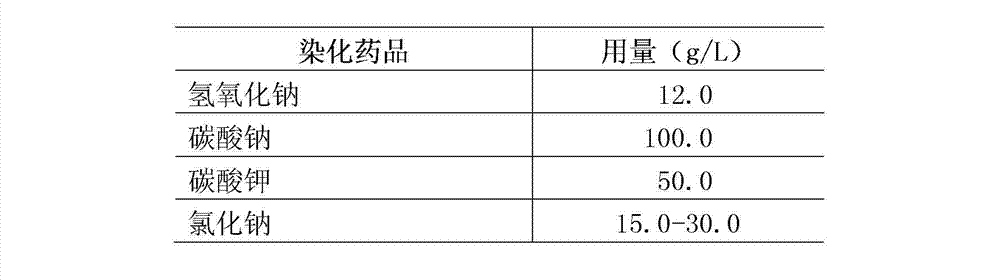

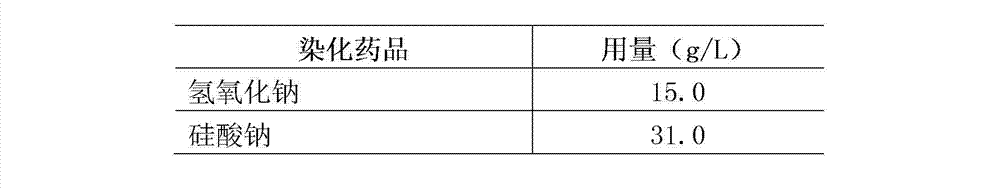

Real silk fabric coloring agent printing decoration light water developing and printing flowers method

InactiveCN101096823AIncrease dye seatImprove dye uptakeFibre treatmentDyeing processColour fastnessFiber

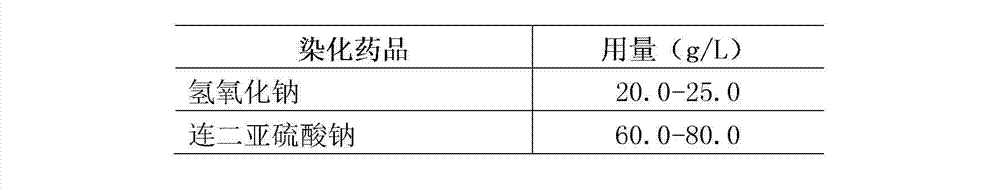

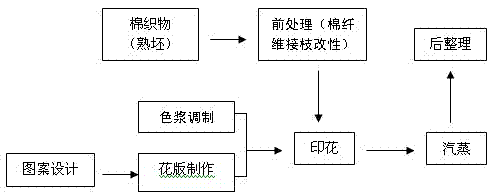

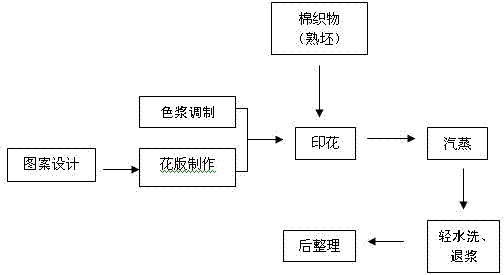

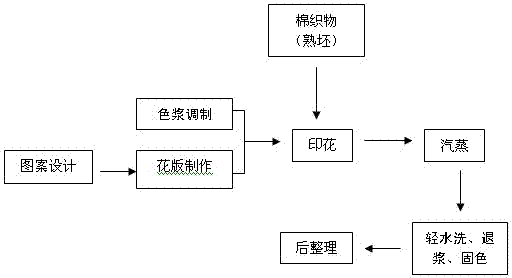

The invention discloses a real silk fabric dye art fine water laundering stamping, which is characterized by the following: proceeding graft modify for real silk fibre; introducing basic ion group into fabric molecule; intensifying dye seat of negative ion (acid, neutral and so on); intensifying dye-uptake of the dye; improving color stability; adopting synthetic thickener with low solid content as main primary pulp of dye art color paste; decreasing the content of slurry in color paste; adding reinforce agent and soften agent into color paste; further-improve color stability of printing textile; modifying hand touch. This invention can shorten dye printing craft, which can reach the goal of light wash.

Owner:ZHEJIANG SCI-TECH UNIV +1

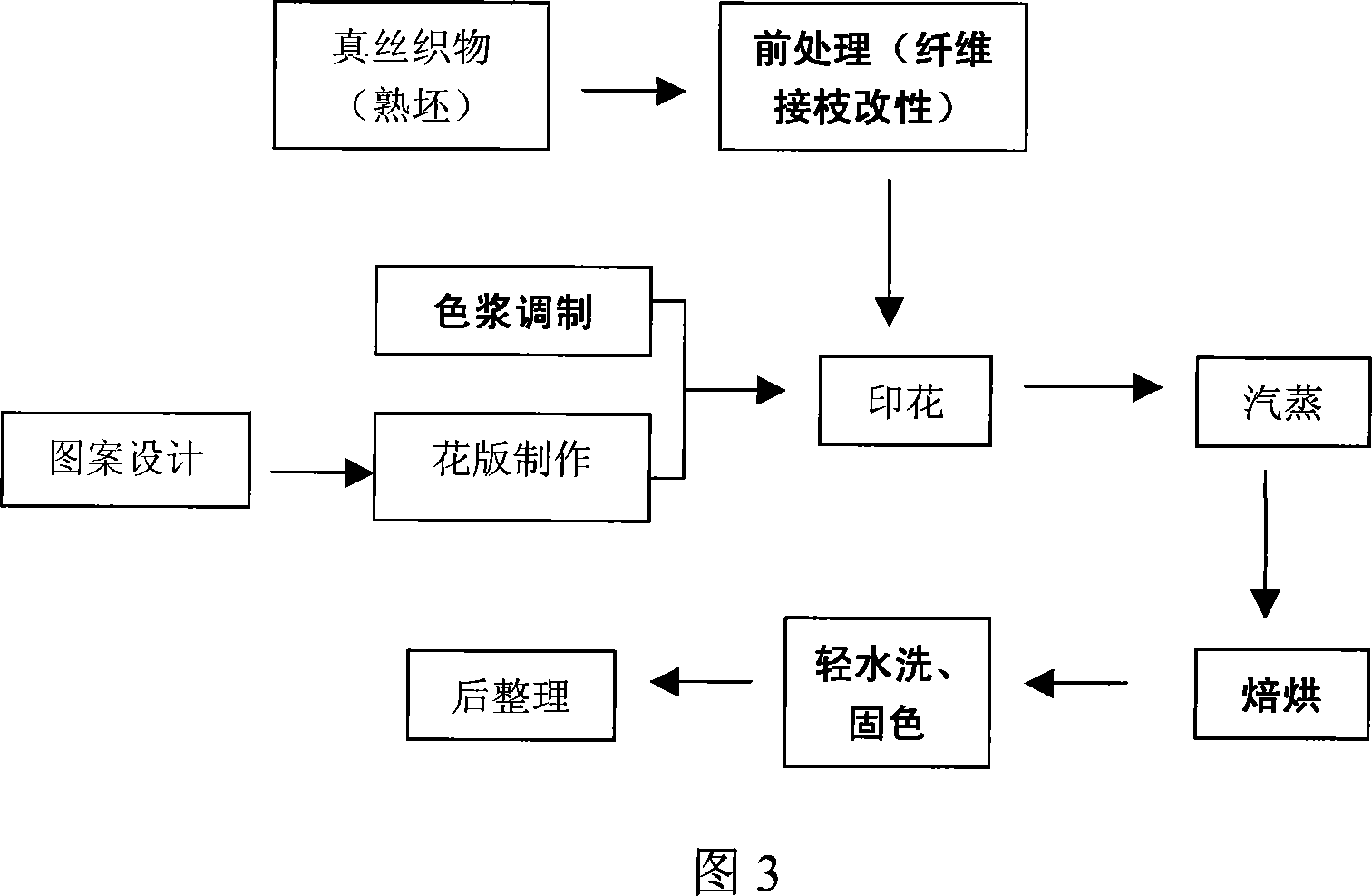

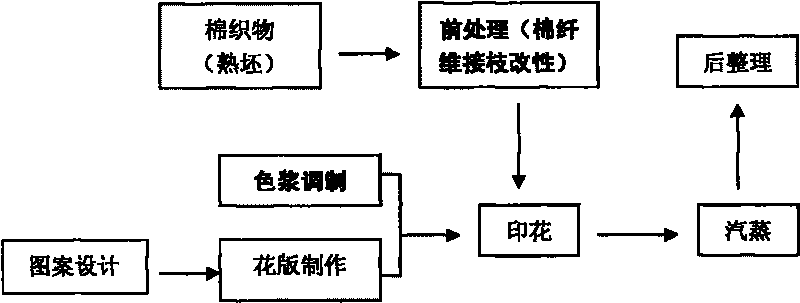

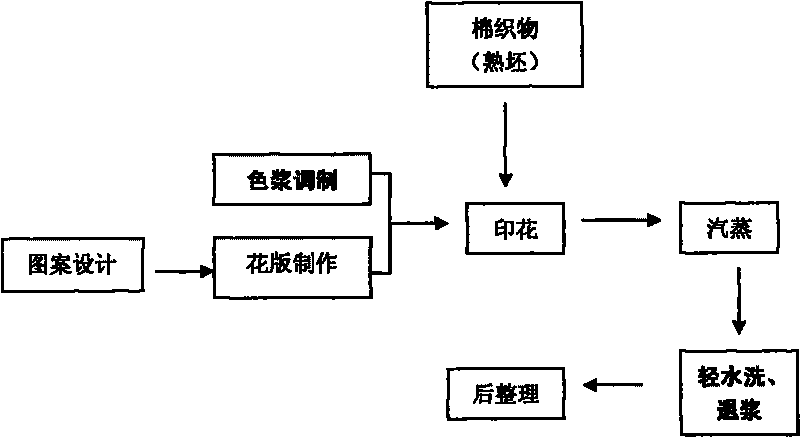

Textile printing method with little amount of water of cotton fabric by utilizing reactive dye

InactiveCN101705626AHigh adsorption rateIncrease dyeing (fixation) rateDyeing processTextile printerColour fastness

The invention discloses a textile printing method with a little amount of water of cotton fabric by utilizing reactive dye. Light-colored textile printing comprises the following steps: graft modification is firstly carried out on the cotton fibre to ensure that cationic group is introduced in the cotton fibre molecules, so as to increase the adsorption rate of the anionic reactive dye to increase the dye uptake (fixing) of the reactive dye and improve color fastness; and simultaneously, synthetic thickening agent with low content of solid is adopted to be served as the rawstock of the printing paste to reduce the content of solid in the sizing agent of the color paste; fixation accelerator and softening agent are added into the color paste to further improve the color fastness of the printed fabric and improve hand feeling; and washing can be avoided after textile printing. With regard to the middle and deep-coloured textile printing: the rawstock of the print paste adopts modified sodium alginate to increase the washability, thus reducing washing time and water consumption and achieving the purpose of light washing. In the textile printing, the pattern designing, flower version manufacturing, textile printing, decatizing and after finishing processes are identical to traditional process. The invention can shorten the process of dye textile printing, save water and reduce the discharge of sewage simultaneously.

Owner:ZHEJIANG SCI-TECH UNIV

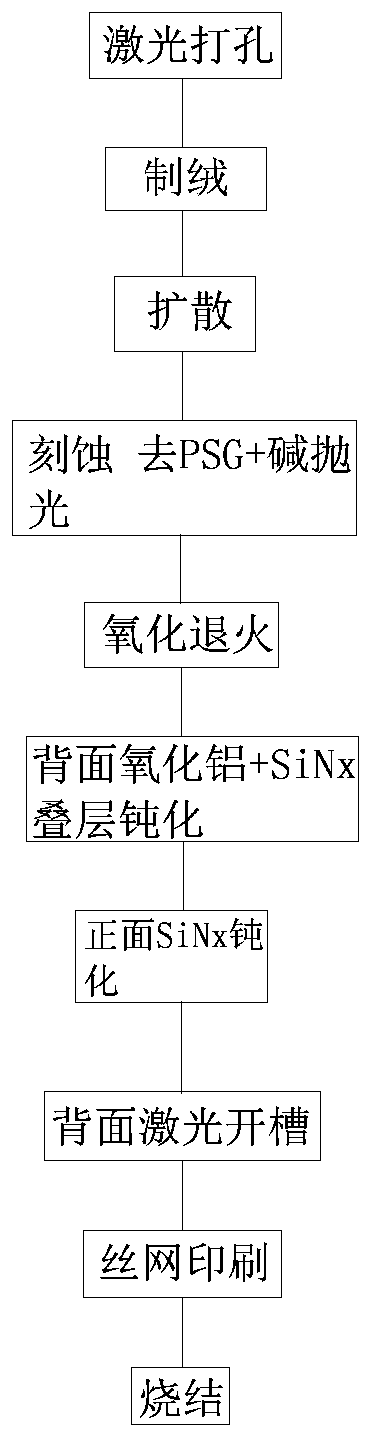

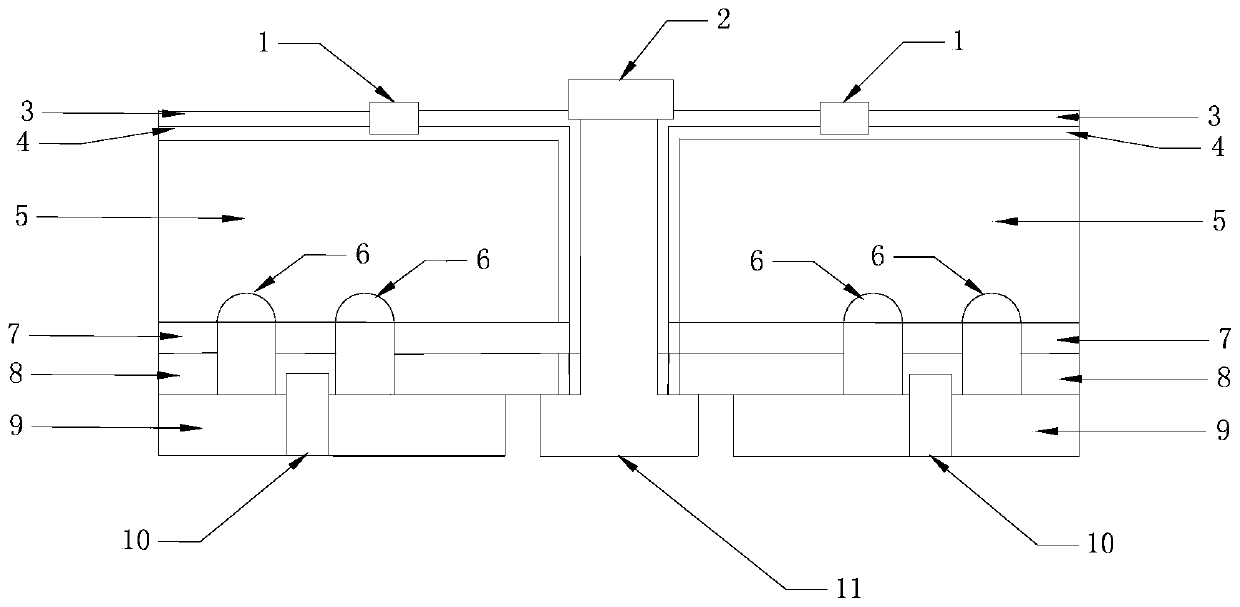

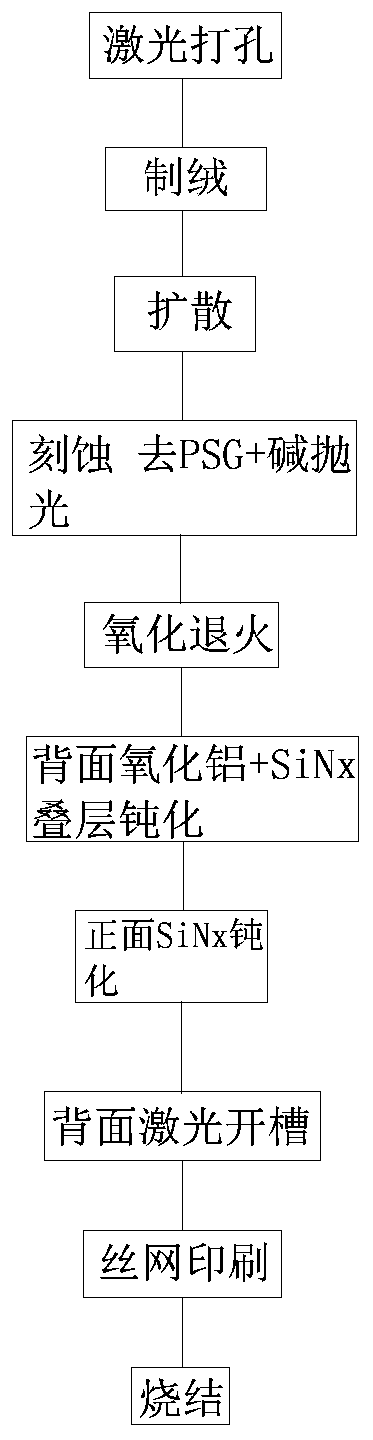

Preparation method of MWT solar cell

InactiveCN109713053AReduce printing processReduce pollutionFinal product manufactureSemiconductor devicesAcid etchingScreen printing

The invention relates to a preparation method of a cell, in particular to a preparation method of an MWT solar cell, and belongs to the technical field of MWT solar cell module processing. The preparation method of the MWT solar cell comprises the steps: performing punching, texturing and diffusion of a silicon wafer, and then performing etching, oxidation annealing, back passivation, front coating, laser grooving, silk-screen printing and sintering to form ohmic contact; and finally obtaining the MWT solar cell. The etching step comprises the substeps: removing phosphorosilicate glass on theback surface and four side surfaces of the silicon wafer, and then adding reaction solution for alkali polishing to obtain the back surface with the reflectivity of 40-50%. Compared with an acid etching process, the groove type alkali polishing process has the advantages that the back polishing effect of the silicon wafer is more excellent, the weight is reduced, and the fragment risk is reduced;the back reflectivity is higher, the internal reflection effect of a long wave band is improved, uniform deposition of a passivation film Al2O3 is facilitated, the passivation effect on a silicon wafer is improved, and the battery efficiency gain is at least 0.15% compared with the prior art.

Owner:JIANGSU SUNPORT POWER CORP LTD

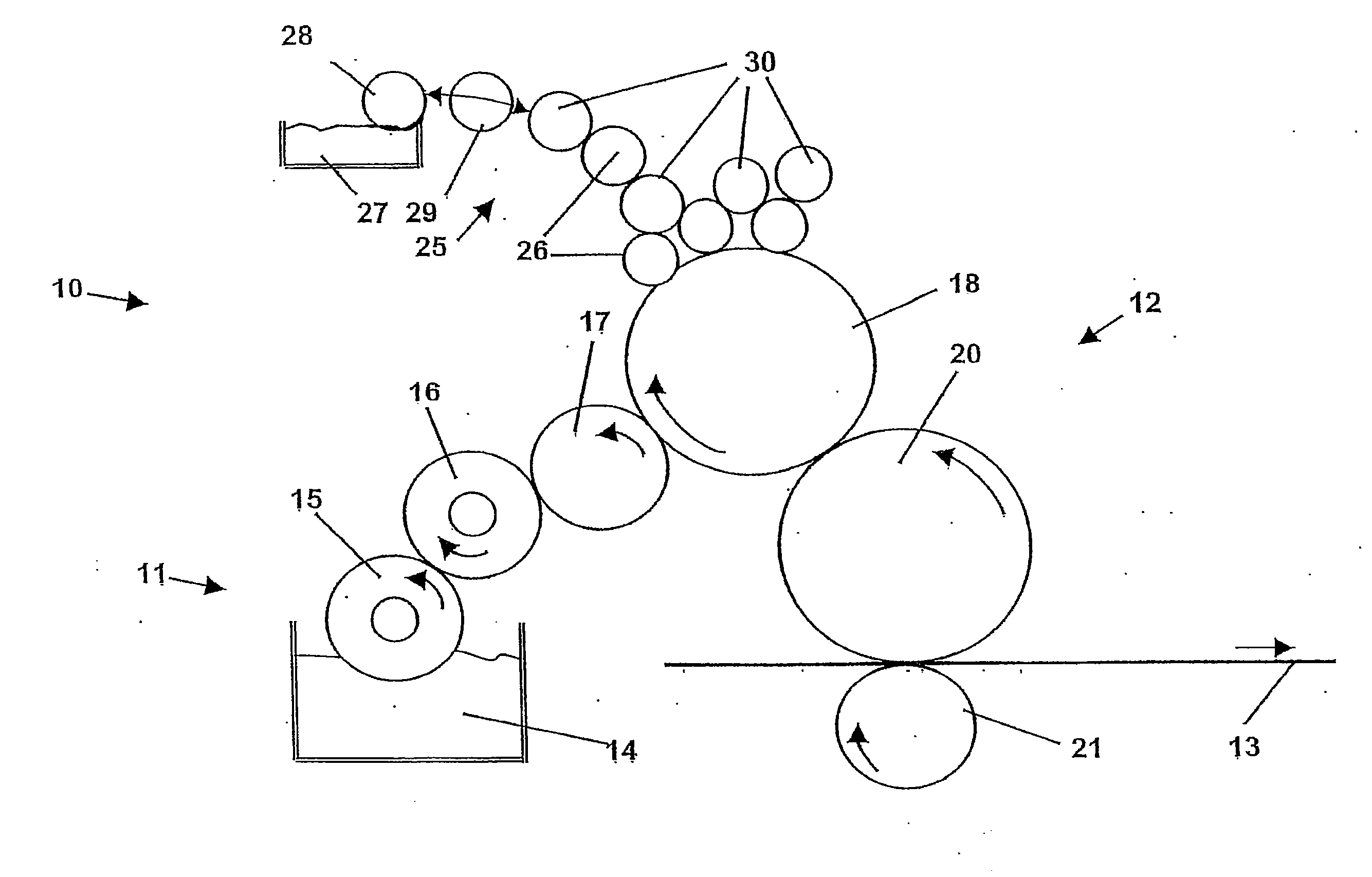

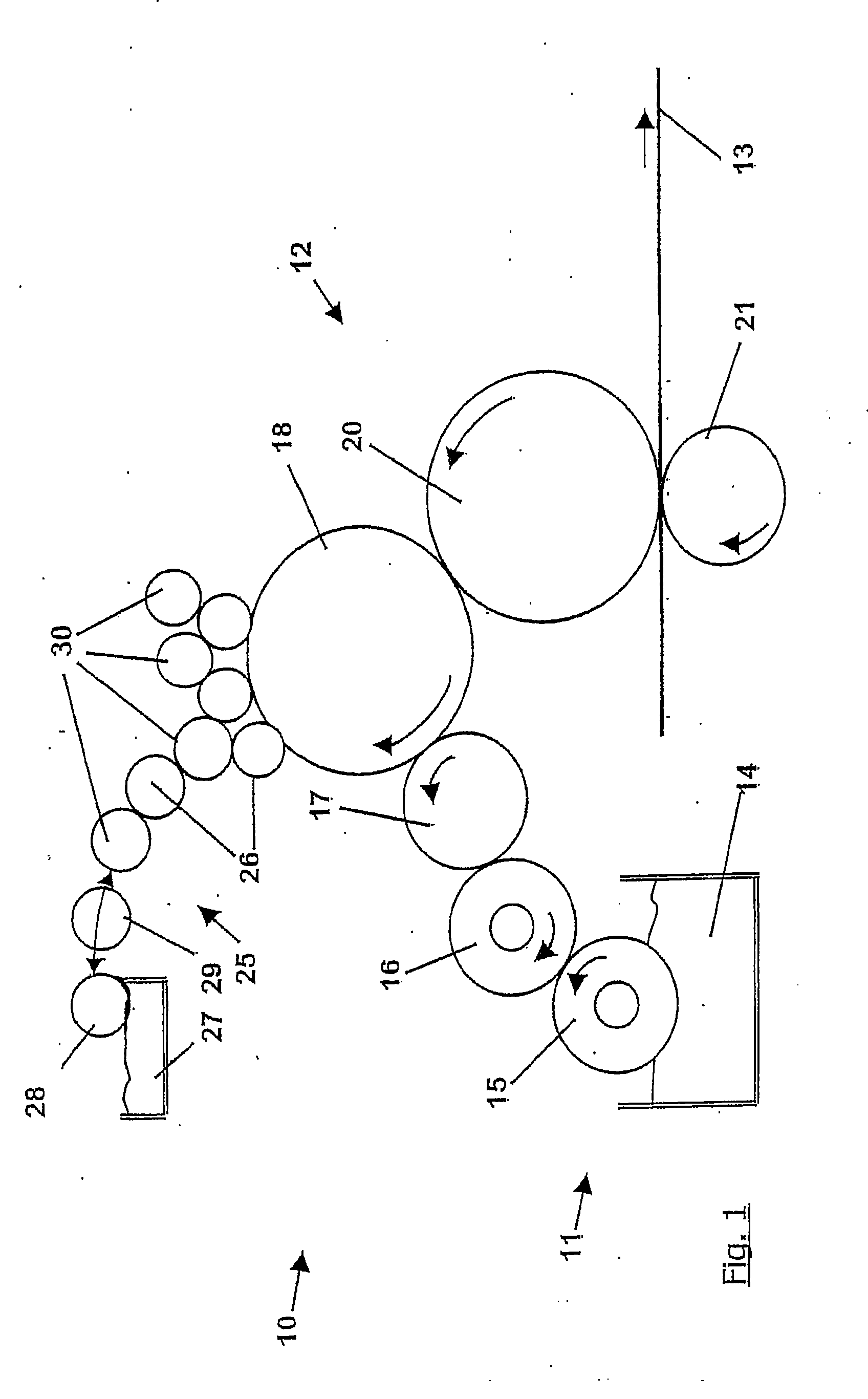

Multi-color roller gravure printing production method of textile dye

ActiveCN102785495AExtended door widthShorten the printing processDuplicating/marking methodsOther printing apparatusFiberWastewater

The invention relates to a multi-color roller gravure printing production method of a textile dye. According to the traditional printing method, more floating colors exist in the washing process, and the excessive wastewater discharge is easily caused. The invention comprises the following steps that: (1) pre-treatment working solutions are selected according to textiles of different types of fibers; (2) the pre-treatment working solutions of different concentrations are padded under the conditions that the immersion time is 5-30 seconds, the expression is between 50% and 100% and the speed is 10 to 40m / min, and are dried; (3) a special dye ink for gravure printing is selected; (4) through an improved multi-color roller gravure printing machine with adjustable printing thickness, lengthened width, enhanced drying and the like, the special dye ink is printed to the textile which is padded with the pre-treatment working solutions and is dried at a speed of 10-40 m / min and is dried; (5) the printed textile enters steaming equipment for steaming fixation; and (6) after fixation, the printed textile is subjected to washing, drying and other treatment processes to complete the entire printing production process of the textile.

Owner:ZHEJIANG YIDE CHEM

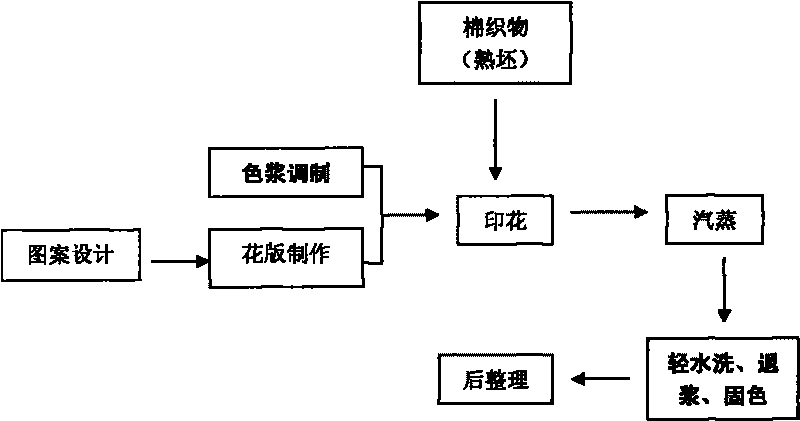

Cotton fabric reactive dye printing method with small water volume

InactiveCN102493221AHigh adsorption rateIncreased dye uptake (fixation) rateDyeing processFiberColour fastness

The invention discloses a cotton fabric reactive dye printing method with small water volume. A light color printing comprises the steps of: carrying out grafting modification on cotton fiber to introduce cation groups into cotton fiber molecules and increase adsorption rate of anion reactive dye, colouring (anchorage) rate of the reactive dye and color fastness; meanwhile, employing a synthesis thickening agent with low solid content as a printing color paste to reduce solid content in a slurry of the color paste; adding reinforcing agent and softener into the color paste to further enhance color fastness and hand feel of the printing fabric. The printing fabric is washing-free after printing. As for medium and dark color printing, modified sodium alginate is employed as protoplasm of the printing color paste to enhance washability, thereby reducing time and water amount for washing and realizing light washing. Processes of pattern design, printing board preparation, printing, steaming and after-treatment are the same as a traditional technology. The method of the invention can shorten dye printing technology, save water and reduce sewage discharge.

Owner:ZHEJIANG SCI-TECH UNIV

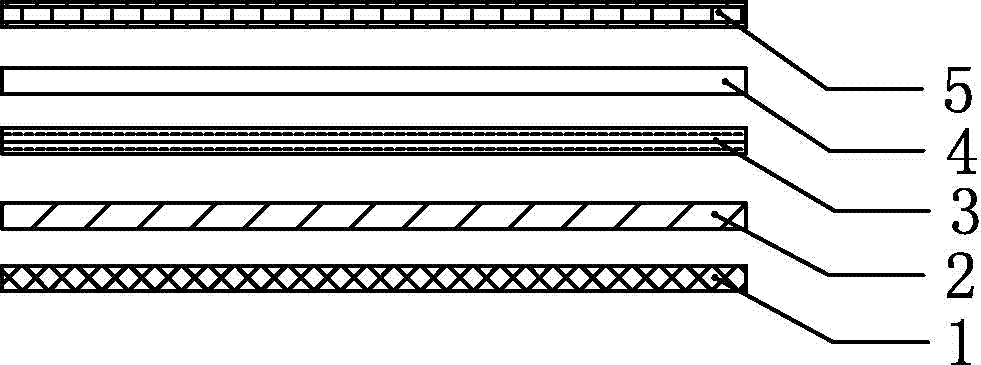

Transfer printing film prepared by means of digital printing and preparation method and application thereof

ActiveCN106808820ASolve the problem of micro-distortion transfer printingTroubleshoot setup issuesMonocarboxylic acid ester polymer adhesivesWax coatingsColor imageWax

The embodiment of the invention discloses a transfer printing film prepared by means of digital printing. The transfer printing film comprises a carrier membrane, a water-borne wax layer and a color image-text layer which are superposed in sequence. The embodiment of the invention further discloses a preparation method of the transfer printing film prepared by means of digital printing and an application of the transfer printing film. According to the transfer printing film prepared by means of digital printing and the preparation method and application thereof, the transparent visual inspection problem of image-text printed by the transfer printing film, the problem of micro-distortion transfer printing of the transfer printing film, the problem of printing plate omission, the problem of reducing printing procedures and lowering losses and the problem of efficient industrial production conventionally are solved, and the transfer printing film and the preparation method and application thereof are particularly suitable for small-single and short-single low-cost operation; the problems of white ink underpainting and glue setting of a transfer printing function layer are also solved; the problem of combining adhesion of the array powdered ink color image-text layer and a separating agent coating and the problem of separating the array powdered ink color image-text layer and the separating agent coating from a carrier base membrane together are even solved; and moreover, volatile organic compounds (VOC) are hardly generated, and therefore the printing environmental protection property is greatly improved, and epoch-making significance is achieved.

Owner:广东宏达印业股份有限公司

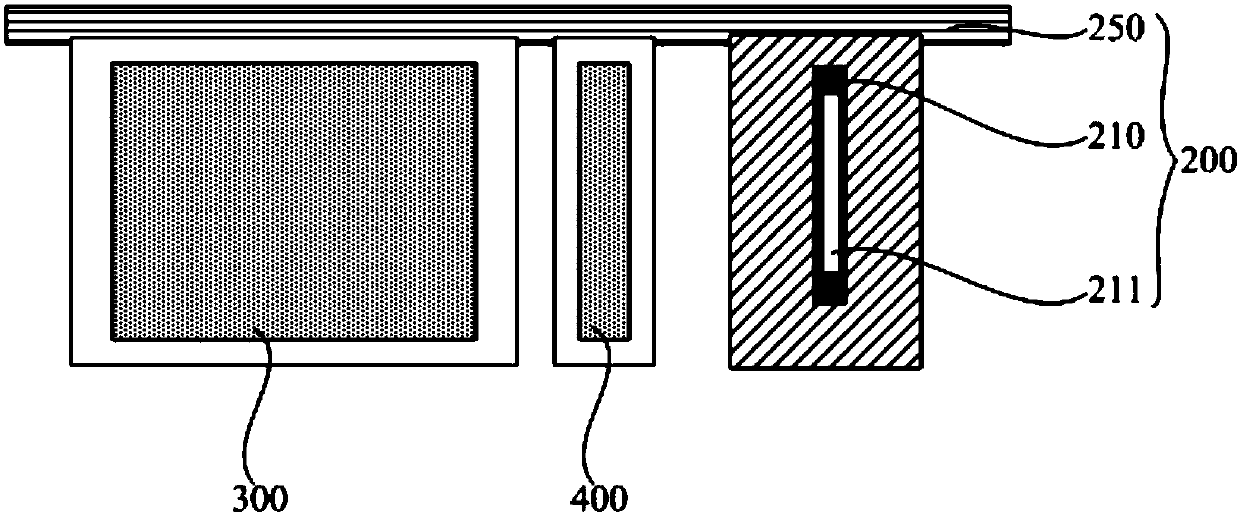

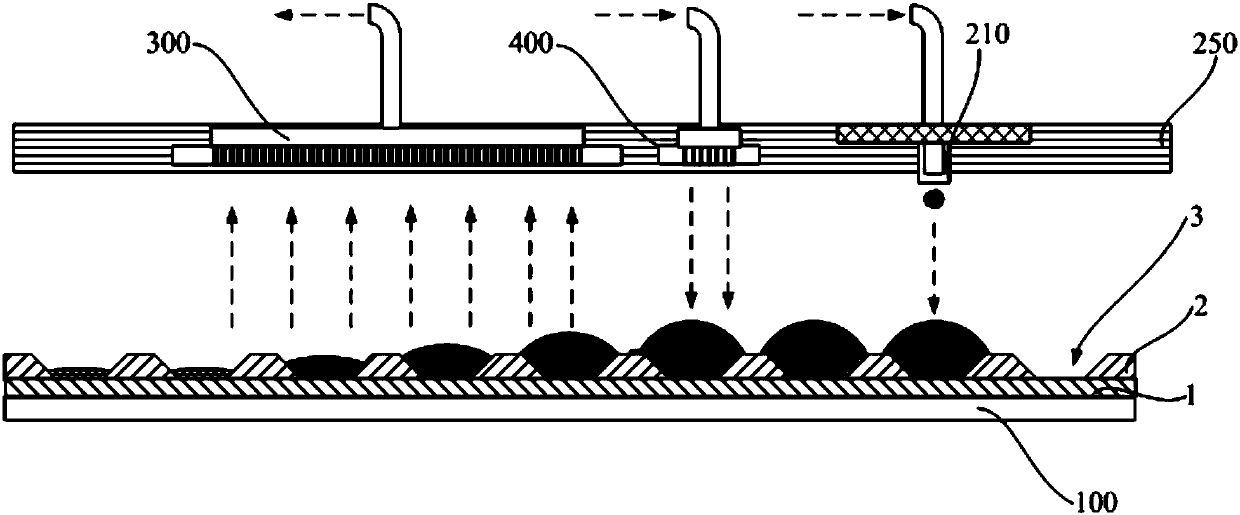

Luminescent device and manufacturing method thereof

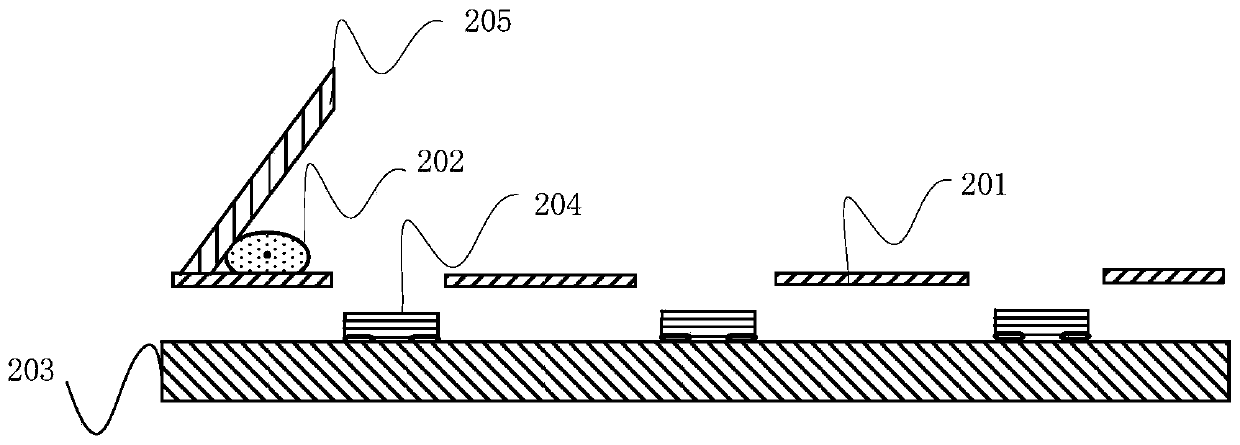

ActiveCN108963046AAvoid unevennessEliminates solvent vapor concentration differencesSemiconductor devicesOptoelectronicsFlow number

The present invention relates to a luminescent device and manufacturing method thereof. The manufacturing method comprises the following steps of: providing a substrate, and forming a first electrodelayer on the substrate; forming a pixel pit on the substrate; forming a luminescent function layer in the pixel pit; forming a second electrode layer on a pixel definition layer and the luminescent function layer, wherein the formation process of at least one layer of the first electrode layer, the second electrode layer and the luminescent function layer comprises the following steps of: performing ink-jet printing, at the same time performing step-by-step vacuum drying processing of ink after printing, performing package and obtaining at least one layer of the first electrode layer, the second electrode layer and the luminescent function layer. The manufacturing method of the luminescent device facilitates improvement of the uniformity of final film formation, greatly shortens the wholeprinting craft process, reduces the craft flow numbers and improves the printing production efficiency.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Method for enhancing jet printing fastness in ink jet digital printing

InactiveCN108978284AReduce precisionAvoid direct contactInksDyeing processWater basedColour fastness

The invention belongs to the technical field of refining chemical engineering, and particularly relates to a method for enhancing jet printing fastness in ink jet digital printing. The method at leastcomprises the following steps of S1, enabling a digital printing jet printing machine to jet and spray a water-based transparent coating ink to the position requiring printing patterns on a fabric, and forming a first water-based transparent coating ink layer; S2, enabling the digital printing jet printing machine to jet and spray a color ink to the surface of the first water-based transparent coating ink layer, and forming a color ink layer; S3, enabling the digital printing jet printing machine to jet and spray a water-based transparent coating ink to the surface of the color ink layer, andforming a second water-based transparent coating ink layer; S4, performing flash drying or natural drying on a fabric, and curing, so as to obtain a finished product. Compared with the prior art, themethod has the advantages that the color developing effect of white ink and color ink on the fabric is greatly improved, the printing technology process is shortened, the color fastness of the digital coating ink is improved, and the energy-saving and environment-friendly effects are realized.

Owner:广东海亚新材料科技有限公司

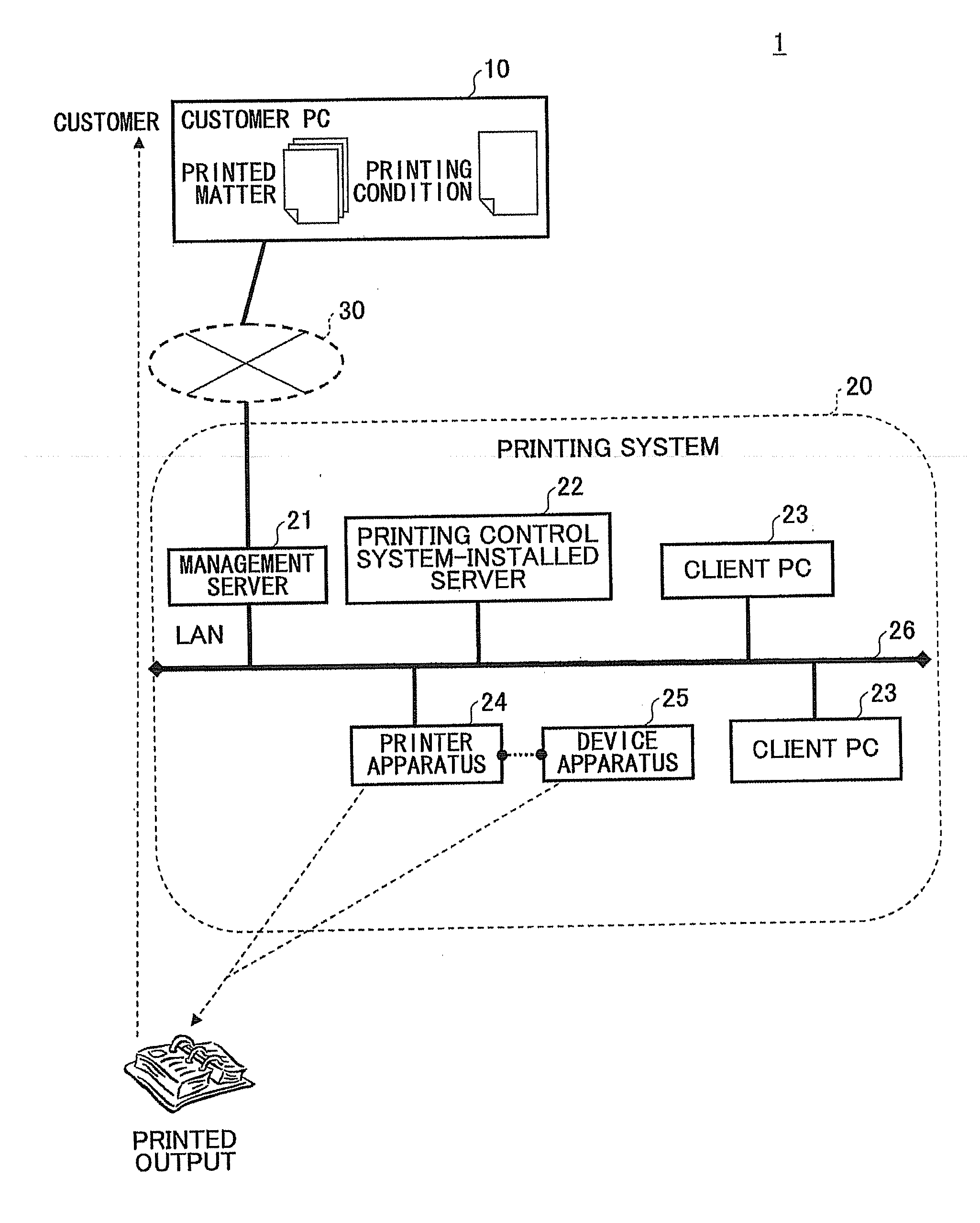

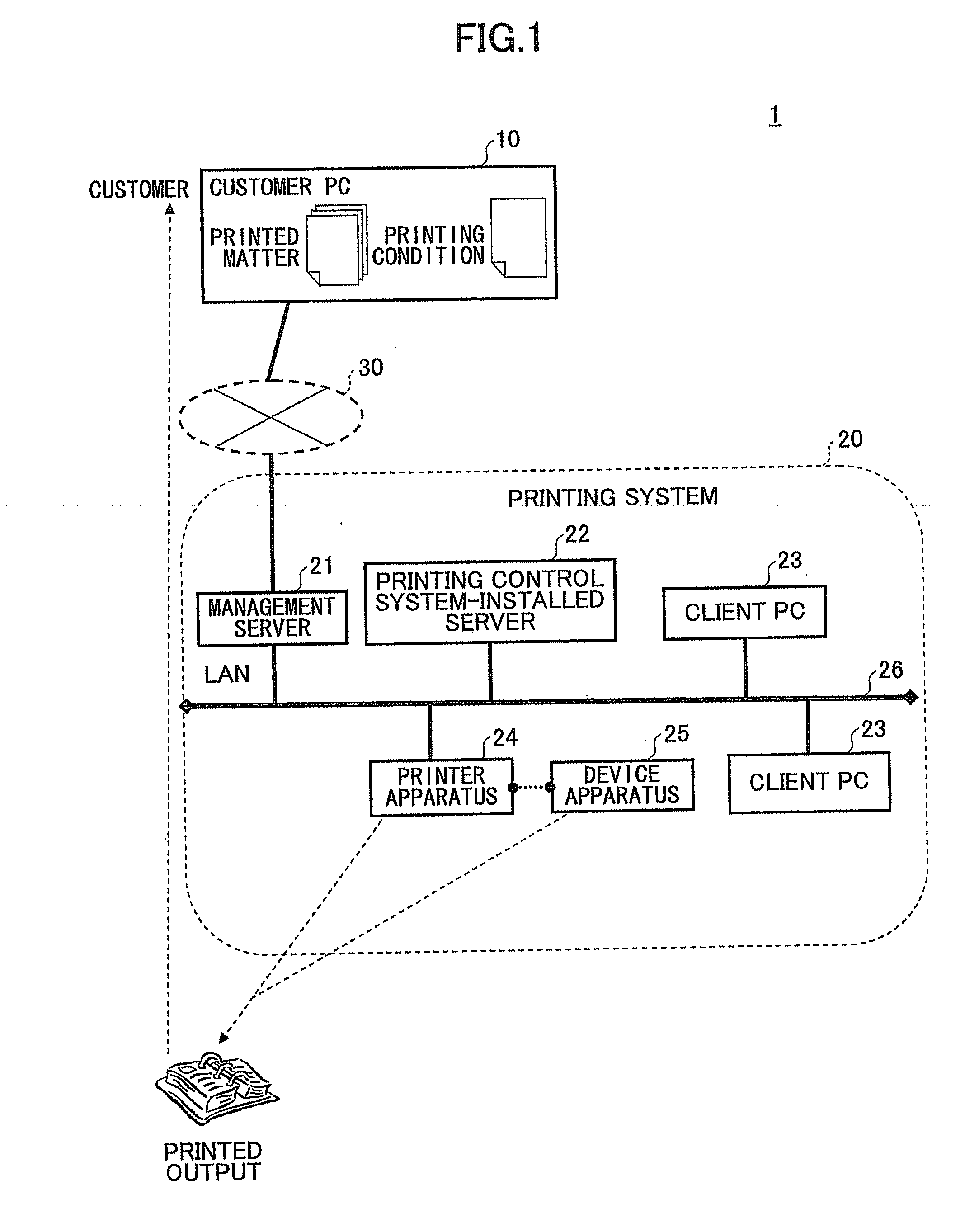

Printing control program product, printing control apparatus, and printing system

InactiveUS20120307262A1Reduce downtimeOperation efficiency can be improvedDigitally marking record carriersDigital computer detailsEngineeringMechanical engineering

A printing control program product is disclosed, which causes a computer to function as a printer control unit; a printing conditions control processing unit; and an overall control unit which, for a printing job with a determined result of not matching, when a size of a sheet onto which printing is to be made can be generated by cutting a mounted sheet, arranges picture drawing data of a printed output in a layout suitable for the size of the sheet onto which the printing is to be made by cutting the mounted sheet, along the layout after the printing, and generating the printed output.

Owner:RICOH KK

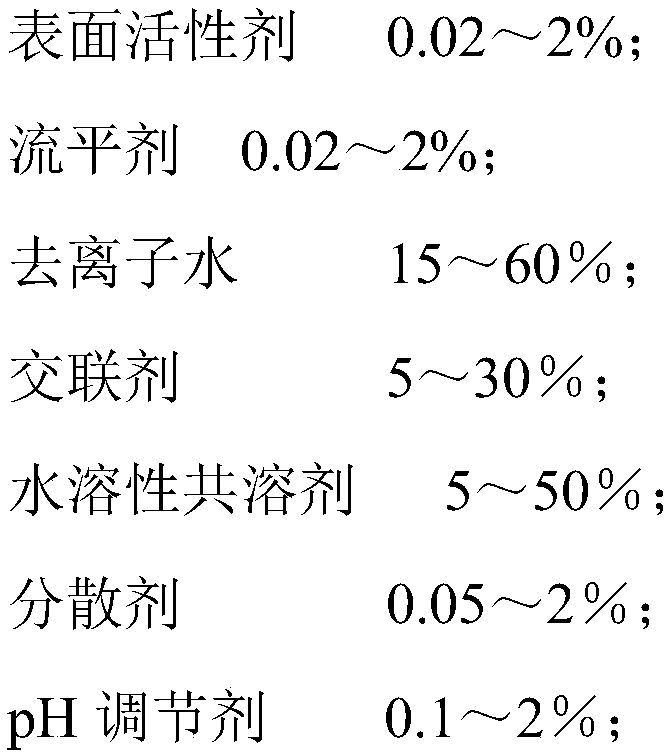

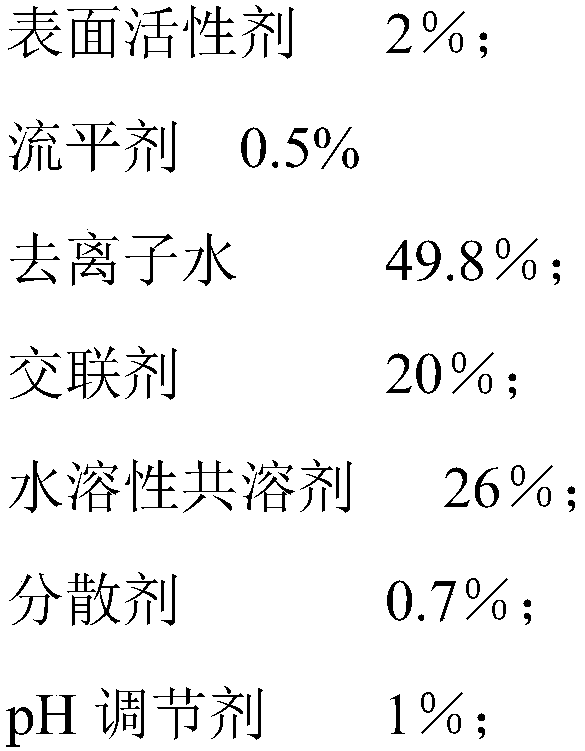

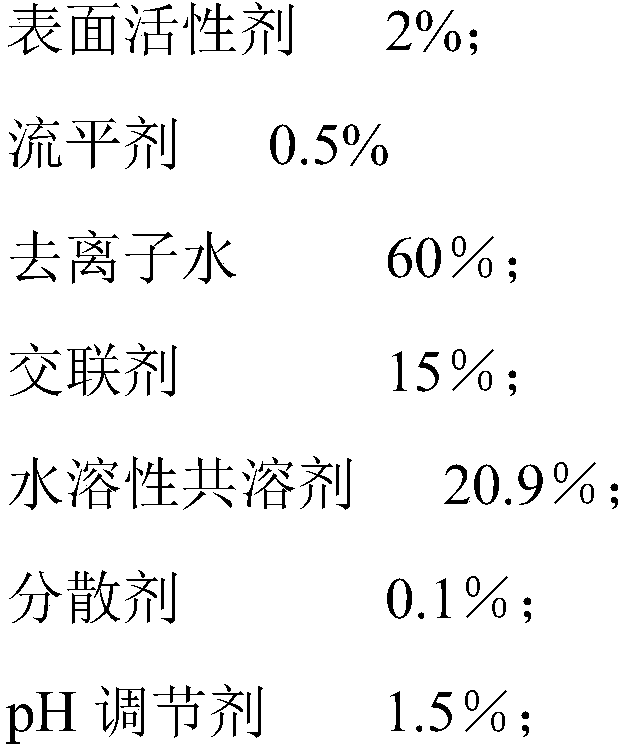

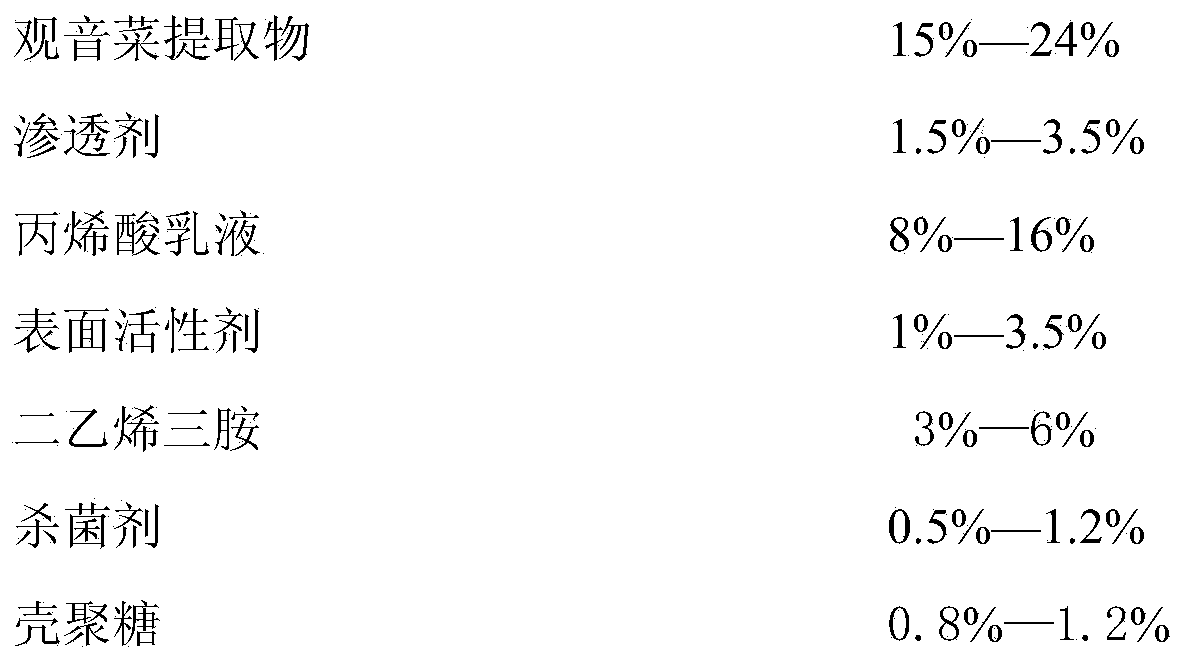

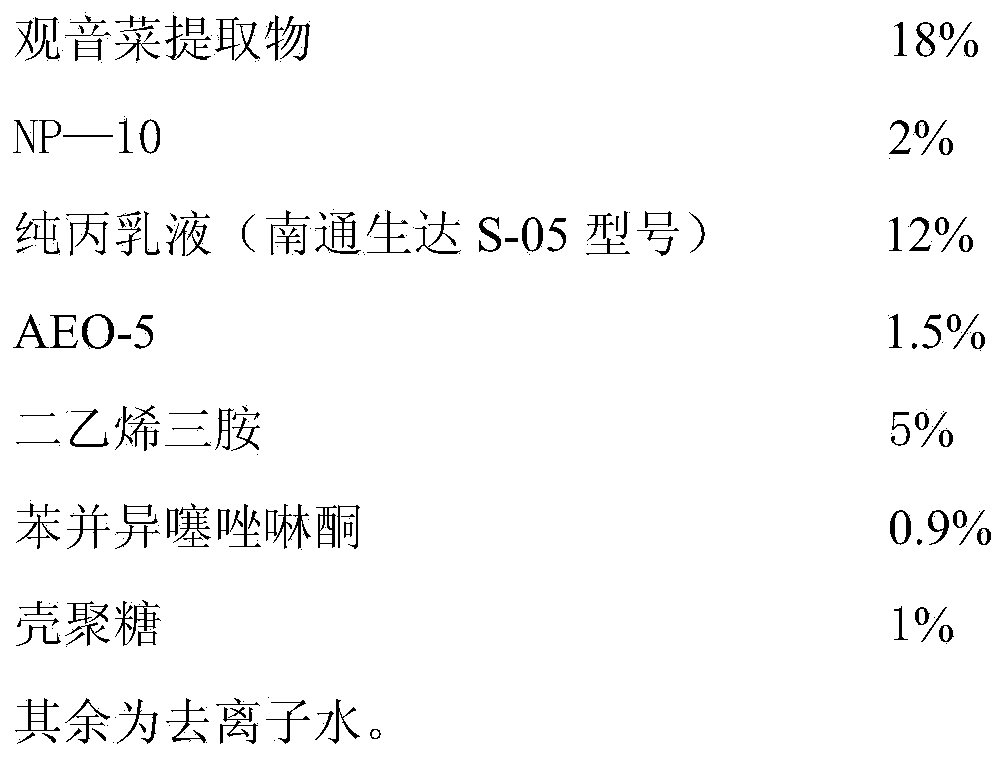

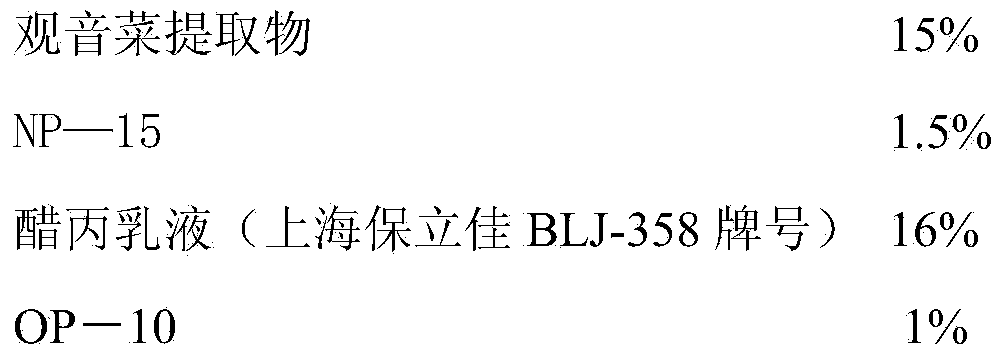

Digital inkjet printing ink based on gynura bicolor extract

The invention belongs to the field of the development of natural vegetable dye, and particularly relates to a preparation method for extracting natural dye from gynura bicolor and an application. All components, namely, a gynura bicolor extract, a penetrant, an acrylic emulsion, a surfactant, diethylenetriamine, a bactericide and chitosan are added to deionized water in percentage by weight and evenly mixed at the normal temperature, a pH regulator is added to regulate the system to be alkaline, the solution is heated to the temperature of 60-70 DEG and continuously stirred for 1-3 h, the solution is cured for 2-5 h at the temperature and then cooled to the normal temperature, the solution is sequentially filtered by membranes with pore diameters of 0.55 mu m and 0.22 mu m, and a digital printing ink product is obtained finally. Pretreatment procedures such as sizing and the like are not required to be performed on a fabric before digital printing jet printing is performed on the fabric with the ink, jet printing procedures are reduced, and the dyed fabric is good in water vapor permeability and comfortable.

Owner:JIAXING MENGDI WEAVING

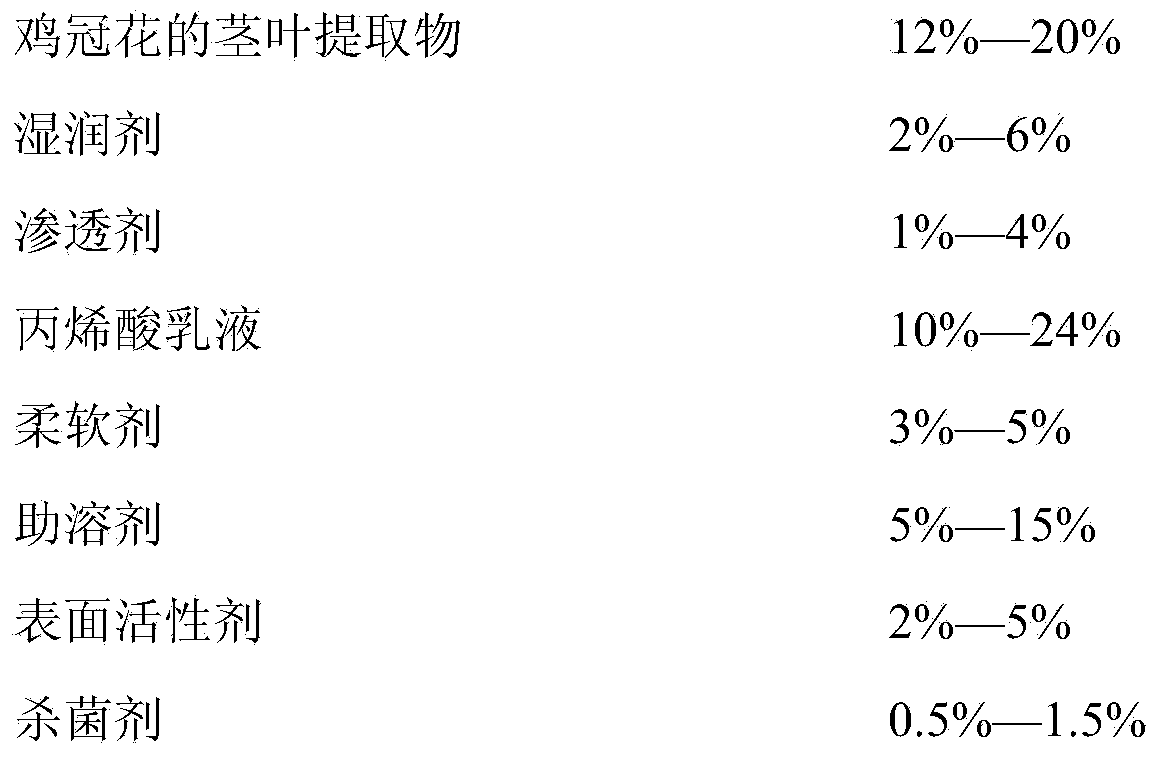

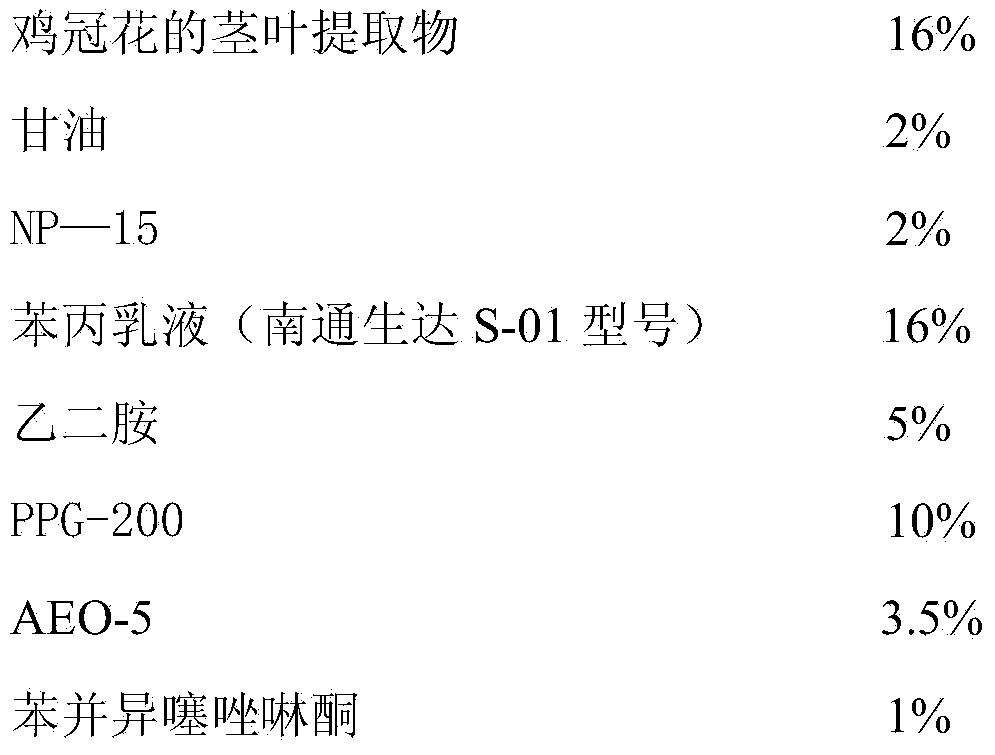

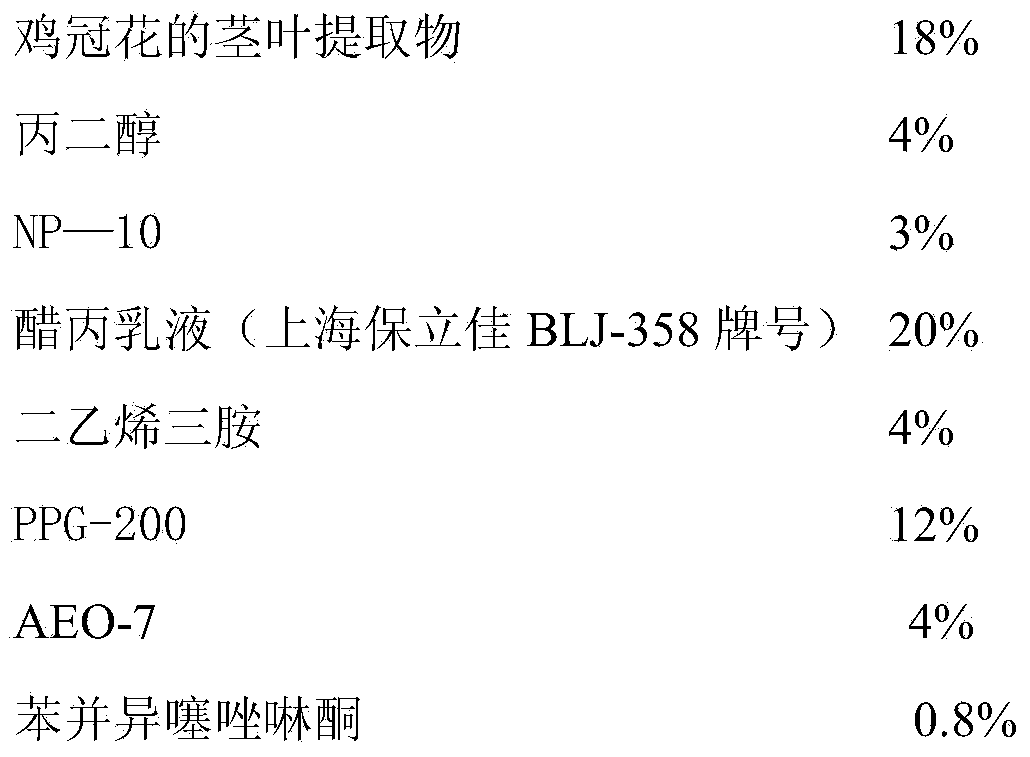

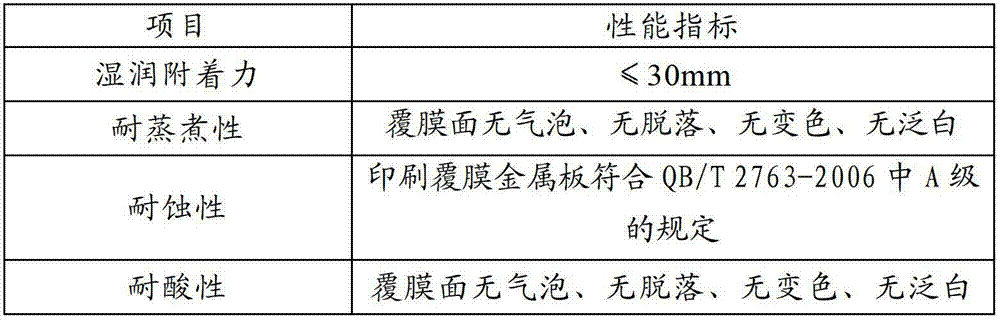

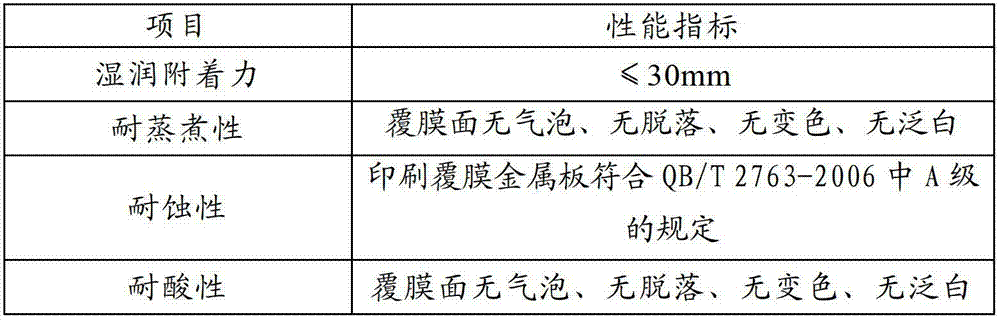

Digital ink-jet printing ink based on extract of stems and leaves of celosia cristata L.

The invention belongs to the field of development of natural plant dyes and particularly relates to a preparation method for extracting a natural dye from stems and leaves of celosia cristata L. and application of the method. The preparation method comprises the following steps: adding extract of stems and leaves of celosia cristata L., a wetting agent, a penetrating agent, acrylic emulsion, a softening agent, a cosolvent, a surfactant and a sterilizing agent into de-ionized water in percentage by weight, and agitating uniformly; adjusting the system to be alkaline; heating to 60-70 DEG C and continually agitating for 1-3 hours; preserving heat and curing for 2-5 hours; cooling the solution to room temperature; and filtering the solution to obtain a final digital ink-jet printing ink product. Before the ink provided by the invention is used for carrying out digital jet printing on a textile, pre-treatment procedures of sizing and the like do not need to be carried out on the textile, so that a jet printing process is shortened; and the dyed textile has good water vapor permeability and has a high comfort level.

Owner:JIAXING MENGDI WEAVING

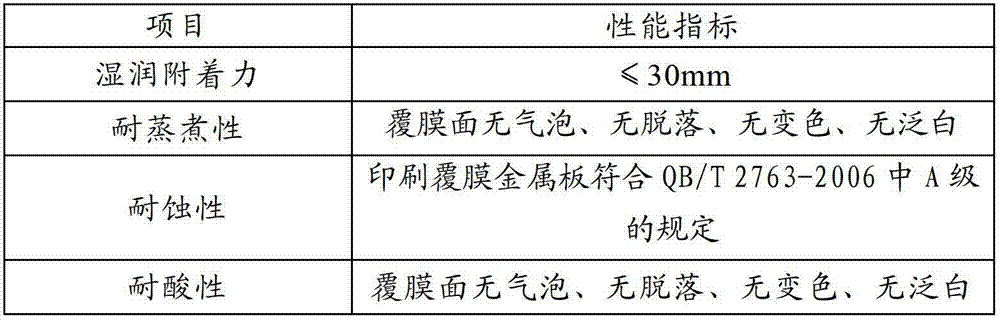

Printing coated metal plate and production method thereof

ActiveCN102825862AImprove barrier propertiesAvoid moving outLaminationLamination apparatusAdhesiveEngineering

The invention provides a printing coated metal plate and a production method thereof. The printing coated metal plate comprises a metal substrate, an outer film and an inner film, wherein the metal substrate is positioned between the outer film and the inner film and are stuck to the outer film and the inner film without any adhesive; at least one of the outer film and the inner film is an intaglio printing film; and a printing pattern is formed on the side, stuck to the metal substrate, of the intaglio printing film. The invention also provides a production method of the printing coated metal plate. The printing coated metal plate is produced by the process that coating is performed after printing, and the printing pattern is sealed between the thin film and the metal substrate, so that the safety quality of the printing coated metal plate is obviously improved and the machining process is simplified.

Owner:ORG TECH CO LTD

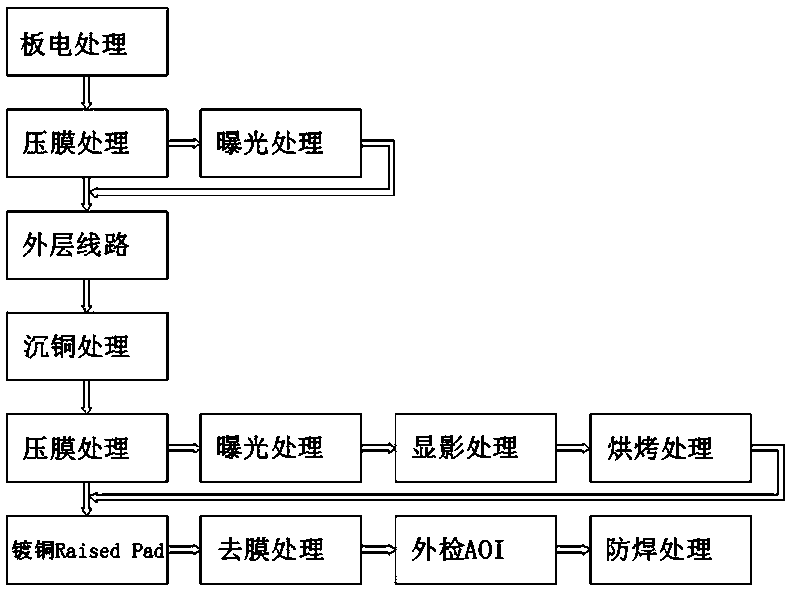

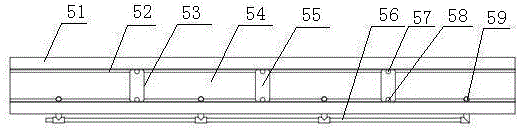

Raised Pad manufacturing method

ActiveCN111511120AOmit the preparation processSimple processPrinted circuit liquid treatmentPrinted circuit secondary treatmentCopper platingElectrical conductor

The invention relates to a Raised Pad manufacturing method, which comprises the steps of manufacturing an outer layer circuit, and the manufacturing of the outer layer circuit comprises the followingsteps of: S1, drilling the inner layer circuit of a PCB, entering a board electrical process, electroplating the whole board in an electroplating mode, and plating a layer of copper on the whole boardsurface and the wall of a drilled hole; S2, pressing a layer of photosensitive anti-corrosion film on the board surface subjected to plate electrification by using a hot roller film pressing machineto ensure the copper plating thickness; S3, manufacturing an outer layer circuit by adopting a developing machine, an etching machine and a film removing machine; S4, depositing a thin copper layer onthe independent units of the outer-layer circuit through copper deposition wires to enable the independent units to be connected together, and providing a conductor for subsequent electroplating; S5,pressing a layer of photosensitive anti-corrosion film on the board surface subjected to plate electrification by using a hot roller film pressing machine for manufacturing a PAD pattern for electroplating; and S6, placing the treated board on a copper plating wire to be subjected to copper plating operation, and obtaining the Raided Pad. The Raised Pad manufacturing method has the advantages ofthe simple process, low cost, high efficiency, the good product yield and the like.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

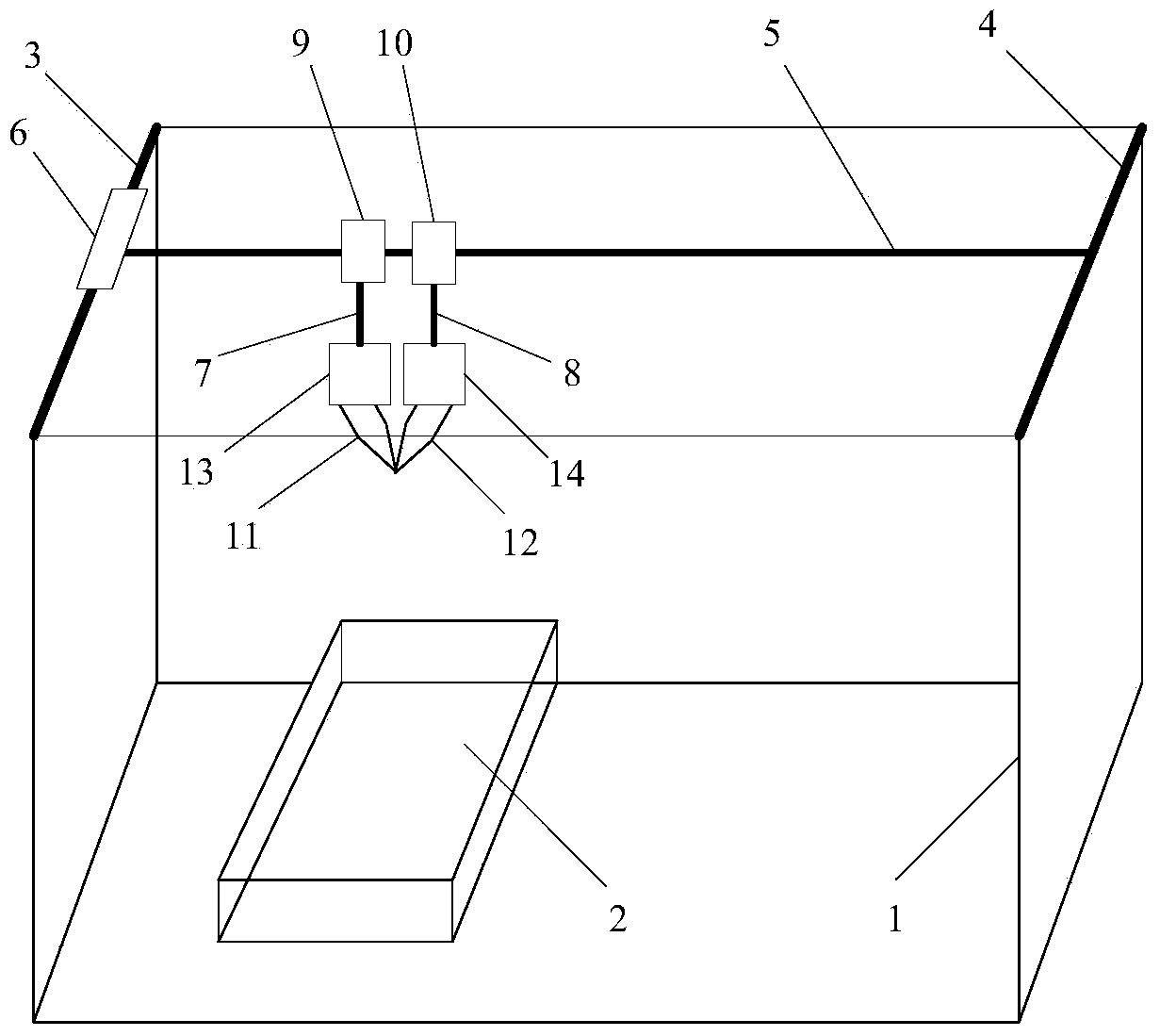

Three-dimensional printer for horizontally bidirectional printing

The invention discloses a three-dimensional printer for horizontally bidirectional printing. A first suspension rod and a second suspension rod are respectively slidingly installed on a sliding rod, a second driving mechanism and a third driving mechanism can respectively drive the first suspension rod and the second suspension rod to horizontally synchronously move on the sliding rod along opposite directions, a first sprayer and a second sprayer are respectively installed on lower ends of the first suspension rod and the second suspension rod, a forth driving mechanism and a fifth driving mechanism can respectively drive the first sprayer and the second sprayer to vertically synchronously move, the first sprayer and the second sprayer are arranged inclinedly, starting points of nozzles of the first sprayer and the second sprayer are coincident, and a control unit is used for controlling the first sprayer and the second sprayer to respectively carry out printing on two halves of a layer of a cross section. The two sprayers are simultaneously used for respectively carry out printing on two halves of a layer of a cross section so that printing stroke is shortened, a printing speed is accelerated and three-dimensional printing efficiency is improved.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

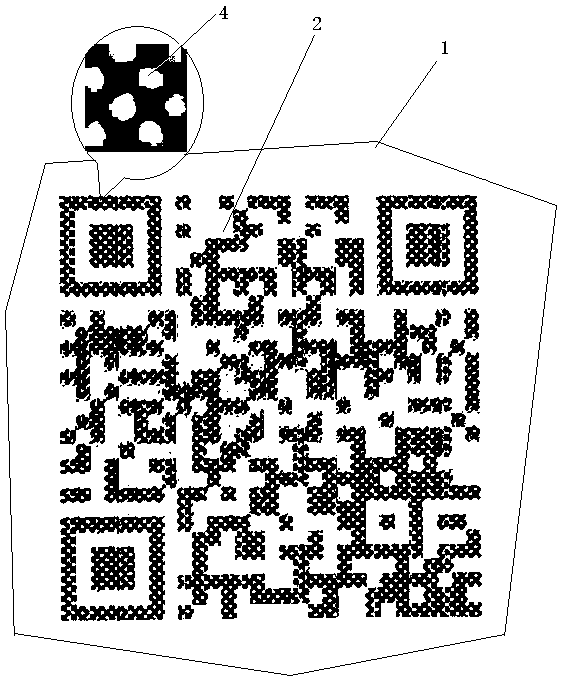

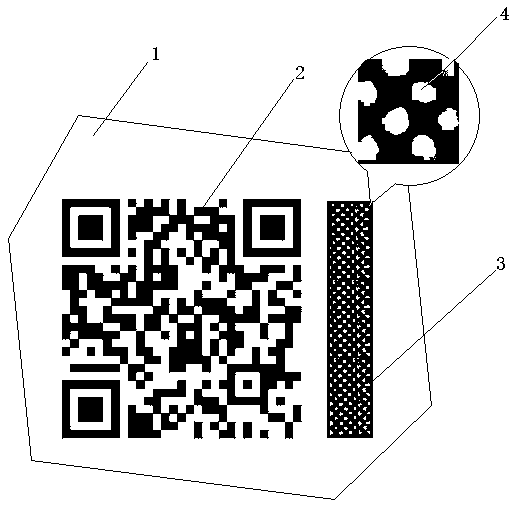

Sawtooth micropore anti-counterfeiting method and printed matter

ActiveCN110428272AEasy to identifyEasy anti-counterfeiting identificationCommerceRecord carriers used with machinesImage resolutionThe Internet

The invention belongs to the technical field of information query type anti-counterfeiting, and particularly relates to a sawtooth micropore anti-counterfeiting method and a printed matter. The methodcomprises the steps of presetting a plurality of artificial micropores on the two-dimensional code or / and the image-text; after the artificial micropores naturally shrink and become sawtooth micropores in random shapes, drying and curing the printing ink; amplifying the shot sawtooth micropores, and storing the shot microscopic characteristic information into an anti-counterfeiting inspection system database accessed to the Internet to serve as an anti-counterfeiting characteristic information file. The method is easy to produce and manufacture, and the authenticity of the low-end smart phonewith the rear lens resolution larger than 5 million pixels can be recognized conveniently.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

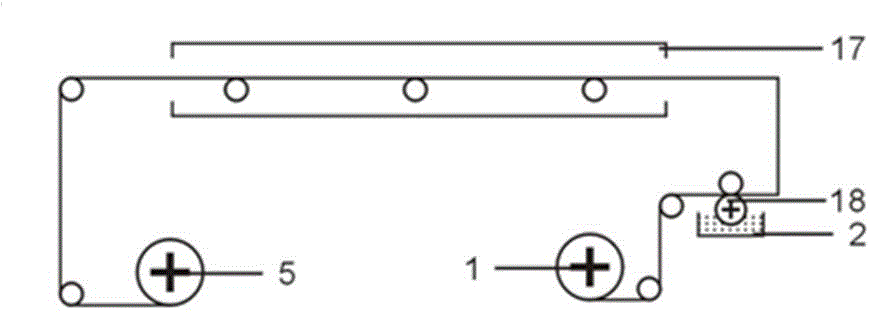

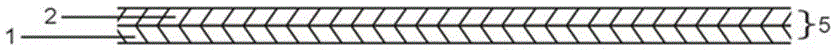

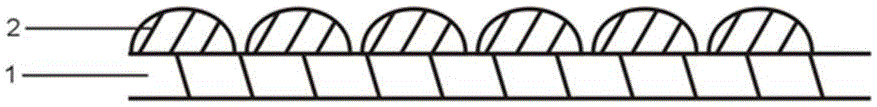

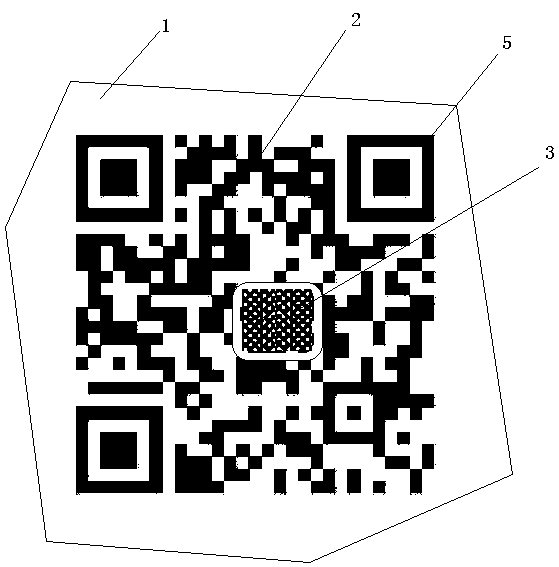

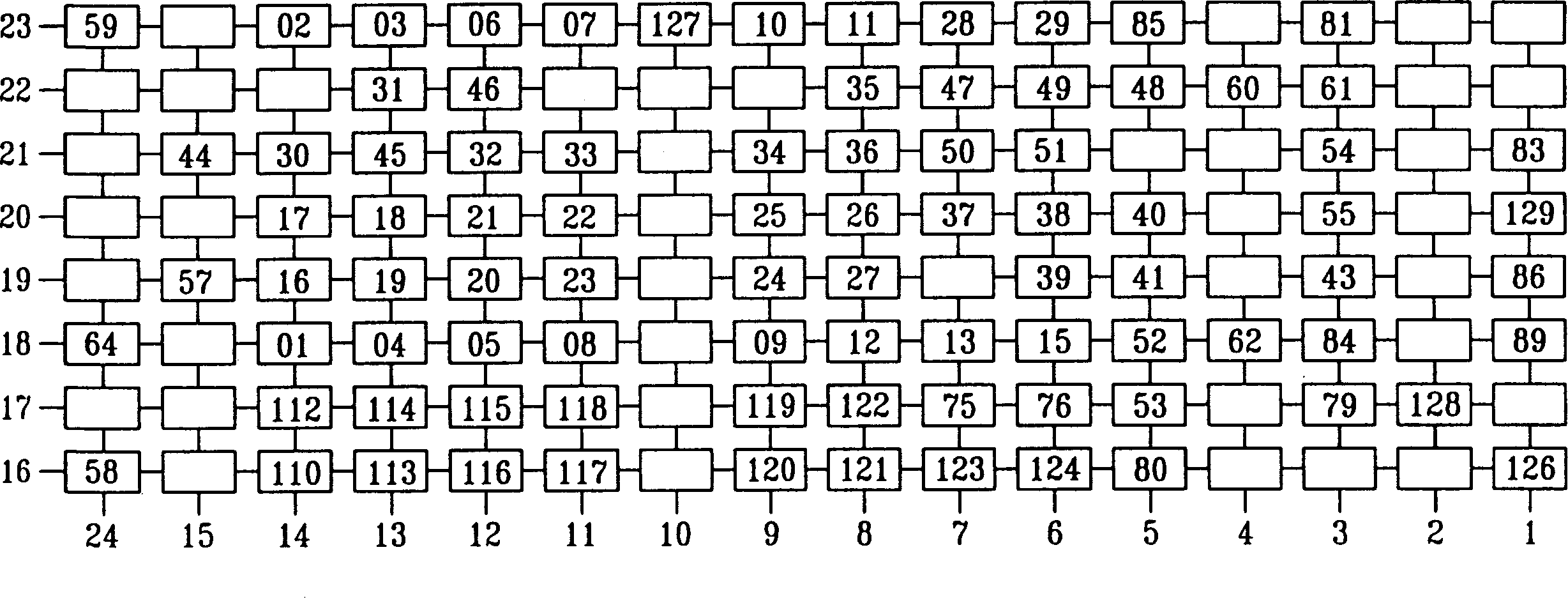

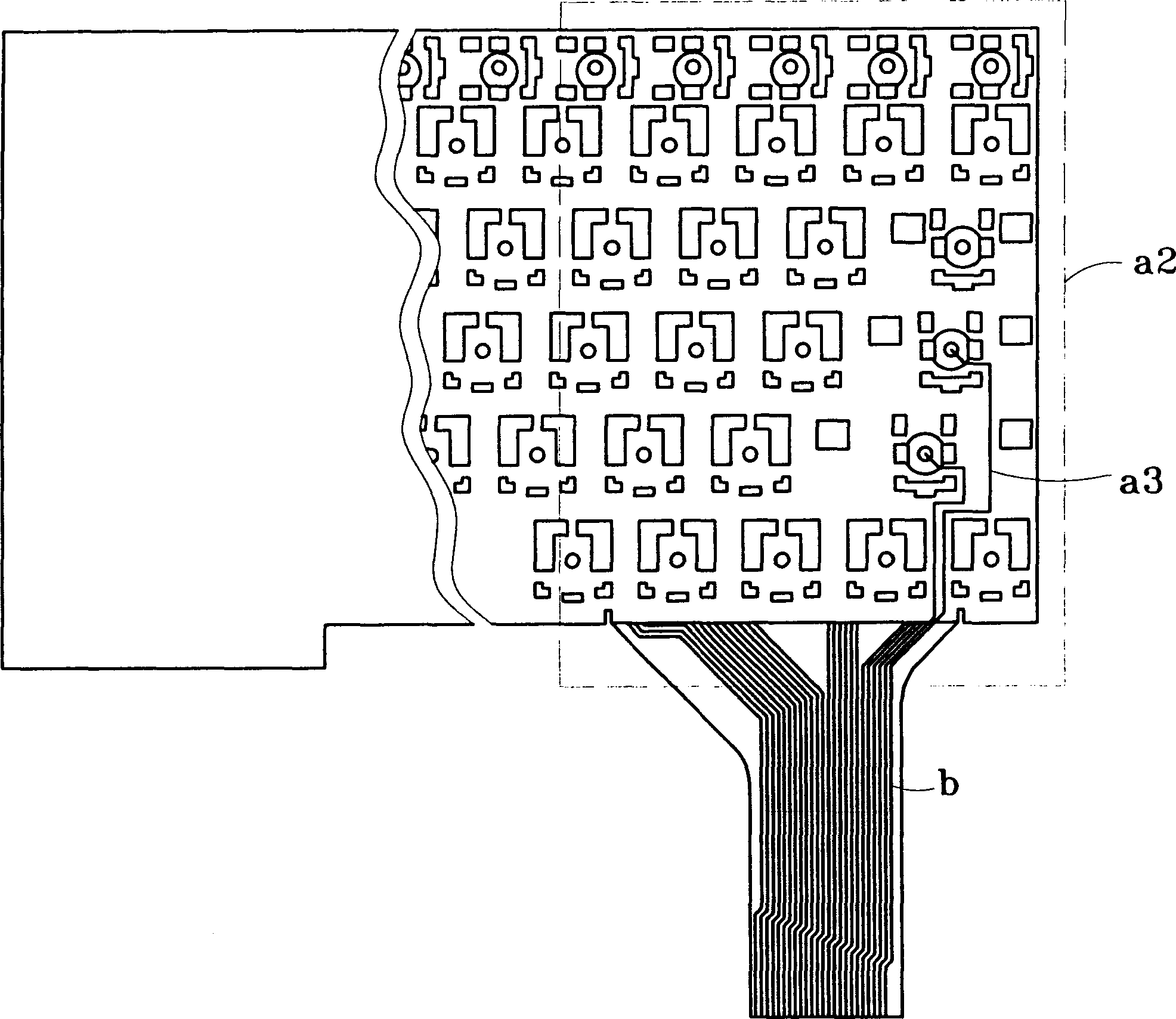

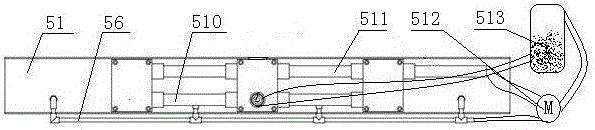

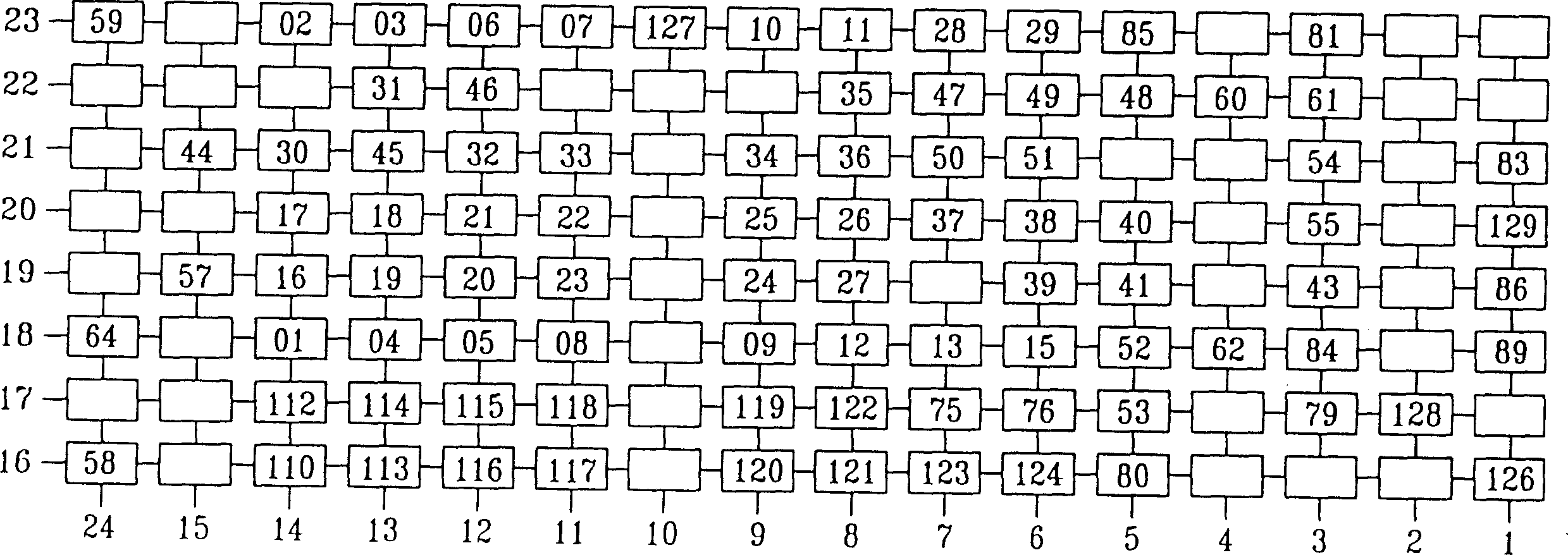

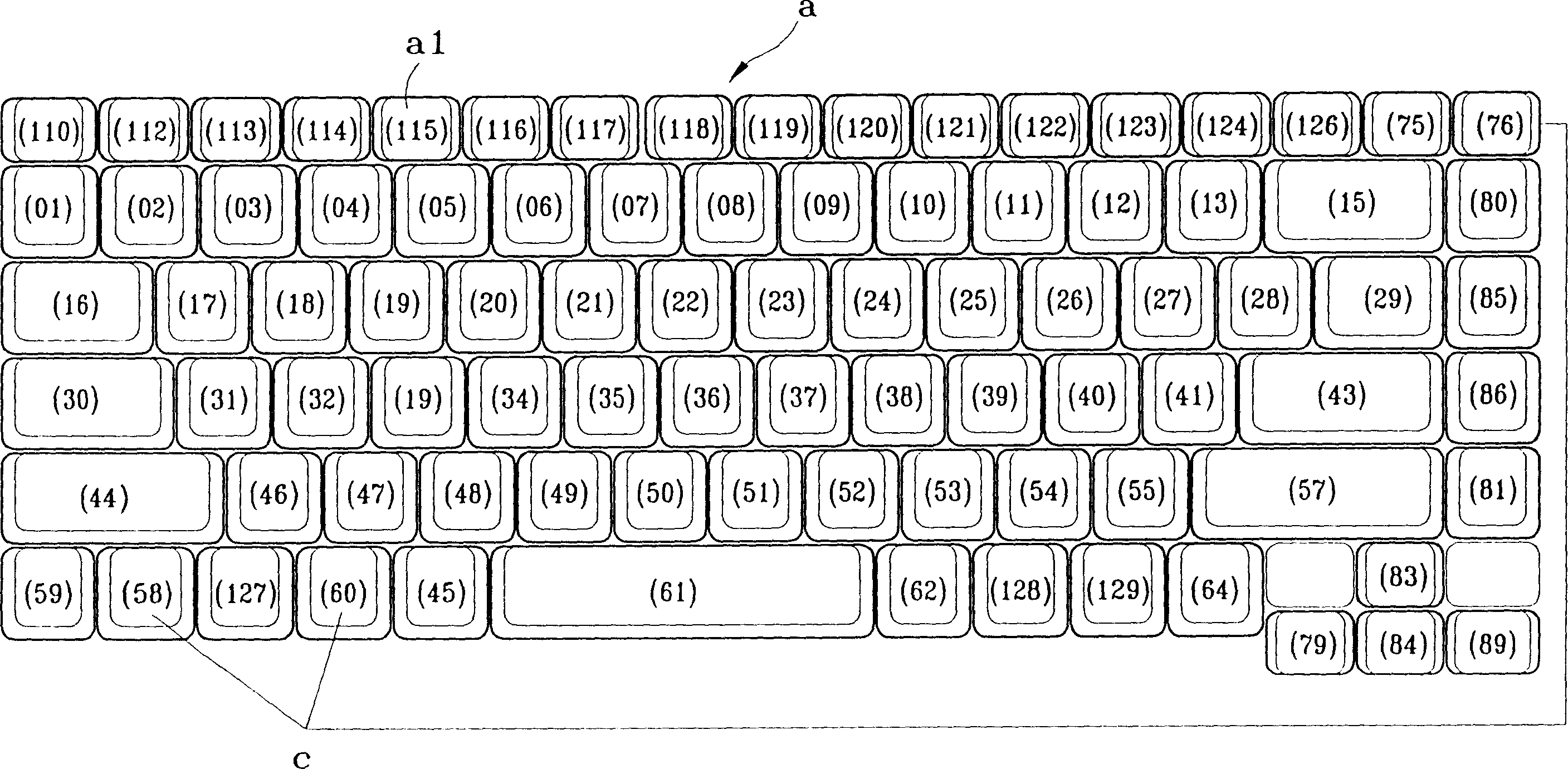

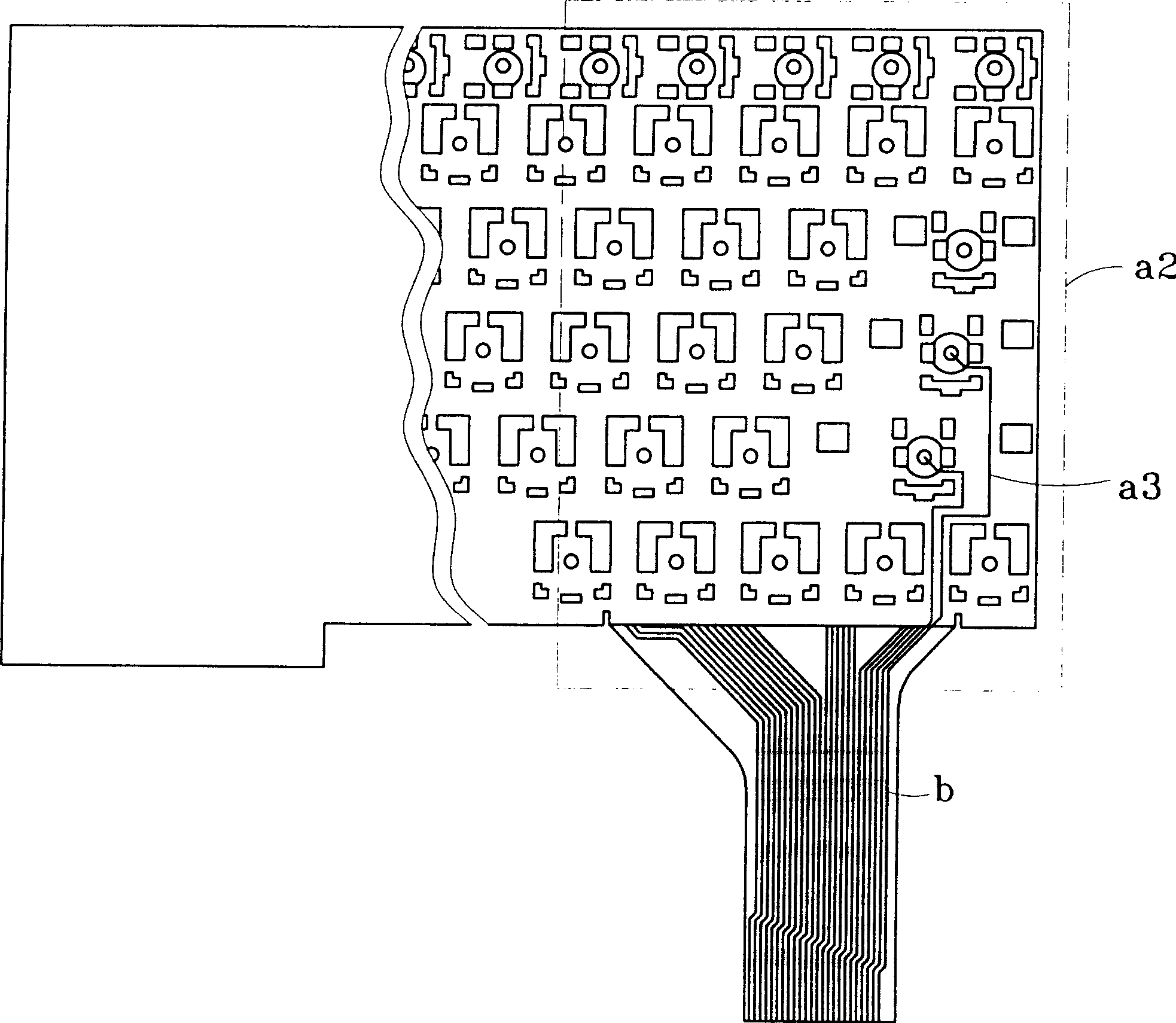

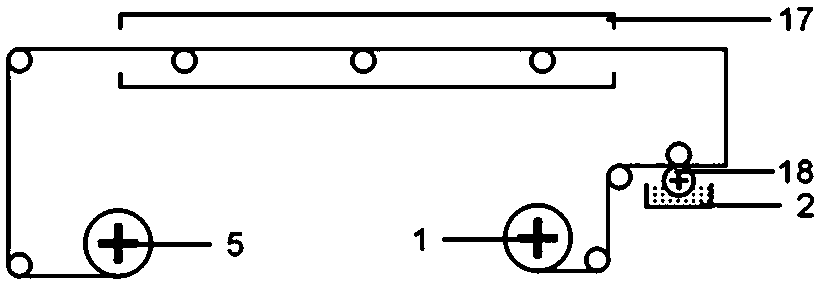

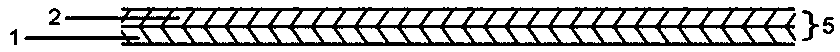

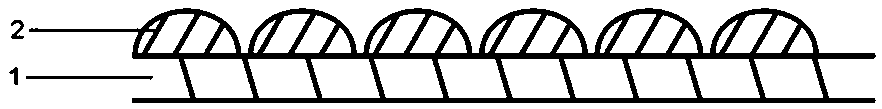

Production method of film circuit plate

InactiveCN1477920AReduce printing processAvoid affecting typingConductive pattern formationCarbon layerSlurry

The present invention relates to a method for making film circuit board. Under the condition of having no wire jumper and preventing production of unknown key signal it adopts the following steps: making key position circuit and matrix arrangement, then when the film circuit board is made, firstly making PET heating preshrinking process of film circuit board, then printing circuit silver slurry on the film circuit board, then printing insulating layer or printing carbon layer on the printed circuit silver slurry, folding the film circuit board and making ultrasonic combination, punching structure holes on the film circuit board so as to obtain the product.

Owner:ZIPPY TECH

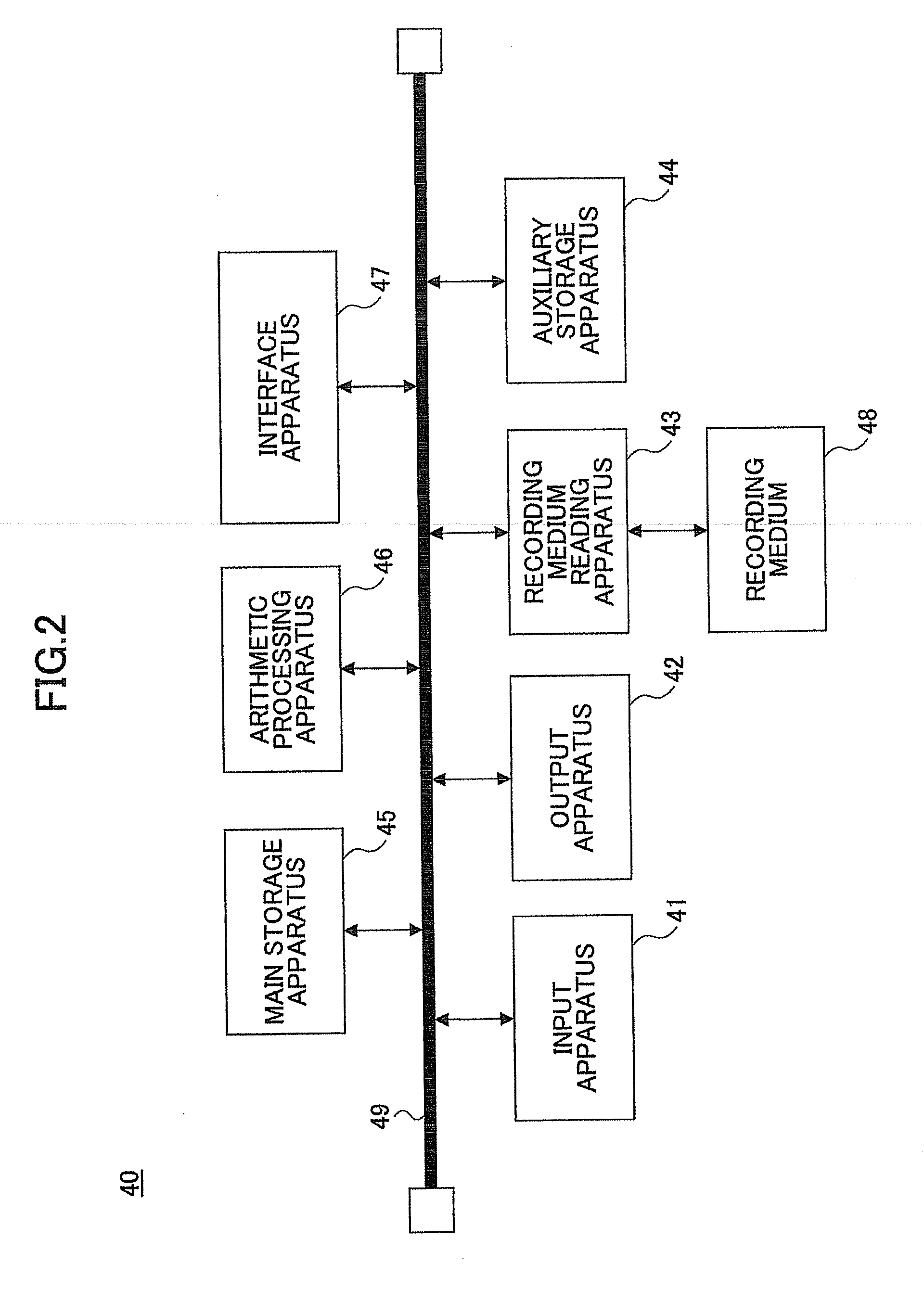

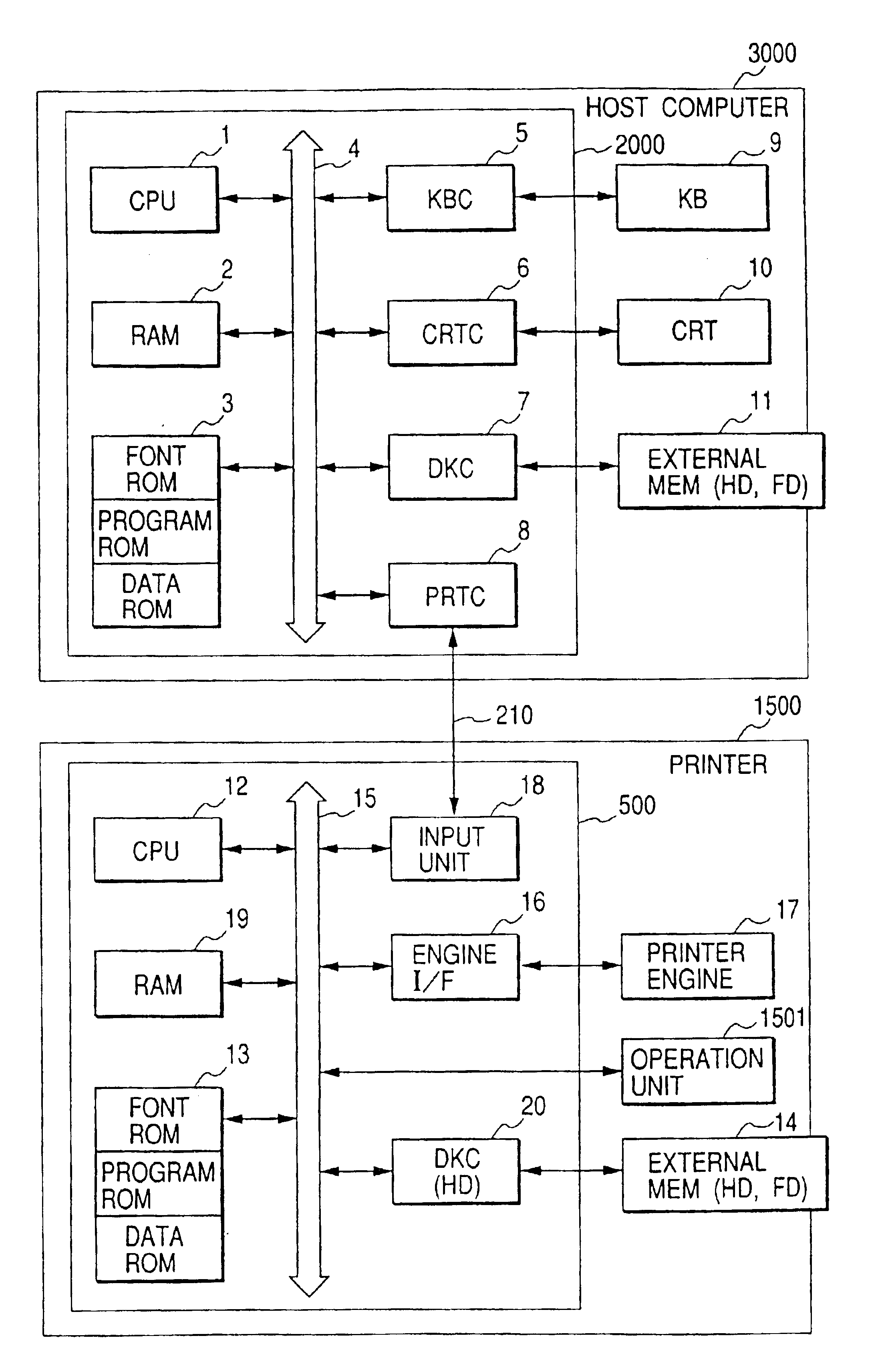

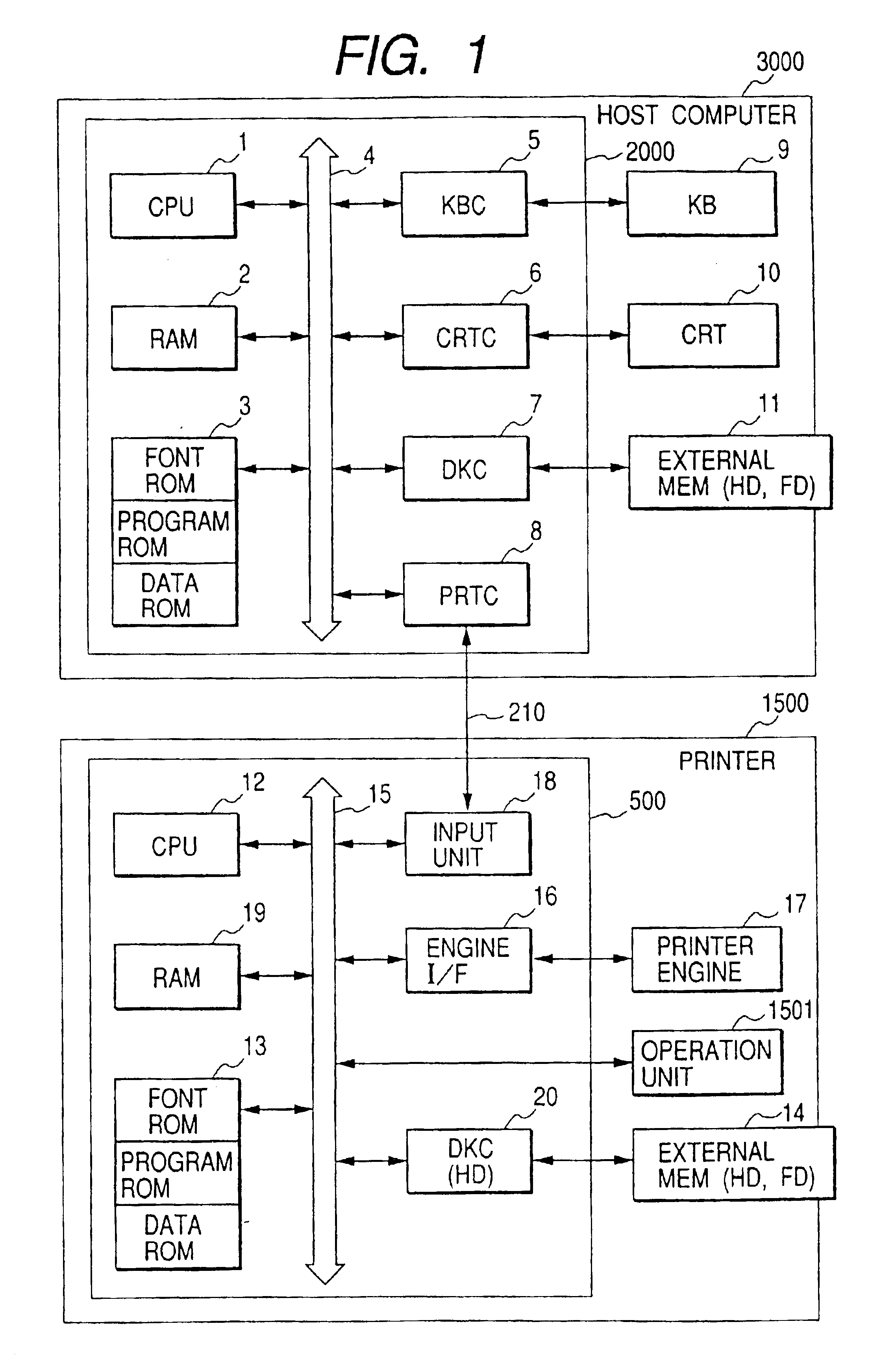

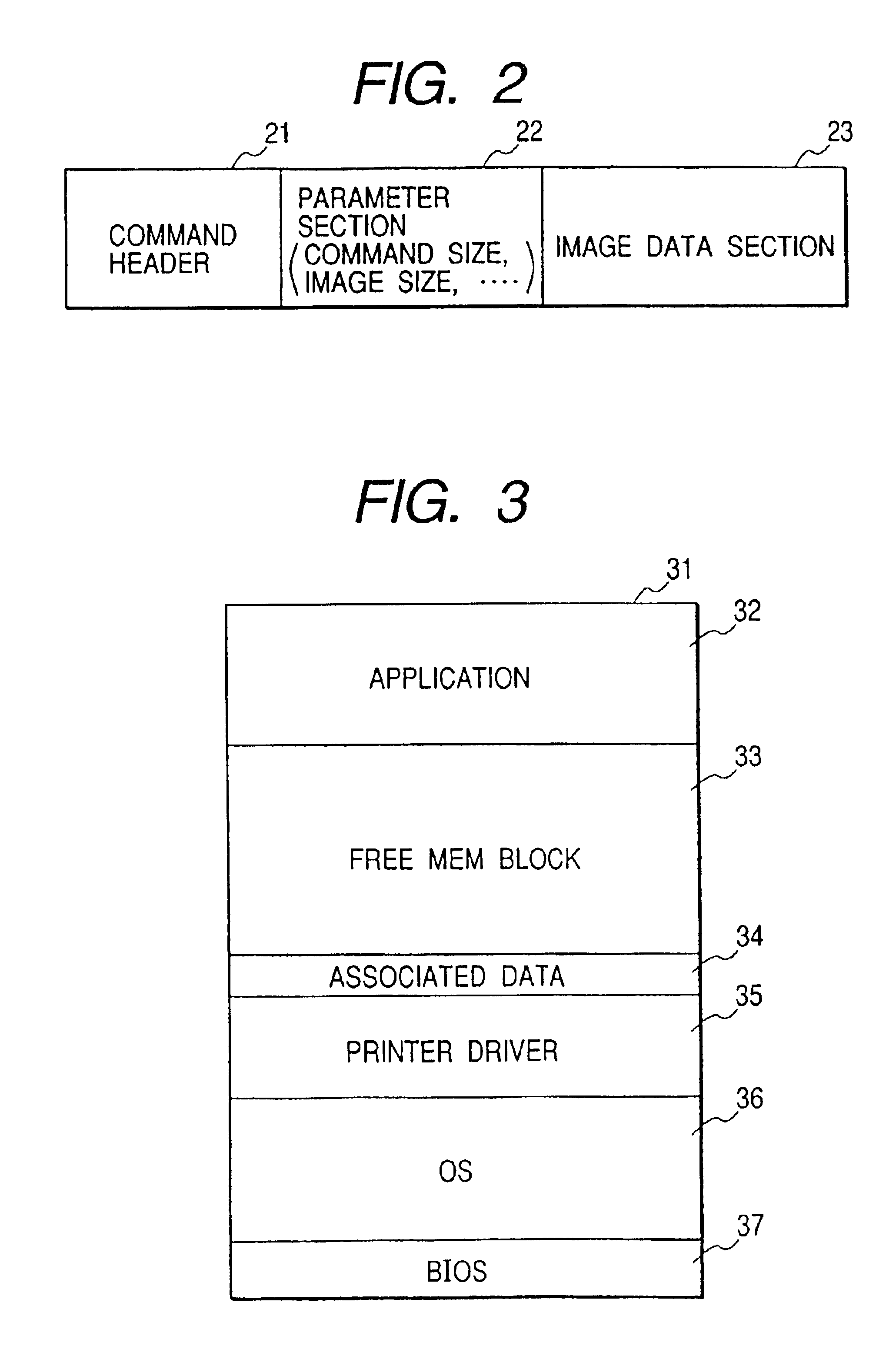

Data processing apparatus capable of communicating with output apparatus and its data processing method

InactiveUS6903829B2Reduce printing processDigital computer detailsVisual presentation using printersData processingCompression method

A data processing apparatus communicating with a printer through a predetermined communication medium, in which a printer command forming unit constructs a print image by analyzing a drawing command formed by an operating system and forms a printer control command based on the print image; a first obtaining unit obtains feature information to presume print processing times by the printer command forming unit where a specific compression method is used and where it is not used; a discriminating unit discriminates whether the printer command forming unit should use the specific compression method or not based on the feature information obtained by the first obtaining unit; and a controller switches and controls whether to apply the specific compression method in forming the printer command based on a discrimination result of the discriminating unit.

Owner:CANON KK

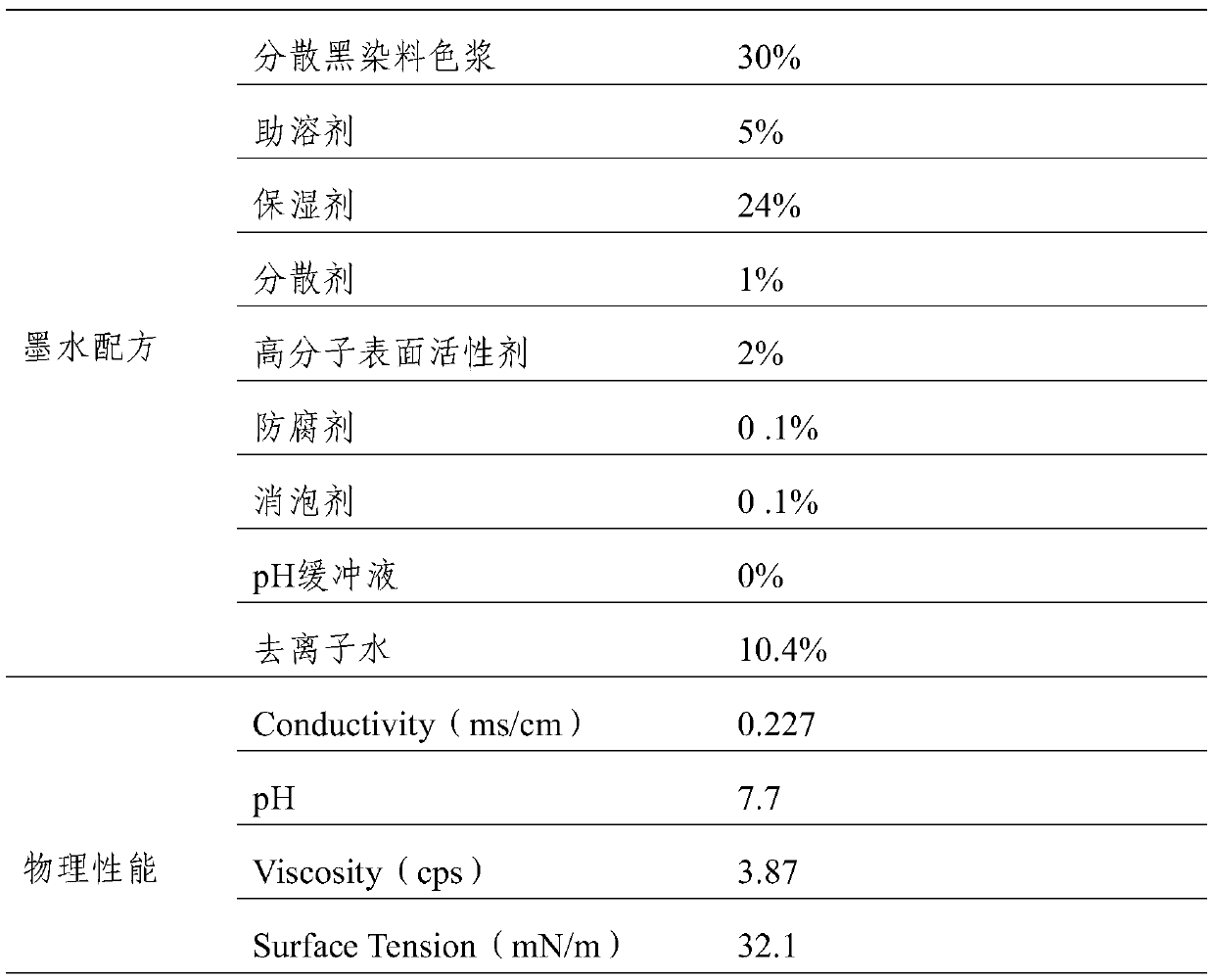

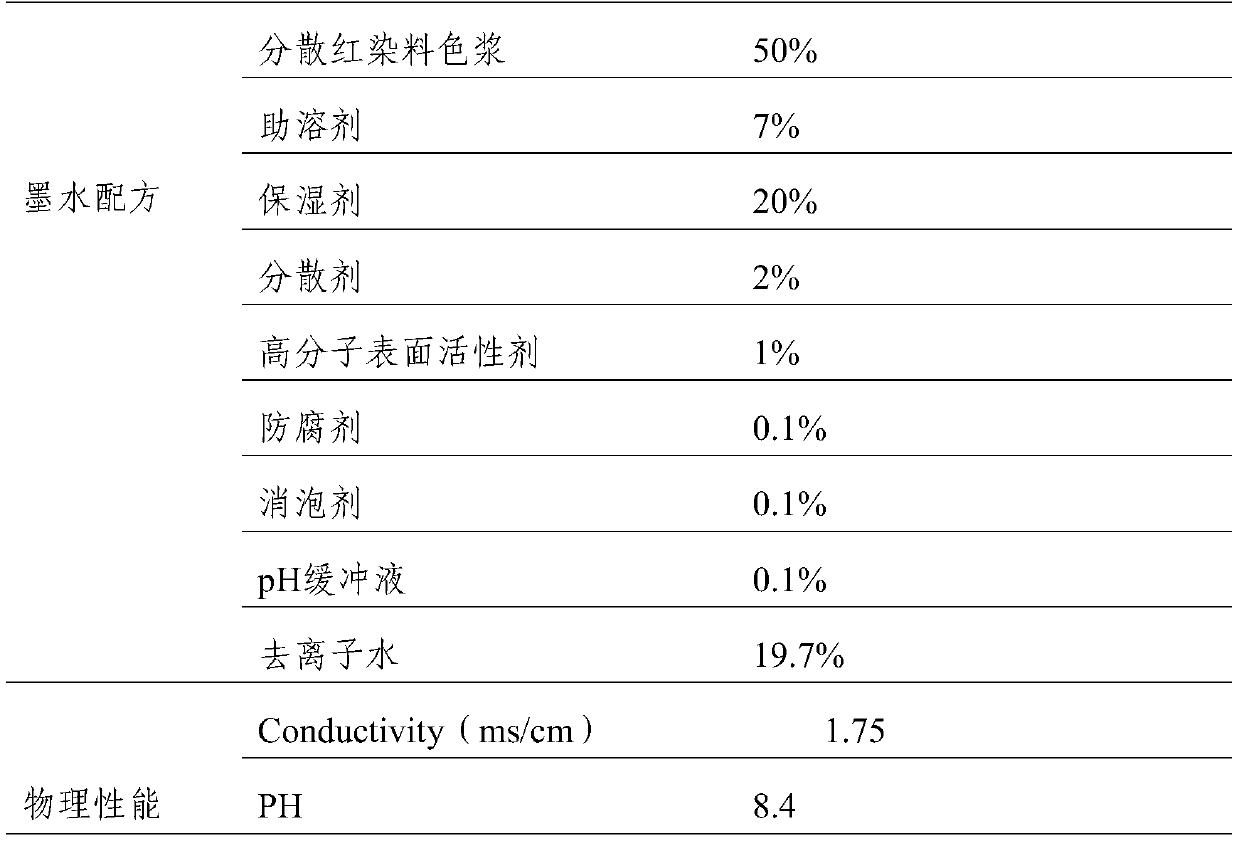

Textile dispersed direct-injected ink and preparation method thereof

InactiveCN110080013AImprove washing fastness and rubbing fastnessAvoid emissionsInksDyeing processCooking & bakingDisperse dye

The embodiment of the invention discloses textile dispersed direct-injected ink. The ink is prepared from the following raw materials in percentage by mass: 15 to 50 percent of direct-injected dispersed dye color paste, 5 to 10 percent of a cosolvent, 24 to 27 percent of a humectant, 0.9 to 2 percent of a high molecular surfactant, 0.1 to 0.2 percent of a defoamer, 1 to 2 percent of a dispersing agent, 0.1 to 0.2 percent of a corrosion remover, 0.1 to 0.2 percent of a pH buffer solution, and the balance of water. The application process of the dispersed direct-injected ink in an inkjet printing technology is as follows: printing the dispersed direct-injected ink to the surface of fiber fabric through an inkjet printing method, and performing baking, so as to obtain printed fiber fabric. The dispersed direct-injected ink can improve the performance, such as color fastness and environmental protection performance, not only improves the washing fastness and rubbing fastness of the dispersed dye and has a wide application range, but also shortens the inkjet printing process, and avoids discharge of sewage during pretreatment.

Owner:上海贝通色彩科技有限公司

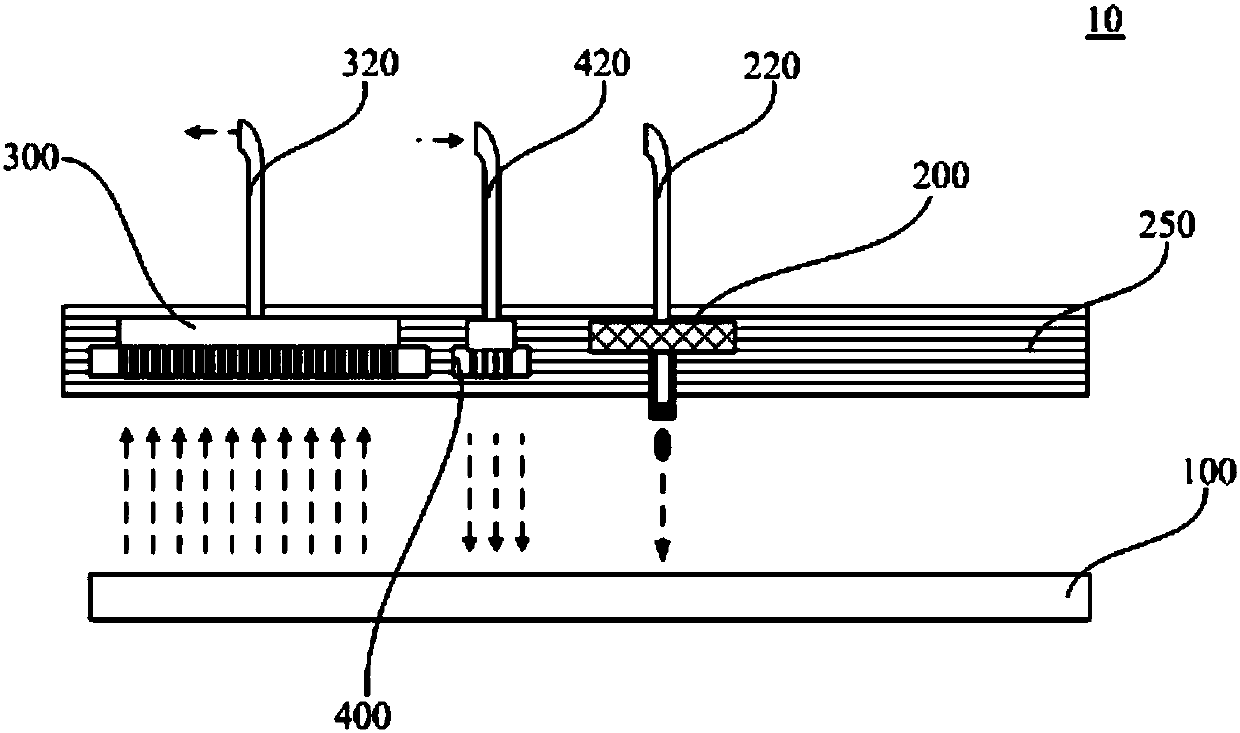

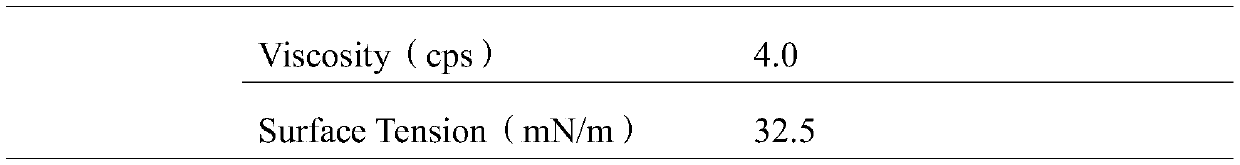

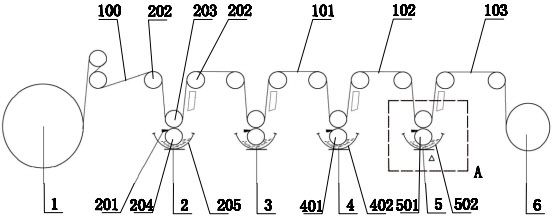

Quantum dot light-emitting device patterning method and quantum dot light-emitting device

ActiveCN110707200AReduce printing processReduce printing timeSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotMaterials science

The embodiment of the invention discloses a quantum dot light-emitting device patterning method and a quantum dot light-emitting device. According to the embodiment of the invention, the method comprises the steps of providing a printing screen with a preset pattern; aligning the printing screen with a first mark preset on a first substrate; printing a quantum dot material on the printing screen to form a first quantum dot layer with the preset pattern on the first substrate; and curing the first quantum dot layer to obtain a second substrate. By printing the quantum dot material through the printing screen, the problems of low speed, complex process and the like caused by using printing, transfer printing and other processes in a common quantum dot light-emitting device patterning methodin the prior art are avoided, the printing process is reduced, and the printing time is saved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

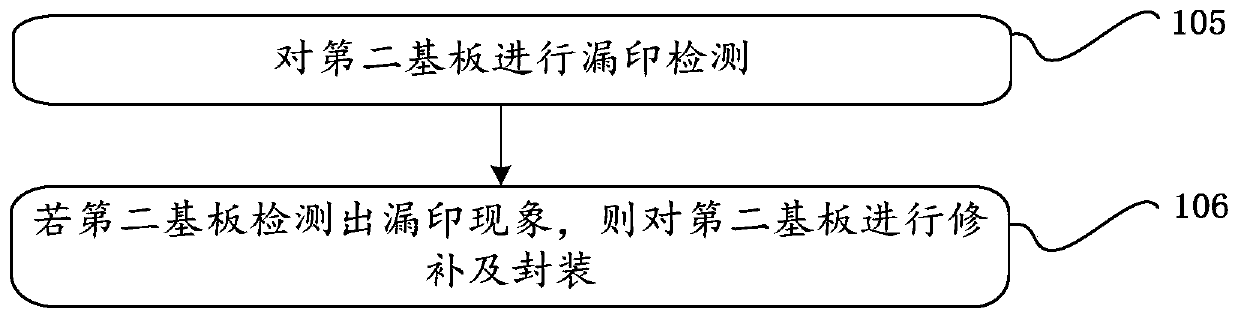

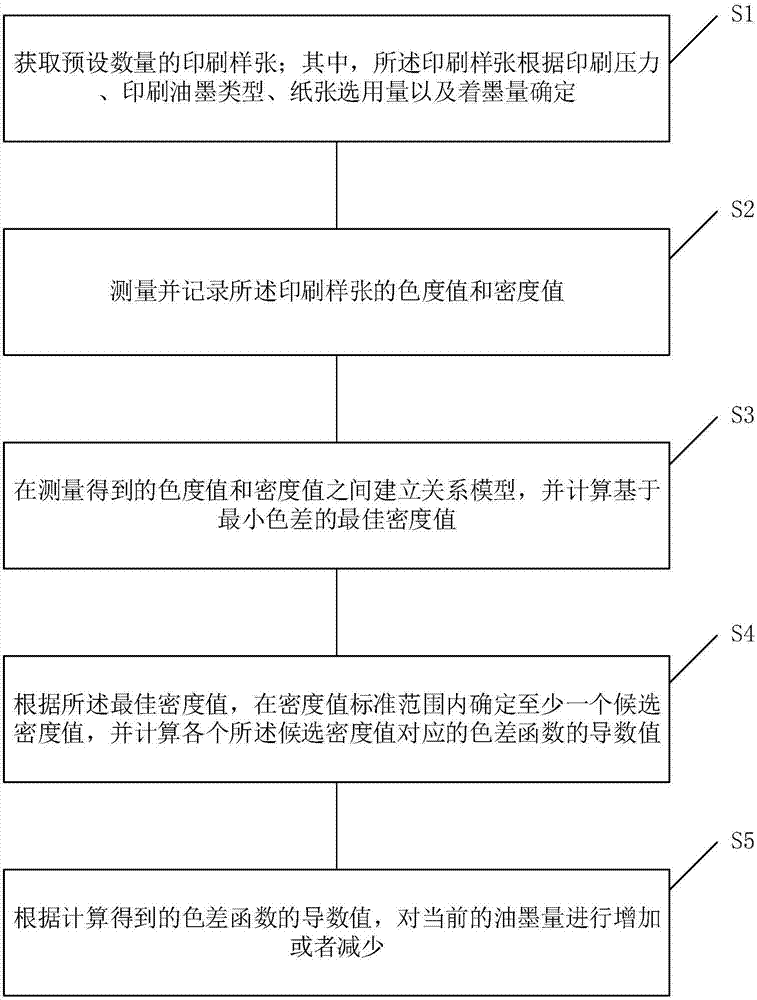

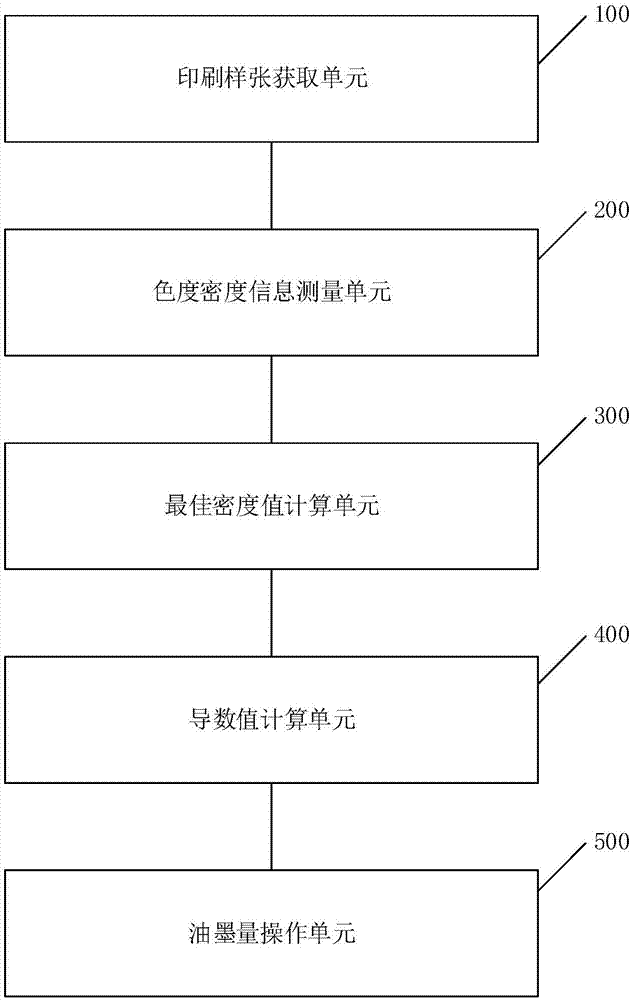

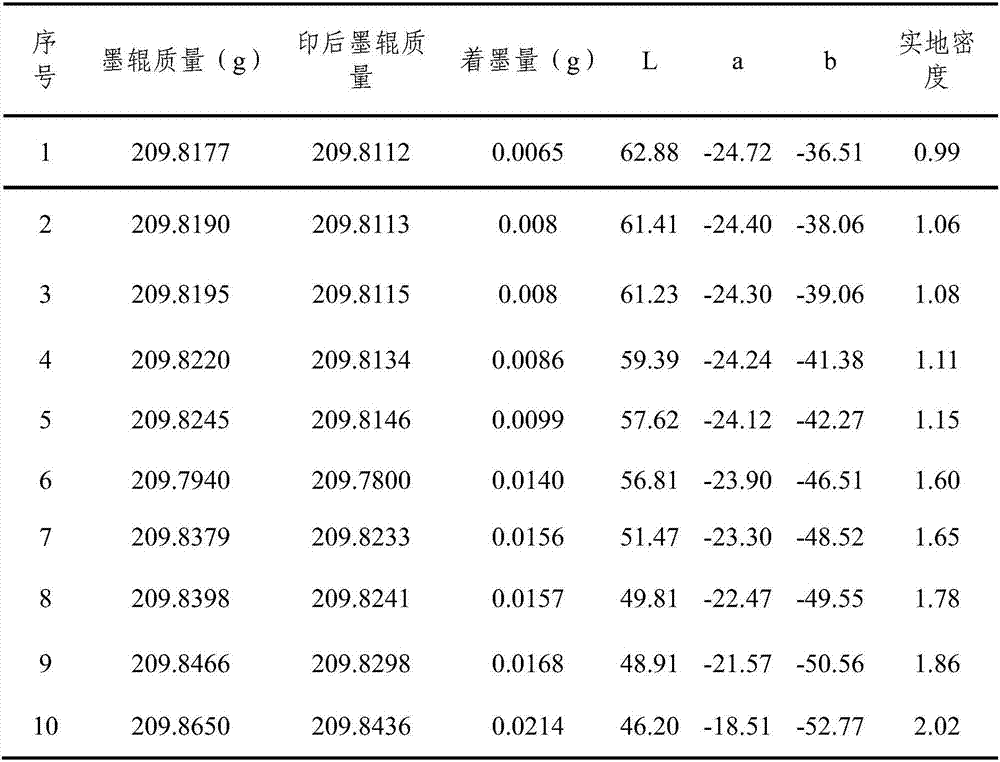

Ink control method and device for printed matter

The invention relates to an ink control method and device for a printed matter. The method comprises the following steps: obtaining a preset number of printing proofs, wherein the printing proofs are determined according to the printing pressure, the type of printing oil, the use amount of paper and the inking amount; measuring and recording chromatic values and density values of the printing proofs; establishing a relation model between the chromatic values and the density values which are obtained through measurement, and calculating the optimal density value based on the minimum chromatic aberration; determining at least one candidate density value within a density value standard range according to the optimal density value, and calculating a derivative value of a chromatic aberration function corresponding to each candidate density value; and increasing or decreasing the current ink amount according to the obtained derivative values of the chromatic aberration function. The ink control method provided by the invention can accurately judge whether to increase or decrease the ink amount at the present, so that the printing quality of the printed matter is improved, and the cost in a printing process is saved.

Owner:北京奇良海德印刷股份有限公司

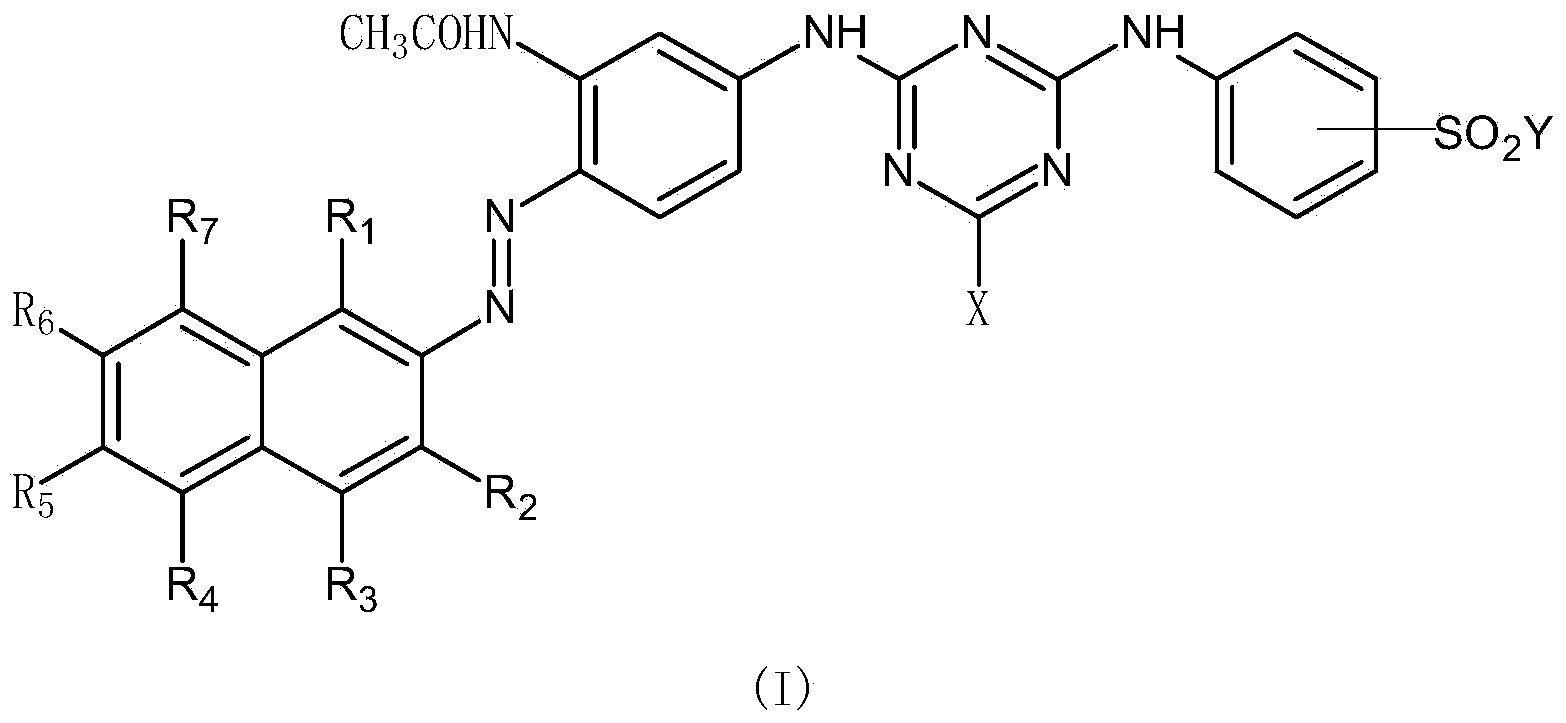

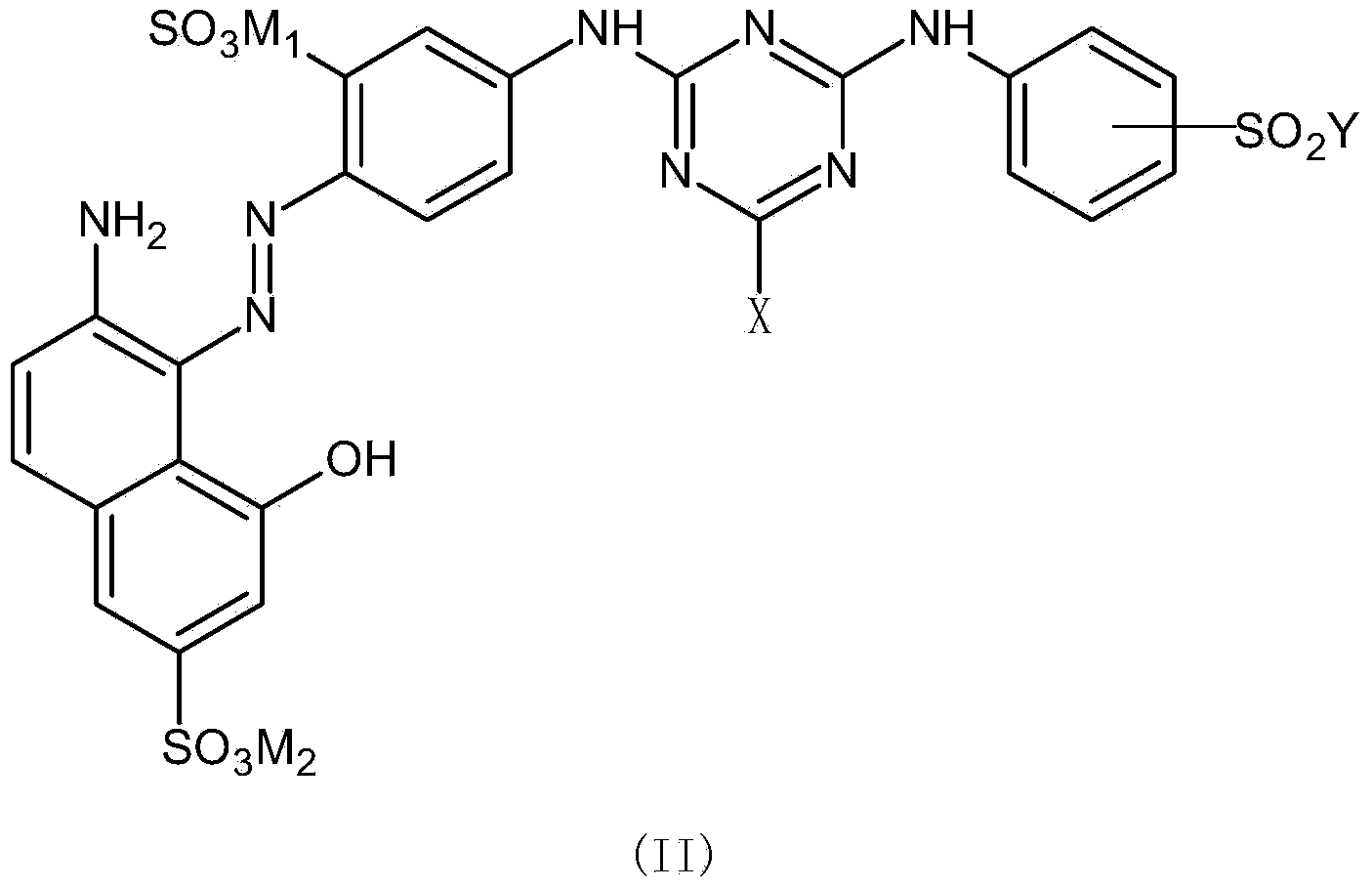

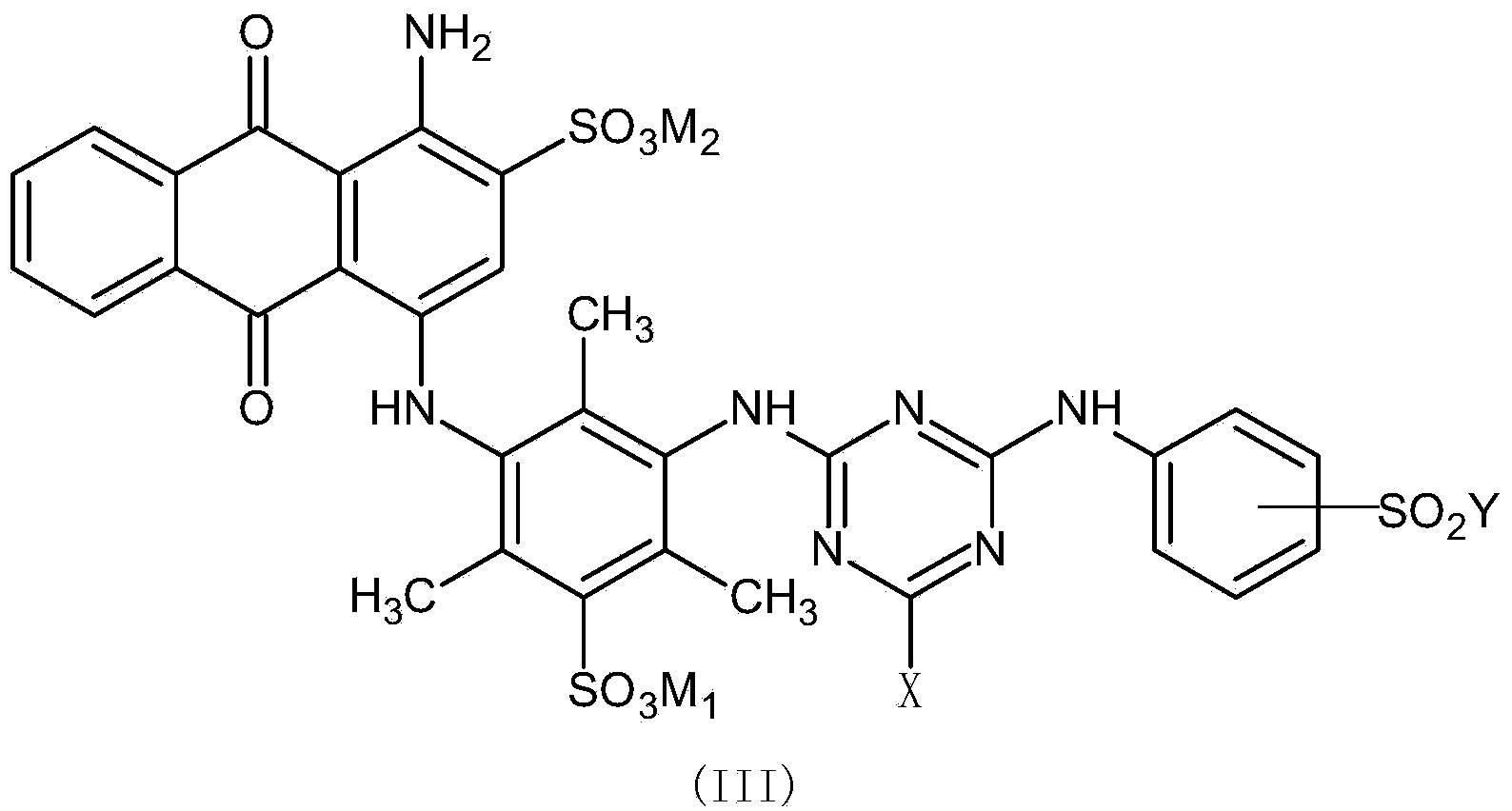

Acid dye and gravure ink as well as preparation method and application of gravure ink

ActiveCN103725041AHigh color fixing rateReduce white ground stainingInksOrganic dyesWastewaterProtein fiber

The invention relates to the dyeing industry, and in particular relates to an acid dye with an improved dye structure and excellent color fastness to washing. The invention relates to composition and a preparation method of acid dye gravure ink containing an acid agent, and relates to composition and a preparation method of the acid agent necessary for the temporary use of the acid dye gravure ink. The invention also relates to a gravure printing process capable of directly executing gravure printing, drying and color fixation through steam for protein fiber fabric and nylon fabric without rolling the acid agent. According to the invention, the dye ink printing process flow can be greatly shortened, a great amount of transfer printing paper which is coated with a special isolation agent can be saved, and the dye ink printing production cost can be greatly reduced; meanwhile, the color layer of the printing patterns is variable and rich, the dye color fixing rate is high, less flooding exists in the water washing process, the emission of the waste water is reduced, and the tarnishing of the dye without being color fixed on the printed fabric can be reduced.

Owner:ZHEJIANG YIDE CHEM

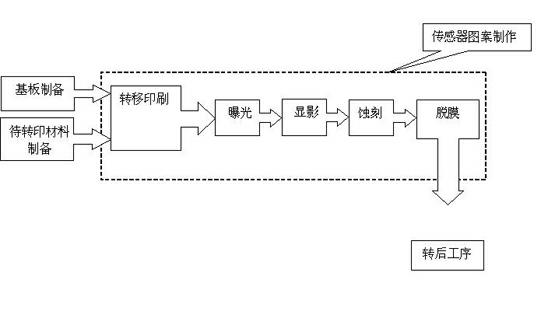

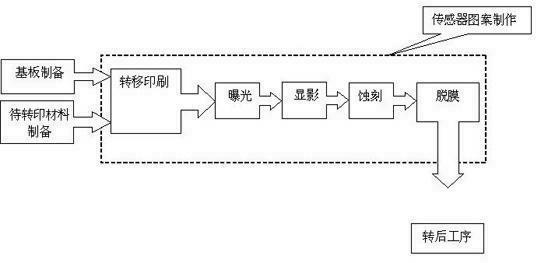

Preparation method for patterns of sensor of capacitance touch screen

InactiveCN102609161AImprove efficiencyImprove reliabilityInput/output processes for data processingCapacitanceEngineering

A preparation method for patterns of a sensor of a capacitance touch screen relates to the technical field of manufacture of capacitance touch screens. The preparation method includes following steps: 1) transferring a transparent conductive layer and a photoresist layer on a panel in a transfer printing manner; and 2) preparing the patterns of the sensor by means of exposure, development, etching and stripping. The preparation method for the patterns of the sensor of the capacitance touch screen is simple in technical process, convenient for controlling the quality of products and high in yield of the products.

Owner:NANJING DIANMIAN PHOTOELECTRICITY

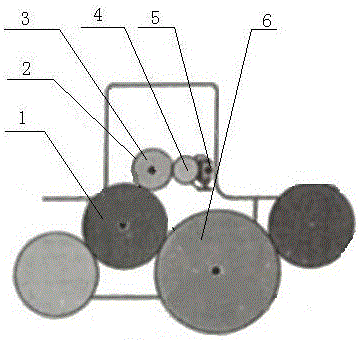

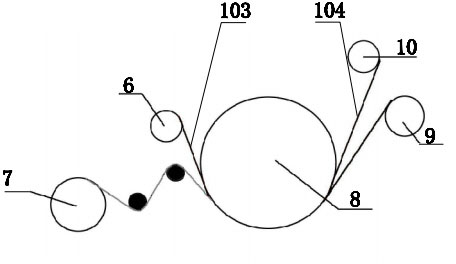

Gloss oil set printing device for optical variable anti-faking ink offset printing and offset printing online printing method

ActiveCN106585087AReduce scratch areaAvoid damagePrinting after-treatmentPrinting press partsEngineeringColor changes

The invention discloses a gloss oil set printing device for optical variable anti-faking ink offset printing. The device comprises a conveying device, a scraper, an anilox roller, a plate roller sleeved with a resin plate, and an impression cylinder; the conveying device is mounted below the impression cylinder for conveying a printed mater onto the impression cylinder; the scraper and the plate roller are mounted on two sides of the anilox roller; the plate roller is mounted above the impression cylinder; the scraper prints optical variable anti-faking ink to the resin plate sleeved on the plate roller through the anilox roller; and under the effect of the impression cylinder, the optical variable anti-faking ink on the resin plate is printed on the printed matter. The invention further discloses an optical variable anti-faking ink offset printing online printing device with the gloss oil set printing device and an optical variable anti-faking ink offset printing online printing method. The printing process and the printing equipment of optical variable anti-faking ink offset printing are simplified; the printing efficiency is improved; the equipment investment and the labor intensity of optical variable anti-faking ink offset printing are reduced; and such technical difficulties as easy color change, blackening and darkening of optical variable anti-faking ink in optical variable anti-faking ink offset printing in the prior art are solved.

Owner:HUNAN FURUI PRINTING CO LTD

Production method of film circuit plate

InactiveCN1247056CReduce printing processAvoid affecting typingConductive pattern formationCarbon layerEngineering

The present invention relates to a method for making film circuit board. Under the condition of having no wire jumper and preventing production of unknown key signal it adopts the following steps: making key position circuit and matrix arrangement, then when the film circuit board is made, firstly making PET heating preshrinking process of film circuit board, then printing circuit silver slurry on the film circuit board, then printing insulating layer or printing carbon layer on the printed circuit silver slurry, folding the film circuit board and making ultrasonic combination, punching structure holes on the film circuit board so as to obtain the product.

Owner:ZIPPY TECH

A transfer film prepared by digital printing, its preparation method and its application

ActiveCN106808820BSolve the problem of micro-distortion transfer printingTroubleshoot setup issuesMonocarboxylic acid ester polymer adhesivesWax coatingsColor imageWax

The embodiment of the invention discloses a transfer printing film prepared by means of digital printing. The transfer printing film comprises a carrier membrane, a water-borne wax layer and a color image-text layer which are superposed in sequence. The embodiment of the invention further discloses a preparation method of the transfer printing film prepared by means of digital printing and an application of the transfer printing film. According to the transfer printing film prepared by means of digital printing and the preparation method and application thereof, the transparent visual inspection problem of image-text printed by the transfer printing film, the problem of micro-distortion transfer printing of the transfer printing film, the problem of printing plate omission, the problem of reducing printing procedures and lowering losses and the problem of efficient industrial production conventionally are solved, and the transfer printing film and the preparation method and application thereof are particularly suitable for small-single and short-single low-cost operation; the problems of white ink underpainting and glue setting of a transfer printing function layer are also solved; the problem of combining adhesion of the array powdered ink color image-text layer and a separating agent coating and the problem of separating the array powdered ink color image-text layer and the separating agent coating from a carrier base membrane together are even solved; and moreover, volatile organic compounds (VOC) are hardly generated, and therefore the printing environmental protection property is greatly improved, and epoch-making significance is achieved.

Owner:广东宏达印业股份有限公司

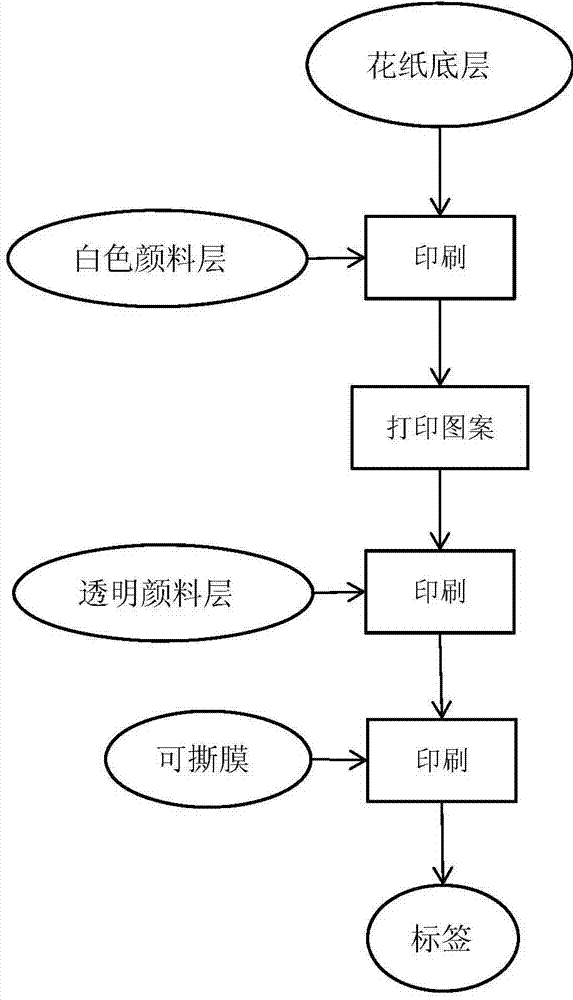

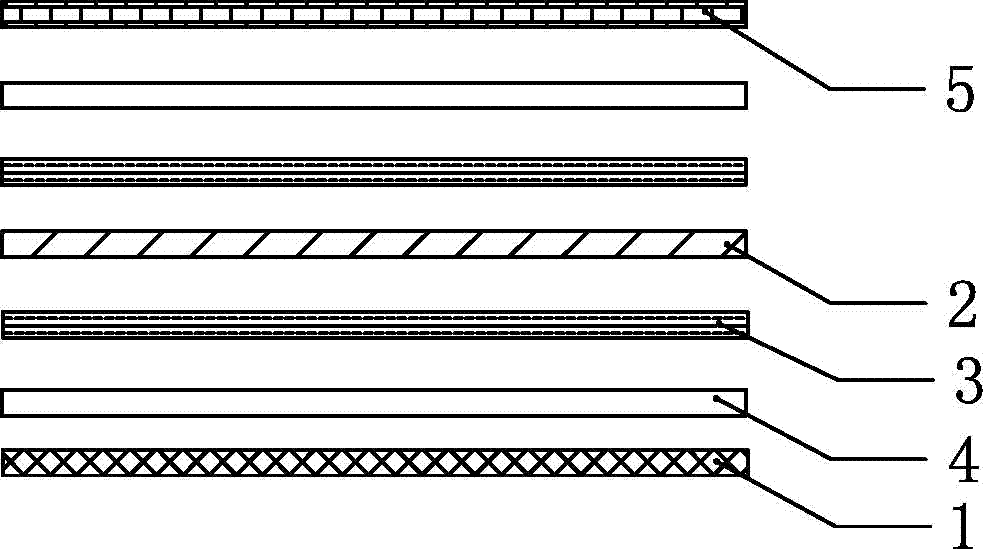

Glass bottle label and manufacturing method thereof

The invention discloses a glass bottle label and a manufacturing method thereof. The glass bottle label comprises a stained paper bottom layer and a patterned layer positioned on the stained paper bottom layer, the patterned layer comprises a white pigment layer, patterns and a transparent pigment layer, the patterns are positioned between the white pigment layer and the transparent pigment layer, and the outermost layer of the label is a tearable film. The manufacturing method includes: printing the white pigment layer or the transparent pigment layer on the stained paper bottom layer, printing the patterns on the white pigment layer or the transparent pigment layer, printing the transparent pigment layer, and finally printing the tearable film on the outermost layer of the label to obtain the glass bottle label. The glass bottle label overcomes defects of high cost, many printing procedures, incapability of seeing patterns in bottles and poor beautifulness, and is low in cost, few in printing procedure, capable of seeing the patterns even in the bottles, good in beautifulness and high in three-dimensionality.

Owner:CHONGQING HAOSHENG GLASS

Equipment for manufacturing multilayer gradual change and light change effect and use method thereof

PendingCN112959807AImproving the technical efficiency of the printing processShorten the printing processScreen printersPrinting press partsScreen printingFluorescence

The invention relates to equipment for manufacturing a multilayer gradual change and light change effect. The equipment comprises a printing stock plane magnetic table arranged in a silk screen machine and a UV drying tunnel, a plane magnet is arranged in the printing stock plane magnetic table, a detonation lamp and a UV lamp are sequentially arranged on the UV drying tunnel, and the detonation lamp is an ultraviolet lamp. The method using the equipment comprises the following steps of 1) aligning a printing product; 2) ink mixing and inking; 3) loading a plate by the silk screen machine; 4) impressing to manufacture a multi-layer gradual change effect; and 5) manufacturing the optical variability effect. The printing stock plane magnetic table is installed on an existing silk screen machine, then prepared magnetic fluorescent ink is printed on the printing product through a silk screen plate, the gradient printing effect is formed through a magnetic field, an optically variable fluorescent pigment layer in the ink is excited through the UV drying tunnel, the ink is cured, the printing technological process is effectively shortened, the printing pattern manufacturing effect with the multi-layer gradual change and light change effect is obtained at a time, and the technical efficiency of the silk-screen printing technology is greatly improved; and the gradual change and light change effects on the pattern have the characteristic of bright color.

Owner:YUNNAN QIAOTONG PACKAGE PRINTING

Contact or transfer roller

InactiveUS20110041713A1Reduce surface tensionIncrease surface tensionPrinting roller shellsPrinting blanketsEpoxyLacquer

A distributor or transfer roller is provided for printing machines, in particular for offset printing machines. The roller has at least a substantially rigid core and a cover made of a polymeric material applied on and permanently fixed to the core. The cover is applied directly on the core or on a hard-elastic intermediate layer having a hardness of ≧10 Shore D, optionally by an adhesion promoting layer. The cover is at least substantially made of a fluorinated polymer and has a hardness of ≧15 Shore D and / or a scratch hardness according to ISO 15184 of 6B or harder. The polymeric material can be a duroplastic material, a fluorinated polyurethane resin, polyester resin, epoxy resin, acrylate resin and / or polyether resin, a highly cross-linked non-elastic fluoropolymer, a fluorothermoplastic, a polymeric non-elastic fluorosilicone, or a fluoropolymer lacquer.

Owner:WEROS TECH

Gold and silver powder transfer printing process and equipment

InactiveCN102189859BQuality improvementSolve the problem that gold and silver powder transfer printing cannot be carried outTransfer printingPattern printingTextile printerDisperse dye

The invention relates to a gold and silver powder transfer printing process and gold and silver powder transfer printing equipment. The process comprise the following steps of: 1, printing transfer printing paper, namely printing transfer printing patterns on blank printing base paper by using disperse dyes, printing a decolored glue block by using a decolorization glue printing device in an arearequired to be subjected to gold and silver powder transfer printing, and printing a gold and silver powder glue block by using a gold and silver powder printing device on the surface of the decolored glue block; and 2, printing the patterns on the transfer printing paper onto a load bearing object by using a printing machine in a transferred way. By the process and the equipment, common transferprinting operation and gold and silver powder transfer printing operation can be simultaneously finished in one process flow, so that human power and resources are greatly saved; the printing speed during continuous operation can reach 600 to 1,200 meters / hour, so that the printing speed and yield are greatly increased; simultaneously, the appearance of a high-quality final product is ensured, and the process and the equipment have obvious economic benefits.

Owner:JIANGSU LONGDA TRANSFER PRINTING TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com