Luminescent device and manufacturing method thereof

A manufacturing method and technology for light-emitting devices, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the number of manufacturing processes, declining performance of light-emitting devices, and low product competitiveness, reducing the number of process processes and eliminating solvents. The effect of poor vapor concentration and shortening of the printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] This embodiment provides a method for manufacturing a printed display, which includes the following steps:

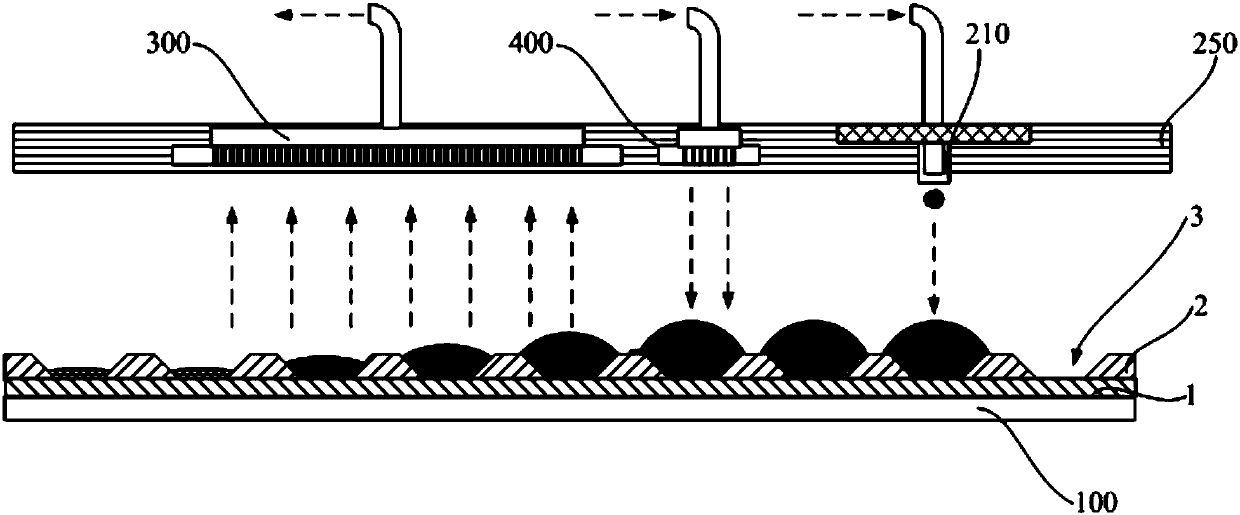

[0114] 1) Prepare a pixel defining layer 2 on a patterned anode TFT substrate 1, and form a pixel pit 3.

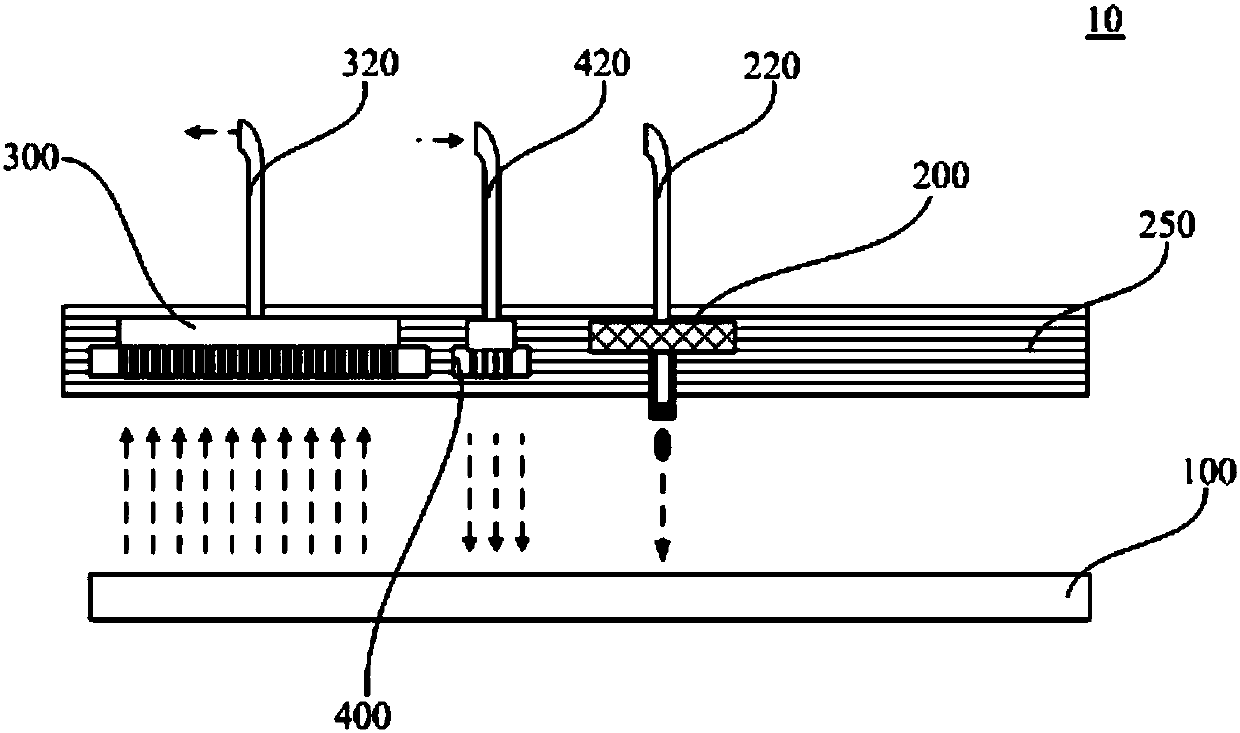

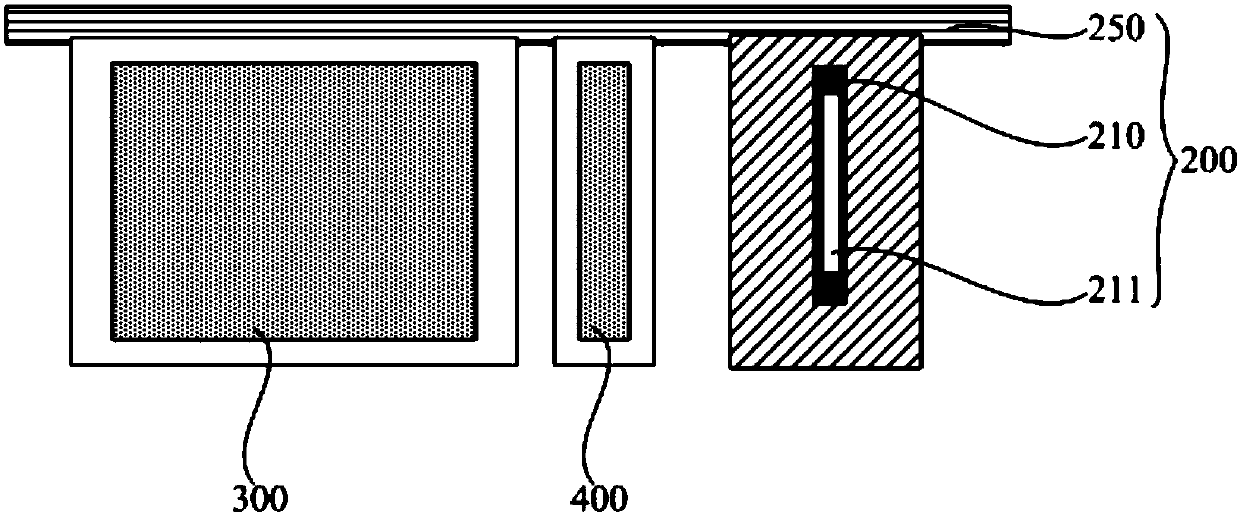

[0115] 2), please further combine image 3 , using the printing device 10 to ink-jet print functional ink into the pixel pit 3, and perform step-by-step vacuum drying treatment on the printed ink to obtain a pre-dried film.

[0116] 3) heat-treating the pre-dried film to make it completely cross-linked and cured to form a light-emitting functional layer.

[0117] Wherein, the light-emitting functional layer includes a hole injection layer, a hole transport layer, and a light-emitting layer, and the formation process of each layer adopts a step-by-step vacuum drying process while inkjet printing is performed.

[0118] 4), evaporating the electron transport layer and the cathode, and finally packaging, that is.

[0119] This embodiment provides a method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com