Method for electrochemical depositing solar cell metallic electrode

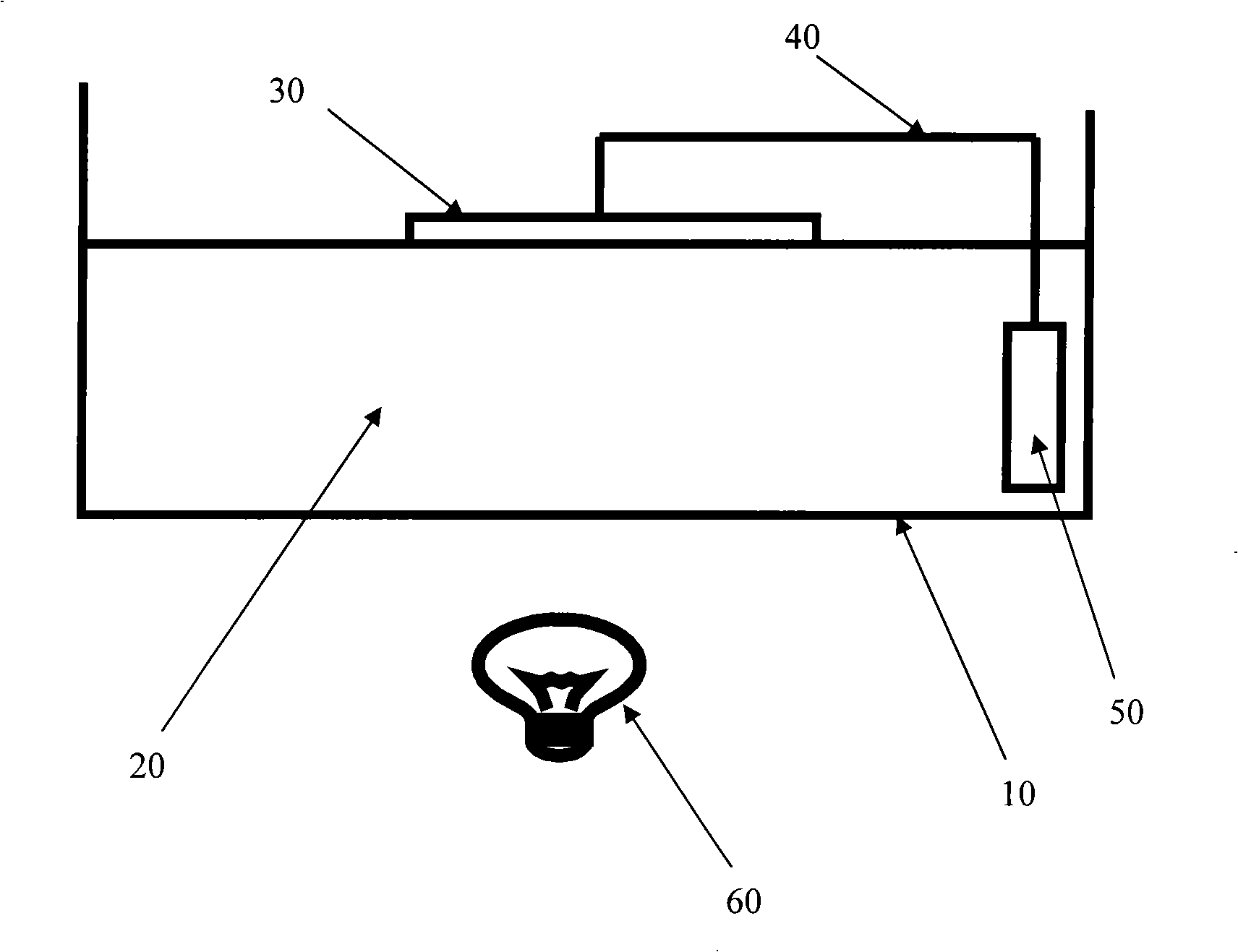

A technology for solar cells and metal electrodes, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as difficult to achieve, achieve uniform illumination intensity, solve the decline of battery efficiency, and avoid uneven deposition of metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0082] The first step is to make a traditional solar cell:

[0083] After P-type silicon wafers are textured, diffused, edge etched, N-type surface is coated with silicon nitride, P-type surface is screen-printed with aluminum paste, N-type surface is screen-printed with silver paste, and the solar cell is measured after sintering. The photoelectric conversion efficiency is 16.57%, and its open circuit voltage, current density, series resistance, parallel resistance and fill factor are 625mV; 35.3mA / cm2; 0.0075Ω; 13.11Ω; 75.1%.

[0084] The second step is to prepare the electrolyte solution:

[0085] Preparation of copper electrolyte solution: Dissolve 200 grams of copper sulfate, 120 grams of sulfuric acid, and 4.5 milliliters of brightener VF100 into 1 liter of water evenly.

[0086] Preparation of tin electrolyte solution: 50 grams of stannous sulfate, 60 grams of sulfuric acid, 48 grams of phenolsulfonic acid, and 2.4 grams of cresol were evenly dissolved in 1 liter of wa...

no. 3 example

[0102] The first step is to make a full backside conductive electrode solar cell:

[0103] Fabricate on N-type silicon wafers, N-type diffusion, oxidation, use photoresist as a mask to open the P-type electrode contact area, P-type deep expansion, use photoresist as a mask to open the N-type electrode contact area, Electroless nickel plating is carried out on the electrode contact area, and nickel-silicon alloy is formed after nickel sintering.

[0104] The second step is to prepare the electrolyte solution:

[0105] Preparation of nickel electrolyte solution: 150 grams of nickel sulfate, 8 grams of sodium chloride, 30 grams of boric acid, and 40 grams of anhydrous sodium sulfate were evenly dissolved in 1 liter of water.

[0106] Preparation of copper electrolyte solution: Dissolve 200 grams of copper sulfate, 120 grams of sulfuric acid, and 4.5 milliliters of brightener VF100 into 1 liter of water evenly.

[0107] Copper-tin electrolyte solution: Dissolve 20 grams of cupro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com