Patents

Literature

61results about How to "Uniform potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for electrochemical depositing solar cell metallic electrode

ActiveCN101257059AAvoid unevennessAvoid damagePhotovoltaic energy generationSemiconductor devicesElectrochemical responseMetallic electrode

Owner:WUXI SUNTECH POWER CO LTD

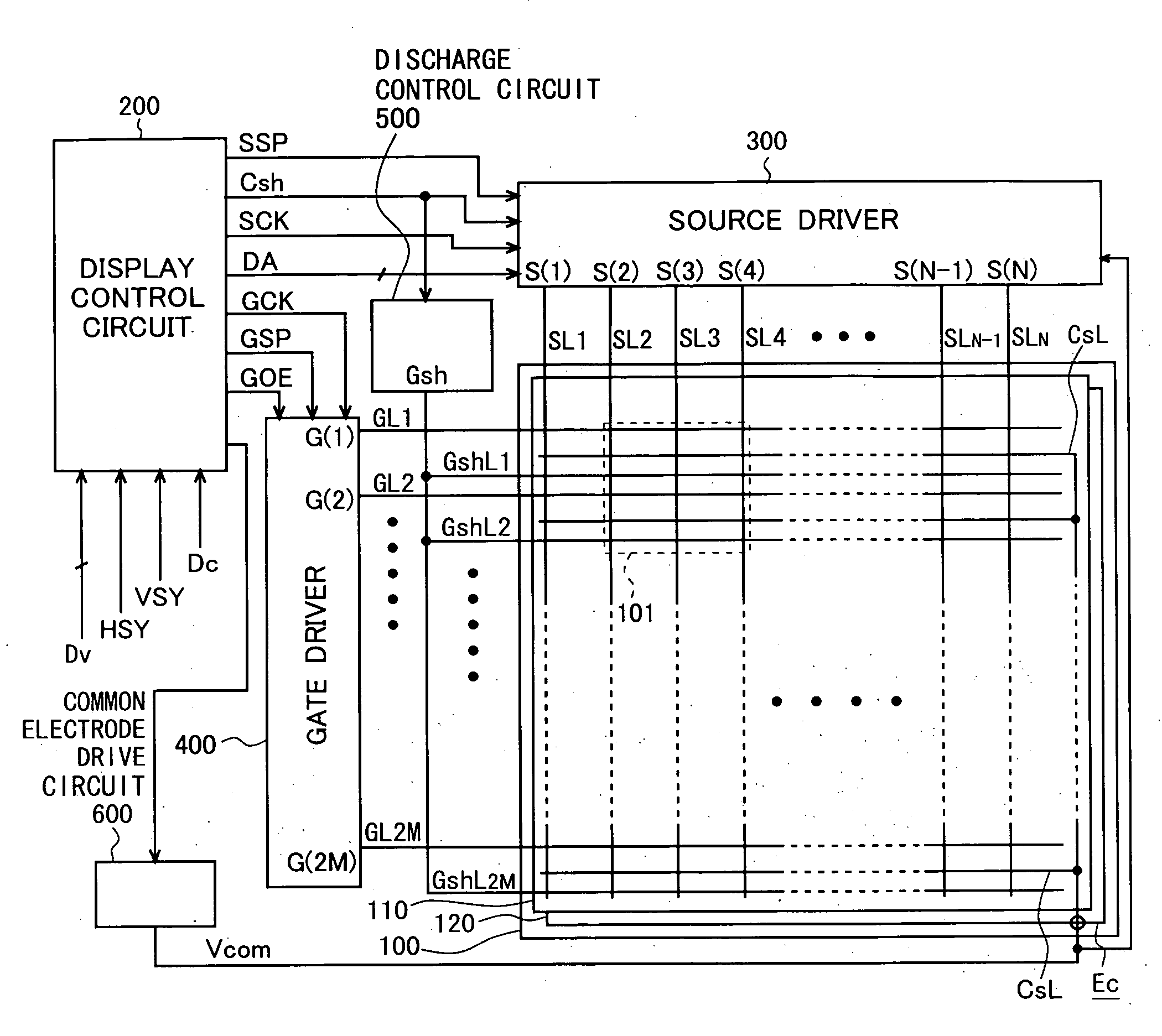

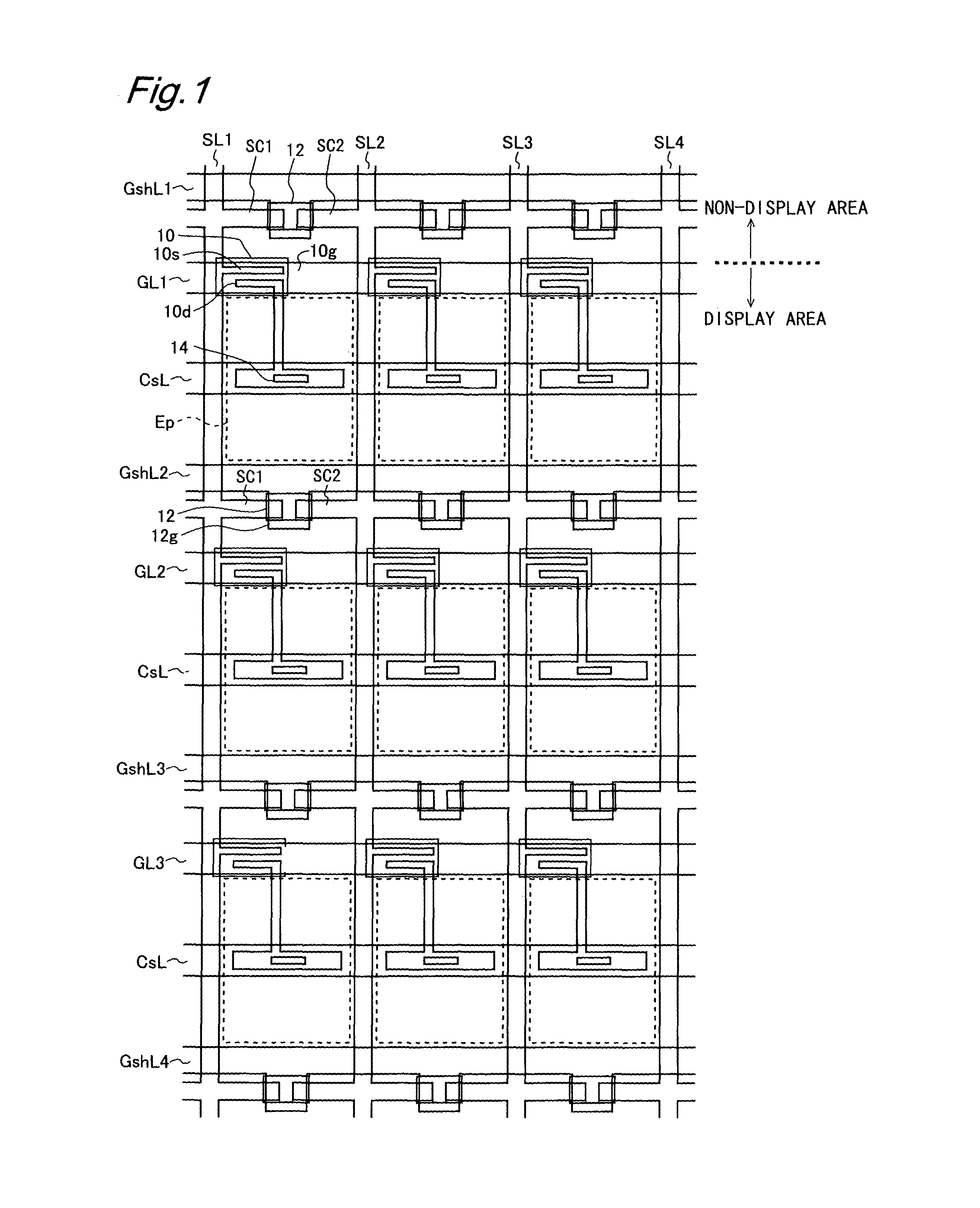

Active Matrix Substrate and Display Device Having the Same

InactiveUS20090167739A1Improve display qualityIncrease drive frequencyTelevision system detailsColor television detailsCapacitanceLiquid-crystal display

One embodiment of the present invention is to prevent deterioration of display quality from occurring in a display device provided with an active matrix substrate even when a larger size or a higher resolution is employed and a drive frequency is increased. In an active matrix substrate of a liquid crystal display device, a discharge control signal line is disposed so as to be arranged along each gate line and discharge TFTs are provided for each source line in numbers equal to the number of the gate lines. The gate terminal, source terminal, and drain terminal of the discharge TFT are connected to the discharge control signal line, the storage capacitance line, and its adjacent source line, respectively. Each storage capacitance line is provided with the common potential Vcom. Each discharge control signal line is provided with a signal which turns on the discharge TFT for a predetermined period of every one horizontal period.

Owner:SHARP KK

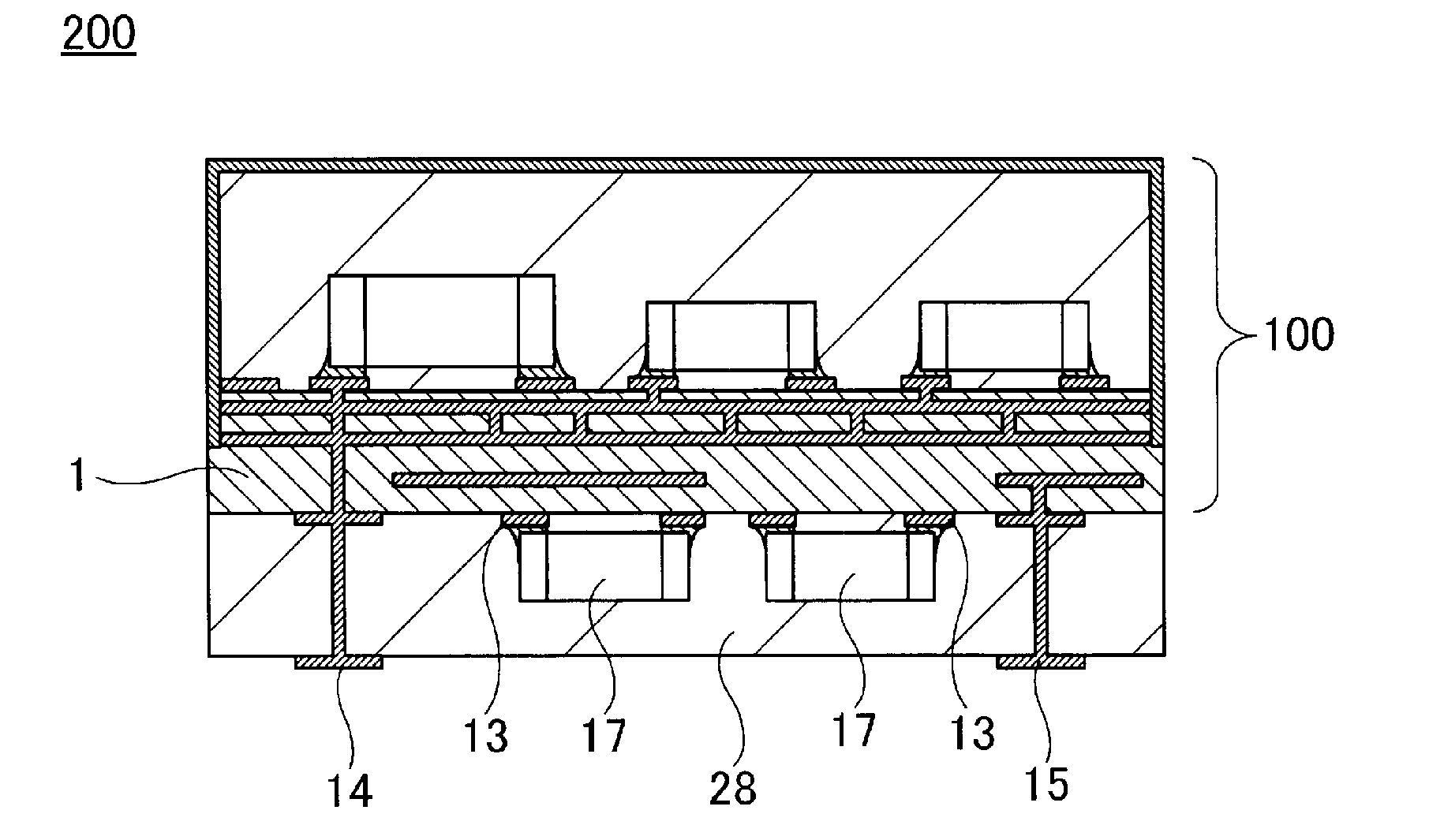

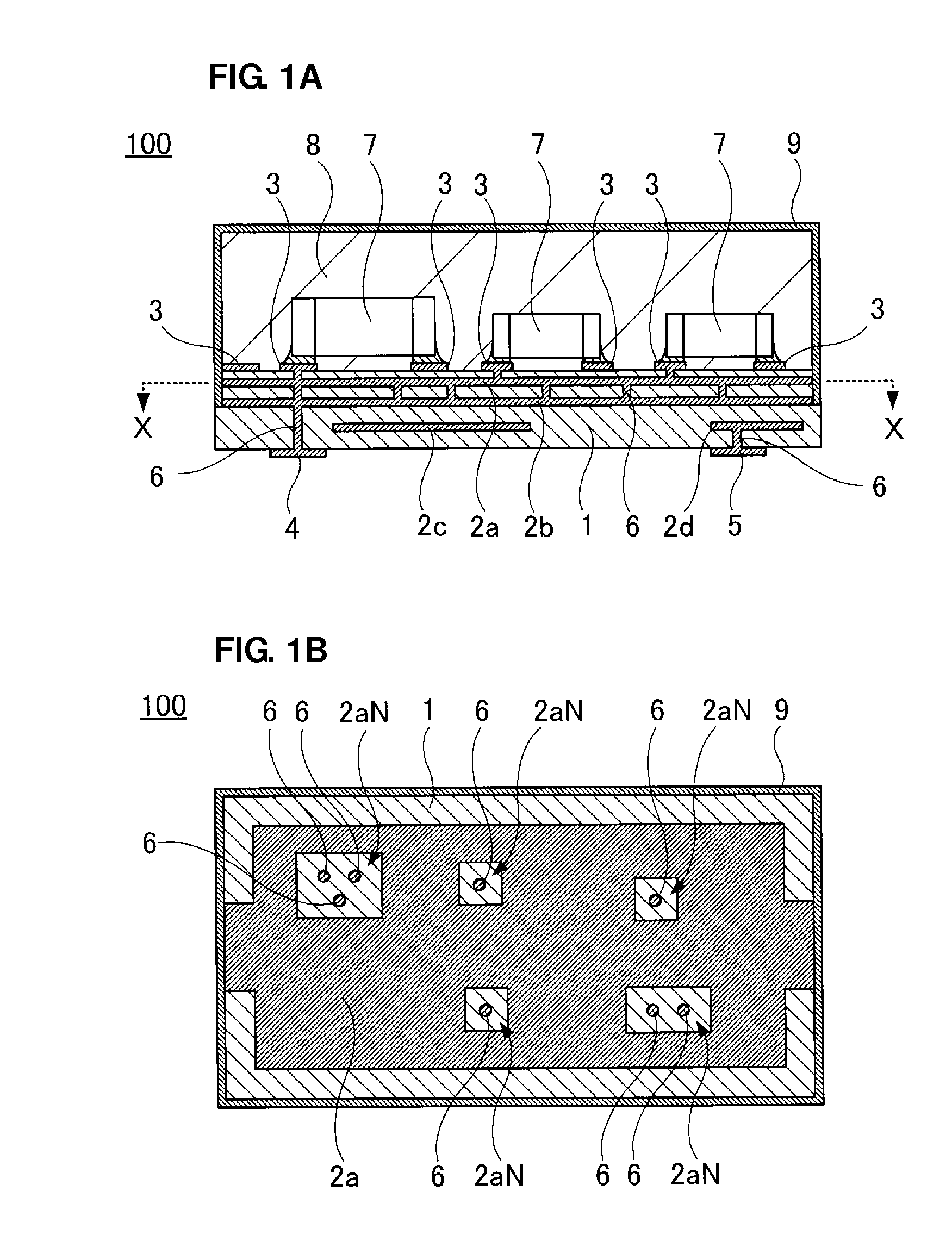

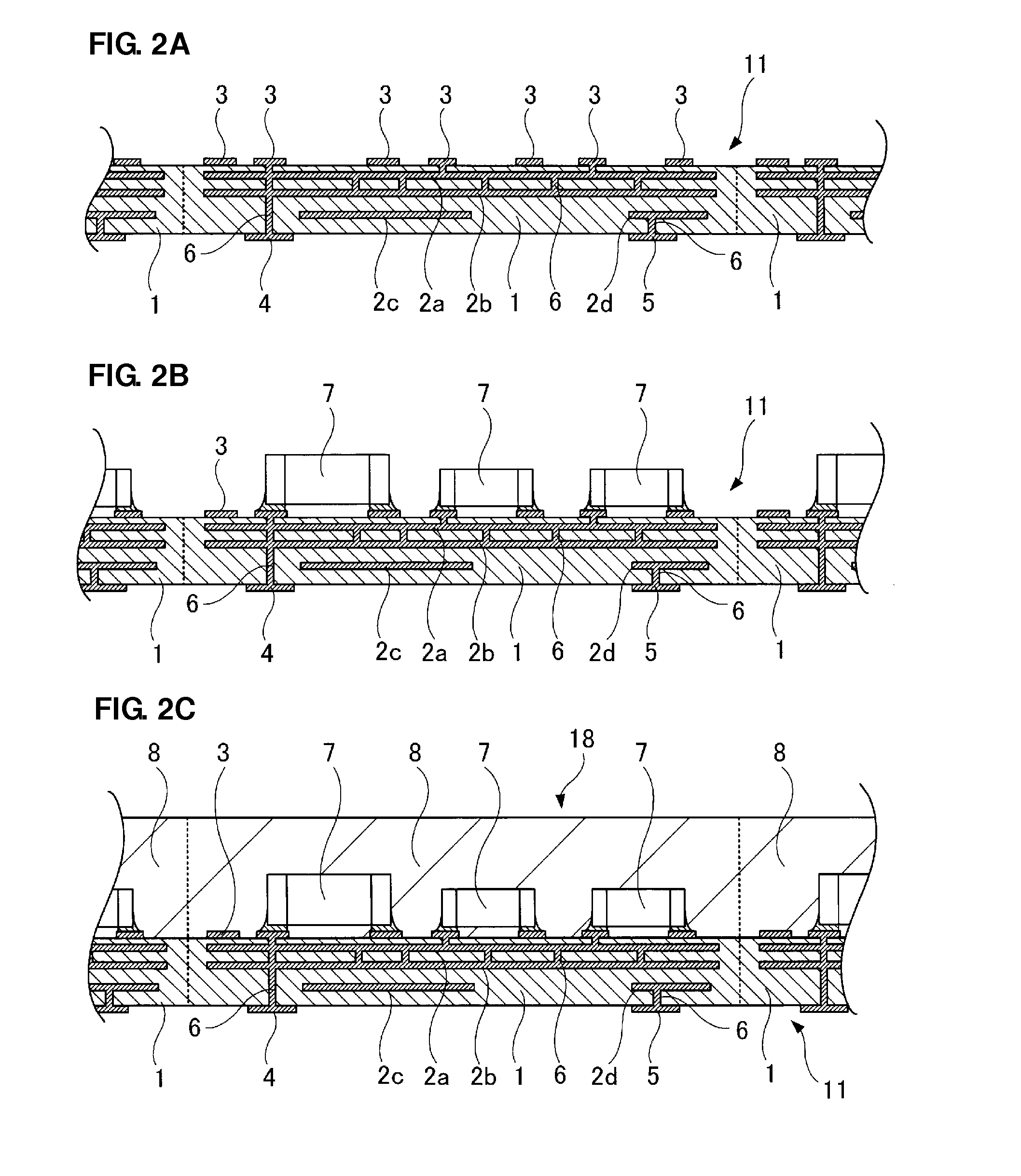

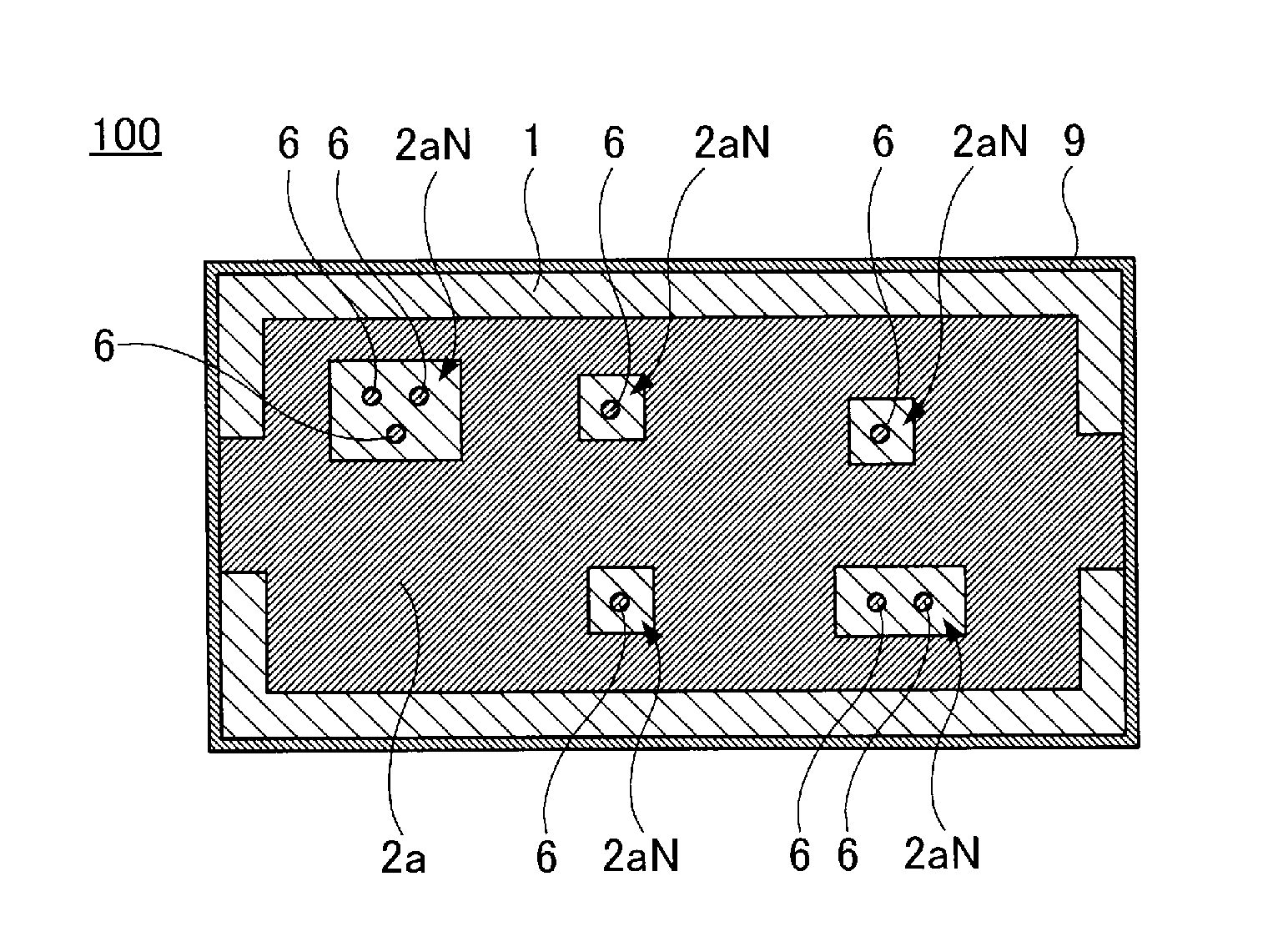

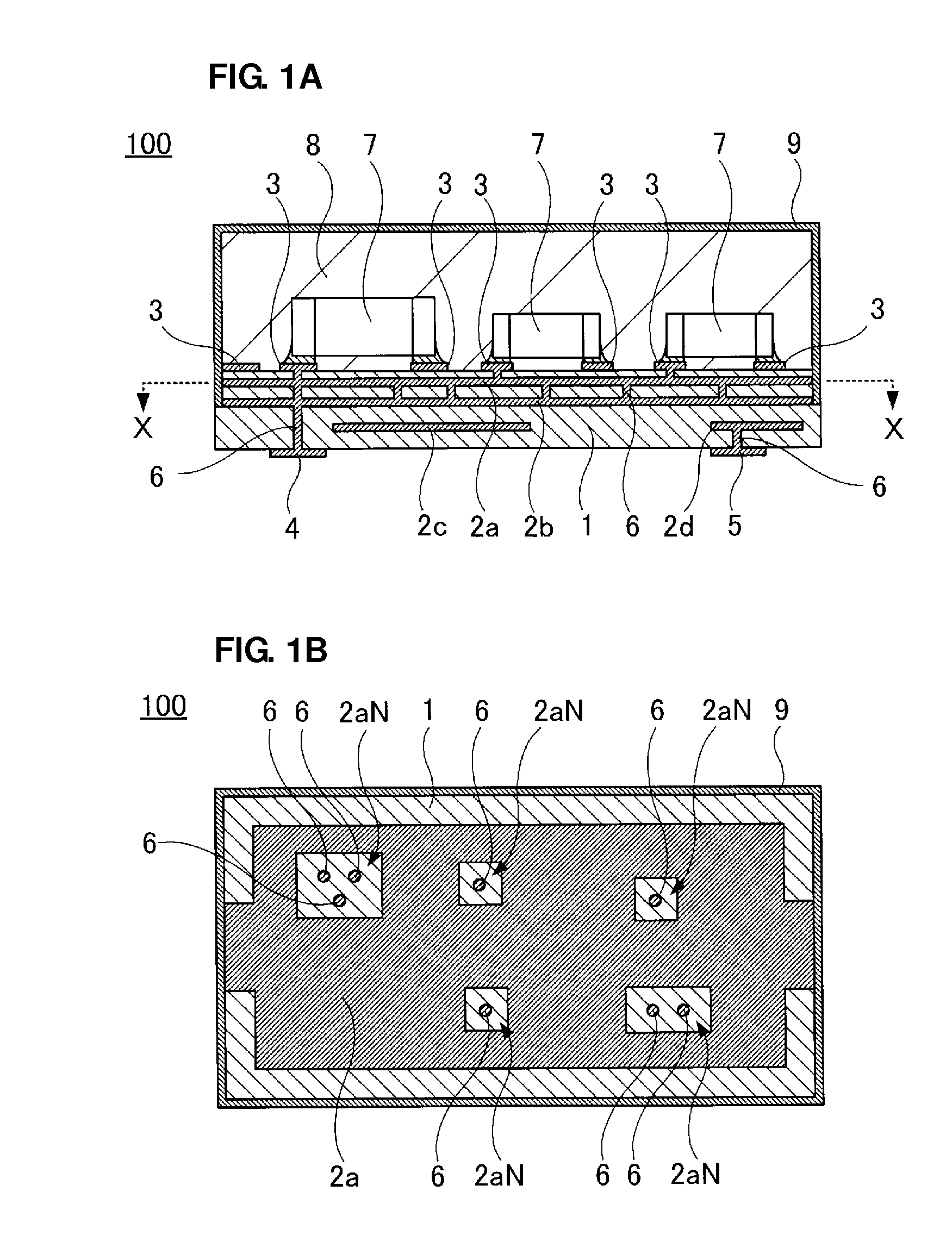

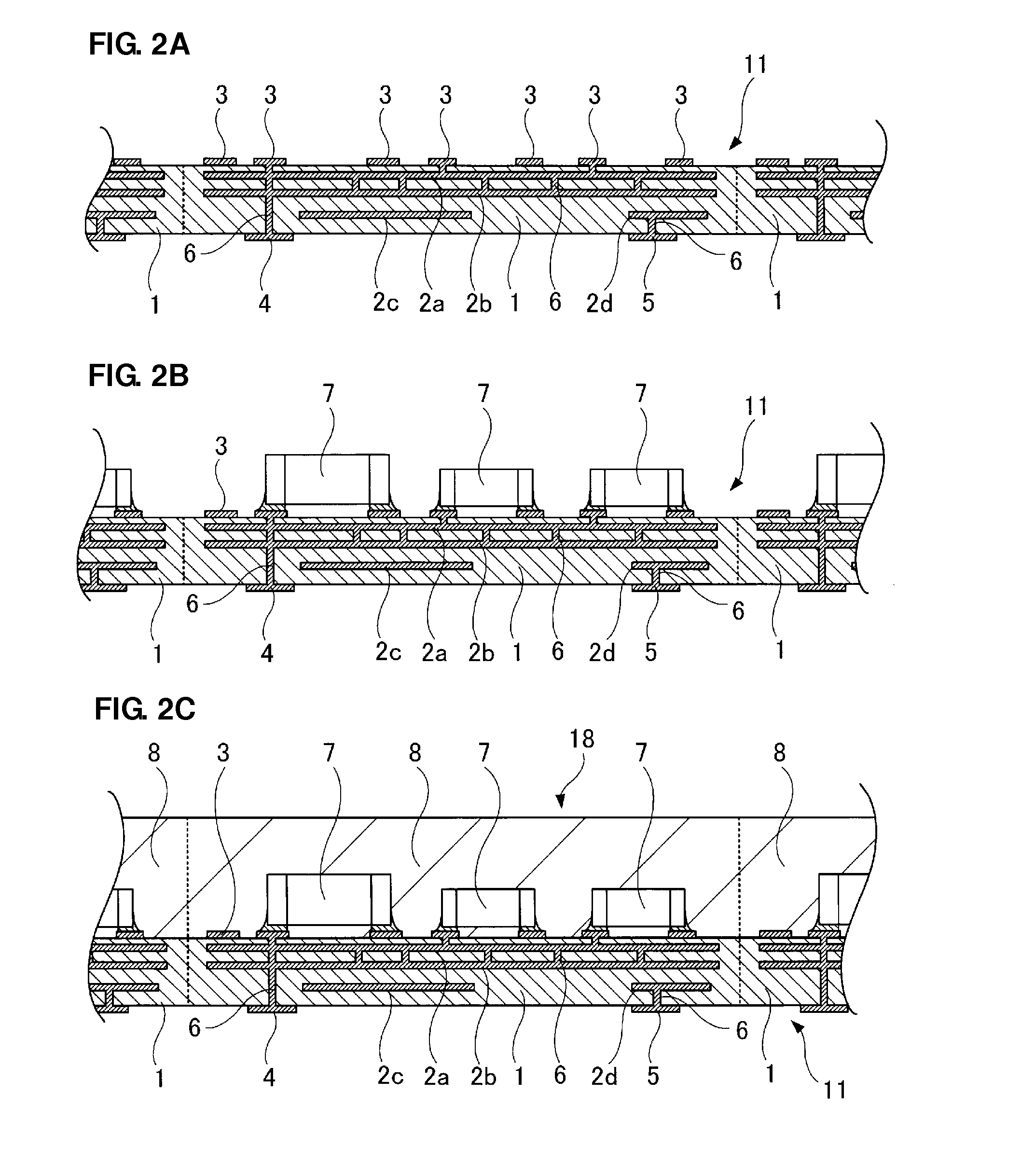

Circuit module

ActiveUS20130020119A1Low resistivityUniform potentialCross-talk/noise/interference reductionSemiconductor/solid-state device detailsEngineeringElectronic component

A circuit module includes a substrate that has a substantially rectangular parallelepiped shape and includes a plurality of inner conductive layers, an electronic component disposed on a first main surface of the substrate, an insulating layer disposed on the first main surface of the substrate so as to cover the electronic component, a shielding layer disposed on a surface of the insulating layer, and a ground electrode connected to the plurality of inner conductive layers. At least two of the inner conductive layers are directly connected to the shielding layer.

Owner:MURATA MFG CO LTD

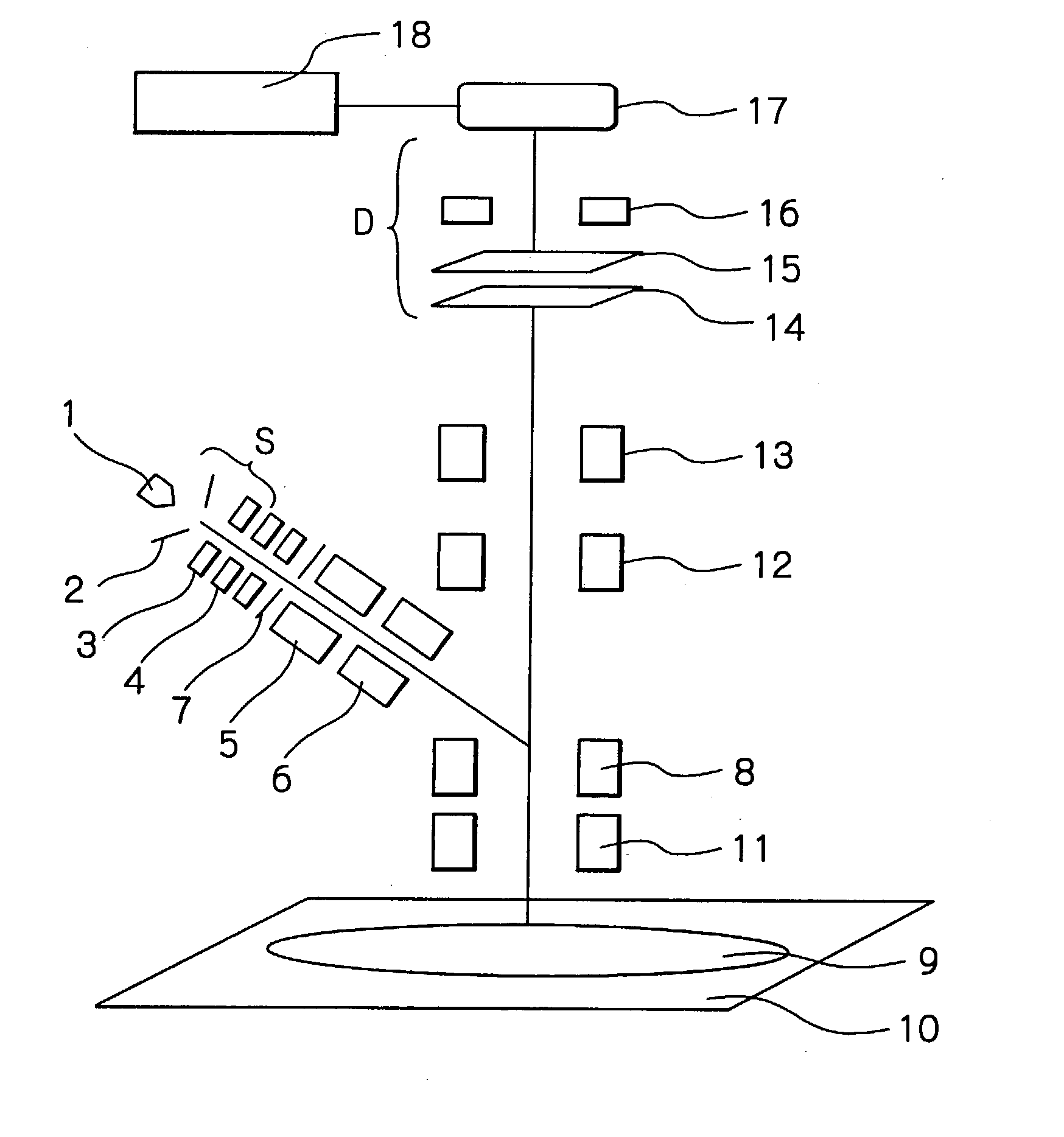

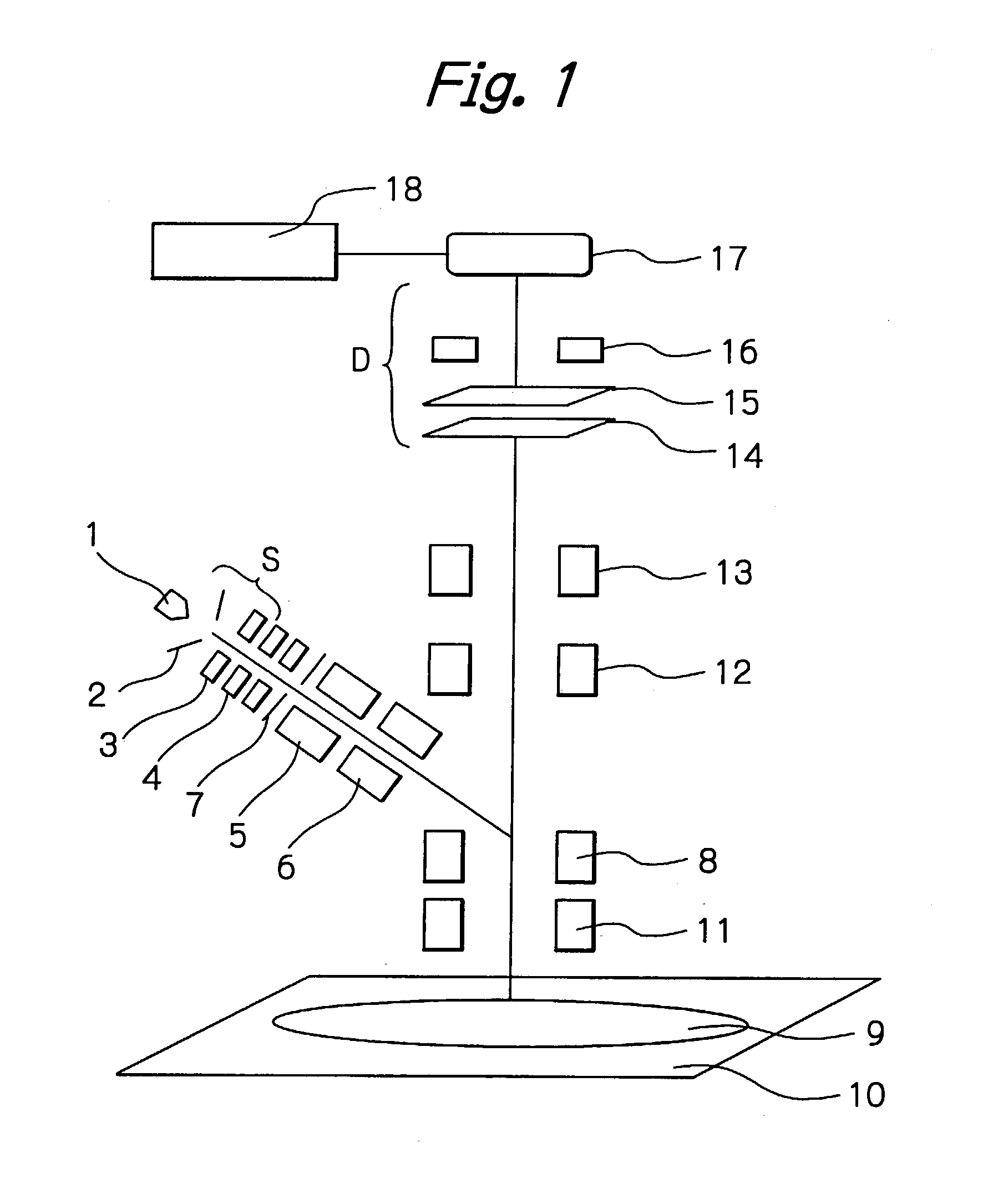

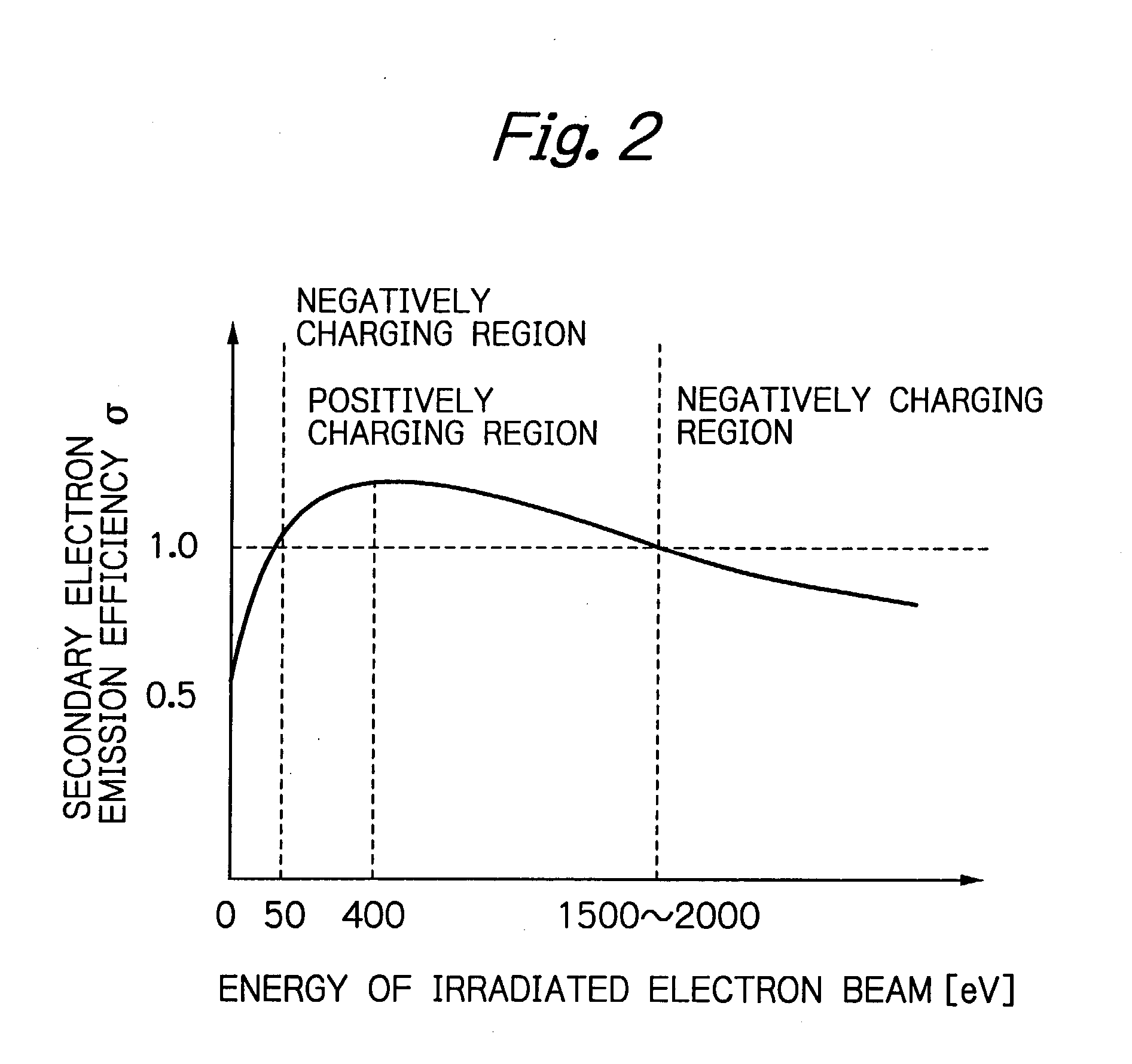

Electron beam apparatus and device manufacturing method using same

InactiveUS20030213893A1Reduce image distortionLess aberrationThermometer detailsMaterial analysis using wave/particle radiationElectron sourceImaging processing

A defect inspecting apparatus is provided for generating a less distorted test image to reliably observe a surface of a sample for detecting defects thereon. The defect detecting apparatus comprises a primary electron beam source for irradiating a sample, electrostatic lenses for focusing secondary electrons emitted from the surface of the sample irradiated with the primary electron beam, a detector for detecting the secondary electrons, and an image processing unit for processing a signal from the detector. Further, a second electron source may be provided for emitting an electron beam irradiated to the sample, wherein the sample may be irradiated with the electron beam from the second electron source before it is irradiated with the primary electron beam from the first electron source for observing the sample. A device manufacturing method is also provided for inspecting devices under processing with high throughput using the defect detecting apparatus.

Owner:EBARA CORP

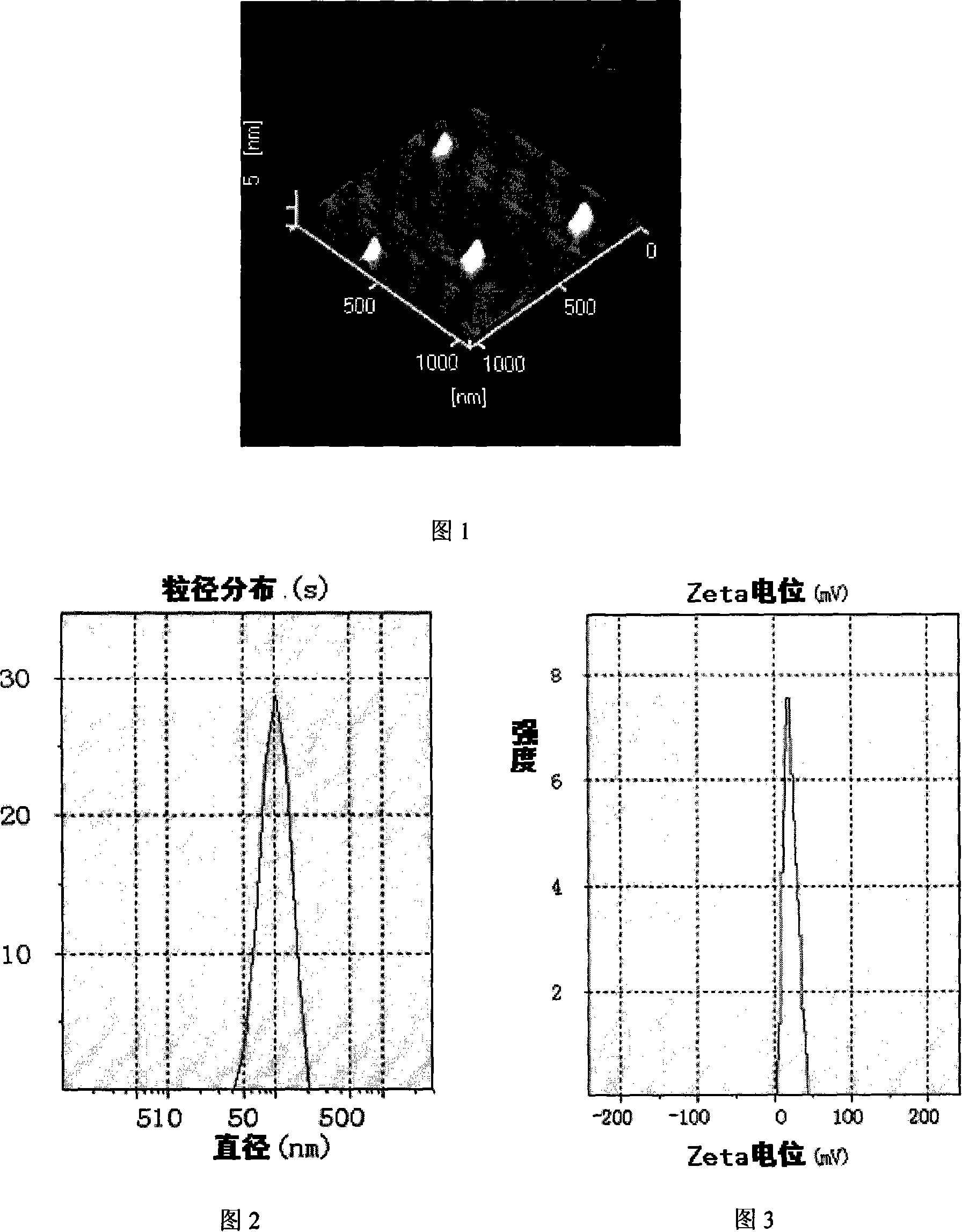

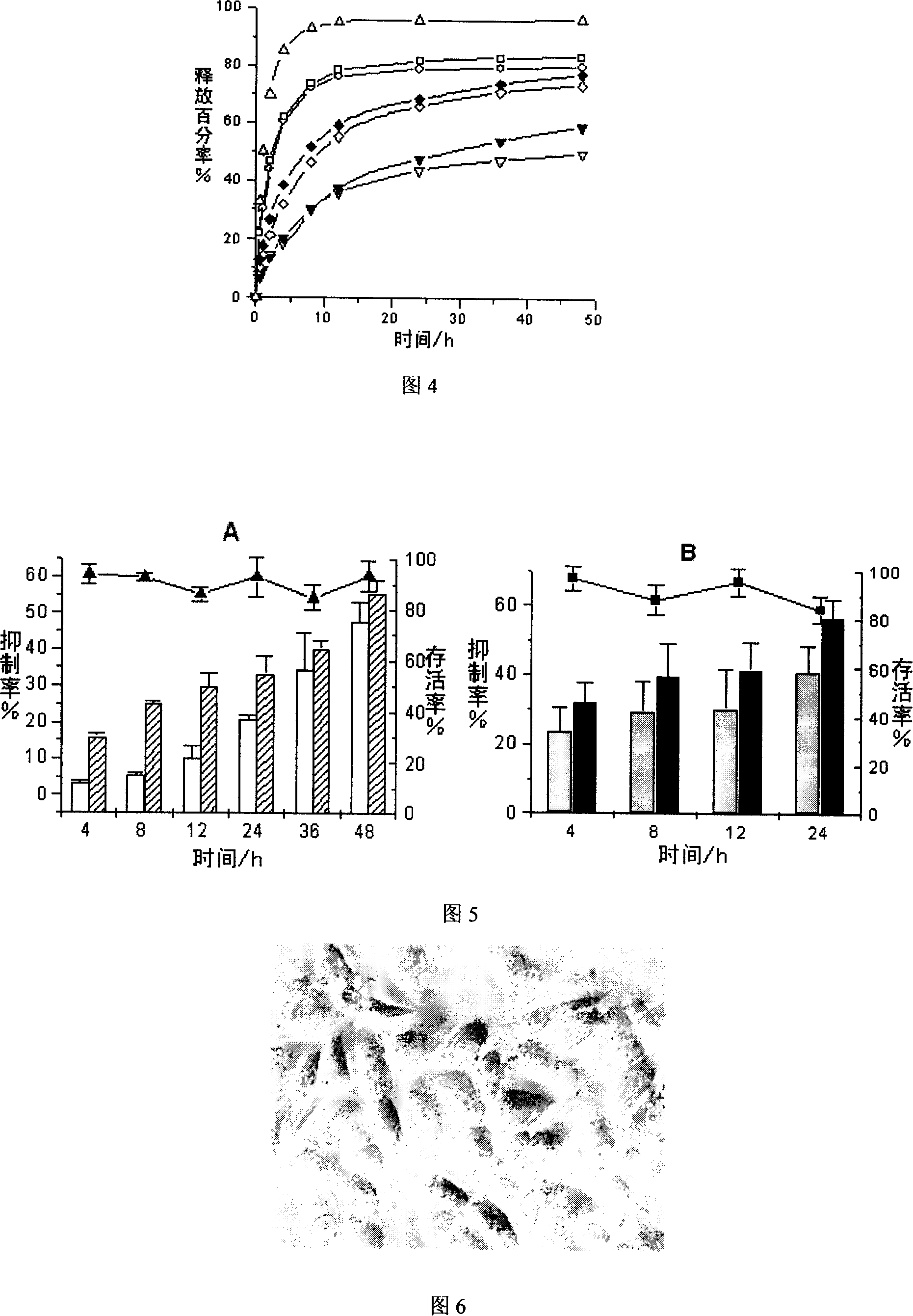

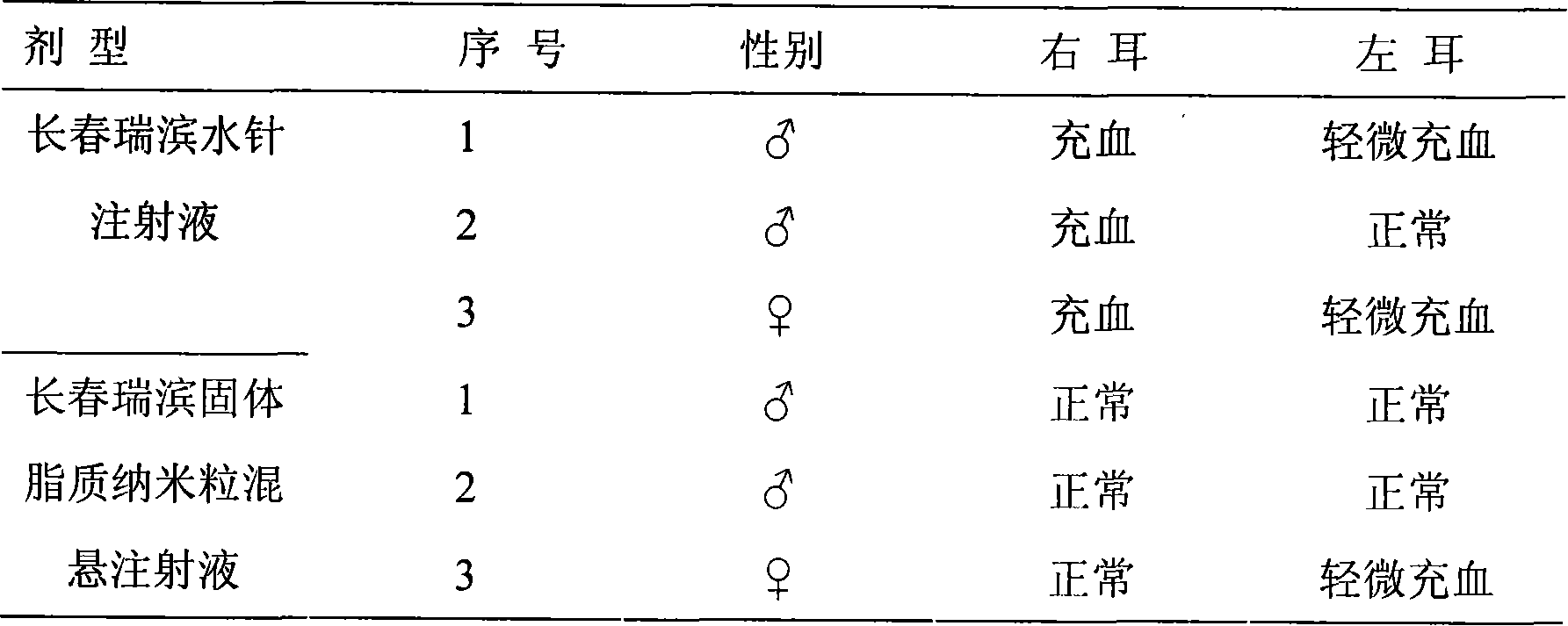

Vinorelbine solid lipid nano granule, freeze drying formulated product and method of preparing the same

InactiveCN101129375AAvoid degradationPrevent proliferationOrganic active ingredientsPowder deliveryWater bathsLipid formation

Disclosed is kind of Vinorelbine solid lipid nanoparticles which comprise (by weight percent) vinorelbine 1-25%, grease material 30-90%, phospholipids 5-50% oleinic acid 0-20%. The preparing process consists of melting liposome material through water-bath, dissolving phosphatides, oleic acid and Vnorelbine with ethanol, dropping into the liposome material, removing ethanol under decompression condition, cooling down and freezing, placing into pH 2-5 aqueous phase, triturating and homogenizing the turbid liquor to obtain the freeze-dried preparation with improved anticancer reactivity of Vinorelbine.

Owner:ZHEJIANG UNIV

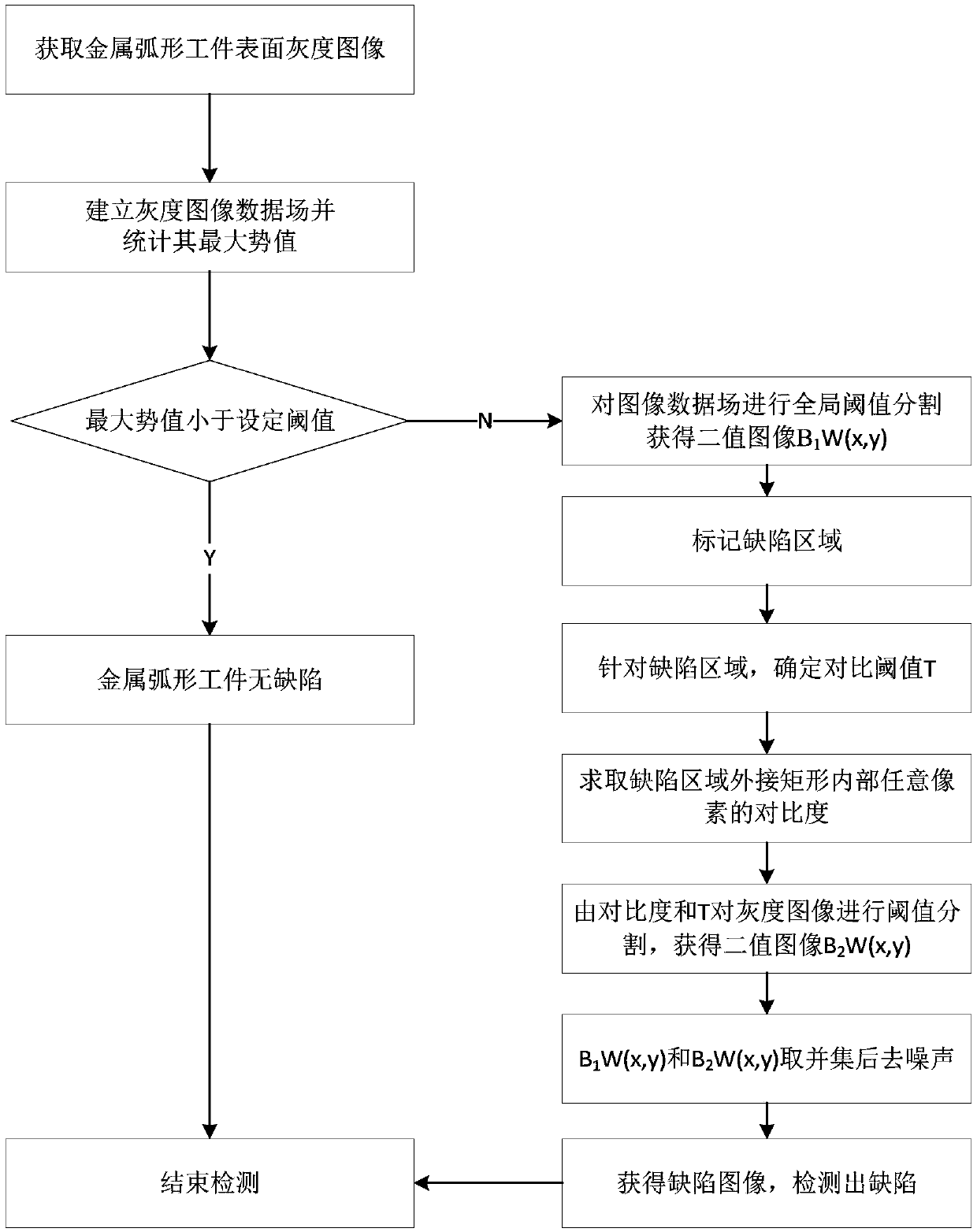

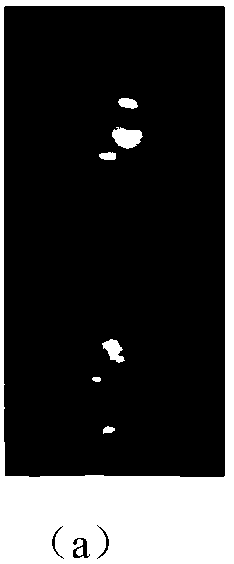

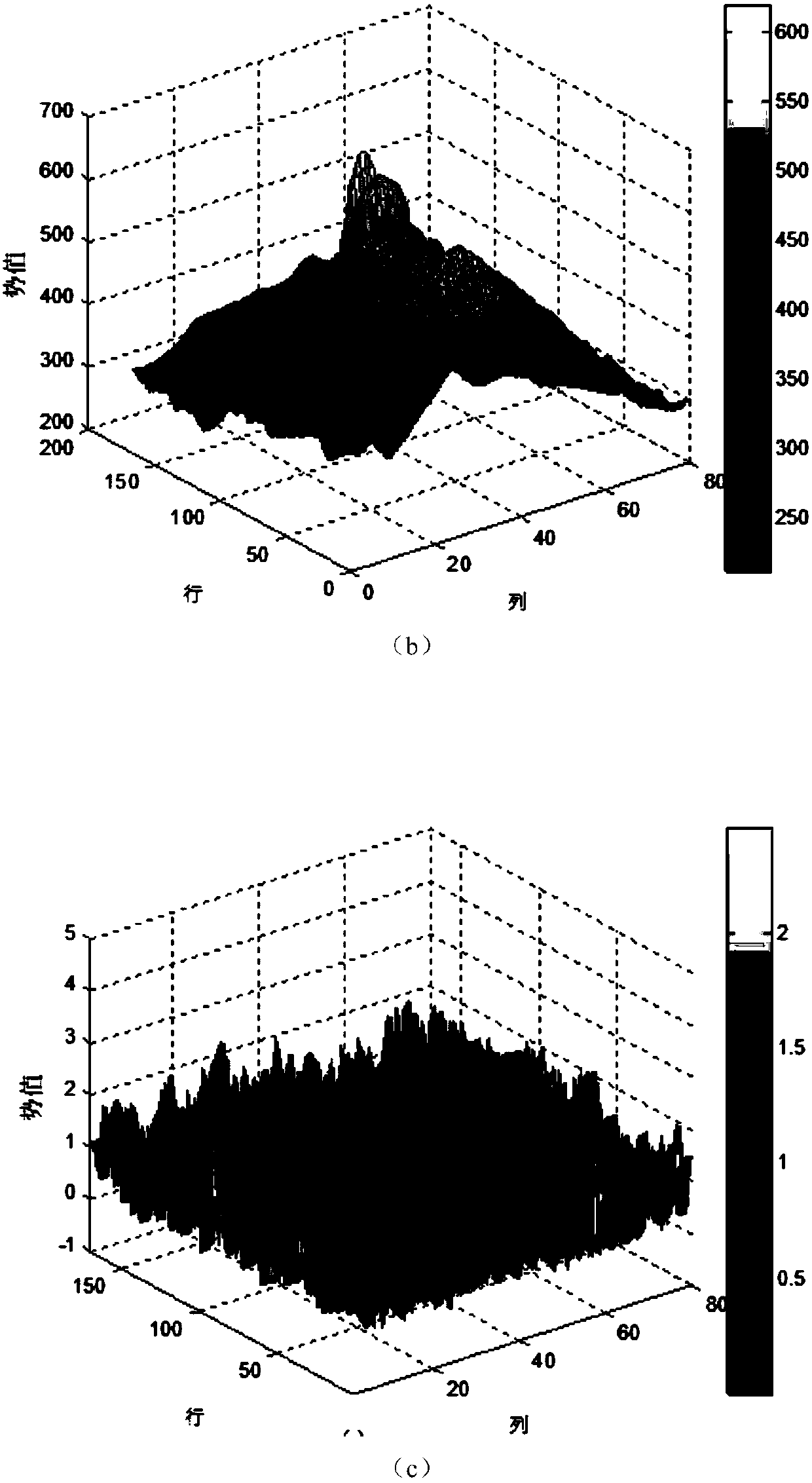

Method for on-line detection of surface defects of metal arc-shaped workpiece

ActiveCN109682839AUniform potentialPotential value contrast is obviousMaterial analysis by optical meansLow contrastDefect region

The invention discloses a method for on-line detection of surface defects of a metal arc-shaped workpiece. The method comprises the steps: first, obtaining grayscale images of the surface of a metal arc-shaped workpiece and establishing a data field; if the maximum potential value of the data field is smaller than a set threshold, determining that the metal arc-shaped workpiece has no defect, ending the detection, if not, executing the next step; conducting threshold segmentation on the image data field to obtain a binary image B1W(x, y), and marking defect areas; then for each defect area, determining a contrast threshold T according to its externally connected rectangular area; then, calculating the contrast of any pixel inside the externally connected rectangle of each defect area, andconducting threshold segmentation according to the contrast and T pairs of grayscale images to obtain a binary image B2W(x, y); finally, uniting the B1W(x, y) and the B2W (x, y) and removing the noiseto obtain a final defect image, thereby detecting defects. The problem of low defect detection accuracy caused by uneven reflection, low contrast and many kinds of defects of the surface of the metalarc-shaped workpiece is effectively solved, and the method has good detection precision and robustness for detection of different defects.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

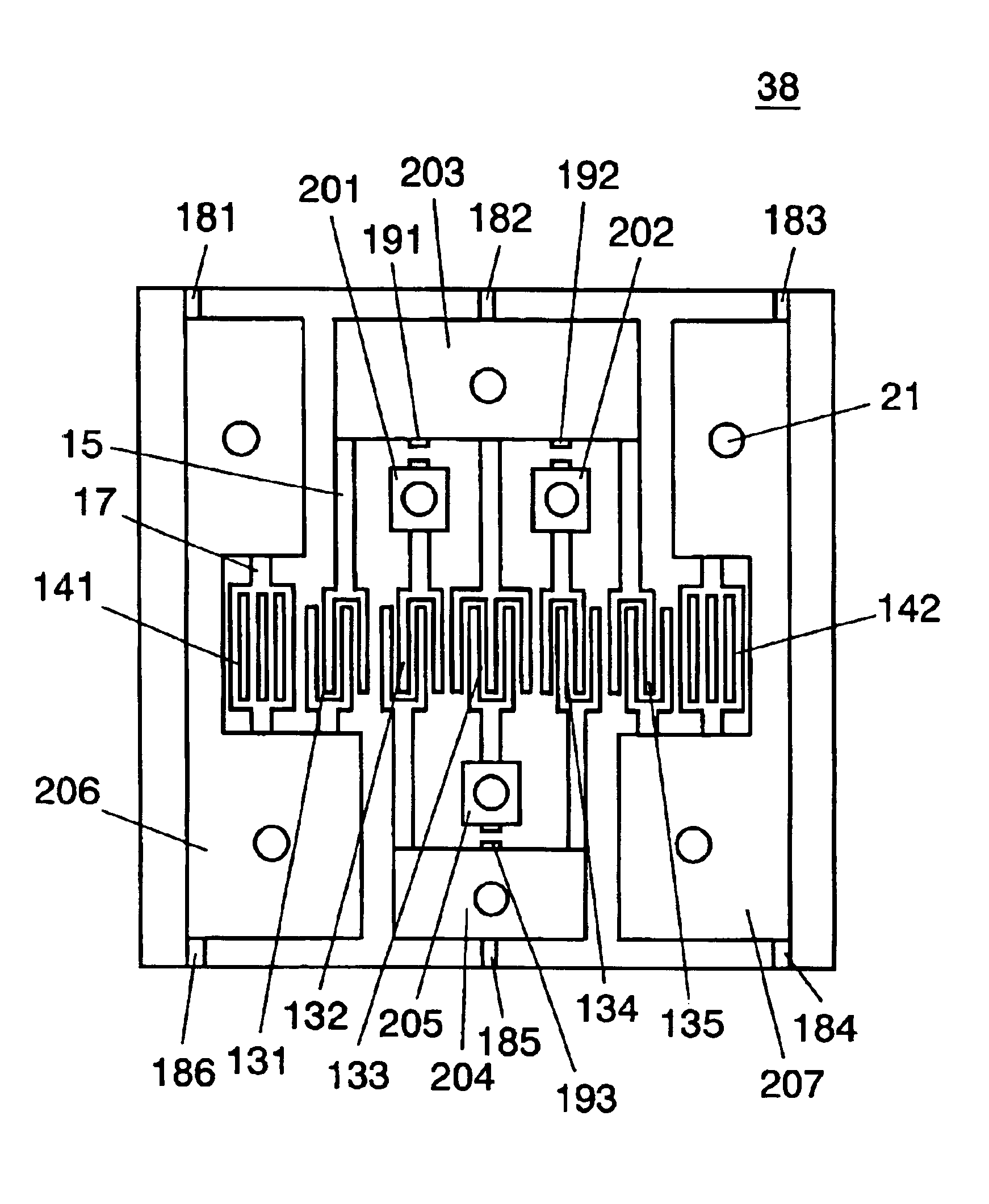

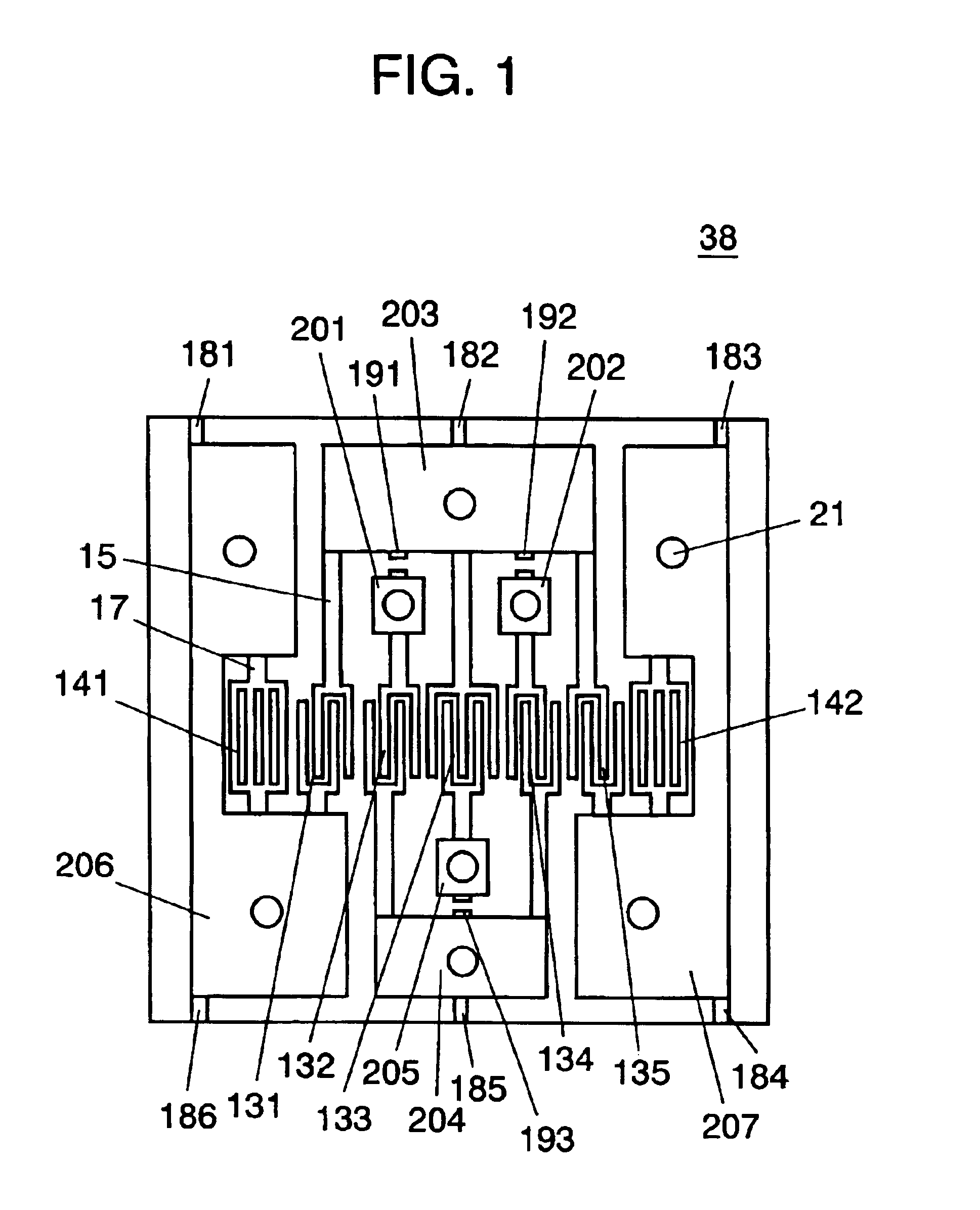

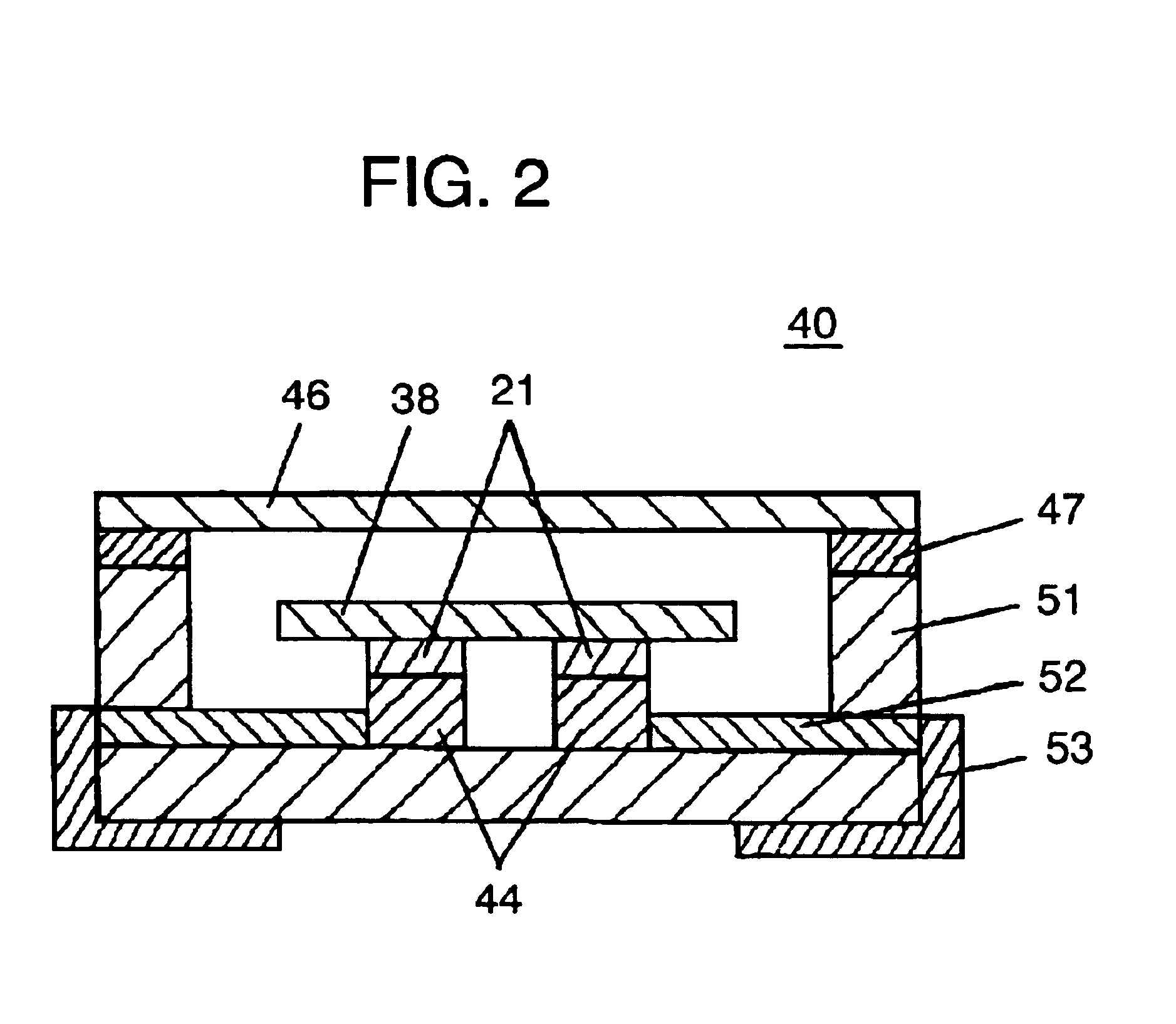

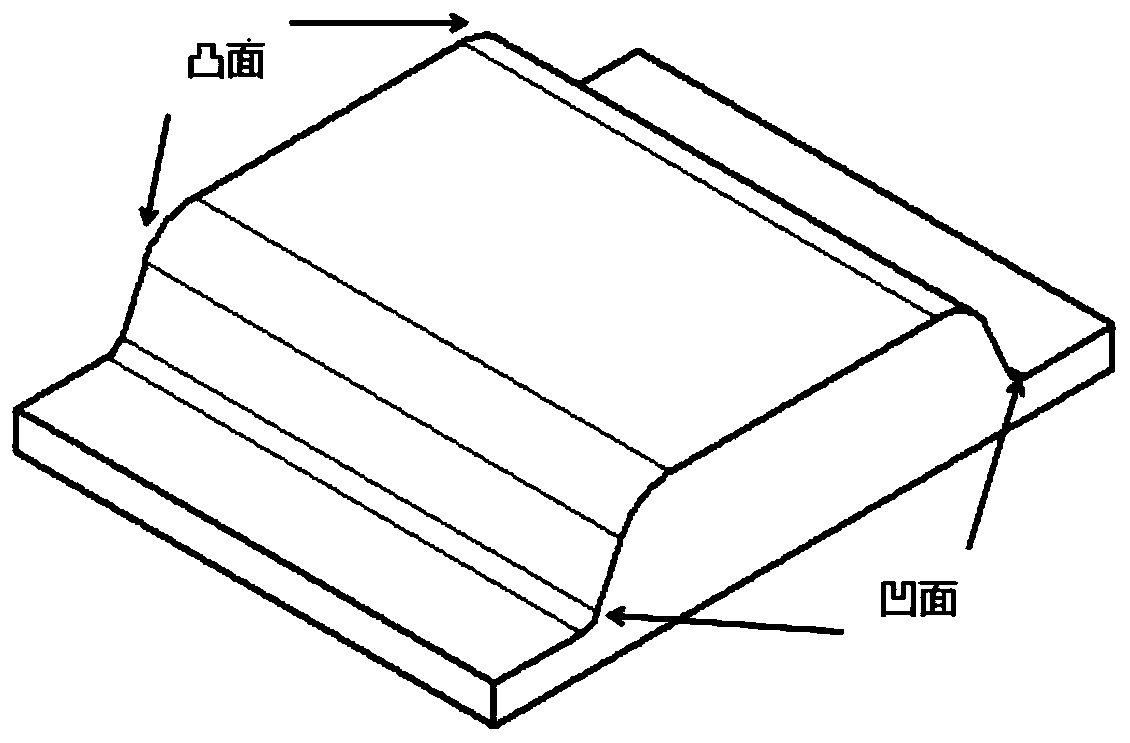

Method of manufacturing a surface acoustic wave element

InactiveUS6951047B2Avoid damageUniform potentialPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyGratingTransducer

A SAW element of the present invention includes a plurality of inter-digital transducer (IDT) electrodes on a piezoelectric substrate, grating reflector electrodes disposed on the sides of the IDT electrodes, and a plurality of pad electrodes led from the IDT electrodes and the grating reflector electrodes. A plurality of the pad electrodes includes isolated pad electrodes not directly opposed to the outer periphery of the SAW element, and adjacent pad electrodes directly opposed to the outer periphery thereof A connecting electrode between the isolated pad electrode and the adjacent pad electrode is removed by etching at least before dicing in order to prevent discharge from occurring due to pyroelectricity, and to prevent the electrodes from being damaged.

Owner:PANASONIC CORP

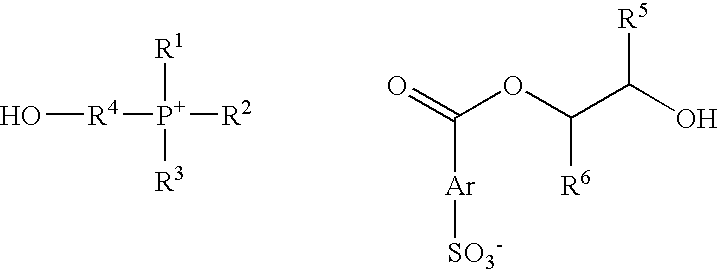

Biasable transfer composition and member

InactiveUS20070075297A1Uniform potentialConductive materialSynthetic resin layered productsPolyurethane elastomerAryl

The invention provides conductivity control agent comprised of a polymeric material containing hydroxyalkylphosphonium (2-hydoxyethoxycarbonyl)arylsulfonate salts. The conductivity control agents can be used with semi-conductive rolls, belts and other biasable members. The inclusion of the conductivity control agent in the polymeric or polyurethane elastomers extends the electrical life of the polyurethane biasable member in low humidity environments. Additionally, the resistivity of the elastomeric polyurethane or polymer on the biasable member is controlled to a desirable value by adjusting the conductivity control agent level in the polymeric or polyurethane elastomers.

Owner:EASTMAN KODAK CO

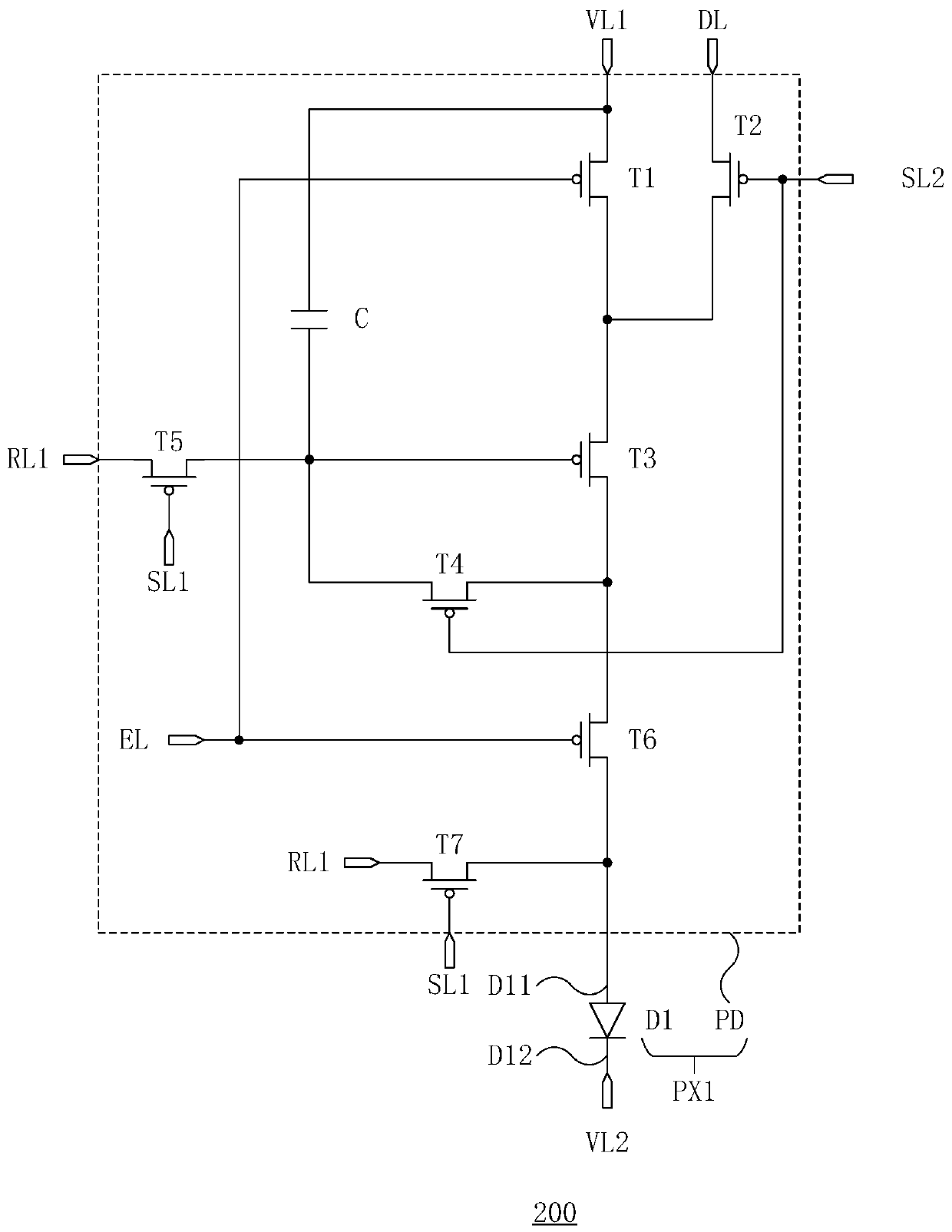

Display panel and display device

The invention provides a display panel and a display device. The display panel comprises a first pixel and a first reference line which are connected, and a second pixel and a second reference line which are connected, wherein the first pixel comprises a first light emitting diode and a pixel driving circuit, the second pixel comprises a second light emitting diode and a pixel driving circuit, andthe pixel driving circuit comprises a driving transistor and a compensation transistor; in the pixel driving circuit, a compensation transistor is used for detecting a threshold voltage of a drivingtransistor; in the first pixel, the pixel driving circuit is used for controlling the potential of the first reference line to be transmitted to the first electrode A of the first light emitting diode; in the second pixel, the pixel driving circuit is used for controlling the potential of the second reference line to be transmitted to the second A electrode of the second light emitting diode; theturn-on voltage of the first light emitting diode is smaller than that of the second light emitting diode, and the potential of the first reference line is smaller than that of the second reference line. According to the invention, the brightness of the display panel is uniform.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

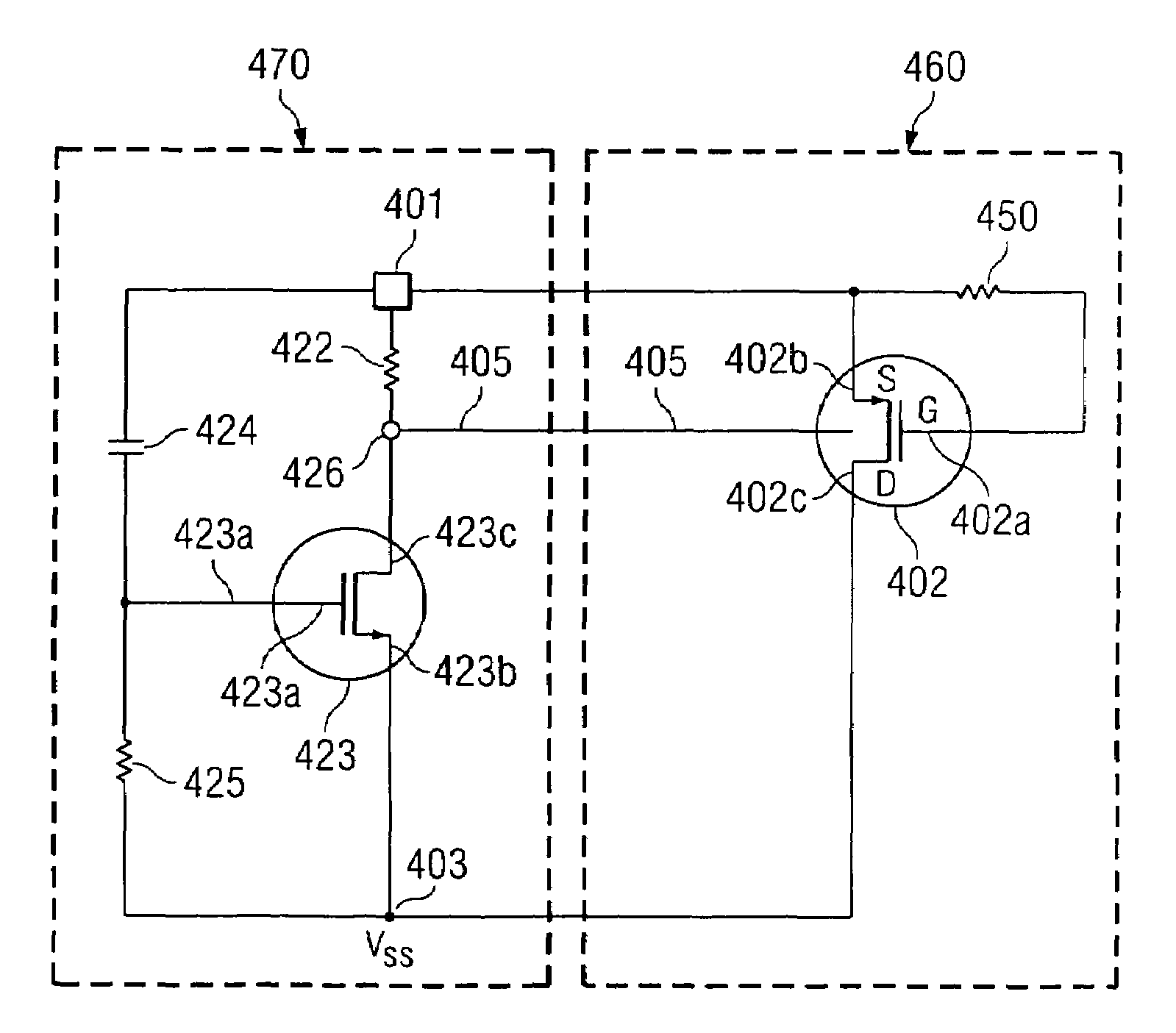

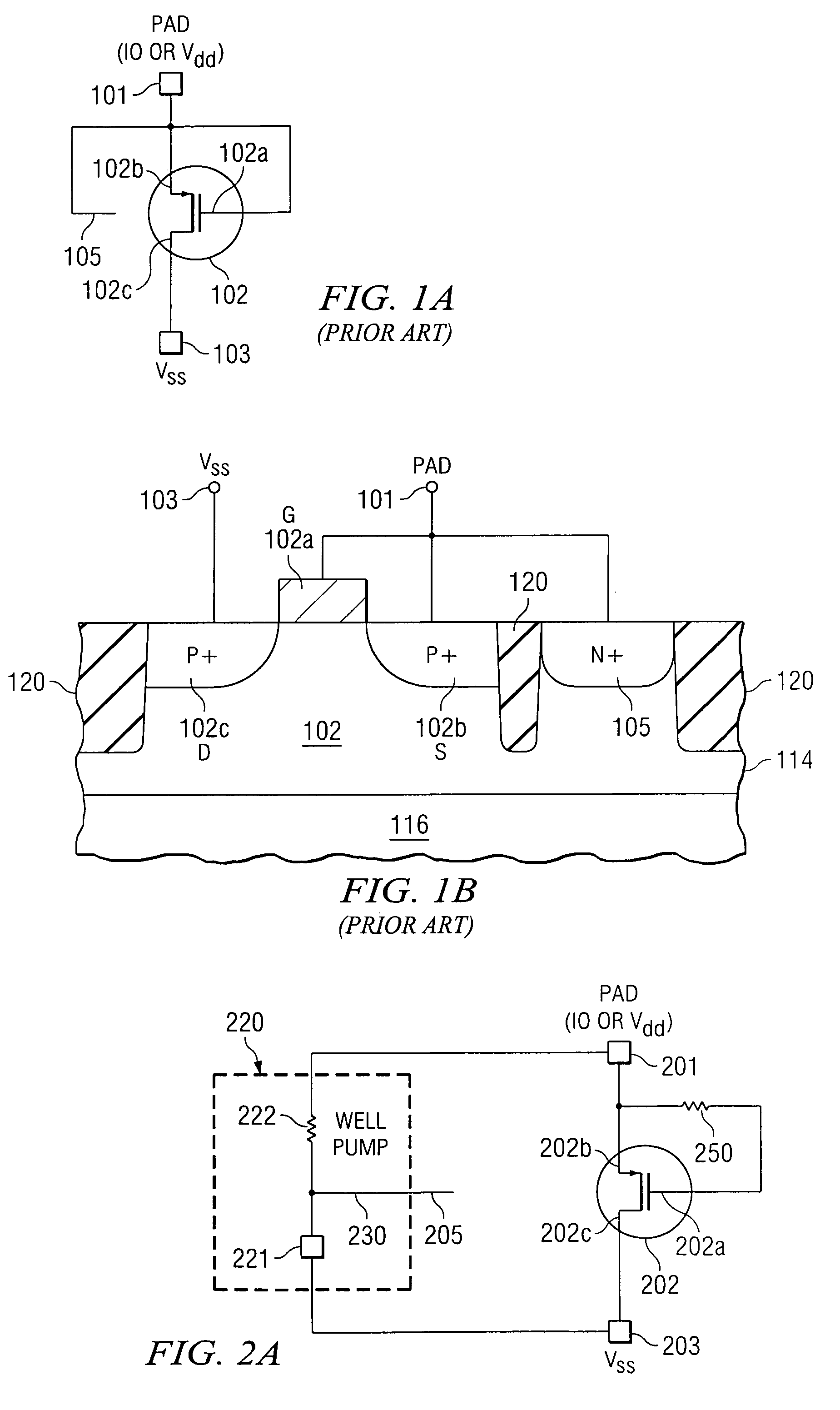

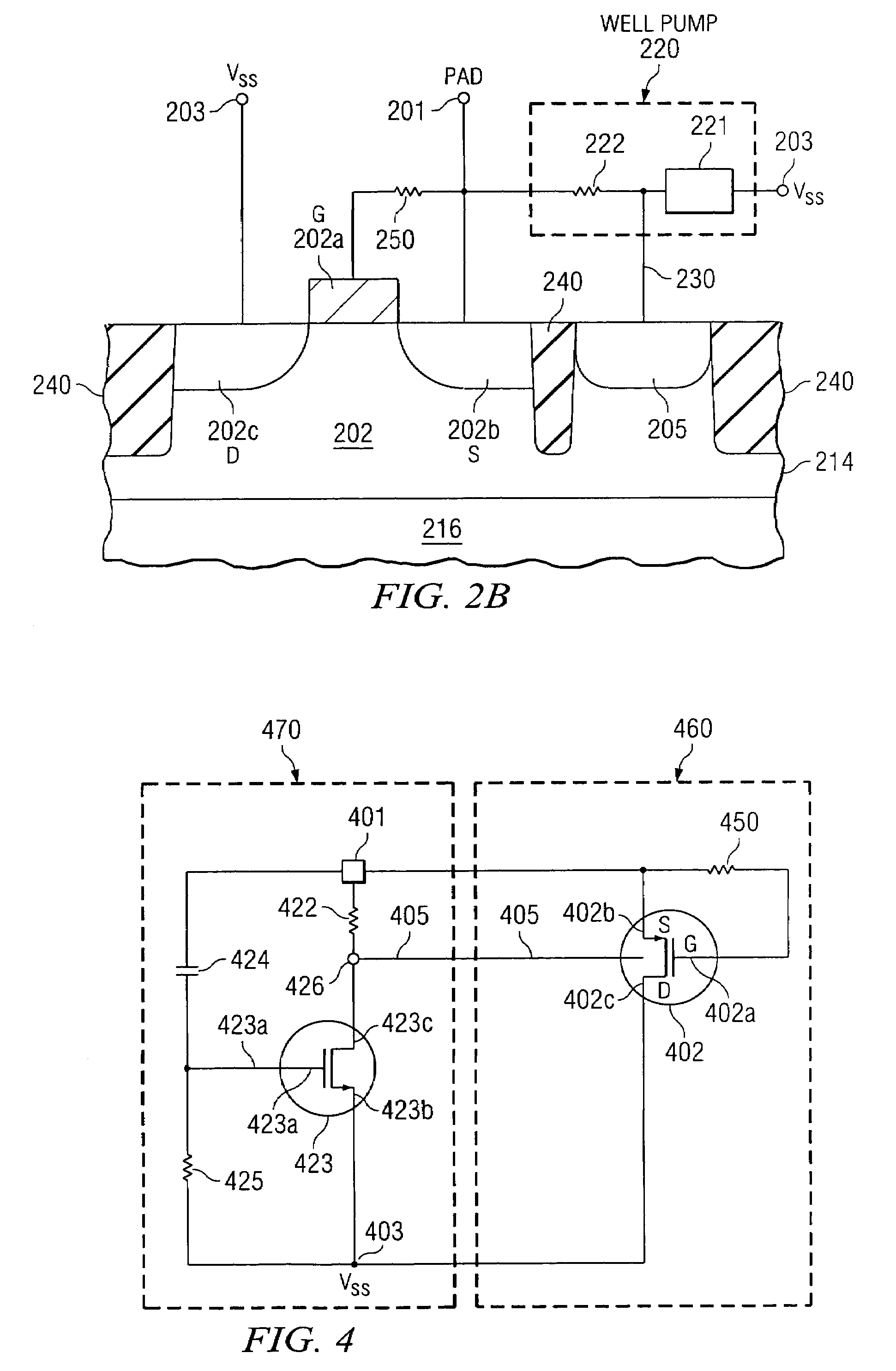

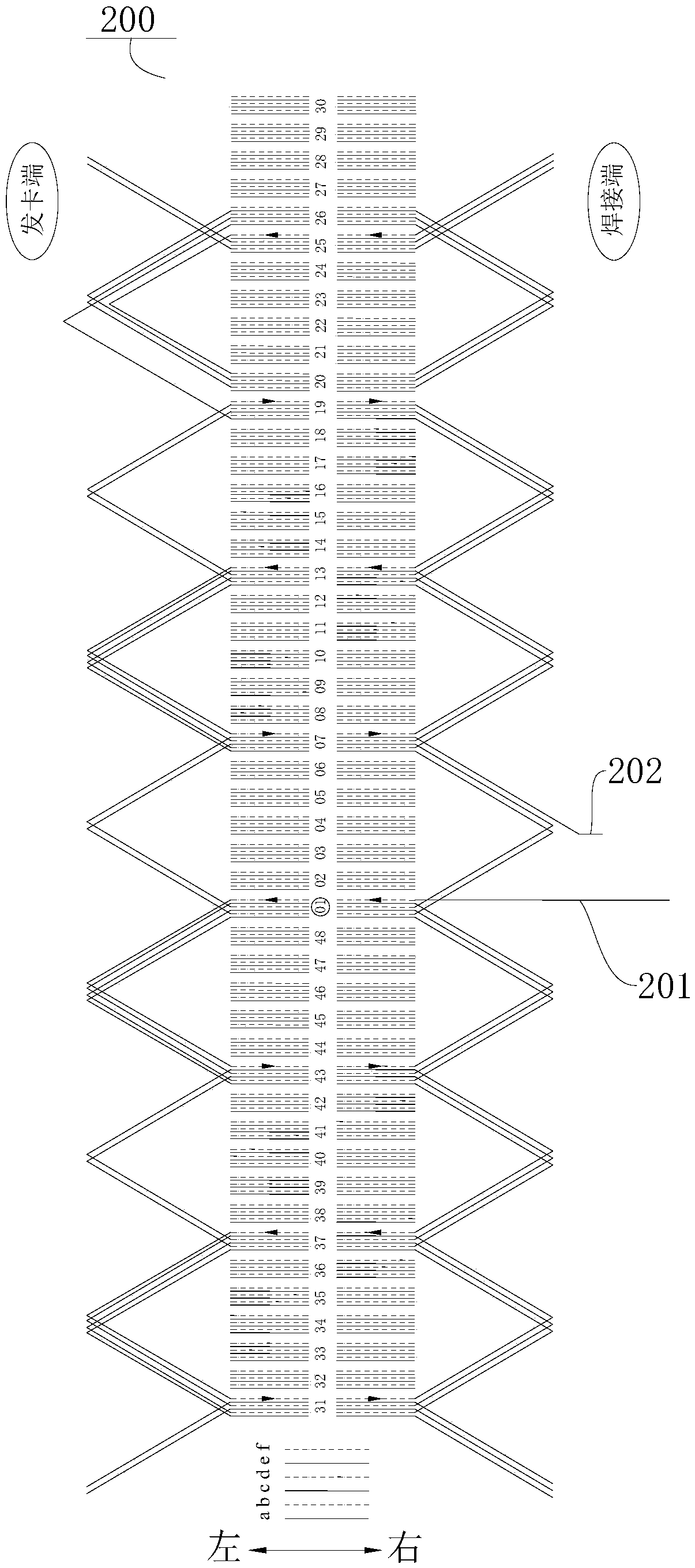

Body-biased pMOS protection against electrostatic discharge

ActiveUS7256460B2Uniform potentialTransistorSemiconductor/solid-state device detailsVoltage dropZener diode

A protection circuit for protecting an integrated circuit pad 201 against an ESD pulse, which comprises a discharge circuit having an elongated MOS transistor 202 (preferably pMOS) in a substrate 205 (preferably n-type), said discharge circuit operable to discharge the ESD pulse to the pad, to ground 203. The embodiment further contains a pump circuit connected to the pad for receiving a portion of the pulse's current; the pump circuit comprises a component 221 determining the size of this current portion (for example, another transistor, a string of forward diodes, or a reverse Zener diode), wherein the component is connected to ground. A discrete resistor 222 (for example about 40 to 60Ω) is connected between the pad and the component and is operable to generate a voltage drop (about 0.5 to 1.0 V) by the current portion. A plurality of contacts to the substrate connects to the resistor so that the voltage drop is uniformly impressed on the substrate to ensure uniform turn-on of the elongated transistor for uniform pulse discharge.

Owner:TEXAS INSTR INC

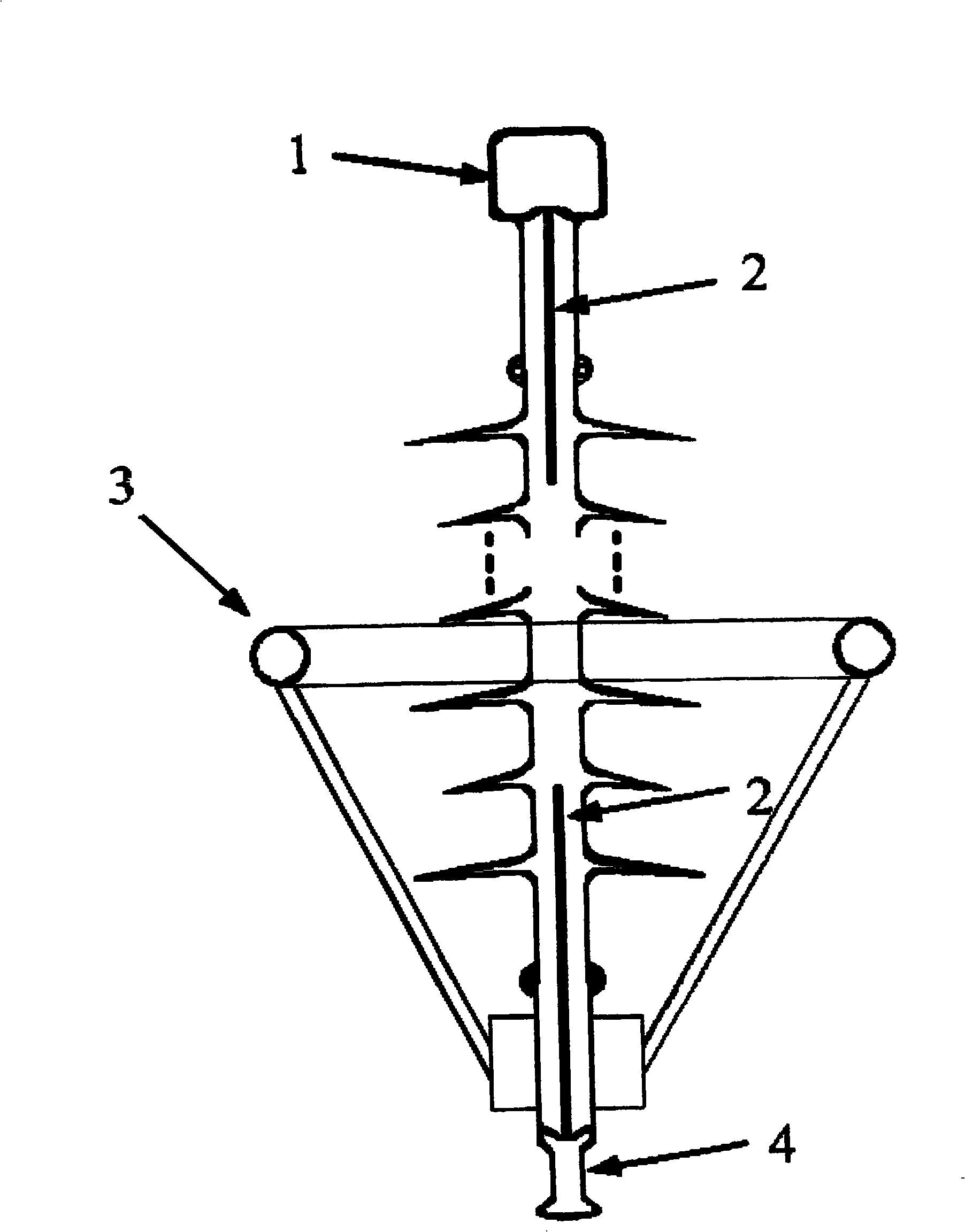

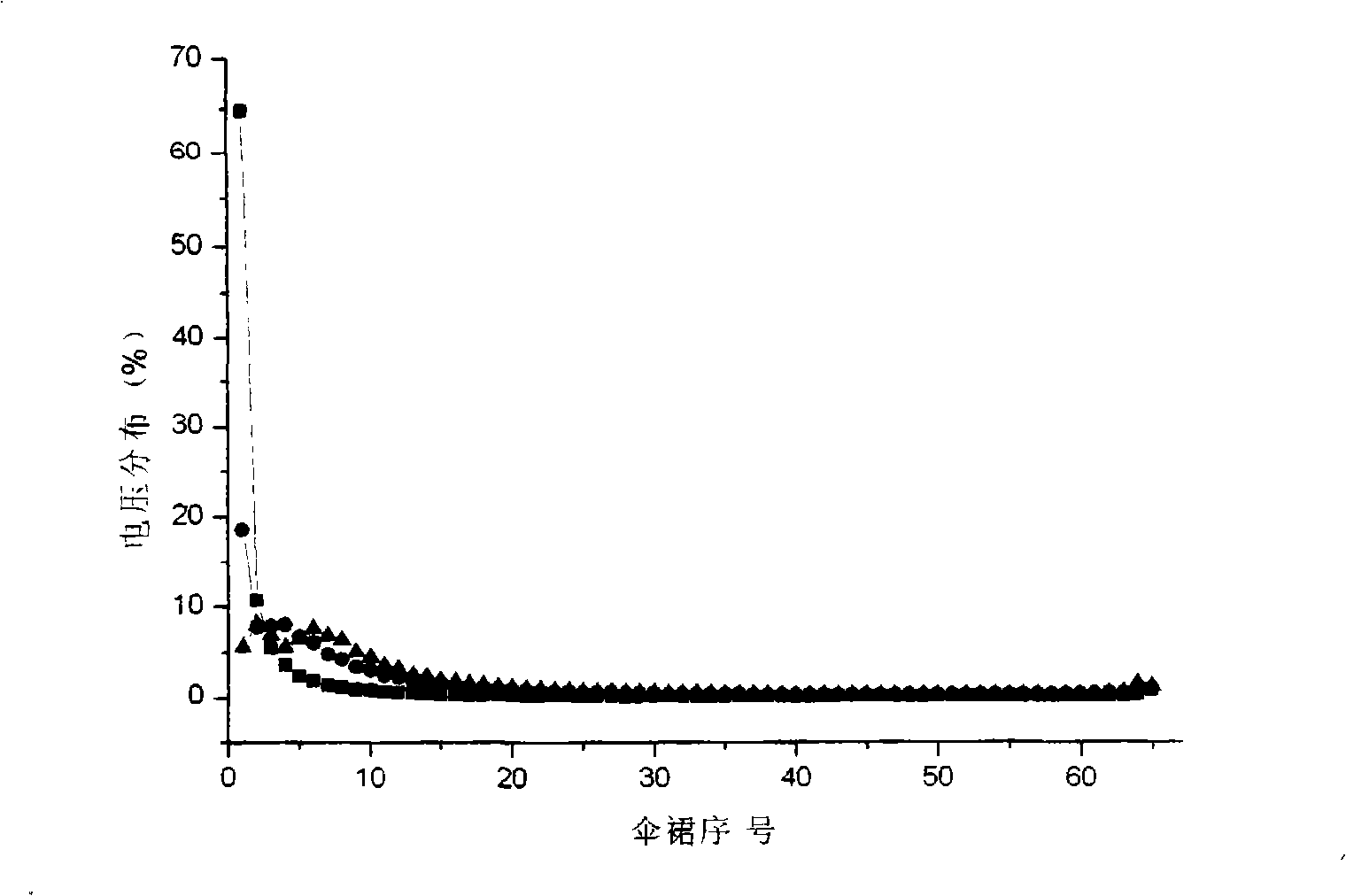

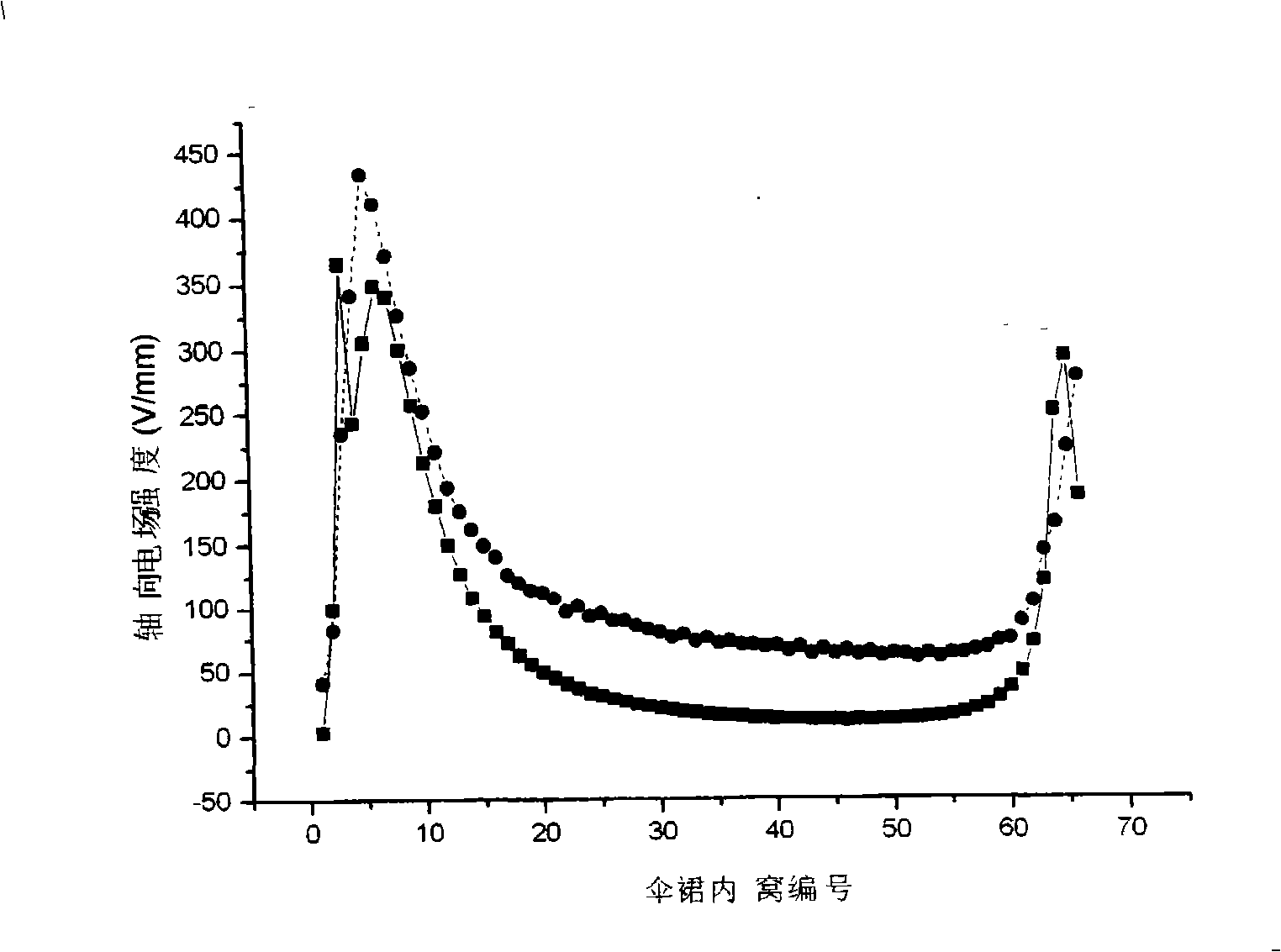

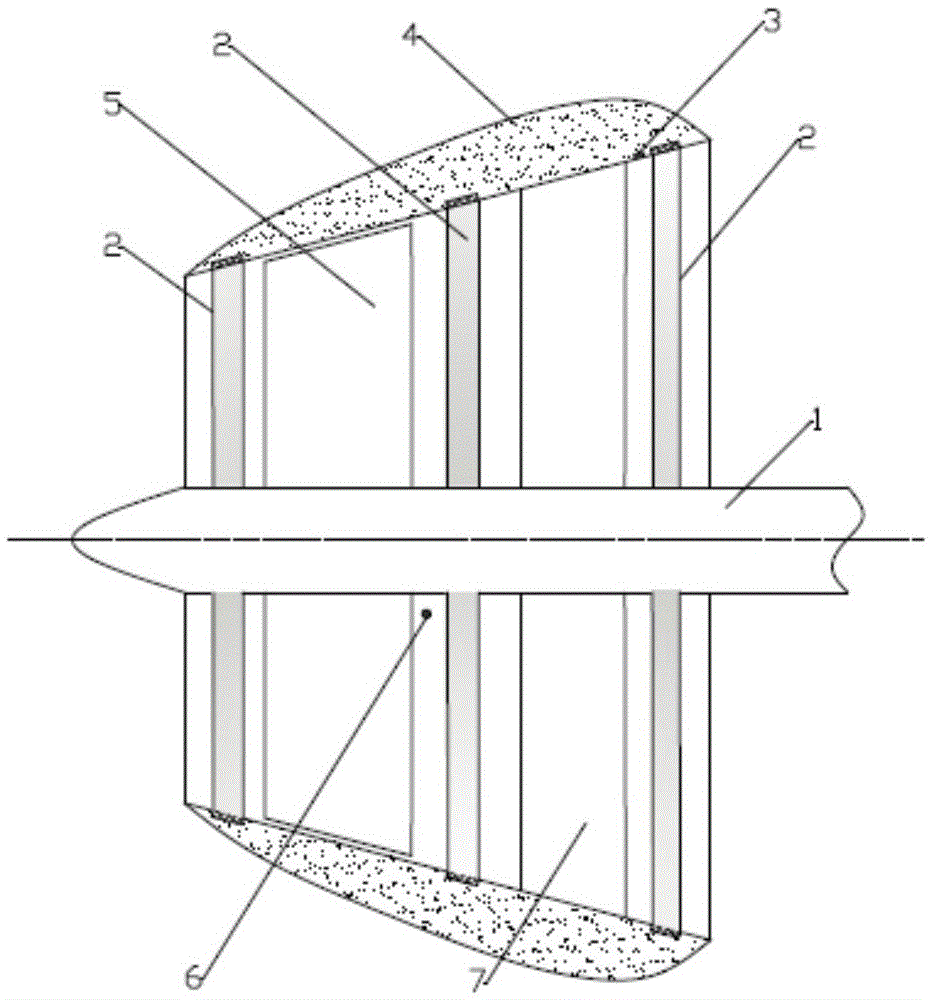

Internal electrode for composite insulator and equalizing ring configuring method as well as composite insulator thereof

ActiveCN101354933AUniform potentialUniform electric field distributionSuspension/strain insulatorsComposite insulatorsElectric power system

The invention relates to a method for improving the distribution of the electrical level of a composite insulator in a power transmission line and controlling an end electric filed thereof. According to the method, an inner electrode and an equalizing ring are arranged on the conducting wire side of the composite insulators for the high-voltage power transmission line; and the pole tower side is only provided with an inner electrode. The composite insulator formed by the method comprises an epoxy core bar with an umbrella skirt and a jacket covered outside, and hardware fittings on two ends; the conducting wire side of the core bar and a bar body of the pole tower side are respectively embedded with an inner slender electrode made of metal material; the conducting wire side of the core bar is provided with an equalizing ring which is made of the metal material and consists of a bracket and a ring; and the shape of the ring can be a cirque, an opening ring, an elliptical ring, etc. The method can realize the even distribution of the electric field of the conducting wire side and the pole tower side of the composite insulator, reduces the distribution of the electric levels on two sides, inhibits the corona discharge and electric deterioration of the composite insulator and improves the reliability of safe operation of an electric power system.

Owner:STATE GRID CORP OF CHINA

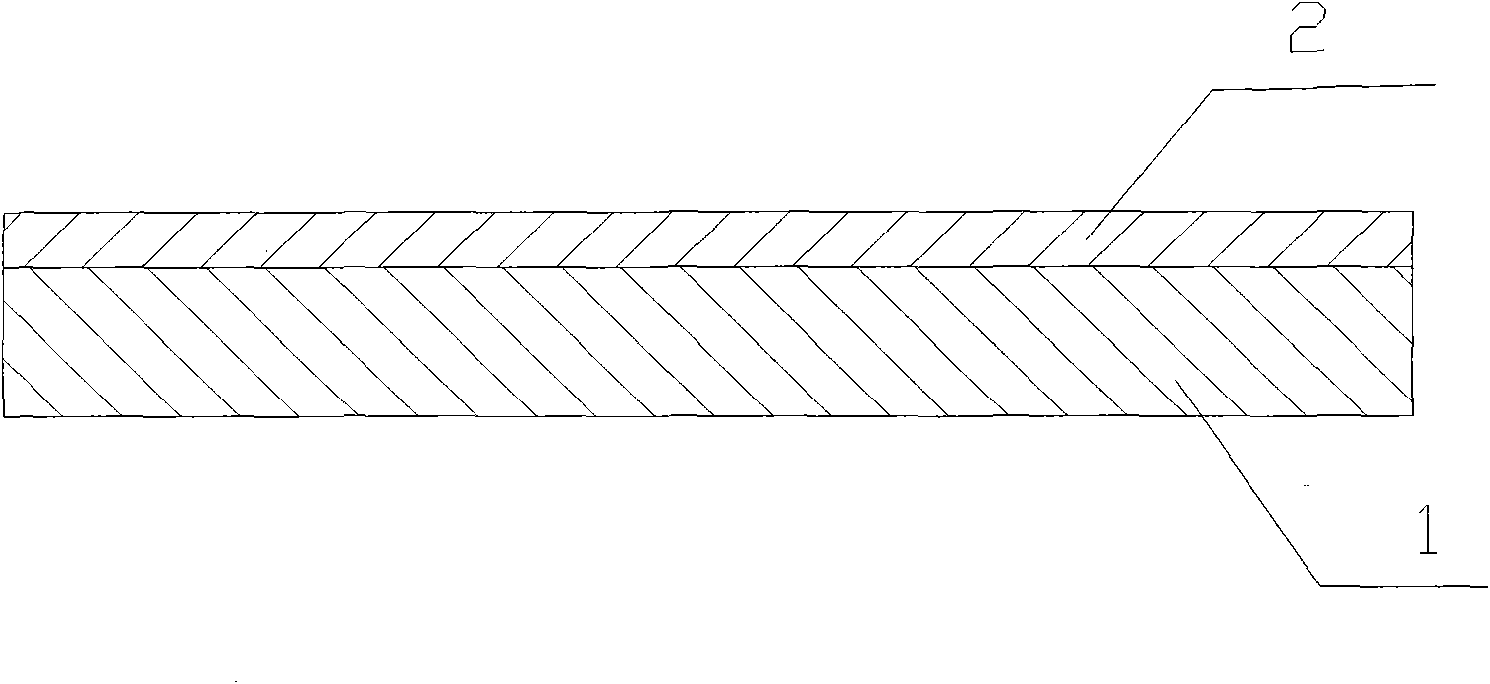

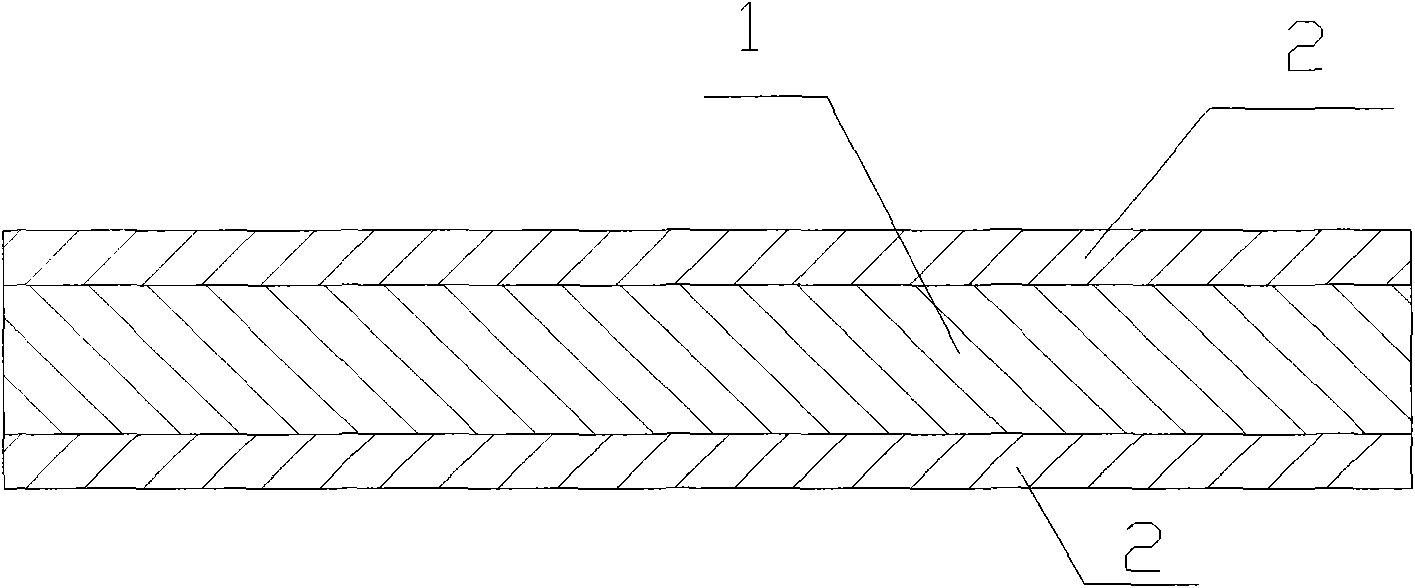

Semiconductor thermal expansion glass mat and production method thereof

ActiveCN101662178AHigh mechanical strengthLong aging lifeWindings insulation shape/form/constructionApplying solid insulationThermal expansionSemiconductor

The invention discloses a semiconductor thermal expansion glass mat and a production method thereof. The semiconductor thermal expansion glass mat is a multi-layer structure, which is characterized bycomprising a thermal expansion glass mat and semiconductor low resistance fabric; and at least one surface of the thermal expansion glass mat is compounded with the semiconductor low resistance fabric. The production method is characterized by comprising the procedures as follows: a. mixing glue; b. fully injecting glue liquid into a glue groove of a horizontal gluing machine; c. mounting the glass mat on the horizontal gluing machine and connecting the glass mat with guiding fabric; d. starting sizing; e. cutting; f. preheating an oil press for standby; g. tidily placing the glass mat according to required thickness to form a glass mat blank, and arranging interval spacers between each glass mat blank; h. pressing to obtain heat expansion glass mat; i. selecting proper semiconductor lowresistance fabric, and arranging the semiconductor low resistance fabric on the single surface or double surfaces of the thermal expansion glass mat; and j. thermally pressing the composite products of the thermal expansion glass mat and the semiconductor low resistance fabric to form the semiconductor thermal expansion glass mat. The semiconductor thermal expansion glass mat and the production method thereof can prolong the service life of a motor as well as save labor and time.

Owner:浙江博菲电气股份有限公司

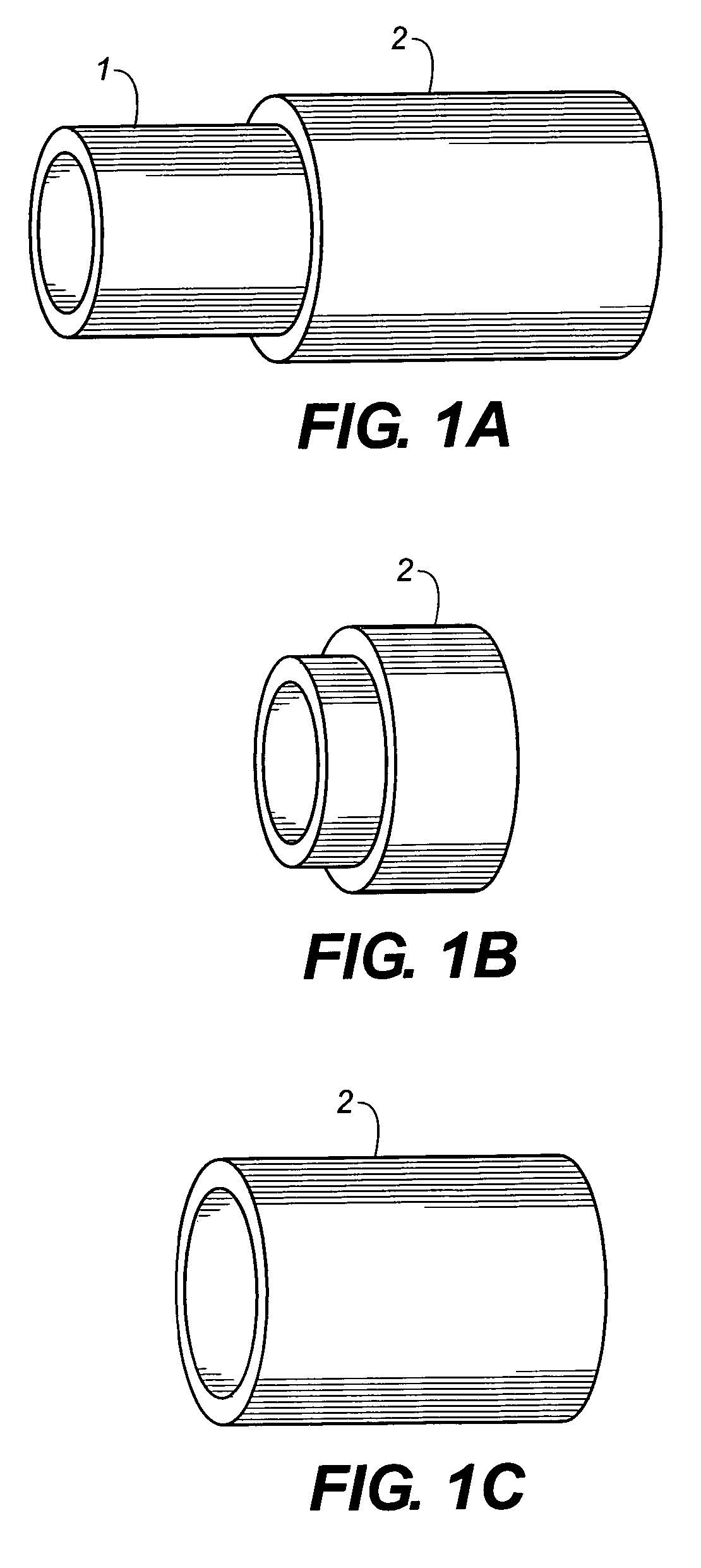

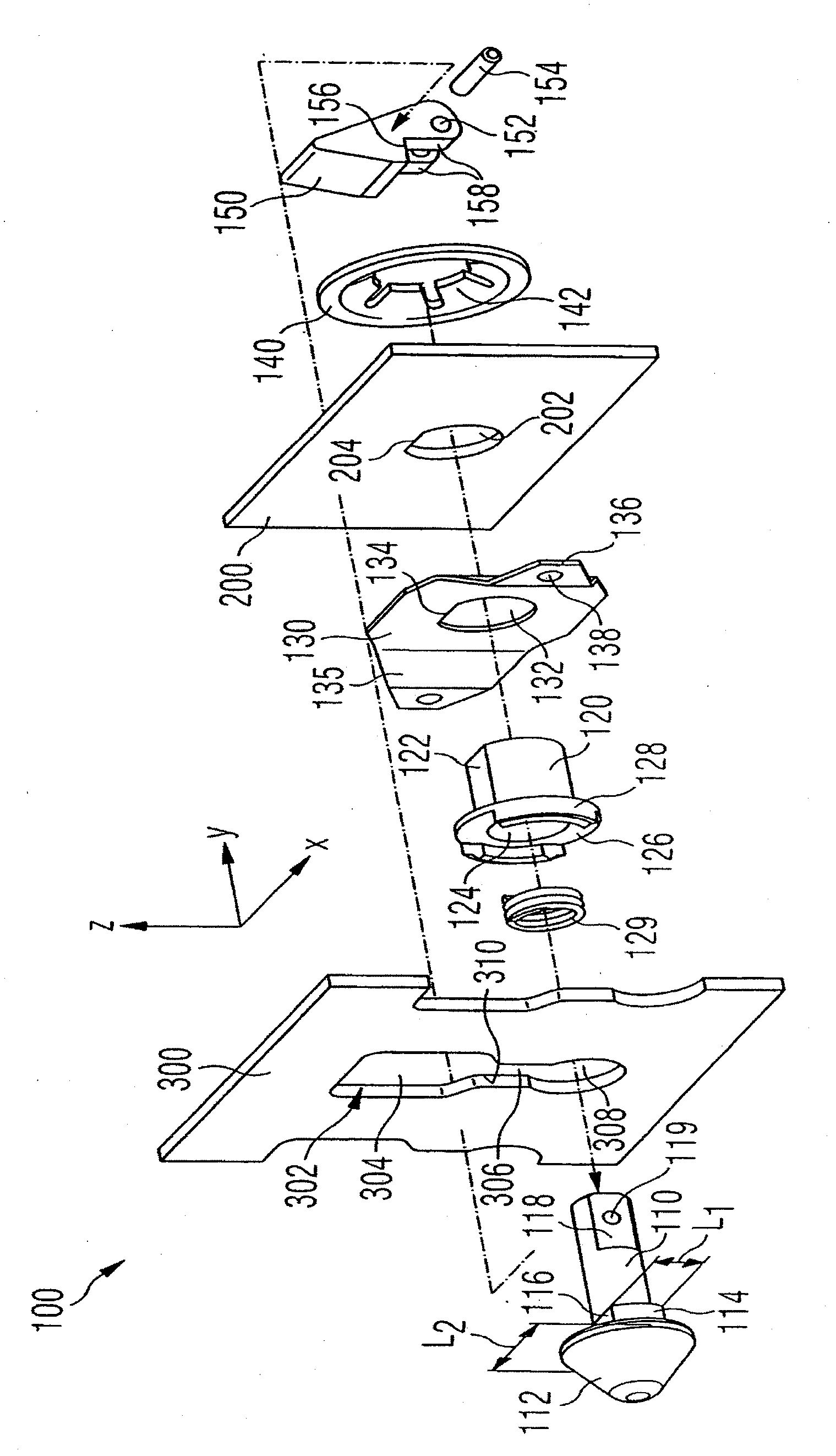

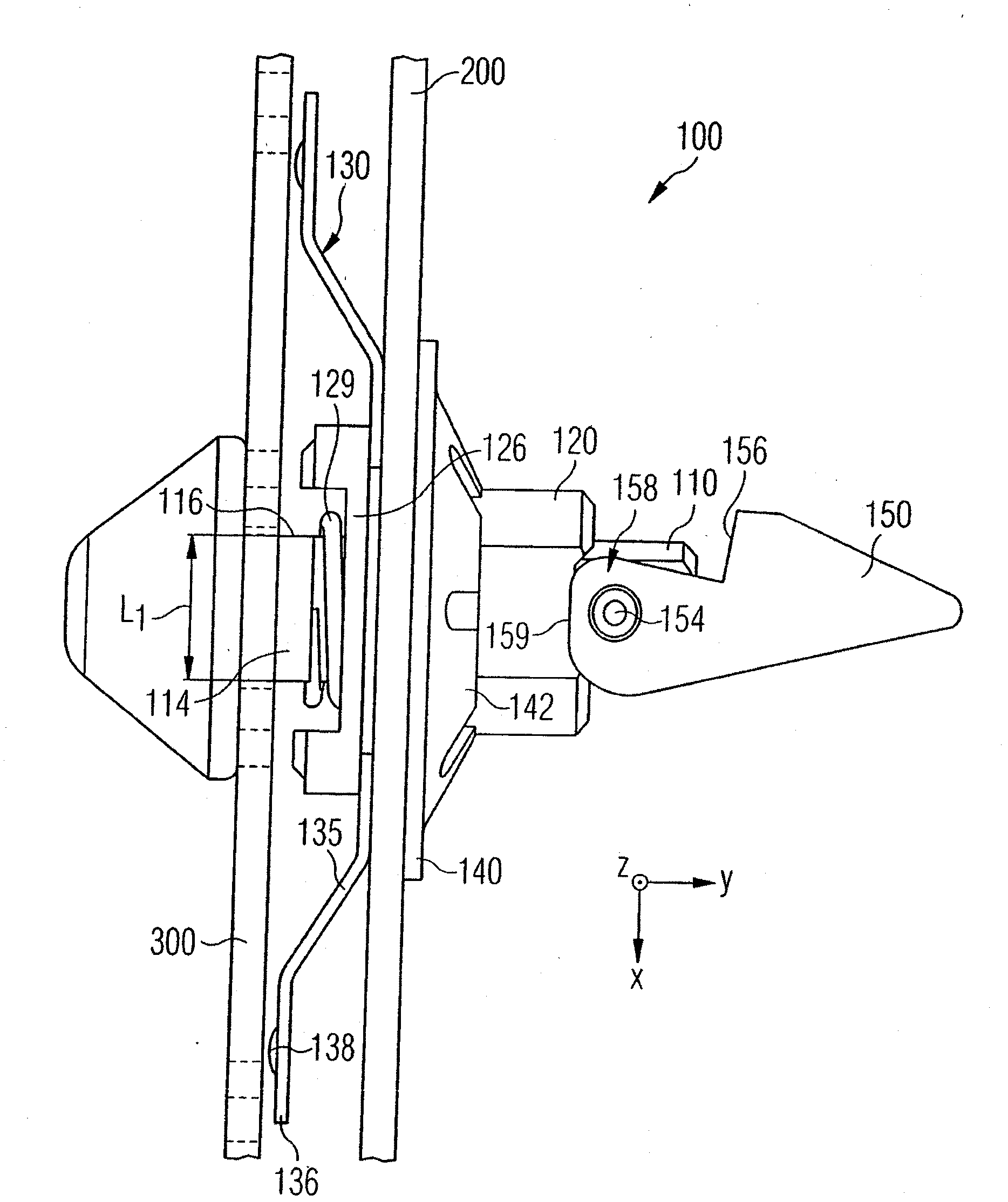

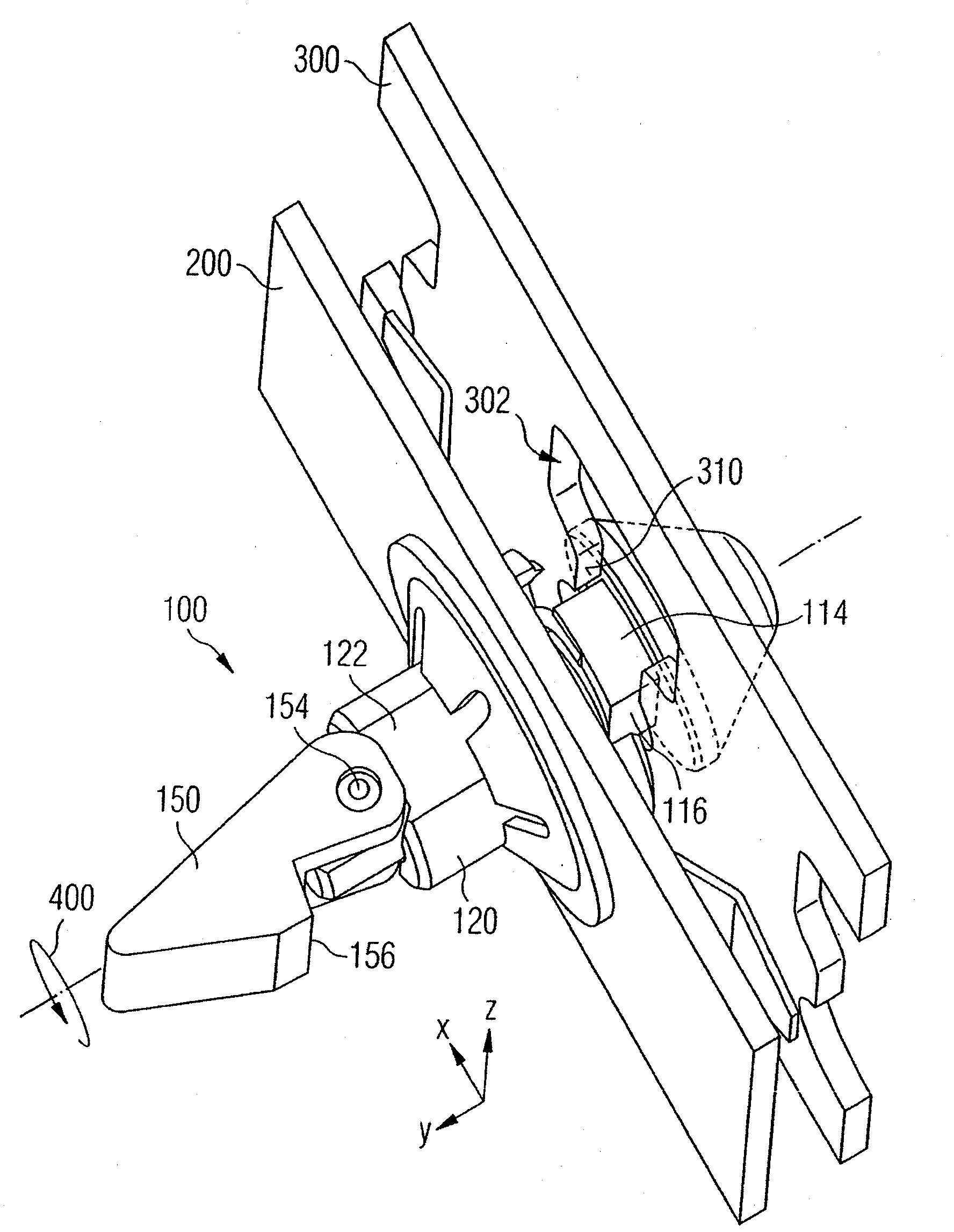

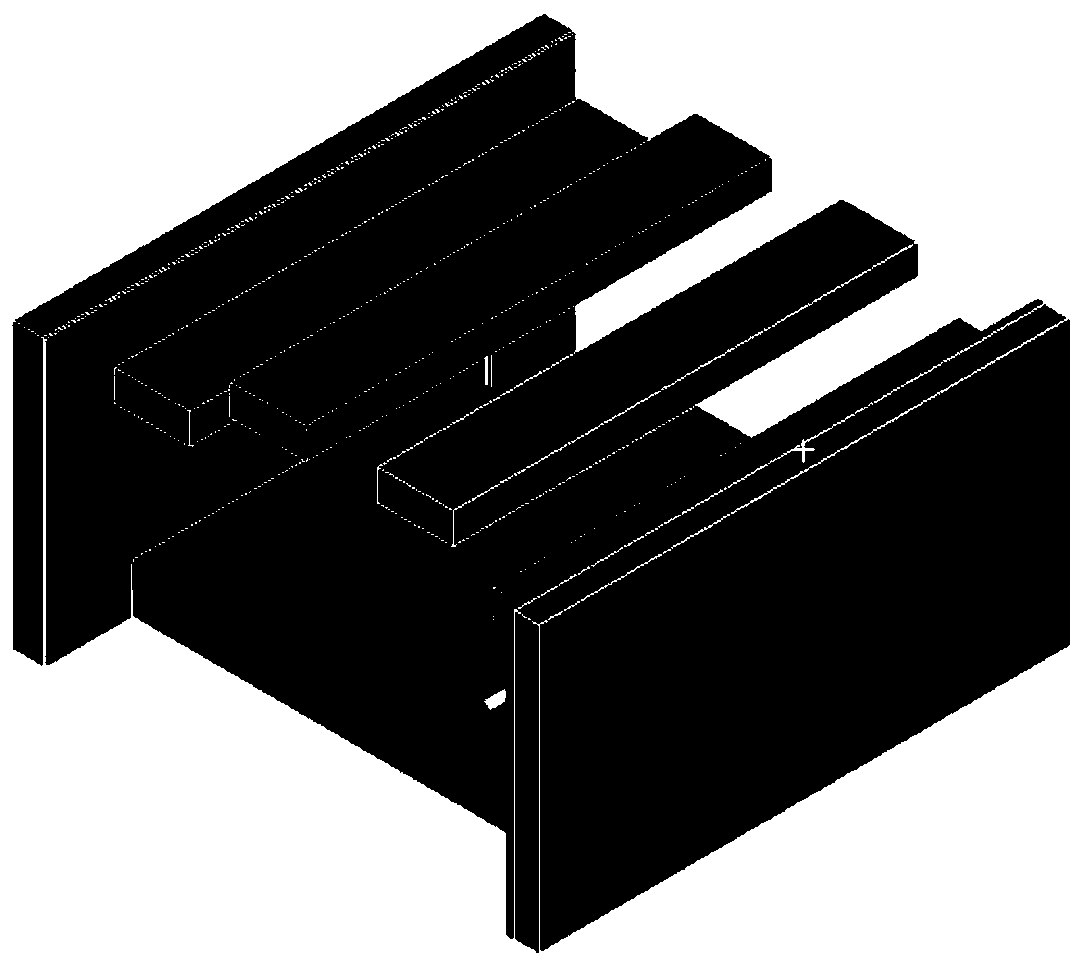

Fastening device for a module element in an airplane

InactiveCN102326004AManufacturingPrevent movementFriction grip releasable fasteningsConnectionsEngineeringAirplane

A fastening device (100) for attaching a module element to a support structure (300) in an airplane is provided. The fastening device (100) comprises a stud (110), having a broadened head (112) at a first end for engaging in a support recess (302) of the support structure (300) and a section (114) that connects to the head (112) and has a first lateral dimension (L1) and a second lateral dimension (L2), which is disposed at least substantially perpendicularly to the first lateral dimension (L1) and is larger than the first lateral dimension (L1). At an opposite second end, the stud (110) is provided with a lever (150), which is connected to the stud (110) for rotation and can be moved into an opening position and a closing position.; A bushing (120), which is provided on the stud (110) so as to be moved longitudinally, is designed to support an outer wall (200) of the module element and supports an electrically conductive leaf spring (130) for contacting the outside of the outer wall (200) on the one side and the support structure (300) on the other side. An eccentric (158), which can be actuated by the lever (150), moves the bushing (120) along the stud (110) toward the head (112) during a movement of the lever (150) into the closing position thereof.

Owner:AIRBUS OPERATIONS GMBH

Circuit module

ActiveUS8809694B2Low resistivityUniform potentialMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

A circuit module includes a substrate that has a substantially rectangular parallelepiped shape and includes a plurality of inner conductive layers, an electronic component disposed on a first main surface of the substrate, an insulating layer disposed on the first main surface of the substrate so as to cover the electronic component, a shielding layer disposed on a surface of the insulating layer, and a ground electrode connected to the plurality of inner conductive layers. At least two of the inner conductive layers are directly connected to the shielding layer.

Owner:MURATA MFG CO LTD

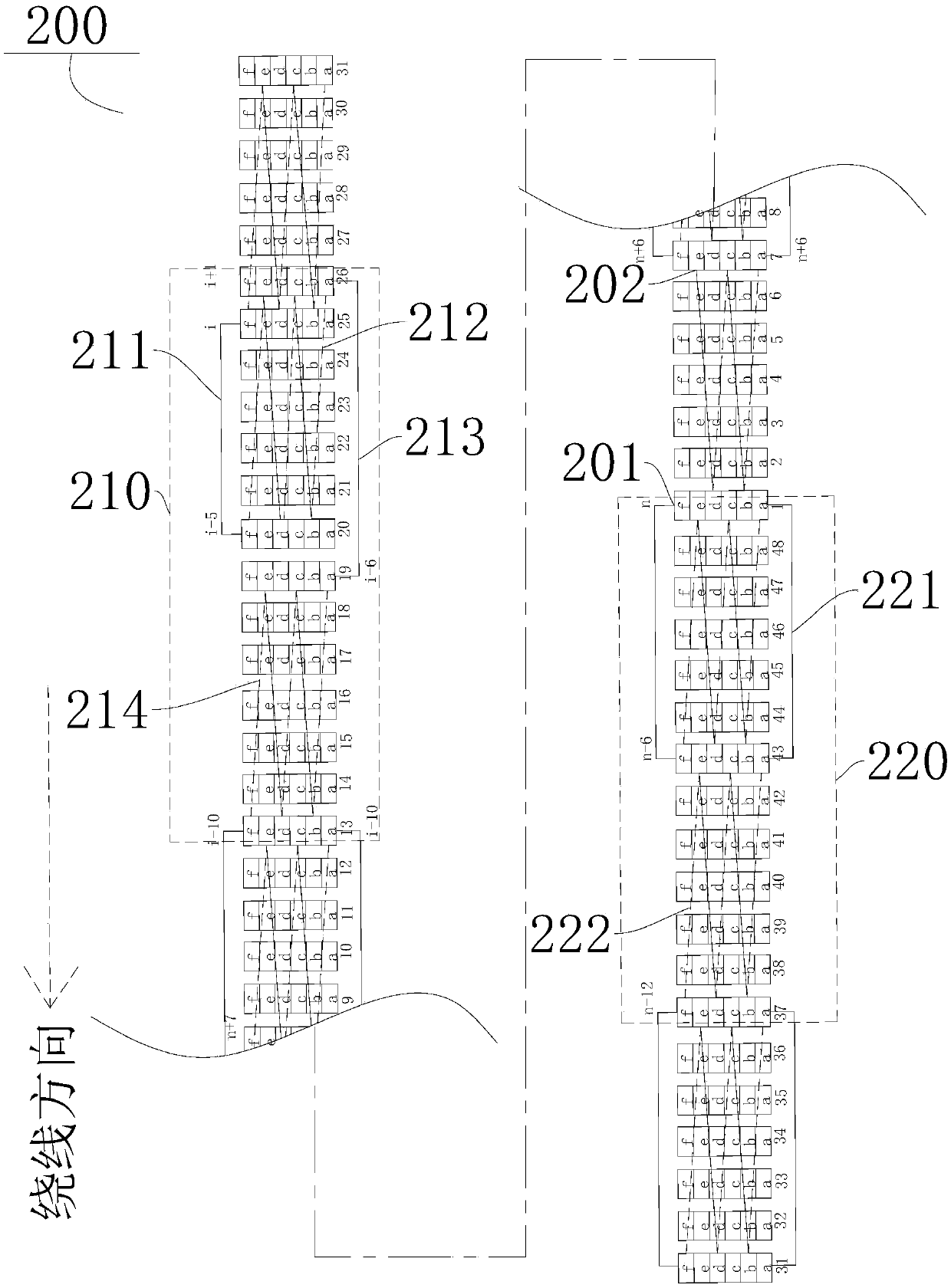

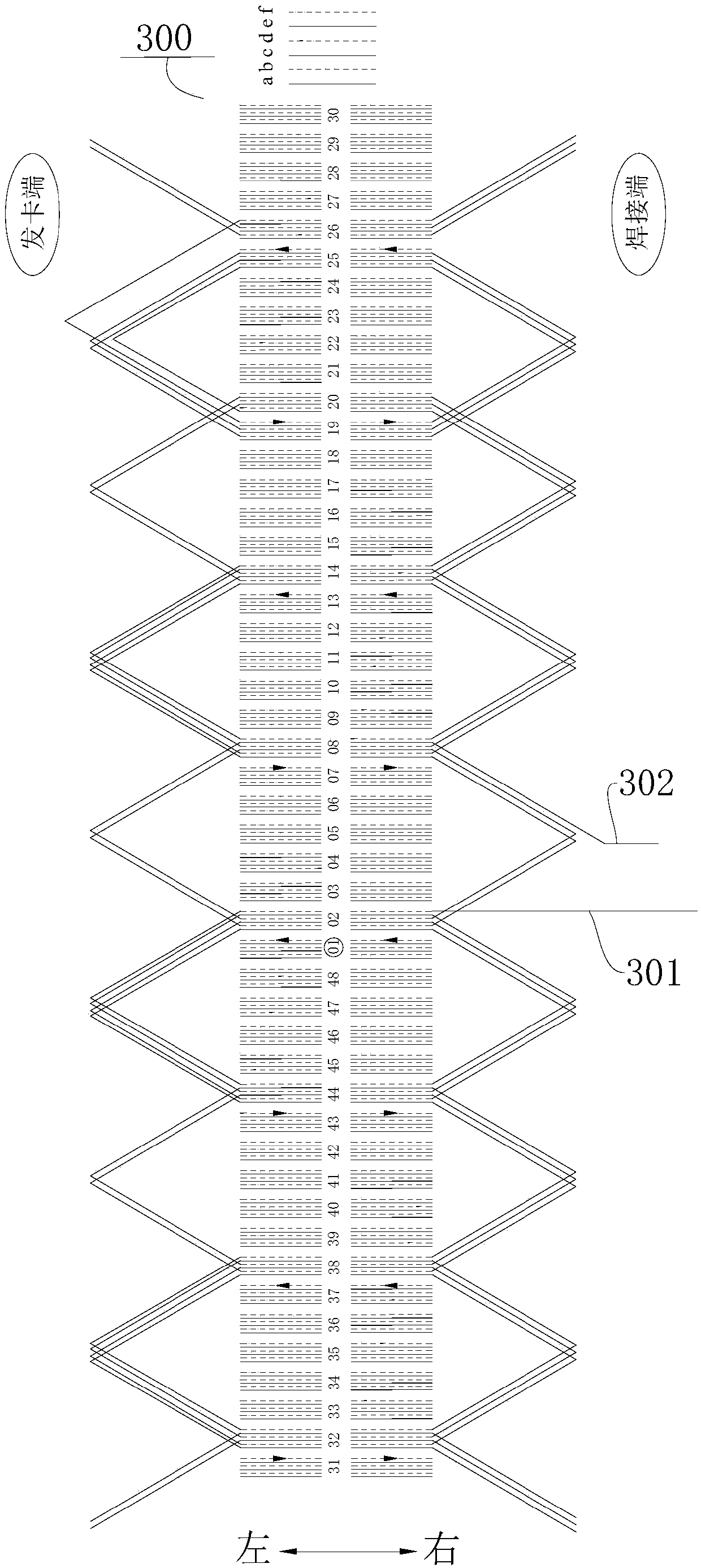

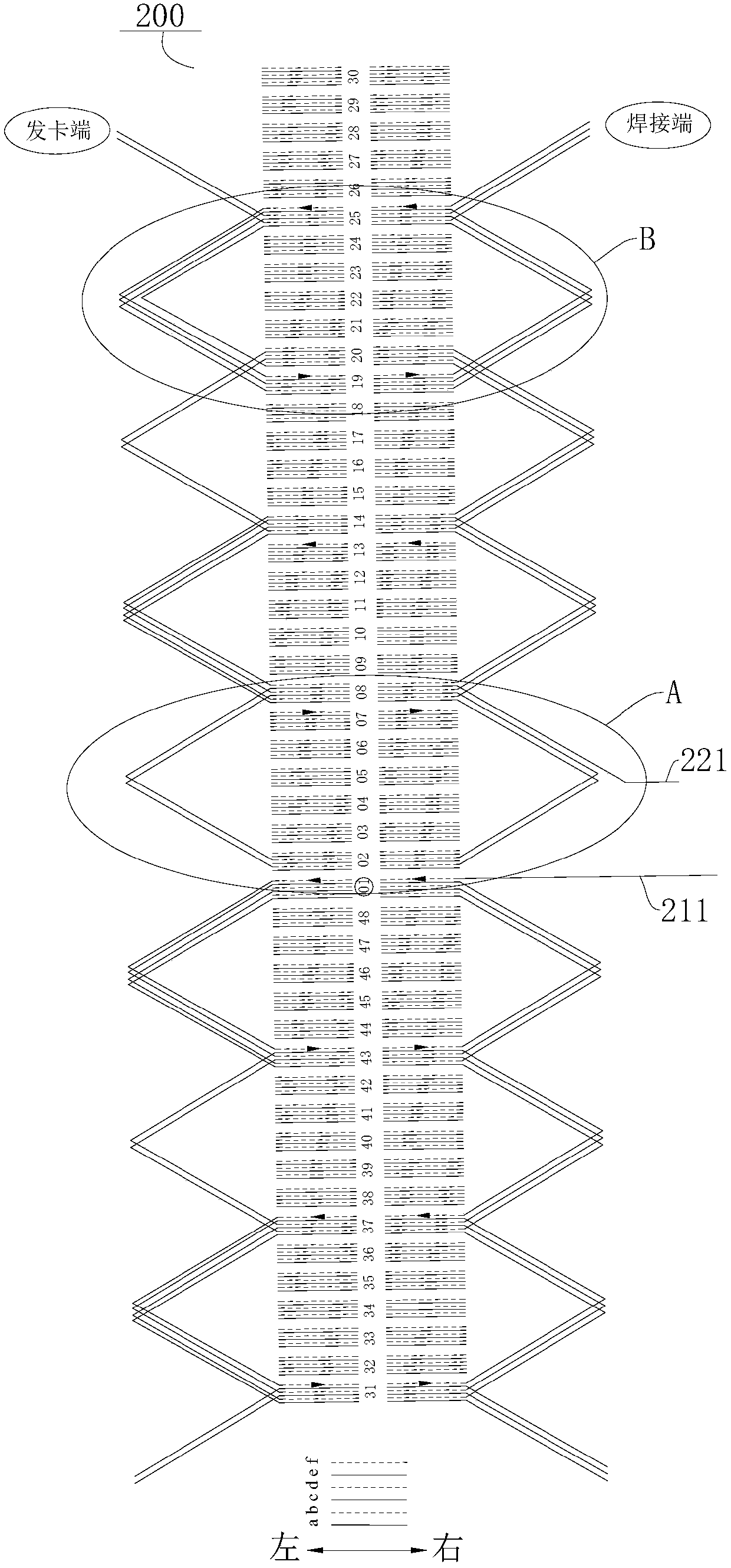

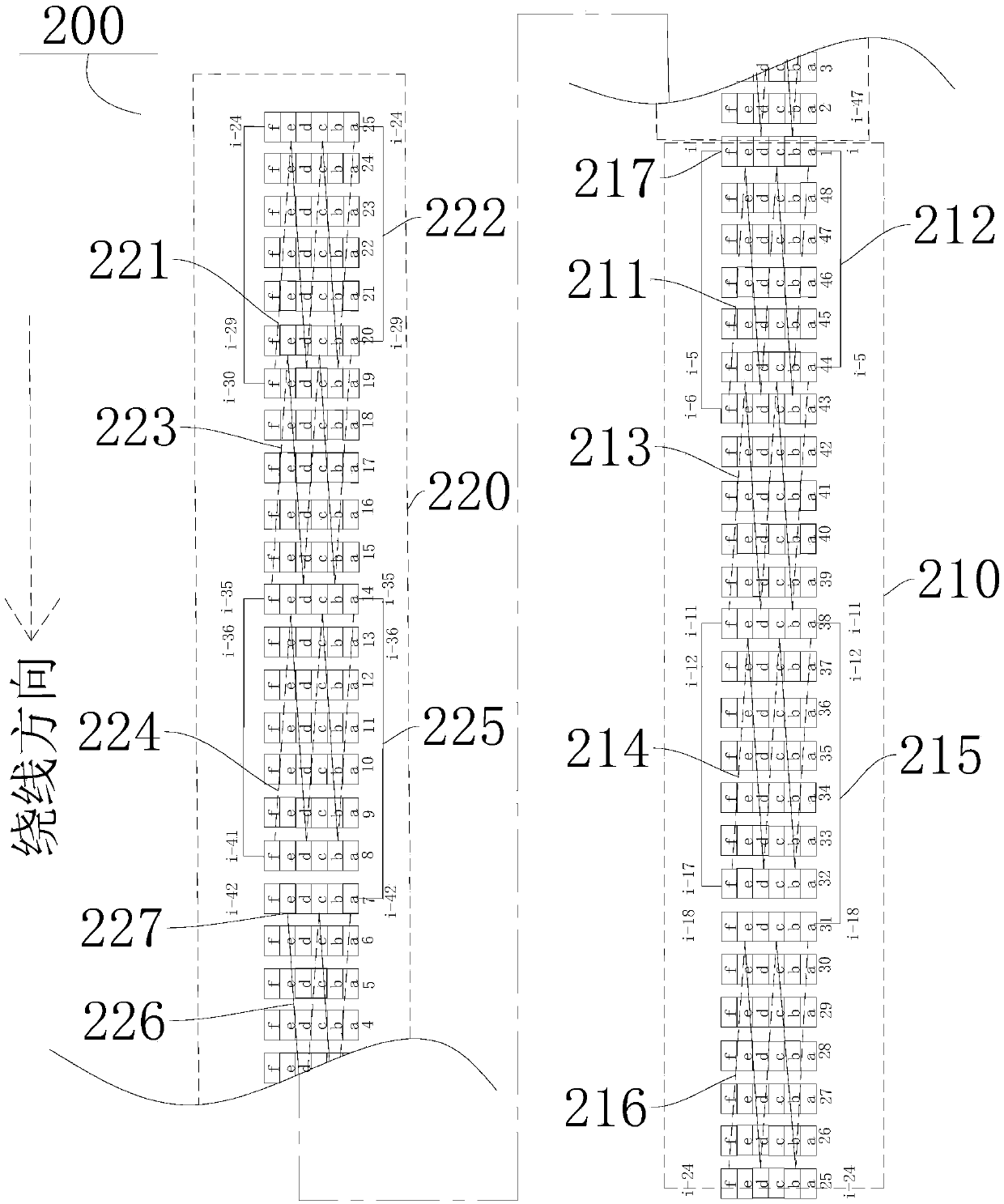

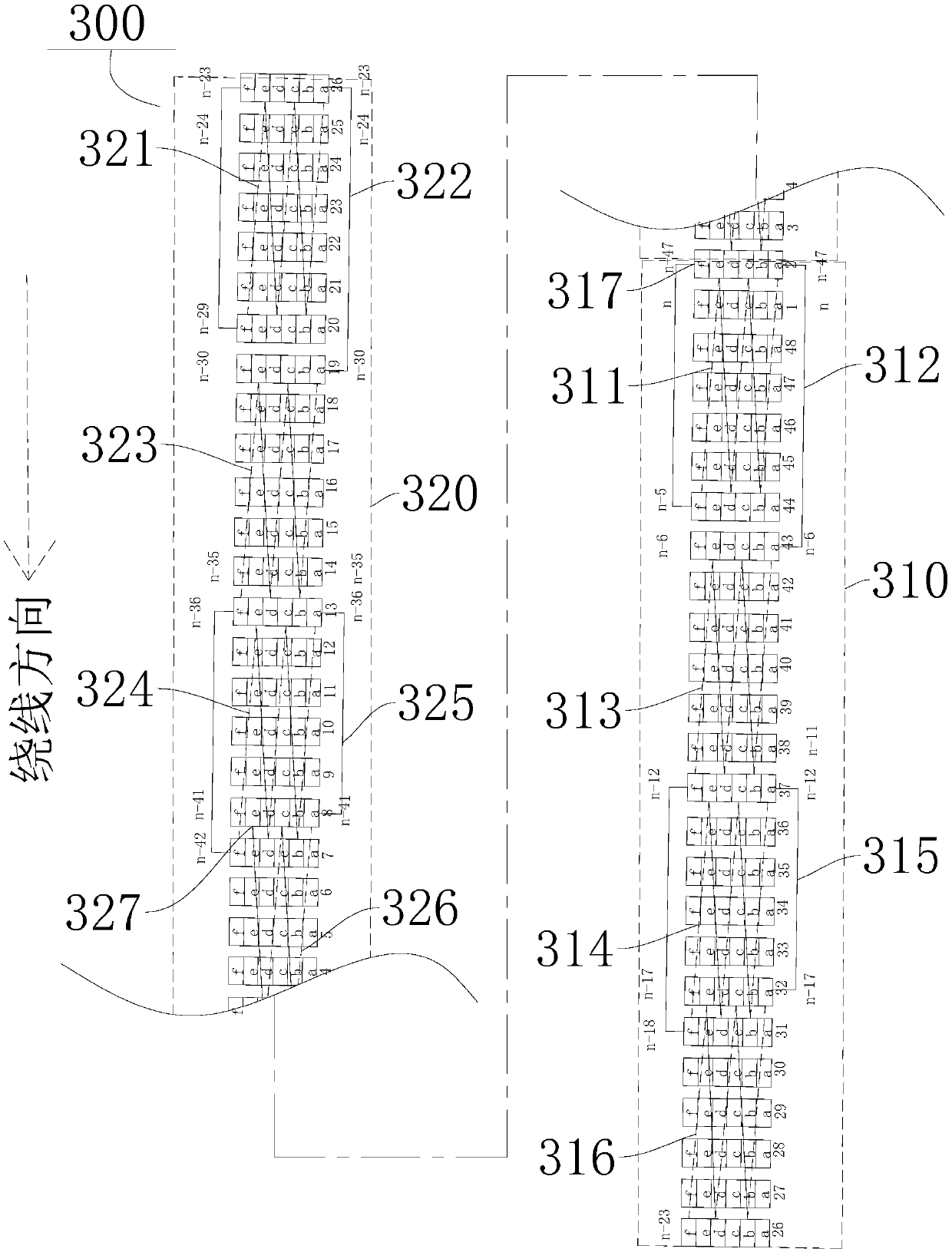

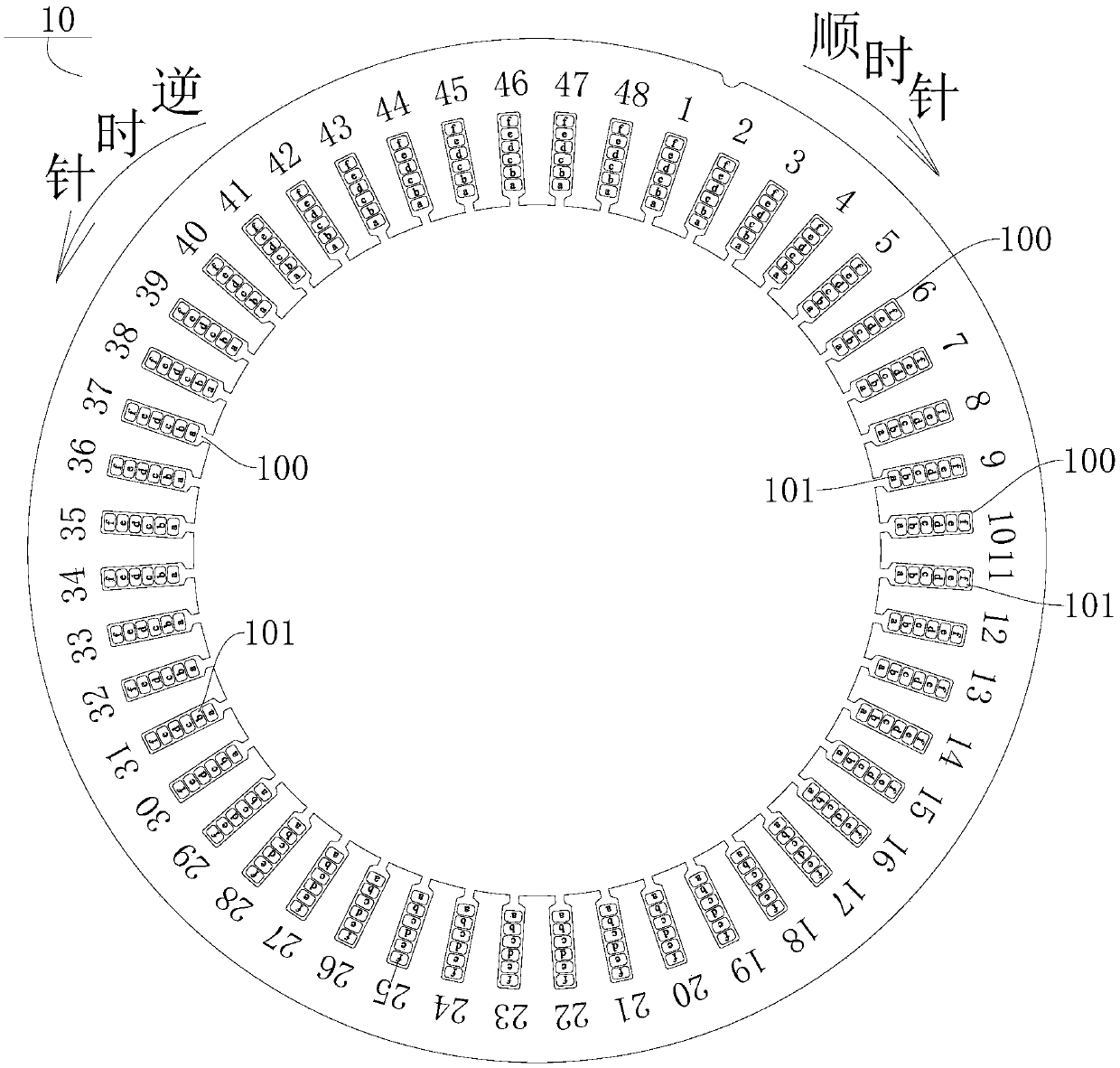

Stator assembly and motor

ActiveCN110556932ASuppress internal circulationSuppression of harmonic electromagnetic excitationMagnetic circuit stationary partsWindings conductor shape/form/constructionPhysicsPhase angle difference

The invention discloses a stator assembly and a motor. The stator assembly comprises a stator core and a stator winding. Each phase of first winding of the stator winding comprises a first winding part and a plurality of second winding parts. The first winding part comprises first to fourth spans. Each second winding part comprises fifth and sixth spans. Each phase of second winding of the statorwinding comprises a third winding part and a plurality of fourth winding parts. The third winding part comprises seventh to tenth spans. The fourth winding part comprises eleventh and twelfth spans. According to the stator assembly, the pitch of a plurality of spans is arranged to be different from that of other spans during the winding process, the potential vector of the stator slots can be balanced, the potential phase angle difference of the slot moment angle can be suppressed, the potential balance between the circuit windings can be realized, the internal circulation of the stator winding can be suppressed, the harmonic electromagnetic excitation generated by the circulation can also be suppressed and the vibration of the motor can be reduced.

Owner:BYD CO LTD

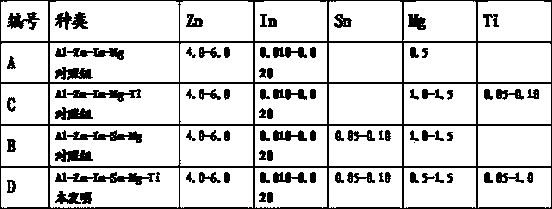

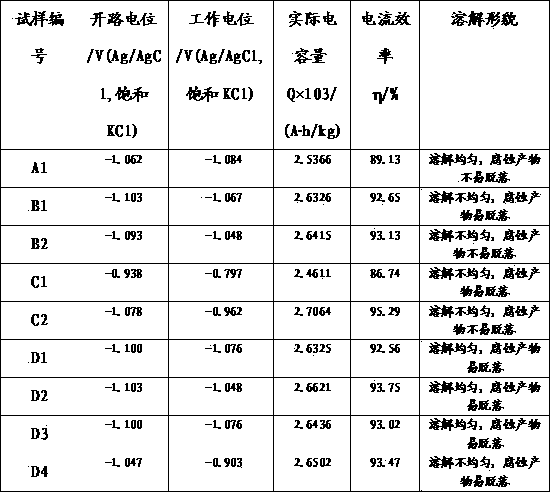

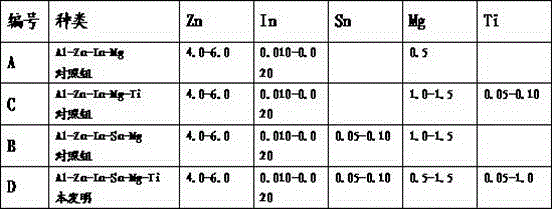

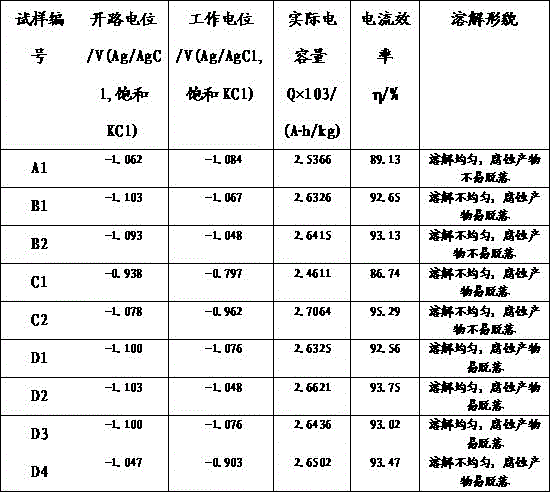

Aluminum alloy sacrificial anode suitable for deep sea environment and high in current efficiency

The invention belongs to the technical field of corrosion prevention, and particularly relates to an aluminum alloy sacrificial anode suitable for the deep sea environment and high in current efficiency. According to the sacrificial anode, with aluminum as the matrix, 4.0-6.0wt% of zinc, 0.020-0.030wt% of indium, 0.05-0.10wt% of tin, 0.5-1.0wt% of magnesium and 0.05-1.0wt% of titanium are added, wherein the weight percentage of iron impurities is smaller than 0.050wt%, the weight percentage of copper is smaller than 0.010wt%, and the balance is the aluminum. The sacrificial anode is manufactured in a vacuum melting mode. As is shown in tests carried out in a simulated deep sea environment, the current efficiency of the sacrificial anode is larger than 92%, the open circuit potential of the sacrificial anode ranges from -1.05 to -1.20, the activation performance is good, dissolution is uniform, and corrosion products can fall off easily. The sacrificial anode can be applied to cathode protection for metal components used in the deep sea environment.

Owner:UNIV OF SCI & TECH BEIJING

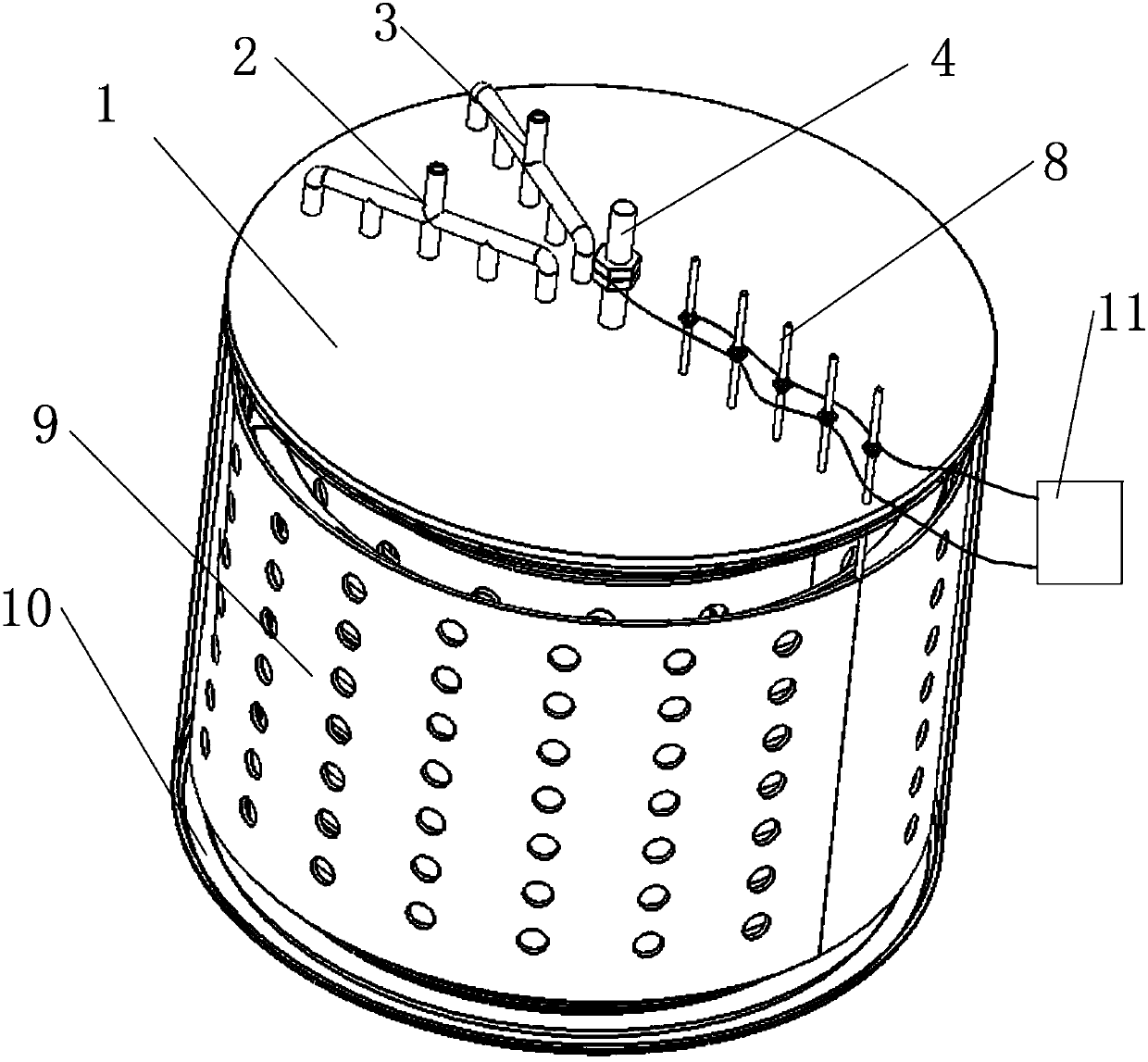

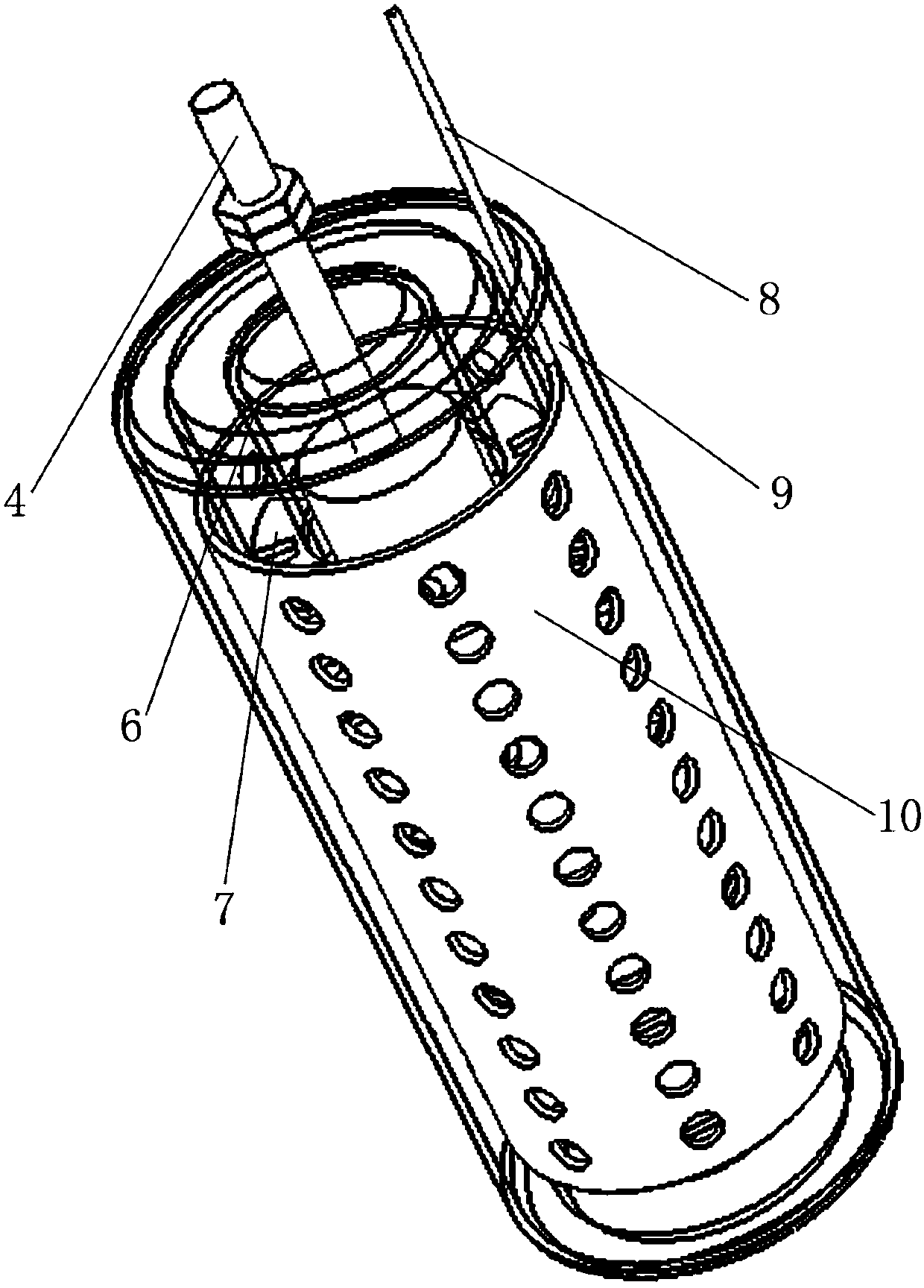

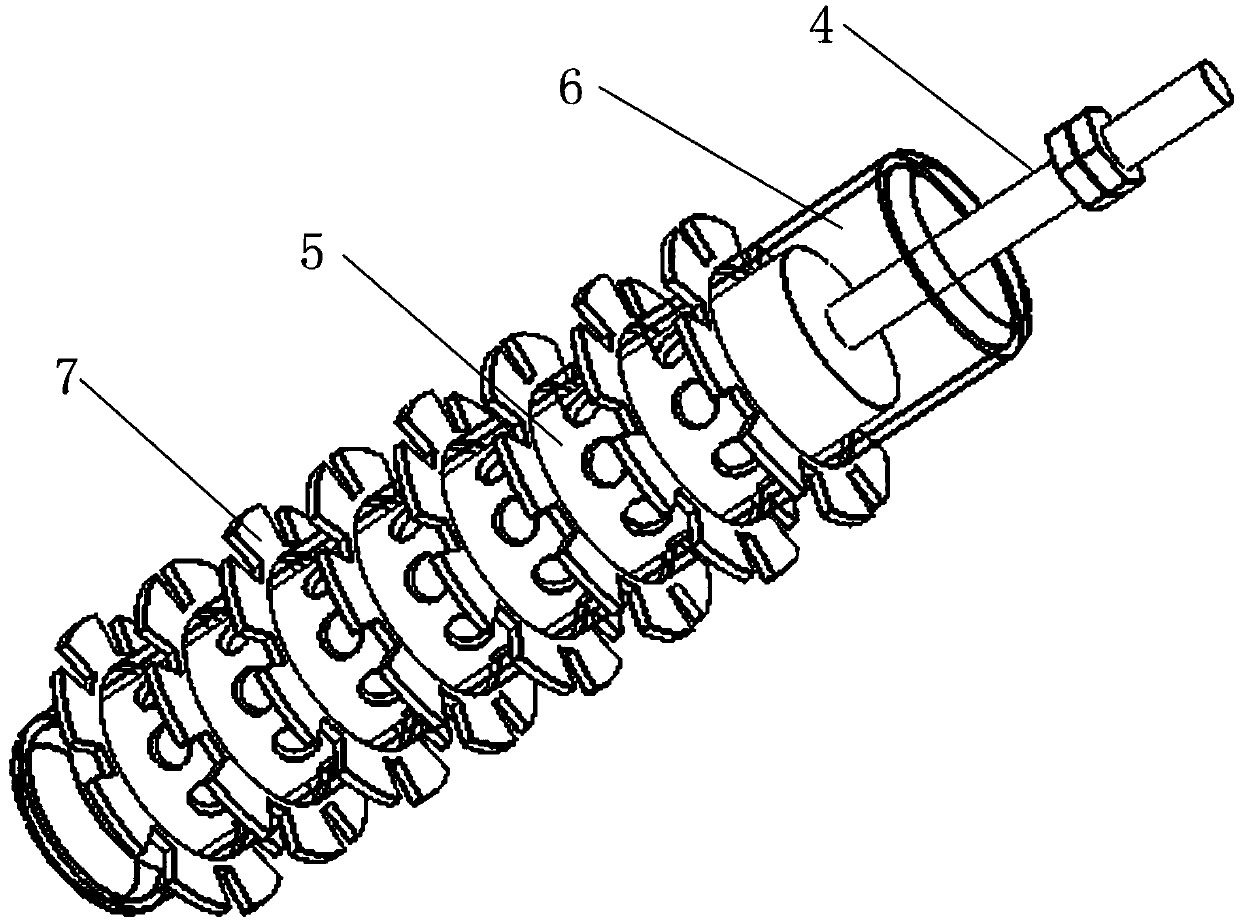

Sterilizing and pesticide-residue-reducing low-temperature plasma generator

ActiveCN107801287AReduce pesticide residuesLarge discharge areaPlasma techniqueElectricityPesticide residue

The invention relates to a sterilizing and pesticide-residue-reducing low-temperature plasma generator, which comprises four parts, namely, an inner tube electrode, a concentric outer tube electrode,a discharge cavity processing device and a high-voltage power supply. The inner tube electrode is composed of an inner electrode lead 4, an inner electrode cylinder 5 and an inner electrode glass tube6. The concentric outer tube electrode is composed of 2-10 layers of concentric glass tubes with electrodes therein. The first layer of outer tube electrode is composed of an outer electrode lead 8,an outer electrode cylinder 9 and an outer electrode glass tube 10, and the other layers are the same. The discharge cavity processing device is composed of an upper cover plate 1, a liquid inlet 2, an air inlet 3 and a liquid separation ring 7. By the invention, liquid to be treated are sterilized and pesticide residues are reduced directly by a low-temperature plasma discharge device. The sterilizing and pesticide-residue-reducing low-temperature plasma generator of the invention has the advantages of large discharge area, stable operation, high efficiency, long service life and the like.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Stator assembly and motor

ActiveCN110556952AAvoid failureInhibition potential phase angle differenceMagnetic circuit stationary partsWindings conductor shape/form/constructionPhysicsStator

The invention discloses a stator assembly and a motor. The stator assembly is provided with a plurality of stator slots. The first span is from the rth layer of the ith slot to the ath layer of the ith slot, the second span is from the ath layer of the ith slot to the ath layer of the (i-5)th slot, the third span is from the ath layer of the (i-5)th slot to the rth layer of the (i-11)th slot, thefourth span is from the rth layer of the nth slot to the ath layer of the (n-6)th slot, the fifth span is from the ath layer of the (n-6)th slot to the rth layer of the (n-12)th slot, the sixth span is from the rth layer of the i'th slot to the ath layer of the i'th slot, the seventh span is from the ath layer of the i'th slot to the ath layer of the (i'-7)th slot, the eighth span is from the athlayer of the (i'-7)th slot to the rth layer of the (i'-13)th slot, the ninth span is from the rth layer of the n'th slot to the ath layer of the (n'-6)th slot and the tenth span is from the ath layerof the (n'-6)th slot to the rth layer of the (n'-12)th slot. According to the stator assembly, the stator winding uses the mode of laminating wiring and the arrangement is simple.

Owner:BYD CO LTD

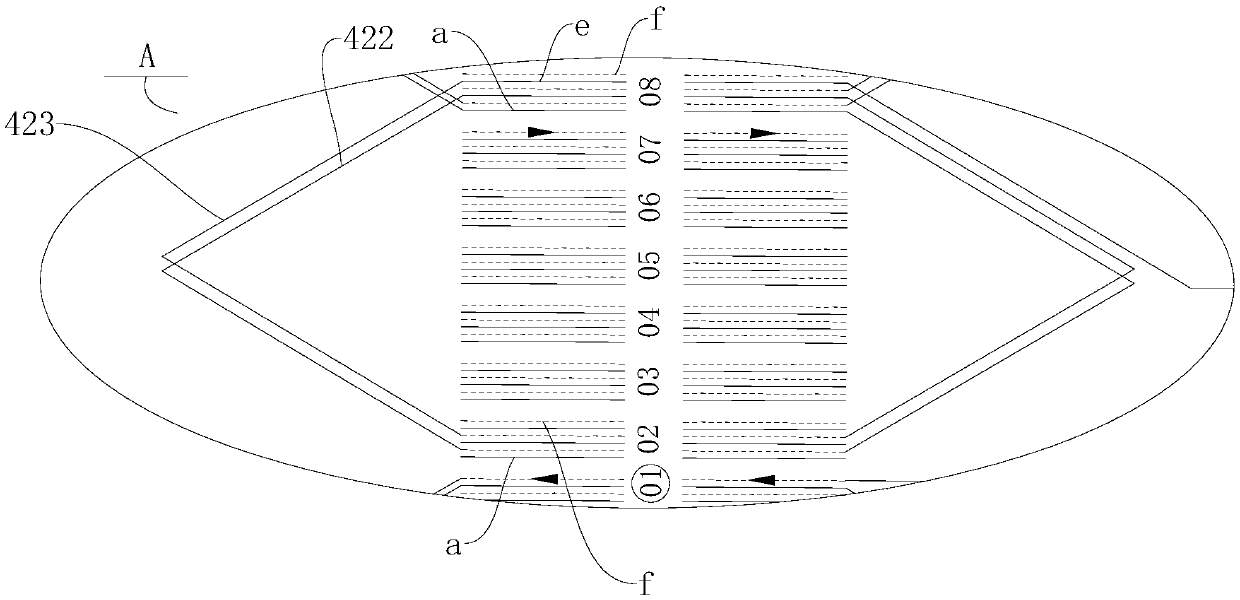

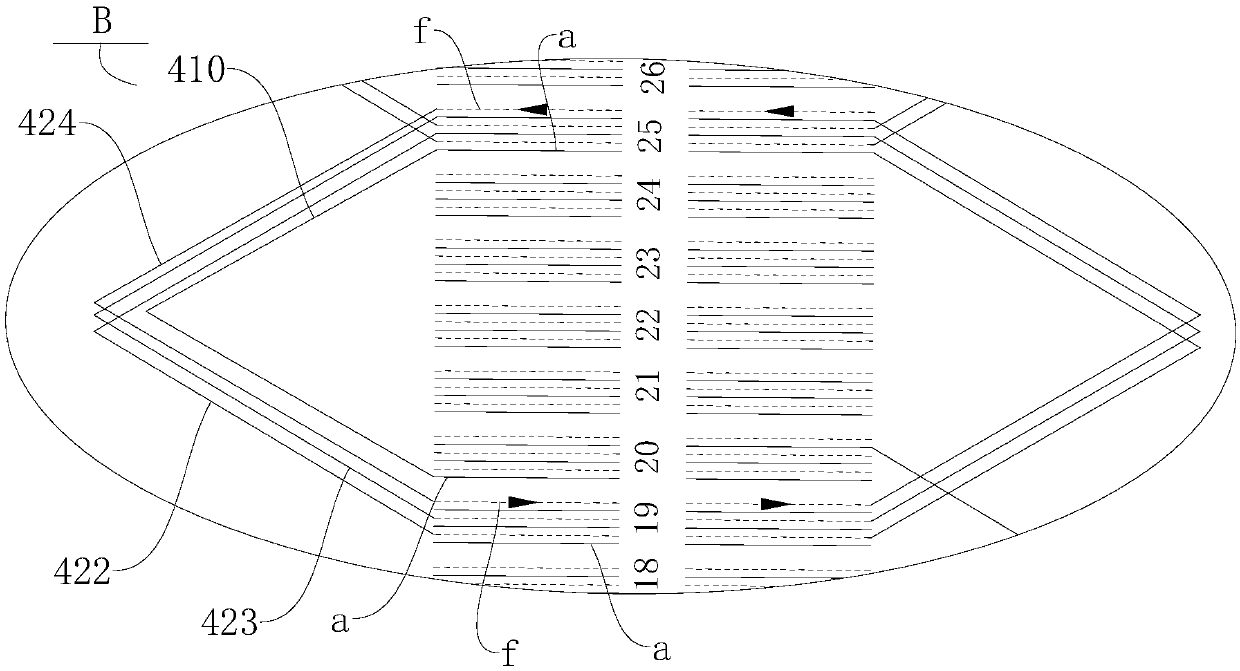

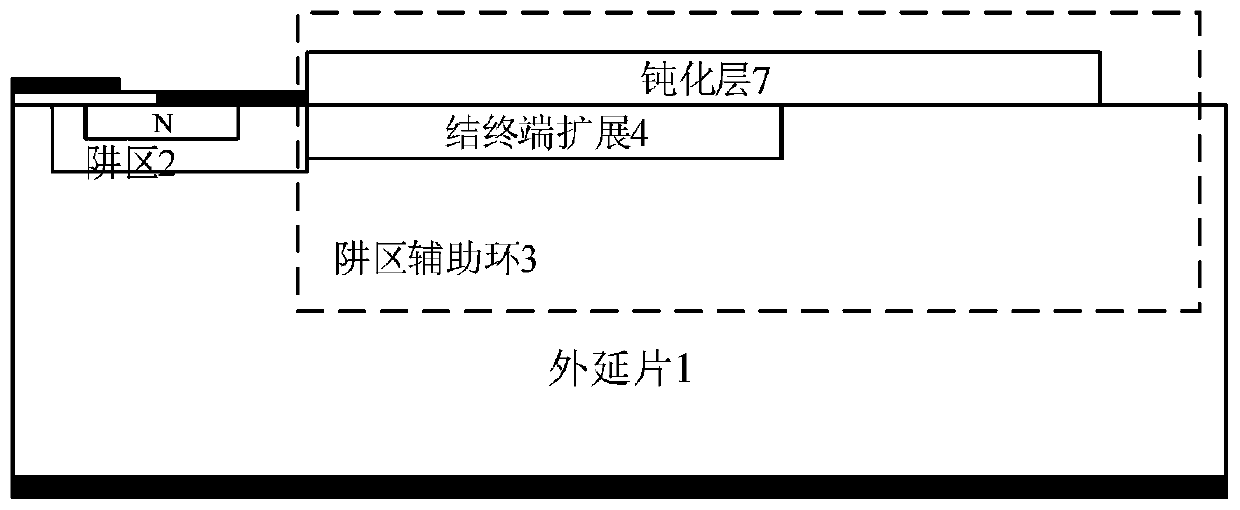

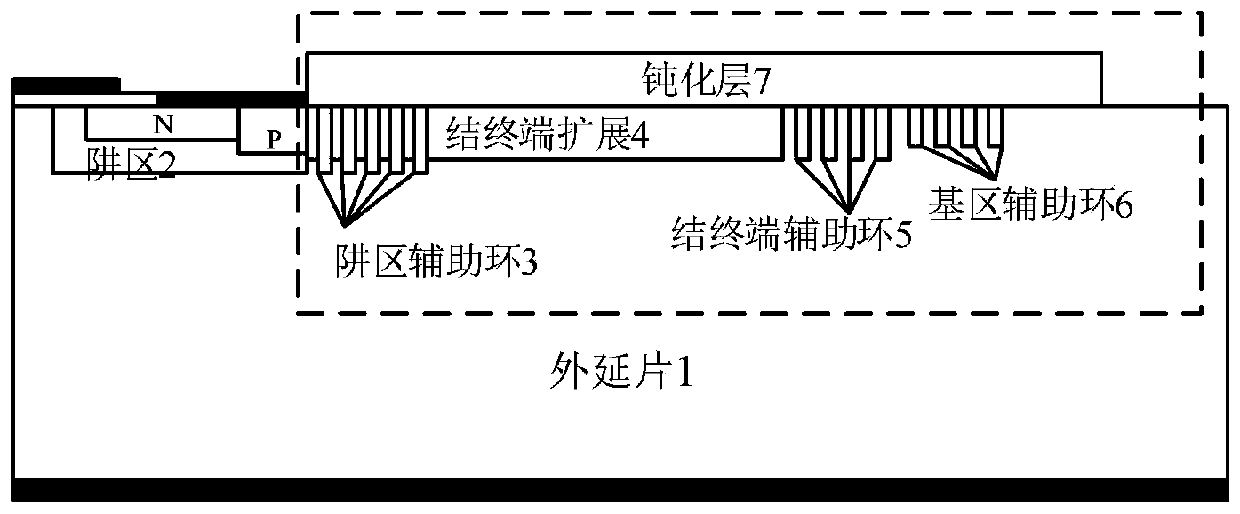

Silicon carbide semiconductor device terminal and manufacturing method thereof

ActiveCN110534559ASmall terminal areaImprove toleranceSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETEngineering

The invention relates to the power semiconductor technology field and discloses a silicon carbide semiconductor device terminal and a manufacturing method thereof. A terminal structure comprises a plurality of well region auxiliary rings, a junction terminal extension, a plurality of junction terminal auxiliary rings, a plurality of base region auxiliary rings and a passivation layer. The well region auxiliary rings are located outside a well region, the junction terminal extension is close to the well region, and a depth is smaller than that of the well region. The junction terminal auxiliaryrings are located on an outer side of the junction terminal extension, and the base region auxiliary rings are located on an outer side of the junction terminal auxiliary rings. By using less photoetching times and ion implantation times and through introducing the well region auxiliary rings, the junction terminal auxiliary rings and the base region auxiliary rings, electric field distribution of a high field region is optimized so that a blocking characteristic of the device is improved, and tolerance of a blocking voltage of the device to a terminal doping concentration is improved. The invention also provides a process method of using the terminal structure in a silicon carbide MOSFET device.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

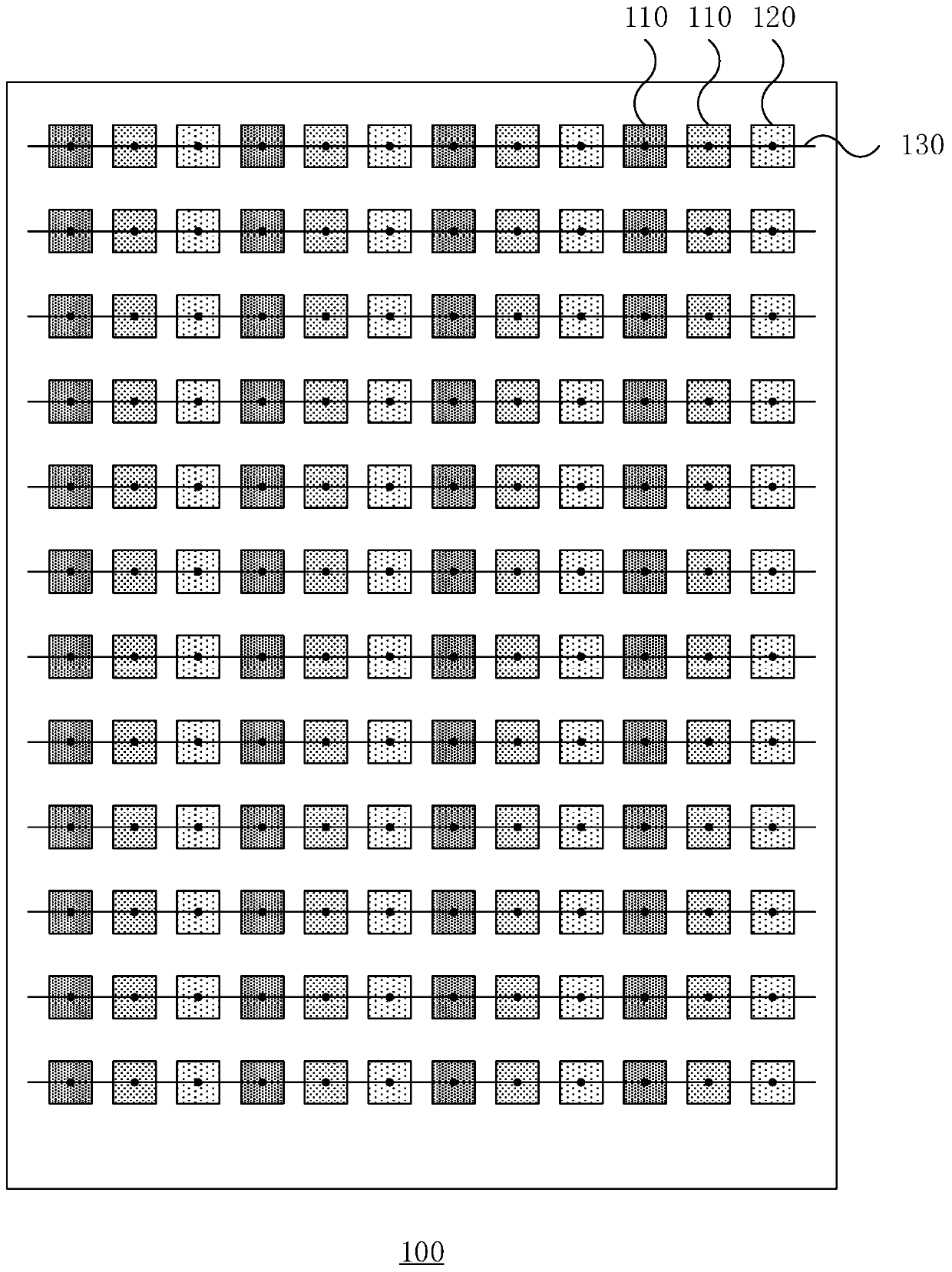

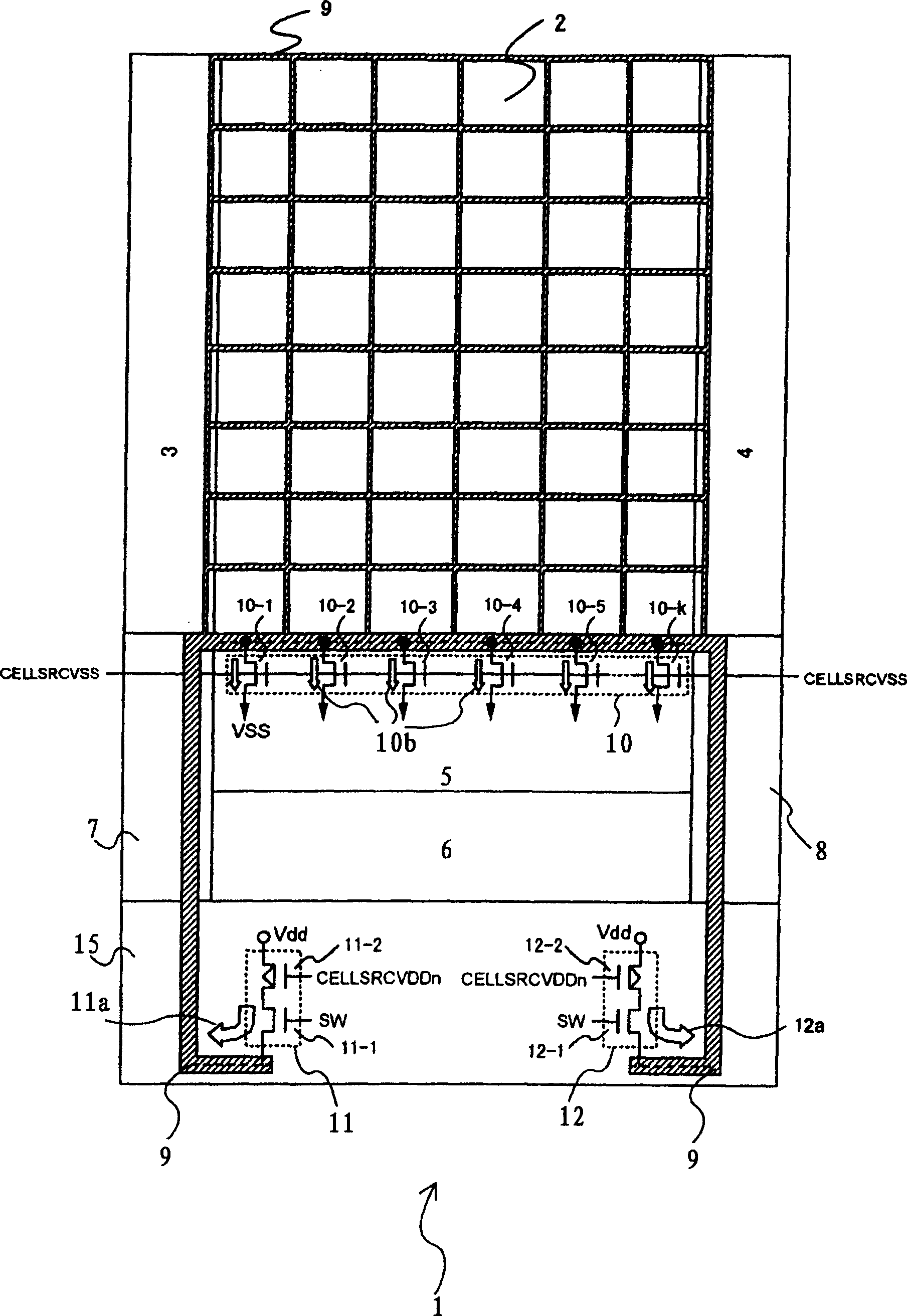

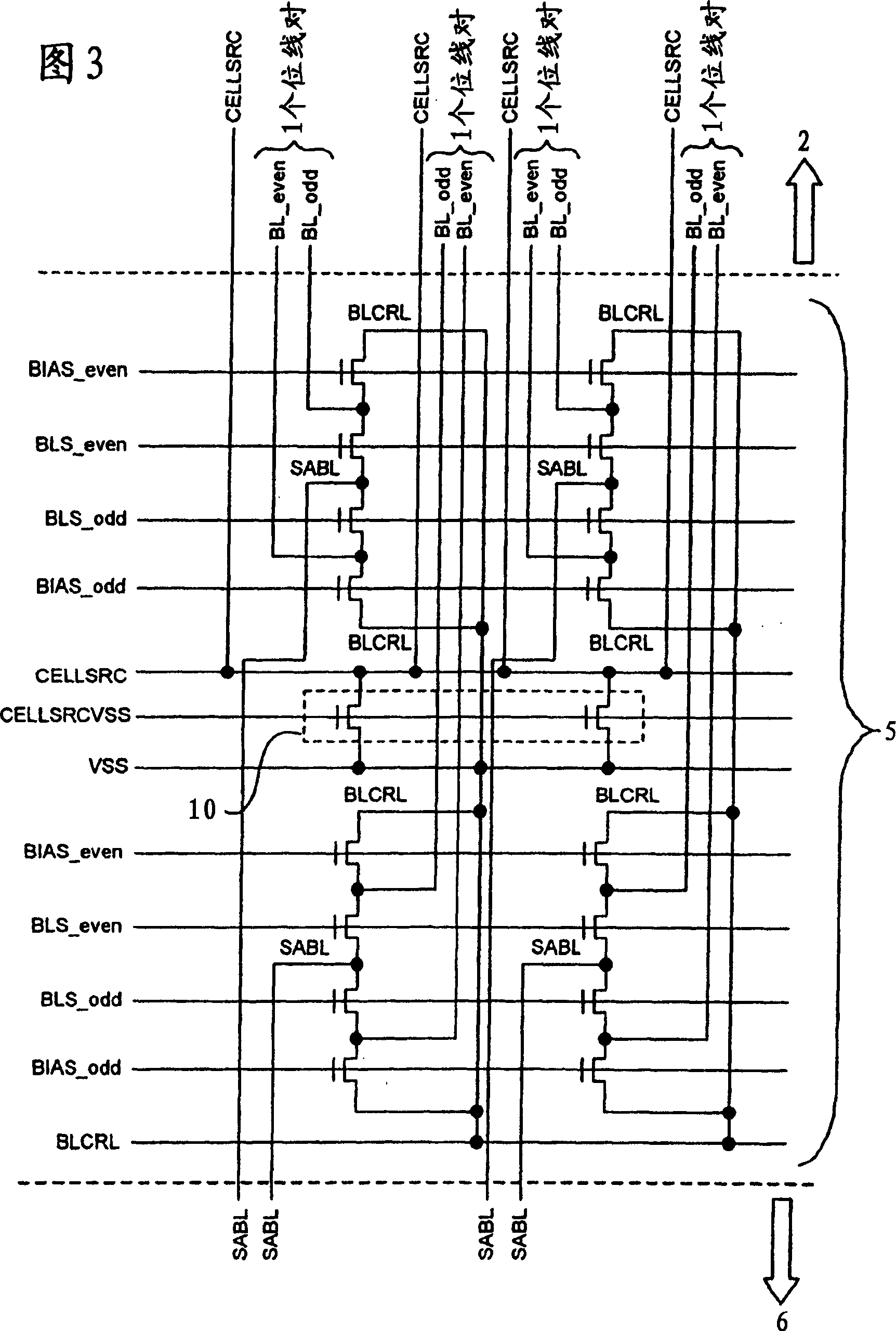

Non-volatile semiconductor memory device

ActiveCN1870274AReduce wire resistanceInhibition decreasedSolid-state devicesRead-only memoriesAudio power amplifierHigh voltage transistors

According to one embodiment of this invention, a non-volatile semiconductor memory device of high speed program operation is realized. It provides a non-volatile semiconductor memory device comprising a cell array in which NAND strings having electrically re-programmable memory cells are connected in series are disposed in a matrix form; sense amplifiers for sensing threshold voltages of said memory cells by sensing potentials of bitlines connected to said memory cells and for having a first region having high voltage transistors and a second region having low voltage transistors; cell source lines connected to an end of said NAND strings; and a first cell source line driver being connected to said cell source lines and having a first transistor for supplying a grounding potential or a low potential to said cell source line, said first transistor of said cell source line driver being disposed in said first region of said sense amplifiers.

Owner:KIOXIA CORP +1

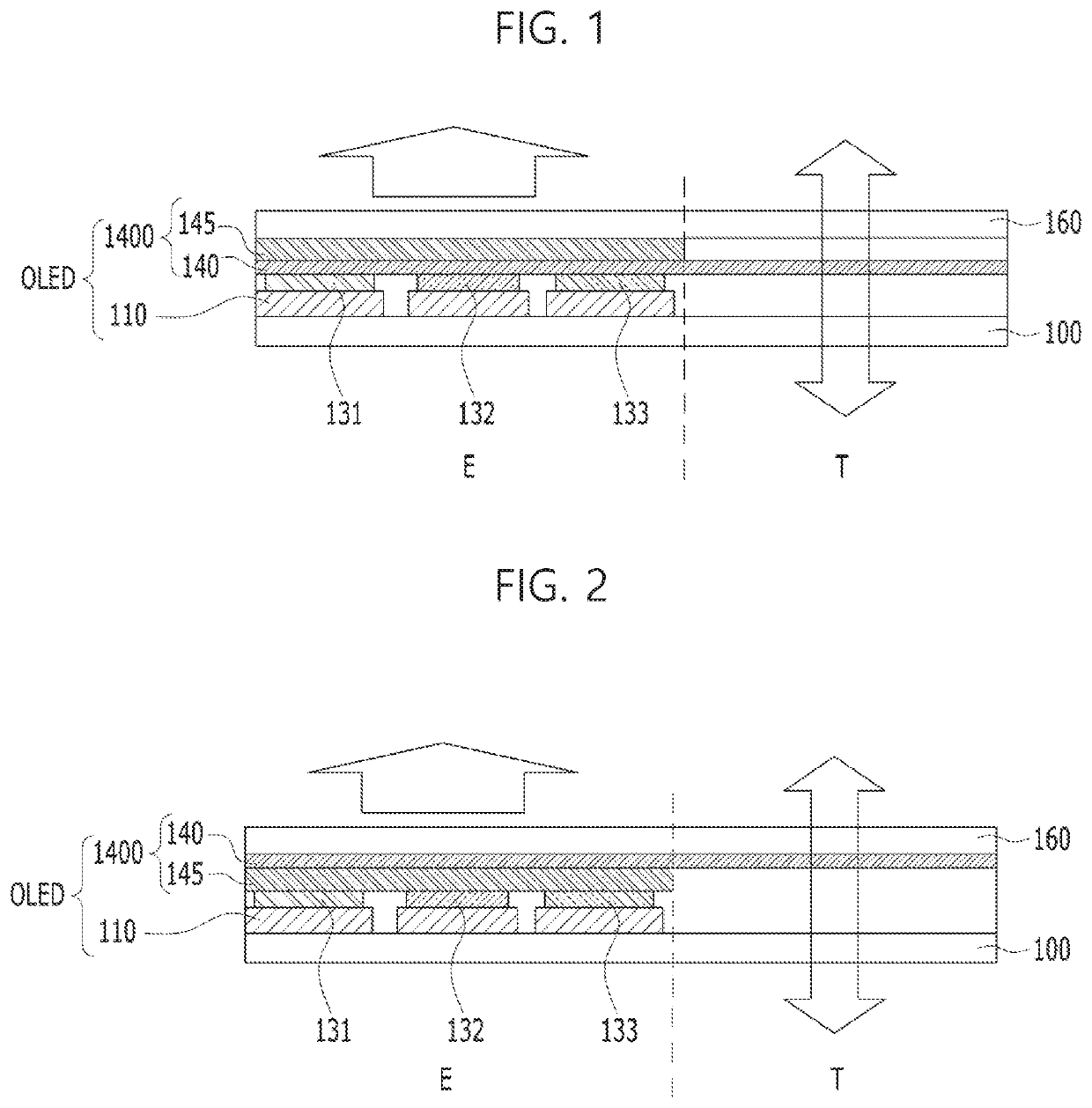

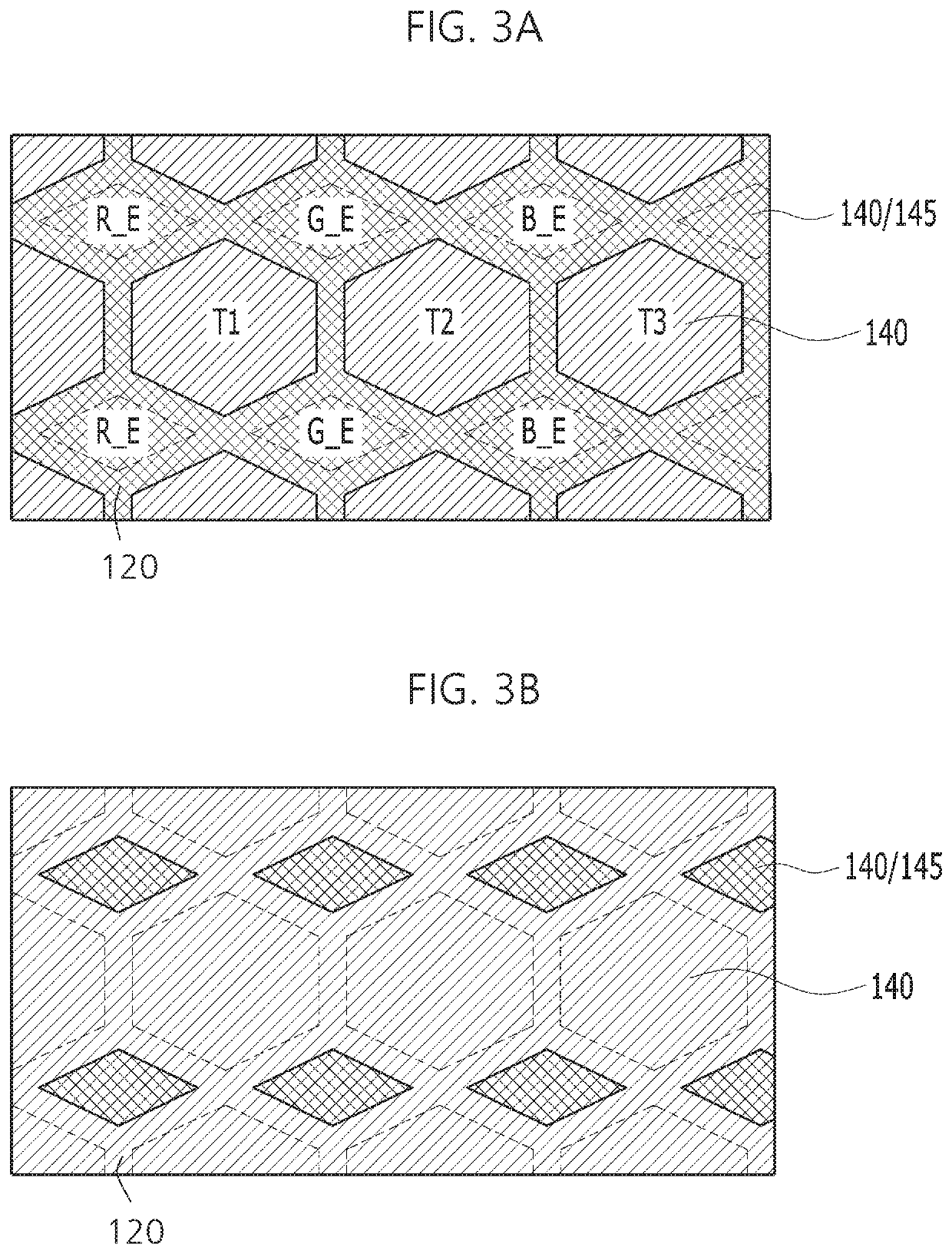

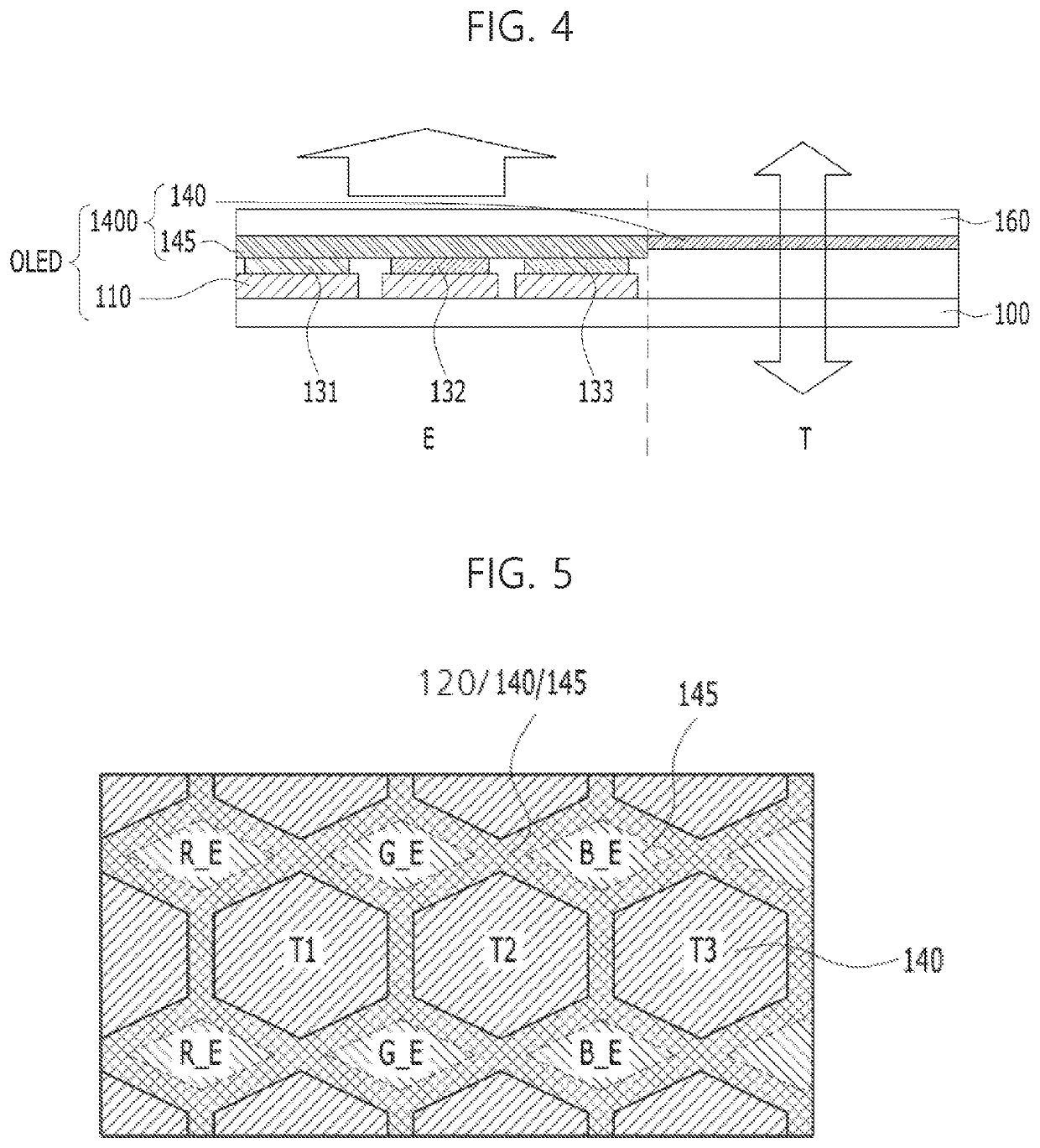

Display device and method for manufacturing the same

ActiveUS20190386242A1Eliminate the problemUniform potentialSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransmittance

Disclosed is a display device. In the disclosed display device, an emission-side electrode is constituted by a transmissive electrode structure having different configurations for an emission part and a transmission part such that a uniform potential is maintained at the entirety of the transmissive electrode structure, and the transmissive electrode structure enables the emission part to emit light at high brightness while enabling the transmission part to perform transparent display at high transmissivity.

Owner:LG DISPLAY CO LTD

An aluminum alloy sacrificial anode with high current efficiency for deep-sea environments

ActiveCN104060280BLong-term effective protectionStable Current EfficiencyIndiumBiological activation

Owner:UNIV OF SCI & TECH BEIJING

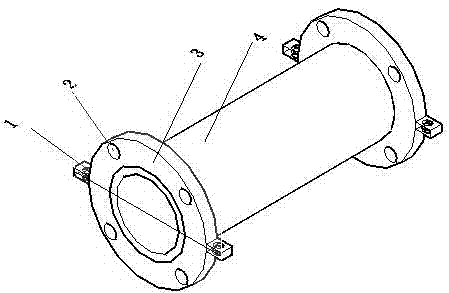

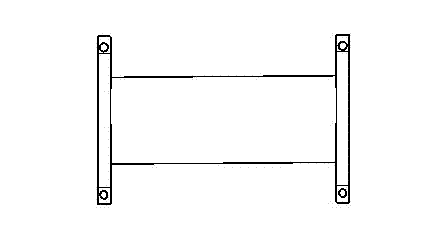

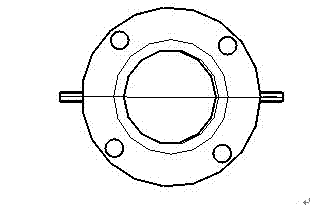

Multifunctional combined secondary cable lightening protection and equipotential protection method and device

ActiveCN103050957AEasy to expandEasy maintenanceEmergency protective arrangements for limiting excess voltage/currentOvervoltageBlocking layer

The invention discloses a multifunctional combined secondary cable lightening protection and equipotential protection method and a multifunctional combined secondary cable lightening protection and equipotential protection device. The device consists of an enclosed pipeline consisting of an upper metal shielding material and a lower metal shielding material, flanges, horizontal connecting bolts and nuts, vertical connecting bolts and nuts, equipotential connection grounding and a ratproof fireproof blocking layer, and has functions of preventing lightning current spark from passing through a secondary cable, preventing inductive thunder overvoltage, preventing rats and fire, equipotential connection and the like. The protection device can be vertically disassembled in sections, and is convenient to expand and maintain. The invention has the advantages of good lightening shielding effect, simple structure, wide application range, safety and reliability.

Owner:李景禄

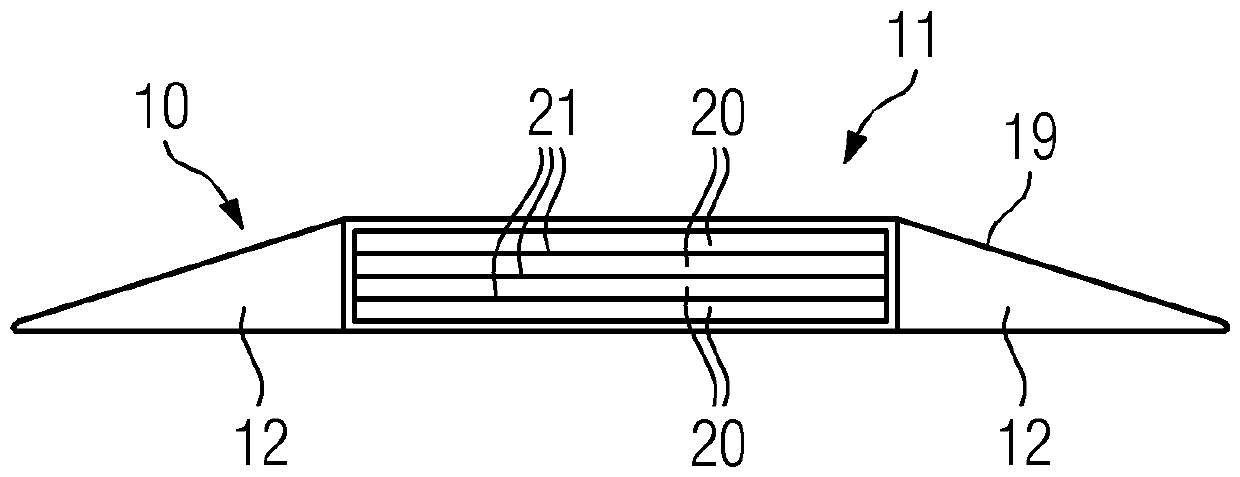

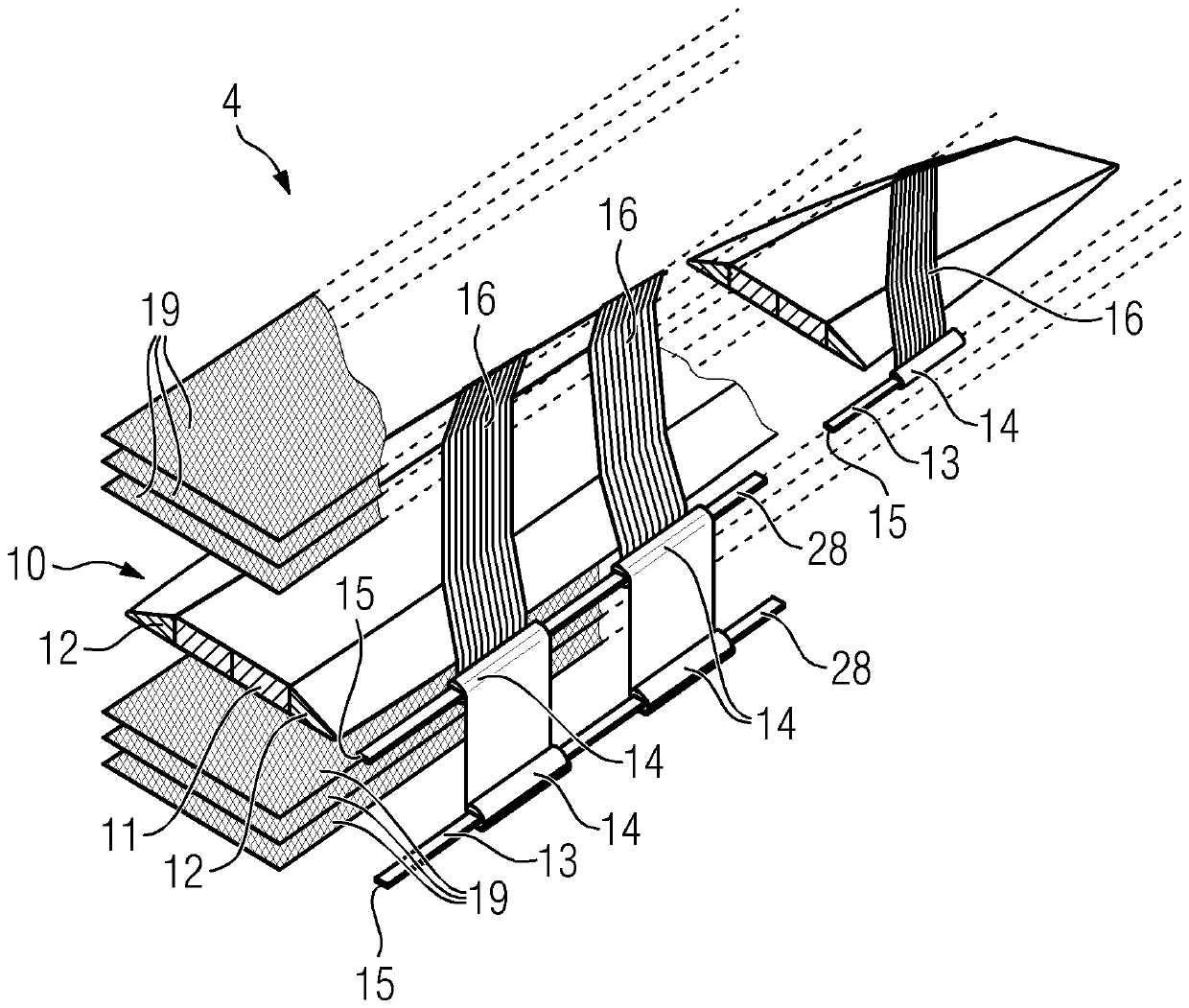

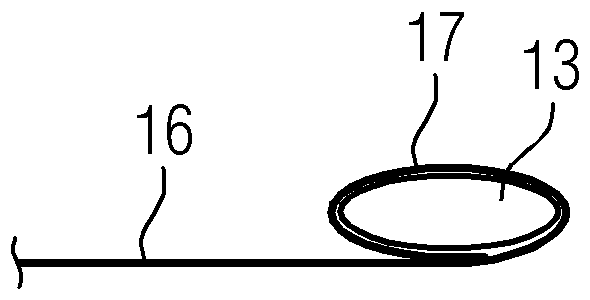

Spar cap, wind turbine blade, method for fabrication of both

ActiveCN110030146AGood and reliable electrical contactEasy to manufactureEngine manufactureFinal product manufactureElectrical conductorTurbine blade

The invention relates to a spar cap, a wind turbine blade, and a method for fabrication of both. A spar cap for a wind turbine blade (3), comprising a main body (10), which comprises an electrically conductive portion (11), and at least one metal conductor (13, 28), wherein the metal conductor (13) comprises a terminal portion (15, 26) and at least one connection portion (14), wherein the connection portion (14) of the metal conductor (13) is wrapped by a first end (17) of an electrically conductive and stripe-shaped carbon fibre mat (16), which abuts with a second end (18) at least partly onthe electrically conductive portion (11) of the main body (10).

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

An integrated control method for anti-corrosion and anti-fouling of water jet propulsion channel system

The invention belongs to the technical field of ship corrosion and fouling prevention and relates to an anti-corrosion anti-fouling integrated control method for a flow channel system of a water-jet propeller. The method comprises the following steps: designing the anodic working area according to a polarization curve of total protection current and an anode, designing an embedded anodic structure pattern along water flow according to the characteristics of a flow channel structure, controlling a multi-channel switch type constant-potential instrument to output current based on a reference electrode B during operation of the flow channel system of the water-jet propeller, and enabling the cathodic protection potential of the flow channel to be -0.80V; detecting the anodic potential through a reference electrode A, controlling the flow channel system of the water-jet propeller to automatically adjust the output current, detecting the cathodic protection potential of the flow channel, and keeping operation of the flow channel system of the water-jet propeller when the potential is -0.80V to -1.05V through measurement, so that the anti-corrosion anti-fouling integrated control is realized. According to the method, a power supply is small in size, convenient to mount and environmentally friendly; the auxiliary anode is low in cost, long in service life, scouring-resistant, low in consumption rate, good in reliability and long in maintenance cycle; the potentials in the flow channel are uniformly distributed.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for obtaining uniform coating of crystallizer copper plate based on finite element simulation

ActiveCN110795881AGuaranteed accuracyImprove the first-time success rate of electroplatingDesign optimisation/simulationCAD numerical modellingProcess engineeringManufacturing engineering

The invention provides a method for obtaining a uniform coating of a crystallizer copper plate based on finite element simulation, and relates to the technical field of special-shaped blank crystallizer electroplating. The method utilizes finite element analysis software to simulate the situation of potential distribution on the surface of a crystallizer copper plate under the two working conditions of not arranging a shielding plate and arranging the shielding plate during crystallizer copper plate electroplating, analyzes the reason for poor uniformity of a crystallizer copper plate coating,analyzes the principle that the shielding plate arranged between the crystallizer copper plate and the anode is beneficial to improving the surface potential distribution of the crystallizer copper plate in the electroplating process, obtains the optimal shielding position, beneficial to uniformity of the crystallizer copper plate coating, of the shielding plate through analysis, enables an analysis simulation result to be effectively combined with actual production, and achieves a good using effect in actual application of crystallizer copper plate electroplating.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

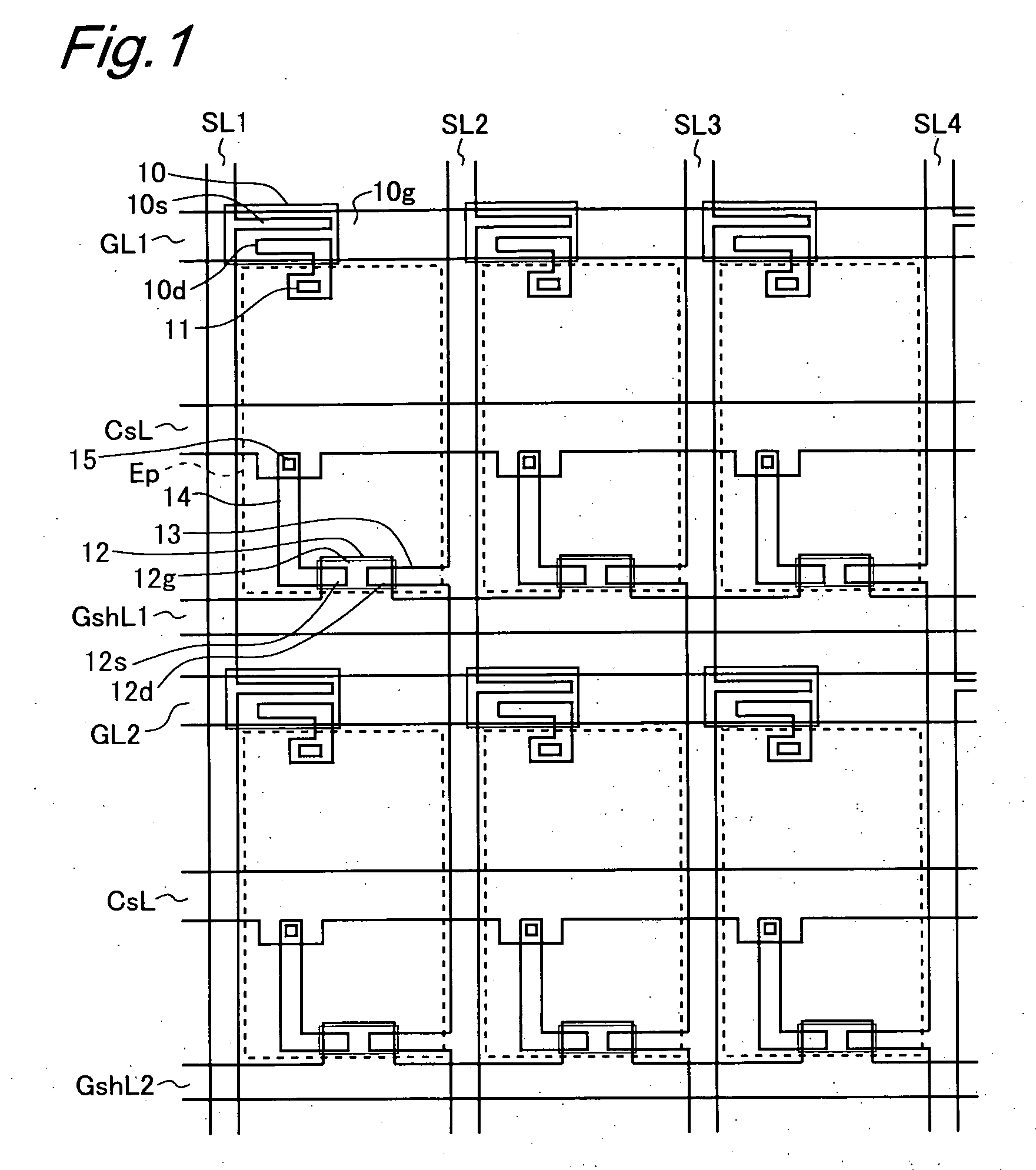

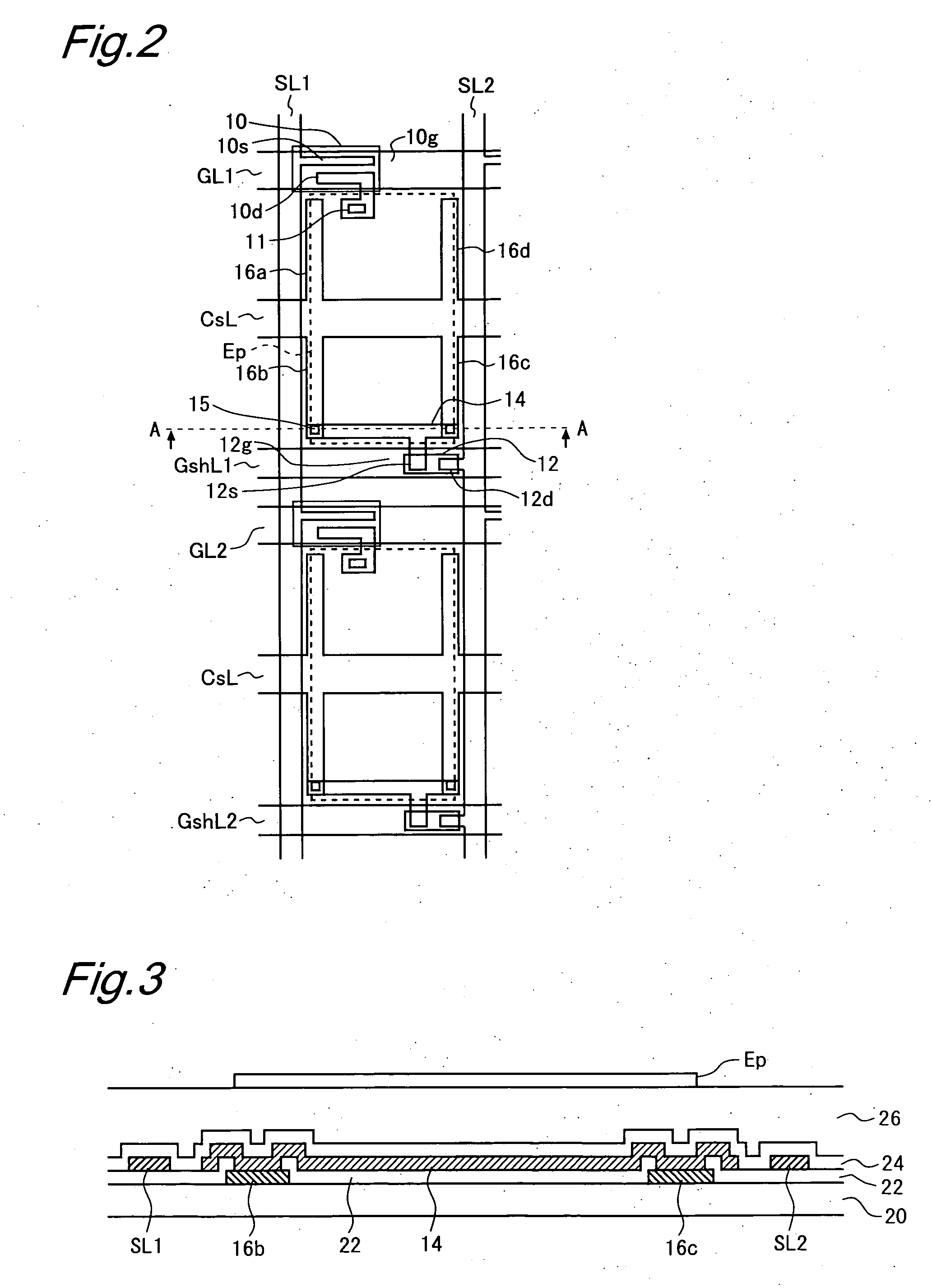

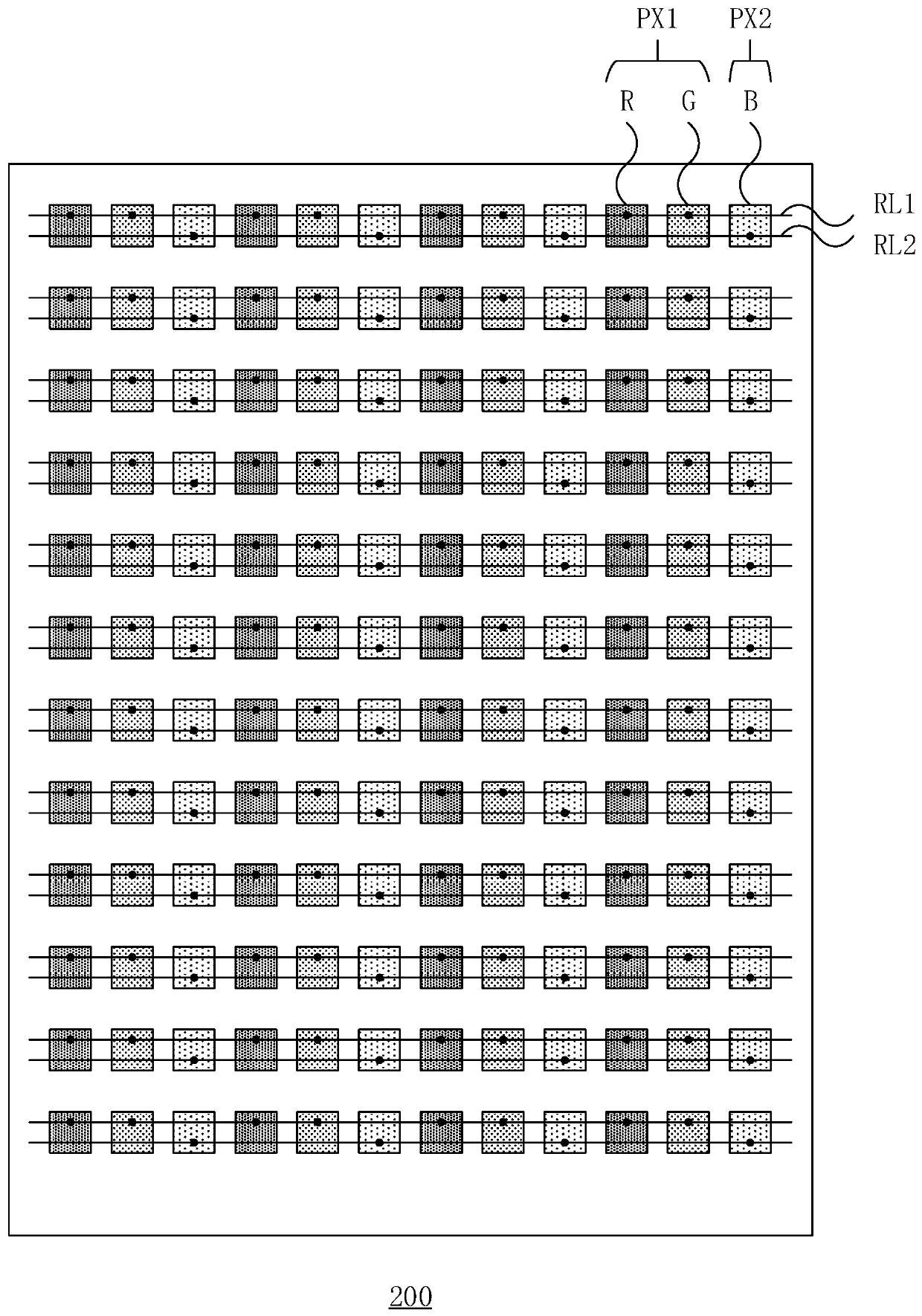

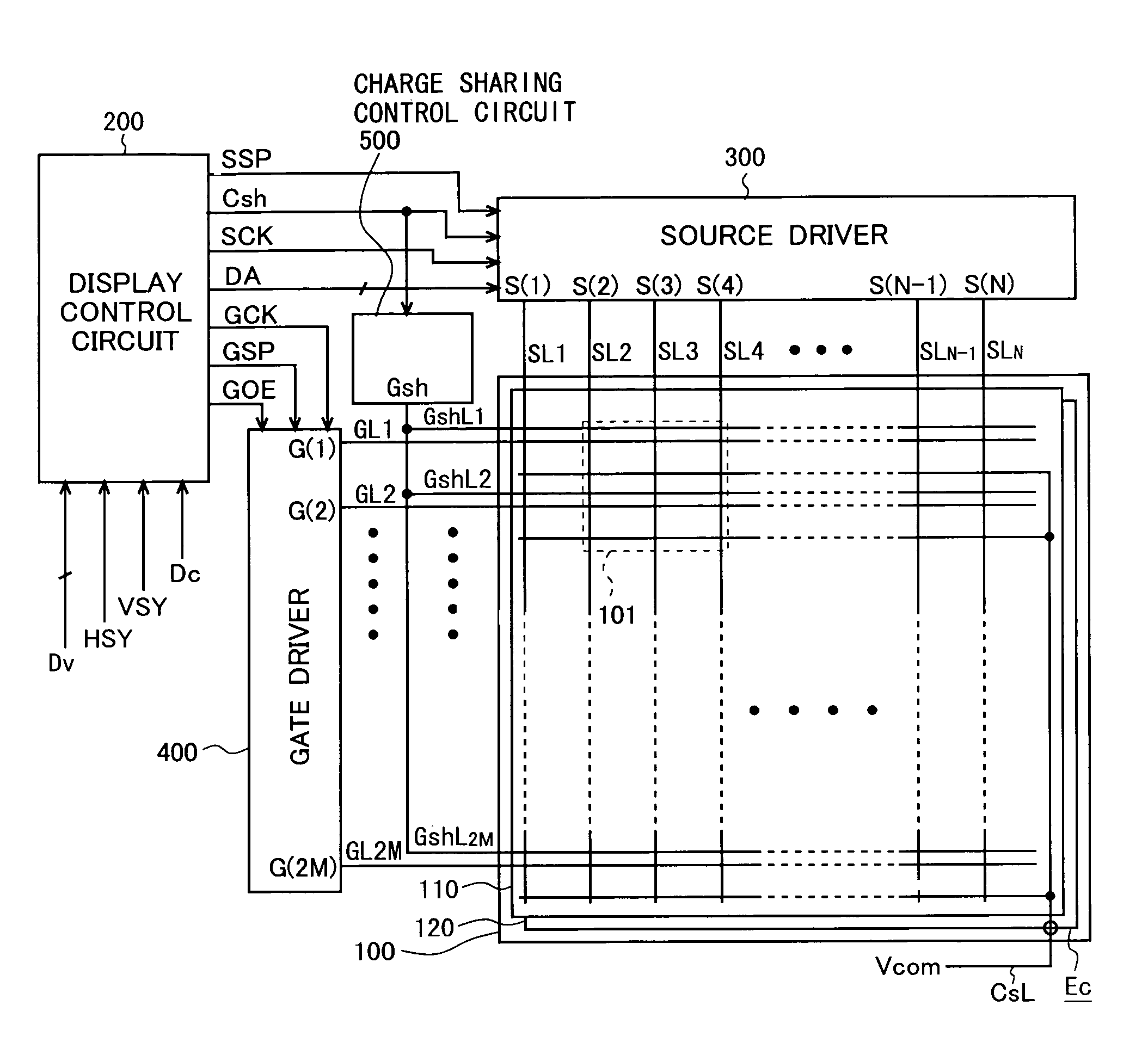

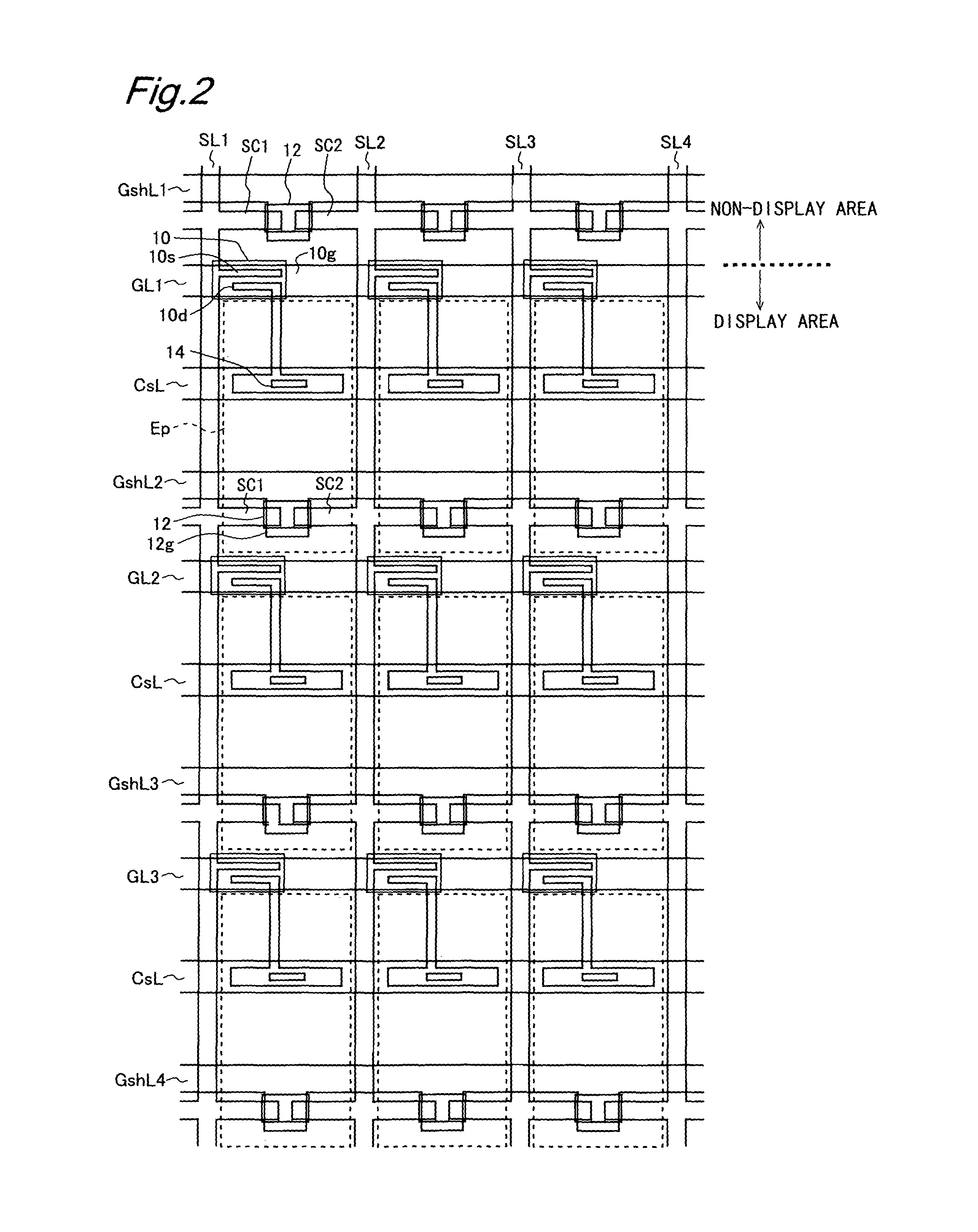

Active matrix substrate and display device having the same

ActiveUS8259046B2Uniform potentialEnhanced charge transferStatic indicating devicesNon-linear opticsLiquid-crystal displayControl signal

In at least one embodiment of the present invention, deterioration of display quality is prevented from occurring in a display device provided with an active matrix substrate even when a larger size or a higher resolution is employed and a drive frequency is increased. In an active matrix substrate of a liquid crystal display device, a charge sharing control signal line is disposed so as to be arranged along each gate line and charge sharing TFTs are provided for each source line in numbers equal to the number of the gate lines. The gate terminal of the charge sharing TFT is connected to the charge sharing control signal line and the source and drain terminals are connected with neighboring source lines via connection electrode portions, respectively. Each of the charge sharing control signal lines is provided with a signal which turns on the charge sharing TFT for a predetermined period of every one horizontal period.

Owner:SHARP KK

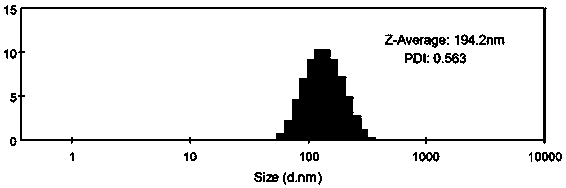

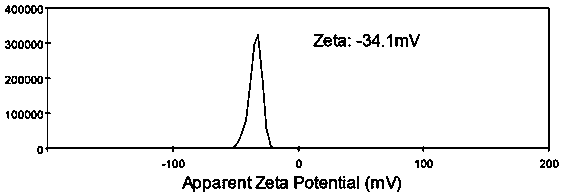

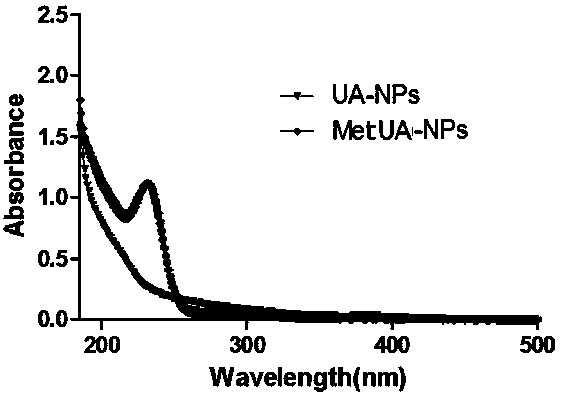

Metformin/ursolic acid nano oral preparation and preparation method thereof

ActiveCN108272745AEasy to prepareImprove bioavailabilityOrganic active ingredientsMetabolism disorderMetformin HydrochlorideNatural product

The invention discloses a metformin / ursolic acid nano oral preparation and a preparation method thereof. The preparation method is characterized by self-assembling metformin and a pentacyclic triterpene natural product-ursolic acid into nanoparticles of which the particle size is 180 to 220 nm through a self-assembly nano technology, and preparing the nanoparticles together with main accessories,additional accessories and a stabilizing agent into the nano oral preparation. The obtained nano oral preparation prepared by the invention has a slow release function and is capable of relieving sideeffects brought by a common oral metformin hydrochloride preparation.

Owner:FUZHOU UNIVERSITY

Stator assembly and motor

ActiveCN110556953AEquilibrium potential vectorUniform potentialMagnetic circuit stationary partsWindings conductor shape/form/constructionConductor CoilPhysics

The invention discloses a stator assembly and a motor. The stator assembly comprises a stator core and a stator winding. The stator core is provided with a plurality of stator slots which are distributed along the circumferential direction of the stator core. Each stator slot is provided with r slot layers which are arranged along the radial direction of the stator core. Each phase of first winding of the stator winding comprises a first winding part and a second winding part which are connected in an end-to-end way. The first winding part comprises first to sixth spans, and the second windingpart comprises seventh to twelfth spans. Each phase of second winding of the stator winding comprises a third winding part and a fourth winding part which are connected in an end-to-end way. The third winding part comprises thirteenth to eighteenth spans, and the fourth winding part comprises nineteenth to twenty-fourth spans. According to the stator assembly, the stator winding uses the plug-informing mode, the arrangement mode is simple, the implementation is convenient and the line adjustment can be facilitated for the user.

Owner:BYD CO LTD

Treatment process for preventing membrane corrosive pitting and perforating on surface of steel and iron base

InactiveCN111321366APrevents galvanic corrosion phenomenaImprove uniformityMolten spray coatingAnti-corrosive paintsThermal sprayingElectrochemical corrosion

The invention provides a treatment process for preventing membrane corrosive pitting and perforating on the surface of a steel and iron base. The treatment process comprises the following steps that (1) an oxidation layer on the surface of a steel and iron base material is polished and removed; (2) a thermal spraying layer is formed on the surface of the steel and iron base material obtained in the first step through a thermal spraying technology; and (3) membrane laminating is conducted on the surface of the thermal spraying layer obtained in the second step. According to the treatment process, a compact particle surface layer can be formed on the surface of the steel and iron base by adoption of the thermal spraying layer, the homogeneity is good and no lattice defect exists; and potential equalization of the steel and iron base material covered with the surface membrane in a high-temperature state is achieved within the high-temperature range of 280-420 DEG C, the potential difference is avoided and the phenomenon of electrochemical corrosion causing breakdown of the surface membrane is prevented.

Owner:PINGDINGSHAN MEIYI METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com