Spar cap, wind turbine blade, method for fabrication of both

一种风力涡轮机、翼梁帽的技术,应用在翼梁帽领域,能够解决难以实现、小容差修复昂贵等问题,达到整体电阻减小、大制造和定位误差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

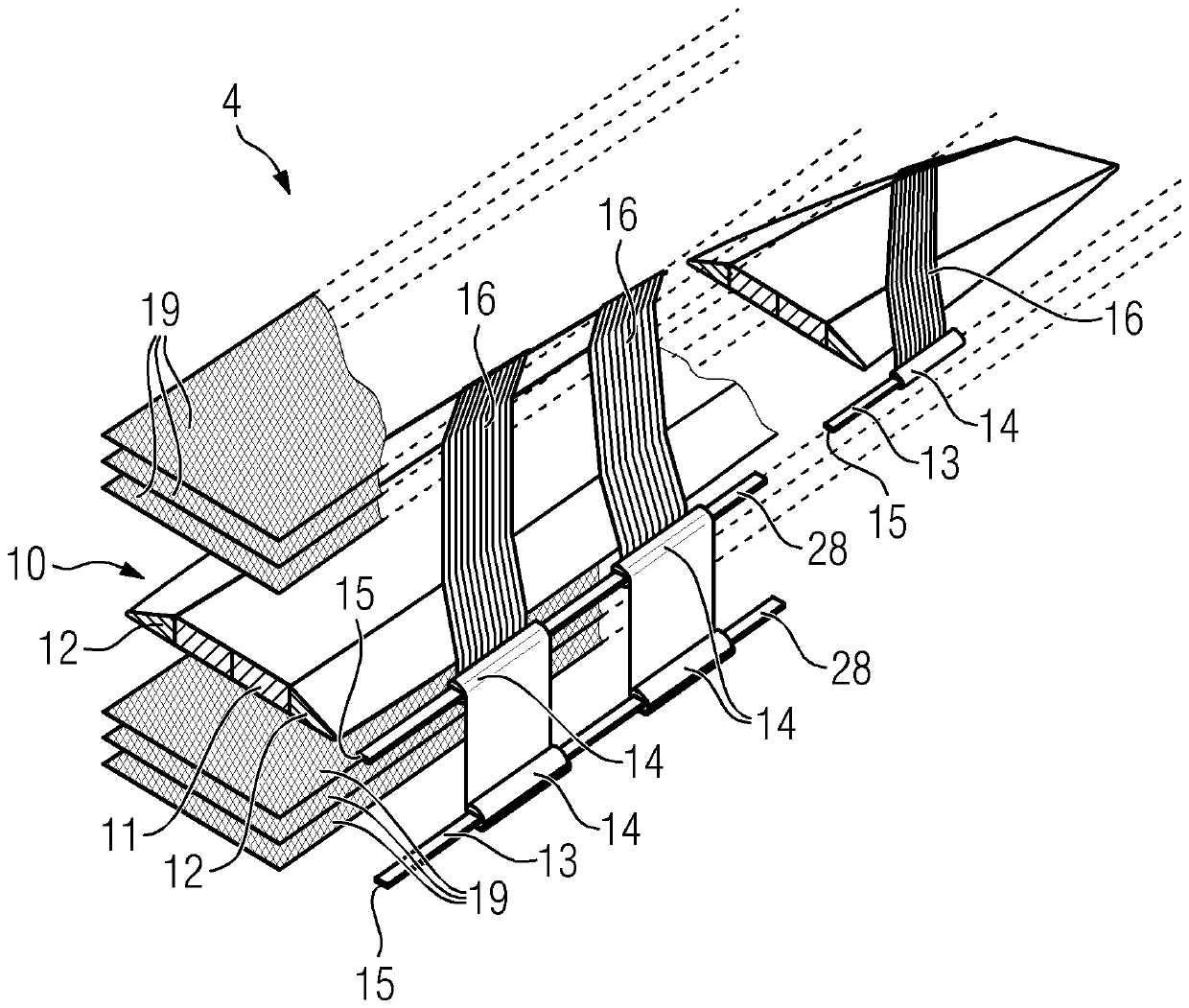

[0052] exist figure 1 , a schematic diagram of a wind turbine 1 is shown. A wind turbine 1 comprises a hub 2 with a rotor comprising a plurality of wind turbine blades 3 attached to the hub 2 . Each wind turbine blade 3 comprises at least one spar cap 4, wherein the position of the spar cap 4 in or in the wind turbine rotor blade 3 is shown by dashed lines. The spar caps 4 serve to increase the mechanical stability of the wind turbine blade 3 during operation of the wind turbine 1, in particular along the longitudinal axis of the spar cap 4 or the longitudinal axis of the wind turbine blade 3, respectively.

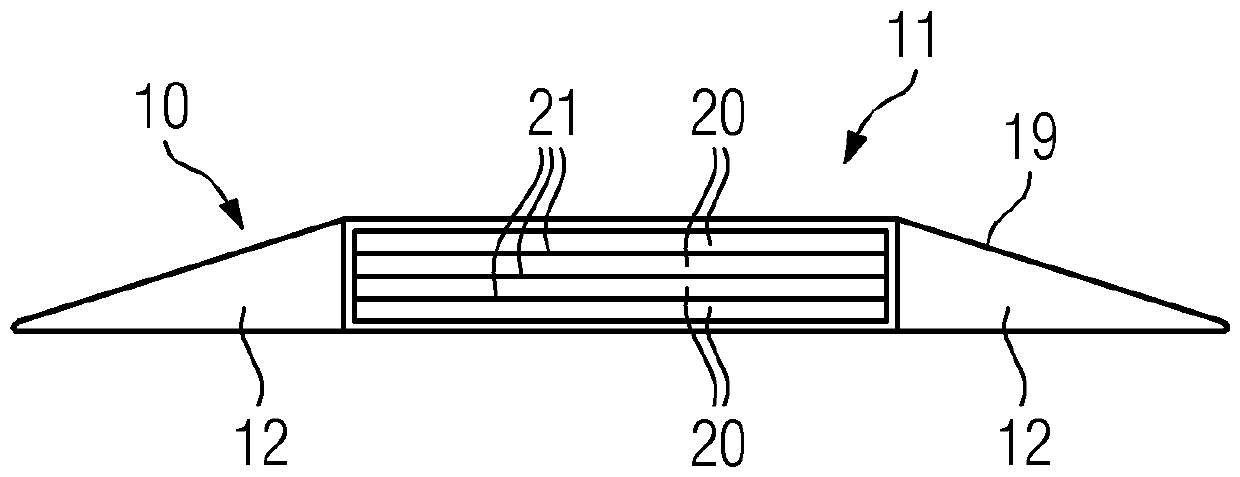

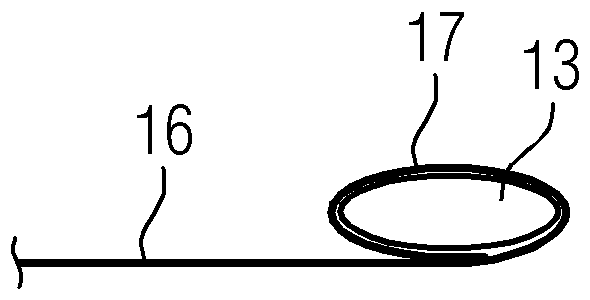

[0053] exist figure 2 , a cross section through a wind turbine blade 3 is shown. The wind turbine blade 3 comprises two spar caps 4 arranged substantially perpendicularly to a web structure 5 arranged in an inner cavity 6 of the wind turbine blade 3 . The wind turbine blade 3 also comprises a panel 7 forming the leading edge of the wind turbine blade 3 , and two pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com