An integrated control method for anti-corrosion and anti-fouling of water jet propulsion channel system

A water-jet propulsion, integrated control technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of increased resistance, accelerated corrosion of aluminum alloys, shortened life, etc., to reduce scour, inhibit corrosion, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

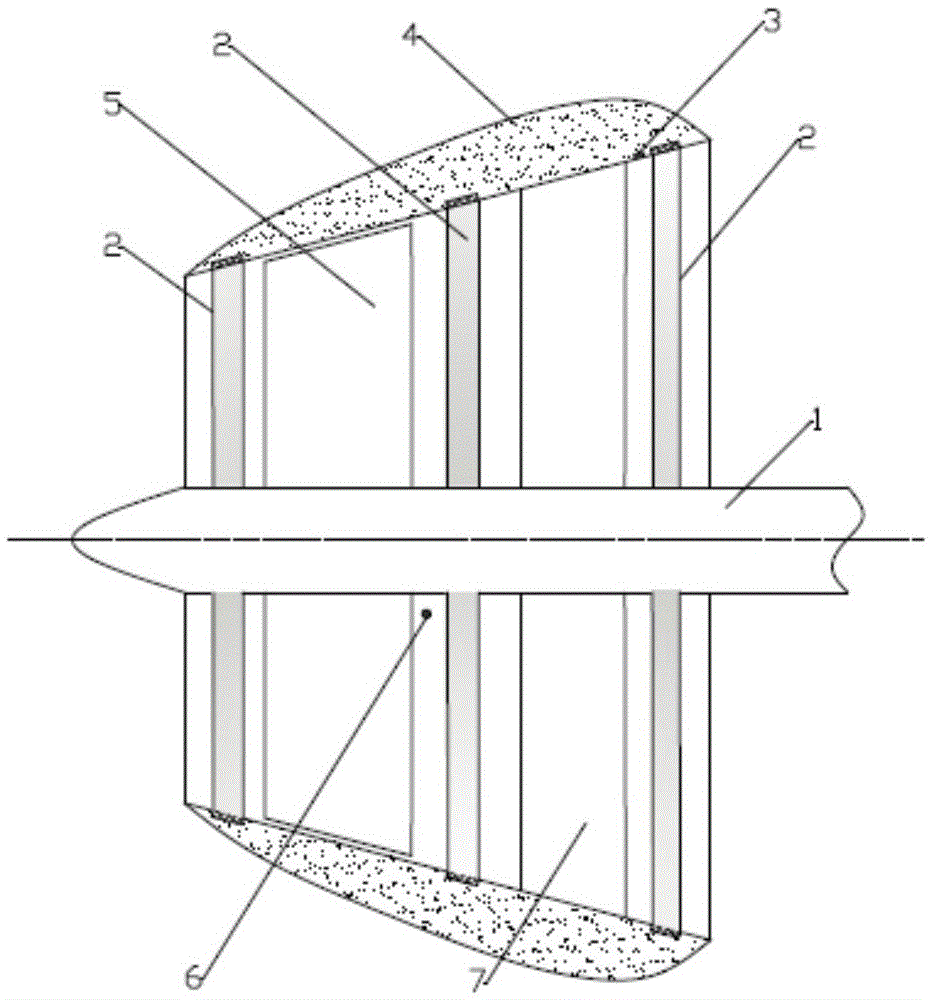

[0015] This embodiment realizes anti-corrosion and anti-fouling integrated control on the basis of the existing conventional water jet propulsion channel system, and uses a multi-channel switch type potentiostat as a power supply, with a rated output voltage of 12V and a rated output current of 40A. -2.000~0.000V and continuously adjustable; the number of channels is greater than 4, the potential control accuracy is ≤±5mV, the current control accuracy is ≤1%, the temperature drift coefficient is ≤0.01% / ℃, and the efficiency is greater than 90% under full load; The chlorine evolution potential of the metal oxide anode is 1.15V~1.30V, and the consumption rate in seawater is 1.2mg / A·a. Ag / AgCl / seawater is used as the reference electrode, and the protection potential range of the flow channel is -0.80V~-1.05 V; the chlorine concentration at the inlet of the runner is greater than 0.5ppm, and the available chlorine concentration at the outlet is greater than 0.2ppm; the specific pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com