Patents

Literature

43results about How to "Effective corrosion protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin-oxidized graphene composite coating and application method thereof

InactiveCN104356860AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated surface

The invention provides an epoxy resin-oxidized graphene composite coating. The composite coating is prepared by using oxidized graphene as a packing and adding the packing to epoxy resin coating. A coating layer prepared on the surface of a matrix by utilizing the composite coating is excellent in binding force of the matrix, and further greatly improved in corrosion resistance, so as to effectively obstruct a corrosive medium from penetrating from the surface of the coating layer to the path of the matrix. Therefore, the epoxy resin-oxidized graphene composite coating is good in application prospect, and in particular suitable for the matrix in a highly-corrosive severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

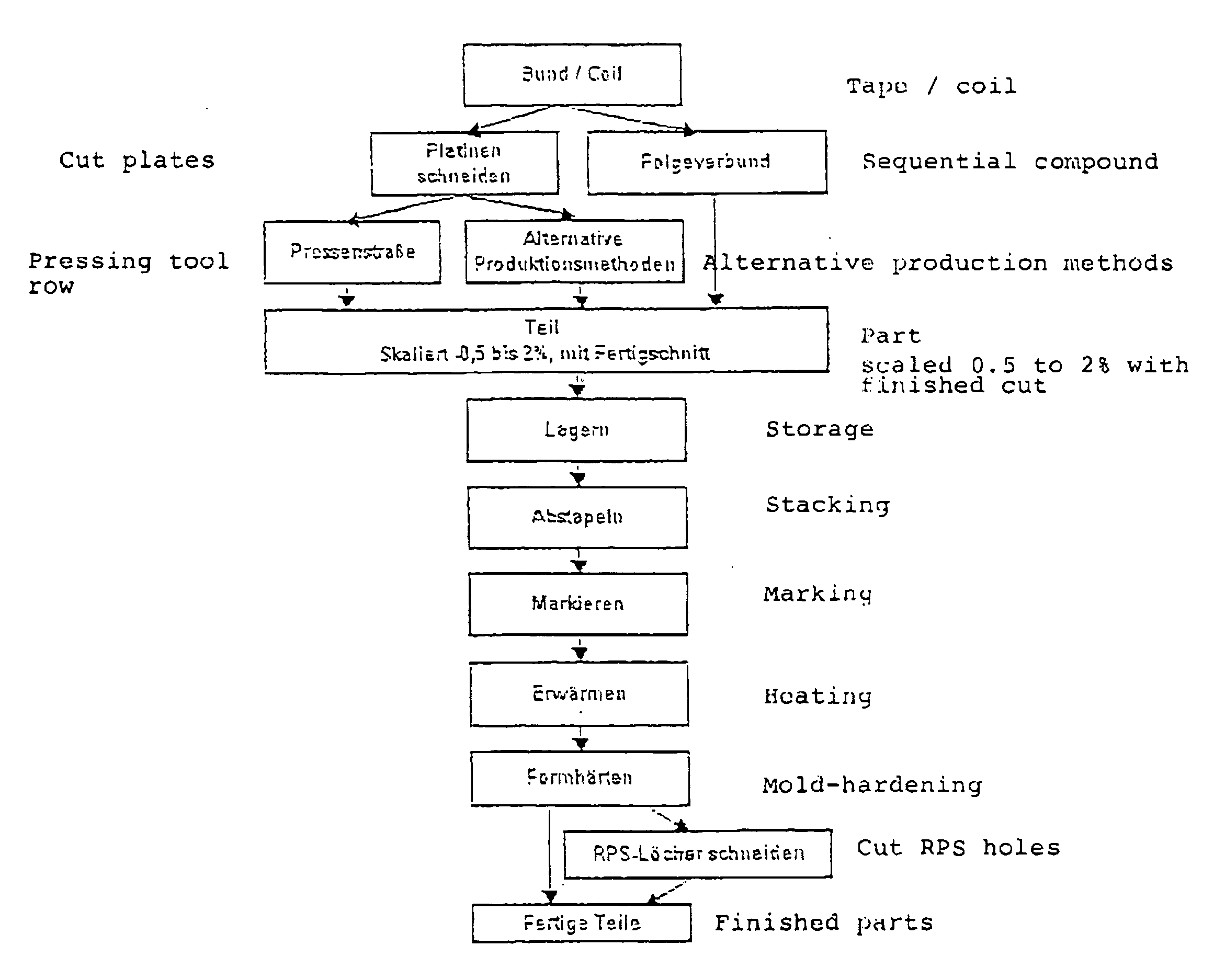

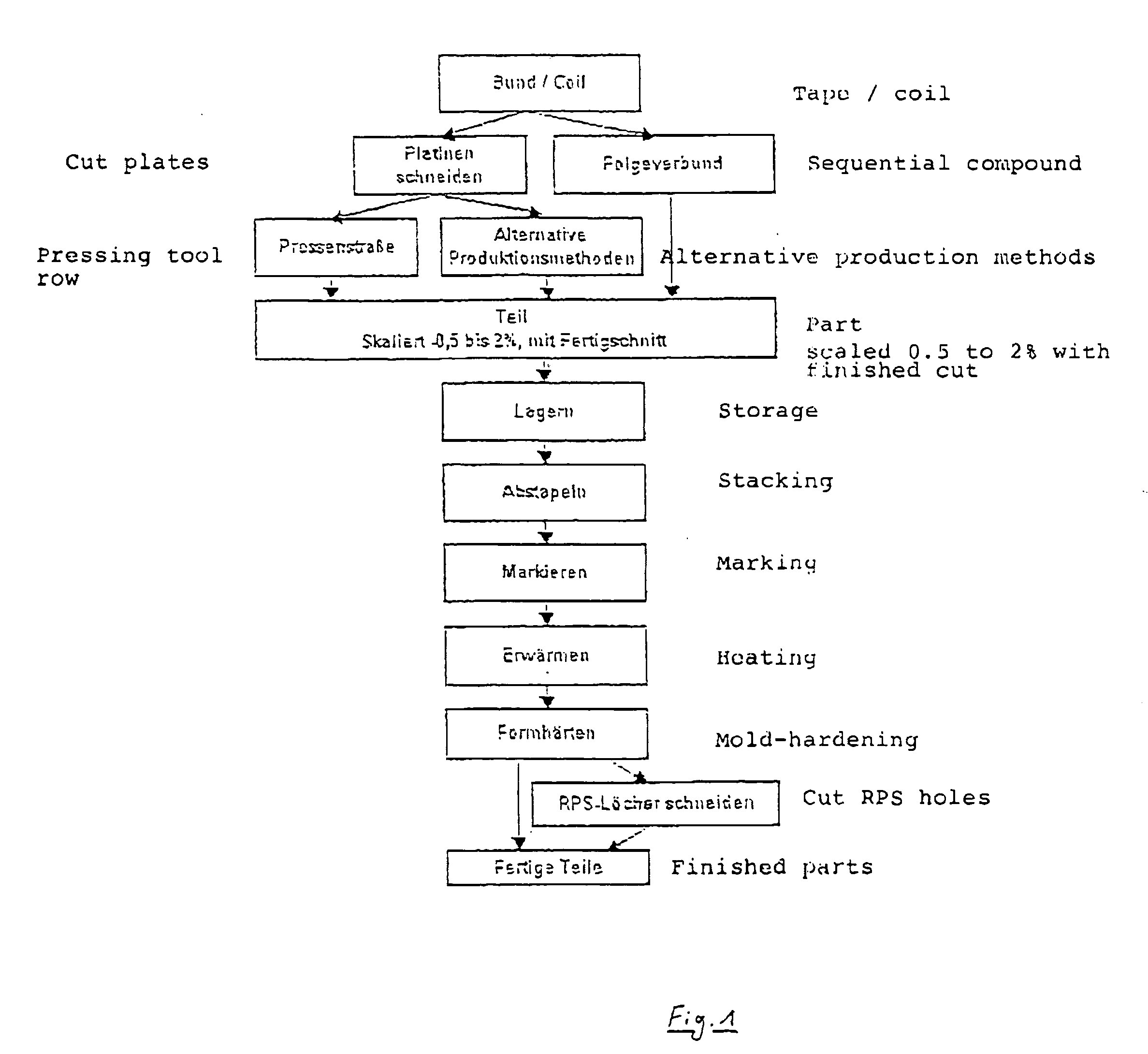

Method for producing hardened parts from sheet steel

ActiveUS20070000117A1Fast coolingEasy to integrateHot-dipping/immersion processesMetal rolling stand detailsPunchingSheet steel

The invention relates to a method for producing hardened structural parts from sheet steel. The method includes shaping at least one shaped part made of sheet steel provided with a cathodic corrosion protection coating, performing any required final trim of the shaped part and possibly any required punching, or the creation of a perforation pattern, subsequently heating the shaped part, at least over partial areas, under the admission of atmospheric oxygen to a temperature which permits austenizing of the steel material, and thereafter transferring the structural part to a mold-hardening tool and performing mold-hardening in the mold-hardening tool, wherein the structural part is cooled by the contact with and pressing by the mold-hardening tool and is hardened thereby.

Owner:VOESTALPINE STAHL GMBH

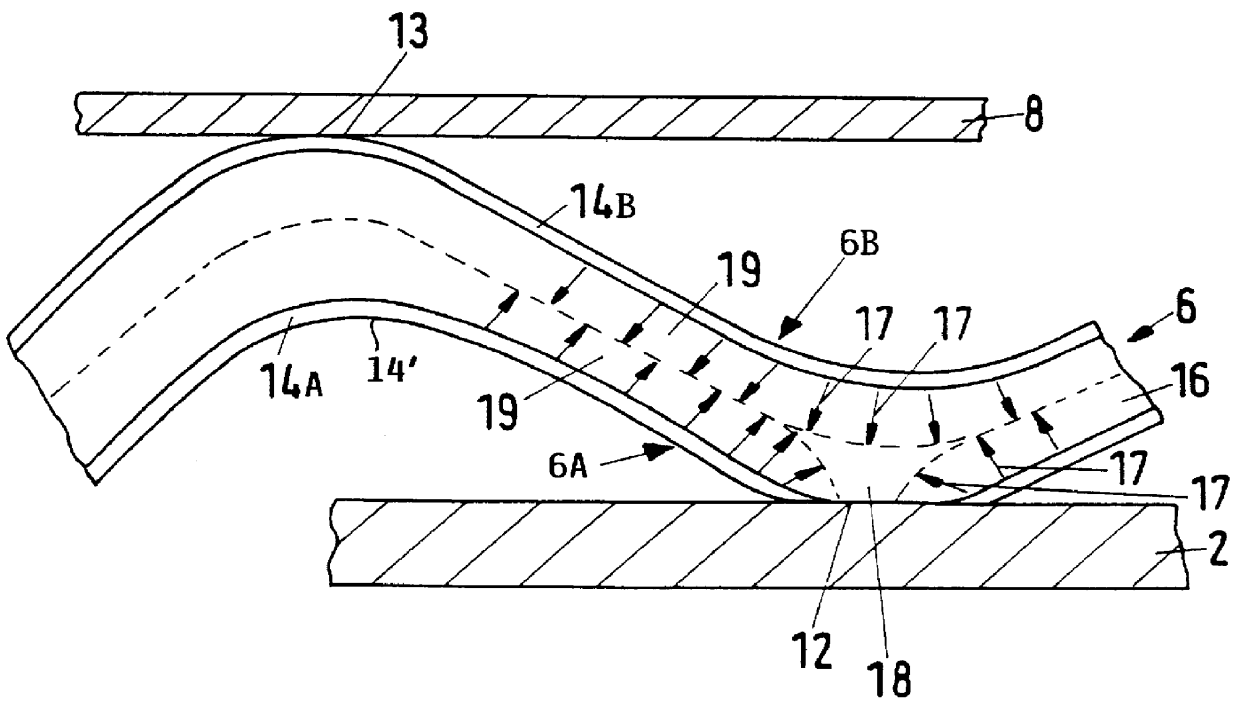

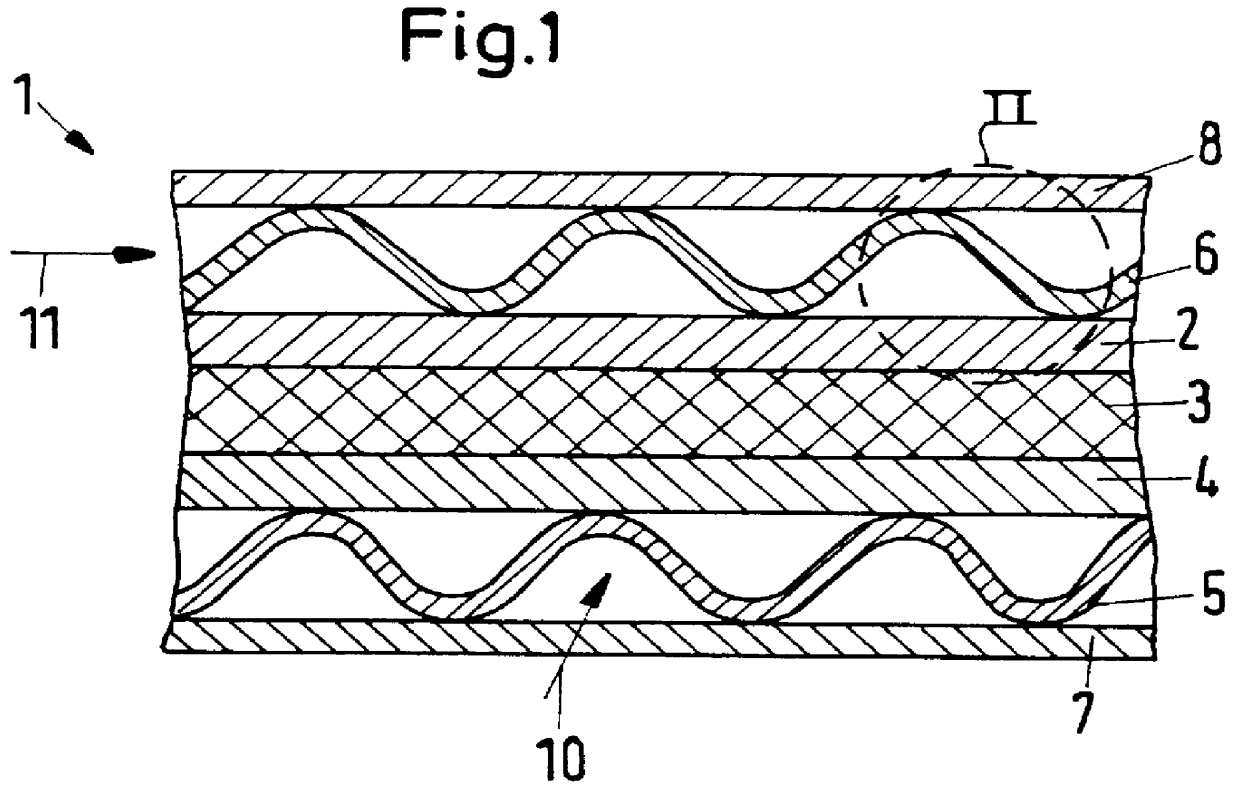

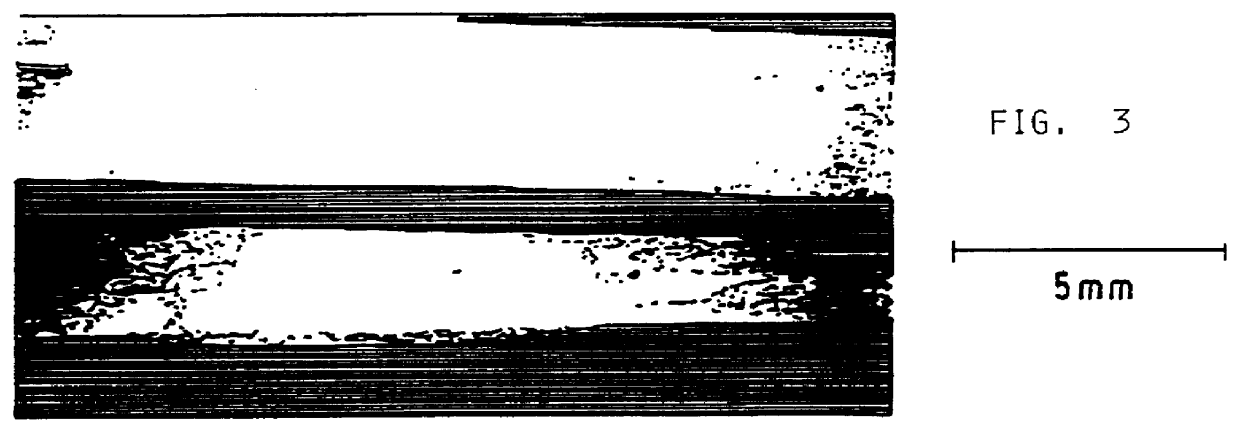

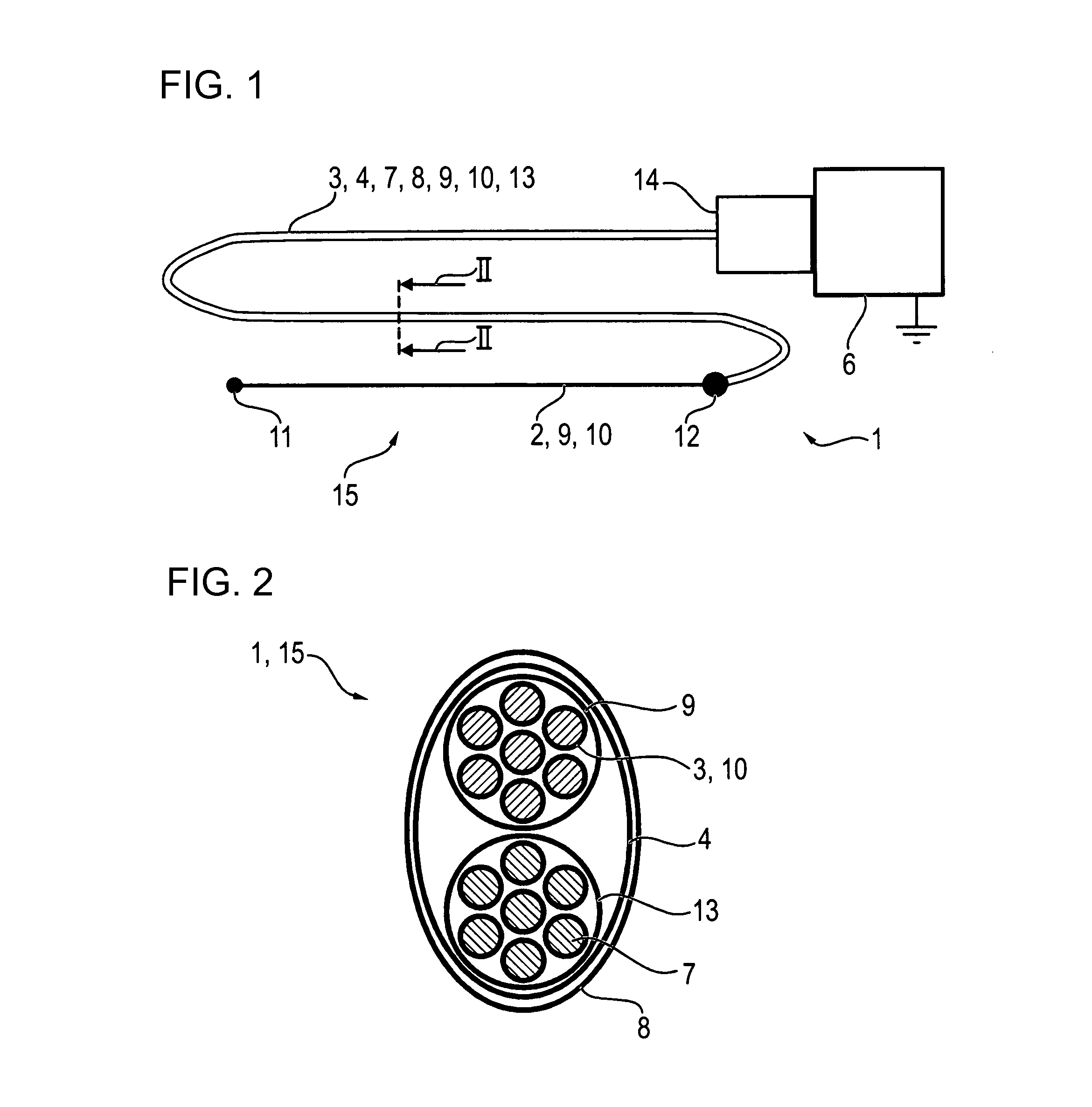

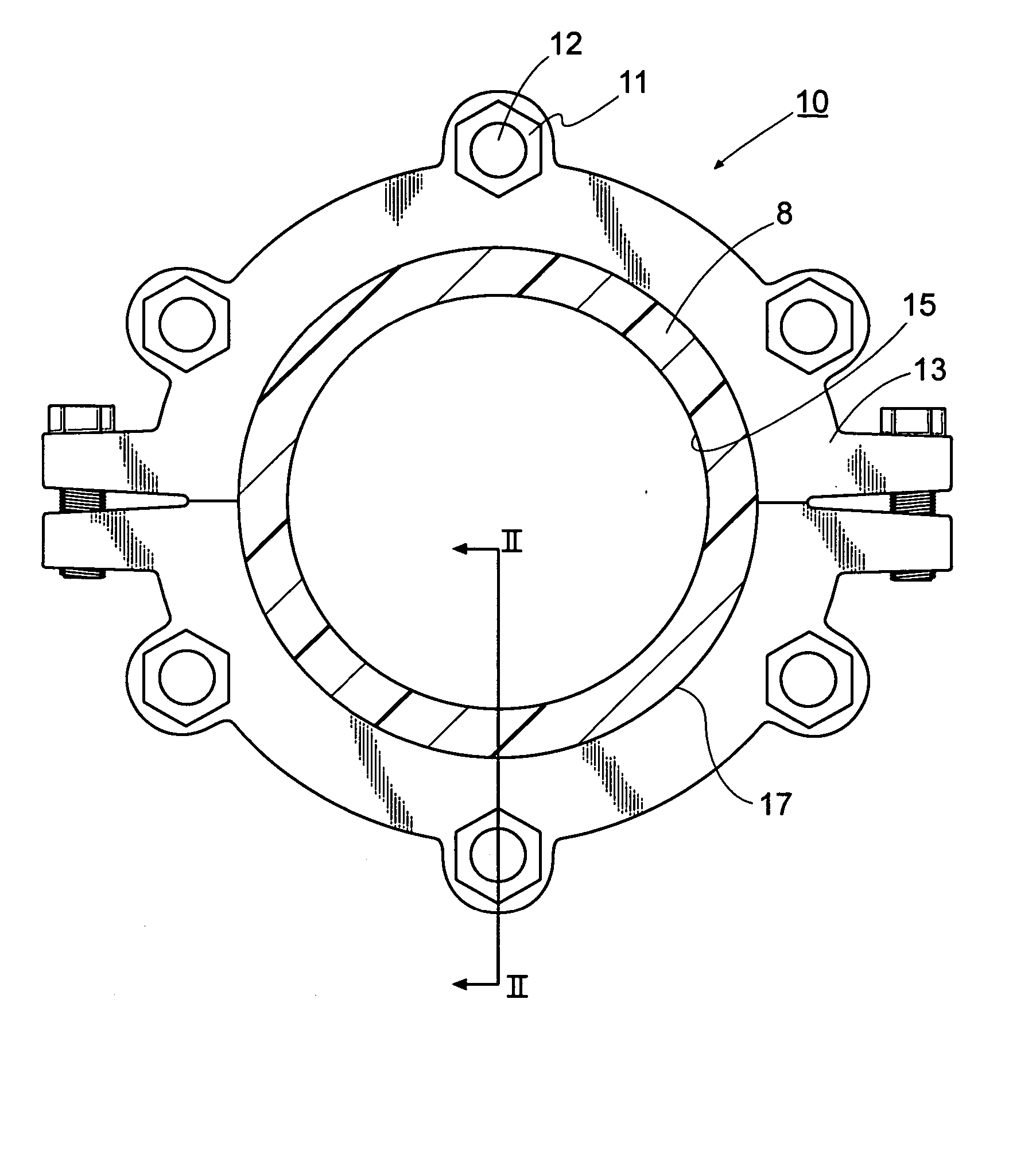

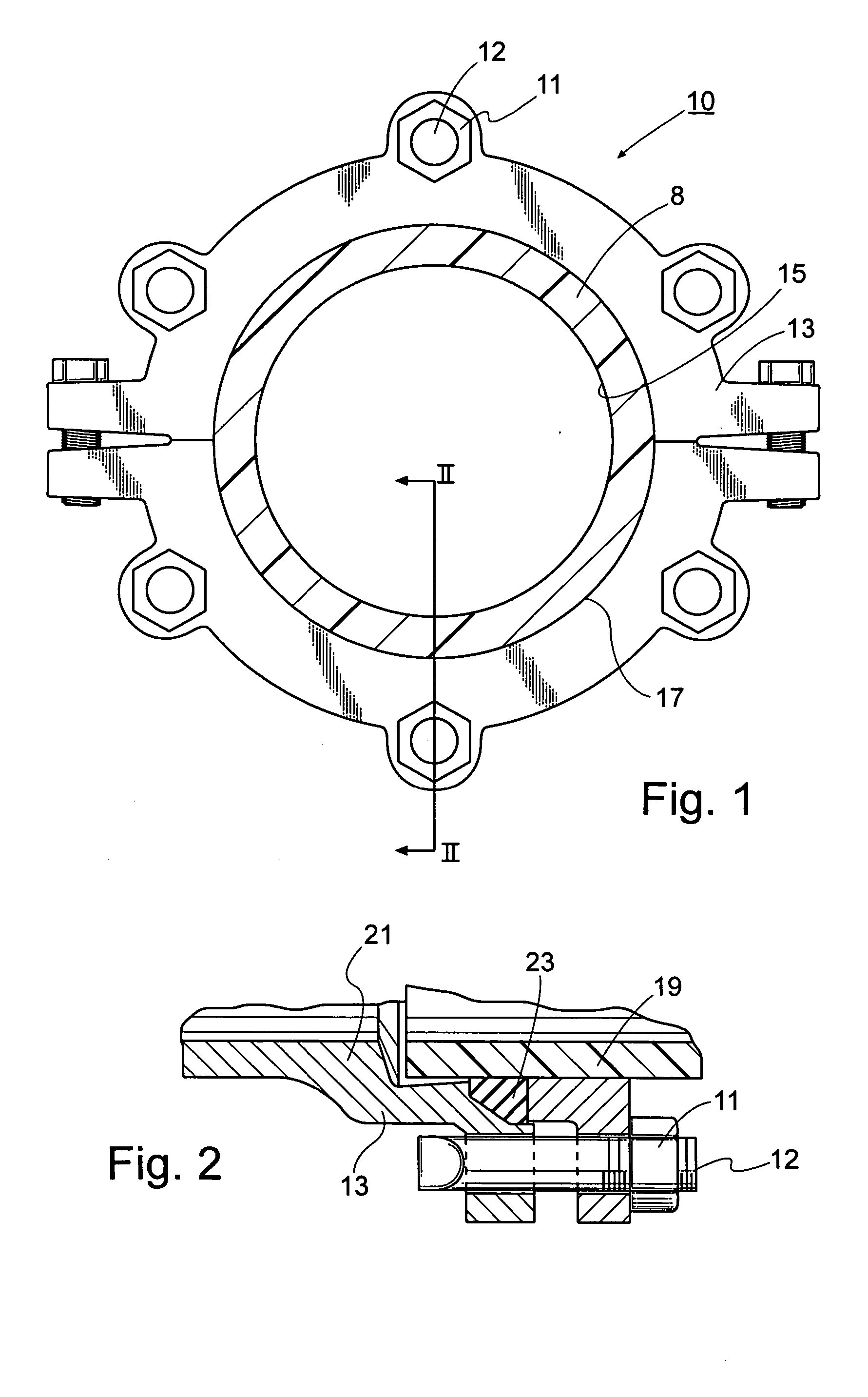

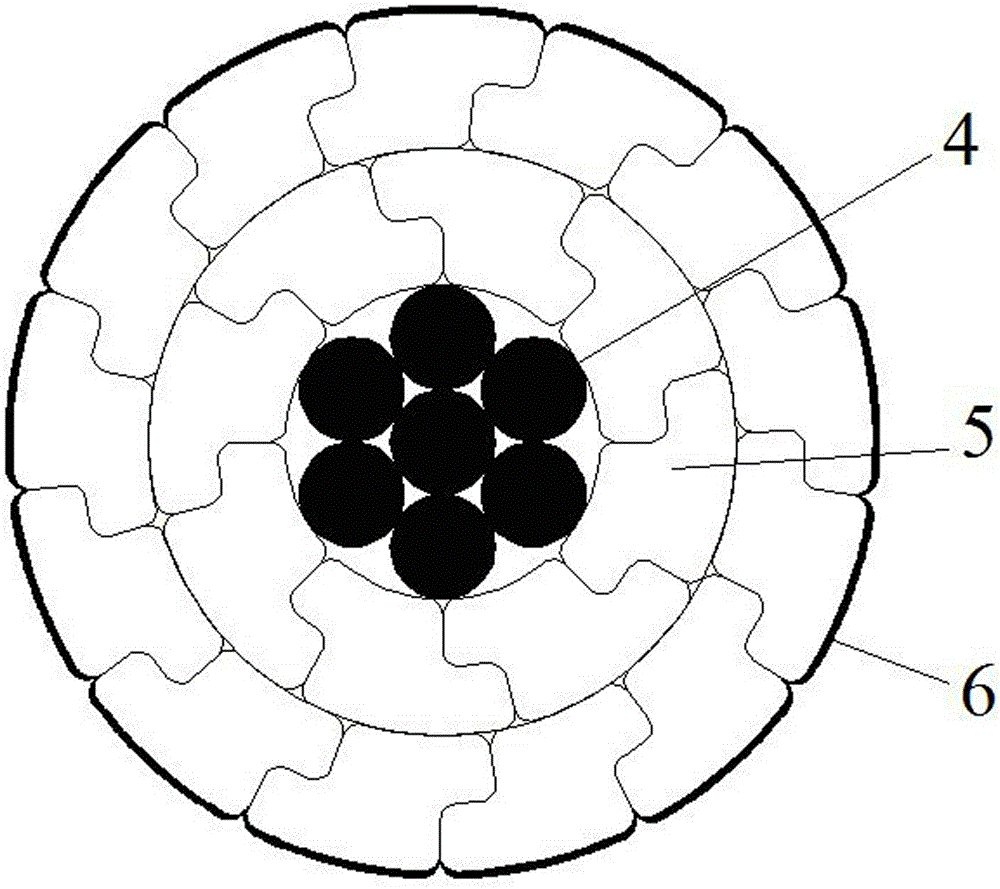

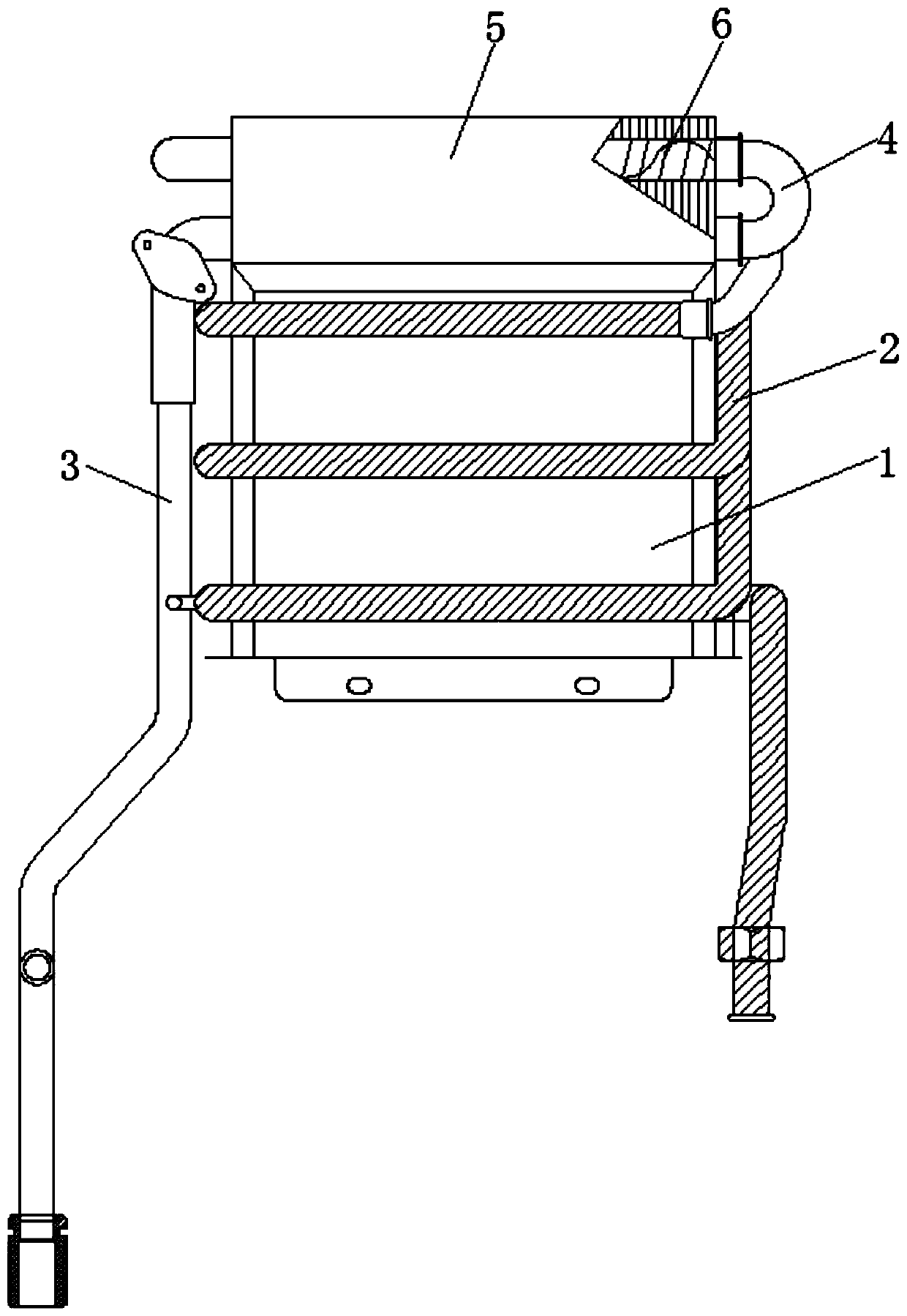

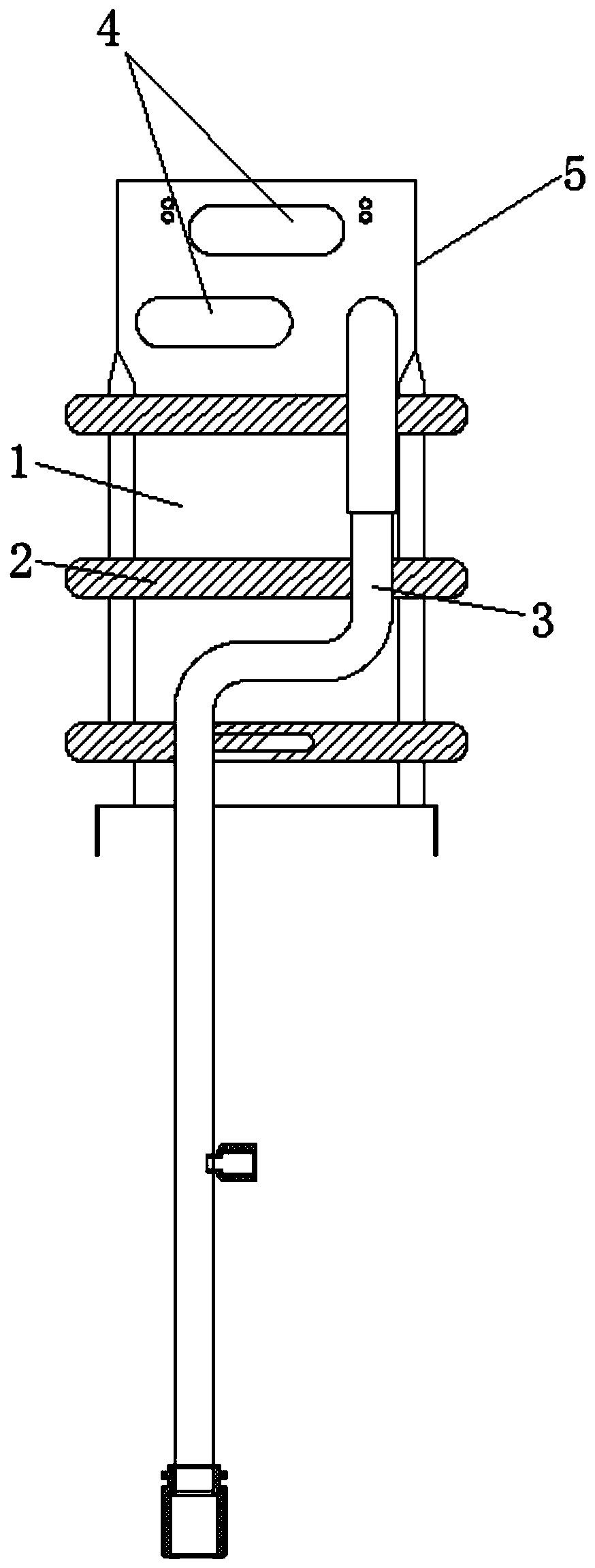

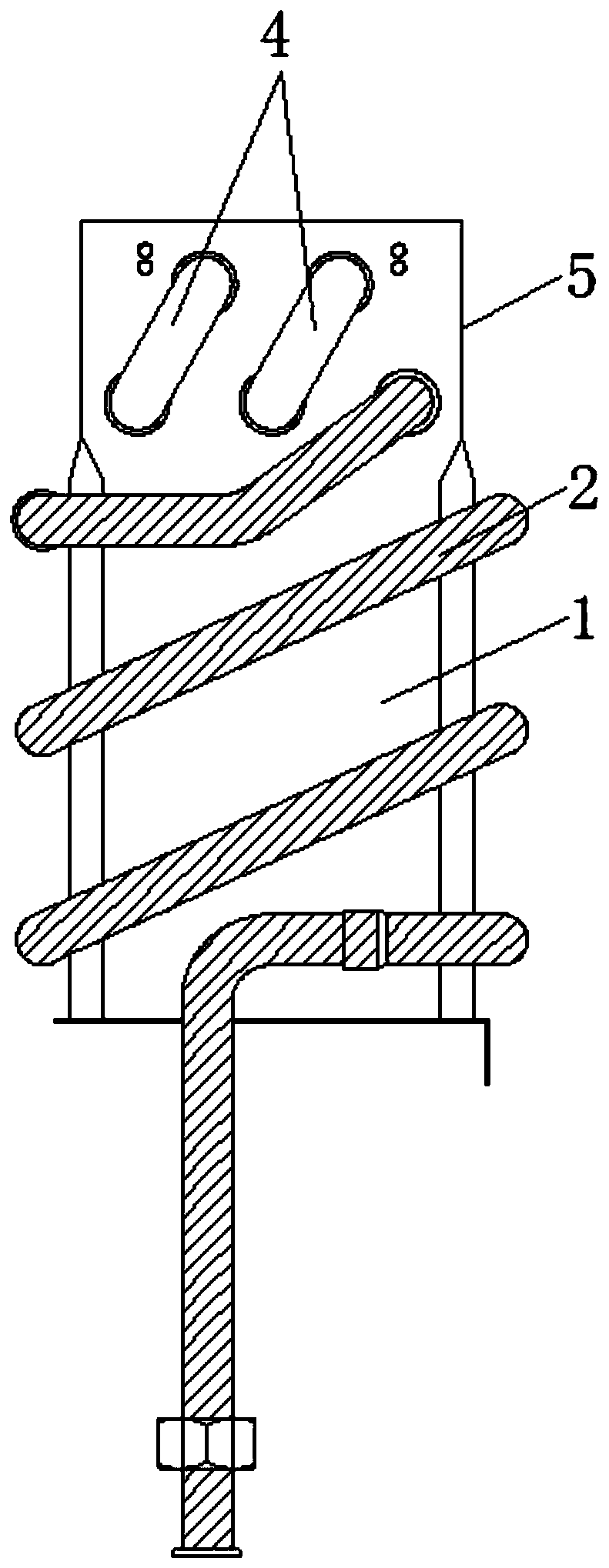

Current collector for a fuel cell and method of making the same

InactiveUS6117580AEffective corrosion protectionAccelerate the lossFuel cells groupingFinal product manufactureFuel cellsMolten carbonate fuel cell

A molten carbonate fuel cell is constructed of plural stacked individual cell units, that each respectively include a porous, electrolyte saturated matrix (3) sandwiched between a cathode (2) and an anode (4), and current collectors (5, 6) respectively arranged between the anode (4) and a first separator plate (7), and between the cathode (2) and a second separator plate (8). Especially the cathode current collector (6) includes a stainless steel core (16) that is coated on at least one surface with an aluminum-containing layer (14). Preferably both surfaces of the stainless steel core (16) are coated with aluminum-containing layers (14A, 14B), except for a contact area (12) at which the stainless steel core (16) directly contacts the cathode (2). The aluminum-containing layer (14) prevents or minimizes the occurrence of an oxidation reaction that would otherwise lead to significant loss of the electrolyte.

Owner:DAIMLER AG

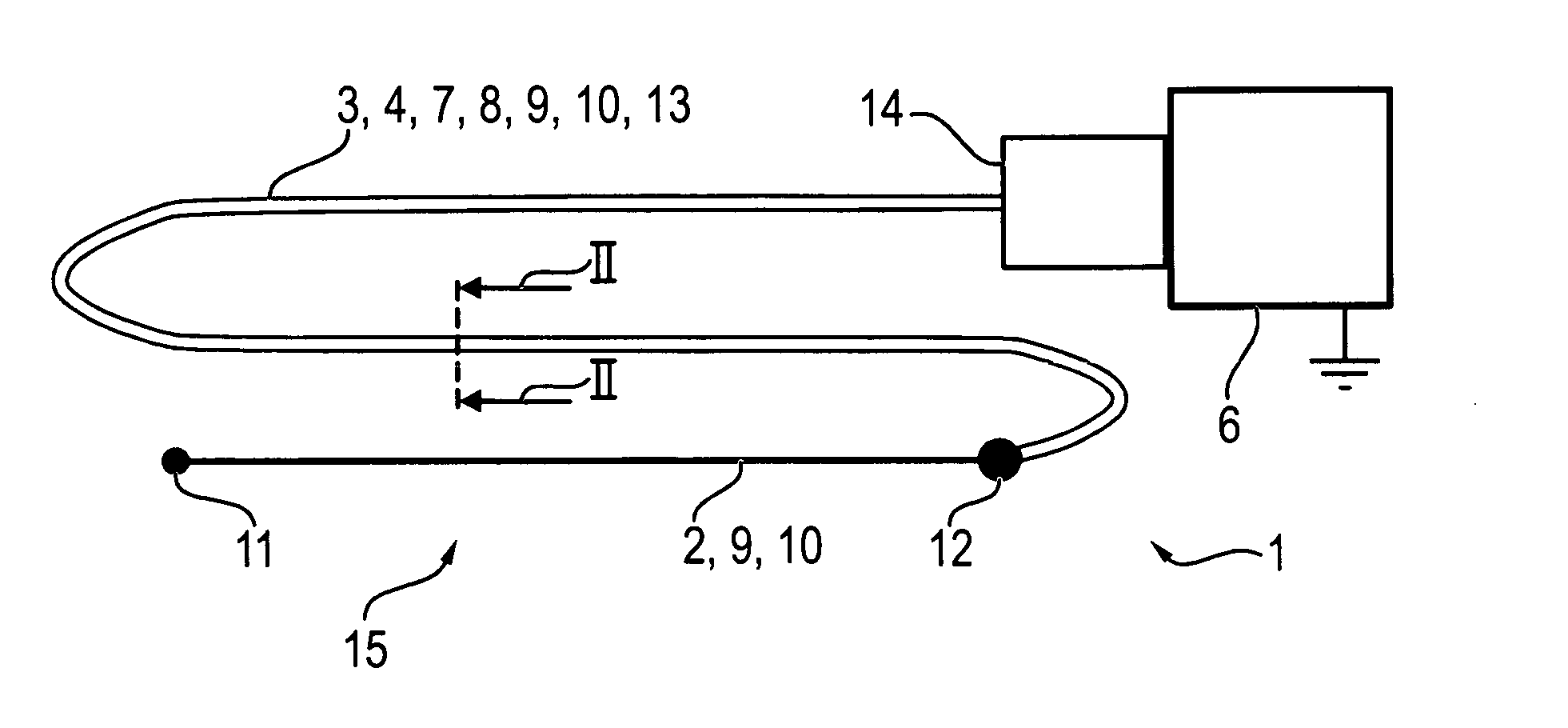

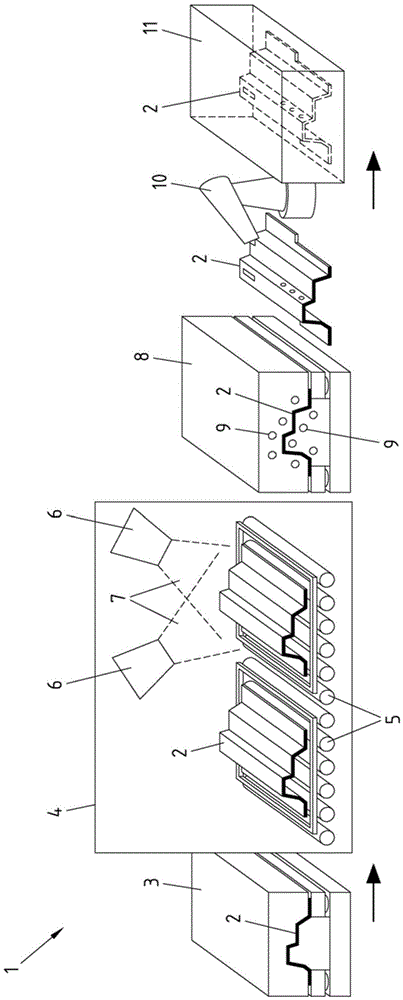

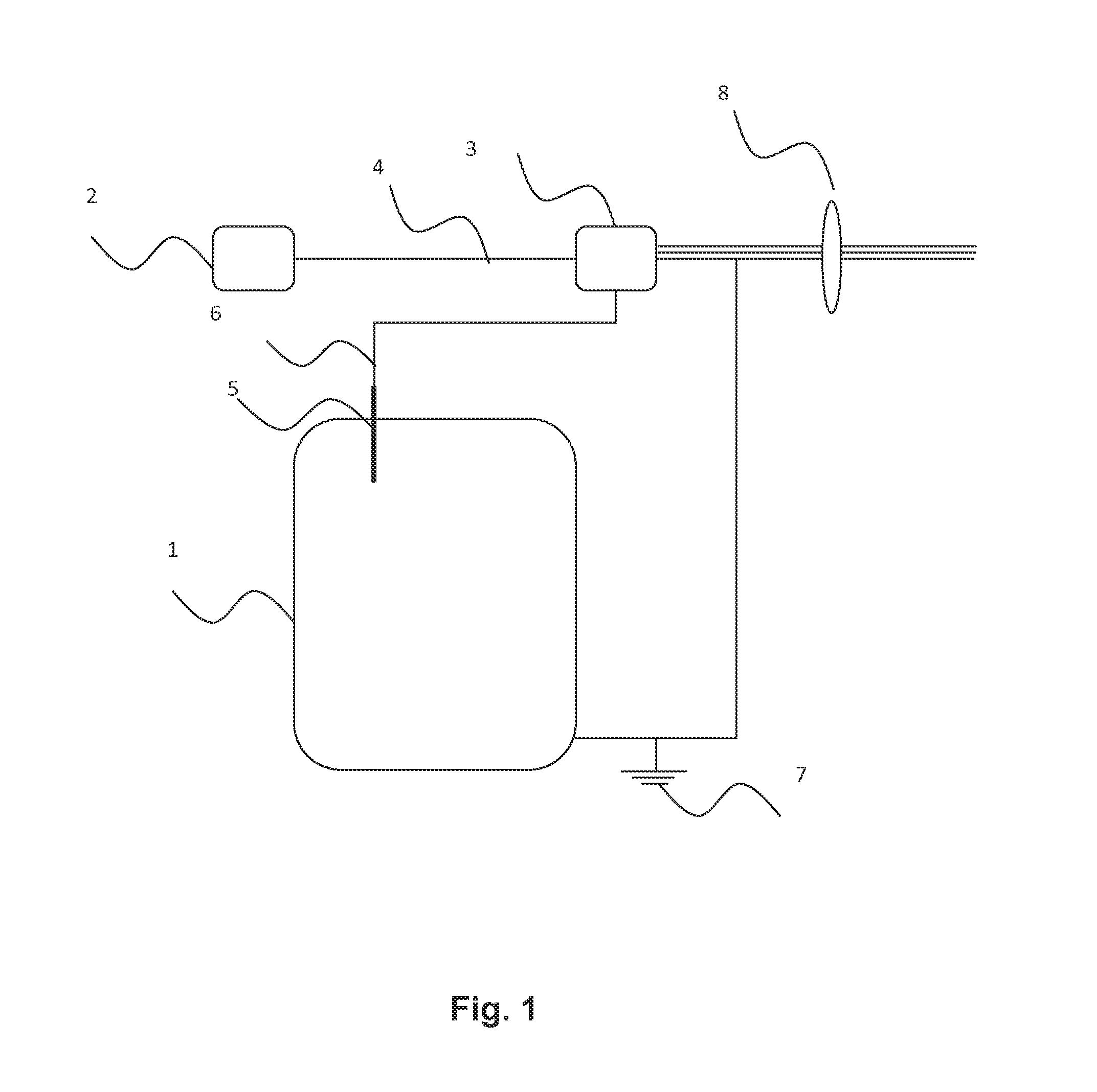

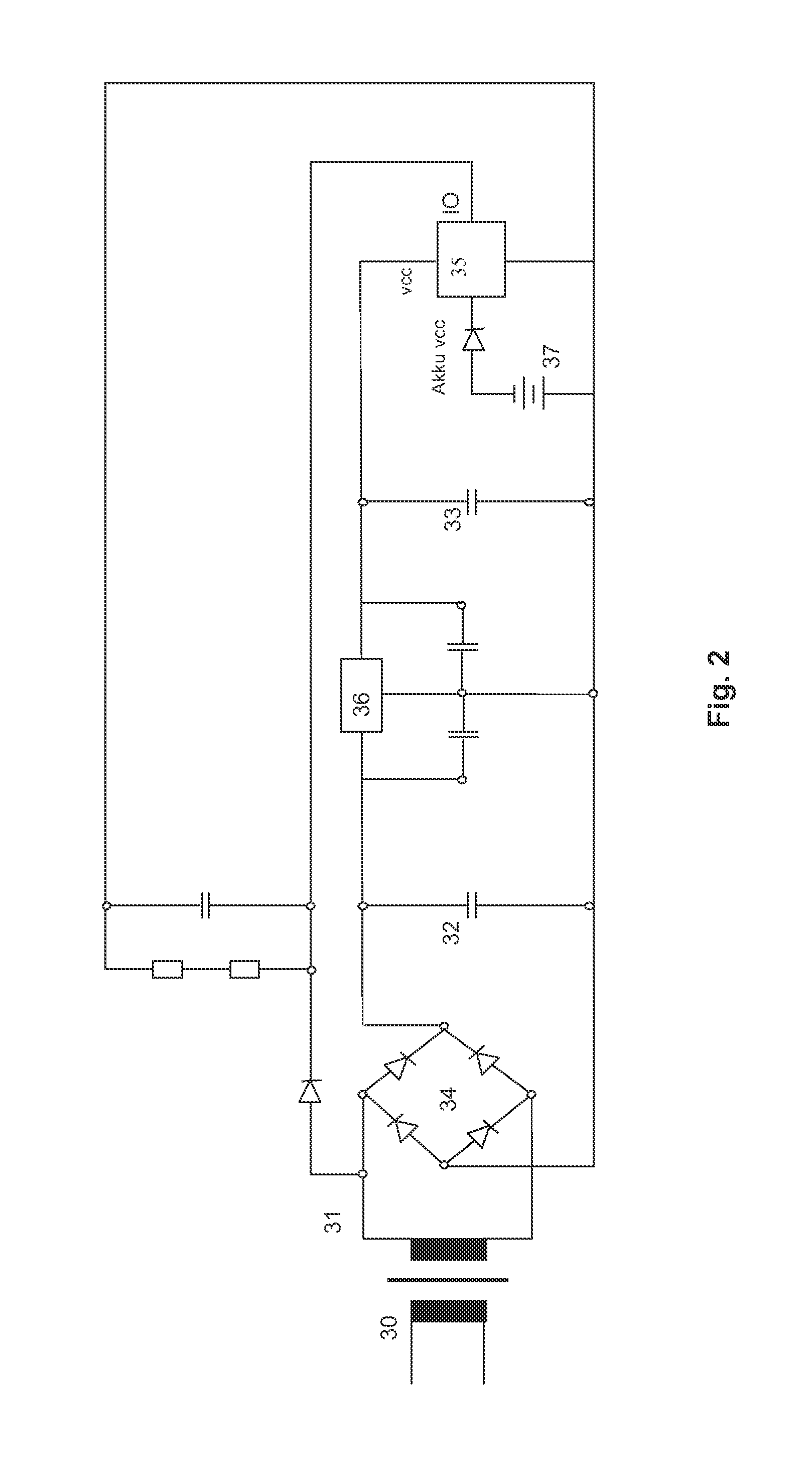

Sensor unit for remotely actuating a vehicle door, vehicle door having the sensor unit and method of producing the sensor unit

InactiveUS20130293245A1Reduce the impact of interferenceReduced measurement accuracyContact member assembly/disassemblyVehicle locksElectricityElectrical conductor

A capacitive sensor unit is not susceptible to failure and remotely actuates a door of a vehicle. The sensor unit contains an electrode assembly having an elongated sensor electrode and a supply line for electrically connecting the sensor electrode to an evaluation unit. The supply line is surrounded by a shield. An additional ground conductor, which is electrically conductively connected to the shield over the entire length of the supply line, is connected in parallel to the supply line.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

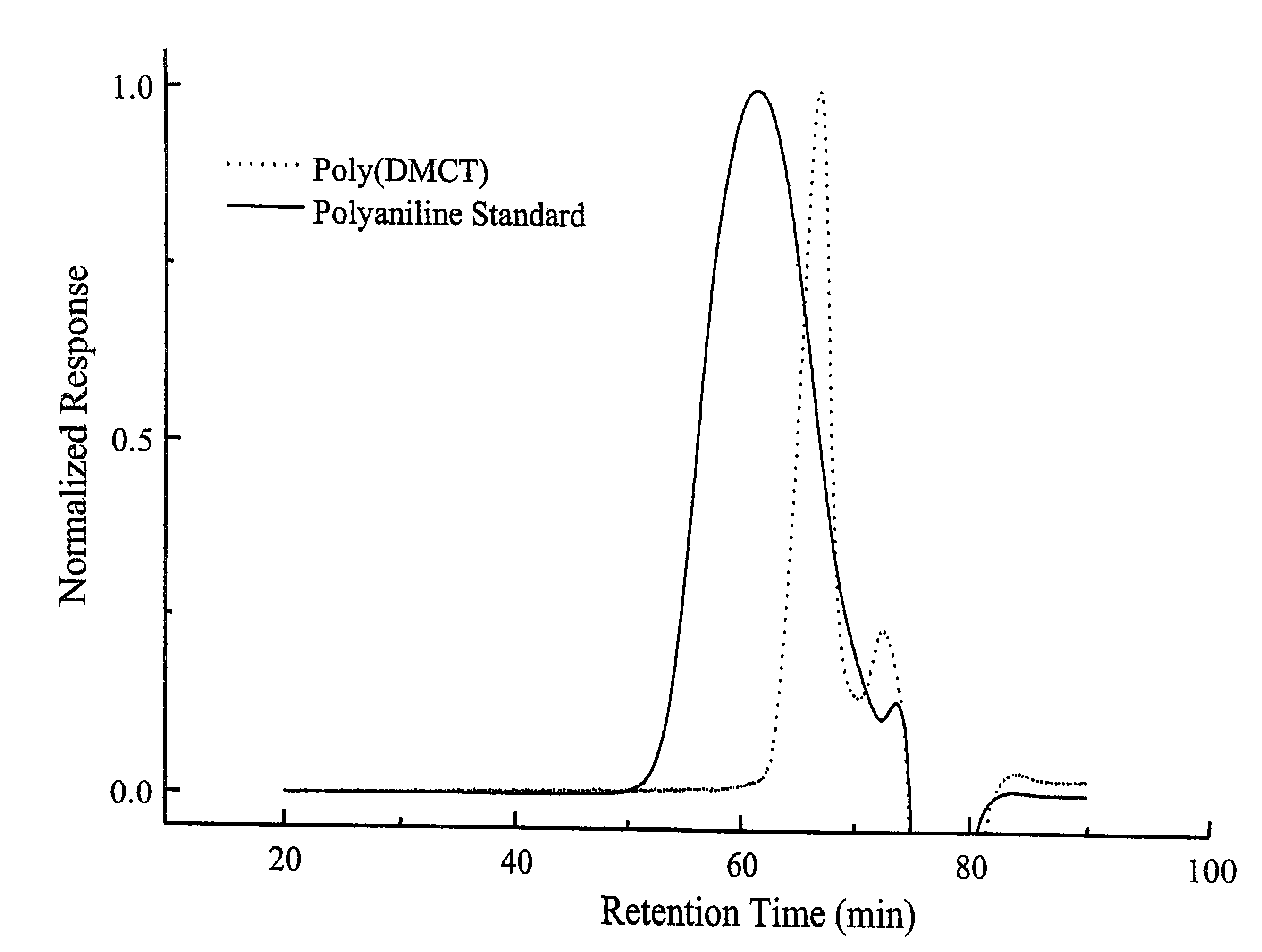

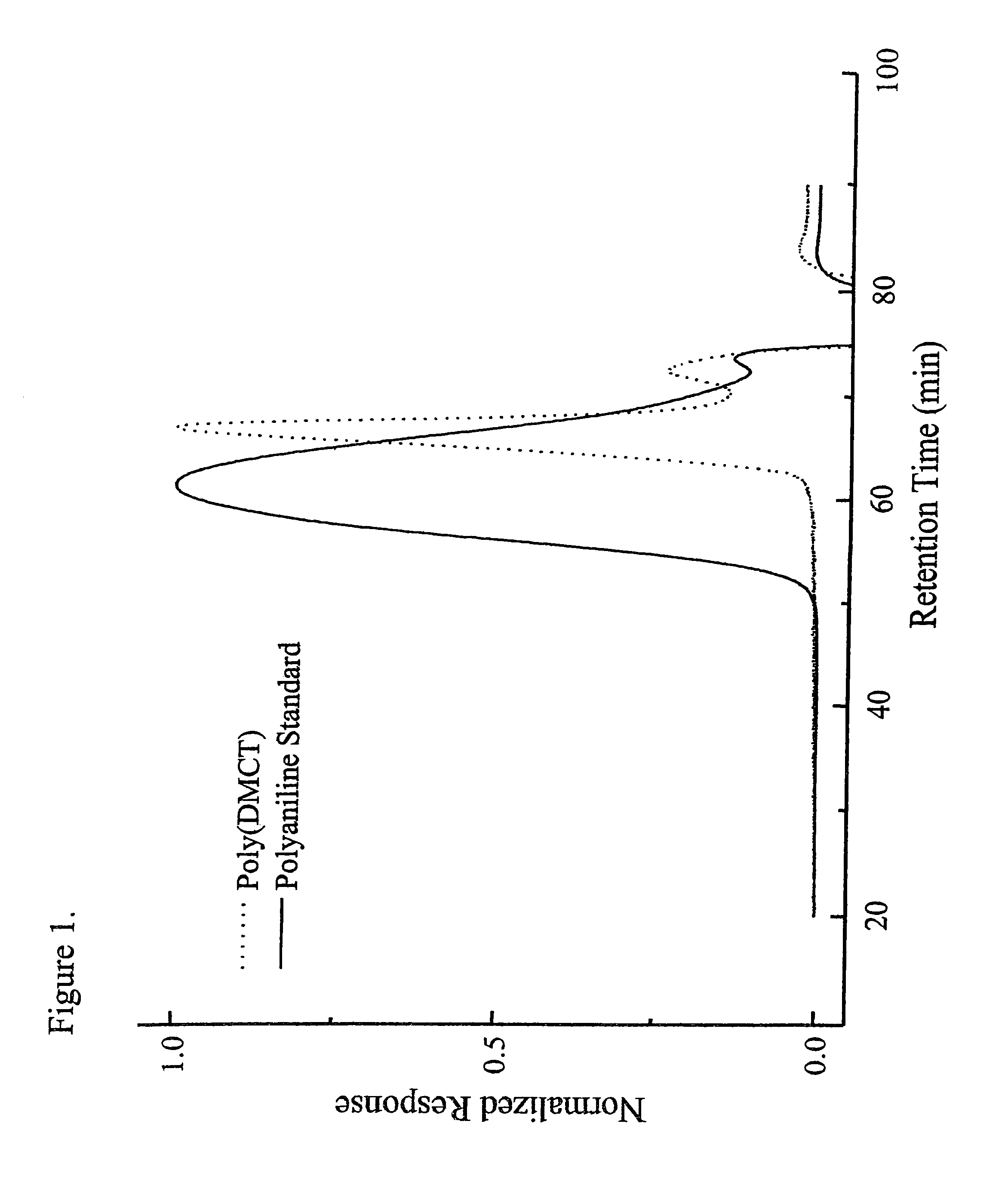

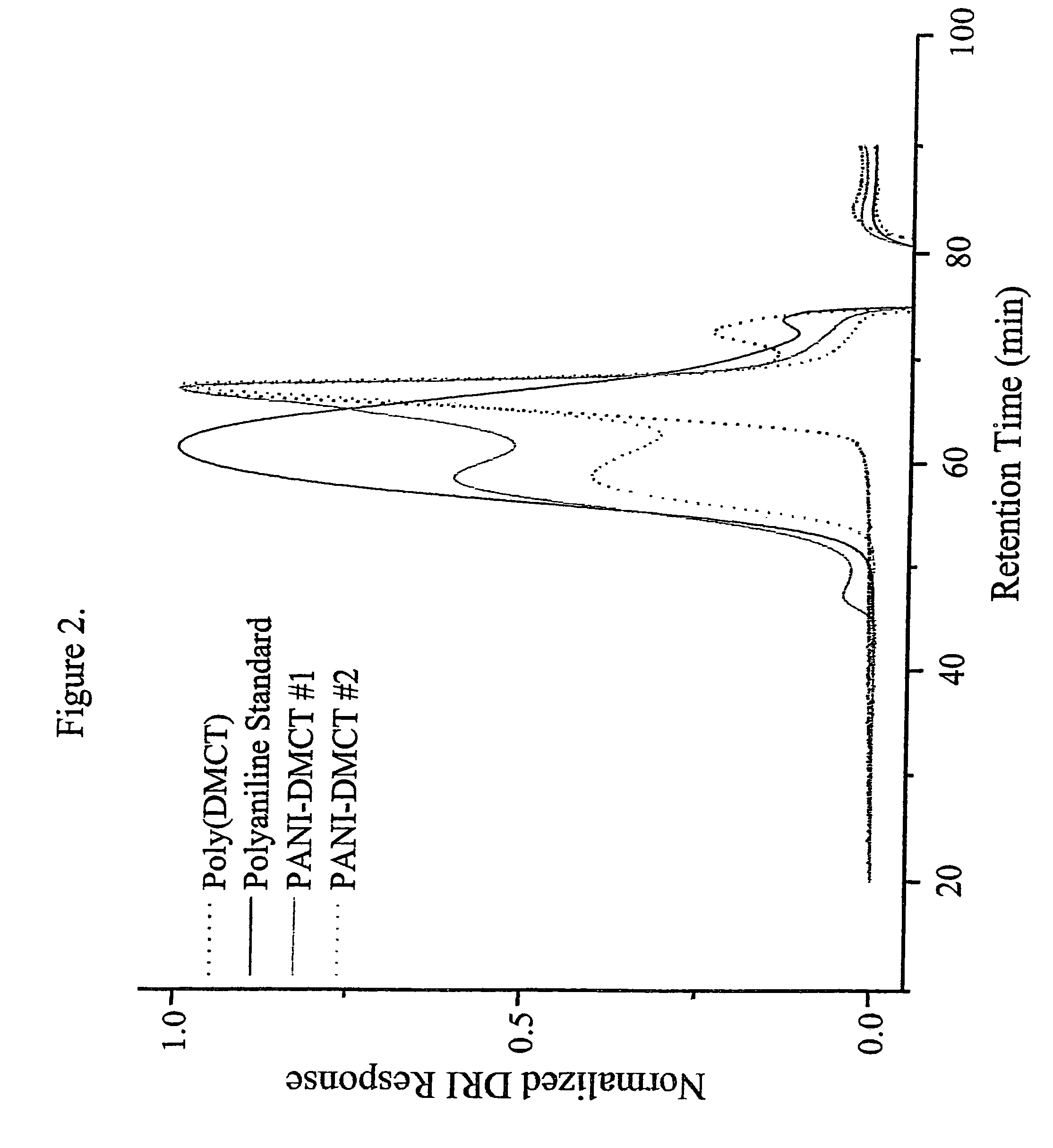

Corrosion-responsive coating formulations for protection of metal surfaces

InactiveUS7601280B2Effective corrosion protectionProvide protectionOther chemical processesConductive materialCorrosion resistantMetal

Methods and compositions are described for protecting a metal surface against corrosion. The method involves applying to the metal surface a coating formulation that comprises a radiation curable resin and a corrosion-responsive agent that is capable of releasing a corrosion-inhibiting ion in response to exposure to ionic species characteristic of those present on a metal surface undergoing oxidative corrosion; and exposing the coating formulation to radiation whereby the radiation curable resin forms a corrosion-resisting coating having a low spontaneous release rate of the corrosion-responsive agent into the environment.

Owner:LUMIMOVE

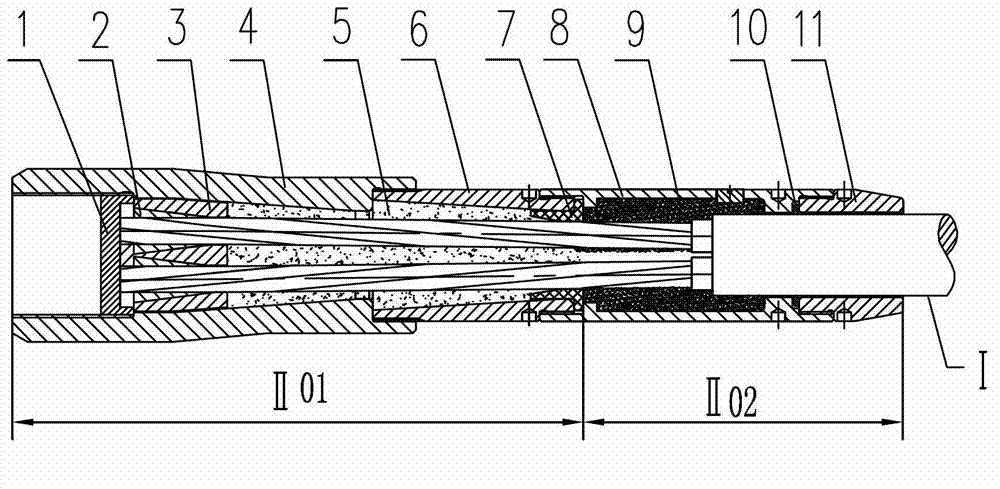

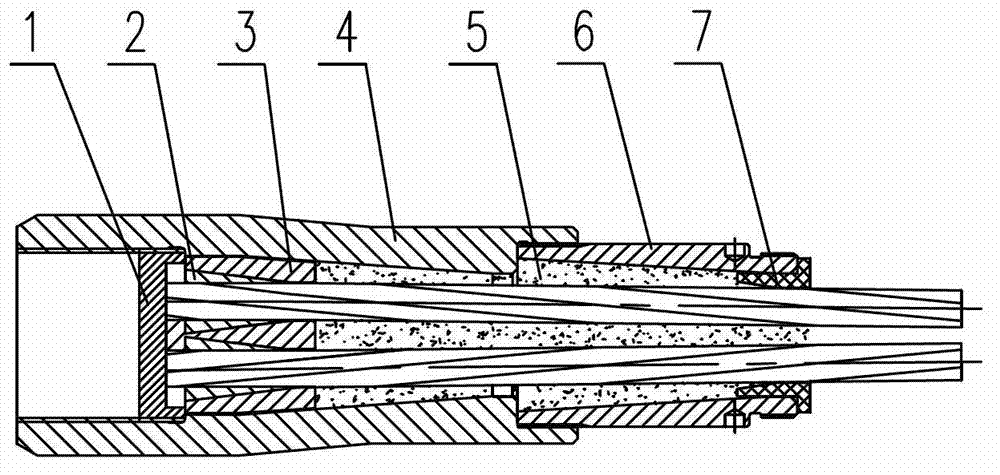

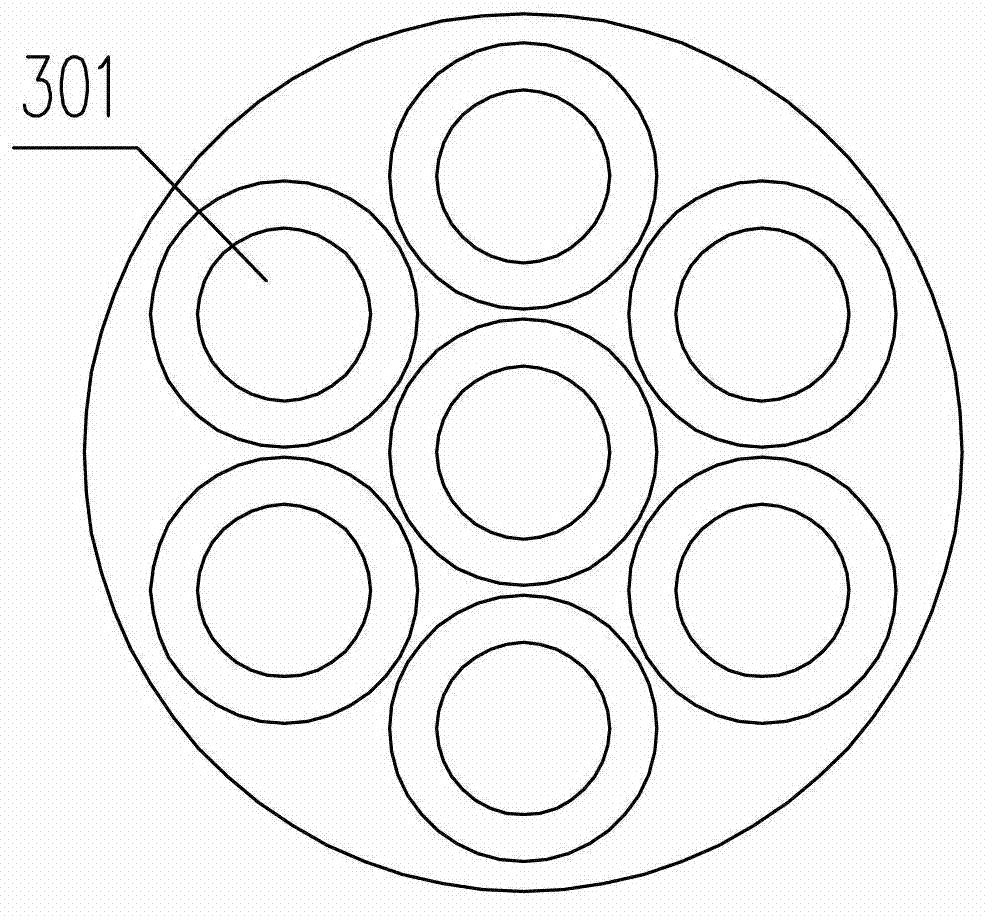

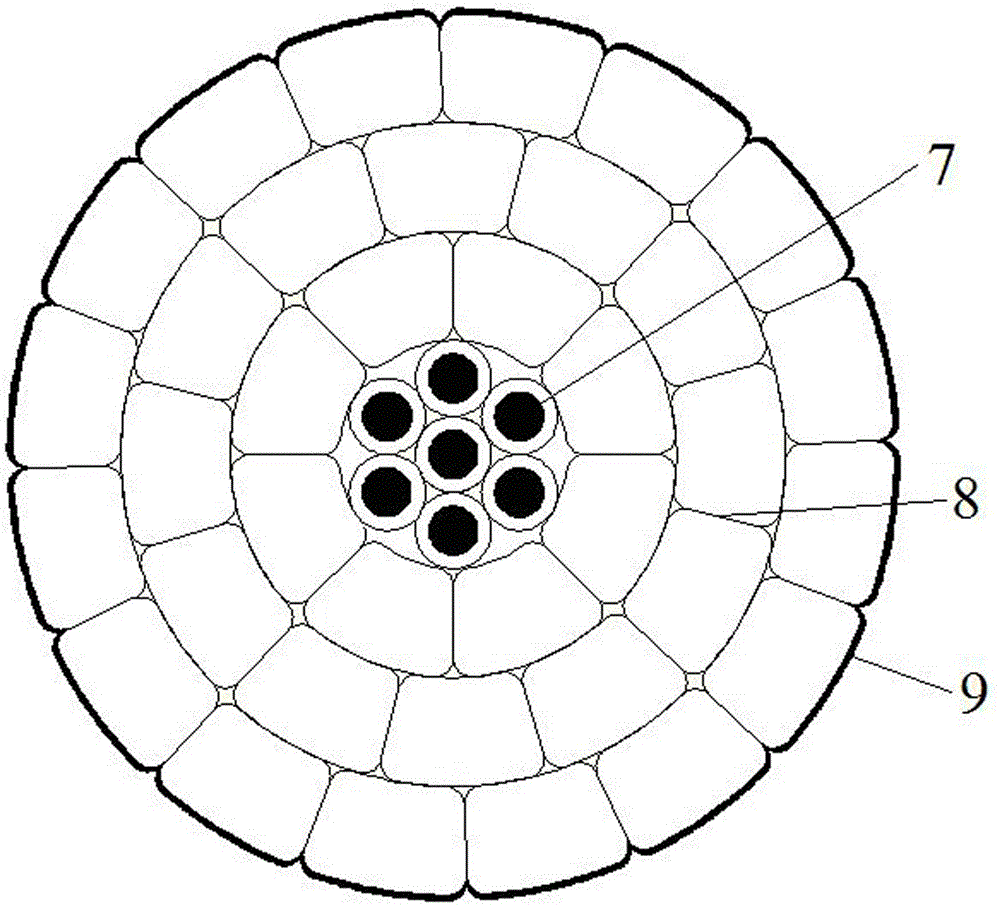

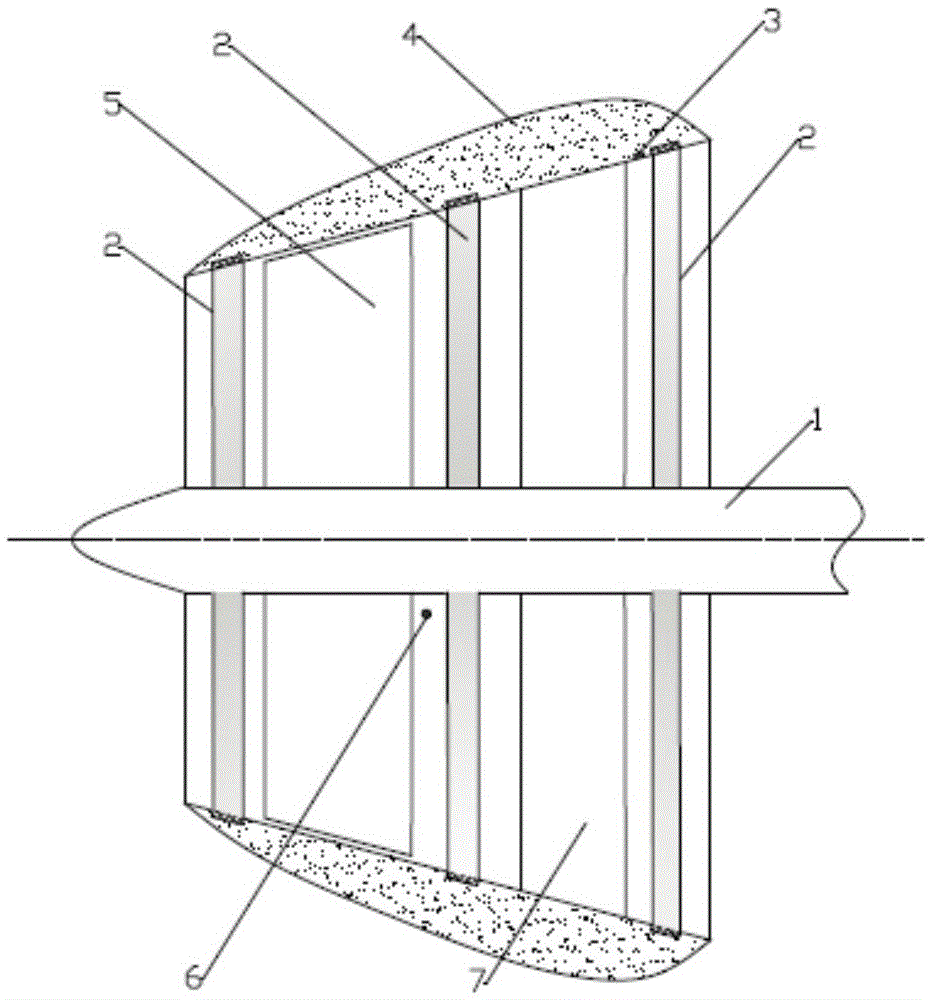

Composite strand tapered anchoring steel strand finished product cable and manufacture method thereof

InactiveCN103074851ASolve the problem of reliable clamping and anchoringGood anti-corrosion sealingBridge structural detailsShock resistanceEngineering

The invention discloses a composite strand tapered anchoring steel strand finished product cable, which comprises a cable body and two anchoring ends positioned on two ends of the cable body, wherein each anchoring end comprises an anchoring and clamping section and a sealing antiseptic section; each anchoring and clamping section comprises an end cover, a clamping piece, a wire splitting anchor plate, an anchor cup, an extension cylinder and a restriction ring; each wire splitting anchor plate is a cone with an external taper; the inner cavity of each anchor cup and the inner hole of each extension cylinder are both inner taper holes; each single steel strand of the steel strand finished product cable body is clamped on the wire splitting anchor plate by the camping piece; each wire splitting anchor plate is positioned in the inner taper hole of each anchor cup to be tightly cooperated with the inner taper hole of each anchor cup so as to form a positioning wedge-shaped anchoring structure; each extension cylinder is filled with epoxy iron sand to form a taper-shaped body which performs an auxiliary anchoring function on the steel strand finished product cable; and each sealing antiseptic section comprises a sealing cylinder, an O-shaped sealing ring and a gland. The finished cable has the advantages of high stress fatigue resistance, good shock resistance, reliable anchoring performance, compact anchorage structure and convenience in manufacture installation and anchorage change construction and is suitable for the bridge inhaul cable under the high-fatigue stress state.

Owner:LIUZHOU OVM MASCH CO LTD

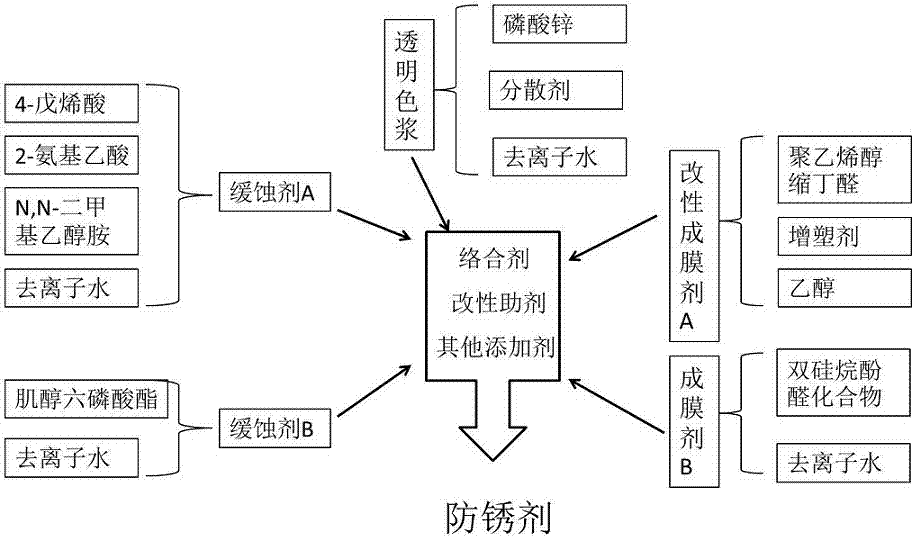

Water-based environmental protection rust inhibitor for steel parts, and preparation method and application of water-based environmental protection rust inhibitor

ActiveCN107299338AImprove anti-corrosion performanceImprove rust resistanceMetallic material coating processesWater basedSilanes

The invention provides a water-based environmental protection rust inhibitor for steel parts, and a preparation method and application of the water-based environmental protection rust inhibitor. The rust inhibitor is prepared from polyvinyl butyral and a bis-silane phenolic compound which are used as film-forming agents, a corrosion inhibitor A, a corrosion inhibitor B, zinc phosphate used as anti-rust pigment, a dispersing agent, a complexing agent, modification additives, other additives, and a solvent formed by ethanol and deionized water. An anti-rust film formed by the rust inhibitor is good in mechanical properties, high in hardness and compactness, wear-resistant and scratch-resistant, and high in impact resistance; the water-based environmental protection rust inhibitor is good in compatibility with the anti-rust pigment, environmentally-friendly and free from pollution; the rust inhibitor is good in rust prevention effect, can be cured at the room temperature and is uniform in film formation; the rust inhibitor is high in binding force with a base material; the rust inhibitor is good in high-temperature stability and low-temperature stability, and enables a whole rust removal system to be stable.

Owner:无锡市恒利弘实业有限公司

Water heater and method of controlling a water heater

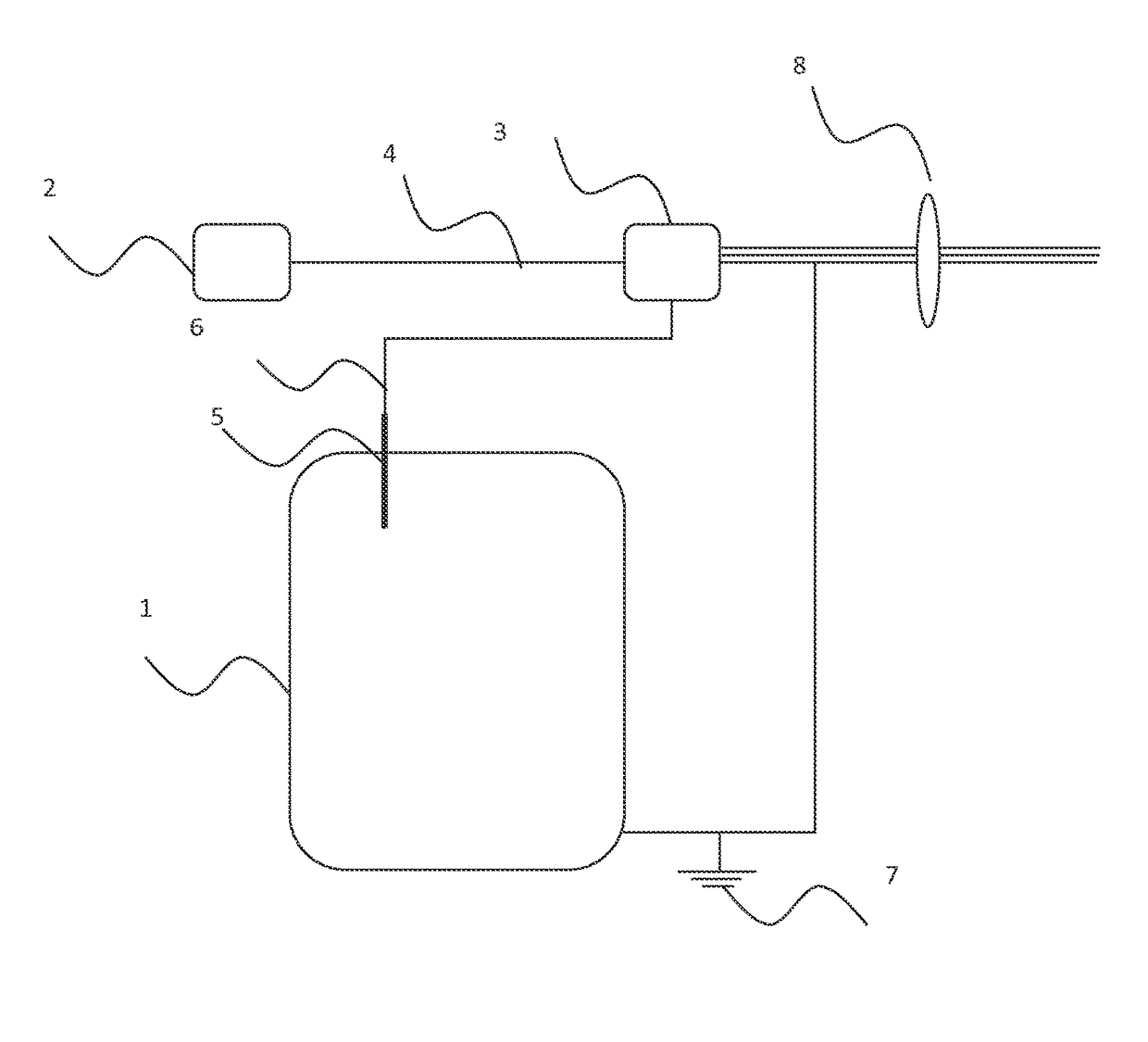

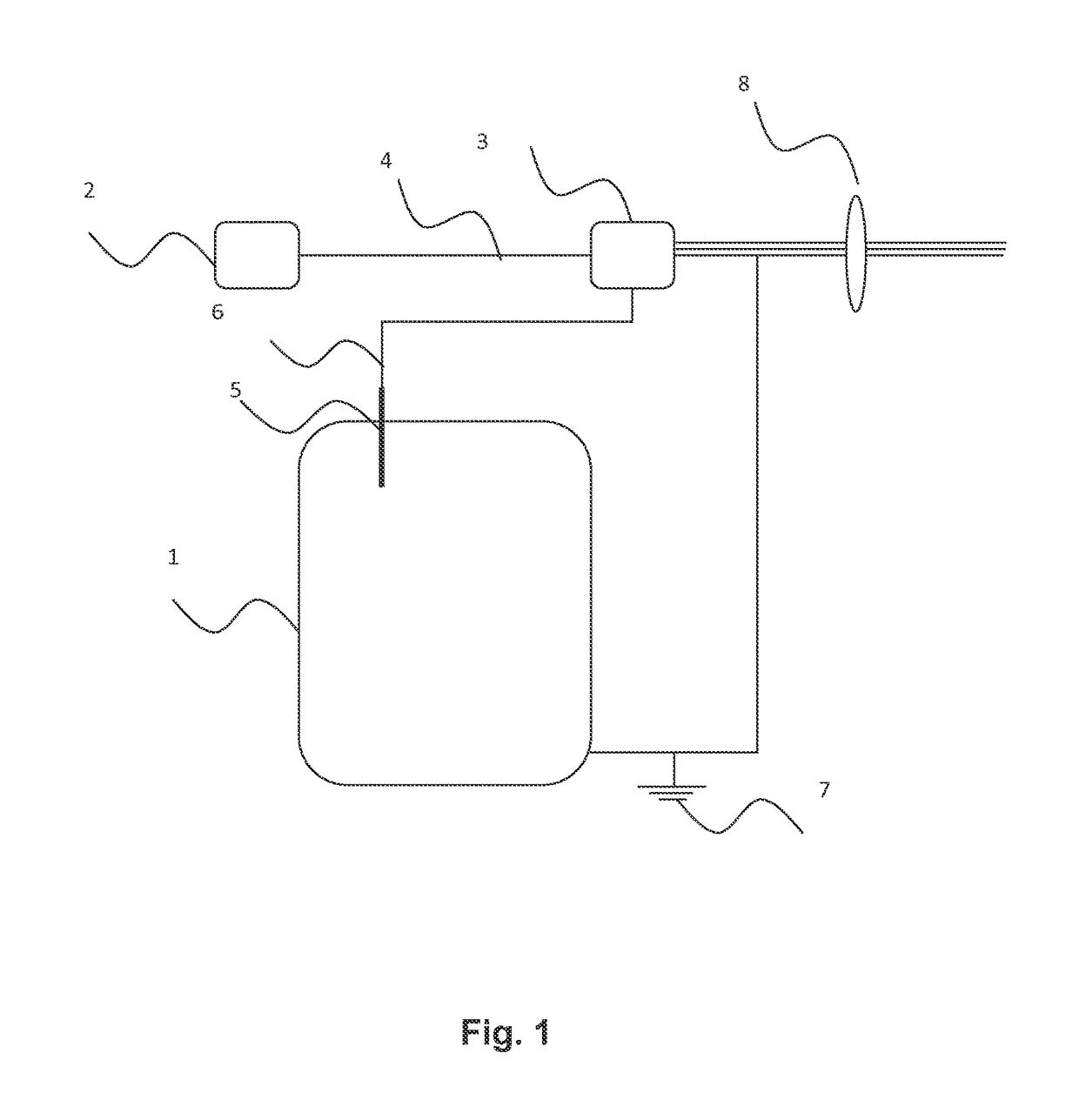

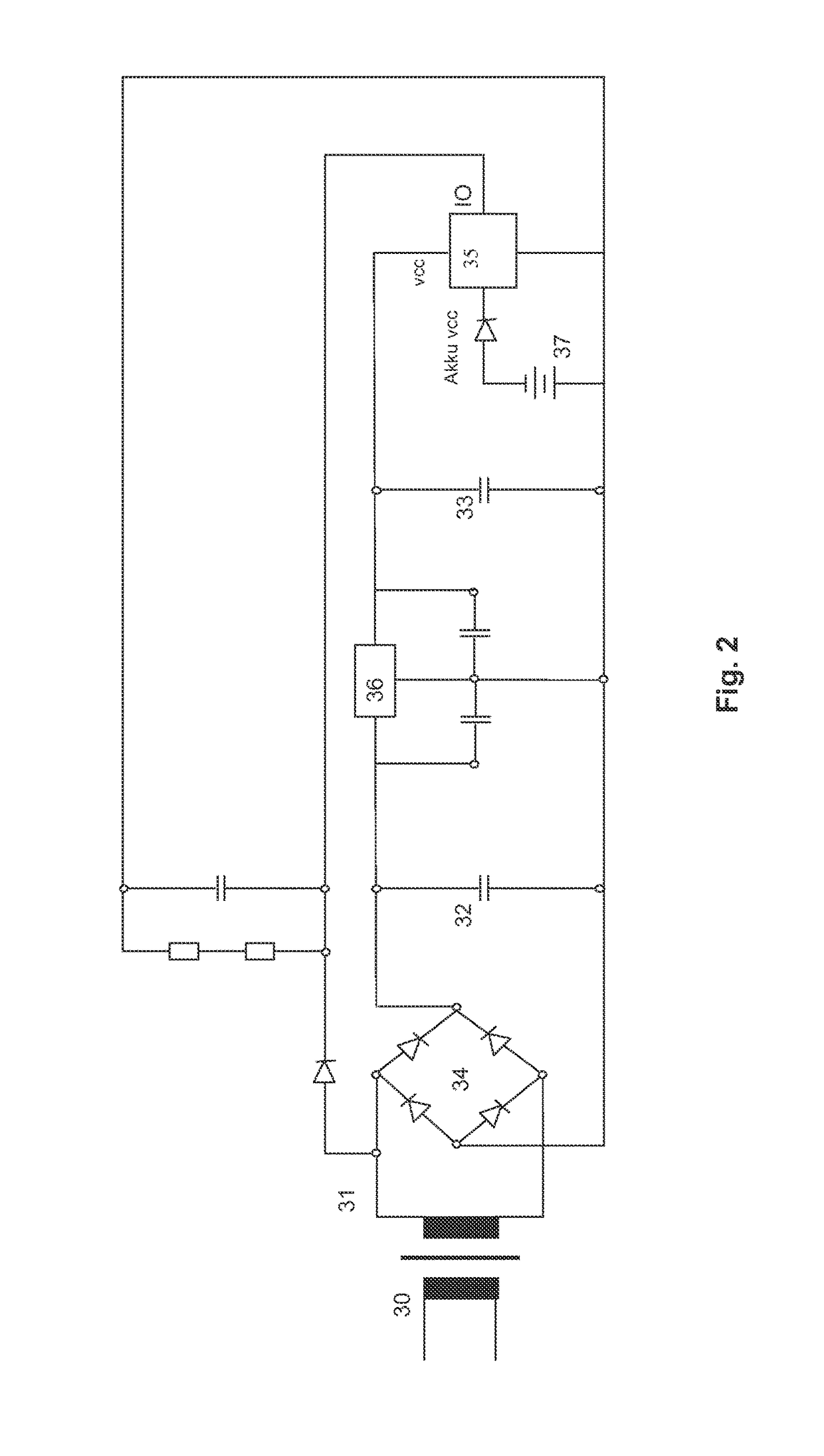

ActiveUS9657965B2Effective corrosion protectionEffective protectionMechanical apparatusImmersion heating arrangementsElectrical batteryWater storage tank

Owner:STIEBEL ELTRON GMBH & CO KG

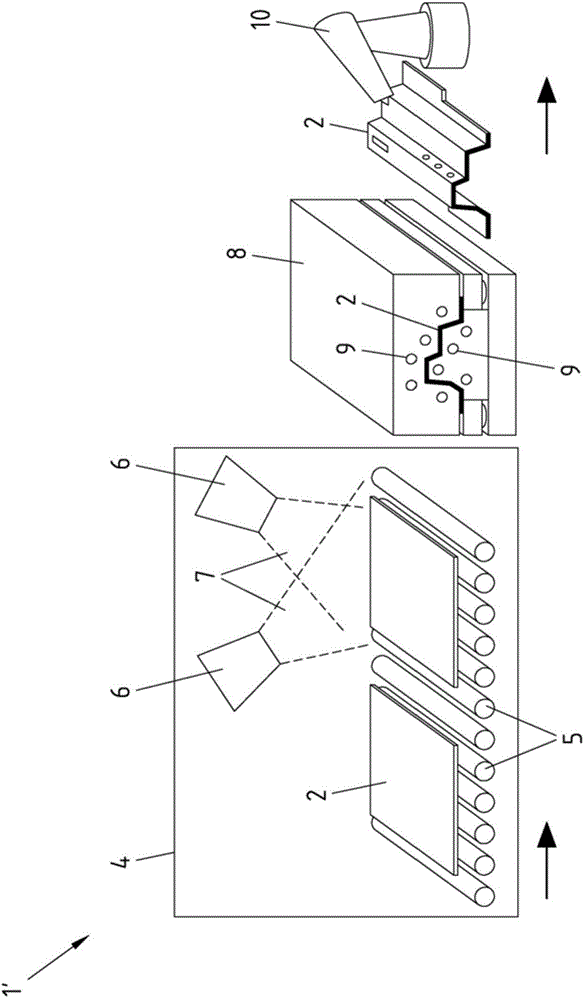

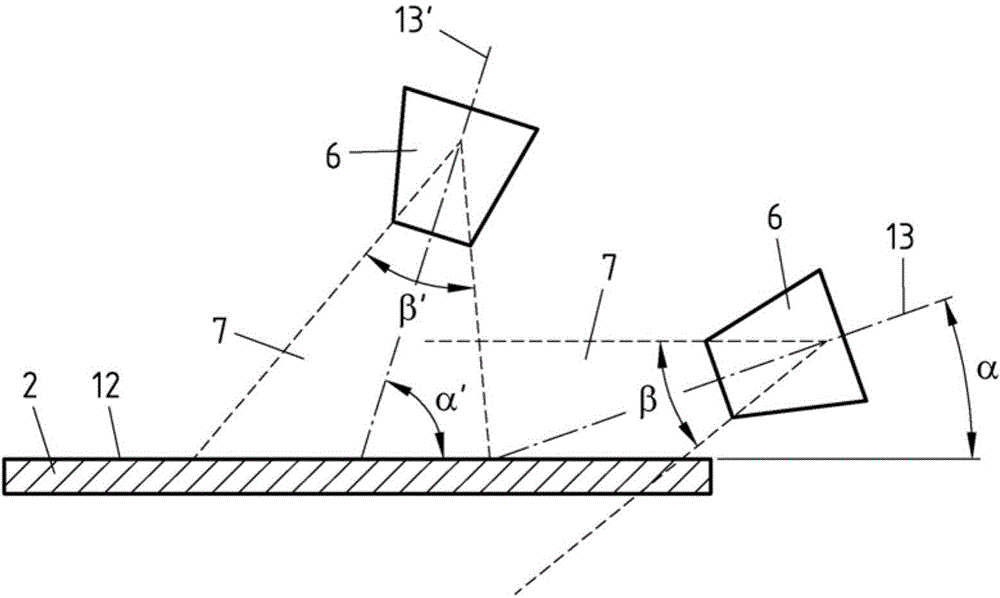

Method for the surface treatment of a workpiece

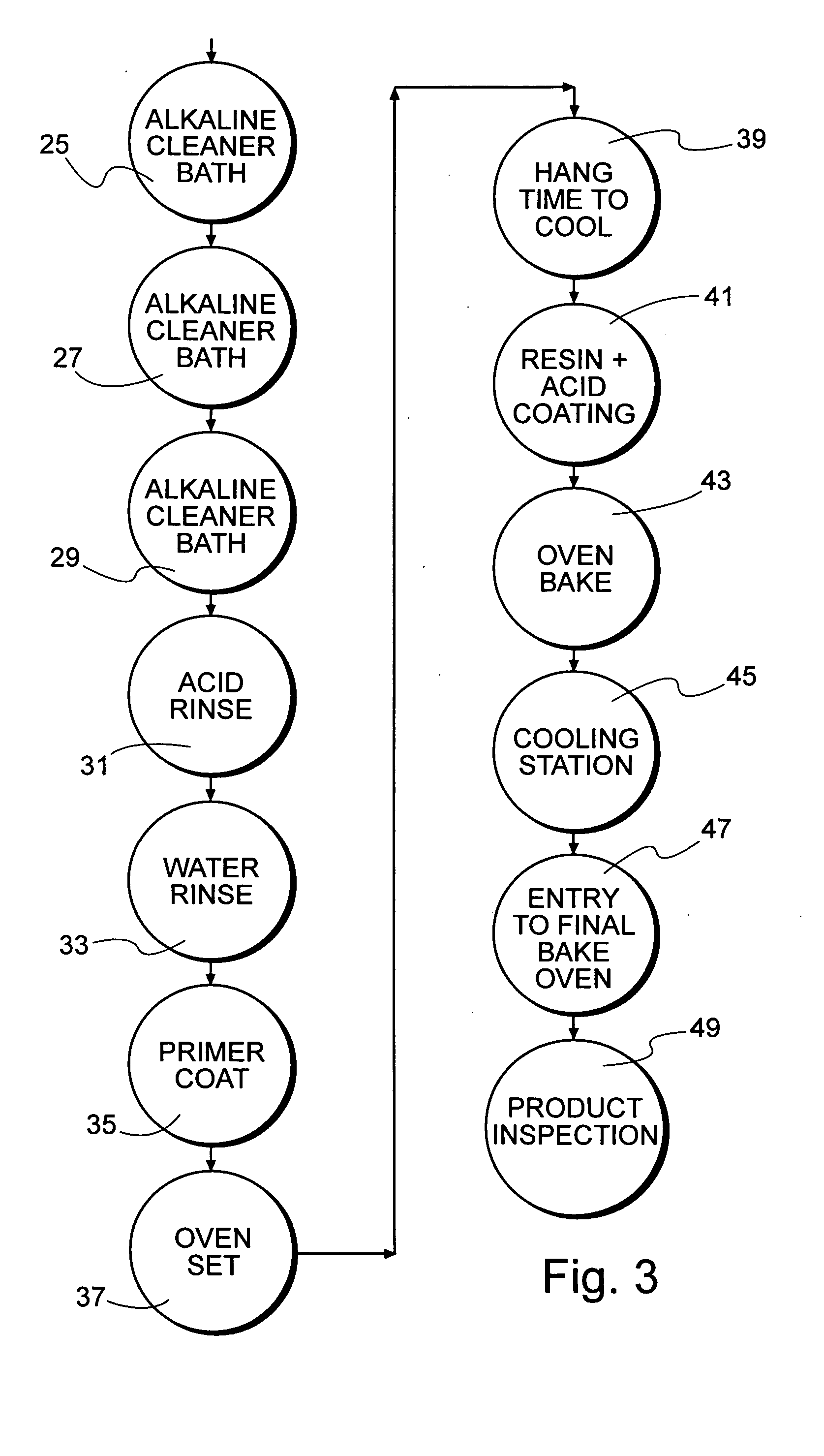

InactiveCN104818373AReduce environmental and health hazardsCleaning Step BenefitsCleaning using gasesHeat treatment furnacesSurface finishingMetal

Shown and described herein is a method for the surface treatment of workpieces, in particular of coated metal workpieces, for hot forming. In order to achieve an improved surface treatment of the workpieces, the following steps are proposed: b) partially or completely heating the workpieces to a temperature of at least Ac1, c) cleaning the workpiece surfaces of the heated workpieces with at least one pressurized air jet, d) forming the heated and cleaned workpieces, and e) cooling down the formed workpieces.

Owner:THYSSENKRUPP STEEL EURO AG

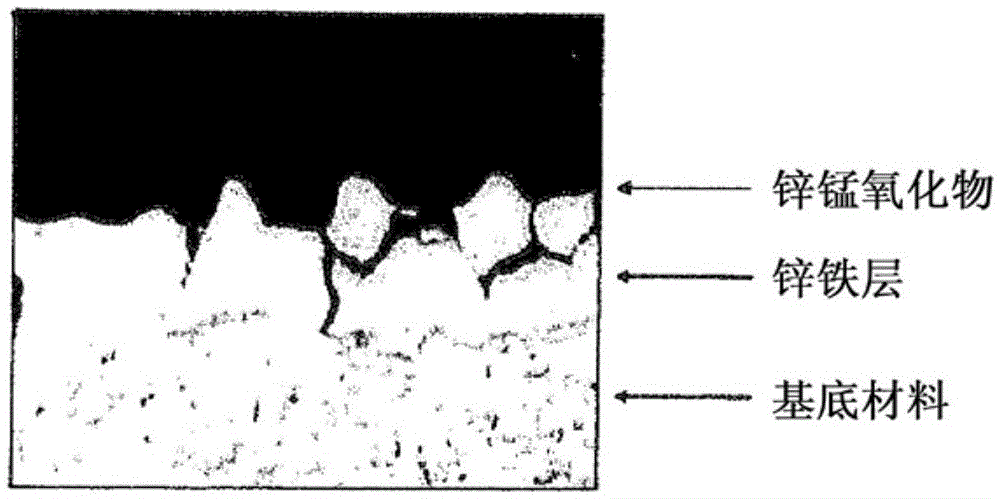

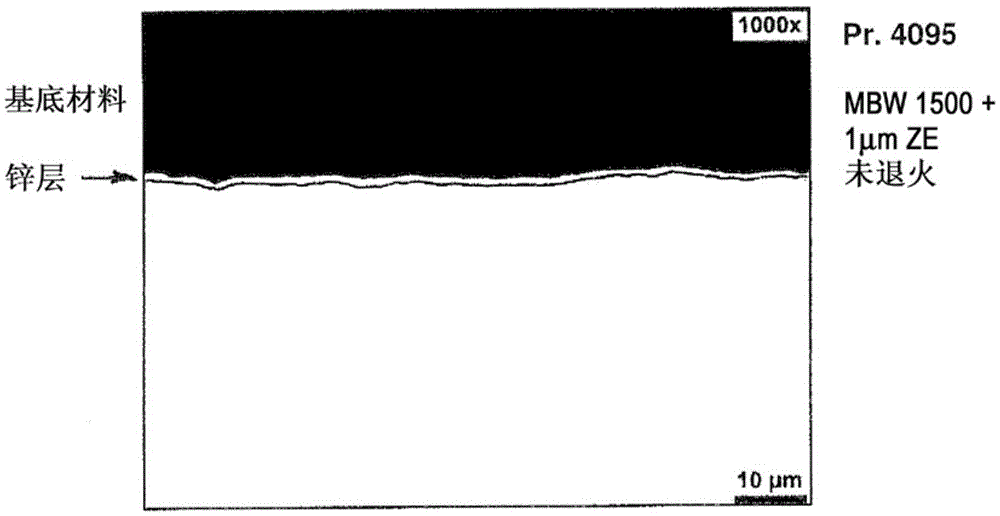

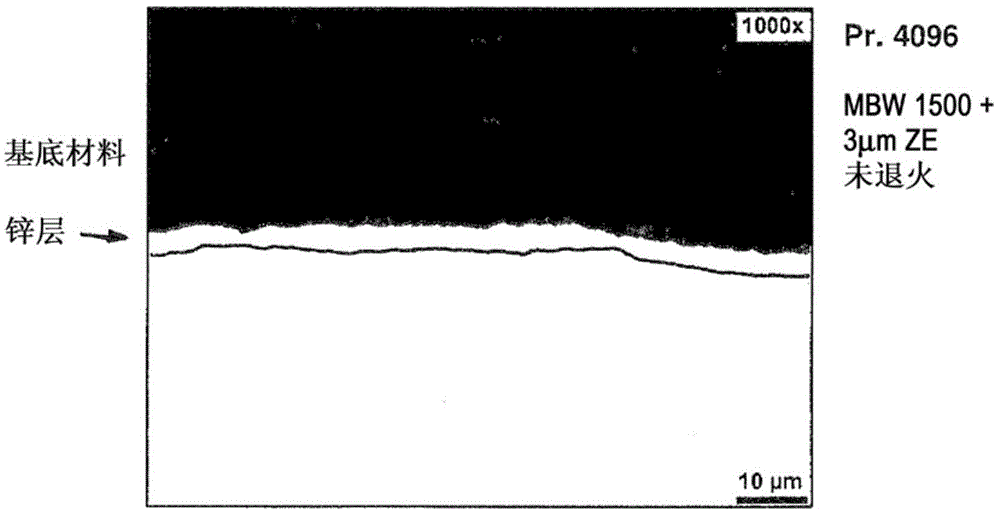

Method for producing a steel component provided with a metallic coating providing protection against corrosion

InactiveCN105531404AReduce absorptionDifferent intensityFurnace typesIncreasing energy efficiencyElectrolysisLayer thickness

The invention provides a method by which a steel component provided with a metallic coating which has good adhesion and provides protection from corrosion can be produced. The problem addressed by the invention is especially that of specifying a corresponding hot forming process which enables a wide range of processing variants. The emphasis here is not on long-lasting corrosion protection but more on high flexibility of the processing properties. For this purpose, a thin zinc layer having a mean layer thickness of less than 5 mum, preferably in the range of 1-4 mum, more preferably in the range of 2-4 mum, is applied by electrolytic means to a flat steel product consisting of a steel material which can be annealed by quenching in a hot forming process and has a yield point of 150-1100 MPa and a tensile strength of 300-1200 MPa. A billet is then obtained from the flat steel product and is heated directly to at least 800 DEG C and then formed to give the steel component, or is first formed to give the steel component which is then heated to at least 800 DEG C. The steel component obtained in each case is subsequently annealed by cooling it with sufficient speed from a sufficiently high temperature.

Owner:THYSSENKRUPP STEEL EURO AG

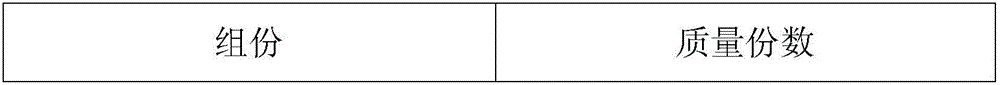

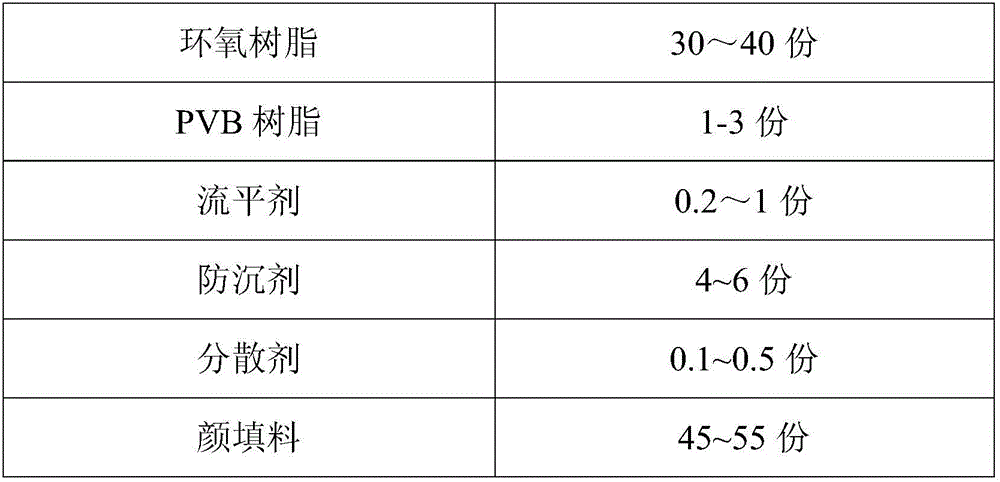

Quick-drying type epoxy primer and preparation method thereof

InactiveCN106433387AReduce pollutionEffective corrosion protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyPerformance index

The invention discloses a quick-drying type epoxy primer and a preparation method thereof. The quick-drying type epoxy primer comprises the following components in parts by weight: 30-40 parts of epoxy resin, 0.2-1 part of leveling agent, 4-6 parts of anti-settling agent, 0.1-0.5 part of dispersant, 45-55 parts of pigment and filler, and 1-3 parts of drier. According to the technical scheme of the invention, all the performance indexes of the paint film of the primer completely reach or even exceed the indexes of commercial epoxy primers. At the same time, the quick-drying type epoxy primer is strong in versatility, and the paint film of the primer is quick to dry. Therefore, the coating period is greatly shortened.

Owner:江苏足迹涂料有限公司

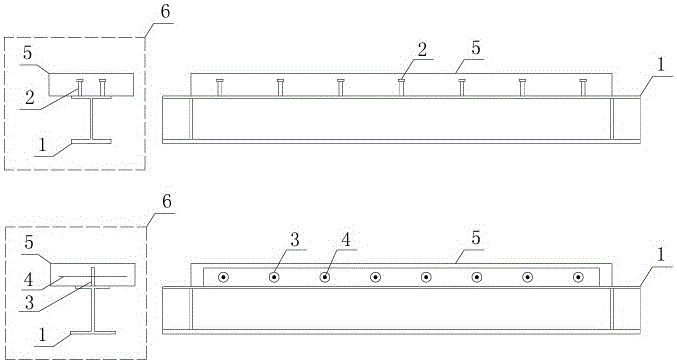

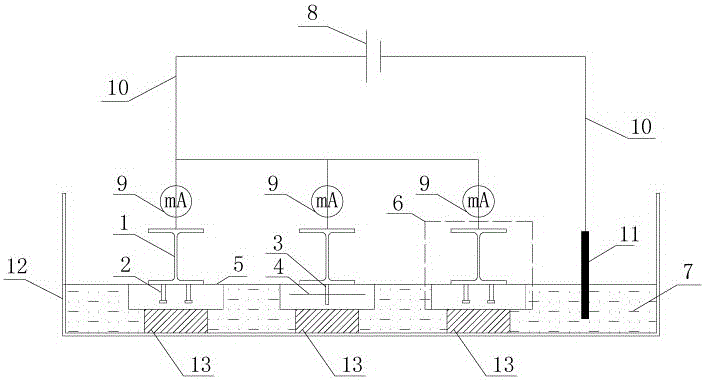

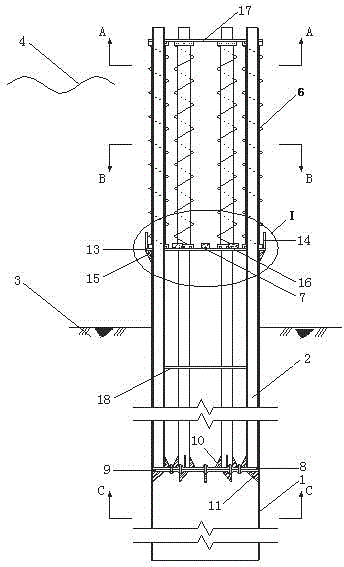

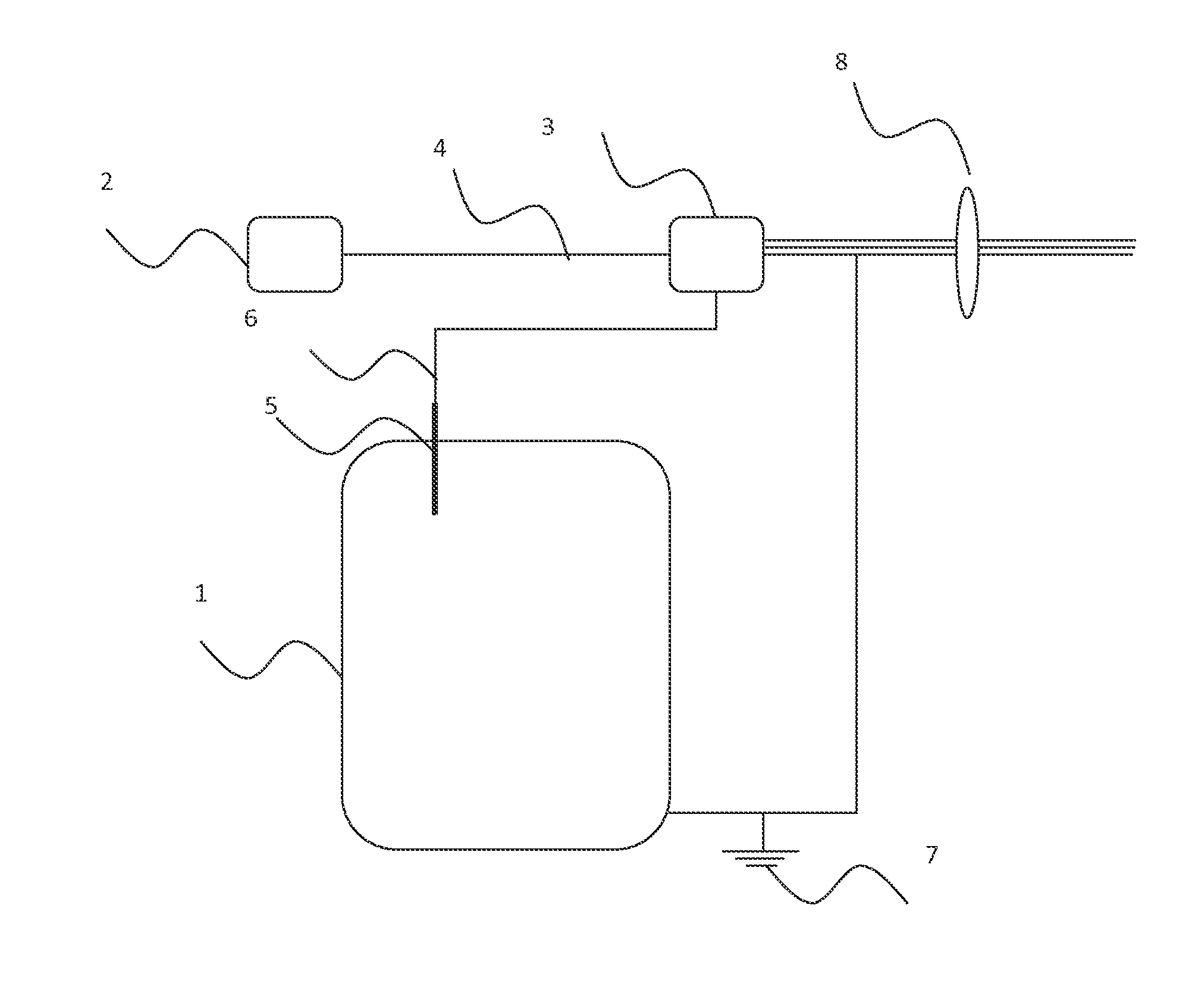

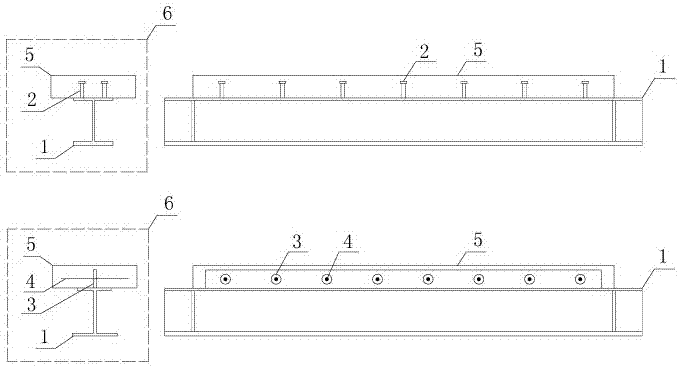

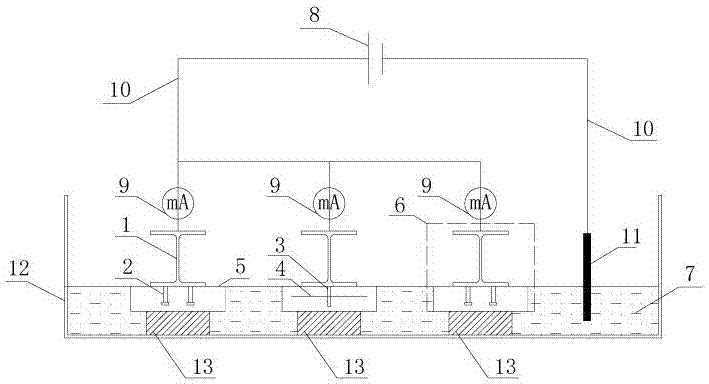

Corrosion testing device and method for steel-concrete composite beam shear connector

ActiveCN105115886AWide range of applicationsEffective corrosion protectionWeather/light/corrosion resistancePower flowAnode

The invention discloses a corrosion testing device and method for a steel-concrete composite beam shear connector. The device comprises a corrosion pool used for containing an electrolytic solution and soaking a concrete wing plate, a steel-concrete composite beam serving as an electrolytic anode, and an electrolysis circuit, wherein the steel-concrete composite beam is mainly composed of a steel beam, the shear connector and concrete, the shear connector is welded to the steel beam, the concrete is poured outside the shear connector, and the electrolysis circuit comprises an ampere meter connected with the anode, a direct current power source and a cathode. According to the method, the steel-concrete composite beam is reversely buckled into the corrosion pool to enable the electrolytic solution to well soak the concrete wing plate, the power source is connected, and currents are recorded. The method is wider in application range and suitable for various shear connectors such as a stud connector and a PBL connector, coincides with the practical situation better, and can simulate the true corrosion condition of the steel-concrete composite beam shear connector.

Owner:SOUTHEAST UNIV

Protective coating compositions and techniques for fluid piping systems

InactiveUS20050074567A1Corrosion resistanceEffective corrosion protectionCorrosion preventionPipe protection against corrosion/incrustationMetallurgyMaterials science

A corrosion resistant coating technique is shown for use with iron and steel pipe, components and accessories. In one form, the corrosion resistant coating used is an aqueous phenolic resin dispersion. An improved coating for ductile iron pipe is shown which utilizes Lord METALJACKET™ Coating sold by Lord Corporation of 1625 Riverfork Drive East, Huntington, Ind. 46750.

Owner:TERRAMIX

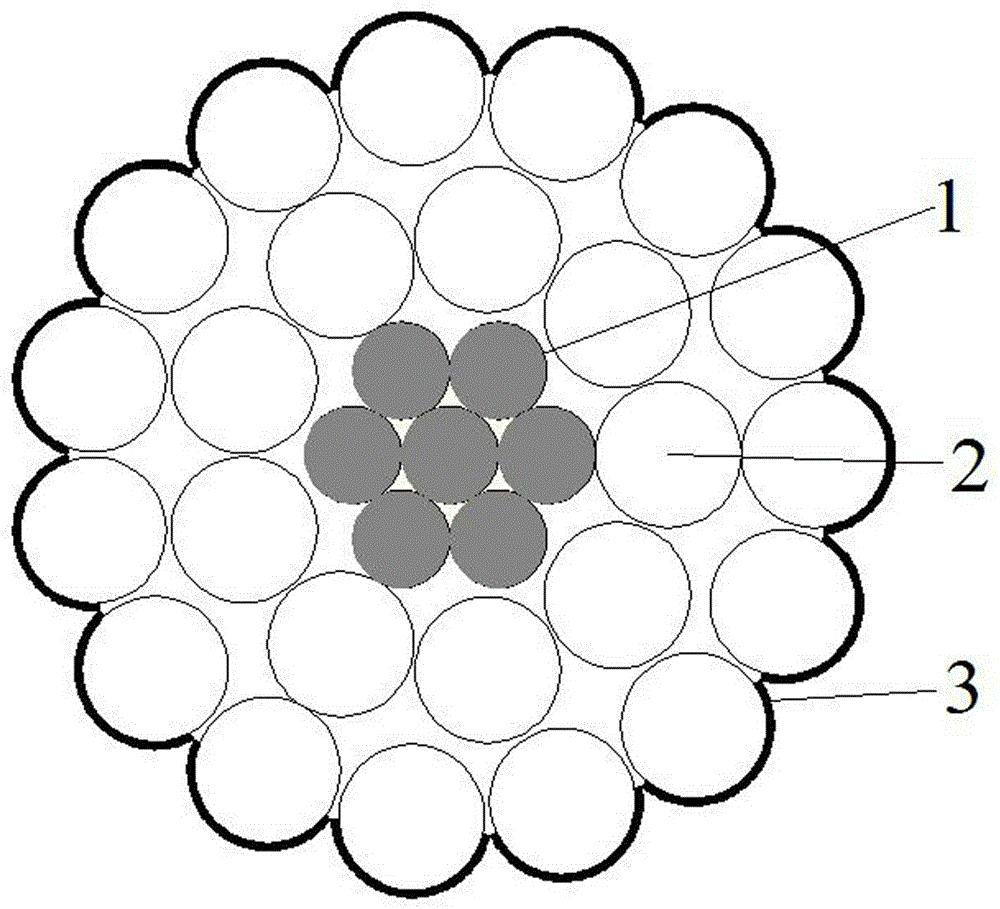

Surface-treated cooled wire

InactiveCN104835553ANo differentiationHigh chemical inertnessNon-insulated conductorsCarrying capacityElectrical conductor

The inventions relates to a surface-treated cooled wire and to the field of overhead conductors, and specifically to a novel cooled wire with a surface coated with high-radiation lowly-endothermic coating. The surface-treated cooled wire comprises central reinforcing cores, conductors, and an outermost coating. The conductors are stranded on the outer side of the central reinforcing cores and are coated with the outermost coating. The outermost coating is a high-radiation lowly-endothermic coating layer and is a fluorocarbon coating containing fluorocarbon element. The surface-treated cooled wire is easy to manufacture, low in cost increase, decreased in used temperature, and resistant to weather and corrosion. The outermost coating forms a permanent layer with high-radiation lowly-endothermic coating on the surface of the surface-treated cooled wire. Compared with a wire with same specification, the novel surface-treated cooled wire is decreased in surface temperature by 5 to 20 degrees centigrade in the case of same current-carrying capacity. As a result, line energy loss in a transmission process is reduced and low-carbon economy is achieved.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

High-performance structural adhesive as well as preparation method and construction method thereof

ActiveCN111607346AHigh bonding strengthGood weather resistanceNon-macromolecular adhesive additivesBridge erection/assemblyEpoxyFiber

The invention discloses a high-performance structural adhesive as well as a preparation method and a construction method thereof. The preparation method comprises the following steps of: mixing and stirring 100 parts of E-44 epoxy resin, 5-30 parts of a mixed solution of potassium silicate and sodium silicate, 20-180 parts of silica powder, 5-30 parts of nano calcium carbonate and 1-4 parts of micron carbon fibers to prepare a mixture A; mixing and stirring 20 parts of polyamide, 30 parts of aromatic amine, 20-60 parts of silica powder, and 1-2 parts of micron carbon fibers to obtain a mixtureB; selecting the mixture A and the mixture B according to the mass ratio of 2: 1, mixing and stirring the selected mixture A and mixture B, and putting an obtained mixture into a closed container soas to subject the mixture to vacuum-pumping and bubble-removing treatment to obtain the high-performance structural adhesive. The high-performance structural adhesive has the advantages of high bonding strength, good weather resistance and durability, few bubbles, excellent waterproof and anti-corrosion effects, high liquidity, environmental friendliness, convenience in construction and the like,has good market prospects and is suitable for popularization.

Owner:GUANGXI UNIV

Low-conductivity cooling liquid and preparation method thereof

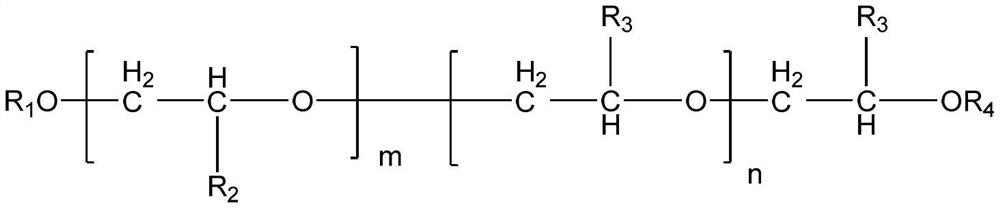

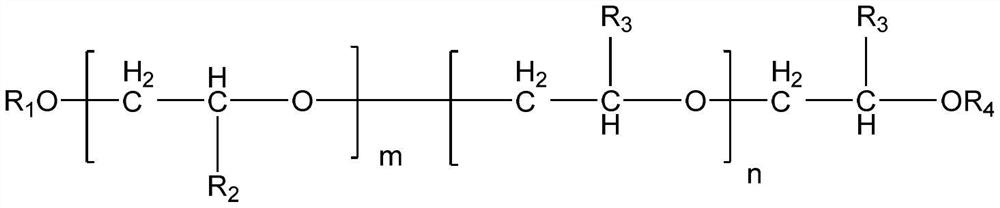

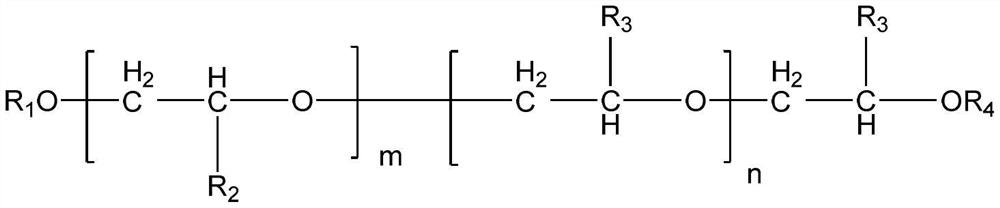

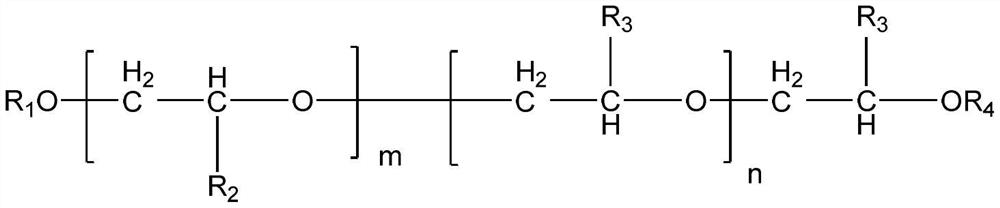

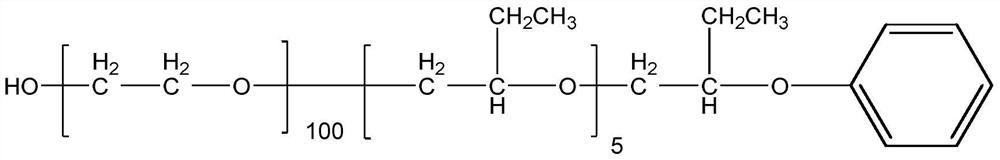

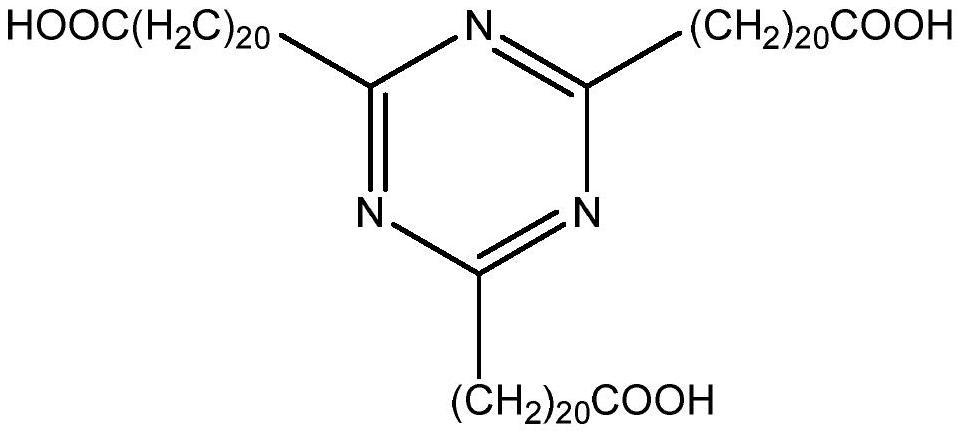

InactiveCN112745809AEffective corrosion protectionCompatibleHeat-exchange elementsTricarboxylic acidCarboxylic acid

The invention discloses a low-conductivity cooling liquid and a preparation method thereof. The cooling liquid comprises the following raw materials in parts by weight: 10-50 parts of deionized water, 50-90 parts of ethylene glycol, 0.01-10 parts of a multi-effect compound preservative and 0.001-0.1 part of a defoaming agent. The preparation method comprises the following steps: A, mixing qualified deionized water with ethylene glycol at 20-60 DEG C, and stirring for 10-30 minutes to form a solution 1; B, mixing polyether, poly(tricarboxylic acid) and dicarboxylic acid in the multi-effect compound preservative according to a certain proportion at 50-70 DEG C, and stirring for 30-60 minutes; C, at the temperature of 50-70 DEG C, adding the multi-effect compound preservative and a defoaming agent into the solution 1, and stirring for 30-60 minutes to form a solution 3; and D, filtering the solution 3 through cation exchange resin to obtain the product. The cooling liquid has the characteristics of low conductivity, good corrosion resistance and good rubber compatibility.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

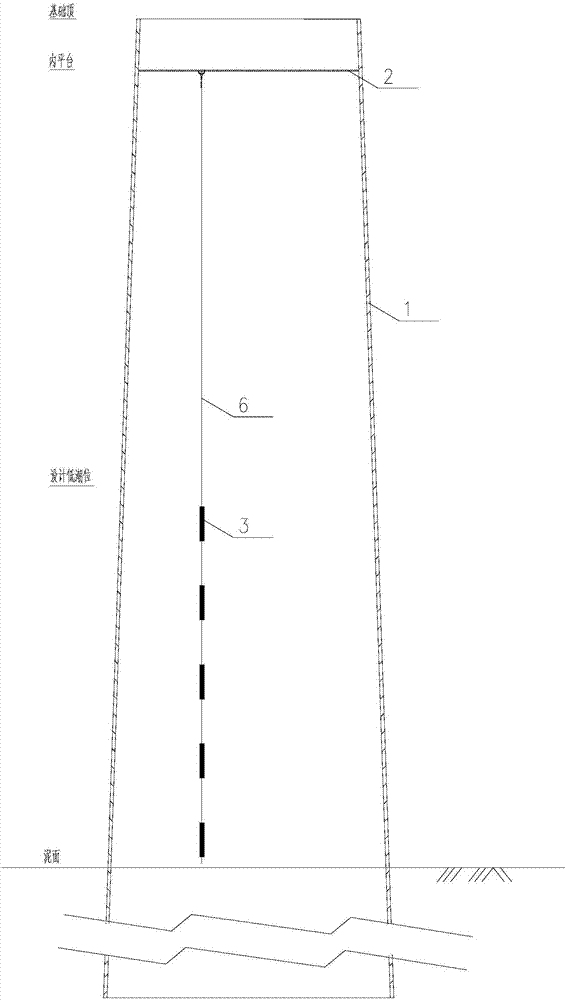

Combined steel pipe pile for reducing wave force and seawater corrosion

InactiveCN104153387AGuaranteed vertical stiffnessLower water surfaceProtective foundationMarine site engineeringSea levelSeawater

A combined steel pipe pile for reducing wave force and seawater corrosion comprises a large-diameter steel pipe pile and a plurality of small-diameter steel pipe piles; the bottom of the large-diameter steel pipe pile is mounted below the seabed level; the top of the large-diameter steel pipe pile is above the seabed level; the small-diameter steel pipe piles are evenly and vertically welded in the large-diameter steel pipe pile; the top of each small-diameter steel pipe pile is above the sea level; the bottom of each small-diameter steel pipe pile is below the seabed level; the top end of the large-diameter steel pipe pile is abutted to a construction guard cylinder; each small-diameter steel pipe pile inside the construction guard cylinder is sleeved with a vortex remover; an anti-corrosion device is disposed between each two adjacent small-diameter steel pipe piles; an upper flange is horizontally welded at the bottom of each small-diameter steel pipe pile; the upper flanges are fixed to a lower flange welded on the inner wall of the large-diameter steel pipe pile. The combined steel pipe pile has the advantages that the acting force of small waves upon a pile foundation is effectively reduced, the capacity of the pile foundation to resist wave bending moment is enhanced, the pile foundation is less corroded by the pile foundation, and the pile foundation is more adaptive to severe sea conditions and safer.

Owner:HOHAI UNIV

An integrated control method for anti-corrosion and anti-fouling of water jet propulsion channel system

The invention belongs to the technical field of ship corrosion and fouling prevention and relates to an anti-corrosion anti-fouling integrated control method for a flow channel system of a water-jet propeller. The method comprises the following steps: designing the anodic working area according to a polarization curve of total protection current and an anode, designing an embedded anodic structure pattern along water flow according to the characteristics of a flow channel structure, controlling a multi-channel switch type constant-potential instrument to output current based on a reference electrode B during operation of the flow channel system of the water-jet propeller, and enabling the cathodic protection potential of the flow channel to be -0.80V; detecting the anodic potential through a reference electrode A, controlling the flow channel system of the water-jet propeller to automatically adjust the output current, detecting the cathodic protection potential of the flow channel, and keeping operation of the flow channel system of the water-jet propeller when the potential is -0.80V to -1.05V through measurement, so that the anti-corrosion anti-fouling integrated control is realized. According to the method, a power supply is small in size, convenient to mount and environmentally friendly; the auxiliary anode is low in cost, long in service life, scouring-resistant, low in consumption rate, good in reliability and long in maintenance cycle; the potentials in the flow channel are uniformly distributed.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Water-based environment-friendly coating and construction method

The invention discloses a water-based environment-friendly coating and a construction method. The water-based environment-friendly coating is characterized in that a netted glass fiber cloth is arranged on a cement wall or cement ground. The water-based environment-friendly coating includes fine sand, medium sand, wood fiber, a thickening agent, a coalescing agent, emulsion, water, auxiliaries, filler and a solvent. The construction method comprises the following steps: leveling the cement wall or cement ground, paving a heat-insulating layer, paving the glass fiber cloth, smearing the water-based environment-friendly coating, and paving a waterproof layer. According to the invention, the heat-insulating layer is paved on the cement wall or cement ground, so that the heat-insulating and auxiliary leveling functions are achieved; meanwhile, the glass fiber cloth is utilized to realize the integrity of the water-based environment-friendly coating, so that the coating is difficult to crack; the fine sand and the medium sand in the coating are utilized to realize the overall strength of the coating; some fine sand and medium sand are embedded in the meshes of the glass fiber cloth, so that the strength is further enhanced; and the wood fiber, the filler and the like in the coating raw materials are utilized to enhance the overall strength of the coating.

Owner:厦门丽邦集团有限公司

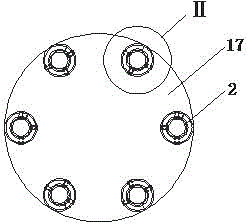

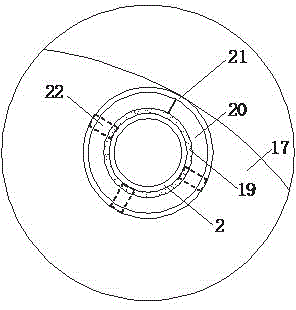

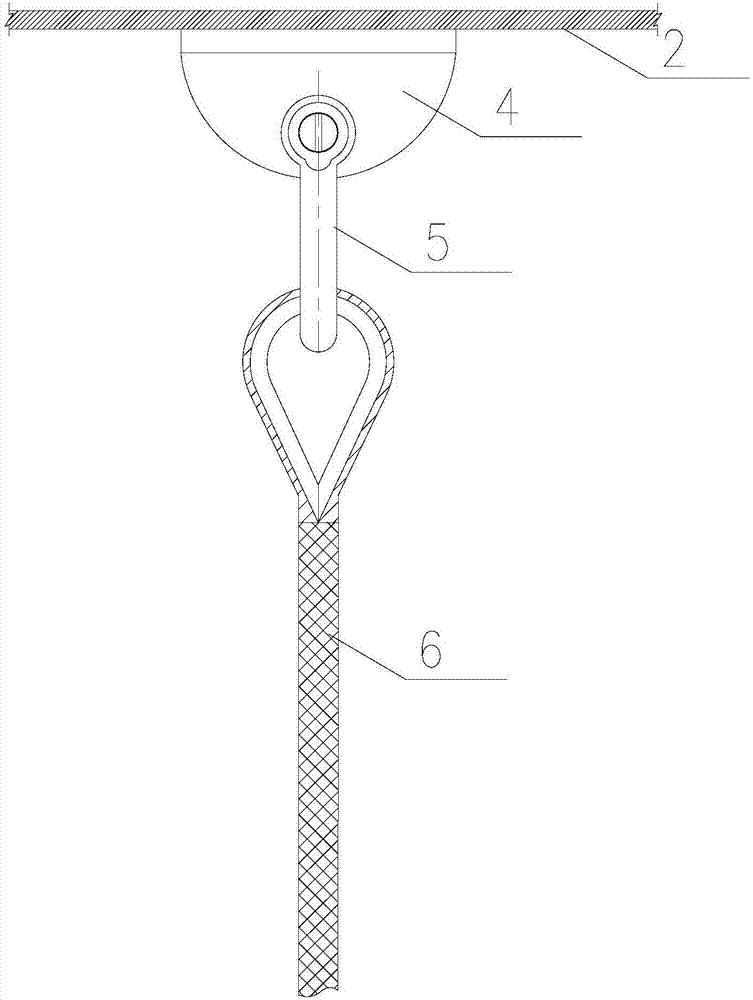

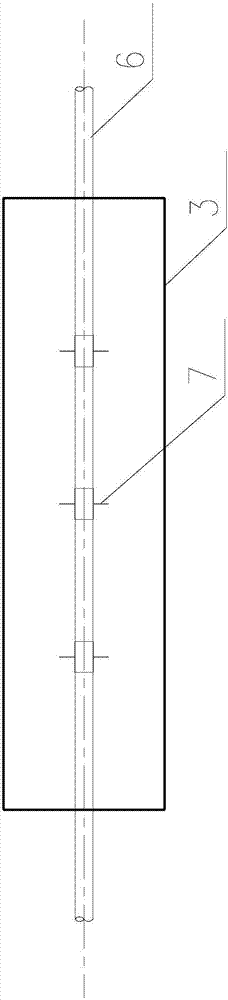

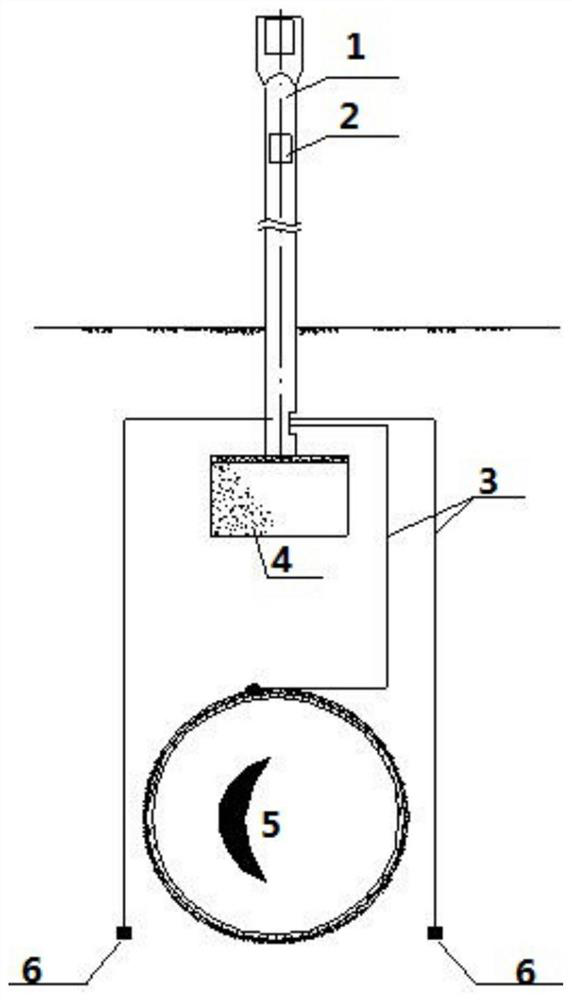

Offshore wind turbine single-pile foundation with internal sacrificial anode structure

InactiveCN106930312AEffective corrosion protectionMature production processFoundation engineeringOffshore wind powerCorrosion

The invention relates to an offshore wind turbine single-pile foundation with an internal sacrificial anode structure. The offshore wind turbine single-pile foundation with the internal sacrificial anode structure is simple in structure and convenient to construct and can achieve a corrosion preventing protection function on the inner wall of a steel pipe pile. According to the technical scheme, the offshore wind turbine single-pile foundation with the internal sacrificial anode structure is provided with the steel pipe pile, and is characterized in that an internal platform connected with the steel pipe pile is arranged in the steel pipe pile, and the lower portion of the lower end face of the internal platform is connected with a plurality of sacrificial anode strings. The sacrificial anode strings comprise steel wire ropes with the upper ends connected to the internal platform and a plurality of sacrificial anodes connected to the steel wire ropes in series. The offshore wind turbine single-pile foundation is suitable for offshore wind power generation work.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Crashproof water-resistant stone-like coating and processing method

ActiveCN107033785AAchieve water resistanceImprove fluencyCovering/liningsAntifouling/underwater paintsGlass fiberEmulsion

The invention discloses crashproof water-resistant stone-like coating and a processing method. The concrete wall surface is coated with the crashproof water-resistant stone-like coating uniformly, the crashproof water-resistant stone-like coating is internally provided with a glass fiber cloth, the four edges of the glass fiber cloth are embedded on the concrete wall, and the crashproof water-resistant stone-like coating is prepared from natural colored sand, acrylic resin, lignocellulose, a defoaming agent, a water repellent, a coalescing agent, an emulsion, a thickening agent, waterproof putty and the balance water. The processing method comprises the steps of concrete wall leveling, glass fiber laying, stone-like coating painting and natural colored sand, acrylic resin, lignocellulose, defoaming agent, water repellent, coalescing agent, emulsion, thickening agent, waterproof putty and water mixing for obtaining the mixed liquid for painting. The stone-like coating is internally provided with the glass fiber cloth, the four edges of the glass fiber cloth are embedded on the concrete wall, and the glass fiber cloth is arranged in the crashproof water-resistant stone-like coating, so that the overall continuity of the coating surface is enhanced, and the surface strength is improved.

Owner:厦门丽邦集团有限公司

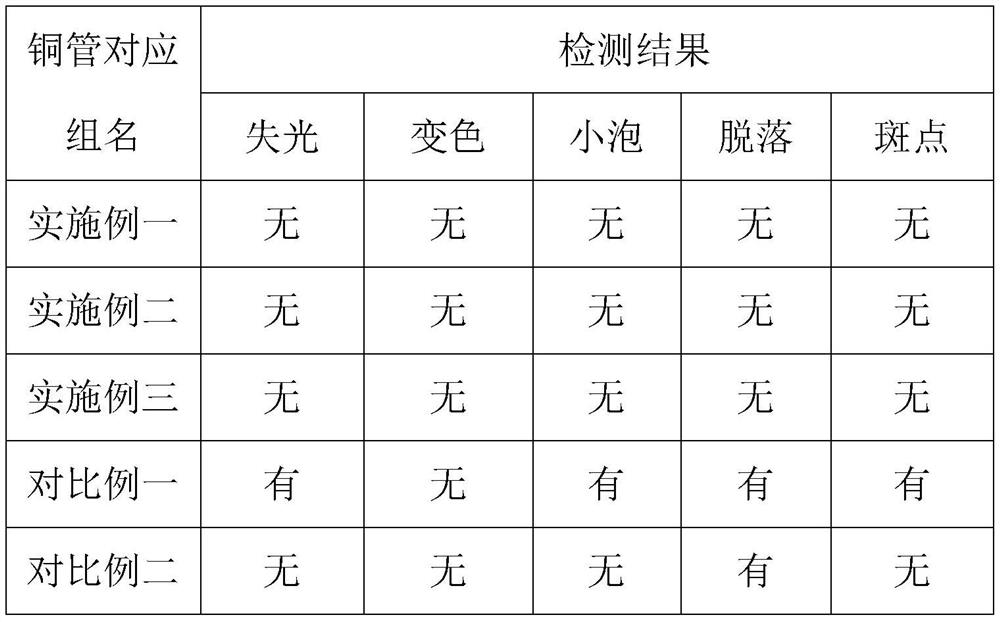

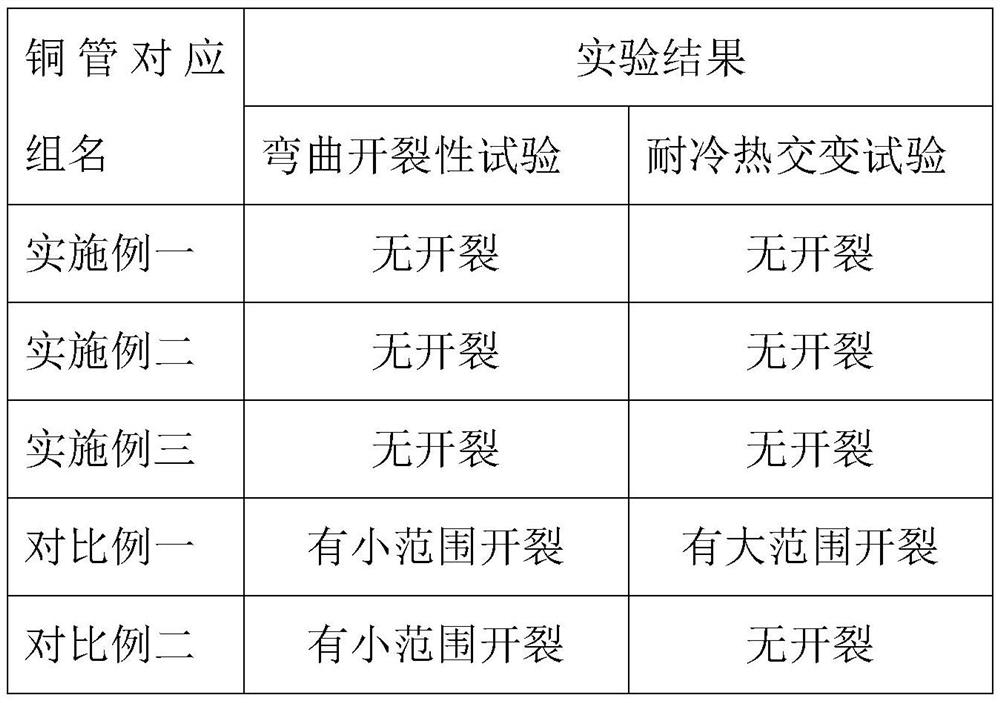

Anti-corrosion film-coating coating for heat exchanger copper pipe and film coating process of anti-corrosion film-coating coating

InactiveCN113025198ANo reduction in thermal conductivityNo reduction in heat transfer performanceChemical industryAnti-corrosive paintsFilm-coated tabletFilm coating

The invention discloses an anti-corrosion film-coating coating for a heat exchanger copper pipe and a film coating process of the anti-corrosion film-coating coating, and relates to the technical field of heat exchanger film coating. In allusion to the problems that the copper pipe film coating effect is poor and a formed protective film is poor in waterproof and anti-corrosion capacity during existing heat exchanger preparation, the invention proposes the following scheme: the film coating process comprises the steps of S1, cleaning and drying the interior of the heat exchanger copper pipe; S2, preparing an anti-corrosion film coating; S3, coating the interior of the heat exchanger copper pipe with the anti-corrosion film-coating coating in the S2; and S4, putting the oxygen-free copper heat exchanger of the gas heat exchanger in the S3 into a baking furnace to be baked till the anti-corrosion film-coating coating on the inner wall of the copper pipe of the heat exchanger is completely dried so as to complete film coating. An environment-friendly protective film formed by the anti-corrosion film-coating coating has excellent heat-conducting property, super-hydrophobicity and corrosion resistance, the film coating process is simple and easy to operate, efficient heat exchange of the gas heat exchanger can be guaranteed after film coating, and the service life of the gas heat exchanger can be prolonged.

Owner:艾森曼热能科技有限公司

Efficient corrosion-resistant environment-friendly film-coated heat exchanger preparation method

InactiveCN110398162AImprove high temperature resistanceAccelerated corrosionPretreated surfacesStationary conduit assembliesEnvironmental resistanceTectorial membrane

The invention discloses an efficient corrosion-resistant environment-friendly film-coated heat exchanger preparation method. The preparation method is characterized by comprising the following steps of S1, cleaning heat exchanger pipe sections, keeping the inner walls of the heat exchanger pipe sections clean and free of oil stains and blots, and welding the heat exchanger pipe sections into a heat exchanger coiled pipe section; S2, preparing a closed protective film coating; S3, pouring the prepared closed protective film coating into the heat exchanger coiled pipe section, and taking out theredundant closed protective film coating from the coiled pipe section after the protective film coating is fully absorbed; and S4, putting the heat exchanger coiled pipe section with the closed protective film coating attached into a baking line with the temperature of 100 DEG C-240 DEG C for baking for 2 min-10 min. According to the method, a brand-new environment-friendly film-coated heat exchanger is adopted, a special sheet-shaped structure of the heat exchanger can play a physical barrier role to prevent the generation of corrosion and has super-hydrophobic property, and the environment-friendly protective film has excellent mechanical properties, adhesiveness, high temperature resistance and corrosion resistance, so that corrosion and water leakage of a copper pipe in a water heatercan be effectively prevented, and the service life is prolonged.

Owner:艾森曼热能科技有限公司

Water heater and method of controlling a water heater

ActiveUS20160258652A1Reduce the amount requiredReduce the numberMechanical apparatusImmersion heating arrangementsElectrical batteryWater storage tank

A water heater is provided which comprises a water storage tank made of enameled metal, an anode electrode (e.g. an anode rod) at least partly inside the water storage tank and a corrosion protection unit configured to impress current into the anode to provide a corrosion protection for the water storage tank. The corrosion protection unit further comprises a microprocessor configured to control the impressing of the current to the anode electrode during impression process cycles and to control the operation of the corrosion protection. The corrosion protection unit furthermore comprises a battery unit or an accumulator unit configured to supply energy to the microprocessor during grid power outages. The microprocessor is configured to activate the power saving mode during grid power outages during which an amount of impressed current and / or an impression process cycle is reduced.

Owner:STIEBEL ELTRON

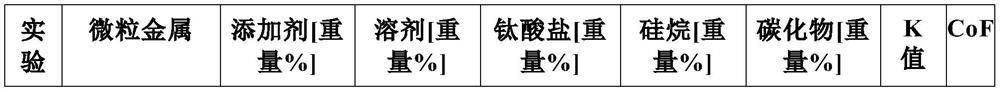

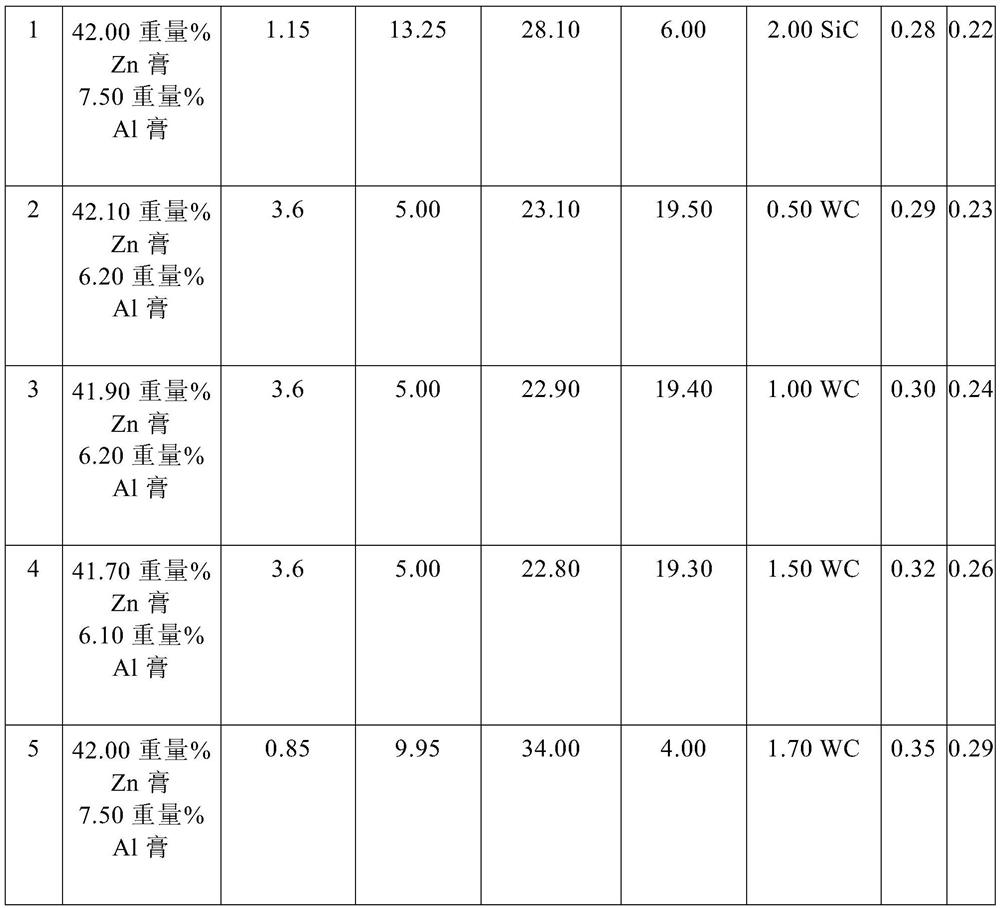

Organic solvent-based coating composition for coating surface of metal substrate to increase coefficient of friction of surface of said metal substrate

PendingCN114514291AIncrease coefficient of frictionEffective corrosion protectionAnti-corrosive paintsOrganic solventPhysical chemistry

The present invention relates to an organic solvent-based coating composition for coating a surface of a metal substrate in order to increase the coefficient of friction of the surface of said metal substrate, said composition comprising (i) at least one organic solvent; (ii) at least one particulate metal provided in a sheet metal and having a diameter in the range of 1 pm to 100 [mu] m; (iii) at least one metal carbide at a total concentration in the range of 0.1 wt% to 5 wt% based on the total weight of the coating composition; and (iv) at least one binder.

Owner:ATOTECH DEUT GMBH

Low-conductivity cooling liquid and preparation method thereof

PendingCN114231258AEffective corrosion protectionHigh purityHeat-exchange elementsTricarboxylic acidCarboxylic acid

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

A Drainage Method for Buried Metal Pipes Near DC Grounding Electrode

The invention discloses a drainage method aiming at a buried metal pipeline near a direct-current grounding electrode, and relates to the field of corrosion prevention of buried metal pipelines, especially the field of corrosion prevention of the buried metal pipelines in a direct-current stray current environment. The drainage method comprises the following steps that the strength and direction of stray current borne by the metal pipeline near the direct-current grounding electrode are tested; the resistance rate of a soil medium where the metal pipeline near the direct-current grounding electrode is located is tested; drained current protection parameters are calculated; and field installation and parameter monitoring are carried out. The drainage efficiency can be improved, the engineering cost and the corrosion risks can be reduced, the anti-corrosion effect of the buried metal pipeline is guaranteed, and the service life of the buried metal pipeline is prolonged.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +2

Corrosion test device and method for steel-concrete composite beam shear connectors

ActiveCN105115886BEffective corrosion protectionWeather/light/corrosion resistanceElectrolysisConcrete beams

The invention discloses a corrosion test device and method for a steel-concrete composite beam shear connector. The device includes a corrosion pool for containing electrolyte and soaking the concrete wing; the steel-concrete composite beam is used as an anode for electrolysis, It is mainly composed of steel beams, shear connectors and concrete, the shear connectors are welded on the steel beams, and the concrete is poured outside the shear connectors; the electrolytic circuit includes an ammeter connected to the anode, a DC power supply and a cathode . The method is to buckle the steel-concrete composite beam upside down in the corrosion pool, so that the electrolyte just soaks the concrete wing, turn on the power and record the current. The invention has a wider scope of application, is applicable to various shear connectors such as stud connectors and PBL connectors, and is more consistent with the actual situation, and can simulate the real corrosion situation of the shear connectors in steel-concrete composite beams.

Owner:SOUTHEAST UNIV

High-efficiency corrosion-resistance paint for saline-alkali soil metallic facility

InactiveCN107603422AExtended service lifeSolving Corrosion ProblemsAnti-corrosive paintsEpoxy resin coatingsAlkali soilAlcohol

The invention provides high-efficiency corrosion-resistance paint for a saline-alkali soil metallic facility. The high-efficiency corrosion-resistance paint is prepared from the following raw materials in parts by weight: 120 to 150 parts of backing material, 30 to 40 parts of methyl isobutyl ketone, 75 to 80 parts of poly isocyan phenolic ester, 20 to 30 parts of alcohol acid-siloxane, 2 to 5 parts of aluminum powder, 30 to 40 parts of talcum powder and 30 to 40 parts of coal tar. The backing material is prepared from the following raw materials in parts by weight: 80 to 85 parts of bisphenolA glycidyl ether and 15 to 20 parts of epoxy resin. The high-efficiency corrosion-resistance paint disclosed by the invention can effectively solve the problem of corrosion of the current saline-alkali soil metallic facility and has a practical and effective corrosion protection effect on metal members.

Owner:WEIFANG YOURONG IND

High-molecular composite adhesive, and preparation method and application thereof

InactiveCN103320081BImprove film formationEasy to shapePolyureas/polyurethane adhesivesLaminationPolyesterPolymer science

The invention relates to a polymer composite adhesive and its preparation method and application, and belongs to the technical fields of chemical adhesives, resource recycling and composite materials. Plant-based polyester polyol is prepared by using agricultural residues of rice straw, diol, catalyst, and dianhydride; then blending the plant-based polyester polyol with konjac glucomannan aqueous emulsion to obtain a polymer composite aqueous emulsion , When in use, mix the separately packaged polymer composite water emulsion with isocyanate at room temperature to obtain a polymer composite adhesive. The adhesive of the present invention is used for bonding wood.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com