Surface-treated cooled wire

A surface treatment and wire technology, applied in the field of new cooling wires, can solve the problems of increased loss, waste of raw materials for wires, and increased difficulty of wire construction, etc., and achieve the effects of reduced energy loss, strong self-cleaning function, and excellent heavy-duty anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

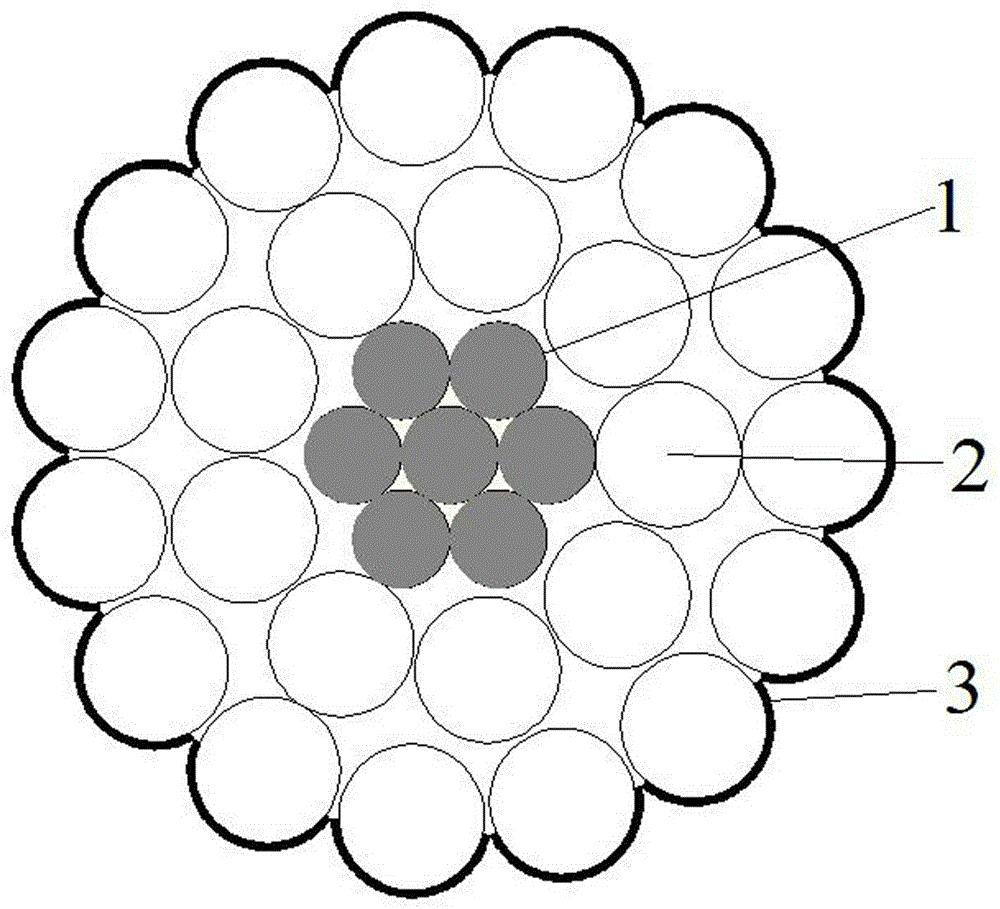

[0039] Embodiment 1: see figure 1 , invented a surface-treated cooling wire, including a central strengthening core aluminum-magnesium-silicon alloy stranded wire 1, a circular aluminum conductor 2, and a fluorocarbon coating 3 containing fluorocarbon elements coated on the outermost layer. The fluorocarbon coating is commercially available fluorocarbon coating.

Embodiment 2

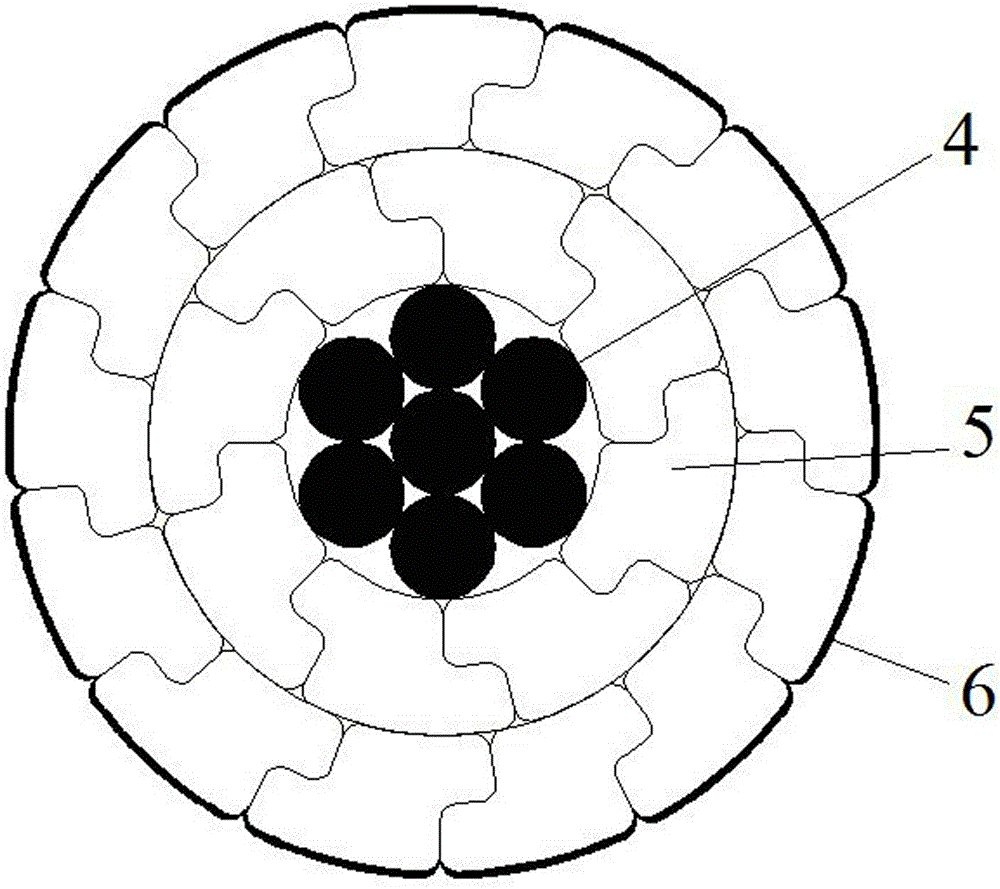

[0040] Example 2: see figure 2 , invented a surface-treated cooling wire, including a central reinforced core steel strand 4, a ZS-shaped aluminum conductor 5, a fluorocarbon coating 6 that contains fluorocarbon elements on the outermost layer, and a fluorocarbon element that is coated on the outermost layer Low absorption color, light brown, yellow, white, pink, light green, light yellow, brown, black, off-white, dark gray and other colors of fluorocarbon coating 6.

Embodiment 3

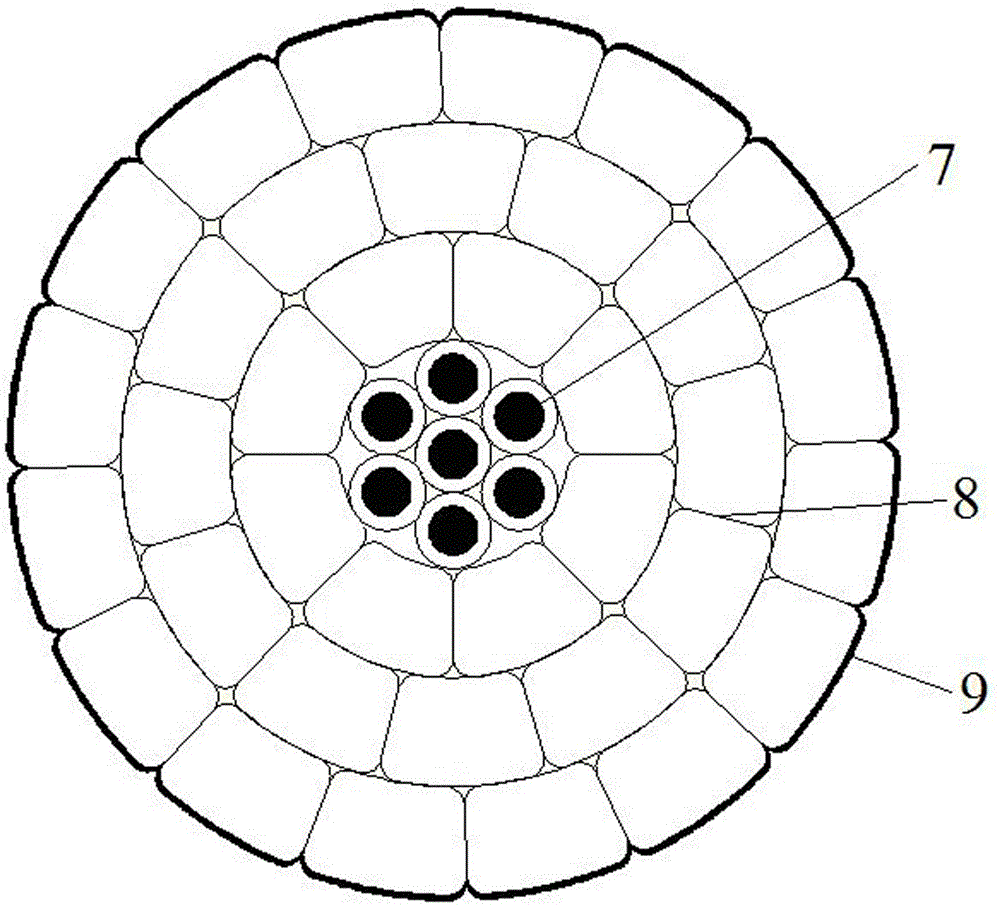

[0041] Embodiment 3: see image 3 , invented a surface-treated cooling wire, including a central reinforcement core aluminum-clad steel strand 7, a T-shaped aluminum conductor 8, a fluorocarbon coating 9 coated with fluorocarbon elements on the outermost layer, and a fluorine-containing carbon element coated on the outermost layer Carbon element low absorption color, light brown, yellow, white, pink, light green, light yellow, brown, black, off-white, dark gray and other colors of fluorocarbon coating9.

[0042] The surface-treated cooling wire of the present invention forms a permanent layer of high-radiation and low-endothermic paint on the surface by spraying the outermost layer of the wire with high-radiation and low-endothermic paint, so that this new type of surface-treated cooling wire is comparable to the same specification Compared with wires, under the same current carrying capacity, the surface temperature of wires can be reduced by 5°C to 20°C. It reduces energy l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com