Novel shoe

A shoe, a new technology, applied in the direction of footwear, shoe soles, footwear, etc., can solve the problems of not being environmentally friendly, affecting the appearance, weathering and yellowing, etc., and achieve the effects of saving production costs, reducing labor costs, and improving tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

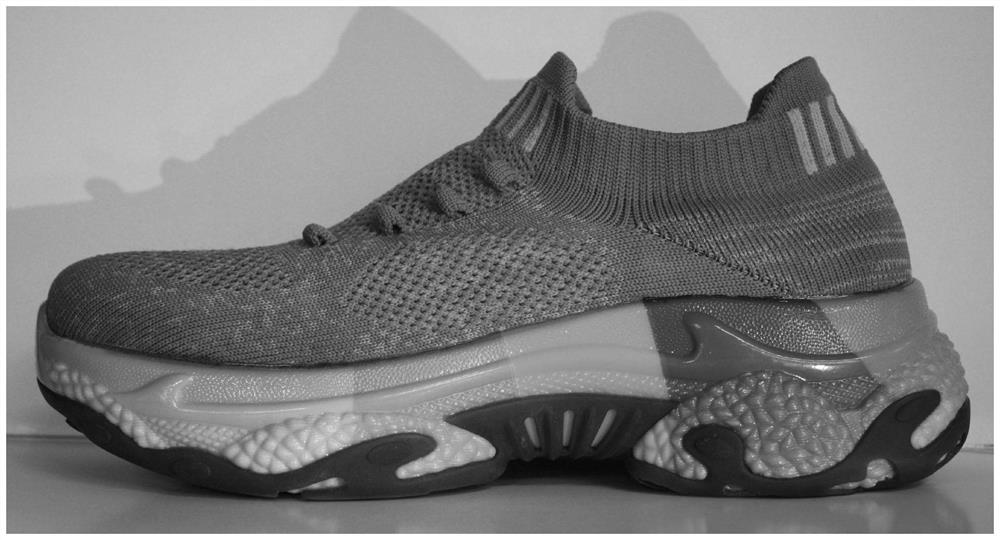

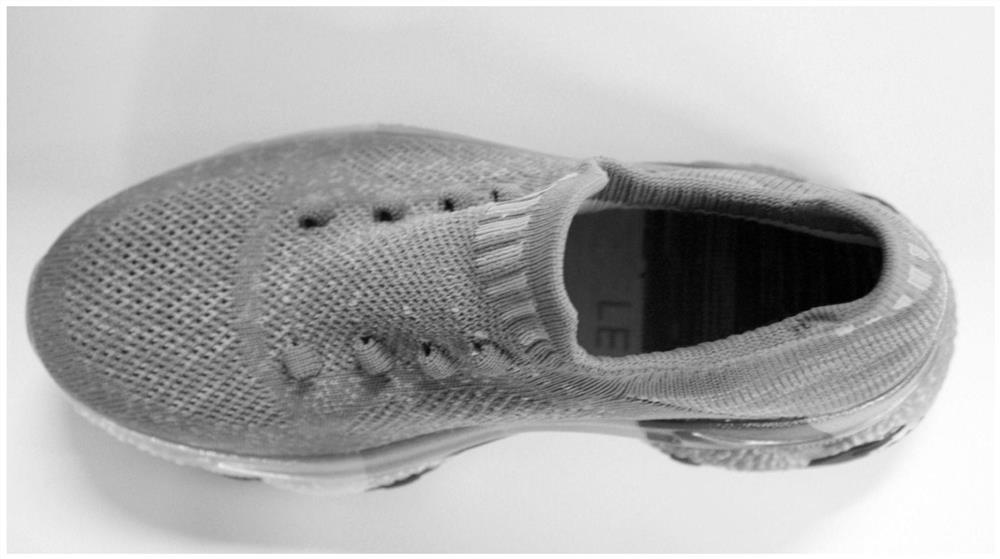

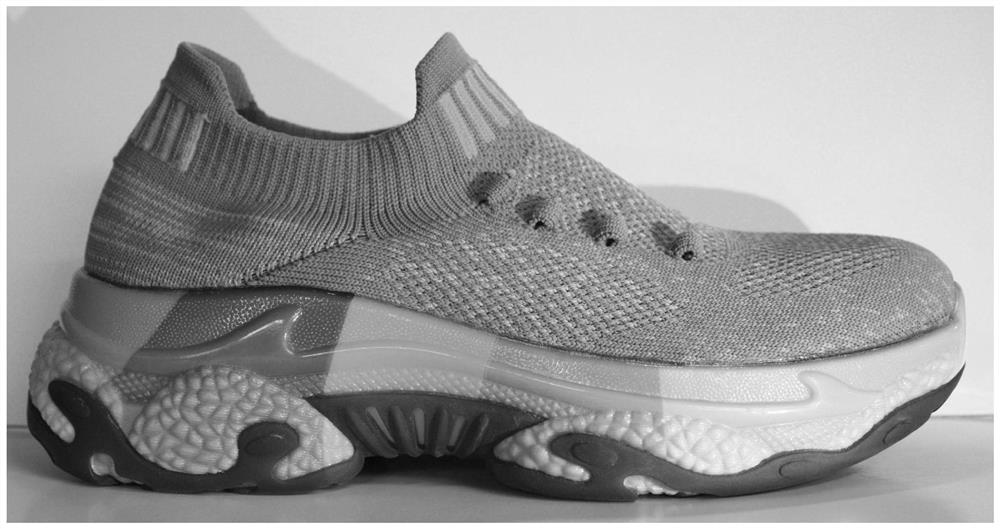

Image

Examples

Embodiment

[0025] Step 1: Prepare the machine, fix the mold on the disc machine trolley, turn it on and heat it up, turn on the baking lamp, cut the TPU film into 38cm sections for later use, pick up the upper and put it on the upper;

[0026] Step 2: Set the upper, fix the last on the handle slot of the table, set the upper surface on the last and straighten it; bake the last in the oven for 5 minutes, take it out and put it on the last hanging place of the machine ;Put the shaped last with uppers on the upper plate of the mould;

[0027] Step 3: Hang the film and bake, hang the film on the lower plate of the last mold, spread the film on the surface of the mold, and fix it at four points; transfer the mold with the film into the baking lamp area for baking , the film is baked until soft; after the film is baked shiny and soft, immediately open the vacuum valve to pump the film to the surface of the inner cavity of the mold;

[0028] Step 4: Keep the raw materials of component A and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com