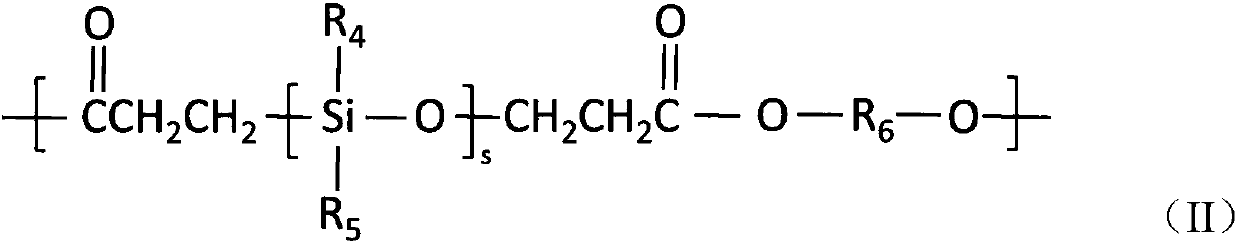

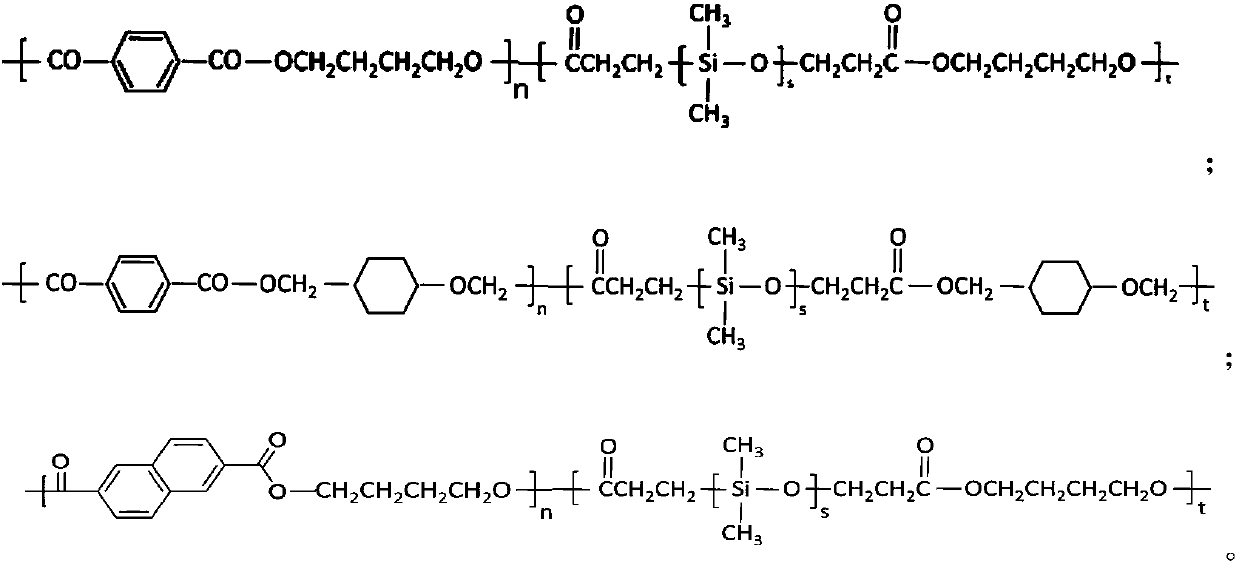

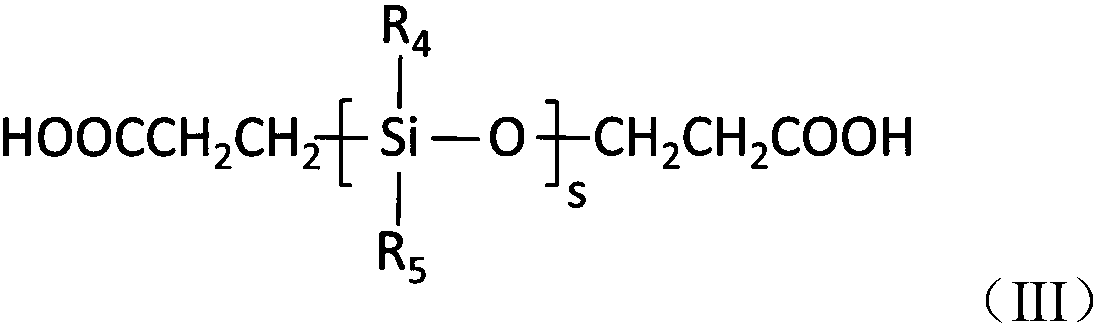

Polyester block copolymer as well as preparation method and application thereof

A polyester block and copolymer technology, which is applied in the field of polyester block copolymer and its preparation, can solve problems such as inability to absorb moisture, harsh environmental requirements, and other performance effects of materials, and achieve excellent low-temperature resistance and low-temperature impact The effect of good sex and low tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1 contains the preparation of the PBT copolyester of silicon unit

[0081] Slurry preparation: 1) Put terephthalic acid (PTA) and 1,4-butanediol (BDO) into the slurry preparation tank U1 respectively through the metering system, stir evenly, and record it as slurry S1, wherein PTA is 773G (G The meaning is the mass unit gram, the same below), and BDO is 520G. 2) Put α, ω-dicarboxyethyl polydimethylsiloxane and 1,4 butanediol (BDO) into the slurry preparation tank U2 respectively through the metering system, stir evenly, and record it as slurry S2, where α , ω-dicarboxyethyl polydimethylsiloxane is 210G, 1,4 butanediol (BDO) is 30G.

[0082] Catalyst preparation: Add 1,4-butanediol (BDO) 100G and catalyst C (tetrabutyl titanate) 158.9G into the preparation tank U3, heat and boil in a vacuum state for 2-3 hours, the vacuum degree is 20-30KPa, The temperature is 180°C. After cooling down, the prepared catalyst is transferred into the catalyst feeding tank.

...

Embodiment 2

[0091] The preparation of the PBT copolyester that embodiment 2 contains silicon unit

[0092] Slurry preparation: 1) Put terephthalic acid (PTA) and 1,4-butanediol (BDO) into the slurry preparation tank U1 respectively through the metering system, stir evenly, and record it as slurry S1, wherein PTA is 773G, BDO It is 520G. 2) Put α, ω-dicarboxyethyl polydimethylsiloxane and 1,4 butanediol (BDO) into the slurry preparation tank U2 respectively through the metering system, stir evenly, and record it as slurry S2, where α , ω-dicarboxyethyl polydimethylsiloxane is 300G, 1,4 butanediol (BDO) is 45G.

[0093] Catalyst preparation: Add 1,4-butanediol (BDO) 100G and catalyst C (tetrabutyl titanate) 158.9G into the preparation tank U3, heat and boil in a vacuum state for 2-3 hours, the vacuum degree is 20-30KPa, The temperature is 180°C. After cooling down, the prepared catalyst is transferred into the catalyst feeding tank.

[0094] Esterification reaction: The slurry S1 in the ...

Embodiment 3

[0102] The preparation of embodiment 3 containing the PBT copolyester of silicon unit

[0103] Slurry preparation: 1) Put terephthalic acid (PTA) and 1,4-butanediol (BDO) into the slurry preparation tank U1 respectively through the metering system, stir evenly, and record it as slurry S1, wherein PTA is 773G, BDO It is 520G. 2) Put α, ω-dicarboxyethyl polydimethylsiloxane and 1,4 butanediol (BDO) into the slurry preparation tank U2 respectively through the metering system, stir evenly, and record it as slurry S2, where α , ω-dicarboxyethyl polydimethylsiloxane is 420G, 1,4 butanediol (BDO) is 60G.

[0104] Catalyst preparation: Add 1,4-butanediol (BDO) 100G and catalyst C (tetrabutyl titanate) 158.9G into the preparation tank U3, heat and boil in a vacuum state for 2-3 hours, the vacuum degree is 20-30KPa, The temperature is 180°C. After cooling down, the prepared catalyst is transferred into the catalyst feeding tank.

[0105] Esterification reaction: The slurry S1 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com