Green drain pipe for municipal garden

A drainage pipe and gardening technology, applied in the field of green drainage pipes, can solve the problems of poor low temperature resistance, narrow applicability, brittleness and cracking, etc., and achieve the goal of not being easy to thermal degradation, reducing excessive fertilizer concentration, and improving physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

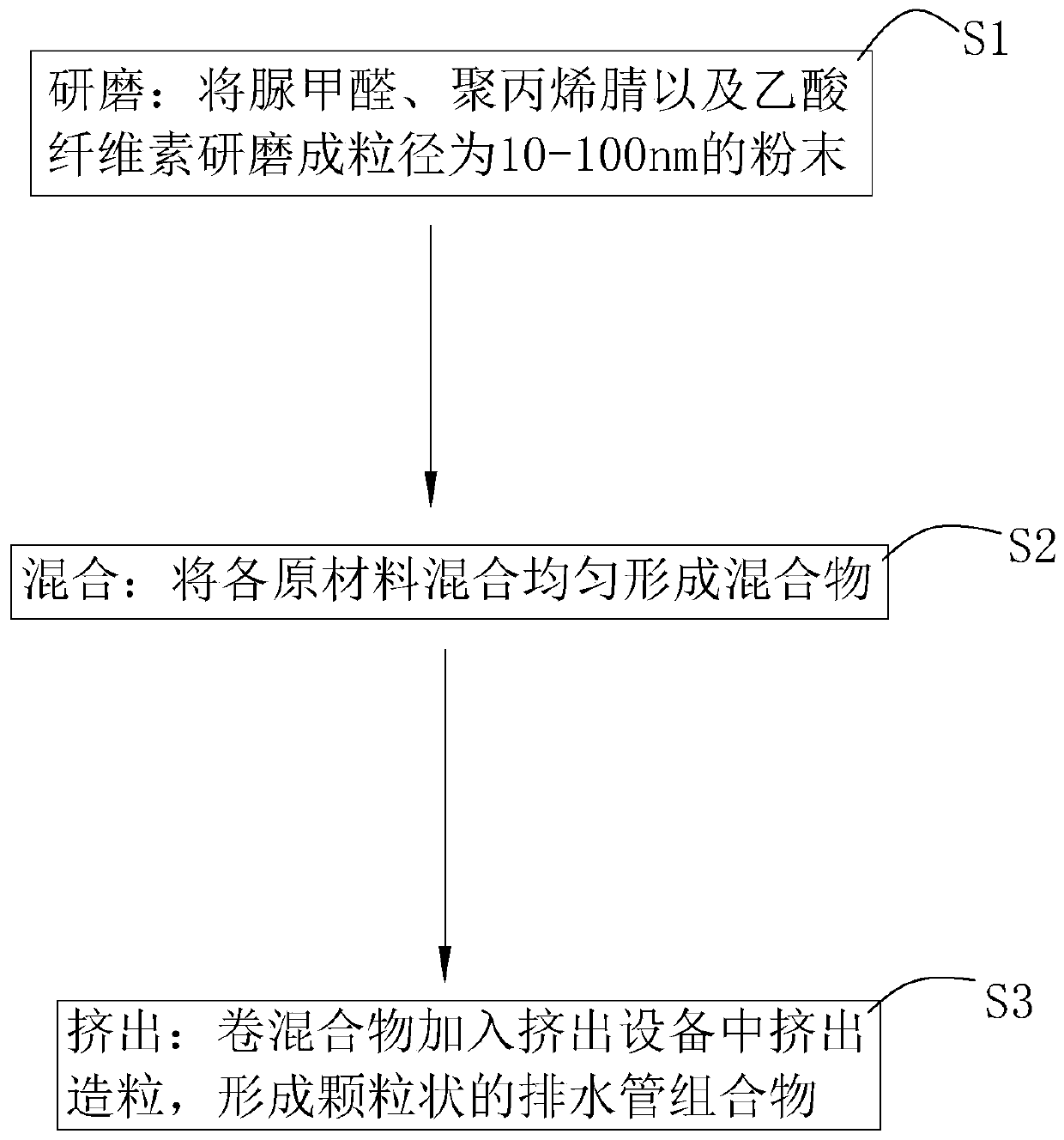

[0056] A green drainpipe for municipal gardens, the green drainpipe for municipal gardens is prepared from the drainpipe composition through a twin-screw extruder using an extrusion molding process, refer to figure 1 , the preparation method of drainpipe composition comprises the following steps:

[0057] S1. Grinding, as follows:

[0058] Grinding urea-formaldehyde, polyacrylonitrile and cellulose acetate into a powder with a particle size of 10-100nm through a grinder;

[0059] Polypropylene was ground into particles with a particle size of 0.1 mm by a grinder.

[0060] S2. mixing, specifically as follows:

[0061] Add 100kg of polypropylene granules, 10kg of urea-formaldehyde powder, 33kg of polyacrylonitrile powder and 15kg of cellulose acetate powder into the stirring tank, close the stirring tank, pass in nitrogen gas to exhaust the air, rotate at a speed of 30r / min, stir for 5min, and form a mixture after stirring evenly .

[0062] S3. extrusion, as follows:

[006...

Embodiment 2

[0065] A green drainpipe for municipal gardens, the green drainpipe for municipal gardens is prepared from the drainpipe composition through a twin-screw extruder using an extrusion molding process, refer to figure 1 , the preparation method of drainpipe composition comprises the following steps:

[0066] S1. Grinding, as follows:

[0067] Grinding urea-formaldehyde, polyacrylonitrile and cellulose acetate into a powder with a particle size of 10-100nm through a grinder;

[0068] Polypropylene was ground into particles with a particle size of 0.1 mm by a grinder.

[0069] S2. mixing, specifically as follows:

[0070] Add 100kg of polypropylene granules, 12kg of urea-formaldehyde powder, 40kg of polyacrylonitrile powder and 17kg of cellulose acetate powder into the stirring tank, close the stirring tank, pass in nitrogen gas to exhaust the air, rotate at a speed of 30r / min, stir for 5min, and form a mixture after stirring evenly .

[0071] S3. extrusion, as follows:

[0072]...

Embodiment 3

[0074] A green drainpipe for municipal gardens, the green drainpipe for municipal gardens is prepared from the drainpipe composition through a twin-screw extruder using an extrusion molding process, refer to figure 1 , the preparation method of drainpipe composition comprises the following steps:

[0075] S1. Grinding, as follows:

[0076] Grinding urea-formaldehyde, polyacrylonitrile and cellulose acetate into a powder with a particle size of 10-100nm through a grinder;

[0077] Polypropylene was ground into particles with a particle size of 0.1 mm by a grinder.

[0078] S2. mixing, specifically as follows:

[0079] Add 100kg of polypropylene granules, 15kg of urea-formaldehyde powder, 44kg of polyacrylonitrile powder and 20kg of cellulose acetate powder into the stirring tank, close the stirring tank, pass in nitrogen gas to exhaust the air, rotate at a speed of 30r / min, stir for 5min, and form a mixture after stirring evenly .

[0080] S3. extrusion, as follows:

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com