Polyamide composite material and preparation method thereof

A composite material, polyamide technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy embrittlement, rupture and damage, large influence of environmental temperature, low toughness, etc. , to achieve the effect of excellent low temperature resistance and good comprehensive performance

Inactive Publication Date: 2019-05-21

江苏博云塑业股份有限公司

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] One of the purposes of the present invention is to provide a polyamide composite material, through the cooperation between polyamide and different fillers and additives, to overcome the defects existing in the existing use, specifically solve the problem of poly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

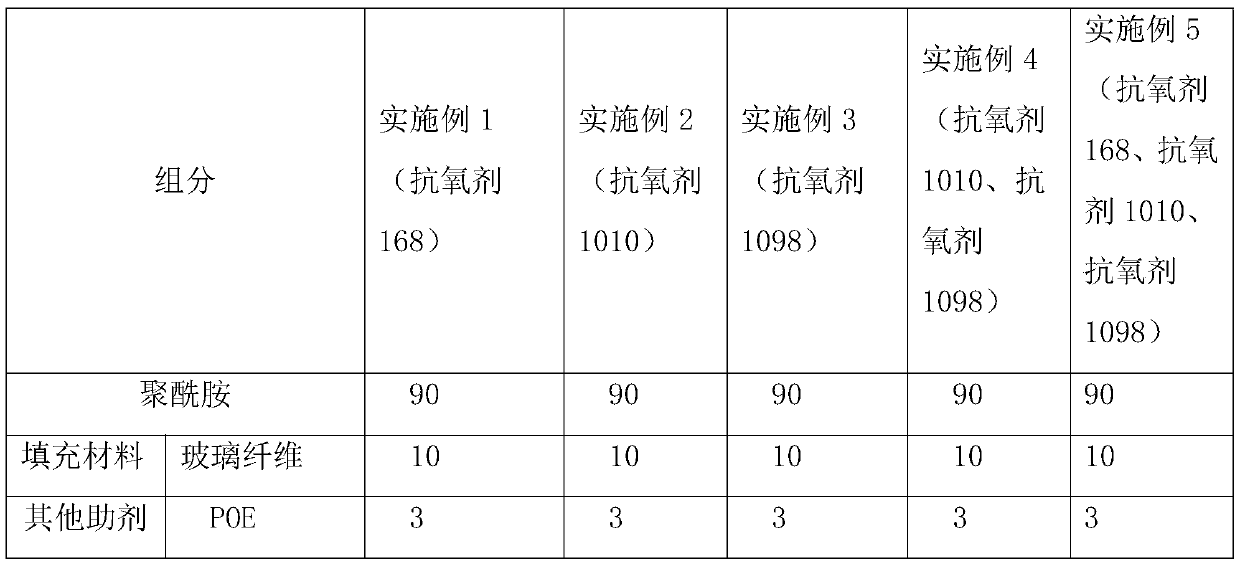

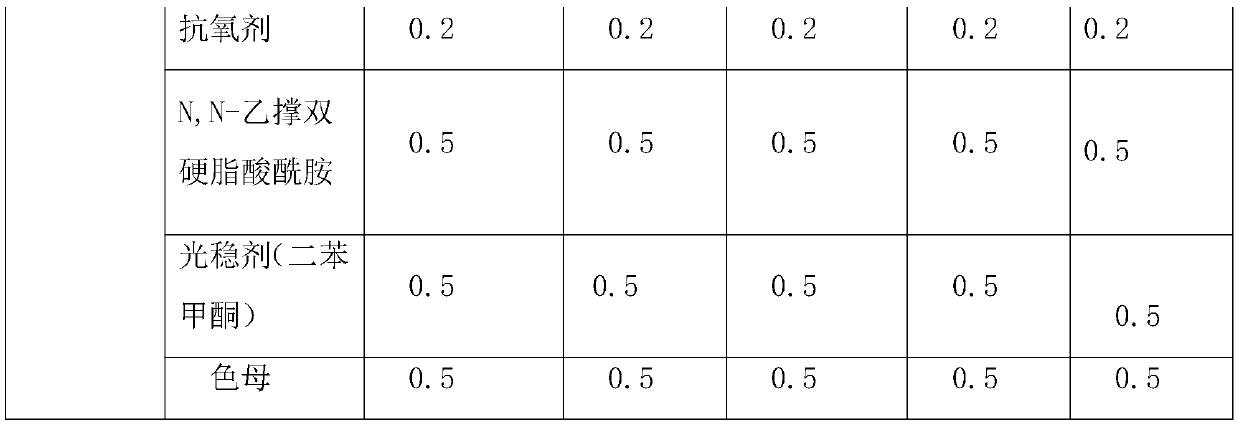

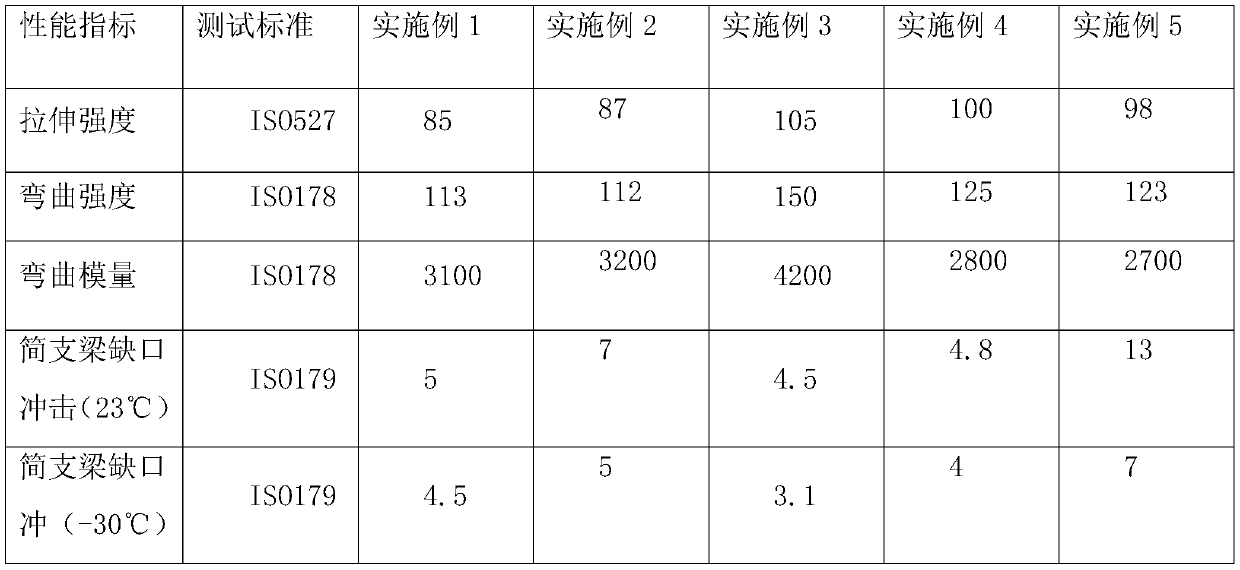

The invention discloses a polyamide composite material. The polyamide composite material comprises the following components in parts by weight: 60 to 98 parts of polyamide, 0.5 to 40 parts of fillingmaterial and 0.5 to 10 parts of other aids. The invention also provides a preparation method of the polyamide composite material. The preparation method of the polyamide composite material comprises the following steps: selecting the raw materials according to the above components and the weight percentage, mixing the polyamide and other aids uniformly by a mixing machine, adding the mixture intoa double-screw extruding machine, mixing, adding the filling material through lateral feeding, extruding material strips, cooling by a water channel, granulating by a granulating machine, drying by adrying machine and packaging to obtain finished products. The obtained finished products show excellent low-temperature resistance on the premise of meeting long-time use of the materials, can be usedin various complex environments, and solves the problems in the prior art that the polyamide composite material and plastic pipe fittings made thereby are influenced by the environment temperature greatly, particularly at low temperature, the lower the temperature is, the lower the toughness is, and the materials are liable to embrittle, break and damage.

Description

technical field [0001] The invention relates to a resin composite material and a preparation method thereof, in particular to a polyamide composite material and a preparation method thereof. Background technique [0002] Water is the source of life, and the quality of drinking water is closely related to people's health. After years of publicity and popularization of drinking water and health knowledge, people have gradually understood the impact of water quality on human health, and paid more attention to drinking water safety, which provides a great market prospect for water purifier products. [0003] Once the water purifier is turned on, water will accumulate inside it, and the accumulated water will not be discharged: so in the cold season, the water purifier is often in an environment below 0°C. As the temperature drops, the water in the filter bottle and other plastic pipe fittings The water in the water gradually freezes and expands, and the expansion to a certain e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/06C08L23/08C08K7/14C02F1/00

Inventor 蒋晓东赵义仁刘艳国

Owner 江苏博云塑业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com