Method for preparing diphenolic propane diglycidol ether

A technology of diglycidyl ether and diphenolic propane, which is applied in the field of preparation of diphenolic propane diglycidyl ether, can solve the problem of high market price, achieve anti-corrosion and good mechanical properties, low cost and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

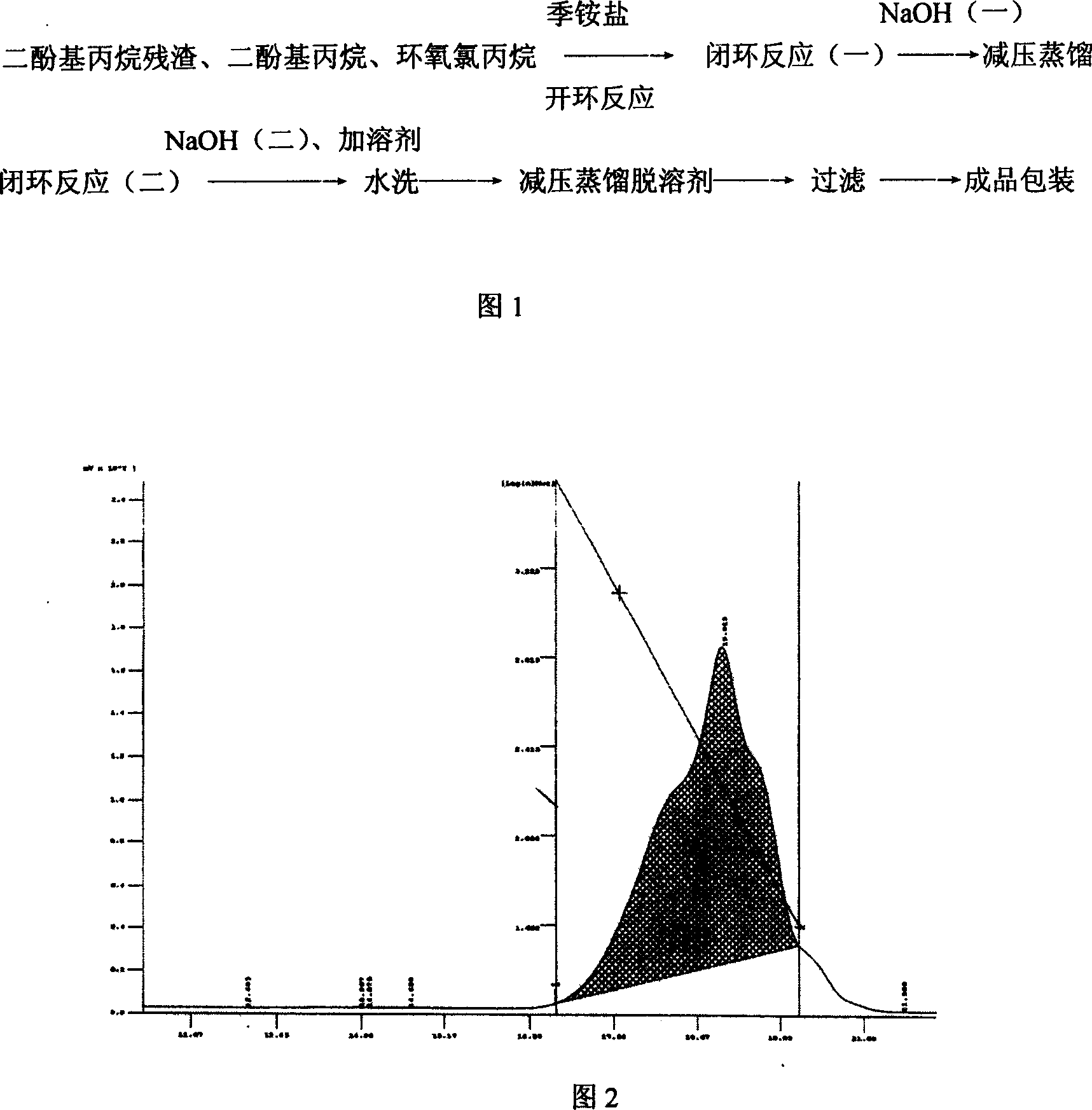

[0021] A preparation method of diphenolic propane diglycidyl ether, comprising the following steps:

[0022] The first step is to mix diphenolic propane, diphenolic propane by-products and epichlorohydrin, and add an aqueous solution of benzyltriethylammonium chloride with a mass concentration of 50-70% as a catalyst, and etherify at 75-125°C The reaction time is 0.5-10 hours, the rice flower reaction temperature can be selected as 80, 90, and the reaction time can be selected as 1 hour, 3 hours, 6 hours, 8 hours, 9 hours,

[0023] Among them, the quality of diphenol-based propane by-products is 1 to 4 times the quality of diphenol-based propane, for example, it can be selected as 1.2, 1.4, 2.0, 2.4, 2.8, 3.5, 3.9 times, and the quality of epichlorohydrin is diphenol-based 4 to 40 times that of propane, for example, it can be selected as 6 times, 8 times, 15 times, 20 times, 28 times, 32 times, 35 times, 38 times, and the quality of benzyl triethylammonium chloride is diphenol...

Embodiment 2

[0029] raw material name

[0030] Time, temperature, reaction process are as described in Example 1.

Embodiment 3

[0032] Time, temperature, reaction process are as described in Example 1.

[0033] raw material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com