Patents

Literature

142 results about "Benzyl triethylammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

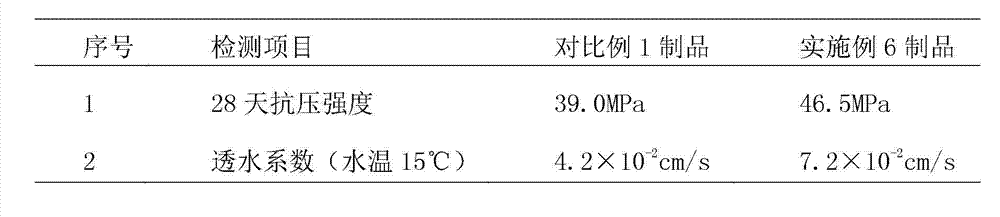

Water-permeable paving material and preparation method and application thereof

The invention discloses a water-permeable paving material and a preparation method and application thereof. The water-permeable paving material comprises, by weight, 60-90 parts of quartz sand, 10-40 parts of Portland cement, 2-10 parts of hydrophilic epoxy resin binders, 0.5-5 parts of curing agents and 1-10 parts of water. The curing agents include one or more of aliphatic polyamine and cycloaliphatic polyamine curing agents or aromatic ring polyamine curing agents. The hydrophilic epoxy resin binders comprise, by weight, 500-950 parts of bisphenol A epoxy resin, 1-200 parts of surfactant span, 1-200 parts of surfactant tween and 0.001-0.005 part of catalysts, wherein the catalysts can be tetraethylammonium chloride, butyl triphenyl phosphorus bromide, benzyl triethyl ammonium bromide, benzyl triethyl ammonium chloride, 2- methylimidazole or optional combination of the above substances. The water-permeable paving material is prepared by uniformly stirring the quartz sand, the Portland cement, the water, the hydrophilic epoxy resin binders and the curing agents; and then placing the stirred mixture into a mould for molding and curing for 24 hours at the normal temperature prior to demolding. The water-permeable paving material is used for preparing pavement bricks, pavement slabs and sewage filtering prefabricated members by means of molding.

Owner:杭锦旗亿嘉环境治理有限公司

Method for separating and extracting lignin from eucalyptus

ActiveCN105908550ALow costReduce pollutionLignin derivativesPaper material treatmentResource utilizationFiltration

The invention discloses a method for separating and extracting lignin from eucalyptus. The method includes the following steps of firstly, adding eucalyptus powder and deep eutectic solvent into a reaction kettle, controlling the reaction temperature to be 60-100 DEG C, and conducting stirring reaction for 4-10 h, wherein the deep eutectic solvent is prepared by evenly mixing lactic acid and benzyl triethyl ammonium chloride according to the molar ratio of 1:3 to 1:9; secondly, taking out a reaction product, conducting decompression and suction filtration, washing away residues through ethyl alcohol, conducting rotary evaporation on filtrate obtained through suction filtration to obtain a concentrated solution, recovering ethyl alcohol, adding deionized water to the concentrated solution, and conducting standing and separating to obtain mixed liquid containing sediment; thirdly, conducting centrifuging on the mixed liquid, conducting solid-liquid separation, and washing a solid phase through deionized water thoroughly to obtain regenerated lignin. Lignin in eucalyptus can be effectively extracted, and the purity of the product is 90% or above. The method is simple in process and mild in condition, biomass resource utilization efficiency is improved, and cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

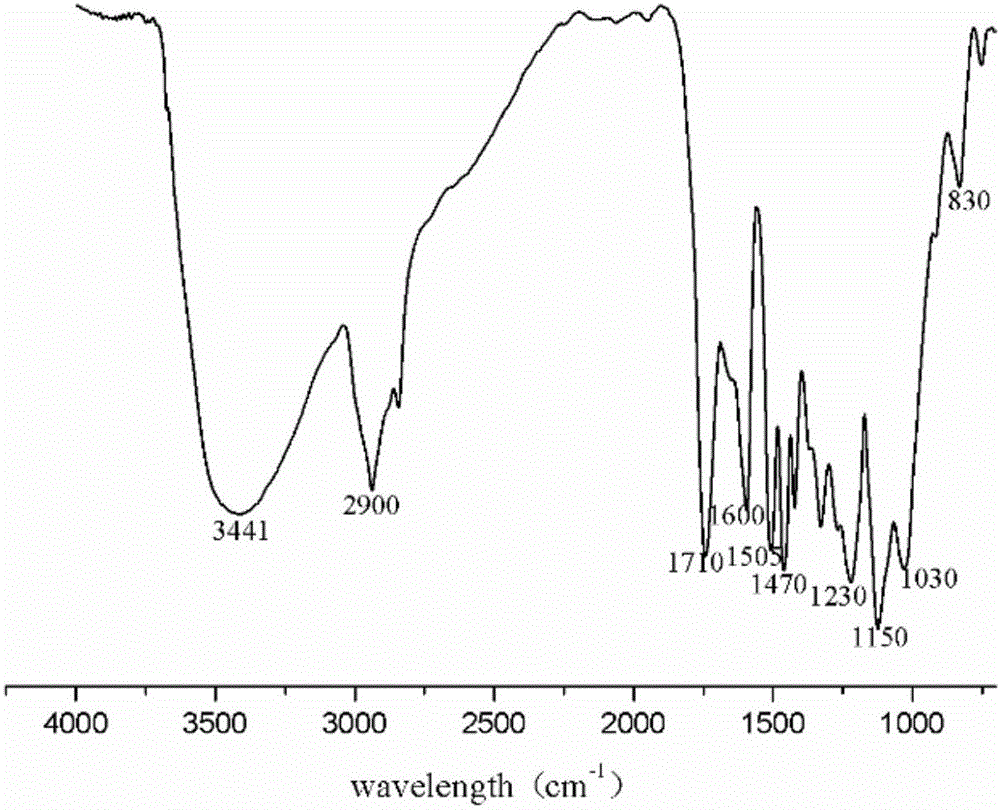

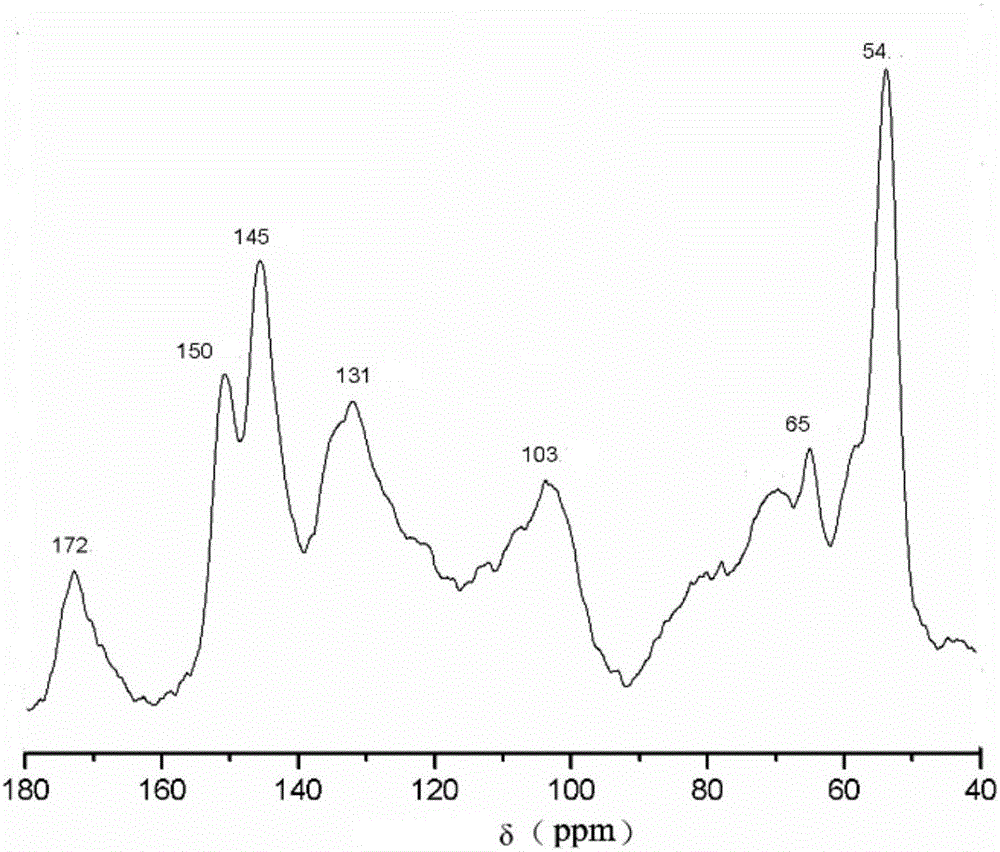

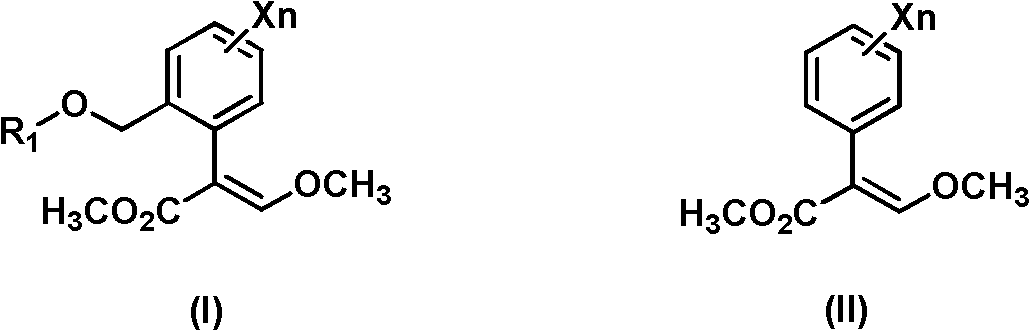

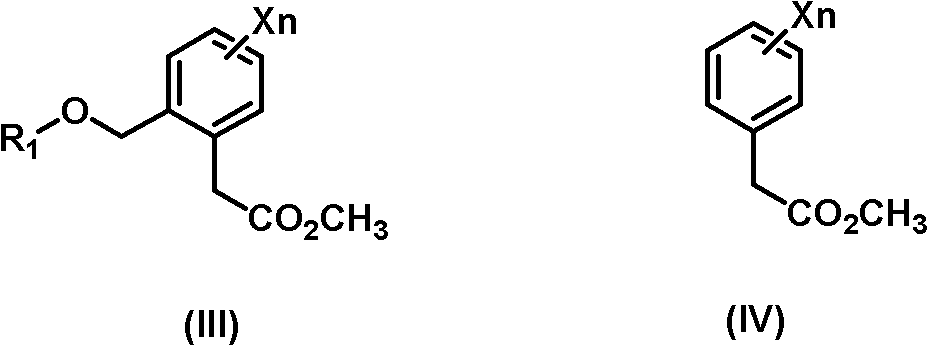

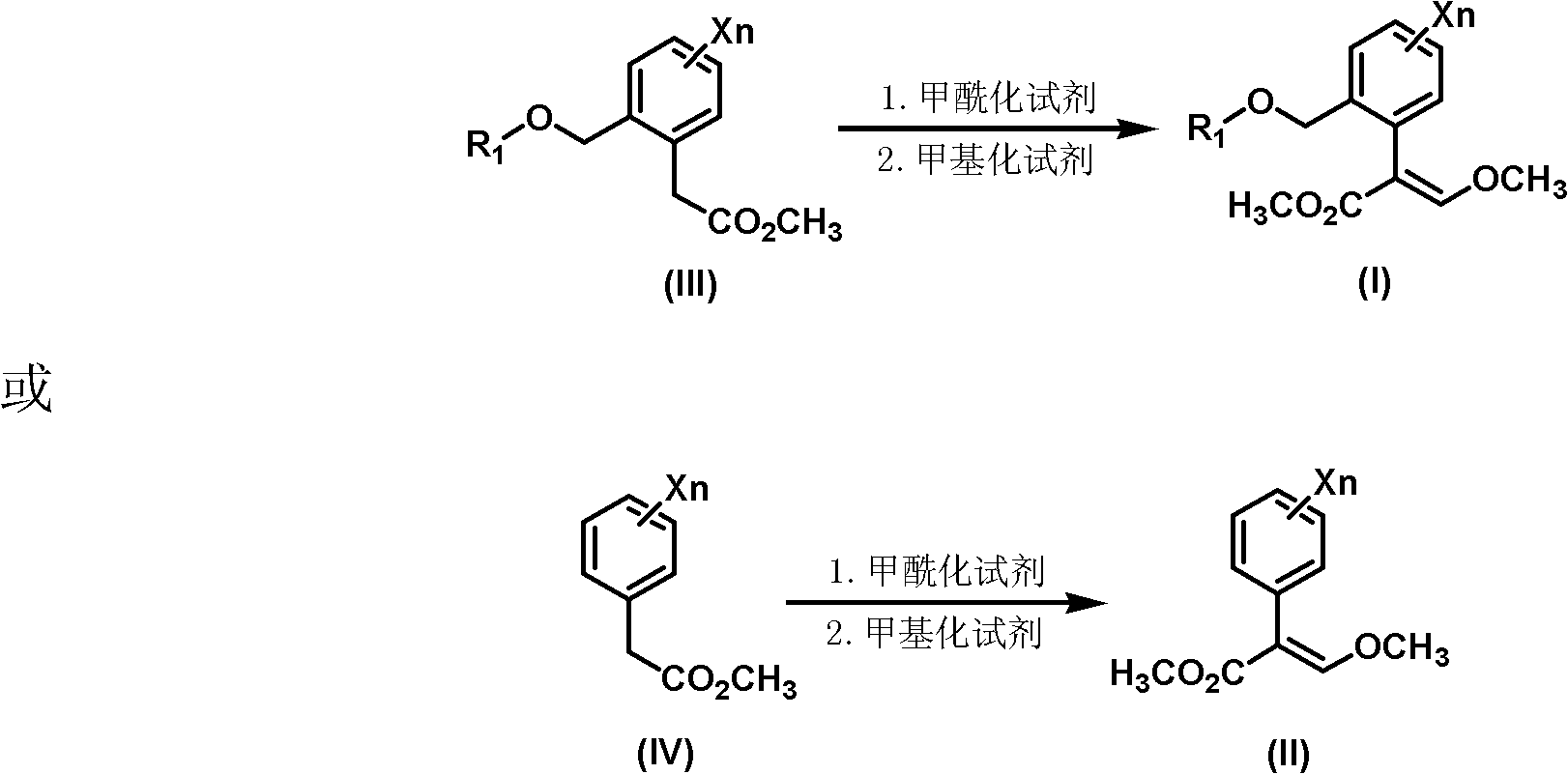

Synthesis method of 3-methoxy-2-aryl(methyl)acrylate compounds

ActiveCN102115458AFew stepsGood choiceOrganic compound preparationCarboxylic acid esters preparationFormylation reactionOrganic base

The invention relates to a synthesis method of 3-methoxy-2-aryl(methyl)acrylate compounds, which comprises the following steps: by using phenylmethyl acetate with or without substituting groups as a raw material, carrying out formylation reaction at -20-100 DEG C for 4-6 hours in a nitrogen atmosphere in the presence of Lewis acid in an aprotic solvent neutralized formylation reagent, dissociating with an organic base, hydrolyzing with hydrochloric acid, and stratifying, wherein the organic layer is an intermediate; carrying out methylation reaction on the intermediate, benzyltriethylammonium chloride, a methylation reagent and an inorganic base at 20-100 DEG C for 1-3 hours; after the reaction finishes, washing with water, desolventizing, and recrystallizing or distilling while depressurizing to obtain the product. The invention has the advantages of fewer processing steps (the methylation reaction can be directly carried out without purifying and separating the intermediate product), favorable selectivity, higher yield and low cost; and the reaction process is easy to control, and is safe and easy to amplify.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

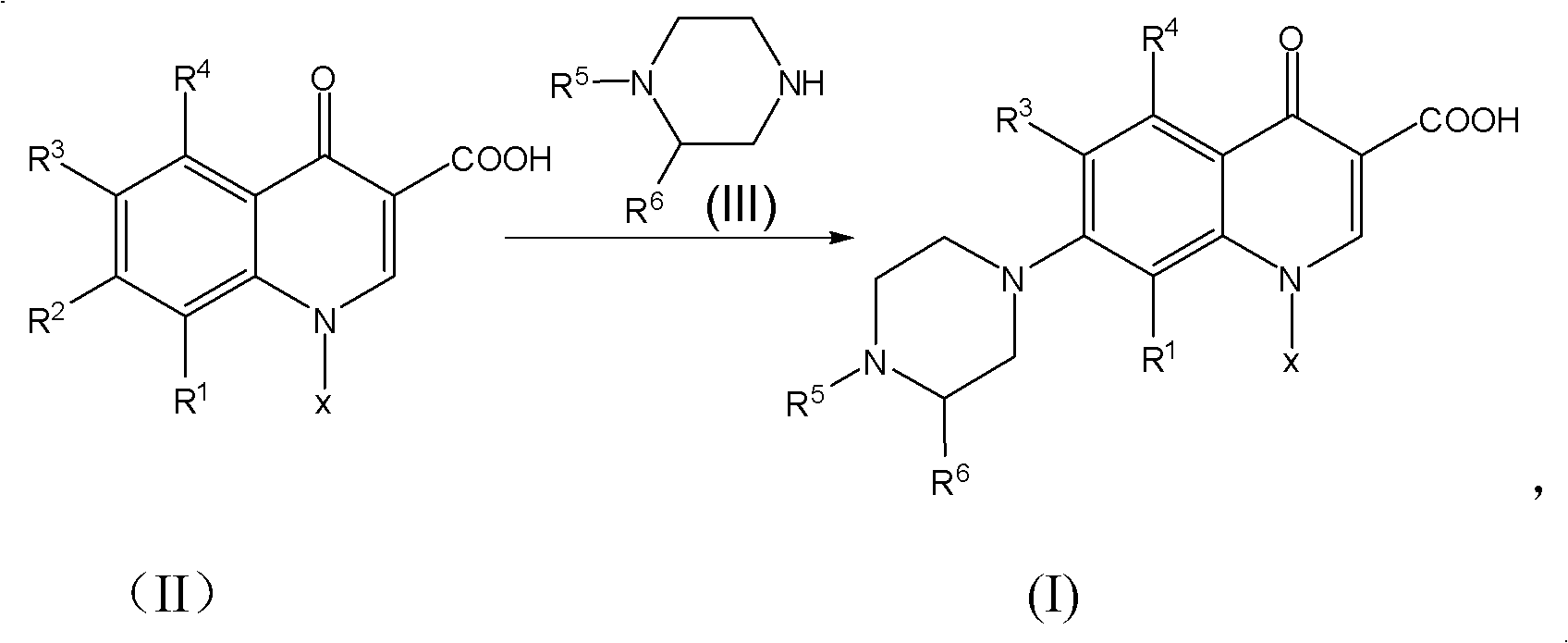

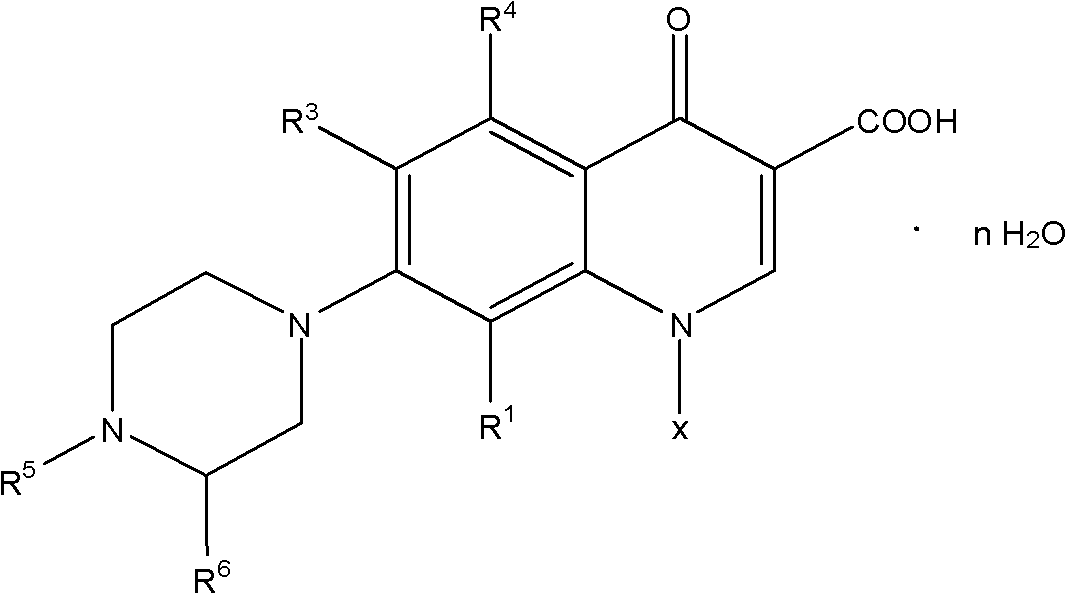

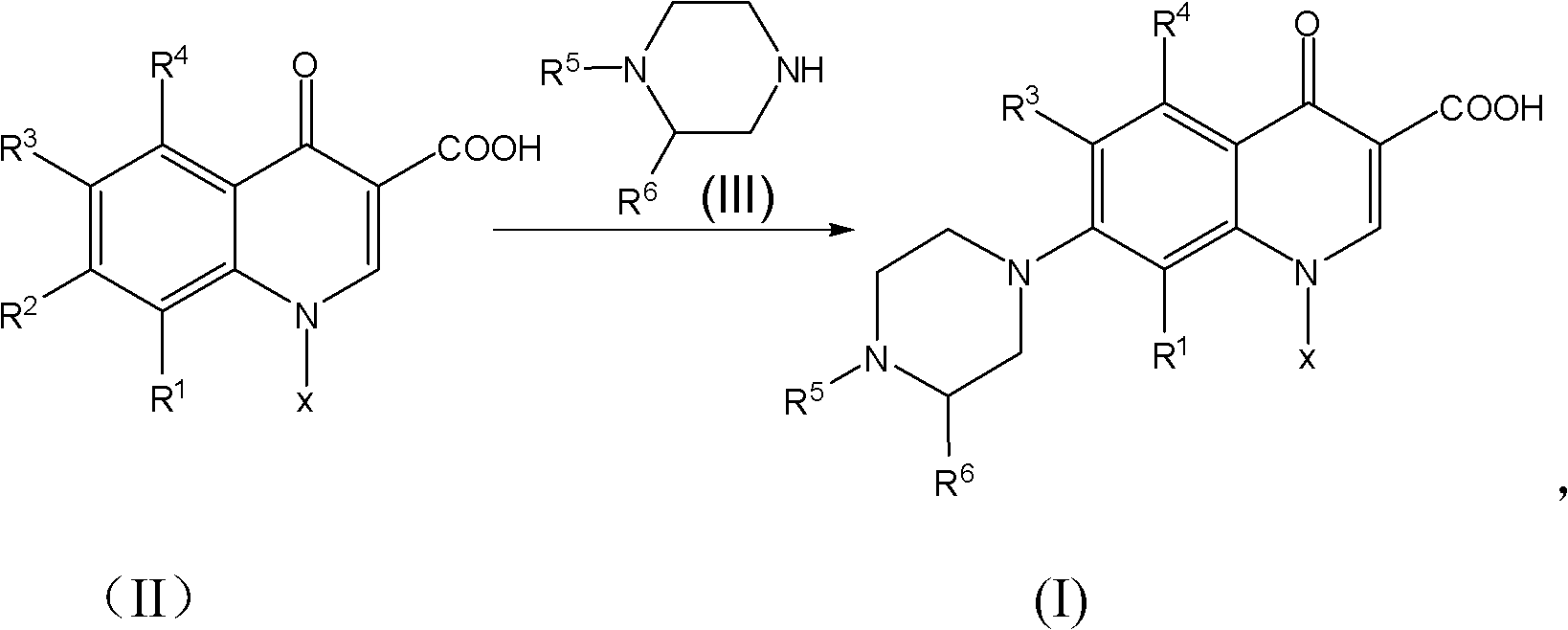

Method for synthesizing quinolone medicaments

InactiveCN101781313ASolve the environmental odor problemRealize cleaner productionOrganic chemistryCarbonyldiimidazoleCarboxylate

The invention discloses a method for preparing quinolone medicaments. The conventional methods using organic solvents with a high boiling pint and a large polarity, adopting other solid alkali materials except reaction materials or using other liquid alkali materials except the reaction materials have obvious defects. The method of the invention adopts a technical scheme that: quinolone compounds are prepared by a piperazidine reduction of quinolone carboxylate nuclear parent and piperazidine derivates in water; the piperazidine reduction is completed in the presence of a catalyst which may be one or a mixture of more than two of cerous chloride heptahydrate, N,N-carbonyldiimidazole, 4-dimethylamino pyridine, tetrabutylammonium bromide, benzyl triethylammonium chloride and tetrabutyl ammonium hydroxide. The method for preparing the quinolone medicaments radically solves the problems of terrible smell, realizes clean production, avoids using the other alkali substances except the reaction materials as an acid-binding agent and overcomes the defects of the prior art.

Owner:ZHEJIANG JINGXIN PHARMA +1

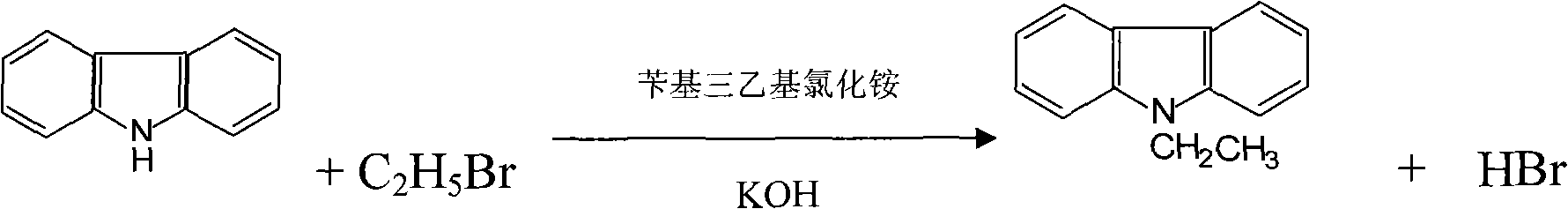

Method for producing N- ethyl carbazole

The invention provides a method for producing N-ethyl carbazole. The method takes toluene as a solvent, and utilizes benzyl triethyl ammonium chloride as a phase transfer catalyst and takes solid KOH as a deproton agent. Carbazole and ethyl bromide react to produce the N-ethyl carbazole. The method for producing N-ethyl carbazole has simple process, is easy to realize the continuous process, can reuse the catalyst of the solid KOH and has the yield of the product up to more than 97 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

Epoxy resin catalytic refining process

ActiveCN101177477AOrganochlorine (hydrolyzed chlorine) content is reducedReduce consumptionTolueneSolvent

The invention relates to a catalytic refining process of the epoxy resin, comprising following preparation steps: feeding according to mass ratio of the bisphenol A to the epichlorohydrin ranges from 1:1.0 to 1:1.2; adjusting the temperature to 55 DEG C to 65 DEG C under 19KPa to 14KPa and adding sodium hydroxide and resin of 166kg per ton theoretical yield; after 3 to 5 hours reaction, distilling the excessive epichlorohydrin to obtain semi-finished expoxy resin; adding benzyl triethyl ammonium chloride of 4.0 per mill to 5.0 per mill of the theoretical mass of the resin as catalyst. The quantity of sodium hydroxide added is calculated according to the organochlorine; the formula is: mass of sodium hydroxide is equal to semi finished organochlorine timing 400 timing the theoretical yield of resin timing 1.1 to 3.5; preparing the sodium hydroxide into the solution with concentration ranging from 12 per cent to 15 per cent and adding the semi-finished epoxy resin; adding solvent toluene of 90 per cent to 110 per cent of the resin theoretical mass; after 2 to 4 hours reaction, washing and removing the solvent to get epoxy resin.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

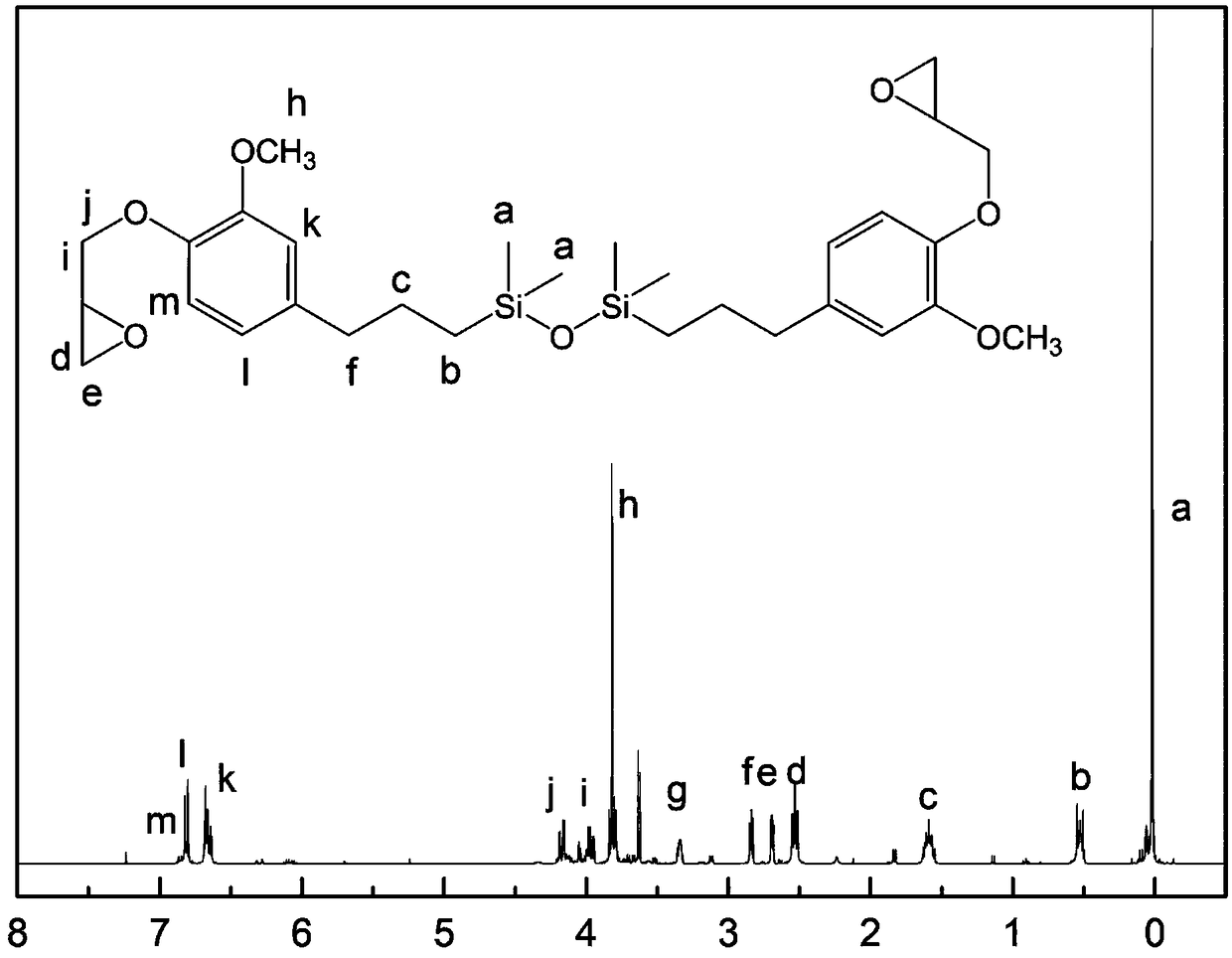

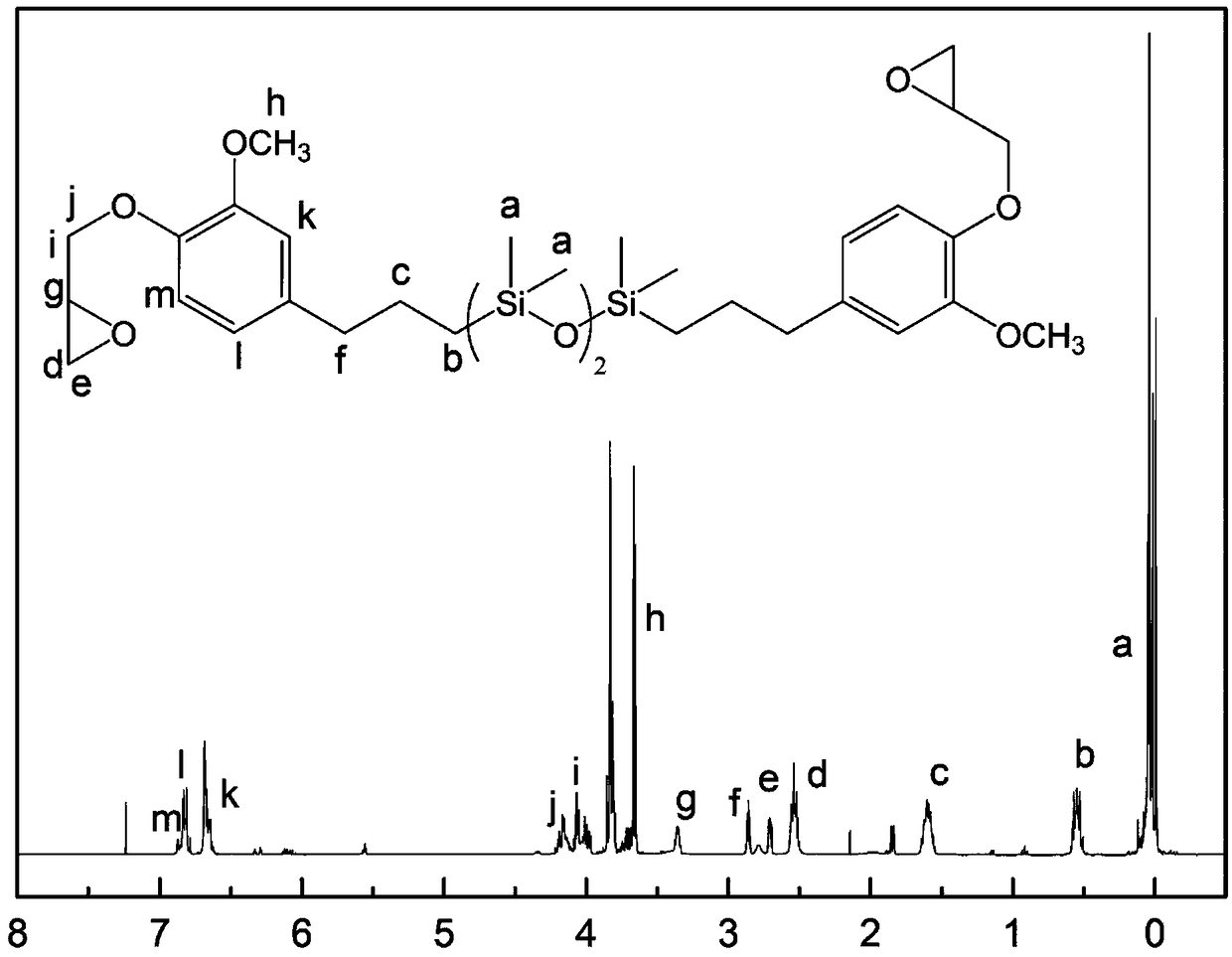

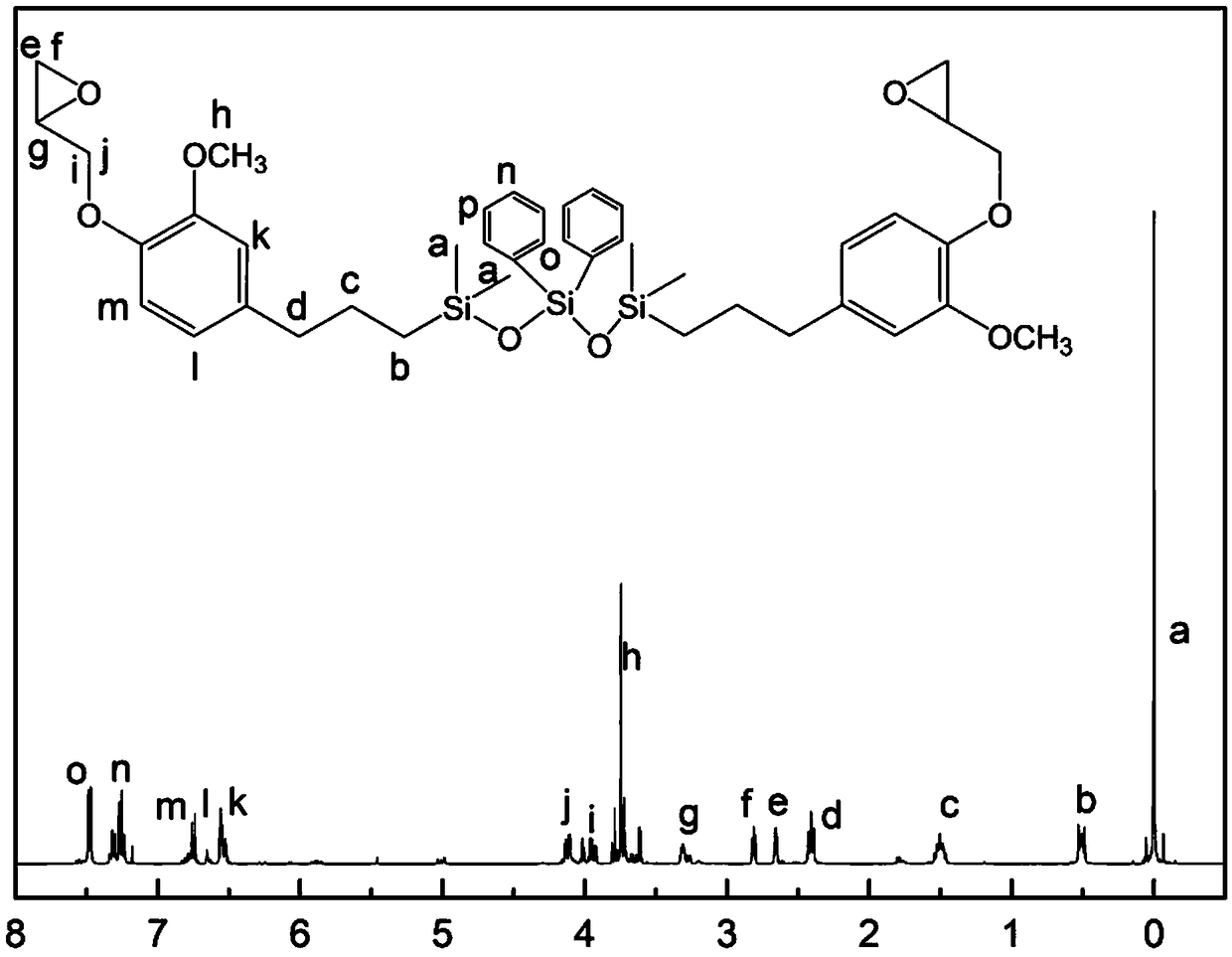

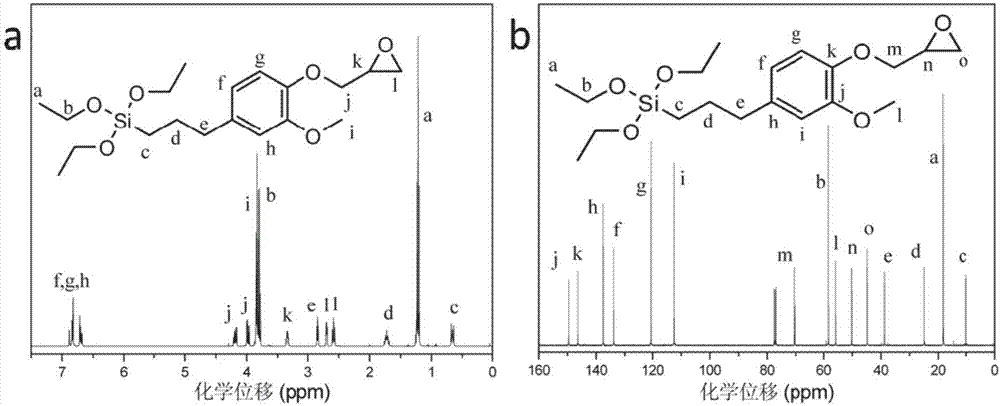

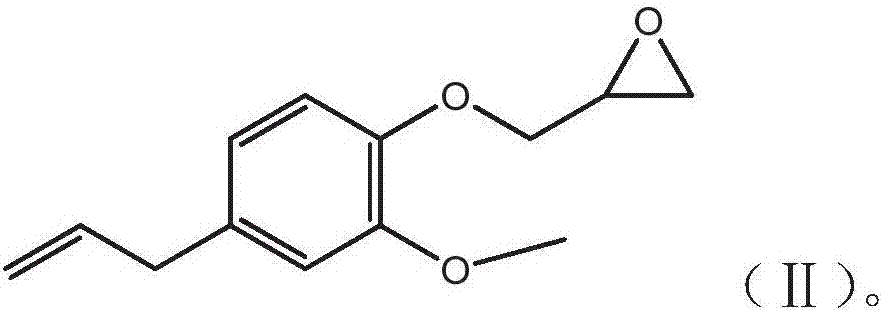

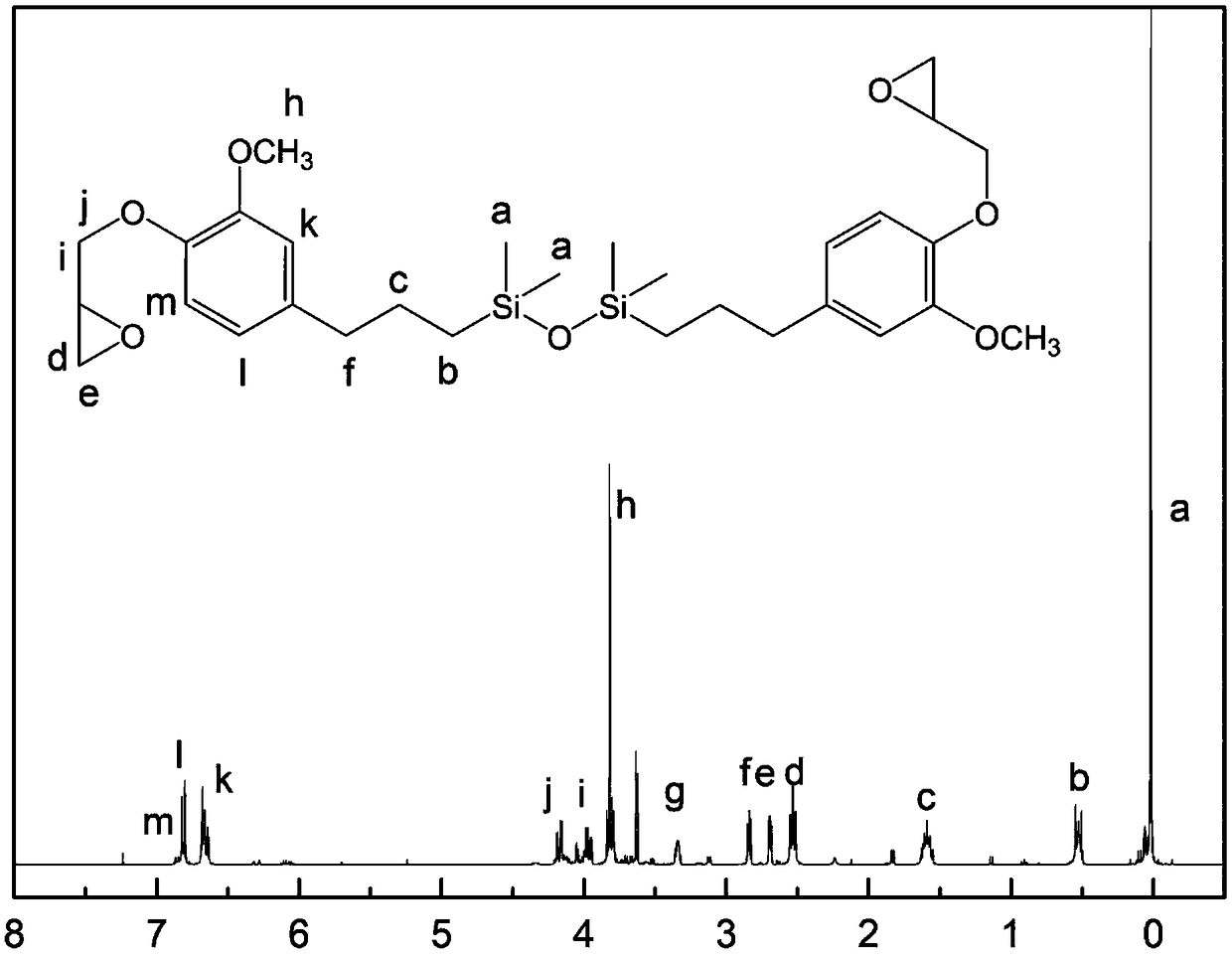

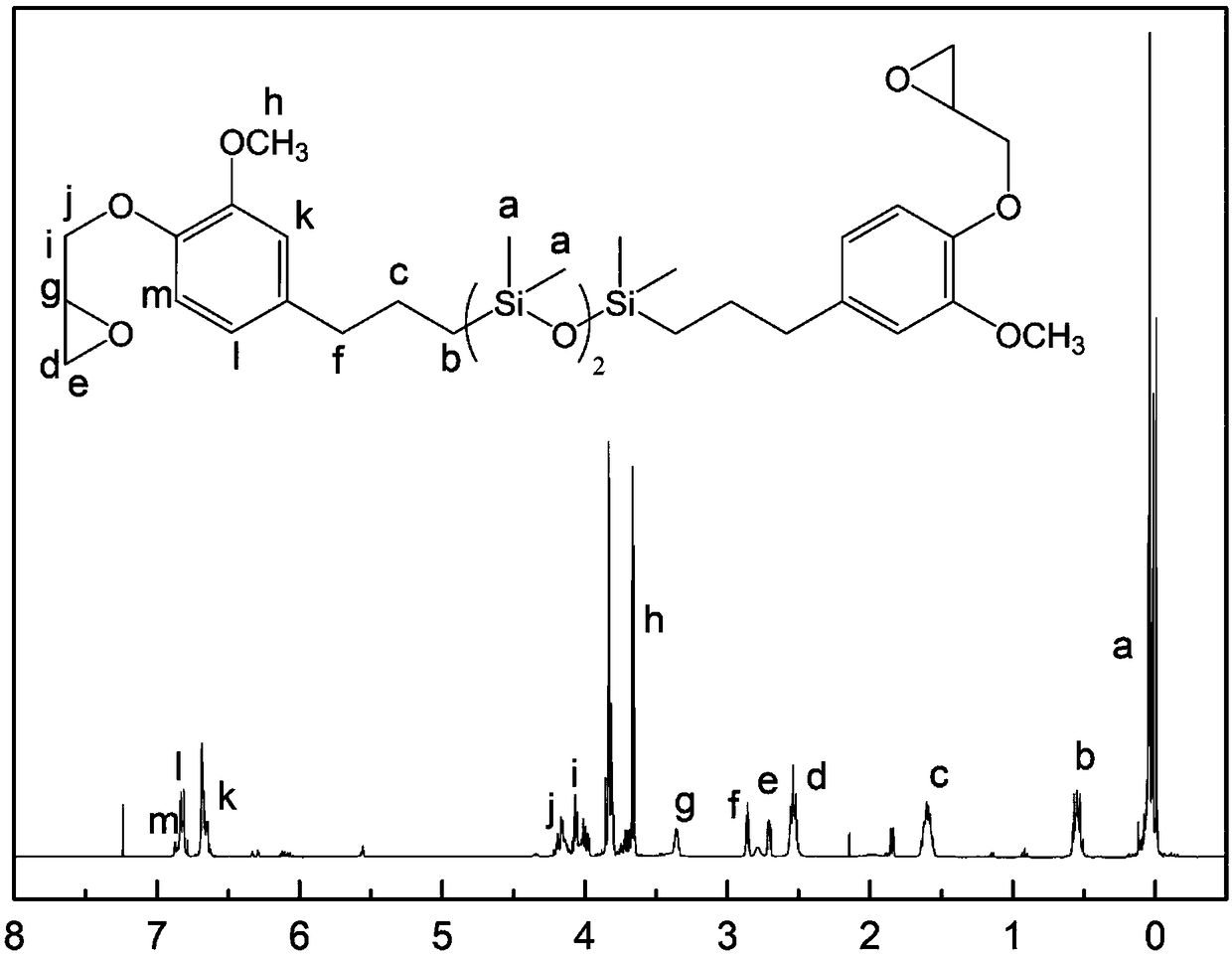

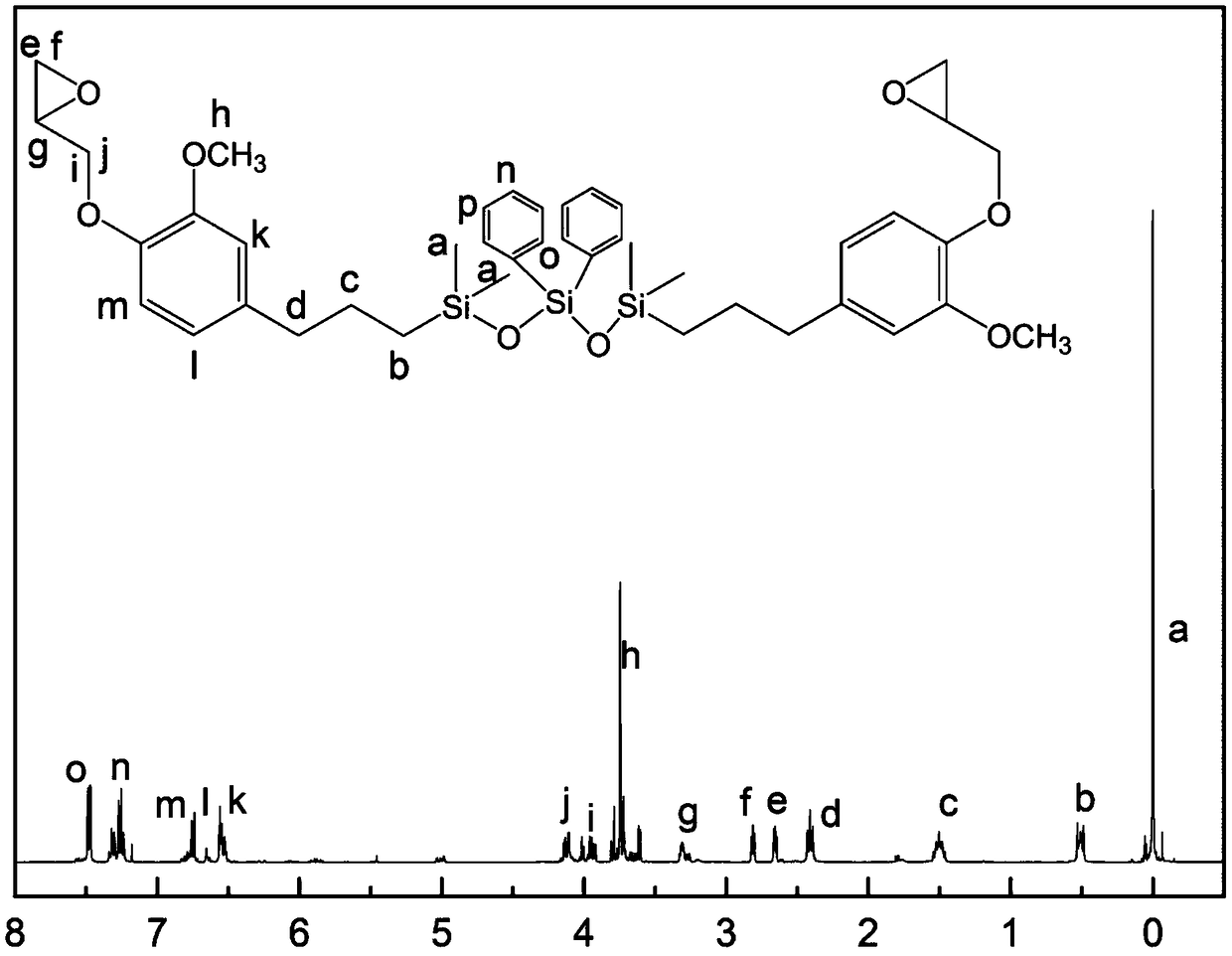

Eugenol-based epoxy resin and preparation process and application thereof

InactiveCN109400638AImprove catalytic performanceImprove flame retardant performanceSilicon organic compoundsEpoxyHalloysite

The invention discloses a preparation process of eugenol-based epoxy resin. The preparation process comprises the steps that (1) eugenol, epichlorohydrin and a catalyst A are added under the normal pressure, etherification ring-opening reaction is conducted at the temperature of 90-120 DEG C, thus chlorinol ether is prepared, and the catalyst A is a halloysite nanotube immobilized with benzyl triethyl ammonium chloride; (2) when a system obtained through reaction in the step (1) is cooled to 40-80 DEG C, alkali is added into the system, heat preservation for reaction is conducted for 1-12 h,then still standing and cooling layering are conducted, and thus collected organic phase products are epoxidized eugenol; and (3) the epoxidized eugenol prepared in the step (2), siloxane containing hydrogen at the two ends, and a catalyst B are mixed, hydrosilylation is conducted, and thus the eugenol-based epoxy resin is prepared. According to the preparation process, the bio-based eugenol serves as an initial raw material, and a prepared eugenol-based epoxy resin curing material simultaneously has the excellent flame retardant property, bonding property and electrical property.

Owner:ZHEJIANG UNIV

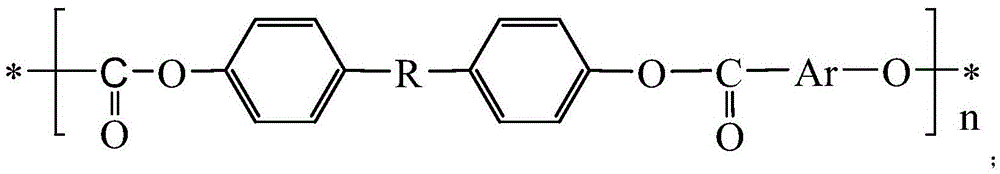

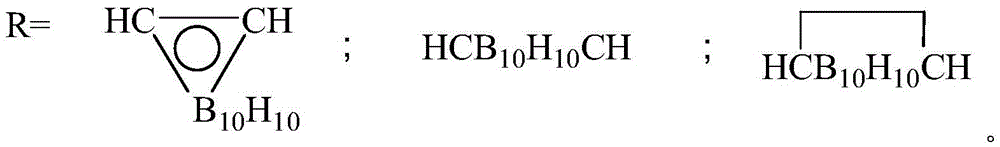

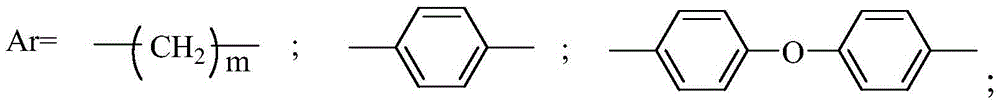

Method for synthesizing carborane polyarylester in greenhouse and carborane polyarylester

ActiveCN105418906ASolve the problem of different proportionsImprove thermal stabilityRoom temperatureChloride

The invention discloses a method for synthesizing carborane polyarylester in a greenhouse and carborane polyarylester. The method is performed under the protection of inert gas and in a water-free and oxygen-free environment by using diacid chloride dissolved by low-molecular-weight halogenated hydrocarbon as an organic phase, using carborane diphenol dissolved by deionized water as an inorganic phase, using benzyl triethyl ammonium chloride and strong alkali as catalyst, slowly dropping the organic phase into the inorganic phase, and performing quick agitation after full dropping to obtain high-molecular-weight carborane polyarylester. Operation is performed at room temperature instead of high temperature at which the traditional carborane-containing polymer is synthesized, the safety and reliability are high, the molecular weight is great and the yield is above 75 percent.

Owner:佛山市南海高拓包装材料有限公司

Negative ion coating capable of being cured by ultraviolet light and preparation method of negative ion coating

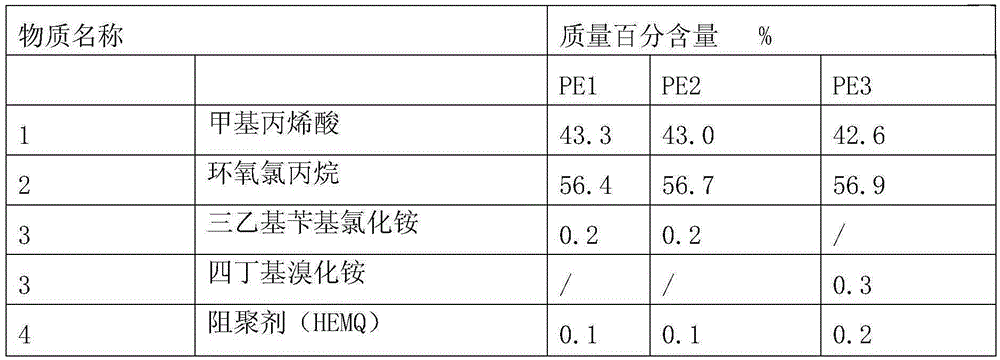

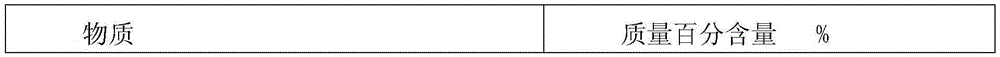

ActiveCN105295671AFast curingFacilitated releasePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxy(Hydroxyethyl)methacrylate

The invention relates to a negative ion coating capable of being cured by ultraviolet light and a preparation method of the negative ion coating. The negative ion coating is a composition capable of being cured by ultraviolet light, and comprises an oligomer, a dilution monomer, halogenated acrylate, an initiator, nano negative ion slurry, and a coating additive, wherein the dosage of the halogenated acrylate is 10 to 15 percent; the halogenated acrylate is a reaction product of epoxy chloropropane, methacrylic acid and a catalyst; the catalyst is, but not limited to, quaternary ammonium salt such as benzyl triethyl ammonium chloride and tetrabutylammonium bromide; the dosage of the catalyst is 0.2 to 0.3 of the total weight of the epoxy chloropropane, the methacrylic acid and the catalyst; the dosage of the nano negative ion slurry is 15 to 25 percent; the nano negative ion slurry is obtained by mixing nano negative ion powder with methacrylic acid hydroxyethyl under the existence of a special dispersing agent, stirring and carrying out temperature control at 50 to 60 DEG C for 3 hours; when the coating quantity reaches 40g / m<2>, the negative ion generation quantity of the composition is equal to or higher than 2000 / m<3>.

Owner:瑞通高分子科技(浙江)有限公司

Method for preparing bisphenol A diether dianhydride

ActiveCN108148029ASimple processEasy to implementOrganic chemistryAqueous sodium hydroxideRoom temperature

The invention relates to a method for preparing bisphenol A diether dianhydride. The method comprises the following steps that: the molar ratio of sodium hydroxide to bisphenol A is (2.1-2.3) to 1, the molar ratio of 4-chlorophthalic anhydride to phenol A is (2-2.1) to 1, the weight of a catalyst benzyl triethyl ammonium chloride is 15% by weight of the weight of bisphenol A, and the amount of a solvent trimethylbenzene is 8 times larger than the weight of bisphenol A; the preparation process is as follows: adding an aqueous solution of sodium hydroxide and bisphenol A to areactor, heating, stirring and dissolving at a temperature, heating to 85 DEG C to 90 DEG C, adding the trimethylbenzene and benzyl triethyl ammonium chloride which accounts 46% by weight of the total weight, heating toreflux, dewatering, stirring at a temperature of 172 DEG C and reacting for 15 to 18 hours, cooling to 130 DEG C, adding 4-chlorophthalic anhydride and benzyl triethyl ammonium chloride which accounts54% by weight of the total weight, heating 140 DEG C to 145 DEG C, performing a reflux reaction for 5 to 6 hours, filtering while hot, cooling a filtrate to room temperature, filtering, washing a precipitate with deionized water and ethanol respectively, filtering to obtain a wet material, and drying to obtain a bisphenol A diether dianhydride product with a yield of 80 to 85%. .

Owner:上海固创化工新材料有限公司

Preparation method of modified active carbon

ActiveCN105233790AOther chemical processesWater/sewage treatment by sorptionActivated carbonBoron trichloride

The invention discloses a preparation method of modified active carbon. The preparation method comprises the following steps: at first, adding active carbon into a mixture of ethylene glycol dimethacrylate and a boron trichloride-trimethyl amine complex, heating to carry out reactions so as to obtain a product (A), then adding the product (A) into oxalic acid, heating to a temperature of 50 to 60 DEG C under a vacuum condition, maintaining the temperature for 60 to 100 minutes, filtering to obtain a product (B); and finally reacting the product (B) with benzyl triethyl ammonium chloride to obtain the modified active carbon. The technology of the provided preparation method is simple, and the prepared modified active carbon has a good performance on adsorbing heavy metal ions.

Owner:江苏富汇通环保科技有限公司

Decontamination solution and method

A chemical warfare agent decontamination solution made up of about 20% of a quaternary ammonium complex containing benzyltrimethylammoniumchloride and benzyltriethylammonium chloride and about 20% by weight of an oxidizer, dissolved in a solvent, such as water or glycol, is provided. This solution is a noncorrosive, nontoxic, nonflammable decontaminant, which may also be used to neutralize organophosphorus agricultural chemicals.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Hydrophilic epoxy resin binder and preparation method and application thereof

ActiveCN102775948AReduce pollutionImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesHigh intensitySurface-active agents

The invention discloses a hydrophilic epoxy resin binder and a preparation method and an application thereof. The hydrophilic epoxy resin binder consists of the following components according to parts by weight: bisphenol A type epoxy resin, a surface active agent Span, a surface active agent Tween and a catalyst, wherein the catalyst can be tetraethyl ammonium chloride, butyl triphenyl phosphonium bromide, benzyl triethyl ammonium bromide, benzyl triethyl ammonium chloride, 2-methyl imidazole or any combination thereof; the bisphenol A type epoxy resin can be bisphenol A type epoxy resin E-44, E-42, E-35, E-31, E-20, E-14, E-12, E-06, E-03 or any combination thereof; the surface active agent Span can be S-20, S-40, S-60, S-80, S-85 or any combination thereof; and the surface active agent Tween can be T-20, T-40, T-60, T-80, T-85 or any combination thereof. The hydrophilic epoxy resin binder is applied in the preparation process of water permeable pavement materials and high-strength cement products.

Owner:杭锦旗亿嘉环境治理有限公司

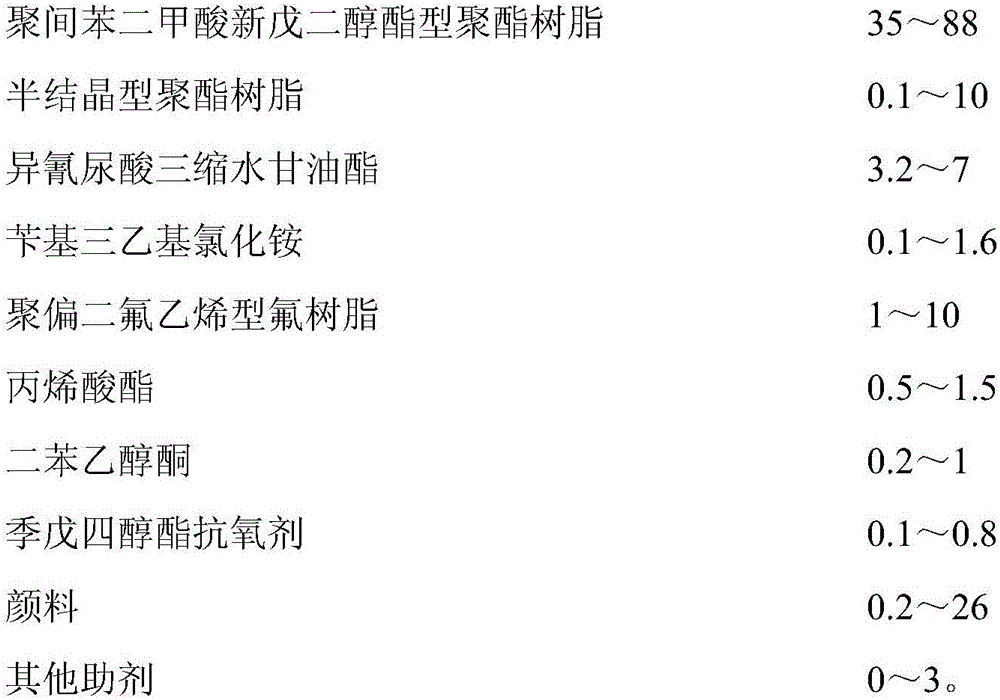

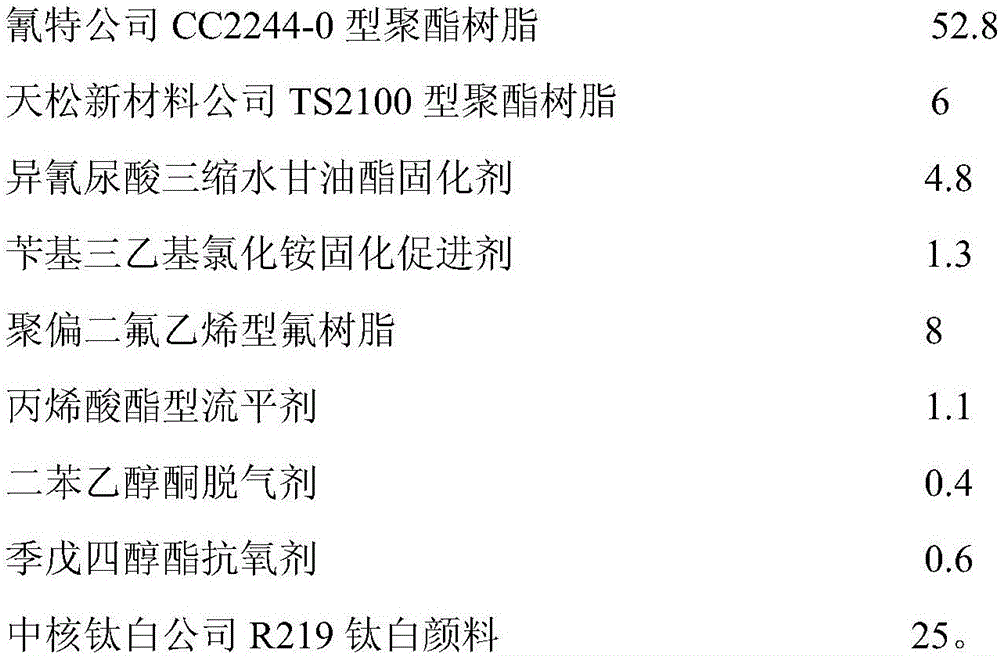

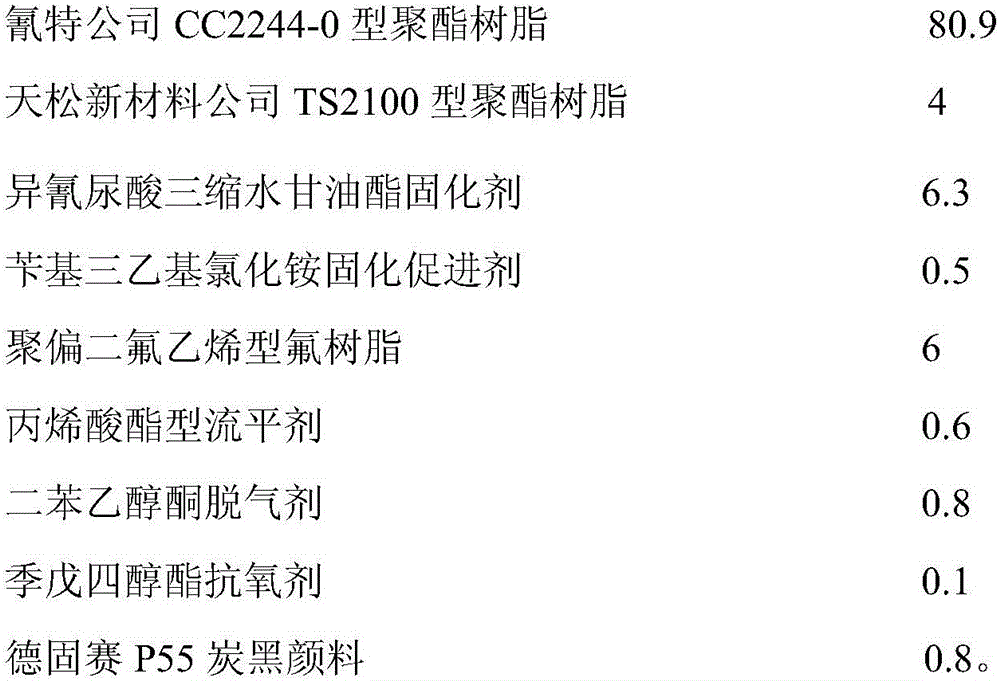

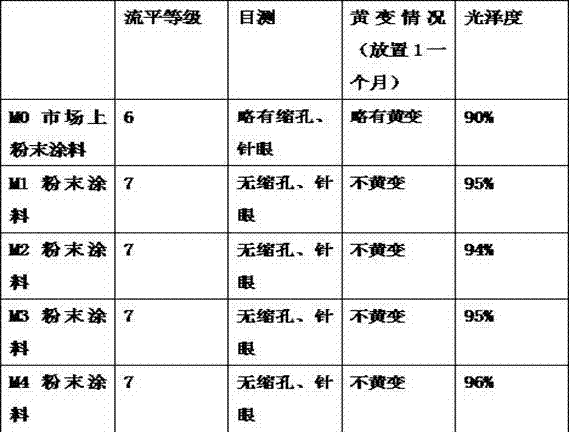

Extra weather-resistant micro-spherical powder coating used for metal coiled material and prepared through supercritical fluid technology and preparation method thereof

ActiveCN106634479AGood weather resistanceSolve the flatnessPowdery paintsBulk chemical productionPliabilityMaterials science

The invention belongs to the technical field of powder coatings, and specifically relates to an extra weather-resistant micro-spherical powder coating used for a metal coiled material and prepared through a supercritical fluid technology and a preparation method thereof. The micro-spherical powder coating is made of, by mass percentage, 35-88 parts of poly-isophthalic acid neopentyl glycol polyester resin, 0.1-10 parts of semi-crystalline polyester resin, 3.2-7 parts of triglycidyl Isocyanurate, 0.1-1.6 parts of benzyl triethyl ammonium chloride, 1-10 parts of kynar fluororesin, 0.5-1.5 parts of acrylic ester, 0.2-1 part of benzoin, 0.1-0.8 part of pentaerythritol ester, 0.2-26 parts of pigment and 0-3 parts of other auxiliaries. A supercritical fluid technology is adopted, and the extra weather-resistant micro-spherical powder coating has the advantages of being simple in process and stable in product quality. The powder coating particles are micro-spherical, small in grain size and concentrated in grain distribution range, the surface is flat when thin coating of the metal coiled material is performed, and the extra weather-resistant micro-spherical powder coating is good in weather resistance, flexibility and low-temperature performance and suitable for fast coating of the metal coiled material.

Owner:江苏多孚多智能装备科技有限公司

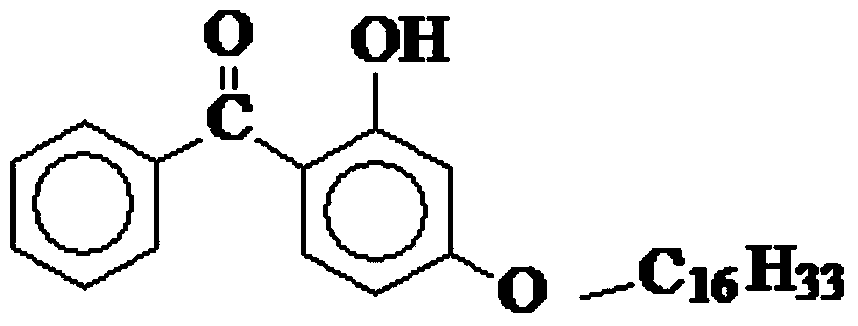

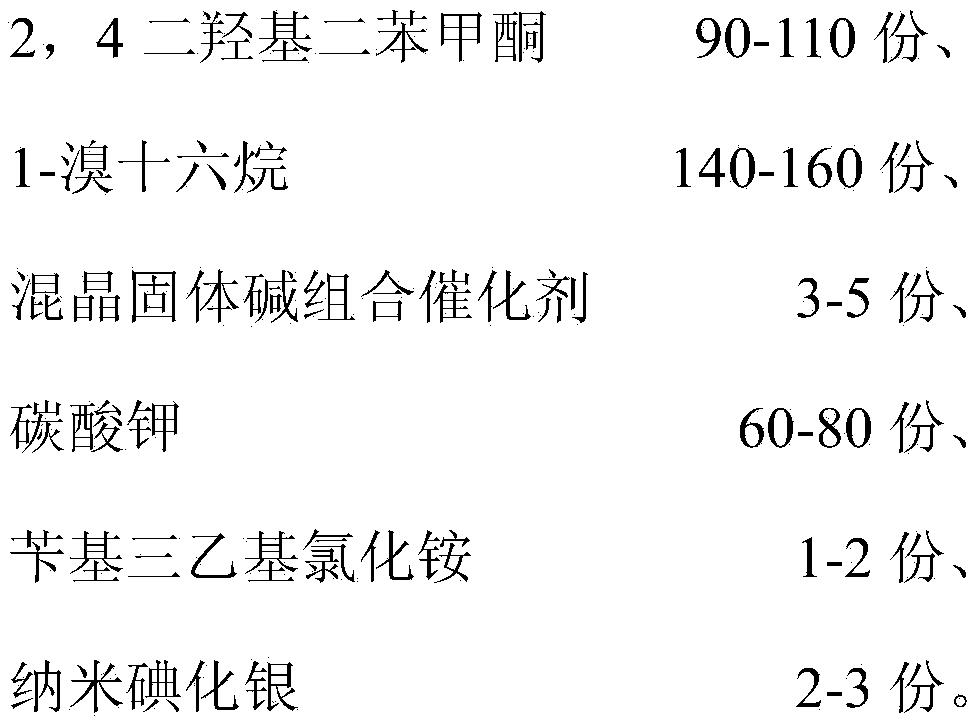

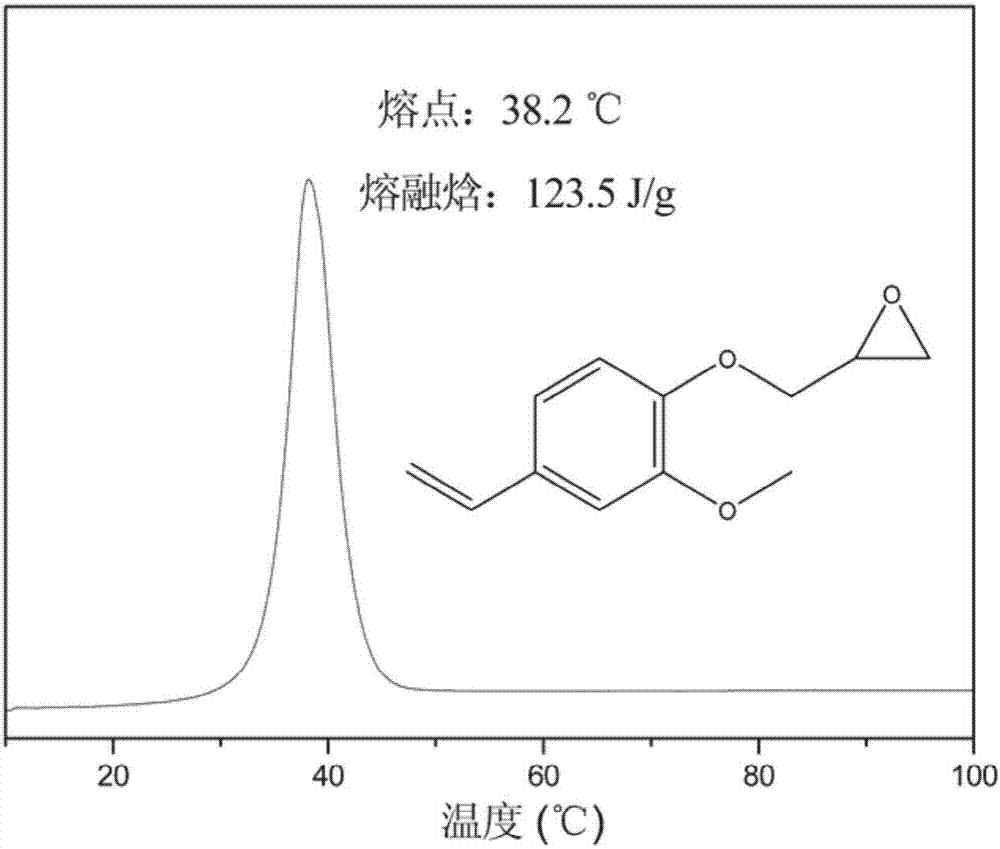

Preparation method of 2-hydroxy-4-cetyloxy-diphenyl ketone

ActiveCN103524311ASimple purificationNo corrosionOrganic compound preparationCarbonyl compound preparationSilver iodide1-bromohexadecane

The invention provides a preparation method of 2-hydroxy-4-cetyloxy-diphenyl ketone, which comprises the following steps: mixing 2,4-dihydroxy benzophenone, 1-bromohexadecane, mixed crystal solid alkali composite catalyst, potassium carbonate, benzyltriethylammonium chloride and nano silver iodide, introducing nitrogen, reacting at 130-155 DEG C under reflux for 8-10 hours, filtering out the solid, separating the water phase from the organic phase after reaction, extracting the organic phase with water, and distilling under reduced pressure to obtain the product. The method has the advantages of simple purifying treatment and no corrosion to equipment; and the prepared 2-hydroxy-4-cetyloxy-diphenyl ketone is mainly used for producing stone paper in the fields of outer wall paints, rubber and plastic industry, and is also suitable for producing specialty paper.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

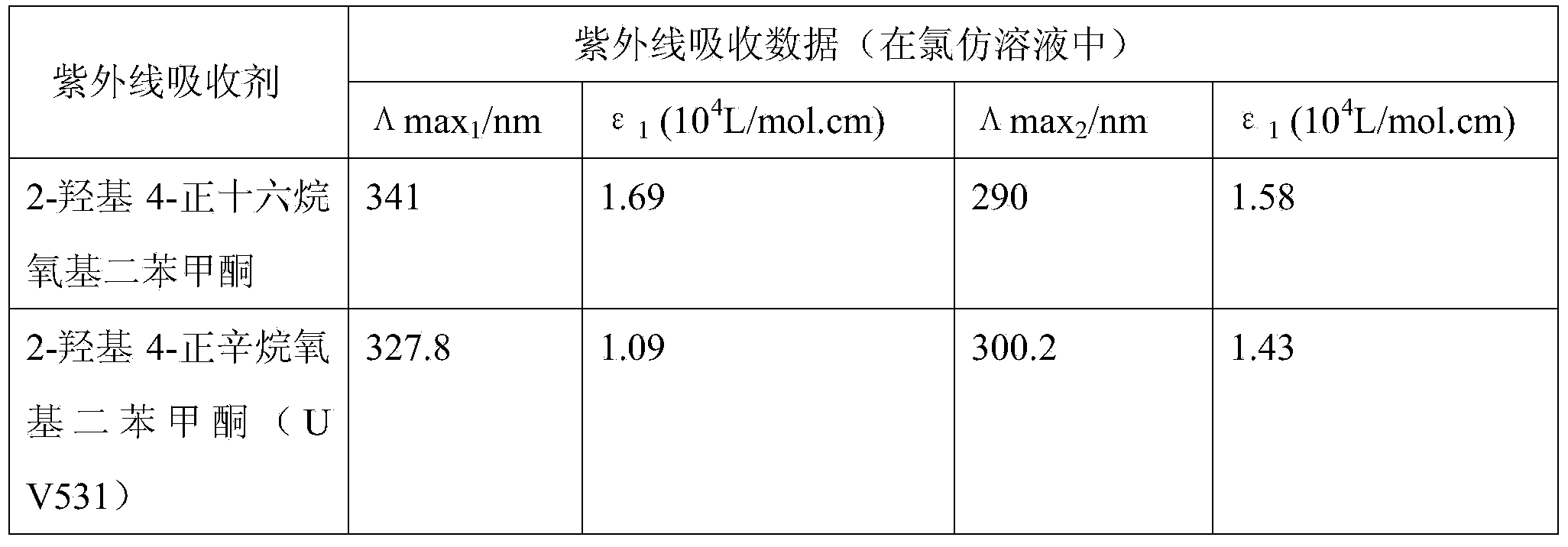

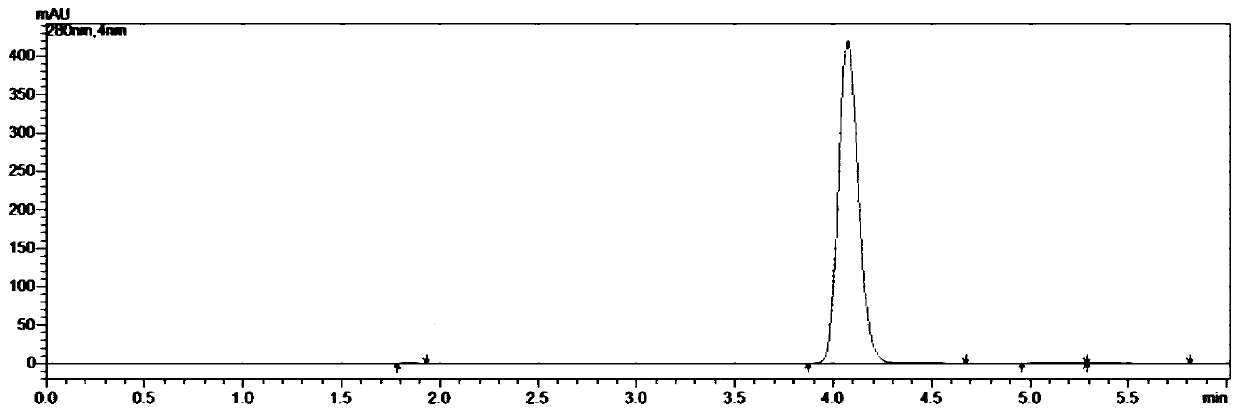

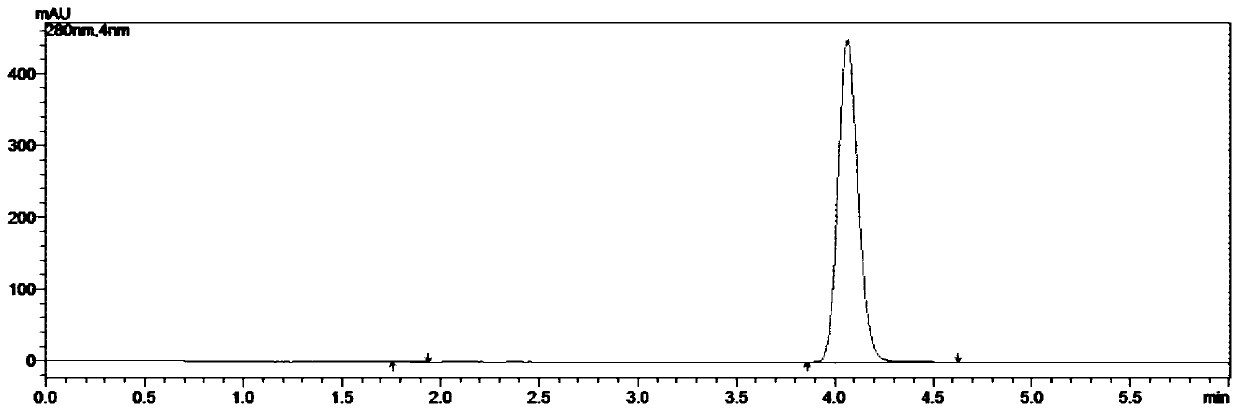

Method for preparing high-purity eugenol epoxy, product and application of product

ActiveCN107445921AHigh purityGood compatibilityGroup 4/14 element organic compoundsEpoxyOrganic solvent

The invention discloses a method for preparing high-purity eugenol epoxy. The method comprises the steps: mixing epoxy chloropropane, eugenol and benzyltriethylammonium chloride, carrying out a ring-opening reaction, then, adding a sodium hydroxide aqueous solution, and carrying out a ring-closing reaction, so as to obtain a crude product; subjecting the crude product to reduced-pressure distillation, and then, carrying out low-temperature recrystallization, thereby obtaining the eugenol epoxy, wherein the low-temperature recrystallization specifically comprises the steps of mixing liquid, obtained through reduced-pressure distillation, with an organic solvent, cooling the temperature of the mixture to -20 DEG C to -0 DEG C, and carrying out filtering, thereby obtaining the purified eugenol epoxy. According to the method for preparing the high-purity eugenol epoxy, provided by the invention, the crude product is subjected to a specific purification process, and thus, the purity of the crude product is remarkably improved to 99% or more from 90%.

Owner:ZHEJIANG UNIV

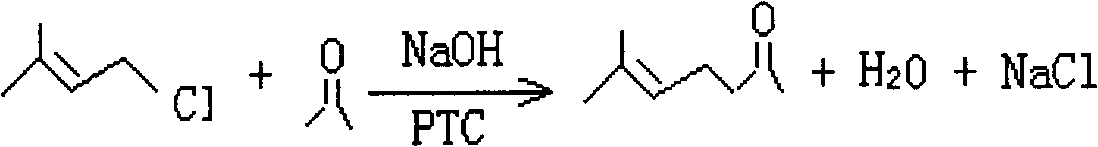

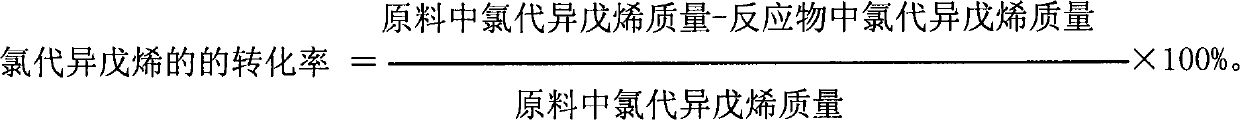

Preparation method of methyl heptenone

The invention discloses a preparation method of methyl heptenone. Under an alkaline condition, benzyl quaternary ammonium salt is used as a catalyst, prenyl chloride and acetone are synthetized into methyl heptenone through condensation reaction, salts in the reaction liquid are removed by filtering, by liquid separation, methyl heptenone in oil phase is obtained from upper liquid, and alkaline liquor in which the catalyst is dissolved is obtained from lower liquid. The preparation method has obvious positive effects, the benzyl triethyl ammonium chloride catalyst has relatively high selectivity to condensation reaction of prenyl chloride and acetone, and yield of methyl heptenone is more than 80%. The problem of failure in recycle of a catalyst in the prior art is solved radically. Since the benzyl quaternary ammonium salt has good dissolvability in the alkaline liquor, the catalyst is dissolved in the alkaline liquor after reaction, and in the alkaline liquor recycle process, the catalyst is recycled with the alkaline liquor so as to be reused.

Owner:CHINA PETROLEUM & CHEM CORP +1

Core-shell structured polyvinylidene fluoride/polycarbonate superfine fiber and preparing method thereof

InactiveCN101586268AUniform fiber morphologyPerfect core/shell structureFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer scienceElectrospinning

The present invention relates to a core-shell structured polyvinylidene fluoride (PVDF) / polycarbonate (PC) superfine fiber and a preparing method thereof. The PC and PVDF are used as raw materials, and the PMMA or BTEAC is added for preparing according to a proportion PVDF / PC=7-9 / 1-3. The adding amount of the PMMA or the BTEAC is respectively 5-20wt% and 1-4wt% of the total mass of the PC and the PVDF, and the diameter of the obtained fiber is 300-500nm. The preparing method of the invention specifically comprises the following processing steps: adding PMMA or benzyl triethyl ammonium chloride into the solution of the DMF / THF mixed solvent of PC, then addign the PVDF and DMF, mixing for obtaining the PVDF / PC dispersion containing PMMA or BTEAC as the electrospinning solution, and injecting the electrospinning solution into an electrospinning device for electrospinning. According to the invention, the PVDF / PC multi-component polymer electrospinning solution is modified through adding a third component (PMMA or BTEAC) into the PVDF / PC electrospinning solution so that the modified PVDF / PC electrospinning solution can form the superfine fiber which has uniform fiber appearance and complete core / shell structure in electrospinning. The preparing method is easy and feasible, and is suitable for preparing the superfine fiber with evident core / shell structure in electrospinning with other multi-component polymer system.

Owner:TIANJIN UNIV

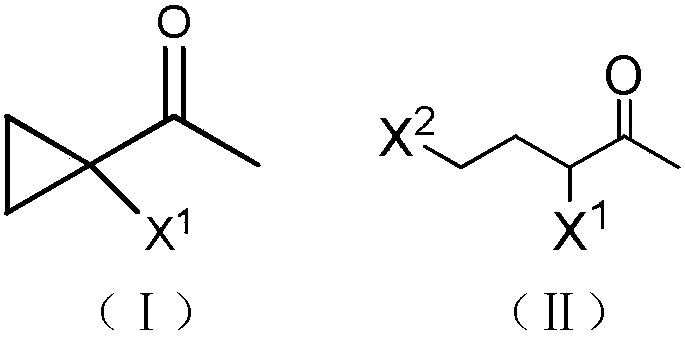

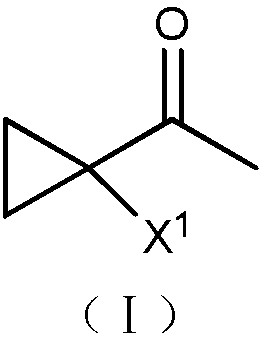

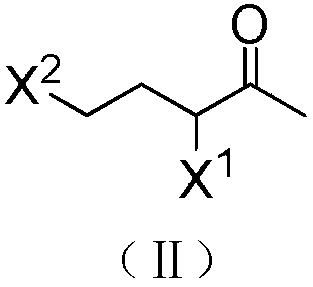

Synthetic method of 1-halo-1-acetyl cyclopropane

InactiveCN107759457ASuitable for industrial productionShort timeOrganic compound preparationCarbonyl compound preparationCyclopropaneStructural unit

The invention discloses a synthetic method of 1-halo-1-acetyl cyclopropane. The synthetic method comprises the step of preparing a 1-halo-1-acetyl cyclopropane compound by taking 3,5-dihalo-pentanoneas a raw material and taking benzyl trimethyl ammonium chloride as a phase transfer catalyst under the action of alkali. The method disclosed by the invention is simple to operate, quick to react andhigh in yield, and solves the problem of quickly and efficiently synthesizing the 1-halo-1-acetyl cyclopropane compound. The synthetic method disclosed by the invention is primarily used for synthesizing organic molecules containing cyclopropane structural units.

Owner:XIAN MODERN CHEM RES INST

Method for synthesizing anchoic acid through combined oxidation of hydrogen peroxide and potassium permanganate

ActiveCN104447279AImprove oxidation capacityEasy to separateOrganic compound preparationCarboxylic preparation by oxidationFiltrationOxygen

The invention relates to a method for synthesizing anchoic acid through combined oxidation of hydrogen peroxide and potassium permanganate. The method comprises the following steps: mixing oleic acid, a phosphotungstic acid catalyst and benzyl triethyl ammonium chloride, and rapidly stirring and heating under the condition of introducing oxygen; adding potassium permanganate, adding a hydrogen peroxide solution, and separating the mixed liquid in a separating funnel after reaction is ended, wherein manganese dioxide is arranged at the lower part of a water layer; an oil layer is arranged on the water layer and is easy to separate; refrigerating and crystallizing the separated water phase, and separating out white powder; and carrying out suction filtration and drying, so as to obtain anchoic acid solid. According to the method disclosed by the invention, other chemical apparatuses do not need to be used in the overall reaction process, so that energy consumption is lowered; the reaction speed is increased; the time is saved; a lot of organic solvents are not required in the reaction; and the method is environment-friendly and relatively high in reaction yield; a one-step reaction process is simple; a reaction system is easy to separate; the production cost is effectively reduced; and the method is environment-friendly.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

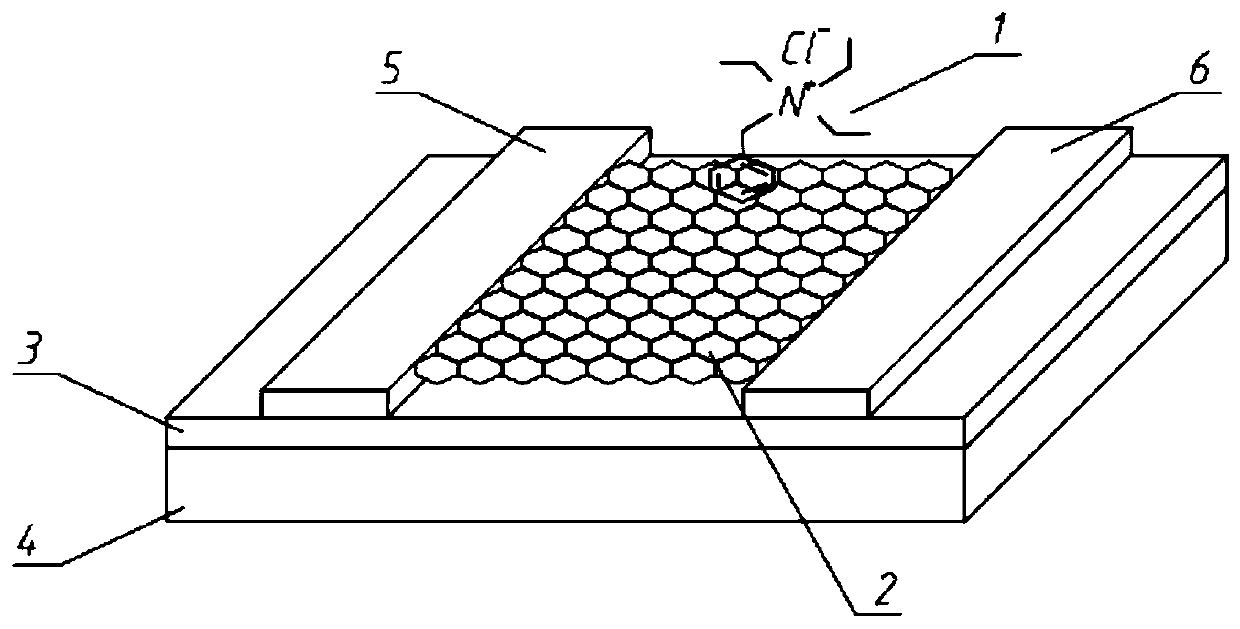

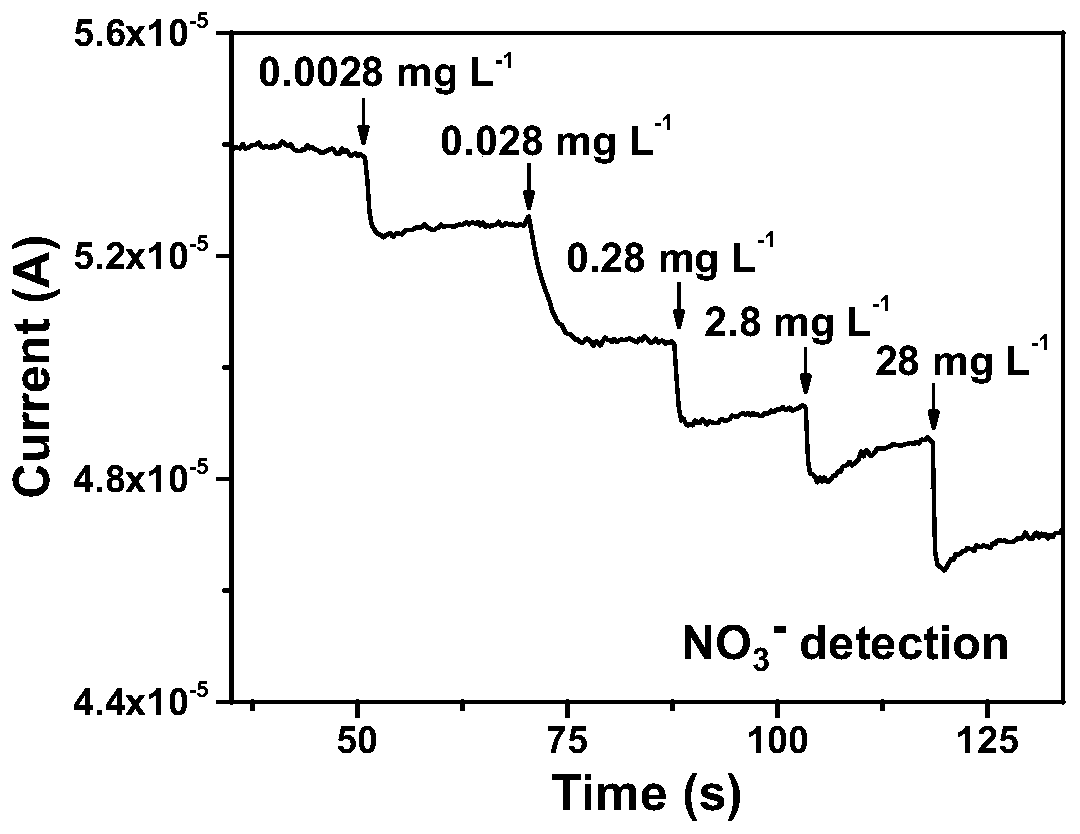

Graphene-based field effect transistor nitrate sensor

InactiveCN109870495ALow detection limitHigh selectivityMaterial analysis by electric/magnetic meansSilicon oxideField-effect transistor

The invention relates to a graphene-based field effect transistor nitrate sensor. The graphene-based field effect transistor nitrate sensor comprises a grid electrode (4), a source electrode (5) and adrain electrode (6), wherein the grid electrode (4) is a silicon slice, the surface of the grid electrode (4) is coated with a silicon oxide layer (3), and the source electrode (5) and the drain electrode (6) are formed on the surface of the silicon oxide layer (3); the source electrode (5) and the drain electrode (6) are connected through a graphene nanosheet layer (2); and the surface of the graphene nanosheet layer (2) is decorated with benzyl triethyl ammonium chloride to serve as a probe layer (1). According to the graphene-based field effect transistor nitrate sensor, compared with theprior art, the detection limit of nitric acid in water is low, the selectivity is high, and the transient response can be realized; and the cost is low, the chemical stability is good, and the reutilization can be achieved.

Owner:TONGJI UNIV

Bio-based epoxy resin as well as preparation process and application thereof

InactiveCN109384906AImprove catalytic performanceImprove flame retardant performanceSilicon organic compoundsEpoxyMolecular sieve

The invention discloses a preparation process of bio-based epoxy resin, the preparation process comprises: 1), adding eugenol, epoxy chloropropane and a catalyst A under normal pressure, carrying outetherification open-loop reaction at the temperature of 90-120 DEG C to prepare chlorhydrin ether; wherein the catalyst A is a mesoporous molecular sieve catalyst immobilized with benzyl triethyl ammonium chloride; 2) cooling the system obtained in the step 1) to 40-80 DEG C, adding an alkali into the system, and carrying out heat preservation reaction for 1-12 hours, standing, cooling and layering, and collecting an organic phase product, namely epoxy eugenol; and 3) and mixing the epoxy eugenol prepared in the step 2) and siloxane containing hydrogen at the two ends with a catalyst B, and carrying out hydrosilylation reaction to prepare the bio-based epoxy resin. The preparation process disclosed by the invention takes the bio-based eugenol as an initial raw material, and the prepared bio-based epoxy resin cured product has excellent flame retardancy, adhesive property and electrical property.

Owner:江苏和和新材料股份有限公司

Epoxy low temperature curable powder paint and preparation method thereof

InactiveCN107400444APerfectly conceals surface imperfectionsAvoid damagePowdery paintsEpoxy resin coatingsEpoxyInorganic pigments

The invention provides an epoxy low temperature curable powder paint and a preparation method thereof. The epoxy low temperature curable powder paint is composed of the following components: epoxy resin; precipitated barium sulfate and activated silica powder filler; benzyltriethylamine chloride; inorganic pigment; a curing agent; a curing assistant; a wetting agent; rosin; and other assistants. The invention also discloses a preparation method of the epoxy low temperature curable powder paint. The method includes the steps of: mixing, melting, tabletting, crushing and sieving. The powder paint provided by the invention not only improves the corner powdering rate, but also improves the coating film appearance and various physical properties, has the advantages of good layer compactness, adhesion, impact strength and toughness, high corner coverage rate, and excellent chemical corrosion resistance and electrical insulation performance.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Preparation method of metamitron

The invention discloses a preparation method of metamitron. The method comprises the following steps of: adding 2-acethydrazide hydrazone-2-phenyl-acethydrazide, a polarity organic solvent, a phase-transfer catalyst and a water absorbent serving as raw materials into a reaction device; heating until reflux to perform a dehydration cyclization reaction; sampling to perform HPLC (high performance liquid chromatography) analysis, and finishing the reaction until the conversion rate of the 2-acethydrazide hydrazone-2-phenyl-acethydrazide reaches over 99 percent; and cooling to a temperature of lower than 0 DEG C and filtering after the reaction is finished, washing and drying the filter cake to obtain the metamitron, wherein the phase transfer catalyst is tetrabutylammonium bromide or benzyl triethyl ammonium chloride. The method is short in reaction time, high in yield, and low in energy consumption and production cost.

Owner:江苏省农用激素工程技术研究中心有限公司

Synthetic method for increasing yield of 5-chloro-1-indanone

ActiveCN111454137AHigh selectivityReduce generationOrganic compound preparationCarbonyl compound preparationPtru catalystOrganic synthesis

The invention provides a synthetic method for increasing the yield of 5-chloro-1-indanone, and belongs to the technical field of organic synthesis. The preparation method comprises the following steps: taking 3,4'-dichloropropiophenone as a raw material, adding an aprotic acid catalyst, then heating to a molten state, and then adding a phase transfer catalyst to carry out reactions; wherein the aprotic acid catalyst is one of AlCl3, ZnCl2, InCl3, TiCl4, BF3, Fe(CF3SO3)3, Fe(CF3SO3)2 and gamma-aluminum oxide; the phase transfer catalyst is one of tetrabutyl ammonium bromide, tetrabutyl ammoniumchloride, trioctyl methyl ammonium chloride, benzyl triethyl ammonium chloride, dodecyl trimethyl ammonium chloride, 18-crown-6, 15-crown-5, polyethylene glycol 400, polyethylene glycol 600 and polyethylene glycol 800. By adding the phase transfer catalyst, the selectivity of a Friedel-Crafts reaction is obviously improved, the side reaction is reduced, and the reaction yield is improved.

Owner:山东京博生物科技有限公司

Super-strong viscous polymer new material and preparation technology thereof

The invention discloses a super-strong viscous polymer new material and a preparation technology thereof. The super-strong viscous polymer new material is obtained through the following steps: mixing 16-18 parts of an epoxy resin slurry, 2-4 parts of an active diluent, 6-8 parts of a solidification mixture and 70-80 parts of a base material, stirring and blending. Modified epoxy resin used in the invention is obtained through the following steps: taking 73.55wt% of epoxy resin E-44, 24.9wt% of Pluronic polyol polyether and 0.55wt% of benzyltriethylammonium chloride, adding the epoxy resin E-44 to a closed reactor, introducing an inert gas, heating to 85DEG C, adding a mixed solution prepared from Pluronic polyol polyether and benzyltriethylammonium chloride in a dropwise manner in a stirring state, heating to 125DEG C after the dropwise addition is finished, continuously reacting for 2.5h, and cooling. The super-strong viscous polymer new material has the advantages of excellent compression, impact, permeation and seawater corrosion resistance, no solvent, and reduction of pollution to environment.

Owner:CHENGDU YISHENGKE BIOTECH

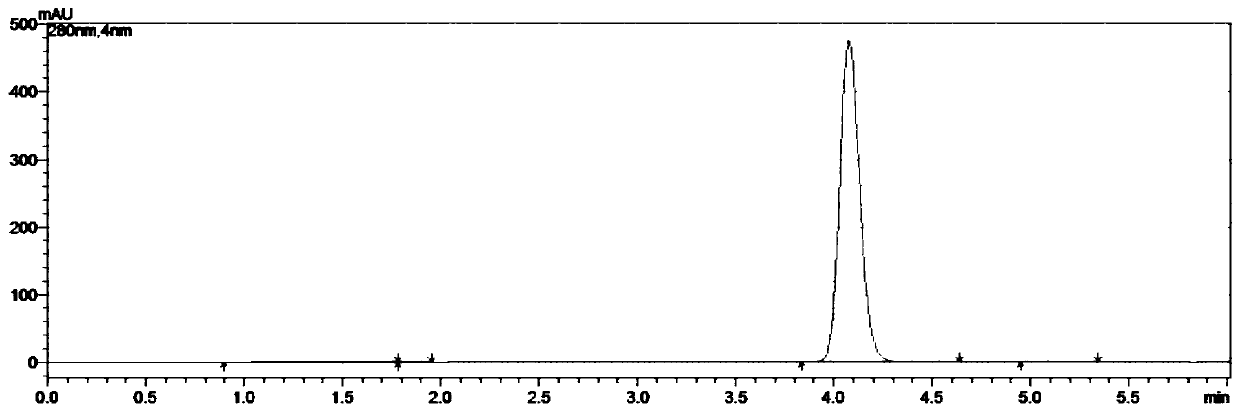

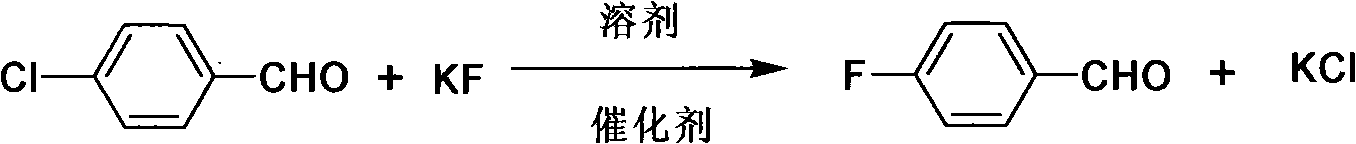

Synthetic method of 4-fluorobenzaldehyde

InactiveCN101353297ALow priceShort synthetic routeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSulfolaneHexamethylphosphoramide

The invention relates to a synthetic method of p-flurobenzaldehyde, which belongs to the chemical and pharmaceutical field. In the synthetic method, the p-chlorobenzaldehyde and potassium fluoride react under the condition of a solvent and a catalyst at high temperature, wherein, the solvent is one of sulfolane, dimethyl sulfoxide, dimethylformamide, dimethylacetamide, hexamethyl phosphoramide, nitrobenzene and ortho-nitrotoluene; the catalyst is one of or the mixture of two or more than two of benzyl triethyl amine chloride, tetrabutylammonium bromide, hexadecyltrimethylammonium chloride, methyltrioctylammonium chloride, tetraphenylphosphonium bromide, methyltriphenylphosphonium bromide, benzyl triphenyl phosphonium bromide and polyethylene glycol dimethyl ether. Compared with the conventional preparation method, the synthetic method of the invention has the advantages of cheap raw materials, short synthetic route and little 'three wastes' discharge. As the amount of the catalyst used is reduced and the price of the solvent is low, the production cost of the p-flurobenzaldehyde is decreased.

Owner:王俊华

Process for preparing 4,4'-dichlorodiphenyl sulfone

InactiveCN109851537ASimple processLow costOrganic chemistryOrganic compound preparationChlorobenzeneOrganic synthesis

The invention belongs to the field of organic synthesis, and particularly relates to a process for preparing 4,4'-dichlorodiphenyl sulfone. The process comprises the following steps of carrying out aFriedel-Crafts reaction on thionyl chloride and chlorobenzene under the action of a catalyst, carrying out cooling for hydrolyzing after the reaction is finished, then carrying out heating for dissolving, carrying out cooling to separate out crystals, carrying out filtering to obtain 4,4'-dichlorodiphenyl sulfoxide, then dissolving the 4,4'-dichlorodiphenyl sulfoxide in glacial acetic acid, addinghydrogen peroxide to carry out an oxidation reaction, carrying out cooling after the reaction is completed, and carrying out filtering to obtain the 4,4'-dichlorodiphenyl sulfone, wherein the catalyst is a mixture of anhydrous aluminum chloride and benzyl triethyl ammonium chloride. The process disclosed by the invention is simple, low in cost and less in impurity, the composite catalyst is adopted, and no additional solvent is added, so that purity of the obtained product is high, and the content of the obtained product is 99.4% or above. The yield reaches 92% or above, the economic benefitis good, and industrial production is facilitated.

Owner:SHANDONG KAISHENG NEW MATERIALS

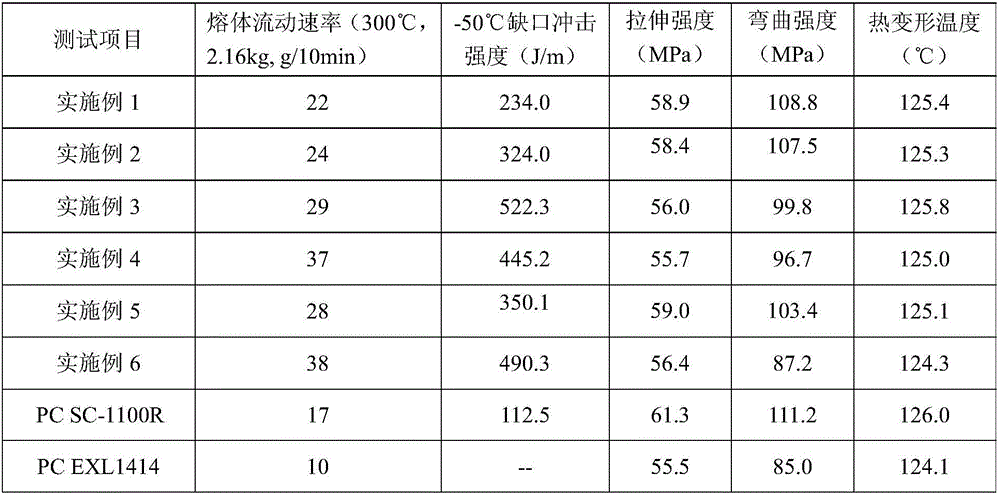

Polyarylester-polydimethylsiloxane block copolymer modified polycarbonate and preparation method thereof

ActiveCN105802175ALower glass transition temperatureImprove the lubrication effectAntioxidantPolycarbonate

The invention discloses polyarylester-polydimethylsiloxane block copolymer modified polycarbonate and a preparation method thereof. A raw material formula of polycarbonate comprises components in percentage by mass as follows: 91.6%-97.8% of bisphenol A type polycarbonate, 2%-8% of a polyarylester-polydimethylsiloxane block copolymer and 0.2%-0.4% of an antioxidant. The preparation method of the polyarylester-polydimethylsiloxane block copolymer comprises steps as follows: bisphenol A, sodium hydroxide and deionized water are mixed and dissolved, benzyl triethyl ammonium chloride is added, and an aqueous phase is formed; isophthaloyl dichloride is dissolved in dried dichloromethane, and an organic phase is formed; the organic phase is dropwise added to the aqueous phase, the temperature is reduced to 5-10 DEG C, the stirring reaction is performed, sodium hydroxide and amino-terminated polydimethylsiloxane are added, the normal-temperature reaction is performed, and a polyarylester-polydimethylsiloxane block copolymer emulsion is obtained. The prepared polycarbonate is good in low-temperature toughness and high in melt fluidity.

Owner:铨盛聚碳科技股份有限公司

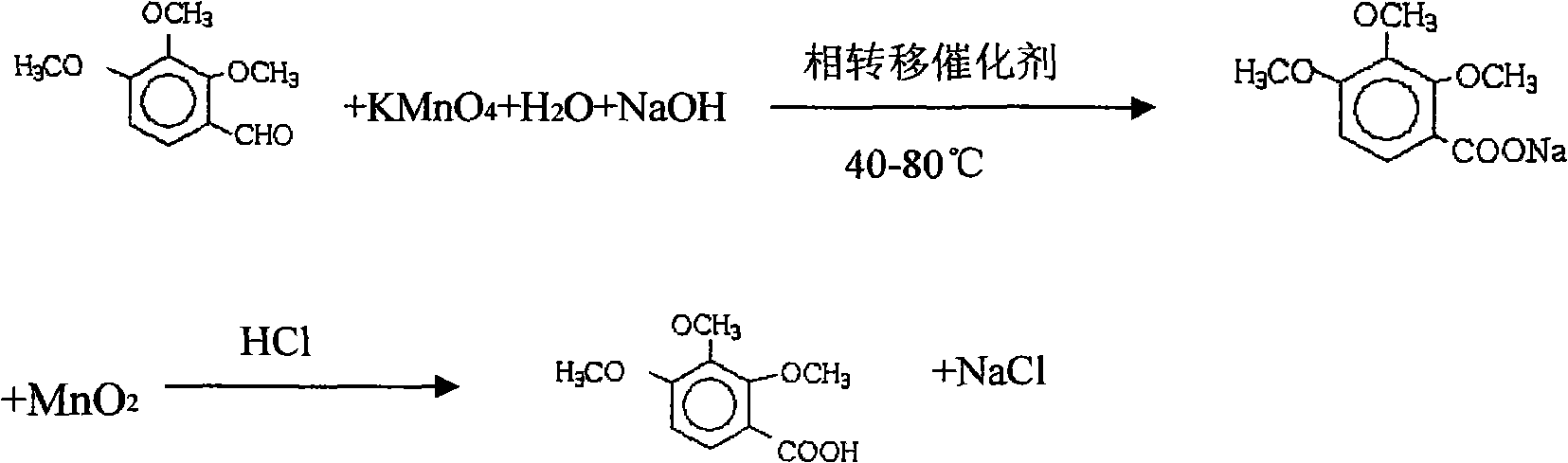

Method for preparing 2,3,4-trimethoxybenzoic acid

InactiveCN101265183AFulfil requirementsEasy to operateOrganic compound preparationCarboxylic compound preparationFiltrationBenzaldehyde

The invention relates to a method of preparing 2, 3, 4-trimethoxybenzoic acid. 2, 3, 4-trimethoxy benzaldehyde which is used as raw material is mixed with alkaline solution and stirred to form two-phase solution; a phase transfer catalyst that is tetrabutyl ammonium chloride or tetrabutyl ammonium bromide or benzyl triethyl ammonium chloride is added, and potassium permanganate is added for reacting for 2 to 4 hours; the mixed solution is processed through vacuum drawing and filtering, and the pH value of filter liquor is adjusted to reach 7 to 9 by using hydrochloric acid or sulphuric acid; active carbon is added and stirred; the mixed solution is decoloured for 10 to 30 minutes under the temperature ranging from 80 to 95 DEG C, and is filtered to remove the active carbon; the filter liquor is added with acid until which the white 2, 3, 4-trimethoxybenzoic acid is completely precipitated and separated out; after vacuum filtration, filter mass is processed through decompression and vacuum drying under the conditions that the pressure ranges from minus 0.08 to 0.09 MPa and the temperature ranges from 40 to 80 DEG C, so that the 2, 3, 4-trimethoxy benzaldehyde products are obtained. The method adopts the phase transfer catalysis technology, enhances the oxidation speed and effect, controls the depth of the oxidation reaction to prevent the 2, 3, 4-trimethoxy benzaldehyde from being further oxidized to form quinine, thereby obtaining the high-purity 2, 3, 4-trimethoxy benzaldehyde. The product yield and the purity are high, and the requirement of the pharmaceutical intermediate can be satisfied.

Owner:南京龙源天然多酚合成厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com