Bio-based epoxy resin as well as preparation process and application thereof

A technology based on epoxy resin and preparation process, which is applied in the fields of silicon organic compounds, chemical instruments and methods, compounds of elements of Group 4/14 of the periodic table, etc. Low and high hydrolyzable chlorine content, to achieve the effects of excellent catalytic performance, improved processing fluidity, and improved dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

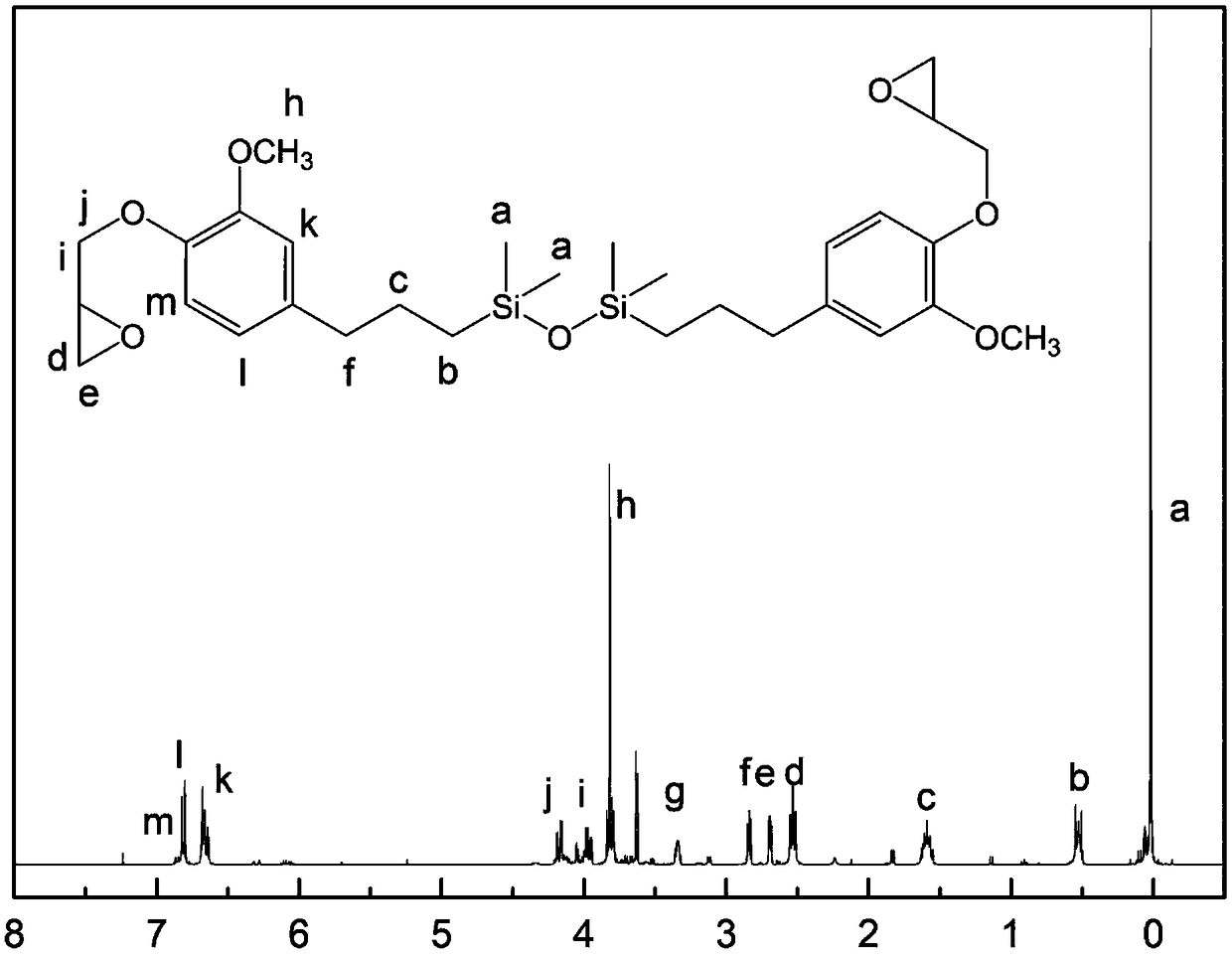

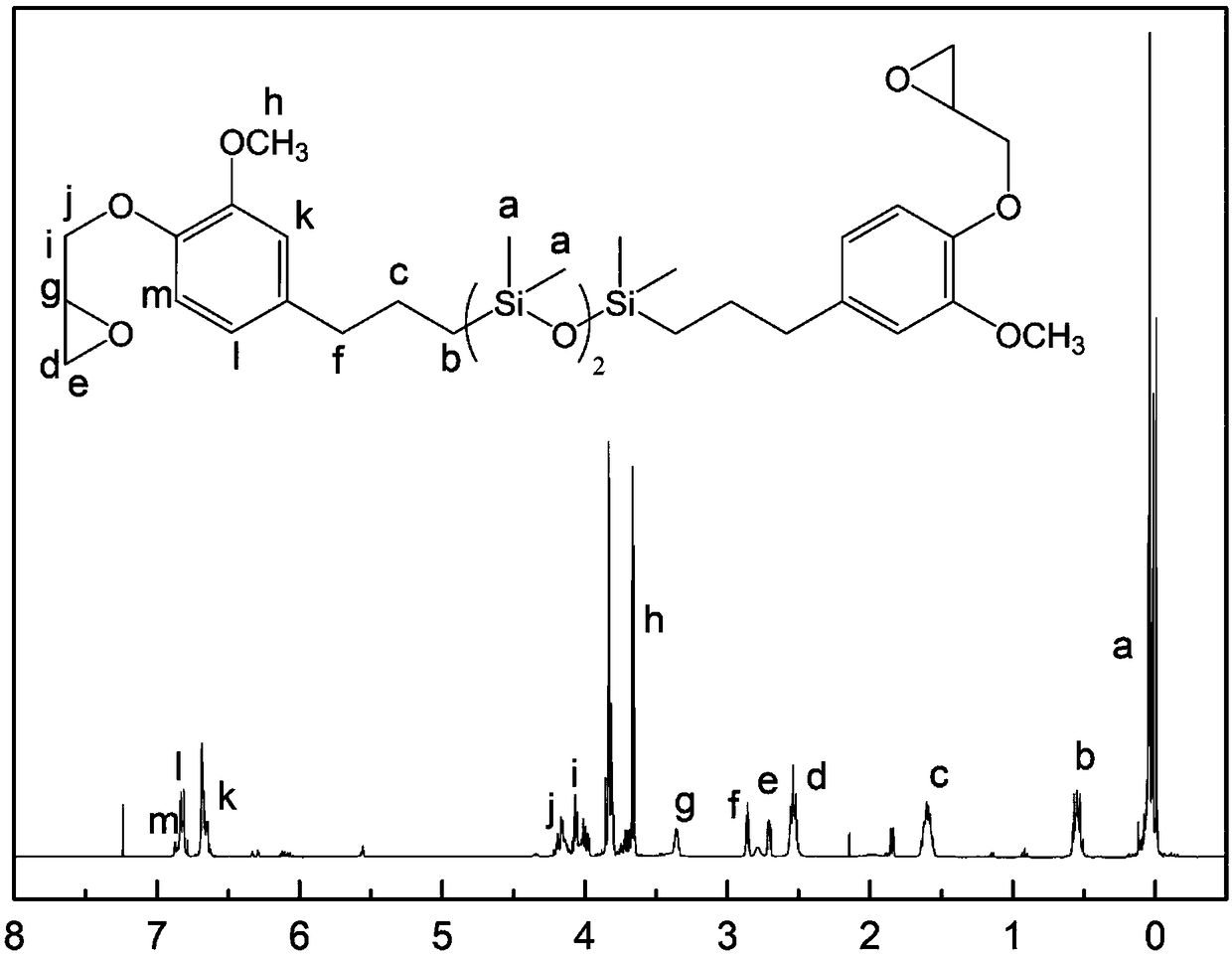

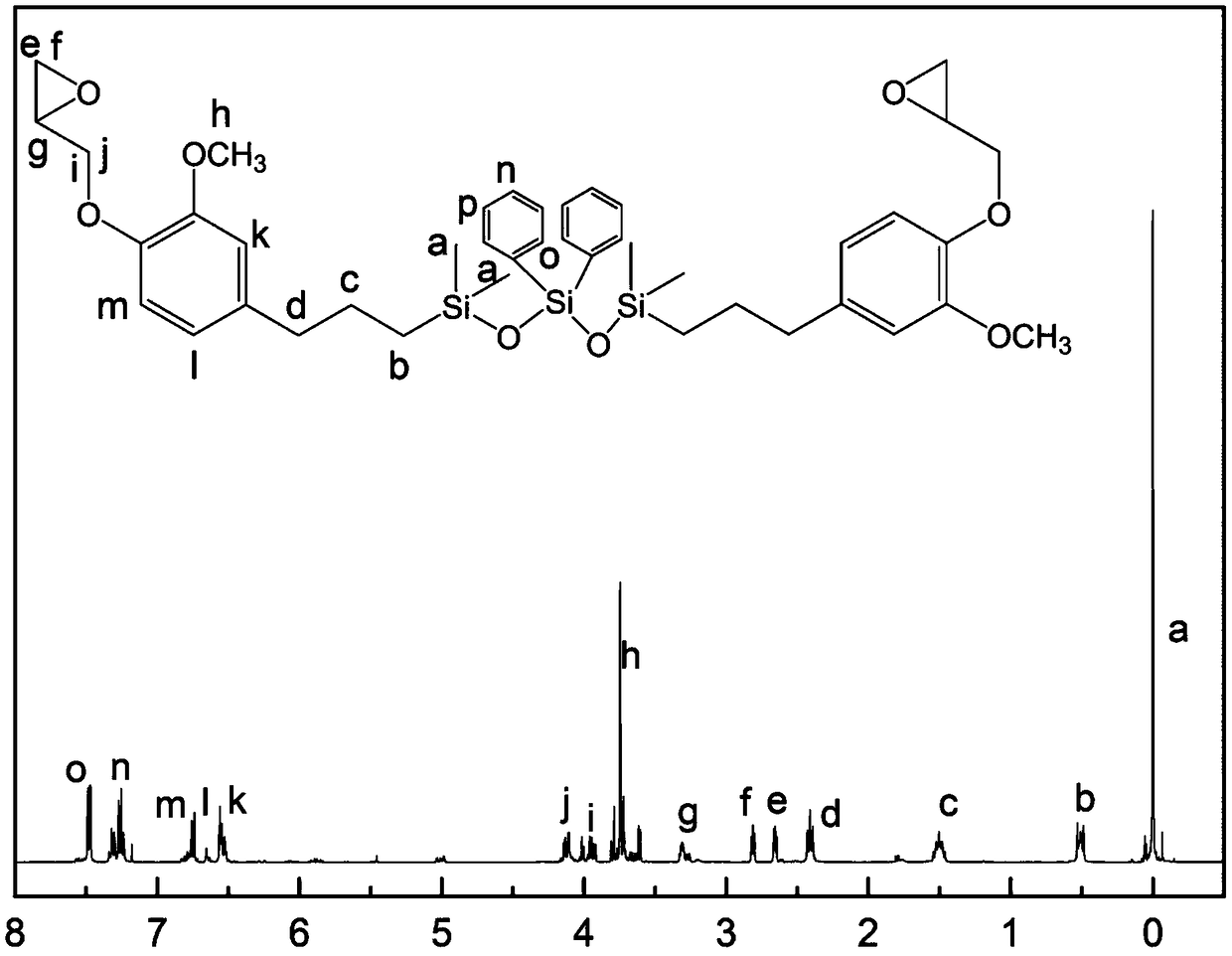

Image

Examples

Embodiment 1

[0074] Soak 5g of SBA-15 mesoporous molecular sieve in 100mL aminopropyltriethoxysilane coupling agent hydrolyzate (concentration 1wt%, adjust pH to 5 with glacial acetic acid, and let it stand for 2 hours); take out after soaking for 2 hours Dry;

[0075] Mix benzyltriethylammonium chloride aqueous solution (concentration: 20g / L, 100mL) with treated SBA-15 mesoporous molecular sieve (5g), remove the water by evaporation, and place the remaining material in an ultrasonic microwave device for 120 ℃ and heated for 20 min to obtain a SBA-15 mesoporous molecular sieve catalyst immobilized with benzyltriethylammonium chloride.

[0076] Eugenol and epichlorohydrin (molar ratio 1:1) were added under normal pressure, and the SBA-15 mesoporous molecular sieve catalyst (benzyltriethylammonium chloride) prepared in this example was added in proportion to the solid-loaded benzyltriethylammonium chloride. The molar ratio of ethylammonium chloride to eugenol=0.05:1), etherification ring-op...

Embodiment 2

[0082] Get the bio-based epoxy resin 100phr prepared in Example 1, isophorone diamine 13phr, 2-methyl-4-ethylimidazole 0.3phr, stir for 2 hours and mix well, according to GB-T7124-1986 (adhesive stretching Shear strength test method) evenly spread on the surface of the steel sheet cleaned with acetone and fixed, cured at 80°C for 30 minutes, and cured at 150°C for 1.5 hours. The iron sheet bonding strength and iron sheet bonding modulus data of the obtained samples are listed in Table 1 below.

[0083] Stir the bio-based epoxy resin, curing agent, and curing accelerator according to the above raw material composition, and then cast it in a steel mold, vacuumize and defoam at 80°C for half a minute, cure at 80°C for 2 hours, and cure at 150°C for 2 hours Hour. The sample released from the mold has no bubbles, and the appearance is transparent without obvious defects. The limiting oxygen index and dielectric constant data of the obtained samples are listed in Table 1 below.

Embodiment 3

[0085] Soak 10g of SBA-15 mesoporous molecular sieve in 500mL aminopropyltrimethoxysilane coupling agent hydrolyzate (concentration 3wt%, adjust pH to 5 with glacial acetic acid, and let it stand for 1 hour); take it out and dry it after soaking for 2 hours ;

[0086] Mix benzyltriethylammonium chloride aqueous solution (concentration: 1000g / L, 50mL) with treated SBA-15 mesoporous molecular sieve (10g), remove the water by evaporation, and place the remaining material in an ultrasonic microwave device for 140 ℃ and heated for 40 minutes to obtain the SBA-15 mesoporous molecular sieve catalyst solidly loaded with benzyltriethylammonium chloride.

[0087] Add eugenol and epichlorohydrin (molar ratio 1:1) under normal pressure, add the SBA-15 mesoporous molecular sieve catalyst (benzyltriethylammonium chloride immobilized with benzyltriethylammonium chloride prepared in this example) in proportion. The molar ratio of triethylammonium chloride to eugenol=0.05:1), etherification r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com