Negative ion coating capable of being cured by ultraviolet light and preparation method of negative ion coating

A technology of negative ion coating and ultraviolet light, which is applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., to achieve the effect of fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation of nano-anion slurry is: nano-anion powder: hydroxyethyl methacrylate = 1:4, first add hydroxyethyl methacrylate in the reaction kettle, and slowly add nano-anion powder and dispersant under stirring state, control Warm at 50-60°C for 3 hours. Wherein the dispersant is a special nanometer dispersant which belongs to the macromolecule anion type, and its consumption is 5-8% of the negative ion powder. Then refine to a fineness of less than 10um.

[0042] The negative ion powder is: nano-scale iron magnesium tourmaline powder, terbium oxide, twelve calcium fourteen aluminum oxide, coral fossils; opal; serpentine; a mixture of at least two kinds of medical stone. Preference is given to a mixture of ferrite powder, terbium oxide, and opal.

[0043] The UV oligomer is one or a mixture of several oligomers in bisphenol A epoxy acrylate, urethane acrylate, amino acrylate and polyester acrylate. Among them, bisphenol A epoxy acrylate and urethane acrylate are...

Embodiment 2

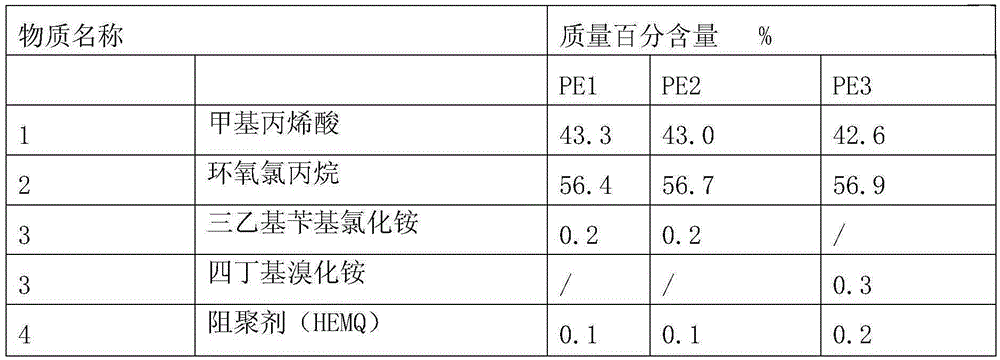

[0050] Pump the above components 1, 2, and 4 into the reactor, heat, add 50% of the catalyst at 65°C, control the temperature at 100-105°C until the acid value is less than 1.0mgKOH / g, then add the rest of the catalyst After 20 minutes of reaction, the temperature can be lowered to 80°C and the material can be discharged. The PE related indicators: viscosity 80-200mpa.s / 60℃; AV<1.0mgKOH / g. The preparation MF of embodiment 2 nano negative ion slurry

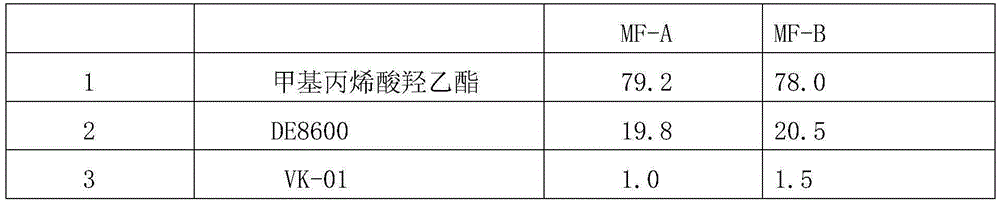

[0051] Prepare the nano-anion slurry according to the formula data in the following table 2

[0052]

[0053]

[0054] Pump hydroxyethyl methacrylate into the reaction kettle, add nano-dispersant and stir evenly, slowly add nano-anion powder, and control the temperature at 50-60°C for 3 hours. Then refine to a fineness of less than 10um for later use.

Embodiment 3

[0055] Embodiment 3 prepares ultraviolet light curing anion coating

[0056] The paint is prepared according to the 3 groups of data formulas in Table 3.

[0057]

[0058] Make the above components into coatings and control related indicators; fineness: 200mj / cm 2 (curing degree RAU95%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com