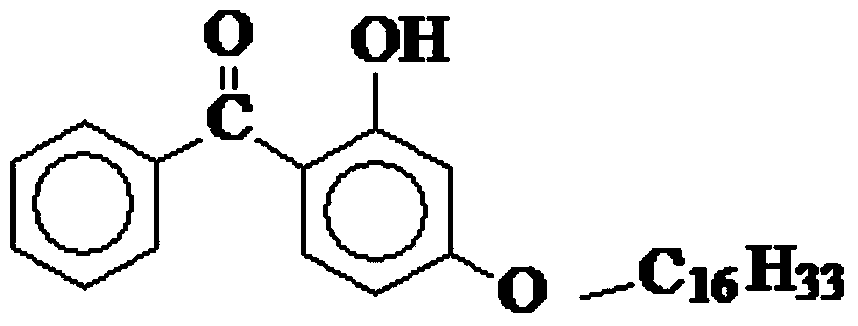

Preparation method of 2-hydroxy-4-cetyloxy-diphenyl ketone

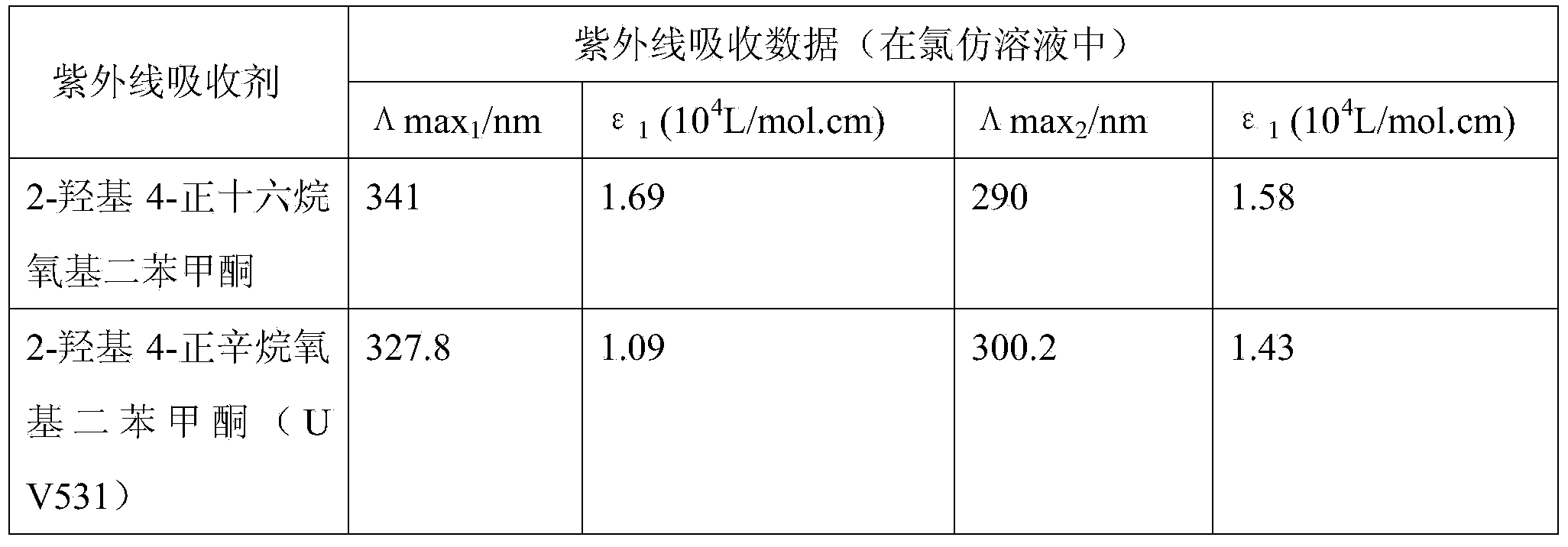

A technology of hexadecyloxybenzophenone and hydroxyl group is applied in the field of preparation of 2-hydroxy 4-n-hexadecyloxybenzophenone, which can solve equipment corrosion, environmental pollution, and preparation technology of ultraviolet absorbers Complex and other problems, to achieve the effect of simple purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] One, the method of 2-hydroxyl 4-n-hexadecyloxybenzophenone;

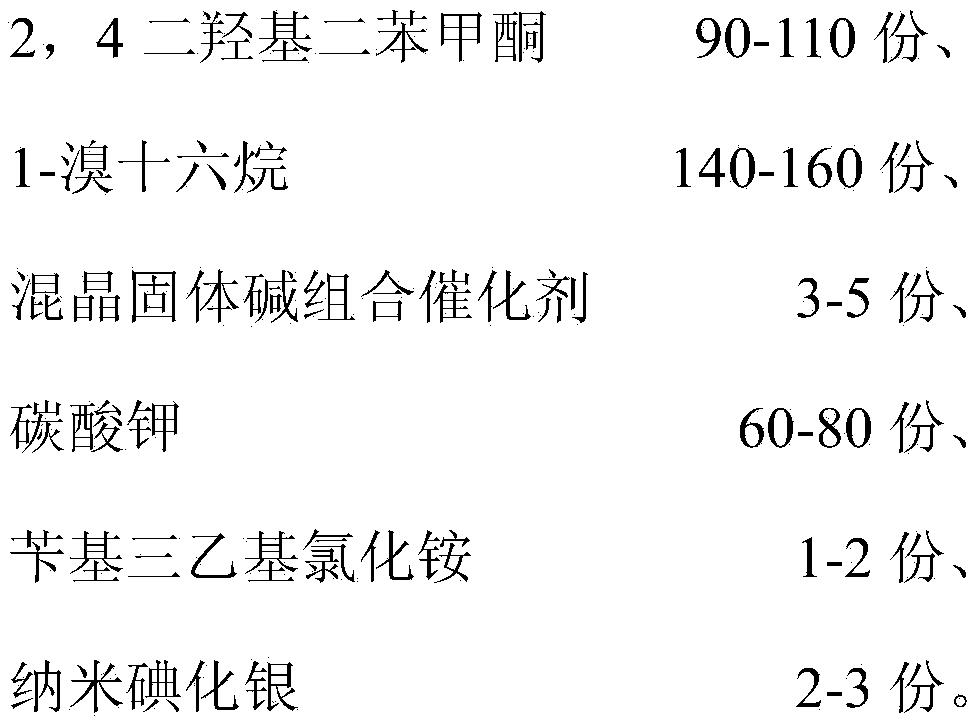

[0020] (a). Chemical composition: 90 parts of 2,4-dihydroxybenzophenone, 140 parts of 1 bromohexadecane, 3 parts of mixed crystal solid alkali combination catalyst, KCO 3 60 parts, 1 part of benzyltriethylammonium chloride, 2 parts of nano-silver iodide;

[0021] (b). Combine 2,4 dihydroxybenzophenone, 1 bromohexadecane, mixed crystal solid base as catalyst, KCO 3 , benzyltriethylammonium chloride, and nano-silver iodide were placed in a four-necked flask, fed with nitrogen, refluxed at 130°C for 10 hours, filtered the solid matter while it was hot, and then separated the reacted aqueous phase from the organic phase, Then extract the organic phase with 100 parts of distilled water for 4 times, and then distill the organic phase under reduced pressure, and then cool to obtain the light yellowish white solid product 2-hydroxyl 4-hexadecyloxybenzophenone. Two, mixed crystal solid alkali combined catalyst, prep...

Embodiment 2

[0028] One, the method of 2-hydroxyl 4-n-hexadecyloxybenzophenone;

[0029] (a). Chemical composition: 110 parts of 2,4-dihydroxybenzophenone, 160 parts of 1 bromohexadecane, 5 parts of mixed crystal solid alkali combination catalyst, KCO 3 80 parts, 1.5 parts of benzyltriethylammonium chloride, 3 parts of nano silver iodide;

[0030] (b). Combine 2,4 dihydroxybenzophenone, 1 bromohexadecane, mixed crystal solid base as catalyst, KCO 3 , benzyltriethylammonium chloride, and nano-silver iodide were placed in a four-necked flask, and nitrogen gas was introduced, and the reaction was refluxed at 155°C for 8 hours, and the solid was filtered while it was hot, and then the reacted aqueous phase was separated from the organic phase, and then The organic phase was extracted 4 times with 100 parts of distilled water, and the organic phase extracted by distilled water was distilled under reduced pressure and then cooled to obtain a light yellow-white solid product, 2-hydroxyl 4-n-hexa...

Embodiment 3

[0033] (a). Chemical composition: 100 parts of 2,4-dihydroxybenzophenone, 150 parts of 1 bromohexadecane, 4 parts of mixed crystal solid alkali combination catalyst, KCO 3 70 parts, 2 parts of benzyltriethylammonium chloride, 2.5 parts of nano silver iodide;

[0034] (b). Combine 2,4 dihydroxybenzophenone, 1 bromohexadecane, mixed crystal solid base as catalyst, KCO 3 , benzyltriethylammonium chloride, and nano-silver iodide were placed in a four-necked flask, fed with nitrogen, and reacted at reflux at 140°C for 9 hours, filtered the solid matter while it was hot, and then separated the aqueous phase and the organic phase after the reaction, and then The organic phase was extracted 4 times with 100 parts of distilled water, and the organic phase extracted by distilled water was distilled under reduced pressure and then cooled to obtain a light yellow-white solid product, 2-hydroxyl 4-n-hexadecyloxybenzophenone.

[0035] 2. The preparation method of the mixed crystal solid su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com