Patents

Literature

184results about How to "Increase the rate of hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roaster-used milk powder material

ActiveCN101766227AImprove palatabilityPromote growth and developmentWhey manufactureAntioxidantDiarrhea

The invention discloses a roaster-used milk powder material, which is formed by mixing and blending popping corn, flour, low egg whey powder, soybean oil, glucose, popping soybean pulp, import steam fish meal, plasma protein powder, natural yeast extract, milk substitute powder, calcium carbonate, calcium hydrophosphate, flavouring agent, acidulant, zinc oxide, roaster microelement premix, threonine, diaminocaproic acid, methionine, choline, roaster multivitamin, antioxidant and mildewproof agent. The preparation process comprises: grinding, popping, secondary grinding, measurement burdening, mixing, packaging and the like. The roaster-used milk powder material in the formula has high nutrition level and balanced amino acid, is rich in food attractant, has good palatability and easy digestive absorption, can effectively substitute breast milk and solves the problem of lack of breast milk; in addition, the roaster-used milk powder material has the advantages of promoting the fast development of the intestinal canal, enhancing the disease resistance and diarrhea resistance, leading to the high neatness of the weaning roaster and the like.

Owner:成都特驱农牧科技有限公司

Preparation method of novel protein feed additive

ActiveCN101530162AIncrease egg productionExtend peak egg productionAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

The invention relates to a preparation method of a hydrolyzed protein mixture and a protein peptide powder feed additive, wherein a multienzyme complex enzyme method is used for hydrolyzing vegetable protein to prepare the hydrolyzed protein mixture and protein peptide powder. The technology of the method is simple, and a non-starch polysaccharide enzyme and a proteinase are compounded so as to be capable of improving the hydrolyzation rate and degree of protein as well as the utilization rate of feed and reducing the production cost. Products prepared by the preparation method can be used as the feed additive to be capable of significantly improving the laying rate of egg-laying poultry, improving the weight increment of meat poultry, reducing the feed-meat rate and improving the production performance of table poultry as well as reducing the incidence rate of diarrhea in young animals and the feed-meat rate of piggy; and the preparation method is applied to aquatic livestock to be capable of improving the weight increment of fish and reducing the bait coefficient and content viscosity in the intestinal tract.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

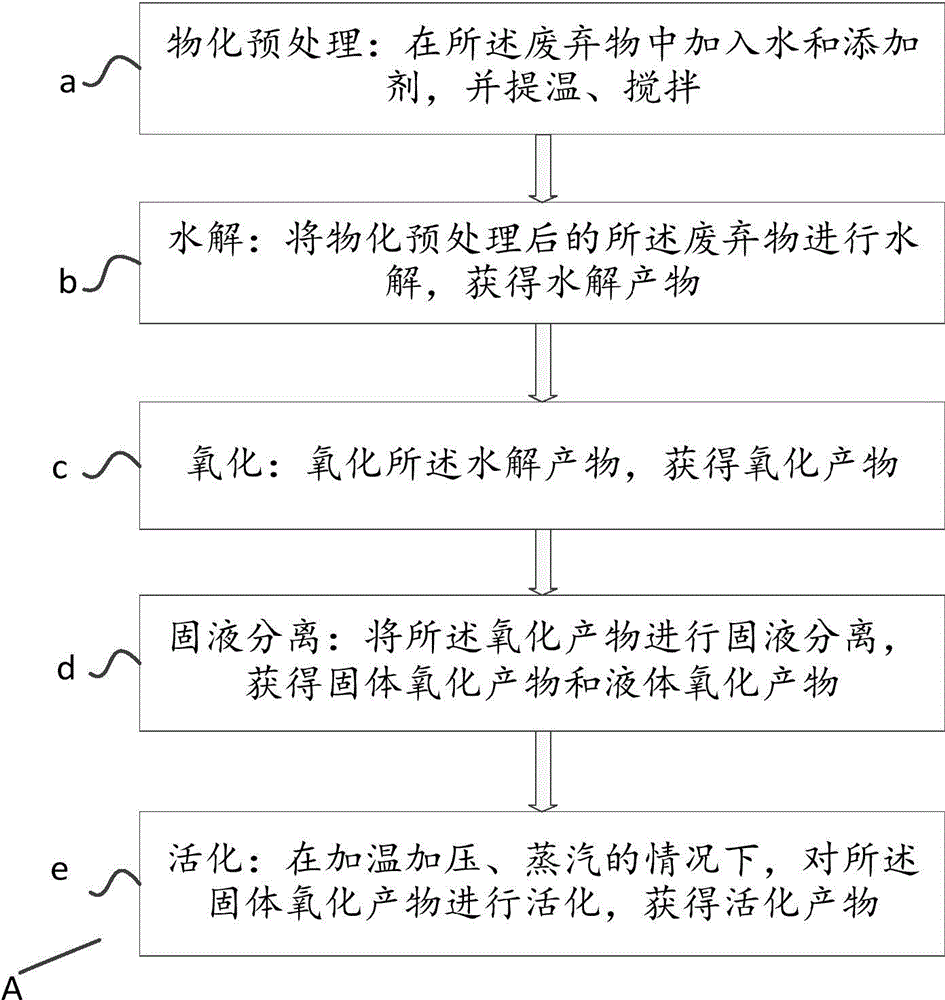

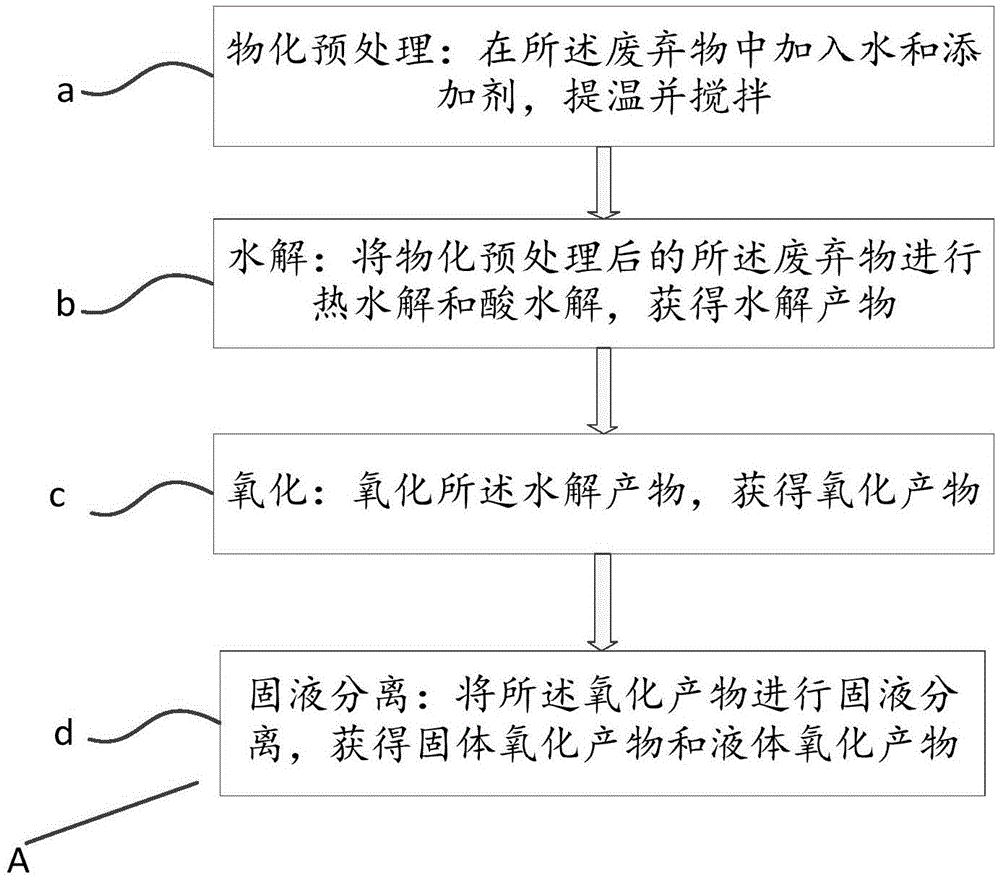

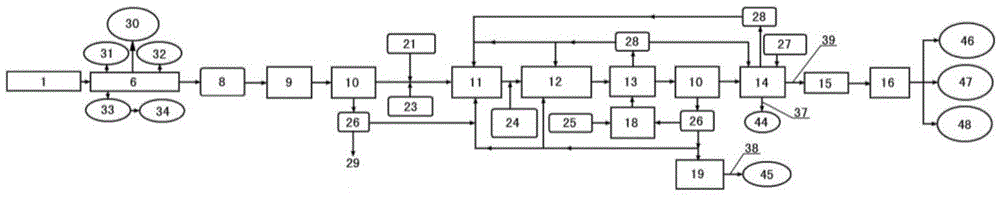

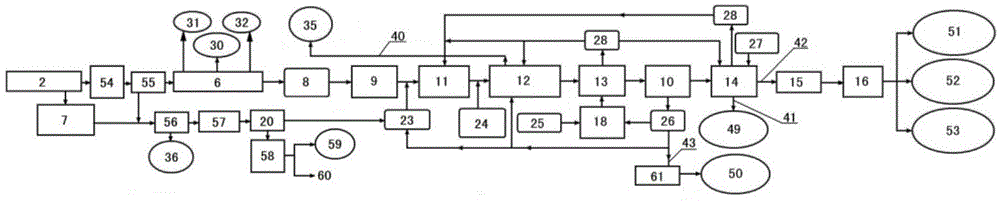

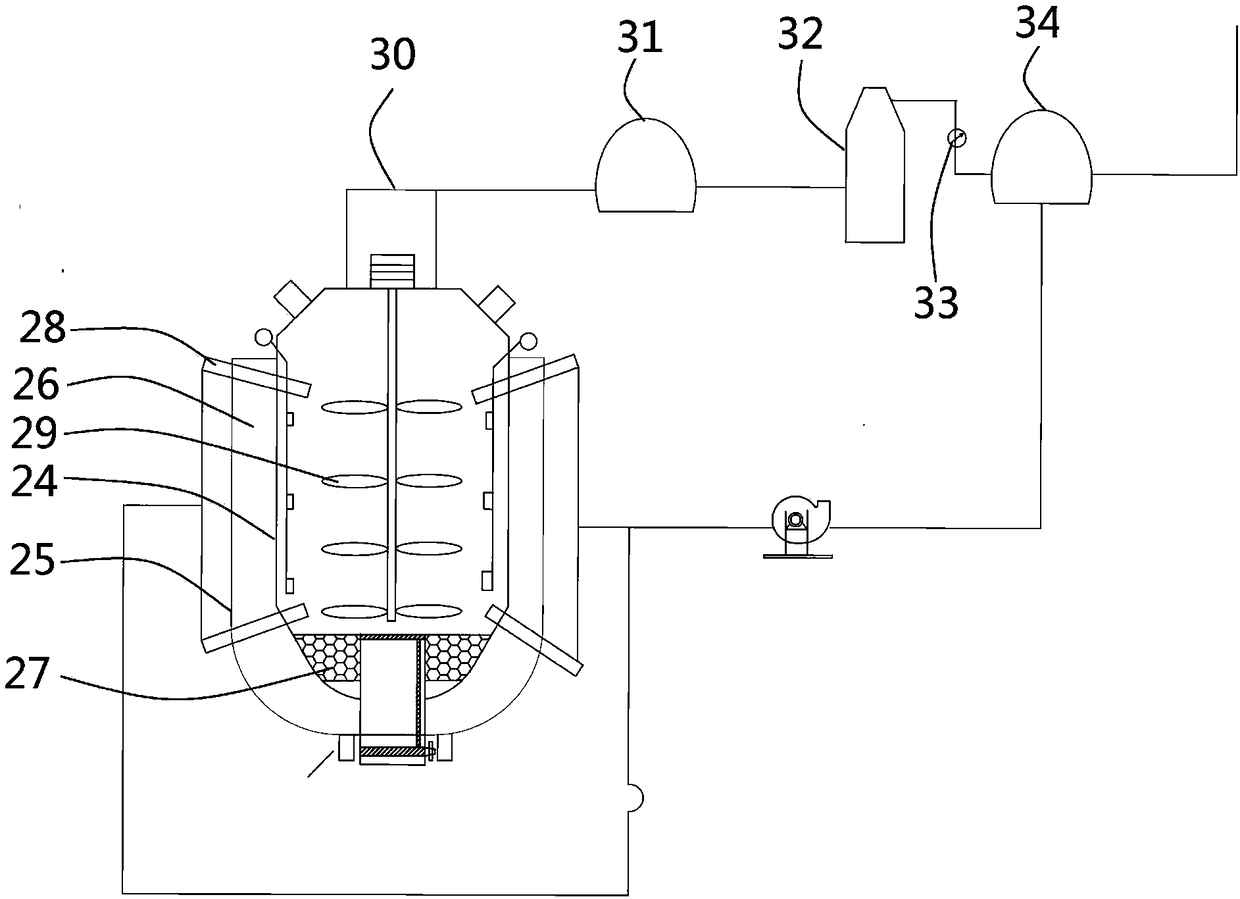

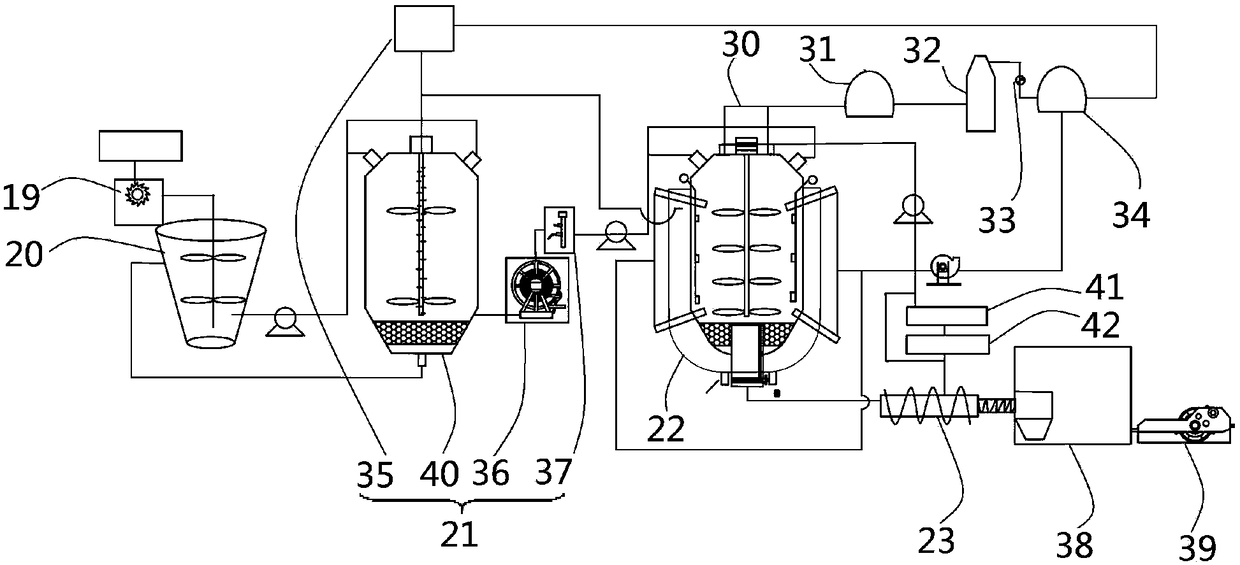

Method and device for treating organic solid waste

ActiveCN104148358AComplete oxidationAvoid lostSolid waste disposalClimate change adaptationCompound (substance)Biological activation

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely hydrolyzing the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; (d) carrying out solid-liquid separation, namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product; and (e) carrying out activation, namely activating the solid oxidization product in the case of heating, pressurizing, steaming and additive adding, thereby obtaining an activated product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

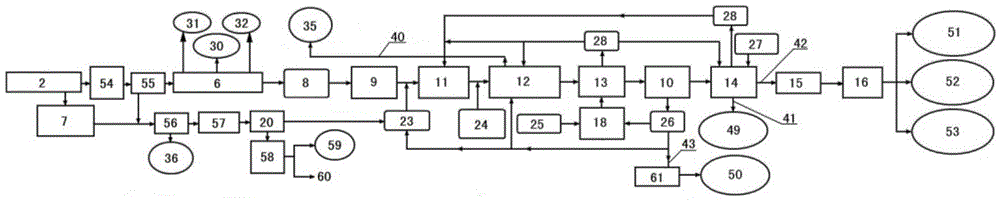

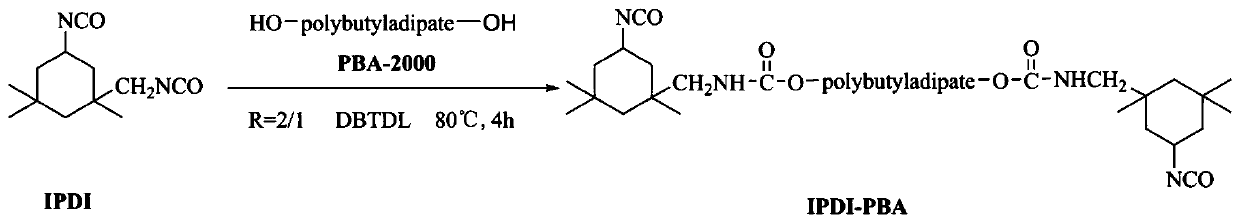

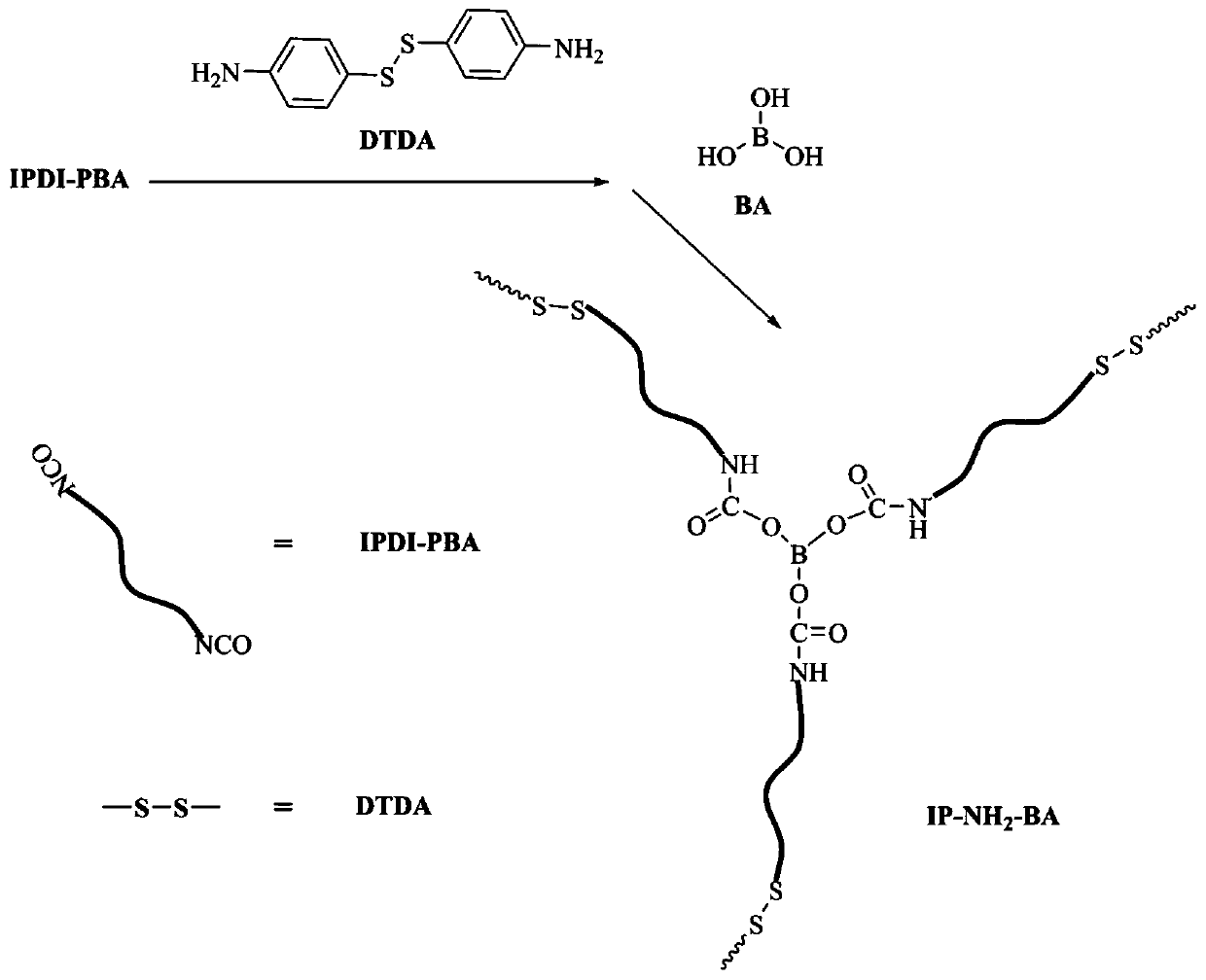

Self-repairing polyurethane elastomer based on multiple dynamic reversible effects, and preparation method thereof

The invention discloses a self-repairing polyurethane elastomer based on multiple dynamic reversible effects, and a preparation method thereof. The preparation method comprises: uniformly mixing and stirring diisocyanate and polyester diol, adding a catalyst, and carrying out a heating stirring reaction for 3-5 h in an oil bath with a temperature of 60-80 DEG C to obtain a prepolymer; adding a disulfide chain extender into the obtained prepolymer mixed solution, carrying out a heating stirring reaction for 0.5-1 h in an oil bath with a temperature of 60-80 DEG C, and adding a solvent to control the viscosity of the reactant so as to prevent gelling; and adding a cross-linking chain extender, carrying out a reaction, pouring into a mold, standing for 16-24 h at a temperature of 60-80 DEG C,and carrying out curing molding. According to the present invention, the obtained self-repairing polyurethane elastomer has the tensile strength of 23.3 MPa at the optimal self-repairing efficiency of 99%, and can be used as the structural material in the fields of vehicles, medical use, buildings, protective materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving sludge anaerobic fermentation and acid production

InactiveCN101768609AAchieve reductionImprove efficiencyFermentationSolid phasesVolatile organic compound

The invention discloses a method for improving sludge anaerobic fermentation and acid production, belonging to the environmental protection technical field. The method is taken as follows: the residual sludge of municipal sewage plants are used as the raw material, wall breaking action is applied to the microorganisms in the sludge by control of the operating parameters of ultrasonic in order to ensure most of the organic substances in the cells of the microorganisms to be dissolved, lye is added to the sludge to regulate the pH value of the sludge, and the sludge is transformed furthest from the solid phase to the liquid phase and made to produce volatile organic matter under the action of the lye and the microorganisms. The invention further improves the quantity of the organic acid produced from the sludge on the basis of sludge innoxiousness and resource utilization.

Owner:TONGJI UNIV

Method for improving methanogenesis of residual sludge by heat and alkali combined pretreatment

ActiveCN103172242AIncrease productionIncrease the rate of hydrolysisWaste based fuelBiological sludge treatmentMethanogenesisSludge

The invention belongs to the technical field of environmental protection and relates to a method for improving the methanogenesis of residual sludge by heat and alkali combined pretreatment. According to the method, after the residual sludge is thermally pretreated, the dissolving in water of organic matters such as protein and polysaccharide in the residual sludge can be improved significantly so that abundant water-soluble organic matrixes can be provided for the fermentation of the sludge and the generation of acids; and in addition, after the residual sludge is pretreated under the initial alkaline condition, the dissolving and the dehydrating of the sludge can be promoted further and short chain fatty acids can be produced continuously. Therefore, the residual sludge dehydrating efficiency and the acid generating efficiency can be improved greatly by the combination of thermal pretreatment and the initial alkaline condition so that the yield of methane can be increased to the maximum extent.

Owner:TONGJI UNIV

Method and device for treating organic solid waste

ActiveCN104148357AAvoid unfit problemsImprove efficiencySolid waste disposalAcid hydrolysisCompound (substance)

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely carrying out thermal hydrolysis and acid hydrolysis on the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; and (d) carrying out solid-liquid separation namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

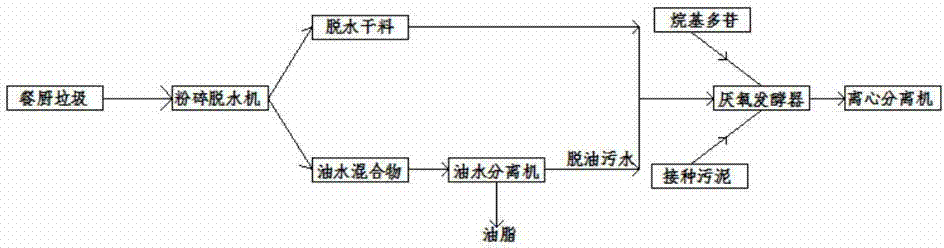

Method for producing short-chain volatile fatty acids by utilizing kitchen wastes and short-chain volatile fatty acids

InactiveCN104498541AIncrease productionGood denitrification and phosphorus removalFermentationBiotechnologyVolatile fatty acids

The invention discloses a method for producing short-chain volatile fatty acids by utilizing kitchen wastes and the short-chain volatile fatty acids. The method specifically comprises the following steps: uniformly mixing and stirring the kitchen wastes serving as a fermentation substrate and sludge serving as an inoculum, thereby obtaining a fermentation matrix; and adding alkyl polyglucosides into the fermentation matrix, and performing anaerobic fermentation under a stirring condition. The reduction, recycling and innocent treatment of the kitchen wastes are realized, and the method has the advantages of low operating cost, high profit, high yield of the short-chain volatile fatty acids and the like.

Owner:HUNAN UNIV

Short-chain volatile fatty acid and preparation method thereof

The invention discloses a short-chain volatile fatty acid and a preparation method thereof. The preparation method for the short-chain volatile fatty acid comprises the following steps of employing sludge as a fermentation substrate; adding sodium nitrite into the fermentation substrate, performing pretreatment in an acid environment, and performing anaerobic fermentation under an alkaline condition to obtain the short-chain volatile fatty acid. According to the short-chain volatile fatty acid and the preparation method thereof, the sludge of a sewage treatment plant is taken as a raw material, and is jointly treated by virtue of free nitrite pretreatment and alkaline anaerobic fermentation, and the concentration of free nitrite in the system, the pretreatment time, the fermentation pH value and the action of microorganisms in the sludge are controlled to maximally convert undissolved sludge organic matters in the sludge into the short-chain volatile fatty acid, so that the yield of the volatile fatty acid produced from the sludge is further increased on the basis of resourcefully utilizing the sludge and reducing environmental pollution caused by the sludge, and the reaction time is shortened; the short-chain volatile fatty acid and the preparation method thereof have the advantages of high product yield, simple preparation method, energy conservation, consumption reduction, low running cost and the like.

Owner:HUNAN UNIV

Method for extracting rapeseed peptides through wet milling combined with enzymic method

The invention discloses a method for extracting rapeseed peptides through wet milling combined with an enzymic method. The method comprises the following steps of: taking dry degreased and unshelled rapeseed dregs, grinding and filtering the dry degreased and unshelled rapeseed dregs through a 40-mesh sieve, adding water which is 5 times of the materials in weight, adding 5-10 u / g of cellulase, and performing wet grinding on black soybean meal for 1-3 hours under the condition of a rotating speed in the range from 250 to 400 rpm (revolutions per minute) by using a ball mill to obtain an ultrathin powder turbid liquid; (2) supplementing water to the ultrathin powder turbid liquid until the concentration of the dry materials is in the range from 50 to 100 g / l, adjusting the pH to 7.0, adding 40u / g of protease, maintaining the temperature at 55 DEG C and the pH at 7.0, and hydrolyzing for 1-2 hours; (3) centrifuging the enzymatic hydrolysate for 15 minutes under the condition of 10000 rpm, continuously adding water which is 5-10 times of residues in weight to the residues, adding 20u / g of protease, hydrolyzing for 1-2 hours at the temperature of 55 DEG C and the pH of 7.0, centrifuging, and blending the two supernates to obtain a rough peptide solution. According to the invention, cellulose dissolving causes large-molecular materials such as protein to be hydrolyzed more easily, and also the hydrolysis rate of the protein can be increased; in addition, the conversion rate of the peptides is greatly increased.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Method for promoting organic acid yield from sludge

InactiveCN101085997AAchieve reductionAchieve stabilizationFermentationBiological sludge treatmentOrganic acidMicroorganism

The invention belongs to envrionmental protection technique field, in detail relates to a method for increasing organic aicd output through adding anion surface active agent and controlling basic pH value. It takes primary sludge, excess sludge or mixture of them in wastewater treatment plant, converses organic matter in insoluble sludge to organic acid maximumly by adding anion surface active agent, controlling basic pH and employing bacteria function in said sludge. The ratio between consumption amount of anion surface active agent and sludge dry amount is 0.01: 1- 0.1- 1, the pH is controlled between 8 to 12 for bacteria action, the retention time of sludge in reactor is from 5 hours to 30 days. The invention increases organic acid output when makes full use of sludge and reduces environmental pollution.

Owner:TONGJI UNIV

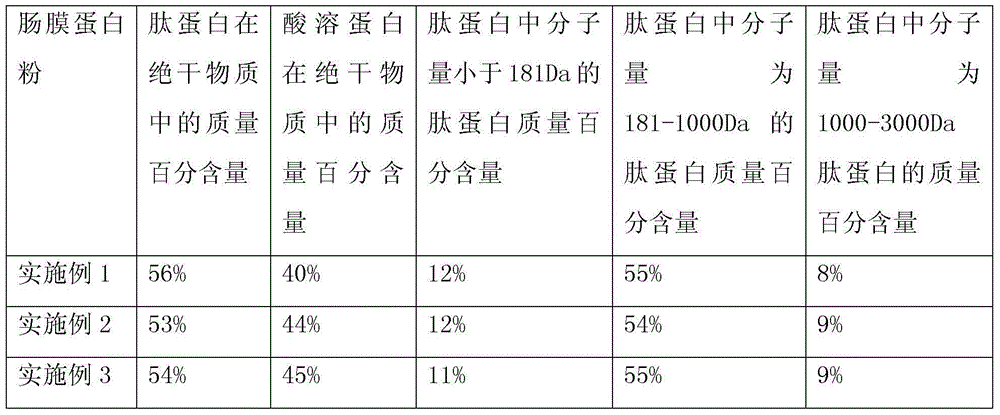

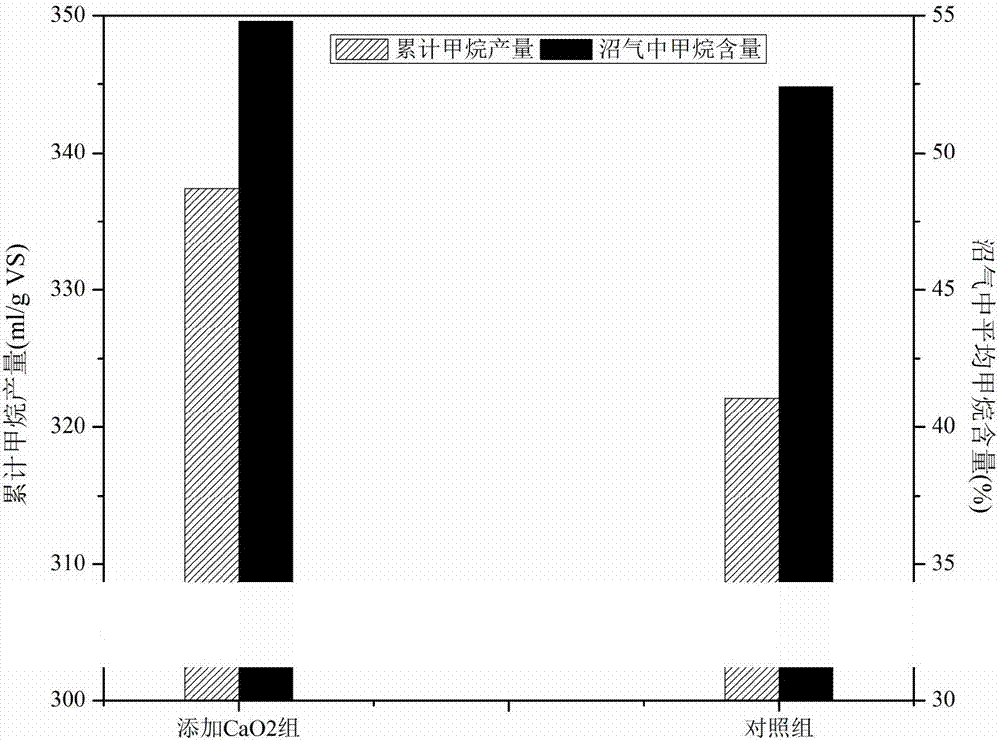

Production and processing process of intestinal membrane albumen powder

ActiveCN104059958AIncrease production capacityGood for healthAnimal feeding stuffFermentationAlkaline proteaseHydrolysate

The invention provides a production and processing process of intestinal membrane albumen powder. By taking intestinal mucosa of a pig or intestinal residues with heparin extracted as a raw material, the process comprises the following steps: 1) after mixing water and the raw material in a weight ratio of (15-30) to 100, stirring for 30-60 minutes at 35-40 DEG C; 2) adding alkaline protease into the mixture of water and raw material in the step 1) in a weight ratio of (0.05-1):100, heating to 40-60 DEG C, adjusting the pH to 9.0-11.0, and preserving heat and hydrolyzing for 1-4 hours at 40-60 DEG C to obtain a hydrolysate; 3) spray drying or roller drying the hydrolysate to prepare the intestinal membrane albumen powder. The process of preparing the intestinal membrane albumen powder by using a small amount of water and alkaline protease under the alkaline condition has the characteristics of simple operation, short hydrolytic time, energy conservation and environmental protection, small use level of water and alkaline protease, low preparation cost and the like, and can satisfy the requirements on industrialized production on a large scale.

Owner:北京中科景明生物技术有限公司

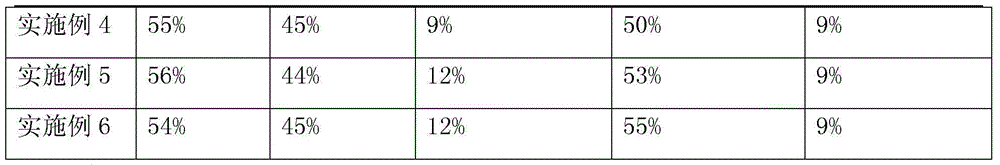

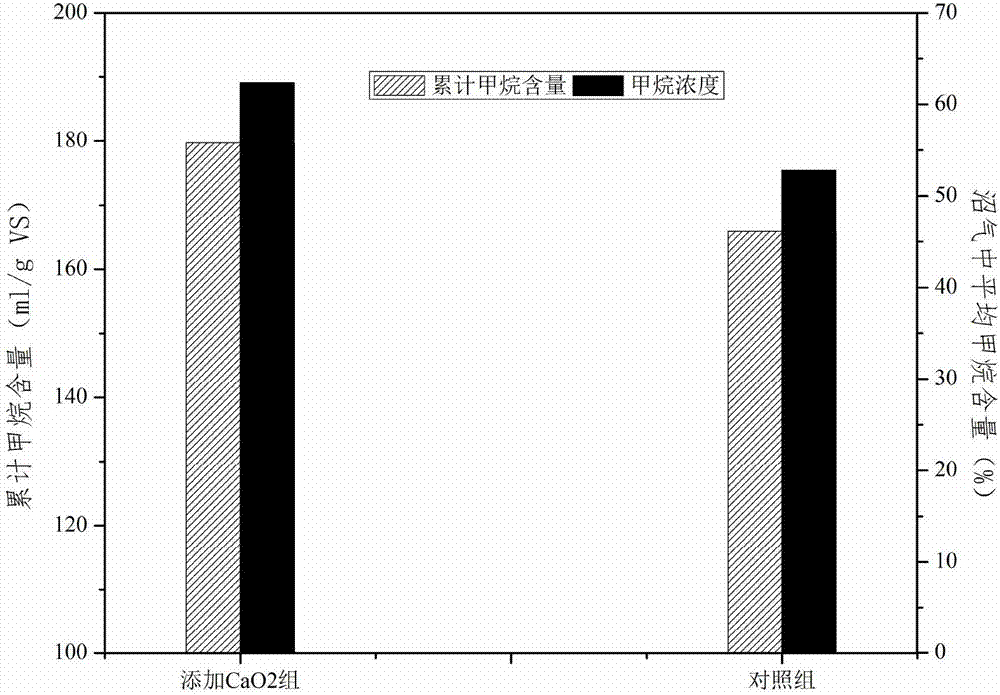

Method for improving efficiency of methane production through anaerobic fermentation and methane content in biogas

InactiveCN106929540AIncrease contentFast hydrolysisWaste based fuelFermentationMethane productionBiogas production

The invention belongs to the field of biogas production through anaerobic fermentation of organic solid wastes and particularly discloses a method for improving the efficiency of methane production through anaerobic fermentation and the methane content in a biogas. CaO2 is added to organic solid waste fermentation raw materials to form a microaerobic environment, thereby improving the efficiency of methane production through anaerobic fermentation and the methane content in the biogas. The method is mainly applied to the field of biogas production through anaerobic fermentation of the organic solid wastes such as straws and manure; the hydrolysis rate of anaerobic fermentation can be improved through adding a little of CaO2 to a reaction system, the methane content in the biogas is increased and the stability of a fermentation system is improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for promoting sludge to produce organic acid utilizing surface active agent

ActiveCN1814764AAchieve reductionAchieve stabilizationSludge treatmentMicroorganism based processesOrganic acidSludge

This invention relates to a method for promoting sludge to producing organic acid with a surface active agent, which takes the elementary deposition mud, residural sludge or their mixtures of a pollutant water process plant as the raw material to turn the undissolved sludge organics in the mud to organic acid acted by microbials in the mud, the ratio of the volume of the surface active agent and the dry sludge is 0.01: 1-0.3 : 1 and sludge stays for 5 hours ¿C 30 days in the reactor, which reduces volume of sludge and pollution to the environment and uses it as the resource.

Owner:TONGJI UNIV

Method for improving short-chain fatty acid produced by excess sludge through hot alkali combined pretreatment

The invention belongs to the technical field of environmental protection, and relates to a method for improving short-chain fatty acid produced by excess sludge through hot alkali combined pretreatment. According to the method, the excess sludge in a sewage treatment plant serves as raw material, through hot pretreatment, controlling of initial alkaline power of hydrogen (PH) value conditions and the functions of microorganism is conducted, not only are non-aqueous resolvable organic matters in the sludge promoted to be dissolved and are the non-aqueous resolvable organic matters hydrolyzed to be converted to resolvable organic matters, but also the resolvable organic matters such as protein and polysaccharide are fully converted into the short-chain fatty acid, and pollution of the sludge to the environment is reduced. The temperature of the hot pretreatment is 60-120 DEG C, the time of the hot pretreatment is 15-60min, the initial PH value range of the functions of the microorganism is 8-12, the standing time of the sludge in a reactor is 1-12 days, and the temperature is 30-40 DEG C.

Owner:TONGJI UNIV

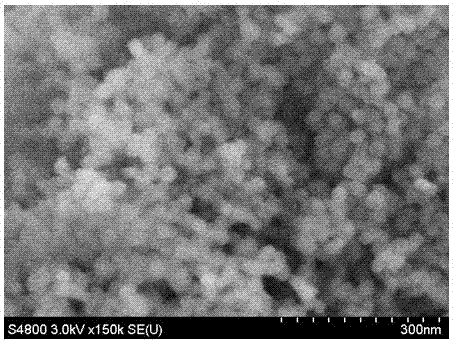

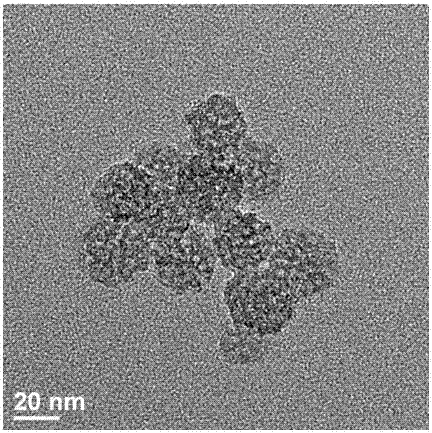

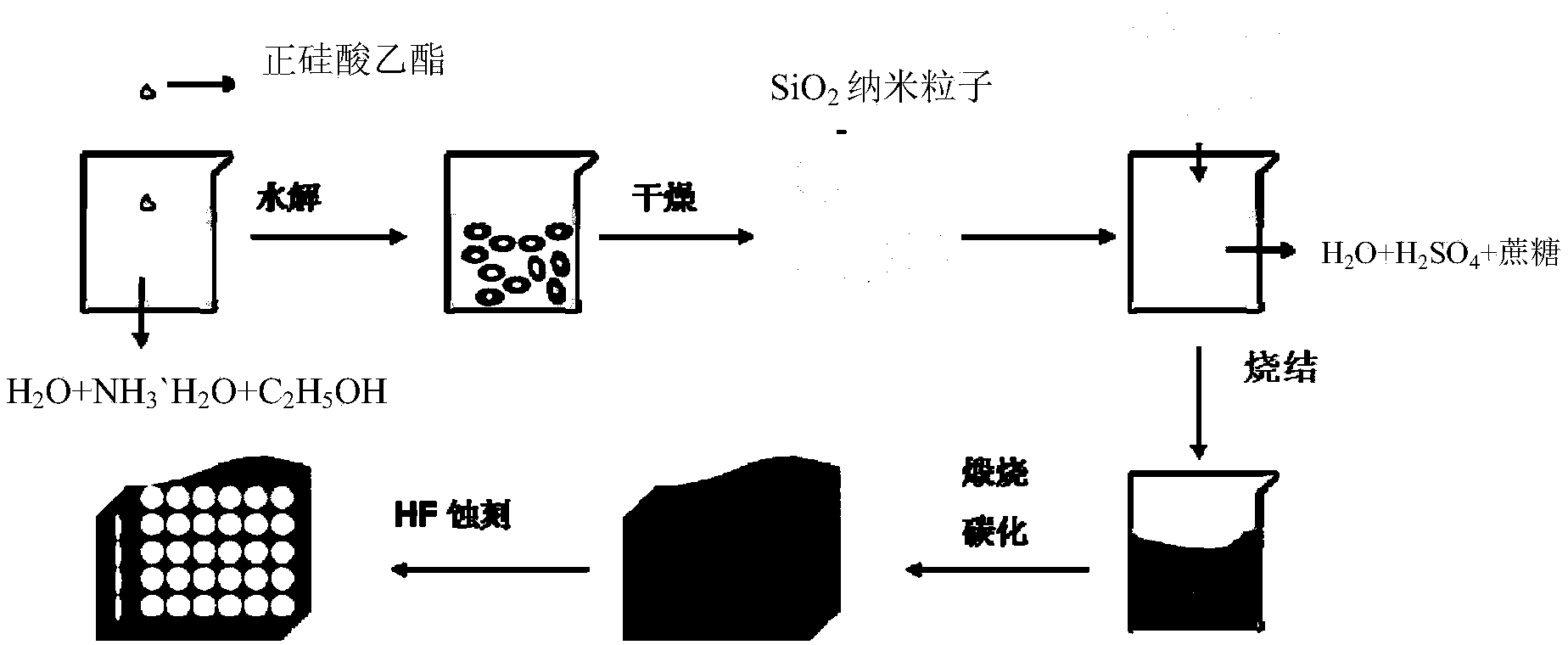

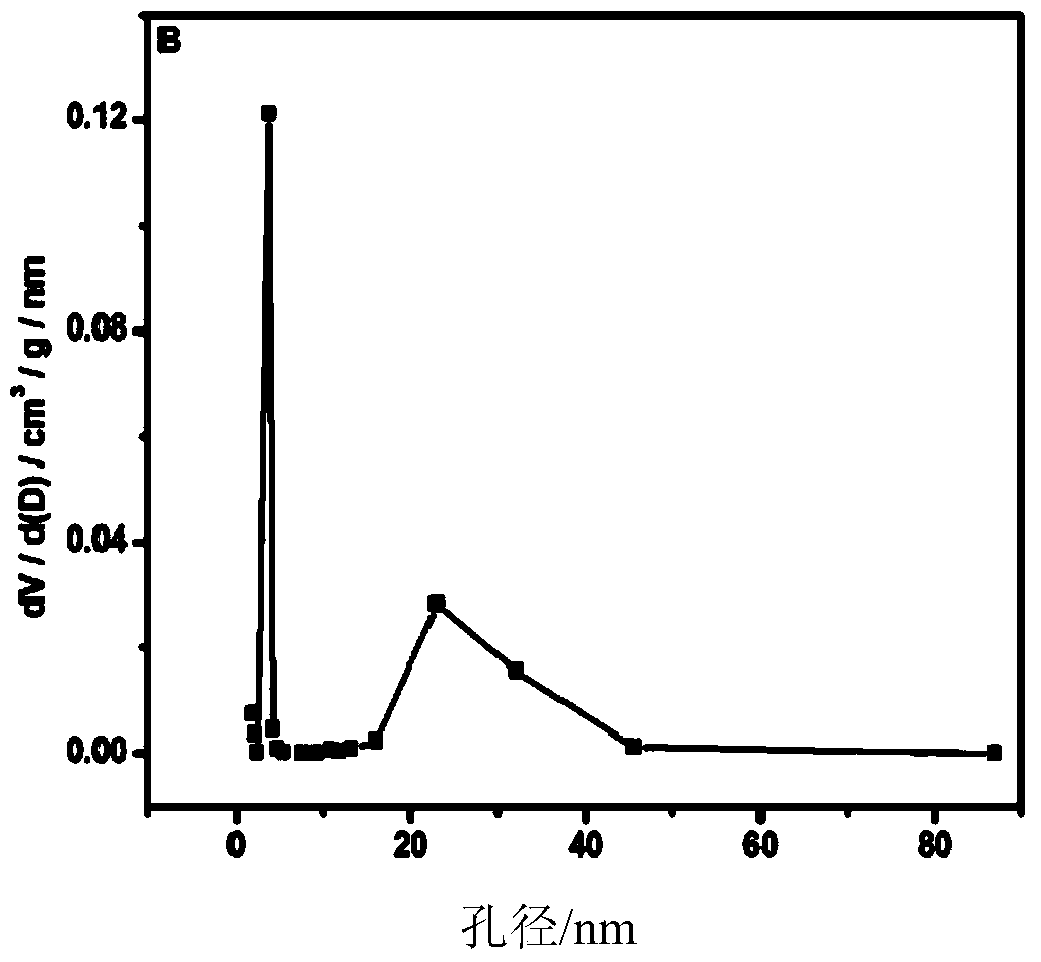

Method for preparing mesoporous silica spherical nanoparticles

InactiveCN107381579ALow costFacilitate macro quantization synthesisSilicaNanotechnologyTetraethyl orthosilicateNanoparticle

The invention discloses a method for preparing mesoporous silica spherical nanoparticles. According to the method, the used template agent refers to cetyl trimethyl ammonium bromide, the alkali source refers to an organic small molecule amine, the silicon source refers to tetraethyl orthosilicate (TEOS), and the organic alcohol salt serves as a promoter. According to the molar composition of the raw materials, a ratio of the silicon source to the cetyl trimethyl ammonium bromide to organic alkali to sodium methylate to water is (1):(0.03-00.06):(0.5-2):(0.001-0.5):(80-500). Accurate synthesis in the particle size range of 25-50nm is realized by regulating the amount of the organic alcohol salt and regulating the nucleation rate of particles. Compared with the prior art, the method disclosed by the invention has the most significant advantage that the hydrolysis and condensation rate of the silicon source is promoted by taking the organic alcohol salt with high nucleophilicity as the promoter. Therefore, the silicon source is subjected to burst nucleation in a very short time, so that the small-size mesoporous silica spherical nanoparticles are prepared. The synthetic method disclosed by the invention is simple, short in cycle, low in cost and high in repeatability and is an environment-friendly green synthetic method.

Owner:EAST CHINA NORMAL UNIVERSITY

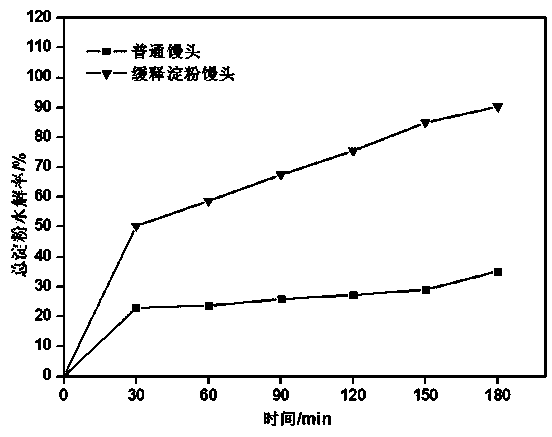

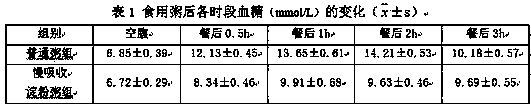

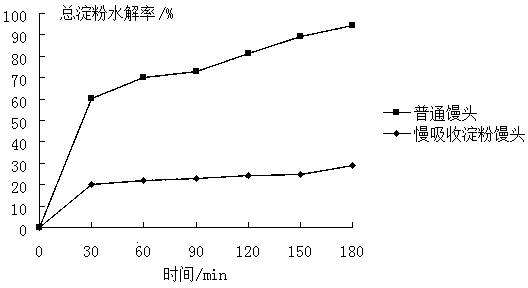

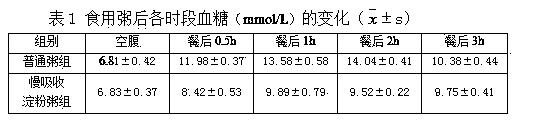

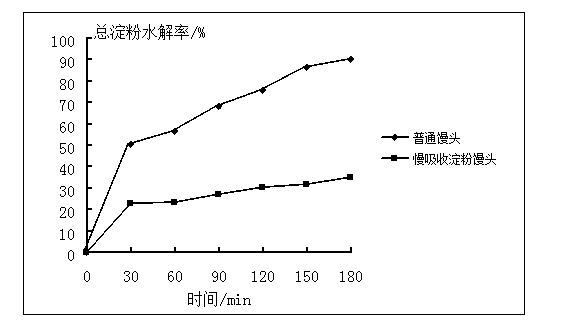

Health food capable of lowering decomposition and absorption speeds of starch in bodies and preparation method thereof

The invention relates to health food capable of lowering decomposition and absorption speeds of starch in bodies and a preparation method thereof. The preparation method is characterized by comprising the steps of adding vegetable powder to normal starch or a starch composition with different digestion rates and preparing starch particles through inclusion for granulation and drying. The health food has the characteristics that as the vegetable powder is added to the starch and serves as a skeleton, not only is the health food abundant in nutrients, but also slow release skeleton powder or particles can be formed, so that decomposition and absorption of the starch is slowed down and the blood glucose can not rise sharply and is in a steady state after people eats the health food; therefore, the postprandial blood glucose is lowered, the probability of various complications caused by blood glucose fluctuation after eating is lowered, and the quality of life of patients with diabetes mellitus is improved.

Owner:江中食疗科技有限公司

Bamboo salt food tea and production method thereof

InactiveCN101816359APowerful PenetrationEfficient removalConfectioneryTea substituesFacial skinBlood pressure

The invention relates to bamboo salt food tea and a production method thereof. The production method comprises the following steps of: drying materials such as lotus leaves, hemp fruits, pine needles, and mulberry leaves respectively; powdering the materials to obtain powder; adding bamboo salt into the powder to obtain a mixture; and performing high temperature sterilization on the mixture to prepare powder, tea bags, tablets or candies, or boiling the mixture in water and filtering the mixture to prepare aqueous beverage. Most people have moist, lustrous and firm facial skin, feel vigorous and difficultly feel tired in work, and the hair hardly becomes dry and yellow, whitens or drops off when the people drink the bamboo salt food tea for 1 to 3 months; and the bamboo salt food tea alsohas effects of lowering blood fat, blood pressure, and blood sugar, and has magical effects of curing stomach diseases, nourishing a stomach, and invigorating the stomach for the people who have all kinds of stomach diseases.

Owner:简丽恒

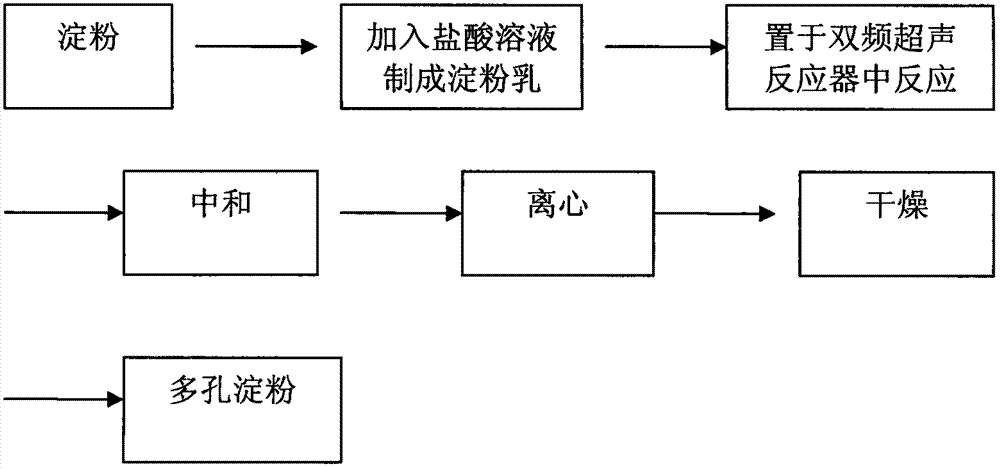

Method for processing porous starch through dual-frequency ultrasonic assisted acid hydrolysis

The invention relates to a method for processing porous starch through dual-frequency ultrasonic assisted acid hydrolysis, belonging to the field of modified starch processing. The method comprises the steps of: by taking starch (such as corn starch, sweet potato starch, mung bean starch, chickpeas starch and pea starch) as raw materials, preparing starch milk by using a hydrochloric acid solution with a certain concentration, putting the starch milk in a dual-frequency ultrasonic reactor for ultrasonic processing, stirring continuously, stopping ultrasonic after reaction for a certain time, adjusting the pH value to be neutral by using a saturated sodium carbonate solution, repeatedly centrifugal washing, drying, and grinding to obtain a porous starch product. The porous starch provided by the invention has deep and dense pores with uniform pore size, the pore volume accounts for above 70% of the particle volume, and the porous starch is strong in adsorbability, short in production cycle and low in processing cost, and can be widely applied in the fields of foods, medicine and health care, agriculture, paper making, printing, cosmetics, detergents and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

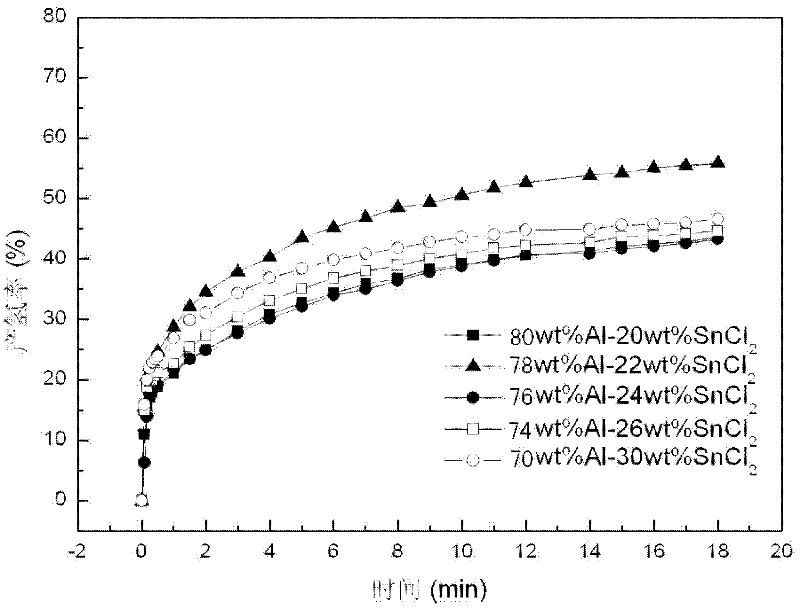

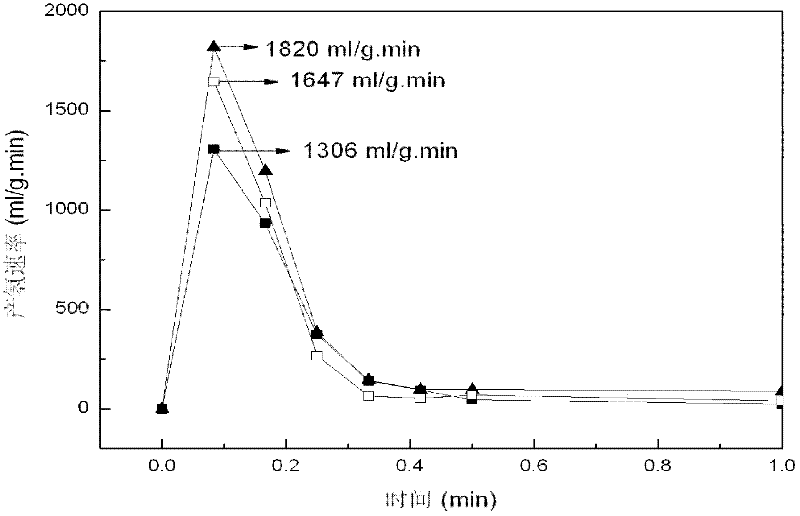

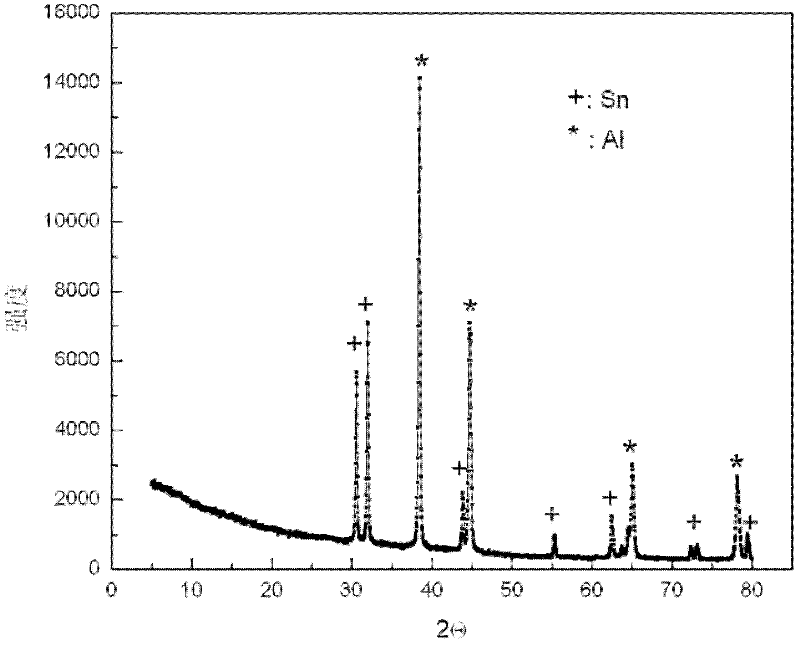

Aluminum-based composite hydrogen manufacturing material and preparation method thereof

InactiveCN102408096ALarge specific surface areaIncrease the rate of hydrolysisHydrogen productionAluminum matrix compositesHydrogen yield

The invention provides an aluminum-based composite hydrogen manufacturing material and a preparation method thereof and belongs to the technical field of energy sources. The invention provides a novel aluminum-based composite material with high hydrogen manufacturing velocity, and the novel aluminum-based composite material is manufactured by a mechanical ball milling method; and different aluminum-based raw materials and additives are selected in the manufacturing process, and the reaction activity of products and water is improved by optimizing the content of each component and ball millingconditions. The aluminum-based composite hydrogen manufacturing material manufactured by the preparation method provided by the invention can quickly react with the water to release hydrogen at normal temperature, the initial hydrogen manufacturing velocity is larger than 2,000ml / g.min, and the hydrogen yield is close to a theoretical value. The aluminum-based composite hydrogen manufacturing material can be used for solving the problem of low hydrogen manufacturing velocity at the normal temperature reported at present, the hydrogen manufacturing method is simple and fast, and the products are portable and can supply hydrogen to fuel batteries, movable devices and the like.

Owner:LIAONING NORMAL UNIVERSITY

Technique for reducing in-vivo decomposition and absorption speed of starch

InactiveCN103519162AIncrease the rate of hydrolysisFood ingredient as thickening agentAlgae medical ingredientsBiotechnologyStarch breakdown

The invention relates to a technique for reducing in-vivo decomposition and release speed of starch, which is characterized by comprising the following steps: pulverizing starch food raw materials into fine powder or directly using starch,, adding a thickener and water, stirring uniformly to form a soft material, putting in a double screw extruder, extruding with a mold to obtain granules, and drying for later use; or drying the soft material, and pulverizing into fine powder for later use. The technique is characterized in that the edible thickener is added into the starch to reconstruct the physical structure of the starch granules, so that the starch decomposition is retarded, and the blood sugar after eating can not increase rapidly but is in a stable state, thereby lowering the postprandial blood sugar, lowering various complications initiated by blood sugar fluctuations after eating, and enhancing the life quality of diabetics.

Owner:JIANGXI SHI FANG SHI FANG CHINESE MEDICINE FOOD

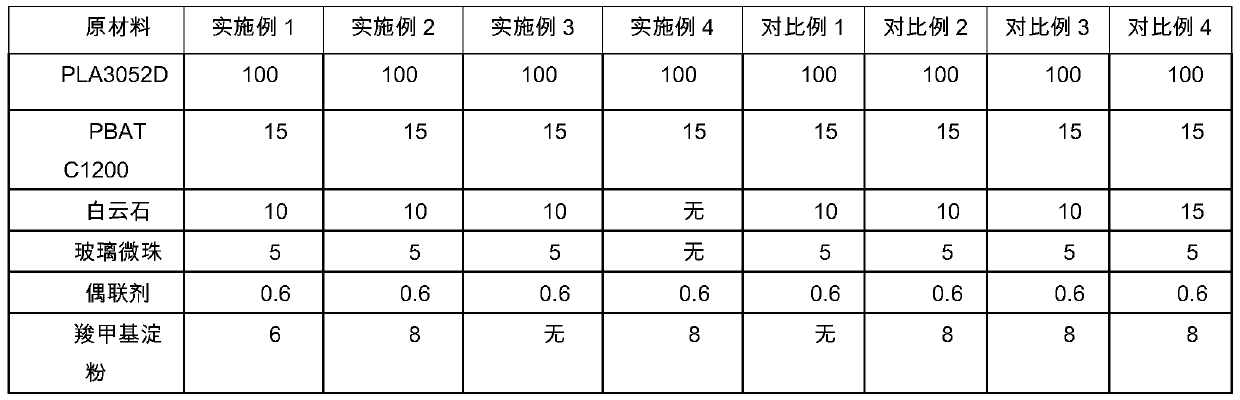

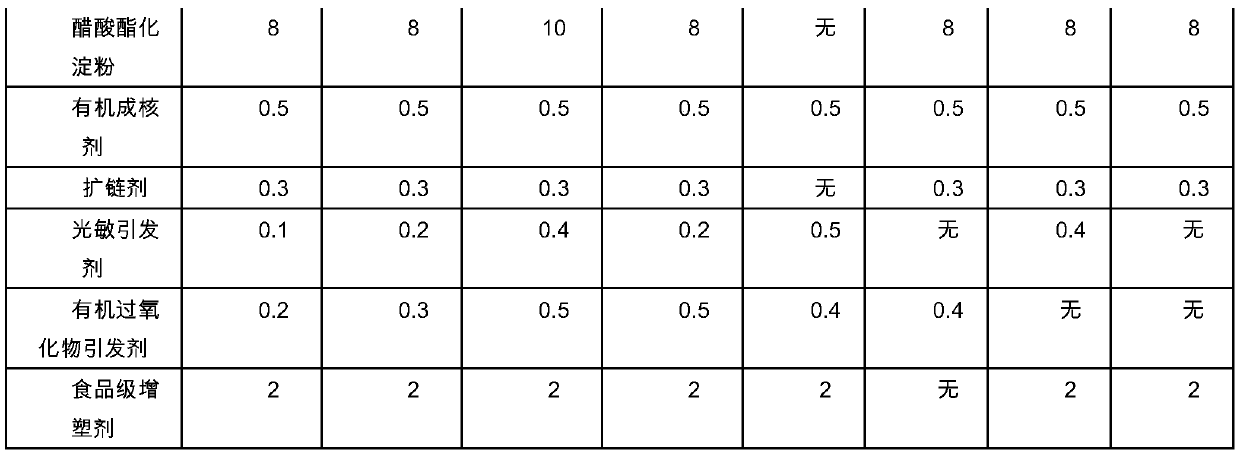

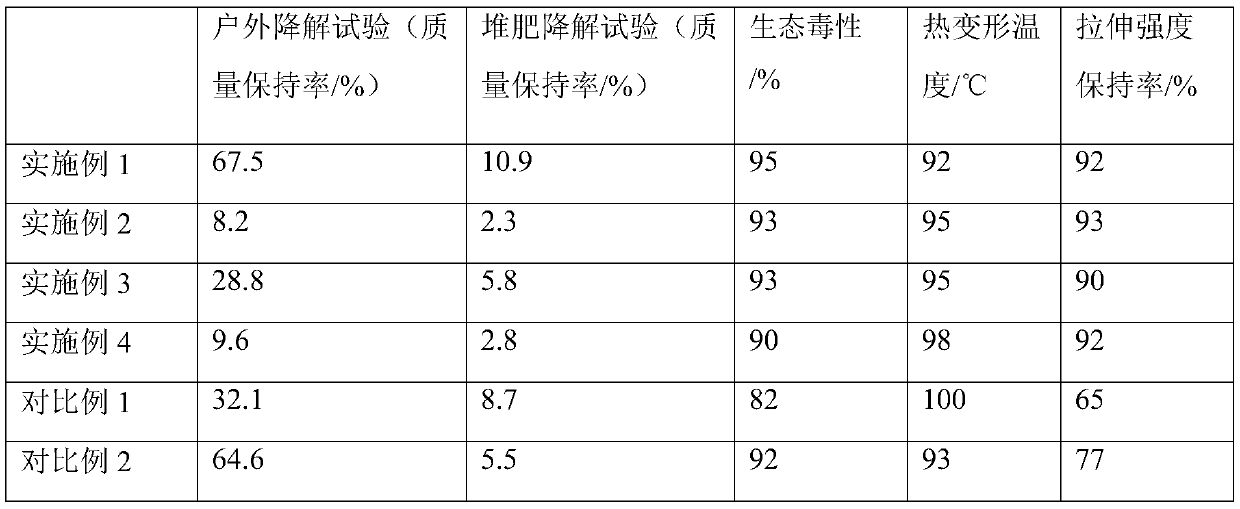

Heat-resistant polylactic acid composite material with short degradation cycle and preparation method of composite material

InactiveCN110128806AAchieve controlled degradationGood compatibilityFlexible coversWrappersOxygenHydrolysis

The invention discloses a polylactic acid (PLA) composite material with a high degradation speed and a preparation method of the composite material. The composite material provided by the invention isprepared by adopting polylactic acid resin, PBAT resin, an inorganic filler, modified starch, an organic nucleating agent, a coupling agent, a chain extender, a compound photosensitive initiator, a thermal oxygen degradation initiator and a food-grade plasticizer, the heat resistance of the polylactic acid material is improved, and the use range of polylactic acid products is expanded; thermal degradation, photodegradation and hydrolysis speeds of wasted PLA products are increased, harsh conditions that require industrial composting are avoided, and the degradation speed faster than that of ordinary polylactic acid can be realized under natural conditions; the auxiliary agents used in the method are all food-grade raw materials and can be applied to food packaging; and the preparation method of the polylactic acid composite material with the high degradation speed provided by the invention employs simple equipment and is low in investment.

Owner:中山市正合色彩资源有限公司

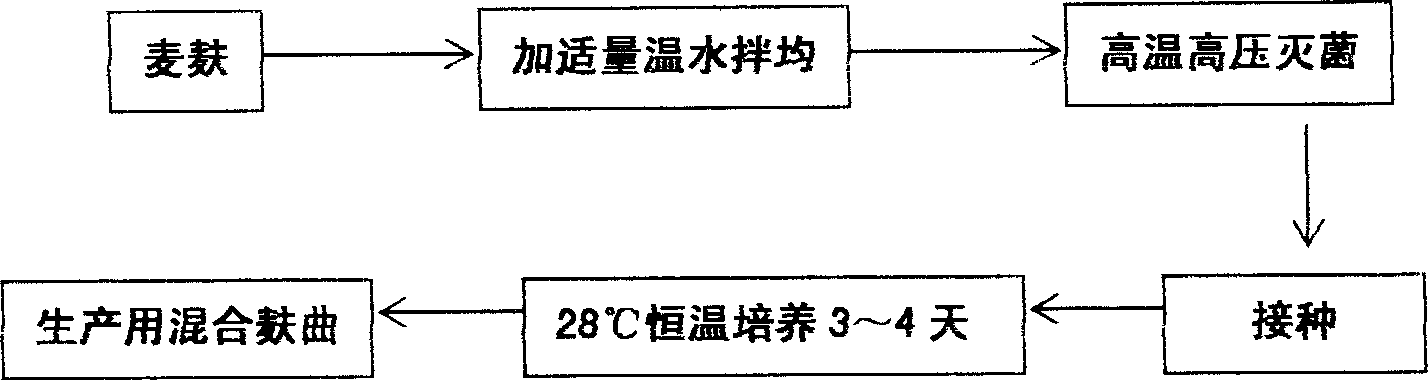

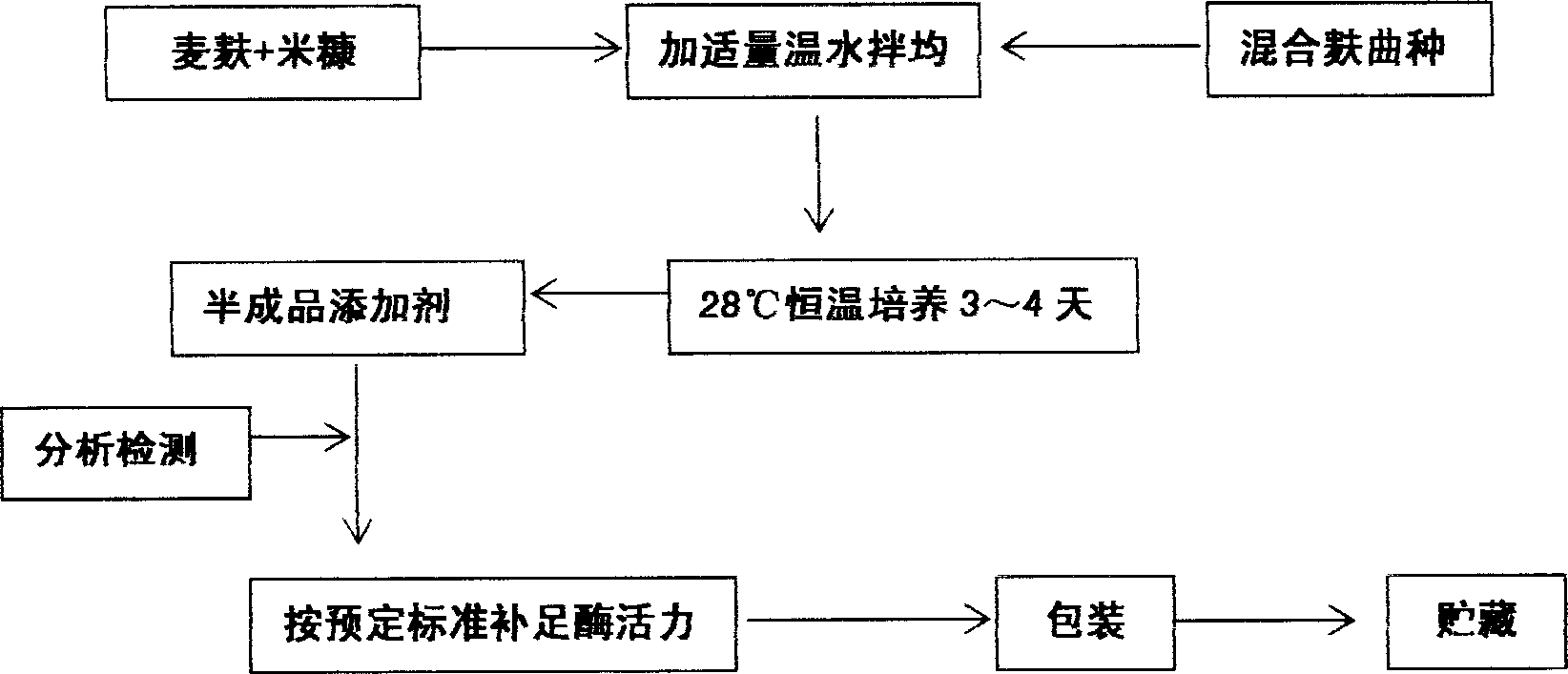

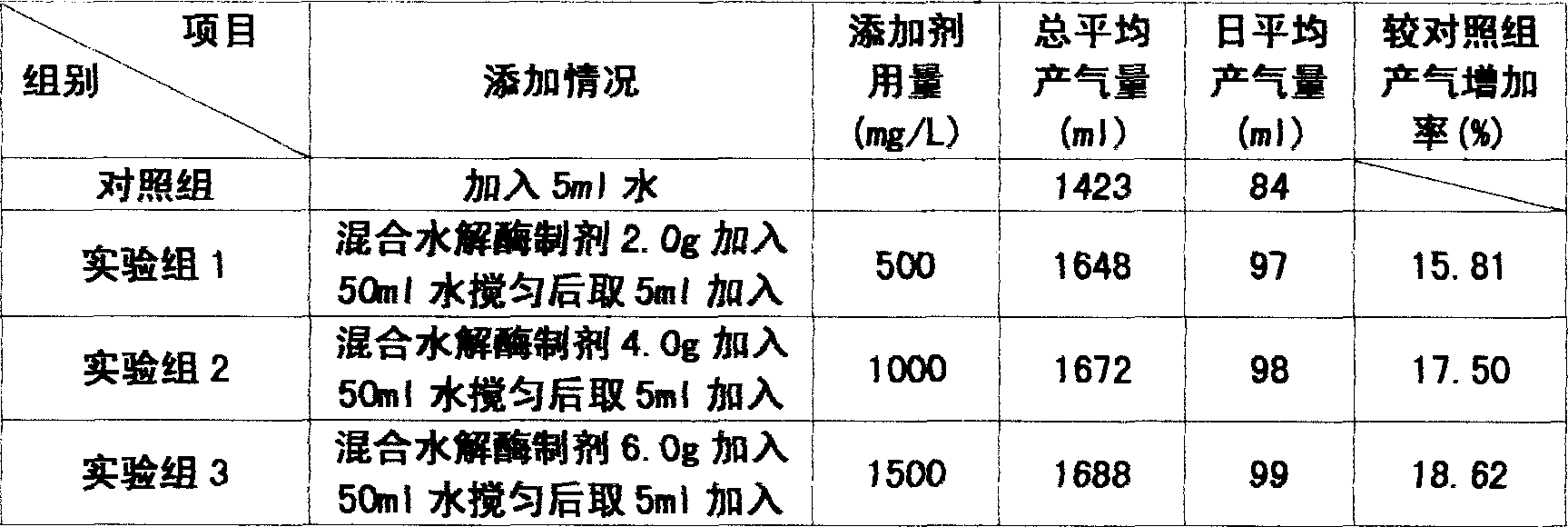

Preparation method of hybrid hydrolase formulation for promoting methane yield from fermentation

InactiveCN1884509AIncrease fermentation gas productionPromote degradationHydrolasesMicroorganismsBiotechnologyMethane yield

The method for preparation of hydrolytic enzyme preparation used for improving gas-producing rate of marsh gas fermentation belongs to preparation of supplementary exoenzyme used for marsh gas fermentation. The invention is to provide a method for preparation of hydrolytic enzyme preparation used for improving gas-producing rate of marsh gas fermentation, which has the production bacteria with the following enzymatic vitality index: selecting wheat bran and rice bran as mixed culture medium, obtaining mixed bran seeds by pedigree breed two-stage enlargement culture of the bacteria with solid method, fermenting for 3-4 days at 28 DEG after evenly mixed, sampling and analyzing every enzymatic vitality index, adding commodity enzyme preparation to reach enzymatic vitality index, and airing until the humidity is lower than 5%. The enzymatic vitality index of the prolease in the said mixed bran seeds is not more than 2000+-5% mug tyrosine / g / min. The bacteria can be obtained by bacteria and fungus separated from different environment. The test proves that when hydrolytic enzyme preparation is input into the methane tank fermentation raw materials, the rate of dissolution and degradation of the marsh gas fermentation raw materials can be improve, and the gas-producing rate of marsh gas fermentation, TS and VS gas-production potential and methane content in marsh gas can be increased.

Owner:YUNNAN NORMAL UNIV

Technology for reducing in-vivo decomposition and absorption speeds of starch

ActiveCN103535708AIncrease the rate of hydrolysisFood ingredient as thickening agentAlgae medical ingredientsBiotechnologyAlglucerase

The invention relates to a technology for reducing in-vivo decomposition and absorption speeds of starch. The technology is characterized by comprising the following steps: crushing starch food raw materials into fine powder or directly utilizing the starch; adding a plant extract and preparing into a soft material by suitable amount of water; then putting the soft material into a double-screw extruder, and extruding into grains by a mould; drying for future use; or after drying the soft material, crushing the soft material into fine powder for future use. The technology has the innovations that the plant extract with an alpha-glucosaccharase inhibition effect is added into the starch so that the deposition and the absorption of the starch slow down; after the starch is eaten, the blood glucose is not suddenly raised and is at a balanced state, so that the postprandial blood glucose is reduced, various complications caused by blood glucose fluctuation after the starch is eaten are reduced and the living quality of diabetics is improved.

Owner:江中食疗科技有限公司

Wool product for preventing electric radiation and manufacturing technology thereof

PendingCN107237038AGood anti-electron radiation effectPromote absorptionWeft knittingBiochemical treatment with enzymes/microorganismsYarnPolyester

The invention provides a wool product for preventing electric radiation. The wool product comprises 10-20% of wool fiber, 30-40% of modified polyester fiber, 25-35% of silver-coated filament and 15-35% of bamboo pulp fiber, wherein the silver-coated filament is coated with the modified polyester fiber to form core spun yarn, the core spun yarn, the wool fiber and the bamboo pulp fiber are blended to form fabric with a function of preventing the electric radiation. Through the coordination of a manufacturing technology, the wool product which has a high electromagnetic shielding effect, comfortable in handfeel, is suitable for being worn can be obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

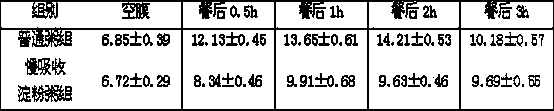

Porous carbon with uniform nano aperture as well as preparation method thereof and application

The invention discloses porous carbon with a uniform nano aperture as well as a preparation method thereof and application. The preparation method comprises the following steps of uniformly mixing ammonia water, ethanol and deionized water to obtain a mixed liquid, dropwise adding ethyl orthosilicate into the mixed liquid to be reacted and dried to obtain a nano spherical SiO2 template; adding the nano spherical SiO2 template into a sugarcane acid solution to be sintered for two times, grinding the solid, and calcining the solid in an inert gas environment for 2 hours to 4 hours; soaking the powder obtained in the calcining for 24 hours to 36 hours, washing the powder by utilizing deionized water to be neutral, and drying the powder to obtain the porous carbon with the uniform nano aperture. The preparation method is simple, the specific surface area of the porous carbon is large, the aperture is uniform, the porous carbon is applicable to the production of microorganisms, the rapid formation of a microorganism fuel cell anode biological membrane can be promoted, and the output power of a microorganism fuel cell can be greatly improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

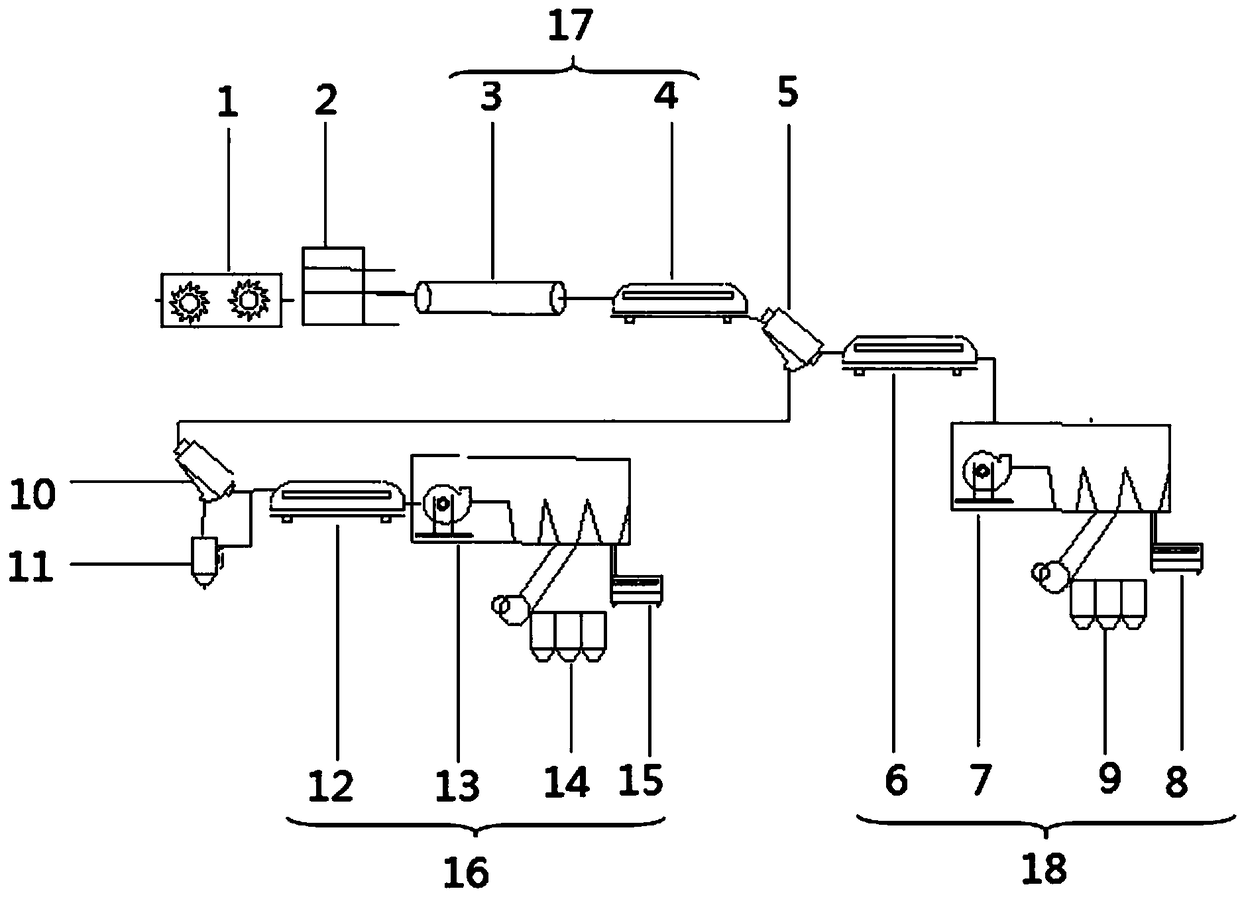

Small and medium-sized city household garbage sorting treatment system and method

ActiveCN108580520AImprove sorting efficiencyAchieving precision and efficiencySolid waste disposalClimate change adaptationBiogasEnvironmentally friendly

The invention discloses a small and medium-sized city household garbage sorting treatment system. The sorting treatment system comprises a household garbage sorting system and a household garbage treatment system; the household garbage treatment system is disposed on the downstream of the household garbage sorting system; the household garbage treatment system comprises an organic matter treatmentsystem, a sewage and waste treatment system and a non-organic regenerant treatment system; and the organic matter treatment system is a pyrohydrolysis-anaerobic fermentation combined system. The small and medium-sized city household garbage sorting treatment system is high in sorting efficiency, low in household garbage treatment cost, high in household garbage recycling ratio, free of secondarypollution and environmentally friendly, the biodegradability of organic wastes is effectively improved, the fertilizing effect and utilization value of fermented biogas residues are improved, and quantity reduction, harmless effect and reclamation of household garbage treatment are achieved.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

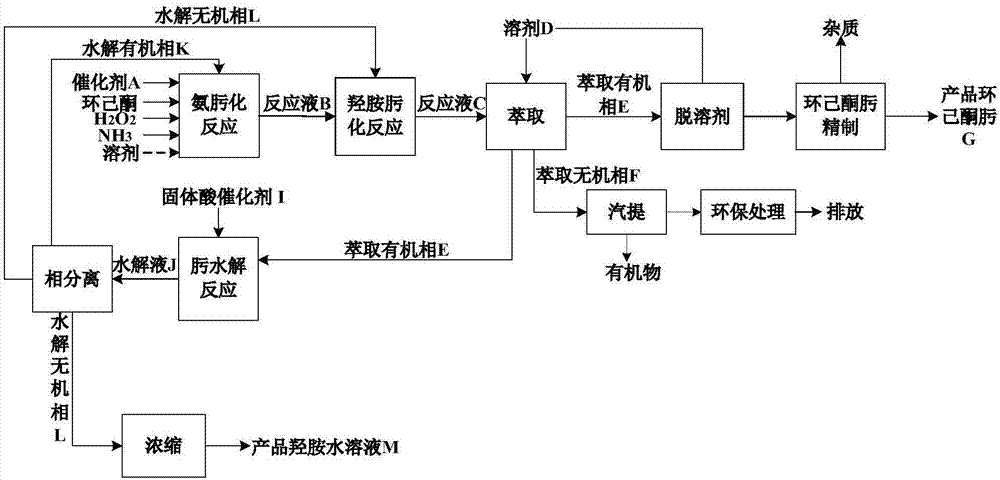

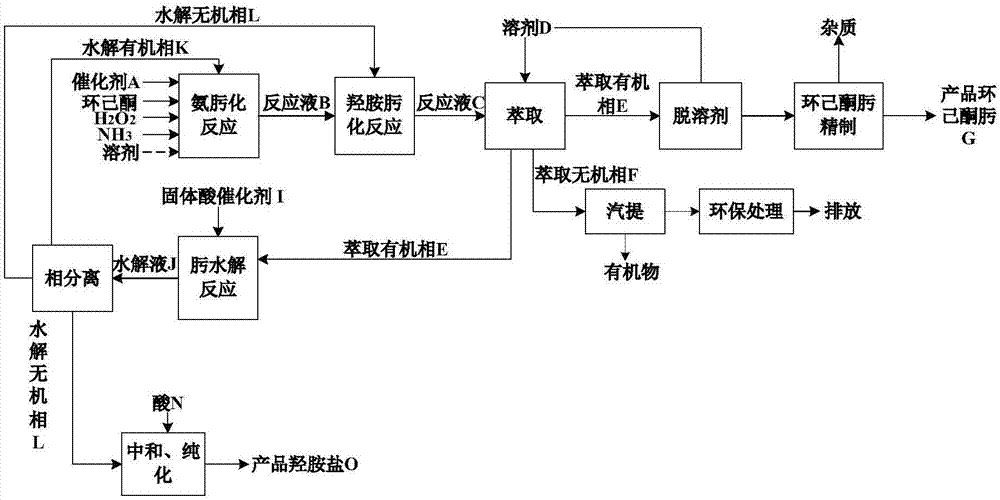

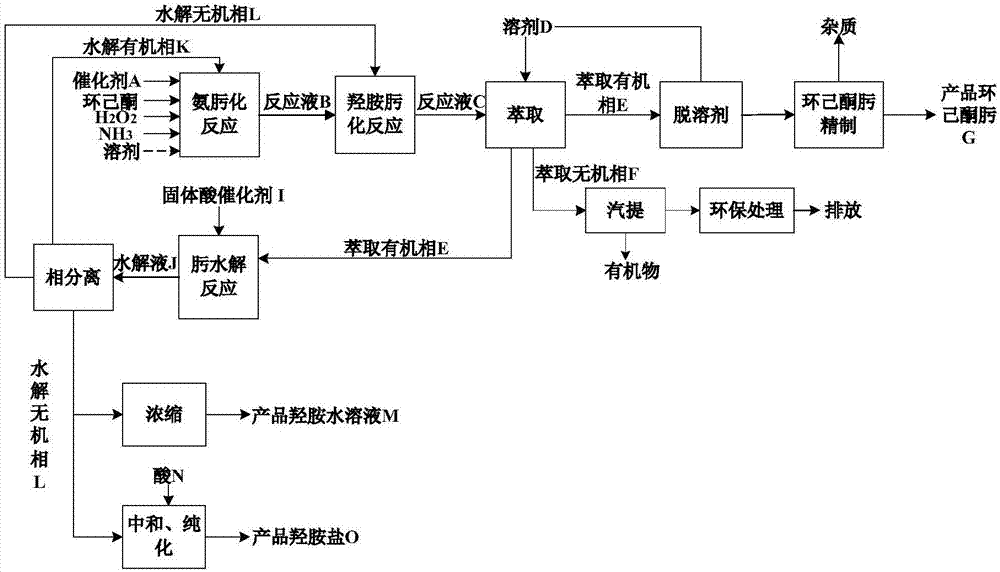

Joint production technology of hydroxylamine, hydroxylammonium salt and cyclohexanone-oxime

ActiveCN107089924AIncrease the rate of hydrolysisLow costHydroxylamineOximes preparationHydroxylamineCyclohexanone oxime

The invention discloses a joint production technology of hydroxylamine, hydroxylammonium salt and cyclohexanone-oxime. The material comprises the steps that reaction liquid obtained by raw materials through an ammoximation reaction and a hydrooximation reaction is extracted and separated to obtain an organic phase, the organic phase is prepared into product cyclohexanone-oxime, or part of the organic phase and part of product cyclohexanone-oxime are adopted as raw materials for an oxime hydrolysis reaction to be hydrolyzed, the organic phase in hydrolysis liquid is circulated to return to a oximation reactor, part of an inorganic phase in the hydrolysis liquid is adopted as a raw material to be circulated to return to a hydroxylamine oximation reactor, and the other part of the inorganic phase is prepared into a hydroxylamine aqueous solution and hydroxylammonium salt. The joint production technology of hydroxylamine, hydroxylammonium salt and cyclohexanone-oxime is simple in procedure, the requirement of the ammoximation reaction for the purity of the raw material cyclohexanone and the catalyst performance is lowered, a high quality cyclohexanone-oxime product without cyclohexanone is obtained, the simplification of the downstream caprolactam technology and the improvement of the product quality are benefited, and the hydroxylamine and hydroxylammonium salt product which have high additional value are obtained simultaneously.

Owner:河北美邦工程科技股份有限公司

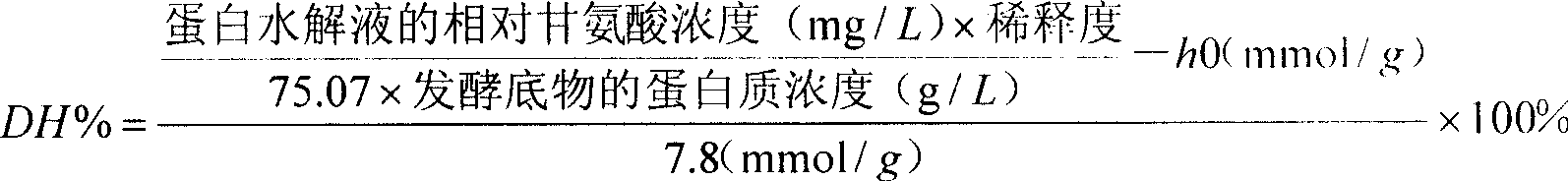

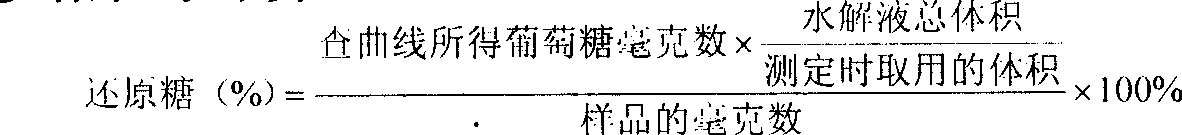

Method for preparing protein powder

ActiveCN101461539AIncrease the rate of hydrolysisRich in nutrientsFood preparationProtein foodstuffs working-upFood additiveAdditive ingredient

The invention pertains to the field of food technology, specially relates to a preparation of protein powder. The invention further discloses a preparation of protein powder, which is characterized in adding probiotics into edible protein powder, anaerobic culturing in water medium, and carrying out proteolysis. By adding probiotics capable of generating prolease in the edible protein powder, which substrates or reinforces prolease in the food additives, the invention makes hydrolysis speed of the protein powder greatly increased in a determined period. The method is more convenient and economic then only adding prolease; the obtained protein powder is more abundant in nutrient, and easier for human body absorption.

Owner:BIOGROWING CO LTD

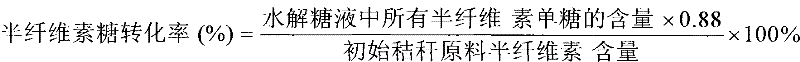

Acid and alkali combination pretreatment method of straw efficient saccharification

ActiveCN102443659ATake advantage ofEfficient removalFermentationLactose productionLiquid productLiquid glucose

The invention discloses an acid and alkali combination pretreatment method of straw efficient saccharification, which comprises the following steps that: firstly, raw material slurry consisting of straw particles, inorganic metal salt, inorganic acid and peroxide takes reaction for 1 to 50 minutes at 100 DEG C to 200 DEG C, then, the temperature is reduced, the reaction stops, finally, solid and liquid products are separated, the liquid product is hydrolytic liquid glucose, the solid product is soaked for 1 to 30 hours by alkali solution with the mass concentration being 0.1 percent to 1.5 percent, and solids obtained through solid and liquid separation after the soaking are used as enzymolysis raw materials. The acid and alkali combination pretreatment method is used, the operation flow process is simple, the treatment time is short, the energy consumption is low, the straw utilization rate is high, and the cellulase enzymolysis effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com