Method for improving efficiency of methane production through anaerobic fermentation and methane content in biogas

A technology of anaerobic fermentation and methane content, applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of high carbon-nitrogen ratio of straw, increased cost input, lack of research, etc., so as to increase methane content and improve methane production. Efficiency, the effect of increasing the hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

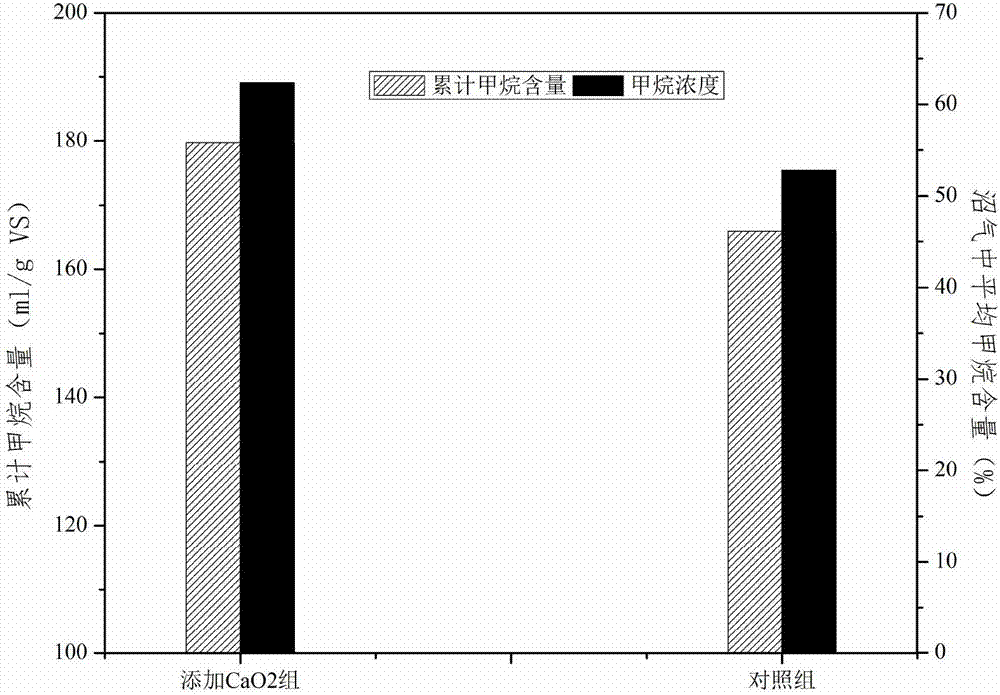

[0022] Corn stalks are used as raw materials for biogas fermentation, using the existing medium-temperature solid-state fermentation technology, and carried out in a solid-state fermentation reactor. The solid-state fermentation reactor is equipped with a water bath temperature control and biogas slurry reflux device. Before the start of fermentation, aerated with nitrogen for 3 minutes to remove the oxygen in the system. Then CaO 2 Mix with the raw materials and add to the solid-state fermentation reactor at one time, in which, CaO 2 The diameter is about 1mm, the dosage is 0.064g / g VS 秸秆 , the solid concentration was set to 15% during fermentation, and the fermentation temperature was 37°C.

[0023] At the same time set the control group, the control group does not add CaO 2 , and the rest of the conditions are the same as the experimental group. Wet gas flowmeter was used to measure biogas production, and gas chromatography was used to measure methane content in biogas ...

Embodiment 2

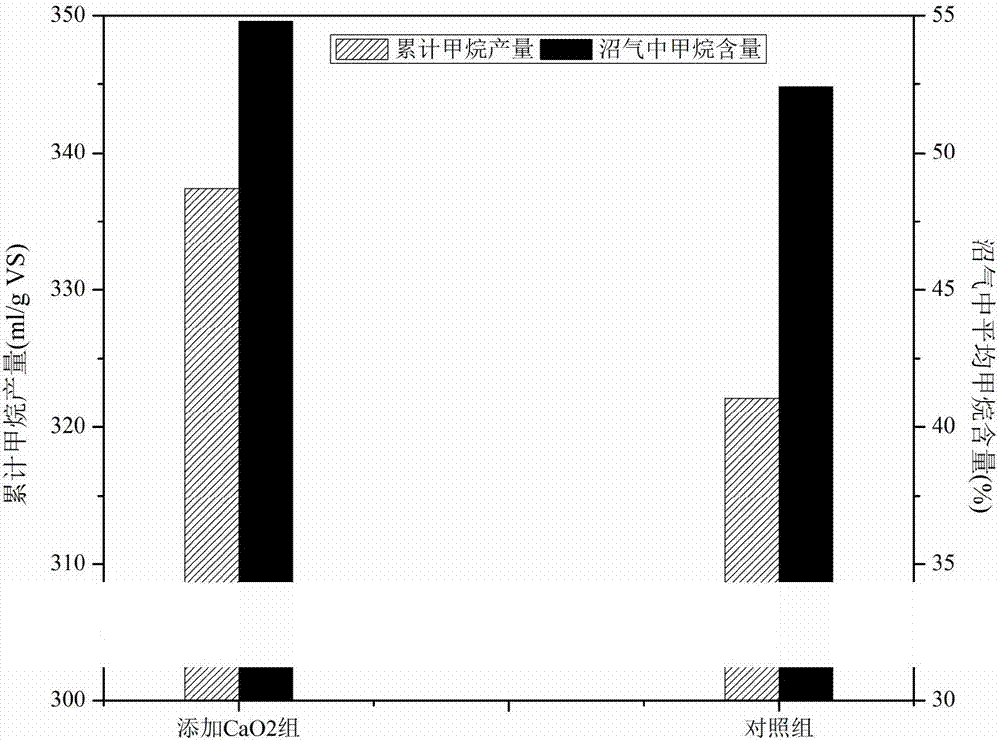

[0025] Corn stalks were used as raw materials for biogas fermentation, and wet fermentation technology was adopted in a 300ml anaerobic fermentation bottle. Before the fermentation started, nitrogen gas was aerated for 3 minutes to remove oxygen in the system. Then CaO 2 Mix with the raw materials and add to the solid-state fermentation reactor at one time, in which, CaO 2 The diameter is about 1mm, the dosage is 0.032g / g VS 秸秆 , the solid concentration was set to 4% during fermentation, and the fermentation temperature was 37°C. The anaerobic fermentation process was carried out in a temperature-controlled water bath shaker at 37°C.

[0026] At the same time set the control group, the control group does not add CaO 2 , and the rest of the conditions are the same as the experimental group. Determination of biogas production by drainage method, determination of methane content in biogas by gas chromatography (see figure 2 ). Depend on figure 2Cumulative methane product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com