Patents

Literature

170results about How to "High methane content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

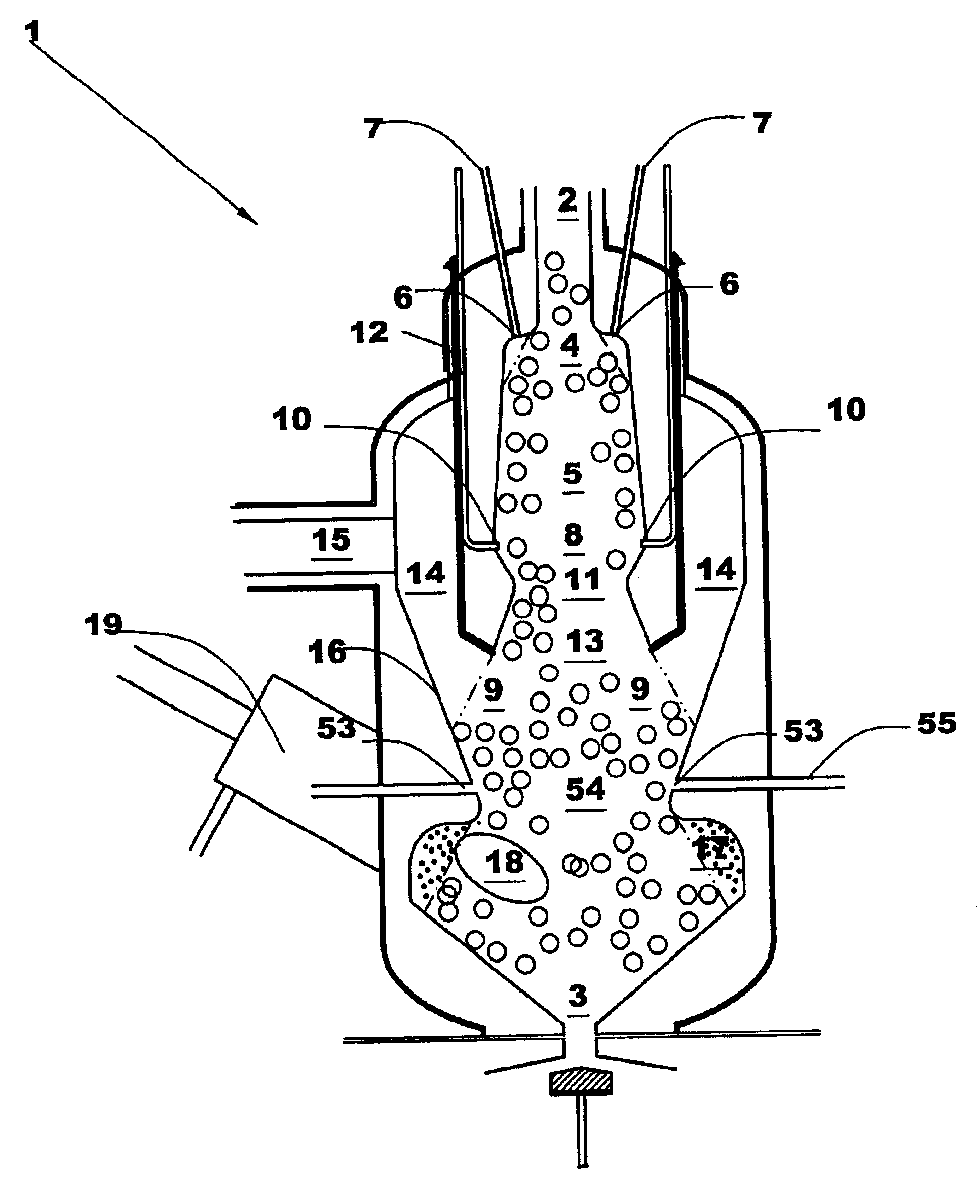

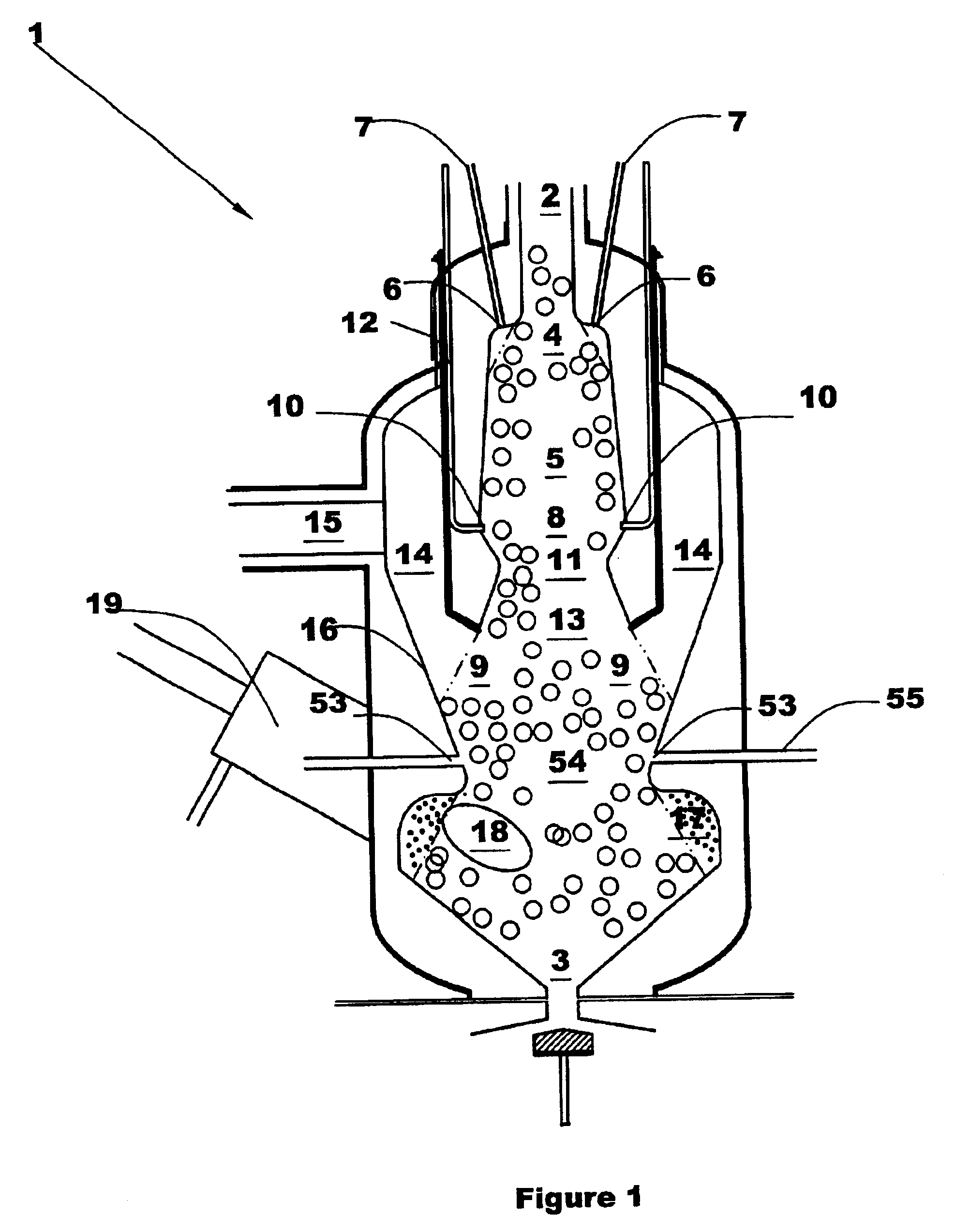

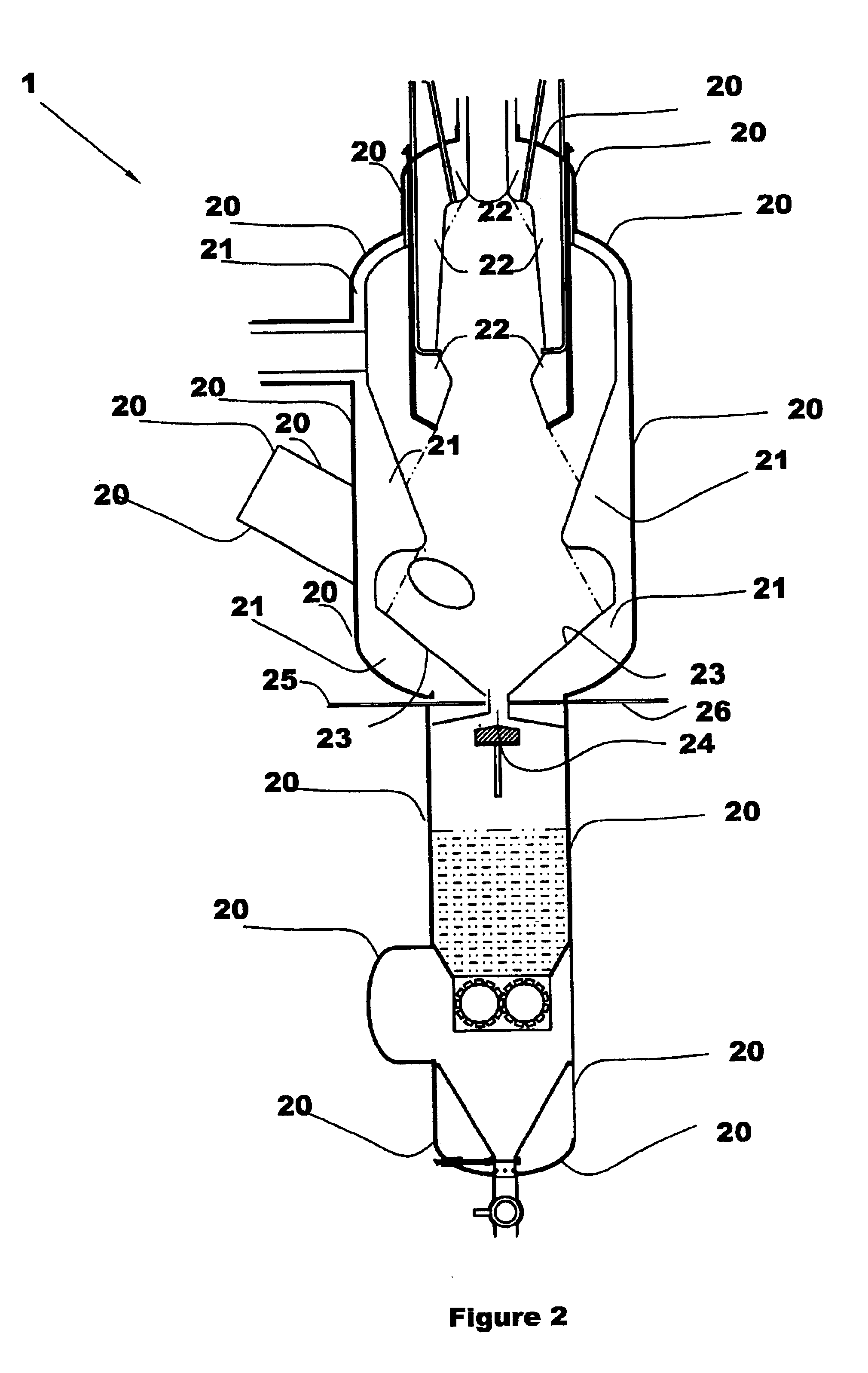

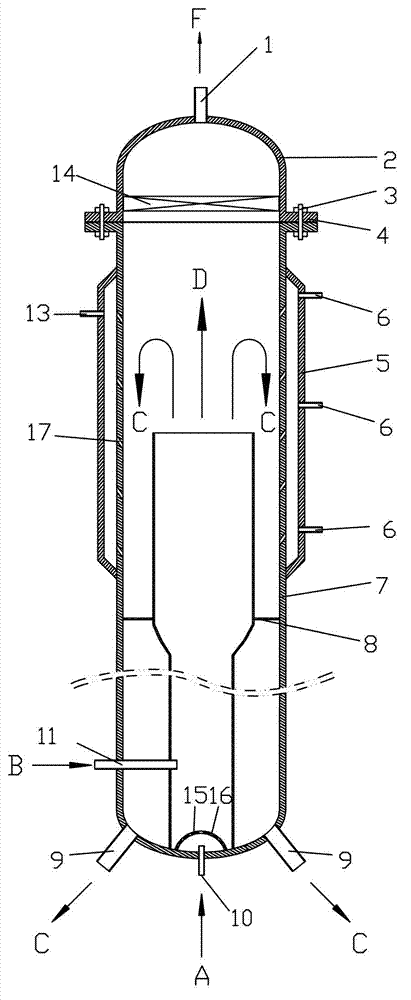

Multi-faceted gasifier and related methods

InactiveUS6960234B2Increased hydrogen productionImprove overall plant economicsLiquid degasificationCoke ovensActivated carbonInjection port

A gasifier is disclosed combining a fixed bed gasification section where coarse fuel is gasified and an entrained flow gasification section where fine fuel is gasified. The fixed bed section includes upper and lower sections. Coarse fuel is devolatilized in the upper fixed bed section and subjected to elevated temperatures sufficient to crack and destroy tars and oils in the effluent gases. The entrained flow gasification section is disposed in a lower plenum adjacent the lower fixed bed section. A plurality of injection ports are configured to introduce oxygen, steam, or air into different sections of the gasifier to control temperature and operating conditions. Activated carbon may be formed in the upper fixed bed section and in the entrained flow section. The activated carbon may be used as a sorbent to remove pollutants from the effluent gases. The gasifier may be used with various coarse and fine fuel feedstocks.

Owner:EMERY ENERGY

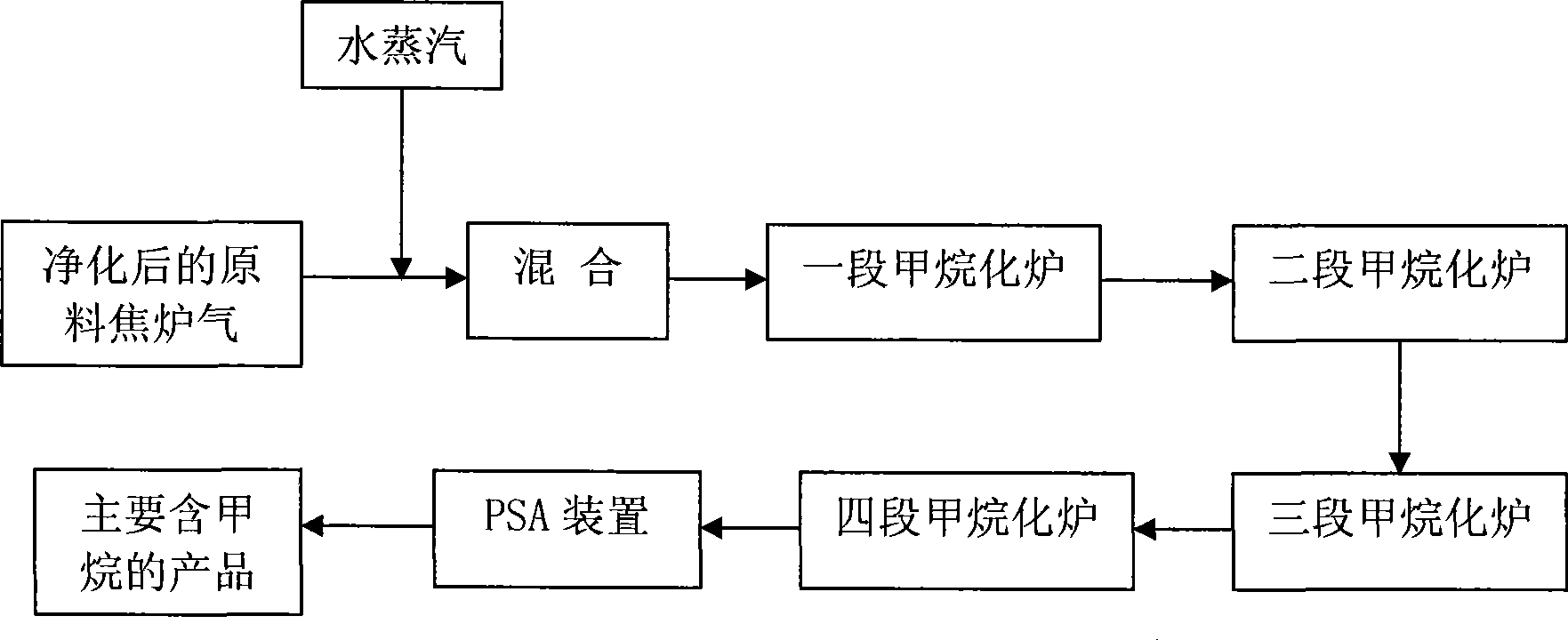

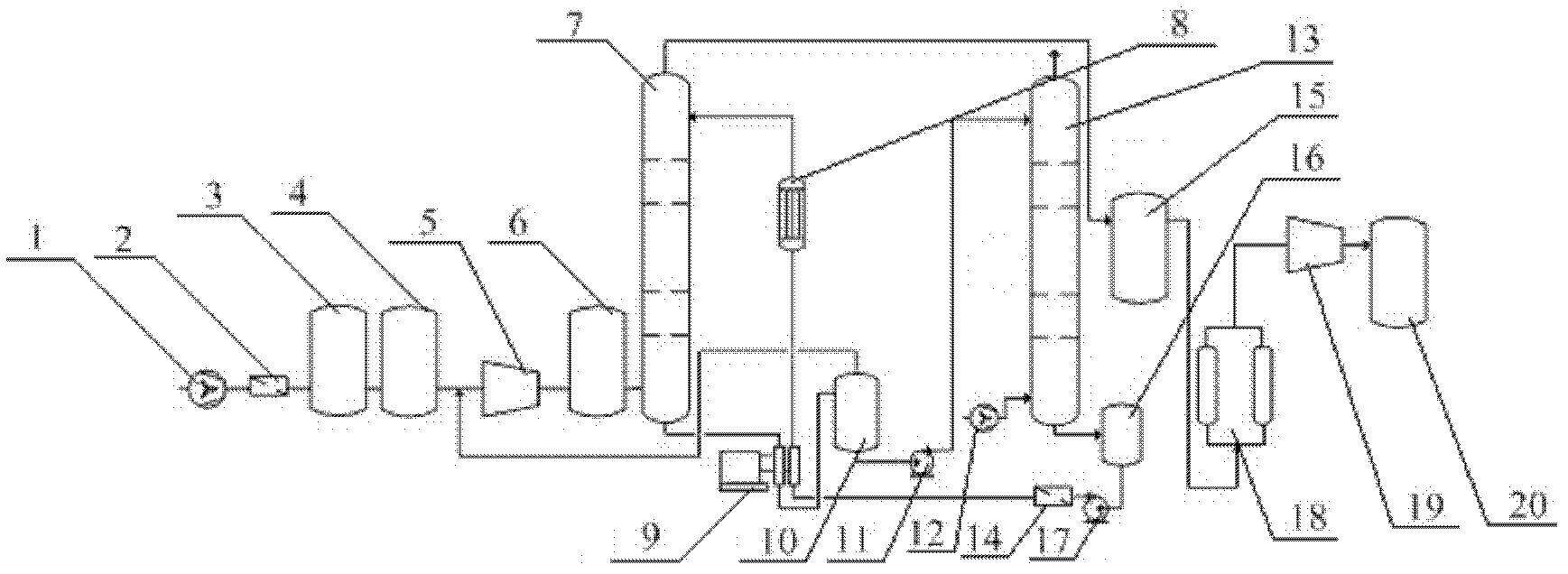

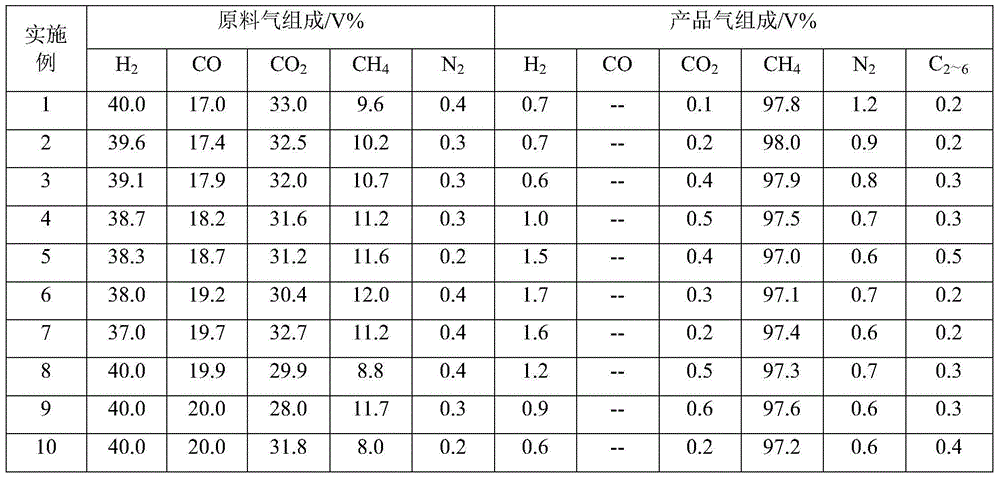

Method for synthesizing methane by using coke-oven gas

ActiveCN101391935AHigh methane contentHigh calorific valueHydrocarbon from carbon oxidesChemical industryWater vaporMethanation

The invention discloses a method for synthesizing methane by utilizing oven gas. Product gas with methane concentration of more than 90 percent is obtained through the main steps of purifying to remove impurities, compressing to exchange heat, adding water vapor, first stage of methanation reaction, second stage of methanation reaction, third stage of methanation reaction, PSA methane separation and the like. By adopting the method and utilizing the oven gas as raw materials, synthetic natural gas with high content of methane, low content of impurities and high heating value can be obtained, which is favorable to protecting the environment, saving energy and developing new energy; in addition, in the method, the addition of appropriate water vapor in the raw materials of oven gas before the fist sage of reaction properly inhibits the depth of the methanation reaction, reduces the heat amount released in the whole reaction process, conduces the cooling of the gas after the reaction and prevents the occurrence of carbon deposition reaction to devitalize the activity of a catalyst, thus being beneficial to the continuous normal operation of the whole synthesizing process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

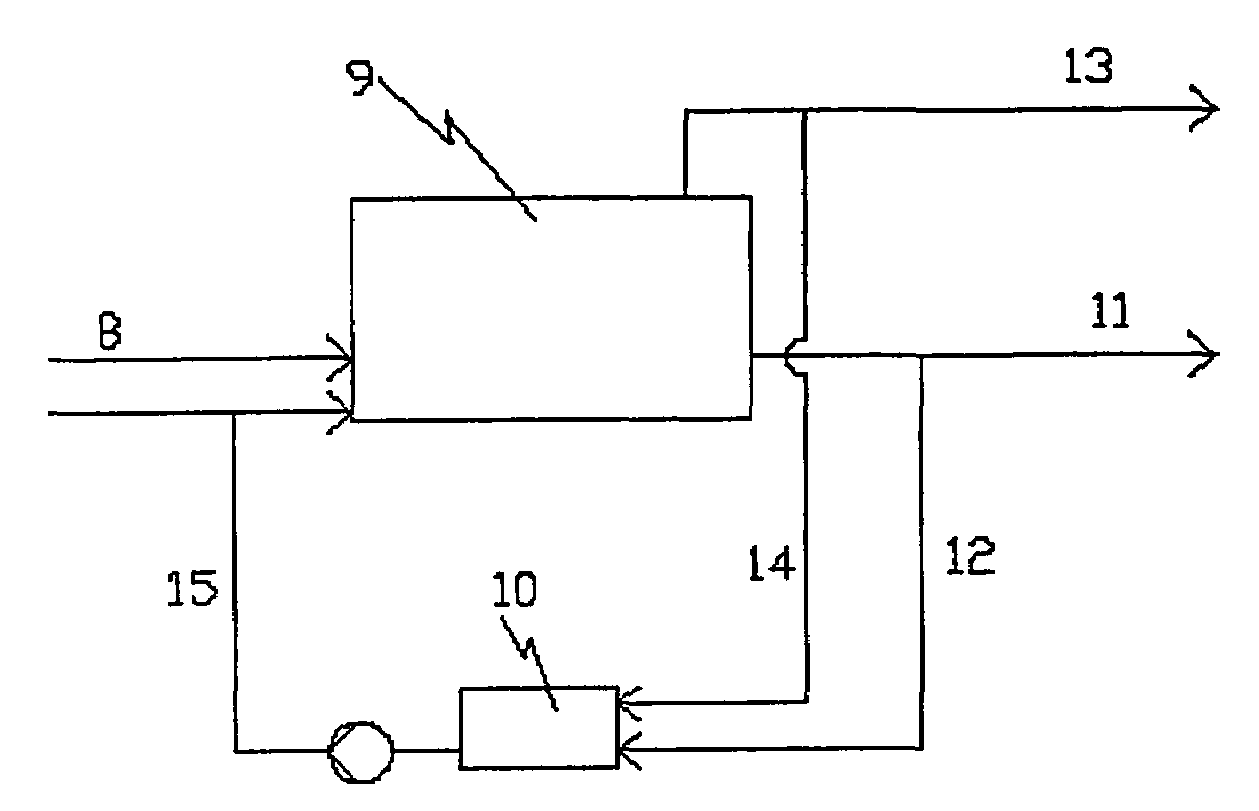

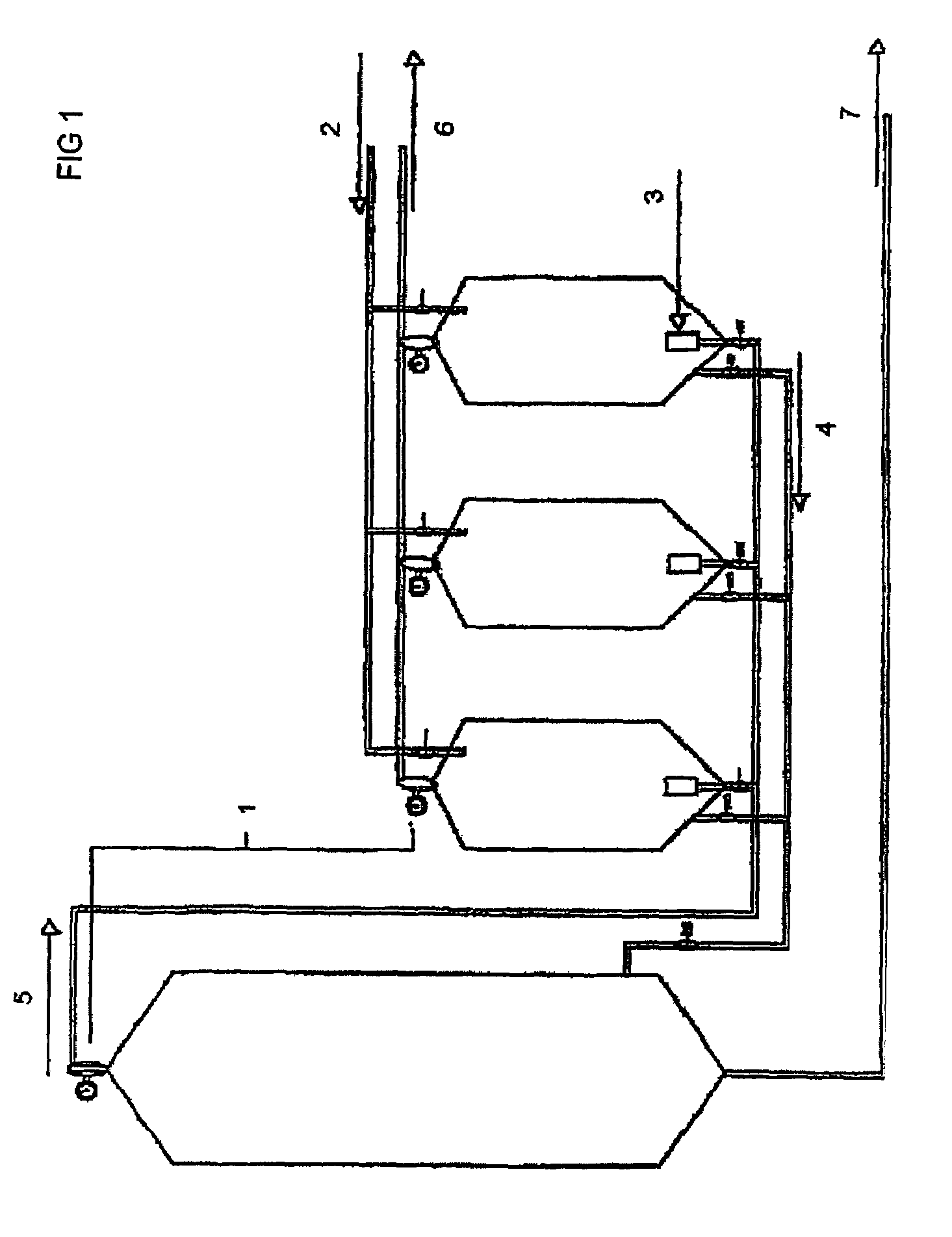

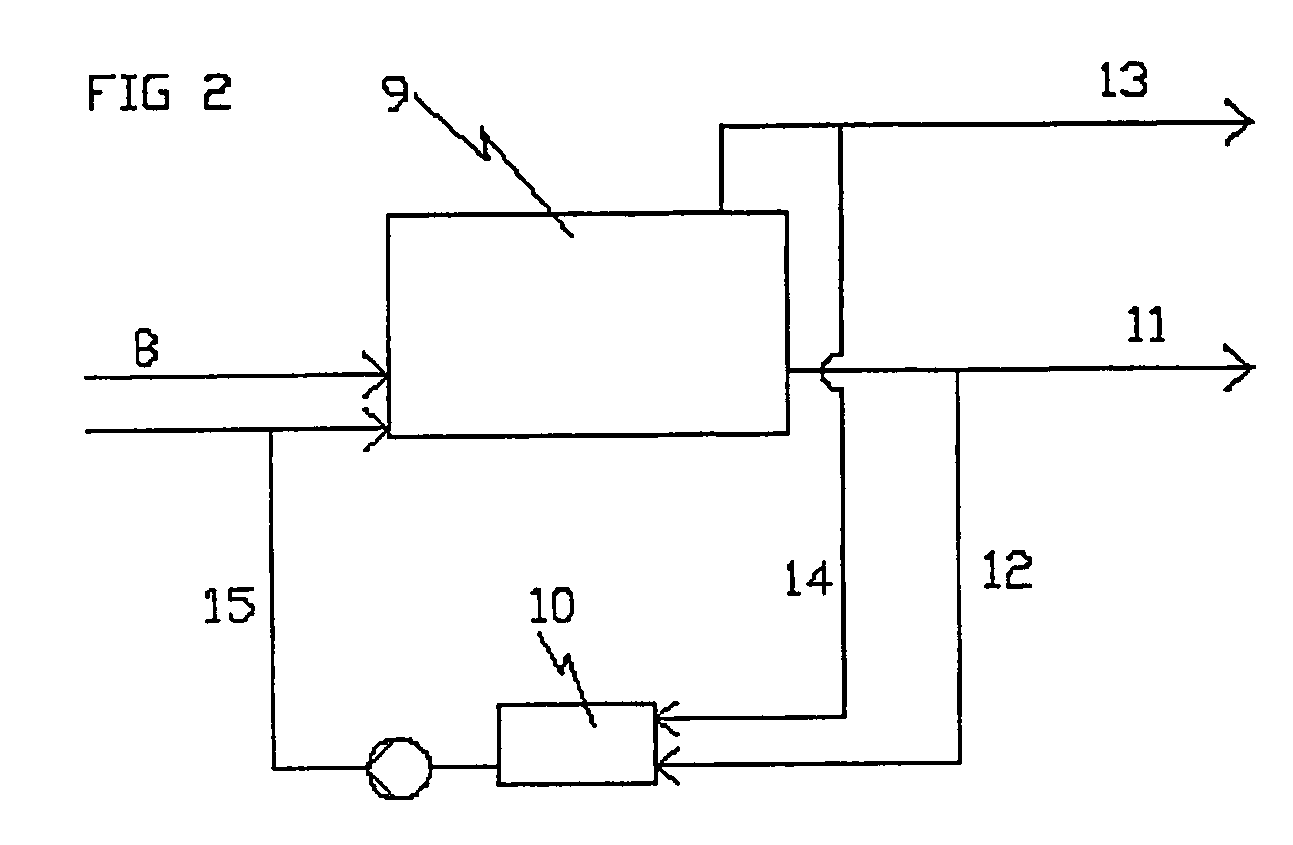

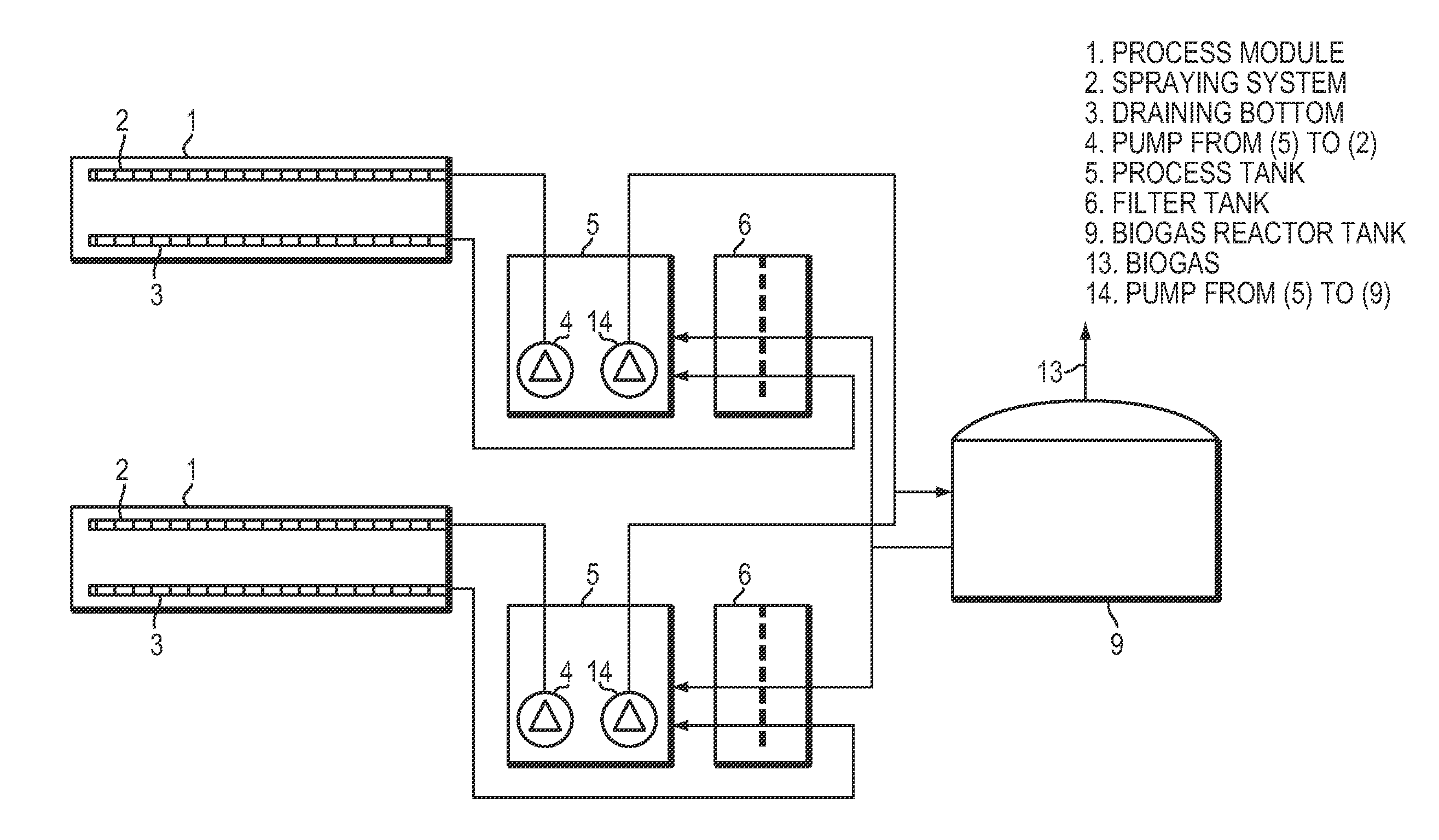

Method and equipment for processing organic material

InactiveUS7160456B2Organic material longerEasy to storeBio-organic fraction processingAnimal corpse fertilisersBuffer solutionAmmonia

A method for processing organic material, in which method bioconversion is performed on the organic material in at least one first reactor, the biogas formed in the bioconversion is treated with ammonia in at least one second reactor and buffer solution produced in the second reactor is recycled to the bioconversion in the first reactor. Thus, the carbon dioxide of the mixed methane / carbon dioxide gas reacts with the ammonia and forms a buffer compound, such as ammonium bicarbonate and / or ammonium carbonate.

Owner:PRESECO

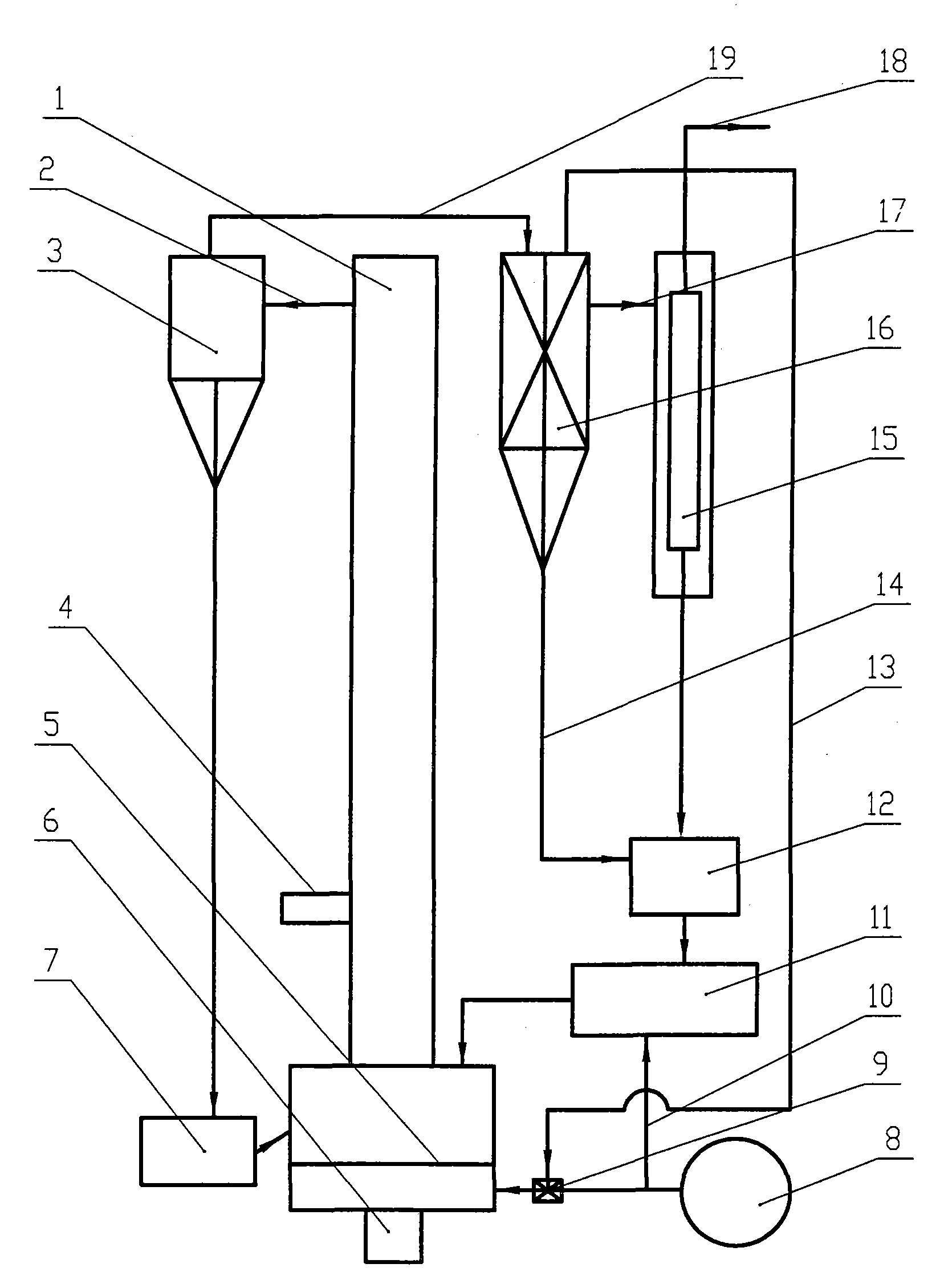

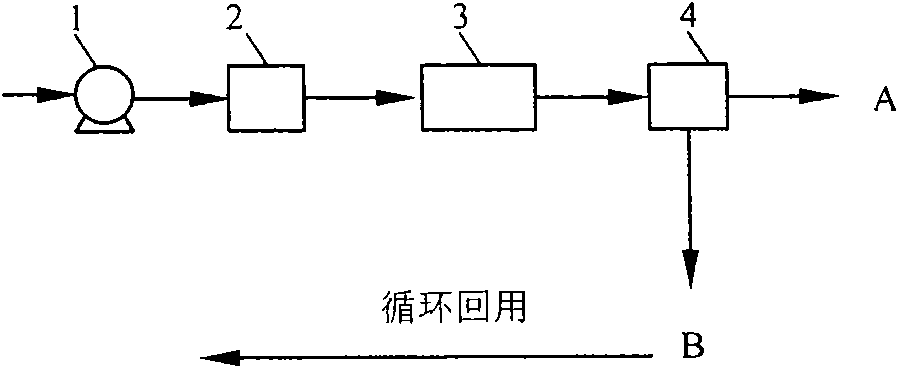

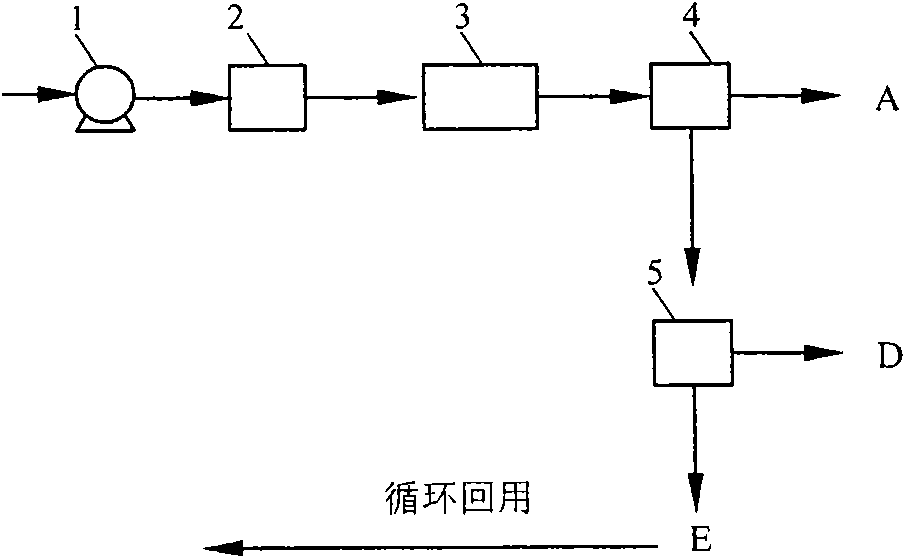

Methane purifying method and equipment thereof

The invention relates to a methane purifying method, comprising working procedures of pressurizing, filtering, biological desulphurizing, deoxidizing, absorbing, dehydrating, compressing, canning and the like. The implementation equipment of the methane purifying method comprises a fan used for conveying methane, a first filter, a biological desulphurization tank, a deoxidizing device, a first compressor used for increasing air pressure in a runner, a buffer tank, a filler tower used for absorbing carbon dioxide and hydrogen sulphide, a freeze drying machine, a fixed bed dehydrating device, a second compressor used for compressing purified methane and a purified methane storage tank which are sequentially connected. Two steps of absorption and adsorption are carried out to remove carbon dioxide and hydrogen sulphide, the advantages of low tower height and stable operation are realized, fixed bed catalytic deoxidation is adopted, and safety of the purified methane is greatly improved; meanwhile, less pollutant is discharged, thus the methane purifying method is more environmentally friendly, and methane yield is higher. The invention belongs to the fields of chemical engineering and technology, agricultural and forestry waste utilization, renewable energy source and the like.

Owner:ZHEJIANG UNIV OF TECH

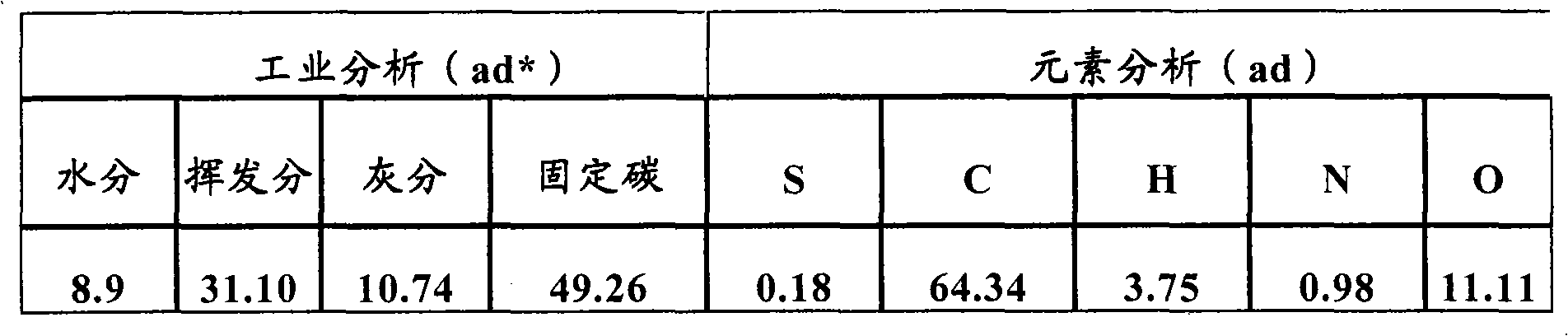

Method for producing coal gas by staged gasification of pulverized coal

InactiveCN102277200AAchieve desulfurizationAdaptableGranular/pulverulent flues gasificationCycloneSuperheated steam

The invention relates to a method for producing coal gas by staged gasification of pulverized coal. The steps are as follows: the pulverized coal fed into the furnace is mixed with rapidly fluidized high-temperature particles and gasification gas in a fluidized bed, and the pulverized coal of small and medium particles flows upwards. Pyrolysis at a high temperature of 900-1000°C, enter the cyclone separator through the gas-solid mixing pipeline for separation, the medium particles return to the lower part of the main body of the circulating fluidized bed through the first-stage feeder, and the gas carries small particles out of the upper port of the cyclone separator, and passes through the high temperature The gas pipeline enters the superheated steam heat exchanger for heat exchange and separation, and then enters the circulation separator, and the gas is discharged from the gas outlet for users. The invention has the characteristics of integrated circulating fluidized bed and entrained flow bed, high gasification intensity, flexible adjustment of production load, stable and reliable operation, high operation rate, reduced gas production cost, and no phenolic water pollution.

Owner:舒克孝

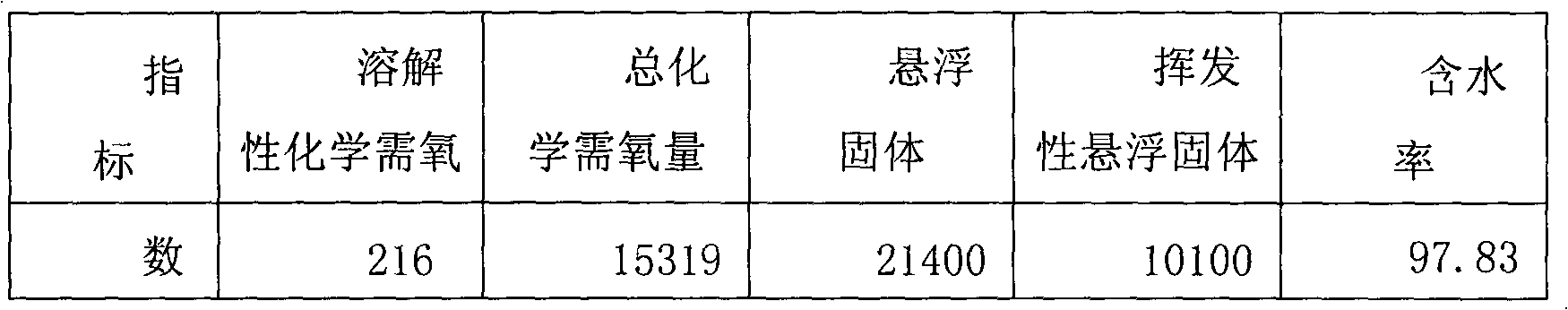

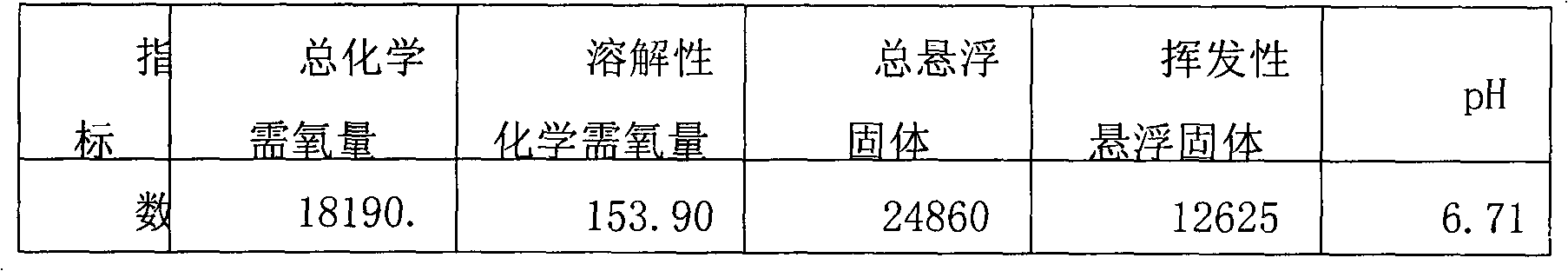

Supercritical water treatment device and method

ActiveCN103030206ASimple structureEasy to operateWater/sewage treatment by oxidationChemical oxygen demandResource utilization

The invention relates to a supercritical water treatment device and a supercritical water treatment method. The device comprises a shell and a top cover which is in sealing connection with the shell; an inner sleeve is arranged in the device; the bottom and the side wall of a reactor are provided with an oxidizing agent inlet, a raw material inlet and a solid product outlet; the top cover is provided with a gas product outlet; and the outer wall of the shell is also provided with a cooling system. The method comprises the following steps: after performing supercritical oxidation reaction on raw materials and an oxidizing agent in the inner sleeve, enabling the obtained product to move upwards to the cooling system to be in a subcritical state so as to implement separation of a solid-liquid product and a gas product; and then respectively discharging the solid-liquid product and a gas product from the corresponding outlets. The supercritical water treatment device can reach and even exceed the level of an existing supercritical water reaction device in the aspect of technical effect and has removal rate of COD (Chemical Oxygen Demand) in wastewater and slurry, can improve content of methane in gas generated after biomass and the like are subjected to supercritical oxidation reaction, and can carry out resource utilization.

Owner:ENN ENVIROTECH CO LTD

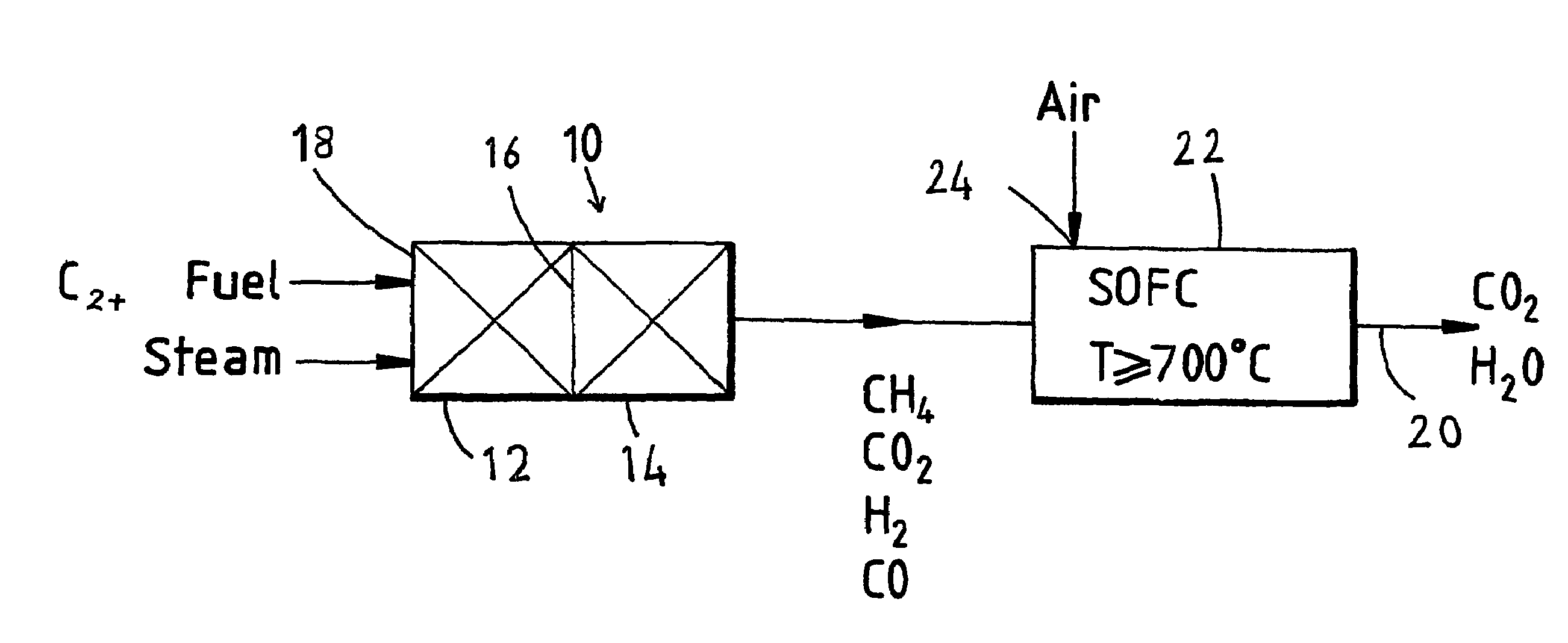

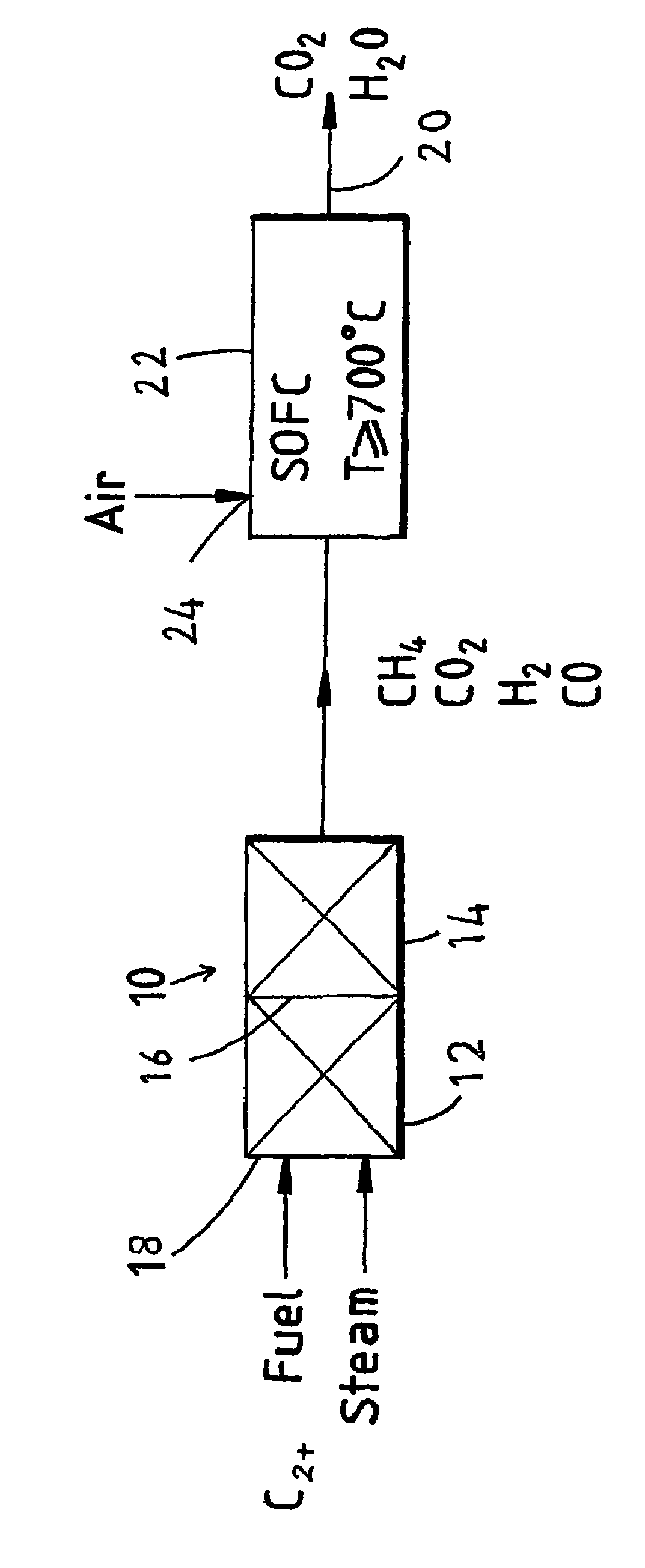

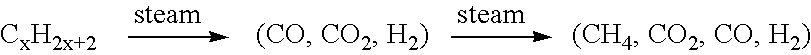

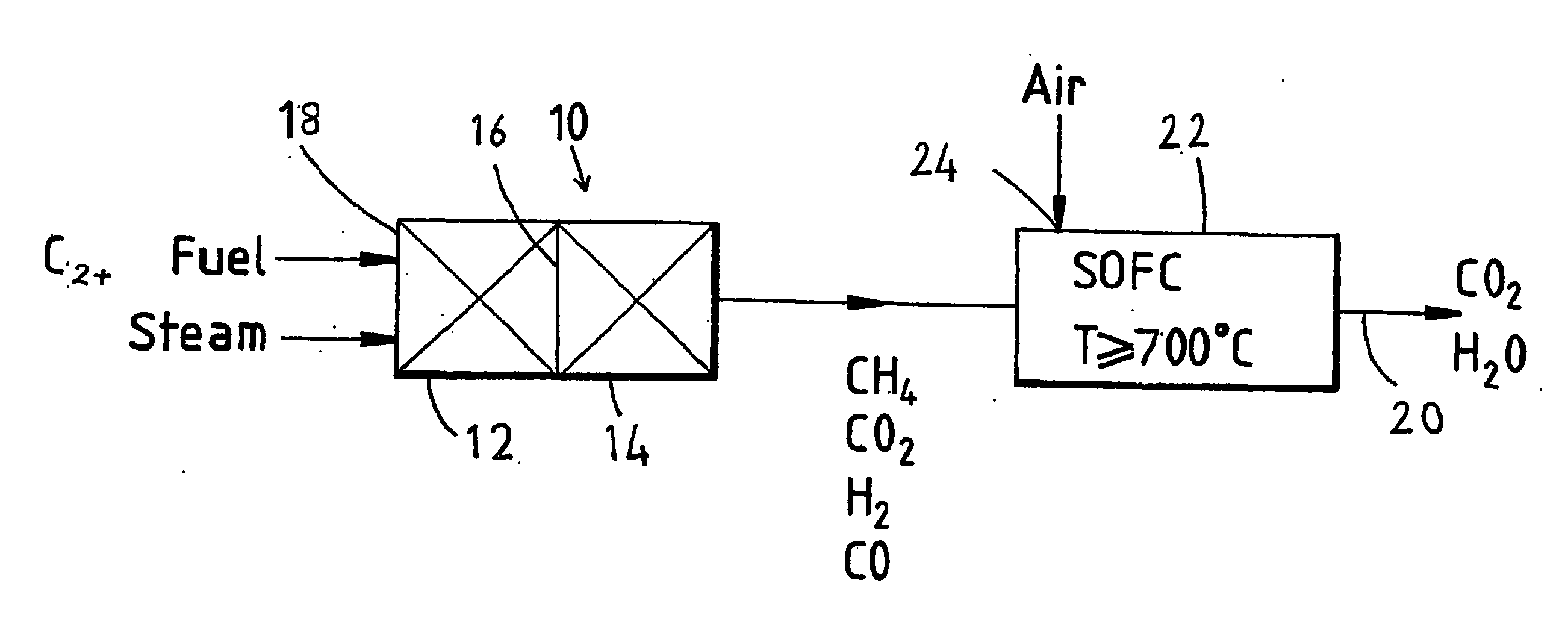

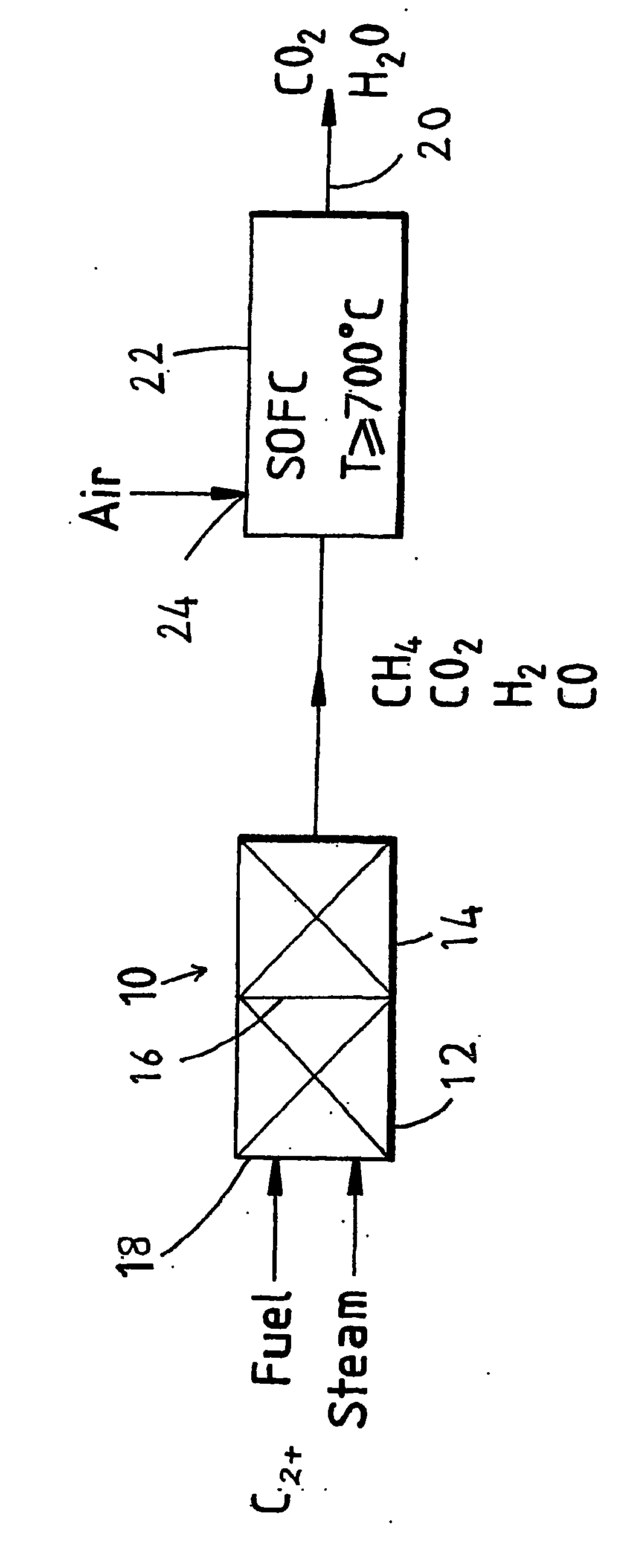

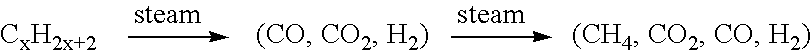

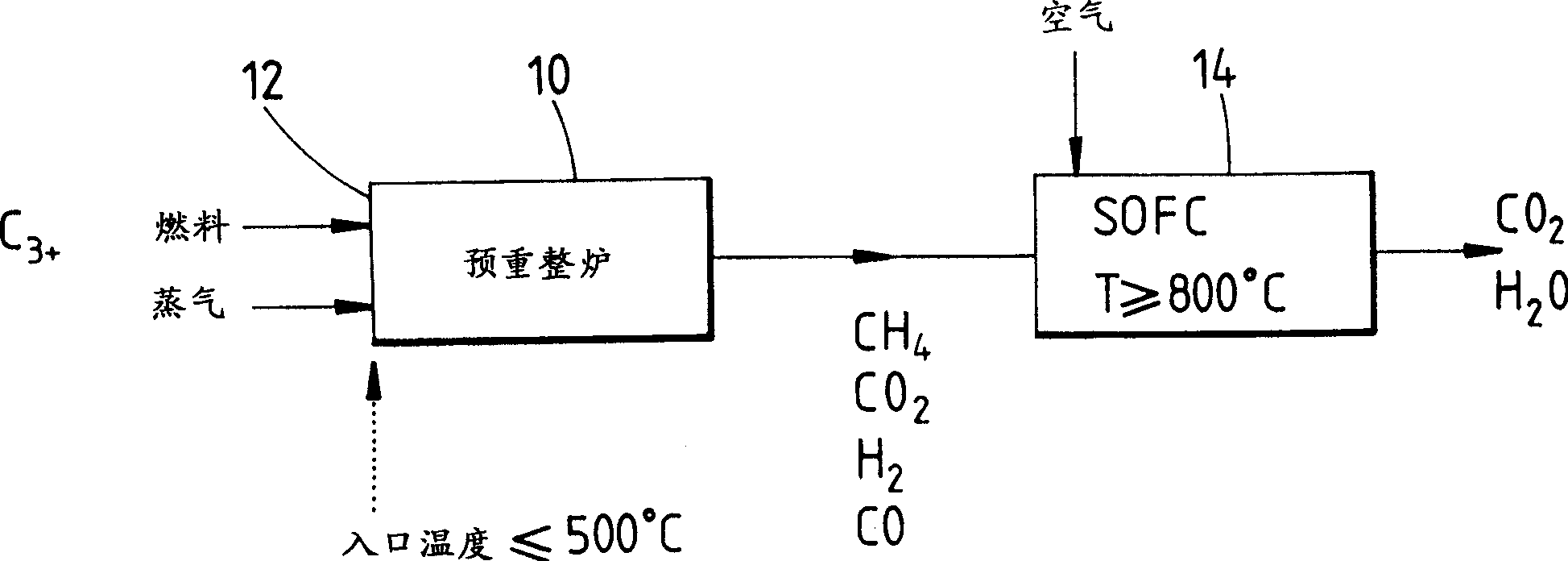

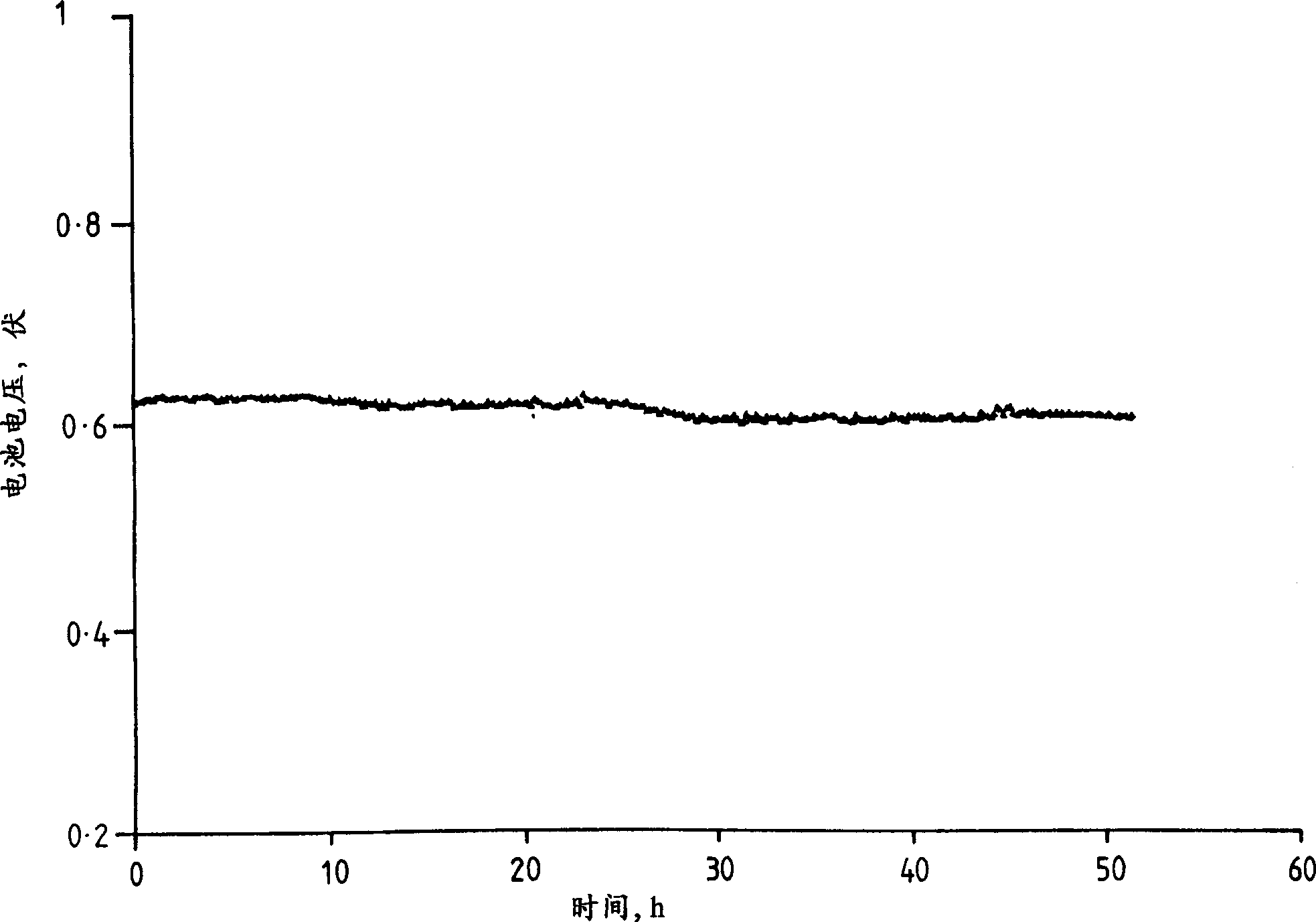

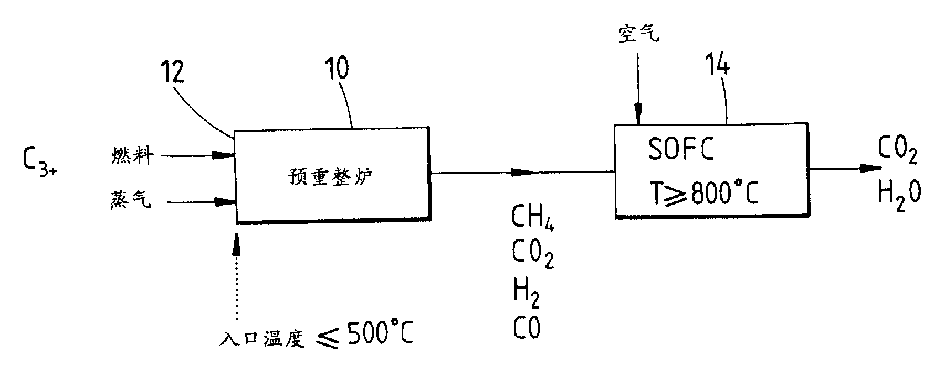

Fuel cell system

InactiveUS7452619B2High methane contentEfficient productionRegenerative fuel cellsFuel cell auxillariesElectricityFuel cells

A process for producing electricity in a fuel cell which comprises: a) pre-reforming a higher carbon (C2+) hydro-carbon fuel in a pre-reformer under conditions effective to achieve substantially complete conversion of higher carbon (C2+) hydro-carbons to produce a pre-reformed fuel stream; b) subjecting the pre-reformed fuel stream to methanation under conditions effective to produce a fuel stream having an increased concentration of methane relative to the pre-reformed fuel stream; and c) supplying the fuel stream and an oxidant to a high temperature fuel cell in which methane is reformed and electricity is produced by reacting the fuel stream at an anode of the fuel cell and reacting the oxidant at a cathode of the fuel cell.

Owner:CHAOZHOU THREE CIRCLE GRP

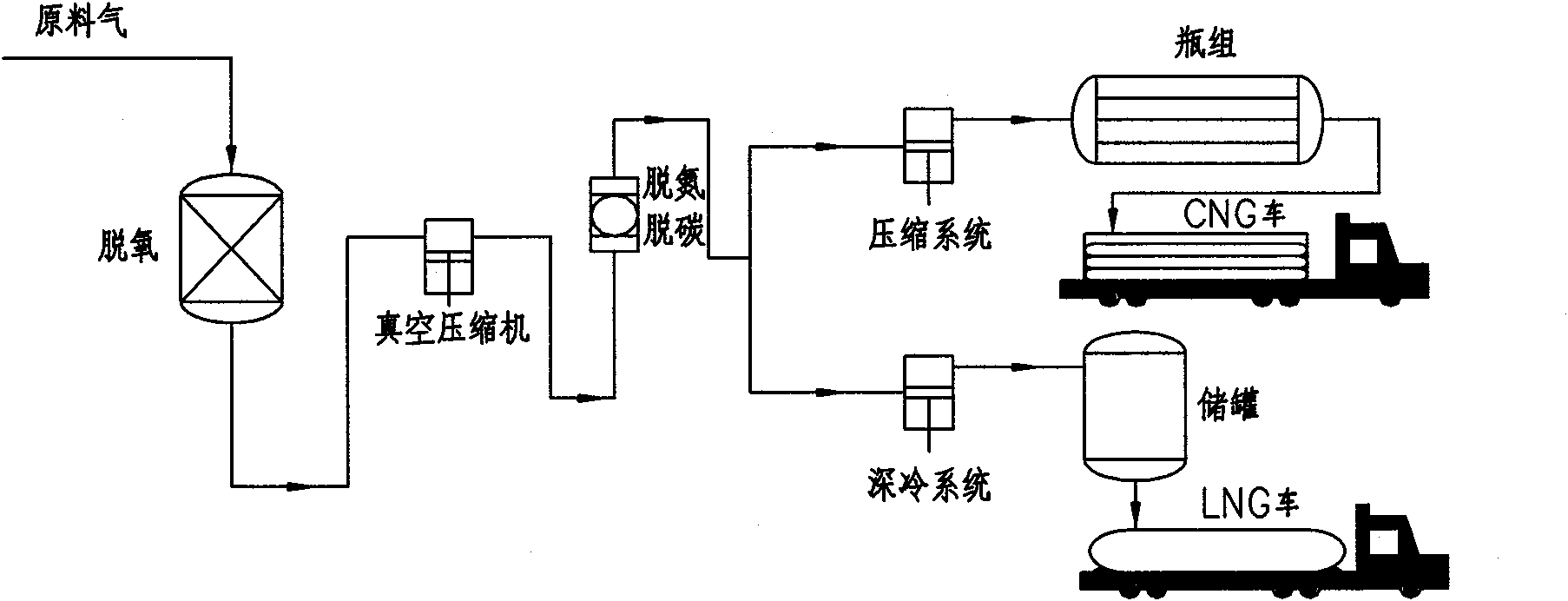

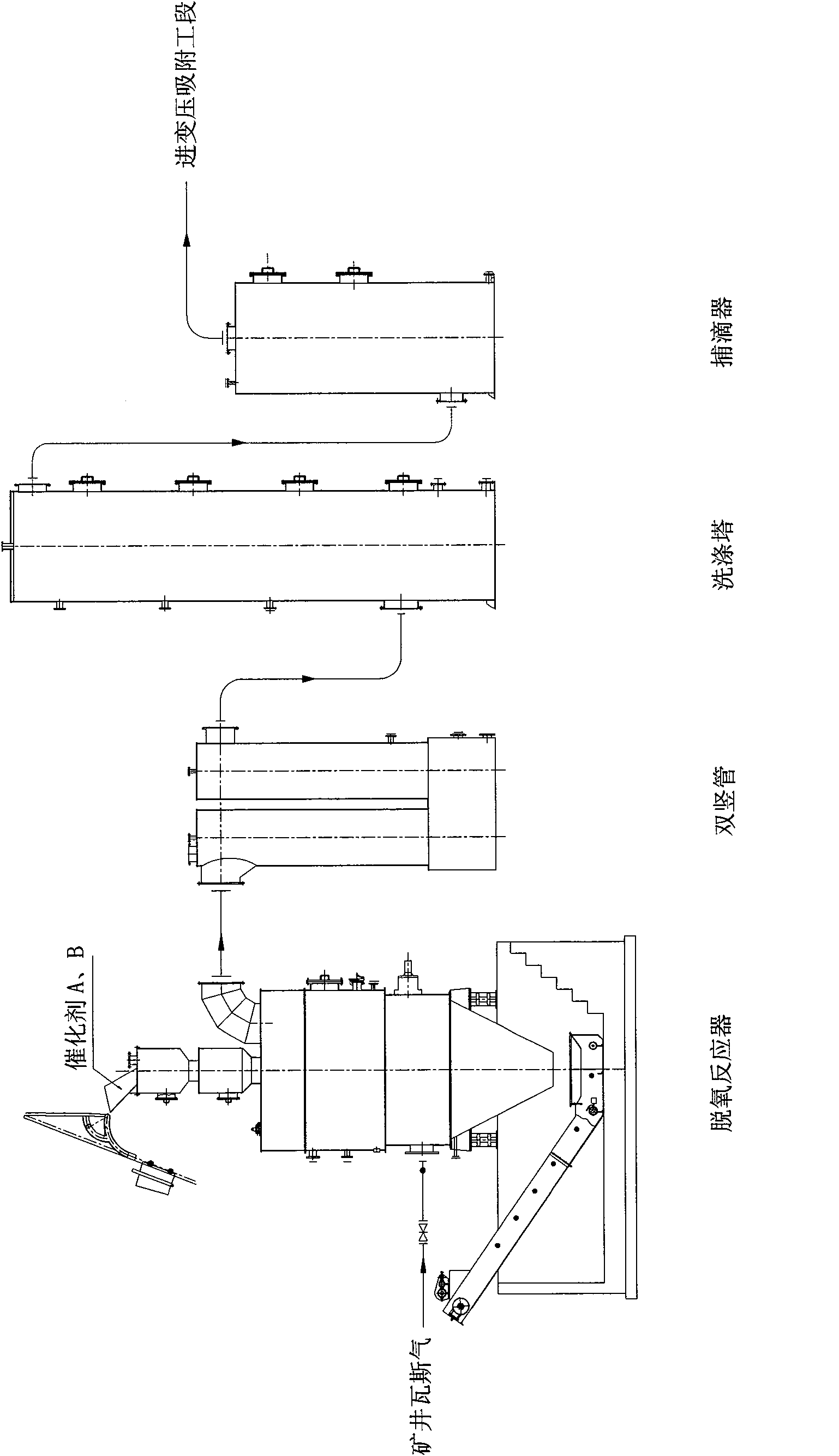

Method for deoxidizing and concentrating mine gas

InactiveCN101591579AEnsure productivityQuality assuranceGaseous fuelsCompressed natural gasCo2 absorption

The invention discloses a method for deoxidizing and concentrating a mine gas, which comprises: a step of deoxidization, in which a raw material gas is delivered into a deoxidization reactor so as to reduce oxygen in the raw material gas from about 10 volume percent to less than 1 volume percent by dense and dilute phase two-stage catalysis process in the deoxidization reactor; a step of system fluctuation control, in which software and hardware are used to monitor and process coal bed gas disturbance and gas composition change; a step of denitrification, in which a pressure swing adsorption denitrifying device is used to remove most nitrogen to purify the methane in a coal bed gas till the content of the methane is above 90 percent; a step of decarbonization, in which gas treated by the denitrification step is subjected to CO2 absorption by an amine method as well as H2S removal; and a step of compression, in which the decarbonized gas is compressed in a compression process, dehydrated and liquefied to be turned into a compressed natural gas or a liquefied natural gas.

Owner:赵昱

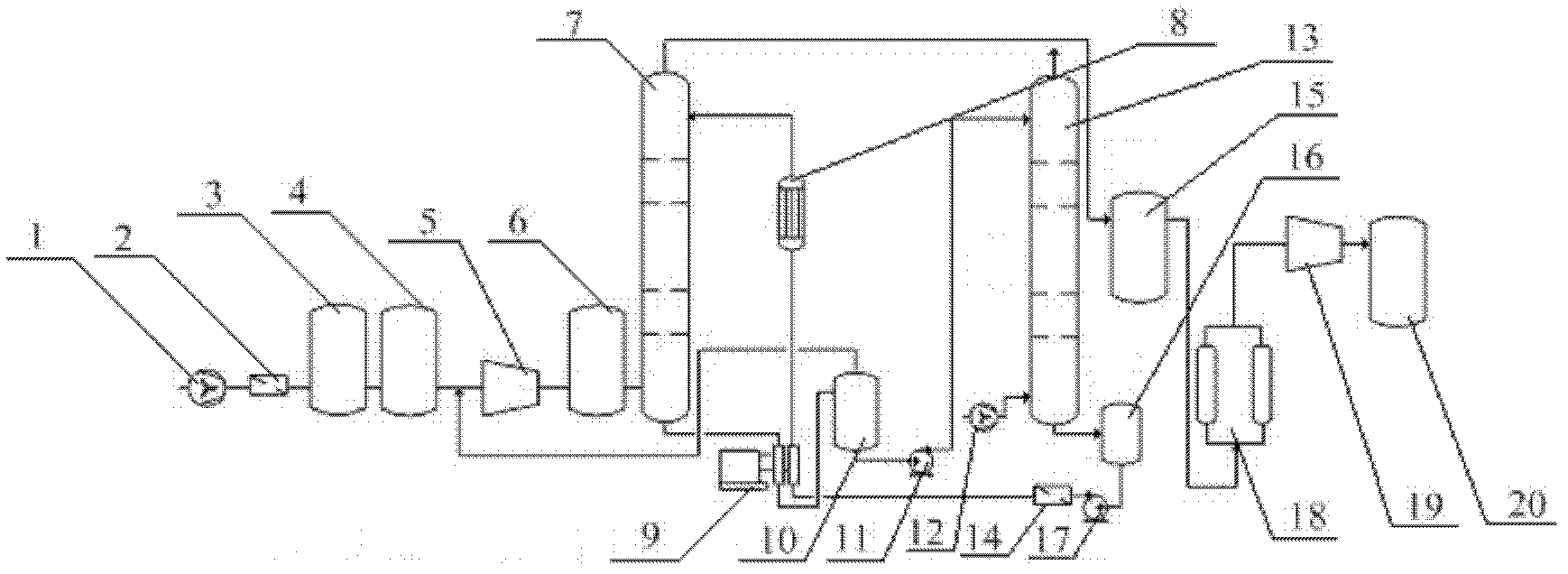

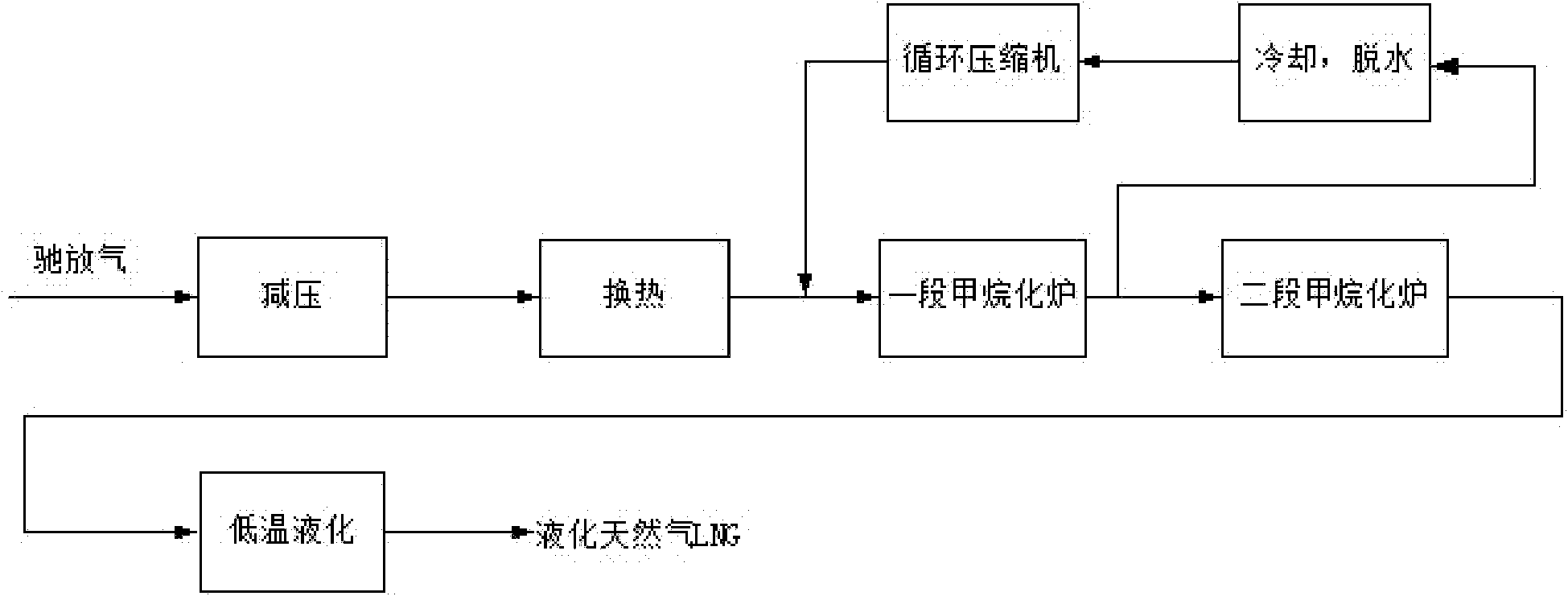

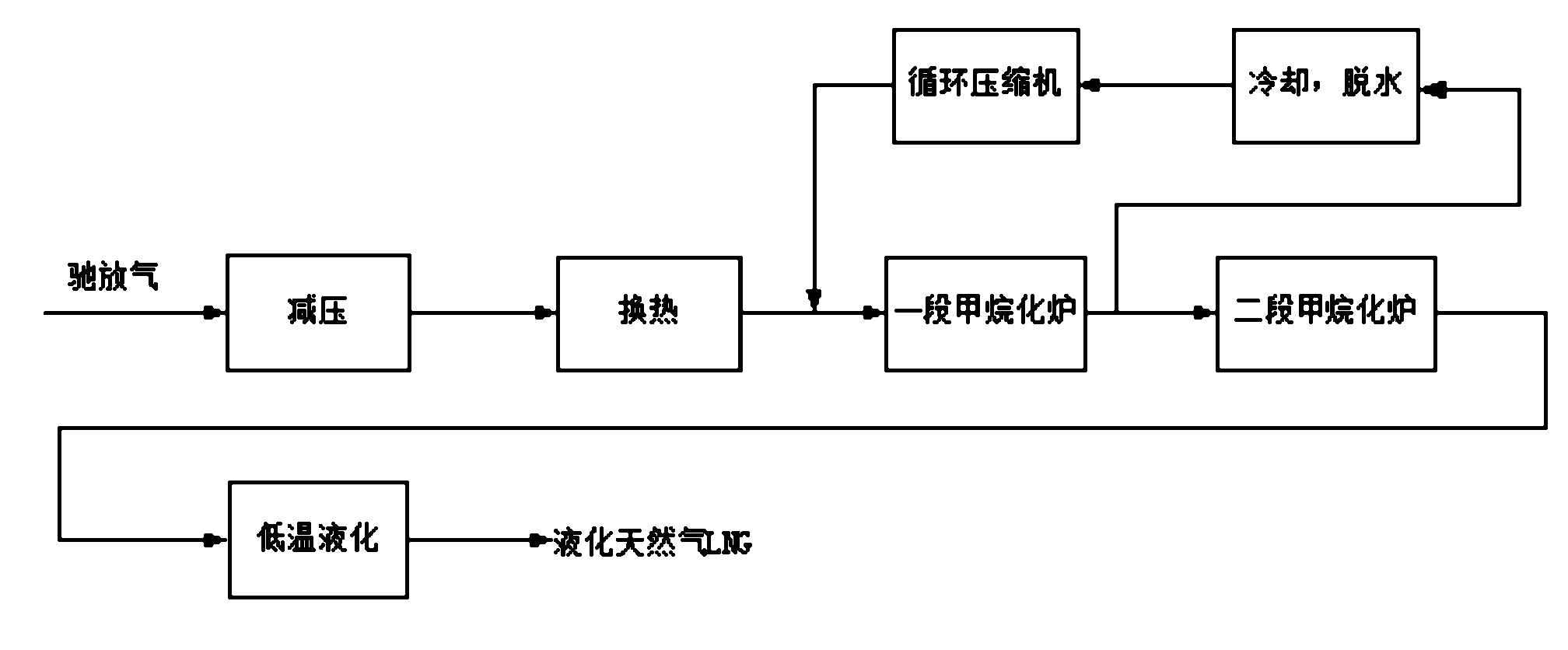

Method for preparing liquefied natural gas by utilizing relief gas of methanol

ActiveCN101892104AHigh methane contentHigh calorific valueGaseous fuelsMethanationSeparation technology

The invention discloses a method for preparing a liquefied natural gas by utilizing a relief gas of methanol, particularly the relief gas of coal methanol. The method comprises the following steps of: regulating the pressure of the relief gas, heating the mixed gas of the relief gas and a recycle gas, performing methanation reaction under the action of a methanation catalyst to react hydrogen with carbonic oxide and carbon oxide in the relief gas to generate methane and obtain the mixed gas mainly containing the methane, and obtaining the product gas, namely, the liquefied natural gas containing over 95 volume percent of methane by utilizing cryogenic separation technology. The method of the invention has the advantages of obtaining the liquefied natural gas with high methane content, no impurities and high calorific value, making for environmental protection, saving energy sources and blazing a new way for clean energy.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Fuel cell system

InactiveUS20060166054A1Improve thermal conductivityExcessive coolingFuel cell auxillariesElectricityFuel cells

A process for producing electricity in a fuel cell which comprises: a) pre-reforming a higher carbon (C2+) hydro-carbon fuel in a pre-reformer under conditions effective to achieve substantially complete conversion of higher carbon (C2+) hydro-carbons to produce a pre-reformed fuel stream; b) subjecting the pre-reformed fuel stream to methanation under conditions effective to produce a fuel stream having an increased concentration of methane relative to the pre-reformed fuel stream; and c) supplying the fuel stream and an oxidant to a high temperature fuel cell in which methane is reformed and electricity is produced by reacting the fuel stream at an anode of the fuel cell and reacting the oxidant at a cathode of the fuel cell.

Owner:CHAOZHOU THREE CIRCLE GRP

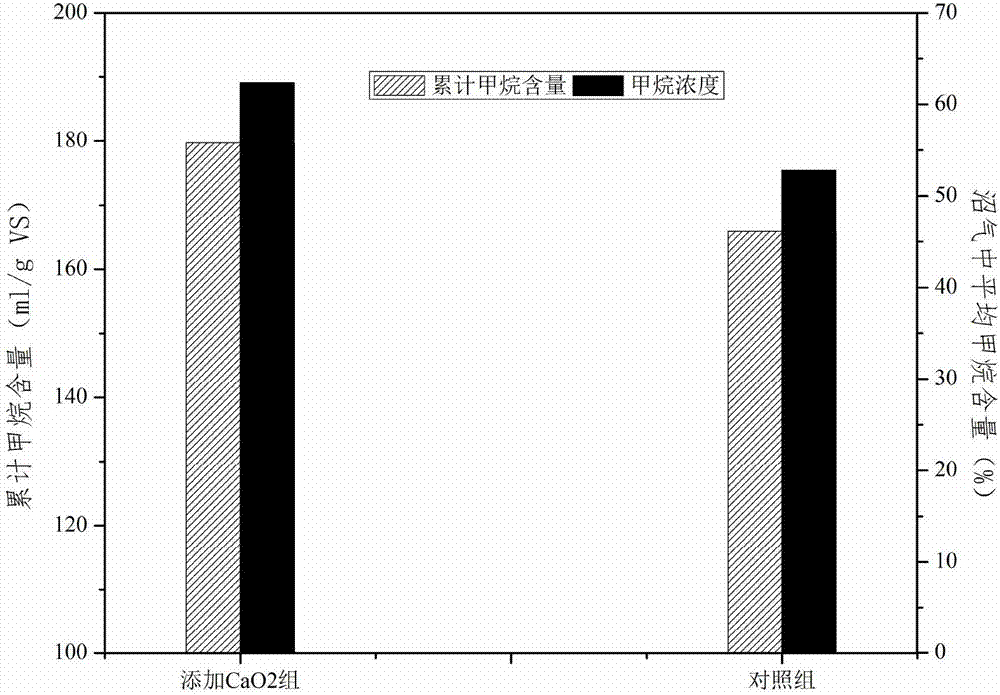

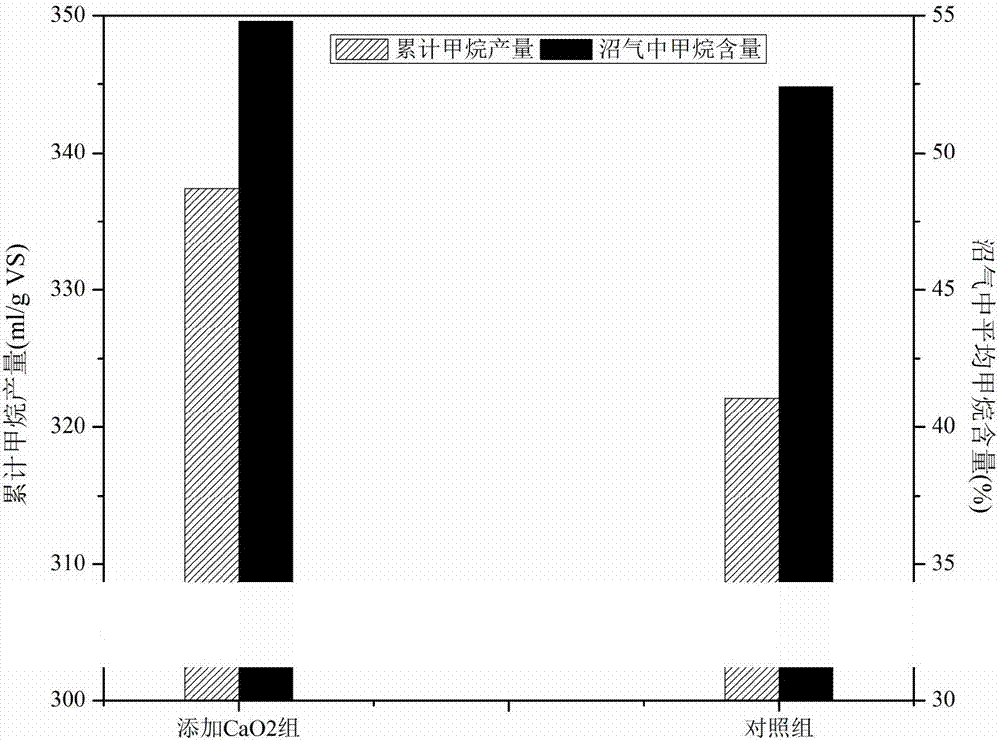

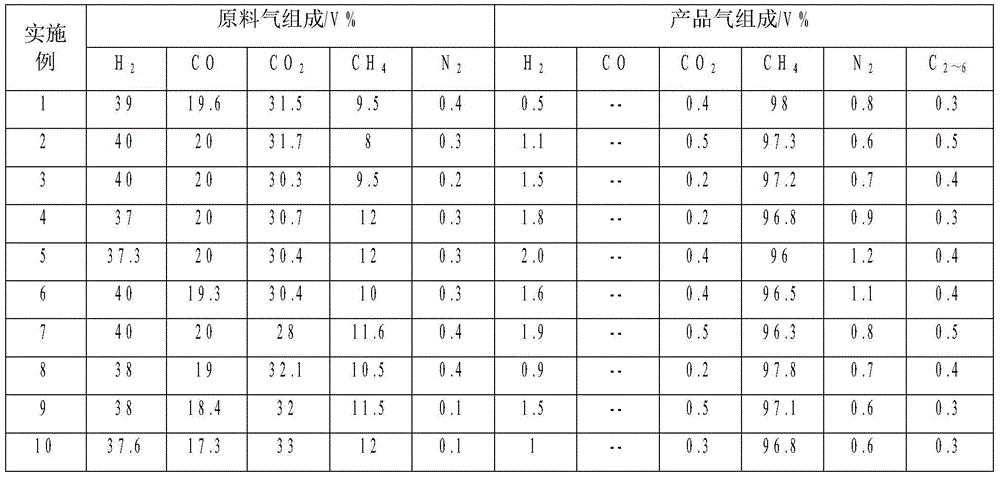

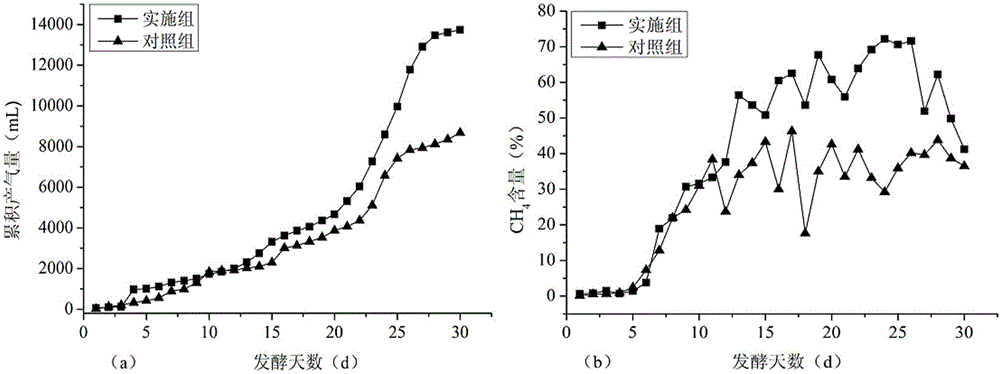

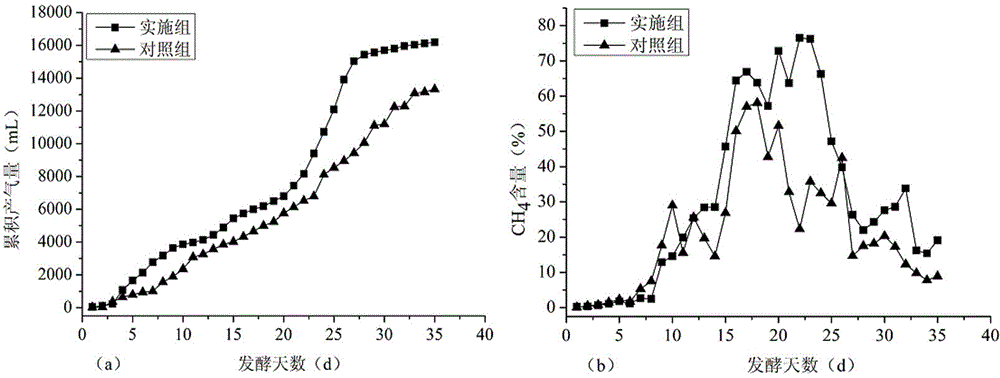

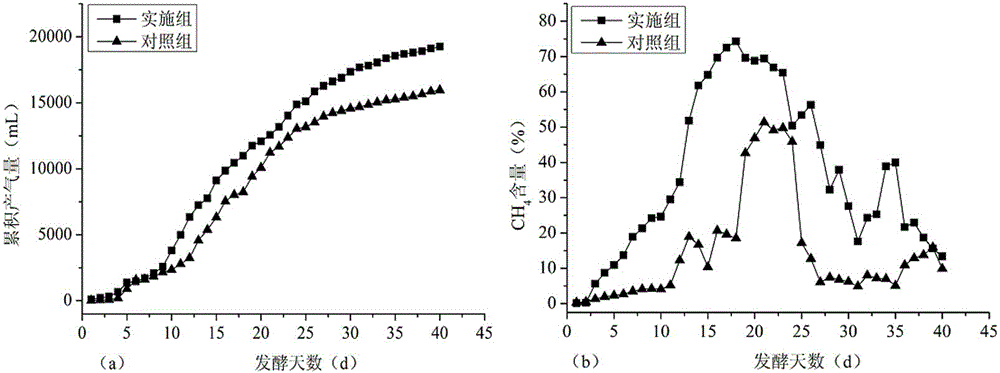

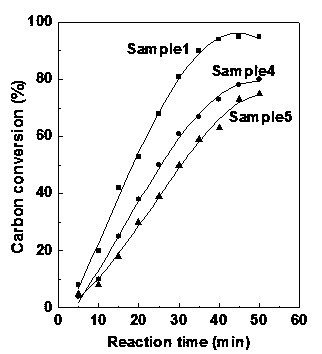

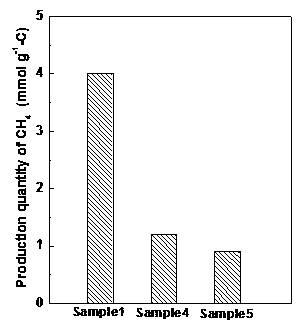

Method for improving efficiency of methane production through anaerobic fermentation and methane content in biogas

InactiveCN106929540AIncrease contentFast hydrolysisWaste based fuelFermentationMethane productionBiogas production

The invention belongs to the field of biogas production through anaerobic fermentation of organic solid wastes and particularly discloses a method for improving the efficiency of methane production through anaerobic fermentation and the methane content in a biogas. CaO2 is added to organic solid waste fermentation raw materials to form a microaerobic environment, thereby improving the efficiency of methane production through anaerobic fermentation and the methane content in the biogas. The method is mainly applied to the field of biogas production through anaerobic fermentation of the organic solid wastes such as straws and manure; the hydrolysis rate of anaerobic fermentation can be improved through adding a little of CaO2 to a reaction system, the methane content in the biogas is increased and the stability of a fermentation system is improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

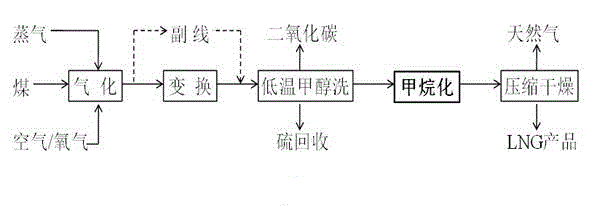

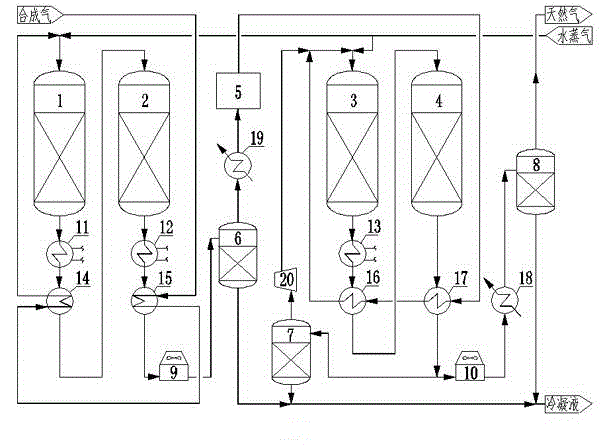

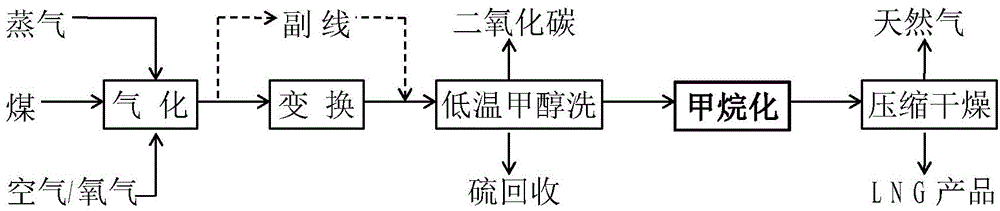

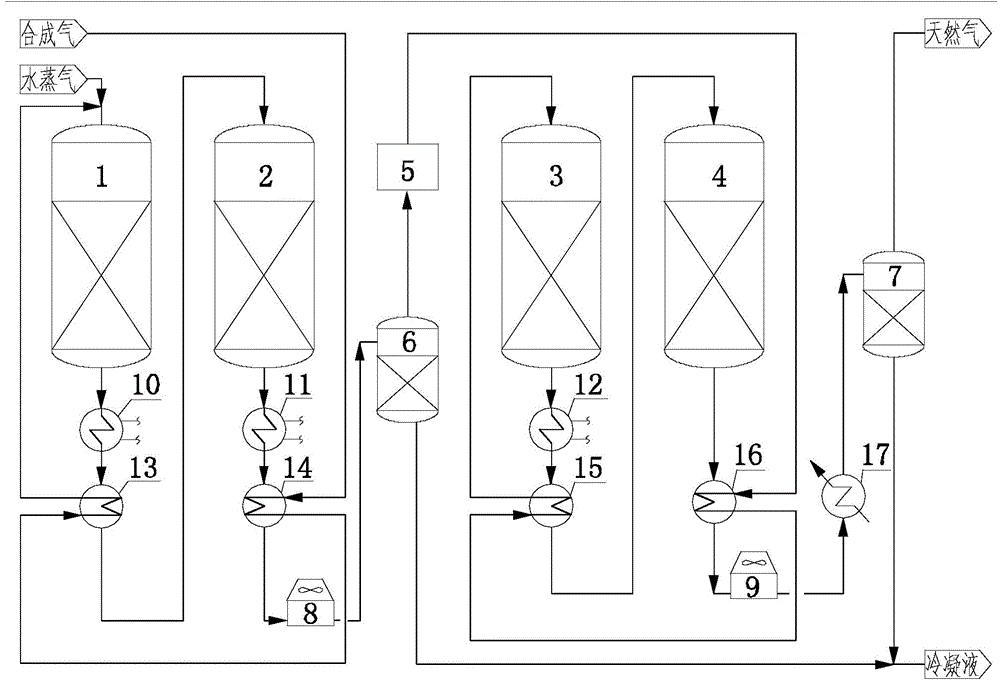

Process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas

ActiveCN104164262AWith characteristicsHave made significant progressGaseous fuelsMethanationWater vapor

The invention provides a process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas. The process is characterized in that the synthesis gas enters sulphur-tolerant methanation reactors I and II in sequence, and the mixed gas of the synthesis gas and water vapor enters a rectisol system so as to remove the impurities such as CO2, H2S and the like in the gas after undergoing sulphur-tolerant shift and sulphur-tolerant methanation reaction on a molybdenum-based bifunctional catalyst and then undergoes methanation reaction in methanation reactors I and II in sequence under the action of Ni-based methanation catalysts, thus obtaining the natural gas product. The process has the advantages of simple process flow, small equipment investment, low comprehensive energy consumption and excellent natural gas products.

Owner:SEDIN ENG +1

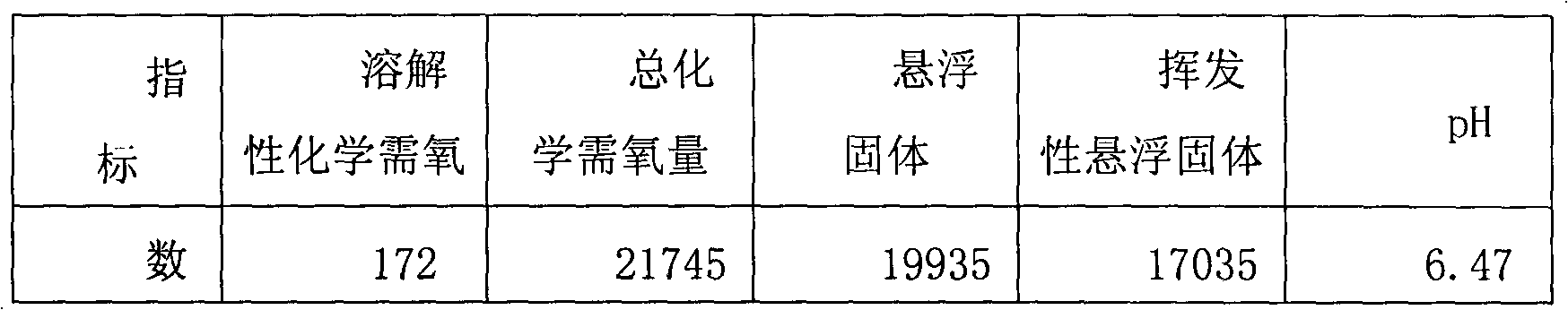

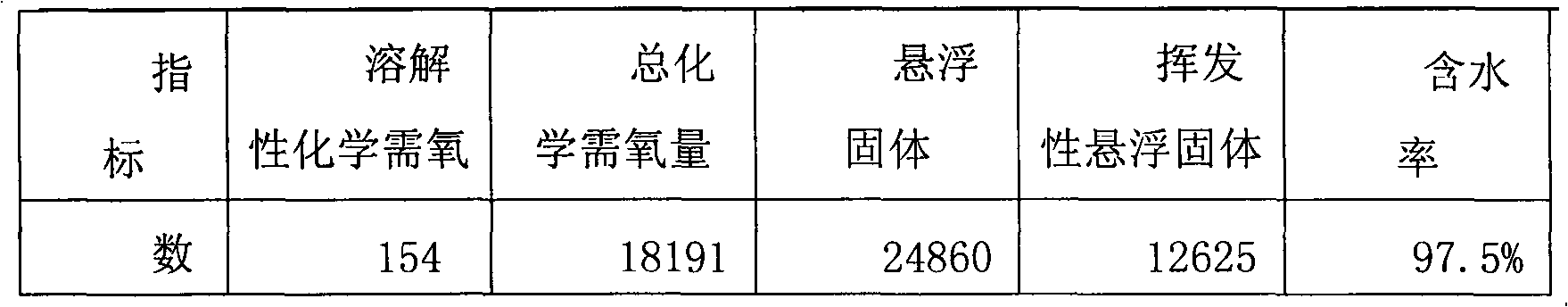

Method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide

InactiveCN102424506AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentChemistryAerobic digestion

Belonging to the technical field of solid waste treatment, the invention relates to a method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide. The method comprises: subjecting the excess sludge of an urban sewage treatment plant to gravity thickening, then adding a certain amount of hydrogen peroxide, conducting rapid stirring and sending the sludge into an ultrasonic reactor for ultrasonic treatment, in which the combined action of ultrasonic waves and hydrogen peroxide destroys the bacterial cell wall structure of the sludge, thus leading to leakage of the cell contents and content increase of dissolved organic matters in water, then sending the treated sludge into an anaerobic digestion reactor for subsequent mesophilic anaerobic digestion; delivering the biogas generated from anaerobic digestion to a gas collection gas for comprehensive utilization. After treatment, the concentration of SCOD (soluble chemical oxygen demand) in the liquid phase sludge can be increased by 23.83 times to 41.18 times, the biogas output can be increased by 17.40%-55.37%, and the methane content of the biogas can be increased by 10%-20%, thus reducing the energy consumption of ultrasonic treatment. For sewage treatment plants of different scales, only by making corresponding modification on existing facilities can good effects be achieved.

Owner:NANKAI UNIV

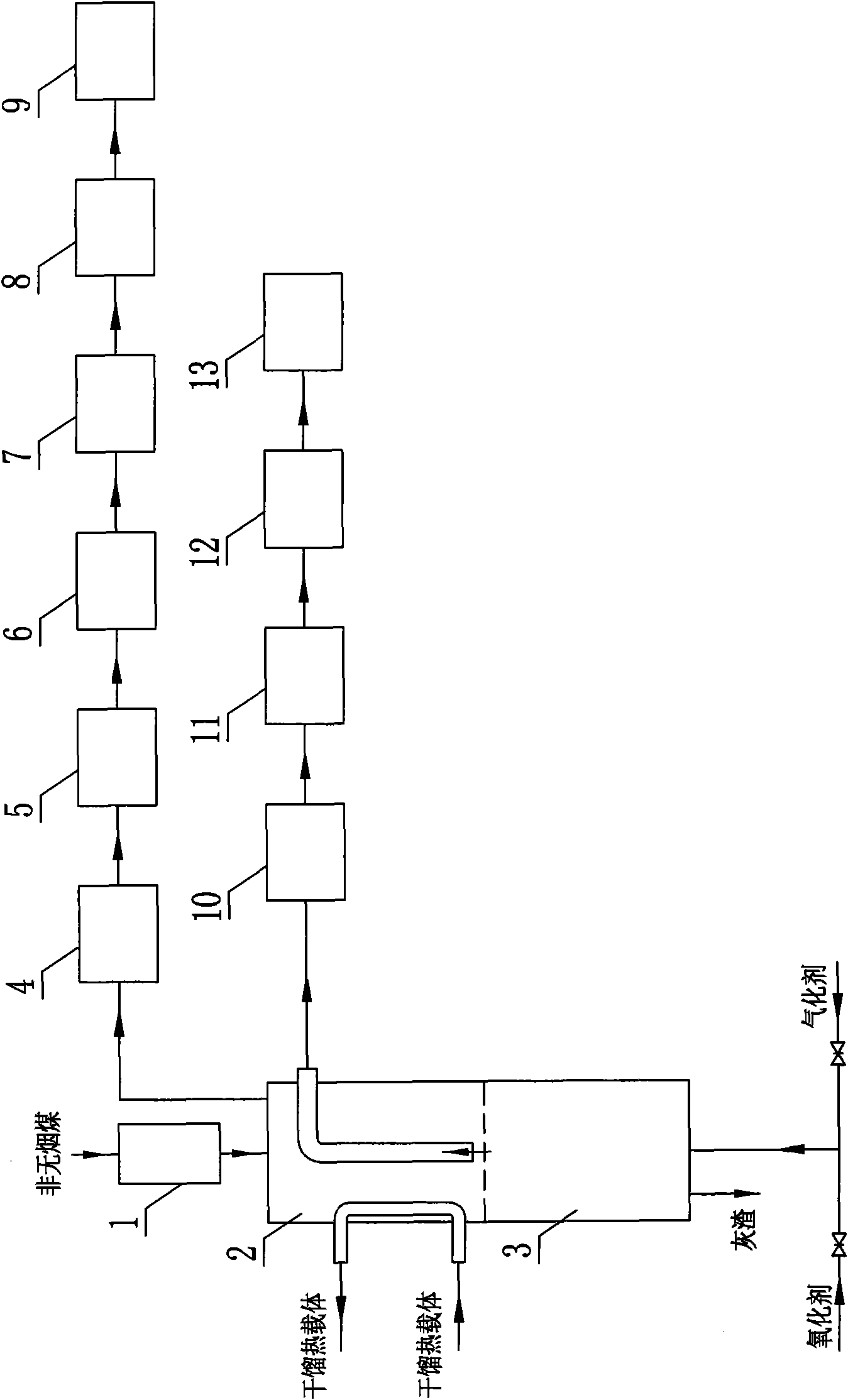

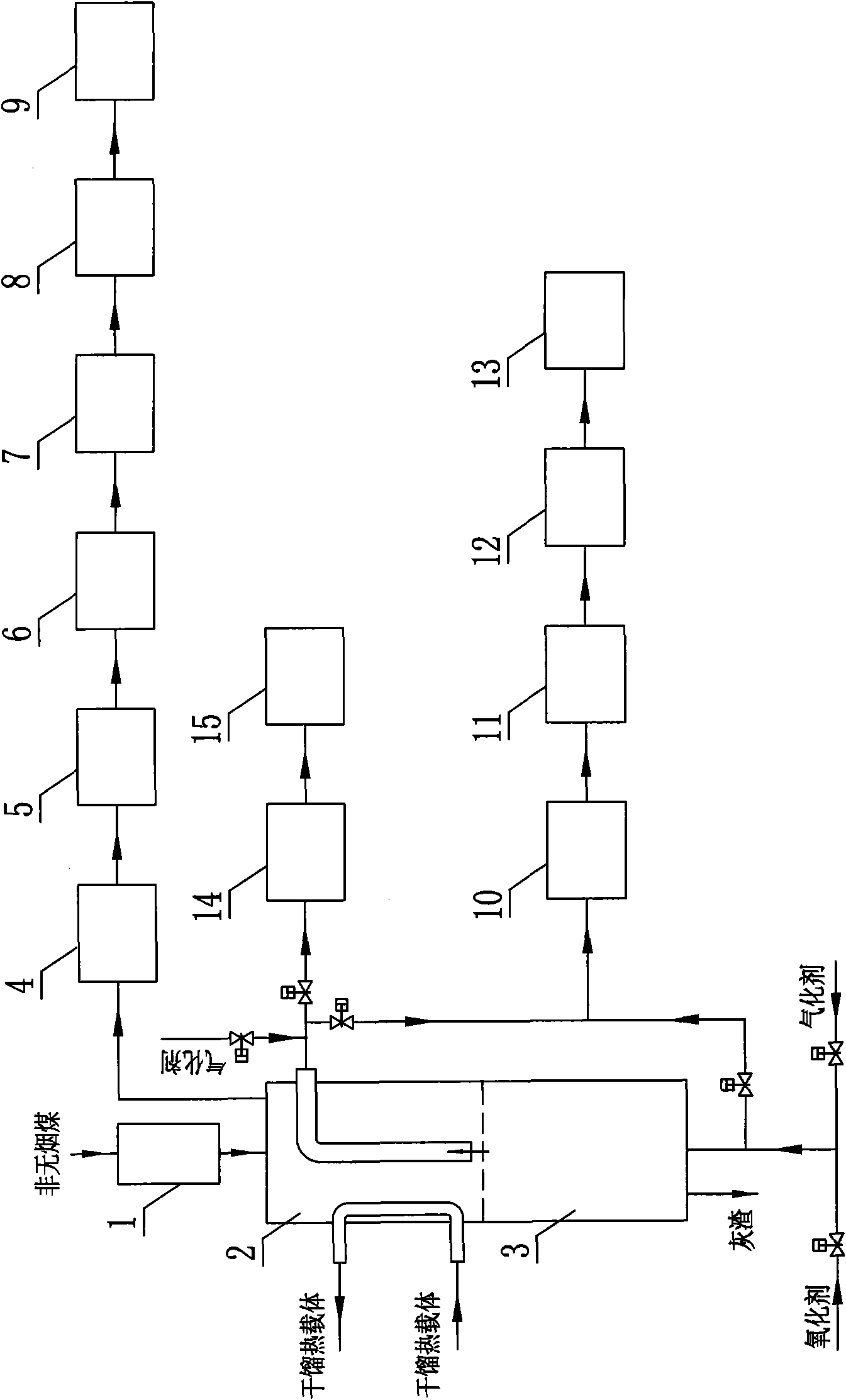

Method for two-stage coal gasification on composite external heat fixed bed and gas furnace

InactiveCN102146301AHigh economic valueReduce manufacturing costEnergy inputCombustible gas productionFixed bedProcess engineering

The invention discloses a method for two-stage coal gasification on a composite externally heated fixed bed and a gas furnace. In the method, by using more than two kinds of external heat for the dry distillation of raw material coal in a dry distillation stage of a two-stage gas furnace, the coal gas in a gasification stage and the coal gas in the dry distillation stage can be utilized efficiently by adopting different simple purification measures respectively, gas generation is performed by a continuous gas generation method and a circulating gas generation method, chemical synthetic raw material gases meeting different component requirements can be produced by using different oxidizers and gasifying agents, and at the same time, tar with high economic value is extract from a raw material soft coal. The method and the gas furnace have the advantages of small investment, simple operation, environmental friendliness, high comprehensive coal gasification efficiency and low gas generation cost, and are suitable for constructing or reconstructing fixed bed gas generation furnaces which operates widely at present.

Owner:王子国

Method for utilizing enhanced pretreatment to promote anaerobic digestion of excess sludge

InactiveCN102424507AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentSolubilityChemical oxygen demand

Owner:NANKAI UNIV

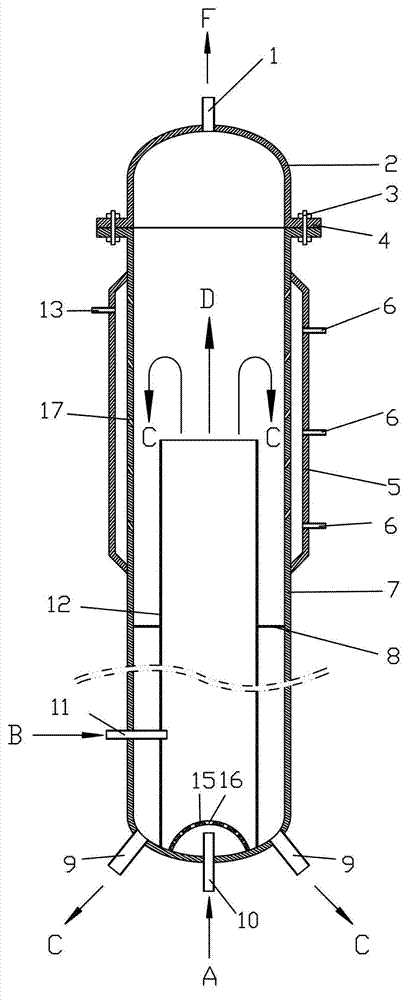

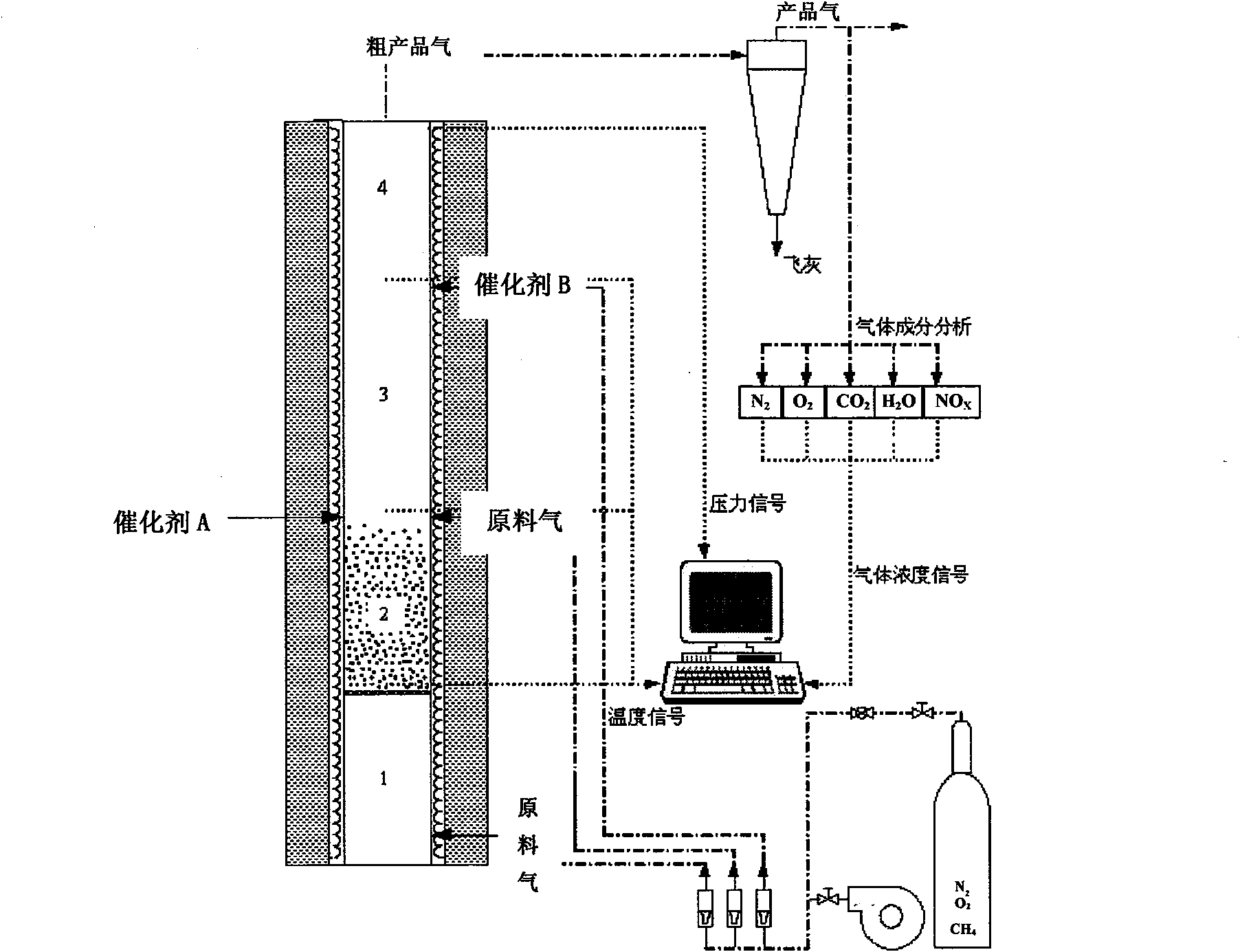

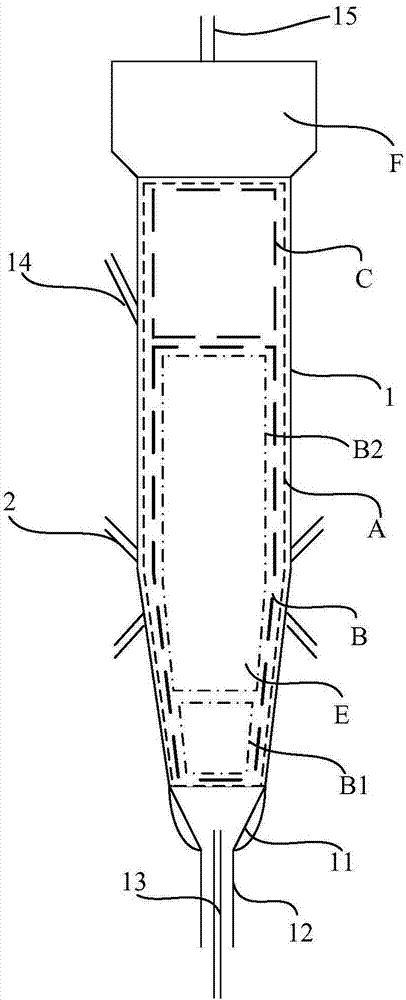

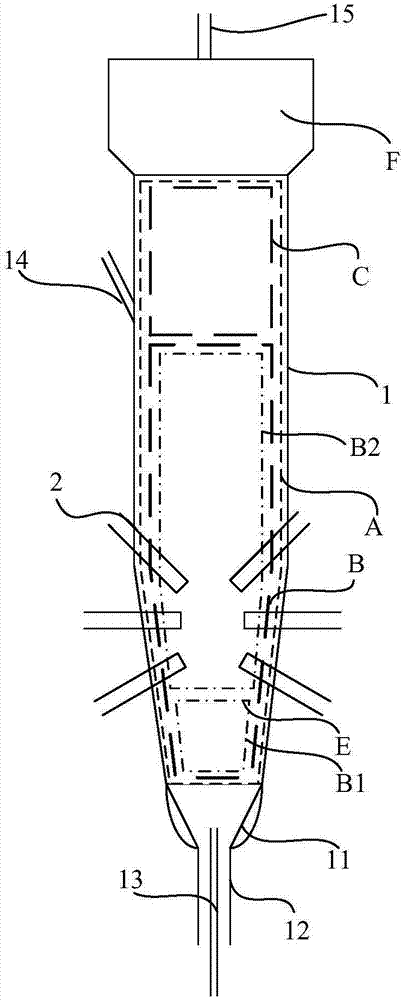

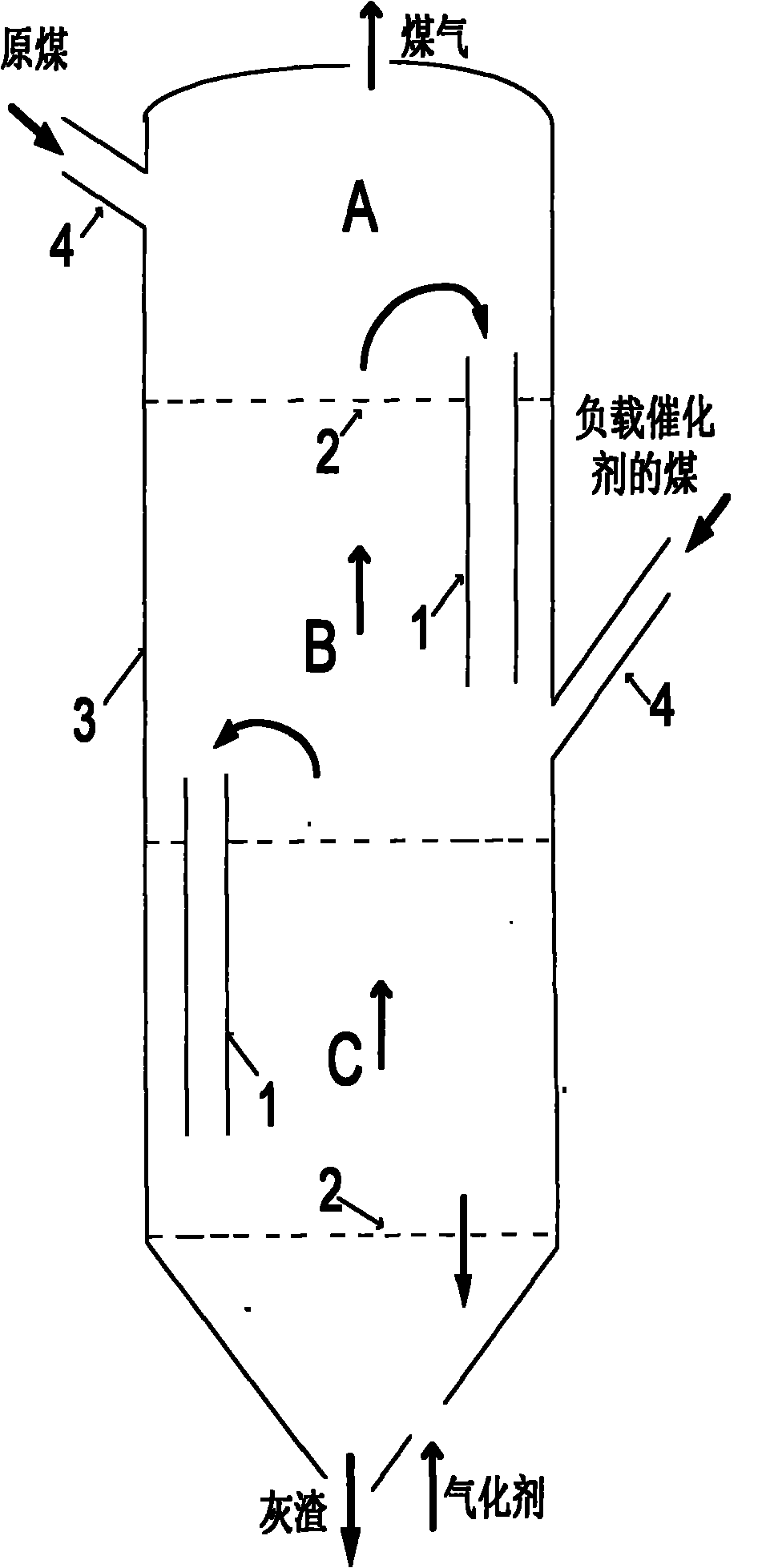

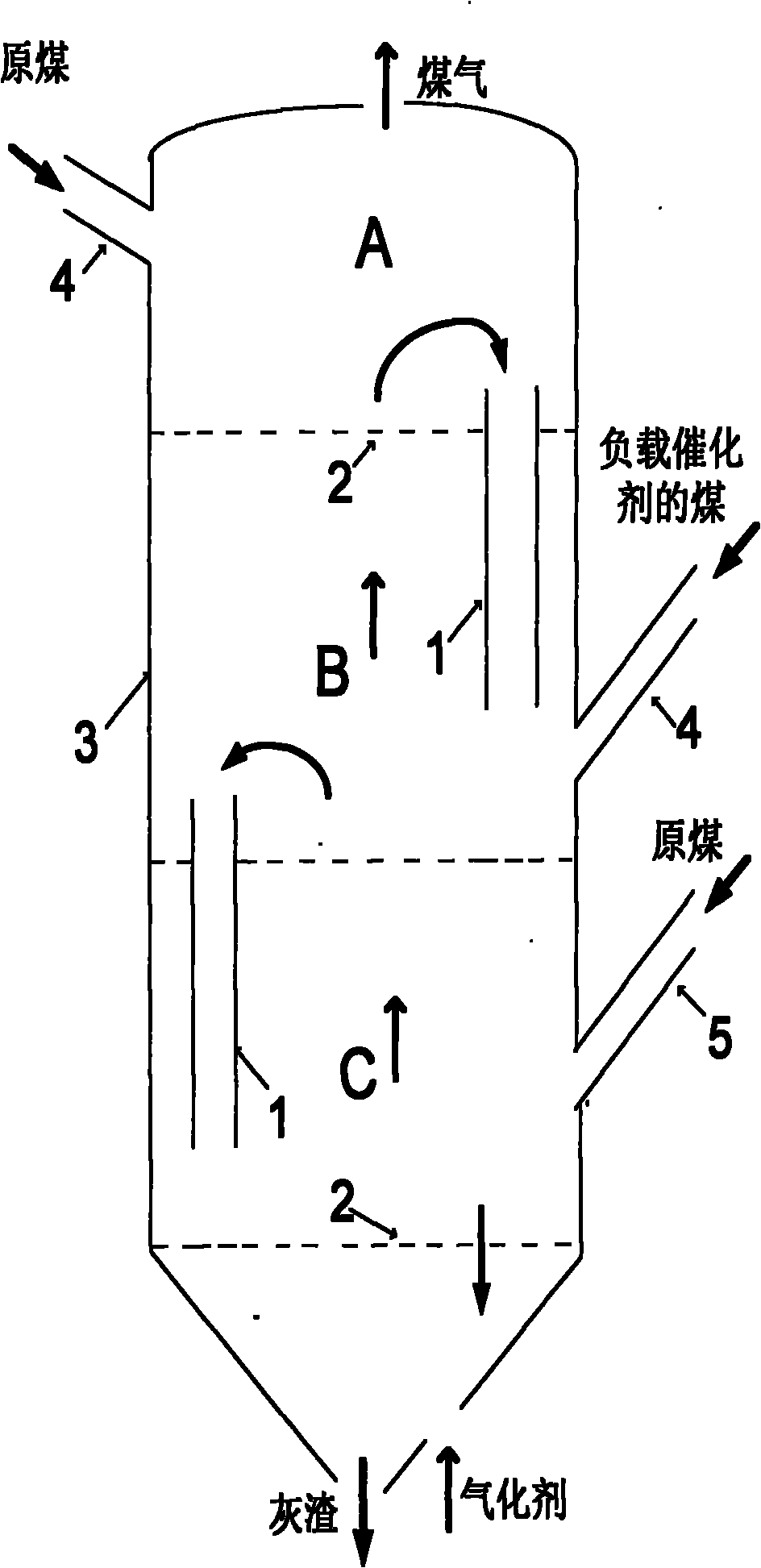

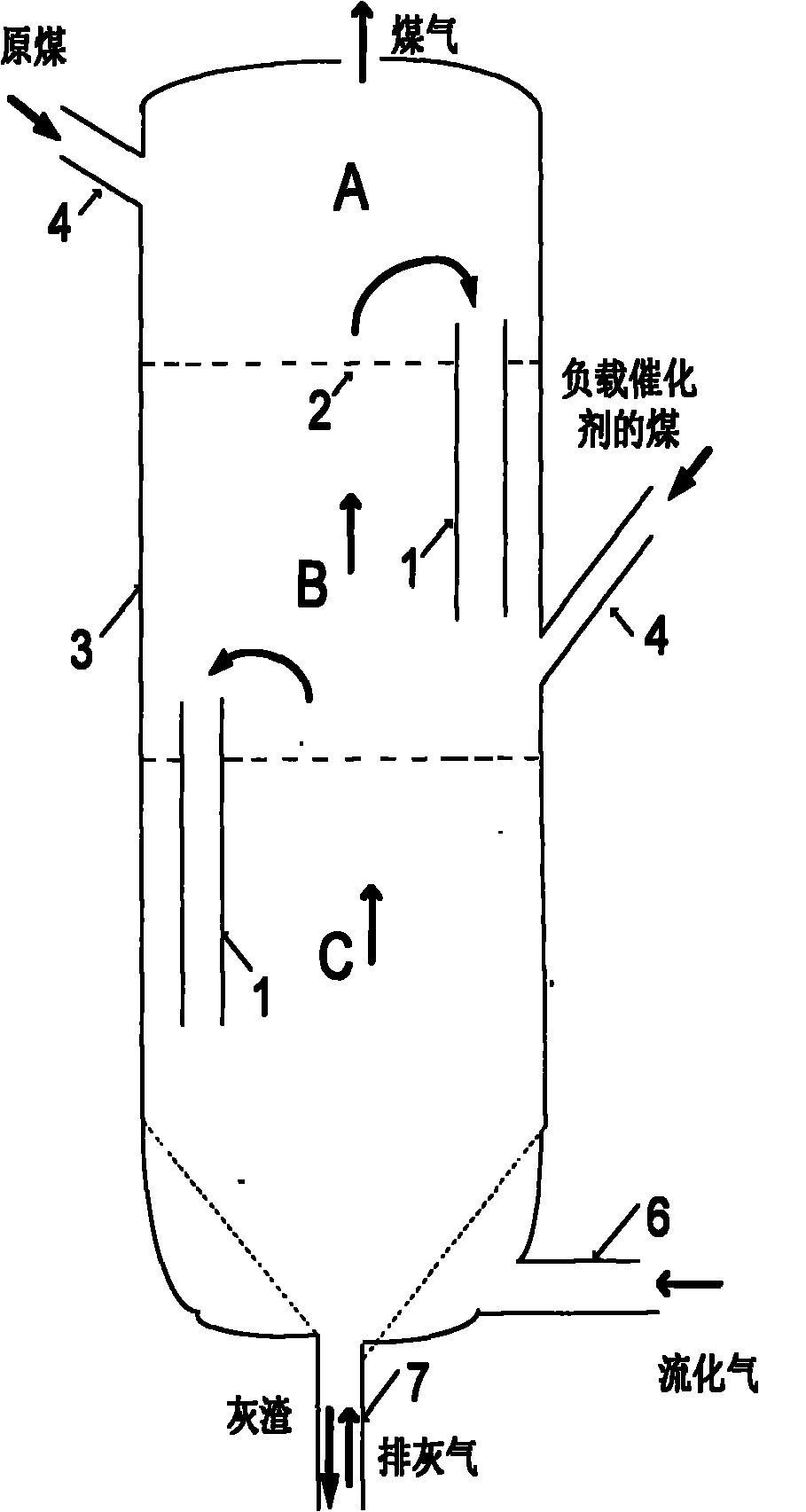

Catalytic gasification device, system and method

ActiveCN107177384AEnsure safetyHigh methane contentGasification catalystsGasification processes detailsHydrogenWater vapor

The invention relates to the technical field of catalytic gasification, in particular to a catalytic gasification device, system and method, solves the problems that energy consumption is higher and industry expanding is difficult due to the fact that high-temperature overheating gasifying agents are required to be provided when carbon monoxide and hydrogen are returned to a furnace for preparation of methane in an oxygen-free gasification process in the prior art, and overcomes the defects of low methane content, poor safety and high oxygen consumption in an oxygen introducing process. The catalytic gasification device comprises a gasification furnace, wherein the gasification furnace comprises a gas distributing plate and at least one gas incident pipe, a fluidized bed reaction zone is arranged above the gas distributing plate, and the gas distributing plate is used for introducing steam and oxygen into the area, close to the gas distributing plate, of the fluidized bed reaction zone; each gas incident pipe is communicated with the area, far away from the gas distributing plate, of the fluidized bed reaction zone and is used for introducing carbon monoxide and hydrogen into the area, away from the gas distributing plate, of the fluidized bed reaction zone. The catalytic gasification device is used for preparing methane through catalytic gasification.

Owner:ENN SCI & TECH DEV

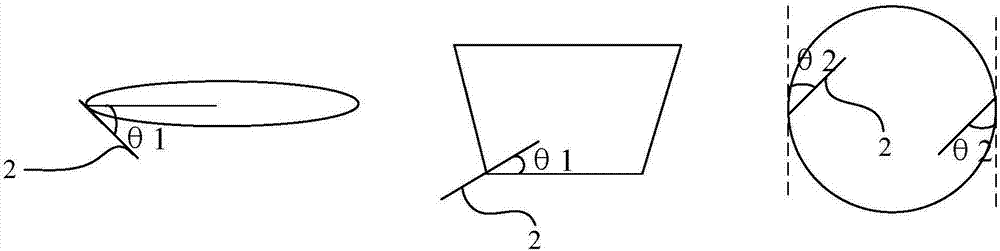

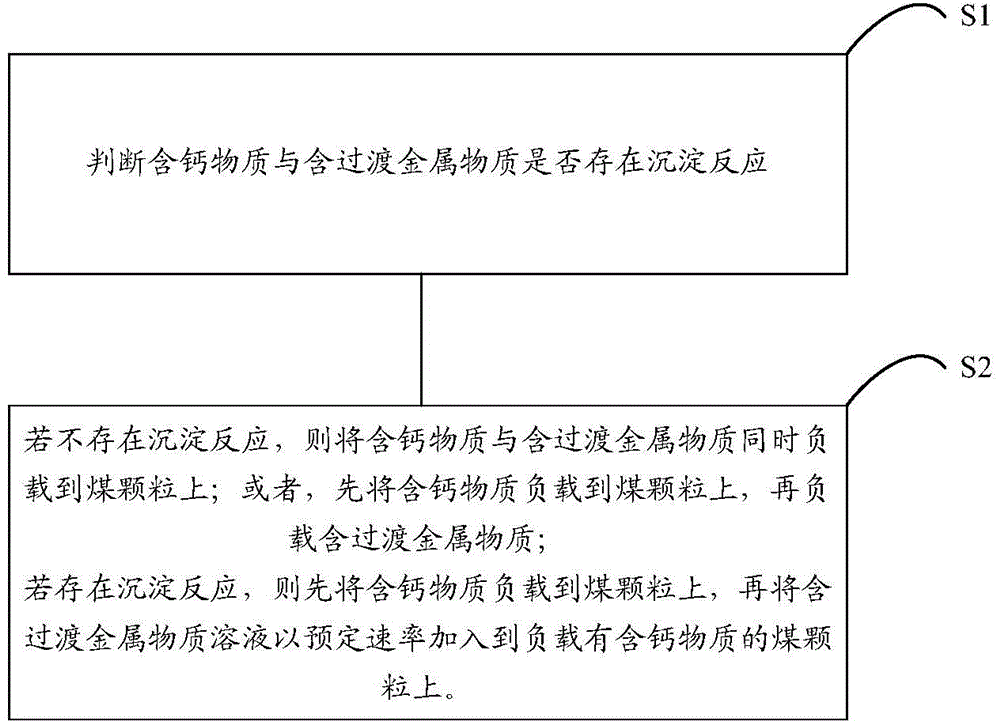

Calcium-based compound catalyst and loading method thereof

ActiveCN104399472AImprove gasification activityPromote generationHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationProduct gas

The invention provides a calcium-based compound catalyst and a loading method thereof and relates to the technical field of catalytic coal gasification. The calcium-based compound catalyst has higher catalytic efficiency in both gasification reaction and methanation reaction, can realize gasification, conversion and methanation reaction coupling in a gasification furnace, and improves the content of methane in product gas. The calcium-based compound catalyst disclosed by the invention comprises a calcium-containing substance and a transition metal-containing substance. The calcium-based compound catalyst and the loading method thereof, disclosed by the invention, are applicable to the catalytic coal gasification process.

Owner:ENN SCI & TECH DEV

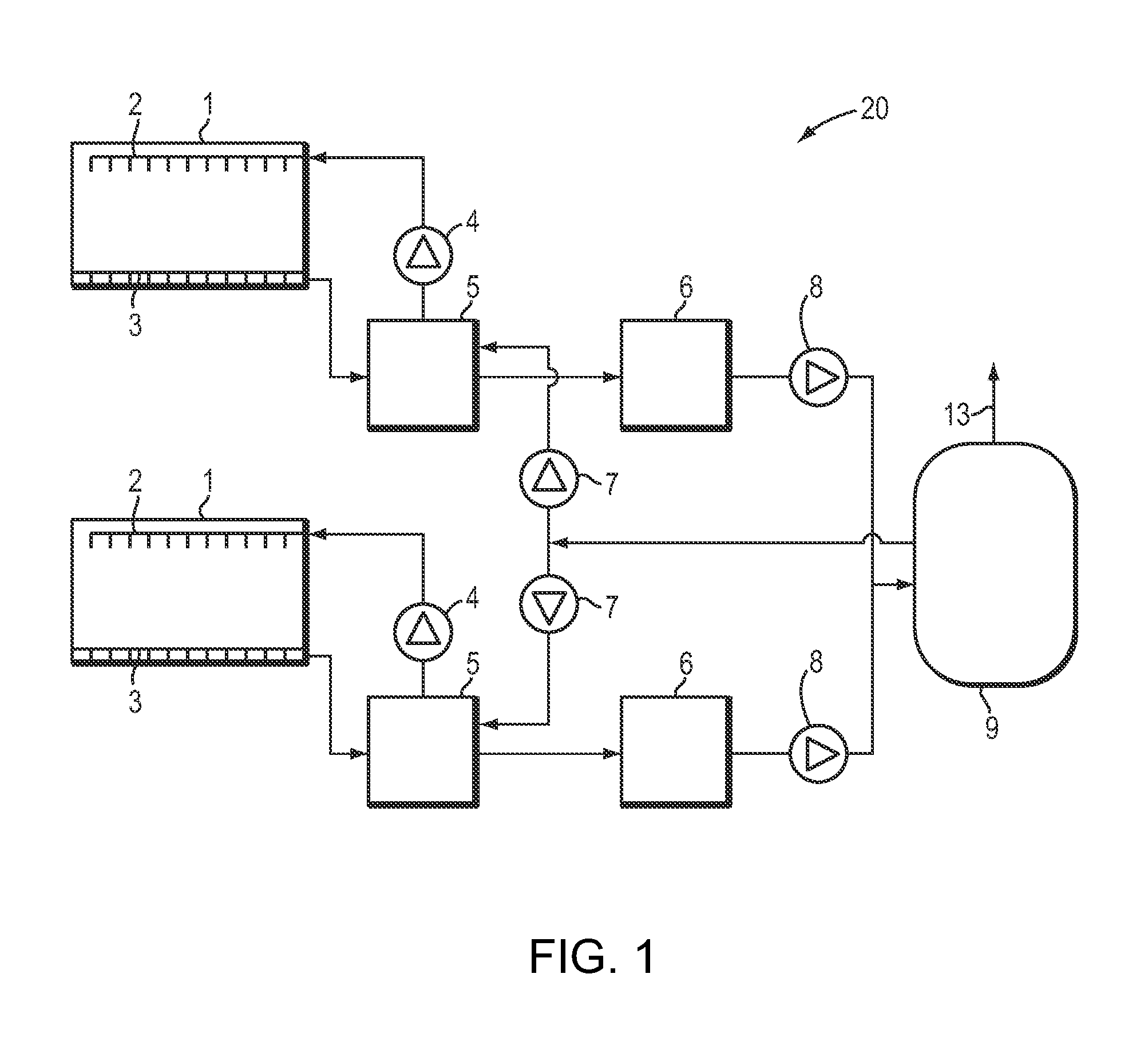

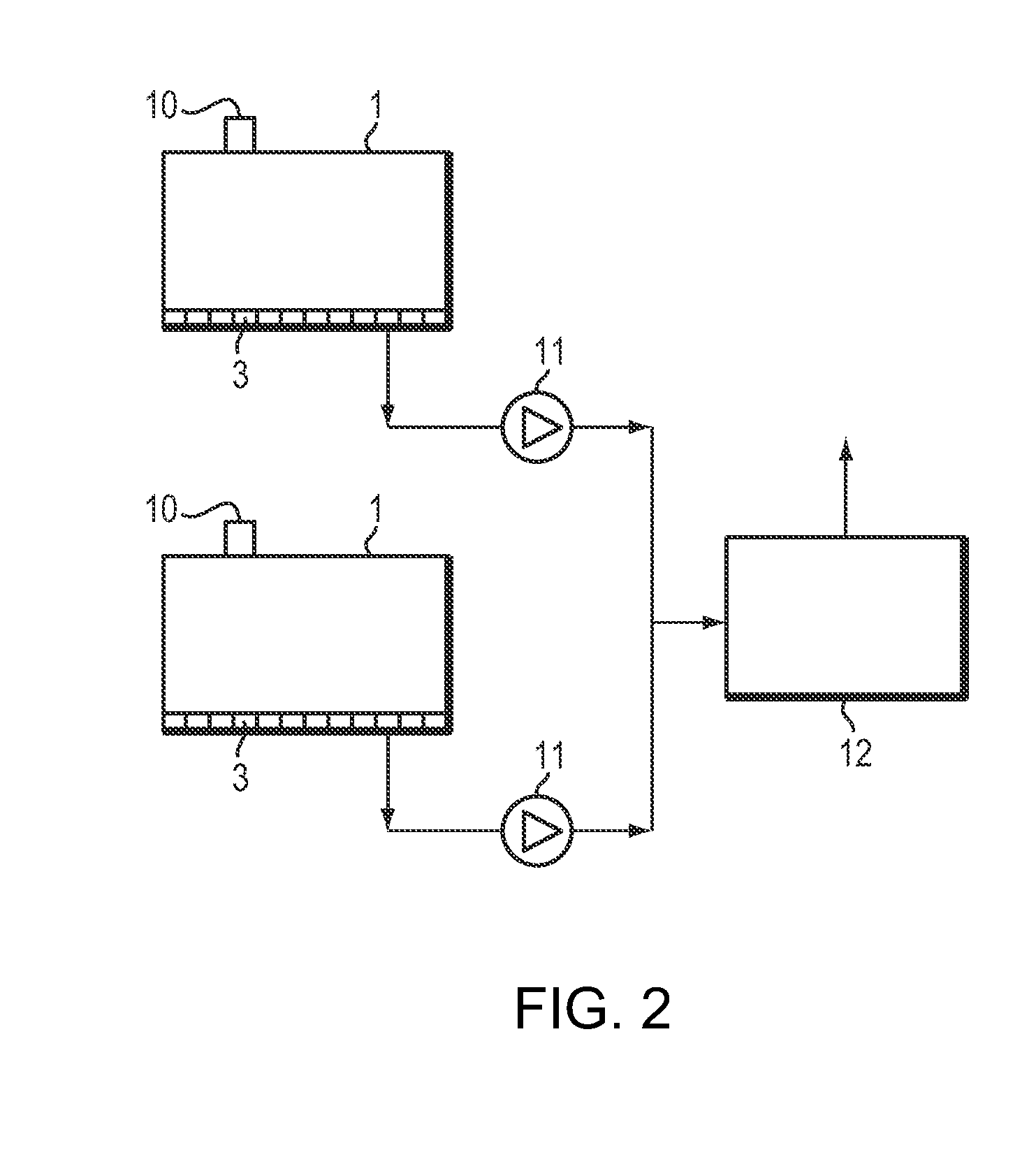

Systems and methods for digestion of solid waste

ActiveUS20120015430A1Improve energy efficiencyIncrease valueBioreactor/fermenter combinationsBio-organic fraction processingEngineeringEnvironmental engineering

This invention relates generally to systems and methods for digestion of solid waste that simplify solids handling. In certain embodiments, anaerobic methane extraction takes place for a period of time (e.g., from 1 to 4 weeks), after which an aerobic composting process begins in the same chamber. The organic waste remains in place and oxygen (e.g., in air) is forced into the chamber for an additional period of time (e.g., from 2 to 4 weeks). At the conclusion of the aerobic phase, the process yields a rough compost product that is stable and pathogen free. The rough compost can be further processed and blended to create high value engineered soils.

Owner:AIKAN NORTH AMERICA

Technology for preparing natural gas through sulfur resistant methanation by coal-prepared synthesis gases

ActiveCN104152199AReduce sulfur tolerance conversion unitReduce investment and operating costsGaseous fuelsChemistryCoal

The invention relates to a technology for preparing natural gas through sulfur resistant methanation by coal-prepared synthesis gases, which is characterized in that coal-prepared synthesis gases is subjected to secondary sulfur resistant transformation and methanation reaction on a molybdenum-based bifunctional catalyst, then is eluted by methanol at low temperature to remove acidic gas, and finally, the Ni-based methanation catalyst is used for performing secondary methanation reaction on unreacted CO and H2 to obtain the excellent natural gas product. The technology for preparing natural gas has the advantages of simple process flow, less equipment investment, low comprehensive energy consumption and excellent natural gas product.

Owner:SEDIN ENG +1

Method for producing biogas by mixing and fermenting attapulgite, crop straw and excrement

InactiveCN104593434AIncrease productionHigh methane contentWaste based fuelSludge processingBiotechnologyFeces

The invention discloses a method for producing biogas by mixing and fermenting an attapulgite, crop straw and excrement. The method comprises the following steps: crushing the crop straw, pretreating for 5-7 days through 4wt%-6wt% NaOH, and then adding three raw materials, namely attapulgite, the pretreated crop straw and the excrement, to a digestion device in a mixing manner for inoculation and fermentation, wherein the initial carbon-nitrogen ratio is regulated to between 20:1 and 30:1, the addition amount of inoculants accounts for 10%-20% of the dry weight of a fermented material, the initial pH value of the fermentation is regulated to 6.5-7.5, the temperature of anaerobic fermentation reaction is 25-35 DEG C, the biogas is generated for 1-2 days, and the fermentation period is 30-40 days. The method disclosed by the invention can be used for improving the efficiency of producing the biogas through the fermentation by taking the crop straw and the excrement as raw materials through adding the exogenous substrate attapulgite, changing the awkward current situation of general low gas output caused by fermenting by taking the crop straw as a main raw material in the vast rural areas and enhancing the additional value of the crop straw as an agricultural waste.

Owner:HUAIYIN TEACHERS COLLEGE

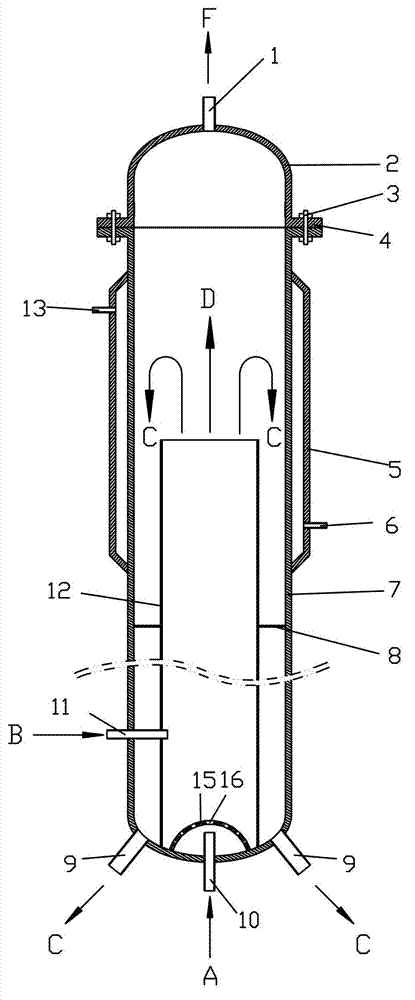

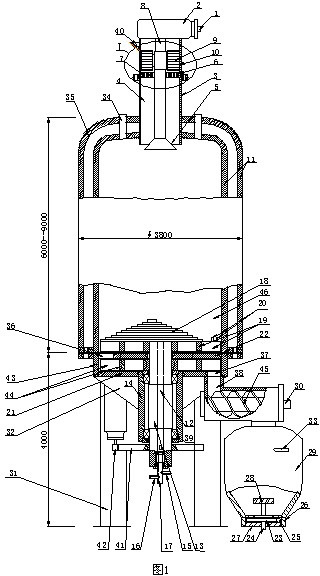

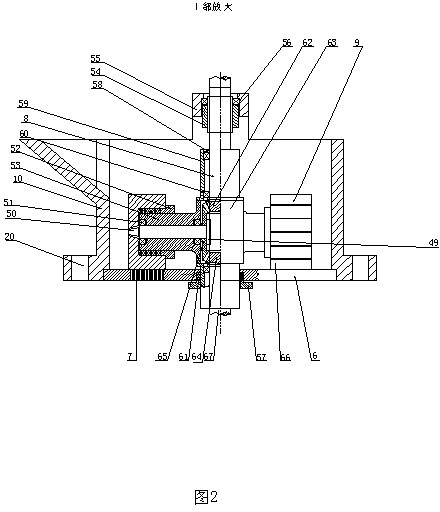

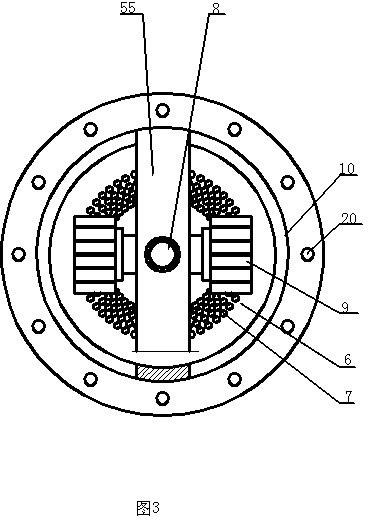

Multilayer fluidized bed gasification furnace for preparing methane-rich gas by coal gasification

ActiveCN102021038ARetain propertiesRetain the advantageGranular/pulverulent flues gasificationFluidized bed gasifierFluidized bed

The invention discloses a multilayer fluidized bed gasification furnace for preparing a methane-rich gas by coal gasification. The multilayer fluidized bed gasification furnace comprises a gasification furnace shell, at least two layers of gas distributors, a raw material inlet, a clinker outlet, a gasification agent inlet, a coal gas outlet, a first overflow device and a second overflow device, wherein the gas distributors are perpendicular to a longitudinal axis and arranged at different heights along the longitudinal axis in a perforated plate form to partition the internal space into an upper space, a middle space and a lower space; the clinker outlet and the gasification agent inlet are positioned at the bottom of the shell; the coal gas outlet is positioned on the top of the shell; and the first overflow device and the second overflow device are penetrated into the first gas distributor and the second gas distributor respectively and each of the first overflow device and the second overflow device is tubular, and has two open ends, so that a raw material flows from the upper space to the middle space through the first overflow device along a curved line and then flows to the lower space from the middle layer through the second overflow device.

Owner:ENN SCI & TECH DEV

Method for preparing high methane content gas from coal

ActiveCN101899339ADoes not affect subsequent sectionsSimple processGaseous fuelsBulk chemical productionCatalytic pyrolysisMethanation

The invention provides a method for obtaining high methane content gas from coal. In the method, the coal and supercritical water undergo catalytic pyrolysis reaction under the action of a pyrolysis catalyst to form semi-coke, and then the semi-coke and the supercritical water undergo gasification reaction under the action of a methanation catalyst. The high methane content gas can be obtained by the two-step reaction.

Owner:ENN SCI & TECH DEV

Method and equipment for processing organic material

InactiveCN1656043AFor long-term storageEasy to storeBio-organic fraction processingAnimal corpse fertilisersAmmoniaBuffer solution

Owner:PRESECO

Biogas composite material

InactiveCN103103216AShort startup timeIncrease gas productionWaste based fuelFermentationDecompositionPoultry litter

The invention discloses a biogas composite material, which is characterized by comprising 70-80kg of excrements of livestocks, 10-15kg of mushroom dreg, 10g of biological bacteria and 5kg of biogas residue by mass. The excrements of livestocks comprise 30kg of dried poultry litter, 10-40kg of dried pig litter and 10-40kg of dried cow litter. The biogas residue is a product which obtained by sediments in a biogas digester through drying and crushing. The biogas composite material has the advantages that the aerogenesis duration is long, the biogas production rate is high, the biogas production speed is fast, the decomposition of cellulose and hemicellulose can be promoted so that the utilization ratio of material can be enhanced, the methane content in biogas is obviously increased, the biogas is convenient for industrialized production and transportation, the usage is convenient for the farmers, the raw materials are easy to be obtained, the rural pollution can be effectively solved, and the waste can be comprehensively used.

Owner:营山县朗润创新能源有限公司

Catalytic coal gasification catalyst and preparation method thereof

InactiveCN103566937AEffective anchoringExcellent methanation abilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFixed bed

The invention belongs to the technical field of catalytic coal gasification catalysts and provides a high-efficiency catalytic coal gasification catalyst and a preparation method thereof. The high-efficiency catalytic coal gasification catalyst takes a complex Ni(NH3)6CO3 as a catalyst precursor, active ingredients are uniformly dispersed on a coal base by adopting an ion exchange technique, and loading capacity of the active ingredients is 2-8%. When the prepared catalytic coal gasification catalyst is applied in a catalytic coal gasification fixed bed reactor, rate of gasification of coal can be effectively improved, and components of coal gas can be improved, so that methane content is increased and utilization rate of the coal is greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fuel cell system

A method for generating electricity in a fuel cell (14), which comprises combining high-grade carbon (C2+) hydrocarbon fuels with steam pre-reforming furnace (10) under the condition that the temperature in the pre-reforming furnace is not higher than 500°C The vapor reacts to produce a fuel stream comprising hydrogen and not less than about 20% methane by volume as measured by the wet method, and the fuel stream and oxidant are delivered to a high temperature fuel cell (14) where the methane is reformed, And electricity is generated by reacting the fuel stream at the anode of the fuel cell and the oxidant at the cathode of the fuel cell.

Owner:CHAOZHOU THREE CIRCLE GRP

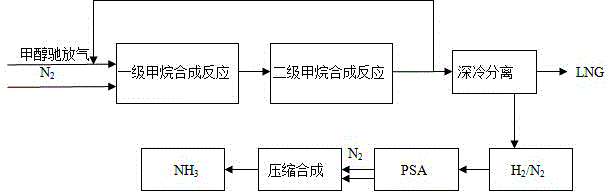

Process for synthesizing LNG (Liquefied Natural Gas) and coproducing liquid ammonia by using methanol purge gas

InactiveCN105733715ANo impuritiesHigh methane contentGaseous fuelsAmmonia preparation/separationChemical industryNitrogen

The invention belongs to the field of energy and chemical industry, and discloses a process for synthesizing LNG and co-producing liquid ammonia by utilizing methanol purge gas. Under the action of a methane synthesis catalyst, the methanol purge gas produced from methanol synthesis is directly preheated to 250°C~350°C and enters the The methane synthesis unit performs a methane synthesis reaction. The obtained methane gas enters the cryogenic separation and liquefaction process after being cooled and dehydrated. Liquefied natural gas (LNG) is obtained in the bottom of the rectification tower. The yield of LNG is 95%~100%. Hydrogen gas and hydrogen-rich gas enter the pressure swing adsorption separation process after recovery of cooling capacity. The hydrogen-rich gas is separated from hydrogen, nitrogen and methane in the pressure swing adsorption separation device to obtain hydrogen, nitrogen and methane respectively, and then the nitrogen is pressurized and mixed with hydrogen to enter the ammonia synthesis process according to the hydrogen-nitrogen ratio of 2.9~3.1 , hydrogen and nitrogen that meet the conditions are mixed and then pressurized to 12.0MPa~30.0MPa to enter the ammonia synthesis tower to produce liquid ammonia.

Owner:CHINA PETROLEUM & CHEM CORP +1

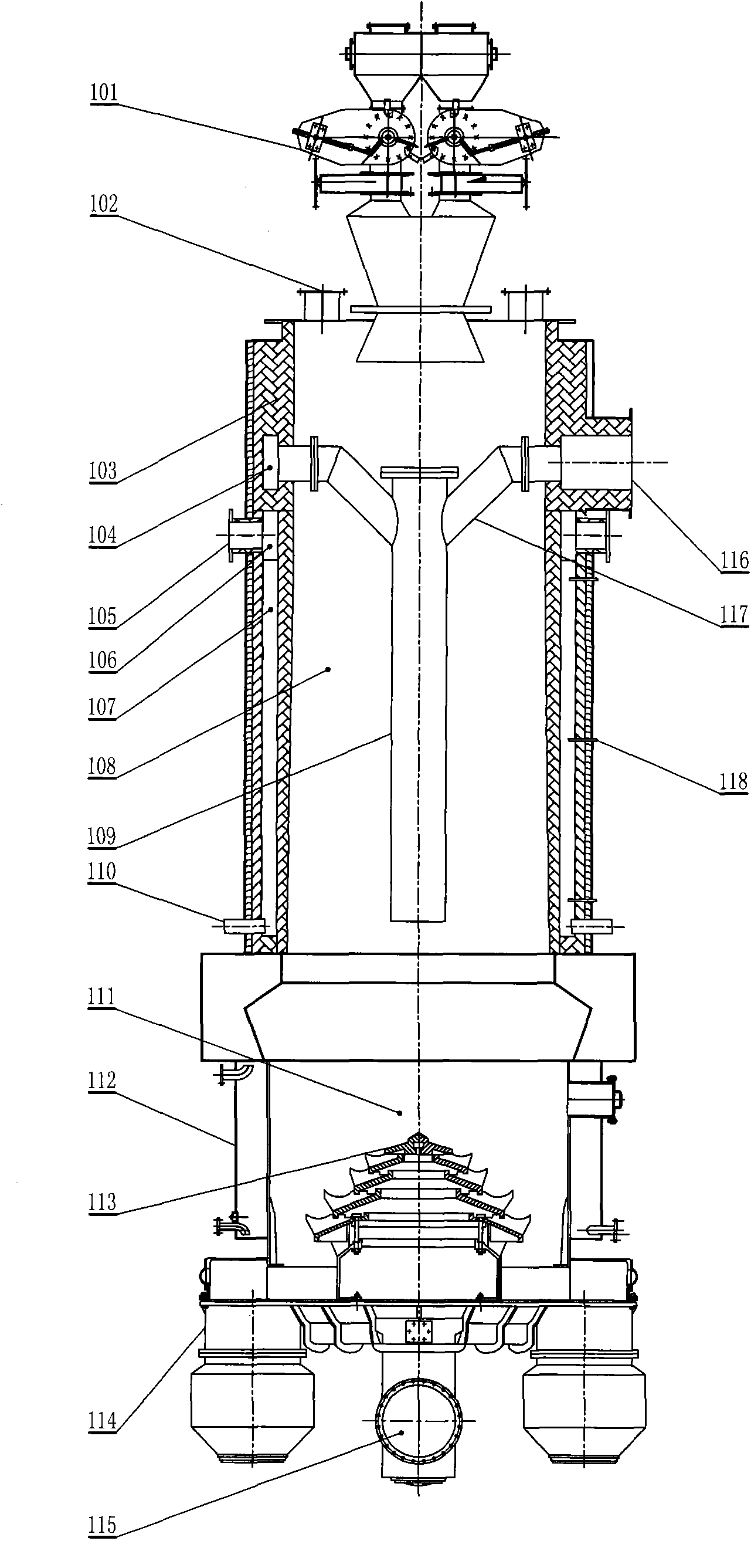

Equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation

ActiveCN102634374AInto a stableSolve the problem of easy to reduce the pressure in the furnaceBiofuelsSolid fuelsDrive shaftEngineering

The invention provides equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation, comprising a furnace body. An idler wheel extruder is installed at the upper end of the furnace body and is provided with a material receiving barrel, and the material receiving barrel is connected with the furnace body in an airtight mode. A transmission shaft is installed in the material receiving barrel, and two idler wheels are installed on the transmission shaft. A round steel disc is installed on the inner wall of the material receiving barrel below the idler wheels, and a through hole is arranged on the round steel disc. A feed port is arranged at the upper end of the material receiving barrel, the lower end of the material receiving barrel is an opening which is positioned in a fuel gas producer. A fire grate is installed at the lower end of the furnace body, and is connected with a second transmission shaft, and a slagging pipe is installed at one side of the bottom end of the furnace body. An air inlet is arranged in the second transmission shaft and is communicated with a gas mixing pipe, and the gas mixing pipe is respectively connected with a steam pipe and an air pipe. A power transmission piece is installed on the second transmission shaft and is connected with a motor. According to the invention, fuel gas prepared by adopting the equipment has high yield, high cleanliness and high calorific value, and the fuel gas is directly supplied for gas turbine-steam turbine combined circulating power generation.

Owner:孔令增 +1

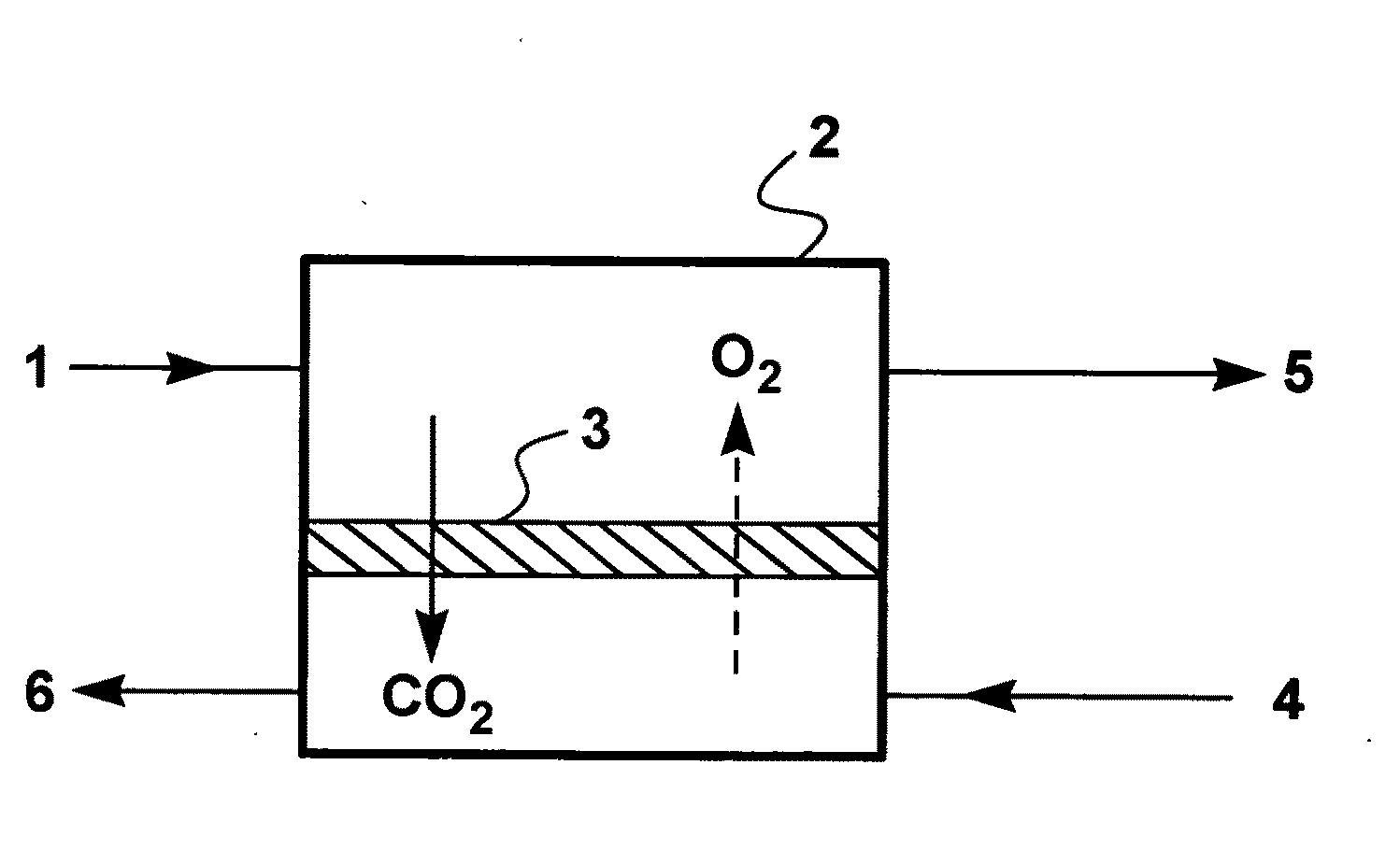

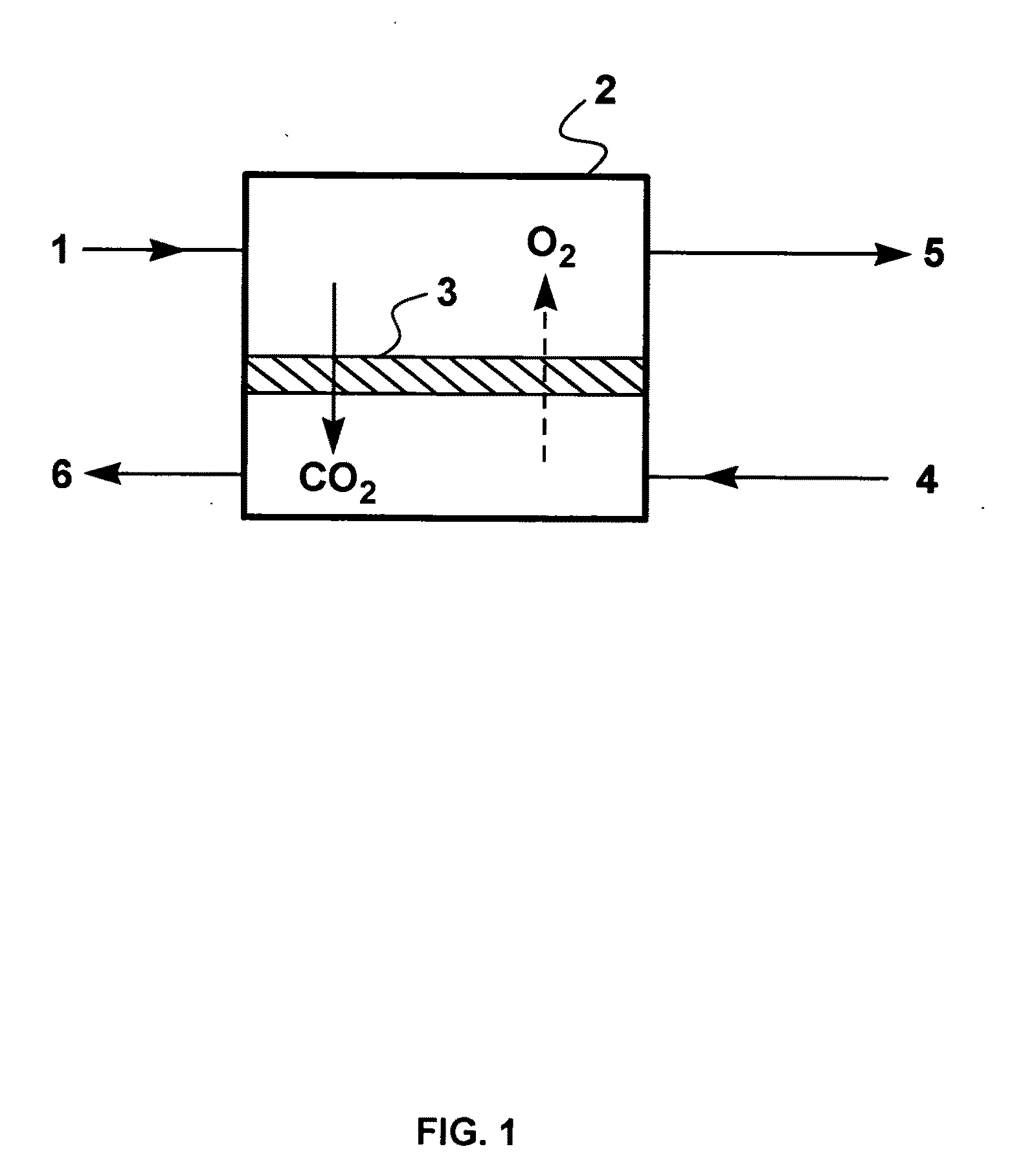

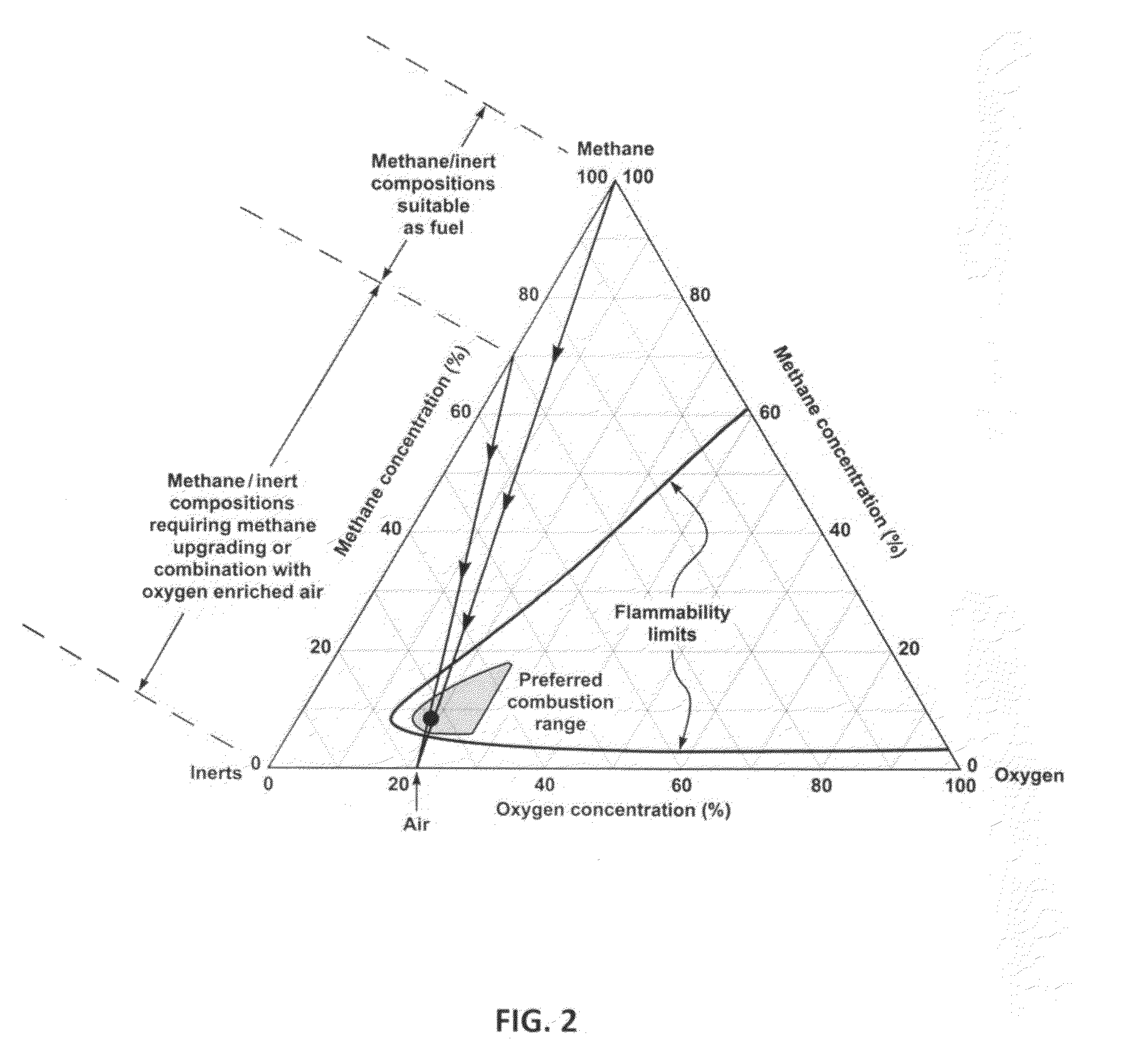

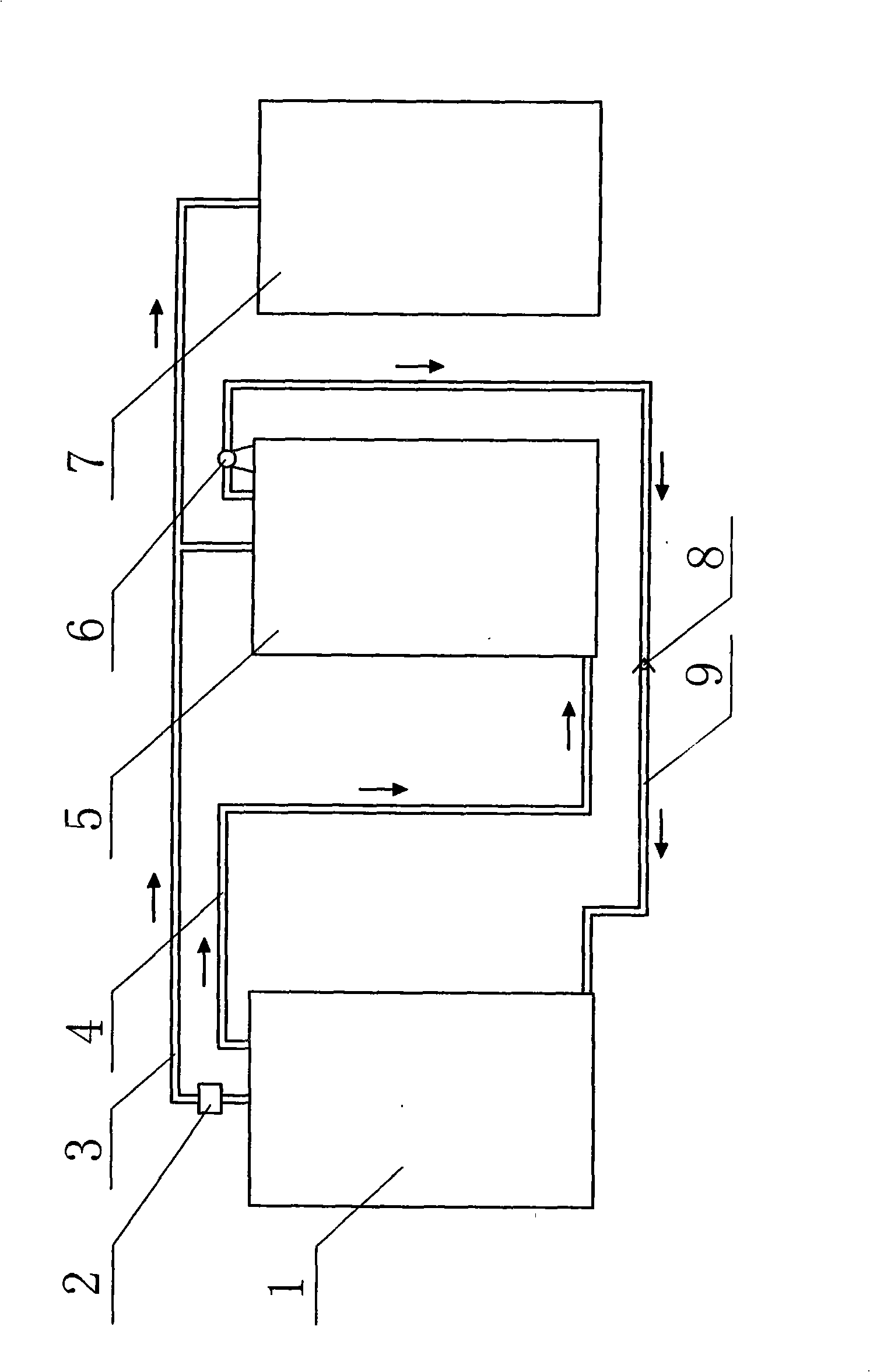

Efficient gas-separation process to upgrade dilute methane stream for use as fuel

ActiveUS20090277328A1Energy efficiencyEmission reductionSolidificationGas treatmentProduct gasOxygen

A membrane-based gas separation process for treating gas streams that contain methane in low concentrations. The invention involves flowing the stream to be treated across the feed side of a membrane and flowing a sweep gas stream, usually air, across the permeate side. Carbon dioxide permeates the membrane preferentially and is picked up in the sweep air stream on the permeate side; oxygen permeates in the other direction and is picked up in the methane-containing stream. The resulting residue stream is enriched in methane as well as oxygen and has an EMC value enabling it to be either flared or combusted by mixing with ordinary air.

Owner:MEMBRANE TECH & RES

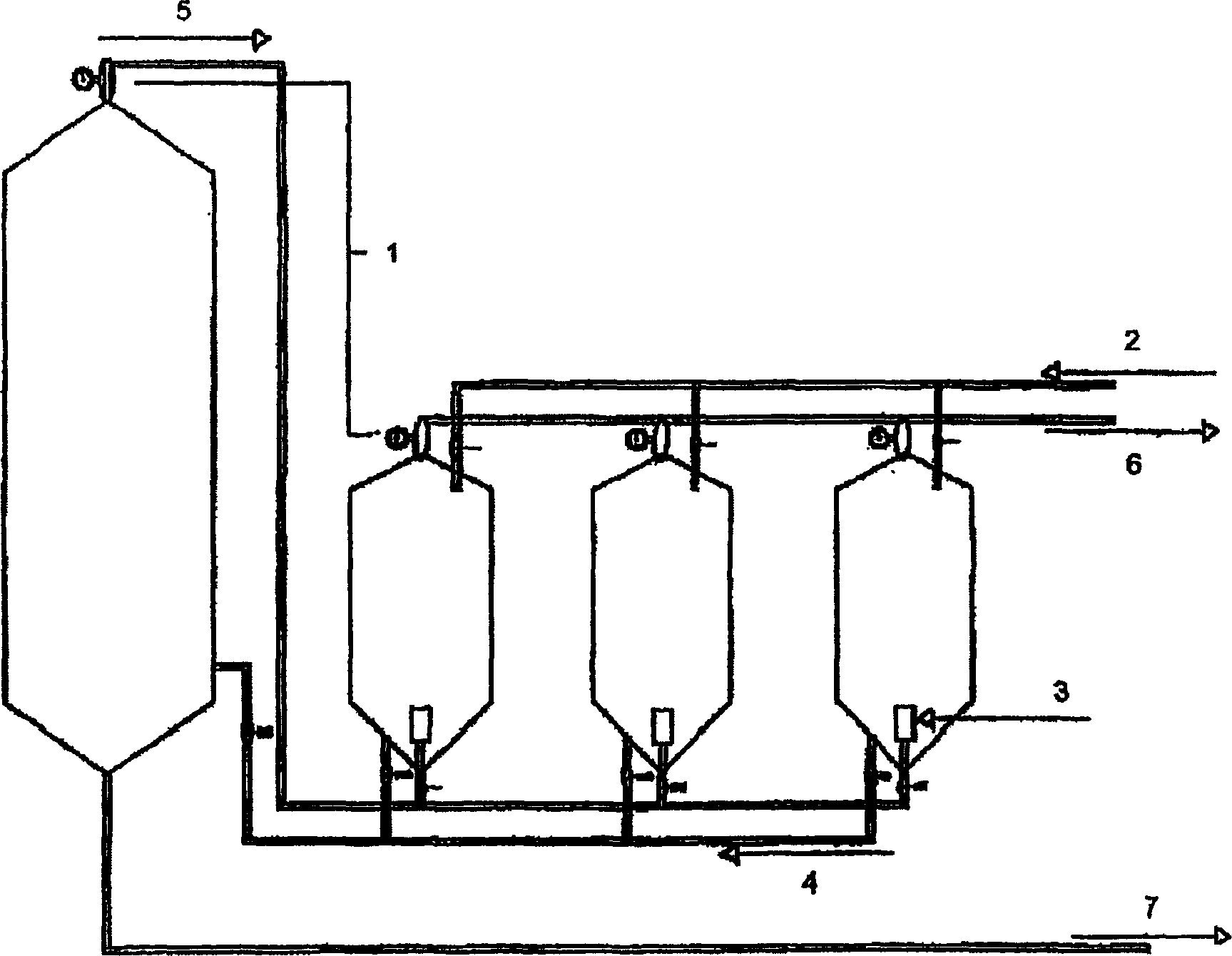

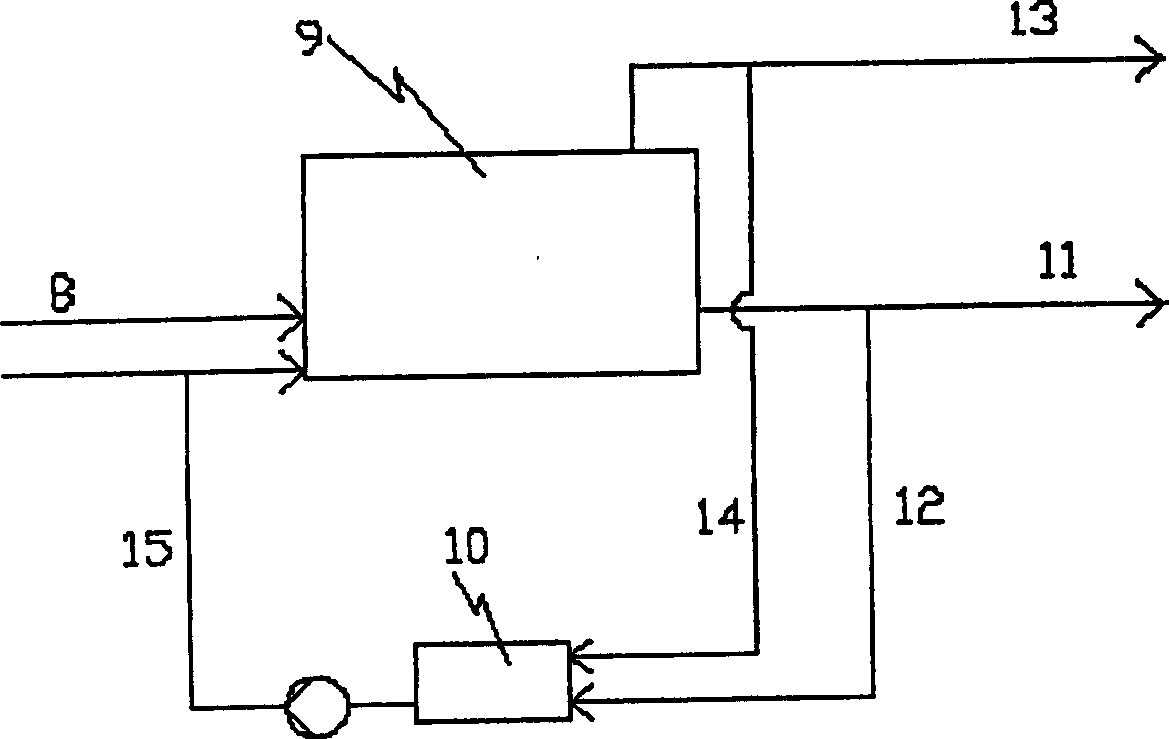

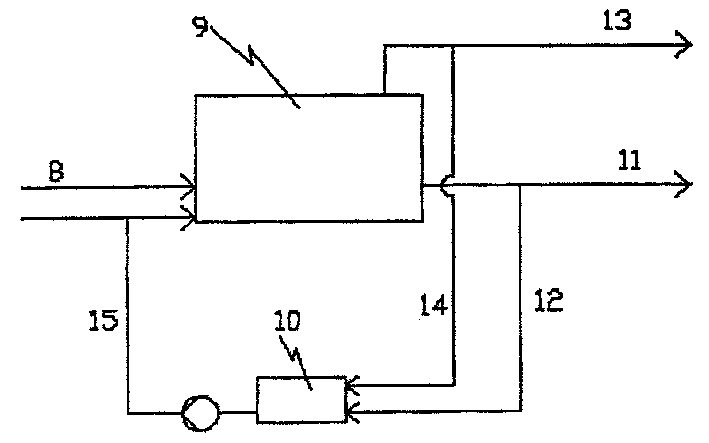

Firedamp biphasic anaerobic fermentation gas stirring system

InactiveCN101265447AReduce propionic acid contentAvoid accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateProcess engineering

The invention relates to a methane two-phase anaerobic fermentation gas mixing system, which belongs to a methane generator. A gas returning pipe and a gas inlet pipe are connected and installed between a hydrolytic acidification tank and a gas production tank, the both ends of the gas returning pipe are respectively connected with the upper part of the hydrolytic acidification tank and the lower part of the gas production tank, the both ends of the gas inlet pipe are respectively connected with the lower part of the hydrolytic acidification tank and the upper part of the gas production tank; an air pump and a one-way valve are arranged on the gas inlet pipe; and a normally open solenoid valve is installed on a gas collector, and is positioned at the gas collector position between the hydrolytic acidification tank and the gas production tank. The system has the advantages that the structure is simple, the operation is convenient, the running is stable, the gas production process is smooth, the gas production rate is high, and the quality is good.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com