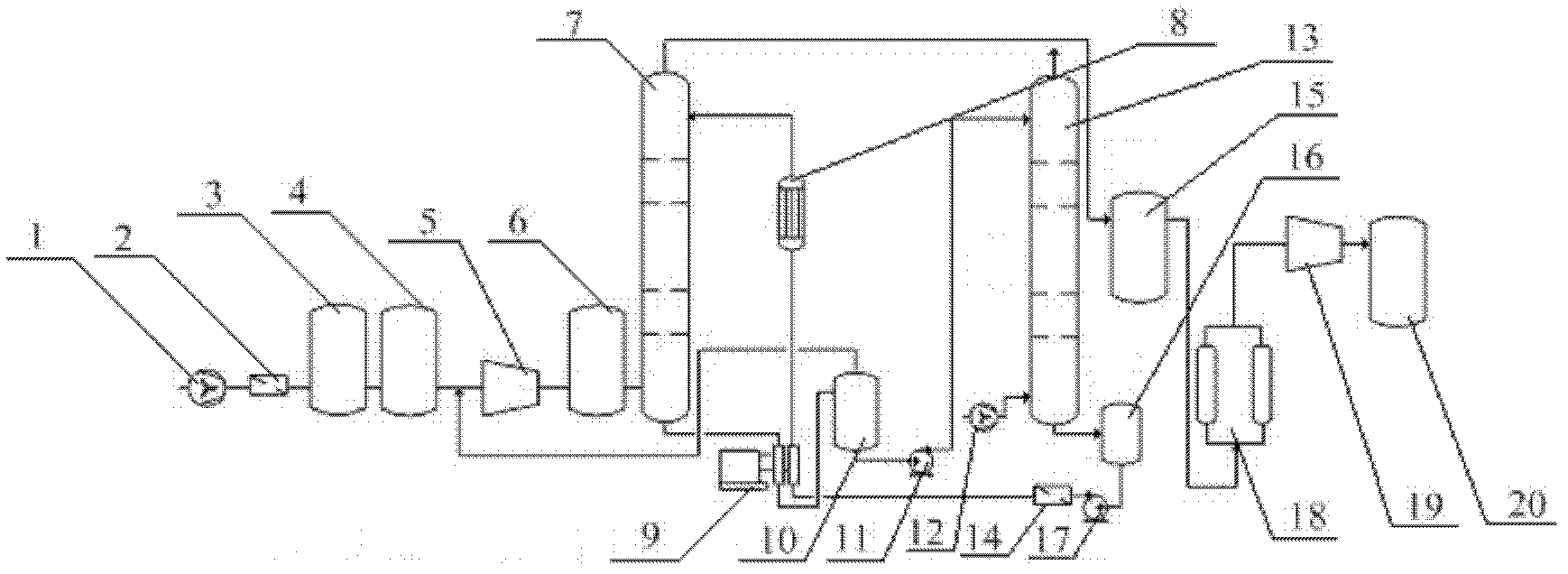

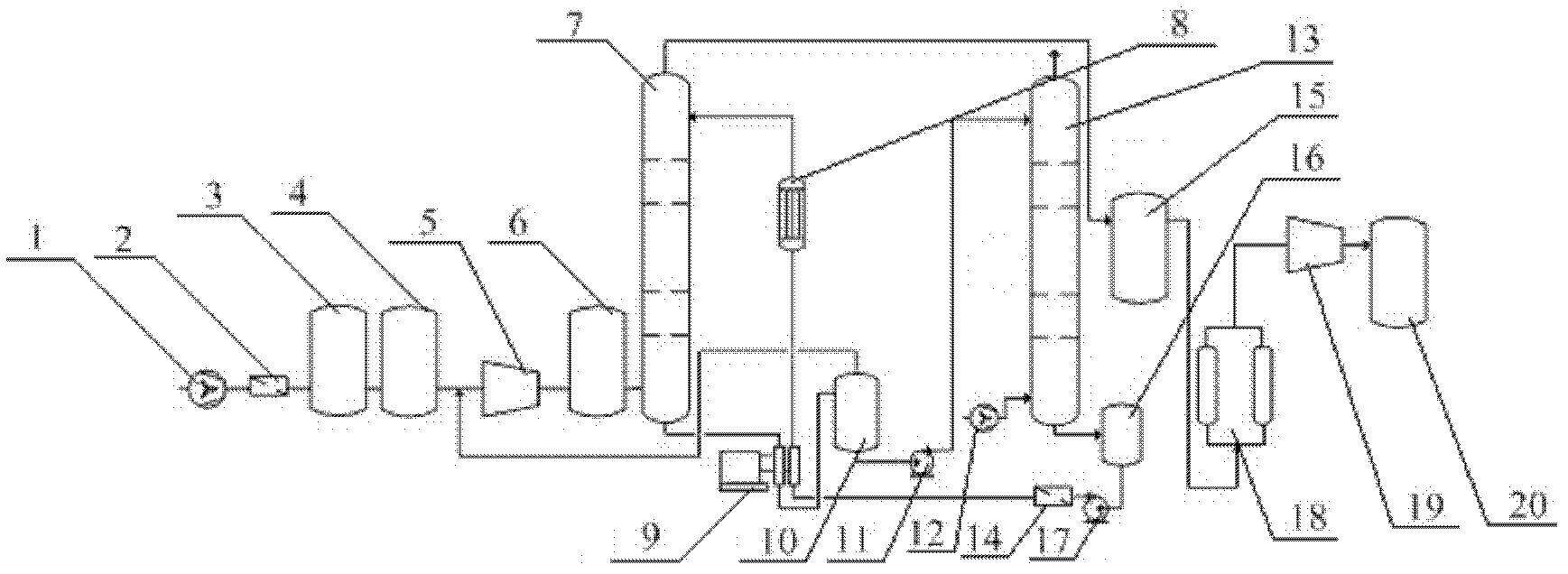

Methane purifying method and equipment thereof

A biogas and equipment technology, which is applied in the field of biogas for dust removal, oxygen and water, carbon dioxide, and hydrogen sulfide removal, can solve the problems of not being able to remove oxygen, etc., and achieve significant economic benefits, environmental friendliness, and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Biogas purification method of the present invention comprises the following steps:

[0032] 1. Use a booster fan to raise the biogas pressure to 1.02 to 1.55 atmospheres;

[0033] 2. Filter to remove dust and impurities, and the filter mesh diameter of the filter used is 0.01-2mm;

[0034] 3. Biological desulfurization, using biological desulfurization bacteria as a desulfurizing agent, converting hydrogen sulfide into elemental sulfur, reducing the concentration of hydrogen sulfide in biogas to below 300ppm;

[0035] 4. Deoxidation, the biogas after deoxidation of hydrogen sulfide is heated to 150-400°C in the preheater, and then enters the fixed-bed reactor filled with deoxidation catalyst, and the reaction of oxygen and methane gas occurs to make O 2 The volume concentration is reduced to below 0.5%. Then enter the cooler, the temperature is reduced to 30 ~ 80 ℃;

[0036] 5. Pressurize to make the biogas pressurized to 0.5 ~ 3MPa;

[0037] 6. Decarbonation, inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com