Equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation

A combined cycle power generation and steam turbine technology, which is applied in the direction of manufacturing combustible gas, combined combustion mitigation, and fuel pre-distillation, can solve the problems of high gas cost, stop, and failure to maintain the normal operation of gas turbines, etc., to achieve reasonable structure, Effects that are cheap to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

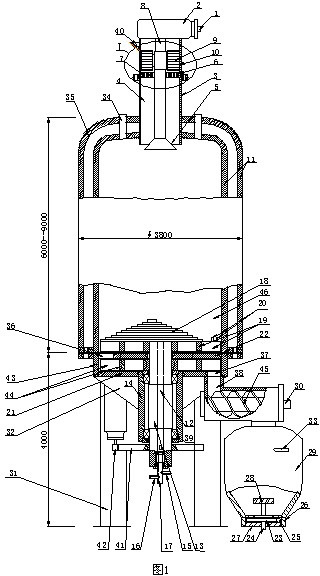

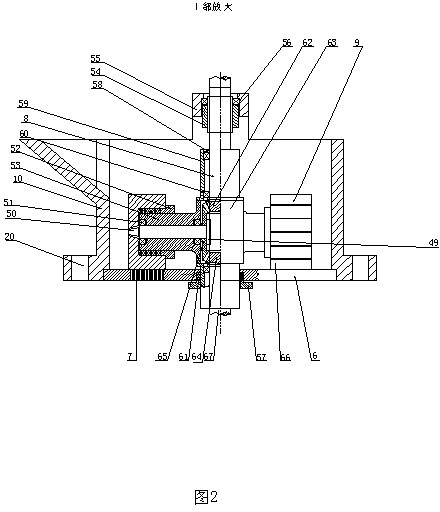

[0008] The present invention will be further described with reference to the accompanying drawings.

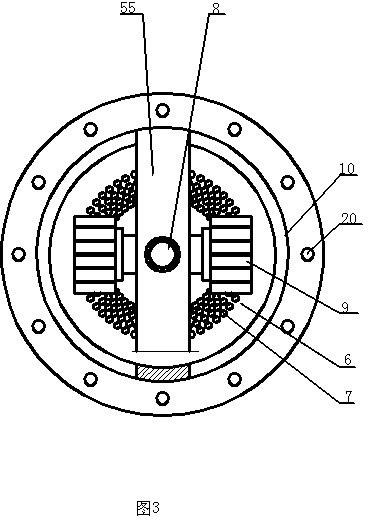

[0009] A kind of equipment for preparing fuel gas for power generation according to the present invention comprises a furnace body 11, a roller extruder is installed on the upper end of the furnace body 11, and the roller extruder has a material receiving barrel 10, and the material receiving barrel 10 is sealed with the furnace body 11 connection, the first transmission shaft 8 is installed in the material receiving barrel 10, and two rollers 9 are installed on the first transmission shaft 8. The two rollers 9 are symmetrically distributed on both sides of the first transmission shaft 8, and the inner wall of the material receiving barrel 10 below the rollers 9 A circular steel disc 6 is installed on the top, and a through hole 7 is provided on the circular steel disc 6. The through hole 7 provided on the circular steel disc 6 is distributed on the track where the roller rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com